HS-1000

Fast Low Noise High Voltage Switch

HS-1000_User_Manual_1_24 .doc

16 - march - 2017

Data Sheet & User Manual

Rev. 1.24

Applications:

● Ion Pulsing / Electrode Switching

● Piezo-Driver

Features:

● fast and low noise switch (SPDT, push-pull)

● max. 1000V switching voltage

● TTL/CMOS level control

● floating up to 800V vs. GND

www.stahl-electronics.com

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

2

TABLE OF CONTENTS

1. Safety Hints ………………………………….…………………………………… 3

2. General Information and Overview………………….………………………….. 4

2.1 Purpose and Description of the Device…………………………….. 4

2.2 Functional Principle and Block Diagram…………………………. 4

2.3 Device Variety……………………………………………………… 5

3. Installation ……………………………………………………………………..… 6

3.1 Mechanical and Electrical Installation……………………………… 6

4. Operation and Control Elements ……………………………………………….. 7

4.1 Elements on the front plate………………………………………… 7

4.2 Elements on the rear side..………………………………………… 7

4.3 Output Characteristics……………………………………………… 8

5. Maintenance………………………………………….…………………………. 10

6. Specifications……………………………………………………………………. 11

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

3

1. Safety Hints

Read all installation, operation, and safety

instructions

Prior to operation, thoroughly review all safety,

installation, and operating instructions accompanying

this equipment.

Rear side switch turns device completely

off

If the device is not in use for a longer time, it is

recommended to turn the mains switch at rear side off.

This equipment must be connected to an

earth safety ground

This product is grounded through the grounding

conductor of the power cord. To avoid electrical

hazard, the grounding conductor must be connected to

protective earth ground.

Do not modify the unit Do not make electrical or mechanical modifications to

this unit.

Change cabling only when device is off Changing the cabling, when voltages are present at the

outputs can lead to formation of harmful sparks.

Do not operate in wet/damp conditions To avoid electric shock hazard, do not operate this

product in wet or damp conditions. Protect the device

from humidity and direct water contact.

Beware of external magnetic fields External magnetic fields can impair, damage or even

destroy this device. A maximum external field strength

of no more than B = 5mT is admissible. Having placed

the device at any time into an external magnetic of

bigger B = 5mT (regardless if power was turned on or

off) can lead to severe overheating of the device and

severely increased hazard of fire.

Service is to be performed by qualified

service persons only

All servicing on this equipment must be carried out by

factory-qualified service personnel only.

Do not block chassis ventilation openings Slots and openings in the chassis are provided for

ventilation purposes to prevent overheating of the

equipment and must not be restricted.

All case vents should continuously be cleared (fan inlet

at rear side, air outlet at rear side), in order to prevent

overheating.

Operate carefully with respect to risk of

electrical shock

This device can produce high voltages at its output

lines, which are harmful in case of direct touch with the

human body or other external circuitry. Care must be

taken to avoid unintentional touching of any output line

to the human body or any devices which might be

endangered by high voltages.

Routinely cleaning from dust After long operation, or operation in a dusty

environment it is strongly recommended to have the

internal parts of the device cleaned by the

manufacturer, or an appropriately qualified workshop

in order to reduce the hazard of overheating.

No outdoor operation Outdoor operation of the device is not admissible.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

4

2. General Information and Overview

2.1 Purpose and Description of the Device

Purpose of the HS series devices is the fast switching of electrodes, electrostatic lenses, beam

deflectors or ion traps. Unlike DC power switches, the outputs expect capacitive loads. The outputs are

optimized for high stability and very low noise. The HS series switches are housed in standard 19-inch

rack-mount cases. They are available in single-channel or dual-channels versions. In the dual channel

version two completely identical switched are housed inside the same housing. These two switches are

completely independent.

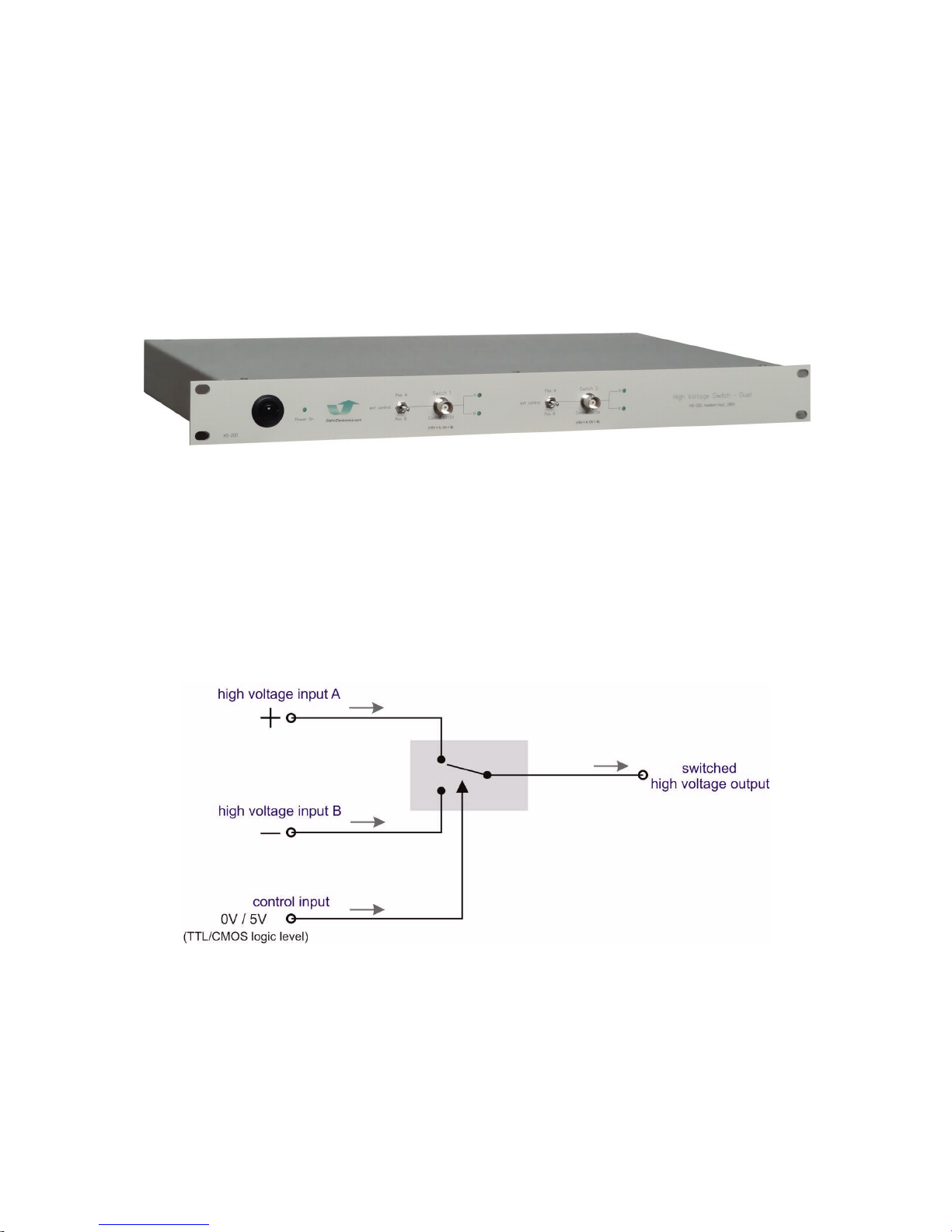

fig 2.1: front view (DUAL version)

2.2 Functional Principle and Block Diagram

The following scheme displays a block diagram of the internal structure and illustrates the functional

principle. The control input (BNC socket on front plate) defines the position of the internal high

voltage switch, which connects either input A or input B to the output. A digital signal (TTL/CMOS

level 0V/5V) may be applied to this control input at a rate between 0Hz (static operation) to 2kHz. A

three-position manual switch on the front side allows to override the digital control signal. The high

voltage switching elements inside the device are implemented as MOSFET-transistors, allowing fast

switching transitions in the order of 100ns and less.

fig 2.2: Block diagram of a HS-1000 device. Inside the DUAL version, the scheme exists twice, i.e. there are

two independent switches.

Unlike high voltage pulse-generators the internal switch circuitry is implemented as fast static switch,

which means that the applied control input level defines the (static) switch position as illustrated in the

scheme above. The output is connected to the selected input by a (transistor based) resistor. The nonselected input is isolated from the output by a high isolation resistance.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

5

Note that the applied supply voltages at inputs A and B must obey a certain order: voltage at input A

always needs to be more positive than voltage at input B. In general both input voltages may float up

to +/-800V versus the case ground. However, for normal operation the voltage difference (A-B) should

not exceed 1000V.

Application example:

Generation of 10µs-duration positive 200Volt-pulse

The subsequent oscilloscope screen shot shows a typical application example. A control pulse of logic

levels (high = 5V, low = 0V) is applied to the control input. High voltage inputs A and B were

provided with an external voltage of 200V and 0V respectively. At the edges of the control signal the

switch is triggered, and switches from 0V to 200V (trace 1: 50V/div.) and after 10µs back to 0 Volt.

Trace 2 shows the control signal, being used to trigger the switch (trace 2: 5V/div.). A rectangular

pulse results with steep slopes and constant-voltage static levels.

fig 2.3: Oscilloscope screen shot of a positive 200V pulse, t = 10s duration.

The lower trace (trace 2) shows the digital control signal, trace 1 (upper trace) the output signal.

2.3. Device Variety

The following devices are currently members of the HS/HVS series device family:

HS-200 single or dual version Output voltages of maximum 200V span

1)

HS-500 single or dual version Output voltages of maximum 500V span

1)

HS-1000 single or dual version Output voltages of max. 1000V span

1)

The devices with outputs up to 500V (vs. GND) are provided by default with BNC outputs at their rear

side, the other variants with higher voltages have SHV connectors. Voltages are referenced to case

ground.

Note

1)

: span is the maximum voltage difference between positive and negative inputs A and B.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

6

3. Installation

3.1. Mechanical and Electrical Installation

Positioning: Provide sufficient air cooling of the device and locate in normal horizontal position to

allow for defined air convection. Rack mounting into a standard 19” rack is as well possible as resting

the device on a table. If mounted in a rack, please make sure that all case vents are permanently

cleared (fan inlet at rear side, air outlets at rear side), in order to prevent overheating.

fig. 3.1: Keep air vents always cleared to ensure sufficient ventilation

Beware of external magnetic fields:

Strong external magnetic fields can impair, damage or even destroy this device (e.g. proximity to a

superconducting magnet). A maximum external field strength of no more than B = 5mT is admissible.

Not observing this important condition can lead to severe overheating of the device and increases the

hazard of fire.

Connecting to mains power:

Connect the device to the mains power supply (220 to 240V ac) by using an appropriate power cord,

being properly wired and providing a grounded outlet. The power cord must be suited with respect to

possible load currents and should be rated to 2A current.

Cabling of voltage outputs:

Always provide appropriate and safe cabling when connecting the device to other devices or

vacuum/experimental setups. Cabling is preferred using high voltage cable with proper shielding.

BNC or SHV connector cables are a suitable choice in order to ensure proper shielding against

external noise pickup and in order to provide protective ground for safety reasons. Always be aware

about the potential hazard of high electrical voltages to human beings and sensitive objects of all kind

(see also safety hints in section 1).

Please note that wiring may only be done when the device is turned off. Connecting a poweredup output to external circuitry can easily cause sparks and electrical discharges. The resulting

overvoltages can severely and permanently damage the device itself and also external circuitry.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

7

4. Operation and Control Elements

4.1 Elements on the front plate

mains supply Switch 1 Switch 2

switch BNC ext. / manual BNC ext. / manual

fig. 4.1: front plate elements (2-channel version shown)

The front plate contains the control elements of the device. It is powered up after turning on the rearside mains supply switch and also the power button on the front plate. The Power-on-LED (green)

indicates proper operation of the internal circuitry.

fig. 4.2: manual switch, BNC input and LED indicators.

Each channel features a three-position manual switch (fig. 4.2). Lifted upwards, the output (rear side)

is connected to the high voltage input A, moved into lower position it connects the output to input B.

In the center position of this switch the control voltage, being applied to the BNC input, defines the

high voltage switch position. A high level connects the output with A, low level to B. Common 5V /

0V signal may be applied to this BNC control input. In practical cases a PC controlled Delay-Gate

generator or function generator is often connected to this BNC input. Switching rates up to 2kHz are

supported. The LED indicators on the right hand side show the switch status, indicating which input

(A or B) is connected to the output.

4.2 Elements on the rear side

fig. 4.3: rear side elements (a dual channel version is shown)

The rear side of the device contains the ventilation elements, 230V supply connector, power on/off

switch (with fuses) and the high voltage inputs and outputs.

fig. 4.4: BNC sockets for at inputs and output

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

8

Fig. 4.4 shows the BNC sockets for the two DC high voltage supply voltages A, and B and the switch

output OUT. Please note that the voltage on input A needs to be more positive compared to the voltage

on input B. This is indicated by the plus and minus sign “+” and “-“. In general, both input voltages

may reside in the range between -800V and +800V versus GND, but their difference should not

exceed 1000V.

The fuse sockets shown in fig. 4.4 contain safety fuses for the two high voltage inputs. In case

extensive currents flow, they may blow. Nominal rating is 0.5 Ampere, fast blow.

The inputs A and B can be connected to an appropriate high voltage supply, e.g. a device from the

stahl-electronics HV-series. The output is supposed to be connected to a switched electrode element or

ion trap. Please note that the capacitive load on this output may impair the switching speed

performance. Nominal loads from 0pF to 300pF may be connected. See also next section for

waveforms.

4.3 Output Characteristics

Dynamic Response

As soon as the internal switch connects either input A or B to the output, the latter assumes the voltage

on the respective input. There is a time constant related to each voltage transition, essentially given by

the internal switch resistance (approx. 250 ), the internal output current limit (approx. ±490mA) and

the capacitive load on the output, including all cables to an experimental setup. In case of BNC cable

type one may count about 100pF each meter cable length, therefore extensively long cables should be

avoided.

The following oscilloscope screen shots show voltage step transitions observed at the output with

small (17pF) and medium capacitive loads (300pF) for further illustration.

fig. 4.5 (left frame) positive voltage step of 100V with small capacitive load (C = 17pF) at the output;

(right frame) voltage step of 200V with small capacitive load (C=17pF); transient rise time (10% to 90% of

voltage step size) is in the order of 25ns in each case. Both graphs have an oscilloscope time grid of 25ns per

division.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

9

fig. 4.6 (left frame) positive voltage step of 200V with medium capacitive load (C = 300pF);

(right frame) negative voltage step of 200V with medium capacitive load (C = 300pF); transient rise (10% to

90%) time is in the order of 148ns each. Both graphs feature a time grid of 100ns per division.

fig 4.7: Oscilloscope screen shot of a positive 200V pulse, t = 10s duration, C = 100pF load at the output.

The lower trace (trace 2) shows the digital control signal, trace 1 (upper trace) the output signal.

Fast Pulses

Upon request the device can be equipped with the capability to create pulses shorter than 10µs. The

subsequent oscilloscope trace shows the output signal of a modified device with 1µs minimum pulse

duration. The output is switched from +500V to -500V and back, resting for 1µs at the negative

voltage level. Capacitive load was 180pF for this measurement.

fig 4.8: Oscilloscope trace of a negative 1kV pulse, t = 1s duration, C = 180pF load at the output.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

10

Noise and Ripple

In contrast to other devices, based on switched circuit / power switching technology, the HS series

devices feature a very low noise level. This makes them specially suited for ion traps, ion sources and

low energy beam line applications. Each output exhibits a very low broadband noise (DC to 20MHz)

of smaller than 350µV

rms

and a low ripple level (50Hz) smaller 50µV

rms

. The outputs are free of

parasitic switching spikes in the RF region.

Floating Voltage

As mentioned above may the two input voltages float versus the case ground. The maximum

admissible voltage is limited by the occurrence of excessive leakage currents and sparking. The HS1000 device is rated for a permanent voltage of 800V (positive or negative) versus the case gound.

During factory commissioning a test voltage of 1200V is applied for a duration of 15min. and the

leakage current observed. Typically a leakage current of 5nA is measured. At a voltage of 1000V

versus case ground the leakage drops to about 3nA, it may therefore be assumed to be safe to run the

device for short times (max. hours) at a maximum voltage of 1000V referenced to case ground.

5. Maintenance

The HS series high voltage switches are designed for years of reliable operation. Under normal

operating conditions, they should not require electrical maintenance, except routine cleaning of dust.

Exchange of ventilation fan is strongly recommended every 50’000 operation hours (see below). If

any question should arise, please contact the manufacturer.

Routine cleaning

All ventilation openings should be checked periodically and kept free of dust and other obstructions. A

vacuum cleaner may be used to clean these vents when the unit is powered off. The front panel may be

cleaned periodically with a clean cloth and mild alcohol solution, when the unit is powered off. It is

recommended to send the device to the manufacturer routinely in 4-year intervals for internal cleaning

from dust.

Fan life time and temperature monitoring

The air ventilation fan is a part which shows unavoidable deterioration in time. Exchange of this part

is strongly recommended after 50´000 hours of operation. Please contact manufacturer for

replacement. Complete failure can lead to overheating of the device. Several temperature fuses and

other protection measures provide a certain degree of safety against fire hazard in this case.

Fire hazard

Please note, that excessive accumulation of dust inside the case of the device can lead to overheating.

This, together with possible discharges increases the risk of fire, caused by electrical sparks. Routinely

cleaning the device from dust minimizes this risk. It is therefore recommended to send the device to

the manufacturer routinely in 4-year intervals for internal cleaning from dust, or to have it cleaned by

an accordingly qualified electronical workshop. Also air conditions containing oil mists (e.g. in

proximity to a vacuum pump or mechanical machines) place a severe danger, since inflammable

substances could enter the device through the ventilation holes. If in doubt, cleaning by an accordingly

qualified electronical workshop or the manufacturer is strongly recommended.

An increased hazard of fire may also occur if the device has been (permanently or temporarily) located

in proximity to a strong (e.g. superconducting) magnet. A maximum external field of B = 5mT is

admissible.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

11

6. Specifications

Control Input

typ. max. Conditions and remarks

required drive level 0V and 5V -2V to +6V

vs. GND

threshold 2.4V

input impedance

1k // 6pF

drive rate / switching rate 1.2kHz output pulse length greater or equal

10µs; for shorter pulses apply rate

max. 500Hz

Output Switch, static

static resistance

from A or B to OUT

“on”-state

250 330

I

OUT

< 200mA

isolation resistance from

A or B to OUT

>10M

voltage differences from A or B to

OUT smaller or equal 1000V

leakage currents from

A or B to OUT 40nA* 200nA*

voltage differences from A or B to

OUT smaller or equal 1000V

intrinsic switch capacitance

on OUT terminal

25pF to 35pF

Noise 350µV

rms

Transfer characteristics

delay from control input

change to output reaction 200ns

200V output step size

(positive or negative going)

delay jitter 1 ns rms T = 25°C +/-1°C

max. pulse duration infinite

min. pulse duration

6.6µs

1.0µs on request

50ns capacitive load of 17pF (probehead)Output rise or fall time,

10% to 90% step size, at

max. 500V voltage step

190ns capacitive load of 300pF

Input Voltage Rating

Input A or B vs. GND +/-800V both polarities may be applied vs.

GND

Voltage difference

from A to B 1000V

input A always needs to be on more

positive level with respect to B

Fuse rating 500mA, fast fuse replaceable on rear side

Environmental

Conditions

Magnetic Field max. 5 mT

Storage Temperature -55 C° to +85

C°

Operating Humidity &

Temperature

noncondensing relative humidity up to 95% between temperatures of

+10°C and +35°C.

Power Supply

AC input voltage 230VACat 50Hz.

The power entry module is EMI/RFI-filtered.

Fuse: medium fast blow 1.0A

Power Consumption typ. 3.9W

Case dimensions

19.00” wide x 10” deep x 1 height unit. Front-panel mounting holes are

configured for M6 rack configurations

weight approximately 1.2kg

Note *): Inputs A and B feature 1G resistors to ground for protection aginst parasitic charge up.

HS/HVS-Series Installation and User Manual, Rev 1.22

www.stahl-electronics.com phone: +49 6242-504882, fax: +49 6242 504884

12

Currents through these protection resistors add to the numbers mentioned above.

DECLARATION OF CONFORMITY

Manufacturer's Name: Dr. Stefan Stahl

- Electronics for Science and Research -

Manufacturer's Address: Dr. Stefan Stahl

Kellerweg 23

67582 Mettenheim

Germany.

Declares, that the product

Product Name: HS series high voltage switches

Model Number: HS-200, HS-500, HS-1000

Product Options: This declaration covers all options of the above product(s)

Conforms with the following European Directives:

The product herewith complies with the requirements of the:

1. Low Voltage Directive 73/73EEC;

2. EMC Directive 89/336/EEC (including 93/68/EEC) and carries the CE Marking

accordingly

Date Of Issue __________________

8. April 2014 General Director

Loading...

Loading...