Page 1

003-2593

FirstLine Parallel Output

Redundant Cabinet

FLP-10-POPC-5-R-4Y-2Y

10kVA

USER MANUAL

Page | i

Page 2

Staco Energy is highly specialized in the development and production of uninterruptible

power systems (UPS). The UPS’s of this series are high quality products, carefully

designed and manufactured to ensure optimum performance.

No reproduction of any part of this manual, even partial, is permitt ed without the

authorization of Staco Energy Products Company. The Staco Energy Products Company

reserves the right to modify the product described herein, in order to improve it, at any time

and without notice.

301 Gaddis Boulevard • Dayton, Ohio 45403

U.S. Toll Free 866-261-1191

(937) 253-1191 • Fax: (937) 253-1723

Web site: www.stacoenergy.com

Thank you for choosing our product.

Page | ii

Page 3

Table of Contents

SECTION 1 .......................................................................................................................... 1

Introduction ....................................................................................................................... 1

Overview ........................................................................................................................... 1

Section 2 .............................................................................................................................. 2

SAFETY WARNINGS ....................................................................................................... 2

DANGER .......................................................................................................................... 2

WARNING ........................................................................................................................ 2

CAUTION ......................................................................................................................... 3

Section 3 .............................................................................................................................. 4

Cabinet Setup ................................................................................................................... 4

Inspecting the Equipment ................................................................................................. 4

Floor Loading .................................................................................................................... 4

CLEARANCES ................................................................................................................. 4

Unloading the Cabinet(s) .................................................................................................. 5

Section 4 .............................................................................................................................. 6

Electrical Installation ......................................................................................................... 6

Wiring Preparation ............................................................................................................ 6

Control Connections ....................................................................................................... 10

Connections Between the Parallel Output Redundant Cabinet and the UPS ................. 10

Terminal Strip Torque Requirements .............................................................................. 10

Switch Settings ............................................................................................................... 10

SECTION 5 ........................................................................................................................ 12

Backfeed Protection ........................................................................................................ 12

Remote EPO (Emergency Power Off) ............................................................................ 13

Section 6 ............................................................................................................................ 14

REPO ............................................................................................................................. 16

Section 7 ............................................................................................................................ 17

Maintenance ................................................................................................................... 17

Section 8 ............................................................................................................................ 17

Parallel Output Redundant Cabinet Technical Specifications ......................................... 17

Table 1 - Symbols ................................................................................................................ 3

Table 2 - Model Floor Loadings ............................................................................................ 4

Table 3 - Wire Size Requirements ....................................................................................... 8

Table 4 - Maximum Current Ratings..................................................................................... 8

Table 5 - Terminal Tightening Torques ................................................................................ 8

Table 6 - Technical Specifications ...................................................................................... 17

Figure 1 - The Firstline Parallel Output Redundant Cabinet ................................................ 1

Figure 2 - Pallet Mounting Hardware .................................................................................... 5

Figure 3 - Inside Front View of Parallel Output Redundant Cabinet ..................................... 7

Figure 4 - Options Control Board Assembly ....................................................................... 11

Figure 5 - Customer Low Voltage Connection Terminal Block ........................................... 11

Figure 6 - Circuit Breaker Sequence Label ........................................................................ 16

Page | iii

Page 4

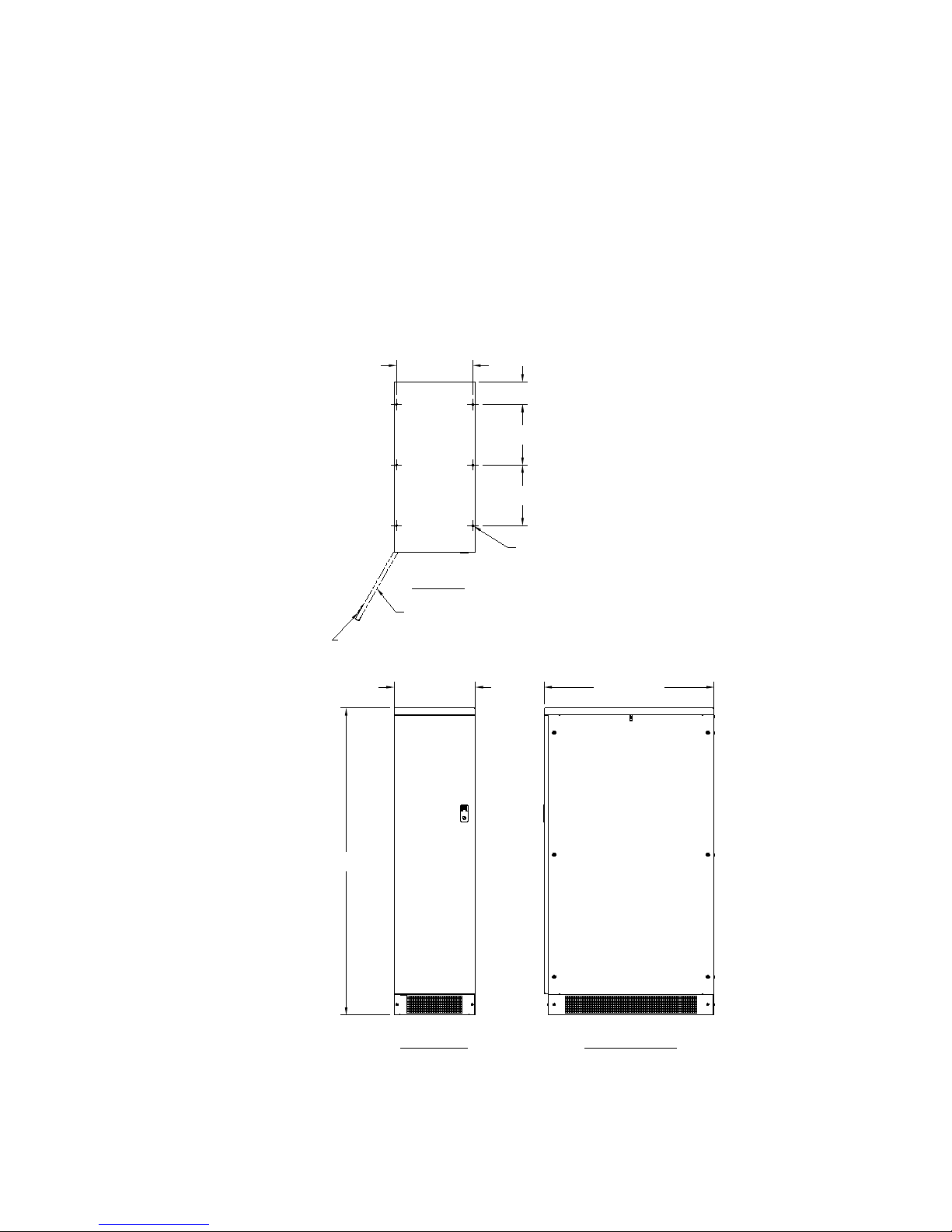

33.35 [847.0]

15.99 [406.1]

60.16 [1528.0]

15.00 [380.9]

4.46 [113.2]

11.85 [301.0]

11.85 [301.0]

(6) Ø.41 [Ø10.3]

MOUNTING HOLES

ON BOTTOM FEET

.11 [2.8] THICK

TOP VIEW

HINGED FRONT DOOR

DOOR LATCH REQUIRES PHILLIPS

SCREWDRIVER TO OPEN

FRONT VIEW RIGHT SIDE VIEW

SECTION 1

Introduction

Overview

The Firstline Parallel Output Redundant Cabinet is a steel cabinet that matches the UPS

cabinet, and provides the maintenance bypass function. The cabinet has conduit

attachment points at the top and the bottom for maximum flexibility in wiring the source and

load power connections.

Please refer to Figure 1 for the outline drawing of the cabinet.

Figure 1 - The Firstline Parallel Output Redundant Cabinet

Page | 1

Page 5

SECTION 2

SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

• Do not use outdoors.

• Do not route wiring across or near hot surfaces.

• Do not install near gas or electric heaters.

• Equipment should be installed where it will not readily be subjected to tampering by

unauthorized personnel.

• The use of accessory equipment not recommended by the manufacturer may cause

an unsafe condition.

• Do not use this equipment for other than intended use.

• This equipment connec ts to the output of an uninterruptible pow er supply.

Hazardous voltages may be present even when the electrical supply to this

equipment is turned off.

• If equipped with a maintenance bypass switch, control connections between this

equipment and the UPS must be present to prevent the possibility of backfeed.

• Read and follow the instructions that came with the associated UPS or emergency

lighting system before operating this equipment.

DANGER

This equipment contains lethal voltages. All repairs and service should only be performed

by authorized service personnel. There are no user serviceable parts inside this

equipment. Operation of switches and breakers require access to the cabinet interior and

should only be performed by qualified personnel exercising appropriate caution.

WARNING

This equipment connects to the output of a UPS which contains its own energy source

(batteries). The UPS output may carry live voltage even when the UPS is not connected to

an AC supply.

To reduce the risk of fire and electric shock, install this equipment in a humidity controlled,

indoor environment, free of conductive contaminants. Do not operate near water or

excessive humidity (95% maximum). If condensation is present, the equipment must be

allowed to completely dry before operation.

Page | 2

Page 6

CAUTION

The UPS associated with this equipment contains batteries. Batteries can present a risk of

electrical shock or burn from high short circuit current. Observe proper precautions.

Servicing should only be performed by qualified service personnel knowledgeable of

batteries and the required precautions. Keep unauthorized personnel away from batteries.

Read, understand and follow all instructions in the UPS manual before attempting any

operations involving the battery.

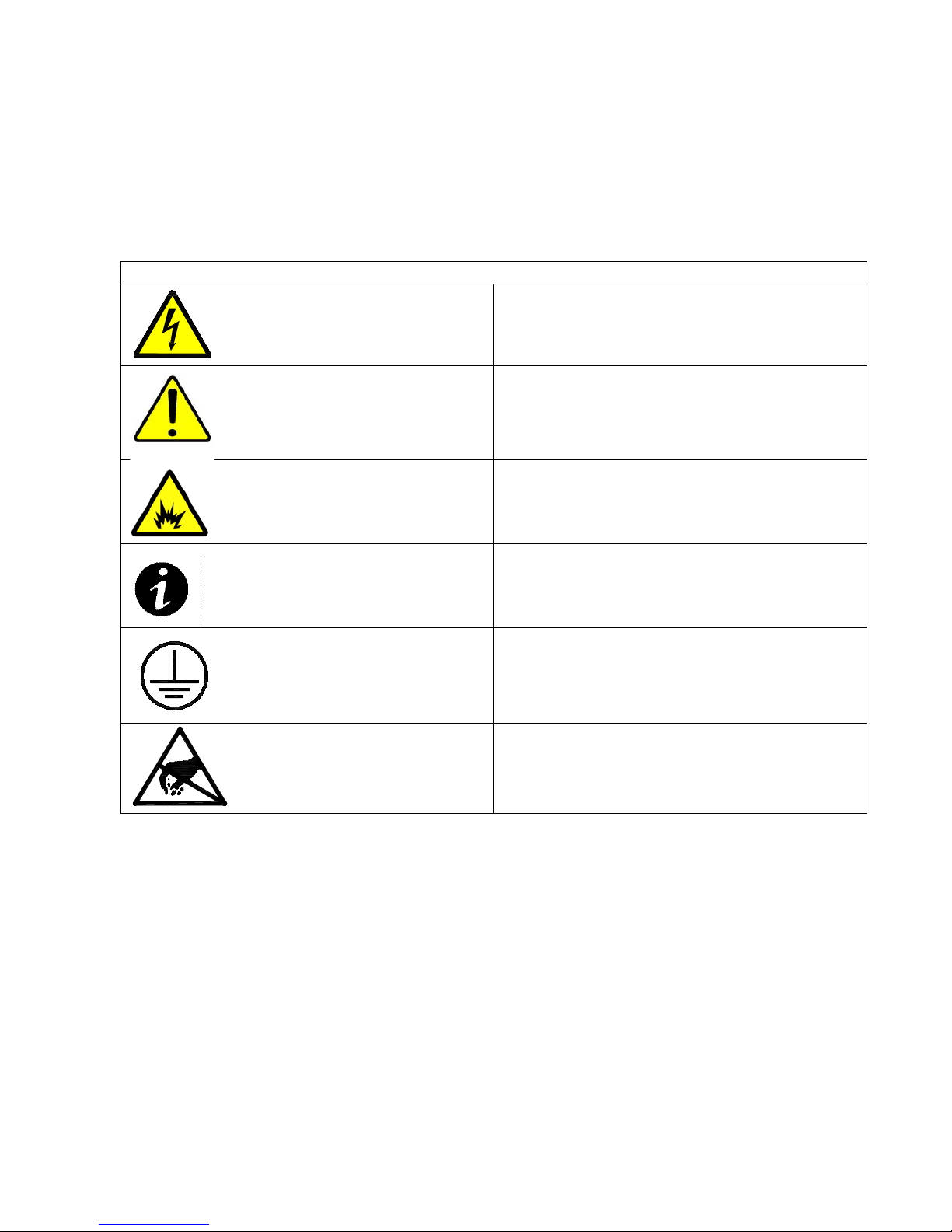

Table 1 - Symbols

Danger / Risk of Electric Shock

Caution

Risk of Explosion

Note

Ground Connection

Electrostatic Sensitive Device

Page | 3

Page 7

STANDARD MODEL FLOOR LOADING

MAXIMUM WEIGHT

POINT LOADING

460 lbs (209 kg)

7.8 lb/in2 (0.48 kg/cm2)

From Front of Cabinet

36” (91.4 cm) working space

SECTION 3

Cabinet Setup

This SECTION describes:

Equipment inspection

Floor loading and clearances

Removing and replacing the cabinet panels

Unloading the cabinet(s)

Attaching the cabinet to the UPS

Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping and packing

materials for the carrier or place of purchase and file a claim for shipping damage. If you

discover damage after acceptance, file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with the carrier within 15

days of receipt o f the equipment, 2) Send a copy of the damage claim within 15 days to your

service representative.

Floor Loading

When planning the installation, consider the battery cabinet weight for floor loading. The

strength of the installation surface must be adequate for point and distributed loading. The

approximate weights are shown in the following table.

Table 2 - Model Floor Loadings

CLEARANCES

The following clearances are recommended for the Maintenance Bypass Switch Cabinet.

Page | 4

Page 8

Unloading the Cabinet(s)

CAUTION

The following tools are required for unloading the cabinet(s):

Wrenches for 3/8” lag bolts.

Forklift or pallet jack

The cabinets are heavy (see Table 2). Unloading the cabinets requires at least two

people to safely remove the cabinets from the pallet.

To remove the Parallel Output Redundant Cabinet from the ship pallet:

1. Make sure the forklift is rated for the cabinet weight.

2. Make sure the path traveled has sufficient support for the combined weight of the

forklift and the cabinet.

3. Mak e sure for k s are at maximum separation.

4. Us e a ver y str ong ratch et str ap (or similar dev ice) of s uffici ent str ength t o tie the u pper

part of the cabinet to the forklift tower before moving.

5. Keep people out of the fall zone. If the cabinet topples over, stand clear

6. With a Phillip’s screwdriver, remove the two kick panels. These will be remounted

when the cabinet is in place.

7. Remove all banding, wrapping and foam protection.

8. Remove the six 3/8” lag bolts securing the cabinet to the pallet. See Figure 2.

9. Lift the cabinet with a forklift one to two inches (1”-2” [2.5-5cm]) above the pallet.

10. Slide the pallet completely away from the raised cabinet.

11. Carefully move the cabinet to the desired location and slowly lower the cabinet to the

floor or other appropriate flat surface.

12. Remount the two kick panels.

Page | 5

Figure 2 - Pallet Mounting Hardware

Page 9

SECTION 4

Electrical Installat i on

Overview

Each of the pieces of equipmen t cov er ed by this manual has six sets of power connections:

1. Input from the power source, typically, from the electric utility.

2. Power routed to the input of the first UPS.

3. Power routed to the input of the second UPS.

4. Power from the output of the first UPS.

5. Power from the output of the second UPS.

6. Power to the load

There are eight control connections between the Parallel Output Redundant Cabinet and

the two UPS cabinets that must be made. The required control connections are described

later in this section.

A user accessible disconnect device must be provided (by others) between the output of

this cabinet and the load. Refer to Table 4 for current requirements.

WARNING

Only qualified service personnel (such as a licensed electrician) should

perform the installation and initial startup. There is a risk of electrical shock.

Wiring Preparation

1. Verify that the equipment is the proper type. The equipment covered by this manual

is 480V 60 Hz input and 208V output, only. The Parallel Output Redundant Cabinet

can only be used in a wye-wye application. An input neutr al con ne c ti on is required.

2. Plan the locations of conduits. Two Conduit landing plates are provided at the

bottom of the cabinet. Power connections between the Parallel Output Redundant

and the UPS must be made through the bottom landing plate in the rear of the

cabinet to the bus bar terminal pads provided behind the circuit breakers on each

side of the cabinet above the lower row of breakers. The conduits must be placed

toward the rear o f the c abi ne t a minimum of 6-1/4 inches away from the low voltage

wiring terminal lock, see Figure 3.

3. Power connections from the utility input and output load must be made through the

top of the cabinet to the bus bar terminal pads located behind the top row of

breakers and in the middle of the lower row of breakers.

Page | 6

Page 10

4. The low voltage control connection wires must be routed from the terminal block

through the bottom lan ding plate in the front of the cabinet to ensur e physical

separation between th em and the power wiring.

5. All wiring is to be in compliance with all applicable codes.

6. Verify that the source circuit capability is in compliance with the requirements shown

in Table 3 and Table 4.

7. Select wire size in compliance with Table 3.

Figure 3 - Inside Front View of Parallel Output Redundant Cabinet

Page | 7

Page 11

Table 3 - Wire Size Requirements

Minimum Input

Minimum

Size

Minimum

Size

Required

#12 AWG

#8 AWG

#10 AWG

25 A

Rated Input

Rated Output Current

18

28

Bolt Size

Torque

¼ - 20

75 inch - pounds

Wire Size

Torque

#10 - #14 AWG

35 inch - pounds

#8 AWG

40 inch - pounds

#4 - #6 AWG

45 inch - pounds

1/0 - #2 AWG

50 inch - pounds

Wire Size

Torque

# 26-10 AWG

5.3 – 7.0 inch - pounds

*Wire must be rated 75°C or higher

Wire Size

Output Wire

Table 4 - Maximum Current Ratings

Current (Amps)

Table 5 - Terminal Tightening Torques

INPUT / OUTPUT / NEUTRAL TERMINAL TORQUE

GROUND LUG TORGUE

Ground Wire

(Amps)

Supply Breaker

LOW VOLTAGE TERMINALTORQUE

Page | 8

Page 12

Wiring Installation

1. Switch off utility power to the distribution point where the UPS will be connected. Be

absolutely sure that there are no hazardous voltages present. Use lockout/tagout

procedures to assure safety.

2. Remove as many panels as needed for adequate access for wiring the cabinet. Open

the front door of the MBS Cabinet.

3. Connect wires from each of the "TO UPS INPUT" terminal pads to the input terminals

of each UPS. (Refer to the UPS manual). The wire must be in compliance with Table

3 and the terminals must be torqued in compliance with Table 5. Make sure that

phase A connects to phase A and so on.

4. Connect wires from each of the "FROM UPS OUTPUT" terminal pads to the output

terminals of each UPS. (Refer to the UPS manual). The wire must be in compliance

with Table 3 and the terminals must be torqued in compliance with Table 5. Make

sure that phase A connects to phase A and so on.

5. Connect wires from the "OU TPU T TO LOA D " termi nal pads to the load. The load may

be an external distribution panel, etc. If neutral is not needed by the load, then it does

not need to be supplied. The wire must be in compliance with Table 3 and the

terminals must be torqued in compliance with Table 5. Make sure that phase A

connects to phase A and so on.

6. A set of eight control connections must be installed from the "CUSTOMER LOW

VOLTAGE CONNECTION TERMINAL BLOCK " to Communication Interface Board in

the front of each UPS cabinet. These control wires must be phys ic al ly separated from

any power wires. The length of the control wires is limited to 30 feet or 10 meters.

These connections are described later in this section.

7. Verify that the input power source is not powered. Connect wires from the "UTILITY

INPUT" terminal pads to the input source power from the building distribution. The

wire must be in compliance with Table 3 and the terminals must be torqued in

compliance with Table 5. Make sure that phase A connects to phase A and so on.

The source needs to have A-B-C phase sequence. If not, exchange two of the phase

connections to correct thi s.

8. Check all work. Replace the panels that were removed for access

Page | 9

Page 13

Control Connections

Eight control connections must be made between the Parallel Output Redundant Cabinet

and the UPS in order to provide backfeed protection, a required safety feature. There is

also a provision to provide Remote Emergency Power Off (REPO). REPO causes the

output breaker to trip, thereby removing power from the load. If the bypass path is active,

then REPO trips the bypass breaker, removing power from the load.

The wiring to these low voltage connections must be kept separated from the higher

voltage wiring. Refer to Figure 3 and Figure 5 regarding the Low Voltage Terminal Block

and to the UPS manual that shows the connection point in the UPS. Details regarding

these connections are described below.

Connections Between the Parallel Output Redundant Cabinet and the UPS

Since these wires affect the operation of the UPS, they should be protected. Running them

in conduit is a good idea, even if local codes do not require conduit. It is also

recommended that the wires are shielded twisted pairs. Alpha 6010C is a shielded cable

with three twisted pairs and is available from a number of sources in various spool lengths.

The Remote EPO arrangement for this Parallel Output Redundant Cabinet is separate from

that in the UPS. If it is desired to use both, a switch with multiple contacts is required, one

set for each UPS and another set for this Parallel Output Redundant Cabinet. Refer to the

UPS manual for the requir ements regarding the UPS Remote EPO. Note that only one

UPS needs to receive the EPO signal for both to be tripped, but you may wish to connect

the REPO on the other so that it still works normally if one UPS is removed from service.

Terminal Strip Torque Requirements

The terminals on the Customer Low Voltage Connection Terminal Block must be torqued to

5.3 to 7.0 inch-lbs. The terminals on the Control Connections (on the UPS) must be torqued

to 4.4 inch-lbs.

Switch Settings

Switch "S2" on the Options Control Boards (refer to Figure 4) is a four position "DIP" switch

that has four small rocker switches. Pushing on the top half of each switch section closes

the switch and turns it ON, pushing on the lower half turns the switch OFF. There are

labels on the board to help identify the switch section.

The first section "PLT" enables "Power Loss Trip" (or Manual Restart), and should be OFF

unless you want the Bypass and Inverter Output Breakers to trip on loss of power.

The second section "NCR" enables the Normally Closed REPO input and should be OFF

unless there is a normally closed REPO switch connected.

The third section "OTT" is not implemented and should be turned OFF to avoid confusion.

The fourth section is not used and should be turned OFF to avoid confusion.

Page | 10

Page 14

DS1

J201

J202

J203

J204

J205

J206

TB9

TB8

TB1

TB7

OTHT

1

1

1

1

1

TB6

TB5

TB4

TB3TB2

TB11TB10

1 2 3 4

1 2 1 2 4321 5

653 4

651 2 3 4

PLT

NCR

OTT

S2

DS4

ATTENTION

ELECTROSTATIC

SENSITIVE DEVICE

1 2

Figure 5 - Customer Low Voltage Connection Terminal Block

Figure 4 - Options Control Board Assembly

Page | 11

Page 15

SECTION 5

Backfeed Protection

In some of the possible combinations of switch positions for the MBS, the output of the

UPS could be connected to the input to the system. If this were to happen while the UPS is

in Normal mode (the load is being supplied power from the inverter), this could cause

damage to the UPS. Further, if the input to the system is not powered, the inverter could

run on battery and supply voltage to the input of the system. This condition is called

backfeed and must be prevented in the interest of safety. For example, service personnel

working on the line feeding the input to the system (or the line feeding that line, etc.) could

be subjected to hazardous conditions. Imagine an electrician opening the supply breaker

feeding the MBS/UPS and expecting that line to be safe to work on. The UPS provides

backfeed protection for its internal bypass circuits, but an external bypass arrangement

requires coordination between the bypass internal to the UPS and the external switch to

allow temporary overlap (for make before break transfer) and to prevent backfeed. This

coordination requires two pairs of signal wires between the MBS and each UPS. The

interlock scheme also has redundancy so that the failure of a single component will not

cause loss of backfeed prevention.

The redundant methods implemented in the MBS are as follows:

1. The Maintenance Bypass Breaker (#2) will have its trip mechanism activated,

thereby preventing its closure unless the UPS system has been transferred to

Bypass Mode or if Breaker #6 is open or if both Breaker #3 and Breaker #5 are

open. This is the primary logic for backfeed prevention.

2. If Breaker #2 and Breaker #6 are both closed, a signal will be sent to UPS #1 if

Breaker #3 is closed and a signal to UPS #2 if Breaker #5 is closed. This signal

commands the UPS to Bypass Mode as a back-up safety should the logic of item 1

fail.

As is explained in Section 6, the proper procedure for putting the MBS into the Bypassed

mode requires that the user first put the UPS in "Manual" Bypass Mode. Thus the signal

that the UPS is On Bypass will be present and the Bypass Breaker in the MBS can be

closed. If the user follows the correct procedures for operating the MBS, these backfeed

prevention schemes will be completely transparent.

Page | 12

Page 16

Remote EPO (Emergency Power Off)

Some applications (notably, data centers) require that there is a provision to remotely shut

down power to the equipment powered by the UPS. Typically, this "remote" control is a red

button switch located next to the exit and wired to the UPS. However, shutting down the

UPS will have no effect on power to the load if the load is being powered by the Bypass

Breaker in the MBS. The Parallel Output Redundant Cabinet with MBS arrangement is

equipped with a Remote EPO input that causes both the Bypass Breaker (Breaker #2) and

both UPS Output Breakers (Breaker #3 and Breaker #5) to trip when a switch activation is

sensed. This way, power to the load is interrupted regardless of which breaker was

actually supplying current to the load. Note that the use of the REPO feature is optional

unless required by local codes.

Each UPS is also equipped with a REPO input, but this is completely independent of the

REPO system that is part of the MBS arrangement in this transformer cabinet. If it is

desired to have the same switch activate both the MBS REPO and the UPS REPO, a

switch with three sets of contacts needs to be used. One set of contacts would wire to this

cabinet as described in Section 4 and the other sets would wire to each of the UPS per the

instructions in the UPS manual. The UPS switch must be “normally closed”.

Some users prefer to use a normally open switch in the REPO system; others prefer a

normally closed switch. Inputs for both types of switches are provided in the Parallel

Output Redundant Cabinet with MBS arrangement, but the normally closed function has to

be enabled by operating a small rocker switch on the Options Control Board. This is to

avoid the problem of not being able to operate the system if the normally closed circuit is

missing, as when the user only chooses to use the normally open configuration, or when

the user does not choose to use the REPO sy s tem at al l .

Historically, REPO systems have caused a lot of confusion due to systems being inhibited

from operation due to a defective REPO switch circuit that causes the REPO to remain

active (examples: latched switch mechanisms, shorted wiring, open wiring). To help identify

this condition, the Options Control Board has a yellow LED lamp (DS1 in the upper right

corner of Figure 4) that indicates that the REPO has been activated. The logic that

operates the lamp latches the indication, so it is possible to determine that the REPO was

activated at some time since power was applied to the system. The latched indication can

be reset by pressing S1 on the Options Control Board. If pressing S1 fails to extinguish

DS1, then the REPO switch circuit is still active.

Page | 13

Page 17

SECTION 6

SECTION 6

Operation

(Refer to the one-line diagram, Figure 6) The purpose of the breakers is as follows:

Breaker 1 – Allows the input of UPS #1 to be isolated from the power source to facilitate

service.

Breaker 2 – “Maintenance Bypass” Allows power to be supplied to the load while the

UPSes are removed from service to perform maintenance.

Breaker 3 – Allows the output of UPS #1 to be isolated from the remainder of the system to

facilitate service.

Breaker 4 – Allows the input of UPS #2 to be isolated from the power source to facilitate

service.

Breaker 5 – Allows the output of UPS #2 to be isolated from the remainder of the system to

facilitate service.

Breaker 6 – Allows the parallel UPS system to be operated independently of the load (while

Breaker 2 supplies power) to facilitate testing during service. Also simplifies make-beforebreak transfers to and from maintenance bypass mode. This breaker also protects the

output wiring so that there is no need to oversize the load wiring in a redundant system that

otherwise could supply twice the rated current.

First time operation (at UPS commissioning)

This procedure initially applies the bypass source to the load. If there is a reason to start

the load using the UPS output, see “Starting on UPS”, below.

1. Make sure that Breaker 6 is open before proceeding.

2. Close Breaker 2. Verify that the load is powered. Verify proper output voltage and

phase sequence.

3. Close Breakers 1, 3, 4, and 5. Start both UPSes in the parallel system per the

procedures in the UPS manual.

4. Using the front panel display control menu, transfer either UPS to bypass mode.

5. Verify that the display panels on both UPSes show that the bypass path is active.

6. Very important: Measure the differential voltage across each pole (phase A top to

phase A bottom, etc.) of Breaker 6 and verify that none of the voltage measurements

are greater than 2 volts ac. If this is not so, power down the UPSes and correct the

wiring issue before continuing.

7. Close Breaker 6, then open Breaker 2. The power to the load is now being supplied

through the UPS system.

8. Using the front panel control menu, return the UPS to normal operation.

Page | 14

Page 18

Starting on UPS

1. Make sure that Breaker 2 and Breaker 6 are open before proc e edi n g .

2. Close Breakers 1, 3, 4, and 5. Start both UPSes in the parallel system per the

procedures in the UPS manual.

3. Close Breaker 6.

4. Measure the differential voltage across each pole (phase A top to phase A bottom,

etc.) of Breaker 2 and verify that none of the voltage measurements are greater than

15 volts ac. If one phase has a small differential and two are high, there is a wiring

error that must be corrected before the system can be considered to be ready for

normal use. If all measurements are greater than 15 Vac, it is possible that the UPS

has not yet synchronized with the bypass source. Wait and try again after a while. If

no progress is made, it will be necessary to transfer the UPS to bypass and check

the measurements, again. In bypass, the differentials should be less than 2 volts ac.

Transfer from Normal Mode to Maintenance Bypass—

1. Verify that the bypass source is suitable to supply the load. The front panel display

on the UPS can be helpful for this.

2. Transfer either UPS to Bypass mode using the front panel control menu.

3. Verify that the front panel display shows that the UPS is in Bypass Mode.

4. Close Breaker 2, then open Breaker 6. The load is now supplied from the bypass

source and there is no battery back-up available.

5. The UPSes can be powered down for service. Open Breakers 1 and 3 to isolate

UPS #1. Open Breakers 4 and 5 to isolate UPS #2. (Do not open Breakers 1 or 4

before the UPS is turned off, unless it is your intent to discharge the batteries.)

6. As long as Breaker 6 is kept open, Breakers 1, 3, 4 and 5 can be operated as

desired to service and test the UPSes.

Transfer from Maintenance Bypass to Normal Mode—

1. Close Breakers 1, 3, 4, and 5. Start the parallel UPS system per the procedures in

the UPS manual.

2. Using the front panel control menu on either UPS, place the UPS in Bypass mode.

3. Verify that the front panel displays on both UPSes show that they are in Bypass

mode.

4. Close Breaker 6, then open Breaker 2.

5. Using the front panel control, place the UPS in Normal Mode.

Potential Problems—

Breaker 2 trips when closure is att em pt ed – Check that the control wiring between the

UPSes and the PORC was properly installed per section 4. Check that the UPS

was in bypass before attempting to close Breaker 2.

Breaker 3 and Breaker 5 seem to trip randomly— There is a problem in the Remote

EPO system.

The UPS is stuck in bypass – There is likely a polarity reversal of the control wires to the

shutdown input on the UPS. Try disconnecting them temporarily to see if the

problem clears.

Page | 15

Page 19

Figure 6 - Circuit Breaker Sequence Labe l

REPO

User provided switch circuits are required to activate the REPO. Upon activation, the

REPO function trips Breaker 2 (if closed) and Breaker 3 and 5 (if closed), interrupting

power to the load. For details on how to connect to the REPO input(s) refer to Section 4 of

this Manual.

To restart the system after activation of the REPO, make sure that the REPO switch is in

the non-activated state before continuing. Then, use the Startup procedure for the MBS.

Page | 16

Page 20

SECTION 7

Environmental

Altitude

De-rate load capability above 1000 meters 1% per 100

meters.

Operating Temperature

40o C Maximum

Humidity

Maximum 95%RH, Non-condensing

Rated Input voltage

480/277

Rated Input Current

18A

Input Breaker Rating

25A

Rated Output voltage

208/120

Rated Output Current

40A

Output Breaker Rating

50A

Minimum Wire

Size INPUT

OUTPUT

#8 AWG

Maintenance

There are no wear items in the Parallel Output Redundant Cabinet that req ui re per i odi c

replacement. However, regular care will assure maximum availability of power.

Keep the ventilation openings in the cabinet free of dust and debris.

Wipe the cabinet exterior with a soft cloth, slightly dampened with water, to remove dust.

Consider performing periodic infrared temperature measurements on the circuit breaker

terminations. This will require access to the cabinet interior. There are hazardous voltages

present and any work must be performed using caution. Only trained service personnel

should perform this work. Elevated temperatures of the terminations usually are the sign of

a loose connection, but can also signal that a breaker is failing. Loose connections should

only be serviced after removal of power.

If the system is powered down, consider removing accumulated dust from the cabinet

interior using a vacuum cleaner.

SECTION 8

Parallel Output Redundant Cabinet Technical Specifications

Table 6 - Technical Specifications

Page | 17

#12 AWG

Loading...

Loading...