Page 1

Original

Installation and service instruction

Knife gate valves

Page 2

2

Document: is-VALVE, 2017-07-01, issue: 14

Original

Installation and service instruction

Knife gate valves

Table of contents

A)

General .................................................................................................................................................................. 3

A1 Symbols ................................................................................................................................................................. 3

A2 Valve destination .................................................................................................................................................... 3

A3 Related documents ................................................................................................................................................ 3

A4 Valve marking ........................................................................................................................................................ 4

A5 Transport, storage and handling................................................................................................................................. 4

Storage and transport: ................................................................................................................................................. 4

Handling: ...................................................................................................................................................................... 4

B) Installation/functional check ............................................................................................................................... 5

B1 Safety warnings at installation ................................................................................................................................ 5

B2 Conditions for installation ....................................................................................................................................... 5

B3 Pressure, flow direction and valve position ............................................................................................................ 6

B4 Necessary support for special cases ...................................................................................................................... 6

B5 Steps to install ........................................................................................................................................................ 6

B6 Installation in an ATEX-classified area ............................................................................................................. 9

B7 Pressure testing after installation (if necessary) ..................................................................................................... 9

B8 Disassembling the valve ........................................................................................................................................ 9

C) Service and maintenance .................................................................................................................................. 10

C1 Safety warnings at service and maintenance ....................................................................................................... 10

C2 Manual and automatic actuation .......................................................................................................................... 11

C3 Maintenance......................................................................................................................................................... 11

C4 Troubleshooting ................................................................................................................................................... 11

Declaration in compliance with EU-Directives ............................................................................................................. 13

All specifications are subject to change without notice.

Page 3

3

Document: is-VALVE, 2017-07-01, issue: 14

A) General

In this instruction a “knife gate valve” is shortly called “valve”.

A1 Symbols

In this instruction notes and warnings are marked with symbols:

XXXXX

Danger / Warning

Points out a dangerous situation which may cause personal injuries or death.

Advice

Has to be respected.

Information

Information useful to follow.

If these notes and warnings are not respected by the user, dangerous situations may occur and may invalidate the

warranty of the manufacturer.

A2 Valve destination

Valve types BV, D2G, HG, HL, HP, HX, JTV, MP, MV, RKO, RKS, SLF, SLV, SLH, SLX, TV, XV and WB are destined

– after installation between flange(s) in a pipe system – to shut off, to open or to control the flow within the admissible

pressure/temperature limits.

These pressure and temperature limits depend on the materials of valve body, gate and seat. Temperature limits are

defined in the valve data sheet of each type. Maximum working pressure are marked at the valve body and on the label

attached on the beam.

The flow shall be without vibrations and/or pressure chocks. The surrounding environment should not imply any risk to

the valve. This also implies to explosive environment – except for valves classified for ATEX- area

and marked

accordingly.

Installation of the knife gate valve is preferred with the actuator in an upward position – except for RKO, JTV and D2G.

At valve operation respect:

• The manufacturers declaration to EC directives,

• This original installation and service instruction which is supplied together with the valve.

Stafsjö Valves AB does not accept any responsibility if this “Valve destination” is not observed.

A3 Related documents

Further information on the valves is available on www.stafsjo.com.

ds+valve type (i.e. ds-BV) = Data sheet with technical information (di men sio ns, mat erial specification etc.)

mi+valve type (i.e. mi-BV) = Instructions for maintenance on each valve type.

sp+valve type (i.e. sp-BV)

= Specify spare parts for each valve type.

acc+type of accessory (i.e. acc-SV)

= Accessory for different types of valves. I.e solenoid valve.

stafsjo-valve-spec = Specification of parts and valve combinations.

Page 4

4

Document: is-VALVE, 2017-07-01, issue: 14

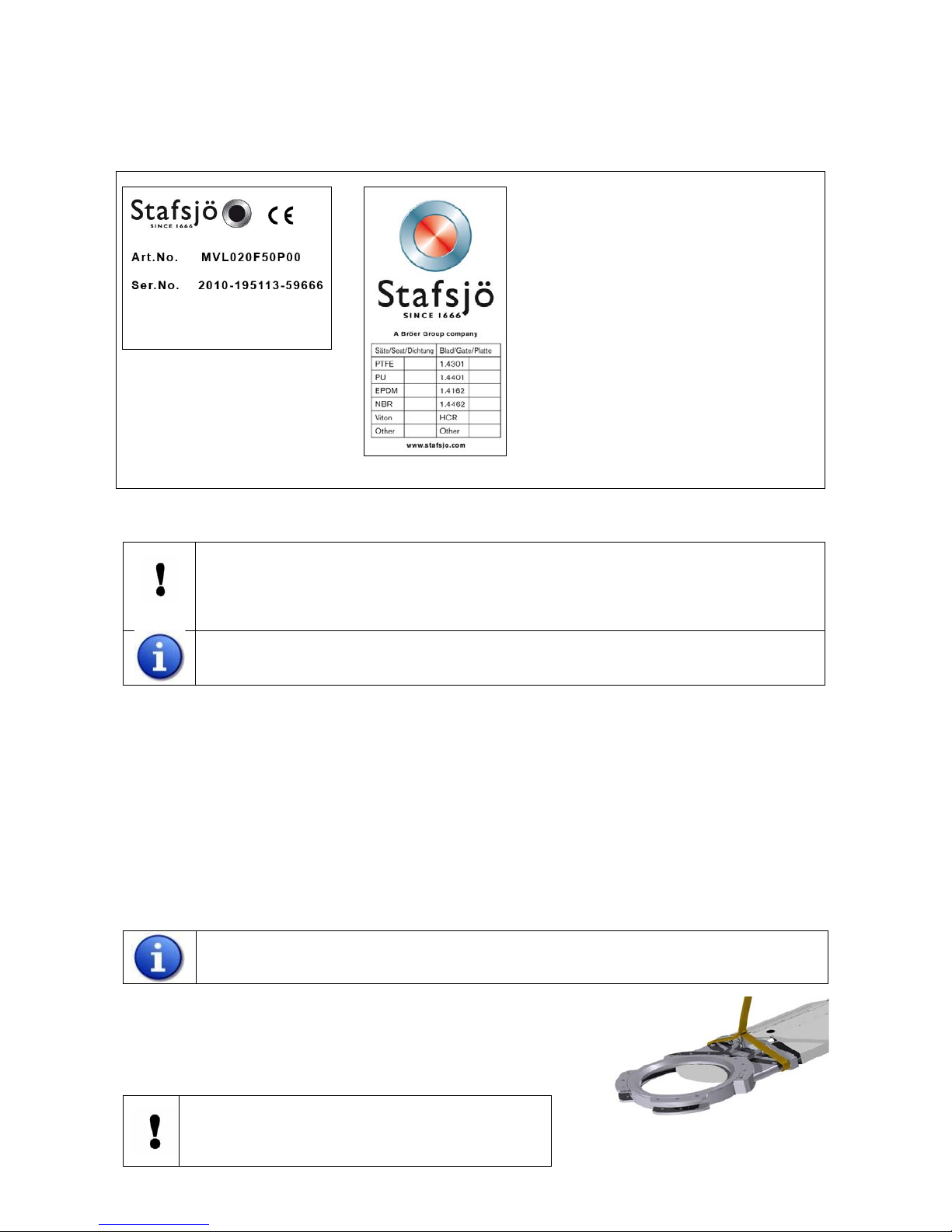

A4 Valve marking

Each valve is labelled as follows:

Additional: Markings on casted valve body:

DN XXXX: (mm) nominal diameter

PN XX: (bar) pressure class of valve body

i.e. GGG50 valve body material

These labels shall not be removed, over coated or otherwise covered.

“Max. PS Valve body” which is marked on the label (see above) is max. allowed pressure when the valve

is open. Max. allowed pressure on closed valves may be lower and is marked on this label as well.

More information on this is available in the data sheet which can be downloaded from www.stafsjo.com.

Refer to the “Serial Number” of the valve marking at any contact with Stafsjö.

A5 Transport, storage and handling

Note

Additional requirements may be found in the actuator instruction, if any.

Storage and transport:

Keep the valve in open position during storage to ensure its function and to protect the polished surface of the gate.

Store the valve in a clean and dry environment and protect it against dirt, dust and other contamination. Do not expose

the valve to direct sunlight. If the valve is stored outside, it shall be wrapped tightly in a plastic foil or similar to protect it

against moisture or any dirt contamination. It should also be stored high enough without any risk to be covered in snow

or enclosed by water.

The valve has been packed according to the terms of delivery. It is important to make a visual inspection at

arrival. If transport damage is detected, report to the transportation company.

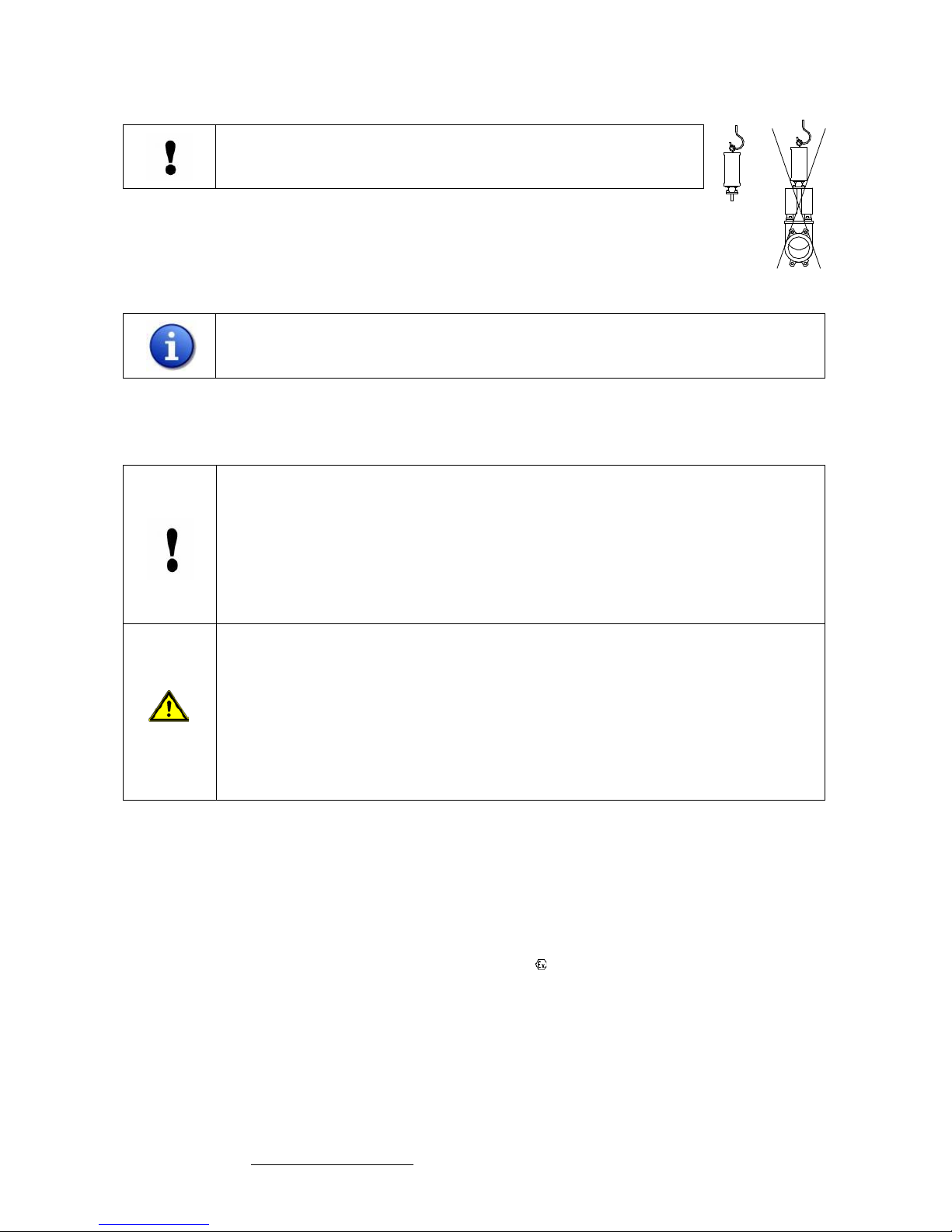

Handling:

Lifting and moving shall be carried out with soft straps. Place and fasten the

soft strap on the valve body as shown in fig.1. Make shure that all equipment is

designed to hold the weight of the valve.

Never place lifting equipment:

• On the actuator, accessories or gate guards.

• In the bore of the knife gate valve, since it cause damages

to the seat and retainer ring.

Label for identification of seat and gate material

Fig.1

Ser.No: Serial number consisting

of year – individual no - order

number.

CE-marking when applicable.

Max PS Valve

body/differential: 10/10 BAR

0045

Page 5

5

Document: is-VALVE, 2017-07-01, issue: 14

Specifically note that threaded hole on top of pneumatic cylinder type EC, is only

for handling the cylinder itself. See figure 2.

B) Installation/functional check

This instruction includes safety recommendations for foreseeable risks at installation into a (pipe)

system. The user is responsible to complete this instruction with warning notes for system-specific

aspects. All requirements of the system shall be observed.

B1 Safety warnings at installation

• Installation shall be performed by qualified personal. Qualified are those persons who, due to

experience, can judge the risks and execute the work correctly and who are able to detect and

eliminate possible risks.

• After installation, the function of the valve shall be in accordance with the valve and the actuator (if

any) destinations, see section A2.

• At the end of the installation the gland bolting shall be tightened according to Table in section B7.

• A valve without an actuator should not be installed into the (pipe) system.

• Some valve types can be installed as end valves. Contact Stafsjö for specific requirements and

information.

Danger

1. A valve with an actuator sh a ll only be operated if:

• The valve is installed between flanges or between a flange and a protective device.

• The gate guards are installed on the beams on automatic operated valves.

2. If the knife gate valve is installed as an end valve in a pipe line, always install protective equipment

to prevent people getting to close to the valve and being exposed to the media transported in the

system when the valve opens.

People’s life and health is at stake if this is not observed. Any other action is the responsibility

of the user.

B2 Conditions for installation

Make sure:

• To install valves according “Valve destination”, see section A2. Observe valve marking, see section A4.

• That the pipe section is not exposed to vibrations or other mechanical stresses which could deform the valve body and

affect the valve’s tightness and/or abil ity to operate.

• That the valve environment does not imply any risk to the valve, the actuator or the accessories. This also implies to

explosive environment – except for valves classified for ATEX- area

and marked accordingly.

• That flanges, pipe line and the valve are empty, free from solid and sharp particles.

• That the valve is installed between flange(s) (fixed or loose) to ensure that the valve is securely fixed and that the

flange keeps tight.

• That the knife gate valve is protected against radiant heat, if the valve is placed near a heat source whose temperature

exceed maximum allowable temperature for the valve or its actuator.

• The mating (=gasket contact) surface of the flange cover the retainer ring completely. Detailed information on flange

drilling, threads, length and number of bolts is available in data sheet on www.stafsjo.com.

• To follow those instructions which are supplied with an actuator (if any).

• The pipe line is free from pressure.

• Additional requirements may be found in the actuator instruction – specifically to adjust the correct OPEN and

CLOSED positions before the valve is installed.

OK

Fig.2

Page 6

6

Document: is-VALVE, 2017-07-01, issue: 14

B3 Pressure, flow direction and valve position

When the knife gate valve is open, P1=P2, the pipe line pressure may not

exceed maximum allowable working pressure body according to each valve.

When the valve is closed, the differential pressure ∆P, is the difference

between P1 and P2 (∆P = ± (P1-P2).

The differential pressure ∆P may not exceed maximum allowable differential

pressure according to each valve. Maximum allowable differential pressure

for closed valve is available in data sheets.

• Valves types XV, HL, HG, HP, HX, BV, WB, D2G , SLV, SLF, SLH and SLX are bi-directional and can therefore be

installed independent of the pressure ratio in any direction in the pipe line.

• Valid for MP only:

This valve type is bi-directional but have a preferred pressure direction. The preferred direction is achieved when the

SEAT SIDE is installed as the valve outlet (towards P2) provided that P1>P2.

• Valid for MV only:

This valve type has different differential pressure ∆P capacities in the flow directions. The maximum ∆P capacity of

the valve is achieved when the SEAT SIDE is installed as the valve outlet (towards P2) provided that P1 > P2. When

the valve is closed, the pressure ratio shall be P1>P2. Some sizes of MV equipped with specific seats are capable to

handle certain differential pressure in reversed pressure direction. For further information, see data sheets on

www.stafsjo.com.

• Valid for RKO and RKS only: These valve types have different differential pressure ∆P capacities in t he flow

direction. The maximum ∆P capacity of the valve is achieved when the seat side is installed as the valve inlet

(towards P1) provided that P1>P2. When the valve is closed, the pressure ratio shall be P1>P2.

• Valid for TV only:

This valve shall be installed with the seat side to the tank. The removable retainer ring shall be mounted towards the

tank which implies that changing of the seat can only be done when the tank is empty.

• All valve types, except for valves D2G, JTV, RKO and RKS are preferred to be installed in a horizontal pipe

(system) with the actuator in a vertical upright position.

Valid for D2G, RKO, JTV and RKS only:

These valve types are designed to be installed in a vertical pipe.

B4 Necessary support for special cases

The dead weight of a valve in large dimension together with its actuator may cause tensions/deformations in the valve

that could affect the valve’s function, specifically when it is installed at inclined positions or in a vertical pipe. In these

cases, the valve and/or actuator shall be supported to avoid functional failure.

Valves that are exposed to vibrations or other mechanical stresses can be subject to forces that will affect valves

tightness and ability to operate. In these cases, the valves and actuators shall be supported to avoid function failure.

Support details are the responsibility of the customer. Stafsjö will assist on request.

B5 Steps to install

On handwheel operated valves, when the handwheel is not assembled at delivery, follow the steps below to assemble

the handwheel to the valve.

Fig. 3

Seat side

RKO, RKS

Seat side MV

P1

P2

Page 7

7

Document: is-VALVE, 2017-07-01, issue: 14

Handwheel with non-rising

stem

Handwheel with rising-stem

1. Assemble the handwheel to

the valve. Check that there is

not any play between the

actuator, bearing and yoke. If

there is, eliminate the play by

rotating the stem 360 degrees

counter clockwise. Then fixate

the handwheel with a locking

nut.

1. Loosen the nuts from the

tie rods and remove the

tempo-rary yoke plate.

2. Assemble the handwheel

unit to the tie rods and fixate it

with washers and nuts. Attach

the gate clevis to the gate and

fixate with clevis pin and split

pins.

3. Remove the safety pin. For

safety reasons, the pin shall

not be removed until the

handwheel unit is assembled

and the gate clevis is

properly attached to the

gate.

When the handwhell is assembled, install the valve into the pipe (system).

When installing the valve, make sure that:

• The valve’s centre line is on the same centre line as the

flanged pipe’s.

• Flange surfaces of the pipe and valve must be exactly

parallel.

If the flanges and the valve are not centred, the valve may be damaged by erosion and a dirt pocket may occur which

can lead to clogging and corrosion of the valve.

• Valve type RKO and XV must be installed in closed position only.

• Valve type SLV, SLF, SLH and SLX must be installed in open position only!

• When the SLV and SLF valve body are closed by bottom cover and/or when SLH and SLX purge ports

are closed by plugs, flushing is recommended through the purge ports at service if it is not clean fluid.

1. Place the gaskets between the valve body and the flange. Check that the gasket is well centered and covers the

complete surface of the retainer ring.

Valve types WB, SLV, SLF, SLH and SLX only:

These valve types are equippe d w ith integrated rubber flange gaskets – additional gaskets are not

necessary.

2. Lubricate the bolts. This allows correct pre-setting of the flange and makes it easier to dismantle the bolting

later.

All Valve types: Flange bolts of right length are necessary:

• Too long bolts could deform the valve body and result in leakage in the flange.

• Too short bolts could deform the threaded holes in the valve body at installation.

Choose bolts with the correct thread and length according to the flange drilling information in the data sheet.

Fig. 4 Assembling of handwheel

Fig. 5

Page 8

8

Document: is-VALVE, 2017-07-01, issue: 14

All Valve types of cast grey iron material (WB): Extra caution is necessary when installation due to the

brittel material. Place the valve between flanges. First tighten the through going bolts so the flanges is close

to the valve to not more than maximum torque as below. Then end by tighten the bolts for blind holes.

DN

350

400

450

500

600

Nm

140

160

160

180

180

Lbf.ft

103

118

118

132

132

3. Tighten the bolts first manually and then evenly and crosswise, for a uniform load of the gasket, with a torque as

required by the gasket manufacturer. Valve type SLV, SLF, SLH and SLX shall be assembled with the mating

surfaces of the valve body and the pipe flanges up to metal/metal contact. See fig. 6.

1=Wrong 2=Wrong 3=Correct

Make sure that the flange is centered and is covering the metal frame around the seat (picture 3).

Tighten flange bolts crosswise to eliminate any gap between body and flange.

To ensure the seats will stay in correct position after every valve manoeuvring, we

recommend to use load distribution rings (LDR) on the SLV, SLF, SLH and SLX valves

when:

• The pipe lines are rubber lined and/or the flanges are partly or entirely rubber covered.

• The inner diameter of the connecting pipes and/or flanges is larger than the inlet

diameter of the valve.

• The outside diameter of the raised flange is not large enough to cover the metal frame around the seat in

order to accomplish metal to metal contact between the valve and flange.

If load distribution rings are ordered they are as standard assembled on the valve upon delivery.

4. To finish the installation, make an operational test by opening /closing the valve. Observe the actuator (if any)

instructions.

• A valve with handwheel should be operated with normal hand force. Exceptional force used to close

the valve can damage it.

• A valve with electric/pneumatic actuator shall be operated by the plant control signals into its end

positions, i.e. OPENED and CLOSED.

• At connection of an actuator to the plant control system the actuator‘s instructions shall be followed.

5. If the pipe line is to be cleaned by flushing in order to wash out impurities, the valve must be opened 100%.

Valves with actuator supplied by Stafsjö are exactly adjusted in the end positions:

This adjustment shall not be changed as long as the valve operates correctly.

Fig. 6

Fig. 7

Page 9

9

Document: is-VALVE, 2017-07-01, issue: 14

Only for Valves with electric actuator:

Ensure that the actuator motor stops by the signal of the limit switch for closed and open position of the

actuator. Exceptional force may damage the valve. The signal of the torque switch may be used for signal for

faulted conditions. For further information, see the actuator instruction.

B6 Installation in an ATEX-classified area

Note:

Additional requirements may be found in the actuator instruction, (if any).

This ATEX instruction is valid along other instructions in this document.

In ATEX-classified zones, in accordance with ATEX Directive 2014/34/EU, only valves with ATEXclassification and the relevant valve marking shall be installed.

Additional to the requirements above make sure that:

• The valve is part of the plants earthed system.

• The user has performed a risk analysis of the pipe line and valve in accordance with the guidelines of ATEX Directive

2014/34/EU.

B7 Pressure testing after installation (if necessary)

Each Valve has been tested before delivery by the manufacturer according to EN12266-1. For pressure test of the pipe

section with a knife gate valve installed the conditions for the system apply but with the following restrictions:

• The pressure test shall not exceed 1,5 x max. working pressure of the valve (see valve marking). The gate shall

be open.

• Pressure test with valve in closed position shall not be tested more than 1,1x max. differential pressure in preferred

pressure direction, (see datasheets) in order to prevent overload of the gate.

Immediately at this operation check the stuffing box tightness:

In case of leakage:

Tighten the gland nuts evenly crosswise and bit by bit until leakage stop. Do not tighten more than

necessary!

Recommended maximum torque

DN

DN 50 – DN 80

DN 100 – DN 150

DN 200 – DN 300

> DN 350

Nm

20

25

30

35

Ibf x ft

15 18 22 26

For the valves HP, HX and other high pressure versions, observe the additional instruction: “Installation of

high pressure knife gate valves – tighten the gland or double gland”.

B8 Disassembling the valve

Note:

Additional requirements may be found in the actuator (if any) instruction.

For the valve the same safety instructions apply as for the pipe (system) and for the control system to which the actuator

(if any) is connected. The respect of these requirements shall be followed.

Danger

Disassembling the valve from the pipe line may only be done when:

• the pipe section is free from pressure and is empty

• all the electronic and/or pneumatic/hydraulic connections have been disconnected

People’s life and health is at stake if this is not observed. Any other action is the responsibility of

the user.

Page 10

10

Document: is-VALVE, 2017-07-01, issue: 14

Disassemble the valve in following steps:

1. Depressurise the pipe se cti on and drain it com plet ely .

2. Disconnect all electric and/or pneumatic/hydraulic connections.

3. Fasten and use soft straps if necessary (see also Fig.1 in section A5). Make sure not to damage the valve, gate,

gate guards or any accessory.

4. Take out the valve from the pipe carefully in order to protect the flange gaskets.

5. At transport and storage observe section A5.

C) Service and maintenance

Note

Additional requirements may be found in the actuator instruction.

The user shall make a risk analysis as per Machinery Directive 2006/42/EC for the pipe system. Stafsjö supplies the

following documents for it:

• The original installation and service instruction of the va lve.

• An installation and service instruction of the actuator (if any)

• The manufacturer’s declaration(s) to EC Directives.

This inst ruction includes safety notes for industrial application for any foreseeable risk at use of the

valve. It is the responsibility of the user/planner to complete this instruction with warning notes for

plantspecific risks.

Further information on Stafsjö’s valves is ava ila ble on www.stafsjo.com.

C1 Safety warnings at service and maintenance

• At operation, the function of the valve shall be in compliance with the <Valve Destination>, see

section A2.

• The service conditions of the valve shall be in compliance with the valve markin gs, se e section A4.

• Service and maintenance shall be performed by qualified personal. Qualified are those persons

who, due to experience, can judge the risk and execute the work correctly and who are able to

detect and to eliminate possible risks.

• At service the valve should be inspected periodically (preferably every day) for leakage or other

external effects that could affect the safety for the personnel.

• If a fault or problem is detected at an inspection or manoeuvre test, the knife gate valve must be

maintained as soon as possible

• Valves, destined for use in a ATEX classified zone, must be marked according to the ATEX

directive.

• At any start up, the gland box shall be visually inspected for leakage. If any are detected, the nuts

shall be tightened according to table in section B7. Except for this action, no maintenance is allowed

on the valve when the pipe line is pressurised.

• At maintenance or repair of an actuator, it shall be disconnected as described in section B8. The

pipe section must be free from pressure and completely drained at both sides of the valve before

any maintenance begins.

• Some valve types can be installed as end valves. Contact Stafsjö for specific requirements and

further information.

• The temperature of the exterior parts of the valve depends of the fluid temperature inside – any

protective insulation is in the responsibility of the user.

• When the SLV and SLF valve body are closed by bottom cover and/or when SLH and SLX purge

ports are closed by plugs, flushing is recommend ed throug h t he purge ports at serv ice if it is not

clean fluid.

Page 11

11

Document: is-VALVE, 2017-07-01, issue: 14

Danger

1. The gland box packing together with the gland makes sure that no media reaches surrounding

environment where the gate exit the valve body. When the gland box packing (braids) shall be

changed, the gland bolts must be loosened and the the pipe section shall be depressuris ed and

empty.

2. A valve with an actuator shall be actuated only if:

• The valve is installed between flanges or between a flange and a protective device.

• The gate guards are installed on the beams, on automatic operated valves.

3. If you install the knife gate valve as an end valve in a pipe line, always install protective equipment to

prevent people getting to close to the valve and being exposed to the media transported in the system

when the valve opens.

People’s life and health is at stake if this is not observed. Any other action is the responsibility

of the user.

C2 Manual and automatic actuation

A knife gate valve with handwheel closes clockwise.

A valve with automatic actuator is operated following the si gn als fr om the plant control system. Valves equipped with

actuator supplied by Stafsjö are exactly adjusted to stop in the exact end positions. This adjustment shall not be changed

as long as the valve operates correctly.

Valves with infrequent operation:

A test with full actuation movement should be performed once a month, to verify that the valve operates correctly.

C3 Maintenance

Seat and box packing are wear parts that have to be replaced regularly. The interval for replacement depends on the

application and operating data such as pressure, temperature, erosion, chemical and mechanical effect of the media on

the materials in the knife gate valve.

A threaded stem is used on hand wheel, bevel gear and electric operated valves to open/close the valve. The stem is

greased upon delivery – make sure to grease it on regular basis.

As long as the valve is tight and the threaded stem is greased, the only maintenance that has to be performed is a visual

control of the stuffing box tightness. Tighten the gland at any leakage; see section B7 for recommended maximum

torque.

C4 Troubleshooting

Problem

Reason

Measure

Leakage from stuffing box

packing

Gland bolting too loose*

Worn-out box packing

Incorrectly installed box packing

Damaged gate

See relevant maintenance instructions

issued by Stafsjö

Download: www.stafsjo.com

Leakage at

flange connection

Wrong length of bolts in flanges

Loose flange bolting

Valve not centred at flange connection

Valve not parallel to flanges

Gasket not centred

Wrong gasket material

See this instruction, section B7

See Stafsjö’s maintenance instructions and

relevant data sheet

Download: www.stafsjo.com

Leakage through valve

bore

Worn-out seat/sealing profile

Valve does not close 100%

Damaged seat or gate

See relevant maintenance instructions

issued by Stafsjö

Download: www.stafsjo.com

See instruction for actuator (if any)

Page 12

12

Document: is-VALVE, 2017-07-01, issue: 14

Gate does not open/close

completely

Fault in actuator

Fault in limit switch setting

Valve clogged

Damaged seat/sealing profil e or gate

See instruction for actuator/accessories

See the relevant maintena nce instr uct ions

issued by Stafsjö

Download: www.stafsjo.com

Gate does not open/close

in a smooth movement

Fault in actuator

Valve clogged

Damaged seat/sealing profile or gate

Not enough air supply pressure

Not enough air flow supply

See the relevant instruction for actuator

See relevant maintenance instructions

issued by Stafsjö

Download: www.stafsjo.com

Too large force to

open/close the gate

(too high hand force as

well)

Gland nuts tightened by too high torque

Valve exposed to stress/tension

Valve clogged or deformed

Damaged seat/gate

See the relevant maintena nce instr uct ions

issued by Stafsjö

Download: www.stafsjo.com

* When tight ening the gland box bolts: See Table section B7

Stafsjö can offer maintenance of valves. Contact Stafsjö or your local representative for further information. Stafsjö does

not accept any responsibility for the product if wear parts not tested and approved by Stafsjö are used on the valve.

Stafsjö does not accept any responsibility for the product if maintenance instructions are not followed during

maintenance.

Page 13

13

Document: is-VALVE, 2017-07-01, issue: 14

Declaration in compliance with EU-Directives

The manufacturer Stafsjö Valves AB, SE-618 95 Stavsjö Sweden, declares that valve types D2G, HG, HL, HP, HX, JTV, MP, MV,

RKO, RKS, SLF, SLV, SLH, SLX, TV, XV and WB are manufactured in accordance with the requirements of the following standard and

EU-Directives.

• EN ISO 12100-2010 ”Safety of machines Basic terms, general design guidelines”

• Pressure Equipment Directive (PED) 2014/68/EU: The valves comply with this directive and f ulfi l t he requirements in EN

12516. The conformity rating procedure used according to Annex III of the Pressure Equipment Directive 2014/68/EU category I

and II module A2. The valve is CE marked when it is applicable.

Notified body: TÜV NORD Systems GmbH & Co. KG, Reg.-No. 0045

• Machine Directive 2006/42 EC (MD). Automatically manoeuvred valves fulfil the demands in this directive as a “partly complete

machine”. This declaration is considered as a declaration of Incorporation. 2006/42 EC (MD) does not apply if the valve is

actuated manually – observe the Table below

• ATEX Directive 2014/34/EU – the directive is fulfilled only when the valve is labelled with EX-marking

The valves comply with this directive. The ATEX Directive 2014/34/EU does not apply if the valve is operated manually. The

conformity rating procedure used according to EN13463-5:2003 “Non electric equipment intended for use in potentially

explosive atmospheres – Part 5: Protection by constructional safety “C”

- For Group II, 3 G/D (zone 2 or 22)

Product documents are available on the following:

Design documentation, Technical data sheets, catalogue pages

Stavsjö, 2017-07-01

Maria Persson, General Manager

To comply with the directive above, the following applies:

1. The use of the valve must comply with the <valve destination> defined in the “Original Installation and Service Manual (“IS-VALVES_EN”)

supplied with the valve and must follow all instructions in this manual.

If this manual is not followed, the manufacturer may – in serious cases – be released from his product liability.

2. The valve shall not be put into operation (and the fitted actuator if any) until the conformity to all applicable EU directives above of the system

into which the valve is fitted has been declared by the persons responsible. A separate declaration is supplied for the actuator named above.

3. Stafsjö Valves AB has made and documented the required risk analysis; the Stafsjö AB employee responsible for this documentation is

Ulrika Björn, SE-618 95 Stavsjö.

Manufacturer STAFSJÖ Valves AB SE 61895 Stavsjö, Sweden, declares that a STAFSJÖ knife gate valve complies Directives 2006/42/EC as follows:

Requirements as per Anne x 1 of the Dir ect i ve 2006 /4 2/ EC

1.1.1, h) Valve destination

See original installation and service instruction.

1.1.2.,c) foreseeable misuse

See original installation and service instruction , section B1 och C1.

1.1.2.,d) protecting measures personnel

Same as the pipe section into which the valve is installed. See original installation and service instruction,

section B1.

1.1.2.,e) accessories for maintenance

No special tools are necessary.

1.1.3 material in contact with the fluid

All valve material in contact with media are specified in the order acknowledgement and/or on the valve’s

marking.

The relevant risk analysis is the responsibility of the user.

1.1.5 handling

See original installation and service instruction

1.2 and 6.2. control system

Is the responsibility of the user in combination with the instruction of the actuator.

1.3.2 withstand to stress es

For parts under pressure: See declaration of conformity to the PED 97/23/EC

For functional parts: Ensured at contractual use of the valve.

1.3.4 sharp edges or angles

Requirements fulfill ed.

1.3.7/.8 risks related to moving parts

Requirements are fulfilled at contractual use of the valve, see original installation and service instruction.

Observe the warnings.

Delivered gate guards must be installed on the valve.

No maintenance is allowed when the pipe line is pressurized or the automatic actuator is connected.

If the valve is modified by the customer (new actuator) necessary protective devices shall be installed. Ask

Stafsjö for support.

1.5.1 – 1.5.3 energy supply

In the responsibility of the user in combination with the instruction of the actuator.

1.5.5 contact to surface with high/low temp.

See warning in the “Original installation and service instruction”

1.5.7 -explosion

-protection may be necessary. This shall be confirmed in Stafsjö’s order acknowledgement. Observe the

valve’s marking and relevant instruction from Stafsjö.

1.5.13 emission of dangerous substances

Not applicable at not dangerous fluids.

For dangerous fluids: pay attention when re-tightening the gland box. Personal safety equipment may be

necessary.

1.6. maintenance

See original installation and service instruction

1.7.3 marking

Knife gate valve: see original installation and service instruction

Actuator: see actuator instruction

1.7.4 service instruction

See original installation and service instruction and actuator instruction.

Requirements from Ann ex III

The knife gate valve is not a complete machine. No CE marking for conformity with the directive 2006/42/EG.

Requirements from Ann ex es IV ,VII I to XI

Not applicable.

Page 14

Stafsjö Valves AB

SE-618 95 Stavsjö

Sweden

Tel: +46 11 39 31 00

Fax: +46 11 39 30 67

info@stafsjo.se

www.stafsjo.com

Loading...

Loading...