TS922

Rail-to-Rail High Output Current Dual Operational Amplifier

■ Rail-to-rail input and output

■ Low noise: 9nV/

√Hz

■ Low distortion

■ High output current: 80mA

(able to drive 32Ω loads)

■ High-speed: 4MHz, 1V/µs

■ Operating from 2.7V to 12V

■ Low input offset voltage: 900µV max

(TS922A)

■ ESD Internal protection: 2kV

■ Latch-up immunity

■ Macromodel included in this specification

■ Dual version available in flip-chip package

Description

The TS922 is a rail-to-rail dual BiCMOS

operational amplifier optimized and fully specified

for 3V and 5V operation.

The device’s high output current allows low-load

impedances to be driven.

Very low noise, low distortion, low offset and a

high output current capability make this device an

excellent choice for high quality, low voltage or

battery operated audio systems.

The device is stable for capacitive loads up to

500pF.

J

TS922IJ

(Flip-chip)

N

DIP-8

(Plastic Package)

D

SO-8

(Plastic Micropackage)

P

TSSOP8

(Thin Shrink Small Outline Package)

Applications

■ Headphone amplifier

■ Piezoelectric speaker driver

■ Sound cards, multimedia systems

■ Line driver, actuator driver

■ Servo amplifier

■ Mobile phone and portable equipment

■ Instrumentation with low noise as key

factor

Order Codes

Part Number Temperature Range Package Packaging

TS922IN/AIN

TS922ID/IDT/AID/AIDT SO Tube or Tape & Reel

TS922IPT/TS922AIPT

TS922IJT Flip-Chip Tape & Reel

May 2005 Revision 3 1/16

-40°C, +125°C

(Thin Shrink Outline Package)

DIP Tube

TSSOP

Tape & Reel

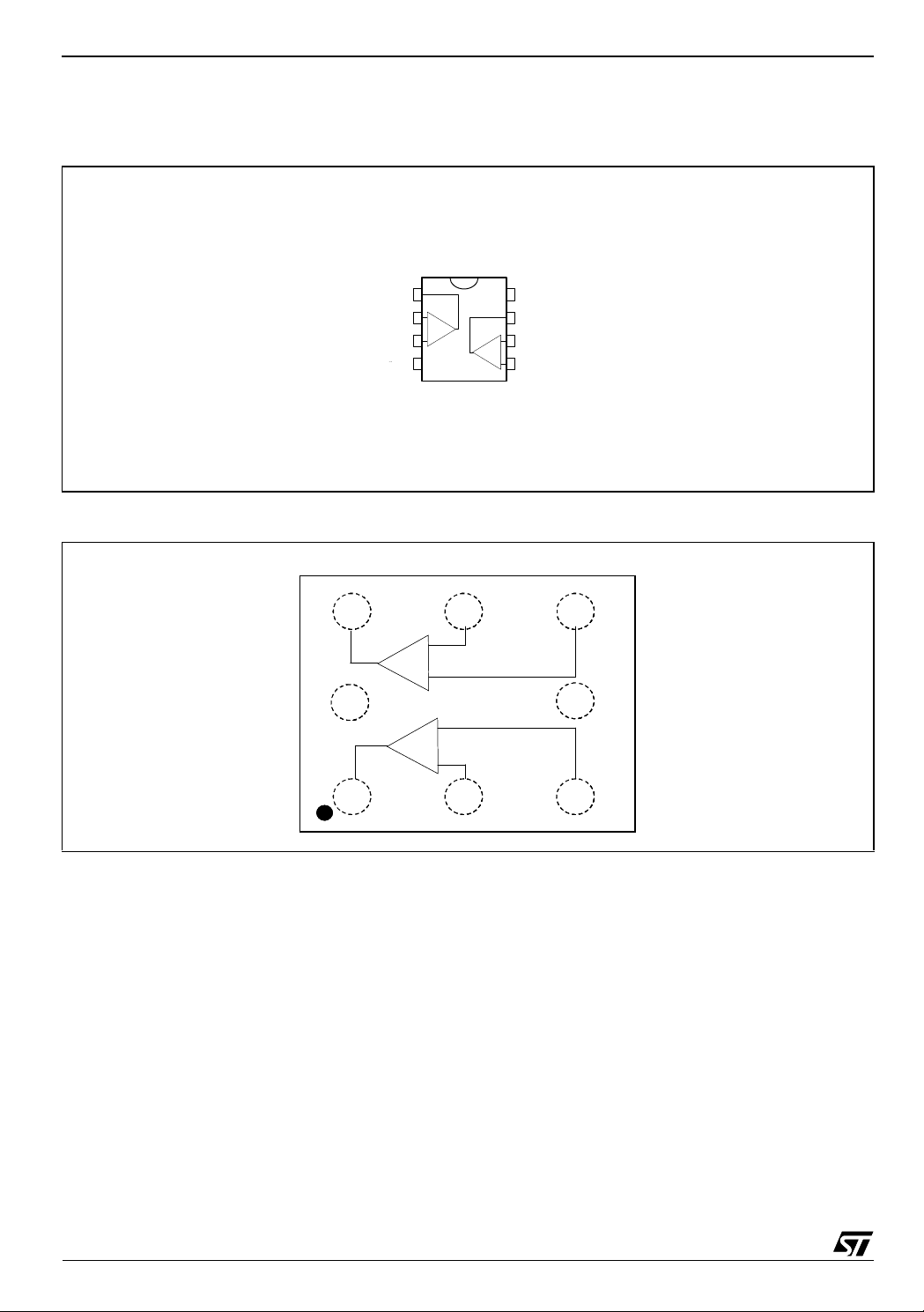

TS922 Pin Diagrams

1 Pin Diagrams

Figure 1: Pin connections (top view)

Output 1

Inverting Input 1

Non-inverting Input 1

1

2

-

+

3

V

45

CC

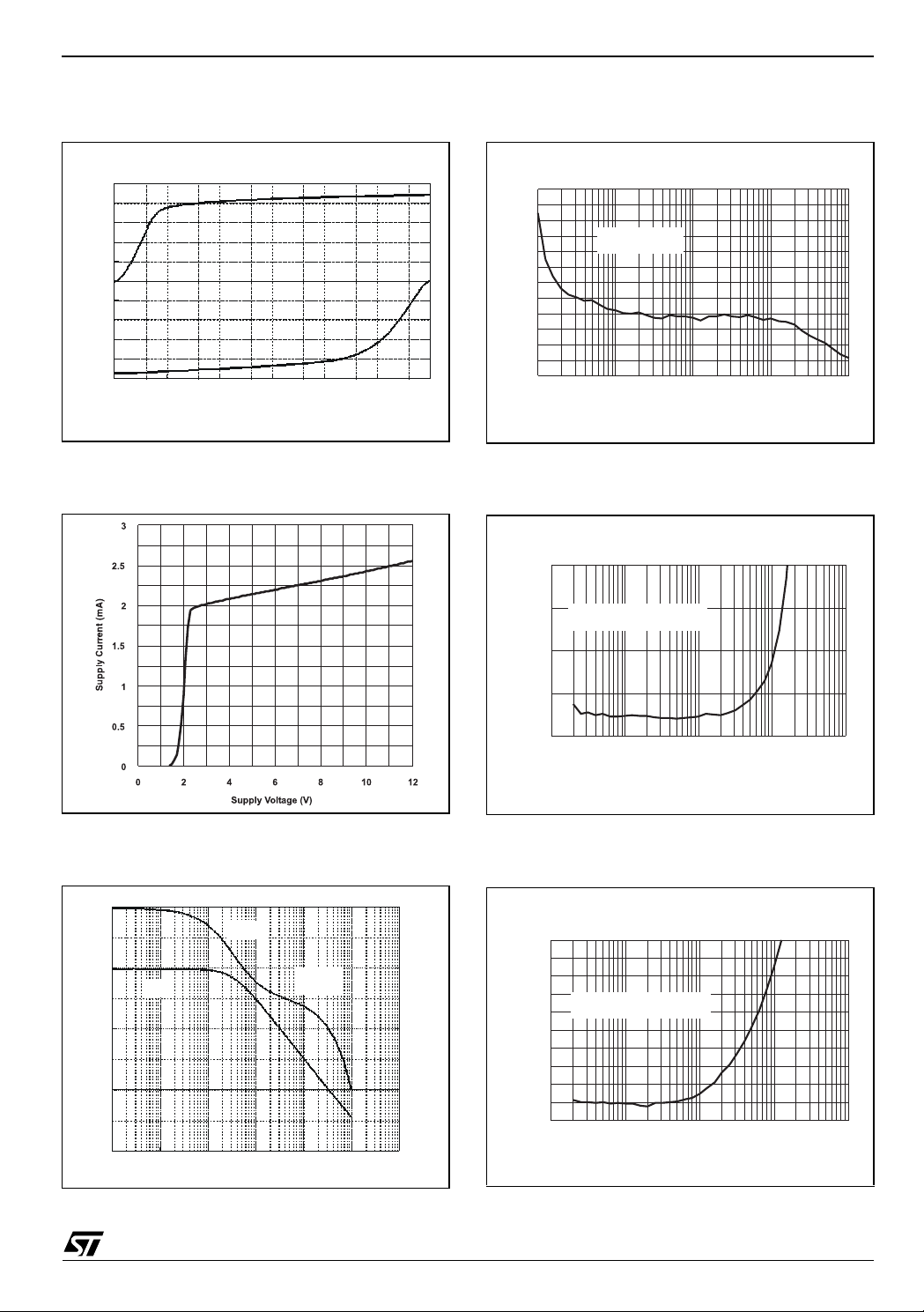

Figure 2: Pin-out for flip-chip package (top view)

OUT2 -IN2 +IN2

OUT2 -IN2 +IN2

-

-

+

+

VCC+

VCC+

+

+

-

-

V

8

Output 2

7

-

Inverting Input 2

6

+

Non-inverting Input 2

CC

+

GND

GND

+IN1-IN1OUT1

+IN1-IN1OUT1

2/16

Absolute Maximum Ratings TS922

2 Absolute Maximum Ratings

Table 1: Key parameters and their absolute maximum ratings

Symbol Parameter Value Unit

V

T

Supply voltage

CC

V

Differential Input Voltage

id

V

Input Voltage

in

Storage Temperature

stg

Thermal Resistance Junction to Ambient

SO8

R

TSSOP8 120

thja

DIP8 85

Flip Chip 90

T

Maximum Junction Temperature

j

HBM: Human Body Model

ESD

MM: Machine Model

CDM: Charged Device Model 1.5 kV

Output Short Circuit Duration

Latch-up Immunity 200 mA

Soldering Temperature (10sec), leaded version 250 °C

Soldering Temperature (10sec), unleaded version 260 °C

1) All voltages values, except differential voltage are with respect to network ground terminal.

2) Differential voltages are the non-inverting input terminal with respect to the inverting input terminal. If Vid > ±1V, the maximum input current must not exceed ±1mA. In this case (Vid > ±1V) an input serie resistor must be added to limit input current.

3) Do not exceed 14V.

4) Human body model, 100pF discharged through a 1.5kΩ resistor into pin of device.

5) Machine model ESD, a 200pF cap is charged to the specified voltage, then discharged directly into the IC with no external series resistor

(internal resistor < 5

6) There is no short-circuit protection inside the device: short-circuits from the output to V

output current is approximately 80mA, independent of the magnitude of V

circuits on all amplifiers.

1

2

3

4

5

Ω), into pin to pin of device.

14 V

±1 V

VDD-0.3 to VCC+0.3

-65 to +150 °C

125

150 °C

2kV

100 V

see note

can cause excessive heating. The maximum

. Destructive dissipation can result from simultaneous short-

cc

cc

6

V

°C/W

Table 2: Operating conditions

Symbol Parameter Value Unit

V

V

T

Supply voltage

CC

Common Mode Input Voltage Range

icm

Operating Free Air Temperature Range

oper

2.7 to 12 V

-0.2 to VCC +0.2

V

DD

-40 to +125 °C

V

3/16

TS922 Electrical Characteristics

3 Electrical Characteristics

Table 3: VCC = +3V, VDD = 0V, V

= VCC/2, T

icm

= 25°C, RL connected to Vcc/2 (unless otherwise

amb

specified)

Symbol Parameter Min. Typ. Max. Unit

Input Offset Voltage TS922

Input Offset voltage TS922A

Input Offset Voltage TS922IJ (Flip Chip)

V

io

T

≤ T

≤ T

TS922

max.

≤ T

TS922A

max.

≤ T

TS922IJ (Flip Chip)

max.

2

130nA

15 100 nA

DV

min.

min.

min.

≤ T

≤ T

amb

amb

amb

T

T

Input Offset Voltage Drift

io

Input Offset Current

I

io

Vout = Vcc/2

Input Bias Current

I

ib

Vout = Vcc/2

High Level Output Voltage

R

= 10k

V

OH

L

R

= 600Ω

L

RL = 32Ω

2.90

2.87

2.63

Low Level Output Voltage

R

= 10k

V

OL

A

I

cc

GBP

L

R

= 600Ω

L

RL = 32Ω

Large Signal Voltage Gain (V

R

= 10k

L

vd

R

= 600Ω

L

RL = 32Ω

Total Supply Current

no load, V

out

= V

Gain Bandwidth Product

(R

= 600Ω)

L

cc/2

= 2Vpk-pk)

out

180

200

35

16

23mA

4MHz

CMR Common Mode Rejection Ratio 60 80 dB

SVR

Supply Voltage Rejection Ratio

= 2.7 to 3.3V

V

cc

I

Output Short Circuit Current

o

60 85

50 80 mA

SR Slew Rate 0.7 1.3 V/

Phase Margin at Unit Gain

φm

G

m

e

n

THD

C

s

= 600Ω, CL =100pF

R

L

Gain Margin

R

= 600Ω, CL =100pF

L

Equivalent Input Noise Voltage

f = 1kHz

Total Harmonic Distortion

= 2Vpk-pk, F = 1kHz, Av = 1, RL =600Ω

V

out

Channel Separation

68 Degrees

12 dB

9

0.005 %

120 dB

3

0.9

1.5

5

1.8

2.5

µV/°C

50

100

mV

V

mV

V/mV

dB

µs

nV

-----------Hz

4/16

Electrical Characteristics TS922

Table 4: Electrical characteristics VCC = 5V, V

to V

/2 (unless otherwise specified)

cc

= 0V, V

DD

= Vcc/2, T

icm

= 25°C, RL connected

amb

Symbol Parameter Min. Typ. Max. Unit

V

V

DV

V

Input Offset Voltage TS922

Input Offset voltage TS922A

Input Offset Voltage TS922IJ (Flip Chip)

io

T

≤ T

≤ T

min.

amb

max.

TS922

TS922A

TS922IJ (Flip Chip)

Input Offset Voltage TS922IJ (flip chip)

io

T

≤ T

≤ T

min.

amb

Input Offset Voltage Drift

io

Input Offset Current

I

io

Vout = Vcc/2

Input Bias Current

I

ib

Vout = Vcc/2

TS922IJ

max.

High Level Output Voltage

R

= 10k

OH

L

R

= 600Ω

L

RL = 32Ω

2

130nA

15 100 nA

4.90

4.85

4.4

3

0.9

1.5

5

1.8

2.5

1.5

2.5

µV/°C

Low Level Output Voltage

V

OL

A

vd

I

cc

GBP

= 10k

L

R

= 600Ω

L

RL = 32Ω

Large Signal Voltage Gain (V

RL= 10k

R

= 600Ω

L

RL = 32Ω

Total Supply Current

no load, V

out

= V

cc/2

Gain Bandwidth Product

(R

= 600Ω)

L

= 2Vpk-pk)

out

300

200

35

16

23mA

4MHz

50

120

R

CMR Common Mode Rejection Ratio 60 80 dB

SVR

Supply Voltage Rejection Ratio

= 4.5 to 5.5V

V

cc

I

Output Short Circuit Current

o

60 85 dB

50 80 mA

SR Slew Rate 0.7 1.3 V/

φm

G

THD

Phase Margin at Unit Gain

= 600Ω, CL =100pF

R

L

Gain Margin

m

R

= 600Ω, CL =100pF

L

Equivalent Input Noise Voltage

e

n

f = 1kHz

Total Harmonic Distortion

V

= 2Vpk-pk, F = 1kHz, Av = 1, RL =600Ω

out

C

Channel Separation

s

68 Degrees

12 dB

9

0.005 %

120 dB

mV

mV

V

mV

V/mV

µs

nV

-----------Hz

5/16

TS922 Electrical Characteristics

Table 5: Electrical characteristics for V

= 3V, V

CC

= 0V, RL, CL connected to VCC/2, T

DD

amb

(unless otherwise specified)

Symbol Conditions Value Unit

V

A

I

CC

V

icm

V

OH

V

OL

I

sink

I

source

GBP

SR

φm

io

vd

RL = 10kΩ

No load, per operator

RL = 10kΩ

RL = 10kΩ

VO = 3V

VO = 0V

R

= 600kΩ

L

R

= 10kΩ, CL = 100pF

L

R

= 600kΩ

L

0mV

200 V/mV

1.2 mA

-0.2 to 3.2 V

2.95 V

25 mV

80 mA

80 mA

4MHz

1.3 V/

68 Degrees

= 25°C

µs

6/16

Electrical Characteristics TS922

3

O

Sh

Ci

i

C

(

A)

60

180

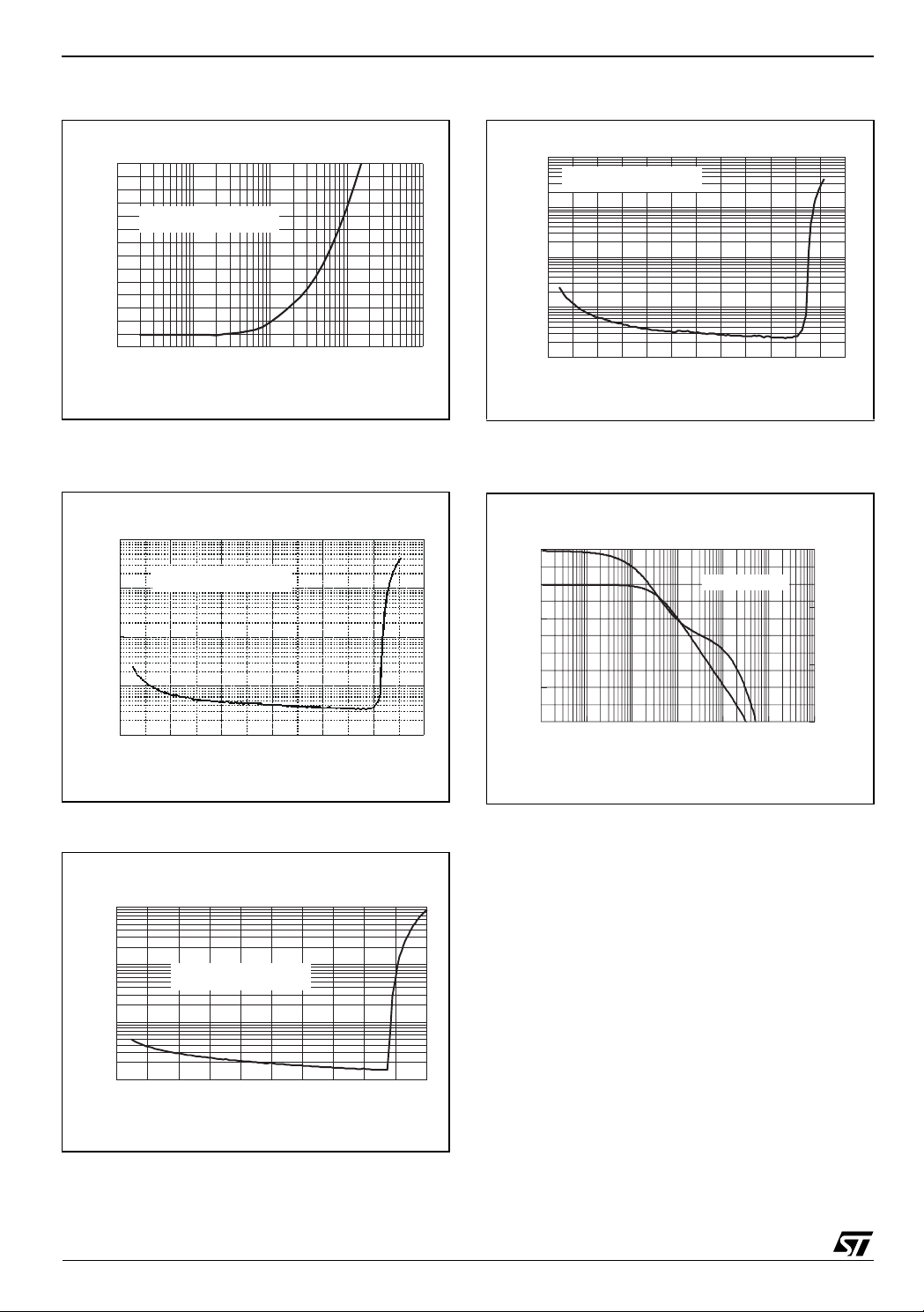

Figure 3: Output Short Circuit Current vs.

Output Voltage

100

80

60

m

40

urrent

20

t

0

rcu

-20

ort-

-40

utput

-60

-80

-100

00,511,522,5

Sink

Vcc=0/3V

Source

Output Voltage (V)

Figure 4: Total supply current vs. Supply

voltage

Figure 6: Equivalent Input Noise Voltage vs.

Frequency

30

25

20

15

10

5

Equivalent Input Noise (nV/sqrt(Hz)

0

0.01 0.1 1 10 100

VCC=±1.5V

R

=100Ω

L

Frequency (kHz)

Figure 7: THD + Noise vs. Frequency

0.02

0.015

0.01

THD+Noise (%)

0.005

RL=2k Vo=10Vpp

V

=±6V A v= 1

CC

0

Figure 5: Voltage Gain And Phase vs.

0.01 0.1 1 10 100

Figure 8: THD + Noise vs. Frequency

Frequency (kHz)

Frequency

phase

40

gain

20

Gain ( dB)

0

-20

1E+02 1E+03 1E+04 1E +05 1E+06 1E+07 1E+08

Frequency (Hz)

Rl=10k

Cl=100pF

120

60

Phase (Deg )

0

-60

0.04

0.032

RL=32Ω Vo=4Vpp

0.024

0.016

THD+Noise (%)

0.008

0

VCC=±2.5V Av= 1

0.01 0.1 1 10 100

Frequency (kHz)

7/16

TS922 Electrical Characteristics

2

)

Figure 9: THD + Noise vs. Frequency

0.7

0.6

0.5

0.4

0.3

THD+Noise (%)

0.2

0.1

0

RL=32Ω Vo=2Vpp

VCC=±1.5V Av= 10

0.01 0.1 1 10 100

Frequency (kHz)

Figure 10: THD + Noise vs. Output Voltage

10,000

RL=600Ω f=1kHz

V

=0/3V Av= -1

1,000

0,100

THD+Noise (%)

0,010

CC

Figure 12: THD + Noise vs. Output Voltage

10

0.1

THD+Noise (%)

0.01

0.001

RL=2kΩ f=1kHz

V

=±1.5V Av= -1

CC

1

0 0.2 0.4 0.6 0.8 1 1.2

Vout (Vrms)

Figure 13: Open Loop Gain And Phase vs.

Frequency

50

40

30

Gain(dB)

20

10

CL=500pF

180

120

60

Phase (Deg)

0,001

0 0,2 0,4 0,6 0,8 1 1,

Vout (Vrms

Figure 11: THD + Noise vs. Output Voltage

10

1

THD+Noise (%)

0.1

0.01

0 0.2 0.4 0.6 0.8 1

RL=32Ω f=1kHz

V

=±1.5V Av= -1

CC

Vout (Vrms)

0

1E+2 1E+3 1E+4 1E+5 1E+6 1E+7 1E+8

Frequency (Hz)

0

8/16

Macromodel TS922

4 Macromodel

Warning: Please consider following remarks before using this macromodel:

All models are a trade-off between accuracy and complexity (i.e. simulation time).

Macromodels are not a substitute to breadboarding; rather, they confirm the validity of a design approach

and help to select surrounding component values.

A macromodel emulates the NOMINAL performance of a TYPICAL device within SPECIFIED OPERATING

CONDITIONS (i.e. temperature, supply voltage, etc.). Thus the macromodel is often not as exhaustive as

the datasheet, its goal is to illustrate the main parameters of the product.

Data issued from macromodels used outside of its specified conditions (Vcc, Temperature, etc) or even

worse: outside of the device operating conditions (Vcc, Vicm, etc) are not reliable in any way.

** Standard Linear Ics Macromodels, 1996.

** CONNECTIONS:

* 1 INVERTING INPUT

* 2 NON-INVERTING INPUT

* 3 OUTPUT

* 4 POSITIVE POWER SUPPLY

* 5 NEGATIVE POWER SUPPLY

*

.SUBCKT TS92X 1 2 3 4 5

*

.MODEL MDTH D IS=1E-8 KF=2.664234E-16 CJO=10F

*

* INPUT STAGE

CIP 2 5 1.000000E-12

CIN 1 5 1.000000E-12

EIP 10 5 2 5 1

EIN 16 5 1 5 1

RIP 10 11 8.125000E+00

RIN 15 16 8.125000E+00

RIS 11 15 2.238465E+02

DIP 11 12 MDTH 400E-12

DIN 15 14 MDTH 400E-12

VOFP 12 13 DC 153.5u

VOFN 13 14 DC 0

IPOL 13 5 3.200000E-05

CPS 11 15 1e-9

DINN 17 13 MDTH 400E-12

VIN 17 5 -0.100000e+00

DINR 15 18 MDTH 400E-12

VIP 4 18 0.400000E+00

FCP 4 5 VOFP 1.865000E+02

FCN 5 4 VOFN 1.865000E+02

FIBP 2 5 VOFP 6.250000E-03

FIBN 5 1 VOFN 6.250000E-03

* GM1 STAGE ***************

FGM1P 119 5 VOFP 1.1

FGM1N 119 5 VOFN 1.1

RAP 119 4 2.6E+06

RAN 119 5 2.6E+06

* GM2 STAGE ***************

G2P 19 5 119 5 1.92E-02

G2N 19 5 119 4 1.92E-02

9/16

TS922 Macromodel

R2P 19 4 1E+07

R2N 19 5 1E+07

**************************

VINT1 500 0 5

GCONVP 500 501 119 4 19.38

VP 501 0 0

GCONVN 500 502 119 5 19.38

VN 502 0 0

********* orientation isink isource *******

VINT2 503 0 5

FCOPY 503 504 VOUT 1

DCOPYP 504 505 MDTH 400E-9

VCOPYP 505 0 0

DCOPYN 506 504 MDTH 400E-9

VCOPYN 0 506 0

***************************

F2PP 19 5 poly(2) VCOPYP VP 0 0 0 0 0.5

F2PN 19 5 poly(2) VCOPYP VN 0 0 0 0 0.5

F2NP 19 5 poly(2) VCOPYN VP 0 0 0 0 1.75

F2NN 19 5 poly(2) VCOPYN VN 0 0 0 0 1.75

* COMPENSATION ************

CC 19 119 25p

* OUTPUT ***********

DOPM 19 22 MDTH 400E-12

DONM 21 19 MDTH 400E-12

HOPM 22 28 VOUT 6.250000E+02

VIPM 28 4 5.000000E+01

HONM 21 27 VOUT 6.250000E+02

VINM 5 27 5.000000E+01

VOUT 3 23 0

ROUT 23 19 6

COUT 3 5 1.300000E-10

DOP 19 25 MDTH 400E-12

VOP 4 25 1.052

DON 24 19 MDTH 400E-12

VON 24 5 1.052

.ENDS;TS92X

10/16

Package Mechanical Data TS922

5 Package Mechanical Data

5.1 Flip-chip package (8 bumps) - TS922IJ

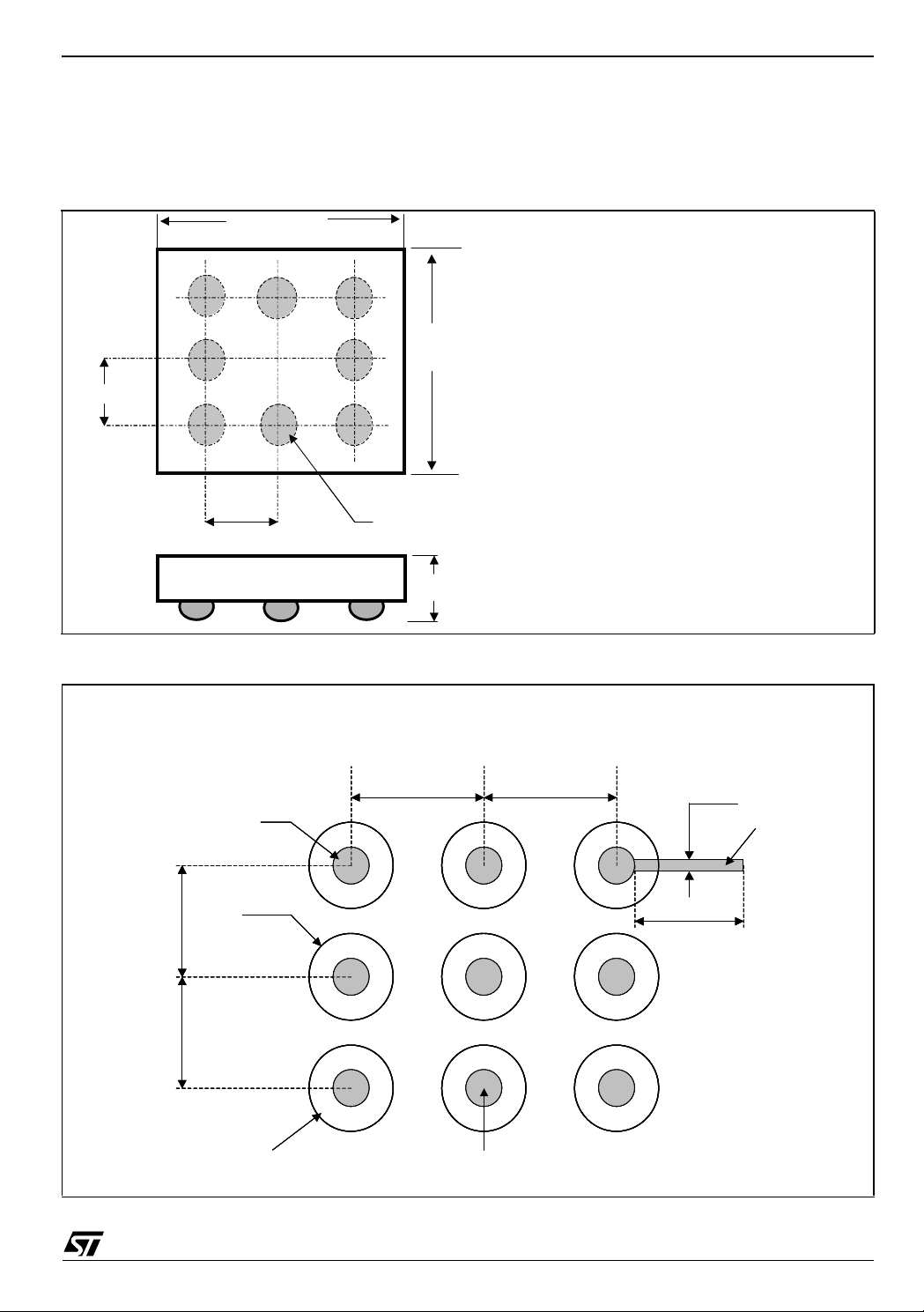

Figure 14: Top view and dimensions of 8-bump flip-chip

1600 µm

1600 µm

■ Die size: 1600µm x 1600µm ±30µm

■ Die height: 350µm ±20µm

■ Die height (including bumps): 600µm

1600 µm

500µm

500µm

500µm

500µm

1600 µm

∅ 315µm

∅ 315µm

■ Bumps diameter: 315µm ±50µm

■ Bumps height: 250µm ±40µm

■ Pitch: 500µm ±10µm

600 µm

600 µm

Figure 15: Flip-chip Footprint recommendation

TS922IJ Footprint

TS922IJ Footprint

500µm

500µm

500µm

Φ=250µm

Φ=250µm

Φ=250µm

Φ=400µm

Φ=400µm

Φ=400µm

500µm

500µm

500µm

500µm

500µm

500µm

500µm

500µm

500µm

75µm min.

75µm min.

75µm min.

100µm max.

100µm max.

100µm max.

150µm min.

150µm min.

150µm min.

Track

Track

Track

Solder mask opening

Solder mask opening

Solder mask opening

Pad in Cu 1 8µm with Flash NiAu (6µm, 0.15µm)

Pad in Cu 1 8µm with Flash NiAu (6µm, 0.15µm)

Pad in Cu 1 8µm with Flash NiAu (6µm, 0.15µm)

11/16

TS922 Package Mechanical Data

Figure 16: Flip-chip marking (top view)

BUMP 1A CORNER

BUMP 1A CORNER

LEADFREE

E

E

922

922

YWW

YWW

■ Logo: ST

■ Part Number: 922

■ Date Code: YWW

■ The dot is for marking the bump

LEADFREE

Table 6: Tape & Reel specification (top view)

1

1

A

A

User direction of feed

User direction of feed

1

1

A

A

Note: Device Orientation: The devices are oriented in the carrier pocket with bump number A1 adjacent

to the sprocket holes.

12/16

Package Mechanical Data TS922

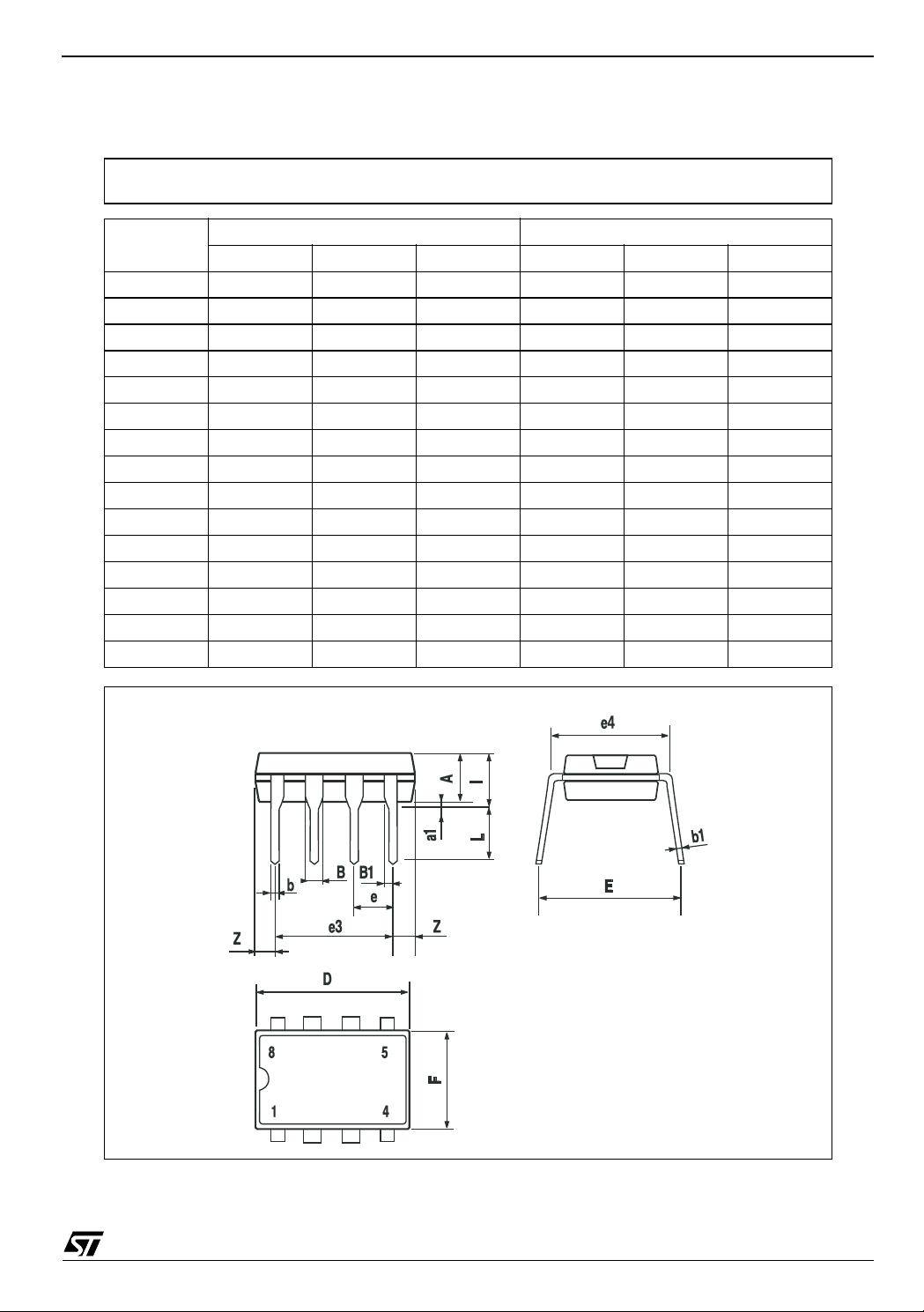

5.2 DIP8 package

Plastic DIP-8 MECHANICAL DATA

DIM.

A 3.3 0.130

a1 0.7 0.028

B 1.39 1.65 0.055 0.065

B1 0.91 1.04 0.036 0.041

b 0.5 0.020

b1 0.38 0.5 0.015 0.020

D 9.8 0.386

E 8.8 0.346

e 2.54 0.100

e3 7.62 0.300

e4 7.62 0.300

F 7.1 0.280

I 4.8 0.189

L 3.3 0.130

Z 0.44 1.6 0.017 0.063

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

P001F

13/16

TS922 Package Mechanical Data

5.3 SO8 package

SO-8 MECHANICAL DATA

DIM.

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.04 0.010

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e 1.27 0.050

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

k ˚ (max.)

ddd 0.1 0.04

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

8

14/16

0016023/C

Package Mechanical Data TS922

5.4 TSSOP8 package

TSSOP8 MECHANICAL DATA

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

A 1.2 0.047

A1 0.05 0.15 0.002 0.006

A2 0.80 1.00 1.05 0.031 0.039 0.041

b 0.19 0.30 0.007 0.012

c 0.09 0.20 0.004 0.008

D 2.90 3.00 3.10 0.114 0.118 0.122

E 6.20 6.40 6.60 0.244 0.252 0.260

E1 4.30 4.40 4.50 0.169 0.173 0.177

e 0.65 0.0256

K0˚ 8˚0˚ 8˚

L 0.45 0.60 0.75 0.018 0.024 0.030

L1 1 0.039

mm. inch

0079397/D

15/16

Revision History TS922

6 Revision History

Date Revision Description of Changes

Feb.2001 1 First Release

July 2004 2 Flip-Chip package inserted in the document

May 2005 3

Modifications on AMR Table 1 on page 3 (explanation of Vid and Vi limits,

ESD MM and CDM values added, Rthja added)

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

16/16

Loading...

Loading...