Page ST325 User Handbook

24

Further copies of this handbook may be found at www.staffordinstruments.co.uk/docs/st32x/user325.pdf

Program No:

Segment

No.

Ramp

Rate

°C/hr

Soak

Temp

°C

Soak

Time

hr.min

Notes

Please photocopy me!

Please photocopy me!

ST325 User Handbook Page

1

ST325

User Handbook

ST325 Temperature Programmer

TAFFOR

S

D

Stafford Instruments Ltd.

Tel: +44(0)1785 255588

Fax: +44(0)1785 255589

www.staffordinstruments.co.uk

email: support@stafford-inst.co.uk

Issue: 1.02

Date: 21 Feb 2011

See separate handbook for User Instructions

© Copyright 2011 Stafford Instruments Ltd.

Page ST325 User Handbook

2

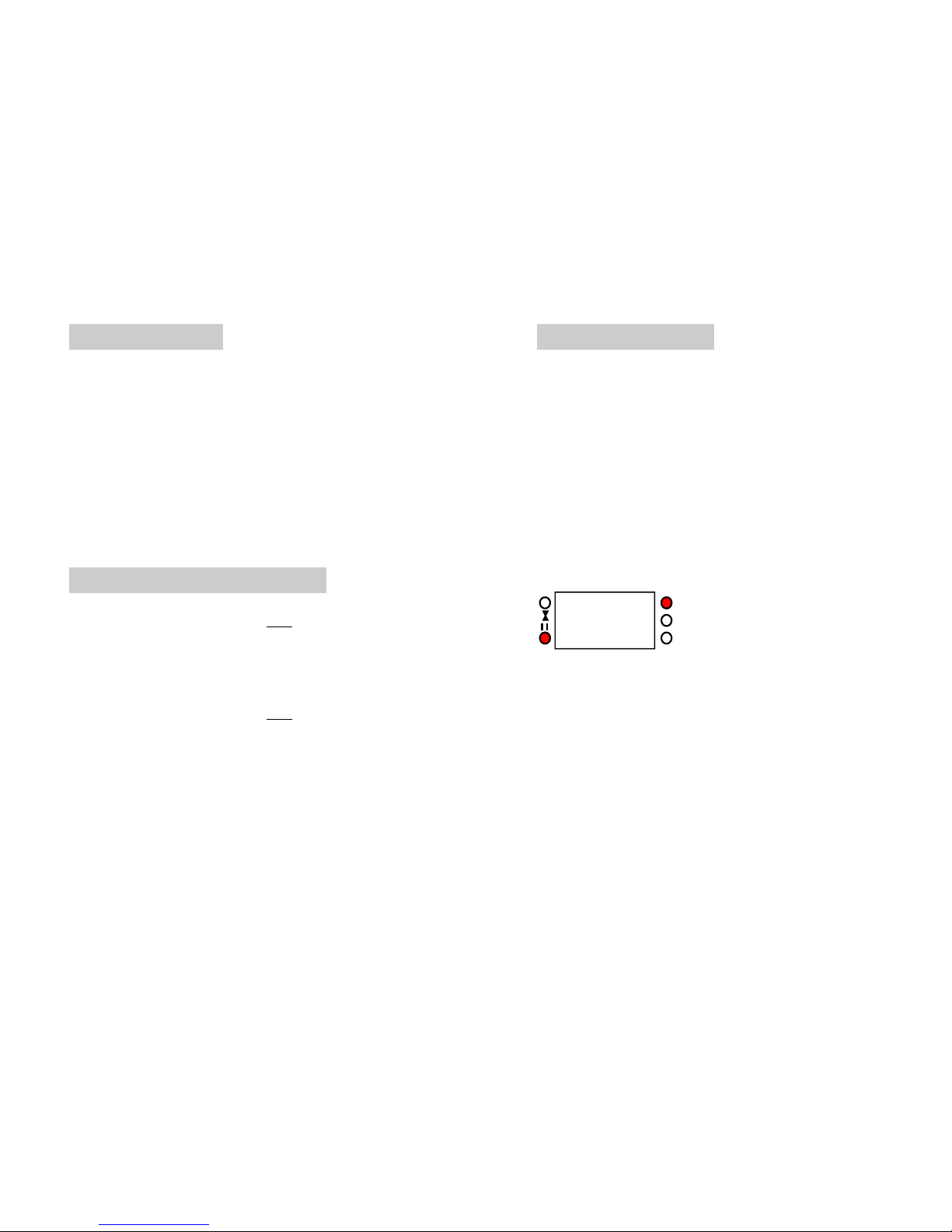

MAIN DISPLAY

SEGMENT

MIMIC

DISPLAY

DISPLAY

INDICATORS

CONTROL

KEYS

(6)

At A Glance

SOAK TIME LAMP

SOAK TEMPERATURE LAMP

COOLING

RAMP LAMP

FIRING LAMP

HEATING

RAMP LAMP

POWER

SWITCH

(ON BASE)

EVENT LAMP

PAUSED LAMP

CARD

READER

(ON SIDE)

ST325 User Handbook Page

23

All error messages cause the ST325 to terminate the firing with all the

keys locked. An alarm buzzer sounds once per second.

SWITCH KILN OFF!

To reset the ST325 turn off the power to the instrument and have the fault

investigated and rectified by your installer or kiln service engineer.

Technical note: any error message will cause the alarm relay to open

- see installation handbook for details.

Note: these error messages are provided to detect kiln faults and so

offer some protection to the kiln. For increased protection the use of

a heat fuse or other independent over-temperature trip is recommended - such as the Stafford Instruments ST121.

Error 7. Maximum room temperature

exceeded. The internal temperature of

the ST325 has exceeded an installer

selectable (30 - 70°C) limit.

Err7

°C

°C/hr

hr.min

Possible causes are: room vent fan failure, ventilation grills blocked, kiln room too

small, damper or bung left open.

Error Messages

Page ST325 User Handbook

22

Error Messages

Error Messages

Error 1. The kiln temperature is not

increasing as required. The kiln has been

on full power for 1 hour but the kiln

temperature has not risen by at least 8°C.

Error 2. Thermocouple or thermocouple

wiring open circuit. Get thermocouple and

wiring checked. Have thermocouple

replaced if necessary.

Error 3. Thermocouple reversed (kiln

temperature apparently less than -40°C).

This is an installation fault. Get wiring

checked.

Error 4. Kiln temperature too high. The

kiln has been on zero power for 30

minutes but the kiln temperature has not

fallen by at least 1°C

Err1

°C

°C/hr

hr.min

Err2

°C

°C/hr

hr.min

Err3

°C

°C/hr

hr.min

Err4

°C

°C/hr

hr.min

Possible causes are: kiln door or lid not closed properly, heater element failure,

elements too old, power phase failure, contactor failure or thermocouple shortcircuit.

Error 5. Kiln temperature overshoot. The

kiln temperature exceeds the desired

temperature by at least 10°C - 50°C

(installer selectable).

Err5

°C

°C/hr

hr.min

Error 6. Maximum firing time exceeded.

The length of the current firing has

exceeded an installer selectable (10 - 999

hours) limit.

Err6

°C

°C/hr

hr.min

Possible causes are: contactor failure or thermocouple connection intermittent or

high resistance.

ST325 User Handbook Page

3

Quick Start Guide

Quick Start Guide

Switch on & wait for kiln temperature display

To run a firing program set up previously press

the START/STOP key

To stop the firing at any time press the START/

STOP key again

To review firing data press the ¨ key to enter

the programming menu

To change firing data press the © & ª keys to

change the displayed value

Use the ¨ key again as necessary to index to

the next firing value or segment to be reviewed

or changed

To mark the end of a program set a ramp rate to

End with the ª key

If the keyboard is locked then press the © & ª

keys together & hold down for 5 seconds to

unlock

To exit the programming menu either wait 10

seconds or press the START/STOP key to start

firing

Page ST325 User Handbook

4

Contents

Contents

At a Glance .......................................................................................... 2

Quick Start Guide................................................................................. 3

Contents............................................................................................... 4

Features ............................................................................................... 4

Turning On ........................................................................................... 5

Programming..................................................................................... 6-8

Sample Ceramics Programs ................................................................ 9

Temperature Display .......................................................................... 10

Firing .................................................................................................. 11

Sample Glass Programs ............................................................... 12-13

Cooling ............................................................................................... 14

Operating Notes ................................................................................. 15

Adjusting While Firing.................................................................... 16-17

Other Features ................................................................................... 18

Card Reader....................................................................................... 19

Control Relay ................................................................................ 19-21

Error Messages............................................................................. 22-23

Program Record Sheet....................................................................... 24

• Multi-zone

• 32 programs each with up to 32 segments

• 1 controlled heating / cooling ramp + soak per segment

• Soak times up to nearly 100 hours

• Ramp rates from 1 to 999°C/hour + full

• Ideal for glass or ceramics use

• Programs can be altered while firing

• Program pause + segment advance facilities

• Event / Damper Relay Output

• Keyboard lockable

• Delayed start facility - up to nearly 100 hours

• Power failure recovery

• Info key for energy used & set point display

• Alarm Buzzer & Alarm Relay Output

• Mains power switch

• Micro-SD memory card reader

Features

Features

ST325 User Handbook Page

21

FAn.1

°C

°C/hr

hr.min

200

°C

°C/hr

hr.min

FAn.0

°C

°C/hr

hr.min

700

°C

°C/hr

hr.min

At the start of the firing the fan remains off while the kiln temperature is

below the fan start temperature. The fan starts when the kiln temperature

has risen to the fan start temperature and remains on until the kiln temperature has risen to the fan stop temperature. The fan then turns off and

stays off until the end of the program.

The instrument will now reset and the new fan control temperatures will

be stored.

Note: in the sequence above it is important that the

¨

key is

pressed a total of 4 times else configuration changes will not be

saved.

Fan Operation

Fan Output

To enter damper temperature configuration mode press and hold down

the

§ & ¨ keys at the same time while the controller is not running a

program (FIRING LAMP not lit).

Note: in the sequence below if no key presses are detected within

15 seconds the instrument will exit configuration mode and configuration changes will not be saved.

The fan start temperature prompt is

shown. Release the

§ & ¨keys.

Press the ¨ key.

The fan start temperature is now shown.

Adjust with the

© & ª keys (hold down

for acceleration).

Press the ¨ key.

The fan stop temperature prompt is now

shown.

Press the

¨ key.

The fan stop temperature is now shown.

Adjust with the

© & ª keys (hold down

for acceleration)

Press the

¨ key.

Control Relay

Page ST325 User Handbook

20

To enter damper temperature configuration mode press and hold down

the

§ & ¨ keys at the same time while the controller is not running a

program (FIRING LAMP not lit).

Note: in the sequence below if no key presses are detected within

15 seconds the instrument will exit configuration mode and configuration changes will not be saved.

dPr.C

°C

°C/hr

hr.min

The damper close temperature prompt is

shown. Release the

§ & ¨keys.

Press the ¨ key.

150

°C

°C/hr

hr.min

The damper close temperature is now

shown. Adjust with the

© & ª keys

(hold down for acceleration).

Press the ¨ key.

dPr.0

°C

°C/hr

hr.min

The damper open temperature prompt is

now shown.

Press the

¨ key.

500

°C

°C/hr

hr.min

The damper open temperature is now

shown. Adjust with the

©& ª keys

(hold down for acceleration)

Press the

¨ key.

The instrument will now reset and the new damper control temperatures

will be stored.

Note: in the sequence above it is important that the

¨

key is pressed

a total of 4 times else configuration changes will not be saved.

Damper Output

Damper Operation

Prior to firing the damper will be open. During firing, when the kiln reaches

the damper close temperature, the damper will closed.

At the end of the firing and when the kiln has cooled naturally to the

damper open temperature, the damper will open.

Control Relay

ST325 User Handbook Page

5

Turning On

tC.r tC.S

tC.n tC.K

When turned on the ST325 performs

a display test by briefly illuminating all

of the display digits and all of the front

panel lamps.

The version number of the embedded

software is now displayed. If you

need technical support you may be

asked for this code together with the

ST325’s serial number.

Next displayed is the thermocouple type to which the ST325 is set. This

thermocouple type setting should match the type of thermocouple fitted to

the kiln and can be R, S, K or N type.

‘R’ type

thermocouple

‘S’ type

thermocouple

‘K’ type

thermocouple

‘N’ type

thermocouple

20

°C

°C/hr

hr.min

. 20

°C

°C/hr

hr.min

20.

°C

°C/hr

hr.min

The final display should show the kiln

temperature (20°C shown here) with

the ‘°C’ indicator on. All other lamps

should be off.

If the left-hand decimal point is on

then the keyboard is locked. This is

an anti-tamper feature. Press the ©

& ª keys together & hold down for 5

seconds to unlock.

If any mimic panel lamps are on then

the ST325 is firing. Press the

START/STOP key to stop the firing.

During firing the right-hand decimal

point will light to show when the kiln

is heating.

Turning On

8888

°C

°C/hr

hr.min

F1.01

°C

°C/hr

hr.min

Turn on the mains supply to the controller using the switch on the base.

Page ST325 User Handbook

6

Programming

A firing segment

An ST325 firing segment comprises a ramp followed by a soak period.

Two segments can be used for simple firing (bisque firing for example)

or up to 32 segments can be used per program for complex firing

(crystal glazing or glass-making for example).

The ST325 ramps the kiln temperature at the required ramp rate until

the kiln reaches the soak temperature. It then soaks (dwells) at the

soak temperature for the soak time. It then runs subsequent segments until the end of the program is reached.

The ST325 is capable of both positive (heating) ramps and negative

(cooling) ramps - as used in glassmaking for annealing. The type of

ramp is clearly shown on the mimic display during firing.

The ramp rate is settable in the range 1°C/hour to 999°C/hour or FULL

(full power) or End (end of program).

The soak temperature is settable over the range 0 to 1320°C.

The soak time is settable over the range 00.00 (no soak) to 99 hours

59 mins.

Note: during soaking the ST325 display alternates every 15

seconds between kiln temperature and soak time remaining.

Programming

soak temperature

heating ramp

cooling ramp

soak period

ST325 User Handbook Page

19

Control Relay

Control Relay Configuration

100

°C

°C/hr

hr.min

While displaying a ramp rate the event

relay can be switched on or off by holding in the f

n (function) key then pressing

the (event) key. The event relay will

be closed when the event lamp is on.

The ST325 has a relay output that can be configured (see installation instructions)

as not used, a damper control output, a fan control output or an event output.

00.15

°C

°C/hr

hr.min

While displaying a soak time the event

relay can be switched on or off by holding in the f

n (function) key then pressing

the (event) key. The event relay will

be closed when the event lamp is on.

Control Relay

Event Output

Card Reader

This controller has a card slot for a micro SD memory card (the same type of card as used on many

mobile phones). The card can only be inserted one

way around with the gold contacts facing away from

you (towards the back of the controller).

Card Reader

Card files can also be used to update the operating

firmware (software) of the controller if necessary for

bug fixes or to add extra features or options.

Files on the card can be used to modify the

configuration of the controller.

You could request a pre-programmed card be sent through the post. Alternatively

the files may be sent via email or downloaded from our website and then copied on

to a suitable card. The controller has been tested with several makes of 1G & 2G

micro-SD cards. Suitable cards are available from Stafford Instruments.

Note: to copy files to the card your computer will need either an SD memory card

slot or a USB card programmer. You may also need an SD to micro-SD card

adapter (often sold with the micro-SD card). Your computer will recognise the card

as a removable disk. The files should reside in the root directory of the card/disk.

Only FAT16 is supported.

To update the controller first turn it off. Insert the card into the controller’s slot.

Press and hold down the green f

n key while turning the controller on. The °C, °C/hr

& hr.min lamps will now flash showing an update is in progress. Release the f

n key.

Wait for the update to finish (might take up to 2 minutes) then remove the card.

Page ST325 User Handbook

18

Other Features

Other Features

Info Key

Hold down the green fn key and then press the i key to display the energy

used in kW hours. If pressed during a firing it shows the energy used so

far. After a firing it shows the total energy used for that firing. This information is stored while power is off and is only reset to zero when a new

firing is started. If the value displayed is always 0.0 then the kiln power

rating has not been configured into the ST325 - see installation handbook.

Keeping the green f

n key pressed down, press the i key again to display

the current set point (target temperature).

Keyboard Lock Facility

1.200

°C

°C/hr

hr.min

The keys on the ST325 can be locked so that pressing them has no effect.

This is an anti-tamper feature used to ensure that the operation of the

ST325 or the program data cannot be altered by un-authorised people.

The ST325 can be locked when it is idle (not firing) or while it is firing. It

cannot be locked while it is being programmed.

If the left-hand decimal point in the

display is lit then the ST325 is locked.

Press and hold in both the © & ª

keys for 5 seconds to unlock the

ST325.

1200

°C

°C/hr

hr.min

If the left-hand decimal point in the

display is not lit then the ST325 is not

locked. Press and hold in both the ©

& ª keys for 5 seconds to lock the

ST325.

Power Failure Recovery

If power fails during firing then the ST325 recovers as follows:For power failure during start delay then by default the ST325 times off the

remaining start delay when power returns (configurable - can be set to fire

immediately when power returns - see installation manual).

For power failure during ramping the ST325 continues the ramp it was previously executing.

For power failure during soaking the ST325 ramps back up to soak temperature at the correct ramp rate then applies the remaining soak period.

Power failure recovery can be disabled if required (see installation handbook) - the ST325 will then lock up with FAIL displayed and kiln off in the

event of power failure.

ST325 User Handbook Page

7

When not firing no lamps lit on the mimic panel, the firing lamp is off

and the display shows the kiln temperature with the °C indicator lit.

Segment 1 is displayed.

Changing / entering a program

. 20

°C

°C/hr

hr.min

If the left-hand decimal point is on then the

keyboard is locked. Press the © & ª keys

together & hold down for 5 seconds to

unlock.

Note: holding down the © or ª keys causes rapid change of the

displayed value.

150

°C

°C/hr

hr.min

¨ then displays the ramp rate in the range

1 to 999°C/hr or FULL or End. This can be

altered with the © & ª keys. The

HEATING RAMP or COOLING RAMP

lamp on the mimic display will flash.

600

°C

°C/hr

hr.min

¨ then displays the soak temperature in

the range 0 to 1320°C. This can be altered

with the © & ª keys. The SOAK

TEMPERATURE lamp on the mimic

display will flash.

Programming

00.15

°C

°C/hr

hr.min

The next push of the ¨ key displays the

soak time in the range 00.00 to 99.59 (99

hours 59 mins). This can be altered with

the © & ª keys. The SOAK TIME lamp on

the mimic display will flash.

A further push of the ¨ key increments the segment display digit and

firing data for the next segment can be entered. Continue

programming susequent segments as required.

Pr.12

°C

°C/hr

hr.min

1

Press the ¨ key to display the currently

selected (flashing) program number. This

can be changed as required with the © &

ª keys. There are 32 programs available.

End

°C

°C/hr

hr.min

Data entry is terminated if End is selected

for a ramp rate with the ª key. Data entry

is also automatically terminated if 32

segments have been entered.

2

Page ST325 User Handbook

8

To exit programming mode at any time wait 10 seconds without

pressing any keys - the ST325 will then revert to the idle display.

Alternatively press the START/STOP key to exit programming and to

begin firing immediately.

The

§

key can be used to reverse through the programming steps to

correct errors or to exit programming mode.

Available ramp rate displays are: End, 1 … 999

& FULL. If End is

shown but another segment is required then push the © key to obtain

the required ramp rate (in the range 1°C/hr to 999°C/hr). If full power

is required then push the © key until FULL is displayed.

Programming Notes

Programming

To declare the end of a program while prompted for a ramp rate push

the ª key until End is displayed.

FAQ (Frequently Asked Questions)

During programming the COOLING lamp sometimes flashes when I want the

kiln to heat - why is this?

The ST325 asks you to input the ramp rate before

it asks for the soak

temperature so if the (still to be set) soak temperature in the current segment is

less than the soak temperature in the previous segment the ST325 will assume

cooling is required. This anomaly will be rectified when all of the program has

been entered. This can be confirmed by stepping through the completed

program with the ¨ key.

Q:

A:

During programming the HEATING lamp sometimes flashes when I want the

kiln to cool - why is this?

The ST325 asks you to input the ramp rate before

it asks for the soak

temperature so if the (still to be set) soak temperature in the current segment is

more than the soak temperature in the previous segment the ST325 will

assume heating is required. This anomaly will be rectified when all of the

program has been entered. This can be confirmed by stepping through the

completed program with the ¨ key.

Q:

A:

During programming End is displayed when I want to enter another segment why is this?

Available ramp rate displays are: End, 1 … 999

& FULL. If End is shown but

another segment is required then push the © key to obtain the required ramp

rate (in the range 1°C/hr to 999°C/hr). If full power is required then push the ©

key until FULL

is displayed.

Q:

A:

How do I declare the end of the program?

Press the ¨ key to advance to the next segment. Push the ª key until End

is

displayed. (Press the ¨ key again to exit programming mode).

Q:

A:

ST325 User Handbook Page

17

Program Pause Facility

While firing press and hold down the green fn (function) key then press the

▌▐ (pause) key. The ST325 will pause the executing program. To unpause the program repeat the above key press sequence. The effects of

pausing are as follows:-

If paused during ramping the kiln temperature will be held (soaked) indefi-

nitely at the current kiln temperature. The ramp will continue when unpause is selected.

If paused during soaking then the soak time will be extended indefinitely.

The remainder of the soak period will be resumed when un-pause is selected.

Segment advance ►►can also be used to terminate the pause. This will

advance the segment and will immediately terminate a paused soak - advancing to the next segment (if any).

Changes made to the operation of the ST325 in this way are temporary

and are not stored.

600

°C

°C/hr

hr.min

As a warning during pause a double

beep is sounded every 10 seconds

and the display scrolls PAUSed. The

PAUSED lamp to the bottom left of

the main display is lit.

Adjusting While Firing

WARNING - PROGRAM PAUSE

The program pause facility should be used with care. Program

execution is suspended and the kiln will be held at its current

temperature indefinitely.

If left too long at high temperatures kiln damage could result.

Page ST325 User Handbook

16

Adjusting While Firing

Firing values can be adjusted while the ST325 is firing. Also there are program pause/un-pause and segment advance features that are particulary

useful for glass work.

Adjusting Firing Values

While firing operate the ¨ key to select the required parameter as shown

by a flashing lamp on the mimic display. The firing value is shown on the

main display and can now be adjusted with the © & ª keys in the usual

way. The contents of the current segment or any segment still to be

executed can be changed. Firing will still carry on as normal while these

changes are being made. The ST325 will return to its normal running

display 10 seconds after key presses cease (or immediately after End is

displayed).

Changes made to programs in this way are stored and are used for

subsequent firings.

Segment Advance Facility

While firing press and hold down the green fn (function) key then press the

►► (advance) key. The ST325 will sound a short beep and the executing

program will immediately advance one step as indicated by lamps on the

mimic panel. The effect of this is as follows:-

If a start delay is currently executing then the ST325 will terminate this and

start firing immediately.

If ramping is currently executing then the ST325 will switch to soak at the

current kiln temperature.

If currently soaking then the ST325 will advance to the next segment if any,

or else it will end the firing.

Changes made to the operation of the ST325 in this way are temporary

and are not stored.

Adjusting While Firing

ST325 User Handbook Page

9

Sample Ceramics Programs

Sample Ceramics Programs

Note

It has been found that a kiln controller will give greater heat work as the temperature

increases. Therefore to achieve a stoneware firing of cone 8-9 we suggest setting

the final soak temperature to 1235°C. A slight adjustment can then be made after

the first firing. It should be remembered that kiln controllers are indicators of

temperature and the effects of faster or slower firings may cause extreme variations

in the end result. This is known within ceramics as “heatwork”. Cones are

measures of heatwork and it is strongly recommended that cones are always used

in conjunction with a kiln controller to appreciate the differences between heatwork

and temperature indicated by the controller. Stoneware firings will also demonstrate

the greatest potential differences between heatwork and indicated temperature.

All of the information on this page was kindly provided by Reg Griggs

of Clayman Supplies Limited (www.claymansupplies.co.uk).

Program Name Segment 1

Ramp Rate

Segment 1

Soak Temp

Segment 1

Soak Time

Segment 2

Ramp Rate

Segment 2

Soak Temp

Segment 2

Soak Time

Slow Bisque 60°C/hr 600°C 00:00 FULL 1000°C 00:00

Normal Bisque 100°C/hr 600°C 00:00 FULL 1000°C 00:00

High Bisque 100°C/hr 600°C 00:00 FULL 1140°C 00:00

Brush-on

Earthenware Glaze

1000°C (Cone 6)

100°C/hr 300°C 00:00 FULL 1000°C 00:00

Standard

Earthenware Glaze

1100°C

100°C/hr 300°C 00:00 FULL 1100°C 00:00

Earthenware High

Temperature Glaze

1140°C

100°C/hr 300°C 00:00 FULL 1140°C 00:00

Mid-Range

Stoneware Glaze

1200°C

100°C/hr 300°C 00:00 FULL 1200°C 00:00

Standard

Stoneware Glaze

1260°C (see note)

100°C/hr 300°C 00:00 FULL 1235°C 00:00

Onglaze 780°C 100°C/hr 400°C 00:00 FULL 780°C 00:00

Lustre 750°C 100°C/hr 400°C 00:00 FULL 750°C 00:00

Segment 3

Ramp Rate

End

End

End

End

End

End

End

End

End

End

Page ST325 User Handbook

10

Temperature Dispaly

Temperature Display

1020

°C

°C/hr

hr.min

For multi-zone kilns the temperature of

each zone can be displayed. Zone 1 is

displayed by default when the ST325 is

powered on.

Ch 1

°C

°C/hr

hr.min

To check which zone / channel is currently

displayed press the © or ª keys. The

zone temperature will be displayed again

after 5 seconds or if the ¨or § keys are

pressed.

Ch 2

°C

°C/hr

hr.min

To change the displayed zone / channel

press either the © or ª keys again. Ch 1

& Ch 2 will be shown for 2-zone kilns and

Ch 3 will be shown for 3-zone kilns.

1023

°C

°C/hr

hr.min

To display the zone temperature either

wait 5 seconds or press the ¨or § keys.

This section only applies to multi-zone (2 or 3 zones) kilns. A single zone

kiln will always show the temperature of zone 1 only.

ST325 User Handbook Page

15

If the ST325 is programmed to heat the kiln at a faster rate than the kiln is

capable of then the ST325 will turn on full power then wait until the kiln

temperature has risen to the correct temperature before proceeding to the

next ramp or soak segment.

Likewise if the ST325 is programmed to cool the kiln at a faster rate than

the kiln is capable of then the ST325 will apply zero power then wait until

the kiln has cooled to the correct temperature before proceeding to the

next ramp or soak segment.

Kiln too slow

Heating & Cooling Ramps

The ST325 is capable of controlled ramps for both heating and cooling.

The type of ramp required is determined by comparing the required soak

temperature to the soak temperature in the previous segment and is shown

on the mimic display.

STOP key operation

If the START/STOP key is pressed during a firing then the firing will be

halted (not paused). Pressing the START/STOP key again will cause the

ST325 to restart the firing from the beginning. The ST325 will look at the

current kiln temperature and if this is greater than the required soak temperature then the ST325 will automatically cool from current temperature to

the soak temperature. This may not be what is desired so the STOP key

should only be used to halt the firing in an emergency.

The program can be paused or program data can be changed while the

controller is firing (see page 14). This is a better option than using the

STOP key. The segment advance feature (see page 16) is however available to recover quickly from STOP key operation if required.

Memory

All programs & necessary data are remembered when the ST325 is turned

off. In the event of power failure during firing the ST325 will automatically

resume firing when power is returned (this feature can be disabled: see

installation handbook).

Operating Notes

Delayed Start

The delayed start time period is by default set to 00.00 when the ST325 is

turned on. This zeroing feature can be changed to allow a previously entered delayed start time to be remembered: see installation handbook.

Operating Notes

Page ST325 User Handbook

14

Cooling

Upon completion of firing the ST325 lights all lamps on the mimic display and the

kiln is allowed to cool naturally.

120

°C

°C/hr

hr.min

Hot

°C

°C/hr

hr.min

39

°C

°C/hr

hr.min

End

°C

°C/hr

hr.min

While the kiln temperature is above 40°C the display alternates every 5 seconds

between the kiln temperature and Hot

When the kiln has cooled to less than 40°C the display alternates every 5 seconds

between the kiln temperature and End

To return the ST325 back to idle condition ready for the next firing press the START/

STOP key (or turn off the power to the instrument).

Cooling

ST325 User Handbook Page

11

00.00

°C

°C/hr

hr.min

Firing

Information: The ST325 operates by calculating the amount of energy required by the kiln

every 30 seconds. If for example 40% of full energy is required to maintain a particular

ramp rate or a particular soak temperature then the ST325 will apply heating power to the

kiln for 12 seconds every 30 seconds. The right-hand decimal point in the display will

light for 12 seconds every 30 seconds. If the kiln has a contactor then a loud click will be

heard both when the decimal point lights up and when it goes out. If full heating power is

required then the decimal point will remain lit. If full cooling is required then the decimal

point will remain off.

Firing

Hint: it is good practice to check that the program is correct by pressing the ¨

key & checking the program number & program contents before starting a

firing.

20.

°C

°C/hr

hr.min

To start a firing press the START/STOP

key. The start delay time will be displayed.

The FIRING LAMP will flash - prompting

you to change the start delay (using the ©

& ª keys). If the delay is 00.00 the firing

will start in 5 seconds (or immediately if the

STOP/START key is pressed again).

During firing the right-hand decimal point

will periodically light - this shows when

heating power is being applied to the kiln

elements.

620

°C

°C/hr

hr.min

When the kiln has ramped to the programmed soak temperature soaking commences for the programmed soak time.

The display alternates between showing

kiln temperature...

00.14

°C

°C/hr

hr.min

… and showing the soak time remaining.

At the end of the soak period the next required segment will be run. If no more

segments are required the kiln is allowed to cool naturally (see page 14).

Page ST325 User Handbook

12

Sample Glass Programs

Program

No.

Program

Description

Seg 1

Ramp

Rate

°C/hr

Seg 1

Soak

Temp

°C

Seg 1

Soak

Time

hr:mn

Seg

Ra

mRat

°C/

h

1 4-6mm Float Glass Fuse 150 538 00:10 FUL

L

2 4-6mm Float Glass Slump 538 538 00:00 FUL

L

3 6mm Bullseye™ Fuse 204 538 00:00 316

4 6mm Bullseye™ Slump 155 704 00:20 FUL

L

5 6mm Spectrum System 96™ Fuse 200 500 00:00 FUL

L

6 6mm Spectrum System 96™ Slump 155 704 00:20 FUL

L

7 Bottle Firing Cycle 170 510 00:00 250

8 Low Stain 200 570 00:10 FUL

L

9 High Stain 200 665 00:10 FUL

L

The ST325 is provided pre-programmed with the sample

programs shown above which may be modified as required.

These programs were kindly provided by Kilncare Ltd

(www.kilncare.co.uk) and The Creative Glass Guild

(www.creativeglassguild.co.uk).

Sample Glass Programs

ST325 User Handbook Page

13

2

p

e

Seg 2

Soak

Temp

°C

Seg 2

Soak

Time

hr:mn

Seg 3

Ramp

Rate

°C/hr

Seg 3

Soak

Temp

°C

Seg 3

Soak

Time

hr:mn

Seg 4

Ramp

Rate

°C/hr

Seg 4

Soak

Temp

°C

Seg 4

Soak

Time

hr:mn

Seg 5

Ramp

Rate

°C/hr

840 00:20 FULL 538 00:45 182 427 00:15 End

824 00:20 FULL 538 00:15 182 427 00:00 End

794 00:20 FULL 516 01:00 66 371 00:00 End

516 01:30 26 371 00:00 End - - -

804 00:12 FULL 540 00:40 150 510 00:20 End

540 01:30 FULL 510 00:10 26 371 00:00 End

780 00:10 FULL 510 01:00 70 400 00:30 End

516 00:30 100 300 00:00 End - - -

550 00:20 FULL 516 00:30 100 300 00:00 End

Bullseye™ is a registered trademark of the Bullseye Glass

Company (www.bullseyeglass.com).

System 96™ is a registered trademark of the Spectrum Glass

Company Inc (www.system96.com)

Loading...

Loading...