S4 USER GUIDE

©Copyright 2016 STACKER, LLC

Minneapolis, MN 55427

http://stacker3d.com

STACKER® is the registered trademark of STACKER, LLC.

Revised: 12 January 2017

User Guide - STACKER S4

TABLE OF CONTENTS

1. Introduction

1.1. Product Registration

1.2. Printer Specifications

2. Warnings

3. Unboxing and Assembly

3.1. Hardware List

3.2. Assembly Instructions

3.3. Uninterruptable Power Supply (UPS)

4. Your First Print

4.1. Running Your First Print

STACKER S4 USER GUIDE 2

4.2. Turning off the Printer

4.3. Troubleshooting Poor Quality Prints

5. Changing Nozzles, Filament Guide Tubes, and BuildTak™

5.1. Remove Nozzle

5.2. Install Nozzle

5.3. Replacing BuildTak™

6. Printer Calibration

6.1. Adjusting First Layer Height

6.2. Volumetric Calibration

6.3. PID Calibration

7. Multi-Head Printing

7.1. Multi-Part Print Mode

7.2. Multi-Material Prints

7.3. Removing Print Heads

8. Maintenance

8.1. Keep Your Printer Clean

8.2. Linear Guides

9. Controls

9.1. Manual Controls via Stacker RUN

9.2. LCD Controls

10. Advanced Calibration

10.1. Leveling the Bed

10.2. Nozzle Height Adjustment

10.3. Calibration of X/Y/Z Motion System

10.4. Vref for Stepper Motor Drives

11. Useful Information

11.1. Connecting & Disconnecting the USB Cable

11.2. Filament Settings Reference

11.3. Printer settings for Slicing Engines

11.4. Power Supply Data Sheet

12. Terms and Conditions

STACKER S4 USER GUIDE 3

STACKER S4 USER GUIDE 4

1. Introduction

The STACKER S4 is a high performance industrial grade 3D printer capable of producing

everything from one-off prototypes to multiple part production runs. To get the most out of your

Stacker 3D printer, please read through the entire User Guide before attempting to operate your

printer.

Understand CAD Modeling: It is helpful to be familiar with solid modeling CAD applications in

order to create and manipulate the parts you want to 3D print. Often a simple design modification or

splitting of a model into multiple sections will allow you to print it faster, better, and without the need

for support materials. The following list of CAD apps is by no means exhaustive, but these

programs offer a good balance of power and value, some of which are free and have robust online

training and user communities. Nearly all of these apps will export your models to the preferred STL

file format.

● SketchUp

● Autodesk Meshmixer, Tinkercad

● FreeCAD, openSCAD, Blender

● Autodesk Netfabb, Autodesk Fusion 360, Geomagic Design

● SolidWorks, Autodesk Inventor, Solid Edge

Learn to use a Slicing Engine: In operating a 3D printer, it is most critical that you have a good

understanding of your preferred slicing engine before attempting your own prints. Slicing engines

are used to convert an STL file into the GCODE file which operates the printer. A GCODE file

provides the commands which enable the printer to print a 3D object. Stacker RUN includes two

open source slicing engines, Slic3r and Cura, and both of these slicing engines do a good job.

Nevertheless, we highly recommend Simplify3D. We have found Simplify3D to be one of the best

slicing engines available. We provide a license of Simplify3D with the purchase of a Stacker S4,

so to receive your copy, please contact sales@stacker3d.com.

The links below can help familiarize you with the operation of a slicing engine:

Slic3r http://manual.slic3r.org/intro/overview

Cura https://ultimaker.com/en/resources/manuals/software

https://www.simplify3d.com/support/

STACKER S4 USER GUIDE 5

For assistance setting up a profile for your Stacker 3D printer within your slicing software, please

refer to chapter 11.3.

Stacker RUN software is an enhanced version of Repetier Host

printers. Additional information and Stacker RUN software download is available on our website.

Additional documentation can be found on the Repetier website.

Stacker RUN http://stacker3d.com/stacker-3d-printer-support

http://www.repetier.com/#documantation

customized for using Stacker

If you are interested in controlling your Stacker printer remotely with a cell phone or computer, we

recommend Repetier Server. Through the combination of a Raspberry Pi and Repetier Server,

you are able to operate your printer from any web enabled device. Please contact Stacker, or visit

Stacker’s support page (http://stacker3d.com/stacker-3d-printer-support/) for more information.

https://www.repetier-server.com/

1.1 Product Registration

It is important to register your printer with Stacker. In order to receive customer service support,

warranty service, or join our community forums, you must register your printer. Complete the

registration form on our website.

http://stacker3d.com/product-registration/

Your Stacker S4 printer has two serial labels. One is serial label is located inside the controller

housing and a second serial label has been attached to the inside of the front right leg.

PRODUCT

Stacker S4

MACHINE TYPE

Cartesian robot

FIRMWARE

RepRap Repetier

BUILD VOLUME

510mm (X), 365mm (Y), 600mm (Z)

PRINT SPEED

1-250mm/sec

X/Y MOVEMENT SPEED

0 to 250mm/sec

POSITIONAL ACCURACY X/Y

6 microns

POSITIONAL ACCURACY Z

4 microns

LAYER RESOLUTION

0.1mm to 1.0mm

NUMBER OF EXTRUDERS

4

EXTRUDER TEMPERATURE

Up to 300°C

HEATED BED TEMPERATURE

Up to 110°C

NOZZLE DIAMETER

0.50mm

OPTIONAL NOZZLE DIAMETERS

0.25mm, 0.40mm, 0.50mm, 0.60mm, 0.80mm, 1.00mm

FILAMENT SIZE

1.75mm

PRINTED MATERIALS

Most filaments which extrude at temperatures below 300°C

POWER REQUIREMENTS

100-240VAC 8.5 AMP

INTERNAL VOLTAGE

24VDC/5VDC

RECOMMENDED UPS SIZE

1000VA or greater

CONNECTIVITY

USB and SD Card

Wireless and Network with optional Raspberry Pi

DEFAULT BAUD RATE

250000

SOFTWARE LICENCES INCLUDED

Simplify3D and StackerRUN

WEIGHT

88kg (195 lbs.)

DIMENSIONS

Width: 735mm (29”)

Depth: 825mm (32½”)

Height: 1380mm (54”)

1.2 Printer Specifications

STACKER S4 USER GUIDE 6

STACKER S4 USER GUIDE 7

STACKER S4 USER GUIDE 8

Burn Hazard! Do NOT touch hot surfaces!

Both the hot ends and heated bed can get HOT! To prevent burns, avoid

touching the hot surfaces of the 3D printer.

Fire Hazard!

Never place flammable materials or liquids on or near the printer. It is your

responsibility to operate your printer in a safe manner. To ensure that it is

safe, you must incorporate the use of fire and smoke alarms and proper fire

suppression technologies like fire extinguishers. Never operate the printer

unattended.

Electric Shock Hazard!

The printer must be kept dry. Attempting to operate the printer in a wet

environment will damage your printer and could lead to injury. Always power

down and disconnect the power cable from your printer before servicing or

opening your controller housing.

Static Charge Hazard!

Ground yourself before touching the printer. Static charge can damage your

printer's electronic components. Discharge your static before touching your

printer!

Pinch Hazard! Keep Hands and Fingers Clear.

During operation, the printer will perform quick and sometimes unpredictable

movements. To avoid injury, never place your hands, fingers or body near

any moving parts of the printer including belts, pulleys, print bed, and hot

ends. Be sure to tie back long hair and remove any clothing or jewelry which

could become caught in the moving parts of the printer.

2. Warnings

Stacker 3D printers are industrial machines that should never be operated around children or left

unattended. Careful setup and training is required for optimal results. Read through this entire User

Guide and view online resources before attempting to use your printer. Please note, this printed

copy of the User Guide may not be the latest version. We recommend downloading the User Guide

from our website to confirm you have the most up to date version.

Please read and take seriously all Warnings below. Unsafe operation of a 3D printer can result

in damage to your printer and serious injury to yourself.

Age Warning.

For users under the age of 18, adult supervision is recommended. Small

printed parts can become a choking hazard for small children. Never operate

the printer unattended!

STACKER S4 USER GUIDE 9

STACKER S4 USER GUIDE 10

3. Unboxing and Assembly

The Stacker S4 has been shipped in a wooden crate to protect the printer during transit. We

recommend keeping both the crate and packaging materials in case you should ever need to

transport the printer or return it to Stacker for warranty service.

Be very careful when removing printer from the crate -- the printer is HEAVY! Begin by

removing the Phillips screws so you can fully detach the top and one side of the crate. Next,

remove the hardware box and foam from underneath the printer so that the printer’s wheels rest on

the floor of the wooden crate. You may need two other people to assist in lifting the printer when

removing the foam from beneath the printer. Finally, use the side of the crate as a ramp to roll the

printer out from the crate.

3.1. Hardware List

STACKER S4 USER GUIDE 11

1. Filament Rail (p/n 30-026)

2. Filament Rail Brackets -- Right (p/n 30-095) and Left (p/n 30-098)

3. (2) Thumbscrews (p/n 40-006)

4. Nozzle Wrench (p/n 50-069)

5. 3mm Hex Key (p/n 50-032)

6. 1.5mm Hex Key (p/n 50-033)

7. 2.5mm Hex Key (p/n 50-046)

8. 2mm Hex Key (p/n 40-048)

9. 7mm Nut Driver (p/n 50-043)

10. 2.5mm Hex Driver (p/n 50-052)

11. 0.007”/0.18mm Feeler Gauge (p/n 50-051)

12. Filament Drive Cleaning Brush (p/n 50-044)

13. USB Cable (p/n 10-042) *attached to the printer

14. (8) Zip Ties (p/n 10-060)

15. (8) M4 x 30mm SHCS (p/n 20-071)

STACKER S4 USER GUIDE 12

16. (8) Compression Spring (p/n 20-056)

17. (8) M4 Knurled Nut (p/n 20-074)

18. SD Card (p/n 10-094)

19. (4)Blower Fan Duct (p/n 50-071)

20. (20) Filament Guide Tube Clip (p/n 50-069) Note, four of these clips have already been

attached to the printer.

21. (2) Power Cord (p/n 10-043)

22. Filament Guide Tube Support Bar (p/n 50-078)

3.2 Assembly

A. Remove Packaging Tape

To protect your printer during shipping, several pieces of low tack tape were attached. You MUST

remove all of this packing tape before attempting to operate the printer. You will find tape attaching

the X-gantry to the front of the printer and the USB cord has been taped to the rear of the printer.

After removing the tape, be sure to use a clean dry cloth or rubbing alcohol to remove any tape

residue.

B. Rub an oiled cloth along the linear rails.

The linears rails require a thin protective coating of oil to prevent rust and allow optimal

performance of the printer. All lubricants will eventually break down, and because of shipping, the

oil applied at the factory to your printer’s linear rails may no longer provide the necessary protection

and lubrication. Therefore, before attempting to operate the printer, we recommend rubbing an oily

rag along the linear rails to remove any rust spots and assure proper lubrication. A coating of

synthetic SAE 75W-90 gear oil was applied at the factory, but please free to use a solvent to

remove our lubrication and apply your preferred lubricant.

1

Note, do not use WD-40 as a lubricant for linear rails. WD-40 will not provide adequate lubrication.

1

STACKER S4 USER GUIDE 13

There are two Z-rails, two Y-rails, and one X-Rail. Rub an oiled cloth along all five of these linear

rails to assure they are clean and free of debris. For most users, you will likely need to wipe down

and apply some oil or grease on a monthly basis. For more information about this routine

maintenance, please refer to section 8.2.

C. Attach the Universal Filament Rail to the Rear of the Printer

Step 1. Locate the Universal Filament Rail, the two Filament Rail Brackets, and the two Filament

Rail Screws.

Step 2. Use the 3mm hex key to carefully remove two M5 x 12mm Socket Head Cap Screws from

the rear left side of the printer frame, see image below. Remove only the two screws on the left.

Remove the screws slowly! The screws are attached to swage nuts, so to avoid damaging the

swage nuts, remove the screws slowly by hand.

STACKER S4 USER GUIDE 14

Use the same two screws to attach the left filament guide rail.

STACKER S4 USER GUIDE 15

Step 3. Remove two M5 x 12mm Socket Head

Cap Screws from the rear right side of the

printer, and use these screws you just removed

to attach the Right Filament Rail Bracket.

Step 4. Place the Universal Filament Rail on the brackets and secure with the filament rail screws.

Filament rolls shown for reference.

D. Install the filament drive hardware to all four filament drives.

Step 1. Locate the filament drive idler assembly hardware. Each filament drive requires (2)

compression springs, (2) M4 x 30mm Socket Head Cap Screws, and (2) M4 Thumb nuts.

Step 2. Attach the filament drive idler assembly hardware to each of your printer’s filament drives,

as shown. The M4 thumb nuts should be flush to the end of the 30mm screws. If necessary, use

the supplied 3mm hex wrench to hold the screws while you hand tighten the thumb nuts. Note,

STACKER S4 USER GUIDE 16

Step 1. Using the 2.5mm hex driver, loosen the

two screws on the filament guide tube mounting

bracket.

Step 2. Push the filament guide tube into the

grey filament guide tube sleeve toward the hot

end to remove any slack.

there is a small amount of red anti-vibration material on each of these screws to prevent the

hardware from loosening during operation.

E. Attach the Filament Guide Tubes to all four filament drives.

STACKER S4 USER GUIDE 17

Step 3. Hold the grey sleeve with both hands as shown. While pushing and holding the tubes

together with one hand above the hotend, insert the opposite end through the filament guide tube

mounting bracket as shown. The gray sleeve will be held in position with the mounting bracket,

and the inner tube will be inserted into the fitting. The filament guide tube will descend

approximately 20mm into the fitting.

Step 4. By turning the grey filament guide tube

sleeve, you can manipulate the tube’s arc. You

want the arc to stand as tall as possible.

STACKER S4 USER GUIDE 18

Step 5. Tighten the screws on the filament

guide tube bracket to secure the grey sleeve

tube.

Step 6. Secure the hot end power cable with

one zip tie as shown. Trim the tail from the zip

tie once it has been tightened.

Step 7. Use the filament guide tube clips to

secure the wire harnesses and guide tubes

together. Use five clips per guide tube/wire

assembly.

STACKER S4 USER GUIDE 19

Step 8. Attach the filament guide tube bar by

clipping the bar at four locations to the grey

filament guide tube sleeves as shown. Note,

the location of the filament guide tube bar is

below the apex of the arc and toward the rear

of the printer to allow full movement of the

printheads. The distance from the top of the

extruder to the filament guide tube bar should

be approximately 235mm.

When attaching the blower duct,

make sure it is attached with the

proper orientation, otherwise the

blower duct will scrape on the bed.

The blower duct has a small “T”

printed on the top to help identify

the top.

F. Attach the blower fans Duct:

Your printer includes four bower fan ducts printed with colorFabb_XT CF20 filament. If you wish to

replace these ducts, you can print them with your 3D printer. Two versions of the STL file is

available on our website.

● http://stacker3d.com/stl/blower-duct-solid.stl

● http://stacker3d.com/stl/blower-duct-1mm-wall.stl

STACKER S4 USER GUIDE 20

Your printer ships with two North American 10 amp cords with

C13 connectors. This is a common “computer” type power cord

and is widely available throughout the world to fit your specific

power outlets. If you are not using North American 115V AC

power and outlets, please purchase a proper cord type at your

local electronics store or online retailer.

G. Connect Power Cords

For typical operation, the Stacker S4 should have at least one dedicated 20 Amp circuit. The power

supply is auto switching and will accept 115 to 230 volts of AC power. We have attached a data

sheet for the power supply to help you properly connect it to your power source and determine

compatibility. Please reference this data in Section 11.4.

3.3. Uninterruptible Power Supply (UPS)

We strongly advise the use of a 1000VA or greater uninterruptible power supply (UPS) with your

printer. Any sudden loss of power, no matter how brief, will likely cause the electronics in your

printer to reset, and this will ruin your print. If you want to avoid the pain and suffering associated

with losing a multi-hour print, then we recommend a UPS. Furthermore, power spikes and

brownouts can damage the printer’s electronics. Any good quality UPS will save you from

momentary power loss or brownouts and will protect your printer from potential damage. We cannot

stress enough the importance of this very inexpensive insurance. Uninterruptible power supplies

(UPS) are widely available from computer and electronics retailers.

4. Your First Test Print

After you have completed all of the assembly steps in Chapter 3, you are ready to run a test print.

Running a test print is the best method of familiarizing yourself with the printer and to confirm it is

properly calibrated. The following steps will also help teach you the basic steps used to produce a

print.

4.1. Running Your First Print

A. Download and Copy GCODE to an SD Card

In most cases, you will be creating your own GCODE by using a slicing engine such as Simplify3D,

but for this test print, we recommend using our GCODE because it should provide proven results.

To download the test print GCODE, go to http://stacker3d.com/stacker-3d-printer-support/ and

select the Stacker Emblem V2 for 050 nozzle GCODE file. If you click on the link, your web

browser will attempt to open the GCODE file within the browser, so in order to save the file to your

computer, right click on the file link and select “save link as…” to download the file to your

computer.

STACKER S4 USER GUIDE 21

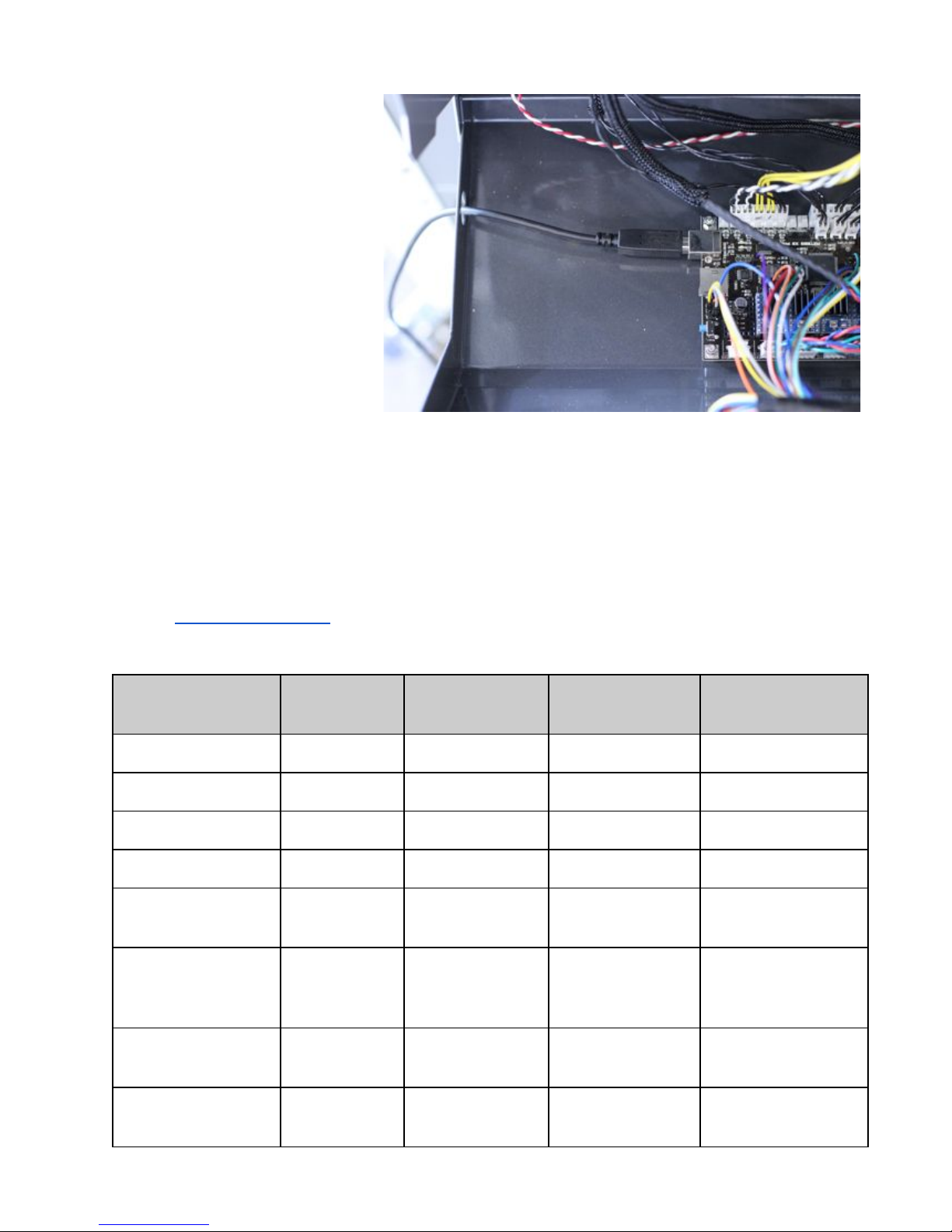

If the printer is ever behaves in a manner in which you feel the printer could

cause damage to itself or others, immediately press the Reset/Emergency

Stop button. The Reset/Emergency Stop button will disable the printer’s

motors, hot ends, and heated bed. Unplugging or turning off the printer

during operation can cause damage to the printer.

Next, transfer the downloaded GCODE file from your computer to the provided SD card. If your

computer does not have an SD card slot, you can purchase an inexpensive pocket sized SD card

reader that will work with an available USB port on your computer.

B. Power Up Printer

The Stacker S4 has two power supplies and two power switches (one for each power supply), be

sure to turn on both power switches. The printer will will not operate if only one of the power

switches is turned on.

C. Load Filament

Step 1. Load Filament Spool. Loosen and remove one of the Universal Filament Rail knobs.

Carefully lift one side of the Rail to slide the spool of filament onto the Rail. Reattach the Filament

STACKER S4 USER GUIDE 22

Rail knobs to secure the rail in place. Place the filament rolls so the filament goes over the top of

the roll as shown by the right image below.

2

Step 2. Preheat the print bed and hot end. Every filament has an optimal extruding temperature.

Please refer to Section 11.2 to see the recommended settings for a variety of filaments. In this

example, we have selected to use colorFabb PLA/PHA filament for our test print.

To preheat the bed and nozzle, begin by depressing the knob next to the LCD panel to open the

LCD menu. Next, turn the knob to highlight Extruder, then push the knob to enter the Extruder

sub-menu.

From the Extruder sub-menu, select Bed temp. Once selected, you can dial the temperature to

where you want it, then push the dial to set the temperature and the printer will immediately begin to

warm the bed to the temperature you requested. In our example, we have call for a bed

temperature of 50°C.

Next, in the same way you adjusted the bed temp, dial the knob and set the temperature for Temp.

1 which sets the nozzle temperature for the first extruder. In our example below, we have called for

2

Note, filament is shown as an example and is included with your printer.

STACKER S4 USER GUIDE 23

a temperature to 220°C. Note, the current temperature of the hot end in the image below is 34.3°C

and rising to 220°C

Step 3. Insert the filament. With the filament drive idler assembly open, insert and push the

filament upward by hand through the small hole beneath the filament gear then continue upward

past the gear and through the filament guide just above the gear.

Please note, if filament has already been installed and you wish to remove it. You must wait for the

hot end to reach the appropriate temperature to melt the filament before you will be able to pull the

filament by hand and remove it from the nozzle, filament guide tube, and extruder.

Step 4. Extrude filament by hand. When extruder 1 has reached the temperature needed for your

filament, you will be able to prime the nozzle by gently pushing the filament by hand through the

filament guide tube. Note, if extruder 1 has not reached the temperature required to melt the

filament, it will be difficult (if not impossible) to push the filament through the nozzle.

By pushing a small amount of filament by hand through the nozzle, you will know that the nozzle is

primed and ready to print. Please note, when you initially extrude by hand, you may see a color of

filament extruded from the nozzle which does not match the filament you are using. Do not be

STACKER S4 USER GUIDE 24

alarmed. You are seeing the remnants of the PLA filament used during your printer’s initial

calibration and testing at Stacker.

Step 5. Secure the Filament Idler Assembly. To close the Idler Assembly, lock the two heads of

the screws into the Filament Idler Assembly.

D. FINAL CHECK! Make Sure the Print Bed is Clear and Heads are Properly Positioned to

Start your Print

STACKER S4 USER GUIDE 25

You should always double check your print bed to confirm that it is clear

of tools and printed objects before starting a print.

Stacker performed a test print at our factory. This test print may still be on the bed, so you need to

remove it before performing your test print.

With your first print, you will only be using one printhead, so it is best practice to slide the three

unused heads to the right side of the gantry away from the printing head. Important, you do not

want the unused heads to trip the X-Max End Stop. If you trip the X-Max End Stop, your printer

will think it has reached the edge of the bed at the beginning of the print, and it will only print a

single line of filament along the left edge of the print bed. Be careful to avoid tripping the X-Max

End Stop with unused heads.

Note, the Guard Plate has been removed to show the endstop, do not operate your printer without

the guard plate in place.

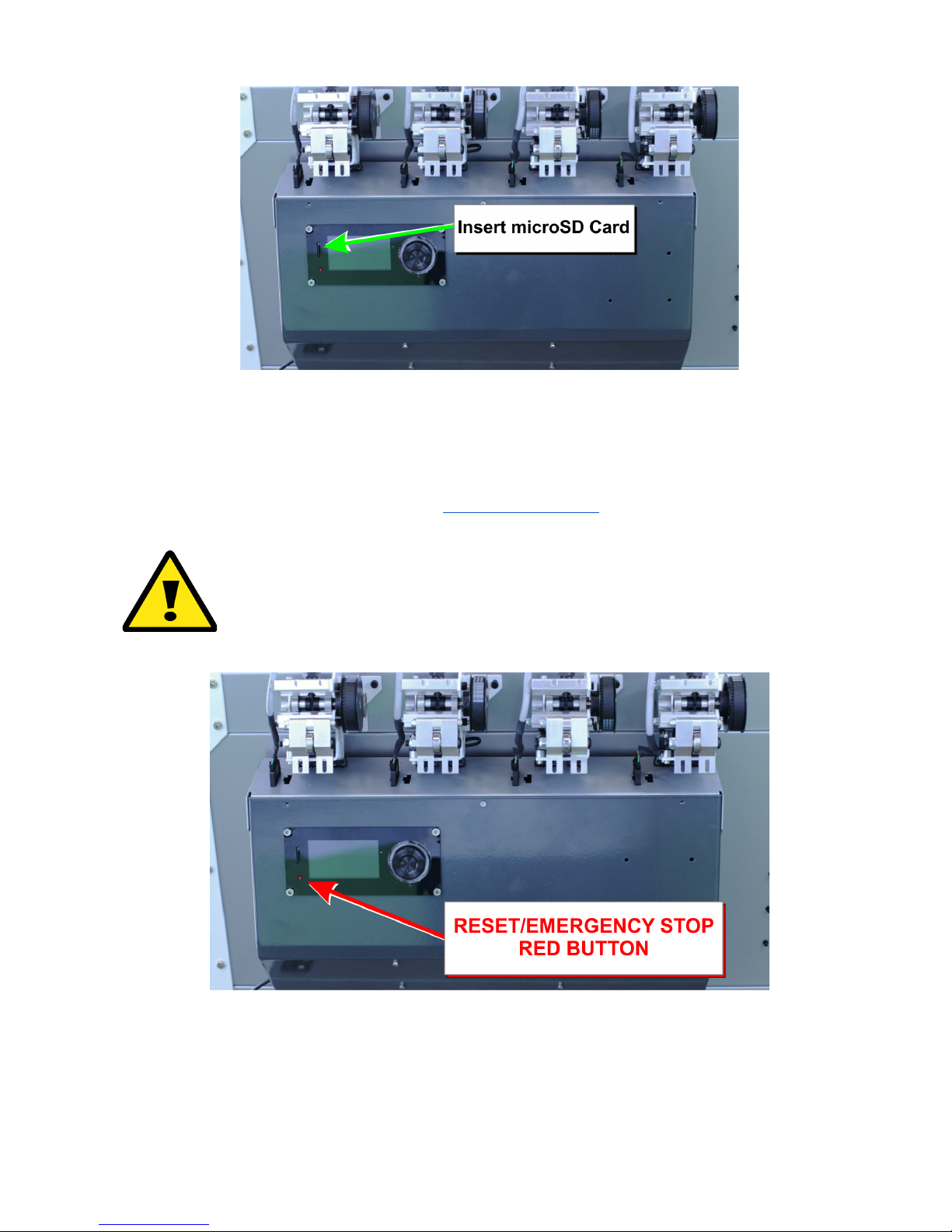

E. Insert the SD Card and Select the File

To start your print, insert the microSD card into the controller. Whenever an SD card is inserted, a

menu of available files will appear on the LCD. Turn and depress the knob to select the GCODE

file you wish to print. Once the knob has been pressed, the selected GCODE file will begin to run

as soon as the bed and nozzles have reach the temperatures specified by the GCODE file.

STACKER S4 USER GUIDE 26

If something seems seriously wrong with the printer, such

as the nozzles crashing or scraping on the bed, you should

immediately press Reset/Emergency Stop button.

F. Watch your Test Print

While your first print is running, watch for any problems with the printer. Although the printer was

calibrated prior to shipping, calibration can sometimes be thrown off during shipping. If the printer is

not performing adequately, calibration may be necessary to improve print quality. For calibration

instructions turn Chapter 6. Please contact info@stacker3d.com if you have any questions.

G. Removing your Test Print from the Print Bed

It is sometimes difficult to remove a printed object from the BuildTak. If you allow the bed to fully

cool, it can sometimes make print removal easier. Also, using the BuildTak Spatula (sold

separately) is a very useful tool which allows you to pry your parts from the build plate.

STACKER S4 USER GUIDE 27

Another option for part removal is the BuildTak FlexPlate, p/n 90-109. The FlexPlate is a removable

build plate which enables you to literally “pop” your parts off the BuildTak. Please check our

website for availability.

4.2. Turning Off the Printer

When turning off your printer, wait for the cooling fans to fully cool your extruders before

turning off the printer. You can observe the temperatures of your extruders on the LCD. Turning

off the printer with hot extruders can damage your printer. Proper cooling is necessary to prolong

the life of your hot ends. We recommend allowing hot ends to cool below 50°C before turning off

the power to the printer.

4.3. Troubleshooting Poor Quality Prints

If your print quality is less than desired, please take a look at the Simplify3D print quality

troubleshooting guide. This User Guide provides excellent visuals of common problems and

solutions.

● https://www.simplify3d.com/support/print-quality-troubleshooting/

If your print failed, please go through the printer calibration steps in chapter 6, and contact Stacker

for help at info@stacker3d.com.

STACKER S4 USER GUIDE 28

Step 1. Remove the filament from your

hotend. From the LCD controller, depress the

knob to open the menu, then turn and depress

the knob to select Extruder.

From the Extruder sub-menu, set the

temperature for the nozzles you will be

removing. The temperature should be the

same as the type of filament which is in the

nozzle. In our example, we are changing

nozzles on head 1, so we have set the

temperature for extruder 1 to 220°C because

we have been using PLA/PHA with our nozzles.

5. Changing Nozzles, Filament Guide Tubes, and BuildTak

Your Stacker printer comes with four 0.50mm mid temp nozzles pre-installed. The 0.50mm nozzles

provide a good balance between printing speed and detail. Nonetheless, we recommend

experimenting with different nozzle sizes because changing your nozzle size can increase print

speeds (with larger nozzle sizes) or improve the fine detail of your prints (with smaller nozzle sizes).

A variety of nozzles are available from our website http://stacker3d.com/product/3d-printer-nozzles/.

Although nozzles and filament guide tubes can last for hundreds of hours of operation, both the

nozzles and filament guide tubes are wear parts which will eventually need to be replaced to

maintain optimal printing performance.

The following steps will instruct you on how to properly remove and install new nozzles and filament

guide tubes. Please follow these steps VERY CAREFULLY. Improper installation of nozzles or

filament guide tubes will result in poor quality prints and filament jams.

5.1. Removing Nozzles

STACKER S4 USER GUIDE 29

When the nozzle is hot, release the filament

drive idler assembly and pull out the filament by

hand. Remove the filament completely from

the filament guide tube by hand by pulling the

filament out of the guide tube.

Note: Whenever you return filament to a spool,

avoid filament crossover by pushing the end

of the filament through one of the side holes on

the filament spool. Filament crossover will

prevent the filament from feeding and cause

the printer to jam.

Step 2. Clean up any filament around the tip of the nozzle. While the nozzle is hot, you will be

able to wipe the warm filament from the nozzle and underneath heater block. Use a dry cotton cloth

and wipe the tip of the nozzle and underside of the heater block to remove any filament. NOTE,

THE NOZZLE IS HOT! PROTECT YOURSELF FROM GETTING BURNED! You will want to

thoroughly remove all the filament from underneath the hot end. If you fail to remove all of the

filament, you may experience difficulty removing the heater block in Step 6.

After the nozzle and heater block are clean, TURN OFF THE EXTRUDER and wait for it to cool.

Pressing the Reset/Emergency Stop button will turn off all of the extruders.

STACKER S4 USER GUIDE 30

IMPORTANT: Turn off the heat and wait until the hot end has cooled down

before proceeding with the next step!

Step 3. Remove the Filament Guide Tube Clips and Filament Guide Tube Support Bar. Detach

the filament guide tube clips and the filament guide tube support bar from the grey filament guide

tube sleeve.

Step 4. Remove the Filament Guide Tube from the Filament Drive. Loosen the filament guide

tube support bracket, and then depress the push-fit type fitting with your finger while pulling the

filament guide tube up and out of the fitting. Once the filament guide tube is removed from the

fitting, slide the grey filament guide tube sleeve off the filament guide tube and set it aside.

STACKER S4 USER GUIDE 31

Step 5. Remove the filament guide tube

from the nozzle. Use the supplied nozzle

wrench to release the grip on the push-type

fitting on the top of the hot end heat sink. With

the fitting compressed, gently pull up on the

filament guide tube until it releases from the

nozzle. Pull the tube all the way out and set it

aside.

Step 5a. What to do if your tube is stuck. If

the guide tube is stuck into the nozzle you must

remove the nozzle and guide tube

TOGETHER. Continue following steps with the

guide tube inside the nozzle. In a later step

you will be instructed to use a pliers to remove

the filament guide tube from the nozzle.

Step 6. Remove the heater block assembly.

First disconnect the electrical connector with

your fingernail by pressing down on the tab and

sliding off the connector. DO NOT USE A

PLIERS because pliers can easily damage

these small plastic connectors.

Next, using a 1.5mm hex wrench, loosen the

two heater block screws on the right side of the

block. These screws hold the block to the

nozzle. Once loosened, the heater block

should slide off the nozzle. If the heater block

will not slide down, then loosen the two screws

a little more until the heater block is free. Be

careful not to drop the heater block because

dropping the block can cause damage to

heater block’s electronics.

STACKER S4 USER GUIDE 32

Step 7. Remove the nozzle. To loosen the nozzle from the heat sink, use the supplied nozzle

wrench or a 5mm wrench to turn the nozzle counterclockwise. Once you loosen the nozzle with the

wrench, you can turn with your fingers unit it is removed.

Step 7a. Removing the nozzle when the Filament Guide Tube is stuck. If the filament guide

tube is still connected to the nozzle because it was stuck (from Step 5a), no worries. Just let the

tube rotate along with the nozzle as you unscrew it with the wrench. Once the nozzle is removed,

twist and turn the guide tube until it can be removed from the nozzle. You may need to use a pliers

to remove the filament guide tube if it is stuck in the nozzle.

SPECIAL NOTE ON FILAMENT GUIDE TUBES. After many hours of use at high temperatures the

filament guide tubes may degrade and get stuck inside the nozzle. If you are unable to remove the

filament guide tubes by hand, use a pliers. If the tube is damaged during removal, then trim the

damaged portion above the point where you gripped it with the pliers. You can usually trim the end

of the tube once or twice before the tube becomes too short for use. We recommend trimming the

end of your tube with a sharp knife at a 90° angle to ensure the end of the tube properly seals within

the nozzle. Make absolutely sure your trim cut is perfectly square. When in doubt, purchase a new

Filament Guide Tube.

5.2. Installing Nozzles

Step 1. Screw the nozzle into the heat sink by hand until it is fully seated. When the nozzle is

finger tight, reverse (and loosen) the nozzle ONE-AND-THREE-QUARTER REVOLUTIONS.

Step 2. Insert the filament guide tube. Check the end of the filament guide tube to be sure it is

cut square and in good condition. If the the tube is not in perfect condition, trim the damaged

portion of the tube with a sharp knife. Install the filament guide tube, and push it all the way into the

nozzle. Make sure the filament guide tube is seated at the bottom of the nozzle! If the guide tube is

not seated within the nozzle, problems can occur with filament extrusion.

STACKER S4 USER GUIDE 33

Step 3. Tighten the nozzle. Use your finger to tighten the nozzle, then use the nozzle wrench to

turn and secure the nozzle. DO NOT OVERTIGHTEN! Just turn the nozzle till it is snug. With the

nozzle snug, look at the filament guide tube to see that the push-type fitting was lifted by the

filament guide tube.

Finally, test for “play” in the filament guide tube system. Take the filament guide tube with your

fingers and pull up and push down. While you push and pull, make sure there is no movement in

STACKER S4 USER GUIDE 34

Step 4. Replace the filament guide tube

sleeve. When the filament guide tube is

attached to the hot end and there is no “play” in

the system, return the grey Filament Guide

Tube Sleeve onto the filament guide tube.

Step 5. Push the filament guide tube into the

grey filament guide tube sleeve toward the hot

end to remove any slack.

Step 6. Hold the grey sleeve with both hands as shown. While pushing and holding the tubes

together with one hand above the hotend, insert the opposite end through the filament guide tube

mounting bracket as shown. The gray sleeve will be held in position with the mounting bracket,

the tube. If the tube and fitting moves up and down, even a little bit, remove the nozzle and go back

to Step 1 and carefully redo each step again.

STACKER S4 USER GUIDE 35

and the inner tube will be inserted into the fitting. The filament guide tube will descend

approximately 20mm into the fitting.

Step 7. By turning the grey filament guide tube

sleeve, you can manipulate the tube’s arc. You

want the arc to stand as tall as possible.

Step 8. Once turned to the correct position,

tighten the screws on the filament guide tube

bracket to secure the grey sleeve tube in place.

STACKER S4 USER GUIDE 36

Step 9. Reattach the filament guide tube clips

and to secure the wire harnesses and guide

tubes together, then attach the filament guide

tube support bar.

5.3. Replacing BuildTak

Your print bed is covered by a thin, durable plastic sheet of BuildTak that adheres to the aluminum

bed. If treated with care, this BuildTak sheet can last for a very long time, but when parts are hastily

scrapped from the build surface, it is possible to damage your BuildTak. Furthermore, the BuildTak

surface will gradually become less reliable over time with heavy use in the same locations. Shifting

the position of parts in your GCODE can reduce the wear upon your BuildTak.

If you wish to clean the BuildTak surface, wipe it down with isopropyl rubbing alcohol. DO NOT use

acetone because acetone will destroy the BuildTak.

Custom BuildTak sheets for Stacker 3D printers are available at www.stacker3d.com.

To replace a sheet of BuildTak,

1. Heat the bed to 50°C.

2. Peel the old worn sheet of BuildTak from the bed.

3. Use isopropyl rubbing alcohol and a clean cloth to wipe the aluminum bed clean.

4. Carefully peel the backing from the new BuildTak sheet.

5. Starting at the front edge of the bed, slowly attach the new sheet while using a

plastic paint scraper to flatten the sheet and remove any air bubbles. Working slowly

and methodically will ultimately provide the best and flattest printing surface.

STACKER S4 USER GUIDE 37

STACKER S4 USER GUIDE 38

6. Printer Calibration

To assist with printer calibration, it is helpful to download and install

Stacker RUN software which is available for free on our website.

● http://stacker3d.com/stacker-3d-printer-support/

Stacker RUN software is an enhanced version of Repetier Host

customized for using Stacker printers. Most of the installation and

documentation available from the Repetier website is applicable. To familiarize yourself with

Repetier Host

● https://www.repetier.com/#documantation

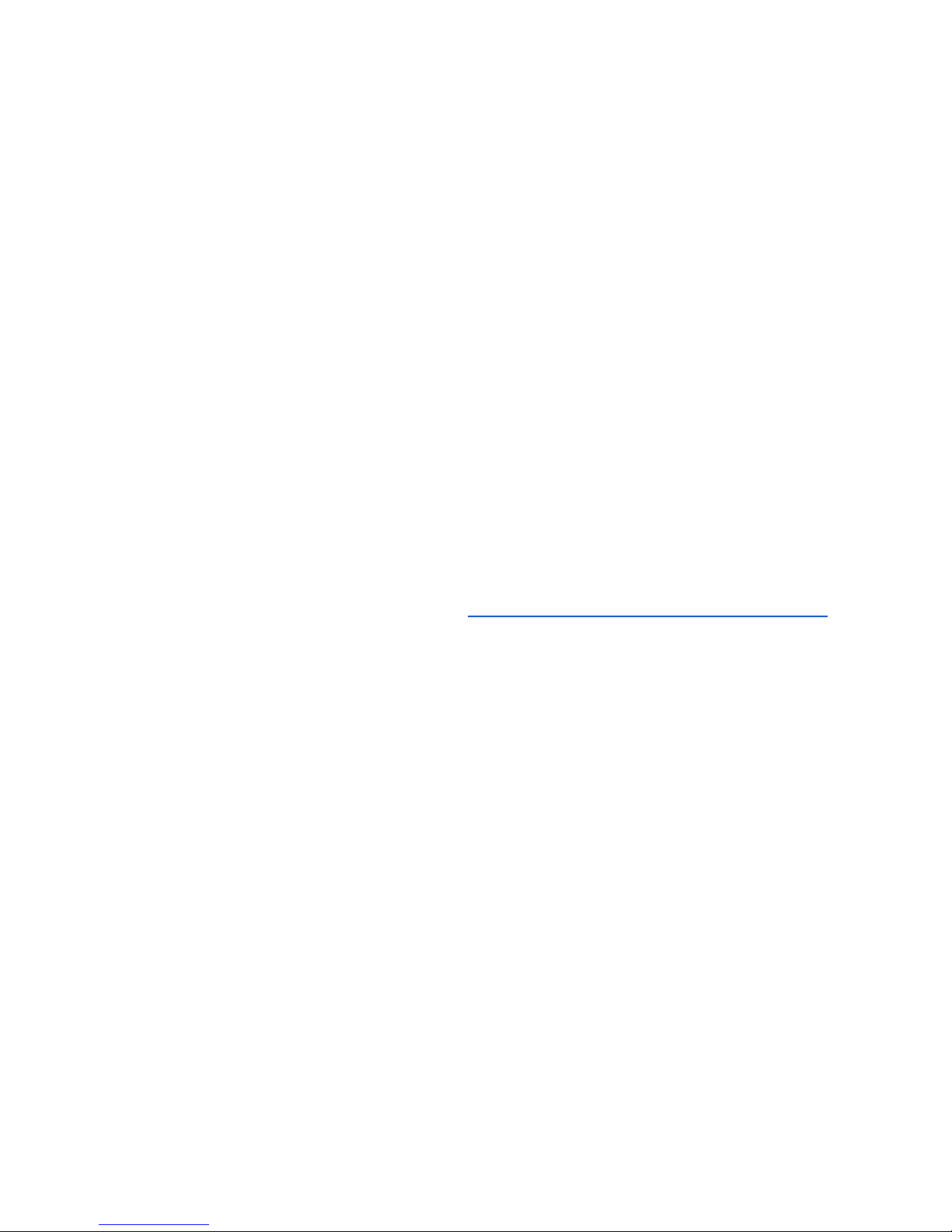

Before attempting to use Stacker RUN, make sure you do not have any other software running

on your computer. If Simplify3D is open, you may be unable to connect to your printer with

Stacker RUN. Turn on the printer and open Stacker RUN. Connect the USB cable between your

computer and the printer. If the USB cable is not connected to your printer, please see chapter 11.1

for instructions on how to install the USB cable.

When all other software has been closed on your computer, click the Connect button located in the

upper left corner of Stacker RUN. A drop down menu will allow you to select the four head model.

, please visit their website.

With some computers, you may need to go into the Printer Settings menu of Stacker RUN and

change the Port setting from Auto to an available COM port. Also note, the Baud Rate should read

250000. In rare cases, some computers seem to have lackluster USB to Serial Bridge

communication. If you are having trouble connecting, even after (1) making sure the printer’s power

is on, (2) making sure the USB cables are connected properly, (3) restarting the computer, and (4)

specifying a specific COM port number within Stacker RUN, then we recommend trying Stacker

RUN with a different computer.

STACKER S4 USER GUIDE 39

When your printer is connected to Stacker RUN, you are ready to calibrate.

6.1. Adjusting First Layer Height

First layer height is critically important to 3D printing. When the printer is calibrated correctly, the

first layer has a perfect amount of “squish”. If your nozzle is too far away from the print bed, the

filament will not adhere properly, and if the nozzle is too close to the print bed, the filament will be

unable to come out of the nozzle and this will inevitably result in the filament stripping out on the

drive gear. Therefore, you want to set all the nozzles at the perfect height.

Although you can alter the layer height in your slicing software, it is always best practice to have

your printer’s actual (mechanical) layer height set perfectly.

Before making any adjustments to your printer, you should first check the gap between the nozzle

and bed with the 0.007”/0.18mm feeler gauge. When sliding the feeler gauge between the nozzle

tip and the bed, you should feel a small amount of friction from the nozzle tip. If there is no friction,

then the nozzle is too high, and if you are unable to slip the gauge between the nozzle and the bed,

then the nozzle is too close to the bed. Be aware that heating the bed will make a difference in the

gap between the nozzle and the bed, so for a more precise test, you should heat the bed to the

temperature you will be using for your print.

When confirming the gap between the bed and nozzle, all four nozzles should have the same gap.

By sliding the feeler gauge between each nozzle and the bed, the friction you feel should be very

similar. If you notice inconsistency in the gaps when comparing nozzles, you might need to perform

some advanced calibration (see section 10.1 and 10.2) to make sure all of the nozzles have equal

gaps. .

The nozzle gap is changed by turning the Z-height adjustment screw with a 2.5mm hex wrench.

Turning the screw clockwise (making the screw go upward) will LOWER the bed upon rehoming the

Z-axis (increase first layer height). Turning the knob counterclockwise will RAISE the bed into the

nozzles upon rehoming the Z-axis (decreasing first layer height). Each full rotation of the Z-height

STACKER S4 USER GUIDE 40

adjustment screw will change the layer height by ±0.2756”/0.7mm, so making quarter-turn

adjustments is often sufficient to make noticeable changes in the first layer height.

After making any change to the Z-height adjustment screw, you will need to re-home the Z-Axis with

either Stacker RUN or the LCD controller (►Main Menu » Position ►Home Z) and then test the

nozzle gap again. It is good practice to move the gantry all the way forward on the printer, so the

nozzles cannot crash into the bed if you have adjusted the Z-height incorrectly. Keep in mind, it

may take multiple attempts at turning the Z-height adjustment screw before you determine the

perfect position.

6.2. Volumetric Calibration

One secret to accurate prints and beautiful surface finish is proper volumetric flow control. Stacker

3D printers use four variables to control volume: (A) filament diameter, (B) filament drive E-STEPS,

(C) nozzle size, and (E) extrusion multiplier. Slicing engines use these variables to determine

exactly how much filament to extrude. Therefore, it is essential to set these variables carefully and

accurately for the best quality prints.

A. Filament Diameter

Stacker printers use 1.75mm diameter filament. It is very important to use filament with a highly

consistent diameter. A reason why Stacker sells and recommends colorFabb filaments is because

colorFabb uses highly advanced laser tools for precise diametric measurements, as well as a host

of other controls to ensure consistent filament diameters.

Regardless of what filament brand you use, always confirm consistent filament diameter with a

digital caliper. Measure the diameter of your filament in few different places to see if it is consistent.

If the diameter is not consistent, return the filament from where you purchased it. Filament with an

inconsistent diameter will inevitably provide inconsistent results and filament jams.

STACKER S4 USER GUIDE 41

Step 2. Clean the Drive Gear. Release the

filament drive idler bearing assembly and

remove any filament from the filament drive.

Look closely at the drive gear with a bright

flashlight. Turn the gear manually and inspect

it for filament debris. If the drive gear is dirty,

you will not get an accurate measurement

during calibration. Use the filament drive

cleaning brush to be sure the gear is clear of

any filament debris. When the gear is

completely clean, you are ready for the next

step.

Step 3. Insert the Filament: Insert the filament

upward through the small hole beneath the

filament gear, then push the filament upward

past the gear and through the filament guide

just above the gear. To avoid wasting filament

during this measuring process, you do not need

to push the filament all the way to the extruder.

Push the filament so it has just entered the

filament guide tube and then reattach the idler

bearing assembly. Note, you have preheated

your extruders just in case the filament is

advanced to the hot ends during this test.

B. Test Filament Drive E-STEPS

Calibrating your filament drive E-STEPS (extruder steps

) is essential to achieving the best quality

prints, and it should be done every time you change filament types or brands.

The calibration process only takes a few minutes and does not require you to waste filament. The

only tools you will need is the filament guide cleaning brush, a metric ruler, a calculator, and an ink

pen for marking the filament.

Step 1. Preheat the Extruder. Preheat your extruder to the filament’s required temperature.

STACKER S4 USER GUIDE 42

Step 4. Mark 120mm of filament: With a pen

and ruler, mark the filament at 120mm.

Step 5. Extrude 100mm of Filament: Open

Stacker RUN, connect to your printer, and use

the Manual Control tab to extrude exactly

100mm of filament.

STACKER S4 USER GUIDE 43

After attempting to extrude 100mm, measure to

see what was actually extruded and write down

the number. Because you marked 120mm and

extruded 100mm, your mark should show

20mm of filament. In other words, you

extruded 100mm of filament, so you should

have 20mm of filament remaining. In the image

to the right, we extruded 115mm of filament

because we only measure 5mm of filament.

For example, I attempted to extrude 100mm of filament but the printer actually extruded 115mm

of filament, so I would get the following result:

100 ÷ 115 = 0.869565

Because my current “steps per mm” in the EEPROM is set to 255, I would do the following:

0.869565 x 255 = 221.739

Step 6. Open your EEPROM window in Stacker RUN by pressing Alt+E or select “Firmware

EEPROM Configuration” under the Config menu to see your current E-STEPS for each extruder.

To calculate the new E-STEPS number, use this formula:

( 100mm ÷ Your Measurement ) x ( Your current E-Steps ) = Your New E-Steps

STACKER S4 USER GUIDE 44

Thus, in this example, I should change the “steps per mm” from 255 to 221.739.

Step 7. Enter your new E-Steps for your extruder, but before you start printing, be sure to confirm

these results. Go back and repeat steps 4 through 6 again to confirm your E-Steps setting.

C. Verify Nozzle Size

Stacker nozzles use a system of small machined dots around the tip for identification purposes. Be

sure to enter the correct nozzle size in your slicing software. Stacker’s standard nozzle size is

0.5mm, also called a 050 nozzle, and these were pre-installed on your printer.

A Note about Stacker’s MID and HIGH temp nozzles: For most filaments and

applications, it is best to use our MID temp nozzles. Our HIGH temp nozzles are only

necessary when using filaments which require temperatures between 275°C and 300°C.

HIGH temp nozzles are identified by a special machined “band” to distinguish them from our

MID temp nozzles.

D. Extrusion Multiplier

For even finer volumetric calibration you can adjust the extrusion multiplier in your slicing engine.

Most filaments will print very accurately with a 100% extrusion multiplier setting in your slicing

engine. Nevertheless, some filaments like XT-CF20 Carbon Fiber filament will over extrude due to

die swell, and will therefore require a lower extrusion multiplier, often a multiplier of 0.95 is sufficient

to compensate for die swell, but sometimes a multiplier as low as 0.88 is necessary. Printing a

simple single wall test cube will allow you to verify the accuracy of your print widths.

STACKER S4 USER GUIDE 45

6.3. PID Calibration

The PID controller on your printer continuously adjusts the power sent to the hot ends and heat bed

in an effort to maintain efficient and consistent temperatures. When the PID settings are incorrect,

the temperature changes of your bed and hot ends can affect your prints. Variations in nozzle

temperatures over a short time may not seem like a problem, but in extreme cases, wide

temperature variations during operation can cause stringing, blobs, or even clogged nozzles. To

best control temperatures, you should run a PID autotune on each of your nozzles. Whenever you

change a heater block, you should always perform a PID autotune and make the necessary

changes to your EEPROM.

To run a PID autotune, you will need to open Stacker RUN and enter the flowing text into the

manual control line.

M303 e0 s240

We should explain that command: M303 is the GCODE command to run a PID Autotune. The “e” is

referring to the extruder number; whereby, e0 = head 1, e1 = head 2, e2 = head 3, and e3 = head 4.

The “s” is setting the temperature, 240°C in our case. Therefore if you were going to run a PID

Autotune on head 2 at 240°C, you would type the following line into Stacker RUN:

M303 e1 s240

Whenever you run PID Autotune from Stacker RUN, you want the heaters to start at room

temperature!

will be invalid.

When Stacker RUN has completed the PID Autotune, you will see three sets of PID numbers with

the letters “Kp”, “Ki”, and “Kd”. Always use the first set of “p”, “i”, and “d” numbers. Enter these

numbers into your EEPROM for the corresponding nozzle you test.

Classic PID

Kp: 8.94

Ki: 0.51

Kd: 20.00

If you are calibrating all four nozzles, then you will need to run the PID autotune four times -- once

for each head.

If the heater blocks begin at a temperature other than “cold

”, then your PID results

STACKER S4 USER GUIDE 46

7. Multi-Head Printing

The Stacker S4 has four printheads, and these heads can be used to print the same part in different

materials, at the same time. When printing copies of the same part, this is called multi-part print

mode

. When using a certain number of printheads to print one part with different materials, it is

called multi-material print mode

7.1. Multi-part Print Mode

With Stacker’s multi-part print mode, each extruder can print a copy of whatever is being printed by

the first extruder. In other words, selected extruders will duplicate (copy) the movements of the first

extruder. Because the S4 has four heads, you are able to print up to four copies in multi-part print

mode.

Step 1. Spacing and Securing the Extruder Heads. In multi-part print mode, each of your heads

will operate on only a portion of the print bed. You must space your printheads apart at specific

distances along the X gantry depending upon the number of printheads you will be using. Use the

“Print Head Spacing Guide for 2/3/4 Copies” on the print bed to determine the locations of the

heads you will be using.

.

For example, if you were printing three copies, then you will be using three heads, and they would

be positioned in the locations shown below.

STACKER S4 USER GUIDE 47

Print Mode

Area (X-Axis)

Area (Y-Axis)

Area (Z-Axis)

No Copies

380

365

625

1 Copy

220

365

625

2 Copies

150

365

625

Once the heads have been positioned along the gantry where indicated by the guide, secure the

heads by pushing the belt clamp bracket upward with your finger and and securing it with the

2.5mm hex driver. Once tightened, make sure it is secure by moving head one. When head one

moves, all of the secured heads should move together along the X-gantry in tandem.

It is best practice to slide the unused heads to the right side of the gantry away from the printing

heads. Be careful to avoid tripping the X-Max End Stop with unused heads.

Step 2. Set Extrusion Mode. To set the number of printheads you will be using in multi-part print

mode

, use the LCD to set the number of copies you wish to print. ►Main Menu » Extruder » (■ 1

Copy/■ 2 Copies/■ 3 Copies).

Be aware that when you are printing in multi-part mode

changes depending upon the number of printheads you are using in multi-part mode

, the total build volume available on the bed

.

STACKER S4 USER GUIDE 48

3 Copies

120

365

625

When using multi-part printing, it is a good idea to adjust the bed size in your preferred slicing

engine, so you see the actual space available for part placement.

Step 3. Run your print. If the spacing is correct, you will be able to print multiple copies of the

same parts.

7.2. Multi-material Print Mode

Printing in multi-material mode is for advanced users and requires a good understanding of the

operation of your Stacker printer and Simplify3D. Multi-material printing involves a critical process

of calibration, and if calibration is not performed correctly, the results will be imperfect. Before

attempting multi-material

printing, Stacker recommends viewing the Simplify3D tutorials to learn the

basics about slicing your objects for multi-material printing.

Because the calibration process for multi-material printing is time consuming, we recommend you

record your settings. In the future, when you switch between multi-material printing and normal

printing, you will be able to easily enter your previous settings into the EEPROM of StackerRUN to

speed the calibration process.

A. Dual Color Prints (2 Head Printing)

Step 1. Set the X Offset for Extruder 2. To begin, remove heads three and four from the X rail

(see section 7.3 for hot end removal instructions). Position head two approximately 150mm from

head one and attach head two to the belt. With head two secured to the belt, use a caliper to

measure the exact distance between the nozzle tip of head one and the nozzle tip of head two.

Connect the printer to StackerRUN and open the EEPROM to enter the offsets. Note, StackerRUN

uses steps per millimeter rather than millimeters, so you must multiply your offset distance

STACKER S4 USER GUIDE 49

measurement by the number of X-axis steps per mm to get the distance in steps for the Extr.2

X-Offset.

For example, if your X-axis steps per mm is 146.1, then you would multiply 146.1 by the

exact distance you measured between the two nozzle tips. Thus, if the nozzle tips were

151mm apart, then 146.1 x 151 = 22,061.10 steps.

Enter the resulting number of steps into the Extr.2 X-offset in the EEPROM. The offset in the

EEPROM will be your starting point, and you will make fine adjustments to this setting using the

LCD after you perform a test print.

Step 2. Prepare your Print in Simplify3D. The Dual Extrusion Wizard in Simplify3D is a useful tool

to prepare your model for printing with two heads. Be sure to view the tutorials on the Simplify3D

website to better understand how to use this wizard. The bullet points below are essential

components for successful two head prints:

● When placing the model, be sure to position it to the far left side of the bed. The

model will automatically reposition to accommodate for the offset, so you want the

model placed as fart to the left as possible.

● You will need to bring in two models for dual color prints. Use the Dual Extrusion

Wizard to align models and establish a grouped process.

● If you are printing with support structures, then be sure to only have the model that

gets support selected and manually place the supports.

● Assign ONLY the ooze shield to extruder 1 and ONLY the wipe and prime tower to

extruder 2.

Step 3. Perform a Test Print. It is best to perform a simple test print to precisely calibrate the X

and Y offsets. We recommend printing a simple dual color calibration object such as the “Dual

Extruder Calibration Print” (http://www.thingiverse.com/thing:533814). Looking at a simple

calibration print and measuring the offset error with a calipers enables you to make small

adjustments to the X and Y offsets.

To make these small adjustments to the X and Y offsets use the LCD controller. Select ►Main

Menu » Configuration » Extruder » Select extr. 2 » X-offset (or Y-offset). Enter the distance for

the offset in mm.

For example, on the test print below, you can see that the silver filament is 0.75mm to the left of

where it should have been printing, so we need to add 0.75mm to the X-offset.

STACKER S4 USER GUIDE 50

Number of Print Heads

on X-Rail

Maximum X travel

distance of head 1

4

3

2

1

390mm

430mm

470mm

510mm

You may need to reprint the test print several times to precisely dial in the settings. Once your X

and Y offsets have been precisely calibrated, you are ready to slice and print your object.

B. Three Color, Four Color, or Multi-material Prints (3 or 4 Head Printing)

The process of calibrating the printer for using three or four heads is nearly an identical process to

dual color printing. Because of the limited travel distance available on the X-rail, you should

position your heads together as a group depending upon the size of the object you are printing.

Because the nozzles are approximately 40mm apart, the expected offsets would be 40mm for

Extruder 2, 80mm for Extruder 3, and 120mm for Extruder 4. Of course, printing a simple

calibration print will help with fine tuning these offsets.

Unfortunately, having the heads positioned together as a group can cause scarring and oozing of

filament on your print, but careful slicing and placement of custom wipe and prime towers can

alleviate many of these problems.

7.3. Removing Print Heads

Depending upon the number of print heads used for a print, any unused hot ends on the X-rail will

reduce the total available print area along the X axis. Each hot end attached to the X-rail reduces

the total available movement by approximately 40mm. Therefore, removing unused hot ends from

the the X-rail will increase the maximum available print area.

On the Stacker S4, you can remove the second, third, and fourth hot ends fairly easily. The first hot

end should never be removed from the printer.

STACKER S4 USER GUIDE 51

Whenever removing hot ends, it is critical that the electrical connections are not detached. If the

wires are disconnected from the hot end, the printer will go into an error state.

When removing one or more hot ends, please follow these steps:

Step 1. Make sure the hot ends are turned off. Confirm that your hot ends are at room

temperature to avoid injuring yourself or damaging the printer. If your hot ends are not at room

temperature, reduce the temperature and wait for them to cool before attempting to detach the hot

end from the X rail.

Step 2. Remove Guard Plate. On the printer frame, use a 2.5mm hex driver to remove the two M3

x 6mm screws and lock washers holding the guard plate in place.

Step 3. Remove Belt Clamp Bracket. On the rear of the hot end, use a 2.5mm hex driver to

remove the two M3 x 8mm screws attaching the belt clamp bracket. After the screws are removed,

slide the belt clamp bracket from the hot end.

STACKER S4 USER GUIDE 52

Step 4. Carefully slide the hot end from the linear rail. Using the space opened by removing the

guard plate, carefully and slowly slide the hot end to the right to remove it from the linear rail.

BE CAREFUL! Whenever a hot end is removed is removed from the rail, you

must handle it very carefully. The linear block which attaches to the linear

rail uses tiny recirculating ball bearings for movement, and if any of these

ball bearings fall out of the block, it will lead to catastrophic failure of the

movement system. Always handle the hot ends carefully to prevent any

damage to the linear blocks!

Step 5. Carefully Handle and Store the Removed Hot Ends. Because the electrical wires must

remain attached to the printer, it is best to attach the hot end directly to the printer. Ideally, the hot

ends should be attached to our Hot End Storage Rail (p/n 50-052).

3

3

The Hot End Storage Rail (p/n 50-052) is sold separately.

STACKER S4 USER GUIDE 53

Step 6. Reattach the Guard Plate. After the heads have been removed and stored carefully,

reattach the guard plate that was removed in Step 1.

STACKER S4 USER GUIDE 54

8. Basic Printer Maintenance

Other than periodically replacing nozzles, filament guide tubes, and BuildTak as needed, the basic

maintenance required on a Stacker 3D printer is minimal.

8.1. Keep Your Printer Clean

Inevitably, from regular use, small bits of filament debris will land on your printer. You must

periodically remove this filament debris to protect your printer from damage. The combination of

blower fans and small bits of filament can result in debris landing upon the moving parts of your

printer. Clean filament debris to prevent damage to your printer’s moving parts.

8.2. Linear Guides

The linear rail system on the S4 uses recirculating linear bearings and profile rail guides. For

optimal performance, lubrication of these parts is essential. Lubrication promotes smooth

operation, minimizes friction and wear along the raceways, dissipates heat, and prevents corrosion.

The absence of proper lubrication will eventually lead to machine failure.

The frequency with which you will need to re-apply lubricant to your linear rail system will largely

depend upon use and environmental conditions. More humid environments will generally require

more frequent re-application of lubricant to protect the printer’s raceways from rust.

Z Rails: To lubricate the vertical Z rails, use Mobil 1™ Synthetic Grease. Lightly apply the

grease to the entire rail. Run the bed up and down a couple times, and then use a clean dry

cloth to remove any excess grease.

X/Y Rails: To lubricate the horizontal X and Y rails, apply a 40 to 90 weight 100% synthetic

oil to a cloth and apply liberally to the raceways. Then manually slide the blocks by hand to

work the oil into the blocks. Finally, use a clean dry cloth to remove any excess oil by wiping

down the raceways

STACKER S4 USER GUIDE 55

9. CONTROLS

9.1. Manual control via Stacker RUN

A. Overview of controls.

The manual control panel in Stacker RUN allows you to make incremental movements and home

the X, Y, and Z axes, manually extrude or retract filament, turn on extruders, fans, and the heat bed.

You can also manually adjust temperatures for the heat bed and extruders. Learn more about the

manual control panel on the Repetier website:

● http://www.repetier.com/documentation/repetier-host/rhmanual-control/

B. Sending G-code to the printer.

From the manual control panel, Stacker RUN can accept most G-code commands. For advanced

users this can be quite helpful. Here is a list of the most codes that are compatible with Stacker.

Implemented Codes

● G0 [X/Y/Z] [Position] - Rapid movement to position

● G1 [X/Y/Z/E] [Position]- Coordinated Movement to position

● G4 [S/P] - Dwell / Wait in ms

● G20 - Set units for G0/G1 to inches.

● G21 - Set units for G0/G1 to mm.

● G28 [X/Y/Z] - Home all axis or named axis.

● G90 - Use absolute coordinates

● G91 - Use relative coordinates

● G92 [X Position/Y Position/Z Position/E Position] - Set position to coordinates given

RepRap M Codes

● M104 S[temperature] - Set extruder target temp

● M105 - Read current temp

● M106 S[0-255] - Set fan speed

● M107 - Fan off

● M109 S[temperature]- Wait for extruder current temp to reach target temp

● M112 - Emergency stop

● M114 - Display current position

Custom M Codes

● M20 - List files on SD card

STACKER S4 USER GUIDE 56

● M21 - mount SD card

● M22 - unmount SD card

● M23 [filename] - Select an SD file for printing

● M24 - Pause/resume SD print

● M25 - Pause SD print

● M26 S[bytes]- Set SD position in bytes

● M27 - Report SD print status

● M28 [filename] - Write program to SD card

● M29 [filename] - Stop program write to SD card

● M82 - Set E codes absolute (default)

● M83 - Set E codes relative while in Absolute Coordinates (G90) mode

● M84 S[value]- Disable steppers until next move, or use S to specify an inactivity timeout, after which the steppers

will be disabled. S0 to disable the timeout.

● M85 S[Value]- Set inactivity shutdown timer with parameter S. To disable set zero (default)

● M92 [X Position/Y Position/Z Position/E Position] - Set axis steps per unit

● M115 - Capabilities string

● M140 S[Target Temperature] - Set bed target temp

● M190 - Wait for bed current temp to reach target temp.

● M201 X[value] Y[value] - Set max acceleration in units/s^2 for print moves (e.g., M201 X1000 Y1000)

● M202 X[value] Y[value] - Set max acceleration in units/s^2 for travel moves (M202 X1000 Y1000)

● M203 S[value]- Set temperature monitor to Sx

● M204 X[Kp] Y[Ki] Z[Kd] - Set PID parameter. Values are 100*real value!

● M205 - Output EEPROM settings

● M206 - Set EEPROM value

● M231 S[OPS_MODE] X[Min_Distance] Y[Retract] Z[Backslash] F[Retract Move] - Set OPS parameter

● M232 - Read and reset maximum advance values

● M280 S0 - Print single head only (cancels ditto mode for more than one head)

● M280 S1 - Ditto print mode for heads 1 and 2 (for making two copies at same time)

● M280 S2 - Ditto print mode for heads 1, 2 and 3 (for making three copies at same time)

● M280 S3 - Ditto print mode for heads 1, 2, 3 and 4 (for making four copies at same time)

9.2. LCD Controls

The LCD controller is a very powerful tool for operating your printer. For most users, the LCD

controls will be used for basic functions like warming up the printer’s nozzles and bed, and starting

and stopping prints. The following section is provided for the advanced users. The LCD menus

provide powerful tools to do just about anything you can do with Stacker RUN. Always be careful

when making changes to your printer’s settings through the LCD.

Default Screen

STACKER S4 USER GUIDE 57

Back ┘

Quick Settings »

Position »

Extruder »

Fan Speed »

SD Card »

Debugging »

Configuration »

Back ┘

Home All

Z babystep. : 0.00mm

Speed mul. : 100%

The Stacker splash screen will appear briefly on your LCD screen during startup. When the splash

screen vanishes, you will see the default screen. The default screen divided into four quadrants

which provide basic information about the printer’s status.

● The top left quadrant shows the actual extruder and bed temperatures, as well as, the

temperatures the bed and extruder are attempting to reach. In the image above, the bed

and extruder are both showing about 25°C which is near room temperature, and they are set

to a temperature of 0°C, so the extruders are turned off. Below the temperatures, it shows

the number of copies selected. On our screen, it shows 0 copes which means multi-part

mode has not been turned on and the printer will only print with head one.

● The lower left displays the speed multiplier and the buffer number.

● The upper right shows the position of extruder one. In our case, the printhead has been

homed to the X, Y, Z position of 0,0,0.

● The lower right quadrant shows the amount of filament that has been extruded during the

print. In our case, the number is 0.00m.

►Main Menu

By pressing the controller once knob, you will open the main menu. From the main menu, you can

choose from a number of a number of sub-menus by turning the knob and depressing it to make

your selection. If you ever wish to go back, select “Back ┘” from the menu to return to the previous

screen.

►Main Menu

►Main Menu » Quick Settings

STACKER S4 USER GUIDE 58

Flow mul. : 100%

Change filament

Preheat PLA

Preheat ABS

Cooldown

Set to origin

Disable stepper

Back ┘

Home All

Home X

Home Y

Home Z

X pos. Fast

X position

Y pos. Fast

Y position

Z pos. Fast

Z position

Extr. position

Set print offsets

»

»

»

»

»

»

»

»

Home All: The X, Y, and Z axes will all move to their home positions.

Z babystep: Will move Z axis incremental distances around 0.01mm per click.

Speed multiplier: While you are printing, this will override the programed rate of movement to increase or decrease the

actual print speed by a percentage.

Flow multiplier: While printing, this will override the programmed filament feed rate to increase or decrease the amount

of filament extruded by a percentage.

Change filament: Drops bed a small amount and enables filament to be changed.

Preheat PLA: Unfortunately, these settings are incorrect for Stacker, but Extruder 1 will be set to 190°C and the bed

temperature will preheat 60°C.

Preheat ABS: Unfortunately, these settings are incorrect for Stacker, but Extruder 1 will be set to 240°C and the bed

temperature will preheat 110°C.

Cooldown: Will turn off the temperatures to allow the printer to cool down prior to turning off the printer.

Set to origin: n/a

Disable Stepper: Turns off the X and Y stepper motors enabling the user to easily move the X/Y gantry by hand.

►Main Menu » Position

Home All: The X, Y, and Z axes will all move to their home positions.

Home X / Home Y / Home Z: Will move the selected axis to its home position.

X pos. Fast / Y pos. Fast / Z pos. Fast: Enables user to change the selected axis position quickly by turning the knob.

Each rotated click moves the axis about 10mm.

X position / Y position / Z position: Enables user to make small changes the chosen position by turning the knob. Each

rotated click moves the axis about 1mm.

Extr. Position: Advance or retract the filament by turning the knob right or left. Note, be sure your extruder is hot

before attempting to advance filament into the extruder. Filament will not move through a cold extruder, and your

filament will strip in the filament drive.

Set print offsets: Allows you to set print offsets for X, Y, and Z in mm.

►Main Menu » Extruder

Back ┘

Bed temp: 25.0/ 0°C

Temp. 1 : 25.5/ 0°C

Temp. 2 : 25.5/ 0°C

Temp. 3 : 25.5/ 0°C

Temp. 4 : 25.5/ 0°C

Turn extr. 1 off

Turn extr. 2 off

Turn extr. 3 off

Turn extr. 4 off

■ Select extr. 1

■ Select extr. 2

■ Select extr. 3

■ Select extr. 4

Ext. position

Set Origin

■ No copies

■ 1 copy

■ 2 copies

■ 3 copies

»

Back ┘

Turn Fan Off

Set Fan 25%

Set Fan 50%

Set Fan 75%

Set Fan Full

Ignore M106 cmd ■

STACKER S4 USER GUIDE 59

Bed temp: Turning the knob will allow you to adjust the bed temperature. The temperature on the right shows the current

temperature of the bed, and the temperature on the left displays the temperature you have requested Adjustments made

during a print will override any GCODE bed temperature settings.

Temp. 1 / Temp 2. / Temp 3. / Temp. 4: Turning the knob will allow you to adjust the extruder temperature. The

temperature on the right shows the current temperature of the extruder, and the temperature on the left displays the

temperature you have requested Adjustments made during a print will override any GCODE bed temperature settings.

Turn extr. 1 off / Turn extr. 2 off / Turn extr. 3 off / Turn extr. 4 off: The extruder selected will be turned off, i.e., the

temperature will immediately be set to 0°C.

Select extr. 1 / Select extr. 2 / Select extr. 3 / Select extr 4: Selects an extruder that will be affected by changes.

Ext. position: Makes changes to the extruder position.

Set origin: This will reset the feed position counter.

No copies / 1 copy / 2 copies / 3 copies: When printing with multi-head mode and making copies of a print, No copies

will only operate extruder 1, 1 copy will enable extruder 1 and extruder 2 to perform duplicate movements, 2 copies will

enable extruders 1, 2, and 3 to perform the same movements, and 3 copies will enable all of the heads to make the same

movements.

►Main Menu » Fan Speed

Turn Fan Off: Shuts down the fan.

STACKER S4 USER GUIDE 60

Back ┘

Print file

Pause print

Resume print

Delete file

Back ┘

Echo

Info

Errors

Dry Run

:Off

:On

:On

:Off

Back ┘

General

Language

Acceleration

Feedrate

Extruder

Heating bed

Store to EEPROM

Load f. EEPROM

»

»

»

»

»

»

»

»

Set Fan 25% / Set Fan 50% / Set Fan 75% / Set Fan Full: Adjusts the blower fan speed on the print from 25% to 100%.

Ignore M106 cmd: Turning this feature on will override any GCODE commands regarding the fan for the remainder of the

print. Therefore you can manually set a fan speed, and the GCODE will not override your manual setting.

►Main Menu » SD Card

Print file: Selecting this option will open a list of files available on the SD card. You can browse and select the file you

wish to print. The selected print will begin immediately

Pause print: To temporarily stop the printing process, pause print will move heads close to Y-max position.

Resume print: This will resume a paused print, and continue the print where it left off.

Delete file: This will permanently remove the selected file from the SD card.

.

►Main Menu » Debugging

Echo: Will enable sending feedback to your host (a PC connected to the printer). To prevent communication errors, it is

best to leave the echo off

Info: Will send diagnostic messages to your host (a PC connected to the printer).

Error: Error messages will be sent to your host (a PC connected to the printer).

Dry Run: If turned on, your printer will ignore any extrusion commands. This is a useful method to watch the movements

of your printheads without wasting any filament.

.

►Main Menu » Configuration

ATTENTION: Be careful with the Configuration menu items. Altering values

in the Configuration menu can have major effects upon the printer. Read and

be sure to fully understand the ramifications of the setting you are changing

before making any changes within the Configuration menu. Improper

settings can damage your printer.

STACKER S4 USER GUIDE 61

Back ┘

Baudrate

Stepper inactive

Max. inactive

Autolevel:

250000

»

»

Off

Back ┘

English

Deutsch

Expanol

Portugues

Francais

Nederlandse

Italiano

Svenska

Cestina

Polski

Türk

Back ┘

Print X

Print Y

Print Z

Move X

Move Y

Move Z

Jerk

Z-Jerk

: 800

: 800

: 50

: 1000

: 1000

: 50

: 15.0

: 0.3

►Main Menu » Configuration » General

Baudrate: This should be set to 250000.

Stepper inactive: This sets a timer as to when the stepper motors to power off after remaining idle for a specified amount

of time.

Max. inactive: This sets a timer as to when the extruders and heated bed are powered off after remaining idle for a

specified amount of time. Note, this has been turned off to allow your GCODE to control heat power off.

Autolevel: Should be set to Off.

►Main Menu » Configuration » Language

The language menu allows to to change all of the menus on the LCD to one of the listed languages.

►Main Menu » Configuration » Acceleration