Page 1

FIRSTLINE PLT

Battery Cabinet

FLP-BAT-080-150-2-B-30K

USER MANUAL

003-2620

Page 2

CONTENTS

Section 1 ......................................................................................................................... 1

Section 2 ......................................................................................................................... 2

Safety Warnings .......................................................................................................... 2

Battery Life .................................................................................................................. 5

Section 3 ......................................................................................................................... 6

Battery Cabinet Setup .................................................................................................. 6

Inspecting the Equipment ............................................................................................ 6

Floor Loading ............................................................................................................... 6

Clearances .................................................................................................................. 6

Unloading the Cabinet(s) ............................................................................................. 7

Section 4 ......................................................................................................................... 8

Electrical Installation .................................................................................................... 8

Wiring Preparation ....................................................................................................... 8

Connecting to the Firstline PL Battery Cabinet .......................................................... 11

Section 5 ....................................................................................................................... 14

Circuit Breaker Interface ............................................................................................ 14

Section 6 ....................................................................................................................... 15

Battery Removal, Installation, and Service ................................................................ 15

Maintenance .............................................................................................................. 17

Table 1 - Symbols ........................................................................................................... 3

Table 2 - Model Floor Loadings ....................................................................................... 6

Table 3 - Terminal Tightening Torques and Wires Sizes ............................................... 13

Table 4 - Replacement Batteries and Operating Temperatures .................................... 17

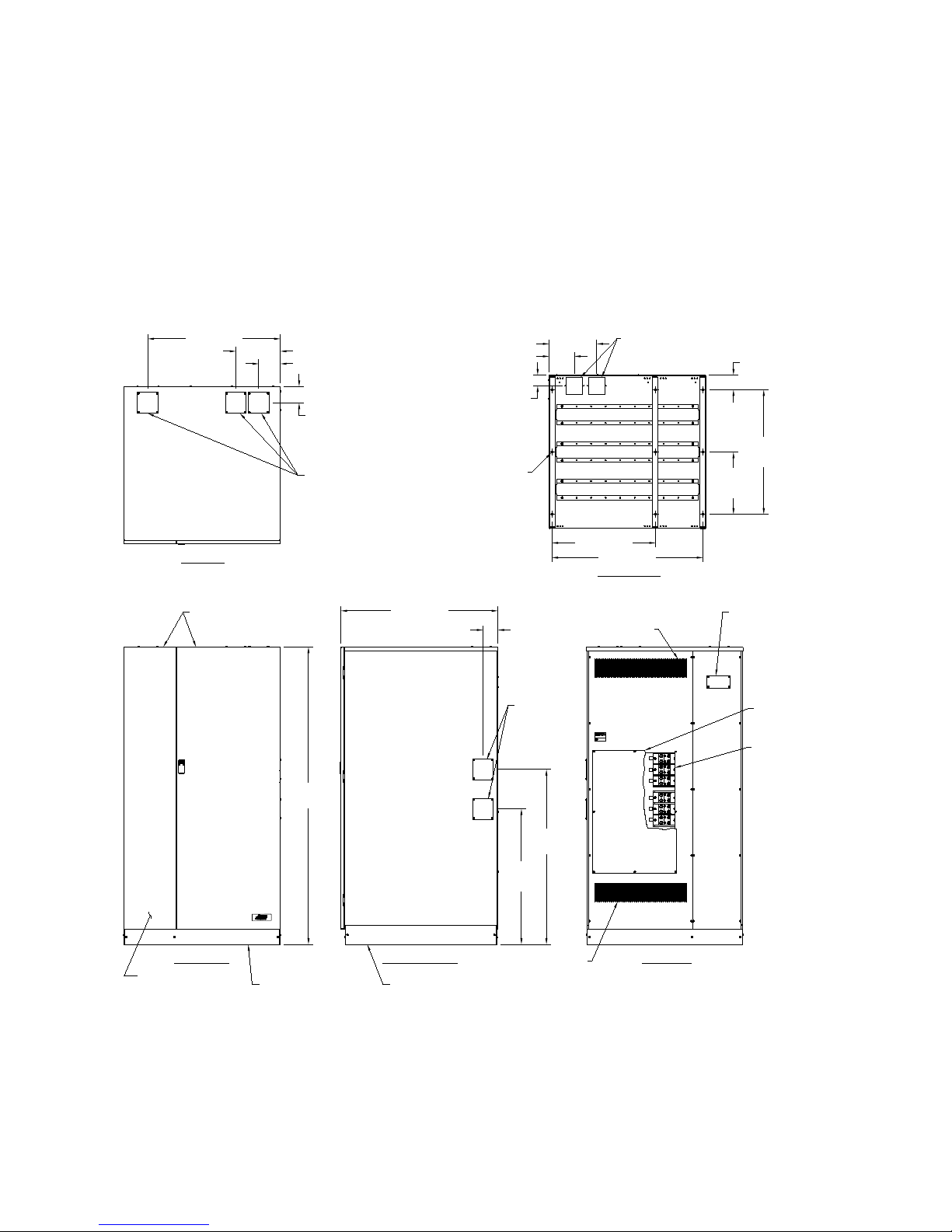

Figure 1 - The FirstLine PL Battery Cabinet .................................................................... 1

Figure 2 - Pallet Mounting Hardware ............................................................................... 7

Figure 3 - Battery Cabinet with Front Doors Removed .................................................... 9

Figure 4 - Front Internal View ........................................................................................ 10

Figure 5 - Power Connections ....................................................................................... 11

Figure 6 – Circuit Breaker Interface Connections .......................................................... 14

Figure 7 - Battery Bus Bar ............................................................................................. 15

Figure 8 - Battery Tray .................................................................................................. 16

Figure 9 - Cabinet Schematic ........................................................................................ 19

Page | ii

Page 3

REMOVABLE COVERS

FRONT AND REAR

REMOVABLE SIDE COVERS

FRONT VIEW

TOP VIEW

RIGHT SIDE VIEW

REAR VIEW

BOTTOM VIEW

AS VIEWED

FROM BOTTOM

U

L

UPS

BATTERY SUPPLY

2DA6

3.56 [90.5]

37.86 [961.6]

32.62

[828.7]

42.12

[1070.0]

71.58

[1818.2]

5.20 [132.2]

10.70 [271.9]

31.95 [811.6]

WIRE ACCESS

COVERS

TOP WIRE ACCESS COVERS

4.00 [101.6] SQUARE

OPENINGS TYPICAL

BOTTOM WIRE ACCESS COVERS TOWARD REAR

4.00 [101.6] SQUARE OPENINGS

(9) Ø.44 [Ø11.1]

MOUNTING HOLES

6.11 [155.2]

11.48 [291.7]

2.58 [65.4]

3.51 [89.2]

15.00

[381.0]

30.00

[762.0]

36.41 [924.7]

N

+

_

N

+

_

POWER TERMINAL

BLOCKS

AIR VENT

AIR VENT

3.94 [100.0]

FUSES AND CIRCUIT

BREAKERS BEHIND

LEFT DOOR

25.00 [635.0]

POWER TERMINAL

ACCESS COVER

BATTERY BREAKER

INTERFACE TERMINAL

BLOCK ACCESS COVER

HINGED FRONT DOORS

SECTION 1

The FirstLine PL Extended Run Time Battery Cabinet for 30kVA are used in conjunction

with the FirstLine PL/PLT 30 KVA uninterruptible power supplies (UPS) to prevent loss

of valuable electronic information and minimize equipment downtime. During brownouts,

blackouts, and other power interruptions, batteries provide emergency power to

safeguard operation .

Figure 1 shows the FirstLine PL Battery Cabinet.

Figure 1 - The FirstLine PL Battery Cabinet

Page | 1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

This manual covers battery cabinets with the following part numbers:

FLP-BAT-030-150-2-B-30K: battery cabinet fused at 90A (suitable for 30 KVA), 2

battery string matched to 208V UPS (204 cell system),

with breakers.

FLP-BAT-030-150-2-N-30K: battery cabinet fused at 90A (suitable f or 30 KVA), 2

battery string matched to 208V UPS (204 cell system),

without breakers.

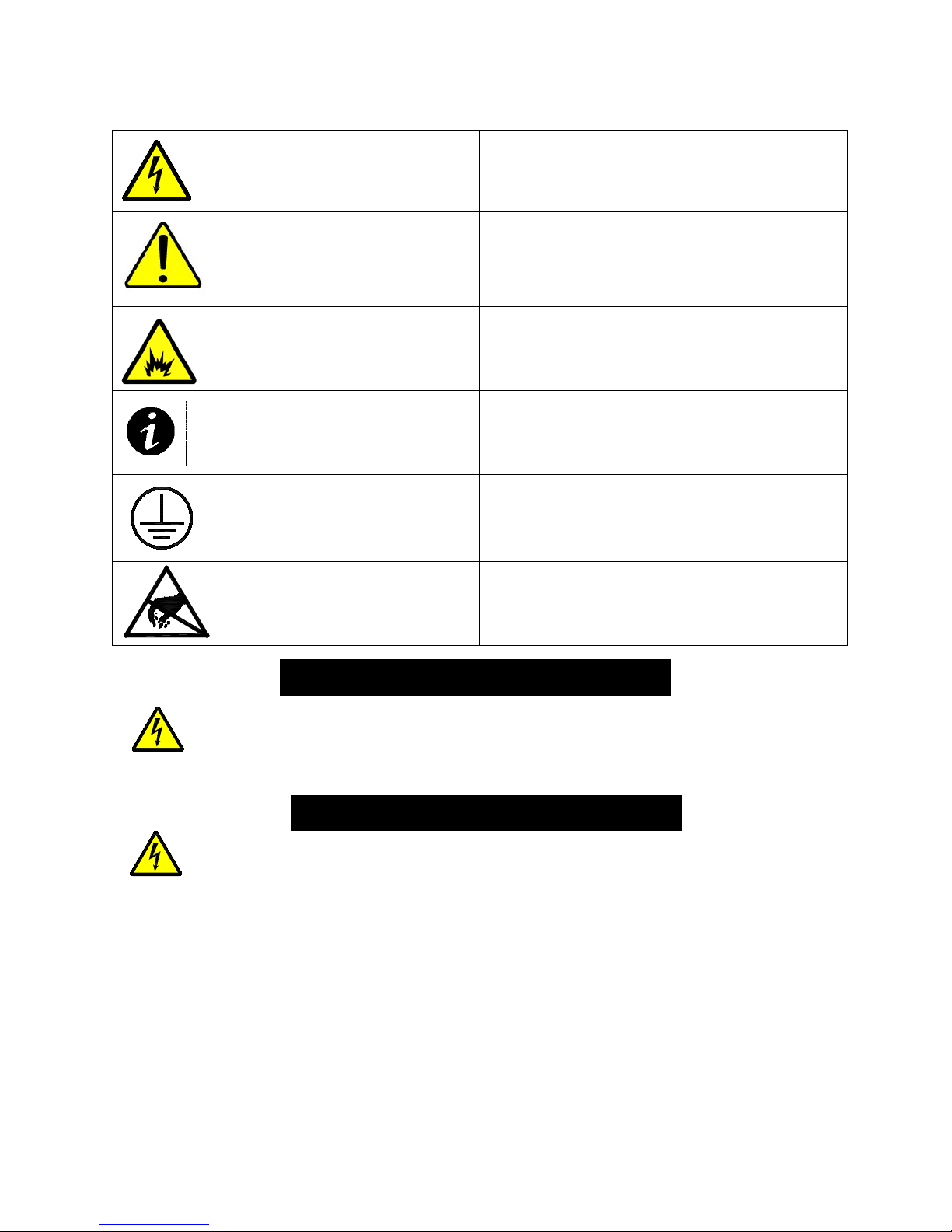

SECTION 2

SAFETY WARNINGS

This manual contains important instructions that you should follow during installation

and maintenance of the battery cabinet. Please read all instructions before operating

the equipment and save this manual for fut ur e re ferenc e.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

a. Do not use outdoors.

b. Do not route wiring across or near hot surfaces.

c. Do not install near gas or electric heaters.

d. Use caution when servicing batteries. Battery acid can cause burns to skin

and eyes. If acid is spilled on skin or in eyes, flush acid with fresh water and

contact a physician immediately.

e. Equipment should be installed where it will not readily be subjected to

tampering by unauthorized personnel.

f. The use of accessory equipment not recommended by the manufacturer may

cause an unsafe condition.

g. Do not use this equipment for other than intended use.

SAVE THESE INSTRUCTIONS

Page | 2

Page 5

DANGER

WARNING

Table 1 - Symbols

Danger / Risk of Electric Shock

Caution

Risk of Explosion

Note

Ground Connection

Electrostatic Sensitive Device

This battery cabinet co ntai ns LE THAL VOLTAGES. All repairs and service

should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There

are NO USER SERVICEABLE PARTS inside the battery cabinet.

This battery cabinet contains its own energy source (batteries). Hazardous

voltage may be present even when the battery cabinet is not connected to a

power source.

To reduce the risk of fire or electric shock, install this battery cabinet in a

temperature and humidity controlled, indoor environment, free of conductive

contaminants. Do not operate near water or excessive humidity (95%

maximum).

Page | 3

Page 6

CAUTION

Batteries can present a risk of electrical shock or burn from high short circuit

current. Observe proper precautions. Servicing should be performed by

qualified service personnel knowledgeable of batteries and required

precautions. Keep unauthorized personnel away from batteries.

Risk of explosion if batteries are replaced by an incorrect type. Replace with

same type and rating only.

Proper disposal of batteries is required. Refer to your local codes for disposal

requirements.

Never dispose of batteries in a fire. Batteries may explode when exposed to

flame.

This product contains Value Regulated Sealed Acid Batteries. These batteries

contain lead, a neurotoxin, and sulfuric acid, a corrosive. Additionally, the

energy stored in the batteries can present a shock hazard and a burn hazard.

Batteries should only be serviced by trained personnel. Appropriate safety

precautions must be observed, including eye protection and skin protection.

Contact with electrolyte requires flushing with a generous amount of clean

water. Seek medical attention immediately following contact with electrolyte.

Unwanted batteries must be recycled and should never be discarded.

CAUTION: A battery can present a risk of electrical shock and short circuit

current. The following precautions should be observed when working on

batteries:

1. Remove watches, rings, or other metal objects.

2. Use tools with insulated handles.

3. Wear rubber gloves and boots.

4. Do not lay tools or metal parts on top of the batteri es .

5. Disconnect charging source prior to connecting or disconnecting battery

terminals.

6. Determine if the battery is inadvertently grounded. If inadvertently

grounded, remove source of ground. Contact with any part of a grounded

battery can result in electric shock. The likelihood of such shock will be

reduced if such grounds are removed during installation and maintenance

(applicable to a UPS and a remote battery supply not having a grounded

supply circuit).

Page | 4

Page 7

BATTERY LIFE

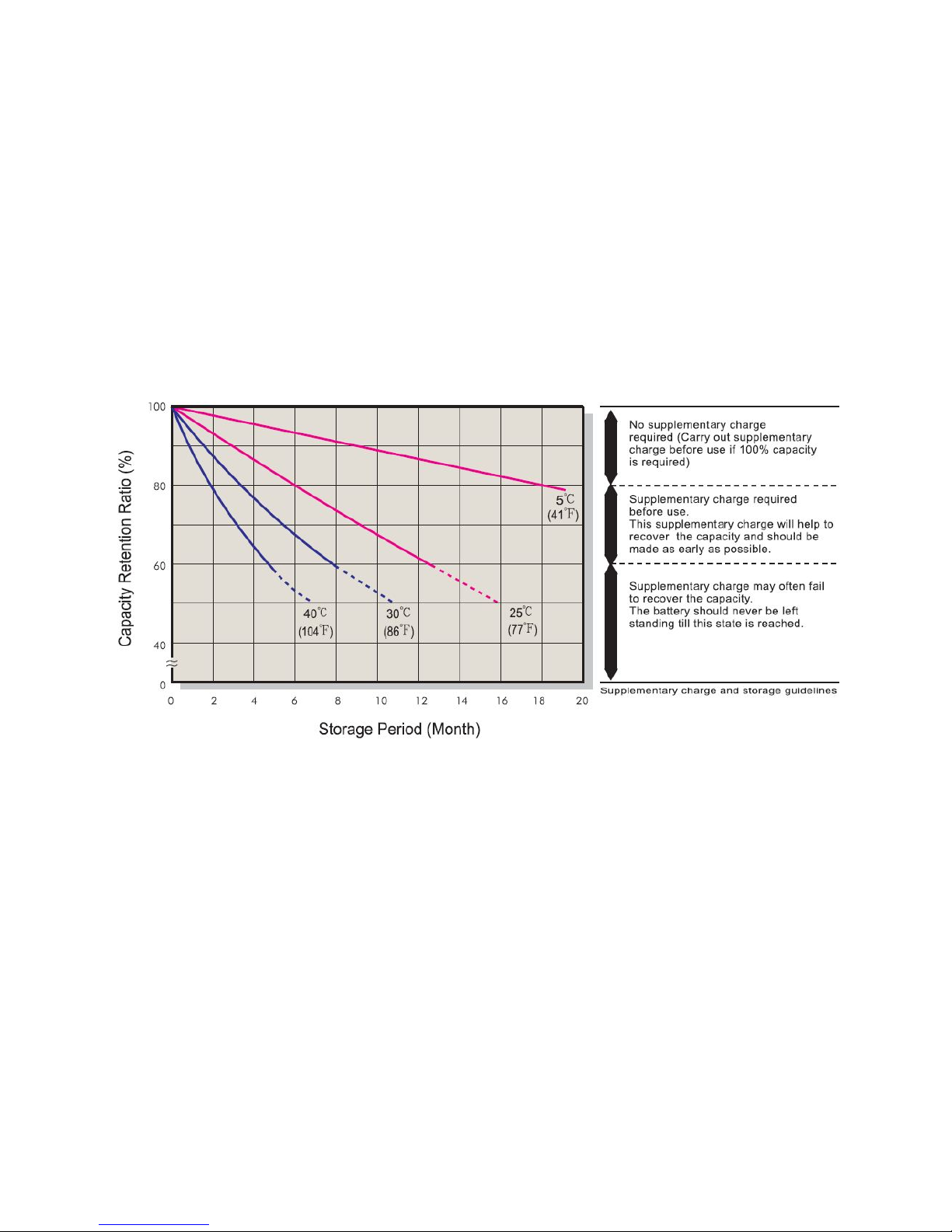

The batteries in your Staco UPS system were shipped from the factory fully charged. If

you plan to place the batteries in storage for any period of time prior to installation and

startup then the following precaution should be followed.

Batteries placed in storage will age. How fast they will age depends on the storage

temperature. The batteries are rated for storage over a temperature range of -15o C to

40o C (5o F to 104o F). The amount of time the batteries may be stored without recharge

varies greatly with storage temperature. Please consult the following table. If the

batteries are allowed to sit in storage for an excessive period of time before recharging

then they are subject to irreversible damage.

Once the batteries are placed into service and fully charged, the useful life of the

batteries will be reduced if they are subjected to high temperatures. The operating

temperature range of -15

short periods of time. Batteries operating continuously at or near 40

a shorter useful life than batteries operating continuously at 25

o

C to 40o C (5o F to 104o F) must not be exceeded for even

o

o

C. Battery life will be

C will experience

further shortened if the batteries are allowed to fully discharge and then left in that

condition for extended per i ods of time. As soon as the load is removed from the battery

it will continue to age at a higher rate than a fully charged battery. The longer the

battery remains discharged the greater the risk of irreversible damage.

Allowing the batteries to become damaged due to; a) operation or storage outside

the rated temperature range, b) storage for extended periods of time without

recharge per the table above, or c) sitting for a period of time in a discharged

state will void the battery warranty.

Page | 5

Page 8

Model

Maximum Weight

Point Loading

FLP-BAT-080-150-2-B-30K

3148 Lbs (1428 kg)

27.4 lb/in2 (1.9 kg/cm2)

FLP-BAT-080-150-2-N-30K

3132 Lbs (1421 kg)

27.3 lb/in2 (1.9 kg/cm2)

From Front of Cabinet

36” (91.4 cm) working space

From Back of Cabinet

6” (15.2 cm)

From Side of Cabinet to UPS

Minimum 24” (61 cm)

SECTION 3

BATTERY CABINET SETUP

This SECTION describes:

Equipment inspection

Floor loading and clearances

Removing and replacing the cabinet panels

Unloading the cabinet(s)

INSPECTING THE EQUIPMENT

If any equipment has been damaged during shipment, keep the shipping and packing

materials for the carrier or place of purchase and file a claim for shipping damage. If you

discover damage after acceptance, file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within

15 days of receipt of the equipment, 2) Send a copy of the damage claim within 15 days

to your service representative.

FLOOR LOADING

When planning the installation, consider the battery cabinet weight for floor loading. The

strength of the installation surface must be adequate for point and distributed loading.

The approximate weights are shown in the following table.

Table 2 - Model Floor Loadings

STANDARD MODEL FLOOR LOADING

CLEARANCES

The following clearances are recommended for the FirstLine PL Extended Run Time

Battery Cabinet.

Page | 6

Page 9

CAUTION

UNLOADING THE CABINET(S)

The following tools are required for unloading the cabinet(s):

Wrenches for 3/8” lag bolts.

Forklift or pallet jack

Phillips screwdriver

The Battery cabinets are heavy (see Table 2). Unloading the cabinets requires at

least two people to safely remove the cabinets from the pallet.

To remove the battery cabinet from the ship pallet:

1. Make sure the forklift is rated for the cabinet weight.

2. Make sure the path traveled has sufficient support for the combined weight of the

forklift and the battery cabinet.

3. Make sure forks are at maximum separation.

4. Use a very strong ratchet strap (or similar device) of sufficient strength to tie the

upper part of the cabinet to the forklift tower before moving.

5. Keep people out of the fall zone. If the cabinet topples over, stand clear.

6. Remove all banding, wrapping and foam protection.

7. Remove the six 3/8” lag bolts securing the cabinet to the pallet. (See Figure 2)

8. Lift the cabinet with a forklift one to two inches (1”-2” [2.5-5cm ]) above the pallet.

9. Slide the pallet completely away from the raised cabinet.

Page | 7

Figure 2 - Pallet Mounting Hardware

Page 10

WARNING

10. Carefully move the cabinet to the desired location and slowly lower the cabinet to

the floor or other appropr iat e fla t sur f ace. Bolt to the floor if desired.

11. With a Phillips screwdriver mount the four kick panels that were wrapped and

placed in the cabinet.

SECTION 4

ELECTRICAL INSTALLATION

The FirstLine PL Extended Run Time Battery Cabinet has the following power

connections:

TB1, 3 pole (positive, neutral, negative) terminal block and ground connection for

battery power input. This goes to the UPS or to the next battery cabinet closer to

the UPS.

TB2, 3 pole (positive, neutral, negative) terminal block and ground connection for

battery power output. This goes to the input of the next battery cabinet in the set.

TB3, 3 pole (positive, neutral, negative) terminal block and ground connection for

battery power output. This goes to the input of the –N version battery cabinet

from the first –B version battery cabinet closest to the UPS.

TB3 is energized at all times. Opening the circuit breakers does not

remove power from this terminal block.

Only qualified service personnel (such as a licensed electrician) should

perform the UPS installation and initial startup. Risk of electrical shock.

WIRING PREPARATION

To begin wiring the UPS:

1. Verify that the electrical connections to the installation site have been properly

installed.

2. A wall-mounted, user-supplied, readily-accessible disconnection device must be

incorporated in the battery input wiring unless at least one of the battery

cabinets is a –B version.

3. Wire the FirstLine PL/PLT UPS per the User’s Handbook.

Page | 8

Page 11

CIRCUIT BREAKERS

For Equipment Service

And Support

1-866-261-1191

Staco Energy Products Co.

301 Gaddis Boulevard

Dayton, OH 45403

Phone: 1-937-253-1191

Fax: 1-937-253-1723

www.stacoenergy.com

Service is to be performed only

Do NOT open.

by authorized personnel.

No user serviceable parts inside.

ATTENTION :

Pour utilisation en atmosphère controlée.

Consulter la notice technique pour les

conditions du milieu.

FOR USE IN A CONTROLLED ENVIRONMENT.

REFER TO HANDBOOK FOR ENVIRONMENTAL

CONDITIONS.

BATTERY

CIRCUIT BREAKER

BATTERY

CIRCUIT BREAKER

DO NOT DISCONNECT

UNDER LOAD

BATTERIES BEHIND

THIS PANEL

FUSES BEHIND

THIS PANEL

Do not close the circuit breakers until

the display of the UPS shows:

Close Battery Switch

Closing the breakers before this may damage

the UPS or blow fuses in the battery cabinet.

WARNING!

4. Switch off utility power to the distribution point where the UPS is connected. Be

absolutely sure there is no power.

5. Open the front doors.

Figure 3 - Battery Cabinet with Front Doors Removed

6. If the optional circuit breakers are included, switch them to the “OFF” position.

7. Remove the inner right front cover by removing the (10) ten screws mounting it to

the enclosure.

8. Remove the terminal access cover on the rear of the cabinet by removing the (8)

eight screws mounting it to the enclosure (see Figure 5).

Page | 9

Page 12

CIRCUIT BREAKERS

BATTERY TRAYS

U1

R3

R2

R1

Q1

J3

J2

J1

F1

D2

D1

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

WARNING!

TO REDUCE RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE

AND RATING OF FUSE.

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

DANGER

RISK OF ELECTRIC SHOCK

Do not touch uninsulated

battery terminals.

CAUTION!

BATTERY FUSES

9. Conduit landing plates are located toward the rear of the cabinet on the top cover,

side panels, and base to accommodate bottom wire entry to the cabinet (see

Figure 1). Remove plates and drill or punch hole to fit conduit bushing with

Greenlee punch or similar device. Make certain that the bushing will be clear

in the opening in the base. Mount bushing to plate and tighten to

manufacturer’s recommendations. Replace the plates and mount conduit.

Figure 4 - Front Internal View

Page | 10

Page 13

REAR VIEW

POWER TERMINAL

ACCESS COVER

TERMINAL BLOCKS

COMPRESSION LUGS

(2) CONNECTIONS PER POLE

500 KCMIL - #4 AWG WIRE EACH

GROUND STUD

BATTERY BREAKER

INTERFACE BLOCK

ACCESS COVER

R

U

L

UPS

BATTERY SUPPLY

2DA6

N

+

_

N

+

_

N

+

_

WARNING!

TB3 is energized at all times. Opening

the circuit breakers does not remove

power from this terminal block.

CONNECTING TO THE FIRSTLINE PL BATTERY C ABINET

To be performed by authorized service personnel:

1. Inspect battery trays for signs of damage. Verify that all terminal connections are

sound. The red and black “powerpole” connectors will be connected, but the

blue and white connectors on the wires joining the trays in the string should not

be connected.

2. If possible, after connecting the loose “powerpole” connections (blue to blue,

white to white), use a voltmeter to verify that the battery string is above 408 VDC

at the TB3 connector. If the voltage is low or the voltage varies significantly from

string to string, please consult Staco service.

Figure 5 - Power Connections

Page | 11

Page 14

3. The battery cabinet(s) to be installed must include the at least one –B version.

The fi rst –B cabinet must have its input terminal block (TB1) wired directly to the

UPS. To wire additional battery cabinets, wire from TB2 of the first battery

cabinet to TB1 of the second –B battery cabinet. Repeat these steps for

additional –B cabinets. Use wire sized per local codes, #6 AWG 75°C copper

wire minimum to #3/0 A WG max i mum.

When a –N version cabinet is installed with a –B cabinet, the –B cabinet must

have its TB1 terminal block wired to the UPS or another –B cabinet. To wire

from the –B cabinet to the –N cabinet, wire from TB3 of the –B cabinet to TB1 of

the –N cabinet. To wire additional –N battery cabinets, wire from TB2 of the first

–N battery cabinet to TB1 of the second –N battery cabinet. Repeat these steps

for additional -N cabinets.

There must be at least one –B cabinet among the battery cabinets. If it is desired

to create a battery system involving all –N version cabinets and a user provided

disconnect switch, contact Staco for requirements for the disconnect switch.

Please note that a custom configuration of this type is not covered by Staco’s UL

Listing, nor is it covered by this manual.

TB3 is energized at all times. Opening the circuit breakers does not

remove power from this terminal block.

4. Connect the ground wire to the ¼-20 ground stud with a ring terminal or pressure

lug by removing and replacing the top nut and washers only with a 7/16” wrench.

5. Before working within the UPS cabinet, verify that the UPS has no pow er applied.

Before touching the Extended Run Time Battery connector in the UPS, verify that

all internal battery strings are disconnected (that is, verify that the blue and white

“powerpole” connectors are NOT mated). Refer to the UPS manual. Repeat

procedures 3 and 4 to the FirstLine PL UPS Extended Run Time Batter y

connector located in the lower left side of the UPS. We recommend that the wires

be marked as to which is positive (+) and negative (-) to ensure that the wires are

not accidentally crossed. See Figure 9.

Never connect the positive to the negative. Severe damage and injury

could result. Check polarity at the TB3 terminal block.

6. For –B cabinets, connect the Circuit Breaker Interface per Sec ti on 5 .

7. Mate the blue connections, blue to blue, and then the white connections, white to

white. See Figure 9. Repeat this procedure for the other battery cabinets, if

present.

8. Rei ns tal l th e fro nt inner panel on each battery cabinet using the screws provided.

Page | 12

Page 15

WIRE SIZE

TORQUE

#2/0 - #6 AWG

120 inch-pounds

WIRE SIZE

TORQUE

#10 – 26 AWG

5.3 – 7.0 inch-pounds

Extended Run Time Battery Cabinet

100 inch-pounds

UPS Cabinet

55 inch-pounds

Minimum Input/Output

Wire Size

Minimum Ground Wire

Size

30

#2 AWG

#8 AWG

9. After the internal batteries in the UPS are connected, reinstall any panels that

were removed and close the UPS doors. Refer to the UPS manual for guidance

regarding this procedure. Do not close the Battery Cabinet circuit breakers until

the display of the UPS shows the message: “Close Battery Switch”. Closing the

breakers before this may damage the UPS or blow fuses in the Battery Cabinet.

Once the Battery cabinet circuit breakers are closed the front doors of the battery

cabinet may be closed.

Terminal blocks on the –N version cabinets are disconnected by unplugging the

“powerpole” connectors in all cabinets. This requires the removal of the inner

panel by authorized personnel only.

Table 3 - Terminal Tightening Torques and Wires Sizes

BATTERY INPUT/OUTPUT TERMIN AL

TIGHTENING TORQUE

TB4 LOW VOLTAGE TERMINAL TORQUE

GROUND STUD TIGHTENING TORQUE

kVA Rating

*Wire must be rated 75°C or higher. Use copper conductors only.

Page | 13

Page 16

SECTION 5

CIRCUIT BREAKER INTERFACE

NOTE: Disregard this section if tripping the battery cabinet breakers via REPO

activation is not required.

Figure 5 shows the location of the Battery Breaker Interface terminal block on the

battery cabinet.

NOTE: Wires to the Battery Breaker Interface terminal block TB4 must not enter

the UPS or battery cabinet through the same port as the input/output or battery

power wires.

Figure 6 – Circuit Breaker Interface Connections

To trip the battery circuit breakers via the REPO of the UPS, connect the battery cabinet

interface connector (TB4) to the UPS per Figure 6. If any additional battery cabinets

are –N versions, no other connections are needed.

CAUTION: The Battery Breaker Interface Board is an electrostatic sensitive

device. The user should be grounded when connecting to this assembly.

CAUTION: If the battery cabinet circuit breakers trip or are opened, the internal

batteries of the UPS are still connected and providing power to the UPS. They

also cause the terminals of the TB1 and TB2 to be energized with hazardous

voltage.

Page | 14

Page 17

+

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

-

+

-

+

-

-

+

REMOVE THESE BUS BARS

BEFORE SERVICING THE

BATTERY TRAYS

SECTION 6

BATTERY REMOVAL, INSTALLATION, AND SERVICE

The batteries must only be serviced by authorized service personnel. Always wear eye

protection and have eye wash near at hand. Never work on any connections that have

not been disconnected from all other sources of voltage. Parallel connected battery

cabinets require that all battery strings in all battery cabinets be disconnected before

working within any particular cabinet. Also, the UPS is usually equipped with internal

batteries that must be disconnected before service (refer to the UPS manual).

Before servicing batteries, the UPS should be turned off, power should be removed

from the UPS input, and all battery breakers and disconnect switches should be open.

If a Maintenance Bypass Switch (MBS) is present, power to the load can be maintained

during service. Refer to the instructions for the MBS to put the system in bypass mode

before removing power from the UPS.

Before any battery service is attempted, the batteries must be disconnected by

unplugging the cables to the battery trays. If it is necessary to remove the cables from

the batteries, the connections should be marked in a way that no confusion will exist

when it is time to reconnect the cables (see Figure 9). The batteries are mounted in

slide out trays that permit access to the battery to battery connections when the trays

are withdrawn from the cabinet.

To service the battery trays, they must be removed from the cabinet by

a fork lift. The 2 bus bars at the back of the tray, as shown in Figure 7,

must be removed before servicing or replacing the batteries.

Page | 15

Figure 7 - Battery Bus Bar

Page 18

Battery tray

Battery shelf

Notch

Extension limit tab

Cutaway side view of battery tray

batteries not shown for clarity

Tray mounting screw

WARNING

Never connect the two cables from a battery tray or from a battery string (two trays)

together as severe damage will occur, resulting in fire and/or injury. Battery connections

If batteries are being replaced, only use the same manufacturer and battery type and

rating as the battery removed. When the bus bars connecting the batteries are

removed, be careful to avoid dropping bolts or shifting the bus bars so that they might

short across adjacent battery terminals. We recommend using a piece of electrical

insulating paper (for example, “Nomex”) as a temporary shield between the bus bars

during service.

It is very important that only one tray at a time be extended from the cabinet. If more

than one tray is extended, the cabinet can become unstable and topple over.

After each tray is installed or serviced, it must be fully inserted and secured using the

supplied threaded fasteners before attempting to install or service another tray.

If the trays are to be removed, always remove the highest tray first. The battery tr ays

are very heavy and it will be necessary to use a lifting device to support the trays as

they are removed. When the trays are to be reinstalled, use the procedure in the

following paragraph.

The battery trays are very heavy and it will be necessary to use a lifting device to

support the trays as they are installed. Do not take away the external support until the

extension limit tabs on the upper sides of the battery tray are inserted past the notches

on the upper edge of the battery shelf (see Figure 8). Always install the lowest battery

tray first. After it is inserted fully into the support shelf, secure the tray with the supplied

threaded fasteners. After all of the trays are reinstalled and secured, reconnect the

cables using the markings as a guide.

should only be made by a person wearing eye protection. It is advised that eye wash be

available. If there are any doubts about the proper connections, do not proceed.

Figure 8 - Battery Tray

Page | 16

Page 19

RECOMMENDED REPLACEMENT INTERVALS

Batteries

2 to 5 years1

OPERATING TEMPERATURE

Recommended Range

15-25º C (59-77º F)

Maximum Range

10-40º C (50-104º F)

Quantity

Required

-080-150

China Storage Battery

HRL12150W

36 Per String

MAINTENANCE

The FirstLine PL Extended Run Time Battery Cabinet is designed to be virtually user

maintenance free, requiring only the occasional wipe with a damp cloth or non-abrasive

cleaner.

Spare kits are available for the FirstLine PL Extended Run Time Battery Cabinet series,

please contact Staco Energy Products Co. service center for details.

For maximum availability of the UPS, the batteries should be replaced as part of a

comprehensive pr ev ent ive maintenance program.

Table 4 - Replacement Batteries and Operating Temperatures

REPLACEMENT BATTERY

Cabinet Model Manufacturer Cat. Number

This product contains Value Regulated Sealed Acid Batteries.

These batteries contain lead, a neurotoxin, and sulfuric acid, a corrosive. Additionally,

the energy stored in the batteries can present a shock hazard and a burn hazard.

Batteries should only be services by trained personnel. Appropriate safety precautions

must be observed, including eye protection and skin protection. Contact with electrolyte

requires flushing with generous amounts of clean water. Seek medical attention

immediately following contact with electrolyte. Unwanted batteries must be recycled

and should never be discarded.

The functional lifetime of batteries is significantly affected by the temperature at which

they are stored and operated. Ideally, batteries should be used in a 70° F (21° C)

environment. For every 15° F (8.3° C) increase in temperature, the life expectancy of a

battery will be halved.

1

Battery life is highly dependent on the ambient temperature and the number and depth of discharge

cycles. A discharged battery should be recharged as soon as possible. If the battery is left in a discharged

state, irreversible sulfation occurs, reducing the capacity (run-time) of the battery.

Page | 17

Page 20

Exposure to temperatures in excess of 90°F (32°C) should be limited to no more than

30 days per year. Under no circumstances should the battery be exposed to

temperatures over 104° F (40° C) which can lead to thermal runaway, a condition that

damages the battery. Thermal runaway can cause batteries to swell. If the battery

cases burst, the hazardous contents may be exposed.

Maintaining proper ambient temperature usually requires installing the product in a

temperature controlled space. Equipment rooms without cooling systems do not

generally maintain the proper conditions for good battery life.

Page | 18

Page 21

TRAY 3

TRAY 2

TRAY 1

WHITE

F1

RED CONNECTORS

BLUE

BLACK CONNECTORS

RED CONNECTORS

+

N

CUSTOMER WIRING

TO UPS

CIRCUIT

BREAKER

INTERFACE

BOARD

CB1

CB2

1

2

1

2

J1

-

+

N

-

+

N

-

TB3

BATTERY

CONNECTOR

1+

2-

3+

TB4

CONTROL

CONNECTOR

4-

TB2

BATTERY

CONNECTOR

TB1

BATTERY

CONNECTOR

U1

R3

R2

R1

Q1

J3

J2

J1

F1

D2

D1

TRAY 6

CB1

CB2

TRAY 5

TRAY 4

TRAY 3

TRAY 2

TRAY 1

F1

F2

F3

F4

CONNECTORS

CONNECTORS

TRAY 6

TRAY 5

TRAY 4

WHITE

BLUE

CONNECTORS

CONNECTORS

RED CONNECTORS

BLACK CONNECTORS

F22

F3

F4

BLACK CONNECTORS

CONTROL TERMINAL BLOCK

LOCATED ON REAR PANEL

TB4

FRONT VIEW

DOORS AND COVERS REMOVED

CIRCUIT BREAKER

INTERFACE BOARD

CIRCUIT BREAKERS

*

* WARNING:

TB3 IS ENERGIZED AT ALL TIMES. OPENING

THE CIRCUIT BREAKERS DOES NOT REMOVE

POWER FROM THIS TERMINAL BLOCK.

CIRCUIT BREAKERS AND

CIRCUIT BREAKER INTERFACE

BOARD NOT PROVIDED ON

-N BATTERY CABINETS

FUSES

Page | 19

Figure 9 - Cabinet Schematic

Loading...

Loading...