查询VS6552供应商

VS6552

VGA Color CMOS Image Sensor Module

FEATURES

■ Small physical size

■ Ultra low power standby mode

■ SmOP (Small Optical Package) technology

featuring integrated lens

■ Class leading low light performance

■ VGA resolution sensor

■ Compatible with STV0974 companion mobile

processor

■ High frame rate to minimize image distortion

■ Low EMI link (VisionLink) to STV0974

■ On-chip 10-bit ADC

■ Automatic dark calibr ati on

2

■ I

C communications

■ On-chip PLL

DESCRIPTION

The VS6552 is a VGA resolution SmOP sensor

module. SmOP technology combines the image

sensor and fixed focus lens system in a single

module. This approa ch provides a nu mber of advantages:

– SmOP technology is suitable for high volume

manufacturing

– S mOP can be plugged into a PCB mounted

flow soldered socket

– SmOP can be mounted close to noisy RF

source as differential signalling used to

transmit data has good immunity from radio

interference.

The sensor outputs raw Bayer colorized data to

the STV0974 companion mobile processor.

STV0974 then perf orms all color processi ng and

exposure control functions before outputting the

data in an appropriate interface format like YCbCr,

RGB or JPEG.

VS6552 offers an ul tra low power standby mode

that consumes less than 15 µW.

The SmOP lens has been designed to combine

class leading low light performance with good

depth of field to ensure excellent overall optical

performance. The lens is a 2 element moulded

plastic design.

The output data an d qualificatio n clock are transmitted over low noi se, low v oltag e and fu lly d ifferential links. VS6552 configuration registers are

controlled via a private I

2

C interface to STV0974.

APPLICATIONS

■ Mobile phone embedded camera system

■ PDA embedded camera or accessory camera

■ Wireless security camera

Table 1. Technical Specifications

Pixel resolution 644 x 484 (VGA)

Pixel size 5.6µm x 5.6µm

Exposure control +81 dB

Analog gain +24 dB (max)

Dynamic range 60 dB (Typical)

Signal to noise at

2

50cd.m

Supply voltage

Power consumption

Package size

Lens

Package type 14 pad SmOP

37 dB (Typical)

2.8 V (analog supply)

1.8 V (digital supply)

<75 mW (@30 frame/s)

<15 µW (standby mode)

10.7mm x 8.7mm x

6mm:SmOP1.5

9.5mm x 8.5mm x 6.1mm

:SmOP2

o

HFOV, f# 2.8

45

System attach Socket or flexible circuit

Rev. 2

1/26October 2004

VS6552

Table 2. Order Codes

Part Number

VS6552V015/T 2 [ -25; +55 ] °C SmOP1.5

VS6552V02C/T 2 [ -25; +55 ] °C SmOP2M

VS6552V02D/T 2 [ -25; +55 ] °C SmOP2ME

Operating

Temperature

Package

2/26

VS6552

TABLE OF CONTENT

Overview ........................................................................................................................................... 4

Sensor Overview 4

Signal Description ........................................................................................................................... 5

Functional Description .................................................................................................................... 6

Analog Video Block 6

Digital Video Block 6

Device Operating Modes 7

Power Management 7

Clock and Frame Rate Timing 8

Control and Video Interface Formats 9

Electrical Characteristics ................................................................................................................ 9

DC Electrical Characteristics 10

AC Electrical Characteristics 10

ESD Handling Characteristics 13

Optical specification...................................................................................................................... 13

Defect Categorization .................................................................................................................... 13

Pixel Defects 13

Package Mechanical Data ............................................................................................................. 13

SmOP1.5 Module Outline 13

SmOP2 M Module Outline 13

SmOP2 ME Module Outline 13

Application Information................................................................................................................. 23

Socket 23

EMC and Shielding 23

Revision History............................................................................................................................. 25

3/26

VS6552

1 OVERVIEW

1.1 Sensor Overview

The VS6552 VGA image sensor produces raw

VGA digital video data at up to 30 frames per second. The image data is digit ized using an internal

10-bit column ADC. The resulting 10-bit output

data includes embe dded codes for synchronization. The data is formatted and transmi tted over a

fully differential link. The data is accompanied by a

qualifying clock th at is transmitted ov er an identical fully differential link .

The sensor is ful ly config urab le us ing an I

2

C inter-

face.

The sensor is optimized for high volume mobile

applications

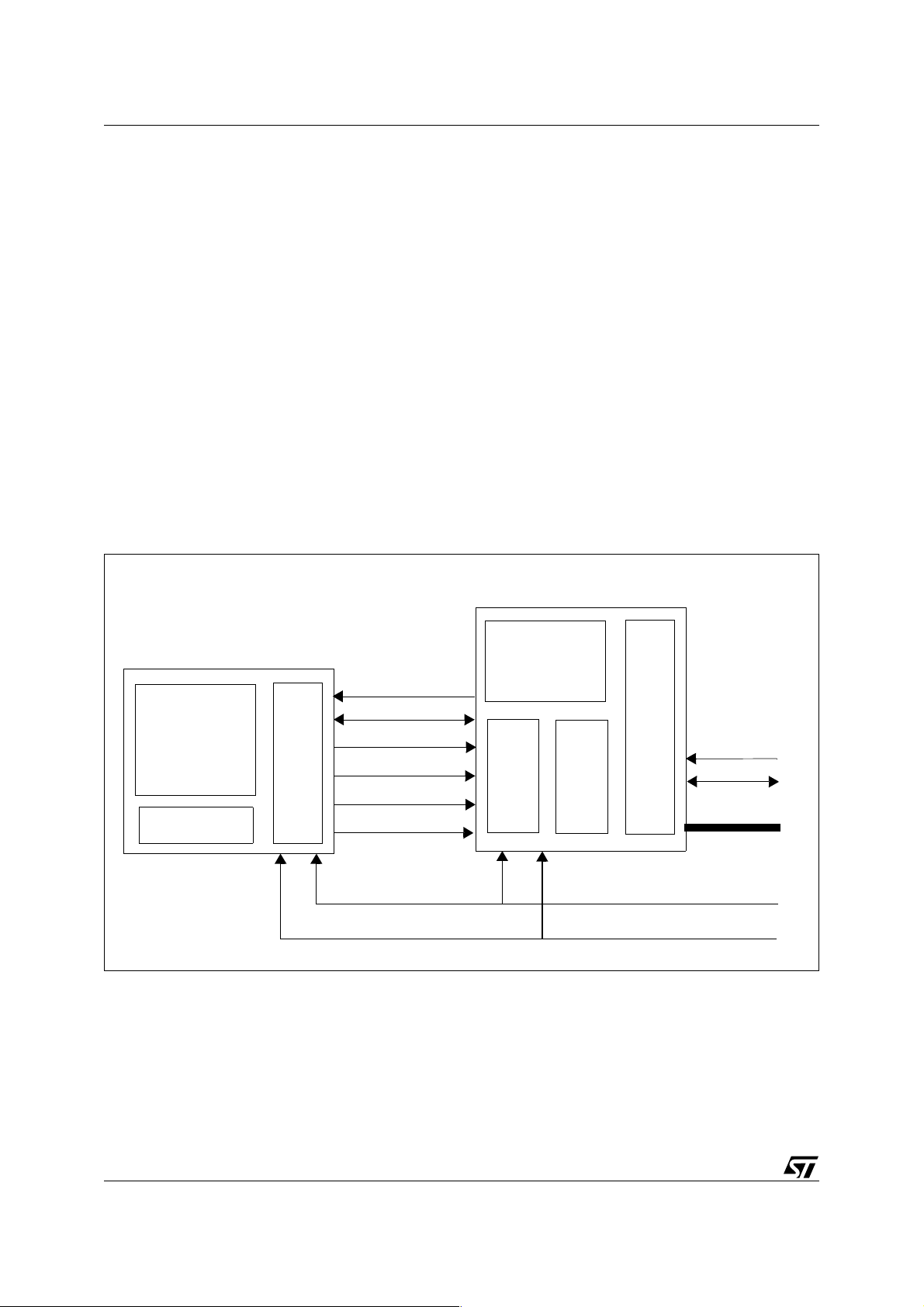

1.1.1 Typical Application - Mobile Application

Figure 1. Camera System Using STV0974

The VS6552 is an image sensor, it should be used

in conjunction with the STMicroelectronics

STV0974 companion processor. The coprocessor

and the sensor together form a complete im aging

system.

The sensors main function is to convert the viewed

scene into a data stream. The companion processor function is to manage the sensor so that it can

produce the best possible data and to process the

data stream into a form which is easily handled by

up stream mobile baseband or MMP chipsets.

The sensor supplies high speed clock signal to the

processor and provides the embedded control sequences which allow the co processor to synchronize with the frame and line level timings. The

processor then performs the color processing on

the raw image data from the sensor before supplying the final image data to the host.

STV0974

VS6552

Pixel

Array

ADC

Microprocessor

MSCL

MSDA

PCLKP

PCLKN

Digital Logic

PDATAP

PDATAN

VP

VC

Interface Logic

SCL

SDA

DIO[0:13]

CLK

PDN

4/26

2 SIGNAL DESCRIPTION

Table 3. Signal Description

Pad Number Pad Name I/O Type Description

Power supplies

VS6552

System

Control

Data

1CEXT PWR

Connection to capacitor

a

2 AGND PWR Analog ground

3 AVDD PWR Analog power

8 GND PWR Digital ground

11 VDD PWR Digital power

4PDN I

Power down control

b

5 CLK I System clock input

6 MSCL I Serial communication clock

7 MSDA I/O Serial communication data

9 PCLKN vLVDS output Output qualifying clock

10 PCLKP vLVDS output Output qualifying clock

12 PDATAN vLVDS output Serial output data

13 PDATAP vLVDS output Serial output data

Not connected

14 Not connected

NC Not connected

a.Internally generated v oltage that needs to be externally decoupled with a 100 nF, 5 V capacitor

b.Signal is active low

Note: The physical position of t he sign als on the pa ckag e can be found by referi ng t o th e pino ut inf ormat ion in Chapter7: Package Mechan-

ical Data.

5/26

VS6552

3 FUNCTIONAL DESCRIPTION

The first sections of this chapter detail the main

blocks in the device:

■ Analog video block

■ Digital video block

The later sections of th is chapter describe other

functional aspects of the de vice. Devic e level op erating modes, including suspend, are detailed

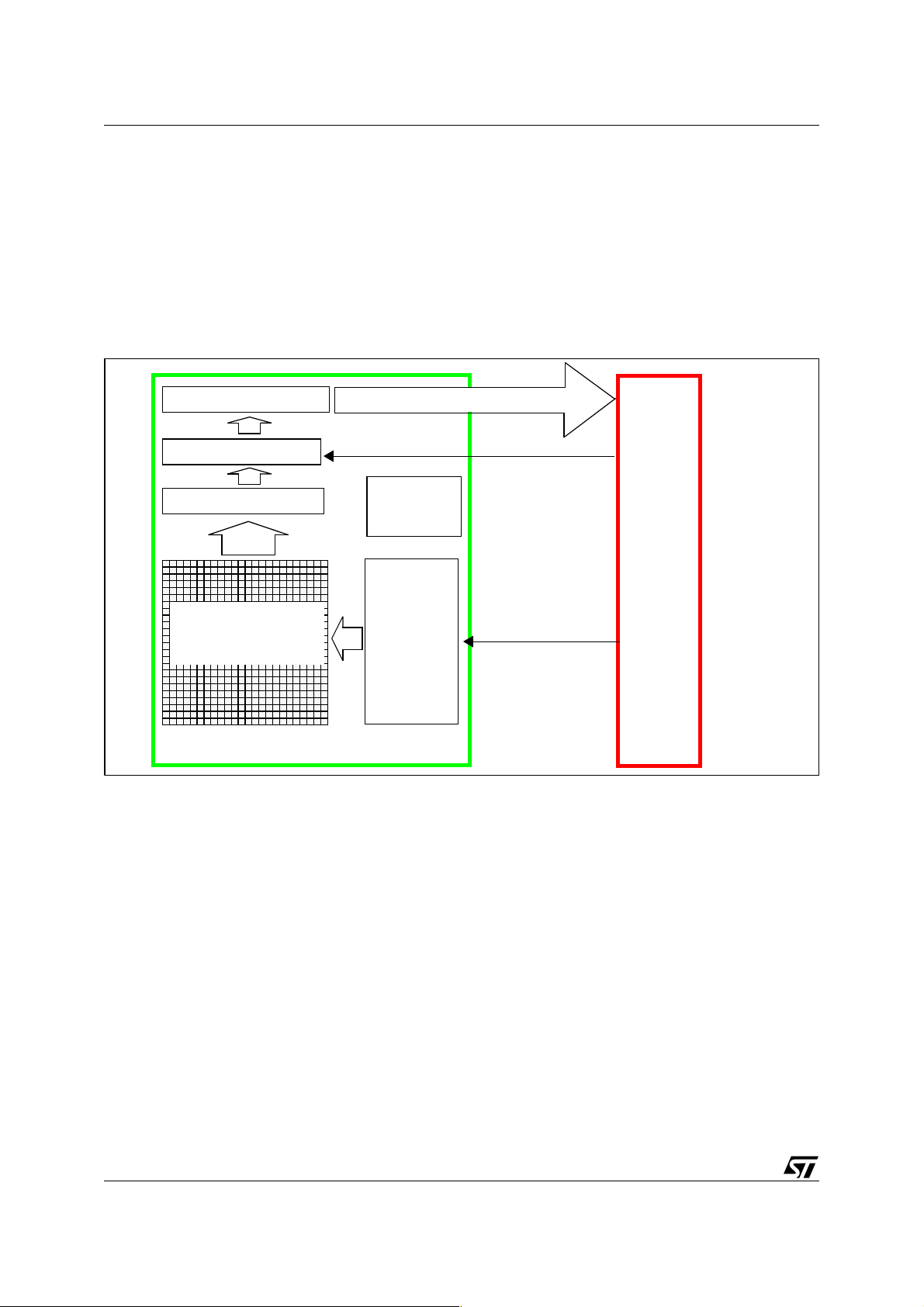

Figure 2. Analog Video Block

SRAM readout

X-Address

Column ADC

raw sensor data

Power

management

3.1 Analog Video Block

3.1.1 Features

■ ADC: 10-bit A/D converter - SRAM readout

■ Dynamic range 60 dB (typical)

■ SNR 37 dB @ 50 cd.m

2

(typical)

Timing signals

Digital

logic

VGA

pixel

array

3.1.2 Analogue Block Diagram

The analog video block f rom Figure 4, consis ts of

a VGA resolution pi xel a rray, p ower m anagem ent

circuitry. The digi tal block provides all timing signals to drive the analog block.

Pixel voltage values are read out and digitized using the address decoders and column ADC

3.2 Digital Video Block

3.2.1 Features

■ Frame rate: 30 frame/s max. (VGA) can be

reduced down to less than 3 frame/s (VGA)

■ Automatic dark calibration to ensure consistent

video level over varying scenes

Y address

Timing signals

■ Fixed pattern noise (FPN) data gathering

■ Line and frame statistics gathering

■ On-chip Power-On-Reset cell

■ Single video output format: VGA 640 x 480

■ H - Scaler function to aid software only

viewfinder implementations

3.2.2 Dark Calibration Algorithm

VS6552 runs a dark calibrati on algorithm on the

raw image data to control the video offsets caused

by dark current. This en sures that a high quality

image is output over a rang e of operating conditions. First frame dark level is corre ctl y cal ibrat ed,

for subsequent frames the a djust ment o f the d ark

level is damped by a leaky integrator function to

avoid possible frame to frame flicker.

6/26

VS6552

3.2.3 Image Statistics

VS6552 generates image s tatistics which can be

used by STV0974 as an input to an auto exposure

controller (AEC), a utomatic gain controller (AGC )

and automatic white balance (AWB). .

3.3 Device Operating Modes

3.3.1 Standby

This is the lowest power consumption mode. I

2

communications to STV 097 4 a re not supported in

this mode. The clock input pad, PLL and the video

blocks are powered down.

3.3.2 Sleep Mode

2

Sleep mode preserves the contents of the I

ister map. I

2

C communications to STV0974 are

C reg-

supported in this mode. The sleep mode is selected via a serial interface command sent by

STV0974. The data pads go high at the end of the

current frame. At this point the video block and

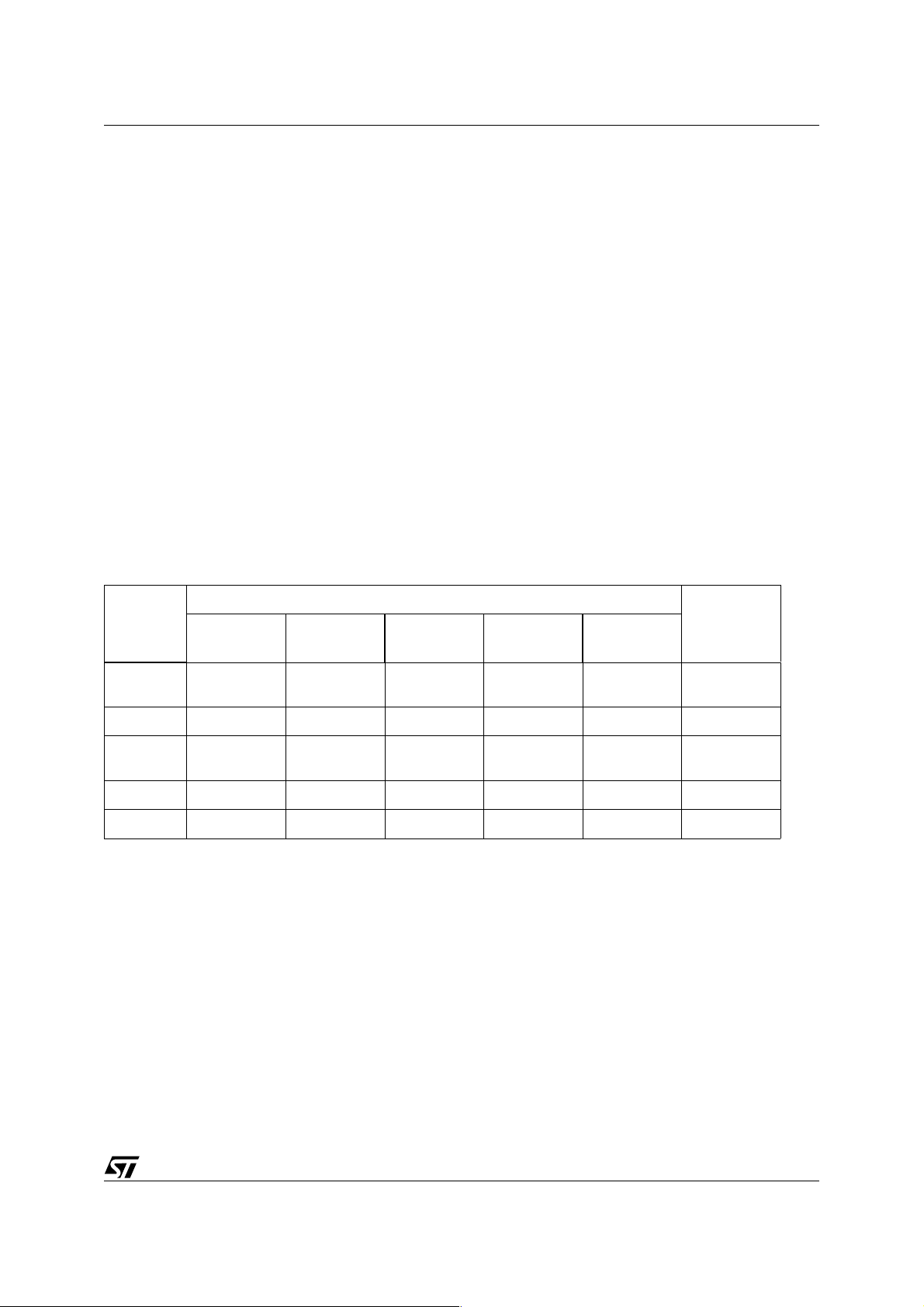

Table 4. VS6552 Power-up Sequence

Design block powered down

Mode

I2C Digital

PLL & CLK

pins

PLL power down. The internal video timing is reset

to the start of a video frame in prepara tion for the

enabling of active vide o. The values of the serial

interface registers like exposure and gain are preserved. The system clock must remain active to allow communication with the sensor.

3.3.3 Clock Active Mode

This mode is sim ilar to ‘sleep mode’ except t hat

the PLL is now powered up to permit a PCLKP/

PCLKN signal to be delivered to STV0974. The

C

PDATAP/PDATAN pads remain in ac tive. The vid eo block is powered down.

3.3.4 Idle Mode

VCAP is generated. The analog video block is now

powered up but the array is he ld in rese t and the

output PDATAP/PDATAN pads remain high.

3.3.5 Video

The VS6552 streams live video to the STV0974.

Video data

a b

Output pins Analog

inhibit

Standby

(PDN low)

Sleep No Yes Yes Yes Yes Yes

Clock

active

Idle No No No No No Yes

Video

a.PLL (Phase Locked Loop) generates fast system clock for STV0974

b.PLL, PCLKP and PCLKN pins

3.4 Power Management

VS6552 requires a dual power supply. The analog

circuits are powered by a nominal 2.8 V supply

Yes Yes Yes Yes Yes Yes

No No No Yes Yes Yes

No No No No No No

3.4.1 Power-up, Power-down Procedures

The power up and power down procedures are de-

tailed in the following Figure 3.

while the digital logic and digi tal I/O are powered

by a nominal 1.8 V supply.

7/26

VS6552

Figure 3. VS6552 Power-up Sequence

VDD (1.8V)

AVDD (2.8V)

PDN

CLK

PCLKP/N

PDATAP/N

MSDA

MSCL

Mode Change: Sleep -> Clock active Mode Command: Idle -> Streaming

and enable data qualification clock and

Standby Idle

general configuration

Sleep Streaming

Clock active

Mode Change: Clock active -> Idle

also enable data output

3.4.2 Active Signals with Unpowered VS6552

All signals going into the VS6552 must be either at

a low state or high impe dance when powe r is removed from the device. The exceptions to this rule

are the I

2

C lines which may be at a low or high

state and the clock which can be active.

3.5 Clock and Frame Rate Timing

3.5.1 Video Frame Rate Control

The output frame rate of VS6552 c an be reduced

by extending the frame length. The extension is

achieved by adding 'blank' video lines to act as

timing padding. This is advantageous as it does

not reduce the pixel readout rate and therefore

does not introduce unwanted motion distribution

effects to the image. The frame rate can be reduced from the default 3 0 fram e/s at VG A res olution to less than 3 frame/s at VGA resolution.

3.5.2 PLL and Clock Input

A PLL IP block is embedded. This block generates

all necessary int ernal clocks from an inp ut range

defined in Table 5. The input clock pad accepts up

to 26 MHz signals.

Table 5. System Input Clock Frequency Range

System clock frequency

Min. (MHz) Max. (MHz)

6.5 26

a.The standard su ppor ted i nput fre quenci es (i n MHz) are as

follows: 6.5, 8.4, 9, 9.6, 9.72, 12,13, 16.8, 18, 19.2,

19.44, 26.

a

3.5.3 Clock Input Type

VS6552 can receive the following clock types:

■ Single ended CMOS

■ Single ended Sine wave

■ Clock can be AC or DC coupled

The clock is fail-safe.

8/26

VS6552

3.6 Control and Video Interface Formats

The transmission line pairs and custom transmit -

ters/receivers realize a very low voltage differential

3.6.1 Overview

Data is transferred from VS6552 to STV0974 via a

high spee d serial link (VisionLink). The serial data

link comprises of two pairs of wires. The serial

control data is transferred between the VS6552 to

STV0974 via a private I

2

C bus.

3.6.2 VisionLink Physical Layer

Data signals (PDATAP and PD ATAN) and clock

signals (PCLKP and PCLKN) are transferred from

VS6552 to STV0974 via 2 pairs of balanced 100 Ω

(vLVDS) signalling scheme that can transfer infor-

mation in a potent ially noisy envi ronment. As im-

plemented in VS6552, VisionLink supports the

transmission of raw Bayer data at VGA resolution

up to 30 frame/s.

3.6.3 Serial I2C Control Bus

The internal registers in VS6552 can be config-

ured by STV0974 via a priv ate I

2

C bus. STV0974

is the bus maste r and VS6552 is the single slave.

VS6552 sends and r eceives co mmands ove r this

bus at up to 400 kHz.

impedance transmission lines.

4 ELECTRICAL CHARACTERISTICS

Table 6. Absolute Maximum Ratings

Symbol Parameter Values Unit

VDIG Digital power supply -0.5 to 3.0 V

VANA Analog power supply -0.5 to 3.6 V

MSCL,

MSDA

PDN, CLK Power Down Control, System Clock Input -0.3 to VDIG + 0.3 V

T

STO

Note: Caution: Stresses abov e those l isted und er “Absolute Maximum Rati ngs” may caus e permanent da mage to the device. This is a stres s

rating only and funct i onal operation of the device at these or any other conditions above those indicated in the operational sections of

the specification is not implied . Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

CCI Signals -0.3 to VDIG + 0.3 V

Storage temperature -40 to + 85

o

C

Table 7. Operating Conditions

Symbol ParTyp.ameter Min. Typ. Max. Unit

Voltag e

V

DD

AV

DD

Tem per atur e

T

AF

T

AN

T

AO

Note: 1. Storage temperature: Camera has no permanent degradation

2. Functional operating temperature: Camera is electrically functional

3. Normal operating temperature: Camera produces ‘acceptable’ images

4. Optimum performance temperature: Camera produces optimal optical performance

Digital power supply voltage 1.7 - 1.9 V

Analog power supply voltage 2.5 - 3.3 V

Temperature (functional operating) -30 - +70 °C

Temperature (normal operating) -25 - +55 °C

Temperature (optimal operating) +5 - +30 °C

9/26

VS6552

4.1 DC Electrical Characteristics

Note: Typical values quoted for nominal voltage and temperature. Maximum values quoted for worse case operating conditions unless oth-

erwise specified.

Table 8. Power Supply VDIG, VANA

Parameter

Typ . M ax. Ty p. Max . U n it

Digital Analogue

Standby 1 5

NM

a

<2 µA

Video, 30fps 15 20 9 15 mA

a.Not Measurable - current is below the minimum calibrated measurement capabilities of the test system (1µA)

Table 9. System Clock

Symbol Parameter Min. Typ. Max. Unit

Leakage current

a.With DC coupled square wave clock

b.With DC 1V9 signal level applied

a

8

29

b

Table 10. I2C Interface - MSDA, MSCL

Symbol Parameter description Min. Typ. Max. Unit

V

IL

V

IH

V

OL

I

IL

I

IH

Low level input voltage - 0.3 VDIG V

High level input voltage

Low level output voltage

0.7 VDIG

b,c

a

-V

- 0.2 VDIG V

Low level input current - -10 µA

High level input current - 10 µA

µA

f Operating frequency range 0 -

a.For positive electros tat ic di scharges above 50 0V, a shift of VIH may happen. However, the device remains fully fu ncti onal ev en

for a stress up to 2000 V included, and VIH<0.9 V

age.

b.VOH not valid for CCI

c.1 mA drive strength

d.For external clock frequencies <19.2MHz Max limit is 200KHz

. Refer to the STV0974 datas heet for recommendations on MSCL/MSDA us-

DIG

400

d

4.2 AC Electrical Characteristics

Table 11. System Clock

Symbol Parameter description Min. Typ. Max. Unit

V

CL

V

CH

V

CAC

10/26

DC coupled square wave (low level) - 0.3 VDIG V

DC coupled square wave (high level) 0.7 VDIG V

AC coupled sine wave

a

0.5 1.0 1.2 V

kHz

Symbol Parameter description Min. Typ. Max. Unit

VS6552

f

CLK

a.Nominal frequencies are 6. 5 to 26MHz with a 1% center frequency tolerance

Clock frequency input

a

6.5 - 1%

a

-

Table 12. Timing Characteristics

Symbol Parameter description Min. Max. Unit

t

MSCL

t

LOW

t

HIGH

t

SP

t

BUF

t

HD.STA

t

SU.STA

t

HD.DAT

t

SU.DAT

t

R

MSCL clock frequency 0 400 kHz

Clock pulse width low 1.3 µs

Clock pulse width high 0.6 µs

Pulse width of spikes which are suppressed

by the input filter

050ns

Bus free time between transmissions 1.3 µs

Start hold tim e 0.6 µs

Start set-up time 0.6 µs

Data in hold time 0 0.9 µs

Data in set-up time 10 0 ns

MSCL/MSDA rise time

20+0.1C

a

b

300 ns

26 + 1%

b

MHz

t

F

t

SU.STO

MSCL/MSDA fall time

Stop set-up time 0. 6 µs

20+0.1 C

b

300 ns

Ci/o Input / Output capacitance (MSDA) 8 pF

Cin Input capacitance (MSCL) 6 pF

a.Cb = total capacitance on the lines

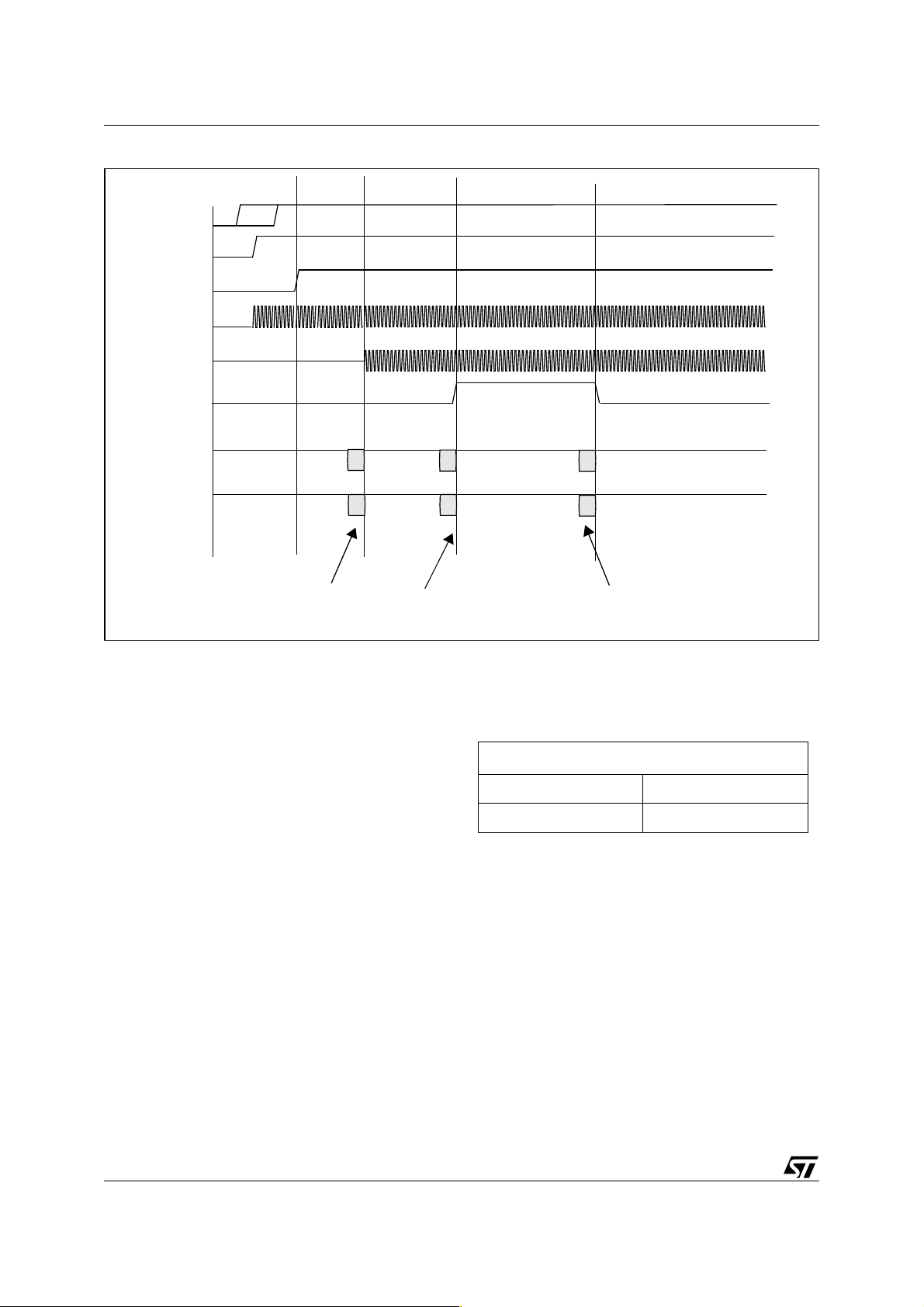

Figure 4. CCI AC characteristics

stopstartstop start

MSDA

MSCL

t

BUF

t

HD.STA

t

LOW

t

R

t

HD.DAT

t

HIGH

t

F

t

SU.DAT

...

t

HD.STA

...

t

SU.STAtSU.STO

Note: The VS6552 maximum I2C frequency of 400 kHz is only valid for external clock frequencies at or above 19.2 MHz. Due to a design

issue, for external clock frequencies below 19.2MHz, the maximum guaranteed I2C frequency is limited to 200 kHz.

11/26

VS6552

Table 13. vLVDS Interface AC Electrical Characteristics

Symbol Parameter description Min. Typ. Max. Unit

V

od

V

cm

R

O

I

DR

Differential voltage swing

Common mode voltage (self biasing) 0.8 0.9 1.0 V

Output Impedance 40 140 W

Drive current range (internally set by bias

circuit)

a,b

100 150 200 mV

0.5 1.5 2 mA

a.Supplies of VDIG = 1.8V and VANA = 2.8 V, Temperature = 25 °C

b.Measured over a 100 Ohm load

Table 14. vLVDS TIming Characteristics

Symbol Parameter Min. Typ. Max. Unit

f

PCLKP/

PCLKN

t

PCLKP/

PCLKN

t

LOW

t

HIGH

t

RISE

PCLKP/PCLKN clo ck freque nc y - - 120 MHz

PCLKP/PCLKN clo ck per iod 8.3 - 10 0 ns

PCLKP/PCLKN du ty cyc le 26 - 74 %

Low period of PCLKP/PCLKN 1.66 - ns

High period of PCLKP/PCLKN 1.66 - ns

Rise time of PDATAP/PDATAN, PCLKP/

PCLKN

0.3 - 0.5 ns

t

FALL

t

HD;DAT

t

SU;DAT

Fall time of PDATAP/PDATAN, PCLKP/

PCLKN

Data hold time 3 - - ns

Data set-up time 1 - - ns

Figure 5. VisionLink AC timing

PCLKP/

PCLKN

t

LOW

PDAT AP/

PDAT AN

t

SU;DAT

t

PCLKP/PCLKN

t

RISE

t

HIGH

0.3 - 0.5 ns

V

/2

DIG

t

FALL

V

/ 2

DIG

t

HD;DAT

12/26

VS6552

4.3 ESD Handling Characteristics

Table 15. ESD Handling Limits

Test Method Criteria

ESD Human

Body Model

ESD Machine

Model

Latch Up JESD78

JESD22 A114A

JESD22 A115A 200V

1.5 * Vddmax,

150mA

2kV

5 OPTICAL SPECIFICATION

The small amount of l ens relative illumina tion effects (field darkening) is corrected by the

STV0974.

Table 16. Optical Specifications

Parameter Value

Effective Focal Length 4 mm ± 0.15 mm

Aperture F2.8 apertu re

o

Horizontal Field of View

TV Distortion

(pin,cushion & barrel)

o

± 2

45

-3% to 3%

6 DEFECT CATEGORIZATION

6.1 Pixel Defects

A packaged CMOS image sensor will display visual imperfections caused either by electrical faults

or optical blemishes which can be introduced in

the product at various stages of the manufacturing

process. These imp urities can result in pixel de fects, that is a pi xel wh ose o utp ut is no t co nsis ten t

with the level of incide nt light fal ling on the image

sensor. The ability to identify and correct these defects is central to both the design requirements

and quality certifi cation, via test of STMicroelec tronics sensor products.

The STMicroelectronics STV0974 co-processor

implements defect correction algorithms which

screens the presence of the se defects in th e final

images. The defect cor rection algorithms ensure

that the VS6552 sensor in conjunction with the

STV0974 co-processor will produce a high quality

final image.

7 PACKAGE MECHANICAL DATA

7.1 SmOP1.5 Module Outline

– Figure 7

– Figure 8

– Figure 9

Figure 6.

MTF (

@ 60 cm @ 45 cycle/mm

)

– On axis: 45 %

– Horizontal field: 30%

– Diagonal field: 30%

Figure 6. MTF Points on the Image Field

on axis

horizontal

field

diagonal

field

7.2 SmOP2 M Module Outline

– Figure 10

– Figure 11

– Figure 12

7.3 SmOP2 ME Module Outline

– Figure 13

– Figure 14

– Figure 15

13/26

VS6552

Figure 7. SmOP1.5 Module Outline

ECN No.

Revision note Date Checked

B See Sheet 2 for details 19/01/04

RevNo

10.56 ±0.06

8.25

8.56

Note 9

Note 13

0.60 ±0.03

7.25

0.80

0.40

3.55 MAX

B

3.26

8.26

4.33

1.40

0.87

1.90 ±0.15

0.15 ±0.03

5.80 ±0.22

Scale

1 of 3

Sheet

3.05 ±0.19

Do Not Scale

SmOP 1.5, Ver 2.22 Low

0.06 B

4.58 ±0.085.42 ±0.08

CL Lensholder

All dimensions

Profile Camera Outline

STMicroelectronics

Title

in mm

Consumer & Micro Group - Imaging Division

7526498

Part No.

5.70 ±0.035

0.00 0.15

CL Ceramic

Sig. Date

Note 9

1.50 TYP

A

C

Drawn

Checked

Appd. Mech.

Appd. Elect.

Appd. Prod.

3.90 ±0.22

Note 10

Appd. Q.A.

3°

8.66 ±0.06

0.00 0.15

4.05 ±0.084.05 ±0.08

CL Lensholder

14/26

draft

3°

Finish

Material

CL Ceramic

Note 10

±0.05

0.10

R

0.75

15°

Gate Position

C (20 : 1)

B

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

written permission of STMicroelectronics.

0.25

Linear

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.25 degrees

Diameter +0.10/-0.00

Position 0.10

Notes:

1. Mass of module 0.50 grammes

2. Volume of Module 278 mm^3

3. 2 max draft angle on all moulded components unless

otherwise stated.

4. Surface finish on external moulded surfaces is RA 16

(Charmille 24).

5. Surface finish on base of ceramic is TBD.

6. All gates on moulded parts will be sub flush.

7. All mouldings to be free from visible flash or mismatch.

8. Uniformly distributed load of 20N may be applied to datum

surfaces A & B.

9. These numbers denote tool No. and cavity.

10. Edge of ceramic and glue bead will not protrude past edge

of lensholder.

11. Dimensions enclosed thus are inspection dimensions.

12. Minimum breaking torque between lensholder and barrel is

40 Nmm.

13. These 3 depressions contain gates or are used for cavity &

tool identification and ejector pin locations.

Tolerances, unless otherwise stated

Surface Finish 1.6 microns

Figure 8. SmOP1.5 Module Outline

Makrolon: 2405

Makrolon: 2405

Colour Black

max.

39°

(Pyramid)

Colour Black

COP: Zeonex E48R

COP: Zeonex E48R

E Glass Coated with

IR Filter Material

Silicon

Ceramic: Alumina

Dark Grey

max.

D-D (8 : 1)

3.36

At Datum B (Cone)

Top of image

VS6552

2 of 3

Sheet

Scale

Datum B (Pyramid)

2.69 max. at

D

Do Not Scale

SmOP 1.5, Ver 2.22 Low

Profile Camera Outline

Title

STMicroelectronics

All dimensions

in mm

Consumer & Micro Group - Imaging Division

7526498

Checked

Date

ECN No.

B

Note 10

, Now 61 17/02/04

1.4 min.

E

E (16 : 1)

Part No.

D

(cone)

61°

max.

B2

B

max.

(Pyramid)

50°

2.01 max. at

Datum B (Pyramid)

Sig. Date

Drawn

Checked

Appd. Mech.

Appd. Elect.

Appd. Prod.

Appd. Q.A.

Sub flush gate posn

See Note 6

Finish

Material

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

written permission of STMicroelectronics.

Field of View Data.

Revision note

A First Release as 7526498. Previous version of camera was 7487715

Barrel flange increased. Diameter on lens holder increased. Laser

weld recesses moved and length was 1.60, 0.30 feature on pin 1 12/05/03

was 0.50

B Tolerance added. Pad 1 dimension changed from 0.5 to 0.3mm 19/01/04

Material changed from Noryl HB1525 to Makrolon 2405.

RevNo

B2 Exclusion Cone corrected was 60

Pyramid

holes must not protrude into the Pyramid.

Edges of circular holes in customer's equipment

must not intrude into the Cone. Edges of rectangular

Cone

Tolerances, unless otherwise stated

Linear

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

0.10

+0.10/-0.00

Position

Surface Finish 1.6 microns

2 Place Decimals 0.00 ±0.07

Angular ±0.25 degrees

Diameter

15/26

VS6552

Figure 9. SmOP1.5 Module Outline

Scale

Sheet

3 of 3

ECN No.

5.70 ±0.05

Revision note Date Checked

Pad material is 0.30 microns

B See Sht 2 19/01/04

RevNo

gold on 2 microns nickel

Part Marking in Hatched areas.

Refer to Spec TBD for details.

1.20 ±0.03 typ

7.10 ±0.05

5.35 ±0.05

4.05 ±0.05

2.65 ±0.05

0

2.90 ±0.05

1.50 ±0.05

Pad 1

Do Not Scale

SmOP 1.5, Ver 2.22 Low

Profile Camera Outline

STMicroelectronics

Title

All dimensions

in mm

Consumer & Micro Group - Imaging Division

7526498

Part No.

0

B

Sig. Date

0.30 ±0.03

Drawn

Checked

Appd. Mech.

Appd. Elect.

Appd. Prod.

Appd. Q.A.

2.65 ±0.03

1.00 ±0.03

Material

Finish

16/26

Underside of module showing connector and test pad layout.

0.48 ±0.22

5.60 ±0.05

7.00 ±0.05

8.40 ±0.05

4.20 ±0.05

2.80 ±0.05

1.40 ±0.05

0

2.35 ±0.03 typ

0.48 ±0.22

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

Linear

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.25 degrees

Diameter +0.10/-0.00

Position 0.10

Surface Finish 1.6 microns

Figure 10. Module Outline (SmOP 2M)

VS6552

Initial

5.46

Note 9

Note 10

See Sheet 3

Revision note Date

B2

RevNo

These cavities may contain glue.

Gate Location

7.20

0.40

0.80

6.10 ±0.10

5

R

2.70 ±0.10

Scale

Do Not Scale

8.95

1 of 3

Sheet

SMOP2-M

OUTLINE DRAWING

Title

STMicroelectronicsSTMicroelectronics

All dimensions

in mm

Consumer & Micro Group - Imaging Division

2 TYP

DBS

18/06/03

Date

Drawn

0.50 At Datum A

A

7540020

Part No.

4.25

B

4.75

0.60

9.50 ±0.06

+0.1

R0.10 0

2.40

0.40

8.50 ±0.06

1.50°

C (20 : 1)

If no radii

8.22 at Datum B

R0.10

R0.10

10°

0.50

0.52

1.68 ±0.10

B

B (20 : 1)

0.50

Note 13

A (20 : 1)

Note 14

Notes:

1. Mass of module: <0.5 grammes.

2. Volume of module: 370.2 mm^3.

3. 2 deg max draft angle on all moulded components unless

otherwise stated.

4. Surface finish on all external moulded surfaces is

Charmille 30 MAX.

5. Surfaces shown in silver to be conductively plated.

See sheet 2 for plating information.

Finish

Material

A

6. All gates to be sub flush.

7. All mouldings to be free from flash or mismatch.

8. Uniformly distributed load of 20N to be applied to datum

surfaces A & B.

9. These numbers denote tool number and cavity.

Text will be subflush with surface.

10.These depressions may be used to indicate

lens type, tool number and cavity.

C

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

11.Dimensions enclosed thus are inspection dimensions.

12.Breaking torque between lens barrel and holder

> 20 Nmm.

All Dimensions

13.Corners of the substrate will not protrude past the

rectangular footprint of the lens holder.

14.Glue bead will not protrude past edge of substrate.

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

17/26

VS6552

Figure 11. SmOP2 Module Outline

Initial

Noryl: N110

Cone

See Table Dim A

See Sheet 3

Revision note Date

B2

RevNo

Noryl: N110

COP or PC

COP or PC

E Glass with IR

Pyramid

See Table Dim B

B

Silicon

Substrate:

Glass/epoxy

filter Material

pre-preg

Pyramid

At Datum B

See Table Dim D

SCALE 5 : 1

SECTION B-B

Dim C

Pyramid

See Table

Cone

At Datum B

See Table Dim E

Scale

Do Not Scale

2 of 3

Sheet

SMOP2-M

OUTLINE DRAWING

Title

STMicroelectronicsSTMicroelectronics

All dimensions

in mm

Consumer & Micro Group - Imaging Division

BB

At Datum B

See Table Dim F

MAX Exclusion Zones Dimensions

DBS

Drawn

18/06/03

Date

7540020

Part No.

Module A B C D E F

4 micron SVGA 64 53.12 41.1 4.15 3.32 2.49

5.6 micron VGA 61 50.36 39.06 4 3.2 2.4

Exclusion Zones.

Edges of circular holes in customer's equipment must not intrude into the cone.

Edges of rectangular holes must not prodrude into the pyramid.

Dimensions shown are maximums.

Note: If an upgrate path from 5.6 micron VGA to 4 micron SVGA is required then the 4 micron SVGA

data should be used.

5

These cavities

See Plating Notes 2 and 3

may contain glue.

120°

AA

this area.

Cosmetics not

guaranteed outside

Probe points to contact

120°

Scallops may contain

US weld marks.

Weld will not protrude

"Class A" Surface

(Top face of barrel)

past cylindrical surface.

inside dotted lines.

2.40

These surfaces

to be plated

+0.3

0.94 - 0.1

Finish

Material

B2

All dimensions in mm

SCALE 6 : 1

SECTION A-A

Plating Notes

1. 4 point probe to be used to check resistance of the metalisation.

2. Probe to must not contact the lens mount in the scalloped areas.

3. Probe to contact the cylindrical section of the lens mount between any 2 of the 3

equi-spaced points around the diameter.

4. Plating Options:

a.1 micron Copper, 0.1micron MIN Stainless Steel

b.1 micron Copper, 0.1micron MIN Nickel Chrome

c.1 micron Copper, 0.1micron MIN TBD

5. Resistance to be less than 1 ohm.

6. Contact force to be 2N.

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

All Dimensions

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

18/26

Figure 12. SmOP2 Module Outline

VS6552

Initial

DBS

010404

Revision note Date

See ADCS Revision A for previous history

B

RevNo

DBS

DBS

110604

160604

Area For Test Pads,

Additional Tracking

& Part Marking

Sheet 2, Note 5, Contact resistance changed to 1 ohm.

Sheet 2, Note 3 reworded.

Step in chamfer added. Note 4 corrected.

Notes revised to remove TBD. Torque spec changed to

20Nmm. Inspection dimension moved.

Surface finish changed to Charmille 30 MAX.

B1

Sheet 3, Pad outline note added.

Top diameter re-defined.

0.10 TYP

B2

1 ±0.03 TYP

0.20 TYP

CLKN

CCP

CLKP

CCP

VDIG

DATAN

CCP

DATAP

CCP

DGND

Test

Test

Test

Test

6.10

3.85

2.75

CCISDA DGND

CCISCL

EXTCLK

DOWN

XSHUT

VANA

AGND

VCAP

1.10 ±0.03

2.20 ±0.03

3.30 ±0.03

4.40 ±0.03

5.50 ±0.03

6.60 ±0.03

Scale

Sheet

Do Not Scale

SMOP2-M

OUTLINE DRAWING

Title

STMicroelectronicsSTMicroelectronics

All dimensions

in mm

Consumer & Micro Group - Imaging Division

DBS

18/06/03

7540020

Date

Drawn

Part No.

Finish

Material

3 of 3

±0.03 TYP

Underside of module showing connector and test pad layout.

1.50

Pad 14

Area for test pads,

additional tracks

and part marking.

No conductive contact

or force allowed in this area.

Pad 1

Pad Material is 0.3

microns minimum

gold on 5 microns

minimum nickel.

B2

Note:

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

Minimum size shown for pad.

All Dimensions

Pad spacing will be maintained.

Actual pad outlines may be extended.

Refer to individual product substrate drawings.

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

19/26

VS6552

Figure 13. SmOP2 Module Outline

Initial

5.46

Note 9

Date

Note 10

See Sheet 3

0.30

Revision note

B4

RevNo

Note 13

7.20

0.40

0.80

5

R

0.50 TYP

2.70 ±0.10

Scale

Do Not Scale

8.95

1 of 3

Sheet

SMOP2-ME

OUTLINE DRAWING

6.10 ±0.10

STMicroelectronicsSTMicroelectronics

Title

All dimensions

in mm

Consumer & Micro Group - Imaging Division

2 TYP

DBS

30/06/03

Date

7545055

Part No.

B

4.75

(7.30)

9.50 ±0.06

14 ±0.15

+0.10

R0.10 0

2.40

Drawn

0.50 at datum A

A

0.40

4.25

8 ±0.15

8.50 ±0.06

1.50°

Gate Location

R0.10

R0.10

0.50

C (20 : 1)

0.52

1.68 ±0.10

If no radii

8.22 at datum B

B

Finish

Material

A

C

0.50

B (20 : 1)

A (20 : 1)

Note 14

Notes:

1. Mass of module: <0.5 grammes.

2. Volume of module: 384.7 mm^3.

3. 2 deg max draft angle on all moulded components unless

otherwise stated.

4. Surface finish on all external moulded surfaces is

Charmille 30 MAX.

5. Surfaces shown in silver to be conductively plated.

See sheet 2 for plating information.

6. All gates to be sub flush.

7. All mouldings to be free from flash or mismatch.

8. Uniformly distributed load of 20N to be applied to datum

surfaces A & B.

9. These numbers denote tool number and cavity.

Text will be subflush with surface.

10.These depressions may be used to indicate

lens type, tool number and cavity.

11.Dimensions enclosed thus are inspection dimensions.

12.Breaking torque between lens barrel and holder

> 20 Nmm.

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

All Dimensions

Tolerances, unless otherwise stated

13.All translational and rotational placement tolerances are included in this area.

14.Glue bead will not protrude past edge of Lens Holder.

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

20/26

Figure 14. SmOP2 Module Outline

VS6552

Initial

Date

Noryl N110

Cone

See Table Dim A

See Sheet 3

Revision note

B4

RevNo

COP or PC

COP or PC

Noryl N110

Pyramid

See Table Dim B

B

Silicon

Substrate:

Glass/epoxy

E Glass with IR

filter Material

pre-preg

SCALE 5 : 1

SECTION B-B

Pyramid

Cone

Pyramid

At Datum B

See Table Dim D

Dim C

See Table

At Datum B

See Table Dim E

Scale

Do Not Scale

2 of 3

Sheet

SMOP2-ME

OUTLINE DRAWING

STMicroelectronicsSTMicroelectronics

Title

All dimensions

in mm

Consumer & Micro Group - Imaging Division

BB

At Datum B

See Table Dim F

DBS

Drawn

30/06/03

Date

Part No.

7545055

MAX Exclusion Zones Dimensions

Module A B C D E F

4 micron SVGA 64 53.12 41.1 4.15 3.32 2.49

5.6 micron VGA 61 50.36 39.06 4 3.2 2.4

Exclusion Zones.

Edges of circular holes in customer's equipment must not intrude into the cone.

Edges of rectangular holes must not prodrude into the pyramid.

Dimensions shown are maximums.

Note: If an upgrate path from 5.6 micron VGA to 4 micron SVGA is required then

the 4 micron SVGA data should be used.

5

These cavities

may contain glue.

See Plating Notes 2 and 3

120°

AA

"Class A" Surface

this area

Cosmetics not

guaranteed outside

120°

(Top face of barrel)

Probe point to contact

inside dotted lines.

2.40

These areas

Scallops may contain

US weld marks.

Weld will not protrude

past cylindrical surface.

+0.3

to be plated.

0.94 - 0.1

Finish

Material

B4

All dimensions in mm

SCALE 5 : 1

SECTION A-A

Plating Notes

1. 4 point probe to be used to check resistance of the metalisation.

2. Probe to must not contact the lens mount in the scalloped areas.

3. Probe to contact the cylindrical section of the lens mount between any 2 of the 3

equi-spaced points around the diameter.

4. Plating Options:

a.1 micron Copper, 0.1micron MIN Stainless Steel

b.1 micron Copper, 0.1micron MIN Nickel Chrome

c.1 micron Copper, 0.1micron MIN TBD

5. Resistance to be less than 1 ohm.

6. Contact force to be 2N.

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

All Dimensions

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

21/26

VS6552

Figure 15. SmOP2 Module Outline

Initial

Date

Revision note

RevNo

DBS

DBS

DBS

DBS

DBS

±0.03

010404

230104

040504

110604

160604

12.10

Notes 4 and 10 corrected. Top edge radius changed from +0.05

to +0.1mm.

Released into ADCS

B

B1

Top diameter defined.

Sheet 2, Note 5, Contact resistance changed to 1 ohm.

Sheet 2, Note 3 reworded.

Notes updated to remove TBD. Torque now aet to 20Nmm.

Inspection dimension moved.

B2

Sheet 3, Pad outline note added.

B4

B3 Surface finish changed to charmille 30 MAX.

6.60 ±0.03

5.50 ±0.03

4.40 ±0.03

3.30 ±0.03

2.20

1.10 ±0.03

DA

CCIS

CCIS

CCP

DGND

0.20 TYP

CL

CLKN

EXT

CCP

CLK

CLKP

DOWN

XSHUT

VDIG

CCP

VANA

DATAN

6.10

AGND

CCP

DATAP

3.85

2.75

VCAP

DGND

Pad 1

Any force applied to

the topside of the substrate

should be balanced by a

counter force directly opposite

on the underside of the

Pad 14

1.50 ±0.03 TYP

1 ±0.03 TYP

Scale

Do Not Scale

STMicroelectronicsSTMicroelectronics

All dimensions

in mm

Consumer & Micro Group - Imaging Division

DBS

Drawn

30/06/03

Date

substrate and vice versa.

3 of 3

Sheet

SMOP2-ME

OUTLINE DRAWING

Title

7545055

Part No.

1.451.45

Area For Test Pads &

Additional Tracking.

Pad Material is 0.3

microns minimum

gold on 5 microns

minimum nickel.

Area for

Part Marking.

DGND

CLKN

CCP

CLKP

CCP

VDIG

DATAN

CCP

CCP

DGND

DATAP

Test

Test

Test

Test

Underside of module showing connector and test pad layout.

1 ±0.03 TYP

Pad 14

(Test Duplicate)

1.50 ±0.03 TYP

DA

CL

CCIS

CCIS

CLK

EXT

DOWN

VANA

AGND

VCAP

XSHUT

1.10

2.20

3.30

4.40

Pad 1

(Test Duplicate)

Area for

Part Marking.

5.50

6.60

B4

No Force

allowed in

this area

Note:

Minimum size shown for pad.

Pad spacing will be maintained.

Actual pad outlines may be extended.

Refer to individual product substrate drawings.

Finish

Material

All dimensions in mm

This drawing is the property of STMicroelectronics

and will not be copied or loaned without the

Interpret drawing per BS308, 3RD Angle Projection

All Dimensions

Tolerances, unless otherwise stated

written permission of STMicroelectronics.

0 Place Decimals 0 ±1.0

1 Place Decimals 0.0 ±0.10

2 Place Decimals 0.00 ±0.07

Angular ±0.5 degrees

Position 0.10

Surface Finish 1.6 microns

22/26

VS6552

8 APPLICATION INFORMATION

8.1 Socket

ST has developed a low-profile socket for the

SmOP 1.5 package, which is suitable for reflow

soldering and manual / automatic inser tion of the

camera module. The socket has been designed to

withstand mobile phone grade reliability tests

(temperature, shocks, vibration, salt mist).

Please contact ST for details on ST P/N XS0015.

See Figure 16 for rec ommended PCB l ayout and

mechanical footprint of the XS0015 socket.

8.2 EMC and Shielding

The VS6552 is a low noise device and is highly tolerant of high leve ls of ra dio fr equenc y (RF ) radia tion. However if this device is closely mounted to a

sensitive receiver it is recommended that the

VS6552 is shielded to prevent reducing the sensitivity or channel masking of the receiver.

Recommended maximum field strength: 1kV/m.

Maximum radiated power transferred from the

VS6552 into a GSM monopo le antenna mounted

15 mm away from the VS6552 has peaks of inter-

ference at around -90 dBm. This is dependen t on

system design and layout.

To minimized the coupling b etween the G SM antenna and the sensor the following guide lines

should be observed.

Camera should be positioned as far away from the

GSM antenna as possible. The distance between

the low frequency (below 1GHz) resonant antenna

elements and the camera should also be maximized.

The VS6552 and its associated decoupling capacitors should NOT be connected together using the

antenna reference ground. The ground connections in the sub circuit should be connected either:

■ by a dedicated ground trace network, that is

connected by a single point to the main ground

of the system

■ by an internal ground plane, which is entirely

covered and single point connec ted to a

protective ground.

The PCLKP and PCLKN lines can be filtered to reduce the induced noise.

The protective ground sh ould be flooded around

the sensor socket pads to reduce the radiation aperture in the protective ground plane.

23/26

VS6552

Figure 16. SmOP1.5 Socket Mechanical Data

03/11/03

7,3

10

1,5

1,1

RECOMMENDED SOLDER

1,4

FM

par: le:Mise à jour version

SMOP 1.5

SOCKET FOR CAMERA MODULE

Ensemble:

Pièce:

Modif:

Le:

-

Dessiné par:

Réf:

04/02/03

FM

24/26

11,7

10,5

VACUUM P&P

CLEARANCE FOR

5/1

Matière:

Echelle:

-

Tolérances

-

-

Générales:

Ra général:

Vérifié par:

9 REVISION HISTORY

Table 17. Revision History

Date Revision Description of Changes

May 2004 1 First Release of Product Preview

Second Release - Document status changed to datasheet. to reflect the

21 October 2004 2

product maturity level.

Changes applied in Electrical Characteristics and Package Information

with the addition of two packages (SmOP2M and SmOP2ME).

VS6552

25/26

VS6552

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infrin gement of patents or other rights of third parties which may resul t from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without not ic e. This publication supersedes and replaces all information previously supplied. ST Microelectronics products are not

authorized for use as critical components in life support devices or systems without express writte n approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israe l - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United Stat es of America

www.st.com

26/26

Loading...

Loading...