ST USBLC6-2 User Manual

查询USBLC6-2供应商

®

ASD

(Application Specific Devices)

MAIN APPLICATIONS

■ USB2.0 ports at 480Mbps (high speed) and

USB OTG ports

■ Backwards Compatible with USB1.1 Low and

full speed

■ Ethernet port: 10/100Mb/s

■ SIM card protection

■ Video line protection

■ Portable and mobile electronics

DESCRIPTION

The USBLC6-2P6 and USBLC6-2SC6 are two

monolithic Application Specific Devices dedicated

to ESD protection of high speed interfaces such as

USB2.0, Ethernet links and Video lines.

The very low line capacitance secures a high level

of signal integrity without compromising in

protection sensitive chips against the most

stringent characterized ESD strikes.

FEATURES

■ 2 data lines protection

■ Protects V

■ Very low capacitance: 3.5pF max

■ Very low leakage current: 1µA max

■ SOT-666 and SOT23-6L packages

■ RoHS compliant

BUS

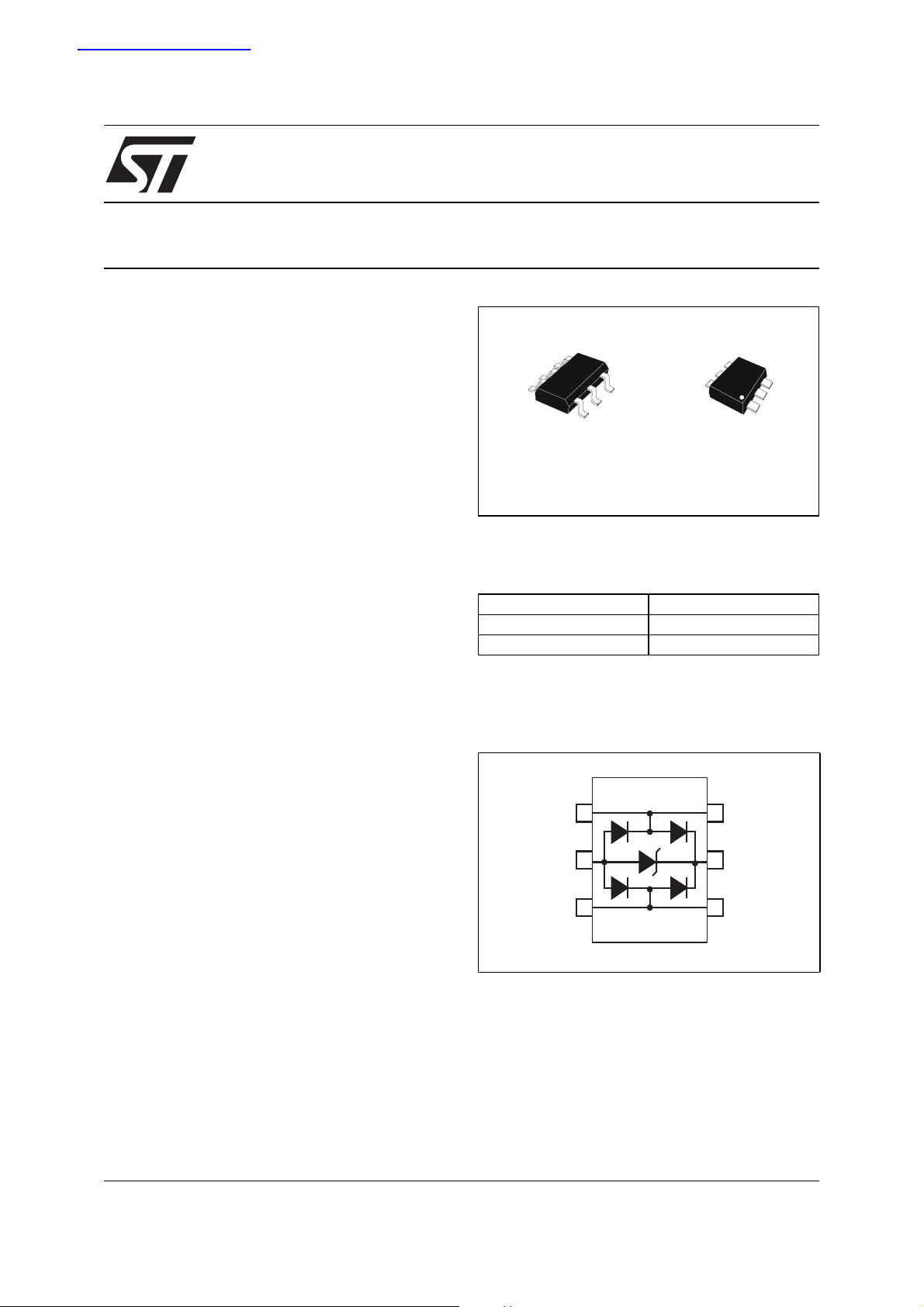

USBLC6-2

VERY LOW CAPACITANCE

ESD PROTECTION

SOT23-6L

USBLC6-2SC6

Table 1: Order Codes

Part Number Marking

USBLC6-2SC6 UL26

USBLC6-2P6 F

Figure 1: Functional Diagram

SOT-666

USBLC6-2P6

BENEFITS

■ Very low capacitance between lines to GND for

optimized data integrity and speed

■ Ultra low PCB space consuming: 2.9mm² max

for SOT-666 package and 9mm² max for

SOT23-6L package

■ Enhanced ESD protection: IEC61000-4-2 level

4 compliance guaranteed at device level,

hence greater immunity at system level

■ ESD protection of V

. Allows ESD current

BUS

flowing to Ground when ESD event occurs on

data line

■ High reliability offered by monolithic integration

■ Very low leakage current for longer operation

of battery powered devices

■ Fast response time

■ Consistant D+/D- signal balance

- Best capacitance matching tolerance I/O to

GND of 0.04pF

- Compliance with USB2.0 requirement (<1pF)

June 2005

11

I/O1 I/O1

2

GND V

3

I/O2 I/O2

6

5

BUS

4

COMPLIES WITH THE FOLLOWING STANDARDS:

■ IEC61000-4-2 level 4:

15kV (air discharge)

8kV (contact discharge)

REV. 2

1/11

USBLC6-2

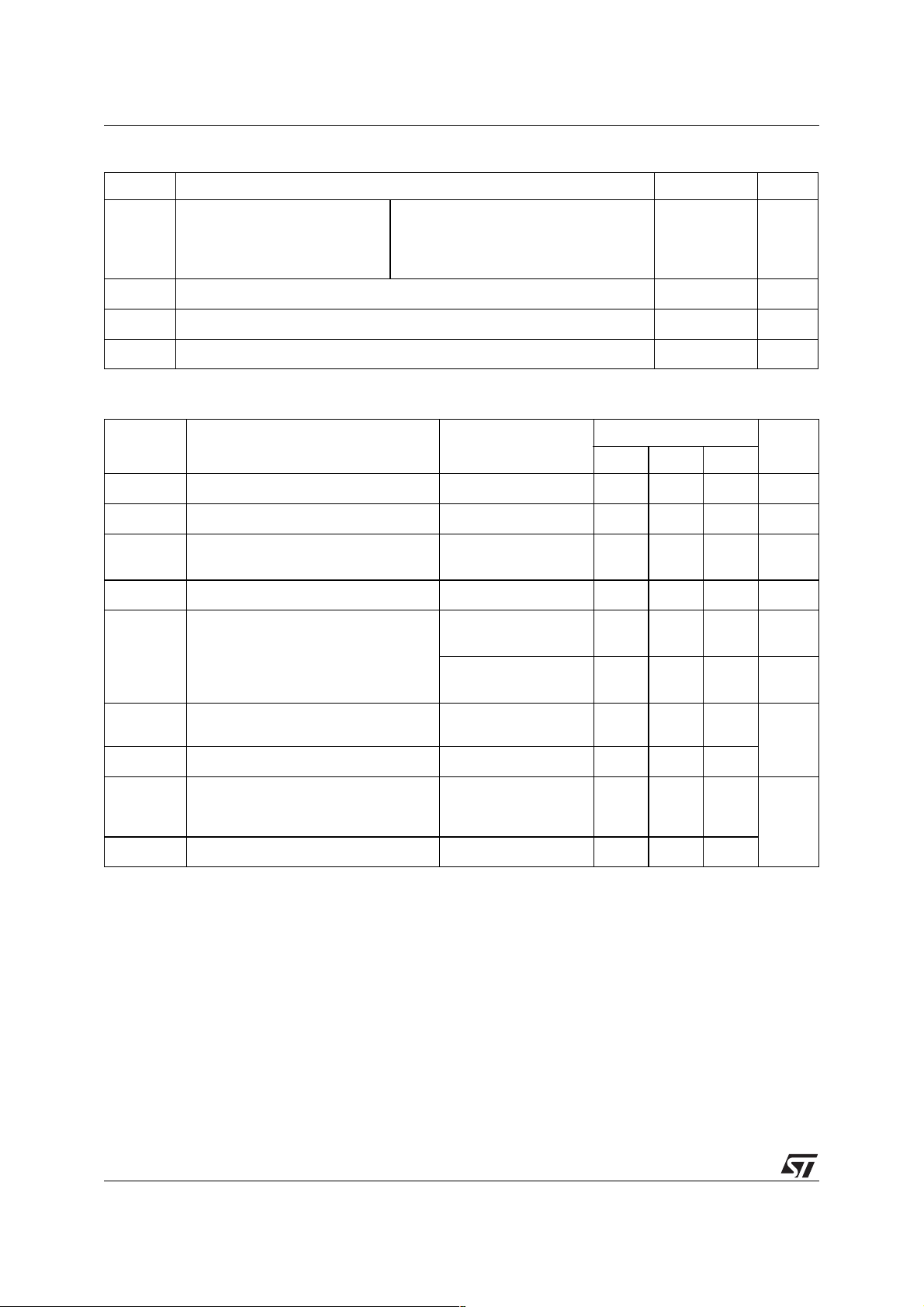

Table 2: Absolute Ratings

Symbol Parameter Value Unit

At device level:

V

Peak pulse voltage

PP

IEC61000-4-2 air discharge

IEC61000-4-2 contact discharge

MIL STD883C-Method 3015-6

15

15

25

kV

T

T

T

Table 3: Electrical Characteristics (T

Storage temperature range -55 to +150 °C

stg

Maximum junction temperature 125 °C

j

Lead solder temperature (10 seconds duration) 260 °C

L

= 25°C)

amb

Symbol Parameter Test Conditions

V

RM

I

RM

V

BR

V

V

CL

Reverse stand-off voltage 5 V

V

Leakage current

Breakdown voltage between V

and GND

Forward voltage

F

BUS

= 5V

RM

= 1mA

I

F

I

= 10mA

F

= 1A, tp = 8/20µs

I

PP

Any I/O pin to GND

Clamping voltage

I

= 5A, tp = 8/20µs

PP

Any I/O pin to GND

C

i/o-GND

∆C

Capacitance between I/O and GND

i/o-GND

V = 0V F = 1MHz

any I/O pin to GND

V = 0V F = 1MHz

C

i/o-i/o

Capacitance between I/O

between I/O, GND

not connected

Value

Unit

Min. Typ. Max.

1µA

6V

1.1 V

12 V

17 V

2.5 3.5

pF

0.04

1.2 1.7

pF

2/11

∆C

i/o-i/o

0.04

USBLC6-2

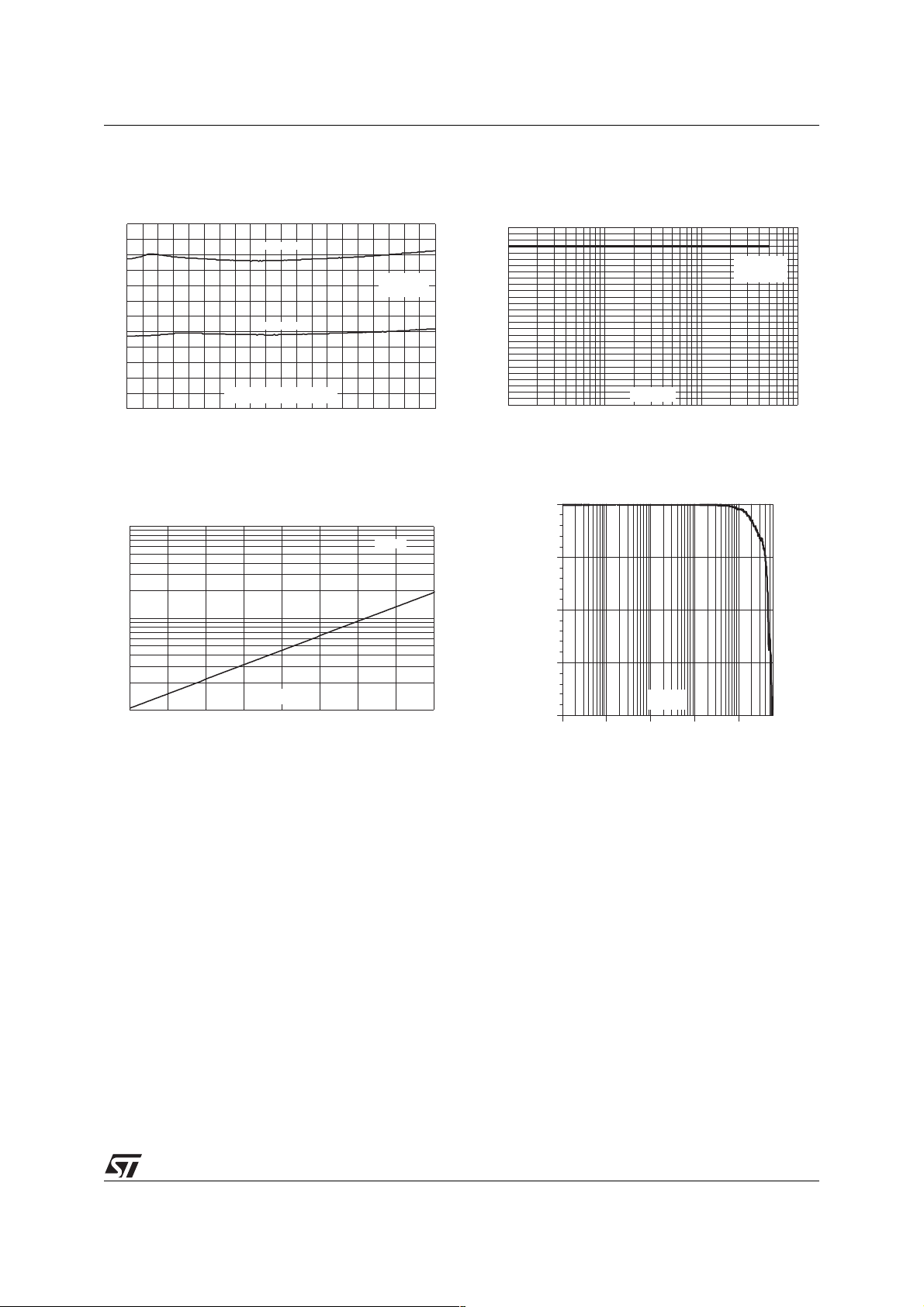

Figure 2: Capacitance versus line voltage

(typical values)

C(pF)

3.0

C =I/O-GND

2.5

2.0

1.5

1.0

0.5

O

C =I/O-I/O

j

F=1MHz

V =30mV

OSC RMS

T =25°C

j

Data line voltage (V)

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Figure 4: Relative variation of leakage current

versus junction temperature (typical values)

I[T

] / I [T

100

RM j

10

RM j

=25°C]

V =5V

BUS

Figure 3: Line capacitance versus frequency

(typical values)

C(pF)

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

1 10 100 1000

F(MHz)

V =30mV

OSC RMS

T=25°C

j

V =0V to 3.3V

LINE

Figure 5: Frequency response

0.00

S21(dB)

-5.00

-10.00

T (°C)

1

25 50 75 100 125

j

-15.00

F(Hz)

-20.00

100.0k 1.0M 10.0M 100.0M 1.0G

3/11

USBLC6-2

TECHNICAL INFORMATION

1. SURGE PROTECTION

The USBLC6-2 is particularly optimized to perform surge protection based on the rail to rail topology.

The clamping voltage V

with: V

= VT + Rd.I

F

(VF forward drop voltage) / (VT threshold voltage)

We assume that the value of the dynamic resistance of the clamping diode is typically:

= 0.5Ω and VT = 1.2V.

R

d

For an IEC61000-4-2 surge Level 4 (Contact Discharge: V

approximation, we assume that : I

So, we find:

V

CL

V

CL

Note: the calculations do not take into account phenomena due to parasitic inductances.

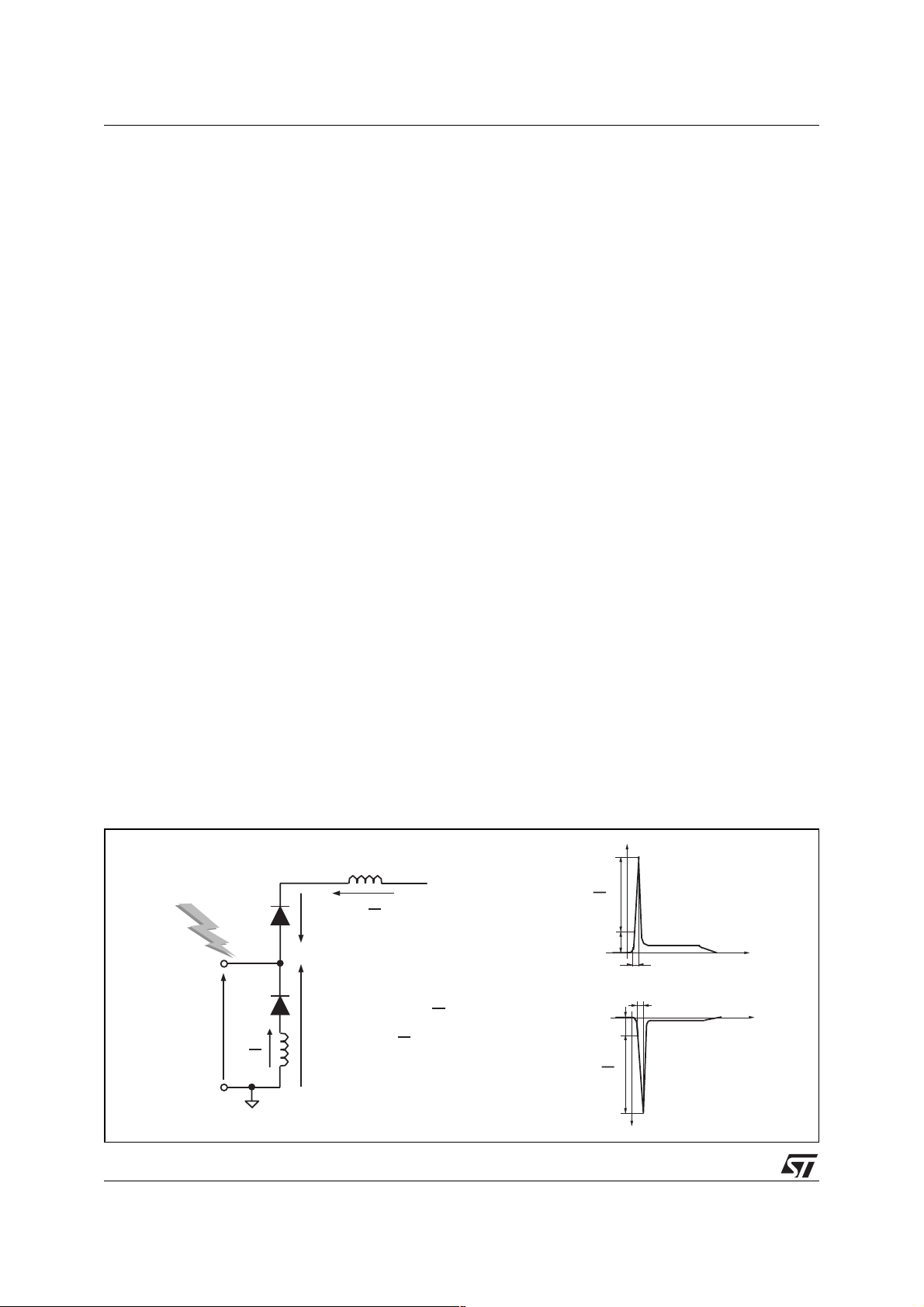

2. SURGE PROTECTION APPLICATION EXAMPLE

If we consider that the connections from the pin V

two tracks of 10mm long and 0.5mm large; we assume that the parasitic inductances Lw of these tracks

are about 6nH. So when an IEC61000-4-2 surge occurs, due to the rise time of this spike (tr=1ns), the

voltage V

has an extra value equal to Lw.dI/dt.

CL

The dI/dt is calculated as: dI/dt = Ip/tr = 24 A/ns

The overvoltage due to the parasitic inductances is: Lw.dI/dt = 6 x 24 = 144V

By taking into account the effect of these parasitic inductances due to unsuitable layout, the clamping

voltage will be :

V

CL

V

CL

We can reduce as much as possible these phenomena with simple layout optimization.

It’s the reason why some recommendations have to be followed (see paragraph “How to ensure a good

ESD protection”).

can be calculated as follow :

CL

+ = V

V

CL

V

- = - VF for negative surge

CL

p

+ VF for positive surge

BUS

= Vg / Rg = 24A.

p

+ = +17V

- = -12V

+ = +17 + 144 = 161V

- = -12 - 144 = -156V

=8kV, Rg=330Ω), V

g

to VCC and from GND to PCB GND are done by

BUS

= +5V, and if in first

BUS

Figure 6: ESD behavior; parasitic phenomena due to unsuitable layout

183V

di

Lw

dt

VV

+

CC F

-V

di

-Lw

dt

-178V

4/11

ESD

SURGE

VI/O

Lw

Lw

F

V+ =

CL

V- =

CL

Lw

di

dt

V +V +Lw

BUS F

di

-V -Lw

F

dt

+V

CC

di

surge >0

dt

surge <0

V

BUS

V

I/O

di

dt

GND

F

V

tr=1ns

tr=1ns

CL

V

+

POSITIVE

SURGE

NEGATIVE

SURGE

-

CL

t

t

Loading...

Loading...