Features

DIP-7

SSO10

6)0%2

$2!). #/-0

'.$ &",)-

6$$

!-V

$#INPUTVOLTAGE

$#OUTPUTVOLTAGE

■ 800 V avalanche rugged power section

■ PWM operation with frequency jittering for low

EMI

■ Operating frequency:

– 30 kHz for VIPER06Xx

– 60 kHz for VIPER06Lx

– 115 kHz for VIPER06Hx

■ No need for an auxiliary winding in low-power

applications

■ Standby power < 30 mW at 265 V

Limiting current with adjustable set point

■

■ On-board soft-start

■ Safe auto-restart after a fault condition

■ Hysteretic thermal shutdown

AC

VIPER06

Fixed-frequency VIPer™ plus family

Datasheet — production data

Figure 1. Typical application

Applications

■ Replacement of capacitive power supplies

■ Home appliances

■ Power metering

■ LED drivers

Description

The VIPER06 is an offline converter with an 800 V

avalanche rugged power section, a PWM

controller, a user-defined overcurrent limit, openloop failure protection, hysteretic thermal

protection, soft startup and safe auto-restart after

any fault condition. The device is able to power

itself directly from the rectified mains, eliminating

the need for an auxiliary bias winding. Advanced

frequency jittering reduces EMI filter cost. Burst

mode operation and the device’s very low power

consumption both help to meet the standards set

by energy-saving regulations.

March 2012 Doc ID 022794 Rev 1 1/28

This is information on a product in full production.

www.st.com

28

Contents VIPER06

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Typical power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Typical circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 High voltage current generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Soft startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11 Adjustable current limit set point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 FB pin and COMP pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

14 Automatic auto-restart after overload or short-circuit . . . . . . . . . . . . 19

15 Open-loop failure protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/28 Doc ID 022794 Rev 1

VIPER06 Contents

17 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

18 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Doc ID 022794 Rev 1 3/28

Block diagram VIPER06

OLP

LOGIC

+

-

E/A

VDD

GND

+

-

PWM

Oscillator

LEB

BURST-MODE

Logic

TURN-ON

LOGIC

SOFT START

UVLO

BURST

OTP

LIM

V

COMPL

HV_ON

SUPPLY

&

UVLO

I

DDch

V

REF_FB

THERMAL

SHUTDOWN

DRAIN

+

-

OCP

I

DLIM

set-up

S

R

Q

Burst

R

SENSE

OTP

Internal Supply BUS &

REFERENCE VOLTAGES

COMP

FB

1 Block diagram

Figure 2. Block diagram

2 Typical power

Table 1. Typical power

230 V

Part number

Adapter

VIPER06 6 W 8 W 4 W 5 W

1. Typical continuous power in non-ventilated enclosed adapter measured at 50 ° C ambient.

2. Maximum practical continuous power in an open-frame design at 50 ° C ambient, with adequate heat

sinking.

4/28 Doc ID 022794 Rev 1

(1)

AC

Open frame

(2)

Adapter

85-265 V

(1)

AC

Open frame

(2)

VIPER06 Pin settings

DRAIN

DRAIN

AM11339v1

DRAIN

DRAIN

DRAIN

DRAIN

DRAIN

GND

VDD

FB

COMP

LIM

3 Pin settings

Figure 3. Connection diagram (top view)

Note: The copper area for heat dissipation has to be designed under the DRAIN pins.

Table 2. Pin description

Pin

Name Function

DIP-7 SSO10

11GND

22VDD

33LIM

44FB

55COMP

7, 8 6-10 DRAIN

Connected to the source of the internal power MOSFET and controller

ground reference.

Supply voltage of the control section. This pin provides the charging

current of the external capacitor.

This pin allows setting the drain current limitation. The limit can be

reduced by connecting an external resistor between this pin and GND.

Pin left open if default drain current limitation is used.

Inverting input of the internal transconductance error amplifier.

Connecting the converter output to this pin through a single resistor

results in an output voltage equal to the error amplifier reference

voltage (see V

in Table 6). An external resistor divider is

FB_REF

required for higher output voltages.

Output of the internal transconductance error amplifier. The

compensation network has to be placed between this pin and GND to

achieve stability and good dynamic performance of the voltage control

loop. The pin is used also to directly control the PWM with an

optocoupler. The linear voltage range extends from V

V

COMPH

(Ta bl e 6 ).

COMPL

to

High-voltage drain pins. The built-in high-voltage switched startup bias

current is drawn from these pins too.

Pins connected to the metal frame to facilitate heat dissipation.

Doc ID 022794 Rev 1 5/28

Electrical data VIPER06

4 Electrical data

4.1 Maximum ratings

Table 3. Absolute maximum ratings

Symbol

V

DRAIN

E

AV

I

AR

I

DRAIN

V

COMP

V

FB

V

LIM

V

DD

I

DD

P

TOT

T

J

T

STG

Pin

(DIP-7)

Parameter

Value

Min Max

7, 8 Drain-to-source (ground) voltage 800 V

7, 8 Repetitive avalanche energy (limited by TJ = 150 °C) 2 mJ

7, 8 Repetitive avalanche current (limited by TJ = 150 °C) 1 A

7, 8 Pulse drain current (limited by TJ = 150 °C) 2.5 A

5 Input pin voltage -0.3 3.5 V

4 Input pin voltage -0.3 4.8 V

3 Input pin voltage -0.3 2.4 V

2 Supply voltage -0.3

Self-

limited

2 Input current 20 mA

Power dissipation at TA < 40 °C (DIP-7) 1 W

Power dissipation at T

< 50 °C (SSO10) 1 W

A

Operating junction temperature range -40 150 °C

Storage temperature -55 150 °C

Unit

V

4.2 Thermal data

Table 4. Thermal data

Symbol Parameter

R

R

R

1. When mounted on a standard single side FR4 board with 100 mm2 (0.155 sq in) of Cu (35 μm thick).

6/28 Doc ID 022794 Rev 1

Thermal resistance junction pin

thJP

(dissipated power = 1 W)

Thermal resistance junction ambient

thJA

(dissipated power = 1 W)

Thermal resistance junction ambient

thJA

(dissipated power = 1 W)

(1)

Max value

SSO10

Max value

DIP-7

35 40 ° C/W

100 110 ° C/W

80 90 ° C/W

Unit

VIPER06 Electrical data

4.3 Electrical characteristics

(TJ = -25 to 125 °C, VDD = 14 V

Table 5. Power section

Symbol Parameter Test condition Min Typ Max Unit

V

BVDSS

I

OFF

R

DS(on)

C

OSS

Table 6. Supply section

Symbol Parameter Test condition Min Typ Max Unit

Vol tag e

Breakdown voltage

OFF state drain current

Drain-source on-state resistance

Effective (energy related) output capacitance V

(a)

unless otherwise specified).

I

= 1 mA,

DRAIN

V

= GND, TJ = 25 °C

COMP

V

V

I

I

= max rating,

DRAIN

= GND

COMP

= 0.2 A, TJ = 25 °C 32 Ω

DRAIN

= 0.2 A, TJ = 125 °C 67 Ω

DRAIN

= 0 to 640 V 10 pF

DRAIN

800 V

60 μA

V

_START

DRAIN

I

DDch1

I

DDch2

V

DD

V

DDclampVDD

V

DDon

V

DDCSon

V

DDoff

Current

I

DD0

I

DD1

I

DDoff

I

DDol

Drain-source startup voltage 25 45 V

= 100 V to 640 V,

V

Startup charging current

Charging current during operation

DRAIN

= 4 V

V

DD

= 100 V to 640 V,

V

DRAIN

= 9 V falling edge

V

DD

-0.6 -1.8 mA

-7 -14 mA

Operating voltage range 11.5 23.5 V

clamp voltage IDD = 15 mA 23.5 V

VDD startup threshold 12 13 14 V

VDD on internal high-voltage current

generator threshold

9.5 10.5 11.5 V

VDD undervoltage shutdown threshold 7 8 9 V

Operating supply current, not switching F

Operating supply current, switching

Operating supply current with VDD < V

DDoffVDD

Open-loop failure current threshold

OSC

V

DRAIN

F

OSC

V

DRAIN

F

OSC

V

DRAIN

F

OSC

V

DD

V

COMP

= 0 kHz, V

= 120 V,

= 30 kHz

= 120 V,

= 60 kHz

= 120 V,

= 115 kHz

< V

DDoff

= V

DDclamp

= 3.3 V,

= GND 0.6 mA

COMP

4 mA

1.3 mA

1.45 mA

1.6 mA

0.35 mA

a. Adjust VDD above V

startup threshold before setting to 14 V.

DDon

Doc ID 022794 Rev 1 7/28

Electrical data VIPER06

Table 7. Controller section

Symbol Parameter Test condition Min Typ Max Unit

Error amplifier

V

REF_FB

I

FB_PULL UP

G

M

FB reference voltage 3.2 3.3 3.4 V

Current pull-up -1 μA

Transconductance 2 mA/V

Current setting (LIM) pin

V

LIM_LOW

Low-level clamp voltage I

Compensation (COMP) pin

V

COMPH

V

COMPL

V

COMPL_HYS

H

COMP

R

COMP(DYN)

Upper saturation limit TJ = 25 °C 3 V

Burst mode threshold TJ = 25 °C 1 1.1 1.2 V

Burst mode hysteresis TJ = 25 °C 40 mV

ΔV

COMP

/ ΔI

DRAIN

Dynamic resistance V

Source / sink current V

I

COMP

Max source current V

Current limitation

I

Dlim

t

SS

T

ON_MIN

I

Dlim_bm

Drain current limitation

Soft-start time 8.5 ms

Minimum turn-on time 450 ns

Burst mode current limitation V

Overload

= -100 μA0.5V

LIM

49V/A

= GND 15 kΩ

FB

> 100 mV 150 μA

FB

COMP

= -10 μA, V

I

LIM

= 25 °C

T

J

COMP

= GND, V

= V

COMPL

= GND 220 μA

FB

= 3.3 V,

COMP

0.32 0.35 0.38 A

85 mA

t

OVL

t

RESTART

Overload time 50 ms

Restart time after fault 1 s

Oscillator section

VIPER06Xx 27 30 33 kHz

F

OSC

Switching frequency

VIPER06Lx 54 60 66 kHz

VIPER06Hx 103 115 127 kHz

= 30 kHz ±3 kHz

F

OSC

F

= 60 kHz ±4 kHz

OSC

F

= 115 kHz ±8 kHz

OSC

D

F

D

F

M

MAX

Modulation depth

Modulation frequency 230 Hz

Maximum duty cycle 70 80 %

8/28 Doc ID 022794 Rev 1

VIPER06 Electrical data

Table 7. Controller section (continued)

Symbol Parameter Test condition Min Typ Max Unit

Thermal shutdown

T

T

HYST

SD

Thermal shutdown temperature 150 160 °C

Thermal shutdown hysteresis 30 °C

Doc ID 022794 Rev 1 9/28

Typical electrical characteristics VIPER06

IDlim/ IDlim@2 5°C

0.94

0.96

0.98

1.00

1.02

1.04

-50 0 50 100 150

TJ [°C]

AM01144v1

AM01145v1

FOSC / FOSC@25°C

0.92

0.94

0.96

0.98

1.00

1.02

1.04

-50 0 50 100 150

TJ [°C]

AM01146v1

VDRAIN_START / VDRAIN_START@25°C

0.960

0.970

0.980

0.990

1.000

1.010

1.020

-50 0 50 100 150

TJ [°C]

AM01147v1

HCO M P / HC OM P@2 5°C

0.80

0.90

1.00

1.10

1.20

1.30

-50 0 50 100 150

TJ [°C]

AM01148v1

GM / GM@ 25°C

0.80

0.85

0.90

0.95

1.00

1.05

1.10

-50 0 50 100 150

TJ [°C]

AM01149v1

VR EF_F B / V REF_ FB@25°C

0.80

0.84

0.88

0.92

0.96

1.00

1.04

1.08

-50 0 50 100 150

TJ [°C]

5 Typical electrical characteristics

Figure 4. I

Figure 6. V

vs. TJ Figure 5. F

Dlim

DRAIN_START

vs. T

J

Figure 7. H

OSC

COMP

vs. T

vs. T

J

J

Figure 8. GM vs. T

10/28 Doc ID 022794 Rev 1

J

Figure 9. V

REF_FB

vs. T

J

VIPER06 Typical electrical characteristics

AM01150v1

ICOM P / ICOM P@25°C

0.80

0.84

0.88

0.92

0.96

1.00

1.04

1.08

-50 0 50 100 150

TJ [°C]

AM01151v1

IDD0 / IDD0 @25°C

0.80

0.84

0.88

0.92

0.96

1.00

1.04

1.08

-50 0 50 100 150

TJ [°C]

AM01152v1

IDD1 / IDD 1@25°C

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

-50 0 50 100 150

TJ [°C]

AM01153v1

IDlim / IDlim@100KOhm

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

020406080100

Rli m [ kO hm ]

Figure 10. I

COMP

vs. T

J

Figure 12. Operating supply current

(switching) vs. T

J

Figure 11. Operating supply current

Figure 13. I

(no switching) vs. T

Dlim

vs. R

LIM

J

Figure 14. Power MOSFET on-resistance

vs. T

J

Figure 15. Power MOSFET breakdown voltage

vs. T

J

Doc ID 022794 Rev 1 11/28

Typical electrical characteristics VIPER06

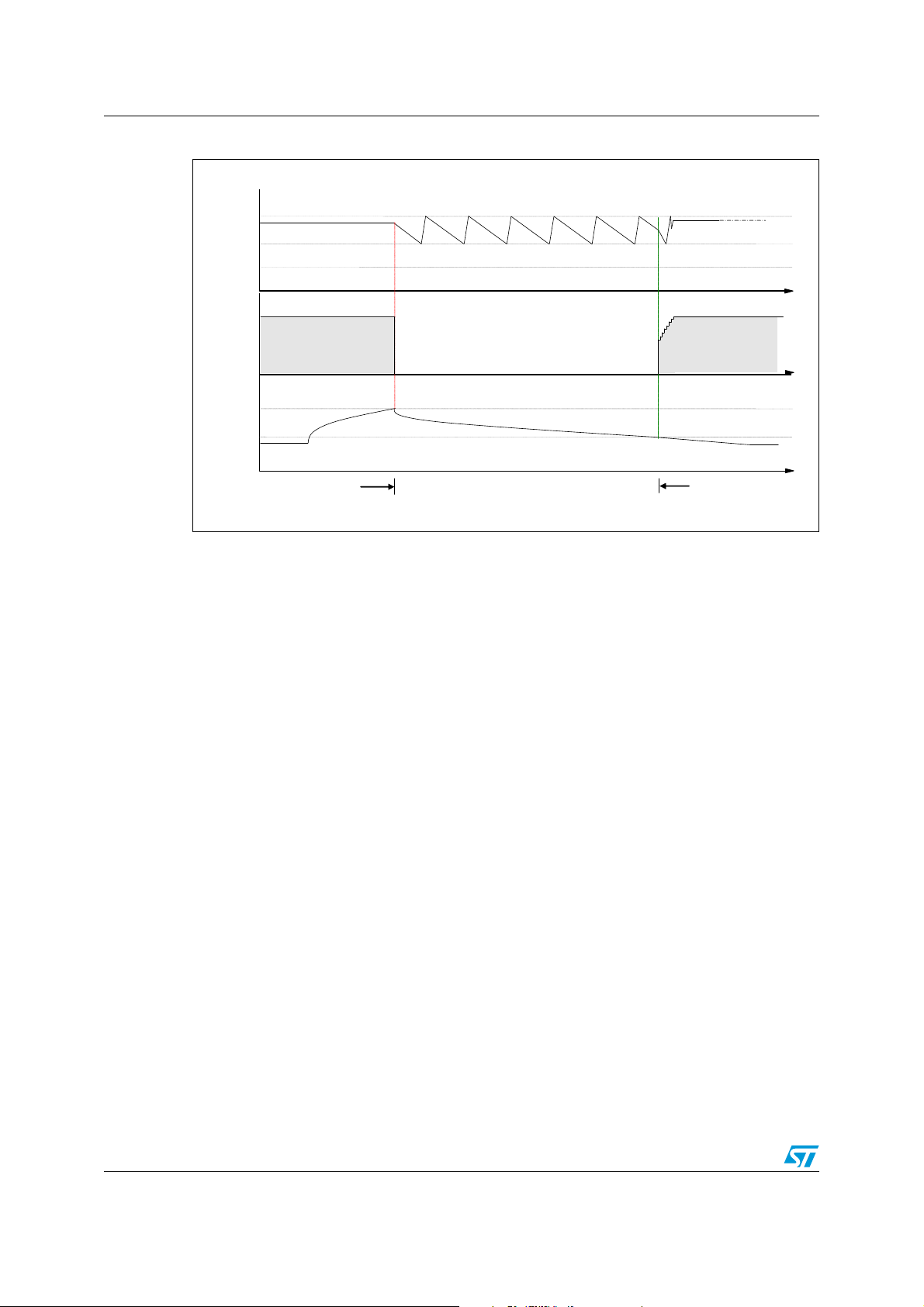

T

J

V

DD

I

DRAIN

V

DDon

time

V

DDCSon

V

DDoff

T

SD

time

time

T

SD -THYST

Shut down after over temperature

Normal operation Normal operation

Figure 16. Thermal shutdown

12/28 Doc ID 022794 Rev 1

VIPER06 Typical circuit

AM01197v1

VOUT

4

12

10

66

+

Cout

+

C2

Rcomp1

Ccl

CONTROL

FB

DRAIN

GND

VDD

COMP

LIM

VIPer16

AC IN

Rcl

D1

Rfb2

AC IN

Ccomp1

RLIM

Dout

Rfb1

Rin

Daux

-+

Din

1

4

3

2

(optional)

+

C3

C1

L1

Ccomp2

AM01195v1

-

AC IN

AC IN

VOUT

L1L1

C5C5

C3C3

C4C4

+C7+

C7

R3R3

R5R5

D3D3

CONTROL

FB

DRAIN

GND

VDD

COMP

LIM

VIPER06

CONTROL

FB

DRAIN

GND

VDD

COMP

LIM

VIPER06

+C2+

C2

C8C8R4R4

D1D1

+C1+

C1

R1R1

R6R6

T2T2

C6C6

IC2IC2

IC3IC3

D2D2

R2R2

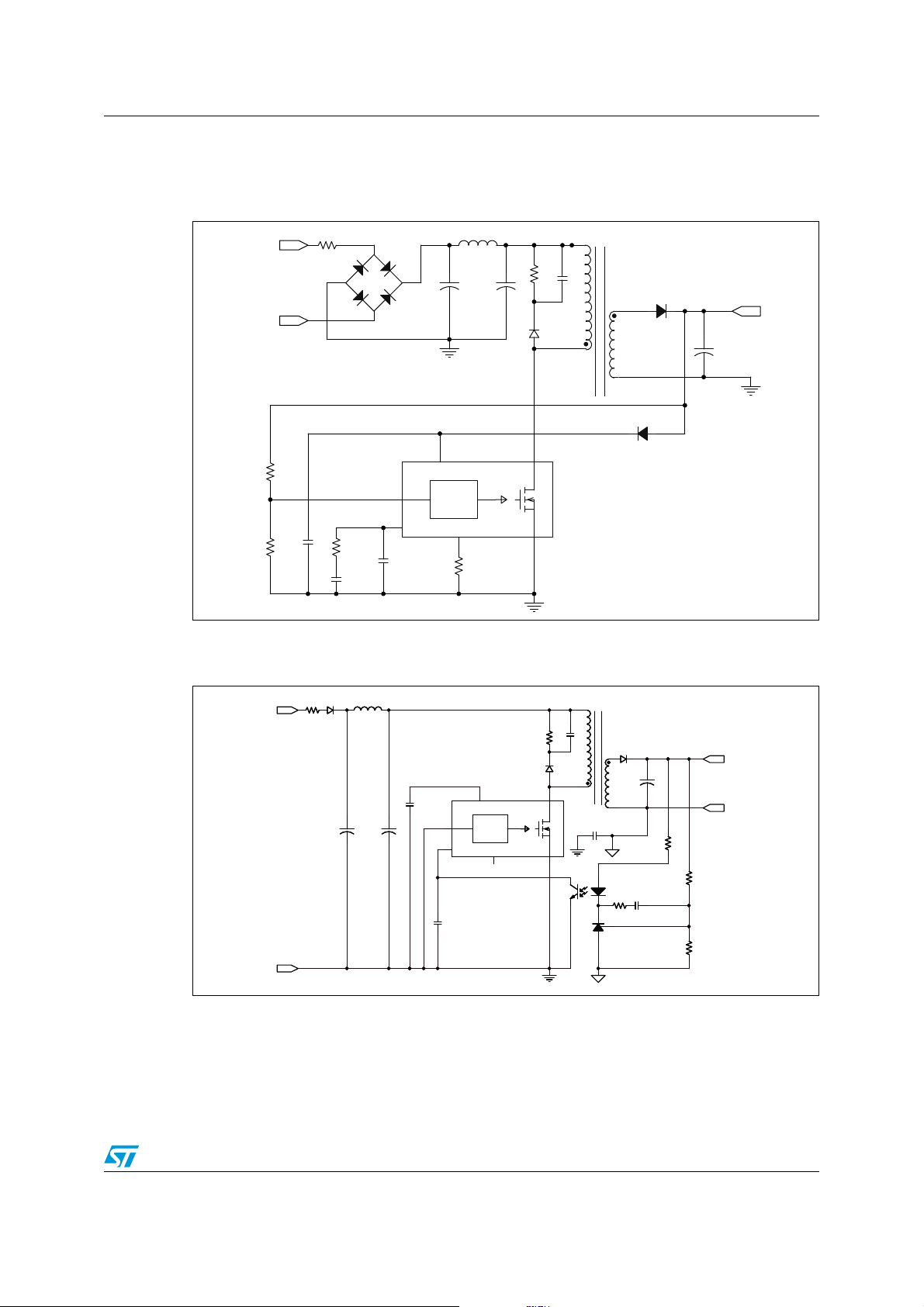

6 Typical circuit

Figure 17. Flyback converter (non-isolated output)

Figure 18. Flyback converter (isolated output)

Doc ID 022794 Rev 1 13/28

Typical circuit VIPER06

(optional)

Rfbl

L1

CONTROL

FB

DRAIN

GND

VDD

COMP

LIM

VIPer06

Rfbh

+

Cout

TRANSF

1

3

4

12

10

66

FUSE

Daux

+

CVDD

Rc

+

C1

D2

Rcl

Cfb

-+

D0

BRIDGE

1

4

3

2

D1

Cc

Cp RLIM

Ccl

+

C2

Raux

Vou t

AC IN

AC IN

.

AM01196v1

(optional)

CONTROL

FB

DRAIN

GND

VDD

COMP

LIM

VIPer06

Ccomp

Rfb2

Cout

C1

D2

Lout

C3

Rfb1

Rcomp

C4

L1

C2

RLIM

Cfb

Dout

AC IN

GND

Vout

AM01194v1

Figure 19. Flyback converter (isolated output without optocoupler)

Figure 20. Buck converter

14/28 Doc ID 022794 Rev 1

VIPER06 Power section

I

DD

V

DD

V

DRAIN

V

DDon

t

t

t

t

V

IN

V

DRAIN_START

t

t

Power-on

Power-off

Normal operat ion

regulation is lost here

VIN< V

DRAIN_START

HV startup is no more ac tivated

With internal self-supply

Without internal se lf-supply

V

DDCSon

V

DDoff

I

DDch1

I

DDch2

7 Power section

The power section is implemented with an N-channel power MOSFET with a breakdown

voltage of 800 V min. and a typical R

of 32 Ω. It includes a SenseFET structure to allow

DS(on)

virtually lossless current sensing and the thermal sensor.

The gate driver of the power MOSFET is designed to supply a controlled gate current during

both turn-ON and turn-OFF in order to minimize common-mode EMI. During UVLO

conditions, an internal pull-down circuit holds the gate low in order to ensure that the power

MOSFET cannot be turned ON accidentally.

8 High voltage current generator

The high-voltage current generator is supplied by the DRAIN pin. At the first startup of the

converter it is enabled when the voltage across the input bulk capacitor reaches the

V

DRAIN_START

voltage reaches the V

voltage current generator is turned OFF. The VIPER06 is powered by the energy stored in

the V

DD

In a steady-state condition, if the self-biasing function is used, the high-voltage current

generator is activated between V

I

, see Table 6 on page 7 to the VDD capacitor during the MOSFET off-time (see

DDch2

Figure 21).

threshold, sourcing a I

DDon

capacitor.

current (see Table 6 on page 7). As the VDD

DDch1

threshold, the power section starts switching and the high-

DDCSon

and V

(see Table 6 on page 7), delivering

DDon

The device can also be supplied through the auxiliary winding in which case the highvoltage current source is disabled during steady-state operation, provided that VDD is

above V

DDCSon

At converter power-down, the V

below the V

.

voltage drops and the converter activity stops as it falls

threshold (see Table 6 on page 7).

DDoff

DD

Figure 21. Power-on and power-off

Doc ID 022794 Rev 1 15/28

Oscillator VIPER06

9 Oscillator

The switching frequency is internally fixed at 30 kHz or 60 kHz or 115 kHz (respectively part

numbers VIPER06Xx, VIPER06Lx and VIPER06Hx).

The switching frequency is modulated by approximately ±3 kHz (30 kHz version) or ±4 kHz

(60 kHz version) or ±8 kHz (115 kHz version) at 230 Hz (typical) rate, so that the resulting

spread spectrum action distributes the energy of each harmonic of the switching frequency

over a number of sideband harmonics having the same energy on the whole, but smaller

amplitudes.

10 Soft startup

During the converter’s startup phase, the soft-start function progressively increases the

cycle-by-cycle drain current limit, up to the default value I

further limited and the output voltage is progressively increased, reducing the stress on the

secondary diode. The soft-start time is internally fixed to t

in Table 7 on page 8, and the function is activated for any attempt of converter startup and

after a fault event.

. In this way the drain current is

Dlim

, see typical value

SS

This function helps prevent saturation of the transformer during startup and short-circuit.

11 Adjustable current limit set point

The VIPER06 includes a current-mode PWM controller. The drain current is sensed cycleby-cycle through the integrated resistor R

inverting input of the PWM comparator, see Figure 2 on page 4. As soon as the sensed

voltage is equal to the voltage derived from the COMP pin, the power MOSFET is switched

OFF.

In parallel with the PWM operations, the comparator OCP, see Figure 2 on page 4, checks

the level of the drain current and switches OFF the power MOSFET in case the current is

higher than the threshold I

The level of the drain current limit I

, see Table 7 on page 8.

Dlim

can be reduced using a resistor R

Dlim

between the LIM and GND pins. Current is sunk from the LIM pin through the resistor R

and the setup of I

R

is shown in Figure 13 on page 11.

LIM

When the LIM pin is left open or if R

fixed to its default value, I

depends on the level of this current. The relation between I

Dlim

has a high value (i.e. > 80 kΩ), the current limit is

, as given in Table 7 on page 8.

Dlim

LIM

and the voltage is applied to the non-

SENSE

connected

LIM

Dlim

LIM

and

16/28 Doc ID 022794 Rev 1

VIPER06 FB pin and COMP pin

FB

COMP

Without Isolation:

switch open & E/A enabled

With Isolation:

switch closed & E/A disabled

No

Isolation

V

OUT

+

-

PWM stop

from R

SENSE

R

Isolation

R

L

nR

SW

V

REF

R

COMP

+

-

E/A

BUS

+

-

to PWM

V

COMPL

R

H

V

REF_FB

12 FB pin and COMP pin

The device can be used both in non-isolated and isolated topology. In non-isolated topology,

the feedback signal from the output voltage is applied directly to the FB pin as the inverting

input of the internal error amplifier having the reference voltage, V

page 8.

REF_FB,

see Ta b le 7 o n

The output of the error amplifier sources and sinks the current, I

, respectively to and

COMP

from the compensation network connected on the COMP pin. This signal is then compared

in the PWM comparator with the signal coming from the SenseFET in order to switch off the

power MOSFET on a cycle-by-cycle basis. See the Figure 2 on page 4 and the Figure 22.

When the power supply output voltage is equal to the error amplifier reference voltage,

V

REF_FB

, a single resistor has to be connected from the output to the FB pin. For higher

output voltages the external resistor divider is needed. If the voltage on the FB pin is

accidentally left floating, an internal pull-up protects the controller.

The output of the error amplifier is externally accessible through the COMP pin and it’s used

for the loop compensation, usually an RC network.

As shown in Figure 22, in case of an isolated power supply, the internal error amplifier has to

be disabled (FB pin shorted to GND). In this case an internal resistor is connected between

an internal reference voltage and the COMP pin, see Figure 22. The current loop has to be

closed on the COMP pin through the opto-transistor in parallel with the compensation

network. The V

dynamic range is between V

COMP

COMPL

and V

COMPH

shown in Figure 23 on

page 18.

When the voltage V

drops below the voltage threshold V

COMP

, the converter enters

COMPL

burst mode, see Section 13 on page 18.

When the voltage V

rises above the V

COMP

COMPH

threshold, the peak drain current, as well

as the deliverable output power, will reach its limit.

Figure 22. Feedback circuit

Doc ID 022794 Rev 1 17/28

Burst mode VIPER06

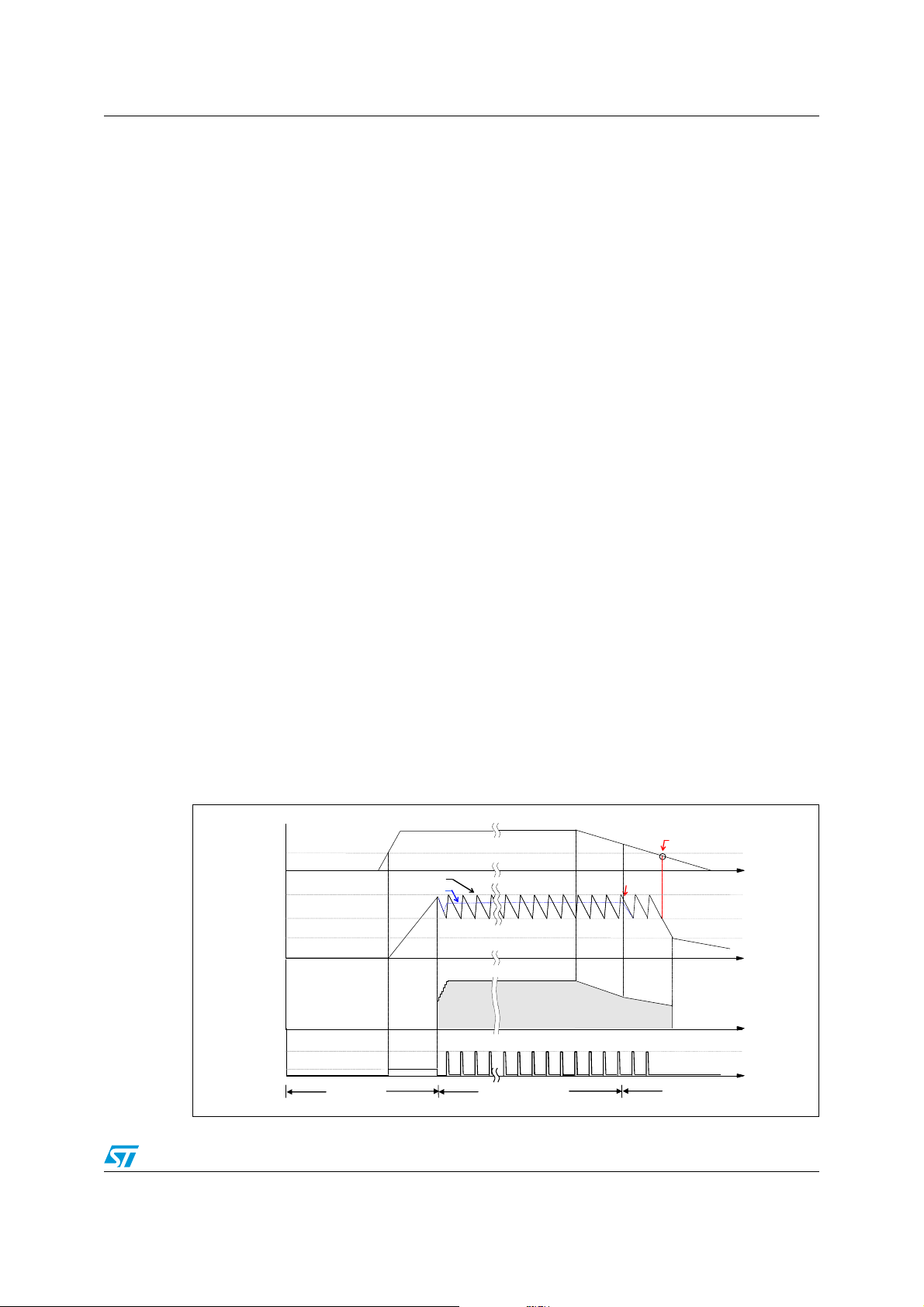

AM01095v1

V

COMPH

V

COMPL

I

Dlim_bm

I

Dlim

I

DRAIN

V

COMP

time

time

time

V

COMP

V

COMPL+VCOMPL_HYS

V

COMPL

I

DD1

I

DD0

I

DD

I

DRAIN

I

Dlim_bm

Burst Mode

Figure 23. COMP pin voltage versus I

13 Burst mode

When the voltage V

the OFF state and the consumption is reduced to the I

page 7. In reaction to the loss of energy, the V

exceeds the threshold V

level of consumption equal to the I

“burst mode” and shown in Figure 24 on page 18, reduces the average frequency, which can

go down even to a few hundreds hertz, thus minimizing all frequency-related losses and

making it easier to comply with energy-saving regulations. During burst mode, the drain

current limit is reduced to the value I

audible noise issue.

DRAIN

drops below the threshold, V

COMP

+ V

COMPL

COMPL_HYS

current. This ON-OFF operation mode, referred to as

DD1

Dlim_bm

, the power MOSFET is kept in

COMPL

current, as reported on Ta ble 6 on

DD0

voltage increases and as soon as it

COMP

, the converter starts switching again with a

(given inTable 7 on page 8) in order to avoid the

Figure 24. Load-dependent operating modes: timing waveforms

18/28 Doc ID 022794 Rev 1

VIPER06 Automatic auto-restart after overload or short-circuit

time

time

V

DD

V

DDon

V

DDCSon

I

DRAIN

I

Dlim_bm

t

1

*

* The time t1 can be lower or equal to the time t

OVL

t

RESTART

t

SS

t

OVL

t

RESTART

t

SS

t

OVL

t

RESTART

t

SS

SHORT CIRCUIT

OCCURS HERE

SHORT CIRCUIT

REMOVED HERE

time

time

V

DD

V

DDon

V

DDCSon

I

DRAIN

I

Dlim_bm

t

1

*

* The time t1can be lower t han or equal to the time t

OVL

t

RESTART

t

SS

t

OVL

t

RESTART

t

SS

t

OVL

t

RESTART

t

SS

SHORT CIRCUIT

OCCURS HERE

SHORT CIRCUIT

REMOVED HERE

14 Automatic auto-restart after overload or short-circuit

The overload protection is implemented automatically using the integrated up-down counter.

Every cycle, it is incremented or decremented depending upon the current logic detection of

the limit condition or not. The limit condition is the peak drain current, I

on page 8 or the one set by the user through the R

resistor, shown in Figure 13 on

LIM

page 11. After the reset of the counter, if the peak drain current is continuously equal to the

level I

, the counter will be incremented until the fixed time, t

Dlim

, at which point the power

OVL

MOSFET switch ON will be disabled. It will be activated again through the soft-start after the

t

RESTART

time (see Figure 25 and Figure 26 on page 19) and the time values mentioned in

Table 7 on page 8.

For overload or short-circuit events, the power MOSFET switching will be stopped after a

period of time dependent upon the counter with a maximum equal to t

sequence continues until the overload condition is removed, see Figure 25 and Figure 26.

This protection ensures a low repetition rate of restart attempts of the converter, so that it

works safely with extremely low power throughput and avoids overheating the IC in case of

repeated overload events. If the overload is removed before the protection tripping, the

counter will be decremented cycle-by-cycle down to zero and the IC will not be stopped.

Figure 25. Timing diagram: OLP sequence (IC externally biased)

given in Ta bl e 7

Dlim ,

. The protection

OVL

Figure 26. Timing diagram: OLP sequence (IC internally biased)

Doc ID 022794 Rev 1 19/28

Open-loop failure protection VIPER06

V

COMPL

D

AUX

nR

FB

VDD

V

AUX

COMP

+

-

to PWM

R

L

+

-

E/A

R

H

R

R

AUX

C

VDD

V

OUT

R

S

V

REF_FB

from R

SENSE

BUS

+

-

PWM stop

C

S

C

P

15 Open-loop failure protection

If the power supply has been designed using flyback topology and the VIPER06 is supplied

by an auxiliary winding, as shown in Figure 27 and Figure 28 on page 21, the converter is

protected against feedback loop failure or accidental disconnections of the winding.

The following description is applicable for the schematics of Figure 27 and Figure 28 on

page 21, respectively the non-isolated flyback and the isolated flyback.

If R

is open or RL is shorted, the VIPER06 works at its drain current limitation. The output

H

voltage, V

output through the secondary-to-auxiliary turns ratio.

, will increase as does the auxiliary voltage, V

OUT

, which is coupled with the

AUX

As the auxiliary voltage increases up to the internal V

active clamp, V

DD

DDclamp

(the value is

given in Table 7 on page 8) and the clamp current injected on the VDD pin exceeds the latch

threshold, I

(the value is given in Table 7 on page 8), a fault signal is internally

DDol

generated.

In order to distinguish an actual malfunction from a bad auxiliary winding design, both the

above conditions (drain current equal to the drain current limitation and current higher than

I

through the VDD clamp) have to be verified to reveal the fault.

DDol

If R

is open or RH is shorted, the output voltage, V

L

voltage V

REF_FB

(for non-isolated flyback) or to the external TL voltage reference (for

, will be clamped to the reference

OUT

isolated flyback).

Figure 27. FB pin connection for non-isolated flyback

20/28 Doc ID 022794 Rev 1

VIPER06 Open-loop failure protection

V

REF_FB

R

H

C

COMP

+

-

PWM st op

R

3

R

TL

R

AUX

R

COMP

C

VDD

-

COMP

+

-

E/A

nR

R

L

V

REF

C

C

U5

Disabled

V

AUX

V

OUT

+

-

to PWM

SW

FB

R

OPTO

BUS

D

AUX

V

COMPL

from R

SENSE

R

C

Figure 28. FB pin connection for isolated flyback

Doc ID 022794 Rev 1 21/28

Package mechanical data VIPER06

16 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

Table 8. DIP-7 mechanical data

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

mm

Dim.

Typ Min Max

A 5.33

A1 0.38

A2 3.30 2.92 4.95

b 0.46 0.36 0.56

b2 1.52 1.14 1.78

c 0.25 0.20 0.36

D 9.27 9.02 10.16

E 7.87 7.62 8.26

E1 6.35 6.10 7.11

e 2.54

eA 7.62

eB 10.92

L 3.30 2.92 3.81

(1)(2)

M

N 0.50 0.40 0.60

N1 0.60

(2)(3)

O

1. Creepage distance > 800 V.

2. Creepage distance as given in the 664-1 CEI / IEC standard.

3. Creepage distance 250 V.

2.508

0.548

Note: 1 The lead size includes the thickness of the lead finishing material.

2 Dimensions do not include mold protrusion, not to exceed 0.25 mm in total (both sides).

3 Package outline exclusive of metal burr dimensions.

4 Datum plane “H” coincident with the bottom of lead, where lead exits body (refer to

Figure 29 on page 23).

22/28 Doc ID 022794 Rev 1

VIPER06 Package mechanical data

Figure 29. DIP-7 package dimensions

Doc ID 022794 Rev 1 23/28

Package mechanical data VIPER06

Table 9. SSO10 mechanical data

Databook (mm.)

Dim.

Typ Min. Max

A 1.75

A1 0.10 0.25

A2 1.25

b 0.31 0.51

c 0.17 0.25

D 4.90 4.80 5

E 6 5.80 6.20

E1 3.90 3.80 4

e 1

h 0.25 0.50

L 0.40 0.90

K 0° 8°

24/28 Doc ID 022794 Rev 1

VIPER06 Package mechanical data

8140761 rev. A

Figure 30. SSO10 package dimensions

Doc ID 022794 Rev 1 25/28

Order codes VIPER06

17 Order codes

Table 10. Ordering information

Order code Package Packaging

VIPER06XN

DIP-7 TubeVIPER06LN

VIPER06HN

VIPER06XS

VIPER06XSTR Tape and reel

VIPER06LS Tube

SSO10

VIPER06LSTR Tape and reel

VIPER06HS Tube

VIPER06HSTR Tape and reel

Tube

26/28 Doc ID 022794 Rev 1

VIPER06 Revision history

18 Revision history

s

Table 11. Document revision history

Date Revision Changes

08-Mar-2012 1 Initial release.

Doc ID 022794 Rev 1 27/28

VIPER06

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

28/28 Doc ID 022794 Rev 1

Loading...

Loading...