Page 1

FIRSTLINE P

Maintenance Bypass

Switch Cabinet

160kVA-250kVA, 480V Input/O utput

With SKRU

USER MANUAL

003-2621

Page 2

Table of Contents

SECTION 1 .......................................................................................................................... 1

Introduction ....................................................................................................................... 1

Overview ........................................................................................................................... 1

Applicability ....................................................................................................................... 2

Part Numbers ................................................................................................................... 2

Section 2 .............................................................................................................................. 3

SAFETY WARNINGS ....................................................................................................... 3

DANGER .......................................................................................................................... 3

WARNING ........................................................................................................................ 3

CAUTION ......................................................................................................................... 4

Section 3 .............................................................................................................................. 5

Cabinet Setup ................................................................................................................... 5

Inspecting the Equipment ................................................................................................. 5

Floor Loading .................................................................................................................... 5

CLEARANCES ................................................................................................................. 5

Unloading the Cabinet(s) .................................................................................................. 6

Attaching the Cabinet to the UPS ..................................................................................... 7

Section 4 .............................................................................................................................. 8

Electrical Installation ......................................................................................................... 8

Wiring Preparation ............................................................................................................ 8

Control Connections ....................................................................................................... 12

Terminal Strip Torque Requirements .............................................................................. 12

Section 5 ............................................................................................................................ 13

Operation ........................................................................................................................ 13

Maintenance Bypass Switch (MBS) ................................................................................ 13

Section 6 ............................................................................................................................ 18

Maintenance ................................................................................................................... 18

Section 7 ............................................................................................................................ 18

FirstLine P Maintenance Bypass Switch Technical Specifications ................................. 18

Table 1 - Symbols ................................................................................................................ 4

Table 2 - Model Floor Loadings ............................................................................................ 5

Table 3 - Wire Size Requirements. .................................................................................... 10

Table 4 - Recommended Crimp Lugs ................................................................................. 10

Table 5 - Maximum Current Ratings................................................................................... 10

Table 6 - Terminal Tightening Torques .............................................................................. 10

Table 7 - Maintenance Bypass Switch States .................................................................... 16

Table 8 - Maintenance Bypass Switch State Change Procedures ..................................... 17

Table 9 - Technical Specifications ...................................................................................... 18

Figure 1 - The FirstLine P Maintenance Bypass Switch Cabinet .......................................... 1

Figure 2 - Pallet Mounting Hardware .................................................................................... 6

Figure 3 - Cabinet to Cabinet Mounting Hole Locations ....................................................... 7

Figure 4 - Inside View of Maintenance Bypass Switch Cabinet ............................................ 9

Figure 5 - Terminal Pa d ........................................................................................................ 9

Figure 7 - Customer Low Voltage Connection Terminal Block ........................................... 12

Figure 8 - Circuit Breaker Sequence Label ........................................................................ 16

Page | ii

Page 3

SECTION 1

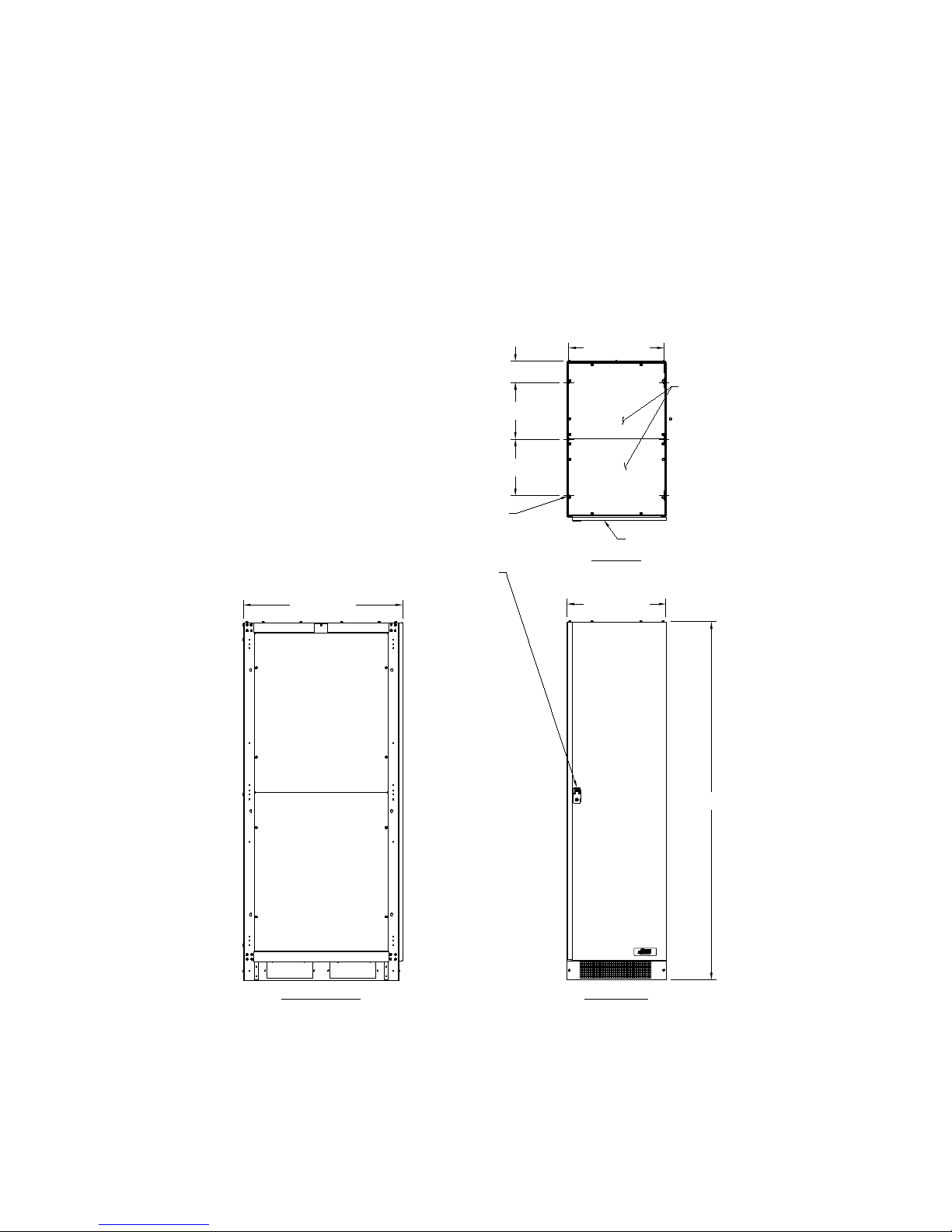

FRONT VIEW

11.85 [301.0]

11.85 [301.0]

20.00 [507.9]

(6) Ø.41 [Ø10.3]

MOUNTING HOLES

ON BOTTOM FEET

4.46 [113.2]

TOP VIEW

.11 [2.8] THICK

DOOR LATCH REQUIRES PHILLIPS

SCREWDRIVER TO OPEN

75.00 [1905.0]

33.35 [847.0]

20.75 [527.0]

LEFT SIDE VIEW

REMOVABLE TOP

COVERS

.08 [2.0] THICK

HINGED FRONT DOOR

Introduction

Overview

The FirstLine P Mai n te nance Bypass Switch C abi net for 160 kVA, 200 kVA, 250 kVA with

480 V Input and Output is a steel cabinet that attaches to the side of the UPS cabinet,

thereby extending the cabinet, and providing the maintenance bypass function. The

cabinet has conduit attachment points at the top and the botto m for max i mu m flexibility in

wiring the source and load power connections. Please refer to Figure 1 for the outline

drawing of the cabinet.

Figure 1 - The FirstLine P Maintenance Bypass Switch Cabinet

All dimensions in Inches (millimeters)

Page | 1

Page 4

Applicability

This equipment can be applied to UPS models FLU-160-00, FLU-200-00, and FLU-250-00.

These UPS models operate at 480 V, 60 Hz and can be wired as delta in and delta out (3

wire plus ground) or wye in and wye out (4 wire plus ground).

For installations requiring other voltages or other wiring configurations, the equipment

covered by this manual is not appropriate. Please contact Staco Energy Products

Company for recommendations regarding the proper equipment.

It is permissible to use a larger Maintenance Bypass Switch Cabinet (MBS) than is required

for the UPS, but special installation requirements must be met: the power source

connected to the MBS must include circuit protection as specified for the input in the UPS

manual and an output breaker must be provided per the UPS manual. For example, if a

250 kVA MBS is applied to a 160 kVA UPS, a 300 A breaker must be provided at the power

source and a 300 A breaker must be provided between the MBS and the load. If the MBS

rating matches the UPS rating, then the breakers that form the MBS switch arrangement

satisfy the input and output breaker requirement for the UPS.

Part Numbers

FLU-P-160-MBPS*SK for use with 160 kVA UPS

FLU-P-200-MBPS*SK for use with 200 kVA UPS

FLU-P-250-MBPS*SK for use with 250 kVA UPS

Page | 2

Page 5

SECTION 2

SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

• Do not use outdoors.

• Do not route wiring across or near hot surfaces.

• Do not install near gas or electric heaters.

• Equipment should be installed where it will not readily be subjected to tampering by

unauthorized personnel.

• The use of accessory equipment not recommended by the manufacturer may cause

an unsafe condition.

• Do not use this equipment for other than intended use.

• This equipment connects to the output of an uninterruptible power supply.

Hazardous voltages may be present even when the electrical supply to this

equipment is turned off.

• If equipped with a maintenance bypass switch, control connections between this

equipment and the ups must be present to prevent the possibility of backfeed.

• Read and follow the instructions that came with the associated UPS or emergency

lighting system before operating this equipment.

DANGER

This equipment contains lethal voltages. All repairs and service should only be performed

by authorized service personnel. There are no user serviceable parts inside this

equipment. Operation of switches and breakers require access to the cabinet interior and

should only be performed by qualified personnel exercising appropriate caution.

WARNING

This equipment connects to the output of a UPS which contains its own energy source

(batteries). The UPS output may carry live voltage even when the UPS is not connected to

an AC supply.

To reduce the risk of fire and electric shock, install this equipment in a humidity controlled,

indoor environment, free of conductive contaminants. Do not operate near water or

excessive humidity (95% maximum). If condensation is present, the equipment must be

allowed to completely dry before operation.

Page | 3

Page 6

CAUTION

The UPS associated with this equipment contains batteries. Batteries can present a risk of

electrical shock or burn from high short circuit current. Observe proper precautions.

Servicing should only be performed by qualified service personnel knowledgeable of

batteries and the required precautions. Keep unauthorized personnel away from batt eri es .

Read, understand, and follow all instructions in the ups manual before attempting any

operations involving the battery.

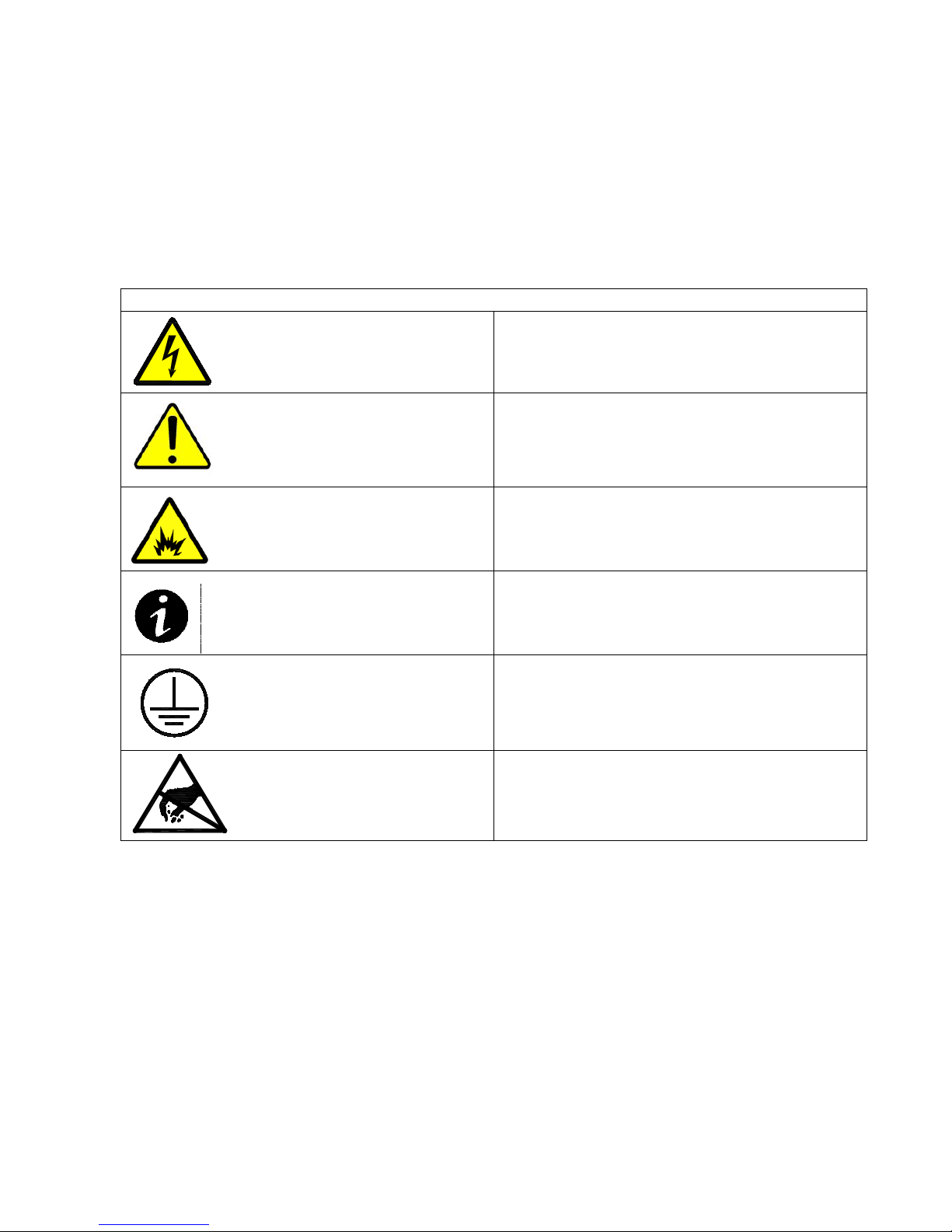

Table 1 - Symbols

Danger / Risk of Electric Shock

Caution

Risk of Explosion

Note

Ground Connection

Electrostatic Sensitive Device

Page | 4

Page 7

STANDARD MODEL FLOOR LOADING

kVA

MAXIMUM WEIGHT

POINT LOADING

160

390 lbs (177 kg)

6.5 lb/in2 (0.5 kg/cm2)

200

390 lbs (177 kg)

6.5 lb/in2 (0.5 kg/cm2)

250

390 lbs (177 kg)

6.5 lb/in2 (0.5 kg/cm2)

From Front of Cabinet

36” (91.4 cm) working space

SECTION 3

Cabinet Setup

This SECTION describes:

Equipment inspection

Floor loading and clearances

Removing and replacing the cabinet panels

Unloading the cabinet(s)

Attaching the cabinet to the UPS

Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping and packing

materials for the carrier or place of purchase and file a claim for shipping damage. If you

discover damage after ac ceptance, file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within 15

days of receipt o f the equipment, 2) Send a copy of the damage claim within 15 days to your

service representative.

Floor Loading

When plan ning the installation, consider the cabinet weight for floor loading. The strength of

the installation surface must be adequate for point and distributed loading. The approximate

weights are shown in the following table.

Table 2 - Model Floor Loadings

CLEARANCES

The following clearances are recommended for the FirstLine P Maintenance Bypass Switch

Cabinet.

Page | 5

Page 8

Unloading the Cabinet(s)

CAUTION

The following tools are required for unloading the cabinet(s):

Wrenches for 3/8” lag bolts.

Forklift or pallet jack

The cabinets are heavy (see Table 2). Unloading the cabinets requires at least two

people to safely remove the cabinets from the pallet.

To remove the Maintenance Bypass Switch cabinet from the ship pallet:

1. Mak e sure the forklift is rated for the cabinet weight.

2. Make sure the path traveled has sufficient support for the combined weight of the

forklift and the cabinet.

3. Make sure forks are at maximum separation.

4. Us e a ver y str ong ratch et str ap (or similar dev ice) of s uffici ent str ength t o tie the uppe r

part of the cabinet to the forklift tower before moving.

5. Keep people out of the fall zone. If the cabinet topples over, stand clear

6. With a Phillip’s screwdriver, remove the two kick panels. These will be rem ounted

when the cabinet is in place.

7. Remove all banding, wrapping and foam protection.

8. Remove the six 3/8” lag bolts securing the cabinet to the pallet. See Figure 2.

9. Lift the cabinet with a forklift one to two inches (1”-2” [2.5-5cm]) above the pallet.

10. Slide the pallet completely away from the raised cabinet.

11. Carefully move the cabinet to the desired location and slowly lower the cabinet to the

floor or other appropriate flat surface.

12. Remount the two kick panels.

Page | 6

Figure 2 - Pallet Mounting Hardware

Page 9

LEFT SIDE VIEW

A

A

A

A

A

A

Attaching the Cabinet to the UPS

The Maintenance Bypass Switch cabinet was constructed so that it can be mounted to the

side of the UPS cabinet if desired. To attach the Maintenance Bypass Switch Cabinet to

the UPS Cabinet:

1. Remove right side panel of UPS and save hardware.

2. Butt left side of MBS cabinet up against the right side of the UPS.

3. Bolt the cabinets together at (6) locations with the supplied 5/16 hardware through

the slots noted as "A" in Figure 3.

4. Mount right side panel of UPS on the right side of the MBS cabinet using the

hardware from the UPS.

Figure 3 - Cabinet to Cabinet Mounting Hole Locations

Page | 7

Page 10

SECTION 4

Electrical Installat i on

Overview

Each of the pieces of equipmen t cov er ed by this manual has four sets of power

connections:

1. Input from the power source, typically, from the electric utility.

2. Power routed to the input of the UPS. If the bypass and rectifier inputs are powered

from separate sources, the bypass input must be fed from the MBS.

3. Power from the output of the UPS.

4. Power to the load

There are four control connections between the Maintenance Bypass Switch Cabinet and

the UPS that must be made. The required control connections are described later in this

section.

A user accessible disconnect device must be provided (by other’s) between the output of

this cabinet and the load. Refer to Table 5 for current requirements.

WARNING

Only qualified service personnel (such as a licensed electrician) should perform

the installation and initial startup. There is a risk of electrical shock.

Wiring Preparation

1. Verify that the equipment is the proper type. The equipment covered by this manual

is 480 V 60 Hz input and output, only. The Maintenance Bypass Switch Cabinet

(MBS) can be used in delta-delta or wy e-wye applications, but the UPS must be

properly configured (refer to the UPS manual). For delta-delta applications where an

input neutral is not provided, the output neutral connection must not be used and the

MBS to UPS neutral connections should be omitted.

2. Plan the locations of conduits. Two Conduit landing plates are provided at the top

(see Figure 1) and bottom of the cabinet. Connections between the MBS and UPS

must be made at the bottom. The landing plates in the rear must be used for the

power connections. As noted above, there are four sets of power connections and

one set of control connections. The low voltage control connection wires must be

routed through the bottom landing plate in the front of the cabinet to ensure physical

separation between th em and the power wiring.

3. All wiring is to be in compliance with all applicable codes.

4. Verify that the source circuit capability is in compliance with the requirements shown

in Table 3 and Table 4.

Page | 8

Page 11

5. Select wire size in compliance with Table 3.

RIGHT SIDE VIEWFRONT VIEW

WITH DOOR AND KICK PANEL REMOVED

NOTE: SHIELD COVER PANELS MUST REMAIN IN

PLACE DURING OPERATION FOR USER SAFETY.

NOTICE

FOR SUPPLY CONNECTIONS,

USE WIRES SUITABLE FOR AT

LEAST 75°C

FOR USE IN A CONTROLLED ENVIRONMENT.

REFER TO HANDBOOK FOR ENVIRONMENTAL

CONDITIONS.

ATTENTION :

Pour utilisation en atmosphère controlée.

Consulter la notice technique pour les

conditions du milieu.

CAUTION!

RISK OF ELECTRIC SHOCK

This Cabinet receives power from more than one

source - disconnection of all ac sources is required

to de-energize this unit before servicing.

NCNOC

CNO NC NCNO

1

1

1

1

1

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

UPS OUTPUT BREAKER

MAINTENANCE BYPASS BREAKER

PANELBOARD 1 BREAKER

PANELBOARD 2 BREAKER

DISPLAY ALARM

TEMP ALARM

TO UPS

REQUEST

BYPASS

INPUT

FRONT PANEL

TRIP SWITCH

KEYLOCK

RELEASE

ON BYPASS

TRANSFORMER

TEMP SWITCHES

HTOT

REPO SWITCH

EXTERNAL DC POWER INPUT

DC POWER

OUTPUT

POWER

INPUTS

AC

D24

TB7

TB6TB5 TB4TB3TB2

TB1

TB11TB10

TB8

TB9

J206

J205

J204

J203

J202

J201

F1

DS3

DS1

D45

C1

C2

D20

1 2

3

X1X3X2X4

H2H1

X1X3X2X4

H2H1

WARNING!

TO REDUCE RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSE.

UTILITY INPUT

CBA

TO UPS INPUT

CBA

OUTPUT TO LOAD

CBA

FROM UPS OUTPUT

CBA

NEUTRAL

REAR VIEW

WITH REAR COVER REMOVED

UTILITY INPUT

CONNECTIONS

CONNECTIONS

TO UPS INPUT

REMOVABLE CONDUIT LANDING

PLATE FOR POWER WIRING

GROUND

CONNECTIONS

OUTPUT TO LOAD

CONNECTIONS

CONNECTIONS FROM

UPS OUTPUT

GROUND

CONNECTION

NEUTRAL CONNECTIONS

WITH 3/8-16 BOLTS

POWER TERMINAL PADS

WITH 3/8-16 BOLTS

REMOVABLE CONDUIT LANDING

PLATE FOR POWER WIRING

REMOVABLE CONDUIT LANDING

PLATE FOR LOW VOLTAGE

CONNECTIONS

LOW VOLTAGE

CONNECTIONS

CIRCUIT

BREAKER

CIRCUIT

BREAKERS

TOP SHIELD

COVER PANEL

MIDDLE SHIELD

COVER PANEL

BOTTOM SHIELD

COVER PANEL

1.00 [25.4]

1.88 [47.6]

COPPER TERMINAL PAD

3/8-16 BOLTS

6. Recommended crimp terminal lugs are shown in Table 4. The power and neutral

terminal pads, see Figure 4 and Figure 5, are provided with 3/8-16 bolts.

Figure 4 - Inside View of Maintenance Bypass Switch Cabinet

Figure 5 - Terminal Pad

Page | 9

Page 12

Table 3 - Wire Size Requirements.

Minimum

Wire Size

Required

Breaker

160

500 kcmil or (2) 2/0

AWG

300 kcmil

3 AWG

300 A

200

500 kcmil or (2) 2/0

AWG

2 AWG

350 A

250

(2) 300 kcmil

(2) 4/0 AWG

1 AWG

450 A

Bolt Size

Wire

Thomas & Betts Two

Hole Connectors

Thomas & Betts Single

Hole Connectors

2/0

54210

54110

3/0

54211

54111

4/0

54212

54112

250 kcmil

54213

54174

300 kcmil

54214

54179

350 kcmil

54215

256-30695-112

400 kcmil

54216

54116

500 kcmil

54218

256-30695-339

kVA Rating

Rated Input

Rated Output Current

160

212

192

200

265

241

250

331

301

Bolt Size

Torque

3/8 - 16

260 inch - pounds

Wire Size

Torque

#6 AWG – 300 kcmil

275 inch - pounds

Wire Size

Torque

# 26-10 AWG

5.3 – 7.0 inch - pounds

*Wire must be rated 75°C or higher. Use copper conductors only.

kVA

Rating

Table 4 - Recommended Crimp Lugs

3/8

Minimum Input Wire

Size

(2) 3/0 AWG

Minimum Output Wire

Size

Ground

Supply

Table 5 - Maximum Current Ratings

Current (Amps)

Table 6 - Terminal Tightening Torques

INPUT / OUTPUT/NEUTRAL TERMINAL TORQUE

GROUND LUG TORGUE

LOW VOLTAGE TERMINALTORQUE

(Amps)

Page | 10

Page 13

Wiring Installation

1. Switch off utility power to the distribution point where the UPS will be connected. Be

absolutely sure that there are no hazardous voltages present. Use lockout/tagout

procedures to assure safety.

2. Remove as many panels as needed for adequate access for wiring the cabinet. Open

the front door of the MBS Cabinet. I f nec es s ar y, remove the top and bottom shield

cover panels located above and below the circuit breakers by removing the four (4)

screws that mount each in place. See Figure 4.

3. Connect wires from the "TO UPS INPUT" bus bar terminal pads, see Figure 4 and

Figure 5, to the input terminals in the UPS. (Refer to the UPS manual). The wire must

be in compliance with Table 3 and the terminals must be torqued in compliance with

Table 6. Make sure that phase A connects to phase A and so on. If the bypass and

rectifier inputs are powered from separate sources, the bypass input must be fed from

the MBS.

4. Connect wires from the "FROM UPS OUTPUT" bus bar termi n al pads to the output

terminals in the UPS. (Refer to the UPS manual). The wire must be in compliance with

Table 3 and the terminals must be torqued in compliance with Table 6. Make sure that

phase A connects to phase A and so on.

5. Connect wir es from the "OUTPUT TO LOAD" bus bar terminal pads to the loa d. Th e

load may be an external distribution panel, etc. If neutral is not needed by the load,

then it does not need to be supplied. The wire must be in compliance with Table 3 and

the terminals must be torqued in compliance with Table 6. Make sure that phase A

connects to phase A and so on.

6. A set of four or five control connections must be installed from the "CUSTOMER LOW

VOLTAGE CONNECTION TERMINAL BLOCK " to the Remote Commands and Alarm

Connections in the front of the UPS cabinet. These control wires must be physically

separated from any power wires. The length of the control wires is limited to 30 feet or

10 meters. These connections are described later in this section.

7. Verify that the input power source is not powered. Connect wires from the "UTILITY

INPUT" bus bar term inal pads to the input source power from the building distribution.

The wire must be in compliance with Table 3 and the terminals must be torqued in

compliance with Table 6. Make sure that phase A connects to phase A and so on.

The source needs to have A-B-C phase sequence. If not, exchange two of the phase

connections to correct thi s.

8. If the system is the used in a wye-wye application, ensure that the neutral wires are

connected to the “Neutral” bus bar terminal pad.

9. Check all work. Replace the panels that were removed for access. Insure that the

shield cover panels have been mounted in place. Failure to do so could subject

personnel to lethal voltages.

Page | 11

Page 14

Control Connections

Four control connections must be made between the Maintenance Bypass Switch Cabinet

(MBS) and the UPS in order to provide backfeed protection, a required safety feature

The wiring to these low voltage (“ELV”) connections must be kept separated from the

higher voltage wiring. Refer to Figure 4 regarding the Low Voltage Terminal Block and to

the UPS manual that shows the connection point in the UPS.

Connections between the Maintenance Bypass Switch Cabinet and the UPS

Since these wires affect the operation of the UPS, they should be protected. Running them

in conduit is a good idea, even if local codes do not require conduit. It is also

recommended that the wires are shielded twisted pairs. Alpha 6010C is a shielded cable

with three twisted pairs and is available from a number of sources in various spool lengths.

Two pairs are required:

Pair 1 - First wire from terminal 2 of the Low Voltage Connecti o n Ter mi nal Bloc k (LV TB) o f

the Maintenance Bypass Switch Cabinet to terminal 11 of the Remote Commands and

Alarms Connections on the UPS (RCA-UPS). Second wire from terminal 1 of LVTB to

terminal 12 of RCA-UPS.

Pair 2 – First wire from terminal 3 of LVTB to terminal 1 of RCA-UPS. Second wire from

terminal 4 of LVTB to terminal 2 of RCA-UPS.

Figure 7 is an electrical wiring schematic summarizing the connections to the Low Voltage

Connection Terminal B l ock .

Terminal Strip Torque Requirements

The terminals on the Customer Low Voltage Connection Terminal Block must be torqued to

5.3 to 7.0 inch-lbs. The terminals on the Control Connections (on the UPS) must be torqued

to 4.4 inch-lbs.

Figure 6 - Customer Low Voltage Connection Terminal Block

Page | 12

Page 15

SECTION 5

Operation

Refer to the User's Manual for the UPS for instructions on operating the UPS part of the

system. If the UPS is part of a parallel system, special operating instructions apply.

Maintenance Bypass Switch (MBS)

The purpose of the Maintenance Bypass Switch (MBS) is to facilitate servicing the UPS

without removing power from the load. The main functional components of the MBS are

three circuit breaker s that are used as disconnect switches. We will designate them

“BKR1”, “BKR2”, and “BKR3”, but they are labeled “1”, “2”, and “3” above the breaker

handles on the front inner cover of the cabinet. The breakers each have three positions: off

(down), on (up), and tripped (in between off and on). To turn on a tripped breaker, reset

the breaker by pushing the handle down to the off position, then raise it to the on position.

If a breaker will not reset or trips as being turned on, the backfeed prevention interlock is

active and the proper conditions (as described below) will have to be present before the

breaker can be operated. When closed, BKR1 supplies power from the supply (utility) to

the bypass input of the UPS. For single input UPS configurations, it also supplies power to

the rectifier input. When closed, BKR3 connects the output of the UPS to the load. When

closed, BKR2 bypasse s the pat h through BKR1, the UPS, and BKR3 and connects the

supply directly to the load. BKR2 and BKR3 must never be closed at the same time unless

the UPS is in bypass mode. It does not matter which type of bypass, but bypass via

SWMB is the simplest to engage. There are signals that support an interlock function to

prevent BKR2 from being closed unless BKR3 is open or the UPS is in bypass mode. For

the UPS to be able to issue this signal, the UPS controls must be powered. Always

observe proper switching sequence to avoid loss of power to the load Common switching

operations are also described, below. There are also some problem scenarios listed.

The three switches (Breaker 1, Breaker 2, and Breaker 3) have eight possible combinations

or "States". Table 7 lists all of the possible states. Note that one possibility (Breaker 1

open, Breaker 2 and Breaker 3 closed) is forbidden as unexpected system behavior could

result, including loss of power to the load. The Overlap State is a transient state. It is the

"make" before the "break". Time spent in this state should be kept to a minimum as

external events could lead to tripping Breaker 2, possibly interrupting power to the load.

Also, please note that the UPS does not condition the power to the load while in bypass

and that battery back-up is not available while in bypass.

To avoid damage to the UPS and to avoid interrupting power to the load, the procedures

listed in Table 8 must be used to change from one state to another. The MBS is equipped

with a label (see Figure 8) that describes the breaker sequenc es for two common

operations. The "To place load on maintenance bypass" sequence describes going from

Normal State to Overlap to UPS Unloaded to Maintenance. The "To place load on UPS"

sequence describes going from Maintenance State to UPS Unloaded to Overlap to Normal.

Page | 13

Page 16

Common MBS operations: (refer to the UPS manual for UPS operations; BKR1,

BKR2, BKR3 are part of the Maintenance Bypass Switch Cabinet; all other switches

are part of the UPS)

To transfer from normal mode on the UPS to maintenance bypass—

1. Verify that the bypass source is satisfactory: at minimum, verify that the bypass

source lamp (LED1 at upper left) on the front panel of the UPS is steady green and

that the legend “BYPASS VOLTAGE FAIL” is not present on the display. If the load

is already being supported by the Static Bypass, the yellow “Load on Bypass” lamp

(LED4, upper right) will be steady (or flashing if the load exceeds the UPS rating).

Refer to Section 6 of the UPS manual regarding the indicators.

2. Close SWMB on the UPS. After SWMB is closed, the yellow “Load on Bypass” lamp

will flash and the inverter will stop and battery supported operation is no longer

possible.

3. Close BKR2.

4. Open BKR3.

5. Shut down the UPS, if desired, by opening SWOUT, SWIN, SWBY, and open the

Battery Disconnect(s). Optionally open SWMB.

6. If the UPS is shut down, open BKR1. The UPS is completely de-energized at this

point.

To transfer from MBS to normal mode—

1. Close BKR1.

2. On the UPS, verify that SWMB is closed, if not, close it.

3. Close SWBY, SWIN, and SWOUT. Wait 5 seconds.

4. Close BKR3.

5. Open BKR2.

6. Open SWMB. The UPS should start and operate normally.

7. When the display no longer shows: “Wait: DO NOT connect the BATTERY”, the

disconnect breakers in each battery cabinet should be closed. Refer to Section 4.6

for the proper procedure for connecting the battery.

Normal start-up with load unpowered—

1. Verify that BKR2 is open; open it if closed.

2. Verify that SWBY is open.

3. Close BKR1 and BKR3.

4. Perform a normal UPS start-up as per Section 4.6 of the UPS manual.

Page | 14

Page 17

Need to get power to the load, but the condition of the UPS is uncertain—

1. Verify that the load is truly not powered.

2. Verify that the utility source is suitable (applying power to the load using the MBS is

at the operator’s risk).

3. Verify that BKR1 and BKR3 are open; open them if necessary.

4. Close BKR2. The load is now powered via the MBS. The UPS is not functional and

battery supported operation is not possible.

Need to operate the UPS as part of maintenance, but wish to maintain power to

load—

1. If UPS is running, perform transfer from normal mode to MBS, as instructed, above.

After opening BKR3, the UPS can be left powered (via BKR1) and/or its mode can

be changed as desired.

2. If BKR2 is already closed, close BKR1 to apply power to the UPS. If the UPS is dual

input, there is another supply that must be applied to power the rectifier.

3. There is some risk in starting the UPS while the load is powered via BKR2 (MBS

mode). A fault in the UPS could cause the upstream circuit protection (circuit

breaker or fuse) to operate, removing power from both the faulted UPS input and the

MBS input and, therefore, the output.

Potential Problems:

MBS will not allow BKR2 to close—

1. Check to see that the UPS is on bypass (SWMB is closed).

2. The UPS controls must be powered (BKR1 and SWBY should be closed).

3. Verify that the backfeed prevention interlock signals were properly wired as part of

the installation and that this wiring has not been damaged.

BKR2 in the MBS trips when power is applied—

1. This is likely due to a procedural error. Note that BKR2 and BKR3 must not be

closed at the same time unless the UPS is powered and the UPS is in bypass mode.

2. It is likely that BKR3 is closed and the backfeed prevention interlock function is

preventing BKR2 from stay i ng clos ed.

3. Since the UPS is not powered, the signal that indicates that the UPS is in bypass

mode cannot be generated.

4. Open BKR3 and close BKR2. BKR2 should close and stay closed.

5. If power to the UPS is not required, open BKR1.

Page | 15

Page 18

Figure 7 - Circuit Breaker Sequence Labe l

Breaker 1 = Left hand breaker = UPS Input

Breaker 2 = Center breaker = Bypass

Breaker 3 = Right hand breaker = UPS Output

State Name

Breaker

1

Breaker

2

Breaker

3

Adjacent State(s)

Normal

closed

open

closed

Test Battery

Overlap

closed

closed

closed

Normal, UPS

Unloaded

UPS Unloaded

closed

closed

open

Overlap, Maintenance

Maintenance

open

closed

open

UPS Unloaded, Load

Off

Load Off

open

open

open

Maintenance, Test

UPS

Test UPS

closed

open

open

Load Off, Normal

Test Battery

open

open

closed

Normal

Not Allowed

open

closed

closed

(none)

Table 7 - Maintenance Bypass Switch States

Overlap, Test UPS,

Page | 16

Page 19

Table 8 - Maintenance Bypass Switch State Change Procedures

(refer to Table 9 for description of states)

From State

To State

Procedure

Normal

Overlap

1. Select Manual Bypass Mode on UPS.

2. Verify load on bypass by observing front panel of UPS.

3. Close Breaker 2.

Overlap

Normal

1. Open Breaker 2.

2. Select Automatic Transfer to Inverter Mode on UPS.

Overlap

UPS

Unloaded

Open Breaker 3.

UPS

Unloaded

Overlap

1. Select Manual Bypass Mode on UPS.

2. Verify load on bypass by observing front panel of UPS.

3. Close Breaker 3.

UPS

Unloaded

Maintenance

1. Turn Off UPS

2. Open Breaker 1.

Maintenance

UPS

Unloaded

1. Close Breaker 1.

2. Turn On UPS

Maintenance

Load Off

Open Breaker 2. (This removes power from load!)

Load Off

Maintenance

Close Breaker 2.

Load Off

Test UPS

1. Close Breaker 1.

2. Turn On UPS, if desired.

Test UPS

Load Off

1. Turn Off UPS.

2. Open Breaker 1.

Test UPS

Normal

1. Turn Off UPS.

2. Close Breaker 3.

3. Turn On UPS.

Normal

Test UPS

Open Breaker 3. (This removes power from load!)

Normal

Test Battery

Open Breaker 1. Battery will discharge while Breaker 1 is open.

Test Battery

Normal

Close Breaker 1.

Page | 17

Page 20

Environmental

Altitude

De-rate load capability above 1000 meters 1% per 100

meters.

Operating Temperature

40o C Maximum

Humidity

Maximum 95%RH, Non-condensing

Electrical

160 kVA

200 kVA

250 kVA

Rated voltage

480/277

480/277

480/277

Rated Current

212A

265A

331A

Breaker Rating

300A

350A

450A

Minimum Wire Size INPUT

500 kcmil or

(2) 2/0 AWG

OUTPUT

500 kcmil or

(2) 2/0 AWG

Heat Rejection – L ess than (BTU/Hr)

800

1000

1250

SECTION 6

Maintenance

There are no wear items in the MBS that require periodic replacement. However, regular

care will assure maximum availability of power.

Keep the ventilation openings in the cabinet free of dust and debris.

Wipe the cabinet exterior with a soft cloth, slightly dampened with water, to remove dust.

Consider performing periodic infrared temperature measurements on the circuit breaker

terminations. This will require access to the cabinet interior. There are hazardous voltages

present and any work must be performed using caution. Only trained service personnel

should perform this work. Elevated temperatures of the terminations usually are the sign of

a loose connection, but can also signal that a breaker is failing. Loose connections should

only be serviced after removal of power.

If the system is powered down, consider removing accumulated dust from the cabinet

interior using a vacuum cleaner.

SECTION 7

FirstLine P Maintenance Bypass Switch Technical Specifications

Table 9 - Technical Specifications

(2) 3/0 AWG (2) 300 kcmil

300 kcmil

(2) 4/0 AWG

Page | 18

Loading...

Loading...