Page 1

FirstLine P

FirstLine P 924

160-250kVA UPS

USER MANUAL

003-2460 Rev C

Page 2

Staco Energy is highly specialized in the development and production of uninterruptible power

manufactured to ensure optimum performance.

No reproduction of any part of this manual, even partial, is permitted without the authorization of Staco

Energy Products Company. The Staco Energy Products Company reserves the right to modify the

product described herein, in order to improve it, at any time and without notice.

301 Gaddis Boulevard • Dayton, Ohio 45403

U.S. Toll Free 866-261-1191

(937) 253-1191 • Fax: (937) 253-1723

Web site: www.stacoenergy.com

Thank you for choosing our product.

systems (UPS). The UPS’s of this series are high quality products, carefully designed and

Page | ii

Page 3

Applicability

WARNING

DANGER

This manual applies to the following models:

FLU-160-xx

160 kVA, 480 V input, 480 V output, 60 Hz, configured as wye-wye or delta-delta

FLU-200-xx

200 kVA, 480 V input, 480 V output, 60 Hz, configured as wye-wye or delta-delta

FLU-250-xx

250 kVA, 480 V input, 480 V output, 60 Hz, configured as wye-wye or delta-delta

The wye output configuration that provides an output neutral connection is only permitted

when an input neutral is provided; delta-wye configuration is prohibited.

The source must have a grounded neutral, even if the neutral is not connected to the UPS; a

delta source may not be ungrounded or corner grounded.

Please refer to Section C.3 Mains and Load Connections. for additional information.

Safety Warnings

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

This manual contains important instructions for Models 65, 80, 100 and 125kVA FIRSTLINE P series

UPS that should be followed during installation and maintenance of the UPS. Please read all instructions

before operating the UPS and save this manual for future reference.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

a. Do not use outdoors.

b. Do not route wiring across or near hot surfaces.

c. Do not install near gas or electric heaters.

d. Use caution when servicing batteries. Battery acid can cause burns to skin and eyes. If acid is

spilled on skin or in eyes, flush acid with fresh water and contact a physician immediately.

e. Unit should be installed where it will not readily be subjected to tampering by unauthorized

personnel.

f. The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

g. Do not use this UPS for other than intended use.

This UPS contains LETHAL VOLTAGES. All repairs and service should be performed by

AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE

PARTS inside the UPS.

Page | iii

Page 4

WARNING

WARNING

To reduce the risk of fire or electric shock, install this UPS in a temperature and humidity

controlled, indoor environment, free of conductive contaminants. Do not operate near water

or excessive humidity (95% maximum).

Input and output over-current protection and disconnect switches must be provided by

others.

High ground leakage current may be present. Do not operate the unit without a proper

protective ground.

WARNING

Batteries can present a risk of electrical shock or burn from high short circuit current.

Observe proper precautions. Servicing should be performed by qualified service personnel

knowledgeable of batteries and required precautions. Keep unauthorized personnel away

from b atterie s.

There i s a risk of explosion if batteries are replaced by an incorrect type. Replace with same

type and rating only.

Proper disposal of batteries is required. Refer to your local codes for disposal requirements.

Never dispose of batteries in a fire

Emergency Interventions

The following information is of a general nature.

First aid interventions

Company regulations and traditional procedures should be followed for any first aid intervention that may

be required.

Firefighting measures

1. Do not use water to put out a fire, but only fire extinguishers that are suitable for use with

electrical and electronic equipment.

2. If exposed to heat or fire, some products may release toxic fumes into the atmosphere. Always

use a respirator when extinguishing a fire.

Page | iv

Page 5

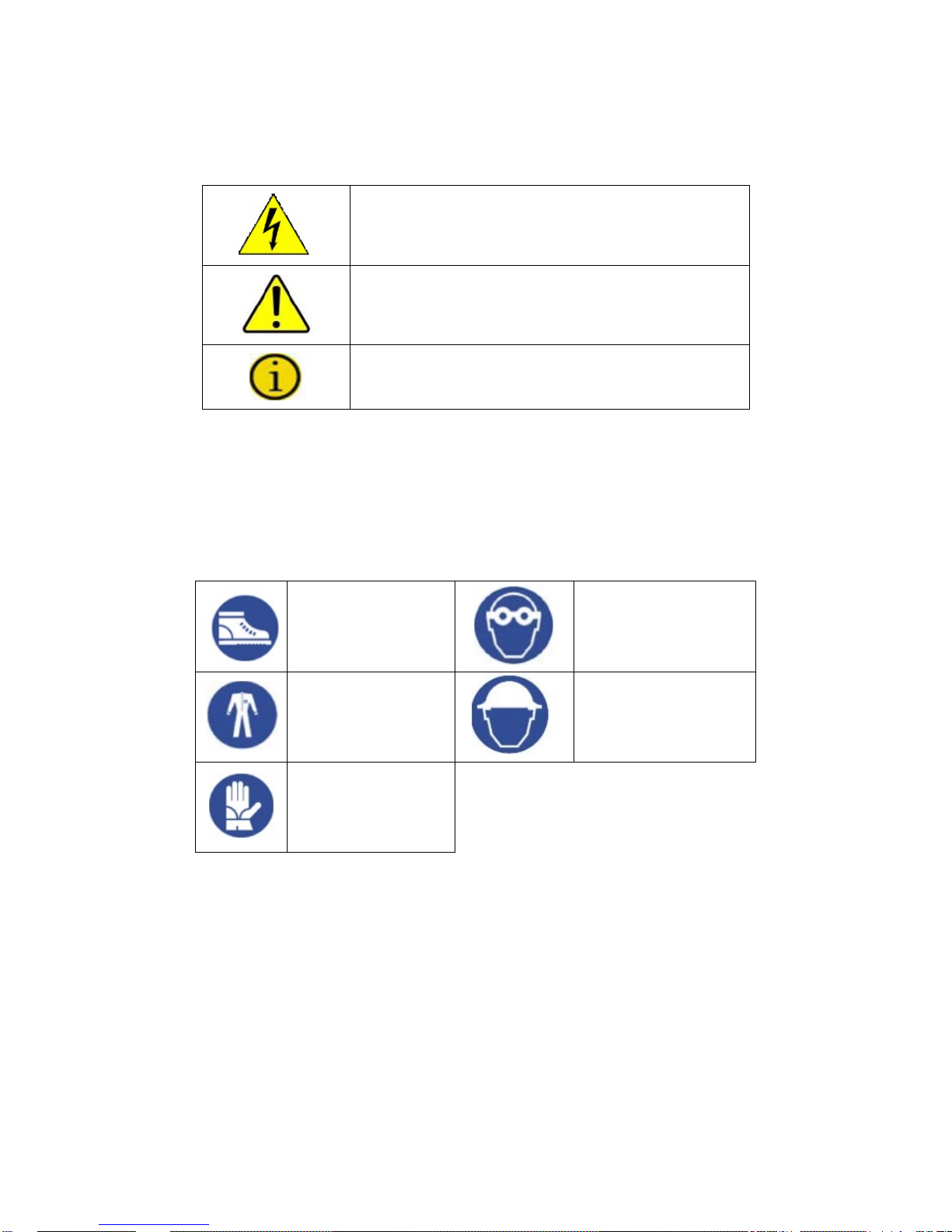

Symbols used in the Manual

Danger / Risk of Electric Shock

adequate precautions are taken.

Warning

taken

In this manual, some operations are shown by graphic symbols to alert the reader to the dangerous

nature of the operations:

This symbol indicates possibility of serious injury

or substantial damage to the unit, unless

This symbol indicates important information which

must be understood and any stated precautions

Note

Protective Equipment

No maintenance operations shall be carried out on the unit without wearing the Personal Protective

Equipment (PPE) described below. Personnel involved in the installation or maintenance of the unit must

be properly clothed.

The following signs show the protective equipment that should be worn. The various items of PPE must

be selected and sized according to the nature of the hazard (particularly electrical) posed by the unit.

Accident

prevention

Protective eyewear

footwear

Protective

clothing

Helmet

Work gloves

General Precautions

This manual contains detailed instructions for the use, installation and start-up of the UPS. Read the

manual carefully before installation. For information on using the UPS, the manual should be kept close

at hand and consulted before carrying out any operation on the UPS.

This UPS has been designed and manufactured in accordance with the standards for the product, for

normal use and for all uses that may reasonably be expected. It may under no circumstances be used for

any purposes other than those envisaged, or in any other ways than those described in this manual. Any

interventions should be carried out in accordance with the criteria and the time-frames described in this

manual.

Page | v

Page 6

Table of Contents

Applicability .............................................................................................................................................. iii

Safety Warnings ...................................................................................................................................... iii

Emergency Interventions ......................................................................................................................... iv

First aid interventions ........................................................................................................................... iv

Firefighting measures ........................................................................................................................... iv

Symbols used in the Manual ..................................................................................................................... v

Protective Equipment ................................................................................................................................ v

General Precautions ................................................................................................................................. v

1. Layout .................................................................................................................................................. 1

1.1 Views .............................................................................................................................................. 1

1.2 Preliminary Operations ................................................................................................................... 3

1.2.1 Removing the Packaging and Positioning the Device .............................................................. 3

1.2.2 Storage .................................................................................................................................... 3

1.2.3 Handling .................................................................................................................................. 3

1.2.4 Cooling of the Premises ........................................................................................................... 4

2. Installation ............................................................................................................................................ 5

2.1 Accessing the UPS terminals ......................................................................................................... 5

2.2 UPS - Single Module Configuration ................................................................................................ 6

2.3 Cable Entry ..................................................................................................................................... 7

2.4 Connect of Power Cables ............................................................................................................... 9

2.4.1 Input Line without Neutral ........................................................................................................ 9

2.4.2 Single Input ............................................................................................................................ 10

2.4.3 Connection of Power Cables for Dual input Unit ..................................................................... 12

2.5 Differential (GFI) ........................................................................................................................... 14

2.6 Emergency Power off Device (EPO) ............................................................................................. 14

2.7 Connection of Signals and Remote Commands ........................................................................... 15

2.7.1 Remote Commands, Alarms and EPO ................................................................................... 17

2.7.2 RS232-1 and RS232-2 ........................................................................................................... 18

2.7.3 SLOT 1 and SLOT 2 .............................................................................................................. 19

2.7.4 Optional Remote Alarm Cards ............................................................................................... 19

2.7.5 Optional MODEM ................................................................................................................... 20

2.7.6 Option a l MULTI I / O .............................................................................................................. 20

2.7.7 Optional Battery Temperature Sensor .................................................................................... 20

2.7.9 Multi Panel ............................................................................................................................. 20

2.7.10 SWOUT and SWMB aux. ..................................................................................................... 21

3. Operation ........................................................................................................................................... 23

3.1 Start up ......................................................................................................................................... 24

3.1.1 Before S tart Up ...................................................................................................................... 24

3.1.2 Start-Up Procedure Single Module ......................................................................................... 24

3.2 Single UPS and Load Shutdown ................................................................................................... 25

3.3 Transfer to Bypass/Inverter .......................................................................................................... 25

3.4 Operating Modes .......................................................................................................................... 25

3.4.1 On-line Factory Setting .......................................................................................................... 25

Page | vi

Page 7

3.4.2 Standby-On / Smart Active ..................................................................................................... 25

3.4.3 Standby-Off (with Mains Present the Load is not Powered) ................................................... 26

3.4.4 Stabilizer (Operation In On-Line Mode Without Battery) ......................................................... 26

4. Control Panel and Display .................................................................................................................. 27

4.1 Signal panel functions .................................................................................................................. 27

4.2 Graphic Display ............................................................................................................................ 29

4.2.1 Diagram Items Shapes........................................................................................................... 30

4.2.2 Keys Numbers and Icons ....................................................................................................... 30

4.3 Basic menu (text lines area) ......................................................................................................... 31

4.3.1 The First Line of the Basic Menu ............................................................................................ 31

4.3.2 The Second Line of the Basic Menu....................................................................................... 32

4.4 Language setting menu (keys 1, 1) ............................................................................................... 33

4.5 Measurements menus (key 2) ...................................................................................................... 34

4.6 Full page Measurements and output waveforms (key 2, 7) ........................................................... 36

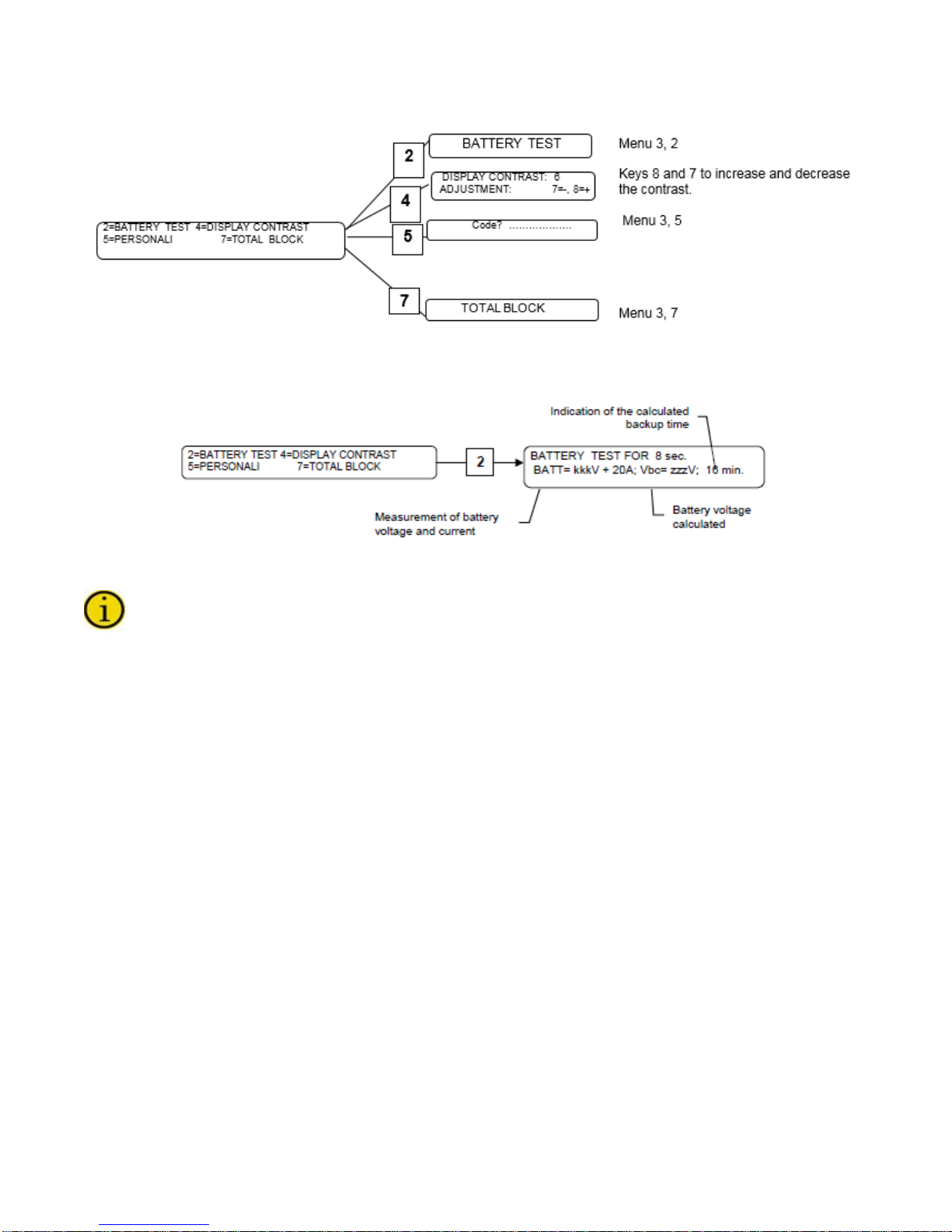

4.7 Controls Menu (key 3) .................................................................................................................. 37

4.7.1 Battery Test (Keys 3, 2) ......................................................................................................... 37

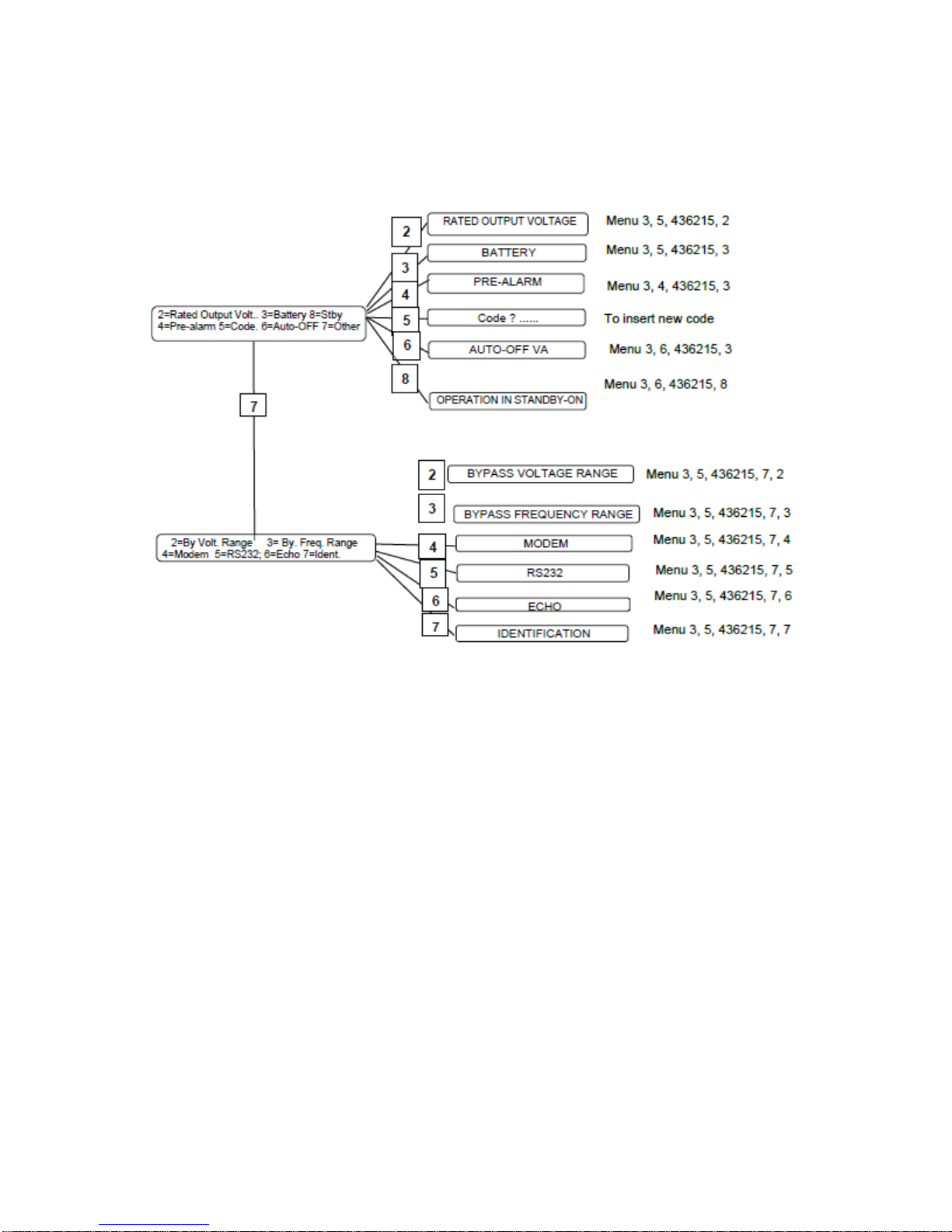

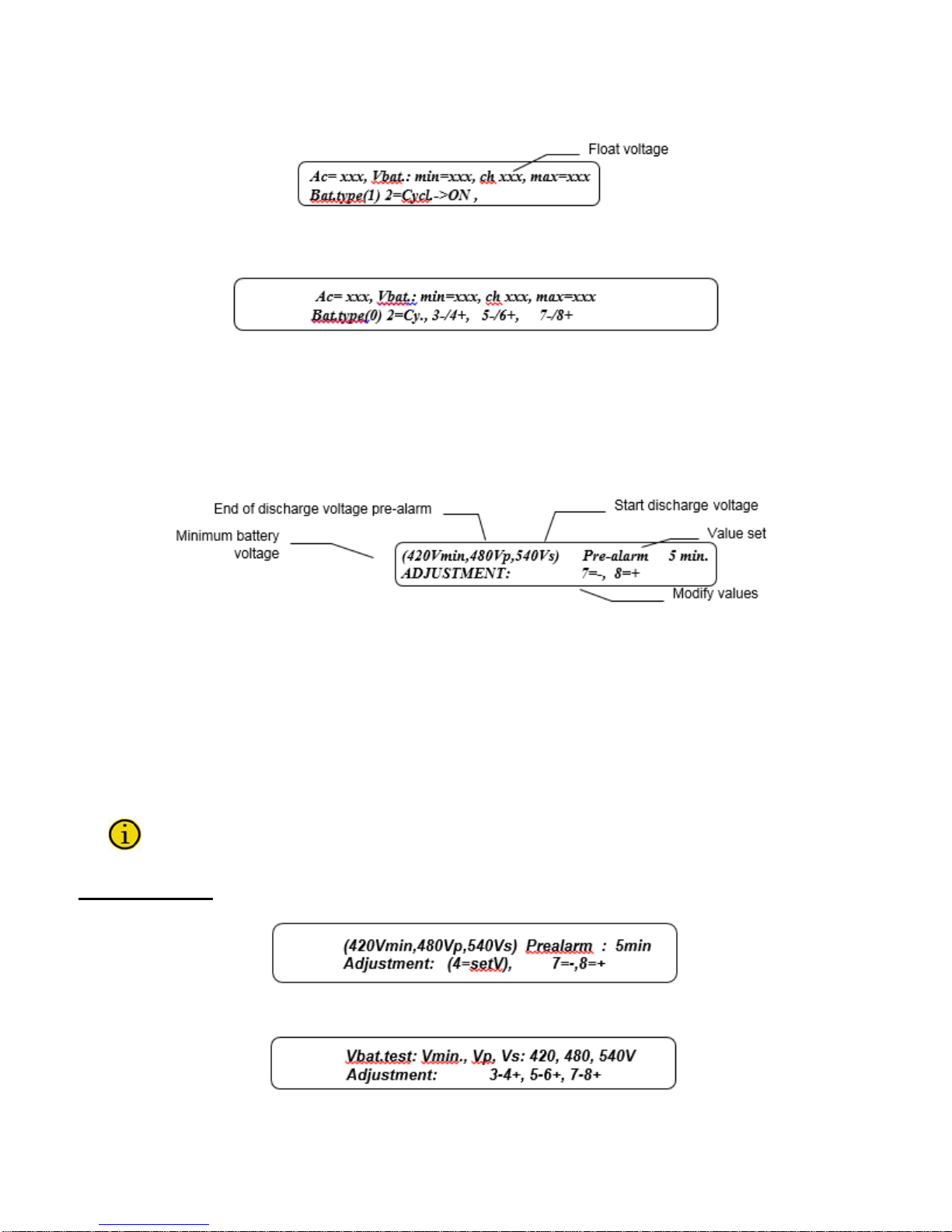

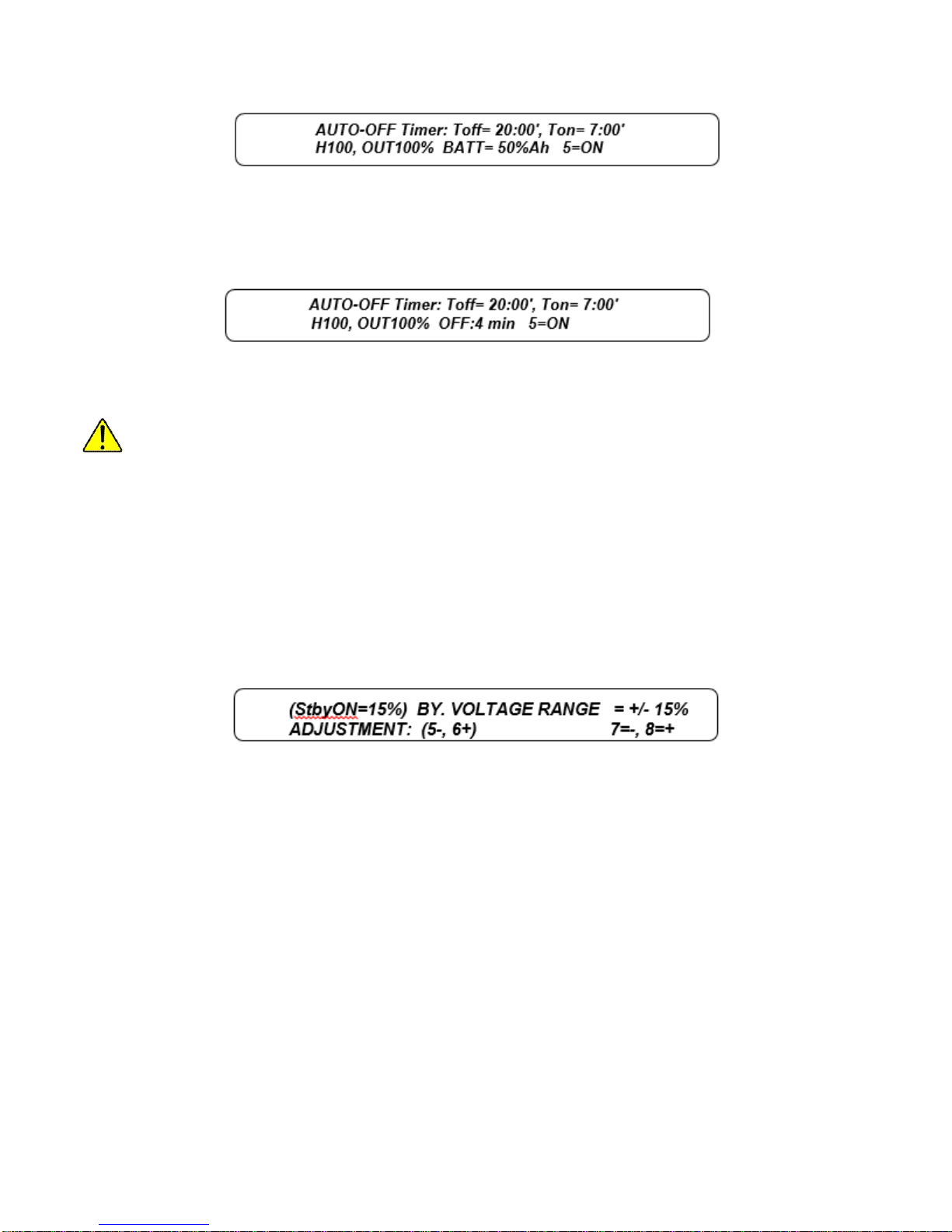

4.7.2 Customizing ........................................................................................................................... 38

4.7.3 "Recorder": Recorded Events (key 4) ..................................................................................... 48

4.7.4 Disabling the Audible Alarm (key 5) ....................................................................................... 50

4.7.5"Clock": Date/Time (key 6) ...................................................................................................... 51

4.7.6 "Arrow Down": Internal Codes, Firmware Ver.(key 7) ............................................................. 51

5. UL924 Emergency Lighting Systems ............................................................................................... 52

6. Maintenance ...................................................................................................................................... 53

6.1 Periodic Maintenance (to be carried out by trained personnel and with doors closed) .................. 53

6.2 Maintenance Inside the UPS (factory authorized personnel only) ................................................. 53

6.3 Ordinary Maintenance for Batteries (trained personnel only) ........................................................ 53

6.4 Recommended Replacement Intervals ......................................................................................... 54

7. Specifications ..................................................................................................................................... 55

7.1 Electrical Specifications ................................................................................................................ 55

7.2 Environmental Requirements ....................................................................................................... 56

7.3 Mechanical Specifications ............................................................................................................ 56

7.4 Rated Currents ............................................................................................................................. 57

7.4.1 Input (Single Input Module) .................................................................................................... 57

7.4.2 Rectifier Input (Dual Input Module) ......................................................................................... 57

7.4.3 Bypass Input (Dual Input Module) .......................................................................................... 57

7.4.4 Output .................................................................................................................................... 57

7.4.5 Battery ................................................................................................................................... 57

7.5 Torque specifications .................................................................................................................... 58

Appendix A – Alarms ............................................................................................................................. 59

Appendix B - Optional remote commands .............................................................................................. 62

Appendix C - Parallel Configuratio n ....................................................................................................... 63

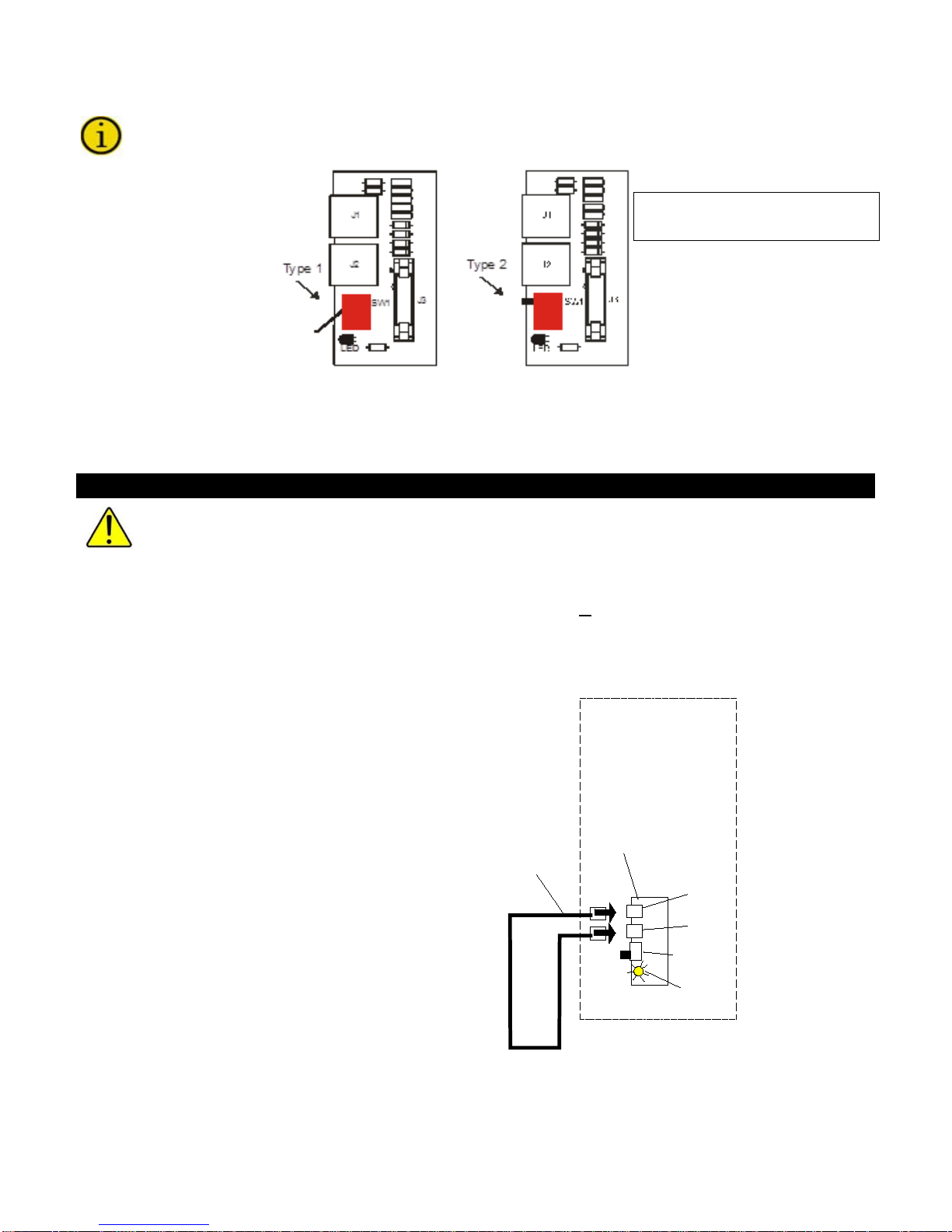

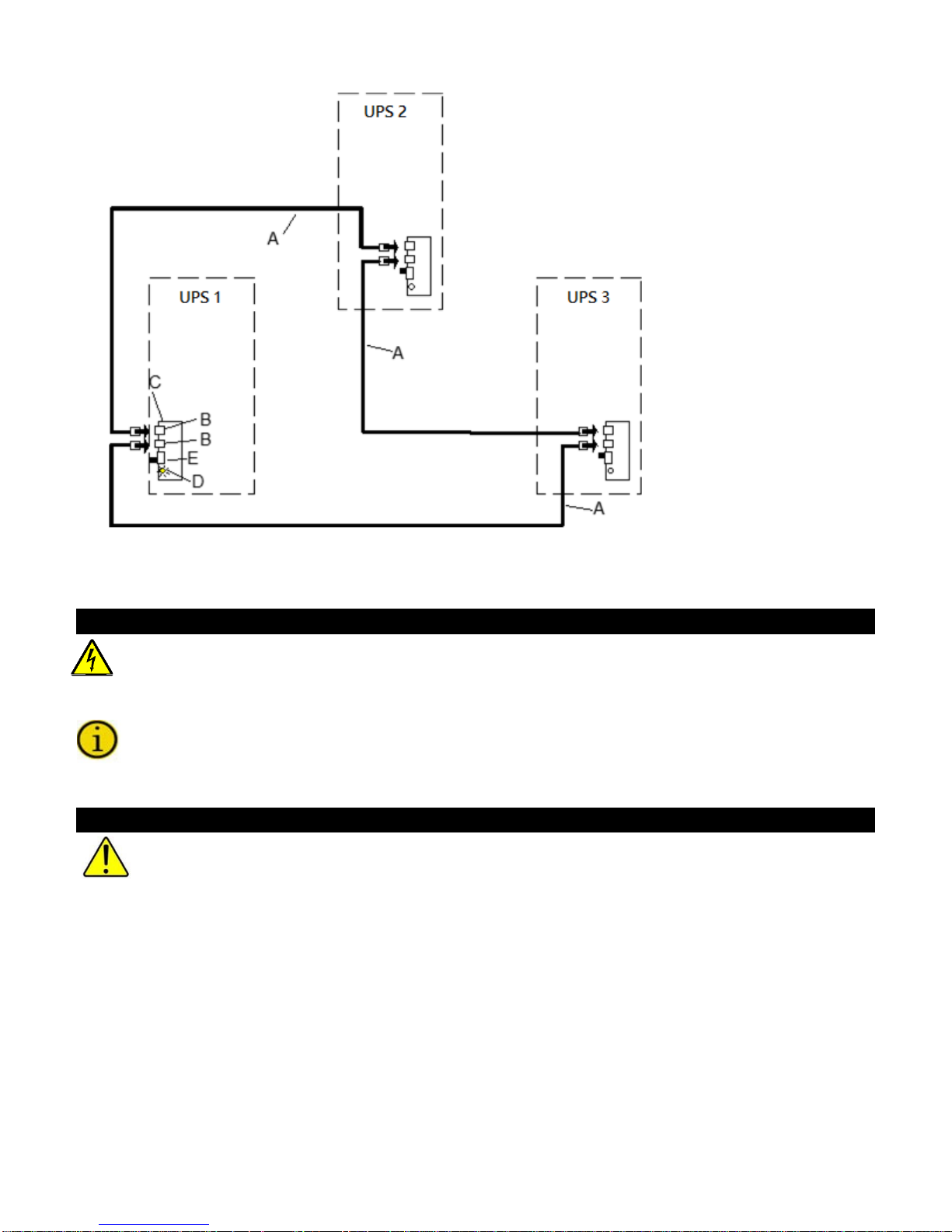

C.1 Introduction .................................................................................................................................. 63

C.2 Electrical System Set-Up ............................................................................................................. 64

C.2.1 Input ...................................................................................................................................... 64

Page | vii

Page 8

C.2.2 Ground Fault ......................................................................................................................... 64

C.2.3 Emergency Power Off Device (EPO) ..................................................................................... 64

C.2.4 External Maintenance Bypass. .............................................................................................. 65

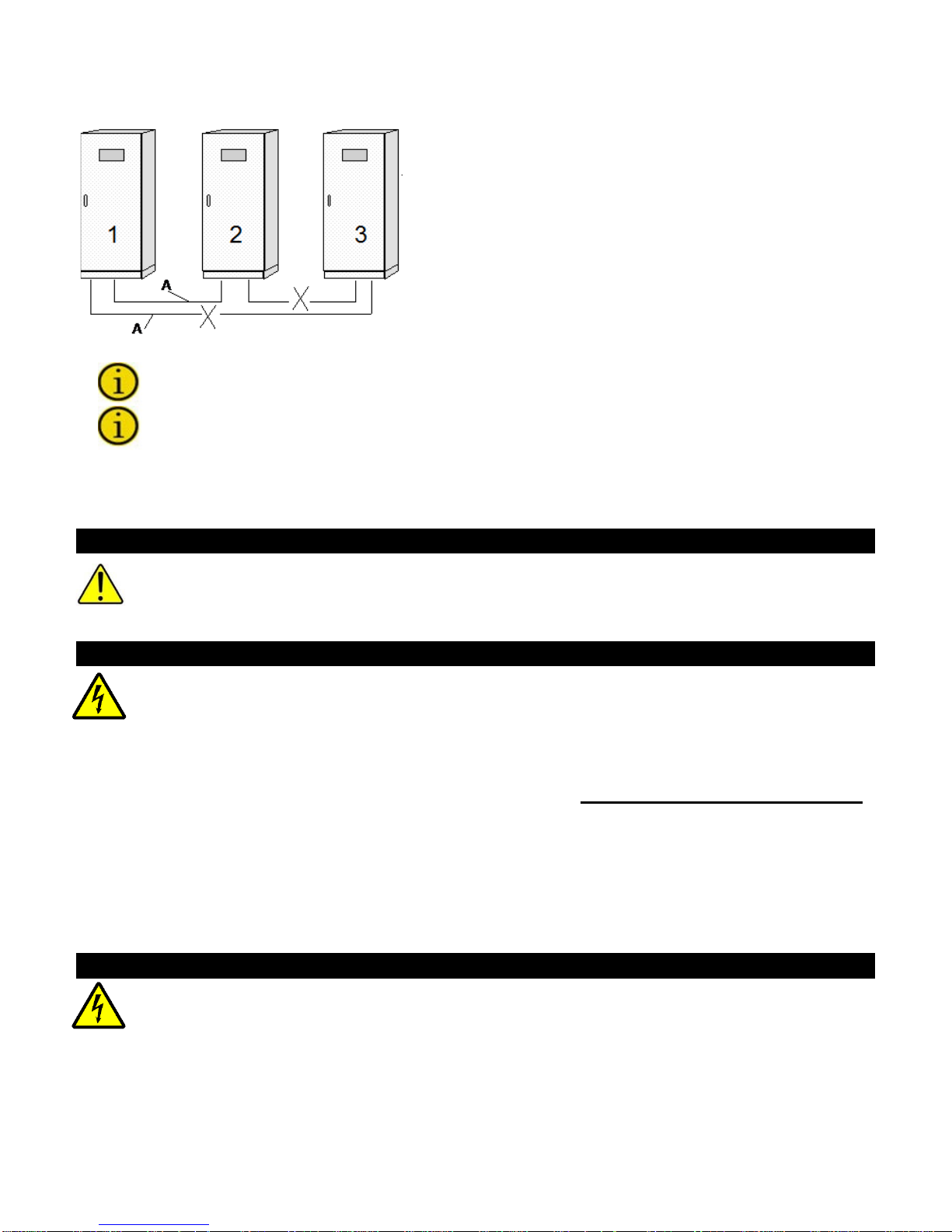

C.3 Mains and Load Connections. ...................................................................................................... 65

C.4 Installing Parallel k it ..................................................................................................................... 66

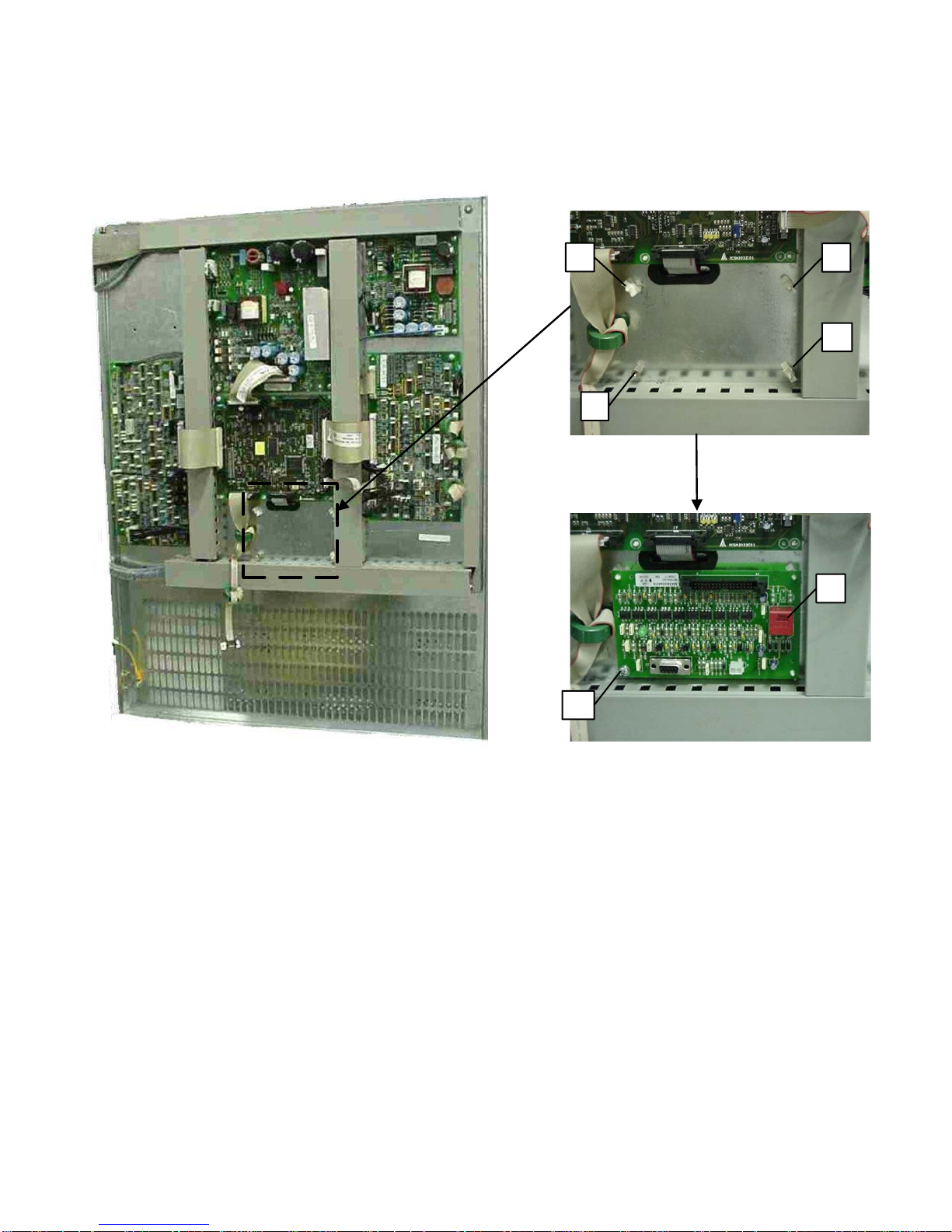

C.4.1 Parallel Card Installation ........................................................................................................ 67

C.4.2 Parallel Card Connections ..................................................................................................... 68

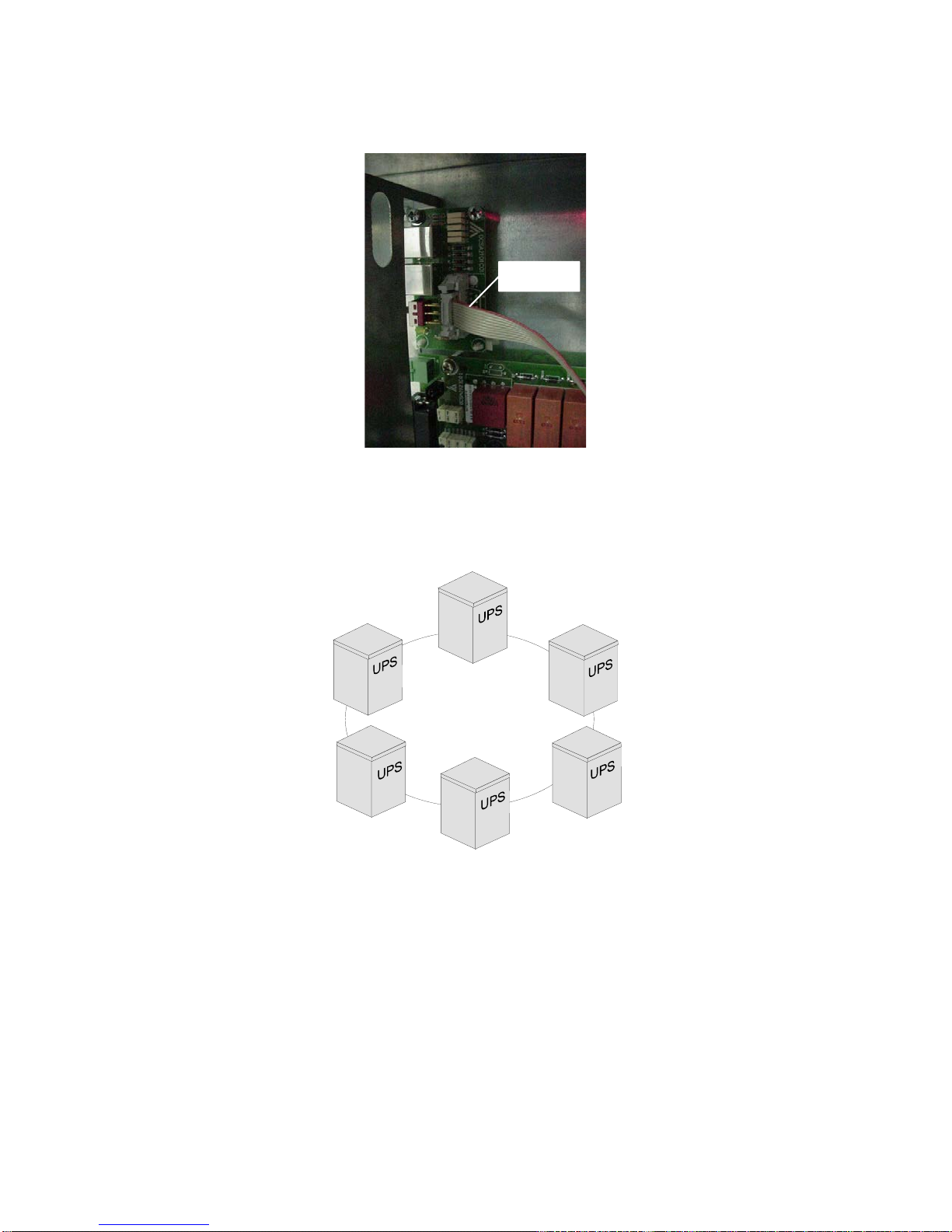

C.4.3 Parallel Card RJ45 Installation .............................................................................................. 68

C.4.4 Parallel Card RJ45 Connections ............................................................................................ 69

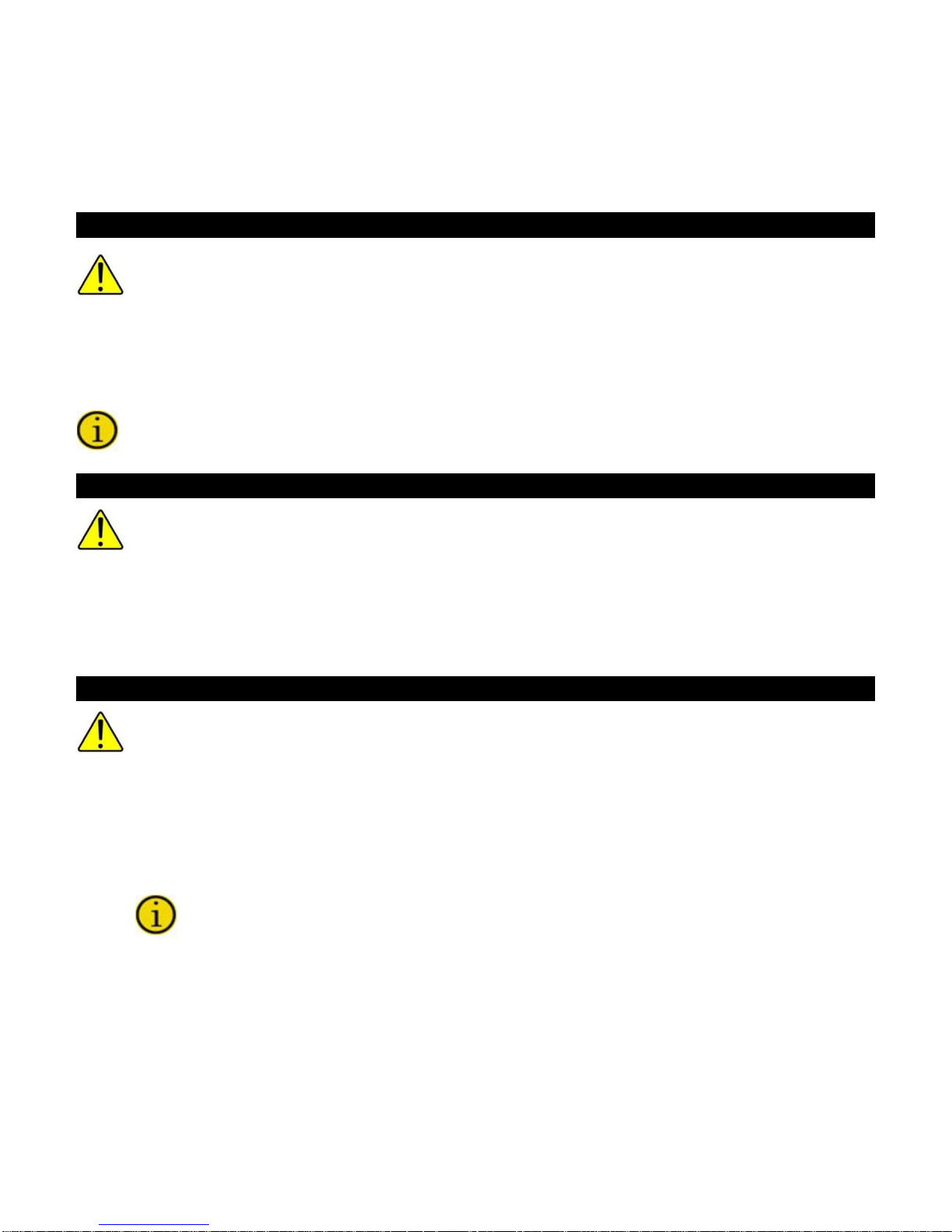

C.5 Connection of Signals .................................................................................................................. 69

C.5.1 RJ45-flat-adapter signals parallel card. ................................................................................. 70

C.5.2 Single UPS Configured in Parallel ......................................................................................... 70

C.5.3 Two UPS’s in Parallel ............................................................................................................ 71

C.5.4 Three UPS’s in Parallel ......................................................................................................... 71

C.6 Parallel Start-up procedure .......................................................................................................... 72

C.7 Parallel Communication Troubleshooting ..................................................................................... 73

C.7.1 Normal Condition ................................................................................................................... 73

C.7.2 Single Opened Parallel Cable ................................................................................................ 73

C.7.3 Multiple Opened Parallel Cable ............................................................................................. 74

C.8 Mechanical Bypass ...................................................................................................................... 74

C.8.1 Mechanical bypass on a single unit ....................................................................................... 74

C.8.2 Mechanical bypass on the whole system ............................................................................... 75

C.9 Insertion and removal with UPS’s operating (hot swap) ............................................................... 76

C.9.1 Example of Hot Insertion ....................................................................................................... 76

C.9.2 Example of Hot Removal ....................................................................................................... 77

Page | viii

Page 9

Figures

Figure 1 - FLU cabinet front view ............................................................................................................. 1

Figure 2 - FLU-T cabinet front view.......................................................................................................... 2

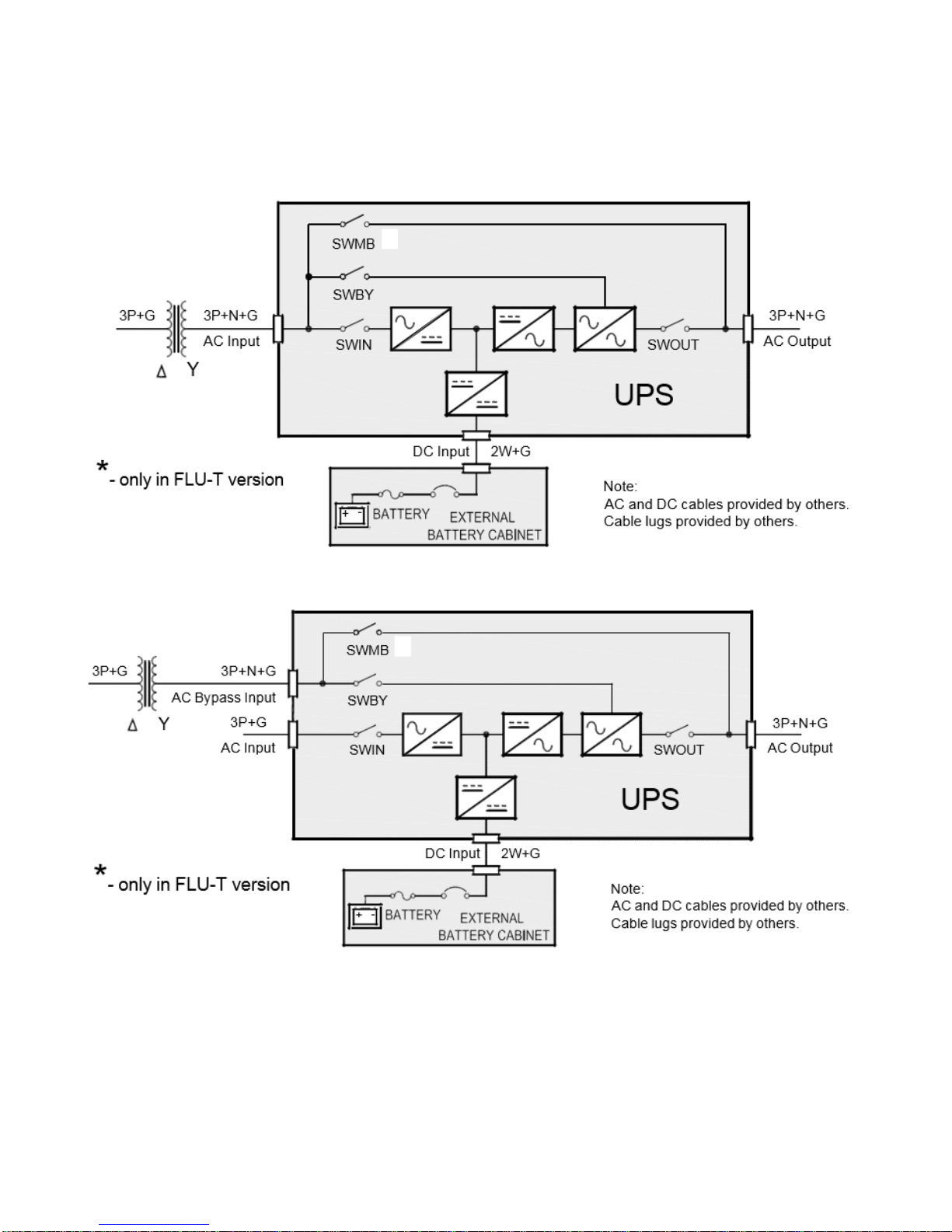

Figure 3 – Single Input 1-Line ................................................................................................................. 6

Figure 4 - Dual Input 1-Line ..................................................................................................................... 6

Figure 5 – FLU bottom Cable Entry Layout .............................................................................................. 7

Figure 6 – FLU-T bottom Cable Entry Layout .......................................................................................... 8

Figure 7 - Schematic diagram: Single In put without Source Neutral ......................................................... 9

Figure 8 - Schematic diagram: Dual Input without Source Neutral ............................................................ 9

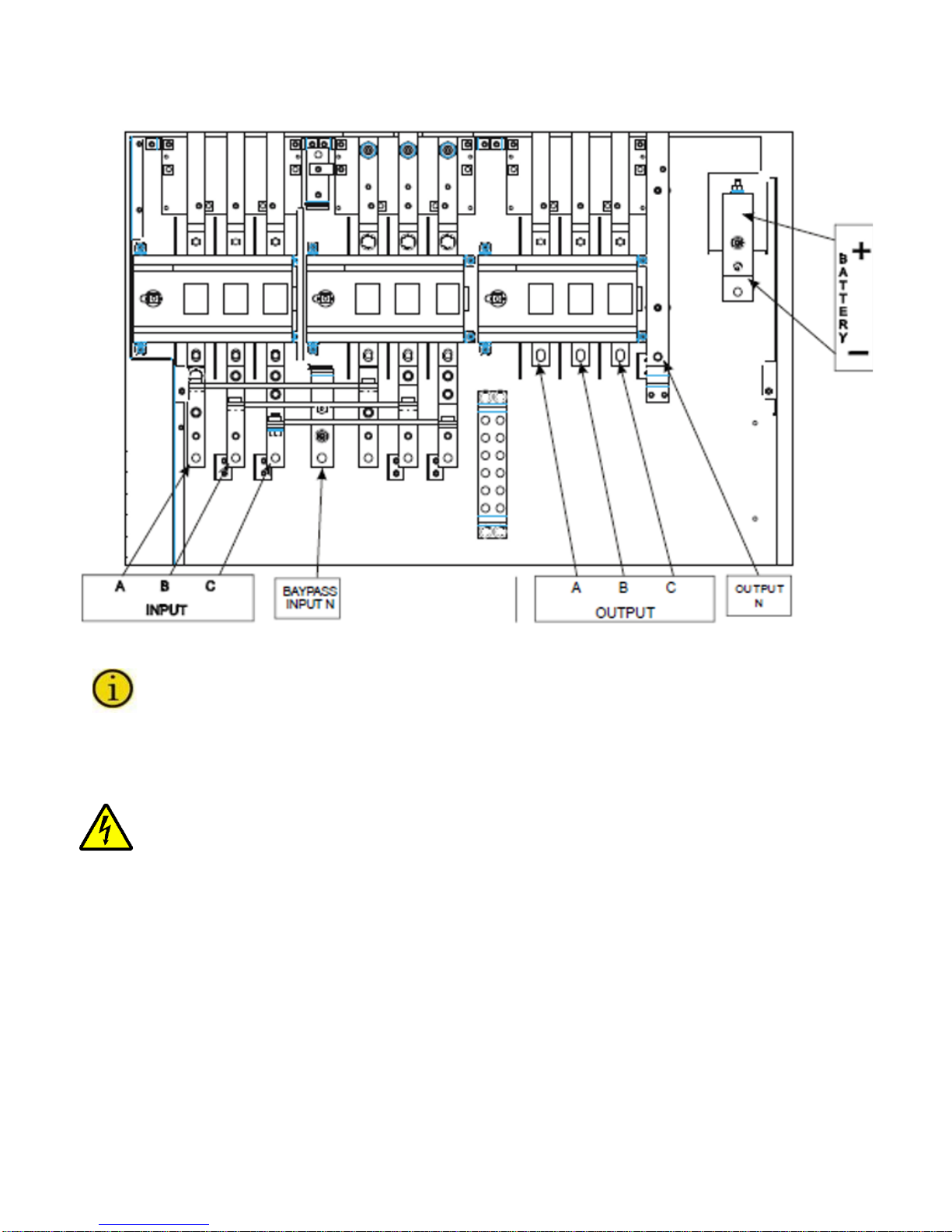

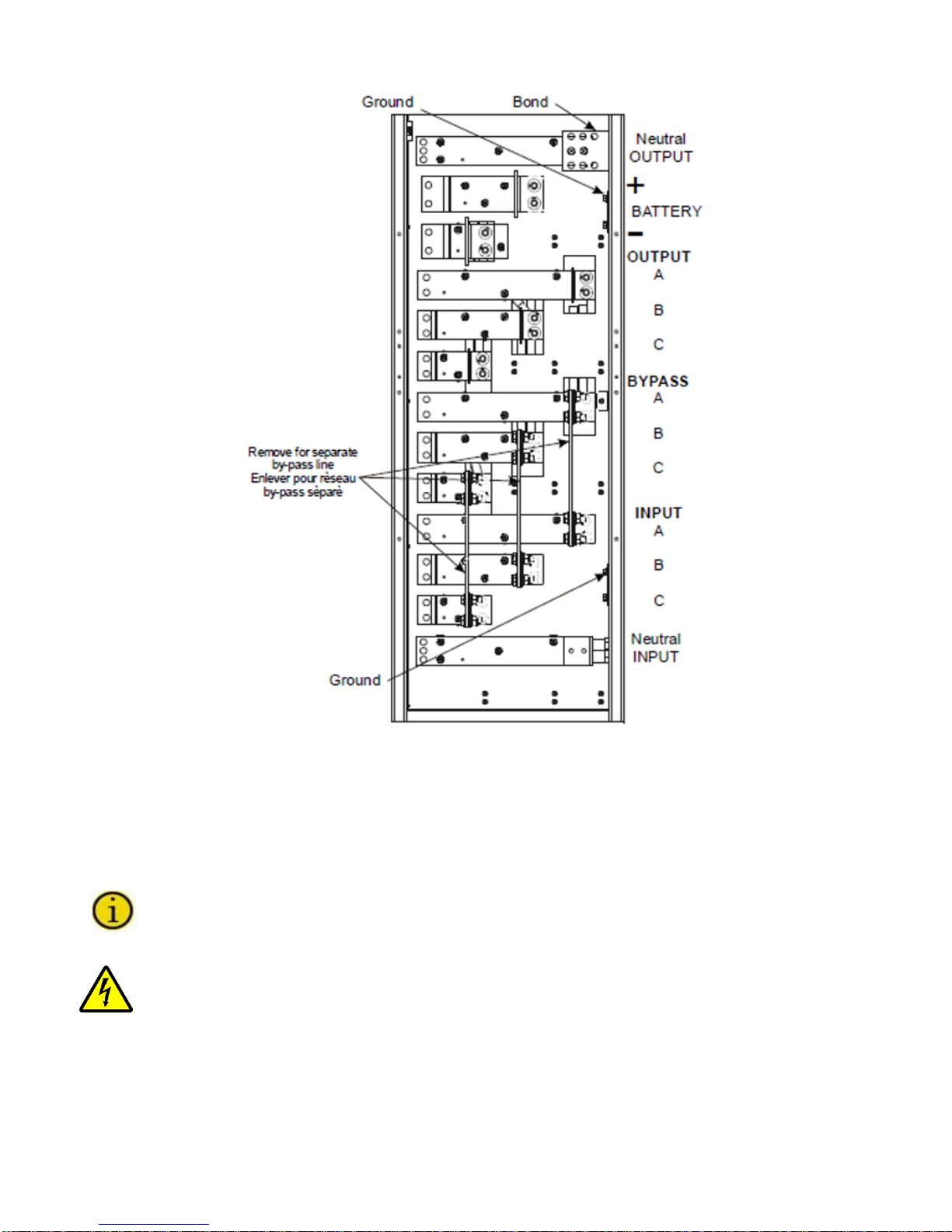

Figure 9 – FLU UPS Single Input Power Connection Terminals ............................................................. 10

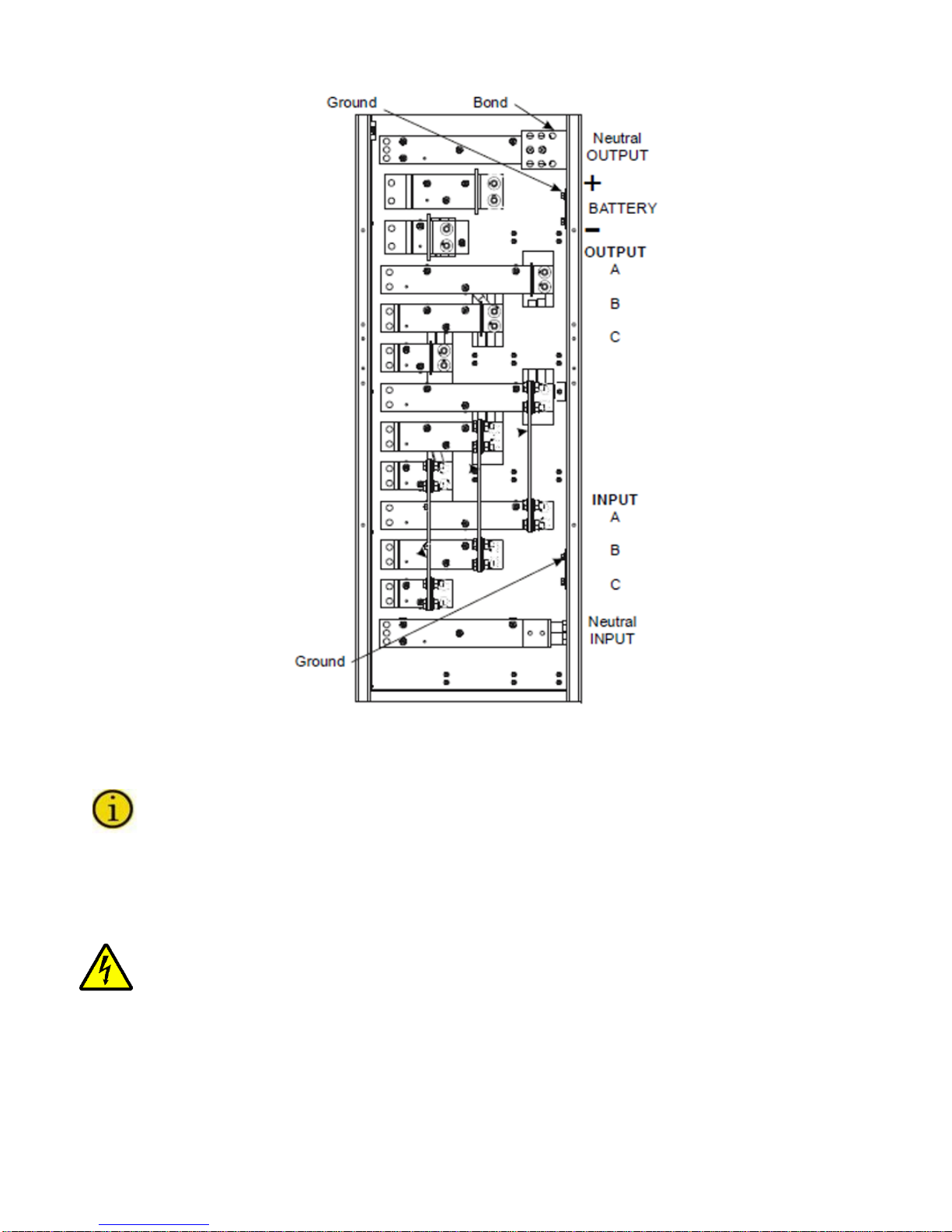

Figure 10 – FLU-T UPS Single Input Power Connection Terminals ....................................................... 11

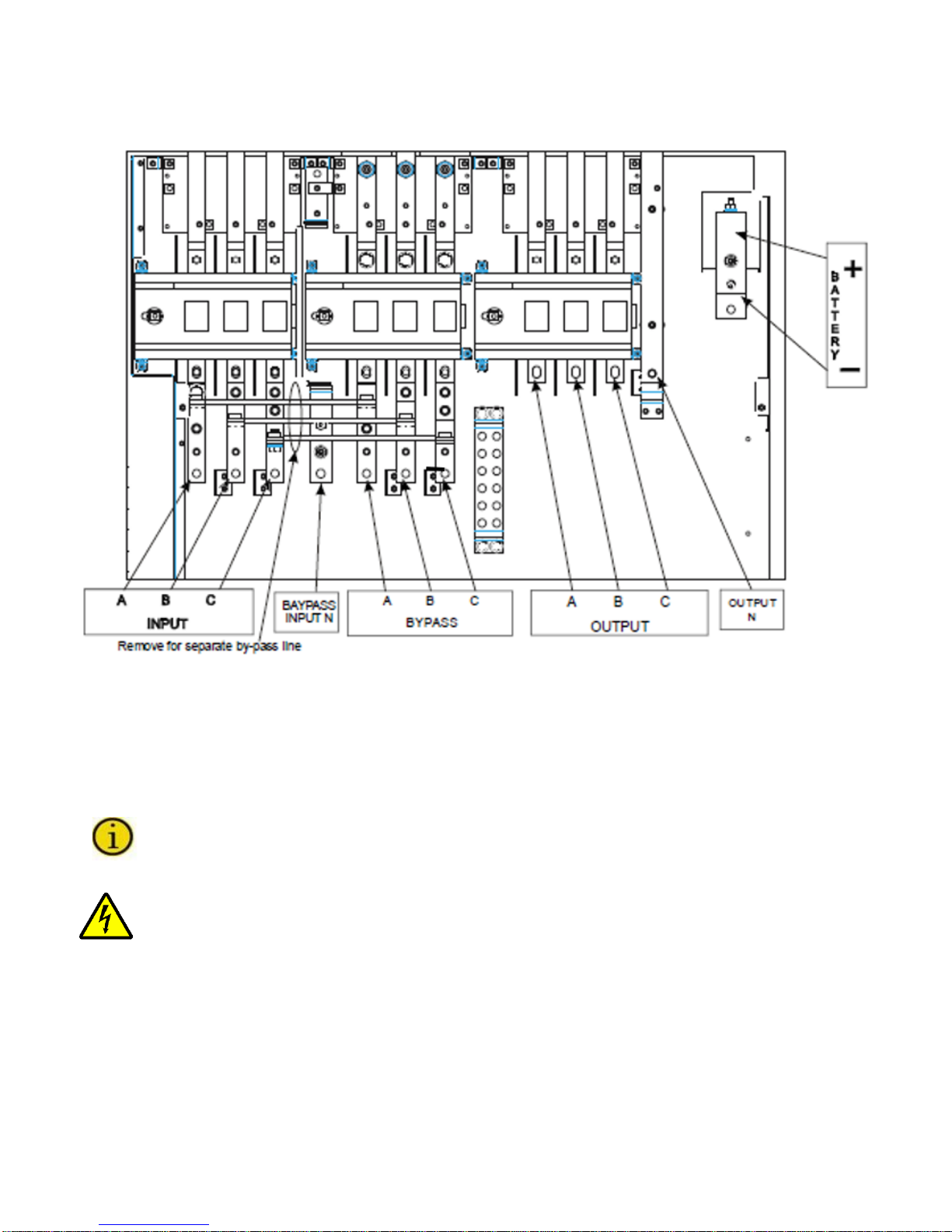

Figure 11 – FLU UPS Dual Input Power Connection Terminals ............................................................. 12

Figure 12 – FLU-T UPS Dual Input Power Connection Terminals .......................................................... 13

Figure 13 – Emergency Power Off (EPO) ............................................................................................. 14

Figure 14 – FLU Signals and Remote Command Connections .............................................................. 15

Figure 15 – FLU-T Signals and Remote Command Connections ........................................................... 16

Figure 16 – Remote Alarm Contacts ......................................................................................................

Figure 17 – RS232-2 Female Connection ............................................................................................. 18

Figure 18 – RS232-1 Male Connection ................................................................................................. 19

Figure 19 – Single Module Wrap-around bypass ................................................................................... 21

Figure 20 – Parallel System Wrap-around bypass ................................................................................. 22

Figure 21 – Single Input 1-Line .............................................................................................................. 23

Figure 22 – Dual Input 1-Line ................................................................................................................ 23

Figure 23 – Signal Panel ....................................................................................................................... 27

Figure 24 – Graphic Display .................................................................................................................. 29

Figure 25 – Typical (3) Module Parallel System .................................................................................... 63

Figure 26 – Recommended Ground Fault Interrupter Layout ................................................................ 64

Figure 27 – Parallel System EPO .......................................................................................................... 64

Figure 28 - Three units connected in parallel (Typical) .......................................................................... 65

Figure 29 – Parallel Card Installation ..................................................................................................... 67

Figure 30 – Parallel Card connections ................................................................................................... 68

Figure 31 – Parallel Card RJ45 Installation ........................................................................................... 68

Figure 32 – Parallel Card Flat Cable Installation.................................................................................... 69

Figure 33 - Parallel Control Routing ...................................................................................................... 69

Figure 34 - RJ45-flat-adapter signals parallel card ................................................................................ 70

Figure 35 – Parallel Connection – Single Module .................................................................................. 70

Figure 36 – Parallel Connection – Two Modules ...................................................................................

Figure 37 – Parallel Connection – Three Modules ................................................................................. 72

18

71

Tables

Table 1 - Torque Specifications for Terminal Blocks on Customer Interface Board ................................. 16

Table 2 - Interface Remote Command Alarms and EPO ........................................................................ 17

Table 3 - Interface Terminal Connector ................................................................................................. 22

Table 4 - Led Status Indicators .............................................................................................................. 28

Table 5 - Diagram Items Shapes ........................................................................................................... 30

Table 6 - Keys Numbers and Icons ........................................................................................................ 30

Table 7 – Battery Models approved for UL924 ....................................................................................... 52

Table 8 – UL924 Approved Systems ...................................................................................................... 52

Table 9 - Recommended Replacement Intervals ................................................................................... 54

Table 10 – Parallel Kit Components ...................................................................................................... 66

Page | ix

Page 10

Page | x

Page 11

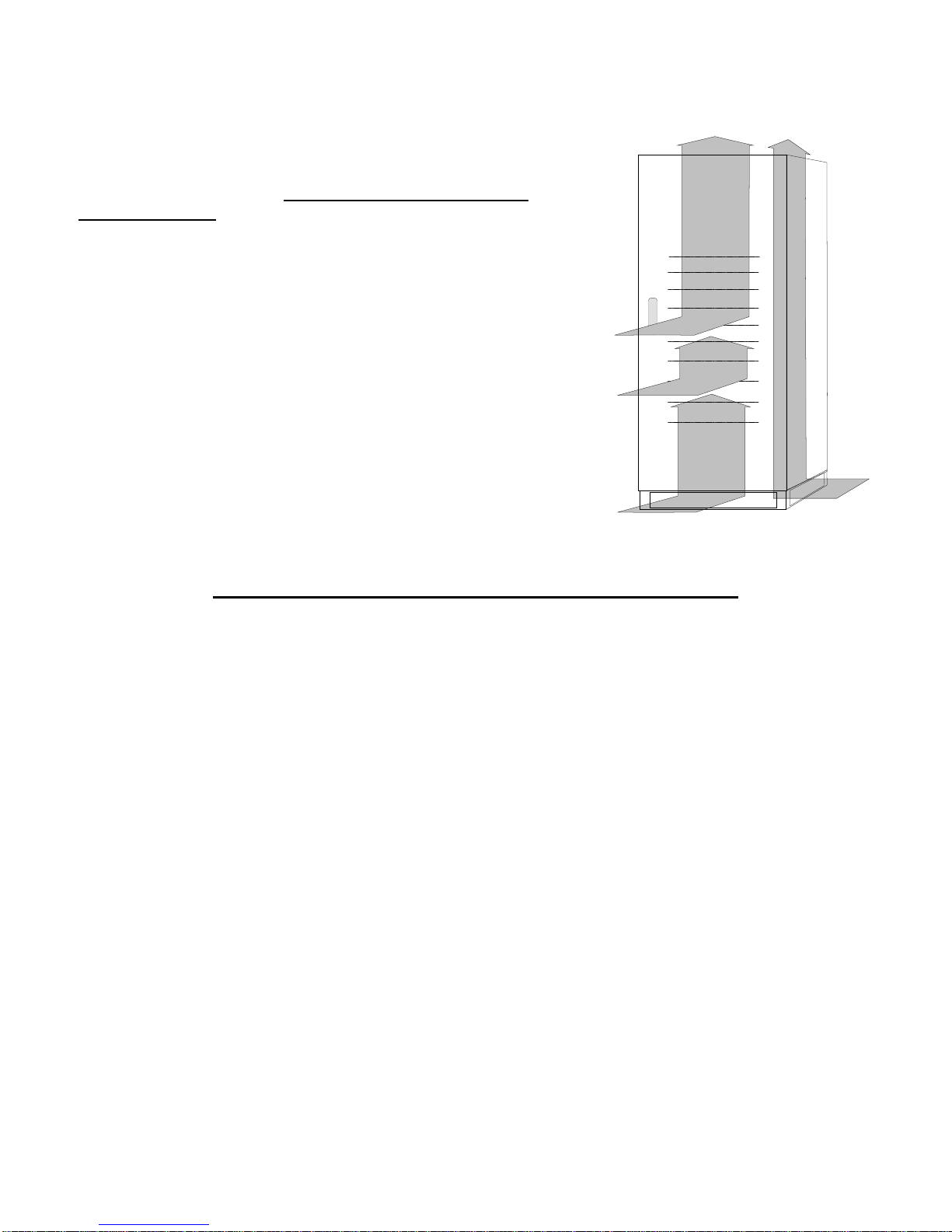

1. Layout

1.1 Views

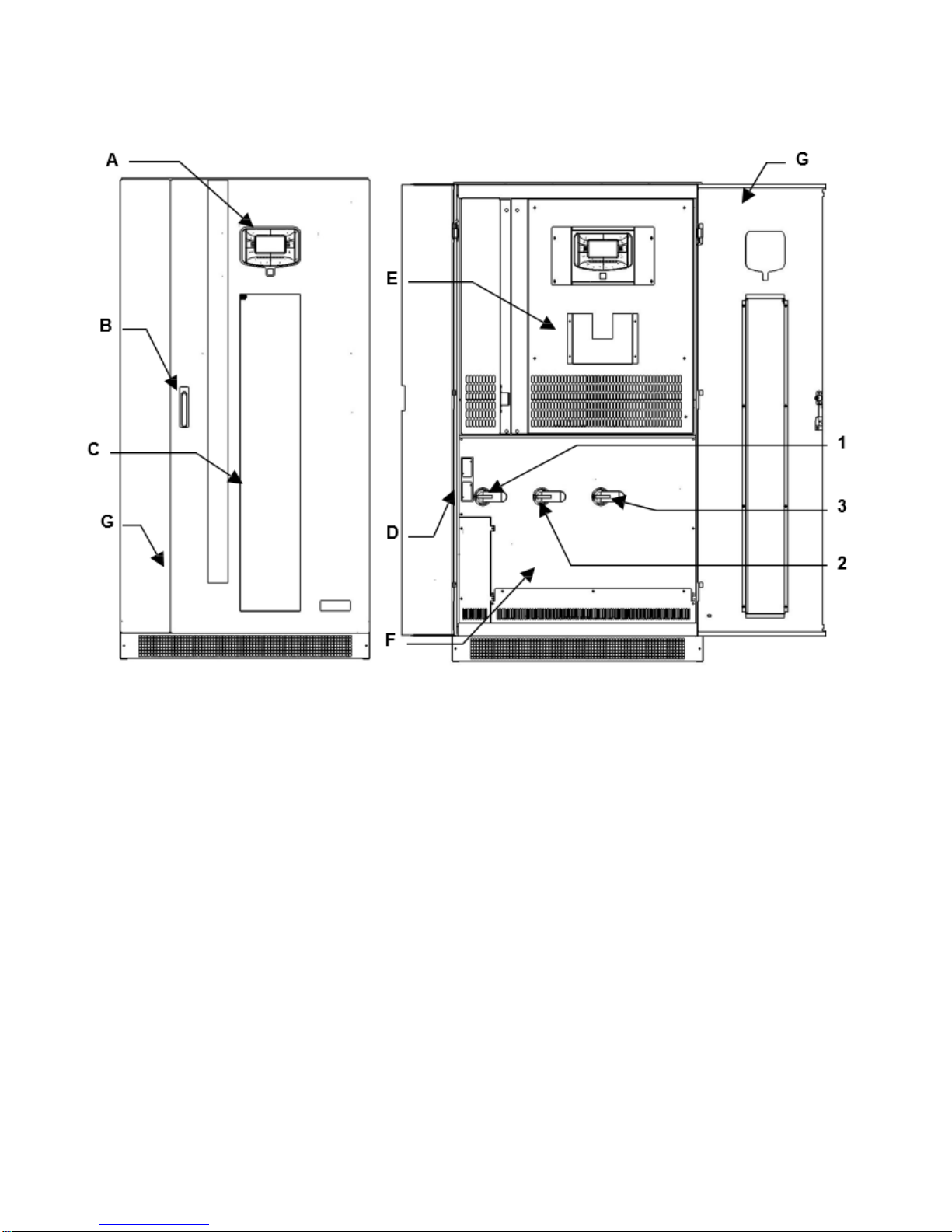

Figure 1 - FLU cabinet front view

A - Control Panel with Graphic Display

B - Door Handle

C - Ventilation Grilles

D - Communication Area

E - Front Cover Panel with Ventilation Grilles

F - Switch Cover Panel

G - Door

1 - SWIN: Input Power Switch

2- SWBY: Static Switch Bypass Input

3 - SOUT: Static Switch Output

Page | 1

Page 12

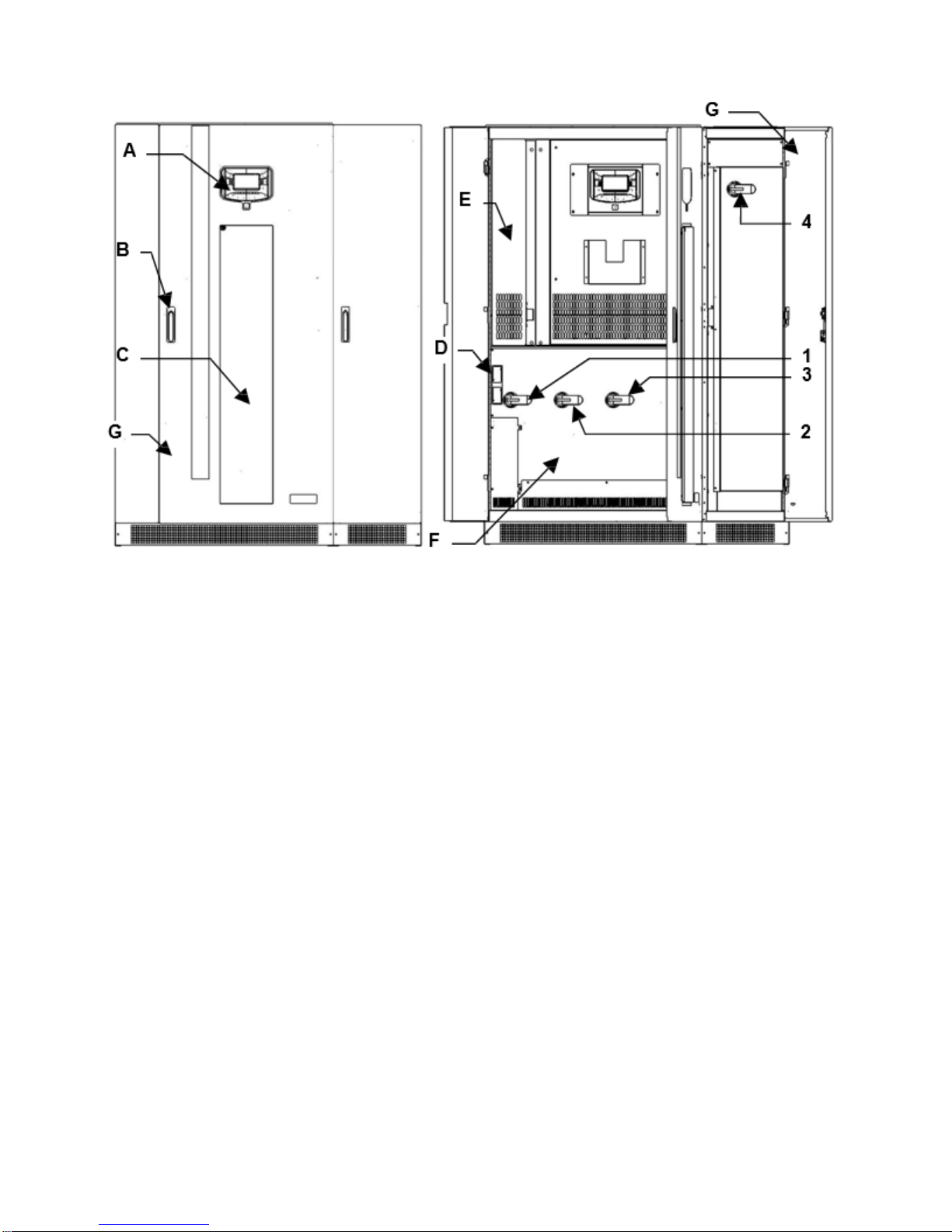

Figure 2 - FLU-T cabinet front view

A - Control Panel with Graphic Display

B - Door Handle

C - Ventilation Grilles

D - Communication Area

E - Front Cover Panel with Ventilation Grilles

F - Switch Cover Panel

G - Door

1 - SWIN: Input Power Switch

2 - SWBY: Static Switch Bypass Input

3 - SOUT: Static Switch Output

4 - SWMB: Mechanical Bypass Switch

Page | 2

Page 13

1.2 Preliminary Operations

DANGER

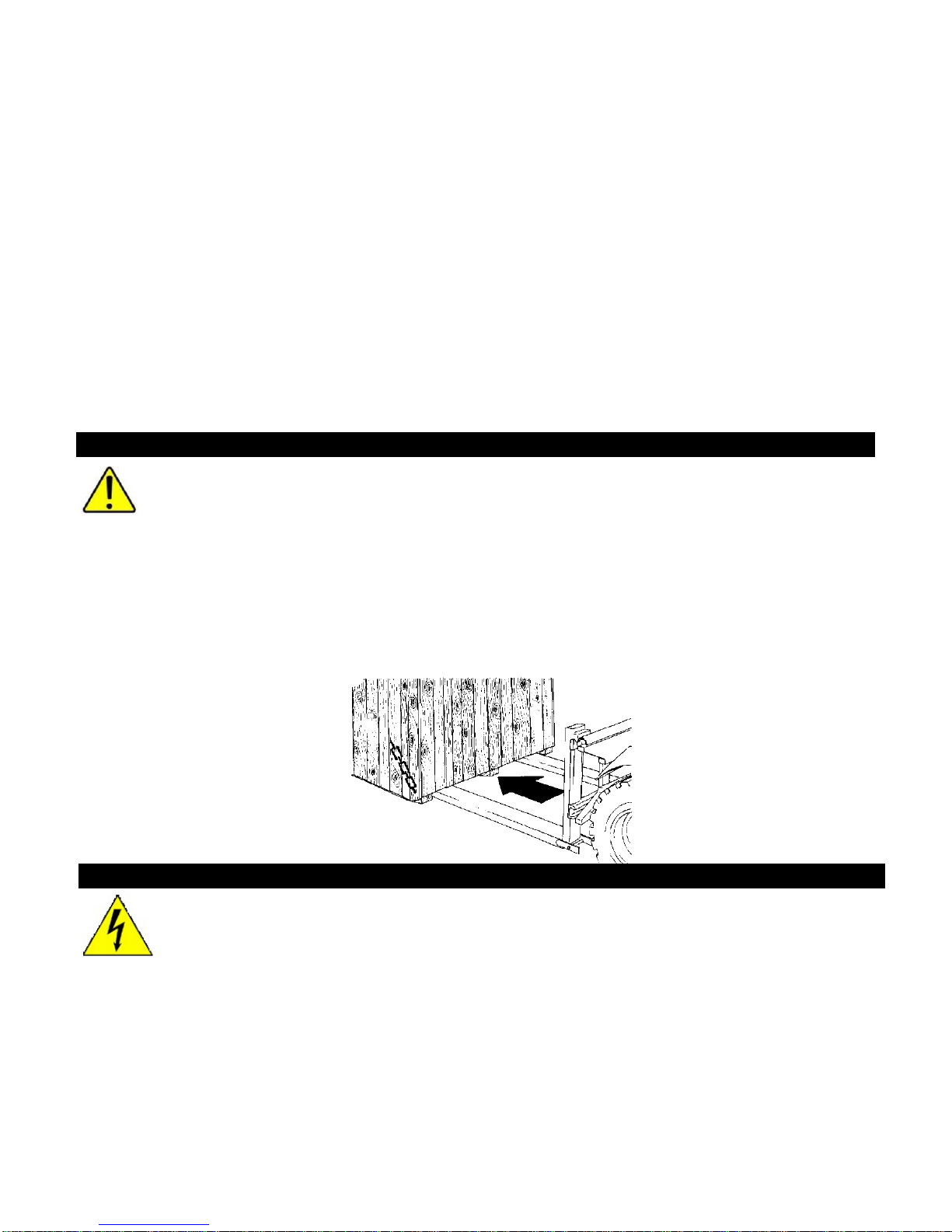

1.2.1 Removing the Packaging and Positioning the Device

On delivery, the packaging must be inspected to ensure that it is whole and that it has not been crushed

or dented. Check in particular that neither of the two impact resistant devices on the packaging is red; if

one of them is red; follow the instructions on the packaging.

The essential details of the device are provided on the shipping document. The marking, weight and

dimensions of the various items making up the packing list are shown.

Check the state of the device by means of a visual inspection of both the inside and the outside. Any

dents seen mean that it has suffered shocks during shipping, which could compromise the normal

operation of the device.

1.2.2 Storage

Place the device in covered premises that are protected from direct contact with atmospheric agents and

dust. The following environmental values are those allowed in the storage area:

Temperature: -13°F to +167°F (-25 to + 75 °C)

Relative humidity: 30-95 % max.

WARNING

For the installation of a battery cabinet, if provided with the uninterruptible power supply, follow

the instructions given in the specific manual.

The list of material provided may vary depending on the order specifications. Most systems include the

following: this manual, the installation drawing, the warranty and eventual accessories.

1.2.3 Handling

The equipment must only be handled by adequately trained personnel.

1 Insert the forks of the fork-lift truck in the lower part of the device, from the front or back, and

ensure that they stick out about 12 inches on the other side.

2 Secure the device to the fork-lift before moving it.

In order to avoid the risk of the device overturning, ensure that it is firmly secured to the

fork-lift truck by means of appropriate ropes before moving it.

When being moved the cabinet should be handled with care; shocks or drops can damage it. Once in

position, remove the packaging carefully in order not to scratch the device.

The packaging should be removed as follows:

1. Cut the bands

2. Slide away the carton from above.

Page | 3

3. Remove the screws securing the cabinet to the wooden base.

Page 14

1.2.4 Cooling of the Premises

The recommended operating temperature for the lifetime of the UPS

and of the batteries is between 20 and 25°C. The lifespan of the

battery depends on the operating temperature; with an operating

temperature increase from 20°C to 30°C, the lifespan of the

batteries is halved.

The airflow inside UPS is by the fans located inside the UPS (forced

convection) and by the air around the side panels (natural

convection).

In order to ensure proper air circulation measures must be taken

during installation to avoid any obstructions to the free circulation of

air. These include the following:

• Ensure a distance of at least 24 inches from the ceiling, so as

not to hinder air extraction,

• Leave a free space of at least 36 inches at the front of the

equipment to ensure both the circulation of the air and

installation and maintenance operations;

• With natural convection the thermal load is dissipated to the

outside through the walls; thus a cabinet placed against a wall or in a hollow dissipates less heat than

one located in a free environment.

The following rule must be observed:

Leave at least one of the three side walls free: right, left or back.

• The bottom side kick panels must not be mounted for installations where cabinets are placed side by

side.

Page | 4

Page 15

2. Installat ion

DANGER

• Check the Safety Instructions.

• Any incorrect connection or handling may cause damage to the UPS and/or the loads

connected to it. Read these instructions carefully and follow the steps indicated.

• This UPS must be installed by qualified electrician.

• It is advisable to provide a maintenance bypass switch or an electrical panel with individual

protection for input, output, and static bypass, as well as a manual bypass. This allows isolation

of unit during preventive maintenance or repair.

2.1 Accessing the UPS terminals

The following operations must be performed while the UPS is disconnected from the utility

mains power, switched off and all the input and output power switches on the equipment are

open. Before performing connection, open all the input and output power switches and

check that the UPS is completely isolated from all power sources: battery and AC power

line. In particular, check that:

- UPS input line is completely isolated;

- Batt er y circuit breaker/disconnect is open;

- All UPS power and load connection switches (SW IN, SWBY, SWOUT and SWMB) are

in the open position;

- No dangerous voltages are present (use a multimeter).

The first connection to be performed is the protective wire (earth ground cable) which has to

be inserted into the terminal labeled PE. The UPS must operate with the grounding system

connected.

WARNING

• Do not connect the output neutral to the input neutral.

• If the input connection is Delta the UPS can supply only Delta load.

• The output neutral must not be connected unless the UPS is the Wye version supplied

with an input neutral.

• TRANSFORMER BOXES (optional) are available for converting the distribution

systems from 3 to 4 wires.

• If a three-phase non-linear load is connected to the output, the current on the neutral

conductor can reach a value equal to 1.5 times the value of the phase current.

Dimension the input/output neutral cable appropriately taking this fact into account.

• The UPS cannot feed from a corner ground or mid-point grounded delta supply

source.

• Use only lugs or cables with tin-plated eyes for the connections.

• Ensure correct phase rotation at the input and output terminals

• Ensure correct polarity battery connections

The DC input requires a disconnect means which is provided in most Staco supplied battery

cabinets.

AC and DC cables and cable lugs are to be provided by others as part of the UPS installation

Page | 5

Page 16

Each model can be configured for a delta input source with a delta connected load or for a wye

input with a wye connected load. If the load requires a neutral connection (i.e. wye), then an

input neutral must be provided. Refer to the Power Connection terminals diagrams later in this

section for details concerning configuration of the neutral to ground bond.

2.2 UPS - Single Module Configuration

The UPS is designed to work as Single input Unit or as Dual input Unit.

Figure 3 – Single Input 1-Line

Figure 4 - Dual Input 1-Line

Page | 6

Page 17

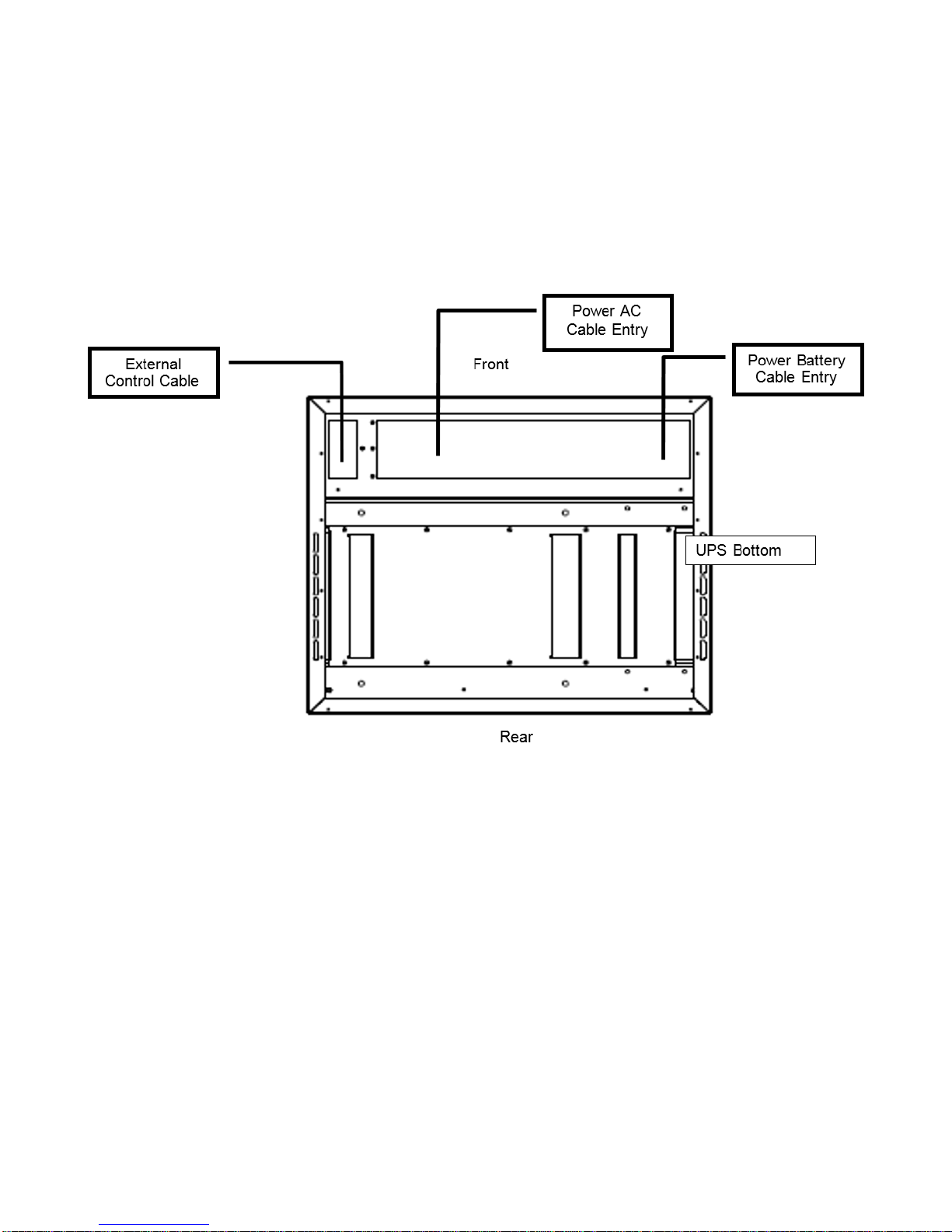

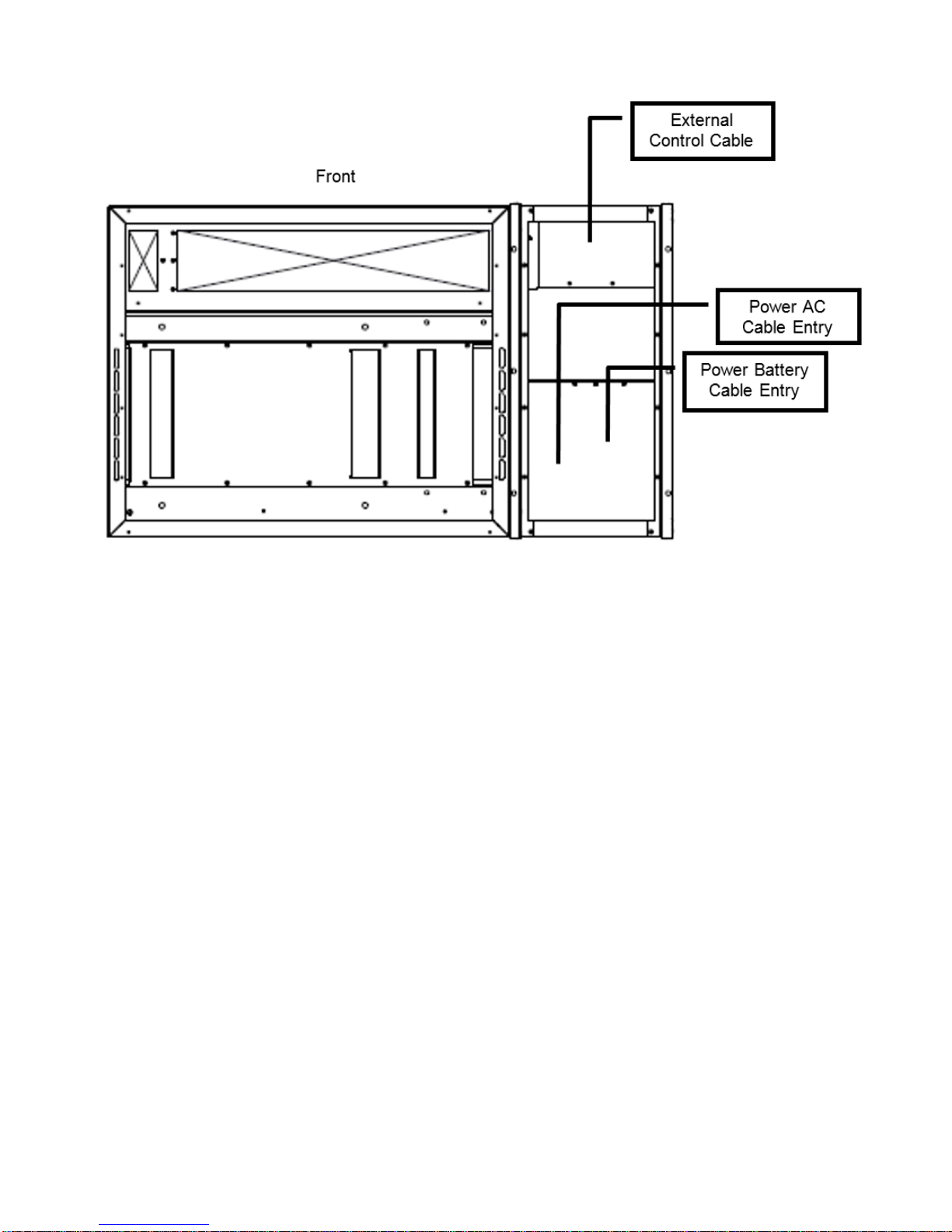

2.3 Cable Entry

The cables can enter in the UPS from the bottom or from the top with the optional (Top Entry Cabinet)

Proceed as follows in order to open the UPS

1. Open the door

2. Remove the switch cover panel

3. Remove the bottom cable entry cover plates

4. Drill or punch conduit holes in the cover plates

5. Route the power cable through the bottom to the UPS terminals in base to your configuration

(see Figure 5 and Figure 6)

Page | 7

Figure 5 – FLU bottom Cable Entry Layout

Page 18

Figure 6 – FLU-T bottom Cable Entry Layout

Page | 8

Page 19

2.4 Connect of Power Cables

2.4.1 Input Line without Neutral

If utility is a 3-wire source and the load requires a neutral, a transformer must be inserted either on the

mains supply line or on the bypass line.

Figure 7 - Schematic diagram: Single Input without Source Neutral

Figure 8 - Schematic diagram: Dual Input without Source Neutral

Page | 9

Page 20

2.4.2 Single Input

Connect the input, output and battery cables to the terminals as shown in Figure 9 and Figure 10:

Figure 9 – FLU UPS Single Input Power Connection Terminals

For the Input, Output and Battery connections, follow the order from the top to bottom, or

right to left, as described in the boxes. The label marked “N” present on the terminal

identifies the neutral terminal.

The single input is a factory default configuration. Do not remove the bypass jumper. The input phase

connections are made using bolts to one of the three holes in the busbar. Do not loosen the bolts that

attach the busbar.

The UPS is provided with a separate busbar that connects the Neutral Output to the frame

Ground for delta input connection. This is required to meet NEC grounding code for separately

derived neutrals. When a Neutral is provided in a Wye configured input connection the busbar

must be removed.

Once installation has been completed inside the equipment, put the switch cover panel back and close

the door.

Page | 10

Page 21

Figure 10 – FLU-T UPS Single Input Power Connection Terminals

For the Input, Output and Battery connections, follow the order from the top to bottom, or right

to left, as described in the boxes. The label marked “N” present on the terminal identifies the

neutral terminal.

The single input is a factory default configuration. Do not remove the bypass jumper. The input phase

connections are made using bolts to one of the three holes in the busbar. Do not loosen the bolts that

attach the busbar.

The UPS is provided with a separate busbar that connects the Neutral Output to the frame

Ground for delta input connection. This is required to meet NEC grounding code for separately

derived neutrals. When a Neutral is provided in a Wye configured input connection the busbar

must be removed.

Once installation has been completed inside the equipment, put the switch cover panel back and close

the door.

Page | 11

Page 22

2.4.3 Connection of Power Cables for Dual input Unit

Connect the input, bypass, out put and battery cables to the terminals as shown in Figure 11 and

Figure 12

Figure 11 – FLU UPS Dual Input Power Connection Terminals

The single input is a factory default configuration. Remove the jumpers present between the SWIN

and SWBY. The input phase connections attach using bolts through the holes that were previously

used to attach the busbars. The main (rectifier) input is located on the left and the bypass input is on

the right. The neutral input comes from the bypass source; no neutral is to run to the rectifier input

source, although the rectifier source must be a grounded wye.

For the Input, Bypass, Output and Battery connections, follow the order from the top to bottom,

or right to left, as described in the boxes. The label marked “N” present on the terminal

identifies the neutral terminal.

The UPS is provided with a separate busbar that connects the Neutral Output to the frame

Ground for delta input connection. This is required to meet NEC grounding code for separately

derived neutrals. When a Neutral is provided in a Wye configured input connection the busbar

must be removed.

Once installation has been completed inside the equipment, put the switch cover panel back and close

the door.

Page | 12

Page 23

Figure 12 – FLU-T UPS Dual Input Power Connection Terminals

The single input is a factory default configuration. Remove the jumpers present between the SWIN

and SWBY. The input phase connections attach using bolts through the holes that were previously

used to attach the busbars. The main (rectifier) input is located on the left and the bypass input is

on the right. The neutral input comes from the bypass source; no neutral is to run to the rectifier

input source, although the rectifier source must be a grounded wye.

For the Input, Bypass, Output and Battery connections, follow the order from the top to bottom,

or right to left, as described in the boxes. The label marked “N” present on the terminal

identifies the neutral terminal.

The UPS is provided with a separate busbar that connects the Neutral Output to the frame

Ground for delta input connection. This is required to meet NEC grounding code for separately

derived neutrals. When a Neutral is provided in a Wye configured input connection the busbar

must be removed.

Once installation has been completed inside the equipment, put the switch cover panel back and close

the door.

Page | 13

Page 24

2.5 Differential (GFI)

UPS

a

b

a - EPO terminal board located on the UPS

b - EPO switch (not provided).

If the UPS protection against electric shock uses a differential current device (Ground Fault Interrupter),

it will have to have the following characteristics:

• Sensitivity 300mA

• Sensitive direct current and unidirectional components (class A or class B)

• Insensitive to transient cur r ent pulses

• Delay greater than or equal to 0.1 s.

In the standard version without an isolation transformer on the bypass line, the neutral from

the mains power supply is connected to the output neutral of the UPS.

THE ELECTRICAL SYSTEMS UPSTREAM AND DO WNSTREAM OF THE UPS MUST BE

EXACTLY THE SAME (DELTA-DELTA or WYE-WYE)

When operating in the presence of mains supply, a differential breaker (GFI) insta l led on the input will

intervene as the output circuit is not isolated from the input cir cuit.

When operating without mains supply (from battery) the input differenti al breaker will intervene only if it

is able to switch as a result of leakage current without any voltage at its poles (for example a

differential breaker with an auxiliary relay is not suitable). However it is possible to install additional

differential breakers on the output of the UPS possibly coordinated with those on the input.

2.6 Emergency Power off Device (EPO)

The UPS has an EPO (Emergency Power Off) function. In the event of an em er gency, using this

function will cause the UPS to shut down the rectifier, inverter, and static switch and completely

disconnect the power to the load. The Output circuit of the UPS should not be considered safe, unless

the UPS is Off and the input power source to the UPS has been removed by opening the input

disconnect devices which are external to the UPS, including the battery.

This function can be activated from the button (under a hinged clear plastic cover) on the control panel

or by a remote contact. This button must be depressed and held down until the UPS shuts down. On

the UPS, the jumper on the EPO terminals must be removed, and the wires from the auxiliary contact

of the button must be connected in place of the jumper. The contact must be closed with the button in

the rest position and must open when the button is pressed.

Figure 13 – Emergency Power Off (EPO)

Page | 14

Page 25

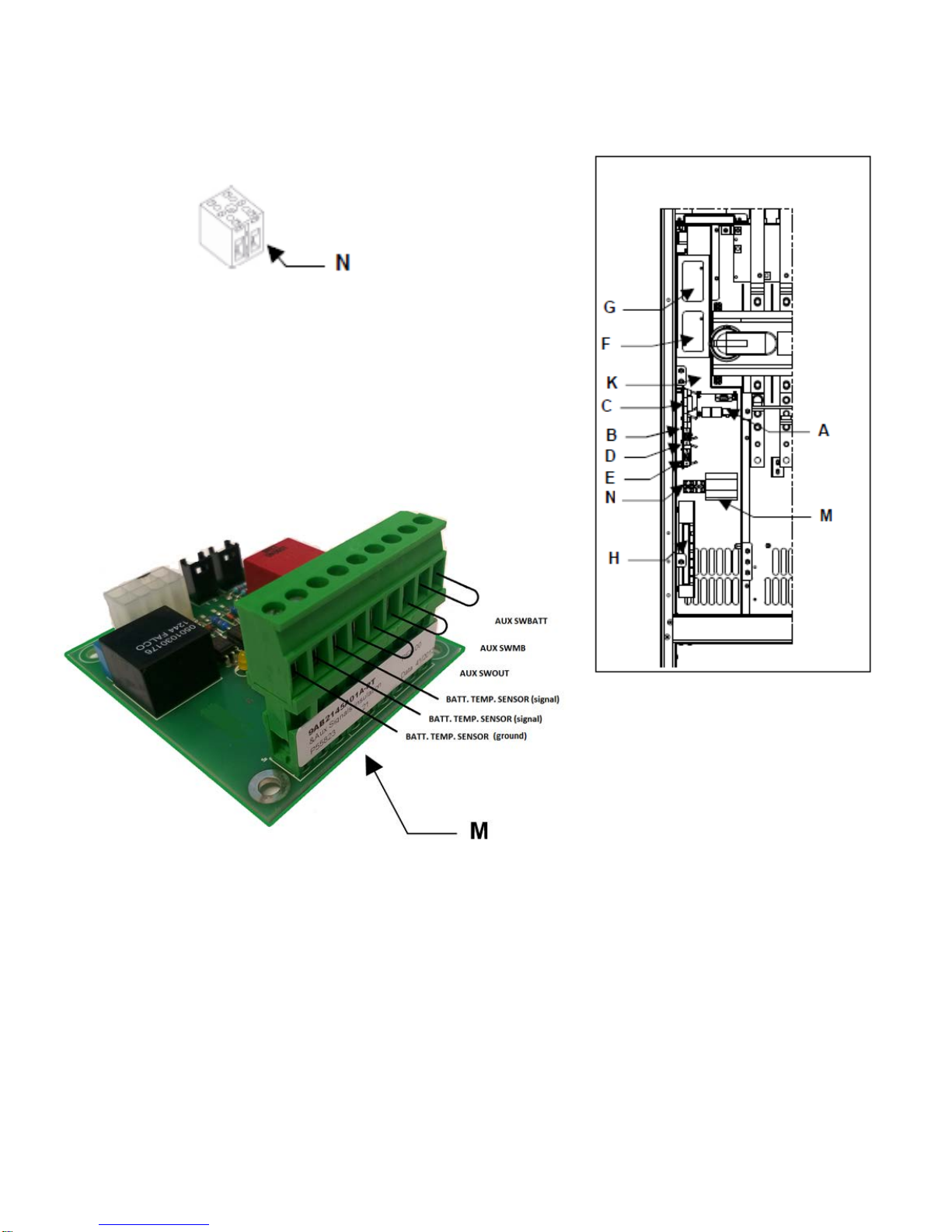

2.7 Connection of Signals and Remote Commands

A-

Parallel

N-

Terminal Block

In order to access the interface cards, open the door and remove the protection panel secured with

screws (K) as shown in the drawing:

B-

EPO (Emergency Power Off control)

C-

Remote Commands and Alarms

D-

RS232-2

E-

RS232-1

F-

Slot 2 (Main)

G-

Slot 1 (Main)

H-

Remote Alarms (Optional)

M-

Aux Signals Isolation Board

Figure 14 – FLU Signals and Remote Command Connections

Page | 15

Page 26

AWG Wire size range

Torque Load

A-

Parallel

B-

EPO (Emergency Power Off control)

C-

Remote Commands and Alarms

D-

RS232-2

E-

RS232-1

F-

Slot 2 (Main)

G-

Slot 1 (Main)

H-

Remote Alarms (Optional)

I-

Remote Alarms (Optional)

M-

Aux Signals Isolation Board

N-

Terminal Block

Figure 15 – FLU-T Signals and Remote Command Connections

Table 1 - Torque Specifications for Terminal Blocks on Customer Interface Board

Page | 16

#22 -12AWG 4.4 lbf-ft

6 Nm

Page 27

PIN

NAME

TYPE

FUNCTION

Bypass / fault, the contact changes position when the UPS switches the load

a result of a fault in the inverter stage. See Note 1

Battery discharging, the contact changes position when the load is powered

from the battery due to a mains power failure

End of battery discharge, the contact changes position when, during a mains

factory-set end of discharge pre-alarm value is 5 minutes)

10

+12V

POWER

Power supply +12Vdc 80mA (max.) [pins 10 and 11]

11

GND

POWER

Inverter OFF. Connect pin 11 to pin 12 (for at least 2 seconds).

not powered). See Note 1

If the jumper on the connector is opened, the voltage on the UPS output will be

2.7.1 Remote Commands, Alarms and EPO

The card is equipped with a terminal board with 14 positions.

Power Supply - 1 power supply 12Vdc 80mA (max.) [Pins 10 and 11];

Alarms - 3 potential-free change-over contacts for alarms (they are capable of switching up to 30 V

AC or DC at UP to 1 A);

Command - 1 command programmable from the panel [Pins 11 and 12]

Table 2 - Interface Remote Command Alarms and EPO

1,2,3

4,5,6

7,8,9

12

13,14

Note 1: If the UPS installation includes a Staco Maintenance Bypass Switch (MBS) Cabinet, this connection is

RL 1 OUTPUT 1

RL 2 OUTPUT 2

RL 3 OUTPUT 3

IN 1 INPUT 1

EPO

required to be connected to the MBS and is not available for other use. An Optional Remote Alarm

interface can be installed if a second function is required in this case.

INPUT

EPO

onto the bypass line either during normal operation (e.g. due to overload) or as

outage, the remaining time for battery discharge has reached the minimum

value defined. Once this time has passed, the load will remain unpowered (the

-

In “NORMAL OPERATION”,

If the INVERTER OFF command is received, the UPS switches the power

supply of the load onto the bypass line (load is not protected should there be a

mains outage).

-

In “EMERGENCY OPERATION”,

If the STOP INVERTER command is received, the UPS shuts down (load is

cut.

The UPS is factory-fitted with the EPO terminals short circuited. If this input is

used, the UPS can be shut down in a hazardous situation from a remote

position simply by pressing a button.

WARNING

If only the mains power supply is removed, for example by opening the switch of the

power supply panel, as a means to shut down the UPS in an emergency the UPS will

keep the load powered using the energy in the batteries.

The functions of the three contacts and the command may be reprogrammed via the display panel.

The ALARMS and the COMMAND are factory-set. The position of the contacts as shown is without

the alarm present. The contacts can take a maximum cur rent of 1A with 24Vac.

Page | 17

Page 28

DB9 female RS232-2

Figure 16 – Remote Alarm Contacts

2.7.2 RS232-1 and RS232-2

2 DB9 connectors are available for RS232 connection. The factory-set transmission protocol is:

9600 baud, -no parity, -8 bits, -1 stop bit.

The transmission speed may be varied from 1200 to 9600 baud, using the PERSONALIZATIONS menu

on the CONTROL PANEL. Depending on the distance of transmission, the recommended values for the

transmission speed are:

• 9600 baud 50m

• 4800 baud 100m

• 2400 baud 200m

• 1200 baud 300m

See the diagrams below for the connection procedure.

For connection with a computer,

use a standard RS 232 cable. See

the diagram for connection with a

modem.

Figure 17 – RS232-2 Female Connection

Page | 18

Page 29

DB9 female RS232-1

For connection with a computer,

use a standard RS 232 cable. See

the diagram for connection with a

modem.

Figure 18 – RS232-1 Male Connection

2.7.3 SLOT 1 and SLOT 2

Following Cards May be Inserted (Optional):

NetMan 102 Plus (in SLOT 1 main or SLOT 2 aux)

Device for management of the UPS’s on the Ethernet. It can send information on the status of the

device with various protocols:

• TCP/IP UDP (compatible with Watch&Save);

• SNMP (for communications with NMS or with PowerNETGuard);

• HTTP (to display the status with a browser);

• TFTP (to configure or update the device when connected to the network).

The main function of this device is to integrate the UPS into the LAN network ensuring a high level of

reliability of communication with the server to enable full management and control of the UPS.

MULTICOM card (in SLOT 1 m ain or SLOT 2 aux)

This device may be used to:

• add a serial port to the UPS;

• monitor the UPS using MODBUS/JBUS protocol on RS485 or PROFIBUS (Multicom 401)

Note: each card connected precludes the use of a standard RS232 port, as follows.

• The use of SLOT 1 (main) inhibits the use of RS232-2

• The use of SLOT 2 (aux) inhibits the use of RS232-1

For the full and updated list of communication accessories, please see the website

www.stacoenergy.com

2.7.4 Optional Remote Alarm Cards

6 outputs: potential-free contacts for alarms

• Programmable from the display panel;

• Capable of switching up to 30 V AC or DC at UP to 1 A;

(2) Inputs

• Programmable from the panel;

• (1) 12V DC maximum 100mA auxiliary input.

Page | 19

Page 30

2.7.5 Optional MODEM

Model compatible with the communication standards between the UPS and the software provided.

Note: the modem must be connected to an RS232 port; a standard RS232 port may not therefore be

used.

2.7.6 Optional MULTI I / O

The function of this accessory is to convert external signals from the UPS (e.g. t emperat ure of

environment, temperature of battery premises, etc.) into signals by means of relay contacts or via serial

output RS485 in MODBUS protocol. It has the following characteristics:

• 8 inputs (e.g. humidity, smoke, etc. sensors)

• communication with the UPS via serial port

• 8 relays configurable with 8 events on the UPS

• RS232 output port with configurable messages

• RS485 output port MODBUS /JBUS with configurable messages.

2.7.7 Option al Battery Temperature Sensor

The UPS has a connector for connection of the kit, which consists of a sensor to be placed inside the

battery cabinet. The use of the temperature sensor allows the UPS control logic to regulate the values of

the charge and maintenance voltage according to the working temperature of the battery.

Optional Battery Temperature Alarm

The battery temperature alarm is active only when Battery Temperature Sensor is connected. The

temperature value to start the alarm can be changed with the following procedure:

1) The following sequence of numbers must be entered into the display to access settings. Press

the front panel display buttons 3, 5, 151515, 7

2) Press 3, 5, 327171, 7 to access the battery temperature settings

3) Press key 5 or 6 as necessary to adjust the minimum battery temperature [default:0 ; range:0-10]

4) Press key 7 or 8 as necessary to adjust the maximum battery temperature [default:50 ; range 2060]

5) Press 1 to exit from the battery temperature menu

6) The alarm temperature value is now adjusted

2.7.9 Multi Panel

The Multi Panel is used to monitor the UPS from a distance and provides a detailed overview of the

module operating status. It allows the operator to consult measurements relating to mains power, output

load, batteries, etc. and also to identify any malfunctions.

The Multi Panel connects from the UPS Serial port on the Multi Panel to the RS232-1 or RS232-2 port in

the UPS. See Section 2.7.2 RS232-1 and RS232-2.

Page | 20

Page 31

2.7.10 SWOUT and SWMB aux.

Terminals to be used for connection of the auxiliary contacts of switches used for a wrap-around bypass

Note:

• Auxiliary switch of SWMB EXT must open in advance, before closing the power contact

• Auxiliary switch of SWOUT EXT must close in advance, before opening the power contact

Figure 19 – Single Module Wrap-around bypass

Parallel System

The auxiliary contacts of the external SWMB and of the SWOUT shall be connected to the board of each

UPS in parallel, see Figure 20.

The UPS has input terminals (for acquiring the status of aux contacts) isolated from the internal circuits

of the UPS. This will be sufficient a single aux contact electrical connection of the External switch brought

to each UPS of the parallel system.

The auxiliary contacts of SWOUT EXT and SWMB EXT must be connected to terminal J1on aux signals

isolation board. The purpose of this board is to isolate the internal circuits of UPS, so that, in case of

parallel of UPS, one auxiliary contact of an external switch is sufficient to be acquired by all the UPS in

parallel.

For safe removal, the UPS must be placed into bypass, closing SWMB EXT, opening SWIN EXT and

SWOUT EXT and disconnecting the UPS.

Aux Contact SWOUT EXT must be N.O. (same position of the power contacts) while aux contacts

SWMB EXT must be N.C., (opposite position of power contacts).

Page | 21

Page 32

1

Aux Swbatt

INPUT

2

Aux Swbatt Return

INPUT

3

Aux Swmb

INPUT

Normally close co ntact used to ind icate when the SW MB EXT is

closed

4

Aux Swmb Return

INPUT

5

Aux Swout

INPUT

Normally open cont act use d to indicat e when th e SWO UT EXT is

closed

6

Aux Swout Return

INPUT

7

Bat. Temp. Sensor

INPUT

Bat. Temp. Sensor

Return

9

Ground

INPUT

Ground

Figure 20 – Parallel System Wrap-around bypass

Table 3 - Interface Terminal Connector

PIN NAME TYPE FUNCTION

Normally open: contact used to indicate when SWBATT is closed

8

INPUT

Battery temperature sensor

Page | 22

Page 33

3. Operation

It is critical that the following procedure be followed in the sequence given.

Figure 21 – Single Input 1-Line

Page | 23

Figure 22 – Dual Input 1-Line

Page 34

3.1 Start up

3.1.1 Before Start Up

1) Verify that all the connections have been made correctly and are properly tighten, following the

labeling of the phase rotation sequence.

2) Check that the UPS switches and any external battery cabinet or cabinets are in off position.

3) Be sure that all the loads are turned off.

3.1.2 Start-Up Procedure Single Module

It is very important to follow the established order during the following instructions. DO NOT

close battery disconnect until instructed to do so.

1) Close input power switch SWIN,

2) O n front LCD, Press button ‘1’ twice, select the language and then press button ‘8’ to return to

the basic menu,

3) Aft er a few seconds, messages on the status of the UPS will start to be shown on the first line of

the display panel.

4) Close t he static switch bypass line input switch SWBY,

5) Close t he static switch output switch SWOUT.

Once these operations have been carried out, the humming of the fans and the sound of the

buzzer will be heard.

6) Wait to close the external battery circuit breaker/disconnect device.

Single Battery Disconnect

Close the external battery circuit breaker/disconnect only when the following message is

shown on the first line of the display panel:

BATTERY CHARGE OFF

Multiple Battery Disconnect

If multiple battery cabinets are present, all breakers must be closed within one minute after the

BATTERY CHARGE OFF message appears. If this time constraint is a problem, do the

following:

1. Disable the automatic battery test by pressing button 3 then 5 on the control panel, followed

by entering the code 323232.

2. Close all of the battery cabinet circuit breakers

3. Re-enter the code 323232 to enable the battery test.

Configure the value of the battery capacity according to the instructions in Section

4.7.2 Customizing.

After the start-up operations have been completed, perform a manual battery test:

1) Press button 3 and then 2 on the control panel.

2) At the end of the test, after approx. 8 seconds, with the UPS started correctly and with the

battery connected on the signals and control panel, the two green input and output LED’s

must be lit continuously.

Once the UPS has been installed, check that the message NORMAL OPERATION appears on the first

line of the display panel

Page | 24

Page 35

3.2 Single UPS and Load Shutdown

This operation will shutdown the load connected to the output. In parallel versions each procedure must

be carried out on all the UPS’s:

1) Open the load switch;

2) Open SWOUT, static switch output switch;

3) Open SWIN, input power switch;

4) Open SWBY, static switch bypass input;

5) Open the battery cabinet circuit breaker/disconnect.

To disconnect the load from the output of the UPS, both switches SWOUT and SWMB must be

open (off).

The load is no longer powered, and after a few seconds the UPS display panel will also shut down.

Neutral is not interrupted by the UPS (the input neutral is also present at the UPS output).

Follow the instructions in the section on Start-Up Procedures (see Section 3.1 Start up) to

restart the UP S .

3.3 Transfer to Bypass/Inverter

Press the following sequence of keys on LCD to access the menu:

1. 3

2. 6

3. 47263

Exit the menu by pressing key 8 or any other key with a sequence other than the one described here.

Pressing keys 4, 7, 2, 6, 3 in succession as shown on the display activates the command for bypass with

shutdown of the inverter. The command is executed after a few seconds’ delay to allow for cancellation.

When this command is active, the following alarm is shown on the display:

"BYPASS COMMAND ACTIVE; 8=DEACTIV. “

To return to normal operation, including after system shutdown, the command has to be cancelled by

pressing key 8, or by sending the key code through the RS232.

3.4 Operating Modes

The various UPS operating modes are described below

The operating mode is set when the UPS is installed; it may be changed subsequently but this

should always be done by a qualified service technician.

3.4.1 On-line Factory Setting

The load is always powered by the inverter, with stabilized voltage and frequency, using the energy from

the mains power supply (INPUT). If there is a fault in the INPUT, the UPS will switch to the batteries in

zero time and the batteries will supply energy to the inverter to keep the load powered for the backup

time of the batteries. When the INPUT is restored the batteries will be automatically recharged by the

rectifier.

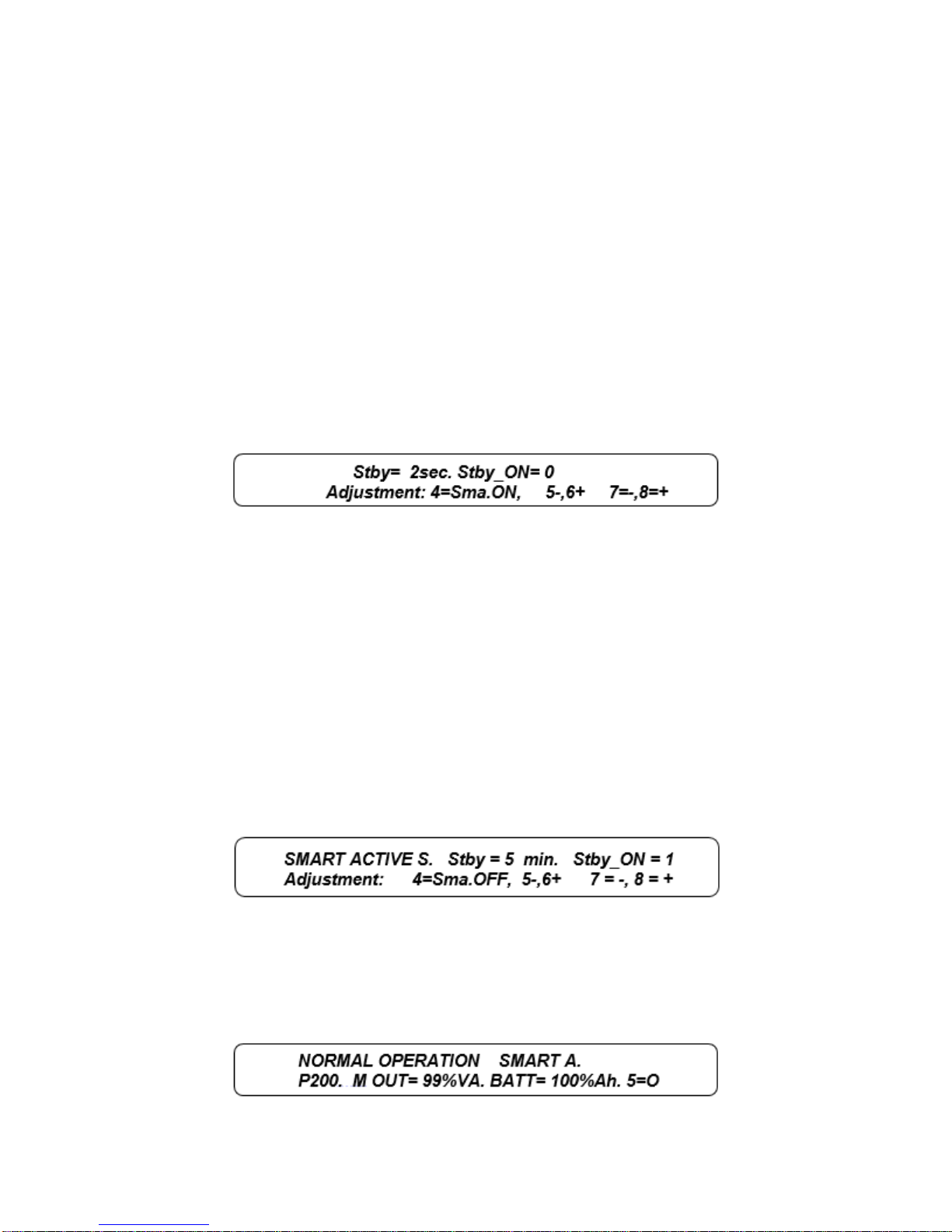

3.4.2 Standby-On / Smart Active

In Standby On or smart active, the load is powered from the bypass line (if the mains power supply is

within acceptable limits); if there is a fault on the mains power supply the load switches automatically

onto the inverter, powered by the battery

Page | 25

Page 36

Standby On:

See Section 4.7.2.18 Inverter-Off/Bypass to place the unit in Standby mode. The switch from

inverter to bypass line may be immediate (time set = 0) or delayed (up to 180 minutes). For the

switch to take place, the bypass line has to remain within acceptable limits for the delay time set.

In Standby On mode, the rectifier remains powered and keeps the batteries charged. If the

bypass line voltage or frequencies go outside of acceptable limits, the load is automatically

switched onto the inverter output. With Standby On operation, the energy dissipated by the

system can be reduced, leading to considerable saving. Before using this function it must be

ensured that, in the event of a mains outage, the load powered can tolerate an interruption of the

power supply of around 2-5 ms, and that it can tolerate any mains interference.

This operating mode is normally used for loads that are not particularly sensitive.

While operating in this mode, the letter N will be displayed on the second line of the BASIC

MENU, near the UPS model.

Smart Active:

The UPS autonomously activates On-Line or Standby-On operation according to the quality of

the power supply (see the 4.7.2.17 Smart Active Operation). When Smart Active mode is

activated, the power supply is monitored for a few minutes, after which, if the voltage has

remained within the pre-set values, the load is switched onto the bypass line; otherwise the load

remains powered by the inverter, while the observation time is approx. one hour. After this time,

provided there has been no disturbance, the load switches onto the bypass line; otherwise the

logic starts monitoring again for approx. one hour. The advantage of this operating mode is its

efficiency, which is greater than 98%.

While operating in this mode SMART A will be displayed on the first line of the BASIC MENU and

the letter M will appear in the second line of the BASIC MENU, near the UPS model.

3.4.3 Standby-Off (with Mains Present the Load is not Powered)

If there is a mains power supply, UPS output is zero. The RECTIFIER remains on and keeps the

battery charged. The output voltage is only present when the mains power supply fails. The

system remains with output voltage = 0V while the voltage and the input frequency are within an

acceptable range. When the mains power supply is restored, the UPS is automatically reset to

Standby-Off mode.

When operating in this mode the letter F will be displayed on the second line of the BASIC

MENU, near the UPS model.

3.4.4 Stabilizer (Operation In On-Line Mode Without Battery)

This mode of operation makes the UPS a power conditioner with no backup capability. The load

is always powered through the inverter, with stabilized voltage and frequency, using the energy

from the input mains. The batteries are not present. In the event of an input mains failure, the

output of the STABILIZER is not powered.

In this mode the letter S is displayed on the second line of the BASIC MENU, near the UPS model.

Page | 26

Page 37

4. Control Panel and Displa y

4.1 Signal panel functions

Figure 23 – Signal Panel

F1, F2, F3, F4, F5, F6, F7, F8 = FUNCTION KEYS. The function of each key is shown at the bottom

of the display and it varies according to the menu.

EPO = Emergency Power Off button.

Page | 27

Page 38

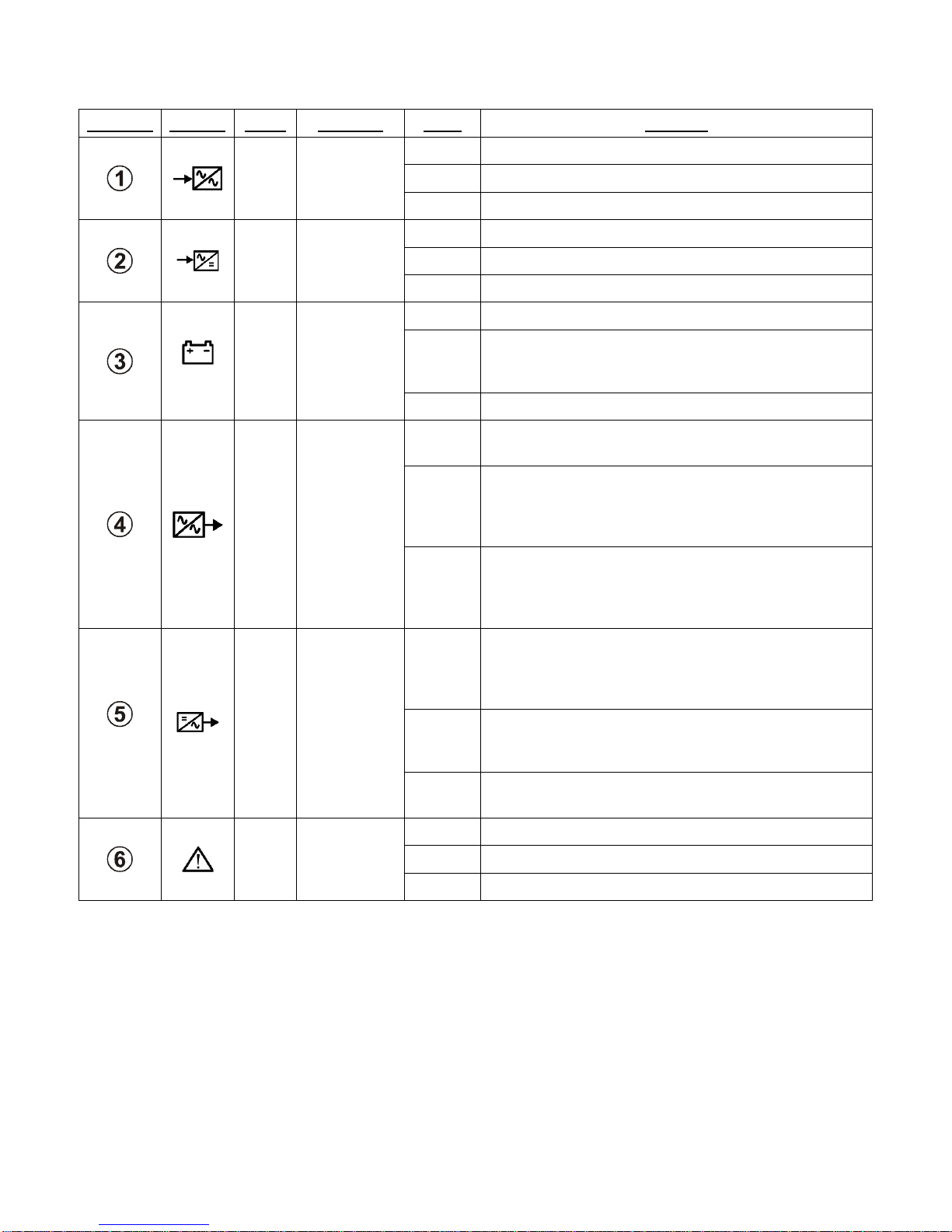

Indicator

Symbol

Color

Function

State

Meaning

On

Input Bypass line is present and correct

Flashing

Input Bypass line is present but not correct

Off

Input Bypass line is not present

On

Mains is present and correct

Flashing

Mains is present but not correct

Off

Mains is not present

On

When the battery is supplying the load

The "LOW VOLTAGE ON BATTERY PRE-ALARM" is

OPEN alarm is active

Off

When the battery is not supplying the load

The system output is switched onto the automatic

bypass line

The system output is switched onto the automatic

closed

When the system output is switched onto inverter or

TOTAL BLOCK command is active

The system output is feed from inverter on normal or

is closed

The system output is switched onto inverter, the

SWMB is closed (if present)

The system output is switched onto automatic bypass,

or switch SWOUT is open.

On

An internal fault is present

Flashing

-

Off

There are no internal faults.

Green

Green

Yellow

Yellow

Bypass line

indicator

Mains line

indicator

Battery

powering the

load

Load on

Bypass

Flashing

On

Flashing

Off

active, or the BATTERY DISCHARGE OR SWB

bypass line with the output power greater tha n

100%VA, or the manual bypass switch SWMB is

the output is switched onto the bypass line and both

switches SWOUT and SWMB are open, or when the

On

Normal

output

Alarm for

internal fault

Flashing

Off

Green

Red

stand-by operation, the output power is correct since it

is less than 100%VA and the output switch SWOUT

output power is greater than 100%VA, or switch

Table 4 - Led Status Indicators

Page | 28

Page 39

4.2 Graphic Display

Area of the display where the UPS status of operation is shown by means of

Area where the UPS operating status is displayed by means of two text lines.

Area that shows the key function by means of numbers and icons. The key

A wide graphic display is present on the UPS door, which allows the user to have a close-up, detailed

overview in real time of the status of the UPS The user can switch the UPS on and off, consult electrical

mains, output, battery measurements etc. and perform the main unit settings.

Figure 24 – Graphic Display

Operation Diagram

UPS MESSAGES

AND MAIN

OPERATING

VALUES.

KEY FUNCTION

shapes with filled lines when they are active and with dotted lines when they are

inactive.

The first line displays messages that are explained in the “alarm message”

paragraph”. The second line displays the main operating values about system,

output load, battery, buzzer and alarm message number.

function is also indicated in the sub menus, on the two text lines with the related

number. When a key is pressed the related box change to filled line

The precision of the measurements are: 1% for voltage measurements, 3% for current

measurements, and 0.1% for frequency measurements. The indication of residual autonomy

time is only an ESTIMATE; it must not, therefore, be considered a precise measuring

instrument.

Page | 29

Page 40

4.2.1 Diagram Items Shapes

Active

Inactive

Meaning

Key Off/ON

Icon

Meaning

Input converter

Output inverter

4.2.2 Keys Numbers and Icons

Battery

Manual bypass line switch

Bypass line input switch

Battery switch

Output switch

Main line input switch

Output load (40%VA or 0%VA)

Battery(70%Ah or 0%Ah)

Table 5 - Diagram Items Shapes

Information or n. 1

Measures or n. 2

Commands or n. 3

History or n. 4

Buzzer OFF/ON or n. 5

Display date/hours or. n. 6

Decrease value or sub menu or n. 7

Increase value or previous menu or n. 8

Table 6 - Keys Numbers and Icons

Page | 30

Page 41

4.3 Basic menu (text lines area)

If no commands have been inserted, the first text line shows messages to inform about status of

operation.

In each operating condition, the display returns to the "basic menu" after two minutes from the

last command. The basic menu shows the signal messages relating to the current operating

state

4.3.1 The First Line of the Basic Menu

When there are no alarms present the first text line of the main menu shows a fixed message,

“NORMAL OPERATION”

When some alarms are present, the first text line of the main menu shows each active ALARM message,

“ALARM MESSAGES”, one at a time for a few seconds:

Page | 31

Page 42

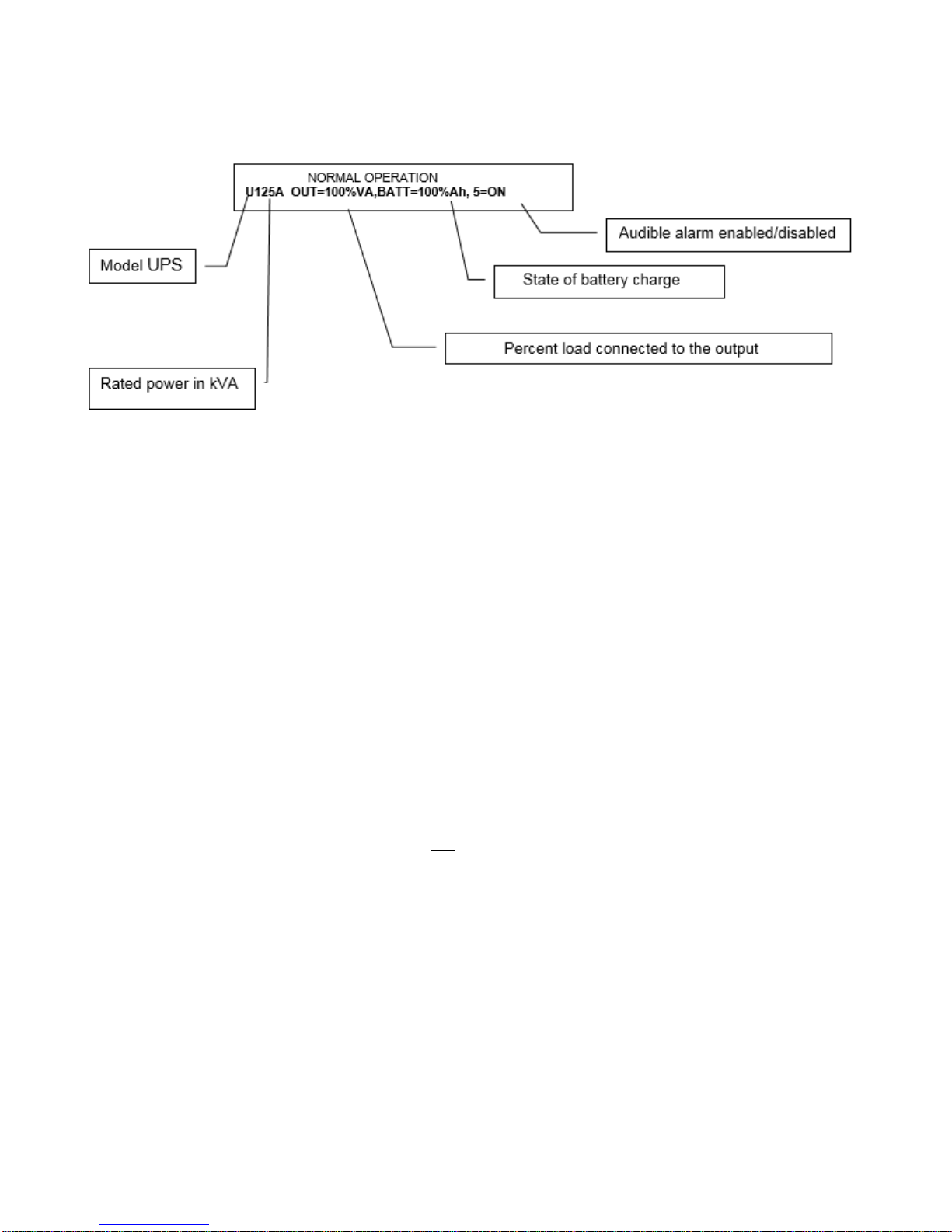

4.3.2 The Second Line of the Basic Menu

The second line displays the main operating values about system, output load, battery, buzzer and alarm

message number

• U125A indicates an UPS model with 125kVA rated power, operating with 60Hz output frequency.

o When the unit is set for the parallel operation the letter “P” is added (U125A P). The letter

“P” became lower case “p” when the unit operate as slave.

• 100%VA provided in the example is obtained from the measurement of the output current.

o The number indicates the output current with the value relating to the absolute rated value

and the value indicated is the greater of the effective current and the peak current.

• BATT= 100%Ah: example of the current state of the percentage of battery recharge.

o The value 100%Ah is obtained from the measurement of the charge current and the time

taken to recharge.

o The number indicates the recharge value as a percentage according to the capacity of the

battery connected and to the quantity of charge used during battery operation.

o The system automatically remains in rapid charging for all the time needed to supply the

battery with the quantity of charge lost during the discharge.

• %Ah changes to "min." (minutes) during operation in the event of a mains failure or when the

battery is discharging.

o The numeric value refers to the remaining minutes of operation, calculated according to

the current supplied by the battery and to the state of charge of the battery.

o The backup time shown is calculated according to the measurement of the discharge

current present at that time, the stored value relating to the capacity of the battery

connected and the stored value relating to the percentage of recharge prior to discharge.

The backup time shown should not be considered indicative due to the many different

factors affecting it. If considerable differences are noted between the expected value and

the actual time of a discharge with constant load, the stored data relating to the battery

must be checked, as must the state of the battery.

• 5=ON: example of the message showing whether or not the audible alarm is enabled; if disabled,

the message changes to 5=OFF.

Page | 32

Page 43

4.4 Language setting menu (keys 1, 1)

o Italian,

o Swedish,

o Polish,

o Portuguese.

From the keys menu, press 1 twice to access the languages menu.

The following languages are available:

o English,

o French,

o German,

o Spanish,

o Dutch,

o Hungarian,

o Turkish,

o Czech,

o Russian,

o Romanian and

The system will show all subsequent messages using the language chosen. The selected language

remains stored even after the shutdown and restart of the system. The current language can only be

changed by accessing the LANGUAGES menu.

Use keys 1 and 8 to return to the basic menu.

Page | 33

Page 44

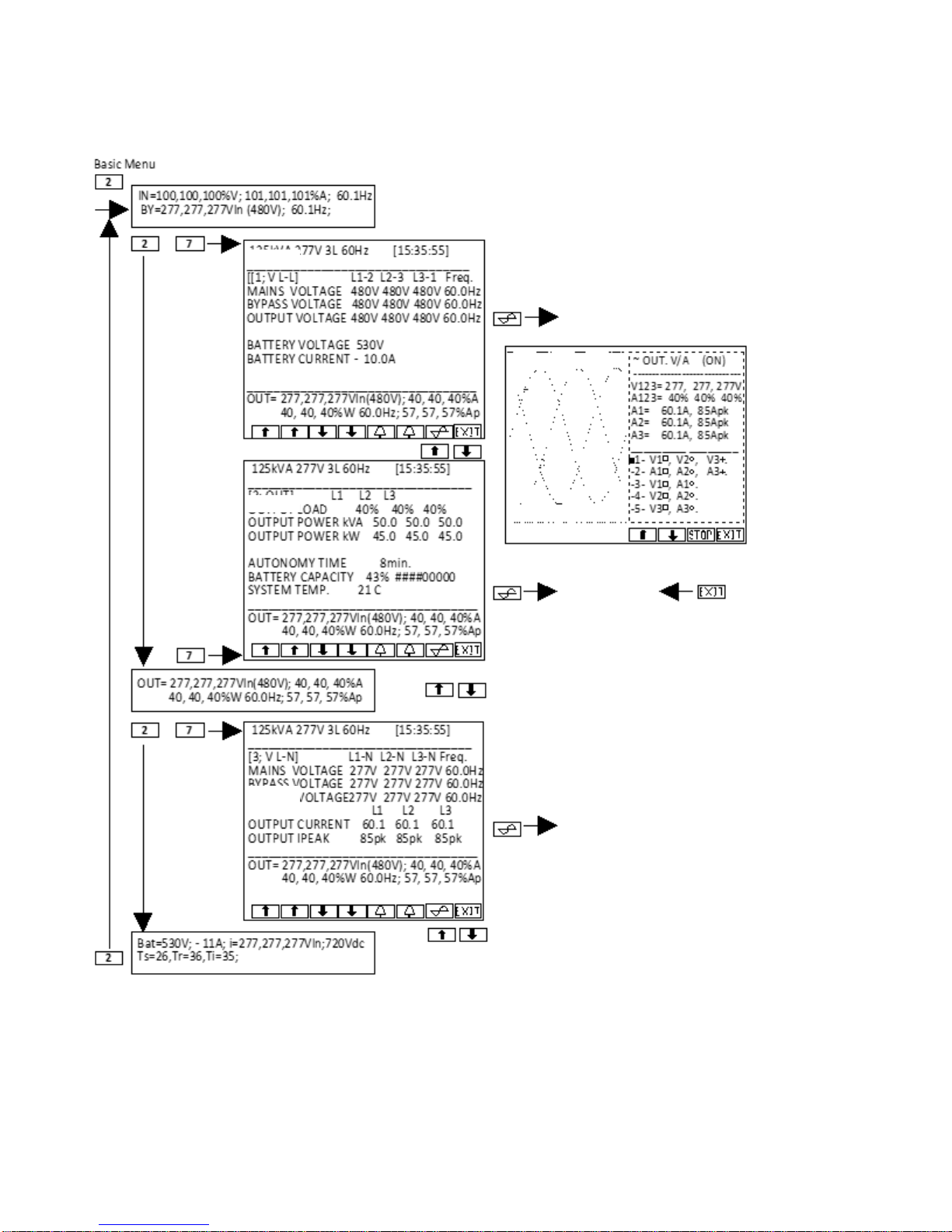

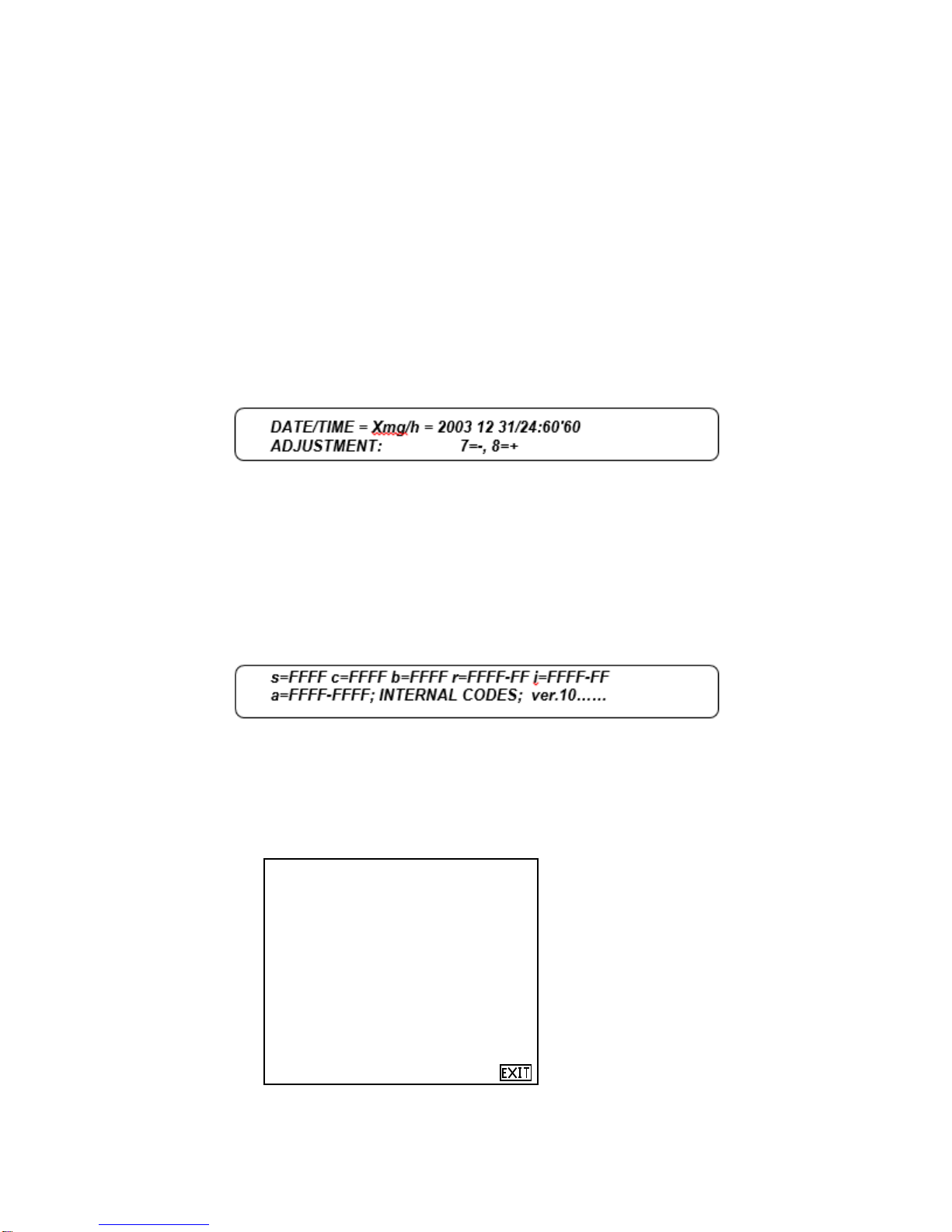

4.5 Measurements menus (key 2)

IN

Out

Batt

Batt Out

The measurements with two line displayed, are selected from the basic menu by pressing key 2

IN

• IN=100,100,100%V, 60.2Hz Measurement of the three voltages, neutral phase and input frequency.

The voltage is indicated as a percentage of the rated voltage; for example 100% is equivalent to

277V.

• 101,101,101%A Measurement of the three input currents. The input currents are expressed as a

percentage of the rated value.

• BY=277,277,277Vln(480V) Measurement of the three input phase voltages of the bypass line, with

the concatenated voltage (the average of the three values) in brackets.

• 60.1Hz Frequency of the bypass line

Out

• OUT=230,230,230Vln Measurement of the three output phase voltages of the UPS, with the

concatenated value in brackets.

• 100,100,100%A Measurement of the three output currents. The output currents are expressed as a

percentage of the rated value.

• 100,100,100%W Measurement of the active output power. The power is expressed as a percentage

of the rated power.

• 60.1Hz Output frequency.

• 147,147,147%Ap Measurement of the three peak currents as a percentage relating to the three

output phases during operation from inverter. During operation from bypass, the message OUT

changes to BY.

Page | 34

Page 45

Batt

• BATT=xxxV Battery voltage value;

• +0.0A Battery current, positive with Battery discharging, negative with battery charging;

• i=230,230,230Vln Inverter output voltage;

• yyyVdc Input inverter DC voltage

• Ts=28, Tr=50, Ti=49, Tb=25; Temperature of the system, and of the rectifier and inverter

modules, Tb is present only if the external temperature the sensor is installed.

Batt Out

• OUT=10000h Hours of normal operation

• BATT=10000sec Time spent in operation from battery

• nBATT = 1000 Number of times the battery has discharged

• n0%Ah = 100 Number of times the battery has discharged fully

• 2007-01-01 Data stored on first start-up of the UPS. These are HISTORY data, and remain

stored even when the device is switched off and may not be reset.

Page | 35

Page 46

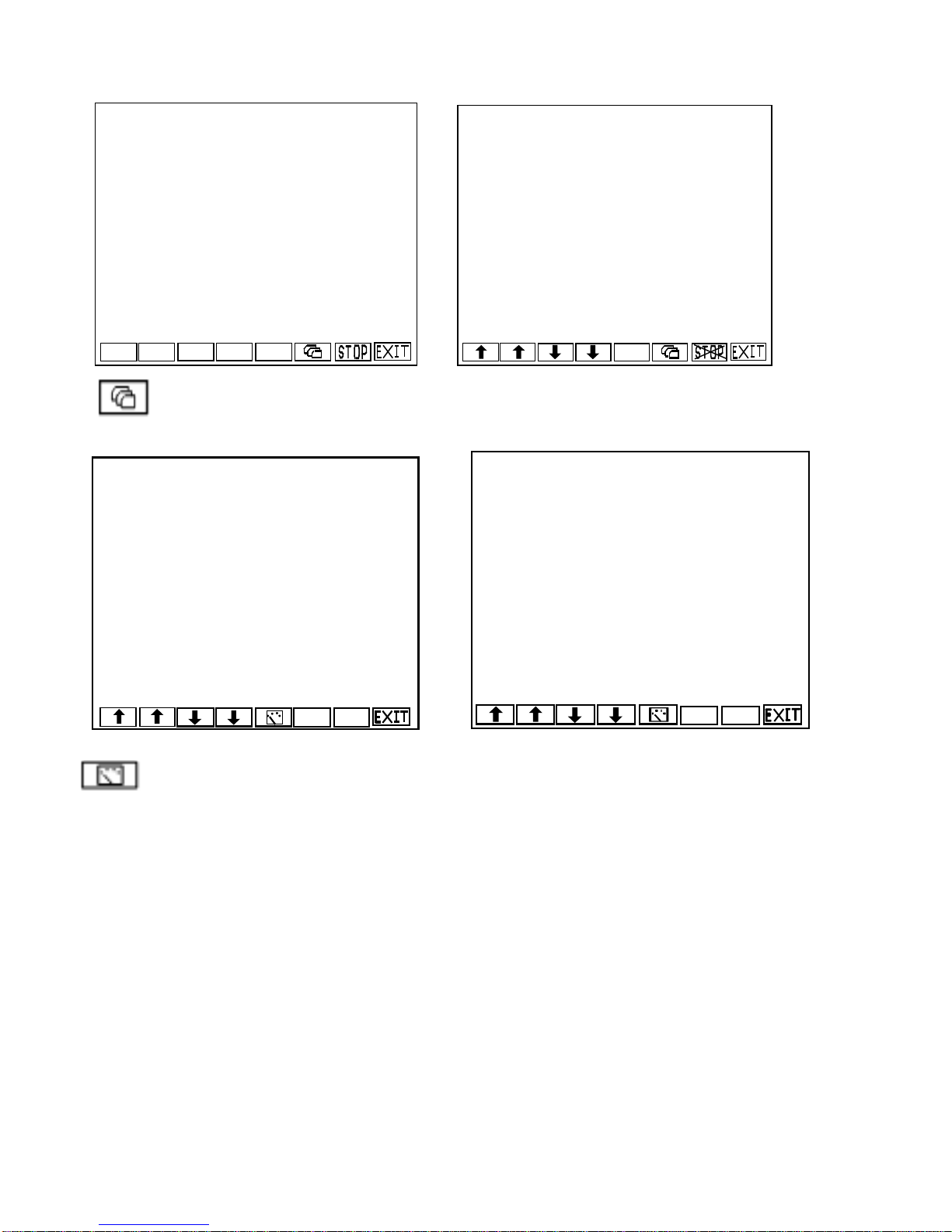

4.6 Full page Measurements and output waveforms (key 2, 7)

The full page measurements and output voltage and current waveform are selected by pressing key 7

from the two line measurement menu.

Page | 36

Page 47

4.7 Controls Menu (key 3)

4.7.1 Battery Test (Keys 3, 2)

This activates the cycle to check the state of the battery, which lasts 8 seconds.

Press key 8 to interrupt the test and return to the basic menu before this time has elapsed.

The battery test cycle lowers the rectifier output voltage so that the battery can be evaluated with the

load even when the input voltage is present. The rectifier output voltage is only lowered if the bypass line

voltage is present, in order to avoid any disruption to the output load without the support of the bypass.

The battery test cycle can be activated:

• Manually;

• Automatically every 60 sec. after each failed test (for three times), or each time the system is

restarted;

• Automatically every 24 hours from system start-up;

• Automatically in invisible mode during operation without mains power supply.

At the end of each test, the alarm is activated if the voltage measured is lower than the calculated

voltage; the charge value stored and the backup time indicated are subsequently halved. A new test is

performed 60 sec. after activation of the alarm and if the result is negative the alarm is activated once

again for another 60 sec.

The alarms continue to halve the charge value stored until the calculated battery voltage is less than the

voltage actually measured. The battery control system produces an alarm each time the battery is seen

to have less than half of the expected charge.

• If this alarm is on PERMANENT, it indicates that the battery capacity is low, the battery circuit is

interrupted, the battery disconnect has remained open or one of the protection device fuses has

been triggered.

• If this alarm is on TEMPORARY, it indicates a reduction in the capacity of the battery; the more

frequent the alarm, the more serious the problem.

Page | 37

Page 48