A. S. D.

EMI filter and line termination for USB upstream ports

Application

EMI Filter and line termination for USB upstream

ports on:

■ USB Hubs

■ PC peripherals

Features

■ Monolithic device with recommended line

termination for USB upstream ports

■ Integrated Rt series termination and Ct

bypassing capacitors.

■ Integrated ESD protection

■ Small package size

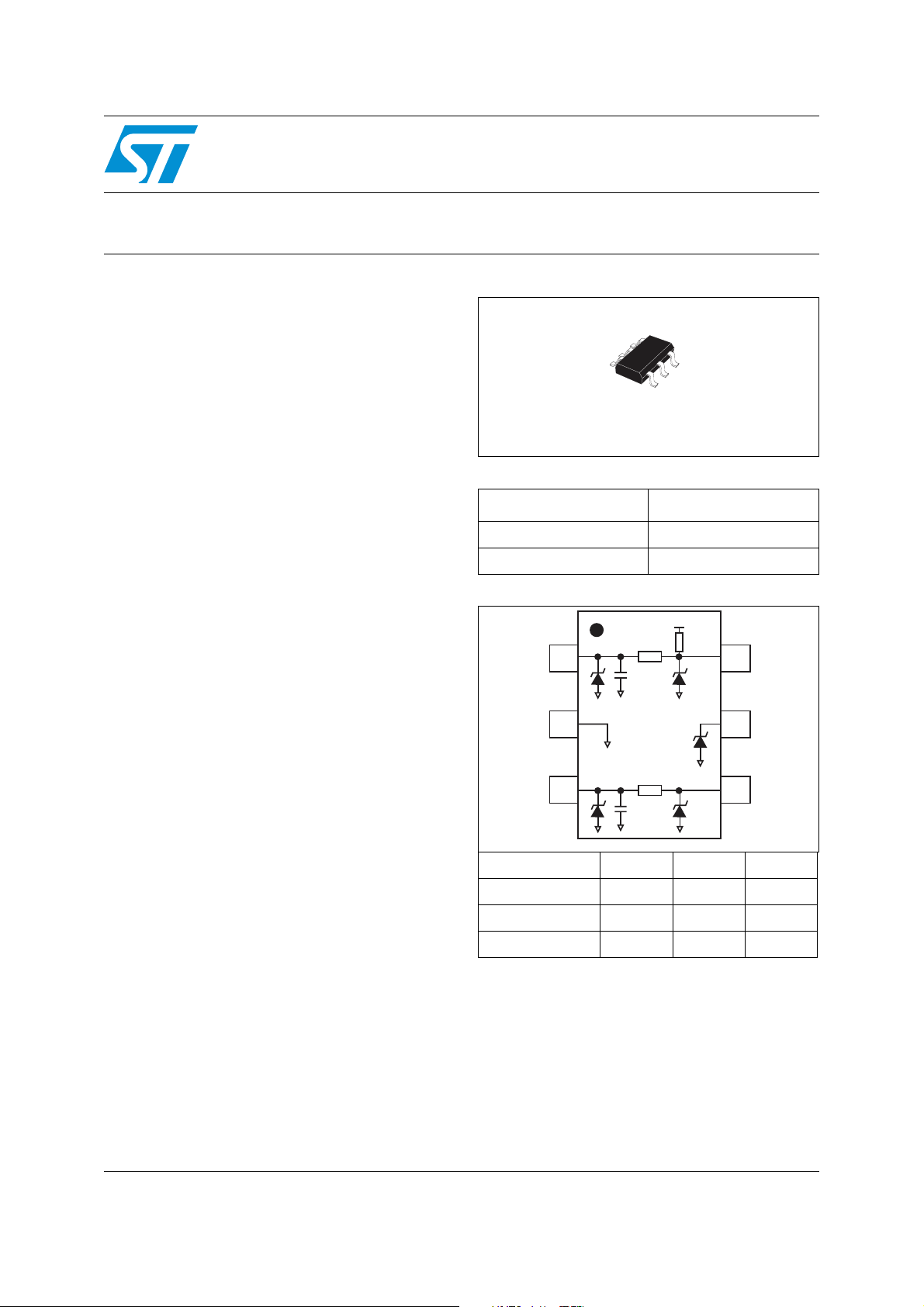

USBUFxxW6

SOTT323-6L

Table 1. Order Codes

Part N umber Marking

USBUF01W6 UU1

USBUF02W6 UU2

Description

The USB specification requires upstream ports to

be terminated with pull-up resistors from the D+

and D- lines to Vbus. On the implementation of

USB systems, the radiated and conducted EMI

should be kept within the required levels as stated

by the FCC regulations. In addition to the

requirements of termination and EMC

compatibility, the computing devices are required

to be tested for ESD susceptibility.

The USBUFxxW6 provides the recommended line

termination while implementing a low pass filter to

limit EMI levels and providing ESD protection

which exceeds IEC 61000-4-2 level 4 standard.

The device is packaged in a SOT323-6L which is

the smallest available lead frame package (50%

smaller than the standard SOT23).

Benefits

■ EMI / RFI noise suppression

■ Required line termination for USB upstream

ports

■ ESD protection exceeding

IEC 61000-4-2 level 4

■ High flexibility in the design of high density

boards

■ Tailored to meet USB 1.1 standard

Figure 1. Functional diagram

3.3 V

Rp

D1

Grd

D2

CODE 01 33 Ω 1.5 kΩ 47 pF

CODE 02 22 Ω 1.5 kΩ 47 pF

Tolerance ± 10% ± 10% ± 20%

Rt

Ct

Rt

Ct

Rt Rp Ct

D4

3.3 V

D3

Complies with the following standards:

IEC 61000-4-2, level 4 ± 15 kV (air discharge)

± 8 kV (contact discharge)

MIL STD 883E, Method 3015-7

Class 3 C = 100 pF R = 1500 Ω

3 positive strikes and 3 negative strikes (F = 1 Hz)

February 2006 Rev 5 1/11

www.st.com

11

Characteristics USBUFxxW6

1 Characteristics

Table 2. Absolute ratings (T

Symbol Parameter Value Unit

amb

= 25° C)

ESD discharge IEC 61000-4-2, air discharge

V

PP

ESD discharge IEC 61000-4-2, contact discharge

ESD discharge - MIL STD 883E - Method 3015-7

T

Maximum junction temperature 150 °C

j

T

Storage temperature range - 55 to + 150 °C

stg

T

Lead solder temperature (10 second duration) 260 °C

L

T

Operating temperature range -40 to 70 °C

op

P Power rating per resistor 100 mW

2 Technical information

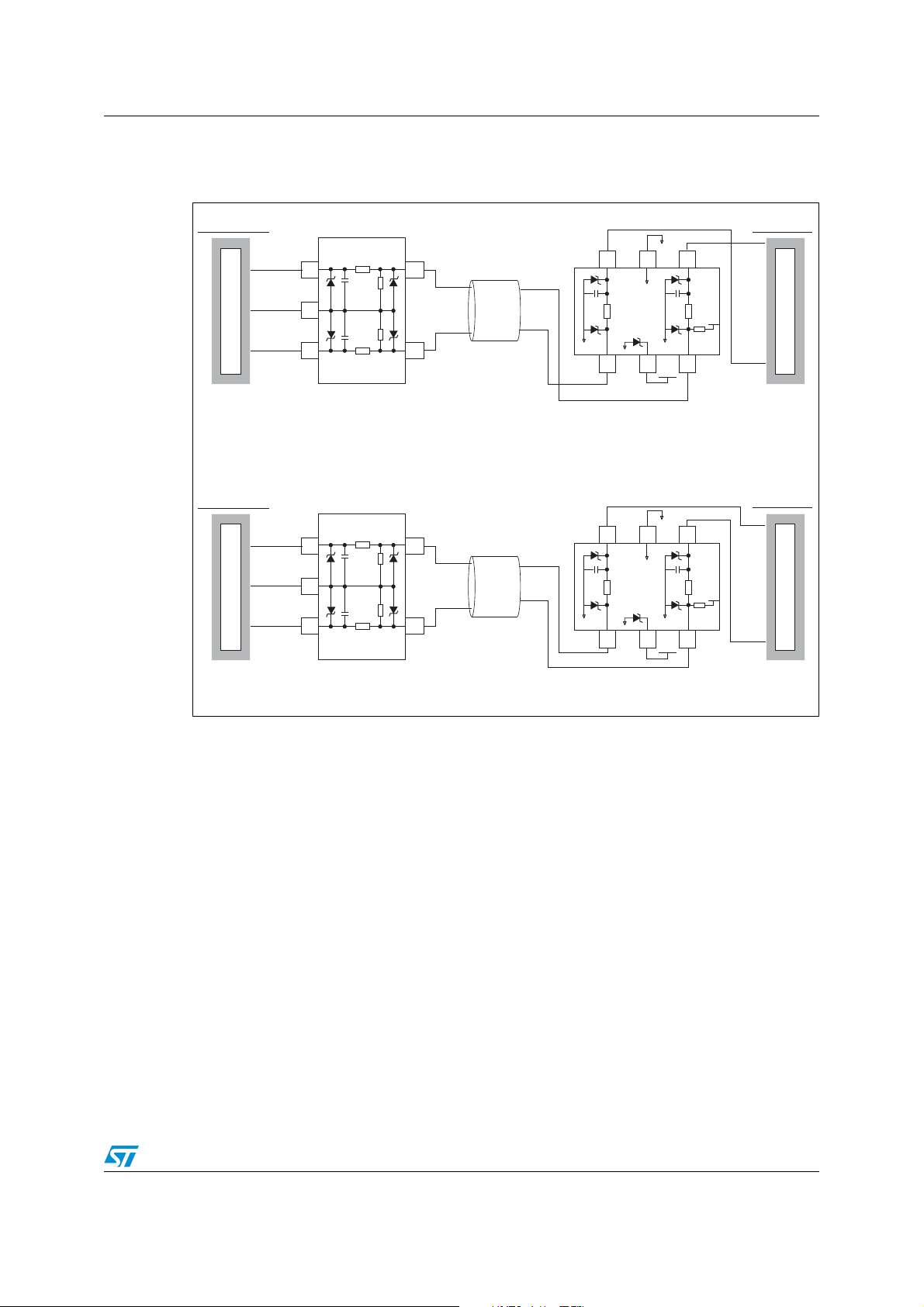

Figure 2. USB standard requirements

Full-speed or

Low-speed USB

Transceiver

Host or

Hub port

Rt

Ct

Rt

15k

Ct

15k

D+

D-

Twisted pair shielded

Zo = 90ohms

5m max

D+

D-

3.3V

1.5k

±16

±9

kV

±25

Rt

Full-speed USB

Ct

Rt

Transceiver

Ct

Hub 0 or

Full-speed function

FULL SPEED CONNECTION

Full-speed or

Low-speed USB

Transceiver

Host or

Hub port

Rt

Ct

Rt

15k

Ct

15k

D+

Untwisted unshielded

D-

LOW SPEED CONNECTION

2/11

3m max

D+

D-

3.3V

1.5k

Rt

Low-speed USB

Ct

Rt

Transceiver

Ct

Hub 0 or

Low-speed function

USBUFxxW6 Technical information

2.1 Application example

Figure 3. Implementation of ST solutions for USB ports

Downstream port

D+

Gnd

D-

Host/Hub USB por transceivert

Downstream port

D+

Gnd

D-

Host/Hub USB por transceivert

D+ in

Gnd

D- in

D+ in

Gnd

D- in

USBDF01W5

Rt

Ct

Rd

Rd

Ct

Rt

USBDF01W5

Rt

Ct

Rd

Rd

Ct

Rt

D+ out

D-

D- out

D+

D-

CABLE

D+

FULL SPEED CONNECTION

CABLE

D+

D+ out

D-

D- out

D+

D-

USBUF01W6

Ct

Rt

USBUF01W6

Ct

Rt

Upstream port

Gnd

3.3V

Gnd

3.3V

D1

Ct

Rt

3.3 V

Rp

D4

D1

Ct

Rt

3.3 V

Rp

D4

D2

D3

D2

D3

D+

Peripheral transceiver

D-

Upstream port

D+

Peripheral transceiver

D-

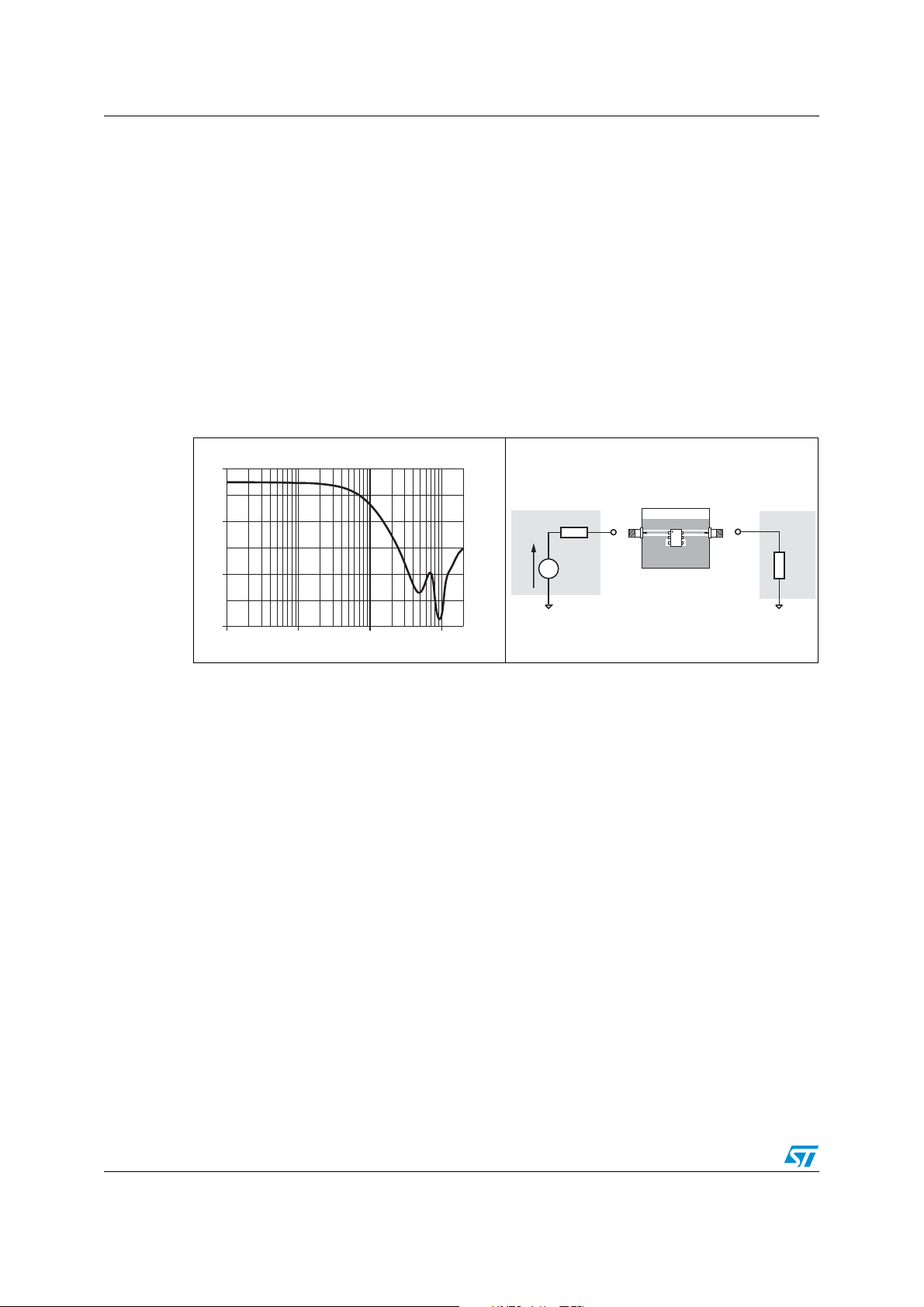

2.2 EMI filtering

Current FCC regulations requires that class B computing devices meet specified maximum

levels for both radiated and conducted EMI.

● Radiated EMI covers the frequency range from 30 MHz to 1 GHz.

● Conducted EMI covers the 450 kHz to 30 MHz range.

For the types of devices utilizing the USB, the most difficult test to pass is usually the

radiated EMI test. For this reason the USBUFxxW6 device is aiming to minimize radiated

EMI.

The differential signal (D+ and D-) of the USB does not contribute significantly to radiated or

conducted EMI because the magnetic field of both conductors cancels each other.

The inside of the PC environment is very noisy and designers must minimize noise coupling

from the different sources. D+ and D-must not be routed near high speed lines (clocks

spikes).

Induced common mode noise can be minimized by running pairs of USB signals parallel to

each other and running grounded guard trace on each side of the signal pair from the USB

controller to the USBUF device. If possible, locate the USBUF device physically near the

LOW SPEED CONNECTION

3/11

Technical information USBUFxxW6

USB connectors. Distance between the USB controller and the USB connector must be

minimized.

The 47 pF (C

) capacitors are used to bypass high frequency energy to ground and for edge

t

control, and are placed between the driver chip and the series termination resistors (Rt).

Both Ct and Rt should be placed as close to the driver chip as is practicable.

The USBUFxxW6 ensures a filtering protection against ElectroMagnetic and

RadioFrequency Interferences thanks to its low-pass filter structure. This filter is

characterized by the following parameters:

● cut-off frequency

● Insertion loss

● high frequency rejection.

Figure 4. USBUFxxW6 typical

Figure 5. Measurement configuration

attenuation

S21 (dB)

0

-10

-20

-30

1 10 100 1,000

Frequency (MHz)

50

Ω

Vg

TEST BOARD

UUx

50

Ω

2.3 ESD PROTECTION

In addition to the requirements of termination and EMC compatibility, computing devices are

required to be tested for ESD susceptibility. This test is described in the IEC 61000-4-2 and

is already in place in Europe. This test requires that a device tolerates ESD events and

remains operational without user intervention.

The USBUFxxW6 is particularly optimized to perform ESD protection. ESD protection is

based on the use of device which clamps at:

V

cl

This protection function is splitted in 2 stages. As shown in figure 6, the ESD strikes are

clamped by the first stage S1 and then its remaining overvoltage is applied to the second

stage through the resistor Rt. Such a configuration makes the output voltage very low at the

output.

4/11

= VBR + Rd.I

PP

USBUFxxW6 Technical information

Figure 6. USBUFxxW6 ESD clamping behavior

V

PP

ESD Surge

Rg

S1

Rd

V

BR

Rt

Vinput

Voutput

USBUF01W6

S2

Rd

Rload

V

BR

Device

to be

protected

Figure 7. Measurement board

ESD

SURGE

16kV

Air

Discharge

TEST BOARD

UUx

Vin Vout

To have a good approximation of the remaining voltages at both Vin and Vout stages, we

give the typical dynamical resistance value Rd. By taking into account these following

hypothesis: R

> Rd, Rg > Rd and R

t

Vouput

> Rd, it gives these formulas:

load

⋅ RdVg⋅+

R

Vinput

------------ ------------- ------------- ---------=

⋅ R

R

tVBR

----------- ------------- ------------- ------------- ---- -=

gVBR

R

g

Vinput⋅+

d

R

t

The results of the calculation done for Vg = 8 kV, Rg = 330 Ω (IEC 61000-4-2 standard),

V

= 7 V (typ.) and Rd = 1 Ω (typ.) give:

BR

Vinput = 31.2 V

Voutput = 7.95 V

This confirms the very low remaining voltage across the device to be protected. It is also

important to note that in this approximation the parasitic inductance effect was not taken into

account. This could be few tenths of volts during few ns at the V

effect is not present at the V

side due the low current involved after the resistance Rt.

output

side. This parasitic

input

The measurements done hereafter show very clearly (figure 8) the high efficiency of the

ESD protection:

● no influence of the parasitic inductances on Voutput stage

● Voutput clamping voltage very close to V

and - V

(forward voltage) in the negative way

F

5/11

(breakdown voltage) in the positive way

BR

Technical information USBUFxxW6

Figure 8. Remaining voltage at both stages S1 (Vinput) and S2 (Voutput) during

ESD surge

Vin

Vin

Positive surge Negative surge

Please note that the USBUFxxW6 is not only acting for positive ESD surges but also for

negative ones. For these kinds of disturbances it clamps close to ground voltage as

shown in Figure 8. (negative surge.

2.4 Latch-up phenomena

The early ageing and destruction of IC’s is often due to latch-up phenomenon which is

mainly induced by dV/dt. Thanks to its structure, the USBUFxxW6 provides a high immunity

to latch-up phenomenon by smoothing very fast edges.

2.5 Crosstalk behavior

Figure 9. Crosstalk phenomenon.

R

G1

Vout

Vout

Line 1

V

G1

V

G2

R

G2

DRIVERS

The crosstalk phenomenon is due to the coupling between 2 lines. The coupling factor (β

or β

) increases when the gap across lines decreases, particularly in silicon dice. In the

21

example above the expected signal on load R

has got an extra value β

. This part of the VG1 signal represents the effect of the

21VG1

crosstalk phenomenon of the line 1 on the line 2. This phenomenon has to be taken into

account when the drivers impose fast digital data or high frequency analog signals in the

disturbing line. The perturbed line will be more affected if it works with low voltage signal or

high load impedance (few kΩ).

6/11

Line 2

R

L1

R

L2

RECEIVERS

is α2VG2, in fact the real voltage at this point

L2

αβ

V+ V

1 G1 1 2 G2

V+ V

αβ

2 G2 2 1 G1

12

USBUFxxW6 Technical information

Figure 10. Figure 10: Analog crosstalk

measurements

Figure 11. Typical analog crosstalk

results

Analog crosstalk (dB)

0

50

Ω

Vg

TEST BOARD

UUx

50

Ω

-20

-40

-60

-80

-100

1 10 100 1,000

Frequency (MHz)

Figure 10. gives the measurement circuit for the analog crosstalk application. In Figure 11.,

the curve shows the effect of the D+ cell on the D-cell. In usual frequency range of analog

signals (up to 100 MHz) the effect on disturbed line is less than -37 db.

Figure 12. Digital crosstalk measurements configuration

+5V +5V

Square

Pulse

Generator

+5V

74HC04

3.3 V

Rt

D+

D1

V

G1

Gnd

D-

D2

Rp

Ct

Rt

Ct

3.3 V

74HC04

D4

D3

β

V

21

G1

Figure 12. shows the measurement circuit used to quantify the crosstalk effect in a classical

digital application.

Figure 13. Digital crosstalk results

VG1

β21 G1V

Figure 13. shows, with a signal from 0 to 5 V and rise time of few ns, the impact on the

disturbed line is less than 250 mV peak to peak. No data disturbance was noted on the

other line.The measurements performed with falling edges gives an impact within the same

range.

7/11

Technical information USBUFxxW6

2.6 Transition times

This low pass filter has been designed in order to meet the USB 1.1 standard requirements

that implies the signal edges are maintained within the 4 -20 ns stipulated USB specification

limits. To verify this point, we have measured the rise time of VD+ voltage with and without

the USBUFxxW6 device.

Figure 14. Typical rise and fall times:

measurement configuration

Figure 15. Typical rise times with and

without protection device

without

Square

Pulse

Generator

+5V

+5V +5V

74HC04

D+

D-

USBDF

01W6

74HC04

with

Figure 14. shows the circuit used to perform measurements of the transition times. In Figure

15., we see the results of such measurements:

trise = 3.8 ns driver alone

trise = 7.8 ns with protection device

The adding of the protection device causes the rise time increase of roughly 4ns.

Note: Rise time has been measured between 10% and 90% of the signal (resp. 90% and 10%)

8/11

USBUFxxW6 Packaging information

3 Packaging information

Table 3. SOT323-6L Package Mechanical Data

DIMENSIONS

REF.

A

E

A 0.8 1.1 0.031 0.043

e

b

e

D

A1 0 0.1 0 0.004

A2 0.8 1 0.031 0.039

b 0.15 0.3 0.006 0.012

Millimeters Inches

Min. Max. Min. Max.

A1

A2

Q1

c

HE

L

Figure 16. Recommeneded footprint

(dimensions in mm)

0.65

1.05

0.80

Table 4. Mechanical specifications

2.9

1.05

0.40

c 0.1 0.18 0.004 0.007

D 1.8 2.2 0.071 0.086

E 1.15 1.35 0.045 0.053

e 0.65 Typ. 0.025 Typ.

HE 1.8 2.4 0.071 0.094

L 0.1 0.4 0.004 0.016

Q1 0.1 0.4 0.004 0.016

Lead plating Tin-lead

Lead plating

thickness

Lead material

5 m min

25 m max

Sn / Pb

(70% to 90%Sn)

Lead coplanarity 10 m max

Body material Molded epoxt

Flammability UL94V-0

9/11

Ordering Information USBUFxxW6

4 Ordering Information

Ordering code Marking Package Weight Base qty Delivery mode

USBUF01W6 UU1 SOT323-6L 5.4 mg 3000 Tape & reel

USBUF02W6 UU2 SOT323-6L 5.4 mg 3000 Tape & reel

5 Revision History

Date Revision Description of Changes

Mar-2002 3A Last update.

Feb-2005 4 Layout update. No content change.

28-Feb-2006 5

Operating temperature range updated to -40 to 70° C.

Layout updated to current standard.

10/11

USBUFxxW6

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZE REPRESENTATIVE OF ST, ST PRODUCTS ARE NOT DESIGNED,

AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS,

NOR IN PRODUCTS OR SYSTEMS, WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR

SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

11/11

Loading...

Loading...