ST uPSD3422E-40T6, uPSD3422EV-40T6, uPSD3422E-40U6, uPSD3422EV-40U6, uPSD3433E-40T6 User Manual

...

查询UPSD3422供应商

Fast Turbo 8032 MCU with USB and Programmable Logic

FEATURES SUMMARY

■ FAST 8-BIT TURBO 8032 MCU, 40MHz

– Advanced core, 4-clocks per instruction

– 10 MIPs peak performance at 40MHz (5V)

– JTAG Debug and In-System

Programming

– 16-bit internal instruction path fetches

double-byte instruction in a single memory

cycle

– Branch Cache & 4 instruction Prefetch

Queue

– Dual XDATA pointers with automatic

increment and decrement

– Compatible with 3rd party 8051 tools

■ DUAL FLASH MEMORIES WITH MEMORY

MANAGEMENT

– Place either memory into 8032 program

address space or data address space

– READ-while-WRITE operation for In-

Application Programming and EEPROM

emulation

– Single voltage program and erase

– 100K guaranteed erase cycles, 15-year

retention

■ CLOCK, RESET, AND POWER SUPPLY

MANAGEMENT

– SRAM is Battery Backup capable

– Flexible 8-level CPU clock divider register

– Normal, Idle, and Power Down Modes

– Power-on and Low Voltage reset

supervisor

– Programmable Watchdog Timer

■ PROGRAMMABLE LOGIC, GENERAL

PURPOSE

– 16 macrocells for logic applications (e.g.,

shifters, state machines, chip-selects,

glue-logic to keypads, and LCDs)

■ A/D CONVERTER

– Eight Channels, 10-bit resolution, 6µs

uPSD34xx

Turbo Plus Series

PRELIMINARY DATA

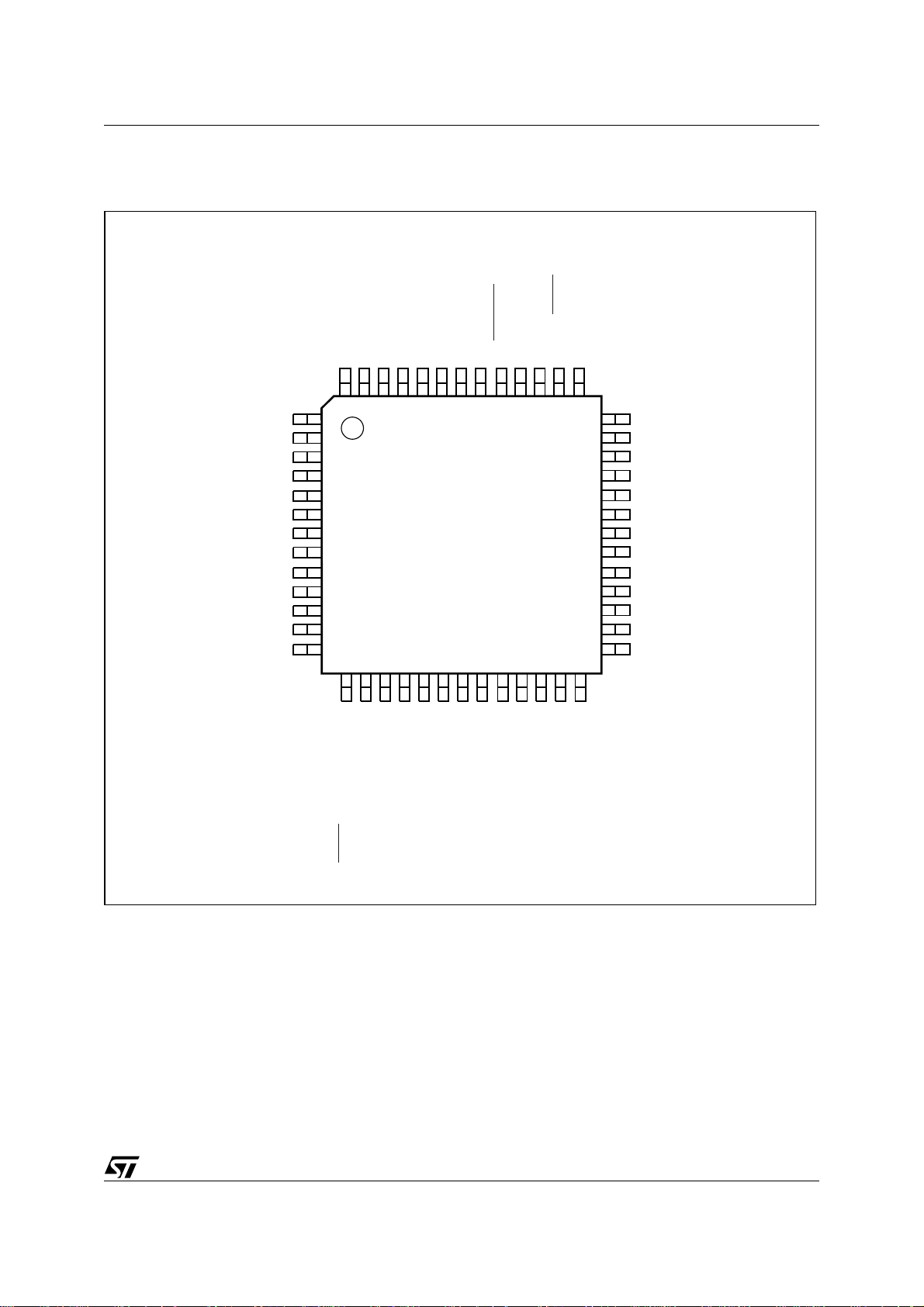

Figure 1. Packages

TQFP52 (T), 52-lead, Thin, Quad, Flat

TQFP80 (U), 80-lead, Thin, Quad, Flat

■ COMMUNICATION INTERFACES

– USB v2.0 Full Speed (12Mbps)

10 endpoint pairs (In/Out), each endpoint

with 64-byte FIFO (supports Control, Intr,

and Bulk transfer types)

2

C Master/Slave controller, 833kHz

–I

– SPI Master controller, 1MHz

– Two UARTs with independent baud rate

– IrDA Potocol: up to 115 kbaud

– Up to 46 I/O, 5V tolerant uPSD34xxV

■ TIMERS AND INTERRUPTS

– Three 8032 standard 16-bit timers

– Programmable Counter Array (PCA), six

16-bit modules for PWM, CAPCOM, and

timers

– 8/10/16-bit PWM operation

– 12 Interrupt sources with two external

interrupt pins

■ OPERATING VOLTAGE SOURCE (±10%)

– 5V Devices: 5.0V and 3.3V sources

– 3.3V Devices: 3.3V source

Rev 2.0

March 2005

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/264

uPSD34xx - FEATURES SUMMARY

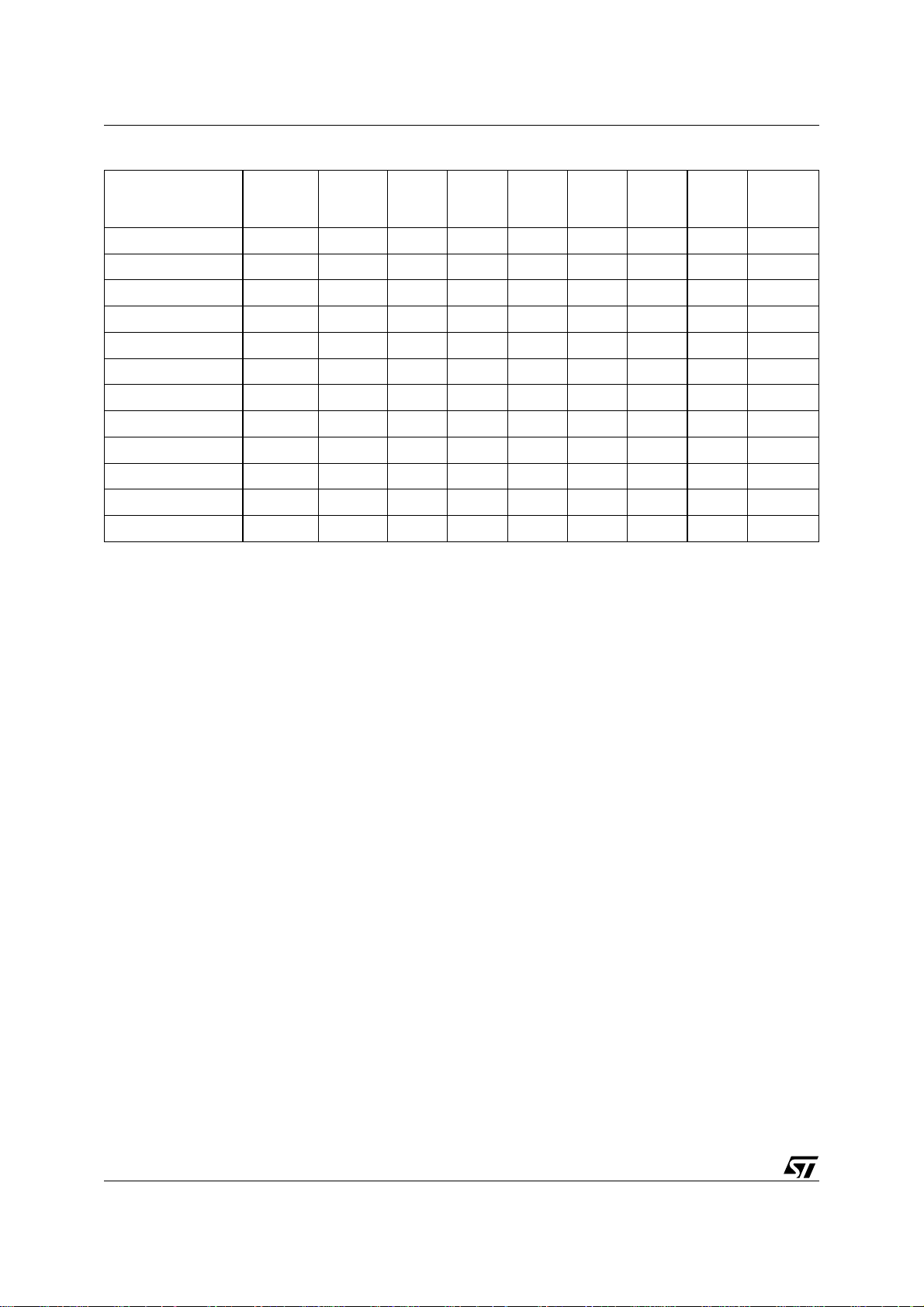

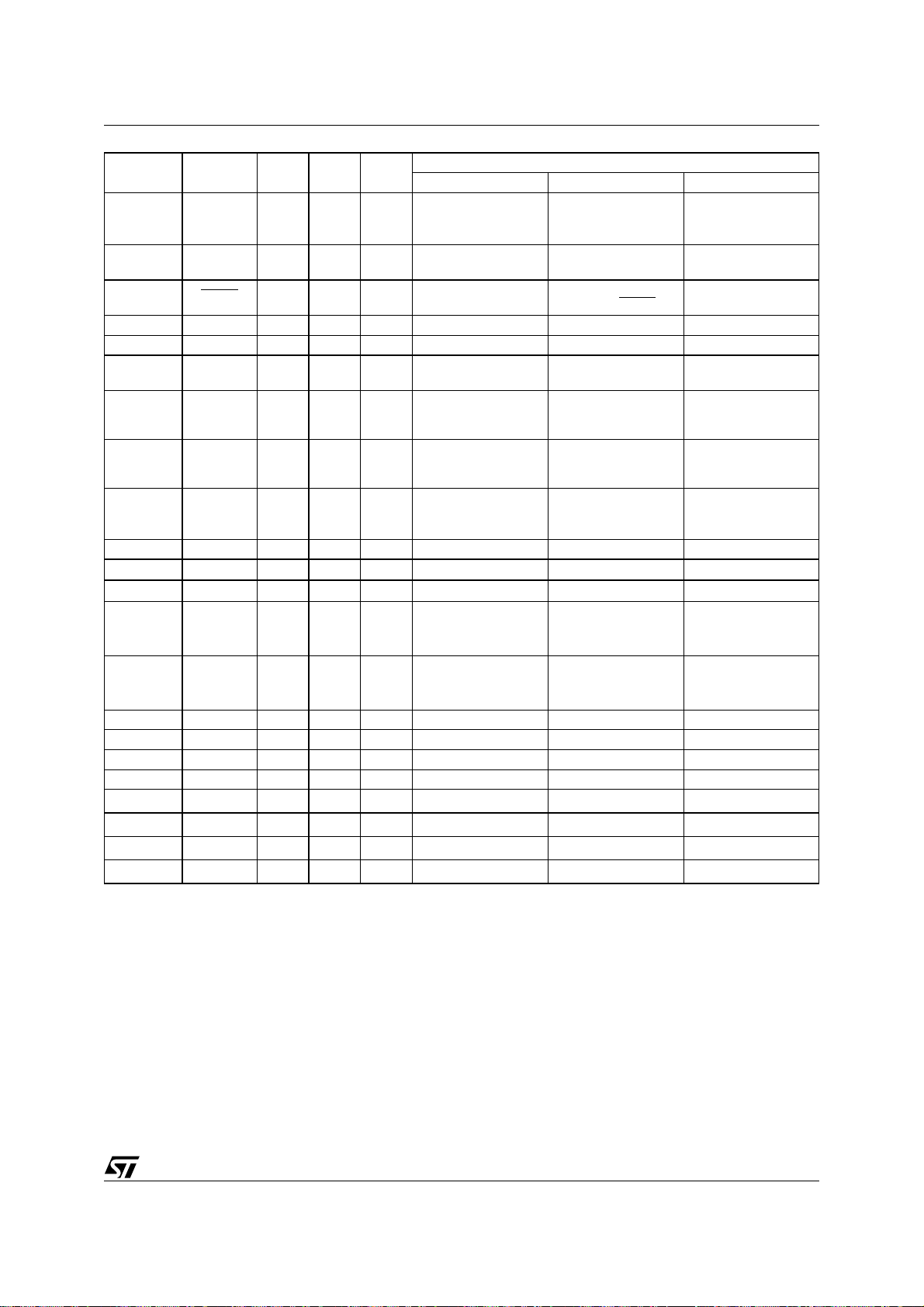

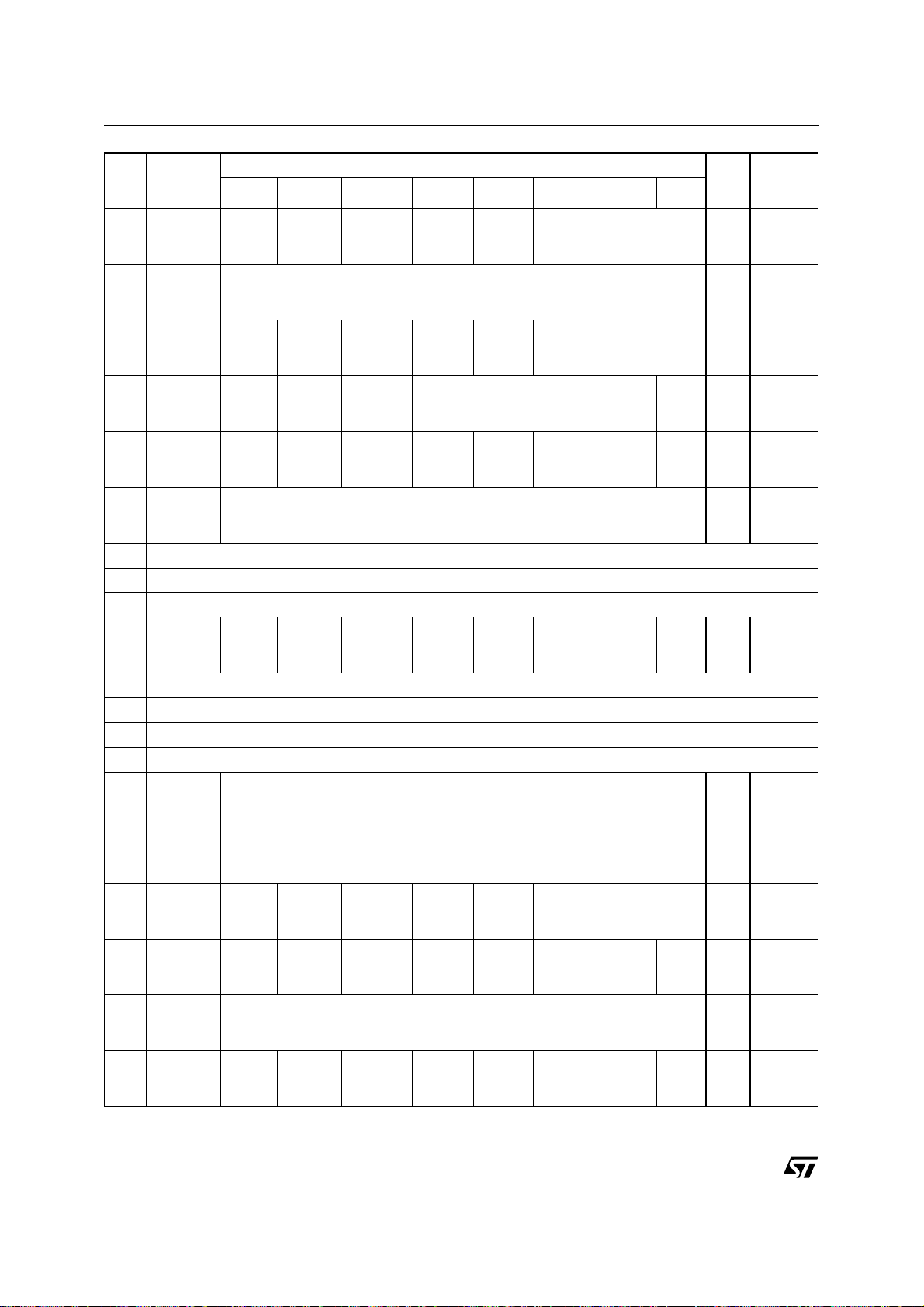

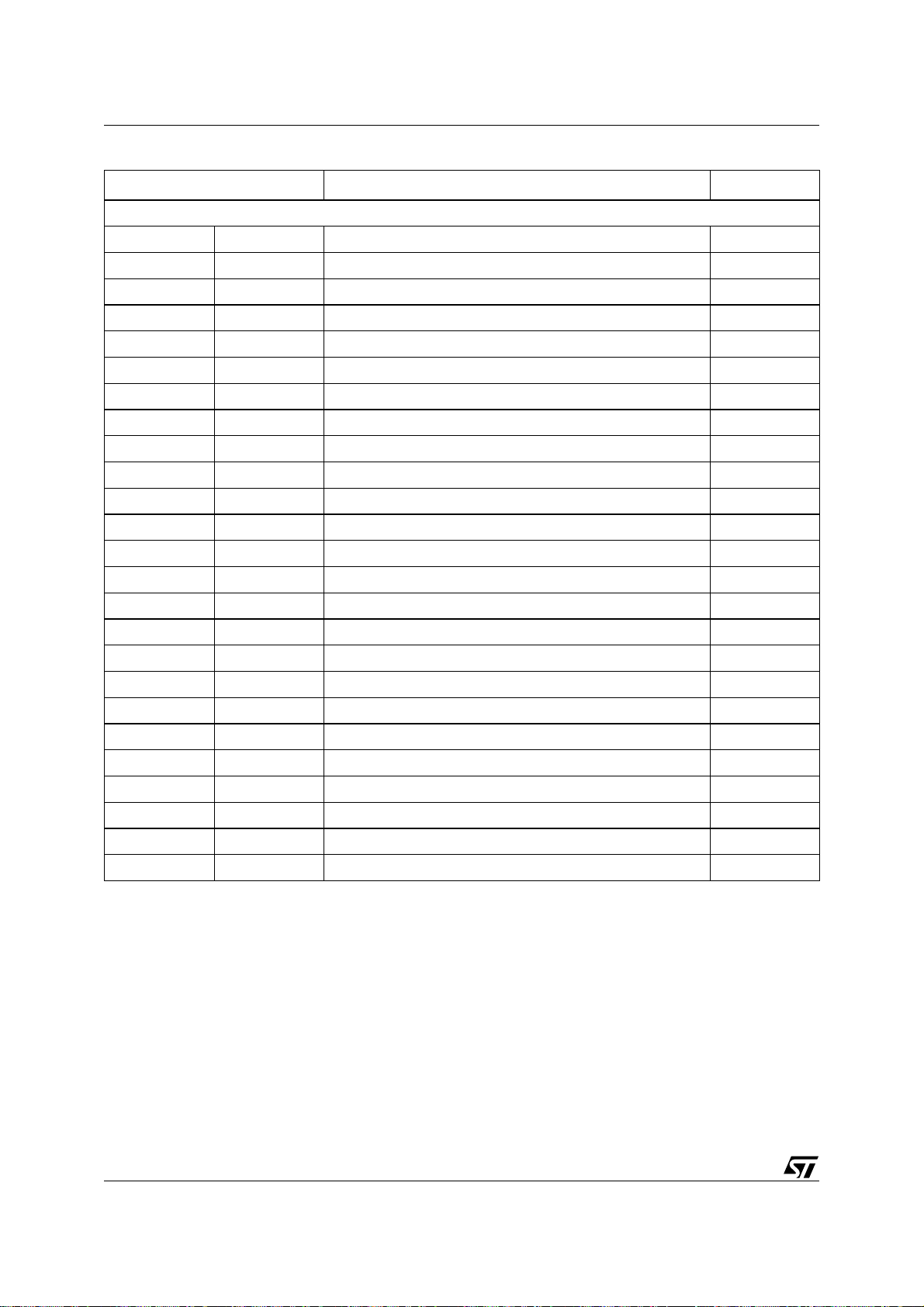

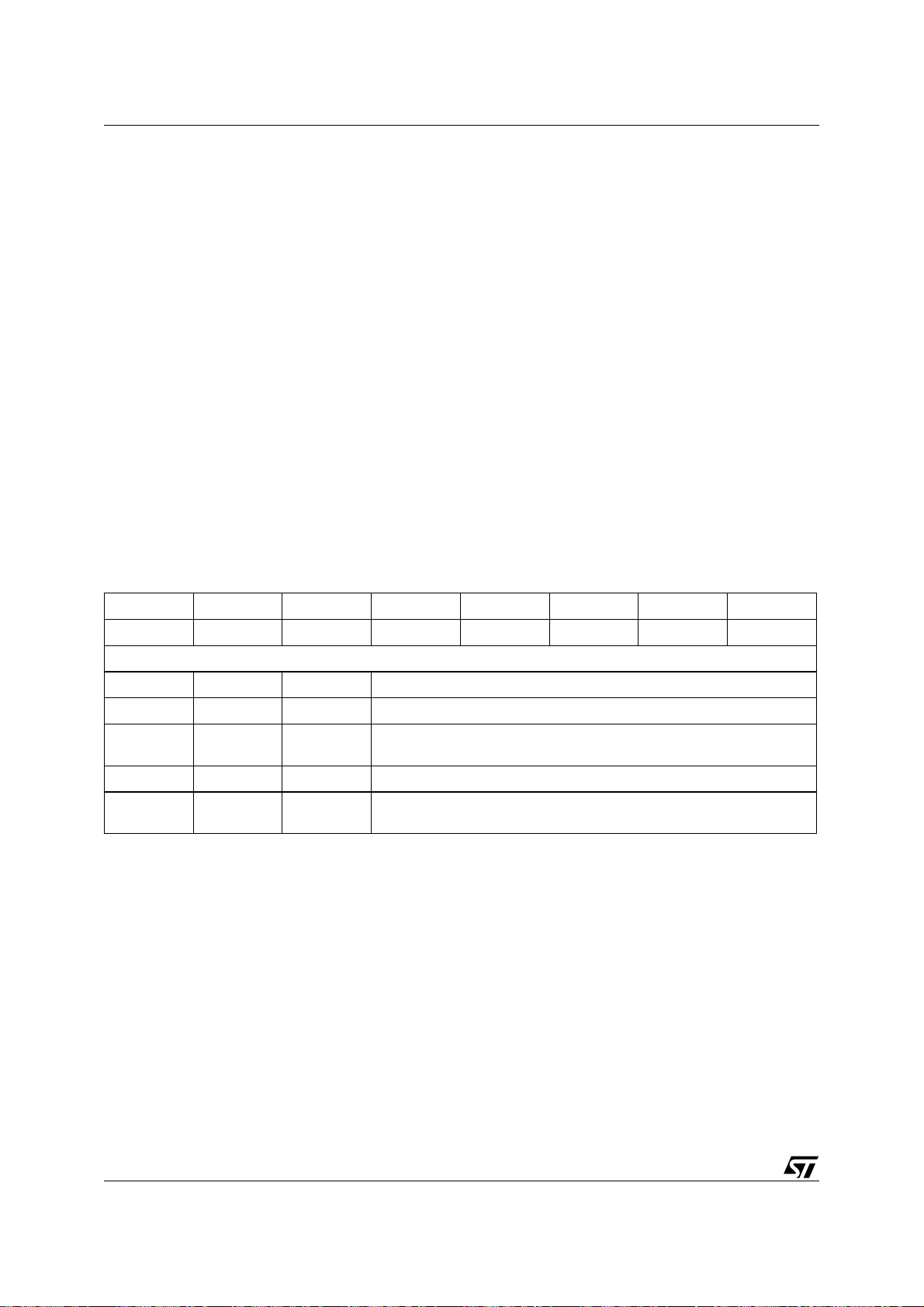

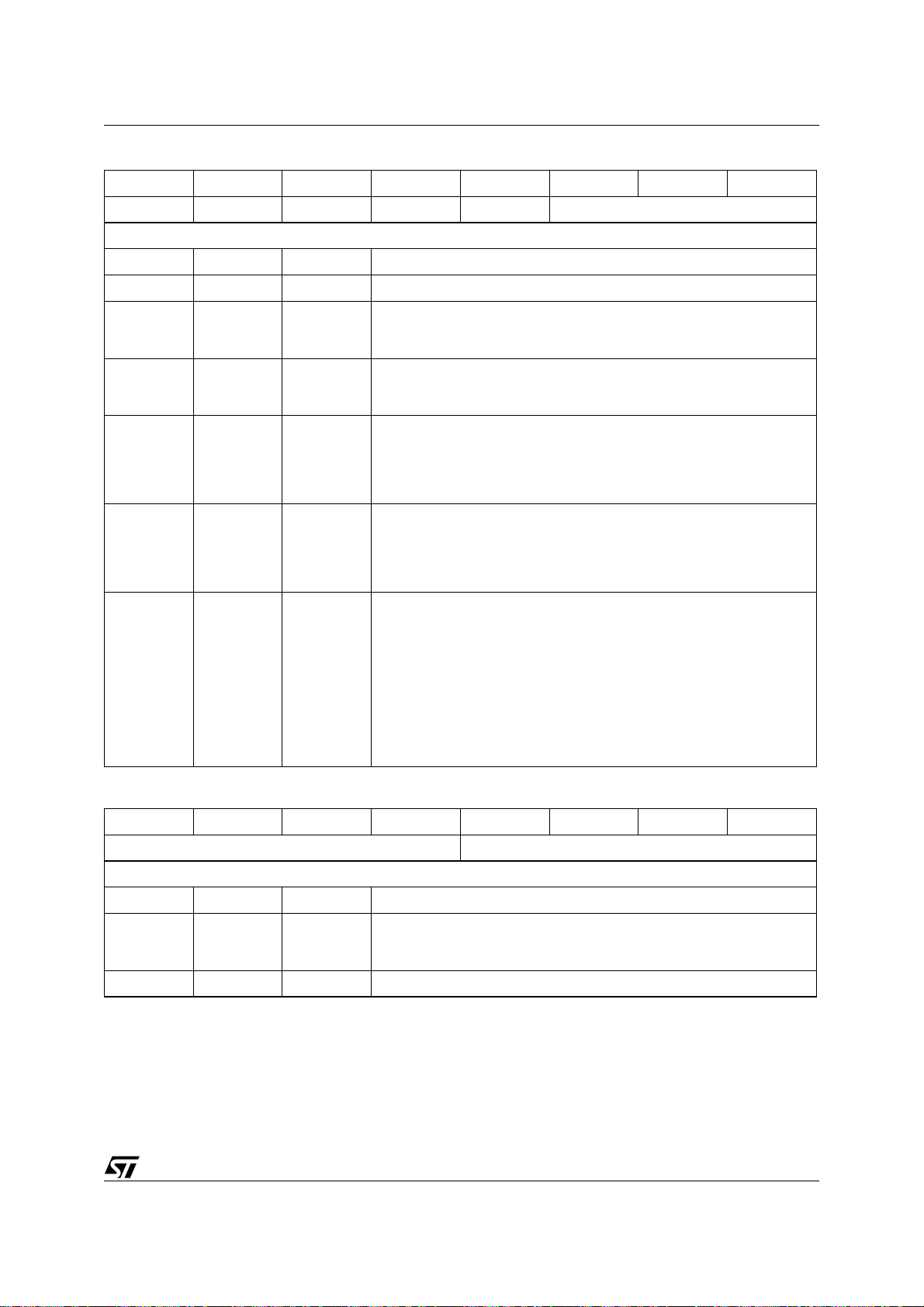

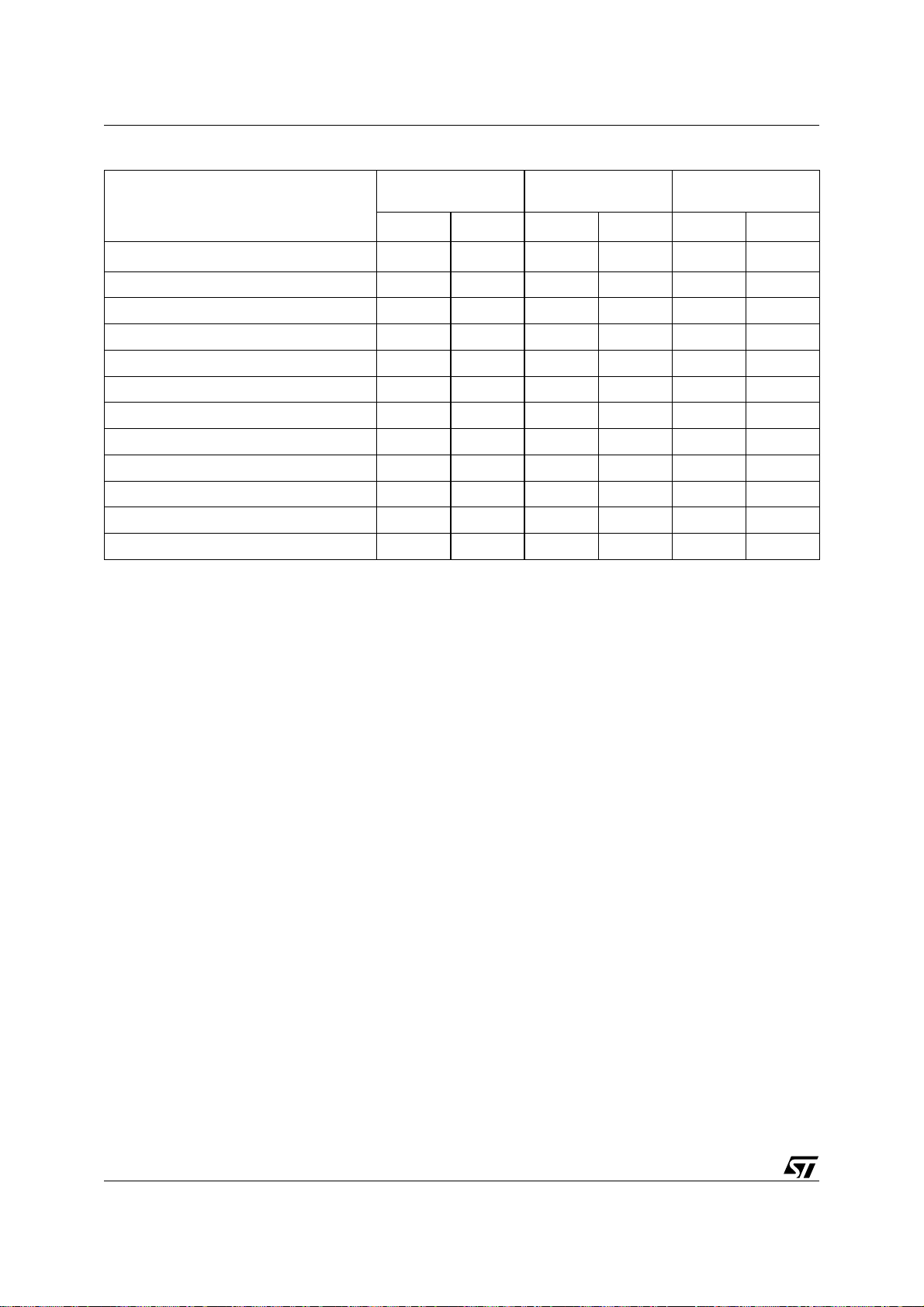

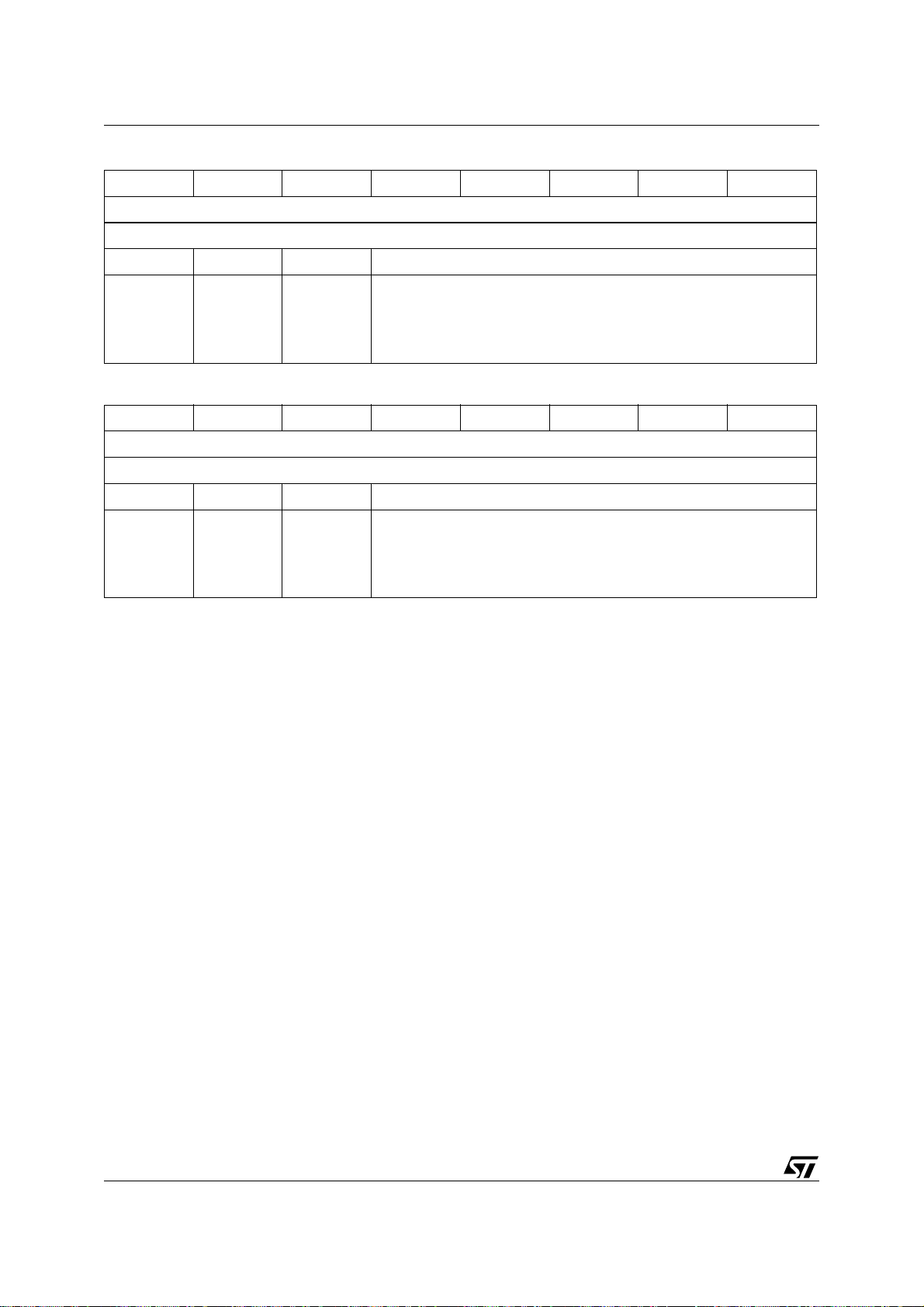

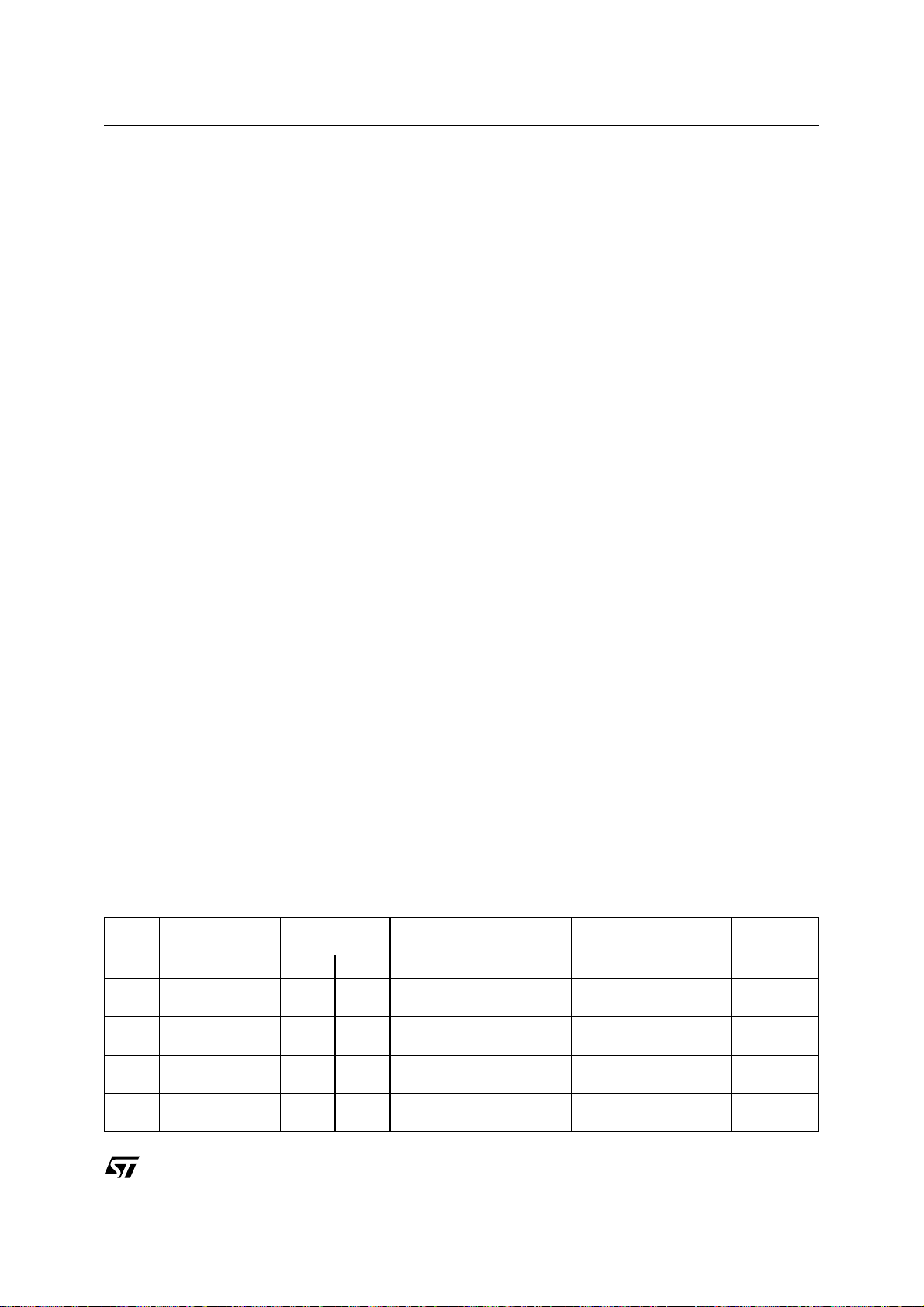

Table 1. Device Summary

1st

Part Number Max MHz

Flash

(bytes)

uPSD3422E-40T6 40 64K 32K 4K 35 No 3.3V 5.0V TQFP52

uPSD3422EV-40T6 40 64K 32K 4K 35 No 3.3V 3.3V TQFP52

uPSD3422E-40U6 40 64K 32K 4K 46 Yes 3.3V 5.0V TQFP80

uPSD3422EV-40U6 40 64K 32K 4K 46 Yes 3.3V 3.3V TQFP80

uPSD3433E-40T6 40 128K 32K 8K 35 No 3.3V 5.0V TQFP52

uPSD3433EV-40T6 40 128K 32K 8K 35 No 3.3V 3.3V TQFP52

uPSD3433E-40U6 40 128K 32K 8K 46 Yes 3.3V 5.0V TQFP80

uPSD3433EV-40U6 40 128K 32K 8K 46 Yes 3.3V 3.3V TQFP80

uPSD3434E-40T6 40 256K 32K 8K 35 No 3.3V 5.0V TQFP52

uPSD3434EV-40T6 40 256K 32K 8K 35 No 3.3V 3.3V TQFP52

uPSD3434E-40U6 40 256K 32K 8K 46 Yes 3.3V 5.0V TQFP80

uPSD3434EV-40U6 40 256K 32K 8K 46 Yes 3.3V 3.3V TQFP80

Note: Operating temperature is in the Industrial range (–40°C to 85°C).

2nd

Flash

SRAM GPIO

8032

Bus

V

CC

V

DD

Pkg.

2/264

uPSD34xx - TABLE OF CONTENTS

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SUMMARY DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PIN DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

HARDWARE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MEMORY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Internal Memory (MCU Module, Standard 8032 Memory: DATA, IDATA, SFR) . . . . . . . . . . . . 17

External Memory (PSD Module: Program memory, Data memory). . . . . . . . . . . . . . . . . . . . . . 17

8032 MCU CORE PERFORMANCE ENHANCEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pre-Fetch Queue (PFQ) and Branch Cache (BC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PFQ Example, Multi-cycle Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Aggregate Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MCU MODULE DISCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8032 MCU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stack Pointer (SP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Data Pointer (DPTR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Program Counter (PC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accumulator (ACC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

B Register (B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General Purpose Registers (R0 - R7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Program Status Word (PSW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SPECIAL FUNCTION REGISTERS (SFR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8032 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Register Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Direct Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Register Indirect Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Immediate Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

External Direct Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

External Indirect Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Indexed Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Relative Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Absolute Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Long Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Bit Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3/264

uPSD34xx - TABLE OF CONTENTS

uPSD34xx INSTRUCTION SET SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DUAL DATA POINTERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Data Pointer Control Register, DPTC (85h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Data Pointer Mode Register, DPTM (86h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DEBUG UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

INTERRUPT SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Individual Interrupt Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

MCU CLOCK GENERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

MCU_CLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

PERIPH_CLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Power-down Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Reduced Frequency Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

OSCILLATOR AND EXTERNAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

I/O PORTS of MCU MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

MCU Port Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

MCU BUS INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

PSEN Bus Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

READ or WRITE Bus Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Connecting External Devices to the MCU Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Programmable Bus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Controlling the PFQ and BC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SUPERVISORY FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

External Reset Input Pin, RESET_IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Low V

Voltage Detect, LVD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

CC

Power-up Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

JTAG Debug Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Watchdog Timer, WDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

STANDARD 8032 TIMER/COUNTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Standard Timer SFRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

SFR, TCON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

SFR, TMOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Timer 0 and Timer 1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Timer 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4/264

uPSD34xx - TABLE OF CONTENTS

SERIAL UART INTERFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

UART Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Serial Port Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

UART Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

More About UART Mode 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

More About UART Mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

More About UART Modes 2 and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

IrDA INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Baud Rate Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pulse Width Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2

I

C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

I2C Interface Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Communication Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Bus Arbitration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Clock Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

General Call Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Serial I/O Engine (SIOE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2

I

C Interface Control Register (S1CON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

2

I

C Interface Status Register (S1STA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

I2C Data Shift Register (S1DAT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2

I

C Address Register (S1ADR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2

I

C START Sample Setting (S1SETUP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2

I

C Operating Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SPI (SYNCHRONOUS PERIPHERAL INTERFACE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

SPI Bus Features and Communication Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Full-Duplex Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Bus-Level Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SPI SFR Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

SPI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Dynamic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

USB INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Basic USB Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Types of Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Endpoint FIFOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

USB Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Typical Connection to USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

ANALOG-TO-DIGITAL CONVERTOR (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Port 1 ADC Channel Selects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

5/264

uPSD34xx - TABLE OF CONTENTS

PROGRAMMABLE COUNTER ARRAY (PCA) WITH PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

PCA Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

PCA Clock Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Operation of TCM Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Capture Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Timer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Toggle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

PWM Mode - (X8), Fixed Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

PWM Mode - (X8), Programmable Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

PWM Mode - Fixed Frequency, 16-bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

PWM Mode - Fixed Frequency, 10-bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Writing to Capture/Compare Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Control Register Bit Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

TCM Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

PSD MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

PSD Module Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Memory Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

PSD Module Data Bus Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Runtime Control Register Definitions (csiop). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

PSD Module Detailed Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

PSD Module Reset Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

AC/DC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

PACKAGE MECHANICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

USB Interrupts with Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

USB Reset Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

USB Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Data Toggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

USB FIFO Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Erroneous Resend of Data Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

IN FIFO Pairing Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

PORT 1 Not 5-volt IO Tolerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

6/264

SUMMARY DESCRIPTION

The Turbo Plus uPSD34xx Series combines a

powerful 8051-based microcontroller with a flexible memory structure, programmable logic, and a

rich peripheral mix to form an ideal embedded

controller. At its core is a fast 4-cycle 8032 MCU

with a 4-byte instruction prefetch queue (PFQ) and

a 4-entry fully associative branching cache (BC).

The MCU is connected to a 16-bit internal instruction path to maximize performance, enabling loops

of code in smaller localities to execute extremely

fast. The 16-bit wide instruction path in the Turbo

Plus Series allows double-byte instructions to be

fetched from memory in a single memory cycle.

This keeps the average performance near its peak

performance (peak performance for 5V, 40MHz

Turbo Plus uPSD34xx is 10 MIPS for single-byte

instructions, and average performance will be approximately 9 MIPS for mix of single- and multibyte instructions).

USB 2.0 (full speed, 12Mbps) is included, providing 10 endpoints, each with its own 64-byte FIFO

to maintain high data throughput. Endpoint 0 (Control Endpoint) uses two of the 10 endpoints for In

and Out directions, the remaining eight endpoints

may be allocated in any mix to either type of transfers: Bulk or Interrupt.

Code development is easily managed without a

hardware In-Circuit Emulator by using the serial

uPSD34xx - SUMMARY DESCRIPTION

JTAG debug interface. JTAG is also used for InSystem Programming (ISP) in as little as 10 seconds, perfect for manufacturing and lab development. The 8032 core is coupled to Programmable

System Device (PSD) architecture to optimize the

8032 memory structure, offering two independent

banks of Flash memory that can be placed at virtually any address within 8032 program or data address space, and easily paged beyond 64K bytes

using on-chip programmable decode logic.

Dual Flash memory banks provide a robust solution for remote product updates in the field through

In-Application Programming (IAP). Dual Flash

banks also support EEPROM emulation, eliminating the need for external EEPROM chips.

General purpose programmable logic (PLD) is included to build an endless variety of glue-logic,

saving external logic devices. The PLD is configured using the software development tool, PSDsoft Express, available from the web at

www.st.com/psm, at no charge.

The uPSD34xx also includes supervisor functions

such as a programmable watchdog timer and lowvoltage reset.

Note: For a list of known limitations of the

uPSD34xx devices, please refer to IMPORTANT

NOTES, page 262.

7/264

uPSD34xx - SUMMARY DESCRIPTION

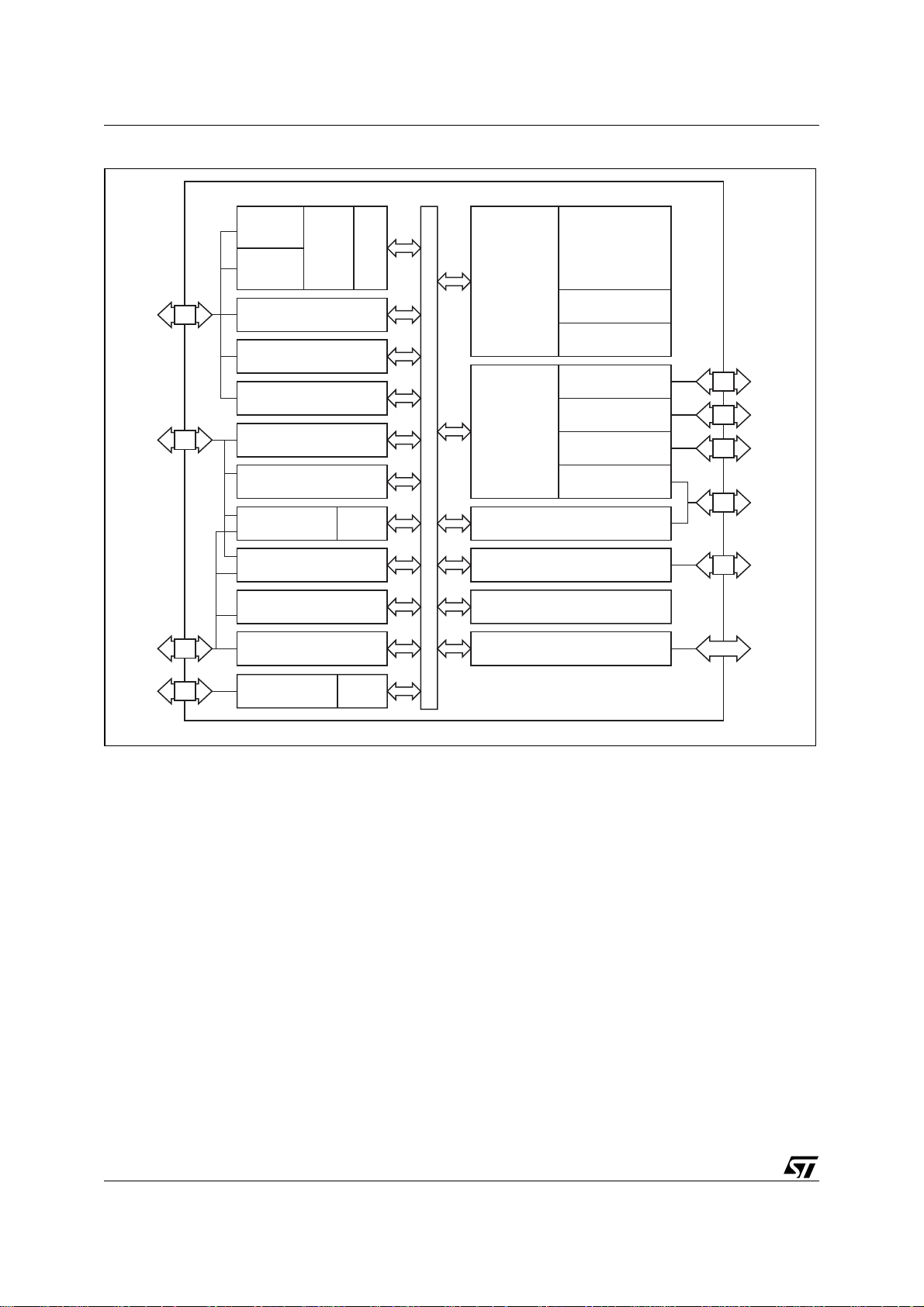

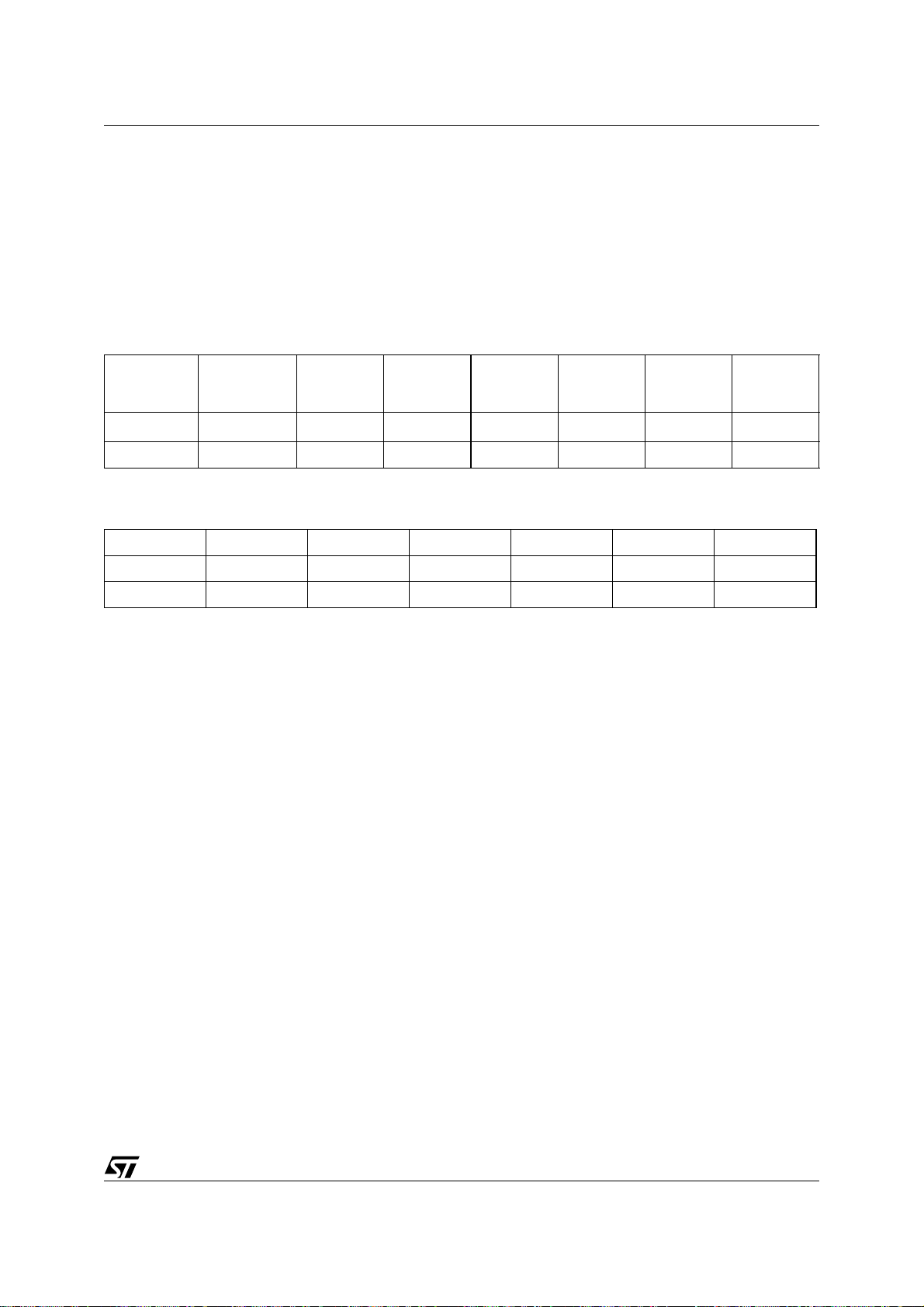

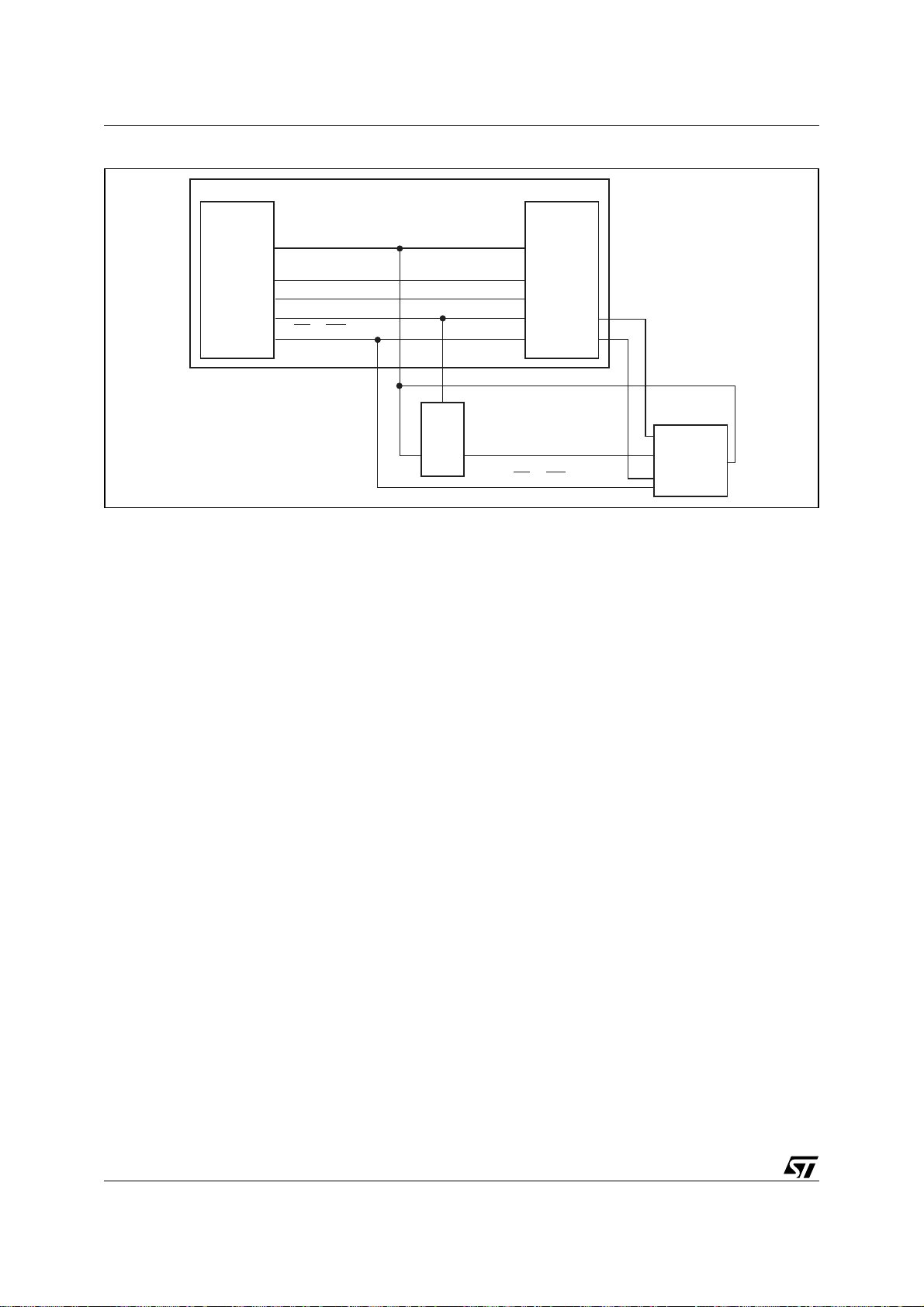

Figure 2. Block Diagram

(3) 16-bit

Timer/

Counters

(2)

External

Interrupts

P3.0:7

P1.0:7

Optional IrDA

Encoder/Decoder

Turbo

8032

Core

I2C

UART0

(8) GPIO, Port 3

(8) GPIO, Port 1

(8) 10-bit ADC

PFQ

&

BC

UART1

uPSD34xx

Programmable

Programmable

SYSTEM BUS

Decode and

Page Logic

General

Purpose

Logic,

16 Macrocells

JTAG ICE and ISP

1st Flash Memory:

64K, 128K, or

256K Bytes

2nd Flash Memory:

32K Bytes

SRAM:

4K or 8K Bytes

(8) GPIO, Port A

(80-pin only)

(8) GPIO, Port B

(2) GPIO, Port D

(4) GPIO, Port C

PA0:7

PB0:7

PD1:2

PC0:7

P4.0:7

USB+,

USB–

SPI

16-bit PCA

(6) PWM, CAPCOM, TIMER

(8) GPIO, Port 4

USB v2.0,

Full Speed

10

FIFOs

8032 Address/Data/Control Bus

(80-pin device only)

Supervisor:

Watchdog and Low-Voltage Reset

VCC, VDD, GND, Reset, Crystal In

MCU

Bus

Dedicated

Pins

AI09695

8/264

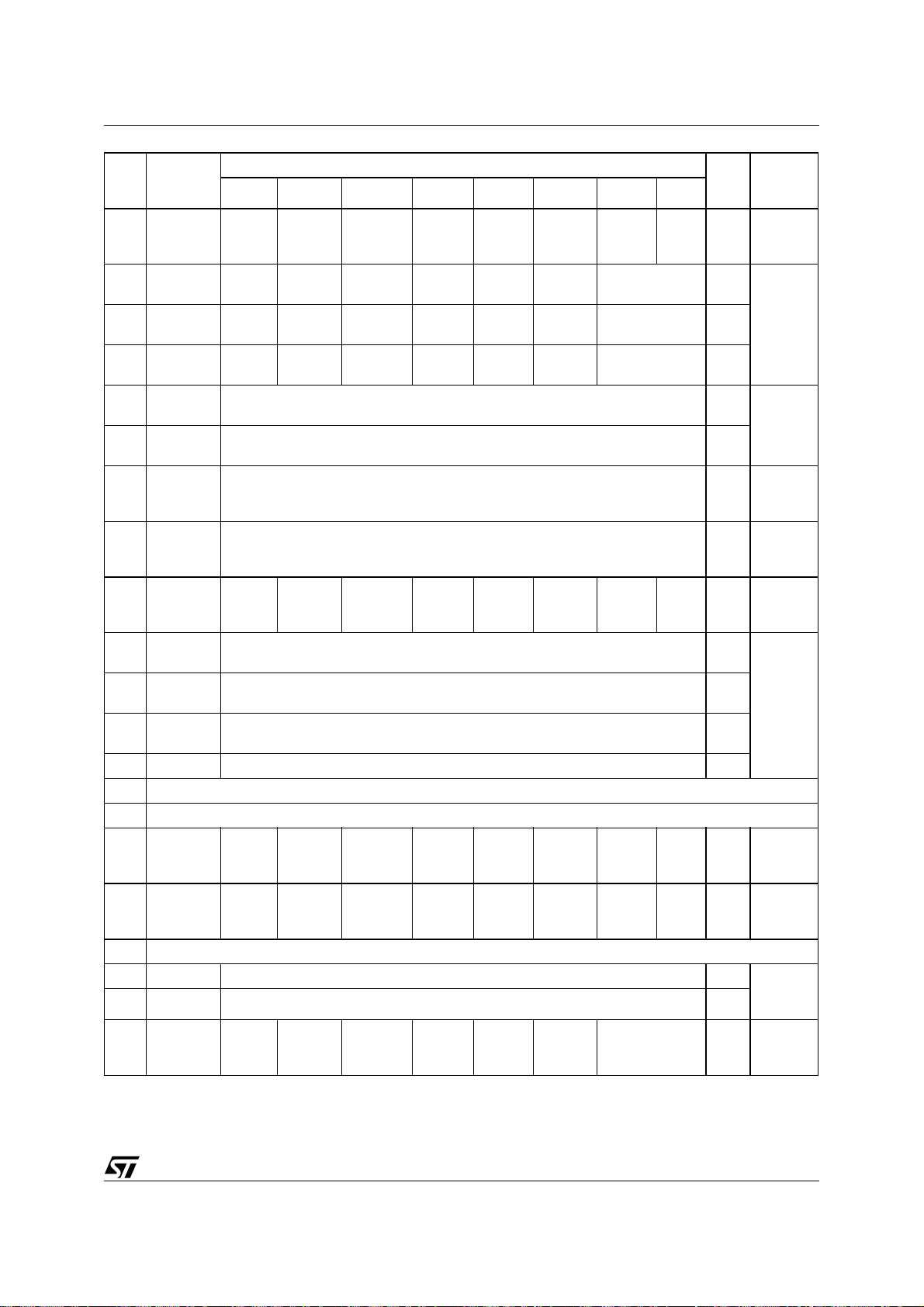

PIN DESCRIPTIONS

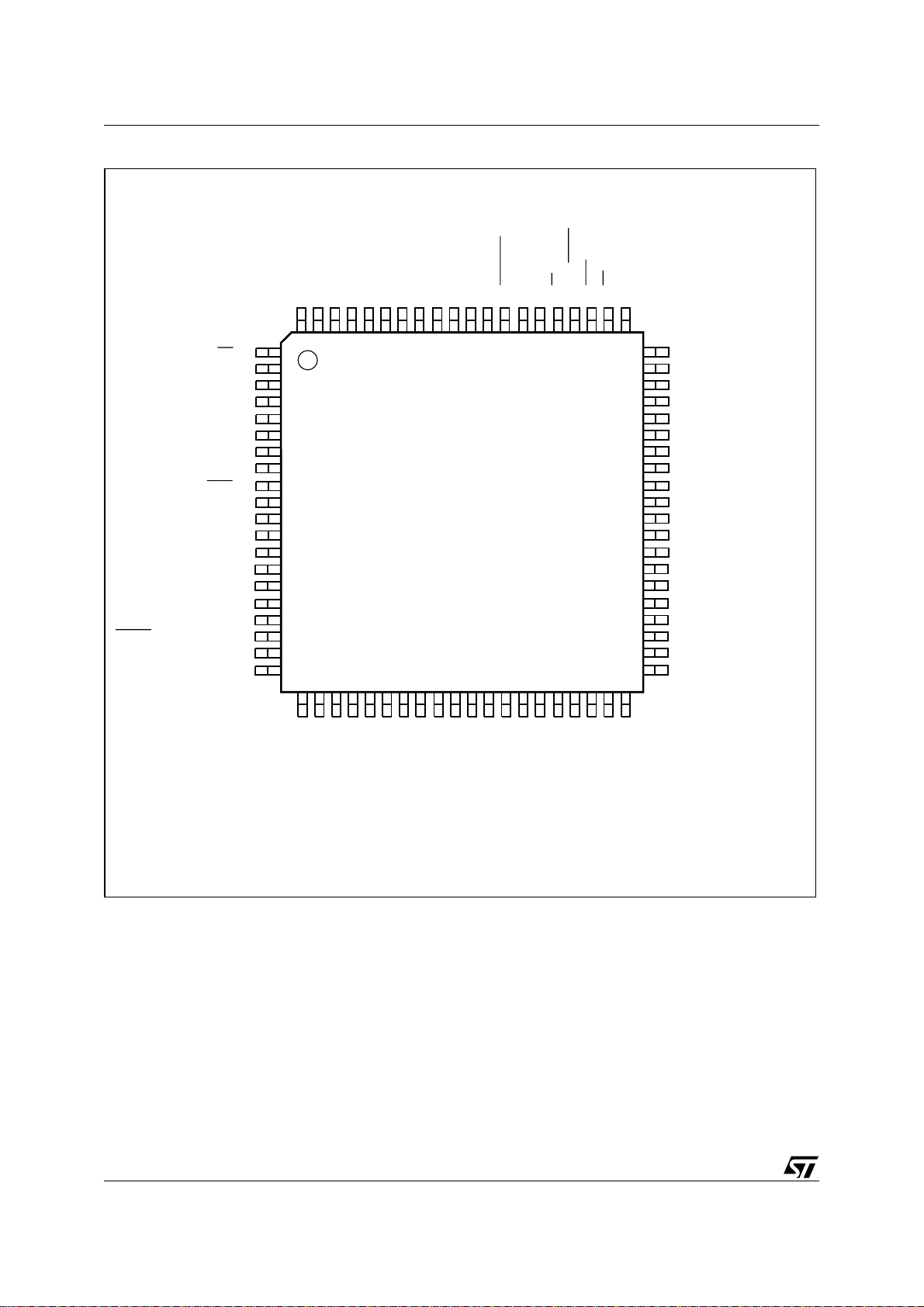

Figure 3. TQFP52 Connections

uPSD34xx - PIN DESCRIPTIONS

/ADC7

(2)

PB6

(2)

PB7

P1.7/SPISEL

(3)

REF

/V

CC

PB5

GND

PB0

PB1

PB2

PB3

PB4

AV

RESET_IN

52515049484746454443424140

/ADC6

P1.6/SPITXD

PD1/CLKIN

PC7

JTAG TDO

JTAG TDI

DEBUG

3.3V V

CC

USB+

V

DD

GND

USB–

PC2/V

STBY

JTAG TCK

JTAG TMS

(2)

(2)

(2)

(2)

/ADC1

/ADC0

/ADC5

/ADC4

(2)

/ADC3

(2)

/ADC2

1

2

3

4

5

6

7

(1)

8

9

10

11

12

13

39 P1.5/SPIRXD

38 P1.4/SPICLK

37 P1.3/TXD1(IrDA)

36 P1.2/RXD1(IrDA)

35 P1.1/T2X

34 P1.0/T2

(1)

33 V

DD

32 XTAL2

31 XTAL1

30 P3.7/SCL

29 P3.6/SDA

28 P3.5/C1

27 P3.4/C0

14151617181920212223242526

GND

TXD0/P3.1

/TCM4/P4.5

/TCM5/P4.6

/TCM3/P4.4

(2)

(2)

SPITXD

SPIRXD

(2)

SPICLK

/PCACLK1/P4.7

(2)

SPISEL

/TCM2/P4.2

(2)

/PCACLK0/P4.3

(2)

RXD1(IrDA)

TXD1(IrDA)

RXD0/P3.0

/TCM1/P4.1

/TCM0/P4.0

(2)

(2)

T2

T2X

EXTINT0/TG0/P3.2

EXTINT1/TG1/P3.3

AI09696

Note: 1. For 5V applications, VDD must be connected to a 5.0V source. For 3.3V applications, VDD must be connected to a 3.3V source.

2. These signals can be used on one of two different ports (Port 1 or Port 4) for flexibility. Default is Port1.

3. AV

and 3.3V AVCC are shared in the 52-pin package only. ADC channels must use 3.3V as AV

REF

for the 52-pin package.

REF

9/264

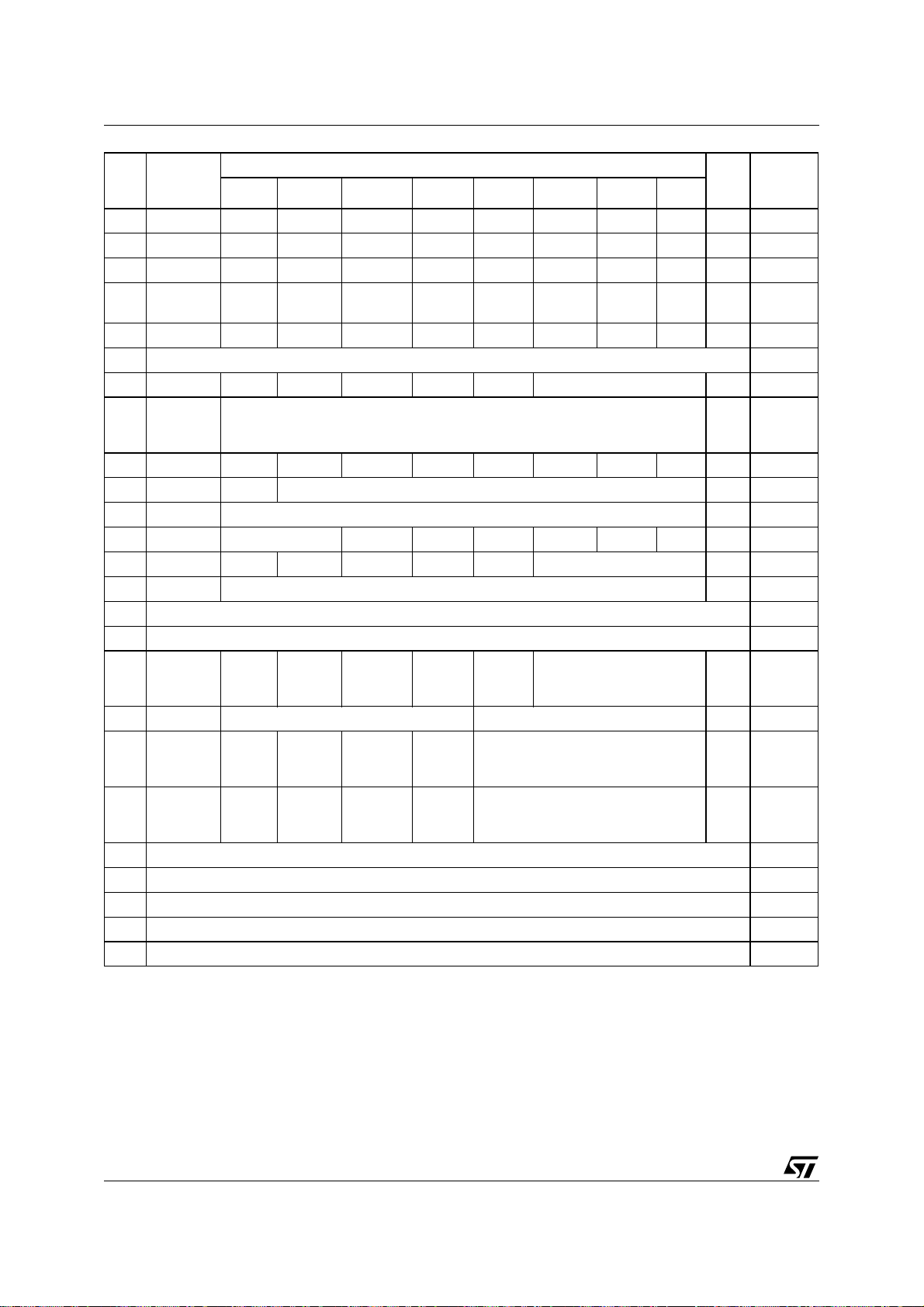

uPSD34xx - PIN DESCRIPTIONS

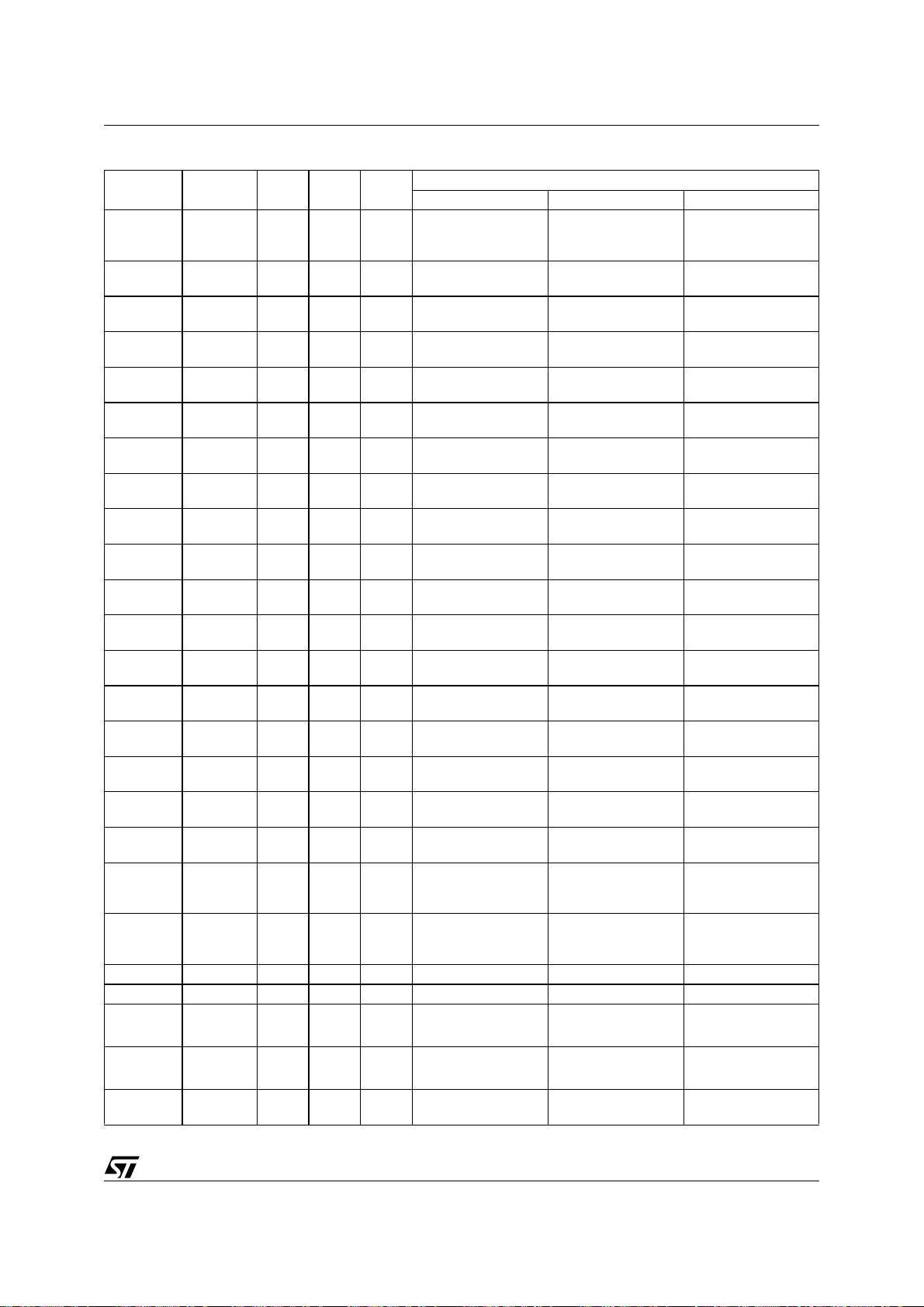

Figure 4. TQFP80 Connections

SPISEL

SPITXD

PD2/CSI

P3.3/TG1/EXINT1

PD1/CLKIN

ALE

PC7

JTAG TDO

JTAG TDI

DEBUG

PC4/TERR

3.3V V

USB+

V

DD

GND

USB–

PC3/TSTAT

PC2/V

STBY

JTAG TCK

(2)

/PCACLK1/P4.7

(2)

/TCM5/P4.6

JTAG TMS

/ADC7

(3)

CC

PB0

P3.2/EXINT0/TG0

PB1

P3.1/TXD0

PB2

P3.0/RXD0

PB3

PB4

AV

PB5

V

REF

GND

RESET_IN

PB6

PB7RDP1.7/SPISEL

80797877767574737271706968676665646362

1

2

3

4

5

6

7

8

9

10

CC

(1)

11

(2)

12

13

14

15

16

17

18

19

20

/ADC6

(3)

PSENWRP1.6/SPITXD

61

60 P1.5/SPIRXD

59 P1.4/SPICLK

58 P1.3/TXD1(IrDA)

57 NC

56 P1.2/RXD1(IrDA)

55 NC

54 P1.1/T2X

53 NC

52 P1.0/T2

51 NC

50 V

49 XTAL2

48 XTAL1

47 MCU AD7

46 P3.7/SCL

45 MCU AD6

44 P3.6/SDA

43 MCU AD5

42 P3.5/C1

41 MCU AD4

(3)

/ADC5

(3)

/ADC4

(3)

/ADC3

(3)

/ADC2

(3)

/ADC1

(3)

/ADC0

(1)

DD

21222324252627282930313233343536373839

PA7

PA6

/TCM4/P4.5

(2)

SPIRXD

PA5

/TCM3/P4.4

(2)

SPICLK

PA3

PA4

/PCACLK0/P4.3

(2)

GND

PA2

/TCM1/P4.1

/TCM2/P4.2

(2)

(2)

T2X

PA1

PA0

/TCM0/P4.0

(2)

T2

MCU AD0

MCU AD1

MCU AD2

RXD1(IrDA)

TXD1(IrDA)

Note: NC = Not Connected

Note: 1. The USB+ pin needs a 1.5kΩ pull-up resistor.

2. For 5V applications, V

3. These signals can be used on one of two different ports (Port 1 or Port 4) for flexibility. Default is Port1.

must be connected to a 5.0V source. For 3.3V applications, VDD must be connected to a 3.3V source.

DD

10/264

40

P3.4/C0

MCU AD3

AI09697

uPSD34xx - PIN DESCRIPTIONS

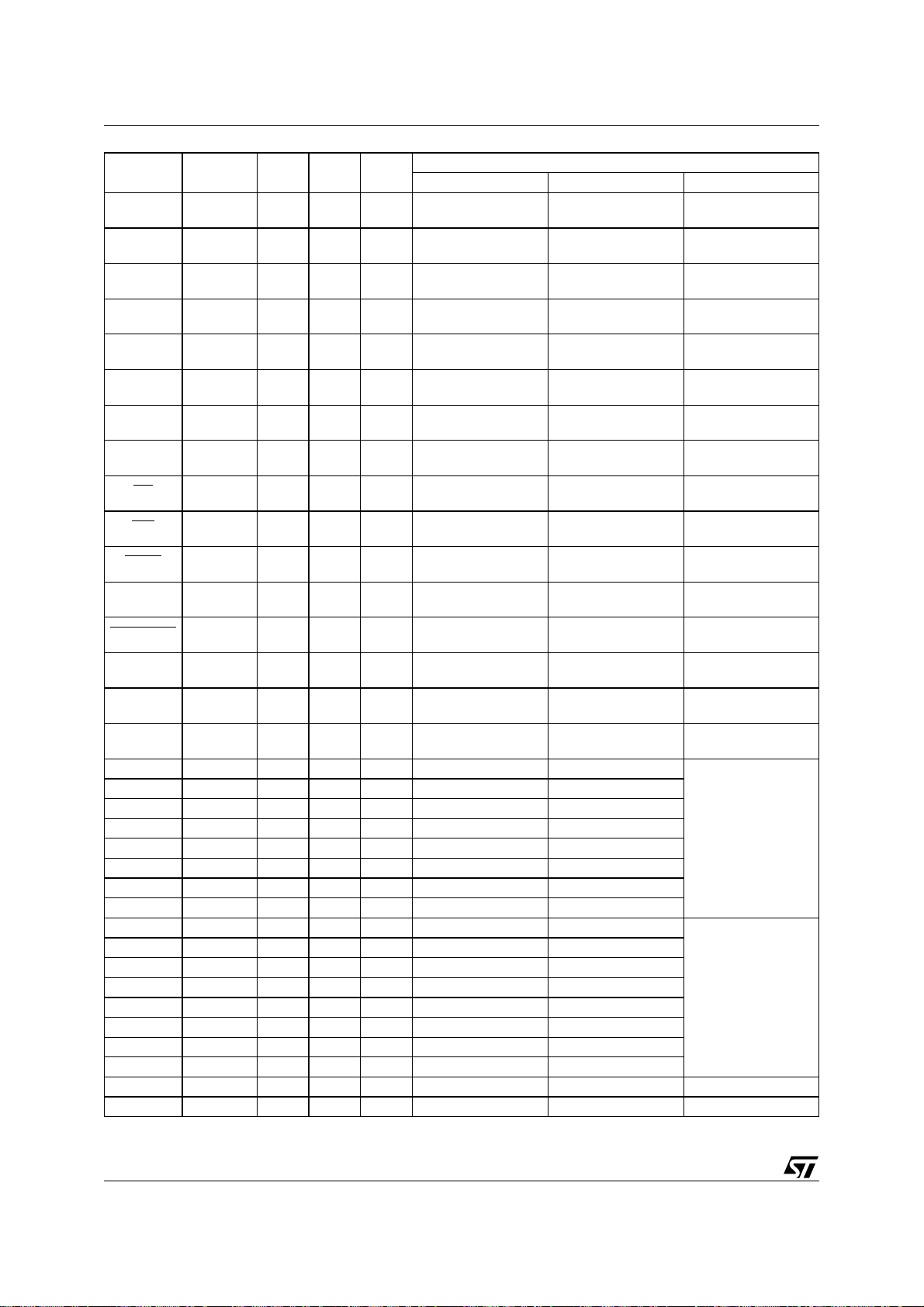

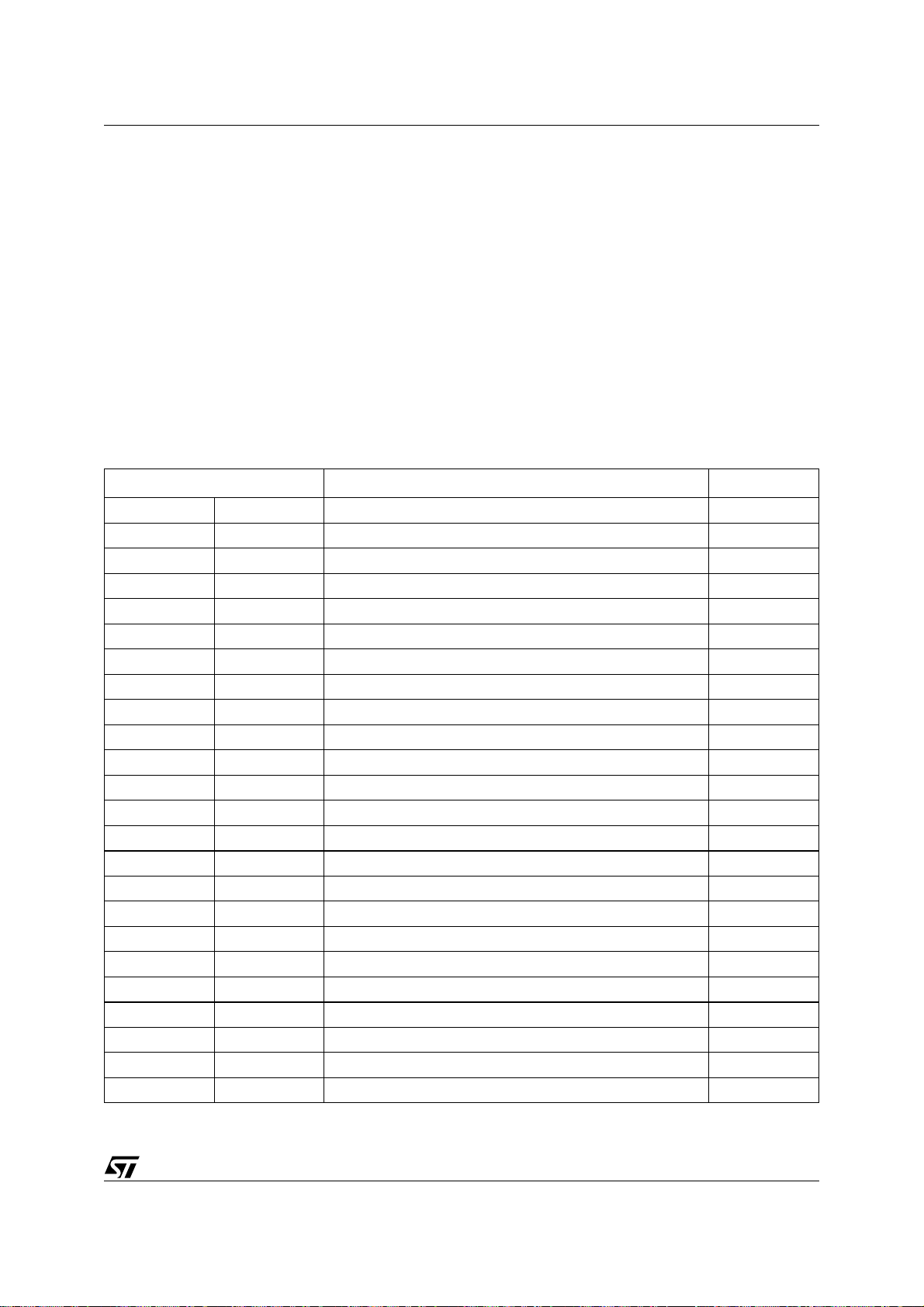

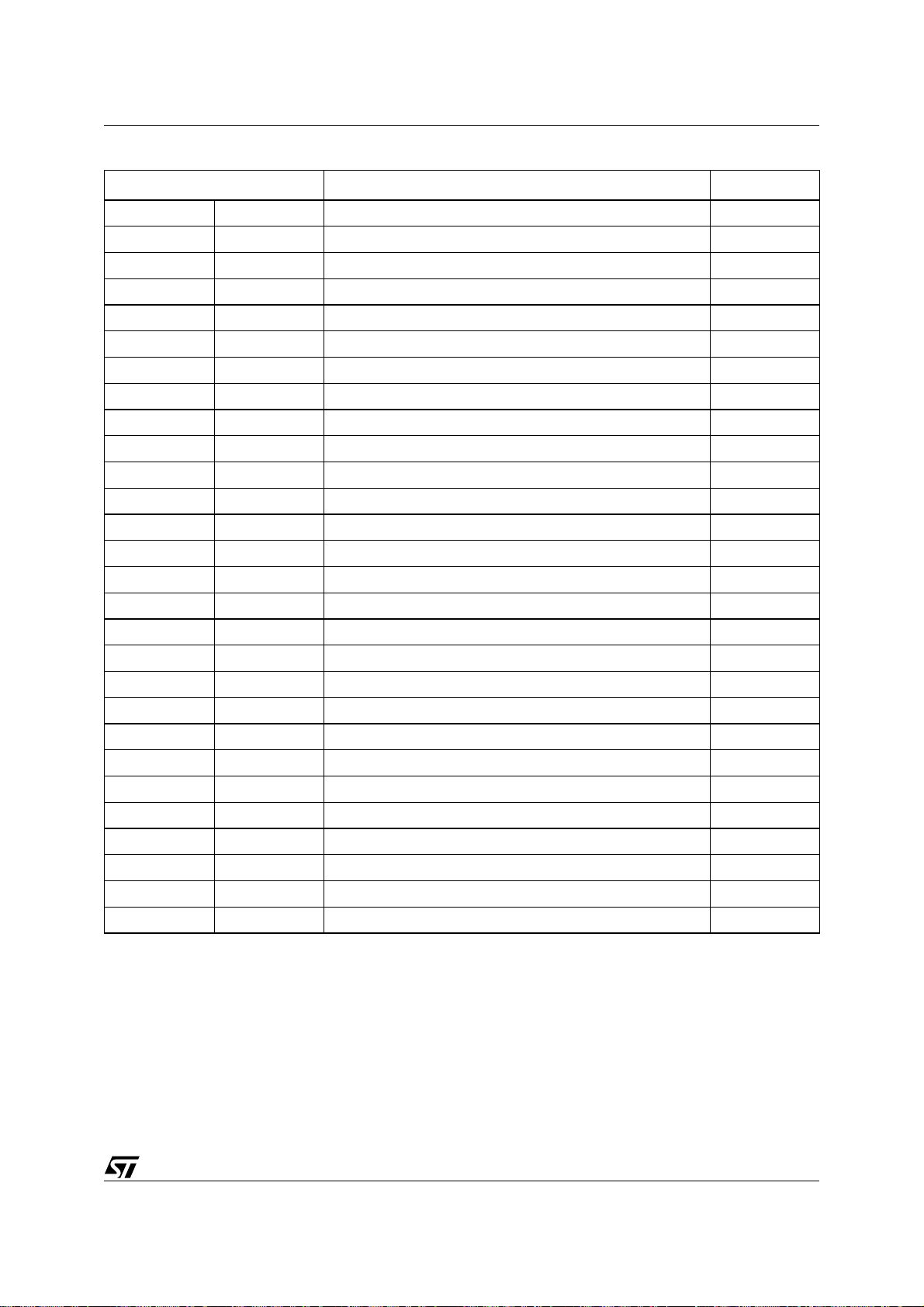

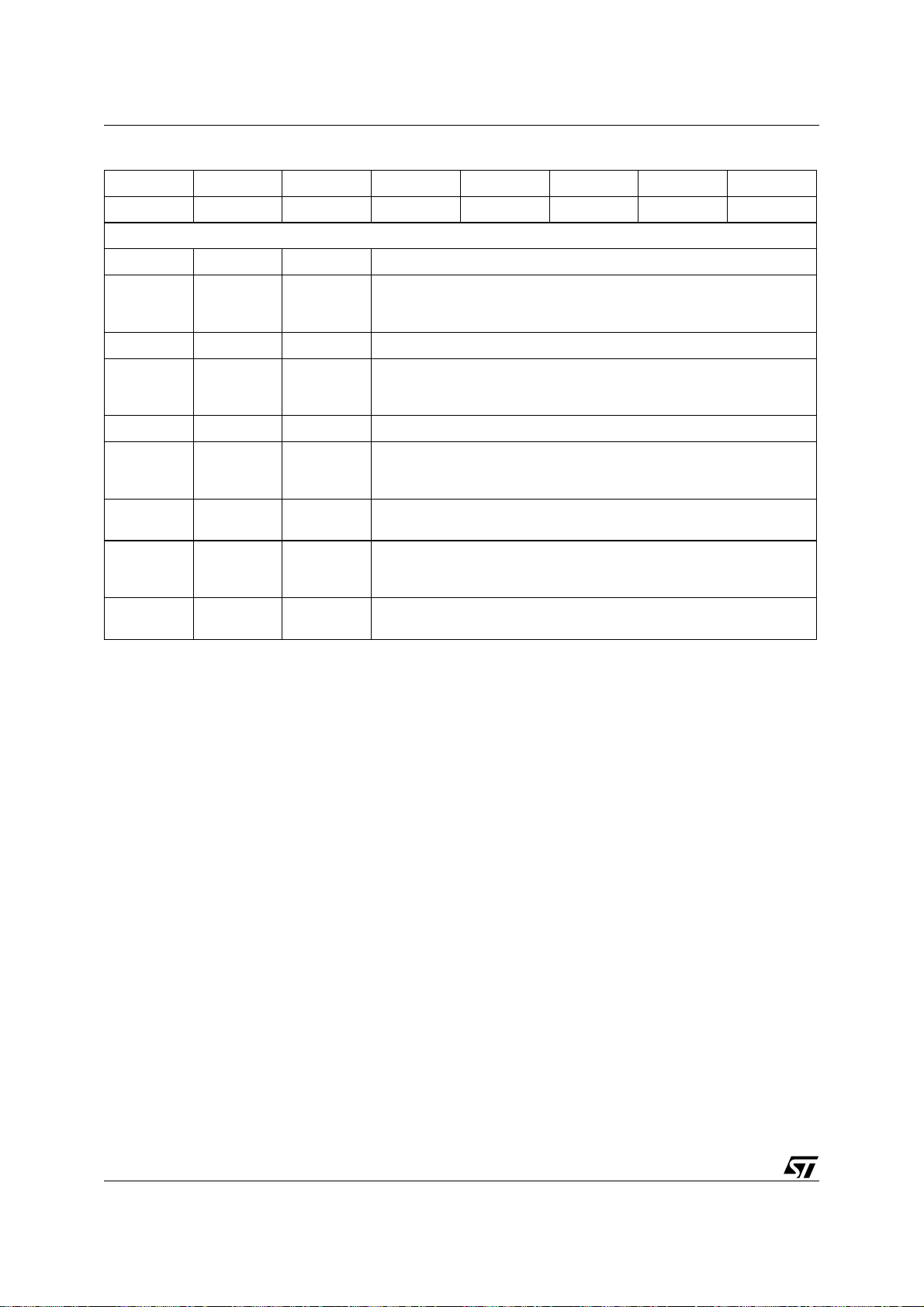

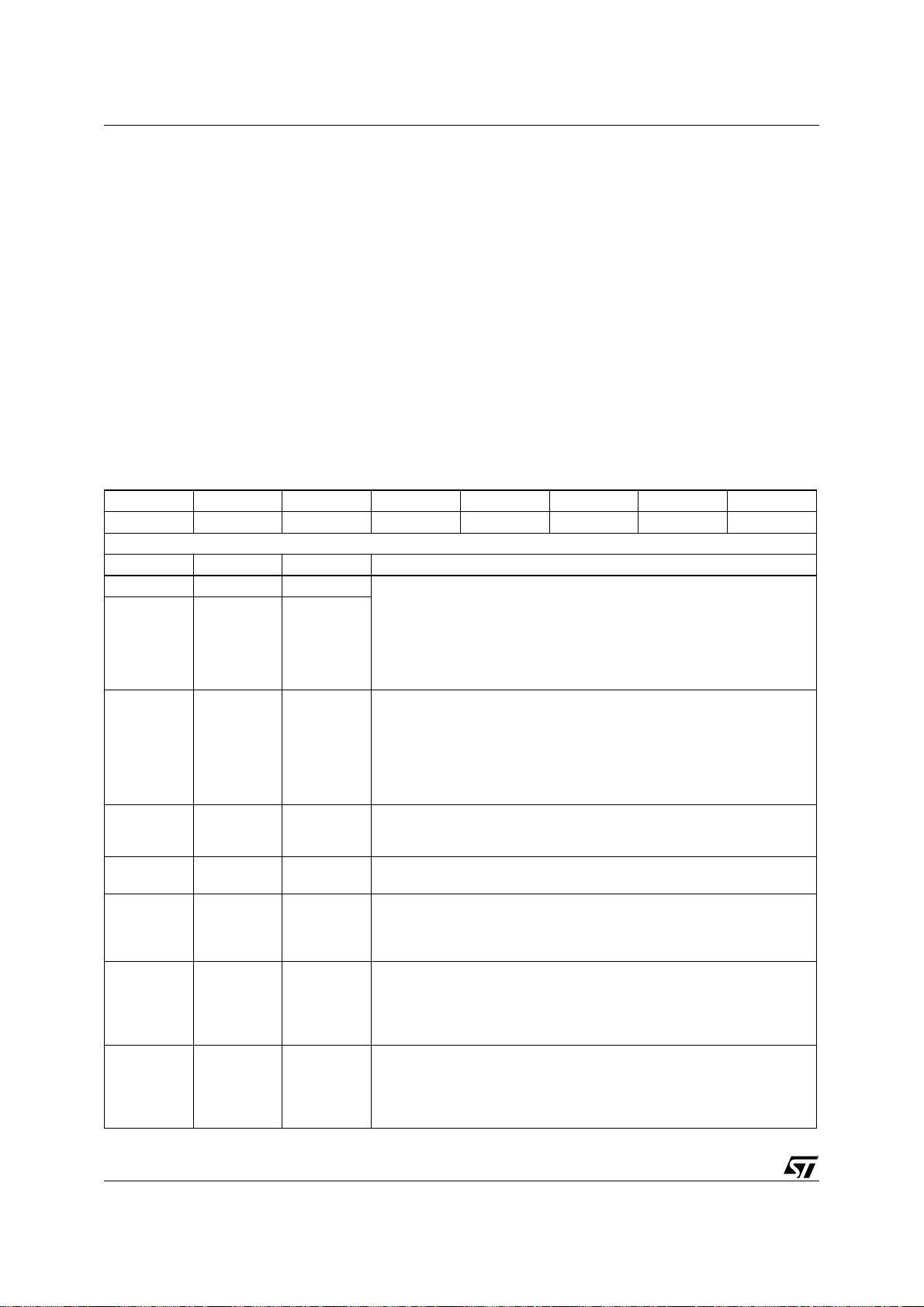

Table 2. Pin Definitions

Function

Timer 2 Count input

(T2)

Timer 2 Trigger input

(T2X)

UART1 or IrDA

Receive (RxD1)

UART or IrDA

Transmit (TxD1)

SPI Clock Out

(SPICLK)

SPI Receive

(SPIRxD)

SPI Transmit

(SPITxD)

SPI Slave Select

(SPISEL)

UART0 Receive

(RxD0)

UART0 Transmit

(TxD0)

Interrupt 0 input

(EXTINT0)/Timer 0

gate control (TG0)

Interrupt 1 input

(EXTINT1)/Timer 1

gate control (TG1)

2

C Bus serial data

I

2

CSDA)

(I

2

I

C Bus clock

2

CSCL)

(I

Program Counter

Array0 PCA0-TCM0

Port Pin

Signal

Name

80-Pin

No.

52-Pin

(1)

No.

In/Out

Basic Alternate 1 Alternate 2

External Bus

MCUAD0 AD0 36 N/A I/O

Multiplexed Address/

Data bus A0/D0

MCUAD1 AD1 37 N/A I/O

MCUAD2 AD2 38 N/A I/O

MCUAD3 AD3 39 N/A I/O

MCUAD4 AD4 41 N/A I/O

MCUAD5 AD5 43 N/A I/O

MCUAD6 AD6 45 N/A I/O

MCUAD7 AD7 47 N/A I/O

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

T2

ADC0

T2X

ADC1

RxD1

ADC2

TXD1

ADC3

SPICLK

ADC4

SPIRxD

ADC6

SPITXD

ADC6

SPISEL

ADC7

52 34 I/O General I/O port pin

54 35 I/O General I/O port pin

56 36 I/O General I/O port pin

58 37 I/O General I/O port pin

59 38 I/O General I/O port pin

60 39 I/O General I/O port pin

61 40 I/O General I/O port pin

64 41 I/O General I/O port pin

Multiplexed Address/

Data bus A1/D1

Multiplexed Address/

Data bus A2/D2

Multiplexed Address/

Data bus A3/D3

Multiplexed Address/

Data bus A4/D4

Multiplexed Address/

Data bus A5/D5

Multiplexed Address/

Data bus A6/D6

Multiplexed Address/

Data bus A7/D7

P3.0 RxD0 75 23 I/O General I/O port pin

P3.1 TXD0 77 24 I/O General I/O port pin

P3.2

EXINT0

TGO

79 25 I/O General I/O port pin

P3.3 INT1 2 26 I/O General I/O port pin

P3.4 C0 40 27 I/O General I/O port pin Counter 0 input (C0)

P3.5 C1 42 28 I/O General I/O port pin Counter 1 input (C1)

P3.6 SDA 44 29 I/O General I/O port pin

P3.7 SCL 46 30 I/O General I/O port pin

P4.0

T2

TCM0

33 22 I/O General I/O port pin

ADC Channel 0

input (ADC0)

ADC Channel 1

input (ADC1)

ADC Channel 2

input (ADC2)

ADC Channel 3

input (ADC3)

ADC Channel 4

input (ADC4)

ADC Channel 5

input (ADC5)

ADC Channel 6

input (ADC6)

ADC Channel 7

input (ADC7)

Timer 2 Count input

(T2)

11/264

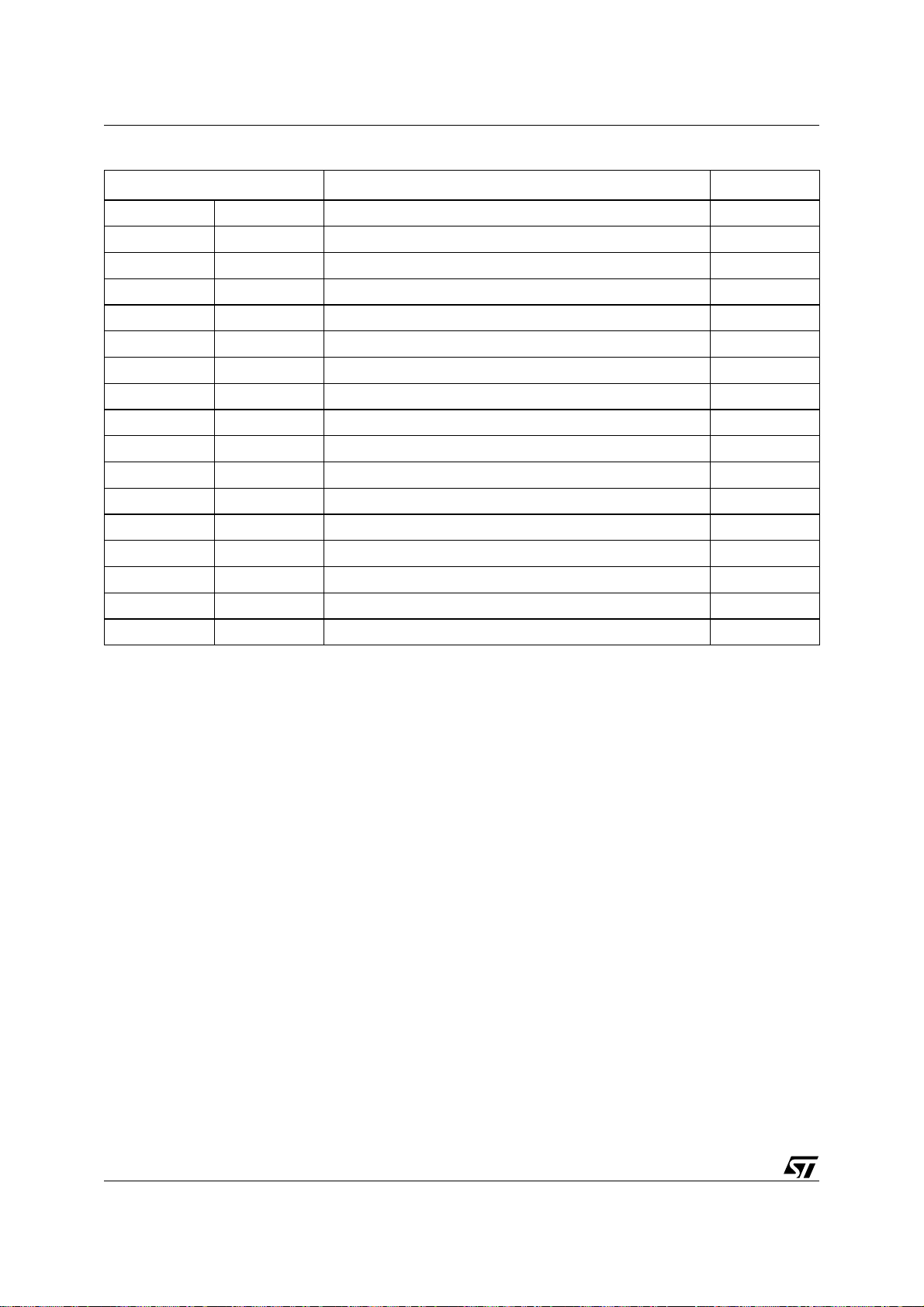

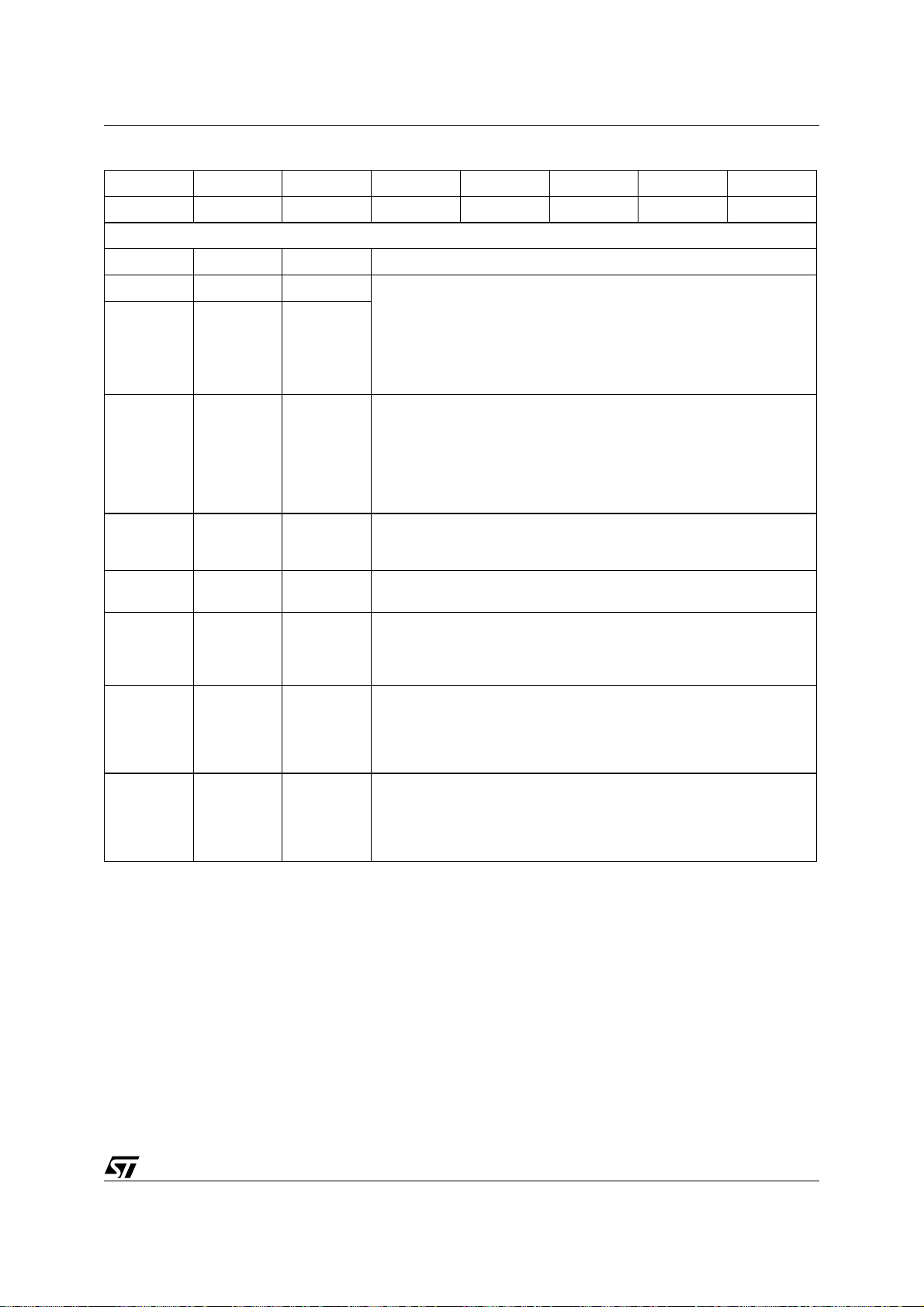

uPSD34xx - PIN DESCRIPTIONS

Port Pin

P4.1

P4.2

P4.3

P4.4

P4.5

Signal

Name

T2X

TCM1

RXD1

TCM2

TXD1

PCACLK0

SPICLK

TCM3

SPIRXD

TCM4

80-Pin

No.

52-Pin

No.

(1)

In/Out

Basic Alternate 1 Alternate 2

31 21 I/O General I/O port pin PCA0-TCM1

30 20 I/O General I/O port pin PCA0-TCM2

27 18 I/O General I/O port pin PCACLK0

25 17 I/O General I/O port pin

Program Counter

Array1 PCA1-TCM3

23 16 I/O General I/O port pin PCA1-TCM4

P4.6 SPITXD 19 15 I/O General I/O port pin PCA1-TCM5

P4.7

V

REF

RD

WR

PSEN

ALE 4 N/A O

RESET_IN

XTAL1 48 31 I

XTAL2 49 32 O

DEBUG 8 5 I/O

SPISEL

PCACLK1

18 14 I/O General I/O port pin PCACLK1

70 N/A I

65 N/A O

62 N/A O

63 N/A O

Reference Voltage

input for ADC

READ Signal,

external bus

WRITE Signal,

external bus

PSEN Signal,

external bus

Address Latch

signal, external bus

68 44 I

Active low reset

input

Oscillator input pin

for system clock

Oscillator output pin

for system clock

I/O to the MCU

Debug Unit

PA0 35 N/A I/O General I/O port pin

PA1 34 N/A I/O General I/O port pin

PA2 32 N/A I/O General I/O port pin

PA3 28 N/A I/O General I/O port pin

PA4 26 N/A I/O General I/O port pin

PA5 24 N/A I/O General I/O port pin

PA6 22 N/A I/O General I/O port pin

PA7 21 N/A I/O General I/O port pin

PB0 80 52 I/O General I/O port pin

PB1 78 51 I/O General I/O port pin

PB2 76 50 I/O General I/O port pin

PB3 74 49 I/O General I/O port pin

PB4 73 48 I/O General I/O port pin

PB5 71 46 I/O General I/O port pin

PB6 67 43 I/O General I/O port pin

PB7 66 42 I/O General I/O port pin

JTAGTMS TMS 20 13 I JTAG pin (TMS)

JTAGTCK TCK 17 12 I JTAG pin (TCK)

Function

Timer 2 Trigger input

(T2X)

UART1 or IrDA

Receive (RxD1)

UART1 or IrDA

Transmit (TxD1)

SPI Clock Out

(SPICLK)

SPI Receive

(SPIRxD)

SPI Transmit

(SPITxD)

SPI Slave Select

(SPISEL)

All Port A pins

support:

1. PLD Macro-cell

outputs, or

2. PLD inputs, or

3. Latched

Address Out

(A0-A7), or

4. Peripheral I/O

Mode

All Port B pins

support:

1. PLD Macro-cell

outputs, or

2. PLD inputs, or

3. Latched

Address Out

(A0-A7)

12/264

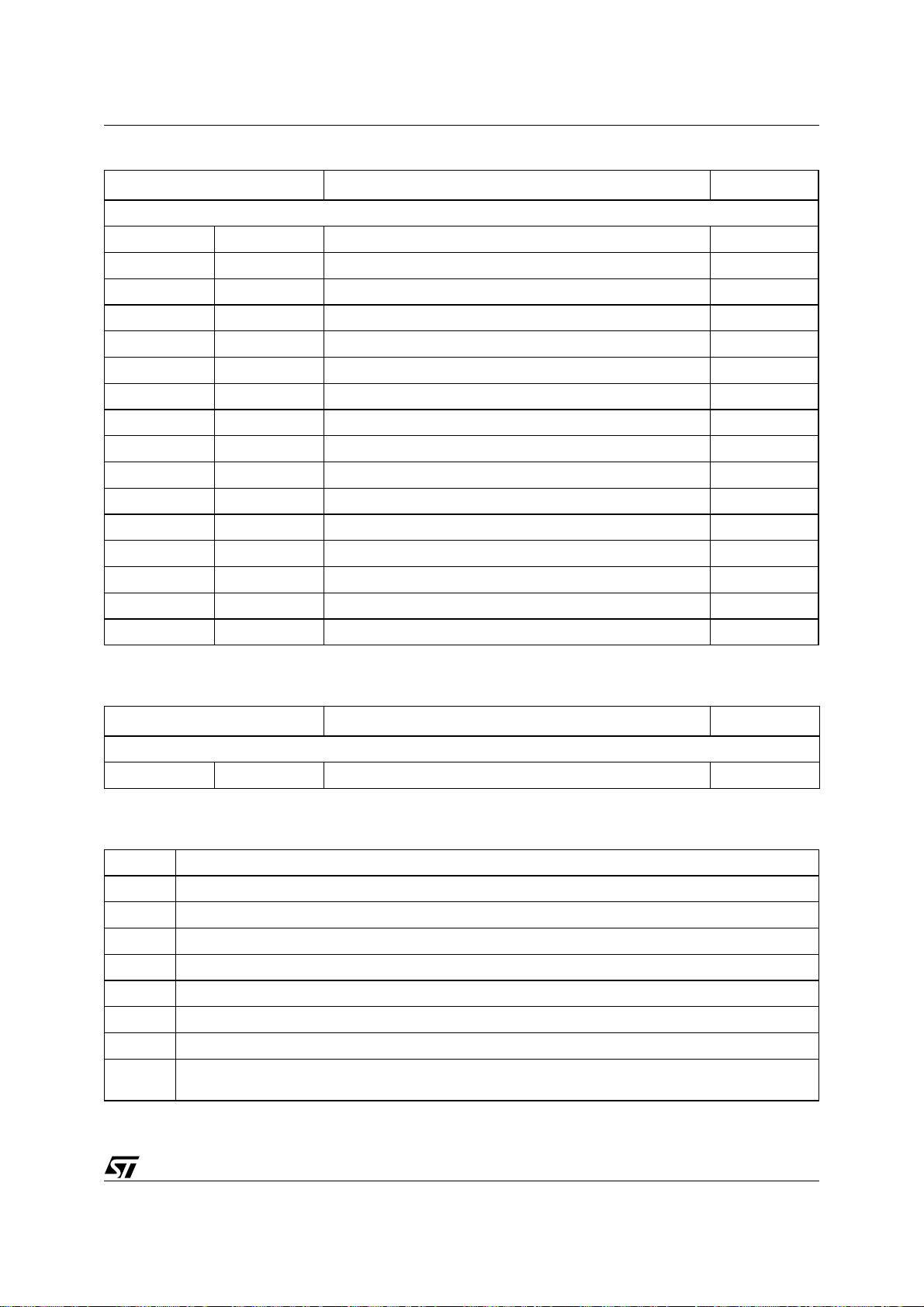

uPSD34xx - PIN DESCRIPTIONS

Port Pin

PC2

Signal

Name

V

STBY

80-Pin

No.

52-Pin

No.

(1)

In/Out

Basic Alternate 1 Alternate 2

16 11 I/O General I/O port pin

PC3 TSTAT 15 N/A I/O General I/O port pin

PC4 TERR

9 N/A I/O General I/O port pin

JTAGTDI TDI 7 4 I JTAG pin (TDI)

JTAGTDO TDO 6 3 O JTAG pin (TDO)

PC7 5 2 I/O General I/O port pin

PD1 CLKIN 3 1 I/O General I/O port pin

PD2 CSI 1 N/A I/O General I/O port pin

USB D+ pin; 1.5kΩ

USB+ 11 7 I/O

pull-up resistor is

required.

USB– 14 10 I/O USB D– pin

3.3V-V

CC

AV

CC

V

DD

3.3V or 5V

V

DD

3.3V or 5V

10 6

72 47

12 8

50 33

V

- MCU Module

CC

Analog V

V

- PSD Module

DD

- 3.3V for 3V

V

DD

- 5V for 5V

V

DD

V

- PSD Module

DD

- 3.3V for 3V

V

DD

- 5V for 5V

V

DD

CC

GND 13 9

GND 29 19

GND 69 45

NC 11 N/A

NC

NC

NC

NC

Note: 1. N/A = Signal Not Available on 52-pin package.

51

53

55

57

N/A

N/A

N/A

N/A

Input

Function

SRAM Standby

voltage input

(V

)

STBY

Optional JTAG

Status (TSTAT)

Optional JTAG

Status (TERR

PLD Macrocell

output, or PLD input

PLD, Macrocell

output, or PLD input

PLD, Macrocell

)

output, or PLD input

PLD, Macrocell

output, or PLD input

1. PLD I/O

2. Clock input to

PLD and APD

1. PLD I/O

2. Chip select ot

PSD Module

13/264

uPSD34xx - HARDWARE DESCRIPTION

HARDWARE DESCRIPTION

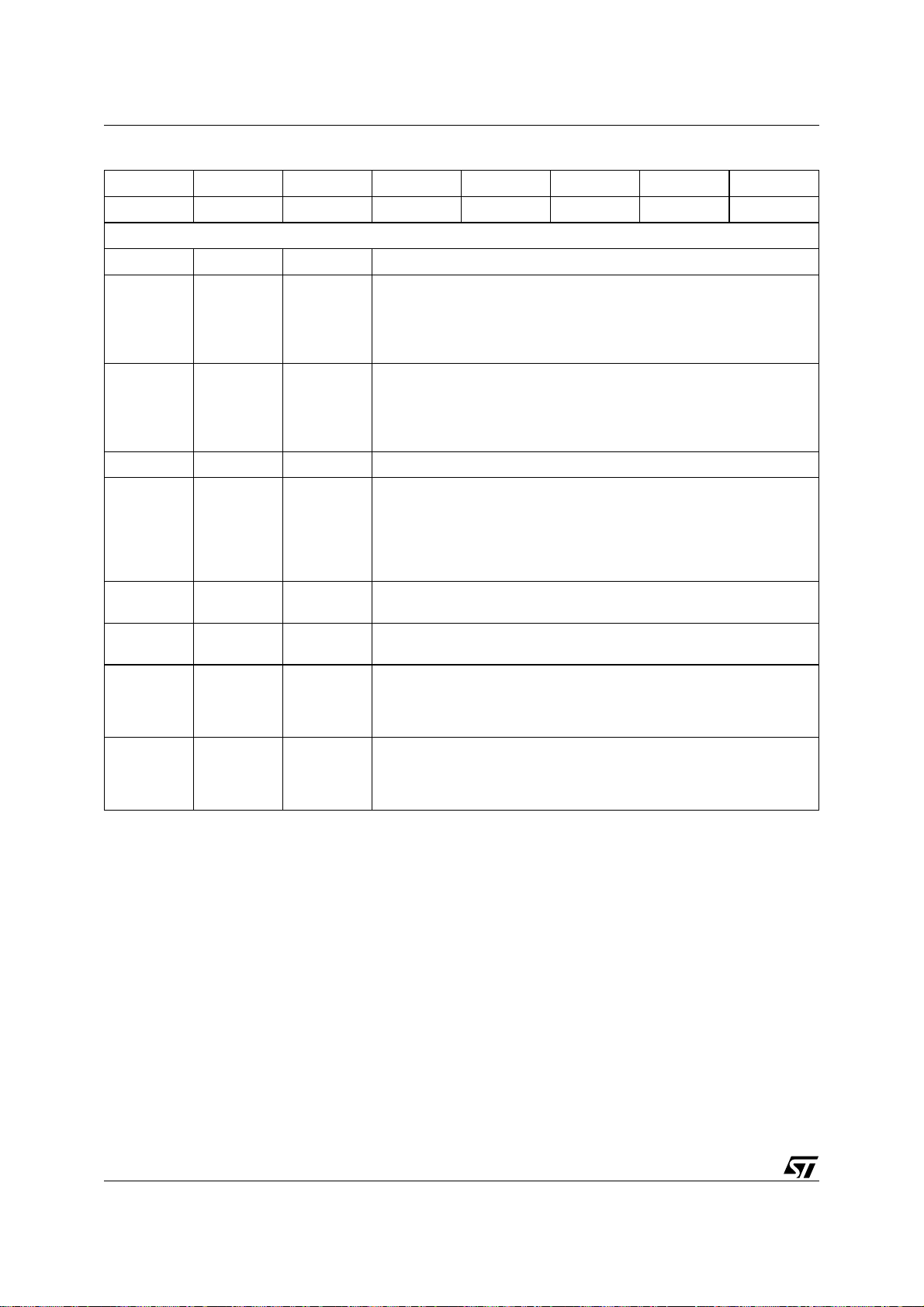

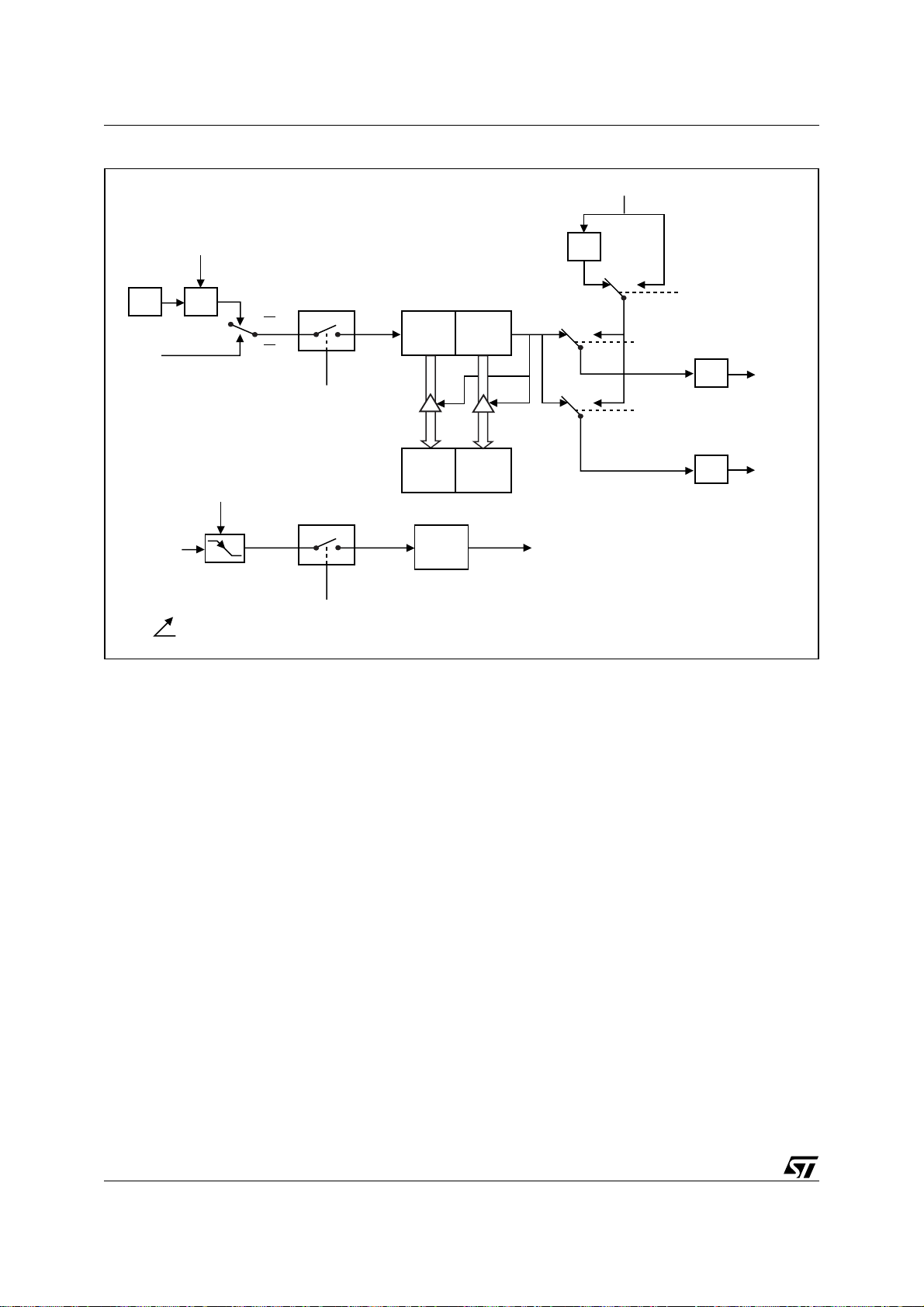

The uPSD34xx has a modular architecture built

from a stacked die process. There are two die, one

is designated “MCU Module” in this document, and

the other is designated “PSD Module” (see Figure

5., page 15). In all cases, the MCU Module die op-

erates at 3.3V with 5V tolerant I/O. The PSD Module is either a 3.3V die or a 5V die, depending on

the uPSD34xx device as described below.

The MCU Module consists of a fast 8032 core, that

operates with 4 clocks per instruction cycle, and

has many peripheral and system supervisor functions. The PSD Module provides the 8032 with

multiple memories (two Flash and one SRAM) for

program and data, programmable logic for address decoding and for general-purpose logic, and

additional I/O. The MCU Module communicates

with the PSD Module through internal address and

data busses (AD0 – AD15) and control signals

, WR, PSEN, ALE, RESET).

(RD

There are slightly different I/O characteristics for

each module. I/Os for the MCU module are designated as Ports 1, 3, and 4. I/Os for the PSD Module are designated as Ports A, B, C, and D.

For all 5V uPSD34xx devices, a 3.3V MCU Module

is stacked with a 5V PSD Module. In this case, a

5V uPSD34xx device must be supplied with

3.3V

PSD Module. Ports 3 and 4 of the MCU Module

are 3.3V ports with tolerance to 5V devices (they

can be directly driven by external 5V devices and

they can directly drive external 5V devices while

for the MCU Module and 5.0VDD for the

CC

producing a V

of 2.4V min and VCC max). Ports

OH

A, B, C, and D of the PSD Module are true 5V

ports.

For all 3.3V uPSD34xxV devices, a 3.3V MCU

Module is stacked with a 3.3V PSD Module. In this

case, a 3.3V uPSD34xx device needs to be supplied with a single 3.3V voltage source at both V

CC

and VDD. I/O pins on Ports 3 and 4 are 5V tolerant

and can be connected to external 5V peripherals

devices if desired. Ports A, B, C, and D of the PSD

Module are 3.3V ports, which are not tolerant to

external 5V devices.

Refer to Table 3 for port type and voltage source

requirements.

80-pin uPSD34xx devices provide access to 8032

address, data, and control signals on external pins

to connect external peripheral and memory devices. 52-pin uPSD34xx devices do not provide access to the 8032 system bus.

All non-volatile memory and configuration portions

of the uPSD34xx device are programmed through

the JTAG interface and no special programming

voltage is needed. This same JTAG port is also

used for debugging of the 8032 core at runtime

providing breakpoint, single-step, display, and

trace features. A non-volatile security bit may be

programmed to block all access via JTAG interface for security. The security bit is defeated only

by erasing the entire device, leaving the device

blank and ready to use again.

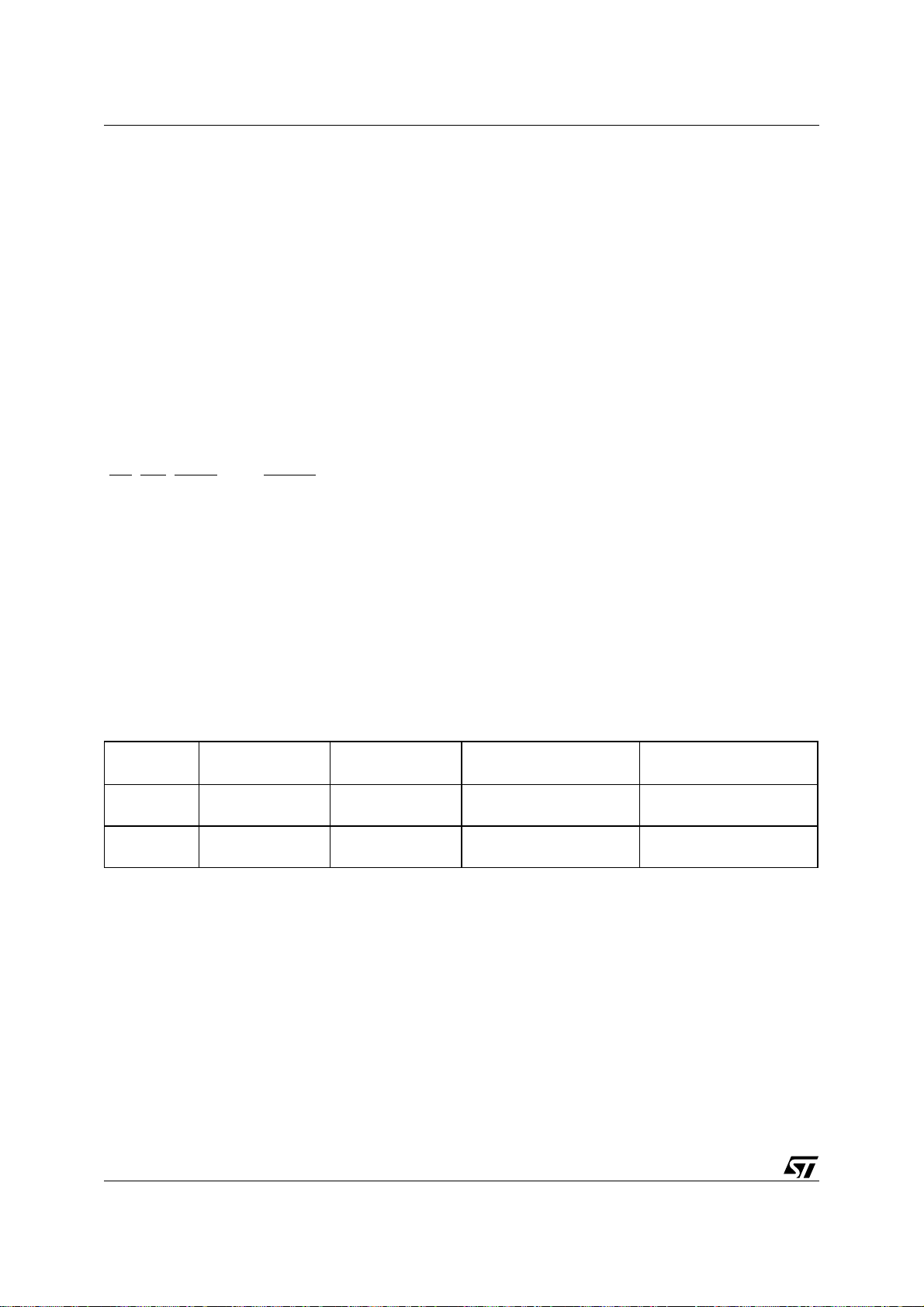

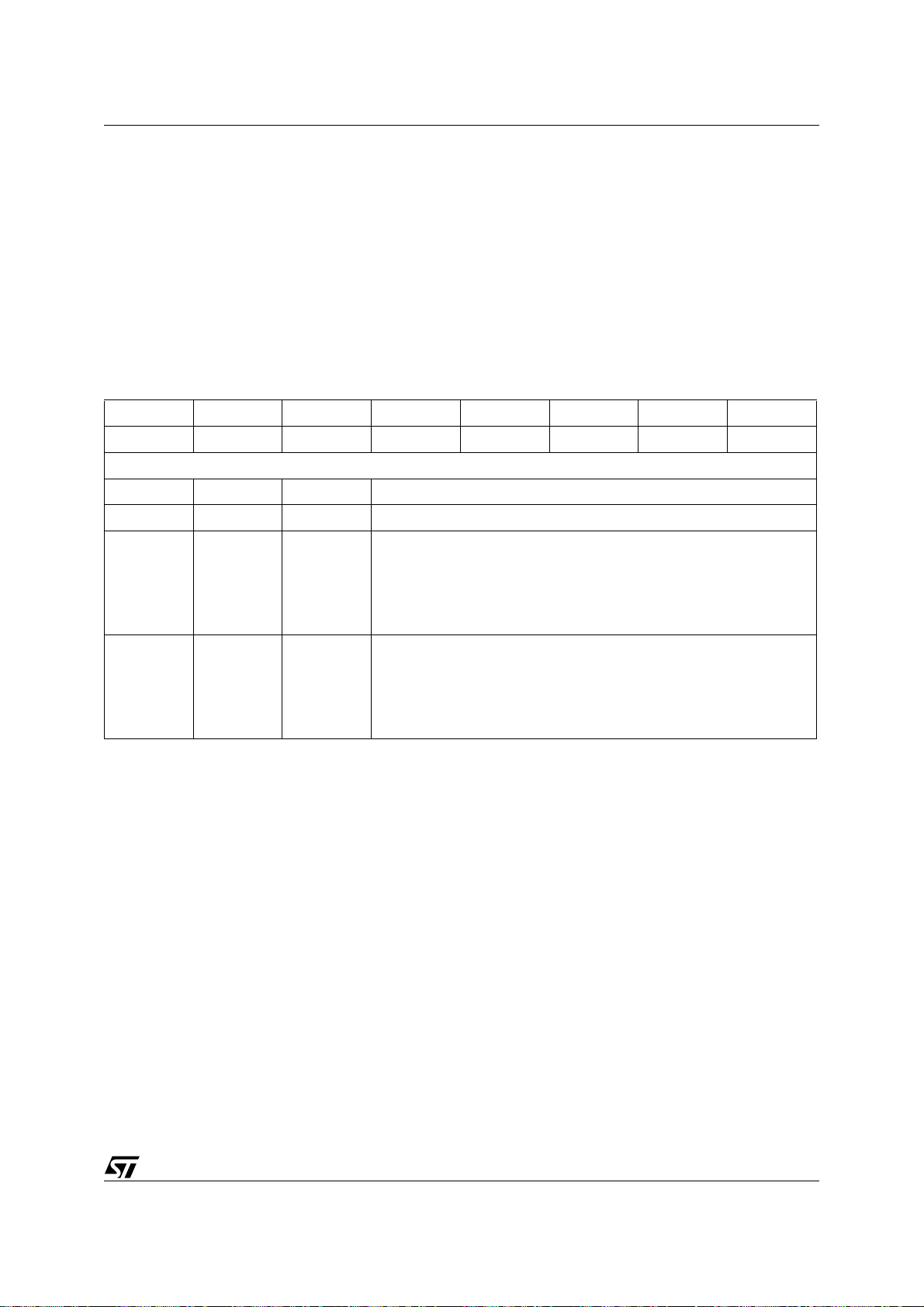

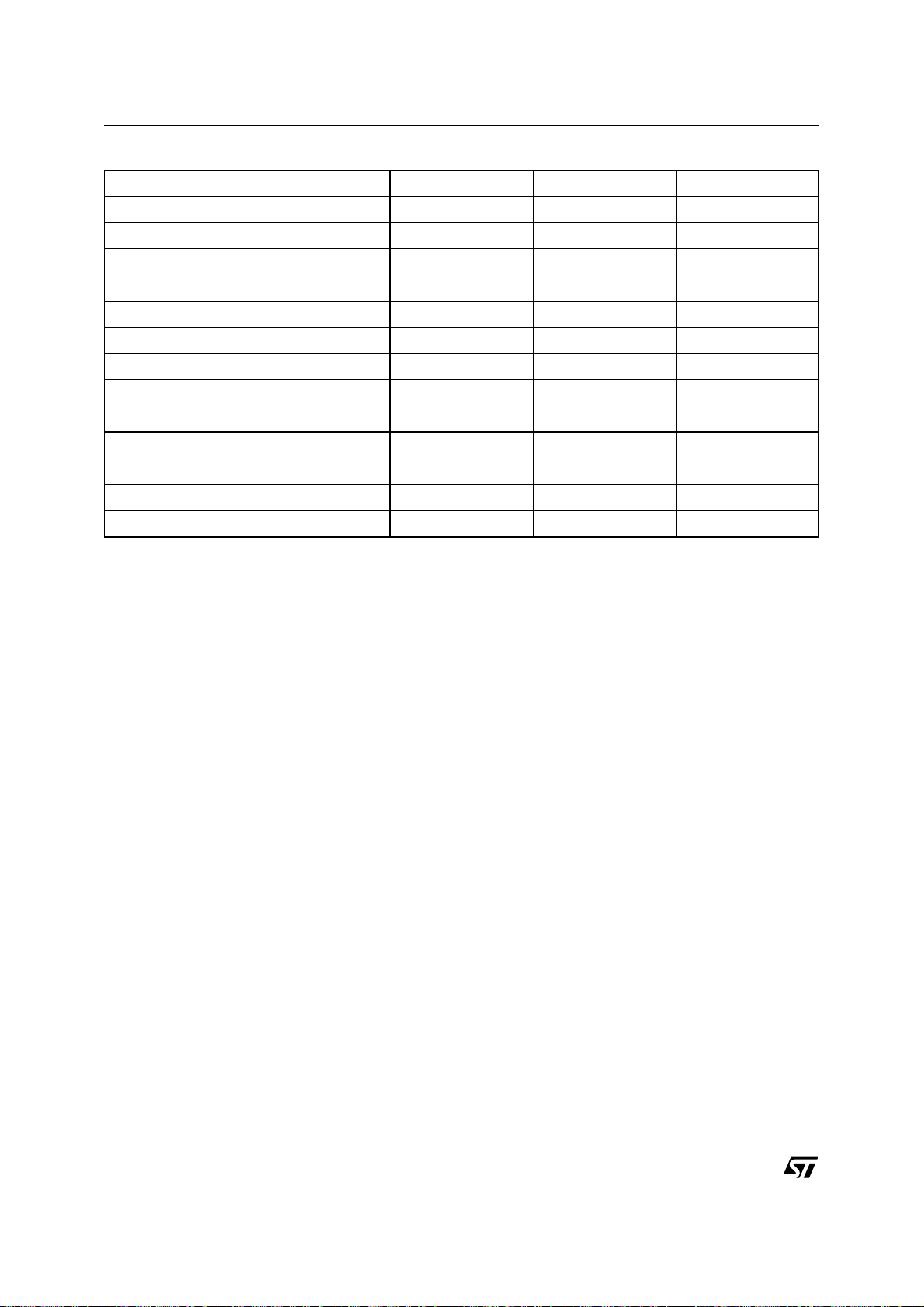

Table 3. Port Type and Voltage Source Combinations

V

Device Type

5V:

uPSD34xx

3.3V:

uPSD34xxV

14/264

for MCU

CC

Module

3.3V 5.0V

3.3V 3.3V

VDD for PSD

Module

Ports 1, 3, and 4 on MCU

3.3V (Ports 3 and 4 are

3.3V (Ports 3 and 4 are

Module

5V tolerant)

5V tolerant)

Ports A, B, C, and D on

PSD Module

5V

3.3V. NOT 5V tolerant

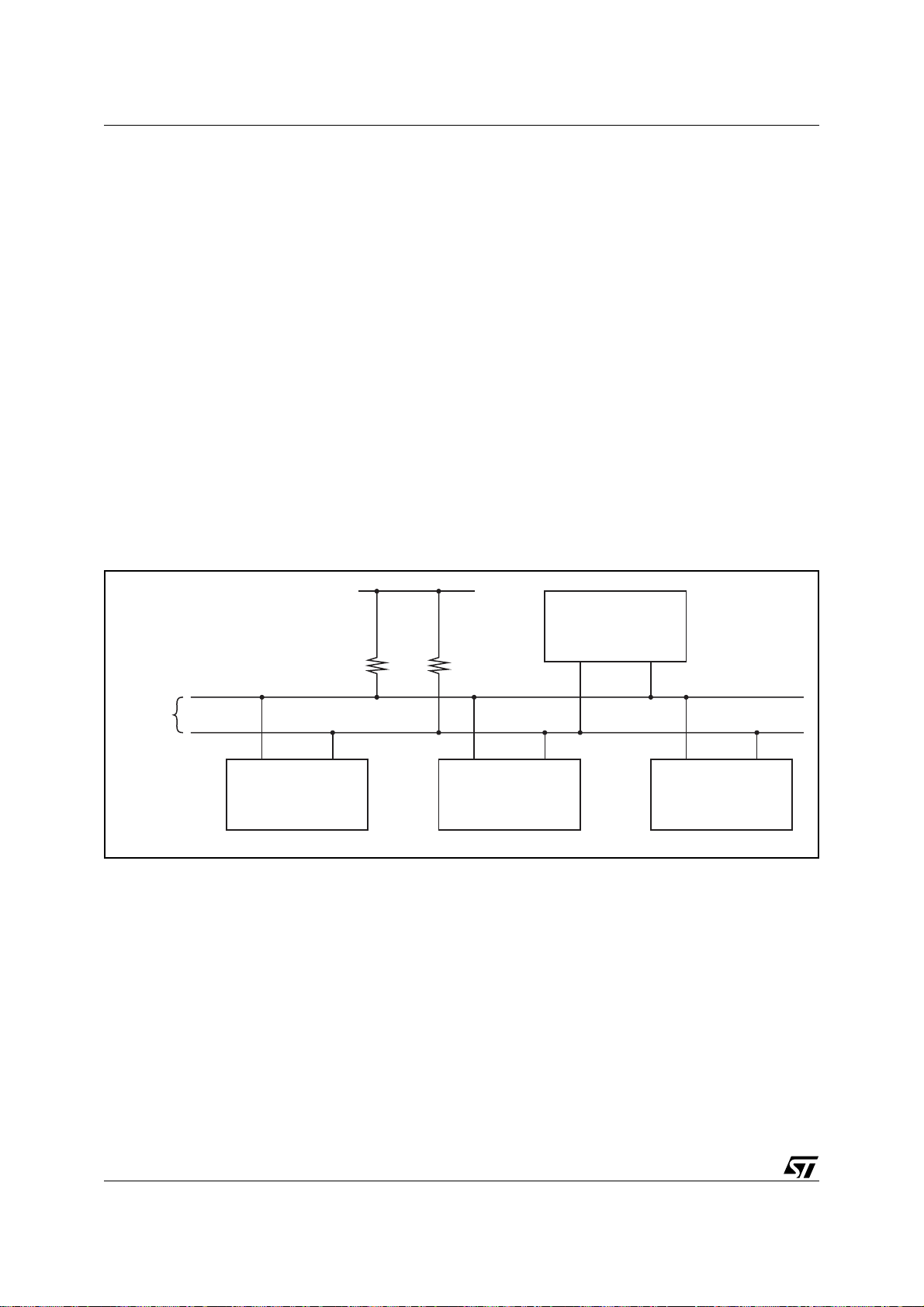

Figure 5. Functional Modules

uPSD34xx - HARDWARE DESCRIPTION

XTAL

Clock Unit

Die-to-Die Bus

8-Bit/16-Bit

Port 3 - UART0,

Intr, Timers

Turbo 8032 Core

Dual

UARTs

Inte rrupt

256 Byte SRAM

Dedicated Memory

Interface Prefetch,

Branch Cache

Enha nce d MCU Interface

PSD Page Register

Dec ode P LD

JTAG ISP

Port 1 - Timer, ADC, SPI

Port 1Port 3

3 Timer /

Counters

JTAG

DEBUG

Main Flash

10-bit

ADC

8032 Internal Bus

SPI

Secondary

Flash

PSD Interna l Bus

CPLD - 16 MACROCELLS

Port 4 - PCA,

PWM, UART1

PCA

PWM

Counters

Internal

Reset

SRAM

LVD

Reset Logic

Port 3

2

I

C

I2C

Unit

WDT

PSD

Reset

USB

pins

USB and

Trans-

ceiver

MCU Module

Reset Input

PSD Module

VCC Pins

3.3V

Ext.

Bus

Reset

Pin

VDD Pins

3.3V or 5V

uPSD34xx

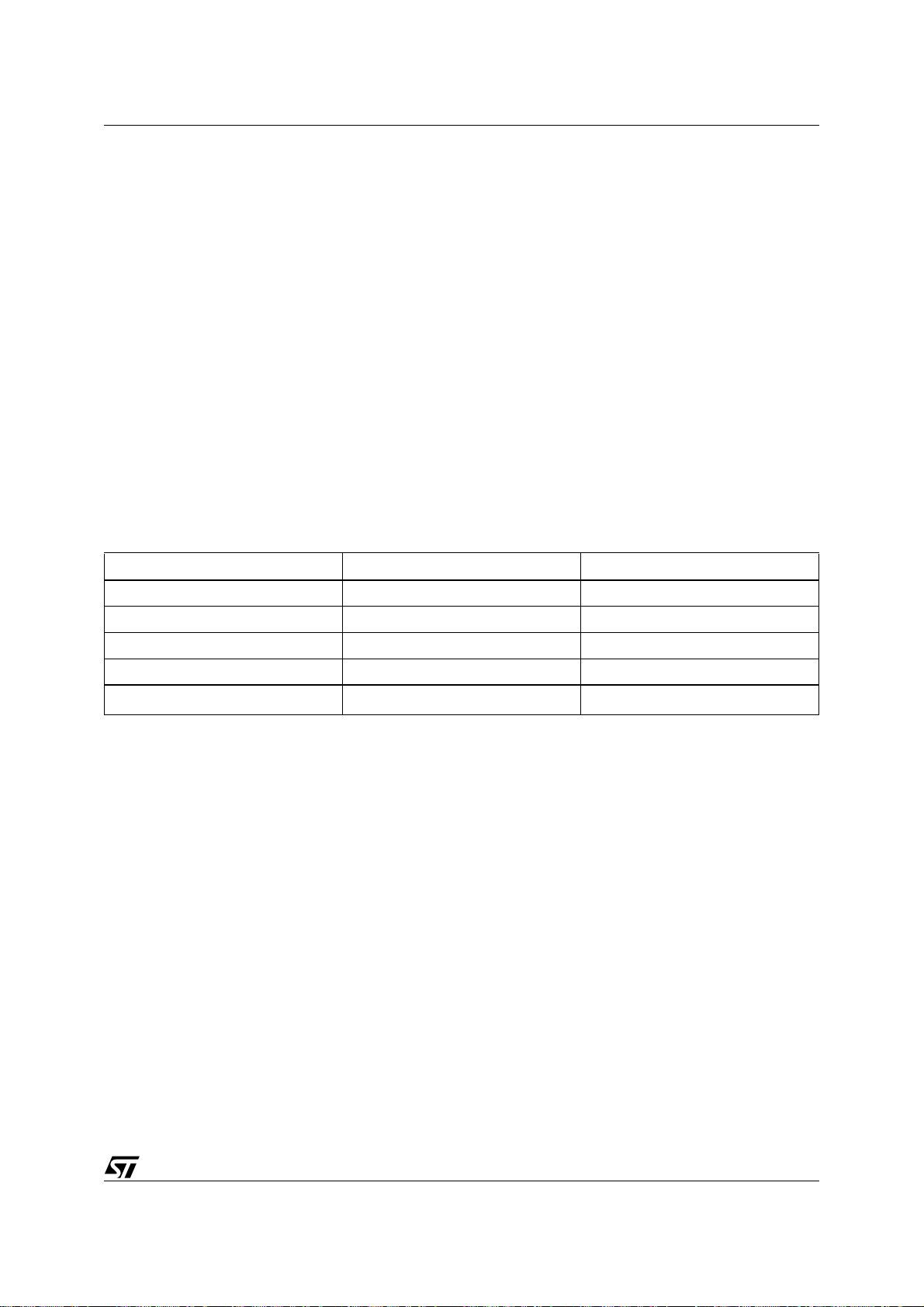

Port C

JTAG and

GPIO

Port A,B,C PLD

I/O and GPIO

Port D

GPIO

AI10409

15/264

uPSD34xx - MEMORY ORGANIZATION

MEMORY ORGANIZATION

The 8032 MCU core views memory on the MCU

module as “internal” memory and it views memory

on the PSD module as “external” memory, see

Figure 6.

Internal memory on the MCU Module consists of

DATA, IDATA, and SFRs. These standard 8032

memories reside in 384 bytes of SRAM located at

a fixed address space starting at address 0x0000.

External memory on the PSD Module consists of

four types: main Flash (64K, 128K, or 256K bytes),

a smaller secondary Flash (32K), SRAM (4K or 8K

bytes), and a block of PSD Module control registers called csiop (256 bytes). These external memories reside at programmable address ranges,

specified using the software tool PSDsoft Express.

See the PSD Module section of this document for

more details on these memories.

External memory is accessed by the 8032 in two

separate 64K byte address spaces. One address

space is for program memory and the other ad-

Figure 6. uPSD34xx Memories

dress space is for data memory. Program memory

is accessed using the 8032 signal, PSEN

. Data

memory is accessed using the 8032 signals, RD

and WR. If the 8032 needs to access more than

64K bytes of external program or data memory, it

must use paging (or banking) techniques provided

by the Page Register in the PSD Module.

Note: When referencing program and data memory spaces, it has nothing to do with 8032 internal

SRAM areas of DATA, IDATA, and SFR on the

MCU Module. Program and data memory spaces

only relate to the external memories on the PSD

Module.

External memory on the PSD Module can overlap

the internal SRAM memory on the MCU Module in

the same physical address range (starting at

0x0000) without interference because the 8032

core does not assert the RD

or WR signals when

accessing internal SRAM.

Fixed

Addresses

FF

80

7F

0

Internal SRAM on

MCU Module

384 Bytes SRAM

Indirect

Addressing

I DATA

128 Bytes

128 Bytes

DATA

Direct or Indirect Addressing

SFR

128 Bytes

Direct

Addressing

Main

Flash

64KB

or

128KB

or

256KB

External Memory on

PSD Module

• External memories may be placed at virtually

any address using software tool PSDsoft Express.

• The SRAM and Flash memories may be placed

in 8032 Program Space or Data Space using

PSDsoft Express.

• Any memory in 8032 Data Space is XDATA.

Secondary

Flash

32KB

SRAM

4KB

or

8KB

AI10410

16/264

uPSD34xx - MEMORY ORGANIZATION

Internal Memory (MCU Module, Standard 8032

Memory: DATA, IDATA, SFR)

DATA Memory. The first 128 bytes of internal

SRAM ranging from address 0x0000 to 0x007F

are called DATA, which can be accessed using

8032 direct or indirect addressing schemes and

are typically used to store variables and stack.

Four register banks, each with 8 registers (R0 –

R7), occupy addresses 0x0000 to 0x001F. Only

one of these four banks may be enabled at a time.

The next 16 locations at 0x0020 to 0x002F contain

128 directly addressable bit locations that can be

used as software flags. SRAM locations 0x0030

and above may be used for variables and stack.

IDATA Memory. The next 128 bytes of internal

SRAM are named IDATA and range from address

0x0080 to 0x00FF. IDATA can be accessed only

through 8032 indirect addressing and is typically

used to hold the MCU stack as well as data variables. The stack can reside in both DATA and

IDATA memories and reach a size limited only by

the available space in the combined 256 bytes of

these two memories (since stack accesses are always done using indirect addressing, the boundary between DATA and IDATA does not exist with

regard to the stack).

SFR Memory. Special Function Registers (Table

5., page 25) occupy a separate physical memory,

but they logically overlap the same 128 bytes as

IDATA, ranging from address 0x0080 to 0x00FF.

SFRs are accessed only using direct addressing.

There 86 active registers used for many functions:

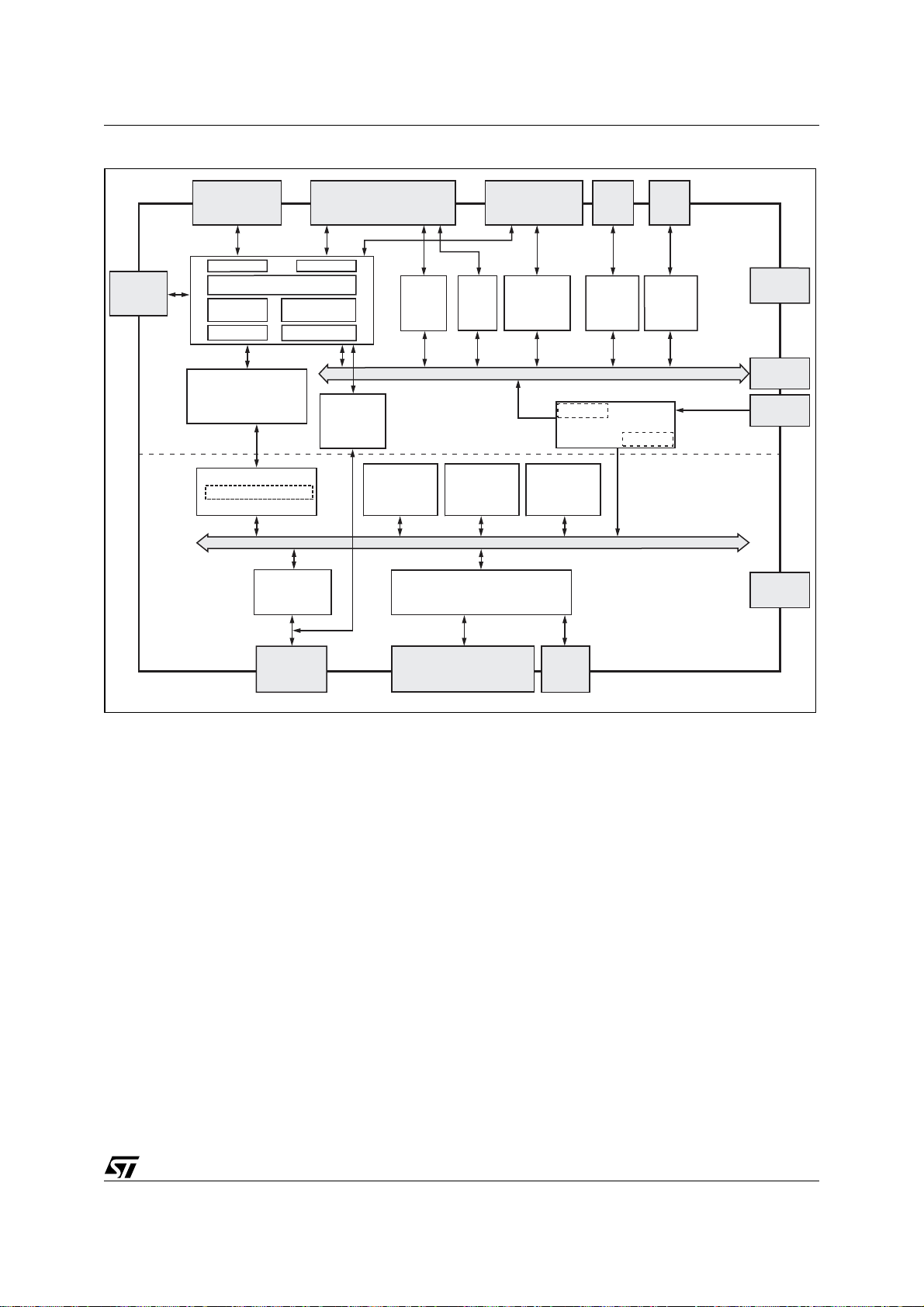

changing the operating mode of the 8032 MCU

core, controlling 8032 peripherals, controlling I/O,

and managing interrupt functions. The remaining

unused SFRs are reserved and should not be accessed.

16 of the SFRs are both byte- and bit-addressable.

Bit-addressable SFRs are those whose address

ends in “0” or “8” hex.

External Memory (PSD Module: Program

memory, Data memory)

The PSD Module has four memories: main Flash,

secondary Flash, SRAM, and csiop. See the PSD

MODULE section for more detailed information on

these memories.

Memory mapping in the PSD Module is implemented with the Decode PLD (DPLD) and optionally the Page Register. The user specifies decode

equations for individual segments of each of the

memories using the software tool PSDsoft Express. This is a very easy point-and-click process

allowing total flexibility in mapping memories. Additionally, each of the memories may be placed in

various combinations of 8032 program address

space or 8032 data address space by using the

software tool PSDsoft Express.

Program Memory. External program memory is

addressed by the 8032 using its 16-bit Program

Counter (PC) and is accessed with the 8032 signal, PSEN

any address in program space between 0x0000

and 0xFFFF.

After a power-up or reset, the 8032 begins program execution from location 0x0000 where the

reset vector is stored, causing a jump to an initialization routine in firmware. At address 0x0003, just

following the reset vector are the interrupt service

locations. Each interrupt is assigned a fixed interrupt service location in program memory. An interrupt causes the 8032 to jump to that service

location, where it commences execution of the

service routine. External Interrupt 0 (EXINT0), for

example, is assigned to service location 0x0003. If

EXINT0 is going to be used, its service routine

must begin at location 0x0003. Interrupt service locations are spaced at 8-byte intervals: 0x0003 for

EXINT0, 0x000B for Timer 0, 0x0013 for EXINT1,

and so forth. If an interrupt service routine is short

enough, it can reside entirely within the 8-byte interval. Longer service routines can use a jump instruction to somewhere else in program memory.

Data Memory. External data is referred to as

XDATA and is addressed by the 8032 using Indirect Addressing via its 16-bit Data Pointer Register

(DPTR) and is accessed by the 8032 signals, RD

and WR. XDATA can be present at any address in

data space between 0x0000 and 0xFFFF.

Note: the uPSD34xx has dual data pointers

(source and destination) making XDATA transfers

much more efficient.

Memory Placement. PSD Module architecture

allows the placement of its external memories into

different combinations of program memory and

data memory spaces. This means the main Flash,

the secondary Flash, and the SRAM can be

viewed by the 8032 MCU in various combinations

of program memory or data memory as defined by

PSDsoft Express.

As an example of this flexibility, for applications

that require a great deal of Flash memory in data

space (large lookup tables or extended data recording), the larger main Flash memory can be

placed in data space and the smaller secondary

Flash memory can be placed in program space.

The opposite can be realized for a different application if more Flash memory is needed for code

and less Flash memory for data.

. Program memory can be present at

17/264

uPSD34xx - 8032 MCU CORE PERFORMANCE ENHANCEMENTS

By default, the SRAM and csiop memories on the

PSD Module must always reside in data memory

space and they are treated by the 8032 as XDATA.

The main Flash and secondary Flash memories

may reside in program space, data space, or both.

These memory placement choices specified by

PSDsoft Express are programmed into non-volatile sections of the uPSD34xx, and are active at

power-up and after reset. It is possible to override

these initial settings during runtime for In-Application Programming (IAP).

Standard 8032 MCU architecture cannot write to

its own program memory space to prevent accidental corruption of firmware. However, this becomes an obstacle in typical 8032 systems when

a remote update to firmware in Flash memory is

required using IAP. The PSD module provides a

solution for remote updates by allowing 8032 firmware to temporarily “reclassify” Flash memory to

reside in data space during a remote update, then

returning Flash memory back to program space

when finished. See the VM Register (Table

104., page 174) in the PSD Module section of this

document for more details.

8032 MCU CORE PERFORMANCE ENHANCEMENTS

Before describing performance features of the

uPSD34xx, let us first look at standard 8032 architecture. The clock source for the 8032 MCU creates a basic unit of timing called a machine-cycle,

which is a period of 12 clocks for standard 8032

MCUs. The instruction set for traditional 8032

MCUs consists of 1, 2, and 3 byte instructions that

execute in different combinations of 1, 2, or 4 machine-cycles. For example, there are one-byte instructions that execute in one machine-cycle (12

clocks), one-byte instructions that execute in four

machine-cycles (48 clocks), two-byte, two-cycle

instructions (24 clocks), and so on. In addition,

standard 8032 architecture will fetch two bytes

from program memory on almost every machinecycle, regardless if it needs them or not (dummy

fetch). This means for one-byte, one-cycle instructions, the second byte is ignored. These one-byte,

one-cycle instructions account for half of the

8032's instructions (126 out of 255 opcodes).

There are inefficiencies due to wasted bus cycles

and idle bus times that can be eliminated.

The uPSD34xx 8032 MCU core offers increased

performance in a number of ways, while keeping

the exact same instruction set as the standard

8032 (all opcodes, the number of bytes per in-

struction, and the native number a machine-cycles

per instruction are identical to the original 8032).

The first way performance is boosted is by reducing the machine-cycle period to just 4 MCU clocks

as compared to 12 MCU clocks in a standard

8032. This shortened machine-cycle improves the

instruction rate for one- or two-byte, one-cycle instructions by a factor of three (Figure 7., page 19)

compared to standard 8051 architectures, and significantly improves performance of multiple-cycle

instruction types.

The example in Figure 7 shows a continuous execution stream of one- or two-byte, one-cycle instructions. The 5V uPSD34xx will yield 10 MIPS

peak performance in this case while operating at

40MHz clock rate. In a typical application however,

the effective performance will be lower since programs do not use only one-cycle instructions, but

special techniques are implemented in the

uPSD34xx to keep the effective MIPS rate as

close as possible to the peak MIPS rate at all

times. This is accomplished with an instruction

Pre-Fetch Queue (PFQ), a Branch Cache (BC),

and a 16-bit program memory bus as shown in

Figure 8., page 19.

18/264

uPSD34xx - 8032 MCU CORE PERFORMANCE ENHANCEMENTS

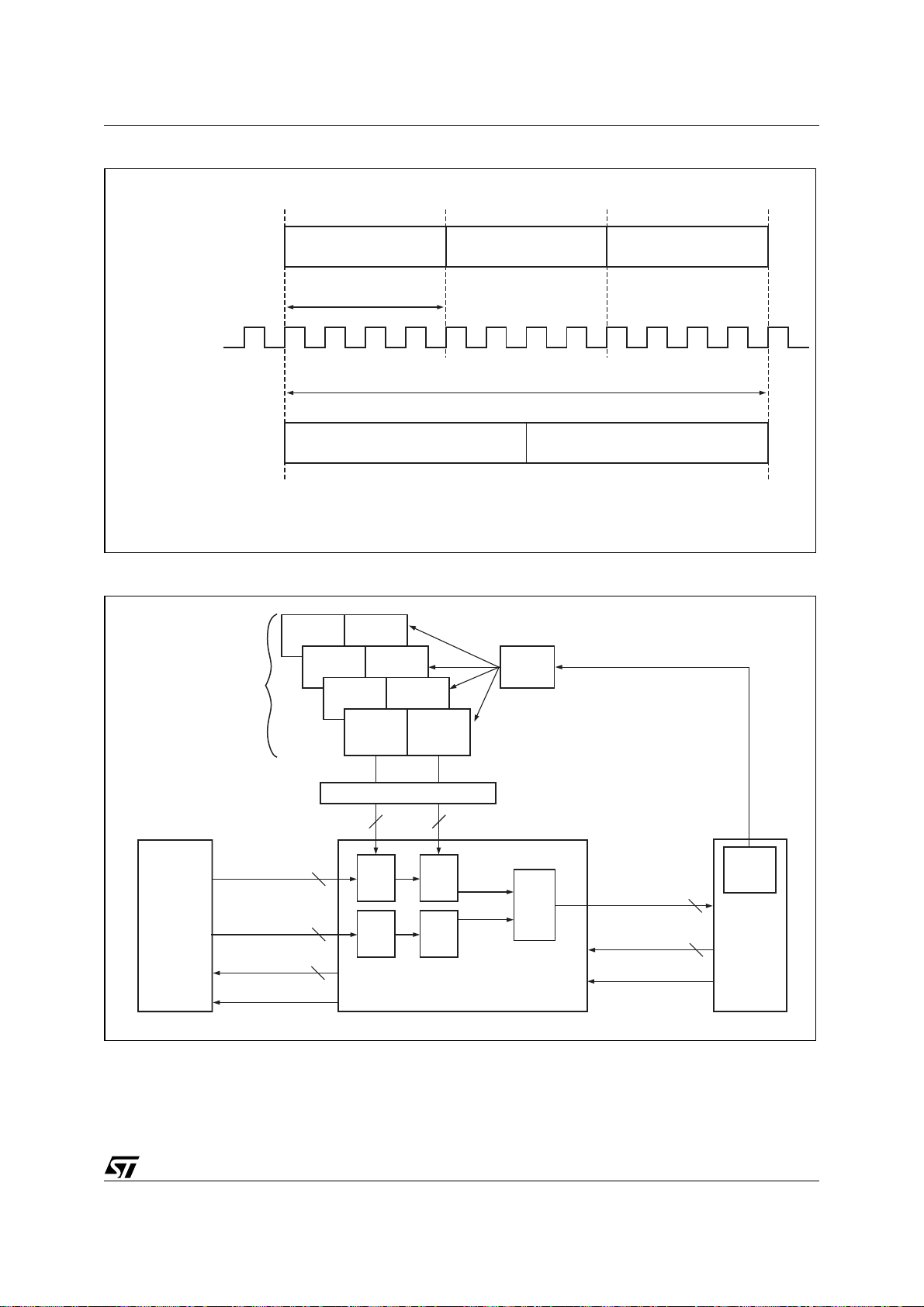

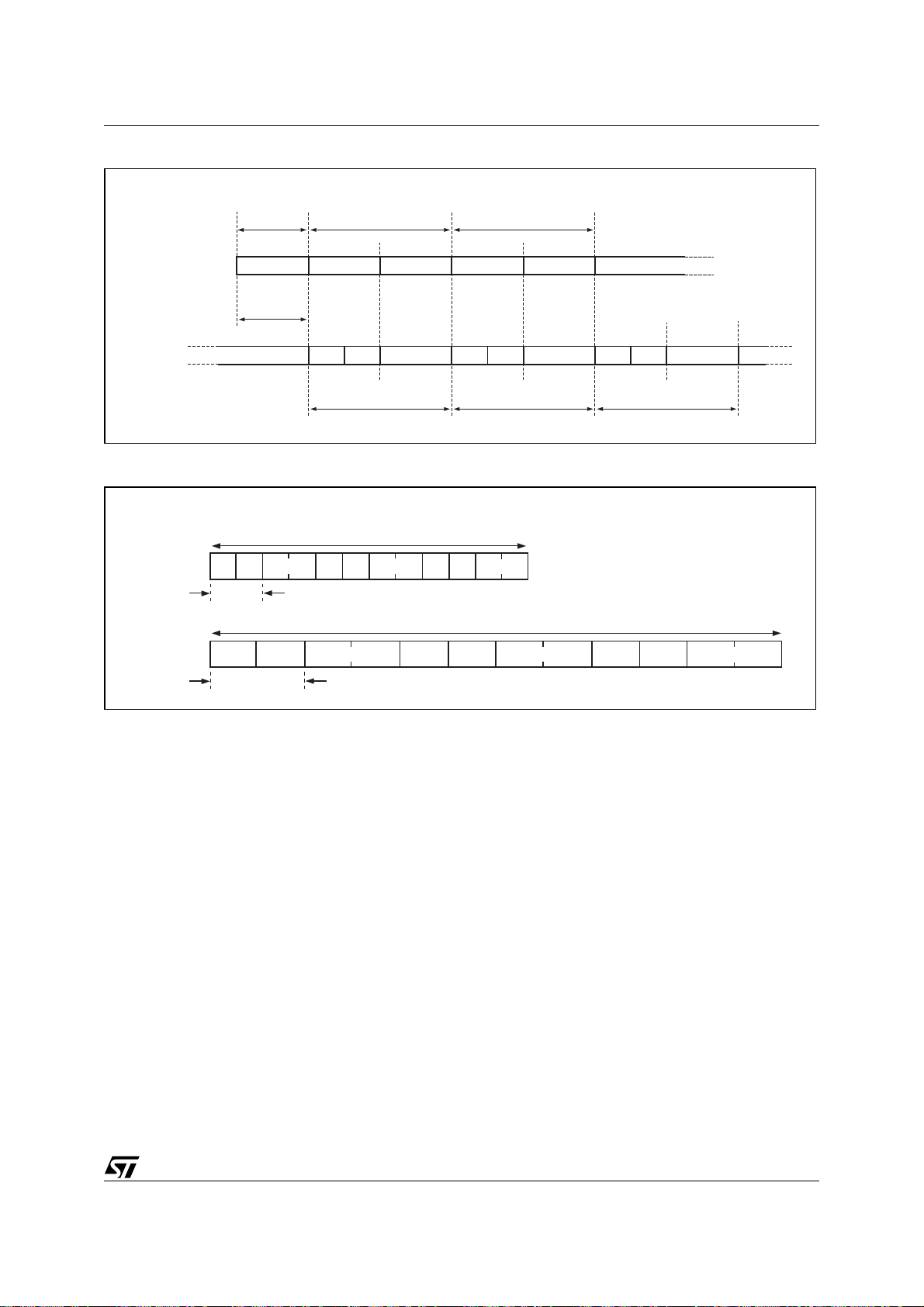

Figure 7. Comparison of uPSD34xx with Standard 8032 Performance

1- or 2-byte, 1-cycle Instructions

Instruction A Instruction B Instruction C

Turbo uPSD34xx

Execute Instruction and

Pre-Fetch Next Instruction

Execute Instruction and

Pre-Fetch Next Instruction

Execute Instruction and

Pre-Fetch Next Instruction

4 clocks (one machine cycle)

one machine cycle one machine cycle

MCU Clock

12 clocks (one machine cycle)

Instruction A

Standard 8032

Fetch Byte for Instruction A

Dummy Byte is Ignored (wasted bus access)

Turbo uPSD34xx executes instructions A, B, and C in the same

amount of time that a standard 8032 executes only Instruction A.

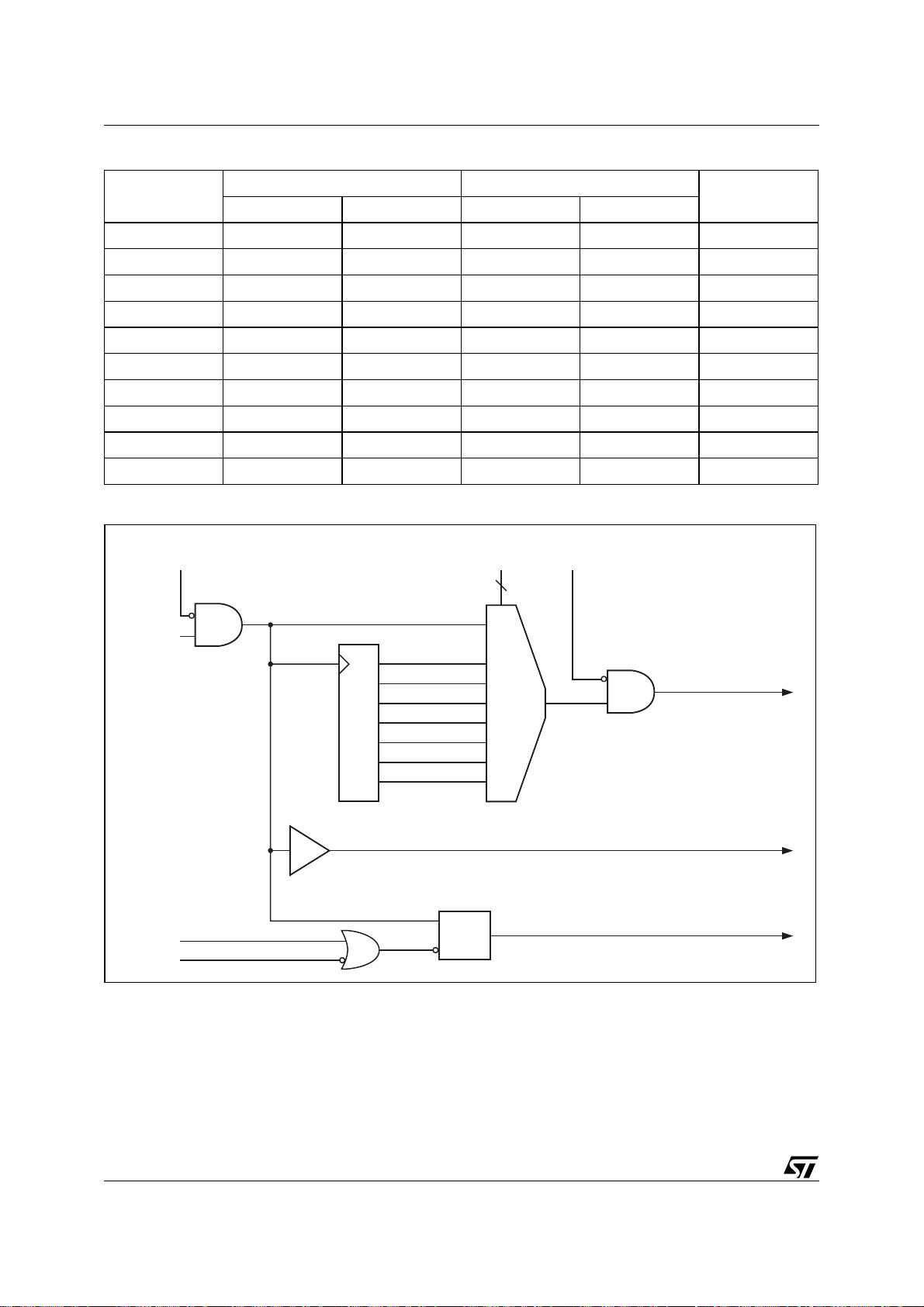

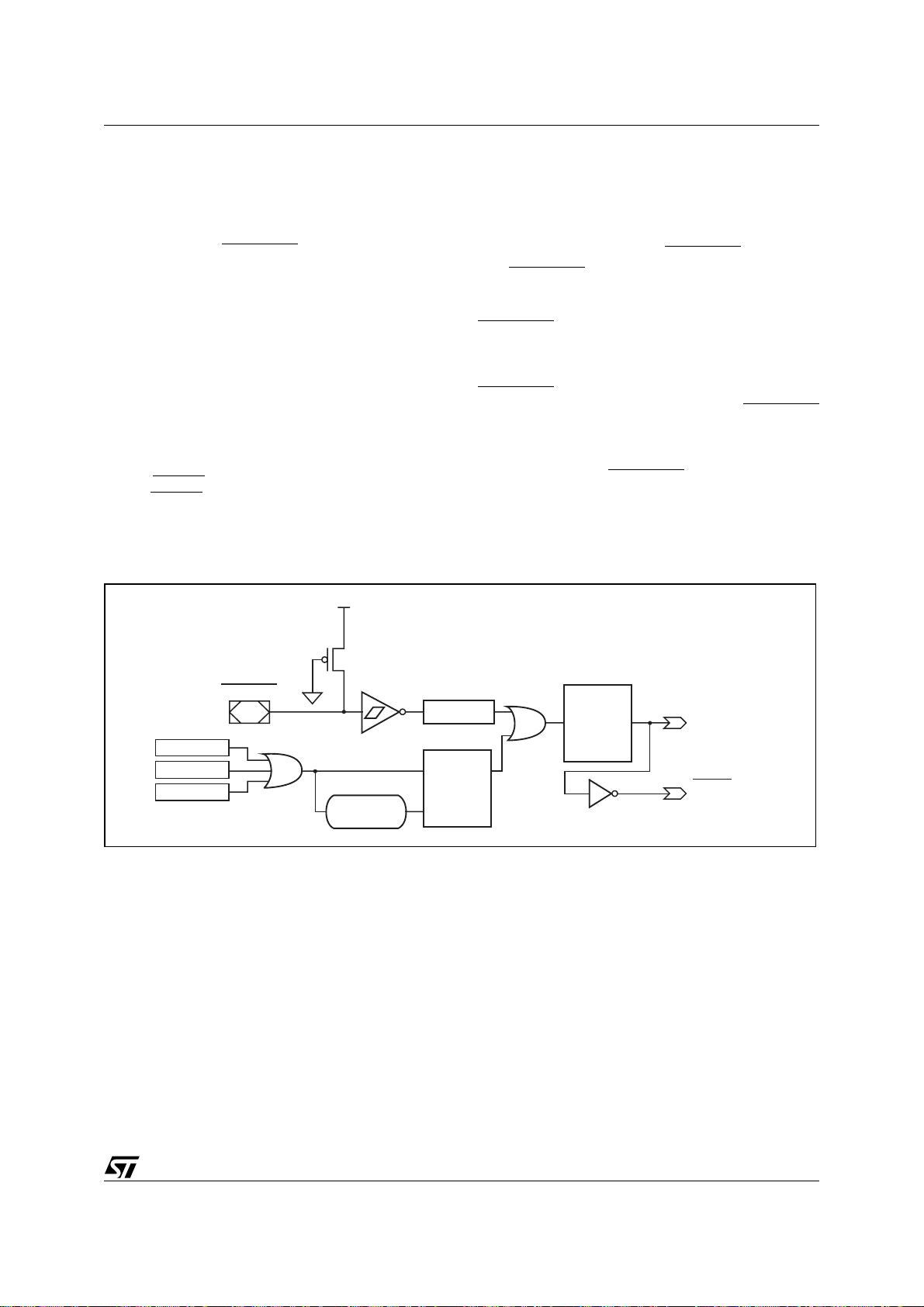

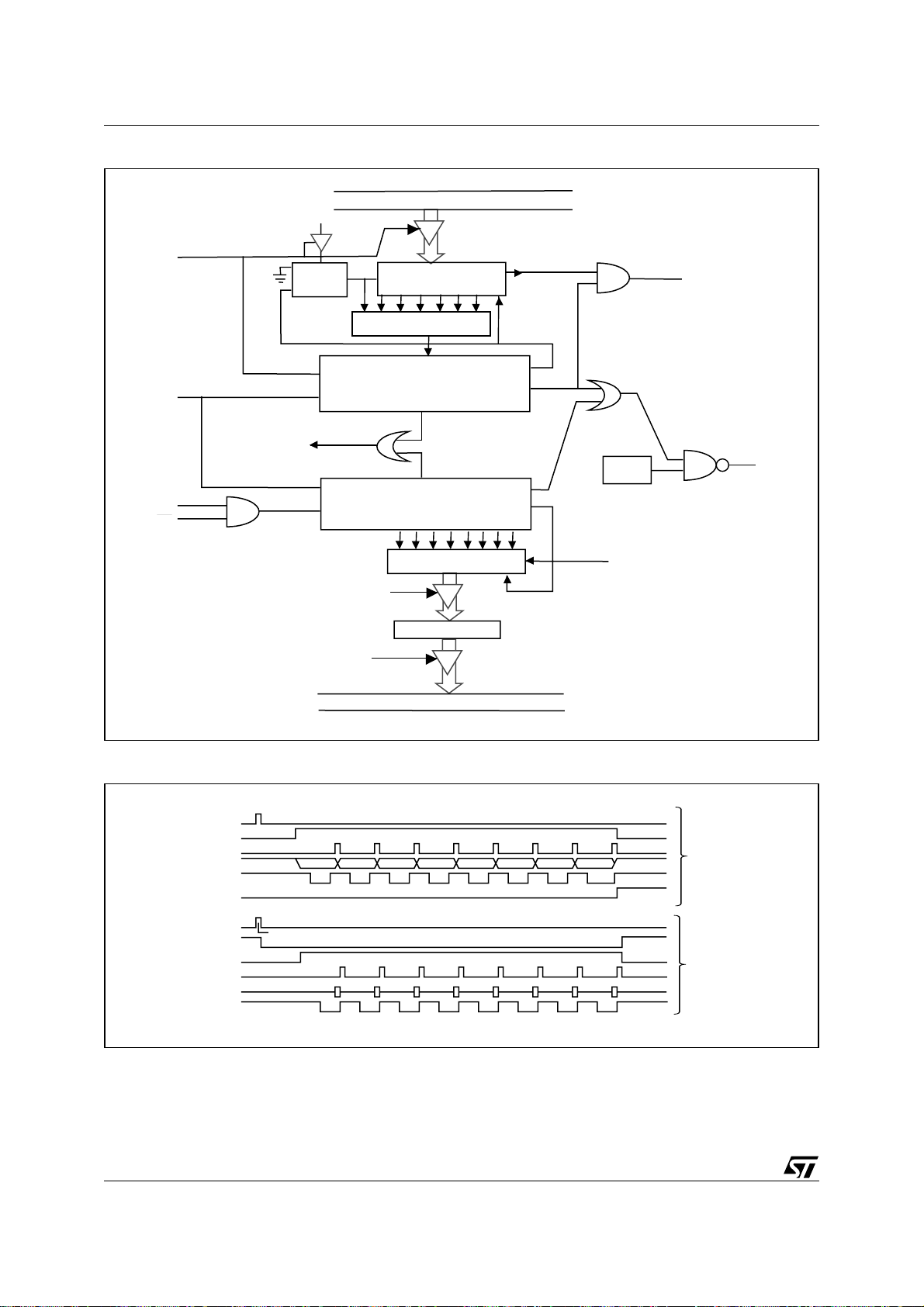

Figure 8. Instruction Pre-Fetch Queue and Branch Cache

Branch 4

Code

Branch

Cache

(BC)

Branch 3

Code

Branch 2

Code

Branch 4

Code

Branch 3

Code

Branch 1

Code

Compare

Branch 2

Code

Branch 1

Code

Execute Instruction A

and Fetch a Second Dummy Byte

AI10411

16-bit

Program

Memory

on PSD

Module

Instruction Byte

Instruction Byte

Address

Wait

Load on Branch Address Match

1616

8

8

4 Bytes of Instruction

16

Instruction Pre-Fetch Queue (PFQ)

Instruction Byte

Address

Wait

Current

Branch

Address

8

8032

MCU

16

AI10431

19/264

uPSD34xx - 8032 MCU CORE PERFORMANCE ENHANCEMENTS

Pre-Fetch Queue (PFQ) and Branch Cache

(BC)

The PFQ is always working to minimize the idle

bus time inherent to 8032 MCU architecture, to

eliminate wasted memory fetches, and to maximize memory bandwidth to the MCU. The PFQ

does this by running asynchronously in relation to

the MCU, looking ahead to pre-fetch two bytes

(word) of code from program memory during any

idle bus periods. Only necessary word will be

fetched (no dummy fetches like standard 8032).

The PFQ will queue up to four code bytes in advance of execution, which significantly optimizes

sequential program performance. However, when

program execution becomes non-sequential (program branch), a typical pre-fetch queue will empty

itself and reload new code, causing the MCU to

stall. The Turbo uPSD34xx diminishes this problem by using a Branch Cache with the PFQ. The

BC is a four-way, fully associative cache, meaning

that when a program branch occurs, its branch

destination address is compared simultaneously

with four recent previous branch destinations

stored in the BC. Each of the four cache entries

contain up to four bytes of code related to a

branch. If there is a hit (a match), then all four code

bytes of the matching program branch are transferred immediately and simultaneously from the

BC to the PFQ, and execution on that branch continues with minimal delay. This greatly reduces the

chance that the MCU will stall from an empty PFQ,

and improves performance in embedded control

systems where it is quite common to branch and

loop in relatively small code localities.

By default, the PFQ and BC are enabled after

power-up or reset. The 8032 can disable the PFQ

and BC at runtime if desired by writing to a specific

SFR (BUSCON).

The memory in the PSD module operates with

variable wait states depending on the value specified in the SFR named BUSCON. For example, a

5V uPSD34xx device operating at a 40MHz crystal

frequency requires four memory wait states (equal

to four MCU clocks). In this example, once the

PFQ has one word of code, the wait states become transparent and a full 10 MIPS is achieved

when the program stream consists of sequential

one- or two-byte, one machine-cycle instructions

as shown in Figure 7., page 19 (transparent because a machine-cycle is four MCU clocks which

equals the memory pre-fetch wait time that is also

four MCU clocks). But it is also important to understand PFQ operation on multi-cycle instructions.

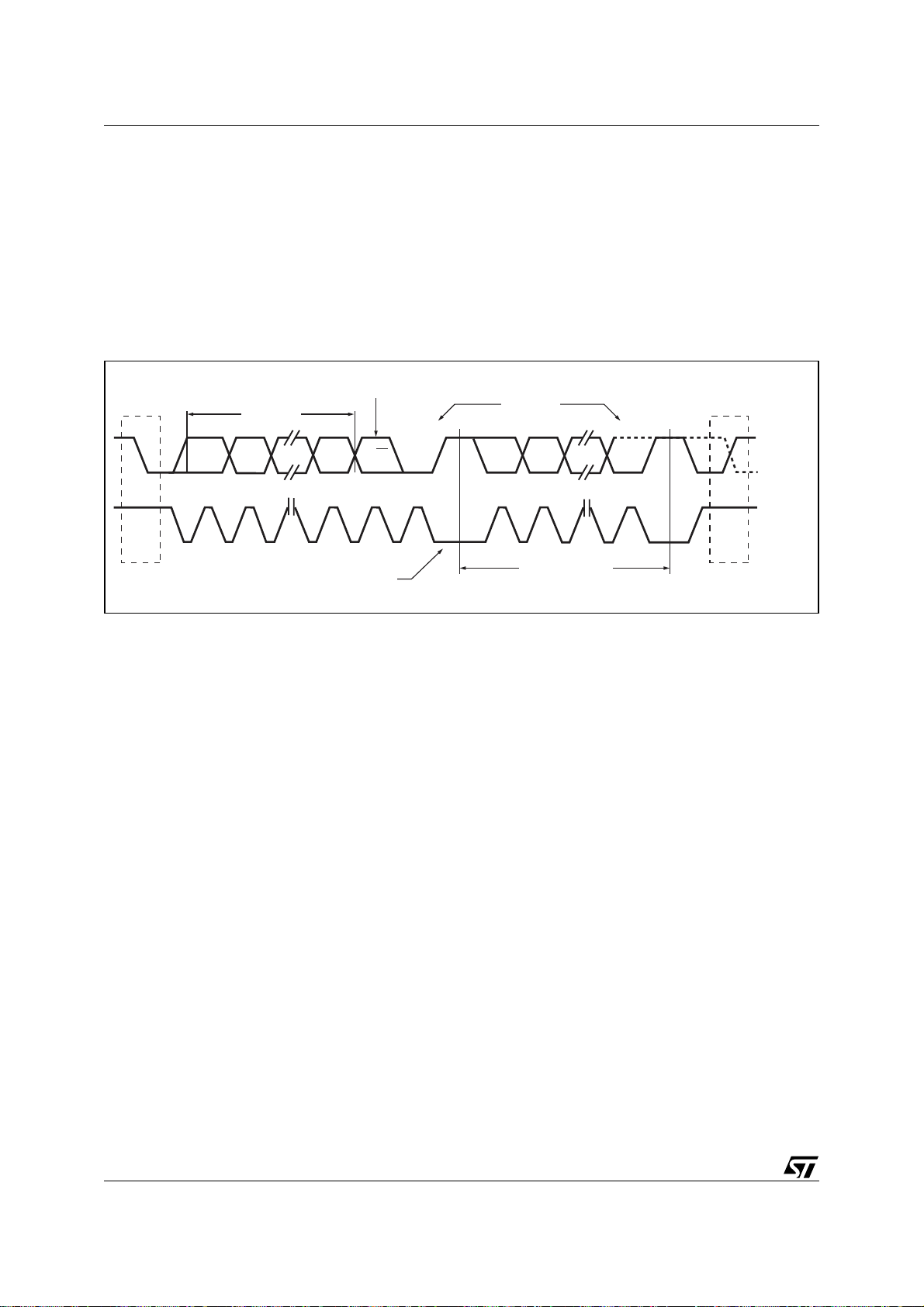

PFQ Example, Multi-cycle Instructions

Let us look at a string of two-byte, two-cycle instructions in Figure 9., page 21. There are three

instructions executed sequentially in this example,

instructions A, B, and C. Each of the time divisions

in the figure is one machine-cycle of four clocks,

and there are six phases to reference in this discussion. Each instruction is pre-fetched into the

PFQ in advance of execution by the MCU. Prior to

Phase 1, the PFQ has pre-fetched the two instruction bytes (A1 and A2) of Instruction A. During

Phase one, both bytes are loaded into the MCU

execution unit. Also in Phase 1, the PFQ is prefetching Instruction B (bytes B1 and B2) from program memory. In Phase 2, the MCU is processing

Instruction A internally while the PFQ is pre-fetching Instruction C. In Phase 3, both bytes of instruction B are loaded into the MCU execution unit and

the PFQ begins to pre-fetch bytes for the next instruction. In Phase 4 Instruction B is processed.

The uPSD34xx MCU instructions are an exact 1/3

scale of all standard 8032 instructions with regard

to number of cycles per instruction. Figure

10., page 21 shows the equivalent instruction se-

quence from the example above on a standard

8032 for comparison.

Aggregate Performance

The stream of two-byte, two-cycle instructions in

Figure 9., page 21, running on a 40MHz, 5V,

uPSD34xx will yield 5 MIPs. And we saw the

stream of one- or two-byte, one-cycle instructions

in Figure 7., page 19, on the same MCU yield 10

MIPs. Effective performance will depend on a

number of things: the MCU clock frequency; the

mixture of instructions types (bytes and cycles) in

the application; the amount of time an empty PFQ

stalls the MCU (mix of instruction types and misses on Branch Cache); and the operating voltage.

A 5V uPSD34xx device operates with four memory

wait states, but a 3.3V device operates with five

memory wait states yielding 8 MIPS peak compared to 10 MIPs peak for 5V device. The same

number of wait states will apply to both program

fetches and to data READ/WRITEs unless otherwise specified in the SFR named BUSCON.

In general, a 3X aggregate performance increase

is expected over any standard 8032 application

running at the same clock frequency.

20/264

uPSD34xx - 8032 MCU CORE PERFORMANCE ENHANCEMENTS

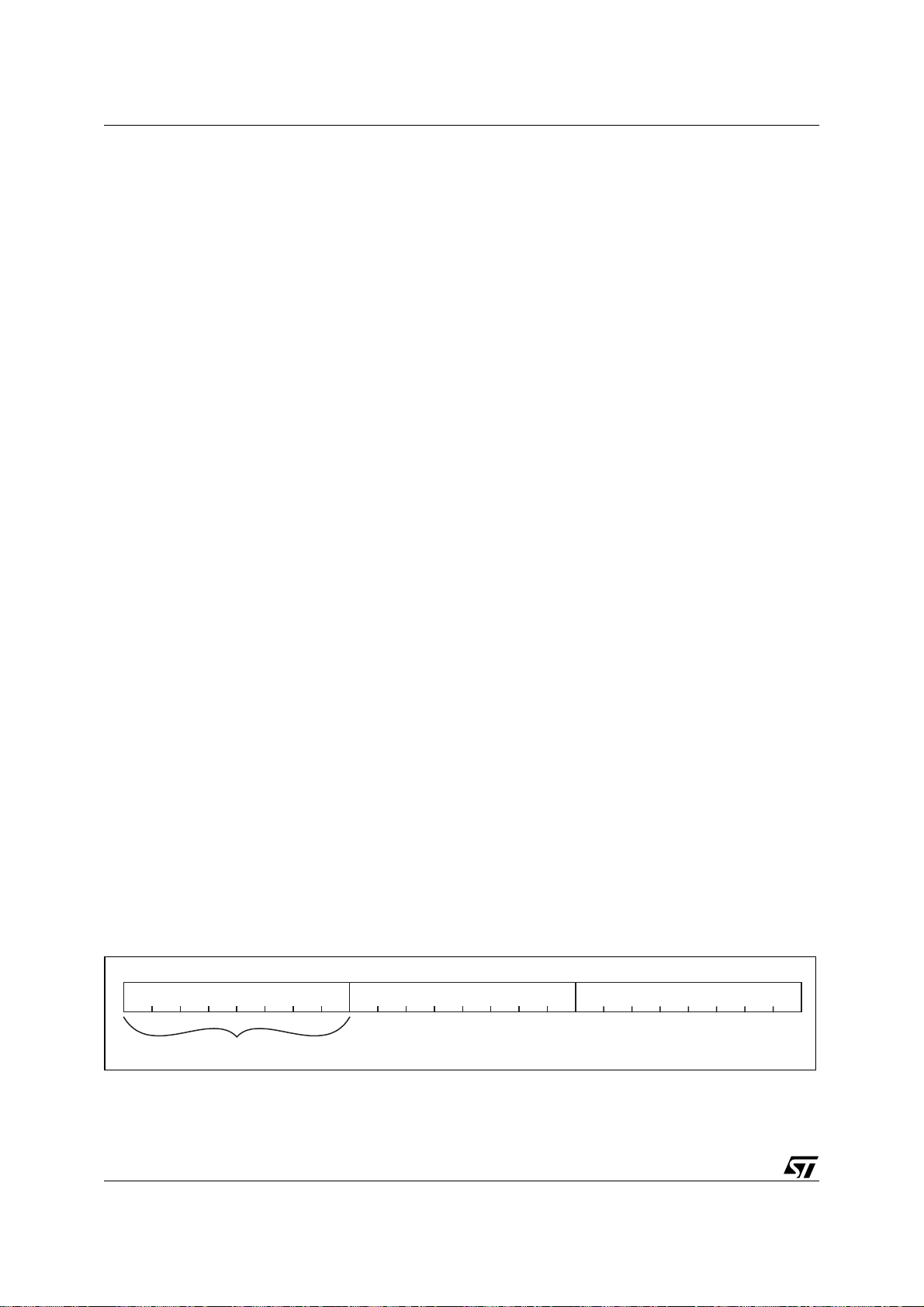

Figure 9. PFQ Operation on Multi-cycle Instructions

Three 2-byte, 2-cycle Instructions on uPSD34xx

Pre-Fetch

Inst A

Pre-Fetch Inst B and C Pre-Fetch next Inst

PFQ

MCU

Execution

Inst A, Byte 1&2 Inst B, Byte 1&2 Inst C, Byte 1&2 Next Inst

4-clock

Macine Cycle

Phase 1 Phase 2 Phase 3 Phase 4 Phase 6Phase 5

Previous Instruction A1 A2 Process A B1 B2 Process B C1 C2

Instruction A Instruction B Instruction C

Continue to Pre-Fetch

Figure 10. uPSD34xx Multi-cycle Instructions Compared to Standard 8032

Three 2-byte, 2-cycle Instructions, uPSD34xx vs. Standard 8032

24 Clocks Total (4 clocks per cycle)

uPSD34xx

Std 8032

A1

Byte 1

A2

Inst A

Byte 2

B1

1 Cycle

Process Inst A

B2

1 Cycle

Inst B

C1

C2

Inst C

72 Clocks (12 clocks per cycle)

Byte 1

Byte 2

Process Inst B

Byte 1

Byte 2

Process C

Process Inst C

Next Inst

AI10432

AI10412

21/264

uPSD34xx - MCU MODULE DISCRIPTION

MCU MODULE DISCRIPTION

This section provides a detail description of the

MCU Module system functions and peripherals, including:

■ 8032 MCU Registers

■ Special Function Registers

■ 8032 Addressing Modes

■ uPSD34xx Instruction Set Summary

■ Dual Data Pointers

■ Debug Unit

■ Interrupt System

■ MCU Clock Generation

■ Power Saving Modes

■ Oscillator and External Components

■ I/O Ports

8032 MCU REGISTERS

The uPSD34xx has the following 8032 MCU core

registers, also shown in Figure 11.

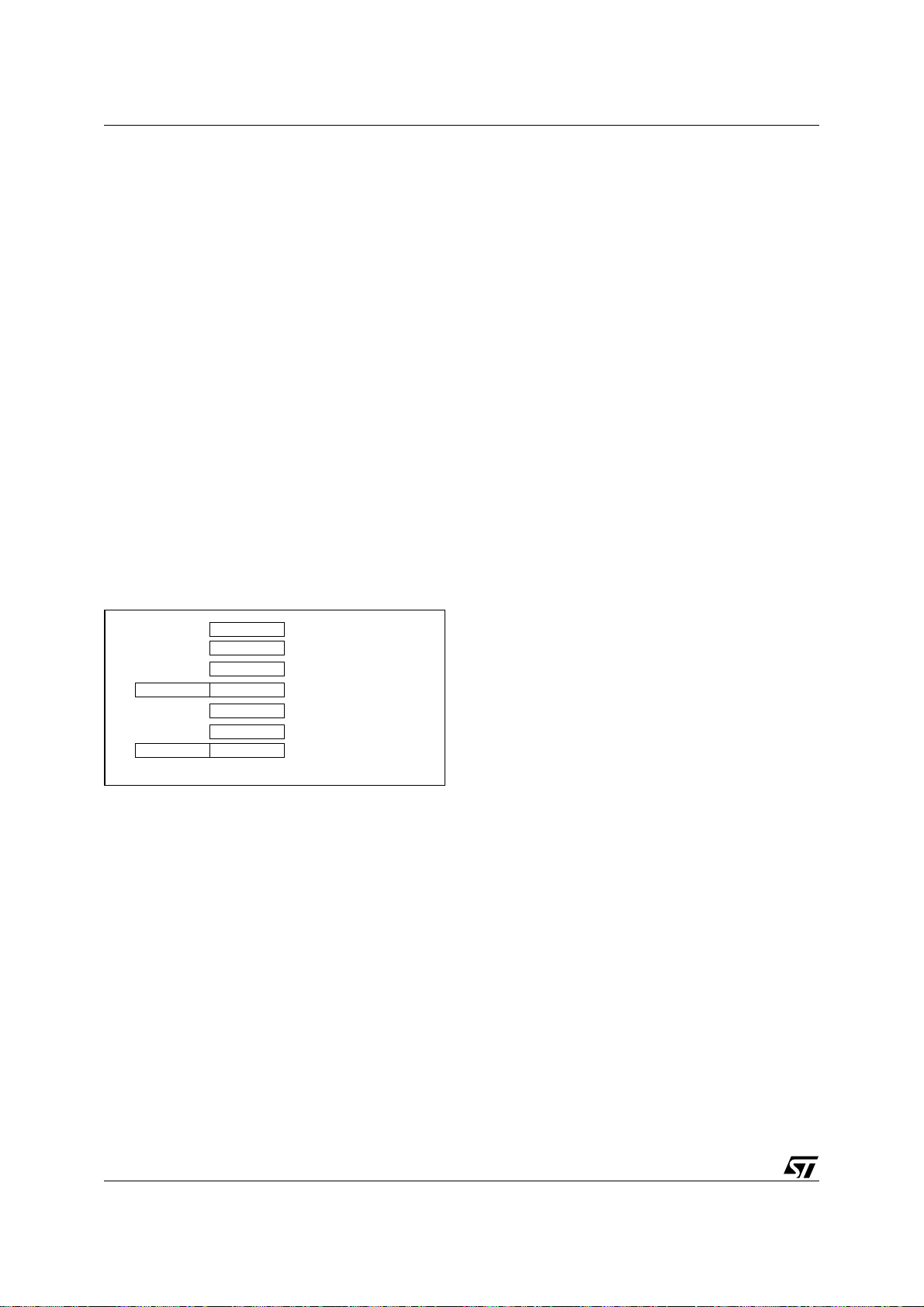

Figure 11. 8032 MCU Registers

A

B

SP

PCH

DPTR(DPH)

AI06636

PCL

PSW

R0-R7

DPTR(DPL)

Stack Pointer (SP)

The SP is an 8-bit register which holds the current

location of the top of the stack. It is incremented

before a value is pushed onto the stack, and decremented after a value is popped off the stack. The

SP is initialized to 07h after reset. This causes the

stack to begin at location 08h (top of stack). To

avoid overlapping conflicts, the user must initialize

the top of the stack to 20h if all four banks of registers R0 - R7 are used, as well as the top of stack

to 30h if all of the 8032 bit memory locations are

used.

Data Pointer (DPTR)

DPTR is a 16-bit register consisting of two 8-bit

registers, DPL and DPH. The DPTR Register is

used as a base register to create an address for indirect jumps, table look-up operations, and for external data transfers (XDATA). When not used for

Accumulator

B Register

Stack Pointer

Program Counter

Program Status Word

General Purpose

Register (Bank0-3)

Data Pointer Register

■ MCU Bus Interface

■ Supervisory Functions

■ Standard 8032 Timer/Counters

■ Serial UART Interfaces

■ IrDA Interface

2

■ I

C Interface

■ SPI Interface

■ Analog to Digital Converter

■ Programmable Counter Array (PCA)

■ USB Interface

Note: A full description of the 8032 instruction set

may be found in the uPSD34xx Programmers

Guide.

addressing, the DPTR Register can be used as a

general purpose 16-bit data register.

Very frequently, the DPTR Register is used to access XDATA using the External Direct addressing

mode. The uPSD34xx has a special set of SFR

registers (DPTC, DPTM) to control a secondary

DPTR Register to speed memory-to-memory

XDATA transfers. Having dual DPTR Registers allows rapid switching between source and destination addresses (see details in DUAL DATA

POINTERS, page 38).

Program Counter (PC)

The PC is a 16-bit register consisting of two 8-bit

registers, PCL and PCH. This counter indicates

the address of the next instruction in program

memory to be fetched and executed. A reset forces the PC to location 0000h, which is where the reset jump vector is stored.

Accumulator (ACC)

This is an 8-bit general purpose register which

holds a source operand and receives the result of

arithmetic operations. The ACC Register can also

be the source or destination of logic and data

movement operations. For MUL and DIV instructions, ACC is combined with the B Register to hold

16-bit operands. The ACC is referred to as “A” in

the MCU instruction set.

B Register (B)

The B Register is a general purpose 8-bit register

for temporary data storage and also used as a 16bit register when concatenated with the ACC Register for use with MUL and DIV instructions.

22/264

General Purpose Registers (R0 - R7)

There are four banks of eight general purpose 8bit registers (R0 - R7), but only one bank of eight

registers is active at any given time depending on

the setting in the PSW word (described next). R0 R7 are generally used to assist in manipulating

values and moving data from one memory location

to another. These register banks physically reside

in the first 32 locations of 8032 internal DATA

SRAM, starting at address 00h. At reset, only the

first bank of eight registers is active (addresses

00h to 07h), and the stack begins at address 08h.

Program Status Word (PSW)

The PSW is an 8-bit register which stores several

important bits, or flags, that are set and cleared by

many 8032 instructions, reflecting the current

state of the MCU core. Figure 12., page 23 shows

the individual flags.

Carry Flag (CY). This flag is set when the last

arithmetic operation that was executed results in a

carry (addition) or borrow (subtraction). It is

cleared by all other arithmetic operations. The CY

flag is also affected by Shift and Rotate Instructions.

Auxiliary Carry Flag (AC). This flag is set when

the last arithmetic operation that was executed results in a carry into (addition) or borrow from (subtraction) the high-order nibble. It is cleared by all

other arithmetic operations.

uPSD34xx - 8032 MCU REGISTERS

General Purpose Flag (F0). This is a bit-addres-

sable, general-purpose flag for use under software

control.

Register Bank Select Flags (RS1, RS0). These

bits select which bank of eight registers is used

during R0 - R7 register accesses (see Table 4)

Overflow Flag (OV). The OV flag is set when: an

ADD, ADDC, or SUBB instruction causes a sign

change; a MUL instruction results in an overflow

(result greater than 255); a DIV instruction causes

a divide-by-zero condition. The OV flag is cleared

by the ADD, ADDC, SUBB, MUL, and DIV instructions in all other cases. The CLRV instruction will

clear the OV flag at any time.

Parity Flag (P). The P flag is set if the sum of the

eight bits in the Accumulator is odd, and P is

cleared if the sum is even.

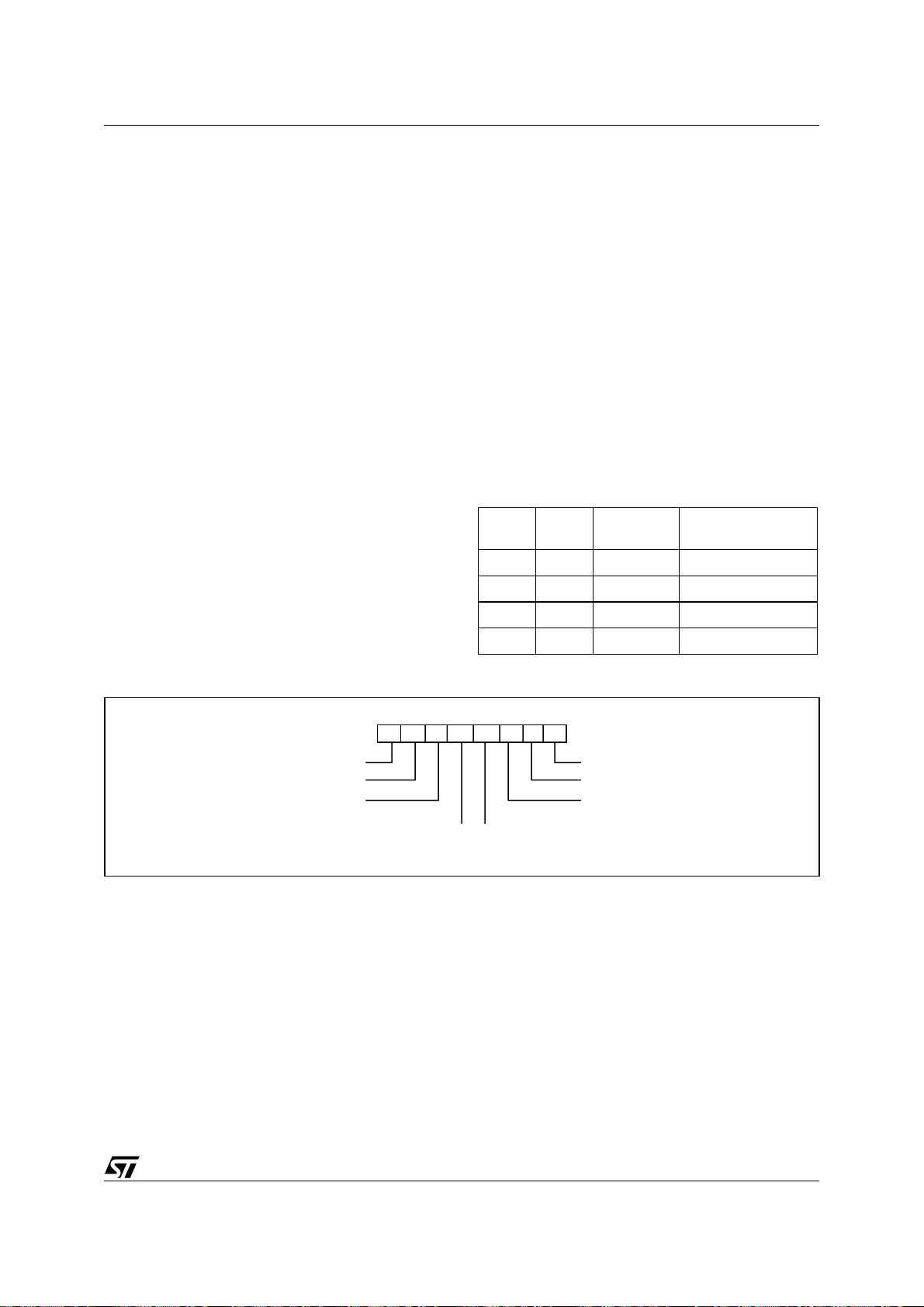

Table 4. .Register Bank Select Addresses

RS1 RS0

0 0 0 00h - 07h

0 1 1 08h - 0Fh

1 0 2 10h - 17h

1 1 3 18h - 1Fh

Register

Bank

8032 Internal

DATA Address

Figure 12. Program Status Word (PSW) Register

MSB

CY

PSW

Carry Flag

Auxillary Carry Flag

General Purpose Flag

AC FO RS1 RS0 OV P

Register Bank Select Flags

(to select Bank0-3)

LSB

Reset Value 00h

Parity Flag

Bit not assigned

Overflow Flag

AI06639

23/264

uPSD34xx - SPECIAL FUNCTION REGISTERS (SFR)

SPECIAL FUNCTION REGISTERS (SFR)

A group of registers designated as Special Function Register (SFR) is shown in Table 5., page 25.

SFRs control the operating modes of the MCU

core and also control the peripheral interfaces and

I/O pins on the MCU Module. The SFRs can be accessed only by using the Direct Addressing method within the address range from 80h to FFh of

internal 8032 SRAM. Sixteen addresses in SFR

address space are both byte- and bit-addressable.

The bit-addressable SFRs are noted in Table 5.

106 of a possible 128 SFR addresses are occupied. The remaining unoccupied SFR addresses

(designated as “RESERVED” in Table 5) should

not be written. Reading unoccupied locations will

return an undefined value.

Note: There is a separate set of control registers

for the PSD Module, designated as csiop, and they

are described in the PSD MODULE, page 164.

The I/O pins, PLD, and other functions on the PSD

Module are NOT controlled by SFRs.

SFRs are categorized as follows:

■ MCU core registers:

IP, A, B, PSW, SP, DPTL, DPTH, DPTC,

DPTM

■ MCU Module I/O Port registers:

P1, P3, P4, P1SFS0, P1SFS1, P3SFS,

P4SFS0, P4SFS1

■ Standard 8032 Timer registers

TCON, TMOD, T2CON, TH0, TH1, TH2, TL0,

TL1, TL2, RCAP2L, RCAP2H

■ Standard Serial Interfaces (UART)

SCON0, SBUF0, SCON1, SBUF1

■ Power, clock, and bus timing registers

PCON, CCON0, CCON1, BUSCON

■ Hardware watchdog timer registers

WDKEY, WDRST

■ Interrupt system registers

IP, IPA, IE, IEA

■ Prog. Counter Array (PCA) control

registers

PCACL0, PCACH0, PCACON0, PCASTA,

PCACL1, PCACH1, PCACON1, CCON2,

CCON3

■ PCA capture/compare and PWM registers

CAPCOML0, CAPCOMH0, TCMMODE0,

CAPCOML1, CAPCOMH1, TCMMODE2,

CAPCOML2, CAPCOMH2, TCMMODE2,

CAPCOML3, CAPCOMH3, TCMMODE3,

CAPCOML4, CAPCOMH4, TCMMODE4,

CAPCOML5, CAPCOMH5, TCMMODE5,

PWMF0, PMWF1

■ SPI interface registers

SPICLKD, SPISTAT, SPITDR, SPIRDR,

SPICON0, SPICON1

2

■ I

C interface registers

S1SETUP, S1CON, S1STA, S1DAT, S1ADR

■ Analog to Digital Converter registers

ACON, ADCPS, ADAT0, ADAT1

■ IrDA interface register

IRDACON

■ USB interface registers

UADDR, UPAIR, WE0-3, UIF0-3, UCTL,

USTA, USEL, UCON, USIZE, UBASEH,

UBASEL, USCI, USCV

24/264

uPSD34xx - SPECIAL FUNCTION REGISTERS (SFR)

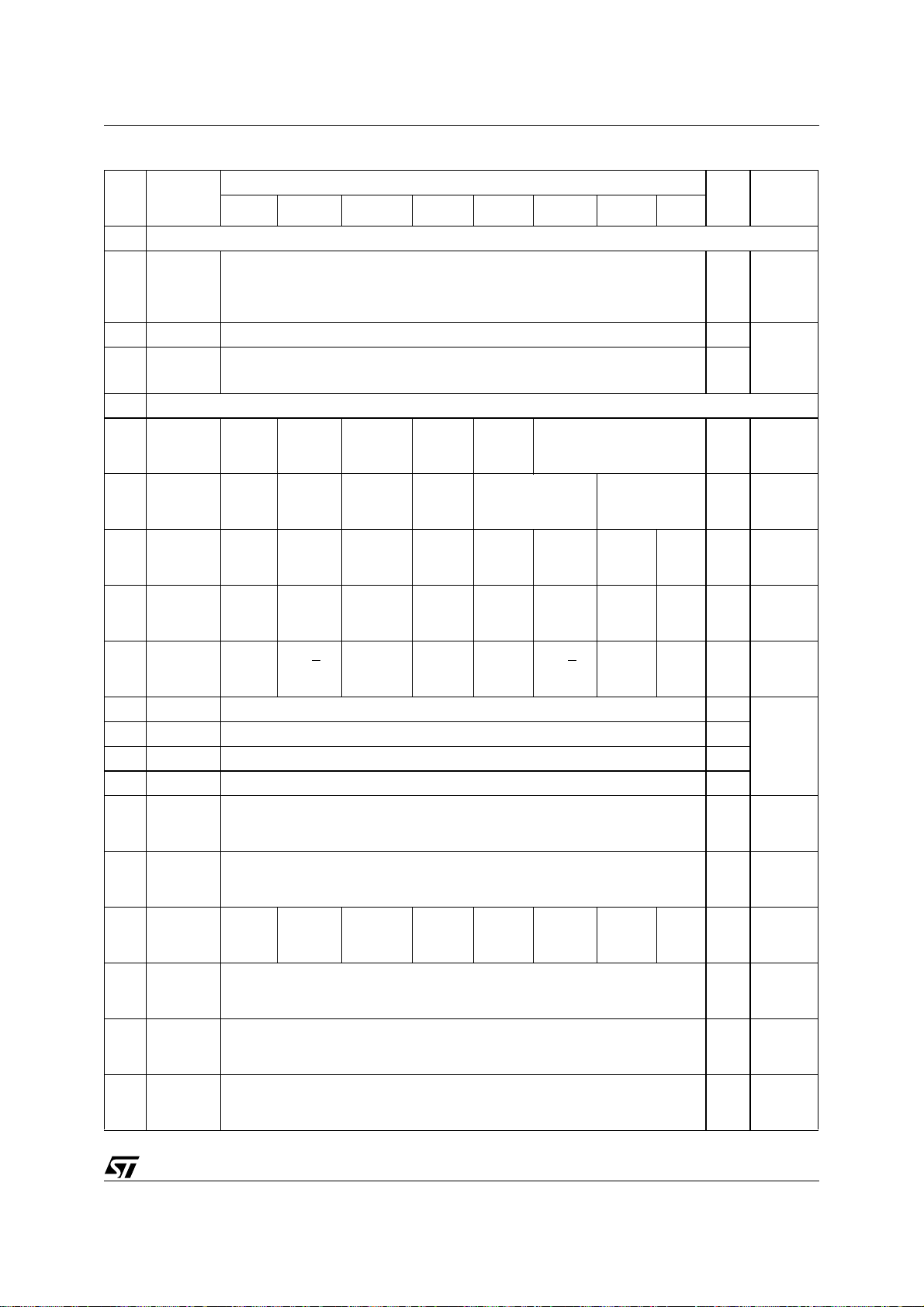

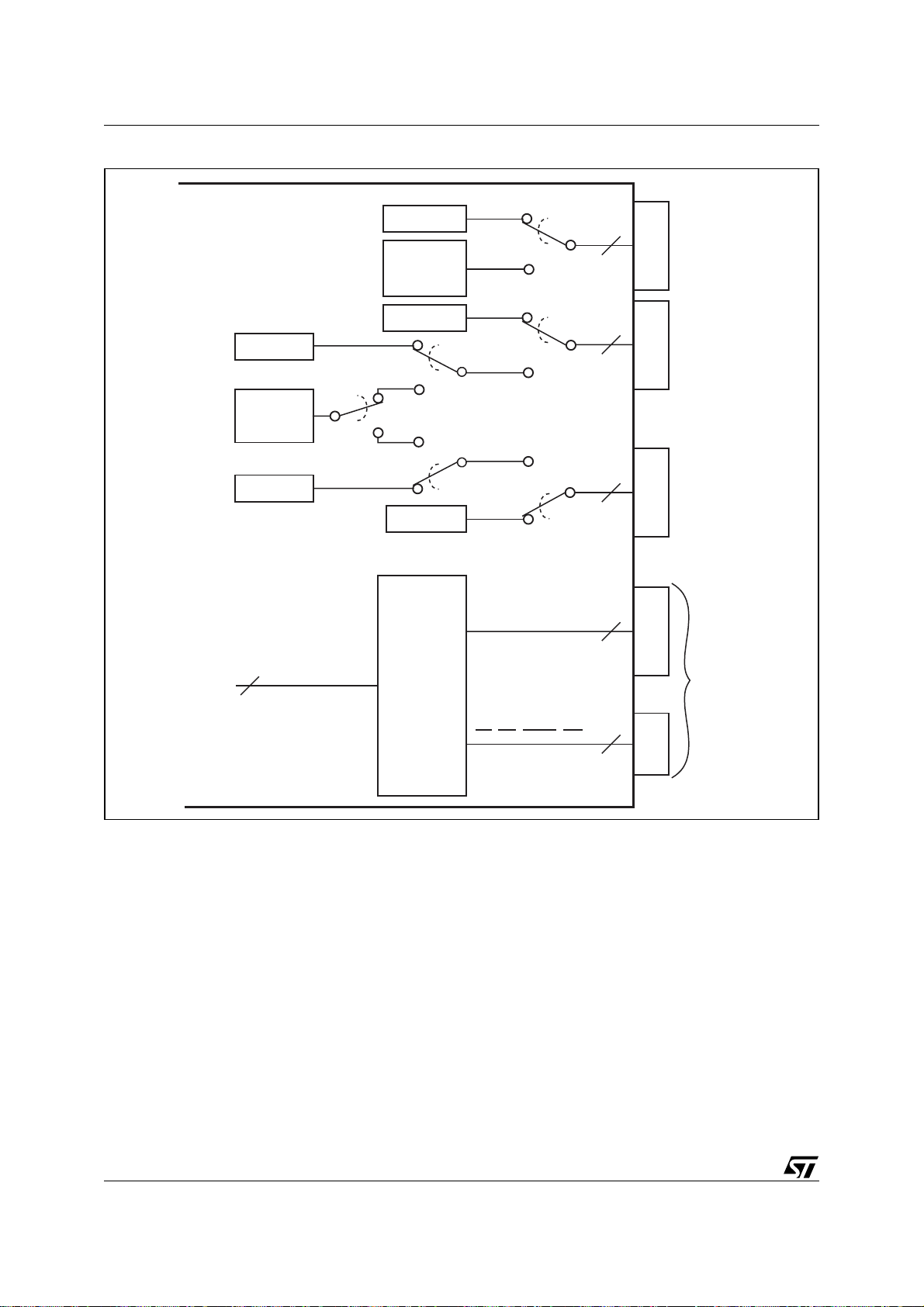

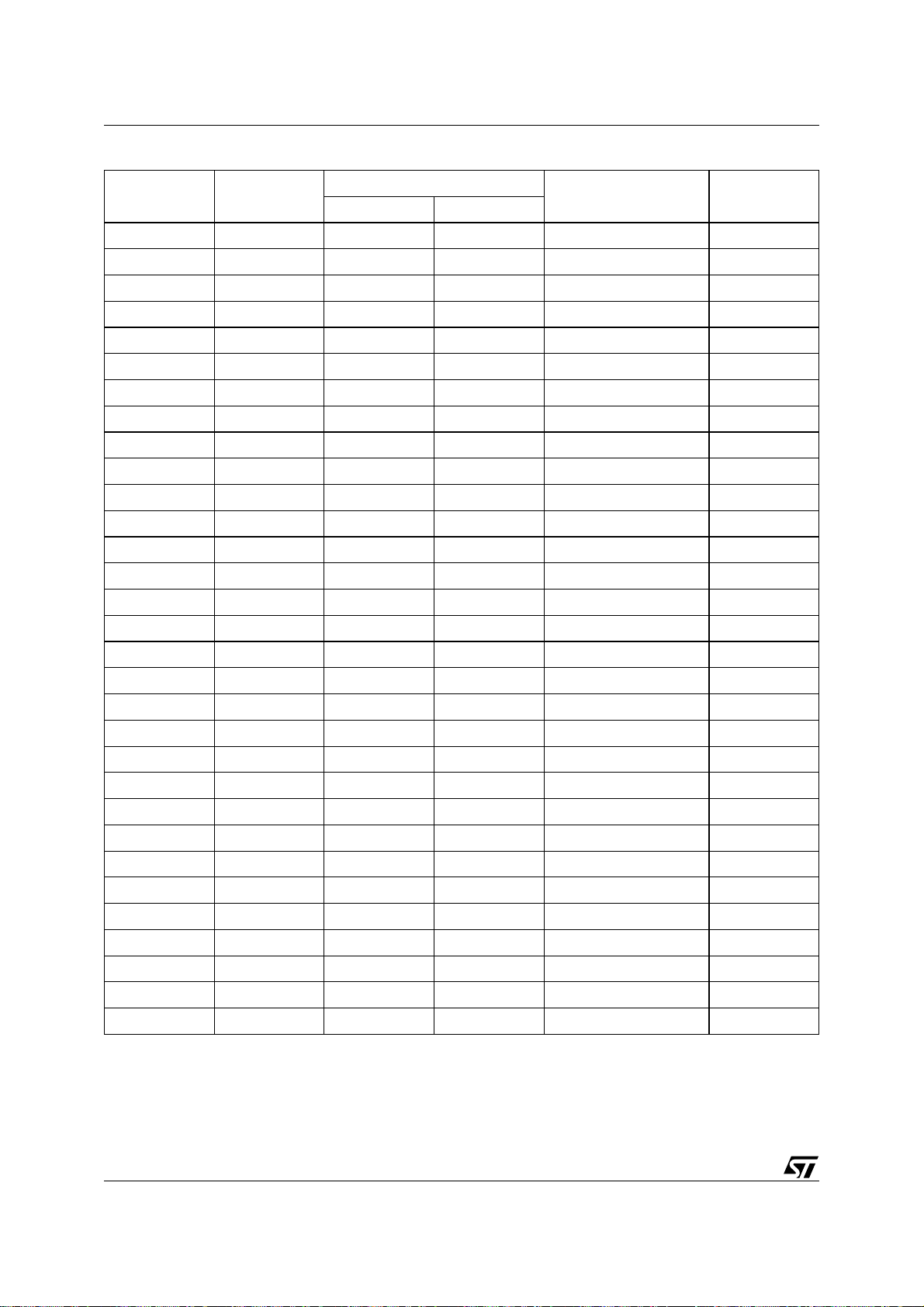

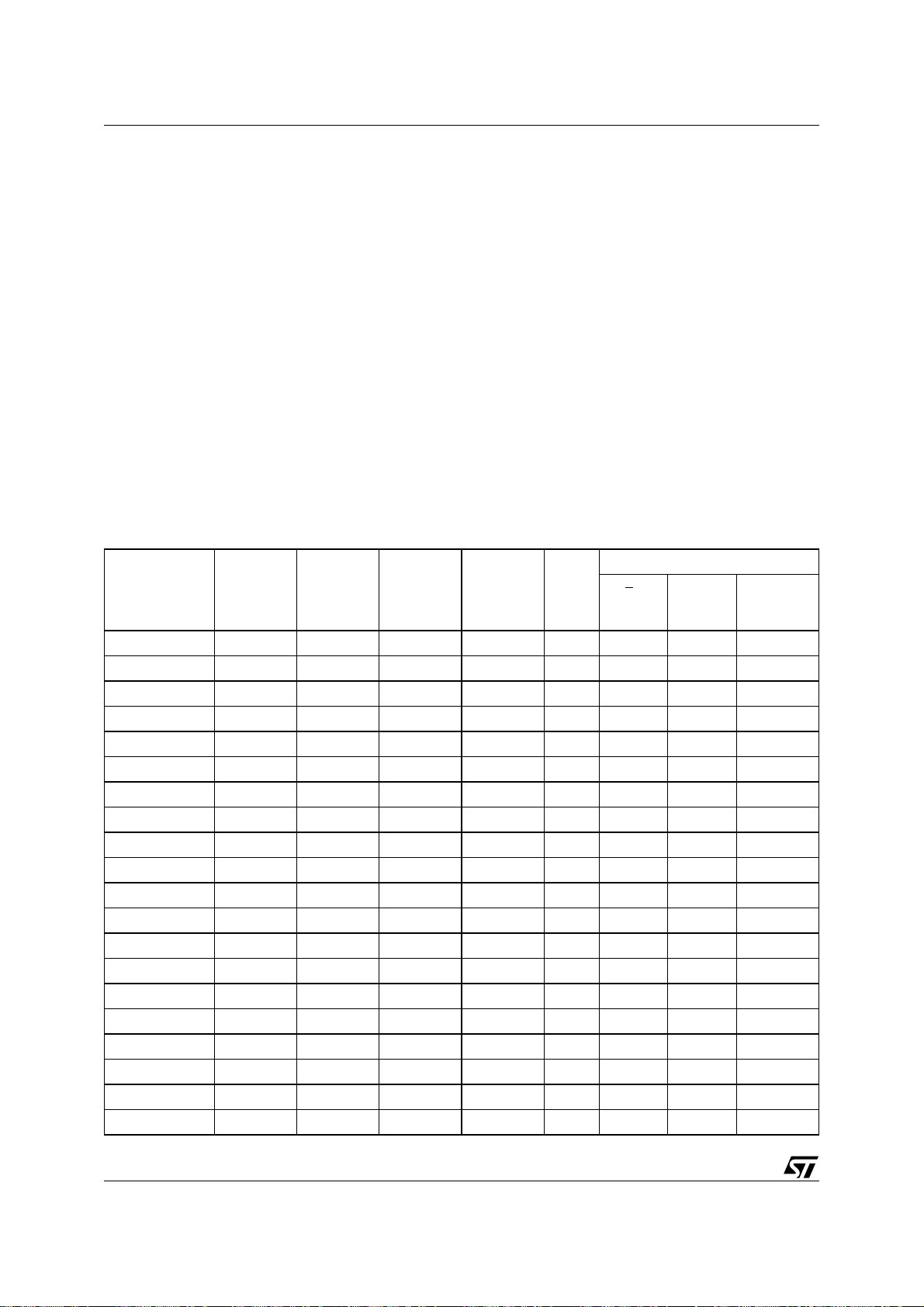

Table 5. SFR Memory Map with Direct Address and Reset Value

SFR

Addr

(hex)

80 RESERVED

81 SP SP[7:0] 07

82 DPL DPL[7:0] 00 Data

83 DPH DPH[7:0] 00

84 RESERVED

85 DPTC – AT – – – DPSEL[2:0] 00

86 DPTM – – – – MD1[1:0] MD0[1:0] 00

87 PCON SMOD0 SMOD1 – POR RCLK1 TCLK1 PD IDLE 00

88

89 TMOD GATE C/T

8A TL0 TL0[7:0] 00

8B TL1 TL1[7:0] 00

8C TH0 TH0[7:0] 00

8D TH1 TH1[7:0] 00

8E P1SFS0 P1SFS0[7:0] 00

8F P1SFS1 P1SFS1[7:0] 00

90

91 P3SFS P3SFS[7:0] 00

92 P4SFS0 P4SFS0[7:0] 00

93 P4SFS1 P4SFS1[7:0] 00

(1)

(1)

SFR

Name

TCON

P1

76 5 43210

TF1

<8Fh>

P1.7

<97h>

TR1

<8Eh>

P1.6

<96h>

Bit Name and <Bit Address> Reset

TF0

<8Dh>

M1 M0 GATE C/T M1 M0 00

P1.5

<95h>

TR0

<8Ch>

P1.4

<94h>

IE1

<8Bh>

P1.3

<93h>

IT1

<8Ah>

P1.2

<92h>

IE0

<89h>

P1.1

<91h>

IT0

<88h>

P1.0

<90h>

Value

(hex)

00

FF

with Link

Pointer

(SP), page

Pointer

(DPTR), p

age 22

13., page

14., page

26., page

41., page

42., page

Standard

SFRs, pag

31., page

32., page

27., page

30., page

34., page

35., page

Reg.

Descr.

Stack

22

Table

38

Table

39

Table

52

Table

72

Table

74

Timer

e71

Table

61

Table

61

Table

58

Table

61

Table

62

Table

62

25/264

uPSD34xx - SPECIAL FUNCTION REGISTERS (SFR)

SFR

Addr

(hex)

94 ADCPS – – – – ADCCE ADCPS[2:0] 00

95 ADAT0 ADATA[7:0] 00

96 ADAT1 – – – – – – ADATA[9:8] 00

97 ACON AINTF AINTEN ADEN ADS[2:0] ADST ADSF 00

98

99 SBUF0 SBUF0[7:0] 00

9A RESERVED

9B RESERVED

9C RESERVED

9D BUSCON EPFQ EBC WRW1 WRW0 RDW1 RDW0 CW1 CW0 EB

9E RESERVED

9F RESERVED

A0 RESERVED

A1 RESERVED

A2 PCACL0 PCACL0[7:0] 00

A3 PCACH0 PCACH0[7:0] 00

A4 PCACON0 EN_ALL EN_PCA EOVF1 PCA_IDL – – CLK_SEL[1:0] 00

A5 PCASTA OVF1 INTF5 INTF4 INTF3 OVF0 INTF2 INTF1 INTF0 00

A6 WDRST WDRST[7:0] 00

A7 IEA EADC ESPI EPCA ES1 – – EI2C – 00

(1)

SFR

Name

SCON0

76 5 43210

SM0

<9Fh>

SM1

<9Eh>

Bit Name and <Bit Address> Reset

SM2

<9Dh>

REN

<9Ch>

TB8

<9Bh>

RB8

<9Ah>TI<99h>RI<9h8>

Value

(hex)

00

Reg.

Descr.

with Link

Table

90., page

153

Table

91., page

153

Table

92., page

153

Table

89., page

152

Table

47., page

84

Figure

28., page

81

Table

37., page

65

Table

93., page

155

Table

93., page

155

Table

96., page

160

Table

98., page

162

Table

40., page

70

Table

18., page

45

26/264

uPSD34xx - SPECIAL FUNCTION REGISTERS (SFR)

SFR

Addr

(hex)

(1)

A8

A9

AA

AB

AC

AD

SFR

Name

IE

TCMMODE

0

TCMMODE

1

TCMMODE

2

CAPCOML

0

CAPCOMH

0

76 5 43210

EA

<AFh>

–

EINTF E_COMP CAP_PE CAP_NE MATCH TOGGLE PWM[1:0] 00

EINTF E_COMP CAP_PE CAP_NE MATCH TOGGLE PWM[1:0] 00

EINTF E_COMP CAP_PE CAP_NE MATCH TOGGLE PWM[1:0] 00