查询UM0087供应商

UM0087

USER MANUAL

Turbo uPSD DK3300 User Manual

WELCOME TO THE DK3300 DESIGN KIT

The DK3300 board is a demo board f or the uPSD 3300 family which is a s eries of 8051 class microc ontrollers (MCUs) that contain a new fast Turbo 8032 core with a large Dual Bank Flash memory, a large

SRAM, many peripherals, programmable logic and a JTAG Debug / In System Programming (ISP) port.

The DK3300 contains all the item s needed to explore the Turbo uP S D3300 MCU. Included in the kit are

demonstration application exampl es along with an evaluation copy of the tools needed to develo p and

compile code for the uPSD3300. The kit also contains the adapters necessary for programming the Flash

inside the uPSD and for accessing the built-in JTAG debug port. Please find or locate the following items:

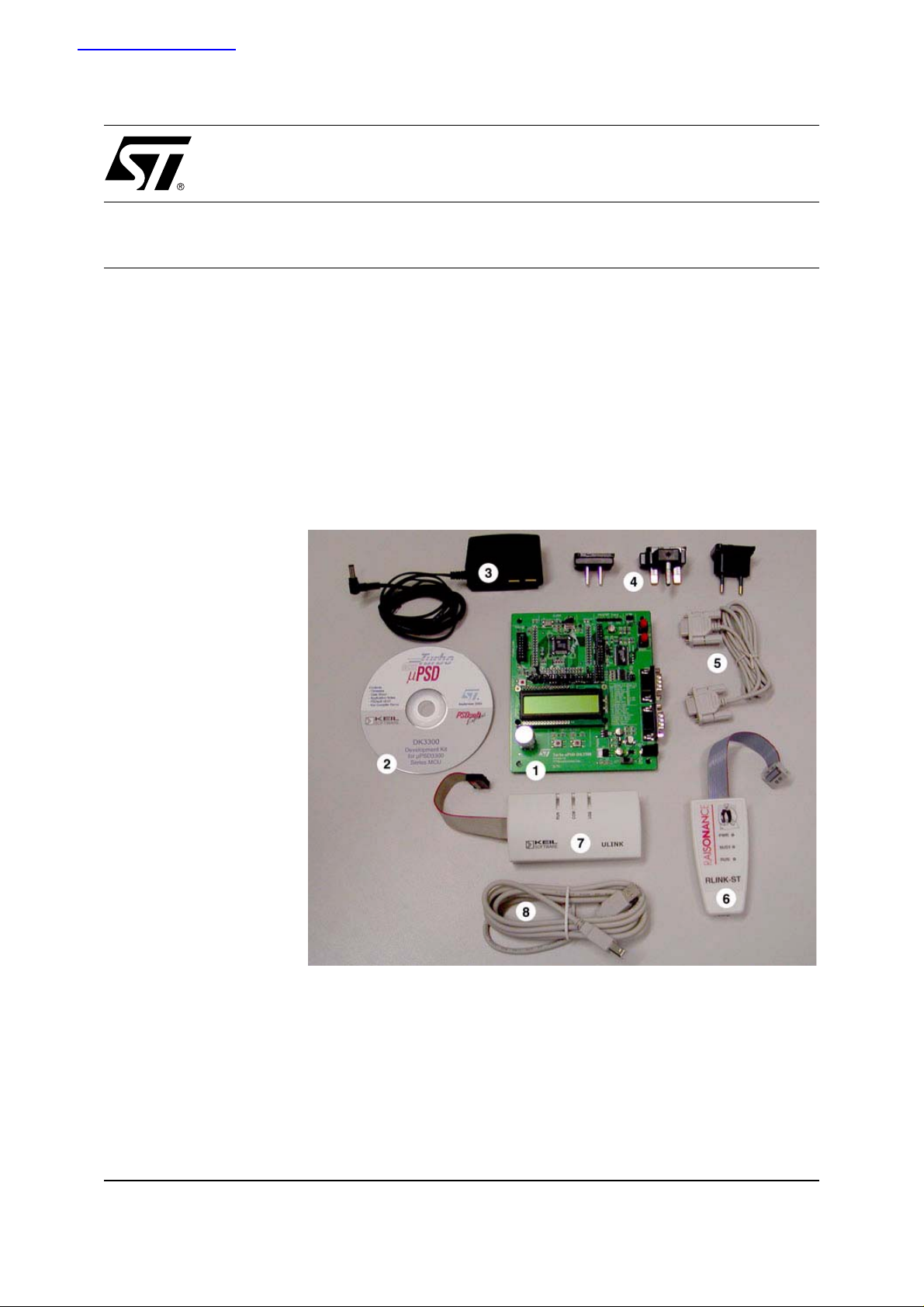

Figure 1. DK3300 Kit Contents

1. DK3300 Board

2. DK3300 CD

3. 110V/220V AC adapter

4. Plug adapters

5. RS232 Serial Cross-Over

Cable

6. USB R-LINK Adapter

7. USB ULink Adapter

8. USB Cable

9. Quick Start Flyer (not

shown)

1/11May 2004

UM0087 - USER MANUAL

TABLE OF CONTENTS

WELCOME TO THE DK3300 DESIGN KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. DK3300 Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you can use the uPSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 1 - Install PSDsoft Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 2 - Install Keil uVision2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 3 - Connecting the DK3300 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Step 4 - Try Your DK3300 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 5 - Starting a Debugging Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 6 - Following the AN1763 Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DK3300 HARDWARE FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 2. DK3300 Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

APPENDIX A.DK3300 JUMPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 1. DK3300 Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APPENDIX B.DK3300 SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 3. MCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 4. Peripheral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Input/Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2/11

UM0087 - USER MANUAL

GETTING STARTE D

Please insert the CD that comes with the Kit and print the following documents. These documents will help

you become familiar with the CD contents, the DK3300 Users Guide and an Application Note that will walk

you through a design example.

■ Read me text file (Readme.txt)

■ DK3300 Users Guide (UM0087.PDF)

■ AN1763 Example Design (AN1763.PDF)

■ Any errata file that may exist (*errata*.PDF)

Before you can use the uPSD

You will need to install some software on your PC system before you can program the DK3300. This includes PSDSoft Express and the Keil uVision Integrated Development Environment. Please follow the following steps to get started using the DK3300:

Step 1 - Install PSDsoft Express. Install the latest version of P SDsoft Express (from the Raisonance

CD).

Note: PSDSoft Express is required to configure the µ PSD device. Please che ck the ST Websi te for the

Latest PSDSoft version: www.st.com/micropsd

If you already have PSDSoft Express installed, then please install the update file by first unzipping the file

called Update_ExpressXXX.zip. This update file will automatically update your version of PSDSoft to support the Turbo µPSD3300.

If you do not have PSDSoft Express installed, then please install it by first unzipping the file called InstallExpressXXX.zip. This will install the s oftware needed to configure and optionally program t he Flash

inside the µPSD3300 product.

Step 2 - Install K e il uVisi on2. Install the latest version of Keil uVision2 Integrated Development Environment (ver 2.39 or greater). or the latest version of Raisonance’s Ride Environment.

Note: The Keil IDE or Raisonance IDE is required in order to make use of the JTAG debug f eat ure builtinto the µPSD3300. Please check the Keil website for the latest version: www.keil.com, or Raisonance

website: www.raisonance.com

If you already have uVision2 Integrated Development Environment from Keil Software Inc., and your Keil

software maintenance period has not expired, just update your uVision2 by double-clicking the file

UP51XXXX.exe located in the Keil directory on the CD.

If you do not have uVision2 Integrated Development Environment, you should install the trial version from

Keil in order to com pile t he ex amp le application des cribed in AN1763. To insta ll the trial version doubleclick the file EK51XXXX.exe located in the Keil directory on the CD.

3/11

UM0087 - USER MANUAL

Step 3 - Connecting the DK3300 Board. Connect the Cables to the DK3300 board (see Figure

2., page 5) by connecting the following cables from the DK330 0 board to your PC system.

1. Connect the AC adapter to the DK3300 board. The DK3300 AC adapter w ill wor k o n eithe r 110V or

220V, and contains several different plug adapters to fit popular European AC outlets. Please set up

your AC adapter to fit your AC plug type and plug in the AC adapter. Then plug the small power plug

into the DK3300 9V DC input.

2. Connect the R-LINK adapter to a USB port on your PC system by using the supplied USB cable.

3. Next, connect the small ribbon cable on the R-LINK adapter to the 14 pin JTAG connector on the

DK3300 board.

4. Start the PSDsoft application on your PC.

5. Make sure that you have selected R-LINK in the PSDsoft environment.

6. Test the R-LINK connection to ensure that PSDsoft and the R-LINK cable is communicating with your

DK3300 board.

7. Follow the Design Guide to program the desired design/demo in the uPSD using R-LINK and JTAG

port.

8. Verify that the correct application or demo is installed by viewing the LCD.

Note: The DK3300 may come with a pre-programmed demo described in AN1763.

9. Refer to the Design Guide and application notes for more details.

Step 4 - Try Your DK3300 Board. Your DK3300 board comes pre-programmed with the ADC demo application that is discussed in AN1763. To test your DK3300 board, you should have the AC adapter power

plugged in and connected to the 9V DC input on the DK3300 board.

Once you hav e confirmed your c onnections physically, turn the DK330 0 board on. Yo u should see t he

DK3300 AC demo running in the LCD window. If you do not see it running, please verify that you have

power by verifying the red power LED is on.

Note: Use the R-LINK adapter in conjunction with PSDsoft and Design guide to flash the other demos in

the DK3300 Kit to configure/reconfigure the uPSD device and then switch to ULink adapter to debug and

re-program the Flash as needed.

Step 5 - Starting a Debugging Session. To continue with the Raisonance debugging suite, leave the RLINK connected, otherwise for starting the Keil Tool chain, swap the R-LINK adapter for the ULink adapter.

The ULink/R-LINK adapters provided with DK3300 kit are used to debug the µPSD3300 with the built-in

JTAG debugger. It can optionally program the Flash in the µPSD3300 as well. This ULink/R-LINK adapter

plugs into the SAME 14-pin JTAG connector. Follow the IDE environment and the associated user’s guide

for debugging the codes.

Step 6 - Following the AN1763 Example. Read a nd follow the examp le in applica tion note A N1763 on

the CD.

This Application Note will guide you through a design cycle of the ADC demo to help you fam iliari ze yourself with PSDSoft Express (used to configure and program the uPSD device) and Keil’s uVision2 (used to

compose, compile, and debug firmware, as well as understand the architecture of the uPSD device).

4/11

UM0087 - USER MANUAL

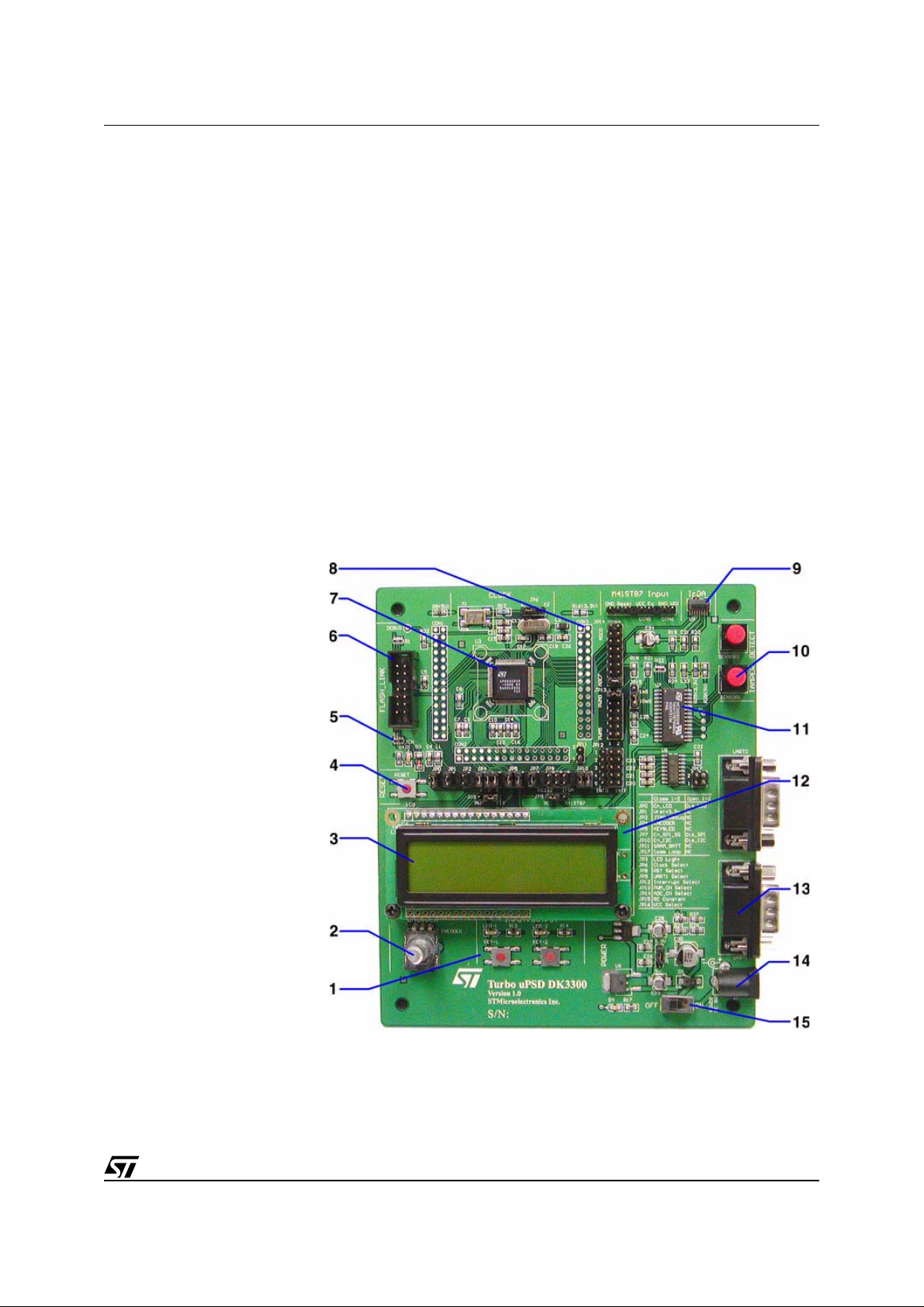

DK3300 HARDWARE FEATURES

The uPSD3300 has many different IP features and the DK3300 board has a variety of hardware capabilities built into the demo board itself. Some hardware on the DK3300 board is provided to enable exploration by the customer and for future demo application software. Over time additional demo applications will

be added, so please check the ST website below for the latest demo applications. Some of the DK3300

board hardware features include (see Figure 2):

2

■ I

C Real Time Clock by ST with built in Crystal and Tamper Detect Logic

■ Tamper Detect switches connected to the ST RTC

■ Dual RS232 connectors driven by ST RS232 level shifter

■ SPI interface EEPR O M

■ IrDA Transceiver

■ Two input switches and two output LED’s

■ Rotary encoder with select switch

■ 2 Line by 16 Character LCD

Please check the ST uPSD website at www.st.com/micropsd for the latest updates to PSDSoft Express

and Demo Applications for the DK3300 kit.

Figure 2. DK3300 Board Connections

1. Switches and LEDs

2. Rotary Encoder

3. LCD Display

4. Reset Switch

5. JTAG LED

6. 14-pin JTAG Connector

7. uPSD33XX

8. Expansion Connectors

9. IrDA Transceiver

10. Tamper Detect Switches

11. Real-Time Clock

12. EEPROM & Battery under

LCD

13. RS232 Connectors

14. 9VDC Power Input

15. On-Off Switch and Power

LED

5/11

UM0087 - USER MANUAL

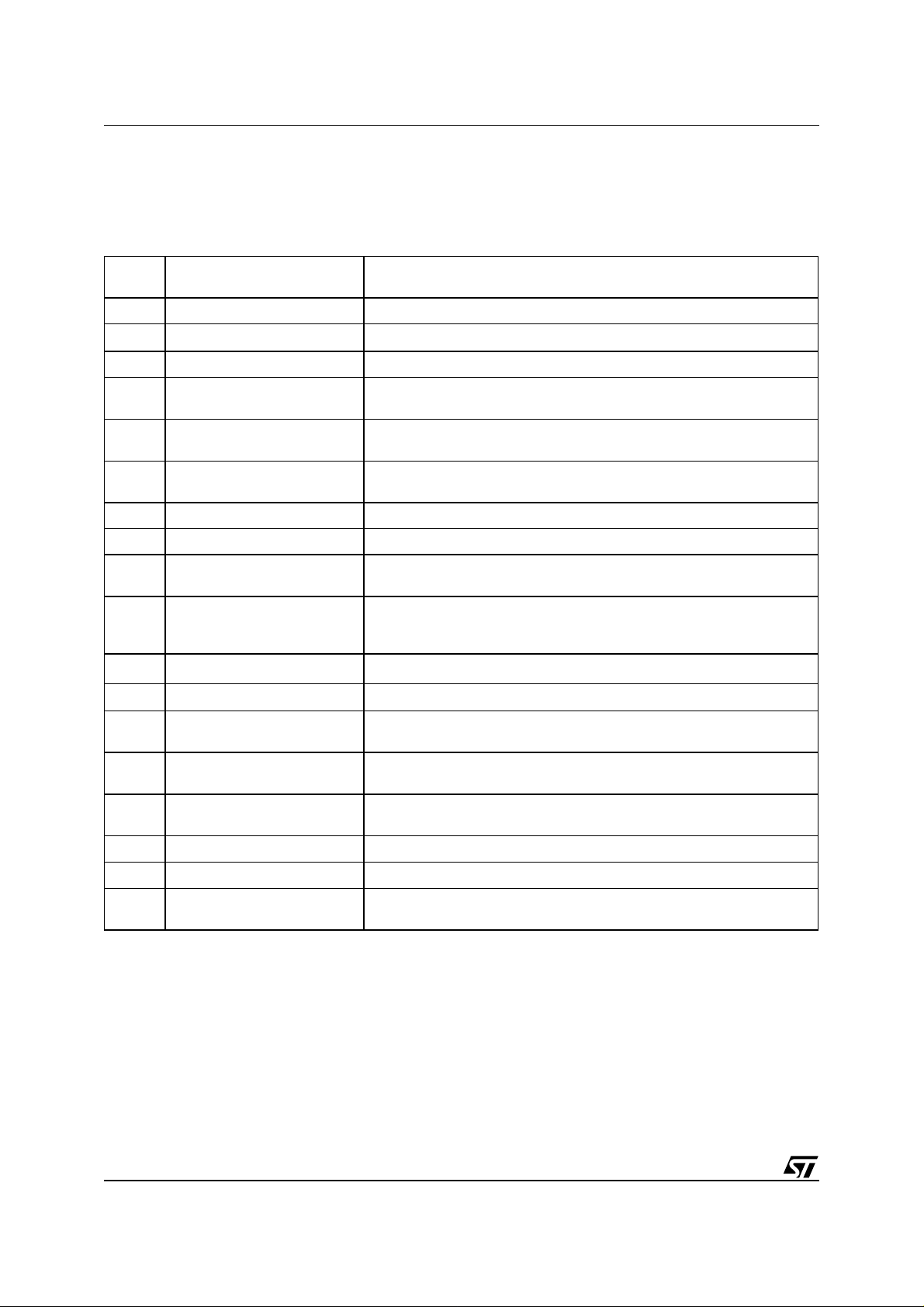

APPENDIX A. DK3300 JUMPERS

Verify JP0, JP1, JP3, JP13, JP14, and JP 15 for the ADC dem o. Se e DK3300 SCHE MAT ICS, page 7 for

more information regarding the jumpers.

Table 1. DK3300 Jumpers

Jumper

No.

JP0 LCD Enable/Disable Normally closed to enable LCD

JP1

JP2 JTAG Debug I/O Pin Should be OPEN

JP3 LCD Contrast

JP4 Encoder Connection to PB

JP5 Switch / LED Connection to PB

JP6 MCU Clock Select Normally closed in position 1-2 for Oscillator. Position 2-3 for Crystal

JP7 Enable SPI Normally closed to enable SPI EEPROM

Description Comments

ADC V

Input Normally closed to set V

REF

Normally closed in position 2-3

Position 1-2 used for PWM control

Normally all 3 positions are closed to enable the encoder connection to

port B

Normally both positions are closed to enable the SW/LED connection to

port B

REF

= 3.3V

JP8 Reset Input Select

JP9 UART1 Select

JP10

JP11

JP12 Interrupt Select for MCU

JP13 PWM Channel Select

JP14 ADC Channel Select

JP15 PWM RC Constant Selects PWM RC constant. Normally position 1-2 (1ms) is closed.

JP16 N/A Not selectable – fixed at 3.3V

JP17

Used to connect UART0 and

Enable I

uPSD V

UART1 in loop back mode

2

C Normally both positions closed to enable I2C access to RTC chip.

STANDBY

Input

Normally closed in position 1-2 for reset switch input. Position 2-3 for RTC

reset.

Normally closed in position 1-3 and 2-4 to select the RS232 connector 1.

Else can be se to position 3-5 and 4-6 to select the Urdu transceiver to be

connected to UART1.

Normally open. Used to enable backup power to uPSD if needed.

Used to map various Interrupt sources to the MCU. Normally open (see

DK3300 SCHEMATICS, page 7).

Selects what PWM channel connects the RC circuit on the board.

Normally PWM0 is connected via position 1-2 closed.

Selects what ADC channel connects the RC circuit on the board. Normally

ADC7 is connected via position 15-16 closed.

Normally open. Can be connected positions 1-2 and 3-4 for loop back.

6/11

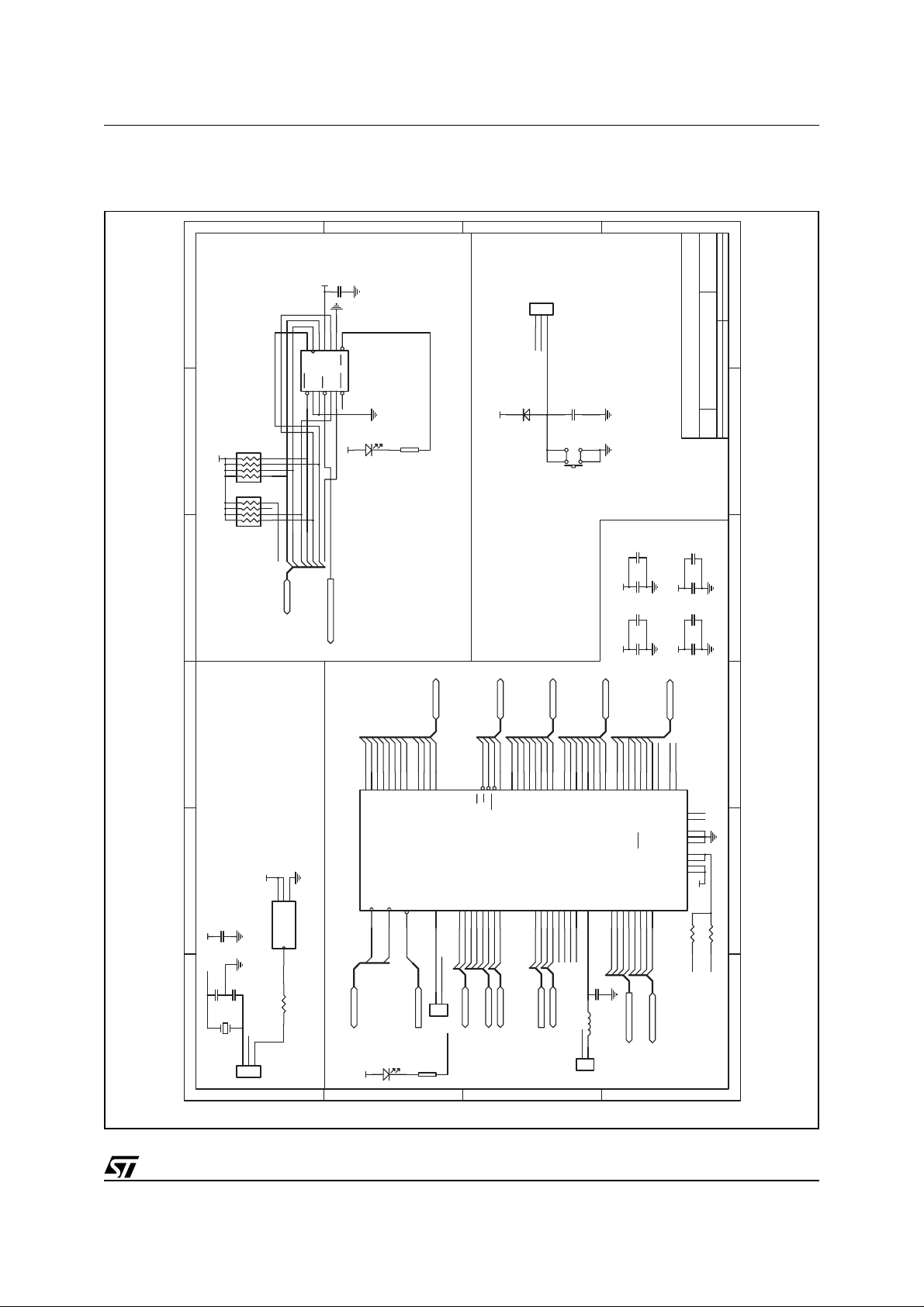

APPENDIX B. DK3300 SCHEM ATI CS

Figure 3. MCU

D

CC

C5

104P

FlashLINK

CPU_TMS

CPU_TCK

CPU_TSTA

CPU_JTAG

9

11

7

13

TCK

TDO

TMS

GND

GND

TERR

8

14

10

12

JTAG_CTRL

CPU_TERR

CPU_TDI

CPU_TDO

V

3

5

CC

TDI

V

TSTAT

RST

4

6

3.3V_RST

1

GND

CNTL

2

V

JEN

TRST

CC

6

54321

R2

10K

CC

V

4 5

3

6

2

7

1

8

R1

10K

4 5

3

6

2

7

1

8

RC_RST

C

D1

JEN

R4

470

B

123

JP8

3.3V_RST

RESET

RC_RST

D3

1N4148

CC

V

C4

105P

FlashLINK JTAG for 3300 Programming/Debugging

RESET

SWITCH

PUSH-BUTTON

UM0087 - USER MANUAL

A

Revision

Reset Circuit

Number

C:\Documents and Settings\bo kang.ST

MCU

SizeBDate: 4-August-2003 Sheet 2 of 4

File:

Title

4 3

1 2

C12

3.3V

C9

C11

104P

104P

103P

3.3V

C10

C7

C16

103P

103P

103P

3.3V low active RESET

MCU

Clock

41 CPU_AD4

37 CPU_AD1

38 CPU_AD2

39 CPU_AD3

36 CPU_AD0

P0.1/AD1

P0.2/AD2

P0.3/AD3

P0.0/AD0

CC

V

1

2

4

CC

OE

V

C13

104P

CC

V

X2

C18

20pf

C17

20pf

40MHz

X2

GND

OSC_OUT

X1

40MHz

3

R12

200

U3

DK3300

CPU_CLOCK

X148X2

X1

49

X2

47 CPU_AD7

45 CPU_AD6

43 CPU_AD5

P0.4/AD4

P0.5/AD5

P0.6/AD6

P0.7/AD7

RESET_IN

68

3.3V_RST

AD[0.. 11]

51 CPU_AD8

53 CPU_AD9

55 CPU_AD10

57 CPU_AD11

P2.1/A9

P2.2/A10

P2.3/A11

P2.0/A8

DEBUG

8

CPU_DEBUG

1

JP2

3.3V Reset

JTAG_CNTRL

2

X1

D2

123

JP6

D

DEBUG

CC

V

C

R7

470

JTAG_CNTRL

Reset

JTAG (FlashLINK)

62 CPU_WR

4 CPU_ALE

63 CPU_PSEN

65 CPU_RD

CTRL0/RD

CTRL0/WR

CTRL2/PSEN

CSDA/P3.6

2

RXD/P3.0

TXD/P3.1

EXINT0/GATE0/P3.2

EXINT1/GATE1/P3.3

T0/P3.4

T1/P3.5

I

44

46

77

79240

42

75

CPU_U1RXD

CPU_U1TXD

CPU_INT0

CPU_INT1

CPU_P3.4

CPU_P3.5

CPU_I2CSDA

CPU_I2CSCL

CPU_P3

CPU_CMM

Control Bus

35 CPU_PA0

34 CPU_PA1

PA0

PA1

ALE(PD0)

CSCL/P3.7

2

I

CPU_I2C

32 CPU_PA2

28 CPU_PA3

26 CPU_PA4

24 CPU_PA5

PA2

PA3

PA4

PA5

.

ADC0/T2/P1.0

ADC1/T2x/P1.1

52

54565859606164

CPU_ADC0

CPU_ADC1

CPU_ADC_IN

B

PA[0.. 7]

22 CPU_PA6

21 CPU_PA7

80 CPU_PB0

78 CPU_PB1

76 CPU_PB2

PA6

PA7

PB0

PB1

ADC2/RXD2/P1.2

ADC3/TXD2/P1.3

ADC4/SPISCLK/P1.4

ADC5/SPIRXD/P1.5

ADC6/SPITXD/P1.6

CPU_ADC4

CPU_ADC5

CPU_ADC6

CPU_ADC7

CPU_U2RXD

CPU_U2TXD

CPU_UART2

JP1

74 CPU_PB3

73 CPU_PB4

71 CPU_PB5

PB2

PB3

PB4

REF

ADC7/SPISEL/P1.7

V

70

REF

V

L1

3.3V

1

2

PB[0.. 7]

67 CPU_PB6

66 CPU_PB7

PB5

PB6

PB7

T2/TCM0/P4.0

33

CPU_PWM0

C8

104P

100µH

C15

VC1

20 CPU_TMS

16 CPU_TCK

15 CPU_PC2

14 CPU_TSTA

9 CPU_TERR

/PC4

/PC2

TCK/PC1

TMS/PC0

STBY

V

TSTAT/RDY/PC3

TERR/V

T2x/TCM1/P4.1

RXD2/TCM2/P4.2

TXD2/PCA0/P4.3

SPISCLK/TCM3/P4.4

SPIRXD/TCM4/P4.5

CPU_PWM1

CPU_PWM2

CPU_PCA0CLK

CPU_SPI_CLK

CPU_SPI_RXD

CPU_PWM_OUT

104P

7 CPU_TDI

BATON

CPU_SPI_TXD

VC1

CPU_JTAG

6 CPU_TDO

5 CPU_PC7

3 CPU_PD1

1 CPU_PD2v

PC7

PD1

PD2

N.C.

TDI/PC5

N.C.

TDO/PC6

GND

GND

GND

DD

V

DD

V

CC

V

CC

V

SPITXD/TCM5/P4.6

SPISEL/PCA1/P4.7

18192325302731

CPU_SPI_SEL

CPU_SPI_BUS

A

C14

104P

17

11

69

29

13

50

12

10

72

3.3V

VC1

R16

0R80

5V

3.3V

1 2 3 4 56

AI09611

7/11

UM0087 - USER MANUAL

Figure 4. Peripheral

D

1

2

JP11

6

OUT

M41ST87_V

CPU_PC2

OUT

TPCLR

ECON

M41ST87_V

25

18

R29

0

3.3V

4K7

4K7

3.3V or 5V

15

28

0

C33

GND

4 5

3

2

1

104pF

RESET

U7

CLR

OUT

V

TP

BAT

V

CC

V

SDA17SCL22EX27WDI9RST INT110RST INT211PFI1

F32K

I2CSDA

I2CSCL

1

CON6

54321

6

7

8

CC

V

BATTERY

Battery Socket

R28

5V

R22

R24

M41ST87_IRQ

M41ST87_SQW

26

IRQ

SQW

ECON

V

2

M41ST87_PFO1

M41ST87_PFO2

RESET

7

12

19168

RST

PFO1

23

CC

1

2

CON5

PFO2

13

R18

1 2

JP13

CPU_PWM0

CPU_PWM1

A

JP15

10K

8

109

3 4

5 6127

CPU_PWM2

CPU_SPI_CLK

CPU_SPI_RXD

Revision

Number

C:\Documents and Settings\bo kang.ST

Peripheral

SizeBDate: 4-August-2003 Sheet 3 of 4

File:

Title

C25

104pF

C24

105pF

11

CPU_SPI_TXD

CPU_PWM

12

13

11

M41ST87_PFO

M41ST87_SQW

SENSOR2

GND

B

15

14

CPU_PB1

GND

1 2163

JP14

CPU_ADC0

4

6

8

5

7

CPU_ADC1

CPU_ADC4

CPU_U2RXD

CPU_U2TXD

7101ADC

LCD_VL

14

12

109

13

11

CPU_ADC5

CPU_ADC6

CPU_ADC7

15

7101UART2

C

CSCL

CSDA

2

2

I

I

1 2

3 4

JP10

CPU_I2CSCL

CPU_I2CSDA

123

4

JP18

F32k

GND

ECON

TPCLR

CPU_INT0

R27

R25

CPU_INT1

1

3254

687910

JP12

2

M41ST87_IRQ

M41ST87_PFO

1k2

1k2

F32k

21

F32k

M41ST87

SS

V

14

PFI2

TP1IN

TP2IN

20

24

SENSOR1

R23

6k8

R26

R21

10K

V_UNREG

3k6

5V

CON4

OUT

M41ST87_V

123

CON3

PWM, ADC

I2C Interface Circuit with Battery

C6

104P

CC

V

2

SPI Interface Circuit

LCD Interface Circuit

CPU_SPI_RXD

3.3V

GND

CC

CPU_SPI_CLK

CPU_SPI_TXD

V

8

6

7

D5C

CC

V

HOLD

SS

W3V

S

Q

U4

M95080W

4

1

2

R15

10K

CC

V

CC

CPU_SPI_RXD

V

SPI_SEL

CPU_SPI_SEL

2

JP7

C19

1

104P

CC

V

D

7

8

Q

D1C

U10

2

CPU_SPI_TXD

CPU_SPI_CLK

3.3V

SS

V

3.3V

6

5

CC

V

RESET

4

3

3.3V_RST

SPI_SEL

C35

104P

W

S

48PE16

C

5V

D07D18D29D310D411D512D613D714VL3RS4R/W5E

LCD

PA[0.. 7]

CPU_PA0

CPU_PA1

CPU_PA2

CPU_PA3

CPU_PA4

CPU_PA5

LCD Module Only Operates on 5V

R11

1K

R10

4K7

5V

LCD_EN

CPU_PB7

1

2

JP0

B

CPU_PA6

CPU_PA7

JP3

R0

4K7

CPU_PB6

CPU_PB5

123

GND

LCD Module

6

LCD_EN

1

PB[5.. 7]

5V

5V

8

7

5

6

CC

IP-B

V

IP_B

OP-B

IP-A2IP_A3GND

OP-A

LM358

U2

1

4

LCD_VL

C3

104pF

1 2 3 4 56

A

AI09612

8/11

Figure 5. Input/Output

UM0087 - USER MANUAL

D

C

B

A

UART2

162738495

UART1

162738495

6

RS232_RXD0

RS232_TXD0

C21

334pF

TXD1

RS232_TXD0

14

C2+

OUT

T1

IN

T1

11

CPU_U1TXD

VREF

CPU_DEBUG

CPU_ADDR_DATA

CPU_AD7

CPU_AD6

CPU_AD5

CPU_PD2

CPU_PD1

CPU_PC7

RXD1

RS232_RXD0

7

8

13

IN

OUT

R1

T2

OUT

IN

R1

T2

9

12

10

CPU_U1RXD

CPU_A11

GND

CPU_A10

CPU_A9

CPU_A8

CPU_AD4

CPU_AD3

CPU_AD2

CPU_AD1

CPU_AD0

CPU_TDO

CPU_TDI

CPU_TERR

CPU_TSTAT

CPU_PC2

IN

R2

OUT

R2

CPU_U1RXD

CPU_U1TXD

CPU_P3

CPU_PWM0

CPU_PWM1

CPU_P4

CPU_TCK

CPU_TMS

CC

V

5

16

4

CC

C2–

V

C1+1C1–

V+

U8

54321

CC

V

CON1

CON3

CON2

3

2

C23

334pF

C22

334pF

CPU_COMM

30

CPU_RD

CPU_PSEN

CPU_WR

CPU_ALE

3.3V_RST

GND

5V

5V

Reset

1234567891011121314151617181920212223242526272829

CPU_ADC0

CPU_ADC1

CPU_U2RXD

CPU_U2TXD

CPU_ADC4

CPU_ADC5

CPU_ADC6

CPU_ADC7

CPU_P1 CPU_CTRL

1234567891011121314151617181920212223242526272829

CPU_PB7

CPU_PB6

CPU_PB5

CPU_PB4

CPU_PB3

CPU_PB2

CPU_PB1

CPU_PB0

D

TXD1

RXD1

15

GND

V–

ST3232

6

RS232 Interface Circuit

C20

334pF

1

CPU_INT0

CPU_INT1

CPU_P3.4

CPU_P3.5

CPU_I2CSDA

CPU_I2CSCL

CPU_PWM2

CPU_PCA0CLK

CPU_SPI_CLK

CPU_SPI_RXD

CPU_SPI_TXD

CPU_SPI_SEL

CPU_PA7

CPU_PA6

CPU_PA5

CPU_PA4

CC

V

U9

TFDU4203

4

IrDA Interface Circuit (disable shutdown)

364

2

5

CPU_U2RXD

CPU_U2TXD

1234567891011121314151617181920212223242526272829

CON30

Connector

X2

VCC

VCC

GND

30

CON30

3.3V

CC

V

30

CON30

CPU_PA3

CPU_PA2

CPU_PA1

CPU_PA0

C

R19

5

CC

RXD

V

TXD

2

3

7

R20

C32

104pF

CC

V

TXD1

RXD1

12

34

JP17

RS232_TXD0

RS232_RXD0

Encoder, Button, & LED

R9

4k7

6

7

CC

V

8

10

C34

C31

GND1GND

4.7µF

104pF

SD

6

8

0

ENCODER

4 5

3

2

1

445

3

JP4

GND5GND

RS232, IrDA

5

11223

*

10K

R5

R3 10K

123456

CPU_PB2

CPU_PB3

CPU_PB4

B

5V

3

OUT

V

IN

V

U6

78M05-5V

1

UNREG

V

D5

1

J1

Power Supply

CC

C1

103P

V

C2

103P

D4

POWER

C26

104pF

GND

2

220µF

C30

1N4004

SWITCH

LED_TWO

R14

LED_ONE

1K5

R13

R17

1K

3.3V

2

OUT

V

IN

V

U5

LD1117-3.3V

3

5V

JP16

KEY2 SW

12

43

KEY1 SW

12

43

JP5

1K5

C28

10µF

C27

104pF

GND

1

C29

10µF

123

3.3V5VVCC

PUSH-BUTTON

PUSH-BUTTON

12

34

CPU_PD2

CPU_PD1

A

Revision

Number

C:\Documents and Settings\bo kang.ST

Input/Output

SizeBDate: 4-August-2003 Sheet 4 of 4

File:

Title

1 2 3 4 56

AI09613

9/11

UM0087 - USER MANUAL

REVISION HISTORY

Table 2. Document Revision History

Date Version Revision Details

May 7, 2004 1.0 First Issue

10/11

UM0087 - USER MANUAL

If

this d

you have any questions or suggestions concerning the matters raised in

ocument, please send them to

the following electronic mail addresses:

ask.memory@st.com (for general enquiries)

Please remember to include your name, company, location, telephone number and fax number.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics a ssumes no responsibility fo r the c onsequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authori zed for use as criti cal components in life support devices or systems without ex press written approval of ST M i croelectronics.

The ST logo is a registered tra dem ark of STMicroelectronics.

All other na m es are the property of their re spective owner s.

© 2004 STMi croelectroni cs - All rights res erved

Australi a - B elgium - Brazi l - Canada - Chin a - Czech Republ i c - Finland - Fra nce - Germany -

Hong Kong - India - Israel - It al y - Japan - Malaysi a - Malta - Morocco - Singapor e -

STMicroelectroni cs GROUP OF COMPANIES

Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

11/11

Loading...

Loading...