Features

Typ e R

VNH5019A-E

■ ECOPACK

■ Automotive Grade: compliance with AEC

DS(on)

18 mΩ typ

(per leg)

®

: lead free and RoHS compliant

I

out

30 A 41 V

guidelines

■ Output current: 30 A

■ 3 V CMOS compatible inputs

■ Undervoltage and overvoltage shutdown

■ High-side and low-side thermal shutdown

■ Cross-conduction protection

■ Current limitation

■ Very low standby power consumption

■ PWM operation up to 20 khz

■ Protection against:

– Loss of ground and loss of V

■ Current sense output proportional to motor

CC

current

■ Charge pump output for reverse polarity

protection

■ Output protected against short to ground and

short to V

CC

Description

The VHN5019A-E is a full bridge motor driver

intended for a wide range of automotive

applications. The device incorporates a dual

monolithic high-side drivers and two low-side

switches. The high-side driver switch is designed

using STMicroelectronics’ well known and proven

proprietary VIPower

to efficiently integrate on the same die a true

®

M0 technology that allows

VNH5019A-E

Automotive fully integrated

H-bridge motor driver

V

ccmax

MultiPowerSO-30™

Power MOSFET with an intelligent

signal/protection circuit.

The three dice are assembled in

MultiPowerSO-30 package on electrically isolated

lead-frames. This package, specifically designed

for the harsh automotive environment offers

improved thermal performance thanks to exposed

die pads. The input signals IN

directly interface to the microcontroller to select

the motor direction and the brake condition.

The DIAG

/ENA or DIAGB/ENB, when connected

A

to an external pull-up resistor, enable one leg of

the bridge. They also provide a feedback digital

diagnostic signal. The CS pin allows to monitor

the motor current by delivering a current

proportional to its value when CS_DIS pin is

driven low or left open. The PWM, up to 20 KHz,

lets us to control the speed of the motor in all

possible conditions. In all cases, a low-level state

on the PWM pin turns-off both the LS

switches. When PWM rises to a high-level, LS

LS

turn-on again depending on the input pin

B

state.

Output current limitation and thermal shutdown

protects the concerned high-side in short to

ground condition.

The short to battery condition is revealed by the

overload detector or by thermal shutdown that

latches off the relevant low-side.

Active V

pin voltage clamp protects the device

CC

against low energy spikes in all configurations for

the motor.

CP pin provides the necessary gate drive for an

external n-channel PowerMOS used for reverse

polarity protection.

and INB can

A

and LSB

A

A

or

December 2011 Doc ID 15701 Rev 8 1/37

www.st.com

1

Contents VNH5019A-E

Contents

1 Block diagram and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Waveforms and truth table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Reverse battery protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Package and PCB thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1 MultiPowerSO-30 thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1.1 Thermal calculation in clockwise and anti-clockwise operation in

steady-state mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1.2 Thermal calculation in transient mode . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Package and packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1 ECOPACK® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 MultiPowerSO-30 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 MultiPowerSO-30 suggested land pattern . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 MultiPowerSO-30 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2/37 Doc ID 15701 Rev 8

VNH5019A-E List of tables

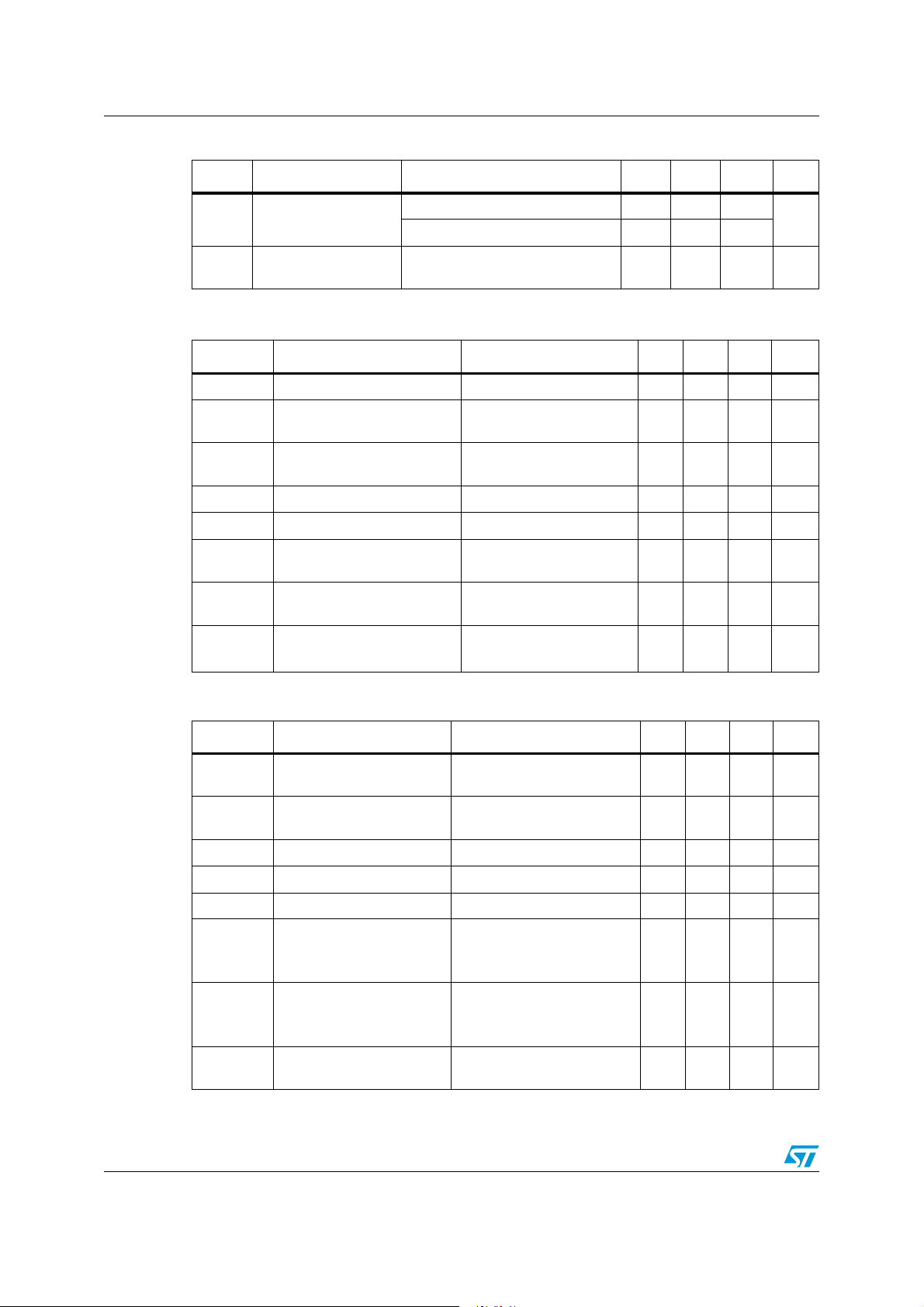

List of tables

Table 1. Suggested connections for unused and not connected pins . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Pin definitions and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Block descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 4. Absolute maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 5. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 7. Logic inputs (INA, INB, ENA, ENB,PWM, CS_DIS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Switching (V

Table 9. Protection and diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 10. Current sense (8 V < V

Table 11. Charge pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 12. Truth table in normal operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 13. Truth table in fault conditions (detected on OUTA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 14. Electrical transient requirements (part 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 15. Electrical transient requirements (part 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 16. Electrical transient requirements (part 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 17. Thermal calculation in clockwise and anti-clockwise operation in steady-state mode . . . . 27

Table 18. Thermal parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 19. MultiPowerSO-30 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 20. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 21. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

= 13 V, R

CC

= 0.87 W, Tj = 25 °C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

LOAD

< 21 V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CC

Doc ID 15701 Rev 8 3/37

List of figures VNH5019A-E

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Configuration diagram (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Current and voltage conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Typical application circuit for DC to 20 kHz PWM operation with reverse battery protection

(option A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5. Typical application circuit for DC to 20 kHz PWM operation with reverse battery protection

(option B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6. Behavior in fault condition (how a fault can be cleared) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Definition of the delay times measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. Definition of the low-side switching times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Definition of the high-side switching times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Definition of dynamic cross conduction current during a PWM operation. . . . . . . . . . . . . . 21

Figure 11. Waveforms in full bridge operation (part 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 12. Waveforms in full bridge operation (part 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13. Definition of delay response time of sense current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Half-bridge configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. Multi-motors configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 16. MultiPowerSO-30™ PC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 17. Chipset configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 18. Auto and mutual Rthj-amb vs PCB copper area in open box free air condition . . . . . . . . . 26

Figure 19. Chipset configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 20. MultiPowerSO-30 HSD thermal impedance junction ambient single pulse . . . . . . . . . . . . 28

Figure 21. MultiPowerSO-30 LSD thermal impedance junction ambient single pulse . . . . . . . . . . . . . 28

Figure 22. Thermal fitting model of an H-bridge in MultiPowerSO-30 . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 23. MultiPowerSO-30 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 24. MultiPowerSO-30 suggested pad layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 25. MultiPowerSO-30 tube shipment (no suffix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 26. MultiPowerSO-30 tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4/37 Doc ID 15701 Rev 8

VNH5019A-E Block diagram and pin description

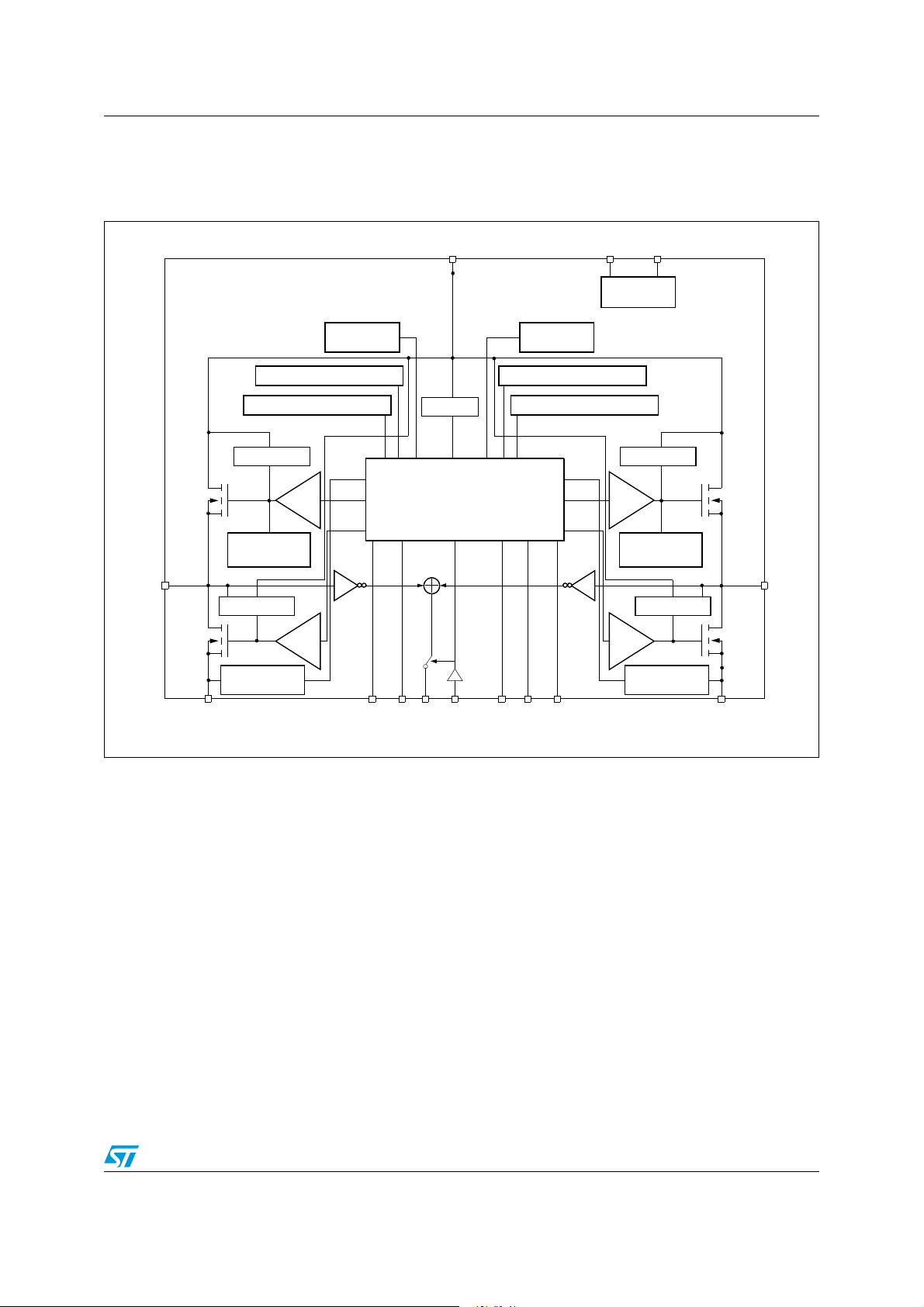

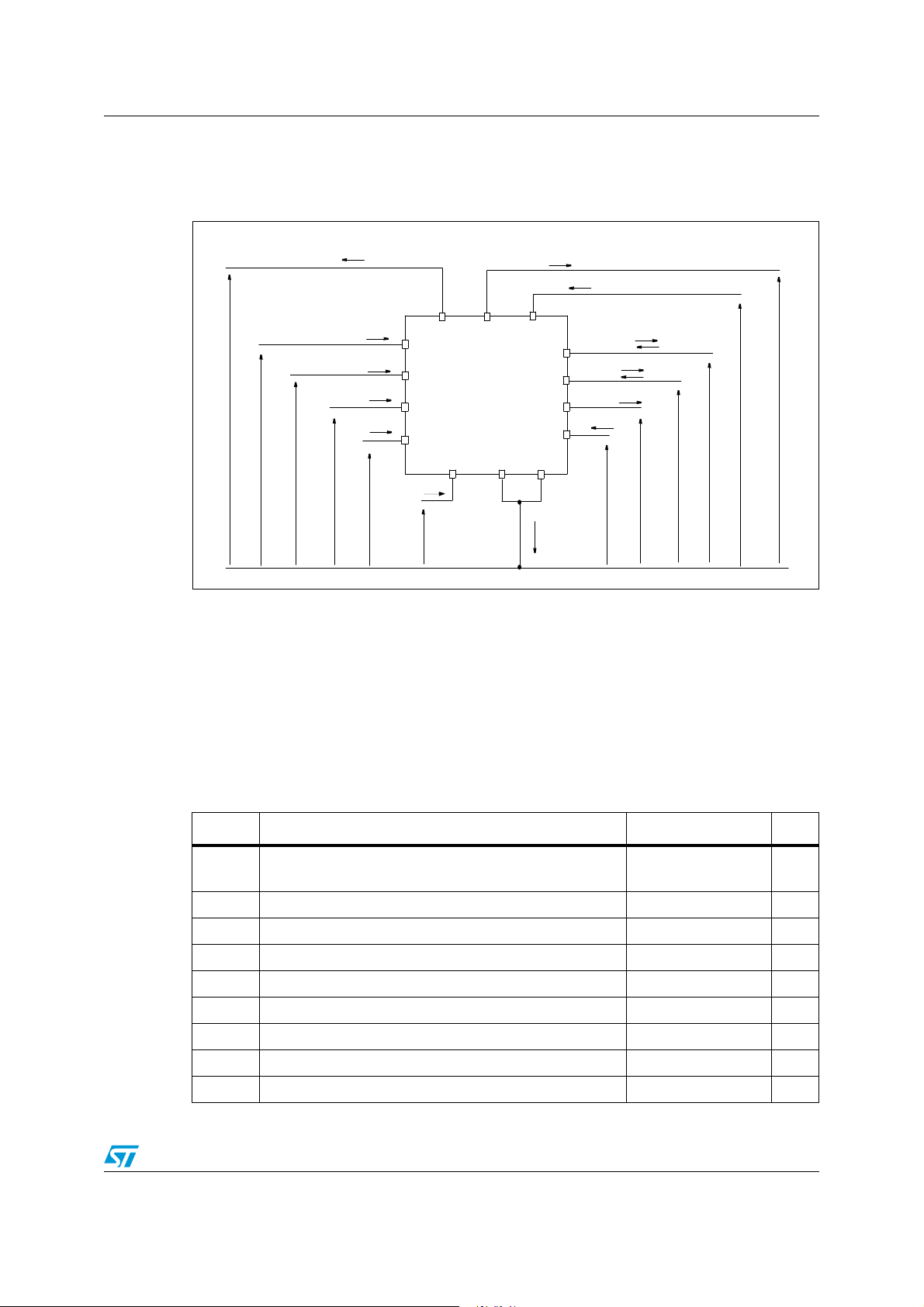

1 Block diagram and pin description

Figure 1. Block diagram

6

##

#(!2'%

05-

0

/54

&!5,4

$%4%#4)/.

,3!?/6%24%-0%2!452%

/65

6

#,!-0?(3

(3

!

#522%.4

,)-)4!4 )/.?!

!

#,!-0?,3

,3

!

/6%2,/!$

$%4%#4/2?!

'.$

!

$2)6%2

!

$2)6%2

!

(3

!

+

,3

!

,/')#

$)!'!%.!).!#3 #3?$)3 07- )."$)!'"%.

0/7%2

,)-)4! 4)/.

,3"?/6%24%-0%2!4 52%

(3"?/6%24%-0%2!452%(3!?/6%24%-0%2!452%

$2)6%2

(3

#522%.4

,)-)4!4 )/.?"

+

$2)6%2

,3

"

#,!-0?(3

"

#,!-0?,3

"

/6%2,/!$

$%4%#4

"

/2?"

(3

"

/54

"

"

,3

"

'.$

"

("1($'5

Doc ID 15701 Rev 8 5/37

Block diagram and pin description VNH5019A-E

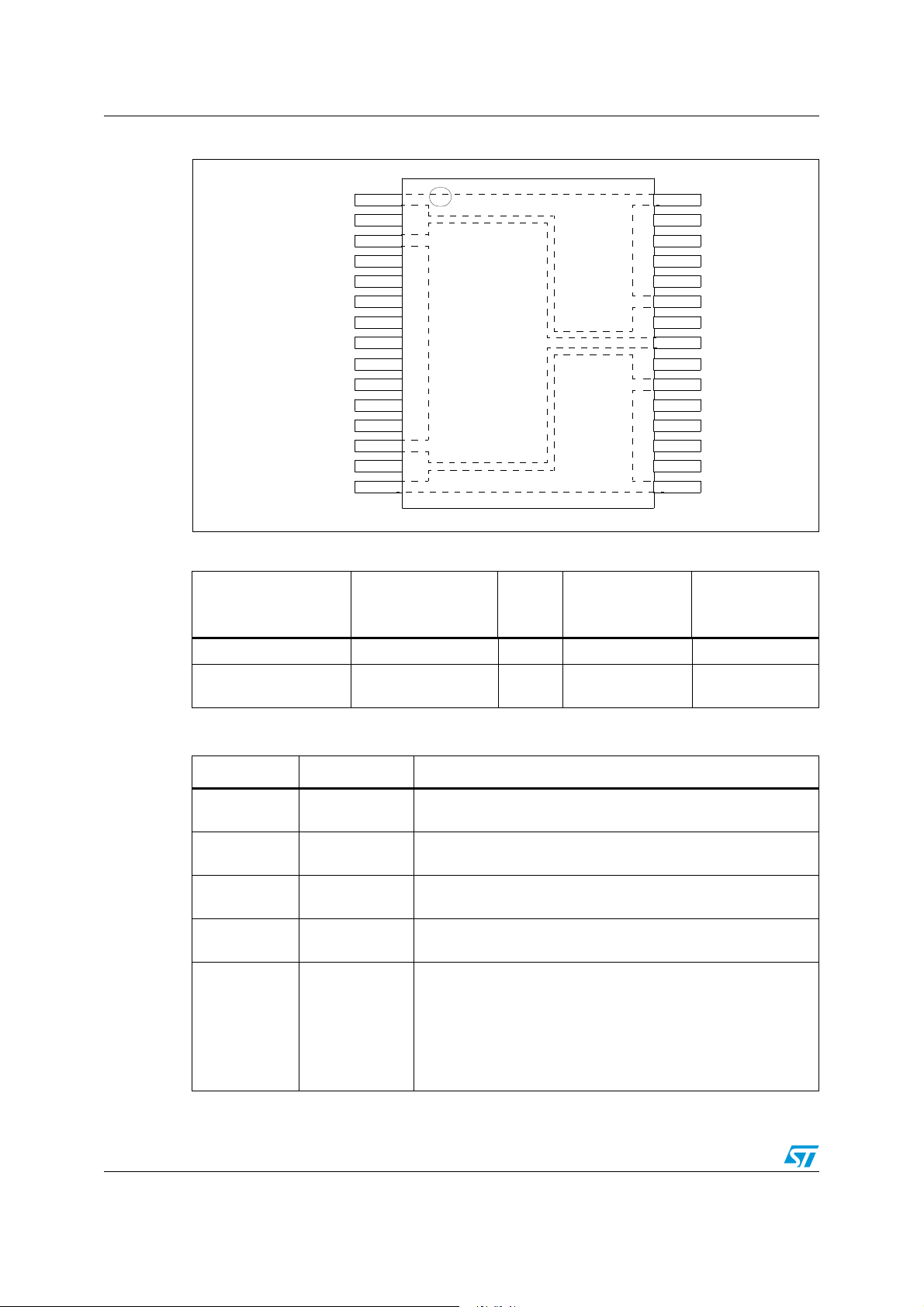

Figure 2. Configuration diagram (top view)

OUT

N.C.

V

IN

ENA/DIAG

CC

A

A

A

1

OUT

A

Heat Slug2

30

CS_DIS

EN

/DIAG

B

PWM

CS

IN

B

B

V

CC

Heat Slug1

CP

V

BAT

V

CC

OUT

B

Heat Slug3

N.C.

OUT

B

Table 1. Suggested connections for unused and not connected pins

15 16

Connection / pin Current sense N.C. OUTx

OUT

A

N.C.

GND

A

GND

A

GND

A

OUT

A

N.C.

V

CC

N.C.

OUT

B

GND

B

GND

B

GND

B

N.C.

OUT

B

INPUTx, PWM

DIAGx/ENx

CS_DIS

Floating Not allowed X X X

To ground Through 1 kΩ resistor X Not allowed

Table 2. Pin definitions and functions

Through 10 kΩ

resistor

Pin Symbol Function

1, 25, 30

2,14,17, 22,

24,29

3, 13, 23

12 V

OUTA,

Heat Slug2

N.C. Not connected

,

V

CC

Heat Slug1

BAT

Source of high-side switch A / drain of low-side switch A, power

connection to the motor

Drain of high-side switches and connection to the drain of the

external PowerMOS used for the reverse battery protection

Battery connection and connection to the source of the external

PowerMOS used for the reverse battery protection

Status of high-side and low-side switches A; open drain output.

This pin must be connected to an external pull-up resistor. When

externally pulled low, it disables half-bridge A. In case of fault

5EN

/DIAG

A

detection (thermal shutdown of a high-side FET or excessive

A

ON-state voltage drop across a low-side FET), this pin is pulled

low by the device (see

(detected on OUTA)

Table 13: Truth table in fault conditions

)

6/37 Doc ID 15701 Rev 8

VNH5019A-E Block diagram and pin description

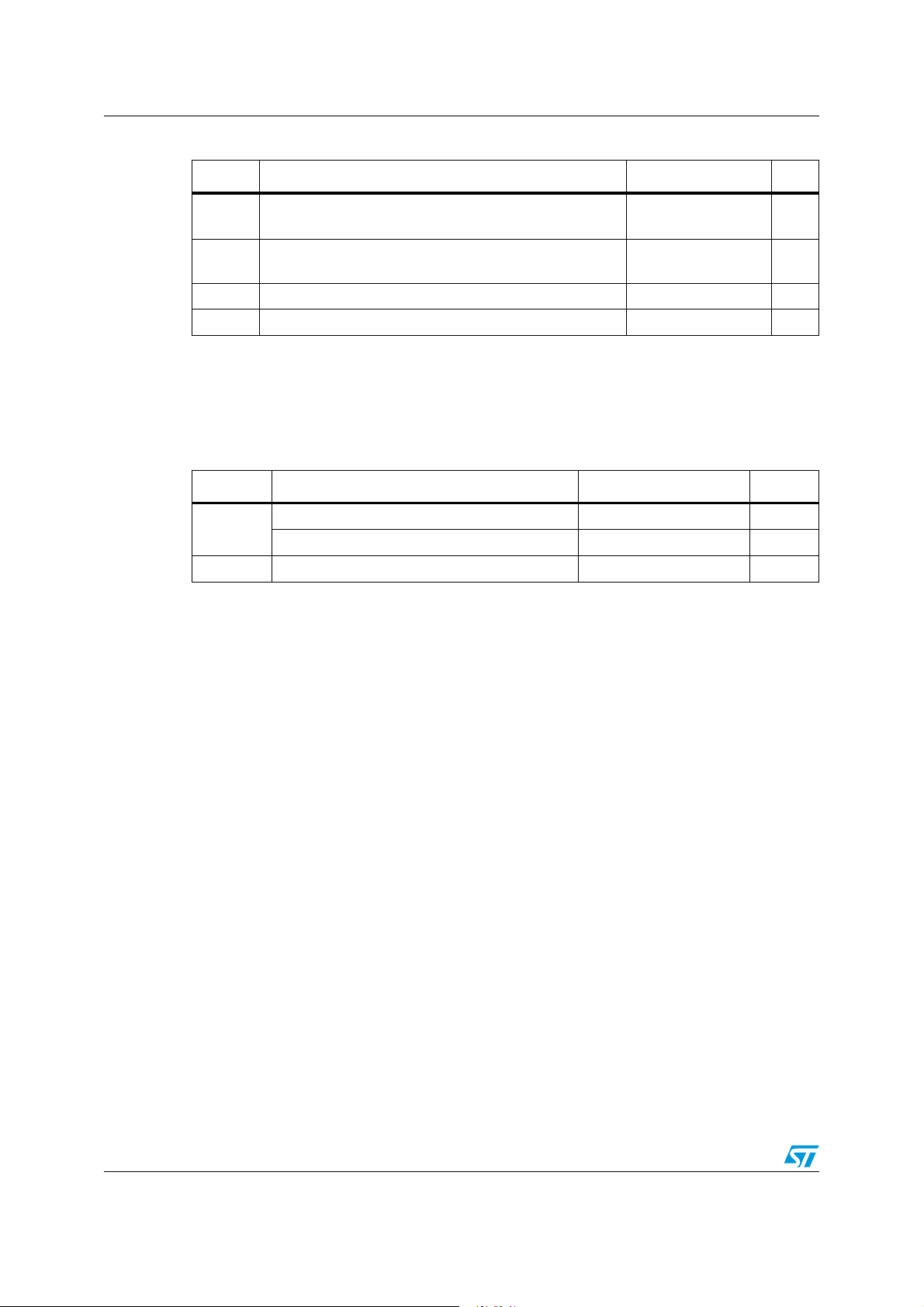

Table 2. Pin definitions and functions (continued)

Pin Symbol Function

6CS_DIS

4IN

A

Active high CMOS compatible pin to disable the current sense

pin

Clockwise input. CMOS compatible

7 PWM PWM input. CMOS compatible.

Output of current sense. This output delivers a current

8CS

proportional to the motor current, if CS_DIS is low or left open.

The information can be read back as an analog voltage across

an external resistor.

Status of high-side and low-side switches B; Open drain output.

This pin must be connected to an external pull up resistor. When

externally pulled low, it disables half-bridge B. In case of fault

9EN

/DIAG

B

detection (thermal shutdown of a high-side FET or excessive

B

ON-state voltage drop across a low-side FET), this pin is pulled

low by the device (see

(detected on OUTA)

10 IN

B

11 CP

OUT

15, 16, 21

26, 27, 28 GND

18, 19, 20 GND

1. GNDA and GNDB must be externally connected together

B,

Heat Slug3

A

B

Counter clockwise input. CMOS compatible

Connection to the gate of the external MOS used for the reverse

battery protection

Source of high-side switch B / drain of low-side switch B, power

connection to the motor

Source of low-side switch A and power ground

Source of low-side switch B and power ground

Table 13: Truth table in fault conditions

.

(1)

(1)

)

Table 3. Block descriptions

(1)

Name Description

Logic control

Overvoltage + undervoltage

High-side, low-side and clamp

voltage

High-side and low-side driver

Linear current limiter

High-side and low-side

overtemperature protection

Low-side overload detector

Allows the turn-on and the turn-off of the high-side and the

low-side switches according to the

Ta bl e 12

.

Shut down the device outside the range [4.5 V to 24 V] for the

battery voltage.

Protect the high-side and the low-side switches from the

high-voltage on the battery line in all configuration for the motor.

Drive the gate of the concerned switch to allow a proper R

DS(on)

for the leg of the bridge.

Limits the motor current, by reducing the high-side switch

gate-source voltage when short-circuit to ground occurs.

In case of short-circuit with the increase of the junction’s

temperature, it shuts down the concerned driver to prevent its

degradation and to protect the die.

Detects when low-side current exceeds shutdown current and

latches off the concerned low-side.

Doc ID 15701 Rev 8 7/37

Block diagram and pin description VNH5019A-E

Table 3. Block descriptions

Name Description

Charge pump

Fault detection

Power limitation

1. See

Figure 1

(1)

(continued)

Provides the voltage necessary to drive the gate of the external

PowerMOS used for the reverse polarity protection

Signalizes an abnormal condition of the switch (output

shorted to ground or output shorted to battery) by pulling

down the concerned ENx/DIAGx pin.

Limits the power dissipation of the high-side driver inside

safe range in case of short to ground condition.

8/37 Doc ID 15701 Rev 8

VNH5019A-E Electrical specifications

2 Electrical specifications

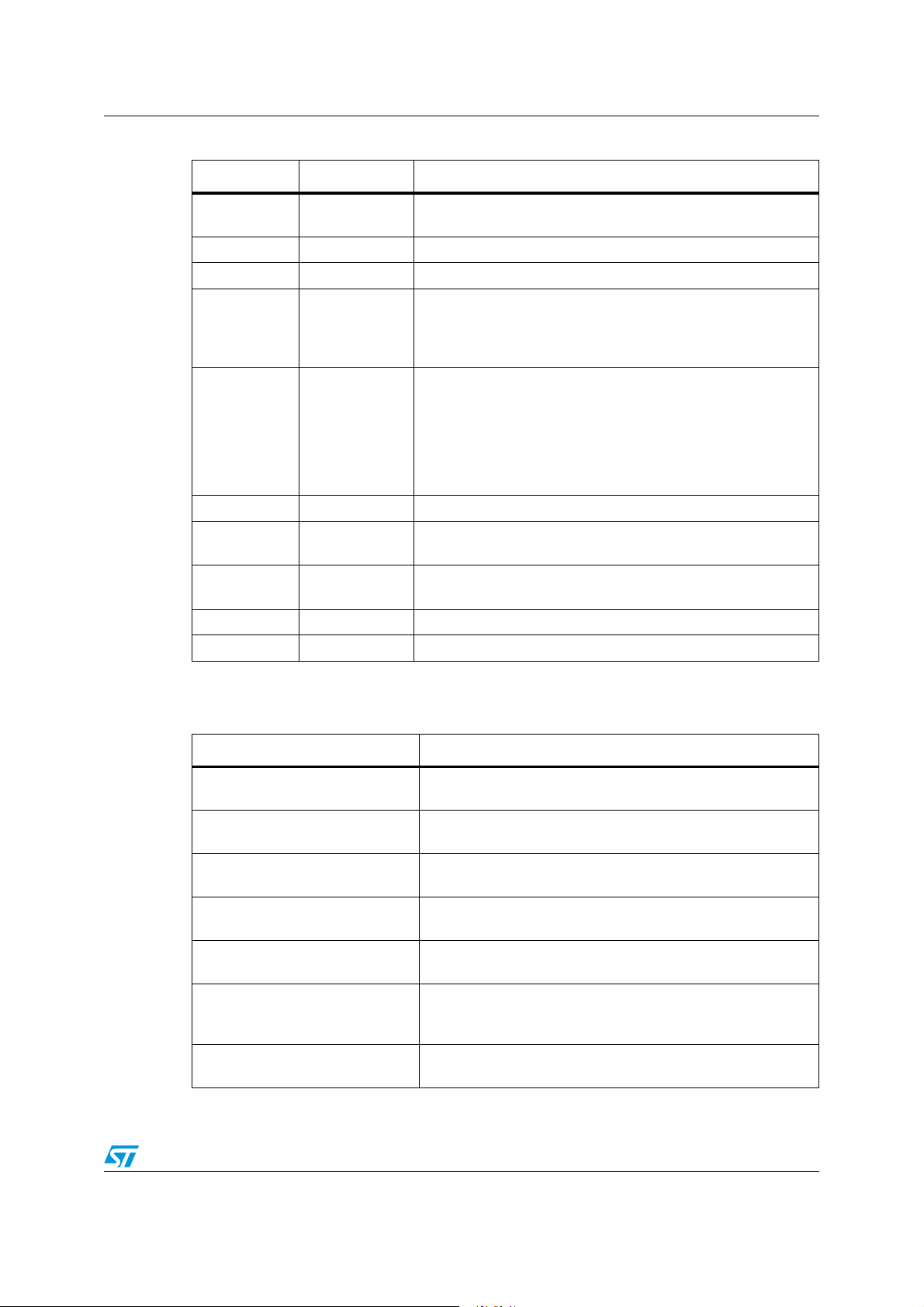

Figure 3. Current and voltage conventions

I

CP

V

CP

I

INA

I

V

INA

V

INB

INB

I

ENA

IN

IN

CP

A

B

DIAGA/EN

I

ENB

V

ENA

V

ENB

DIAGB/EN

PWM

I

pw

V

pw

2.1 Absolute maximum ratings

Stressing the device above the rating listed in the “absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

program and other relevant quality document.

Table 4. Absolute maximum rating

I

BAT

I

S

BAT

GND

V

CC

CS_DIS

GND

A

OUT

OUT

CS

I

A

B

I

SENSE

I

CSD

V

B

CSD

I

OUTB

V

SENSE

OUTA

V

OUTB

V

OUTA

V

A

B

V

BAT

V

CC

GND

I

GND

Symbol Parameter Value Unit

V

V

I

max

I

I

I

I

CS_DIS

Maximum battery voltage

BAT

Maximum bridge supply voltage + 41 V

CC

Maximum output current (continuous) 30 A

I

Reverse output current (continuous) -30 A

R

I

Input current (INA and INB pins) +/- 10 mA

IN

Enable input current (DIAGA/ENA and DIAGB/ENB pins) +/- 10 mA

EN

PWM input current +/- 10 mA

pw

CP output current +/- 10 mA

CP

CS_DIS input current +/- 10 mA

(1)

-16

+41

V

V

Doc ID 15701 Rev 8 9/37

Electrical specifications VNH5019A-E

Table 4. Absolute maximum rating (continued)

Symbol Parameter Value Unit

V

- 41

V

V

T

1. This applies with the n-channel MOSFET used for the reverse battery protection. Otherwise V

shorted to VCC.

Current sense maximum voltage

CS

Electrostatic discharge (human body model: R = 1.5 kΩ,

ESD

C = 100 pF)

Case operating temperature -40 to 150 °C

T

c

Storage temperature -55 to 150 °C

STG

CC

+V

CC

2kV

has to be

BAT

V

V

2.2 Thermal data

Table 5. Thermal data

Symbol Parameter Max. value Unit

R

thj-case

R

thj-amb

Thermal resistance junction-case HSD 1.7 °C/W

Thermal resistance junction-case LSD 3.2 °C/W

Thermal resistance junction-ambient See

Figure 18

°C/W

10/37 Doc ID 15701 Rev 8

VNH5019A-E Electrical specifications

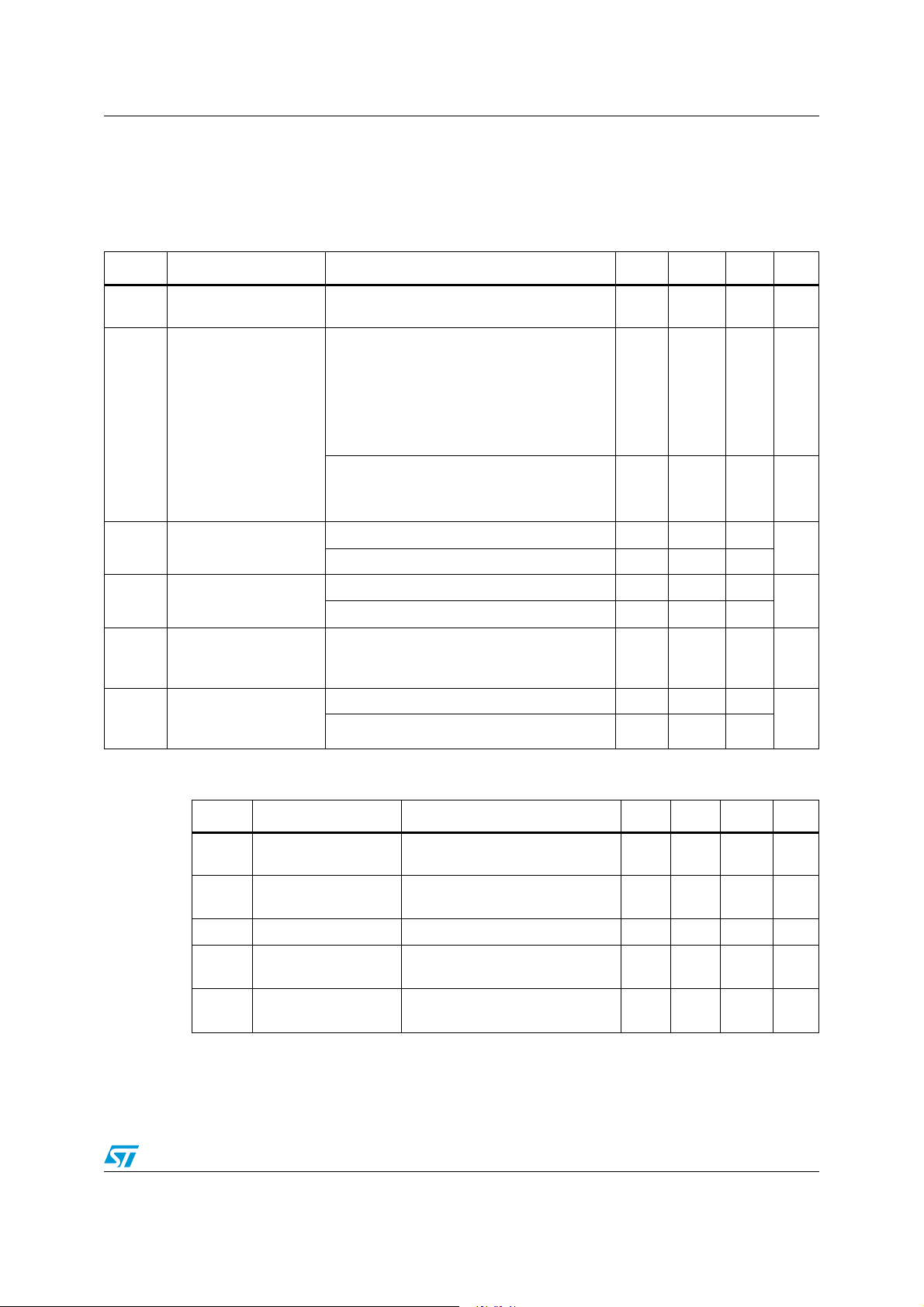

2.3 Electrical characteristics

Values specified in this section are for 8 V < V

< 21 V, -40 °C < Tj < 150 °C, unless

CC

otherwise specified.

Table 6. Power section

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

CC

I

S

R

ONHS

R

ONLS

V

f

I

L(off)

Operating bridge supply

voltage

Supply current

Static high-side

resistance

Static low-side

resistance

High-side

free-wheeling diode

forward voltage

High-side OFF-state

output current (per

channel)

5.5 24 V

OFF-state with all fault cleared and ENx = 0 V

(standby):

= INB = PWM = 0; Tj = 25 °C; VCC = 13 V

IN

A

IN

= INB = PWM = 0

A

10 15

OFF-state (no standby):

INA = INB = PWM = 0; ENx = 5 V

ON-state:

IN

or INB = 5 V, no PWM

A

488mA

INA or INB = 5 V, PWM = 20 kHz

I

= 15 A; Tj = 25 °C 12.0

OUT

I

= 15 A; Tj = - 40 °C to 150 °C 26.5

OUT

= 15 A; Tj = 25 °C 6.0

I

OUT

= 15 A; Tj = - 40 °C to 150 °C 11.5

I

OUT

= 15 A,

I

f

= 150 °C

T

j

= 25 °C; V

T

j

= 125 °C; V

T

j

= ENX = 0 V; VCC = 13 V 3

OUTX

= ENX = 0 V; VCC = 13 V 5

OUTX

0.6 0.8 V

60

6

µA

µA

mA

mA

mΩ

mΩ

µA

Table 7. Logic inputs (INA, INB, ENA, ENB,PWM, CS_DIS)

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

Low-level input voltage

IL

High-level input

V

IH

voltage

I

Low-level input current V

INL

High-level input

I

INH

current

IHYST

Input hysteresis

voltage

V

Normal operation (DIAG

acts as an input pin)

Normal operation (DIAGX/ENX pin

acts as an input pin)

= 0.9 V 1 µA

IN

V

= 2.1 V 10 µA

IN

Normal operation (DIAGX/ENX pin

acts as an input pin)

/ENX pin

X

0.9 V

2.1 V

0.15 V

Doc ID 15701 Rev 8 11/37

Electrical specifications VNH5019A-E

Table 7. Logic inputs (INA, INB, ENA, ENB,PWM, CS_DIS) (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

I

= 1 mA 5.5 6.3 7.5

V

V

Table 8. Switching (VCC = 13 V, R

Input clamp voltage

ICL

Enable low-level

DIAG

output voltage

Symbol Parameter Test conditions Min Typ Max Unit

f PWM frequency 0 20 kHz

t

d(on)

HSD rise time

IN

= -1 mA -1.0 -0.7 -0.3

I

IN

Fault operation (DIAGX/ENX pin

acts as an output pin); I

= 0.87 Ω, Tj = 25 °C)

LOAD

= 1 mA

EN

Input rise time < 1µs

(see

Figure 9

)

V

0.4 V

250 µs

t

d(off)

t

t

t

DEL

t

rr

I

RM

Table 9. Protection and diagnostic

HSD fall time

LSD rise time (see

r

LSD fall time (see

f

Delay time during change of

operating mode

High-side free wheeling

diode reverse recovery time

Dynamic cross-conduction

current

Input rise time < 1µs

(see

(see

(see

I

OUT

(see

Figure 9

Figure 8

Figure 8

Figure 7

Figure 10

= 15 A

Figure 10

)

)12µs

)12µs

) 200 400 1600 µs

)110ns

)

250 µs

2A

Symbol Parameter Test conditions Min Typ Max Unit

V

USD

V

USDhyst

V

OV

I

LIM_H

I

SD_LS

VCC undervoltage

shutdown

V

undervoltage

CC

shutdown hysteresis

V

overvoltage shutdown 24 27 30 V

CC

4.5 5.5 V

0.5 V

High-side current limitation 30 50 70 A

Low-side shutdown current 70 115 160 A

High-side clamp voltage

V

CLPHS

(1)

(VCC to OUTA = 0 or

= 0)

OUT

B

= 15 A 43 48 54 V

I

OUT

Low-side clamp voltage

(1)

V

CLPLS

T

TSD

(OUTA = V

OUT

B

Thermal shutdown

(2)

temperature

or

CC

= VCC to GND)

= 15 A 27 30 33 V

I

OUT

= 2.1 V 150 175 200 °C

V

IN

12/37 Doc ID 15701 Rev 8

Loading...

Loading...