Constant voltage and constant current controller

Features

■ Secondary-side constant voltage and constant

current control

■ Very low voltage operation

■ Very low quiescent consumption

■ High-accuracy internal reference

■ Low external component count

■ Wired-or open-drain output stage

■ Easy frequency compensation

■ SOT23-6 micro package

Applications

TSM1052

for battery chargers and adapters

SOT23-6

■ Battery chargers

■ AC DC adapters

Description

The TSM1052 is a highly integrated solution for

SMPS applications requiring a dual control loop to

perform CV (constant voltage) and CC (constant

current) regulation.

The TSM1052 integrates a voltage reference, two

op amps (with OR-ed open-drain outputs), and a

low-side current sensing circuit.

The voltage reference, along with one op amp, is

the core of the voltage control loop; the current

sensing circuit and the other op amp make up the

current control loop.

Table 1. Device summary

Part number Package Packaging

TSM1052 SOT23-6 Tape and reel

The external components needed to complete the

two control loops are:

■ A resistor divider that senses the output of the

power supply (adapter, battery charger) and

fixes the voltage regulation set point at the

specified value;

■ A sense resistor that feeds the current sensing

circuit with a voltage proportional to the dc

output current; this resistor determines the

current regulation set point and must be

adequately rated in terms of power dissipation;

■ Frequency compensation components

(RC networks) for both loops.

The TSM1052, housed in one of the smallest

package available, is ideal for space-shrunk

applications such as adapters and chargers.

February 2008 Rev 2 1/15

www.st.com

15

Contents TSM1052

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Internal schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Typical application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Voltage and current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.1 Voltage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.2 Current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Start up and short circuit conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2/15

TSM1052 Description

1 Description

1.1 Pin connection

Figure 1. Pin Connection (top view)

6

6

6

6

6

6

6

Vctrl

Vctrl

Vctrl

Vctrl

Vctrl

Vctrl

1

1

1

1

1

1

1

1

6

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

1.2 Pin description

Table 2. Pin description

N. Name Function

1V

2GND

3OUT

4I

5V

ctrl

ctrl

sense

GND

GND

GND

GND

GND

GND

OUT

OUT

OUT

OUT

OUT

OUT

Inverting input of the voltage loop op amp. The pin will be tied to the mid-point

of a resistor divider that senses the output voltage.

Ground. Return of the bias current of the device. 0 V reference for all

voltages. The pin should be tied as close to the ground output terminal of the

converter as possible to minimize load current effect on the voltage regulation

set point.

Common open-drain output of the two internal op amps. The pin, able to sink

current only, will be connected to the branch of the optocoupler’s photodiode

to transmit the error signal to the primary side.

Non-inverting input of the current loop op amp. It will be tied directly to the hot

(negative) end of the current sense resistor

Inverting input of the current loop op amp. The pin will be tied to the cold end

of the current sense resistor through a decoupling resistor.

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

5

5

5

5

5

5

5

5

4

4

4

4

4

4

4

4

Vsense

Vsense

Vsense

Vsense

Vsense

Vsense

Ictrl

Ictrl

Ictrl

Ictrl

Ictrl

Ictrl

Supply Voltage of the device. A small bypass capacitor (0.1 µF typ.) to GND,

6Vcc

located as close to IC’s pins as possible, might be useful to get a clean

supply voltage.

3/15

Description TSM1052

1.3 Internal schematic

Figure 2. Internal schematic

Vcc

Vcc

Vcc

Vcc

6

6

6

1.21 V

1.21 V

1.238 V

1.238 V

1.238 V

1.238 V

+

+

+

+

200 mV

200 mV

200 mV

200 mV

VsenseIctrl

VsenseIctrl

VsenseIctrl

VsenseIctrl

6

+

+

+

+

-

-

-

-

+

+

+

+

-

-

-

-

54

54

54

54

OUT

OUT

OUT

OUT

3

3

3

3

Vctrl

Vctrl

Vctrl

Vctrl

1

1

1

1

GND

GND

GND

GND

2

2

2

2

1.4 Absolute maximum ratings

Table 3. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

CC

V

OUT

I

OUT

V 1, 4, 5 Analog inputs -0.3 to 3.3 V

1.5 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

T

T

thJA

OP

max

STG

Thermal resistance, junction-to-ambient 250 °C/W

Junction temperature operating range -10 to 85

Maximum junction temperature 150

Storage temperature -55 to 150

6 DC supply voltage -0.3 to 20 V

3 Open-drain voltage -0.3 to V

3 Max sink current 100 mA

CC

V

°CTj

4/15

TSM1052 Electrical characteristics

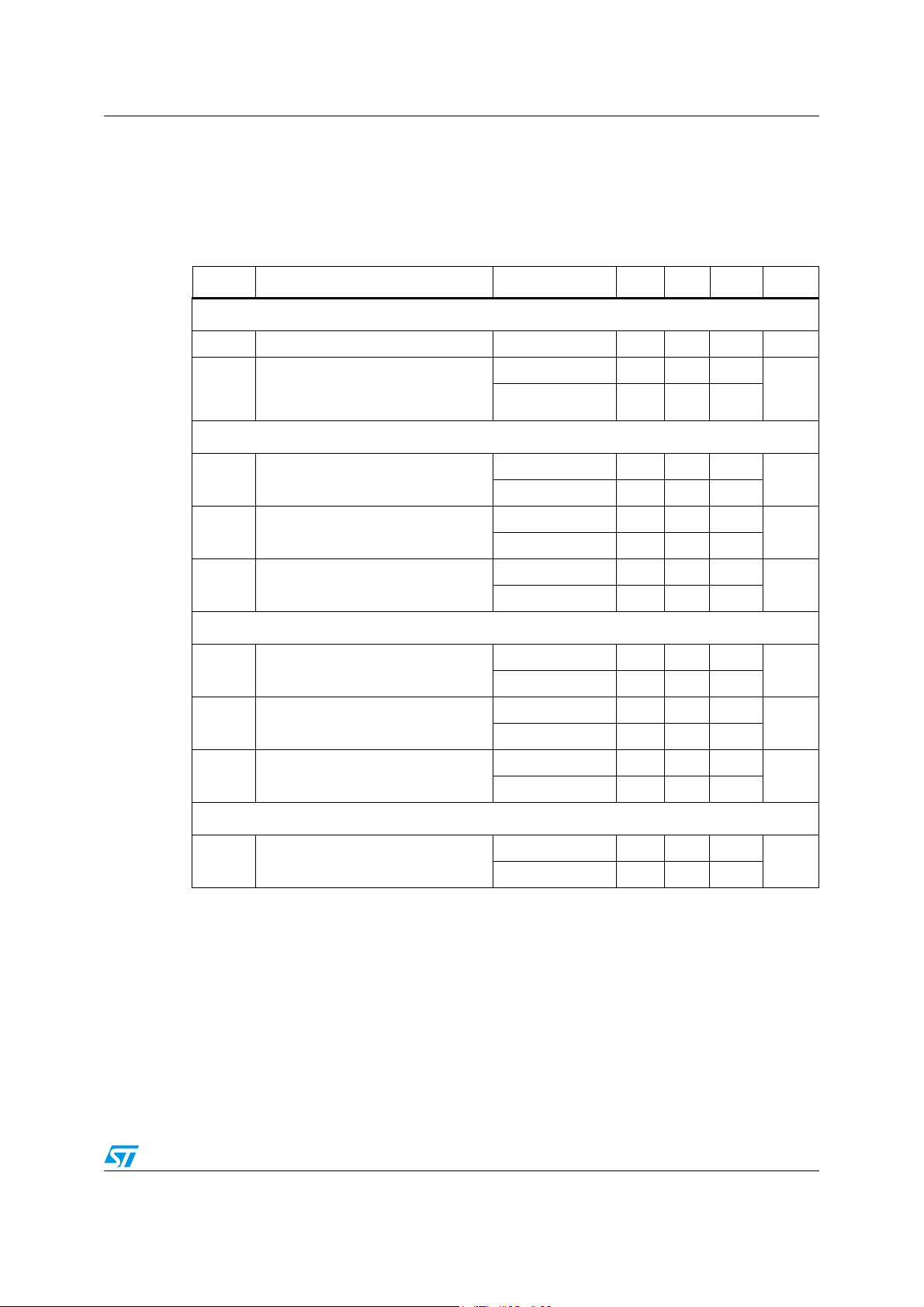

2 Electrical characteristics

TJ = 25 °C and VCC = 5 V, unless otherwise specified

Table 5. Electrical characteristics

Symbol Parameter Test conditions Min Typ Max Unit

Device supply

V

Voltage operating range 1.7 18 V

CC

Quiescent current

I

(Ictrl = Vsense = Vctr = 0,

CC

OUT = open)

Voltage control loop op amp

Gm

Vref Voltage reference

Transconductance

v

(sink current only)

(2)

(3)

Ibias Inverting input bias current

Current control loop

Gm

Vsense

Ibias

Transconductance

i

(sink current only)

(4)

Current loop reference

@ I(Iout) = 1 mA

Non-inverting input source current @

V(Ictrl) = -200 mV

(5)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

150

µA

300

13.5

S

2.5

1.198 1.21 1.222

V

1.186 1.234

50

nA

100

1.5 7

S

196 200 204

mV

192 208

20

µA

40

Output stage

100

V

OUTlow

1. Specification referred to -10 °C < TA < 85 °C

2. If the voltage on Vctrl (the negative input of the amplifier) is higher than the positive amplifier input

3. The internal Voltage Reference is set at 1.21 V (bandgap reference). The voltage control loop precision

4. When the positive input at Ictrl is lower than -200 mV, and the voltage is decreased by 1mV, the sinking

5. The internal current sense threshold is set at -200 mV. The current control loop precision takes into

Low output level @ 2 mA sink current

(Vref = 1.21 V), and it is increased by 1mV, the sinking current at the output OUT will be increased by

3.5 mA.

takes into account the cumulative effects of the internal voltage reference deviation as well as the input

offset voltage of the transconductance operational amplifier. The internal Voltage Reference is fixed by

bandgap, and trimmed to 0.5% accuracy at room temperature.

current at the output Out will be increased by 7 mA.

account the cumulative effects of the internal voltage reference deviation as well as the input offset voltage

of the transconductance operational amplifier.

(1)

200

5/15

mV

Typical characteristics TSM1052

3 Typical characteristics

Figure 3. V

vs ambient temperature Figure 4. V

ref

Vcc=18V Vcc=5V Vcc=1.7V

vs ambient temperature

SENSE

Vcc=18V Vcc=5V Vcc=1.7V

1.230

1.220

1.210

Vref (V)

1.200

1.190

-20 0 20 40 60 80 100

Temp ( °C )

Figure 5. V

50

40

30

20

Iibv(nA)

10

0

ambient temperature

-20 0 20 40 60 80 100

pin input bias current vs

SENSE

Vcc=18V Vcc=5V Vcc=1.7V

Temp ( °C )

208

206

204

202

200

198

196

Vsense (mV)

194

192

-20 0 20 40 60 80 100

Temp ( °C )

Figure 6. I

pin input bias current vs

CTRL

ambient temperature

Vcc=18V Vcc=5V Vcc=1.7V

15

14

13

12

Iibi(uA)

11

10

-20 0 20 40 60 80 100

Temp ( °C )

Figure 7. Transconductances (sink current

only) of voltage control loop op amp

18

16

14

12

10

8

6

Gmv(mA/mV)

4

2

0

6/15

vs ambient temperature

Vcc=18V Vcc=5V Vcc=1.7V

-20 0 20 40 60 80 100

Temp ( °C )

Figure 8. Transconductance (sink current

only) of current control loop op amp

vs ambient temperature

Vcc=18V Vcc=5V Vcc=1.7V

20

15

10

5

Gmi(mA/mV)

0

-20 0 20 40 60 80 100

Temp ( °C )

TSM1052 Typical characteristics

Figure 9. Low output level of voltage control

loop op amp vs ambient

120

100

80

60

40

Volv(mV)

20

temperature (2 mA sink current)

Vcc=18V Vcc=5V Vcc=1.7V

0

-20 0 20 40 60 80 100

Temp ( °C )

Figure 11. Output short circuit current of

voltage control loop op amp vs

70

60

50

40

30

Iosv(mA)

20

10

0

ambient temperature

Vcc=18V Vcc=5V Vcc=1.7V

-20 0 20 40 60 80 100

Temp ( °C )

Figure 10. Low output level of current control

loop op amp vs ambient

temperature (2 mA sink current)

Vcc=18V Vcc=5V Vcc=1.7V

140

120

100

80

60

Volc(mV)

40

20

0

-20 0 20 40 60 80 100

Temp ( °C )

Figure 12. Output short circuit current of

current control loop op amp vs

ambient temperature

Vcc=18V Vcc=5V Vcc=1.7V

80

70

60

50

40

30

Iosc(mA)

20

10

0

-20 0 20 40 60 80 100

Temp ( °C )

Figure 13. Supply current vs ambient

0.350

0.300

0.250

0.200

0.150

Icc(uA)

0.100

0.050

0.000

temperature

Vcc=18V Vcc=5V Vcc=1.7V

-20 0 20 40 60 80 100

Temp ( °C )

Figure 14. Low output level vs sink current

2.5

2

1.5

1

Vol (V)

0.5

0

1 6 11 16 21 26 31

Isink (mA)

7/15

Application information TSM1052

4 Application information

4.1 Typical application schematic

Figure 15. Typical adapter or battery charger application using the device

Vcc

TSM1052

TSM1052

1.210 V

1.210 V

+

+

200 mV

200 mV

Vcc

6

6

+

+

-

-

+

+

-

-

54

54

3

3

OUT

OUT

1

1

Vctrl

Vctrl

2

2

GND

GND

Rled

Rled

Cvc1

Cvc1

Ric1

Ric1

Cic1

Cic1

Rvc1

Rvc1

R1

R1

R2

R2

Vout

Vout

VsenseIctrl

VsenseIctrl

Rsense

Rsense

Iout

Iout

In the above application schematic, the device is used on the secondary side of a flyback

adapter (or battery charger) to provide an accurate control of voltage and current. The

above feedback loop is made with an optocoupler.

4.2 Voltage and current control

4.2.1 Voltage control

The voltage loop is controlled via a first transconductance operational amplifier, the voltage

divider R

choose the values of R1 and R2 resistors using Equation 1:

Equation 1

, R2, and the optocoupler which is directly connected to the output. Its possible to

1

a)

b)

Ric2

Ric2

)RR(VV+

⋅=

refout

⋅=

21

21

R

2

)VV(RR−

refout

V

ref

where Vout is the desired output voltage.

As an example, with R1 = 100 kΩ and R2 = 27 kΩ, V

8/15

OUT

= 5.7 V

TSM1052 Application information

=

⋅

⋅

=

4.2.2 Current control

The current loop is controlled via the second trans-conductance operational amplifier, the

sense resistor Rsense, and the optocoupler. The control equation verifies:

Equation 2

where I

a)

b)

is the desired limited current, and V

lim

R =

sense

V

sense

I

lim

SENSE

VIR

senselimsense

is the threshold voltage for the current

control loop.

As an example, with I

= 1 A, V

lim

= 200 mV, then R

SENSE

SENSE

= 200 mΩ.

Note: The Rsense resistor should be chosen taking into account the maximum dissipation (P

through it during full load operation.

Equation 3

IVP

limsenselim

As an example, with I

= 1 A, and V

lim

= 200 mV, P

sense

= 200 mW.

lim

Therefore, for most adapter and battery charger applications, a quarter-watt, or half-watt

resistor is sufficient. V

threshold is made internally by a voltage divider tied to the V

SENSE

voltage reference. Its middle point is tied to the positive input of the current control

operational amplifier, and its foot is to be connected to lower potential point of the sense

resistor as shown in

Figure 15 on page 8. The resistors of this voltage divider are matched

to provide the best possible accuracy. The current sinking outputs of the two

transconductance operational amplifiers are common (to the output of the IC). This makes

an ORing function which ensures either the voltage control or the current control, driving the

optocoupler's photodiode to transmit the feedback to the primary side.

lim

)

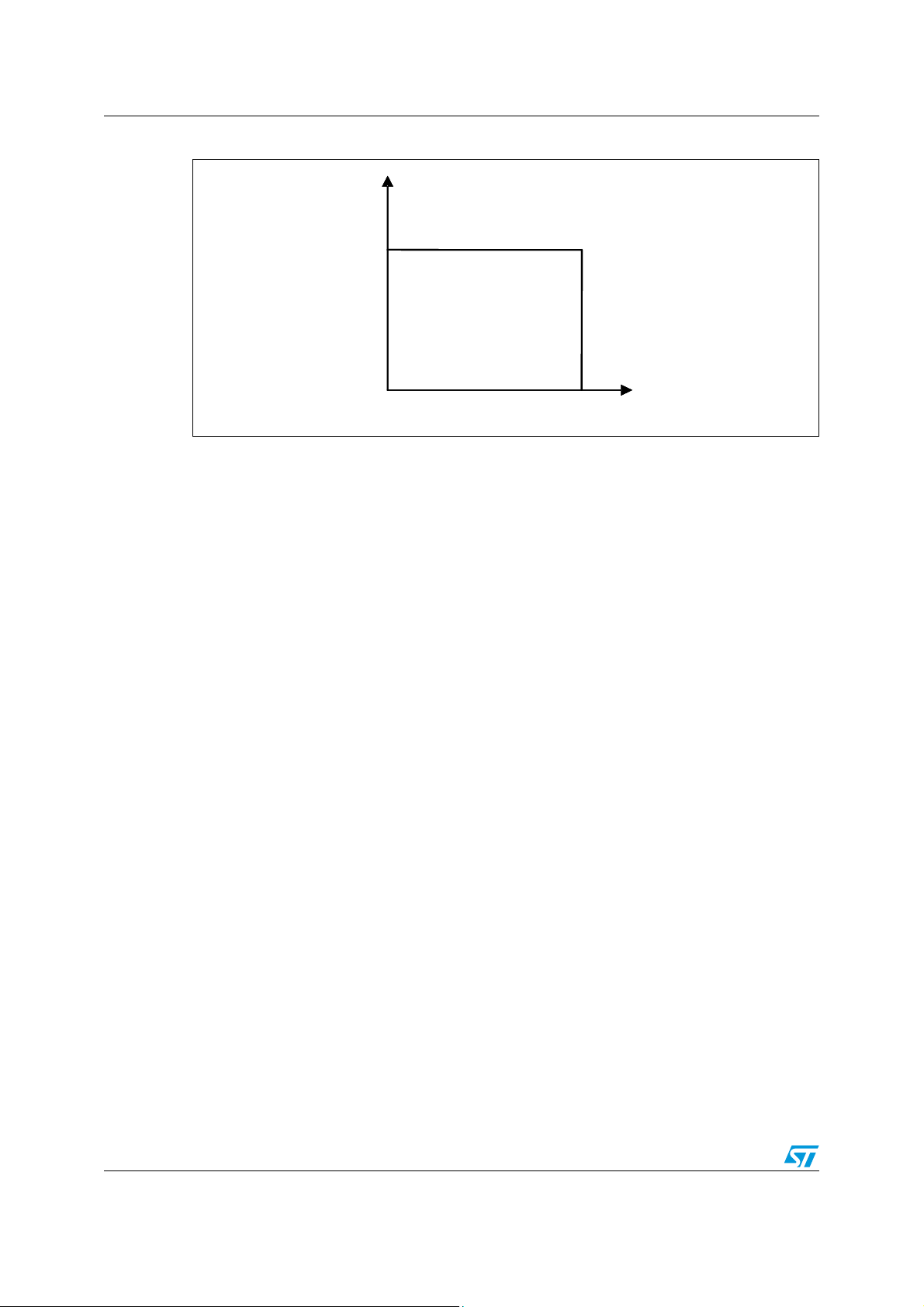

ref

The relation between the controlled current and the controlled output voltage can be

described with a square characteristic as shown in the following V/I output-power diagram.

(with the power supply of the device indipendent of the output voltage)

9/15

Application information TSM1052

Figure 16. Output voltage versus output current

Vout

Vout

Voltage regulation

Voltage regulation

Current regulation

Current regulation

( Vcc of the device independent of output voltage)

( Vcc of the device independent

Iout

Iout

4.3 Compensation

The voltage control transconductance operational amplifier can be fully compensated. Both

of its output and negative input are directly accessible for external compensation

components.

An example of a suitable compensation network is shown in

capacitor C

= 2.2 nF and a resistor R

VC1

= 470 kΩ in series.

CV1

The current-control transconductance operational amplifier can be fully compensated. Both

its output and negative input are directly accessible for external compensation components.

An example of a suitable compensation network is shown in

capacitor C

= 2.2 nF and a resistor R

IC1

= 22 kΩ in series. In order to increase the

IC1

stability of the application it is suggested to add a resistor in series with the optocoupler. An

example of a suitable R

value could be 330 Ω in series with the optocoupler.

LED

4.4 Start up and short circuit conditions

Under start-up or short-circuit conditions if the device is supplied from SMPS output and the

output voltage is lower than Vcc minimum the current regulation is not guaranteed.

Therefore, the current limitation can only be ensured by the primary PWM module, which

should be chosen accordingly.

If the primary current limitation is considered not to be precise enough for the application,

then a sufficient supply for the device has to be ensured under any condition. It would then

be necessary to add some circuitry to supply the chip with a separate power line. This can

be achieved in numerous ways, including an additional winding on the transformer.

The following schematic shows how to realize a low-cost power supply for the device (with

no additional windings).

Figure 15. It consists of a

Figure 15. It consists of a

10/15

TSM1052 Application information

Figure 17. Application circuit able to supply the device even with V

Vcc

Vcc

Vcc

6

6

6

+

+

+

-

-

-

+

+

+

-

-

-

54

54

54

VsenseIctrl

VsenseIctrl

VsenseIctrl

Iout

Iout

Ric2

Ric2

OUT

OUT

OUT

3

3

3

Vctrl

Vctrl

Vctrl

1

1

1

GND

GND

GND

2

2

2

Rled

Rled

Cvc1

Cvc1

Ric1

Ric1

Cic1

Cic1

Rvc1

Rvc1

Rs

Rs

Ds

Ds

Cs

Cs

TSM1052

TSM1052

TSM1052

1.210 V

1.210 V

1.210 V

+

+

+

200 mV

200 mV

200 mV

Rsense

Rsense

OUT

R1

R1

R2

R2

= 0

Vout

Vout

11/15

Package mechanical data TSM1052

5 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect. The category of

second Level Interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com.

12/15

TSM1052 Package mechanical data

Table 6. SOT23-6 mechanical data

mm. inch

Dim.

Min Typ Max Min Typ Max

A 0.9 1.45 0.035 0.057

A1 0 0.1 0 0.0039

A2 0.9 1.3 0.035 0.0512

b 0.35 0.5 0.014 0.02

c 0.09 0.2 0.004 0.008

D 2.8 3.05 0.11 0.120

E 1.5 1.75 0.059 0.0689

e 0.95 0.037

H 2.6 3 0.102 0.118

L 0.1 0.6 0.004 0.024

θ 0 10° 0 10°

Note: Dimensions per JEDEC MO178AB

Figure 18. Package dimensions

13/15

Revision history TSM1052

6 Revision history

Table 7. Document revision history

Date Revision Changes

20-Feb-2007 1 Initial release.

07-Feb-2008 2 Updated: Section 5 on page 12

14/15

TSM1052

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

15/15

Loading...

Loading...