Page 1

STMPE2401

24-bit Enhanced port expander with Keypad and PWM controller

Xpander logic

Features

■ 24 GPIOs

■ Operating voltage 1.8V

■ Hardware key pad controller (8*12 matrix ma x)

■ 3 PWM (8 bit) output for LED brightness control

and blinking

■ Interrupt output (open drain) pin

■ Configurable hotkey feature on each GPIO

■ Ul tr a-l ow St an db y- mo de cu rr ent

■ Package TFBGA - 36 pins 3.6x3.6mm, pitch

0.5mm

Description

The STMPE2401 is a GPIO (General Purpose

Input / output) port expander able to interface a

Main Digital ASIC via the two-line bidirectional

bus (I2C); separate GPIO Expander IC is often

used in Mobile-Multimedia platforms to solve the

problems of the limited amounts of GPIOs usually

available on the Digital Engine.

TFBGA

The STMPE2401 offers great flexibility as each

I/Os is configurable as input, output or specific

functions; it's able to scan a keyboard, also

provides PWM outputs for brightness control in

backlight, rotator decoder interface and GPIO.

This device has been designed very low

quiescent current, and is including a wake up

feature for each I/O, to optimize the power

consumption of the IC.

Potential application of the STMPE2401 includes

portable media player, game console, mobile

phone, smart phone

Figure 1. Device summary

Part number Package Packaging

STMPE2401TBR TFBGA36 Tape and reel

May 2007 Rev 2 1/55

www.st.com

55

Page 2

Contents STMPE2401

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Pin assignment and TFBGA ball location . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 GPIO Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Pin mapping to TFBGA ( bottom view, balls up) . . . . . . . . . . . . . . . . . . . . . 9

3 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Absolute maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 I/O DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 DC input specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 DC output specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/55

Page 3

STMPE2401 Contents

6 I2C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Start condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Stop condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Acknowledge bit (ACK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4 Data input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5 Slave device address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.6 Memory addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.7 Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 System controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Identification register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 System control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.3 States of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Clocking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.1 Programming sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9 Interrupt system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.1 Register map of interrupt system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.2 Interrupt control register (ICR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.3 Interrupt enable mask register (IER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.4 Interrupt status register (ISR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.5 Interrupt enable GPIO mask register (IEGPIOR) . . . . . . . . . . . . . . . . . . . 25

9.6 Interrupt status GPIO register (ISGPIOR) . . . . . . . . . . . . . . . . . . . . . . . . 26

9.7 Programming sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 GPIO controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1 GPIO control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 GPIO alternate function register (GPAFR) . . . . . . . . . . . . . . . . . . . . . . . . 30

10.3 Hot key feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.3.1 Programming sequence for hot key . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.3.2 Minimum pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3/55

Page 4

Contents STMPE2401

11 PWM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11.1 Registers in the PWM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11.2 PWM control and status register (PWMCS) . . . . . . . . . . . . . . . . . . . . . . . 35

11.3 PWM instruction channel x (PWMICx) . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12 PWM commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

13 Keypad controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

13.1 Registers in keypad controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

13.2 KPC_col register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

13.3 KPC_row_msb register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

13.4 KPC_row_lsb register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

13.5 KPC_ctrl_msb register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

13.6 KPC_ctrl_lsb register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.7 Data registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13.7.1 Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13.7.2 Using the keypad controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

14 Rotator controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

14.1 Rotator_Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

14.2 Rotator_Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

15 Miscellaneous features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15.1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15.2 Under voltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15.3 Clock output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

16 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

17 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4/55

Page 5

STMPE2401 Block diagram

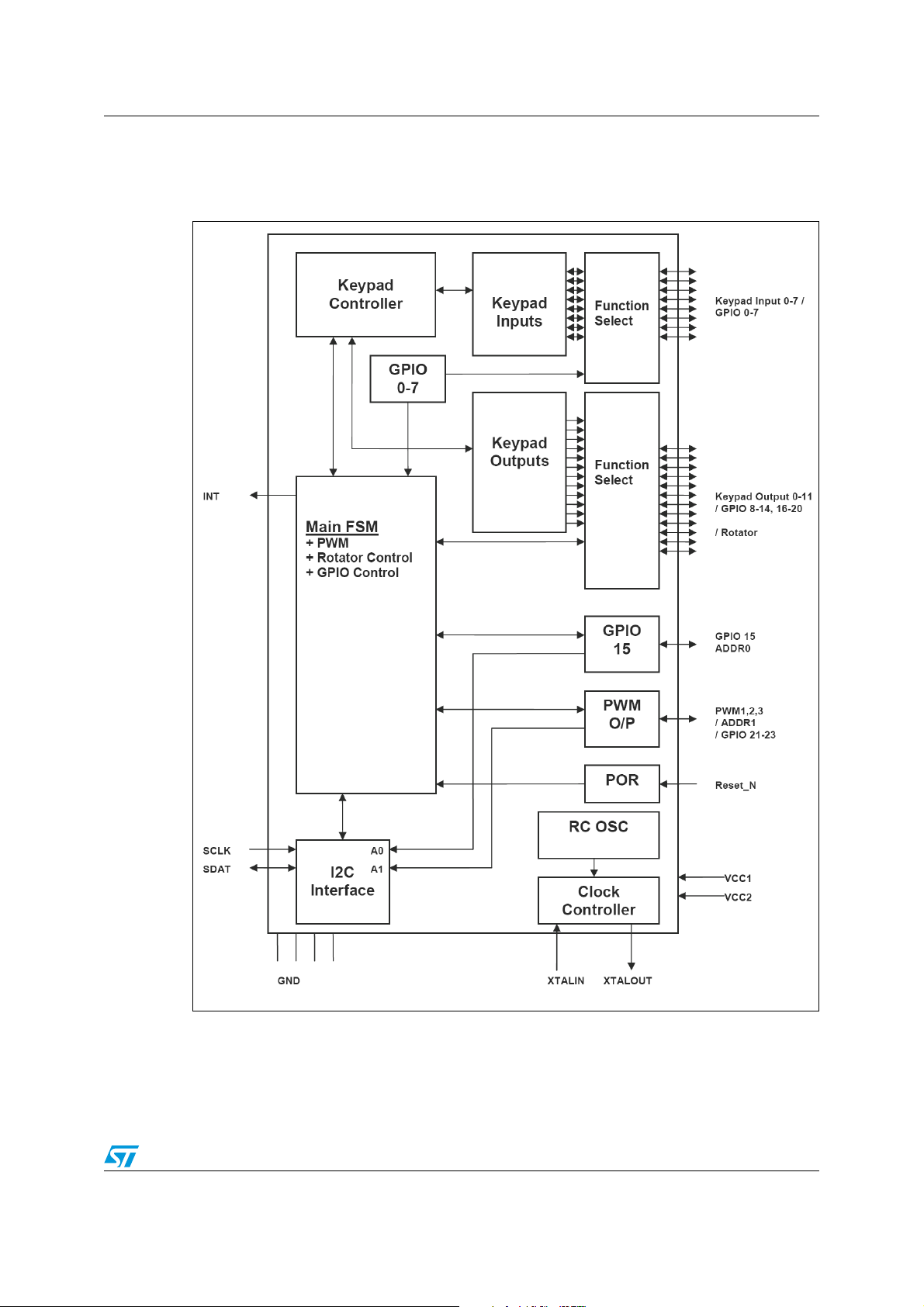

1 Block diagram

Figure 1. Block diagram

5/55

Page 6

Pin settings STMPE2401

2 Pin settings

2.1 Pin connection

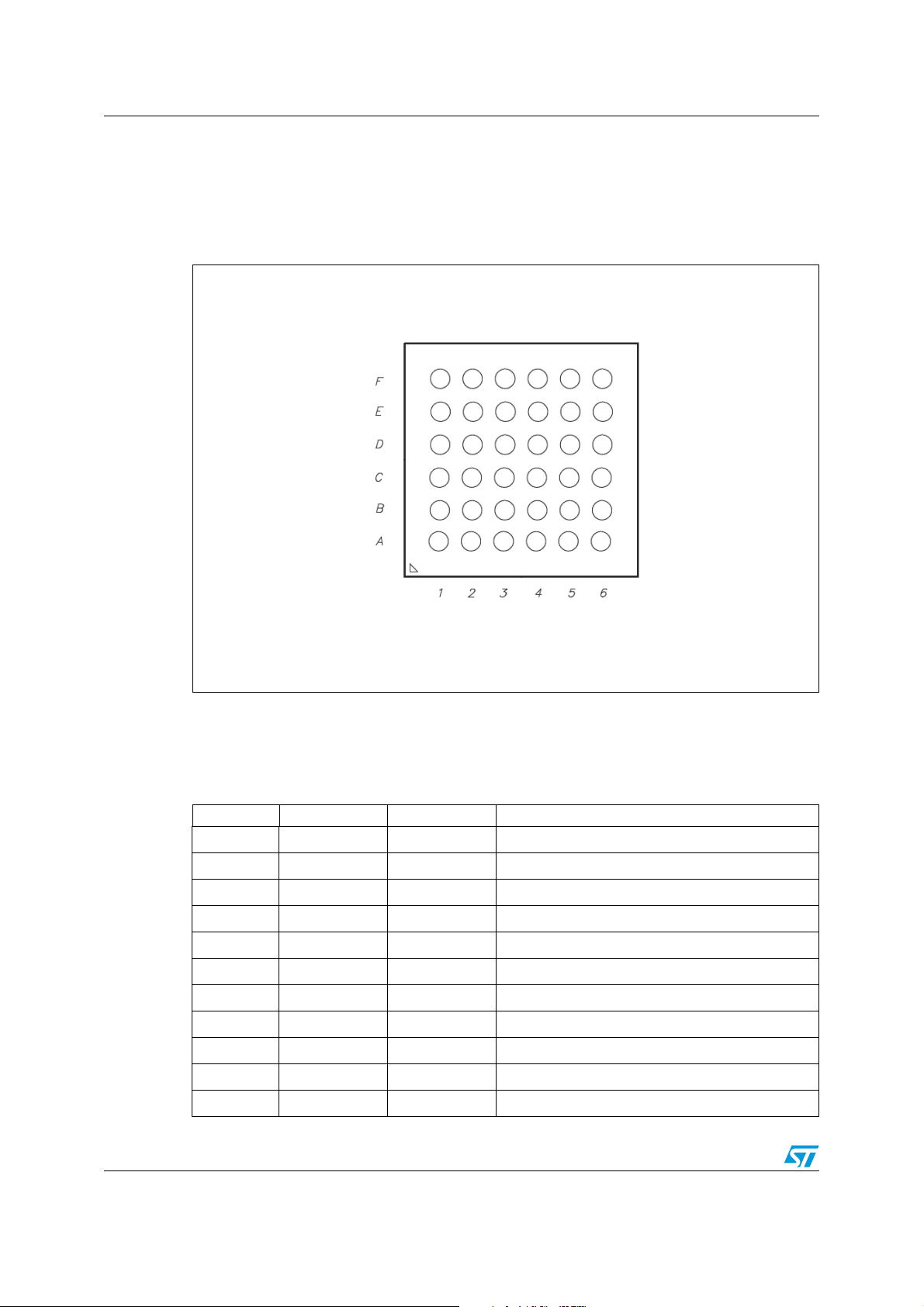

Figure 2. Pin connection

TFBGA

2.2 Pin assignment and TFBGA ball location

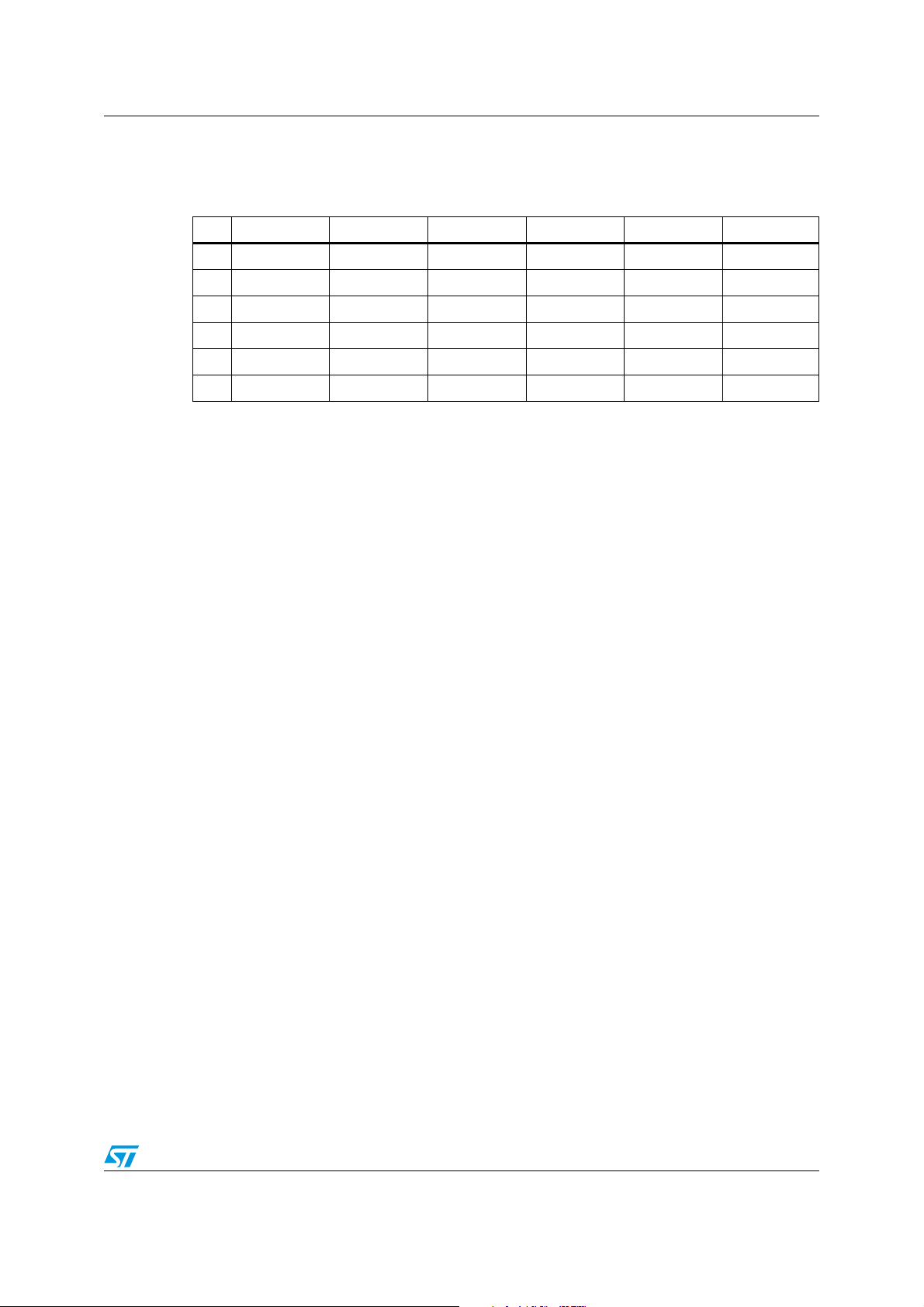

Table 1. Pin assignment

Ball Name Type Name and function

C3 GND -

C2 KP_X0 IO GPIO

C1 Reset_N I External reset input, active LOW

B1 KP_X1 IO GPIO

A1 KP_X2 IO GPIO

B2 KP_X3 IO GPIO

A2 KP_X4 IO GPIO

B3 KP_X5 IO GPIO

A3 KP_X6 IO GPIO

C4 GND -

A4 VCC1 - 1.8V Input

6/55

Page 7

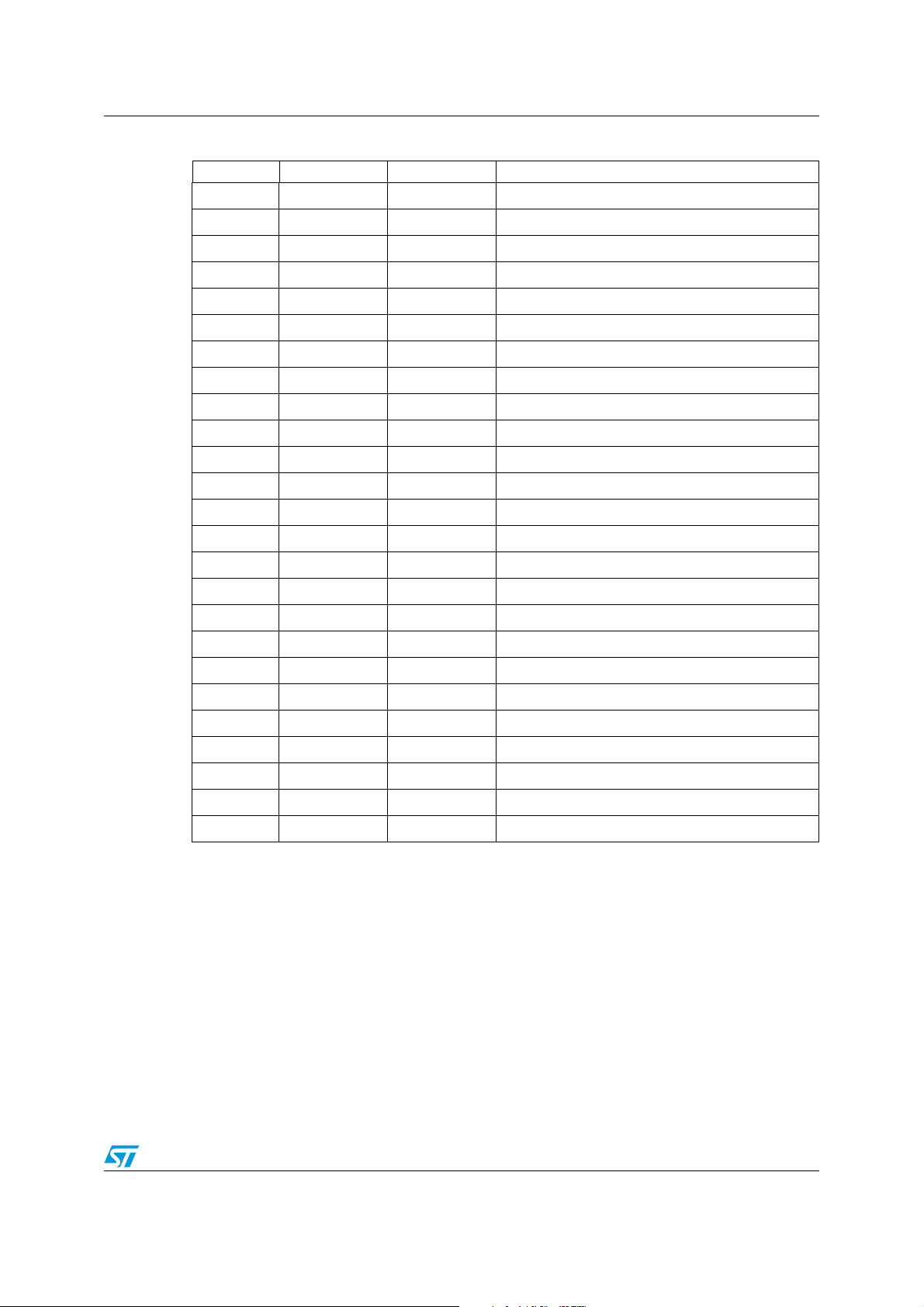

STMPE2401 Pin settings

Table 1. Pin assignment

Ball Name Type Name and function

B3 KP_X7 IO GPIO

A5 KP_Y5 IO GPIO

A6 KP_Y4 IO GPIO

B5 KP_Y3 IO GPIO

B6 KP_Y2 IO GPIO

C5 KP_Y1 IO GPIO

C6 KP_Y0 IO GPIO

D3 GND -

D6 ADDR0 IO GPIO and I2C ADDR 0 (in reset)

D5 KP_Y9 A/IO GPIO

E6 KP_Y10 A/IO GPIO

F6 KP_Y11 A/IO GPIO

E5 PWM3 A/IO GPIO and I2C ADDR 1 (in reset)

F5 PWM2 A/IO GPIO

E4 PWM1 A/IO GPIO

F4 VCC2 - 1.8V Input

D4 GND -

F3 INT O Open drain interrupt output pin

E3 KP_Y8 IO GPIO

F2 KP_Y7 IO GPIO

F1 KP_Y6 IO GPIO

E2 SDATA A I2C DATA

E1 SCLK A I2C Clock

D2 XTALIN A XTAL Oscillator or External 32KHz input

D1 XTALOUT A XTAL Oscillator

7/55

Page 8

Pin settings STMPE2401

2.3 GPIO Pin functions

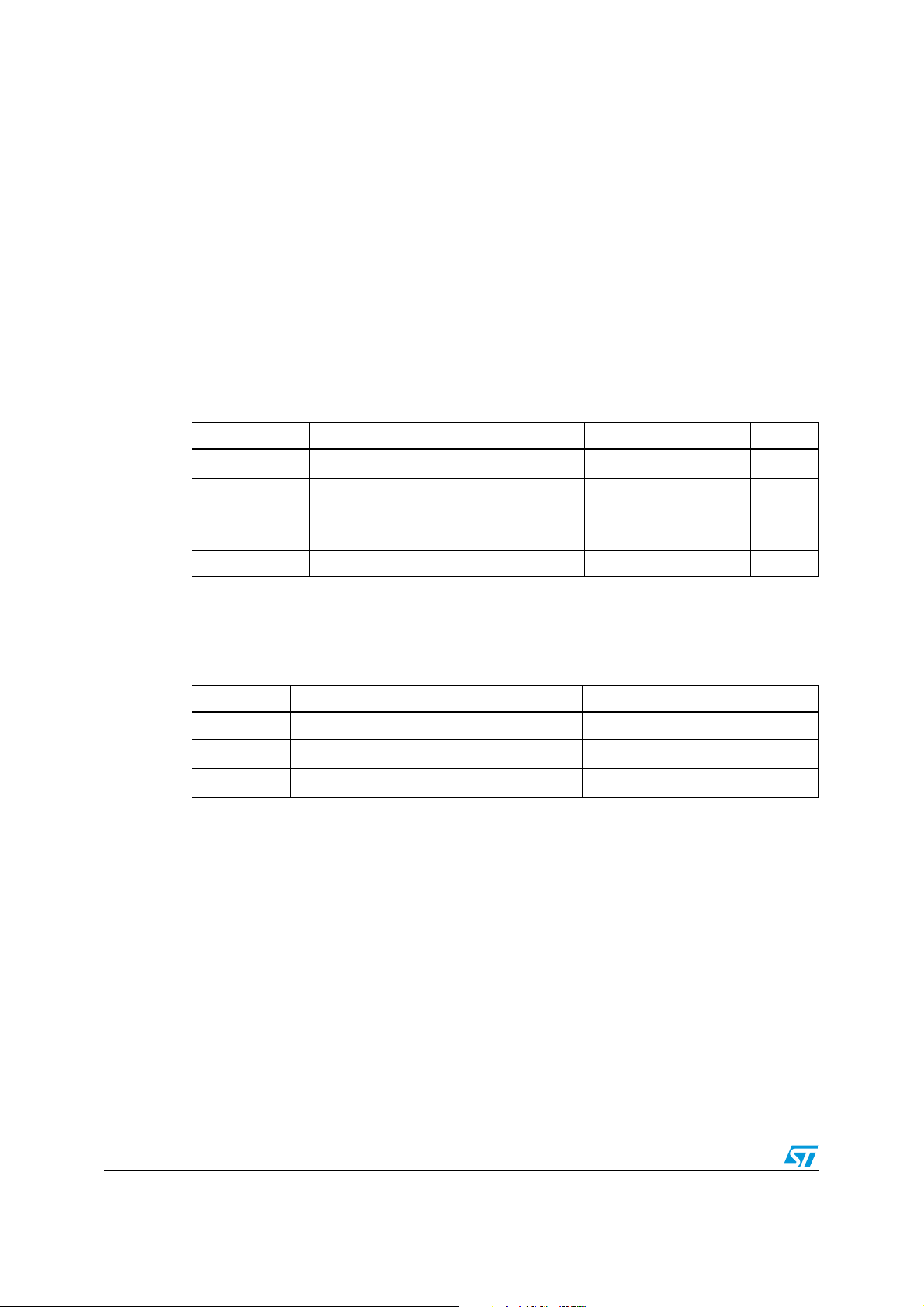

Table 2. GPIO Pin functions

Pin N° Name

2 KP_X0 GPIO 0 Keypad input 0

4 KP_X1 GPIO 1 Keypad input 1

5 KP_X2 GPIO 2 Keypad input 2

6 KP_X3 GPIO 3 Keypad input 3

7 KP_X4 GPIO 4 Keypad input 4

8 KP_X5 GPIO 5 Keypad input 5

9 KP_X6 GPIO 6 Keypad input 6

12 KP_X7 GPIO 7 Keypad input 7

13 KP_Y5 GPIO 13 Keypad output 5

14 KP_Y4 GPIO 12 Keypad output 4

15 KP_Y3 GPIO 11 Keypad output 3

16 KP_Y2 GPIO 10 Keypad output 2

Primary

Function

Alternate Function 1 Alternate Function 2 Alternate Function 3

17 KP_Y1 GPIO 9 Keypad output 1

18 KP_Y0 GPIO 8 Keypad output 0

20 ADDR0 GPIO 15

21 KP_Y9 GPIO 18 Keypad output 9 Rotator 0

22 KP_Y10 GPIO 19 Keypad output 10 Rotator 1

23 KP_Y11 GPIO 20 Keypad output 11 Rotator 2

24 PWM3 GPIO 23 Channel 3

25 PWM2 GPIO 22 Channel 2

26 PWM1 GPIO 21 Channel 1

30 KP_Y8 GPIO 17 Keypad output 8 ClkOut

31 KP_Y7 GPIO 16 Keypad output 7

32 KP_Y6 GPIO 14 Keypad output 6

8/55

Page 9

STMPE2401 Pin settings

2.4 Pin mapping to TFBGA ( bottom view, balls up)

Table 3. Pin mapping to TFBGA

ABCDEF

1 KP-X2 KP-X1 Reset_N XTALOUT SCLK KP-Y6

2 KP-X4 KP-X3 KP-X0 XTALIN SDATA KP-Y7

3 KP-X6 KP-X5 GND GND KP-Y8 INT

4 VCC KP-X7 GND GND PWM-1 VCC

5 KP-Y5 KP-Y3 KP-Y1 KP-Y9 PWM-3 PWM-2

6 KP-Y4 KP-Y2 KP-Y0 ADDR0 KP-Y10 KP-Y11

9/55

Page 10

Maximum rating STMPE2401

3 Maximum rating

Stressing the device above the rating listed in the “Absolute Maximum Ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the Operating sections of

this specification is not implied. Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality documents.

3.1 Absolute maximum rating

Table 4. Absolute maximum rating

Symbol Parameter Value Unit

V

CC

V

Input voltage on GPIO pin 2.5 V

IN

V

Input voltage on I2C pin

I2C

VESD (HBM) ESD protection on each GPIO pin 2 KV

Supply voltage 2.5 V

4.5 V

(SDATA,SCLK, INT)

3.2 Thermal data

Table 5. Thermal data

Symbol Parameter Min Typ Max Unit

R

thJA

T

A

T

J

Thermal resistance junction-ambient 100 °C/W

Operating ambient temperature -40 25 85 °C

Operating junction temperature -40 25 125 °C

10/55

Page 11

STMPE2401 Electrical specification

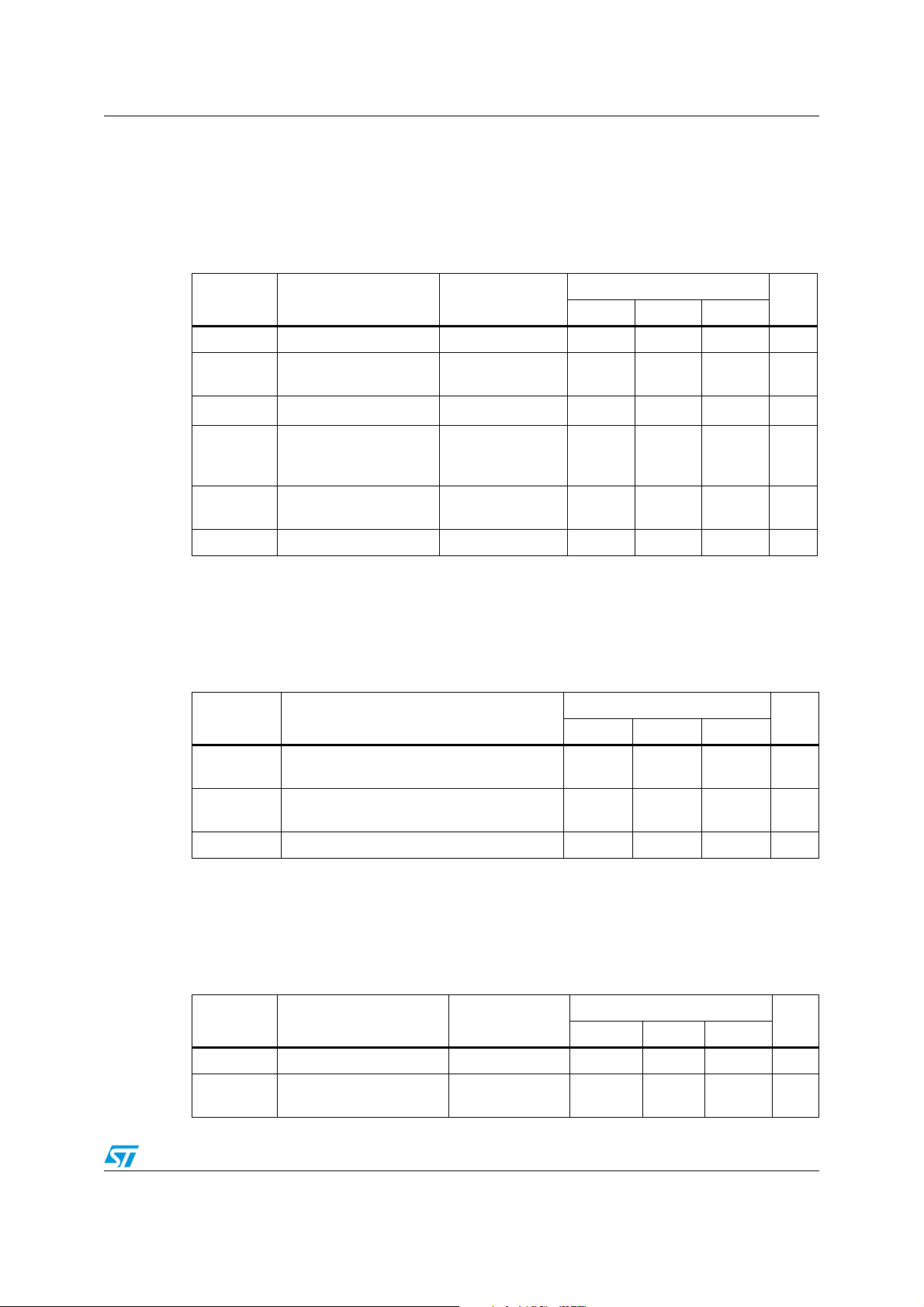

4 Electrical specification

4.1 DC electrical characteristics

Table 6. DC electrical characteristics

Symbol Parameter Test conditions

VCC1,2 1.8V supply voltage 1.65 1.8 1.95 V

I

HIBERNATE

HIBERNATE mode

current

Min. Typ. Max.

Val ue

Unit

612uA

I

SLEEP

Icc Operating current

I

_INT Open drain output

O

V_INT Voltage level at INT pin 3.6 V

SLEEP mode current 15 50 uA

(FSM working – No

peripheral activity)

current

4.2 I/O DC electrical characteristics

The 1.8V I/O complies to the EIA/JEDEC standard JESD8-7.

Table 7. I/O DC electrical characteristic

Symbol Parameter

Vil

Vih

Vhyst Schmitt trigger hysteresis 0.10 V

Low level input voltage 0.35*Vcc

High level input voltage 0.65*Vcc

0.5 1.0 mA

4mA

Val u e

Min. Typ. Max.

= 0.63

= 1.17

Unit

V

V

4.3 DC input specification

(1.55V < VDD < 1.95V)

Table 8. DC input specification

Symbol Parameter Test conditions

Vol Low level output voltage Iol = 4mA 0.45 V

Voh High level output voltage Ioh = 4mA

Val ue

Min. Typ. Max.

Vcc - 0.45

= 1.35

11/55

Unit

V

Page 12

Electrical specification STMPE2401

4.4 DC output specification

(1.55V < vdd < 1.95V)

Table 9. DC output specification

Symbol Parameter

Ipu Pull-up current Vi = 0V 15 35 65 µA

Ipd Pull-down current Vi = vdd 14 35 60 µA

Rup Equivalent pull-up resistance Vi = 0V 30 50 103.3 KΩ

Rpd Equivalent pull-down resistance Vi = vdd 32.5 50 110.7 KΩ

Test

conditions

Min. Typ. Max.

Val ue

Unit

Note: Pull-up and Pull-down characteristics

4.5 AC characteristics

Table 10. AC characteristics

Symbol Parameter

Frequency 16 32 kHz

F

O

C

Load capacitance 27 pF

L

Min. Typ. Max.

Val ue

Unit

12/55

Page 13

STMPE2401 Register map

5 Register map

All registers have the size of 8-bit. Some of the registers are composed of 2-byte to form 16bit registers. For each of the module, their registers are residing within the given address

range.

Table 11. Register map

Address Module registers Description

0x00 – 0x07

0x80 – 0x81

Clock and Power

Manager module

Clock and Power Manager register

range.

Auto-Increment

(during read/write)

Ye s

0x10 – 0x1F Interrupt Controller

module

0x30 – 0x37 PWM Controller Module PWM Controller register range Yes

0x38 – 0x3F PWM Controller register range No

0x60 – 0x67 Keypad Controller

Module

0x68 – 0x6F Keypad Controller register range No

0x70 – 0x77 Rotator Controller

Module

0x82 – 0xBF GPIO Controller Module GPIO Controller register range Yes

Interrupt Controller register range Yes

Keypad Controller register range Yes

Rotator Controller register range Yes

13/55

Page 14

I2C Interface STMPE2401

6 I2C Interface

The features that are supported by the I2C interface are as below:

2

● I

C Slave device

● SDAT and SCLK operates from 1.8V to 3.3V

● Compliant to Philip I

● Supports Standard (up to 100kbps) and Fast (up to 400kbps) modes.

● 7-bit device addressing mode

● General Call

● Start/Restart/Stop

● Address up to 4 STMPE2401 devices via I

The address is selected by the state of two pins. The state of the pins will be read upon

reset and then the pins can be configured for normal operation. The pins will have a pull-up

or down to set the address. The I2C interface module allows the connected host system to

access the registers in the STMPE2401.

2

C specification version 2.1

2

C

6.1 Start condition

A Start condition is identified by a falling edge of SDATA while SCLK is stable at high state.

A Start condition must precede any data/command transfer. The device continuously

monitors for a Start condition and will not respond to any transaction unless one is

encountered.

6.2 Stop condition

A Stop condition is identified by a rising edge of SDATA while SCLK is stable at high state.

A Stop condition terminates communication between the slave device and bus master. A

read command that is followed by NoAck can be followed by a Stop condition to force the

slave device into idle mode. When the slave device is in idle mode, it is ready to receive the

2

next I

C transaction. A Stop condition at the end of a write command stops the write

operation to registers.

6.3 Acknowledge bit (ACK)

The acknowledge bit is used to indicate a successful byte transfer. The bus transmitter

releases the SDATA after sending eight bits of data. During the ninth bit, the receiver pulls

the SDATA low to acknowledge the receipt of the eight bits of data. The receiver may leave

the SDATA in high state if it would to not acknowledge the receipt of the data.

14/55

Page 15

STMPE2401 I2C Interface

6.4 Data input

The device samples the data input on SDATA on the rising edge of the SCLK. The SDATA

signal must be stable during the rising edge of SCLK and the SDATA signal must change

only when SCLK is driven low.

6.5 Slave device address

The slave device address is a 7 address, where the least significant 2-bit are programmable.

These 2-bit values will be loaded in once upon reset and after that these 2 pins no longer be

needed with the exception during General Call. Up to 4 STMPE2401 devices can be

connected on a single I

Table 12. Slave device address

ADDR 1 ADDR 0 Address

0 0 0x84

0 1 0x86

1 0 0x88

11 0x8A

2

C bus.

6.6 Memory addressing

For the bus master to communicate to the slave device, the bus master must initiate a Start

condition and followed by the slave device address. Accompanying the slave device

address, there is a Read/Write

operation.

If a match occurs on the slave device address, the corresponding device gives an

acknowledgement on the SDA during the 9

from the bus by not responding to the transaction.

bit (R/W). The bit is set to 1 for Read and 0 for Write

th

bit time. If there is no match, it deselects itself

15/55

Page 16

I2C Interface STMPE2401

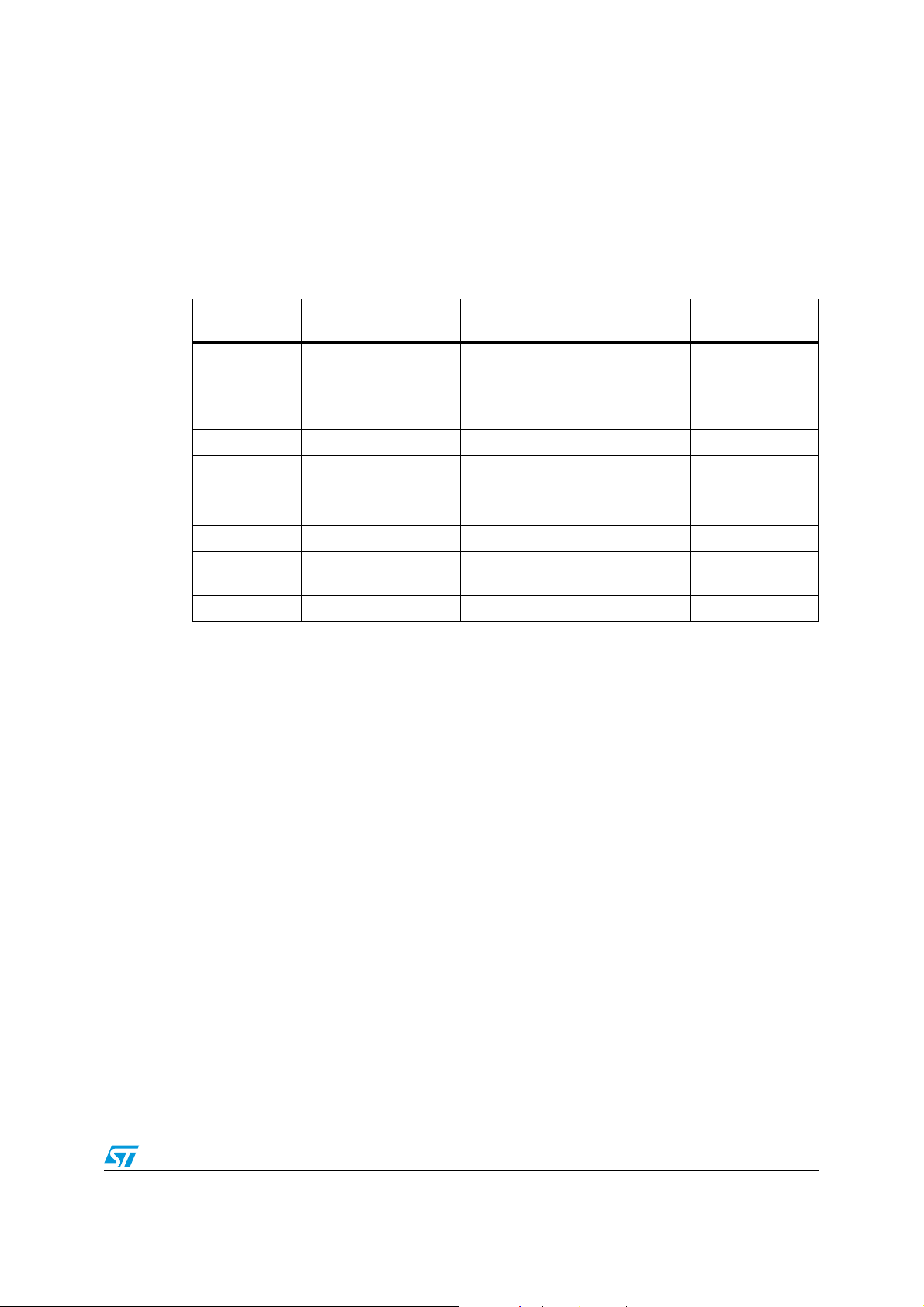

6.7 Operation modes

Table 13. Operating modes

Mode Bytes Programming sequence

START, Device Address, R/W

= 0, Register Address to be read

RESTART, Device Address, R/W

If no STOP is issued, the Data Read can be continuously preformed. If the register

Read ≥1

Write ≥1

address falls within the range that allows address auto-increment, then register

address auto-increments internally after every byte of data being read. For register

address that falls within a non-incremental address range, the address will be kept

static throughout the entire read operations. Refer to the Memory Map table for the

address ranges that are auto and non-increment. An example of such a nonincrement address is FIFO.

START, Device Address, R/W

If no STOP is issued, the Data Write can be continuously performed. If the register

address falls within the range that allows address auto-increment, then register

address auto-increments internally after every byte of data being written in. For

register address that falls within a non-incremental address range, the address will

be kept static throughout the entire write operations. Refer to the Memory Map table

for the address ranges that are auto and non-increment. An example of a nonincrement address is Data Port for initializing the PWM commands.

=0, Register Address to be written, Data Write, STOP

Figure 3. Master/slave operation modes

= 1, Data Read, STOP

16/55

Page 17

STMPE2401 I2C Interface

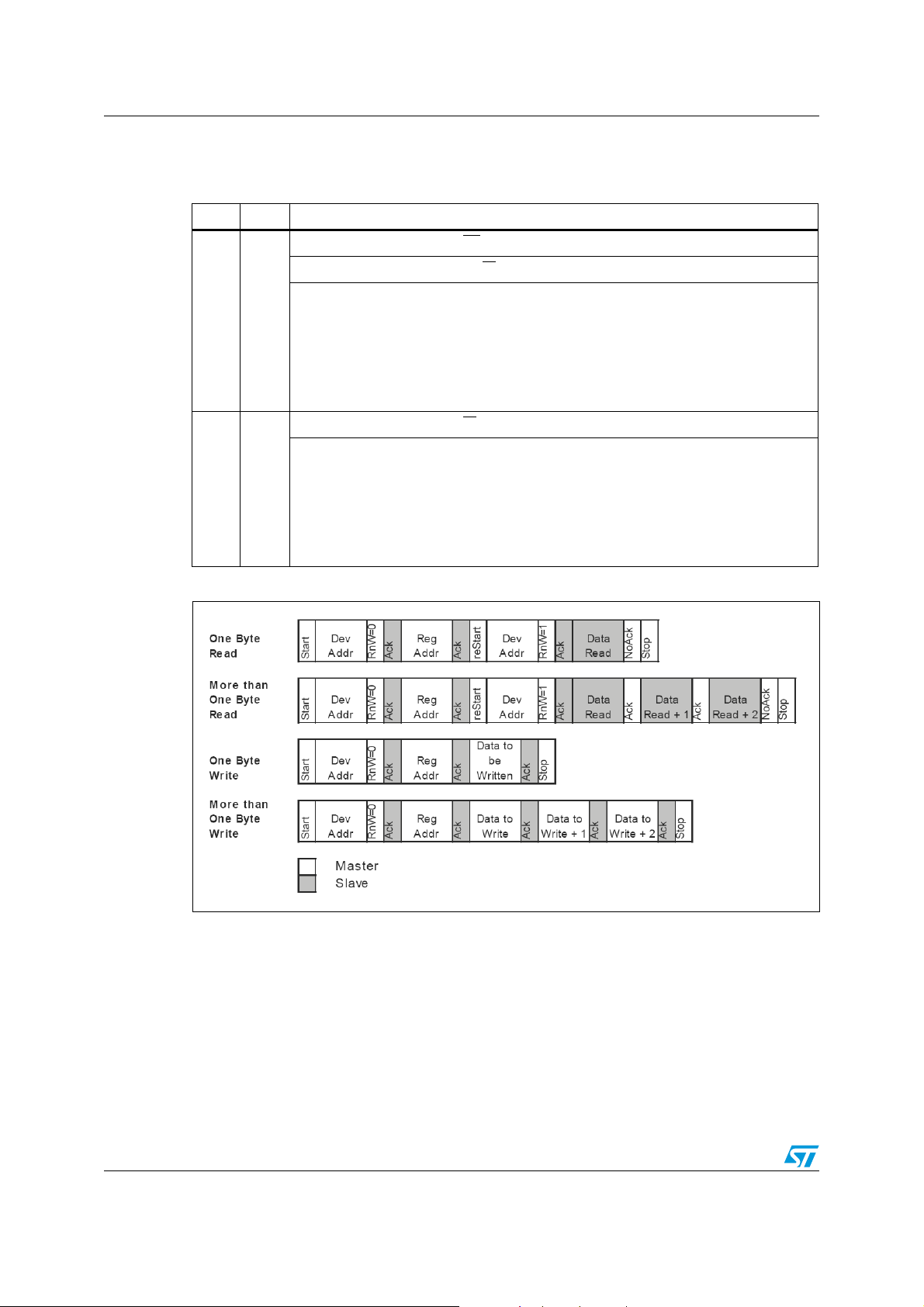

Figure 4. I2C timing

Table 14. I2C address

Symbol Parameter Min Typ Max Unit

f

SCL

t

LOW

t

HIGH

t

F

t

HD:STA

t

SU:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

SCL clock frequency 0 400 kHz

Clock low period 1.3 µs

Clock high period 600 ns

SDA and SCL fall time 300 ns

START condition hold time

(After this period the first clock is generated)

START condition setup time

(Only relevant for a repeated start period)

600 ns

600 ns

Data setup time 100 ns

Data hold time 0 µs

STOP condition setup time 600 ns

Time the bust must be free before a new

trasmission can start

1.3 µs

17/55

Page 18

System controller STMPE2401

7 System controller

The system controller is the heart of the STMPE2401. It contains the registers for power

control, and the registers for chip identification.

The system registers are:

Table 15. System controller

Address Register_Name

0x00 Reserved (Reads 0x00)

0x01 Reserved (Reads 0x00)

0x80 CHIP_ID

0x81 VERSION_ID

0x82 Reserved (Reads 0x00)

0x02 SYSCON

7.1 Identification register

Table 16. CHIP_ID

Bit 76543210

Read/Write(IIC) RRRRRRRR

Reset Value 00000001

Table 17. VERSION_ID

Bit 76543210

Read/Write(IIC) RRRRRRRR

Reset Value 00000001

8-bit LSB of Chip ID

8-bit Version ID

18/55

Page 19

STMPE2401 System controller

7.2 System control register

Table 18. System control register

Bit 7 6 5 4 3 2 1 0

Soft_Reset - Disable_32KHz Sleep Enable_GPIO Enable_PWM Enable_KPC Enable_ROT

Read/Writ

e (IIC)

WRWRWRWRWRWRW

Read/Writ

e(HW)

Reset

Val ue

RW R RW R R R R

0001111

Table 19. System control register writing

Bits Name Description

0 Enable_ROT Writing a ‘0’ to this bit will gate off the clock to the Rotator module, thus stopping

its operation

1 Enable_KPC Writing a ‘0’ to this bit will gate off the clock to the Keypad Controller module,

thus stopping its operation

2 Enable_PWM Writing a ‘0’ to this bit will gate off the clock to the PWM module, thus stopping

its operation

3 Enable_GPIO Writing a ‘0’ to this bit will gate off the clock to the GPIO module, thus stopping

its operation

4 Sleep Writing a ‘1’ to this bit will put the device in sleep mode. When in sleep mode, all

the units which need to work on clocks synchronous to 32KHz will get the clocks

derived from the 32K domain. The RC Oscillator will be shut off.

5 Disable_32KHz Set this bit to disable the 32KHz OSC, thus putting the device in hibernate

mode. Only a Reset or a wakeup on IIC will reset this bit

6--

7 Soft_Reset Writing a ‘1’ to this bit will do a soft reset of the device. Once the reset is done,

this bit will be cleared to ‘0’ by the HW.

19/55

Page 20

System controller STMPE2401

7.3 States of operation

The device has three main modes of operation:

● Operational Mode: This is the mode, whereby normal operation of the device takes

place. In this mode, the RC clock is available and the Main FSM Unit routes this clock

and the 32 KHz clock to all the device blocks that are enabled. In this mode, individual

blocks that need not be working can be turned off by the master by programming the

bits 3 to 0 of the SYSCON register.

● Sleep Mode: In this low-power mode, the RC Oscillator is powered down. All the blocks

which need clocks derived from the 32KHz clock will continue getting a 32KHz clock. In

this mode also, individual blocks can be turned off by the master by programming the

bits 3 to 0 of the SYSCON register. However, the master needs to program the

SYSCON register before coming into this mode, as in the sleep mode, the IIC interface

is not active except to detect traffic for wakeup. Any activity on the I2C port or Wakeup

pin or Hotkey activity will cause the device to leave this mode and go into the

Operational mode. When leaving this mode, the I2C will need to hold the SCLK till the

RC clock is ready.

● Hibernate Mode: This mode is entered when the system writes a ‘1’ to bit 5 of the

SYSCON register. In this mode, the device is completely inactive as there is absolutely

no clock. Only a Reset or a wakeup on IIC will bring back the System to operational

mode. All I2C activities are ignored.

Caution: Hotkey detection is not possible in hibernate mode.

Figure 5. State of operation

20/55

Page 21

STMPE2401 Clocking system

8 Clocking system

Figure 6. Clocking system

The decision on clocks is based on the bits written into SYSCON registers. Bits 0 to 4 of the

SYSCON register control the gating of clocks to the Rotator, Keypad Controller, PWM and

GPIO respectively in the operational mode. When in sleep mode, the operating clock is cut

off from every functional blocks (including the I

8.1 Programming sequence

To put the device in sleep mode, the following needs to be done by the host:

1. Write a ‘1’ to bit 4 of the SYSCON register.

2. To wakeup the device, the following needs to be done by the host:

3. Assert a wakeup routine on the I

address and the R/W bit.

4. If there’s a NOACK, keep sending the wakeup routine till there is an ACK from the

slave.

5. To do a soft reset to the device, the host needs to do the following:

6. Write a ‘1’ to bit 7 of the SYSCON register.

7. This bit is automatically cleared upon reset.

8. To go into Hibernate mode, the following needs to be done by the host:

9. Set the Disable_32K bit to ‘1’

10. To come out of the Hibernate mode, the following needs to be done by the host:

11. Assert a system reset or

12. Put a wakeup on the I

2

C

2

C) except Keypad Controller and GPIO.

2

C bus by sending the Start Bit, followed by the device

21/55

Page 22

Interrupt system STMPE2401

9 Interrupt system

STMPE2401 uses a highly flexible interrupt system. It allows host system to configure the

type of system events that should result in an interrupt, and pinpoints the source of interrupt

by status register. The INT pin could be configured as ACTIVE HIGH, or ACTIVE LOW.

32KHz clock input or crystal must be available for the interrupt system to be functional.

INT pin is 3.3V tolernat.

Once asserted, the INT pin would de-assert only if the corresponding bit in the

InterruptStatus register is cleared.

Figure 7. Interrupt system

9.1 Register map of interrupt system

Table 20. Register map of interrupt system

Address Register Name Description

0x10 ICR_msb

0x11 ICR_lsb Yes

0x12 IER_msb

0x13 IER_lsb Yes

0x14 ISR_msb

0x15 ISR_lsb Yes

0x16 IEGPIOR_msb

0x17 IEGPIOR_mid Yes

0x18 IEGPIOR_lsb Yes

0x19 IEGPIOR_msb

0x1A ISGPIOR_mid Yes

0x1B ISGPIOR_lsb Yes

22/55

Interrupt Control Register

Interrupt Enable Mask Register

Interrupt Status Register

Interrupt Enable GPIO Mask

Register

Interrupt Status GPIO Register

Auto-Increment

(during sequential R/W)

Ye s

Ye s

Ye s

Ye s

Ye s

Page 23

STMPE2401 Interrupt system

9.2 Interrupt control register (ICR)

ICR register is used to configure the Interrupt Controller. It has a global enable interrupt

mask bit that controls the interruption to the host.

ICR_msb ICR_lsb

Bit 1514131211109 8 7 6 5 4 3 2 1 0

Reserved IC2 IC1 IC0

R/W R R R R R R RRRRRRRRW RW RW

Reset

Value

Table 21. ICR

Bits Name Description

0 0 0 0 0 0 0000000 0 0 0

0 IC[0] Global Interrupt Mask bit

When this bit is written a ‘1’, it will allow interruption to the host. If it is written

with a ‘0’, then, it disables all interruption to the host. Writing to this bit does not

affect the IER value.

1 IC[1] output Interrupt Type

‘0’ = Level interrupt

‘1’ = Edge interrupt

2 IC[2] output Interrupt Polarity

‘0’ = Active Low / Falling Edge

‘1’ = Active High / Rising Edge

9.3 Interrupt enable mask register (IER)

IER register is used to enable the interruption from a particular interrupt source to the host.

IER_msb IER_lsb

Bit1514131211109876543210

Reserved IE8 IE7 IE6 IE5 IE4 IE3 IE2 IE1 IE0

R/W R R R R R R R RW RW RW RW RW RW RW RW RW

Reset

Val ue

0000000000000000

23/55

Page 24

Interrupt system STMPE2401

Table 22. IER

Bits Name Description

8:0 IE[x] Interrupt Enable Mask (where x = 8 to 0)

IE0 = Wake-up Interrupt Mask

IE1 = Keypad Controller Interrupt Mask

IE2 = Keypad Controller FIFO Overflow Interrupt Mask

IE3 = Rotator Controller Interrupt Mask

IE4 = Rotator Controller Buffer Overflow Interrupt Mask

IE5 = PWM Channel 0 Interrupt Mask

IE6 = PWM Channel 1 Interrupt Mask

IE7 = PWM Channel 2 Interrupt Mask

IE8 = GPIO Controller Interrupt Mask

Writing a ‘1’ to the IE[x] bit will enable the interruption to the host.

9.4 Interrupt status register (ISR)

ISR register monitors the status of the interruption from a particular interrupt source to the

host. Regardless whether the IER bits are enabled or not, the ISR bits are still updated.

ISR_msb ISR_lsb

Bit1514131211109876543210

Reserved IS8 IS7 IS6 IS5 IS4 IS3 IS2 IS1 IS0

R/W R R R R R R R RW RW RW RW RW RW RW RW RW

Reset

Val ue

0000000000000000

Table 23. ISR

Bits Name Description

8:0 IS[x] Interrupt Status (where x = 8 to 0)

Read:

IS0 = Wake-up Interrupt Status

IS1 = Keypad Controller Interrupt Status

IS2 = Keypad Controller FIFO Overflow Interrupt Status

IS3 = Rotator Controller Interrupt Status

IS4 = Rotator Controller Buffer Overflow Interrupt Status

IS5 = PWM Channel 0 Interrupt Status

IS6 = PWM Channel 1 Interrupt Status

IS7= PWM Channel 2 Interrupt Status

IS8 = GPIO Controller Interrupt Status

Write:

A write to a IS[x] bit with a value of ‘1’ will clear the interrupt and a write with a

value of ‘0’ has no effect on the IS[x] bit.

24/55

Page 25

STMPE2401 Interrupt system

9.5 Interrupt enable GPIO mask register (IEGPIOR)

IEGPIOR register is used to enable the interruption from a particular GPIO interrupt source

to the host. The IEG[15:0] bits are the interrupt enable mask bits correspond to the

GPIO[15:0] pins.

IEGPIOR_msb

Bit 2322212019181716

IEG23IEG22IEG21IEG20IEG19IEG18IEG17IEG

16

R/W RWRWRWRWRWRWRWRW

Reset

Val u e

Bit 1514131211109876543210

IEG15IEG14IEG13IEG12IEG11IEG10IEG9IEG8IEG7IEG6IEG5IEG4IEG3IEG2IEG1IEG

R/W RW RW RW RW RW RW RWRWRWRWRWRWRWRWRWRW

Reset

0 0 0 0 0 0 0000000000

Val u e

00000000

IEGPIOR _lsb

0

Table 24. GPIO

Bits Name Description

23:0 IEG[x] Interrupt Enable GPIO Mask (where x = 23 to 0)

Writing a ‘1’ to the IE[x] bit will enable the interruption to the host.

25/55

Page 26

Interrupt system STMPE2401

9.6 Interrupt status GPIO register (ISGPIOR)

ISGPIOR register monitors the status of the interruption from a particular GPIO pin interrupt

source to the host. Regardless whether the IEGPIOR bits are enabled or not, the ISGPIOR

bits are still updated. The ISG[15:0] bits are the interrupt status bits correspond to the

GPIO[15:0] pins.

ISGPIOR _lsb

Bit 2322212019181716

IEG23IEG22IEG21IEG20IEG19IEG18IEG17IEG

16

R/W RWRWRWRWRWRWRWRW

Reset

Value

ISGPIOR_msb ISGPIOR _lsb

Bit 1514131211109876543210

ISG15ISG14ISG13ISG12ISG11ISG10ISG9ISG8ISG7ISG6ISG5ISG4ISG3ISG2ISG1ISG

R/W RWRWRWRWRWRWRWRWRWRWRWRWRWRWRWRW

Reset

0 0 0 0 0 0 0000000000

Value

00000000

0

Table 25. GPIO

Bits Name Description

23:0 ISG[x] Interrupt Status GPIO (where x = 23 to 0)

Read:

Interrupt Status of the GPIO[x].

Write:

A write to a ISG[x] bit with a value of ‘1’ will clear the interrupt and a write with a

value of ‘0’ has no effect on the ISG[x] bit.

26/55

Page 27

STMPE2401 Interrupt system

9.7 Programming sequence

To configure and initialize the Interrupt Controller to allow interruption to host, observe the

following steps:

● Set the IER and IEGPIOR registers to the desired values to enable the interrupt

sources that are to be expected to receive from.

● Configure the output interrupt type and polarity and enable the global interrupt mask by

writing to the ICR.

● Wait for interrupt.

● Upon receiving an interrupt, the INT pin is asserted.

● The host comes to read the ISR through I

that the corresponding interrupt source is triggered.

● If the IS8 bit in ISR is set, the interrupt is coming from the GPIO Controller. Then, a

subsequent read is performed on the ISGPIOR to obtain the interrupt status of all 16

GPIOs to locate the GPIO that triggers the interrupt. This is a feature so-called ‘Hot

Key’.

● After obtaining the interrupt source that triggers the interrupt, the host performs the

necessary processing and operations related to the interrupt source.

● If the interrupt source is from the GPIO Controller, two write operations with value of ‘1’

are performed to the ISG[x] bit (ISGPIOR) and the IS[8] (ISR) to clear the

corresponding GPIO interrupt.

● If the interrupt source is from other module, a write operation with value of ‘1’ is

performed to the IS[x] (ISR) to clear the corresponding interrupt.

● Once the interrupt is being cleared, the INT pin will also be de-asserted if the interrupt

type is level interrupt. An edge interrupt will only assert a pulse width of 250ns.

● When the interrupt is no longer required, the IC0 bit in ICR may be set to ‘0’ to disable

the global interrupt mask bit.

2

C interface. A ‘1’ in the ISR bits indicates

27/55

Page 28

GPIO controller STMPE2401

10 GPIO controller

A total of 24 GPIOs are available in the STMPE2401 port expander IC. Most of the GPIOs

are sharing physical pins with some alternate functions. The GPIO controller contains the

registers that allow the host system to configure each of the pins into either a GPIO, or one

of the alternate functions. Unused GPIOs should be configured as outputs to minimize the

power consumption.

Table 26. GPIO controller

Address Register name Description

0xA2 GPMR_msb

0xA3 GPMR_csb Yes

0xA4 GPMR_lsb Yes

0x83 GPSR_msb

0x84 GPSR_csb Yes

0x85 GPSR_lsb Yes

0x86 GPCR_msb

0x87 GPCR_csb Yes

GPIO Monitor Pin State Register

GPIO Set Pin State Register

GPIO Clear Pin State Register

Auto-Increment

(during sequential R/W)

Ye s

Ye s

Ye s

0x88 GPCR_lsb Yes

0x89 GPDR_msb

0x8A GPDR_csb Yes

0x8B GPDR_lsb Yes

0x8C GPEDR_msb

0x8D GPEDR_csb Yes

0x8E GPEDR_lsb Yes

0x8F GPRER_msb

0x90 GPRER_csb Yes

0x91 GPRER_lsb Yes

0x92 GPFER_msb

0x93 GPFER_csb Yes

0x94 GPFER_lsb Yes

0x95 GPPUR_msb

0x96 GPPUR_csb Yes

0x97 GPPUR_lsb Yes

0x98 GPPDR_msb

0x99 GPPDR_csb Yes

0x9A GPPDR_lsb Yes

GPIO Set Pin Direction Register

GPIO Edge Detect Status Register

GPIO Rising Edge Register

GPIO Falling Edge Register

GPIO Pull Up Register

GPIO Pull Down Register

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

28/55

Page 29

STMPE2401 GPIO controller

Table 26. GPIO controller

Address Register name Description

0x9B GPAFR_U_msb

0x9C GPAFR_U_csb Yes

0x9D GPAFR_U_lsb Yes

0x9E GPAFR_L_msb

0x9F GPAFR_L_csb Yes

0xA0 GPAFR_L_lsb Yes

0xA5 – 0xAF RESERVED Reserved Yes

GPIO Alternate Function Register

(Upper Bit)

GPIO Alternate Function Register

(Lower Bit)

Auto-Increment

(during sequential R/W)

Ye s

Ye s

10.1 GPIO control registers

A group of registers are used to control the exact function of each of the 24 GPIO. All GPIO

registers are named as GPxxx_yyy, where

Xxx represents the functional group

Yyy represents the byte position of the GPIO

Lsb registers controls GPIO[7:0]

Csb registers controls GPIO[15:8]

Msb registers controls GPIO[23:16]

Table 27. Register

Bit 76543210

GPxxx_msb IO-23 IO-22 IO-21 IO-20 IO-19 IO-18 IO-17 IO-16

GPxxx_csb IO-15 IO-14 IO-13 IO-12 IO-11 IO-10 IO-9 IO-8

GPxxx_lsb IO-7 IO-6 IO-5 IO-4 IO-3 IO-2 IO-1 IO-0

Note: This convention does not apply to the GPIO Alternate Function Registers

The function of each bit is shown in the following table:

Table 28. Bit’s function

Register name Function

GPIO Monitor Pin State Reading this bit yields the current state of the bit. Writing has no effect.

GPIO Set Pin State Writing ‘1’ to this bit causes the corresponding GPIO to go to ‘1’ state.

Writing ‘0’ has no effect.

GPIO Clear Pin State Writing ‘1’ to this bit causes the corresponding GPIO to go to ‘0’ state.

Writing ‘0’ has no effect.

GPIO Set Pin Direction

‘0’ sets the corresponding GPIO to input state, and ‘1’ sets it to output

state

29/55

Page 30

GPIO controller STMPE2401

Table 28. Bit’s function

Register name Function

GPIO Edge Detect Status Set to ‘1’ by hardware when there is a rising/falling edge on the corre-

sponding GPIO. Writing ‘1’ clears the bit. Writing ‘0’ has no effect.

GPIO Rising Edge Set to ‘1’ to enable rising edge detection on the corresponding GPIO.

GPIO Falling Edge Set to ‘1’ to enable falling edge detection on the corresponding GPIO.

GPIO Pull Up Set to ‘1’ to enable internal pull-up resistor

GPIO Pull Down Set to ‘1’ to enable internal pull-down resistor

10.2 GPIO alternate function register (GPAFR)

GPAFR is to select the functionality of the GPIO pin. To select a function for a GPIO pin, a

bit-pair in the register (GPAFR_U or GPAFR_L) has to be set.

GPAFR_U_msb

Bit2322212019181716

AF23 AF22 AF21 AF20

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

Bit151413121110 9 8

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

Bit76543210

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

00000000

GPAFR_U_csb

AF19 AF18 AF17 AF16

00000000

GPAFR_U_lsb

AF15 AF14 AF13 AF12

00000000

30/55

Page 31

STMPE2401 GPIO controller

Table 29. Bit description

Bits Name Description

23:0 AF[x] GPIO Pin ‘x’ Alternate Function Select (where x = 23 to 12).

‘00’ – The corresponding GPIO pin (GPIO[x]) is configured to Primary

Function.

‘01’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 1.

‘10’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 2.

‘11’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 3.

GPAFR_L_msb

Bit2322212019181716

AF11 AF10 AF9 AF8

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

00000000

GPAFR_L_csb

Bit151413121110 9 8

AF7 AF6 AF5 AF4

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

Bit76543210

R/WRWRWRWRWRWRWRWRW

Reset

Val ue

00000000

GPAFR_L_lsb

AF3 AF2 AF1 AF0

00000000

31/55

Page 32

GPIO controller STMPE2401

Table 30. Bit description

Bits Name Description

23:0 AF[x] GPIO Pin ‘x’ Alternate Function Select (where x = 11 to 0).

‘00’ – The corresponding GPIO pin (GPIO[x]) is configured to Primary

Function.

‘01’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 1.

‘10’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 2.

‘11’ – The corresponding GPIO pin (GPIO[x]) is configured to Alternate

Function 3.

10.3 Hot key feature

A GPIO is known as ‘Hot Key’ when it is configured to trigger an interruption to the host

whenever the GPIO input is being asserted. This feature is applicable in Operational mode

(RC clock is present) as well as Sleep mode (32kHz clock is present).

10.3.1 Programming sequence for hot key

1. Configures the GPIO pin into GPIO mode by setting the corresponding bits in the

GPAFR.

2. Configures the GPIO pin into input direction by setting the corresponding bit in GPDR.

3. Set the GPRER and GPFER to the desired values to enable the rising edge or falling

edge detection.

4. Configures and enables the interrupt controller to allow the interruption to the host.

5. Now, the GPIO Expander may be put into Sleep mode if it is desired.

6. Upon any Hot Key being asserted, the device will wake-up and issue an interrupt to the

host.

Below are the conditions to be fulfilled in order to configure a Hot Key:

1. The pin is configured into GPIO mode and as input pin.

2. The global interrupt mask bit is enabled.

3. The corresponding GPIO interrupt mask bit is enabled.

10.3.2 Minimum pulse width

The minimum pulse width of the assertion of the Hot Key must be at least 62.5us. Any pulse

width less than the stated value may not be registered.

32/55

Page 33

STMPE2401 PWM controller

11 PWM controller

The STMPE2401 PWM controller provides 3 independent PWM outputs used to generate

light effect; if the PWM outputs are not used, these pins can be used as GPIO.

Figure 8. PWM controller

Instructions are downloaded into the memory via the I2C connection.

33/55

Page 34

PWM controller STMPE2401

11.1 Registers in the PWM controller

The main system registers are:

Table 31. Main system registers

Auto-Increment

Address Register Name Description

0x30 PWMCS PWM Control and Status register Yes

PWM instructions are initialized through this

data port. Every instruction is 16-bit width and

0x38 PWMIC0

0x39 PWMIC1

0x3A PWMIC2

therefore, the MSB of the first word is written

first, then, followed by LSB of the first word.

Subsequently, MSB of second word and LSB

of second word and so on.

PWM instructions are initialized through this

data port. Every instruction is 16-bit width and

therefore, the MSB of the first word is written

first, then, followed by LSB of the first word.

Subsequently, MSB of second word and LSB

of second word and so on.

PWM instructions are initialized through this

data port. Every instruction is 16-bit width and

therefore, the MSB of the first word is written

first, then, followed by LSB of the first word.

Subsequently, MSB of second word and LSB

of second word and so on.

(during

Read/Write)

No

No

No

34/55

Page 35

STMPE2401 PWM controller

11.2 PWM control and status register (PWMCS)

Bit 76543210

Reserved II2 II1 II0 EN2 EN1 EN0

Read/Write R R R R R RW RW RW

Reset Value 0 0 0 0 0 0 0 0

Table 32. Bit description

Bits Name Description

0 EN0 PWM Channel 0 Enable bit.

‘1’ – Enable the PWM Channel 0

‘0’ – Reset the PWM Channel 0. Only when the PWM channel is in reset

state, the stream of commands can be written into its data port, which in

this case is PWM_Command_Channel_0.

1 EN1 PWM Channel 1 Enable bit.

‘1’ – Enable the PWM Channel 1

‘0’ – Reset the PWM Channel 1. Only when the PWM channel is in reset

state, the stream of commands can be written into its data port, which in

this case is PWM_Command_Channel_1.

2 EN2 PWM Channel 2 Enable bit.

‘1’ – Enable the PWM Channel 2

‘0’ – Reset the PWM Channel 2. Only when the PWM channel is in reset

state, the stream of commands can be written into its data port, which in

this case is PWM_Command_Channel_2.

3 II0 PWM Invalid Instruction Status bit for PWM Channel 0

‘0’ – No invalid command encountered during the instruction execution.

‘1’ – Invalid command encountered and this puts the PWM Channel 0 into

reset state.

4 II1 PWM Invalid Instruction Status bit for PWM Channel 1

‘0’ – No invalid command encountered during the instruction execution.

‘1’ – Invalid command encountered and this puts the PWM Channel 1 into

reset state.

5 II2 PWM Invalid Instruction Status bit for PWM Channel 2

‘0’ – No invalid command encountered during the instruction execution.

‘1’ – Invalid command encountered and this puts the PWM Channel 2 into

reset state.

35/55

Page 36

PWM controller STMPE2401

11.3 PWM instruction channel x (PWMICx)

This PWMICx is the dataport that allows the instructions to be loaded into the PWM

channel. The loading of the instructions is achieved by continuously writing to this dataport.

As this dataport address falls on the non-auto increment region, continuous write operation

2

on I

C will write into the same dataport address. The ‘x’ value is from 0 to 2 as there are 3

independent PWM channels. To access these dataports, the corresponding ENx in the

PWMCS register must be set to 0 first to put the PWM channel in reset state.

Bit 76543210

IB7 IB6 IB5 IB4 IB3 IB2 IB1 IB0

Read/Write RW RW RW RW RW RW RW RW

Reset Value00000000

Table 33. Pin description

Bits Name Description

7:0 IB[x] PWM Instruction Channel x, where x is 7 to 0

As an instruction is 16-bit width, writing the instruction into this 8-bit

PWMICx dataport requires two 8-bit data write. The most significant byte

of the 16-bit instruction is to be written in first and followed by the least

significant byte of the instruction. The same effect applies to the read

operation.

36/55

Page 37

STMPE2401 PWM commands

12 PWM commands

The STMPE2401 PWM Controller works as a simple MCU, with program space of 64

instructions and a simple instruction set. The instructions are all 16 bits in length. The 3

most significant bits are used to identify the commands.

Table 34. PWM commands

Instruction Description

RAMP This instruction starts the PWM counters and set the pwm_x_out with the

result from the counting.

Set Maximum

(SMAX)

Set Minimum (SMIN) Load the PWM counter with the value of 0x0 and the pwm_x_out will result in

Go to Start (GTS) Branch to the address 0x0 and execute from 0x0 and onwards.

BRANCH Branch to a relative or an absolute address to execute with the looping

END End the instruction execution by resetting and interrupting to the host.

Trigger (TRIG) Capable of waiting as well as sending triggers to another PWM channel.

Load the PWM counter with the value of 0xff and the pwm_x_out will result in

logic level low.

logic level high.

capability. There are 4 loop counters available and these allow 4 nested

loops.

Table 35. Identification of instructions

Instruction Bit 15 Bit 14 Bit 13

Ramp 0- -

SetFullScale 0--

SetMinimum 0--

GoToStart 0- -

Branch 101

End 110

Trigge r 111

Reserved 100

37/55

Page 38

PWM commands STMPE2401

Table 36. Instruction

Bit

Instruction

Timing in 2kHz

15 14 1312 11 10 9 8 7 6 5 4321 0

RAMP 0 Prescale

0=16

1=512

Step Time

0 - 63

0 = immediate action

Sign

0=stepup

Increment

1 – 126

Increment value

of 0 is not

allowed.

1=stepdown

prescale = 16 :-

Consumes

[(step

time)

nt)] cycles

prescale = 512 :-

Consumes

[(32)

time)

nt)] cycles

SMAX 0

(2)

x

0 0 127 Consumes 1

cycle

SMIN 0

(2)

x

0 1 127 Consumes 1

cycle

GTS 0 0 0 0 0 Consumes 1

cycle

(1)

(increme

(1)

(step

(1)

(increme

BRANCH 1 01 Loop Counter to

use

0 - 3

Loop Count

0 – 15

0 = forever

loop

0=absol

ute step

size

1=relativ

e step

(1)

size

Step Size

(1)

0 – 63

Consumes 1

cycle

Once the loop

count has been

reached, the

loop counter

resets.

END 1 10 Interr

upt to

host

Reset

instructi

on

RESERVED Consumes 1

cycle

counter

and

output

level to

zero

TRIG 1 11 Wait for Trigger

on channel 0 – 2

Continues if all selected triggers

present.

Each bit signifies wait for the

Send Trigger

on channel 0 – 2

Continues if no Wait

for Trigger in this

instruction.

Consumes 1 or

x

(2)

more cycles

corresponding channel.

reserved 1 00 RESERVED Reserved.

1. Absolute Branch jumps to the absolute address (relative to address 0x0) using the value of step size. The Relative Branch

jumps in a backward manner relative to the current address location, ie. 1 means jump to the previous instruction location

and 0 means NOP.

2. Don’t care.

38/55

Page 39

STMPE2401 PWM commands

In order to enable a PWM channel, the programming sequence below should be observed.

● The ENx of the PWMCS register should be kept in ‘0’. By default, it has a value of ‘0’.

● Loads the instructions into the PWM channel x by writing the corresponding PWMICx.

● The PWM channel x has a 64-word depth (16-bit width). Any instructions of size less

than or equal to 64 words can be loaded into the channel. Any attempt to load beyond

64 words will result in internal address pointer to roll-over (0x1f ◊ 0x00) and the excess

instructions to be over-written into the first address location of the channel and

onwards.

● After the instructions are loaded in, then, the PWM channel x can be enabled by setting

a ‘1’ to the ENx bit.

● Enables the corresponding interrupt mask bit to allow interruption to the host.

39/55

Page 40

Keypad controller STMPE2401

13 Keypad controller

The main operations of the keypad controller are controlled by four dedicated key controllers

that support up to four simultaneous dedicated key presses and a key scan controller and

two normal key controllers that support a maximum of 12x8 key matrix with detection of two

simultaneous key presses.

Four of the column inputs can be configured as dedicated keys through the setting of

Dkey0~3 bits of KPC_ctrl register.

The normal key matrix size is configurable through the setting of KPC_row and KPC_col

registers. The scanning of each individual row output and column input can be enabled or

masked to support a key matrix of variable size from 1x1 to 12x8.

The operation of the keypad controller is enabled by the SCAN bit of KPC_ctrl register.

Every key activity detected will be de-bounced for a period set by the DB_0~7 bits of

KPC_ctrl register before a key press or key release is confirmed and updated into the output

FIFO. The key data, indicating the key coordinates and its status (up or down), is loaded into

the FIFO at the end of a specified number of scanning cycles (set by ScanCount0~3 bits of

KPC_row_msb register). An interrupt will be generated when a new set of key data is

loaded. The FIFO has a capacity for four sets of key data. Each set of key data consists of

three bytes of information when any of the four dedicated keys is enabled. It is reduced to

two bytes when no dedicated key is involved. When the FIFO is full before its content is

read, an overflow signal will be generated while the FIFO will continue to hold its content but

forbid loading of new key data set.

Figure 9. Keypad controller

40/55

Page 41

STMPE2401 Keypad controller

The keypad column inputs enabled by the KPC_col register are normally ‘HIGH’, with the

corresponding input pins pulled up by resistors internally. After reset, all the keypad row

outputs enabled by the KPC_row register are driven ‘LOW’. If a key is pressed, its

corresponding column input will become ‘LOW’ after making contact with the ‘LOW’ voltage

on its corresponding row output.

Once the key scan controller senses a ‘LOW’ input on any of the column inputs, the

scanning cycles will then start to determine the exact key that has been pressed. The twelve

row outputs will be driven ‘LOW’ one by one (if the row output is enabled) during each

scanning cycle. While one row is driven ‘LOW’, the other rows are driven ‘HIGH’. (The pullups and pull-downs of row outputs are always disabled). If there is any column input sensed

as ‘LOW’ when a row is driven ‘LOW’, the key scan controller will then decode the key

coordinates (its corresponding row number and column number), save the key data into a

de-bounce buffer if available, confirm if it is a valid key press after de-bouncing, and update

the key data into output data FIFO if valid.

13.1 Registers in keypad controller

Table 37. Register in keypad controller

Auto-Increment

Address Register name Description

0x60 KPC_col Keypad column scanning register Yes

(during sequential

R/W)

0x61 KPC_row_msb Keypad row scanning register Yes

0x62 KPC_row_lsb Yes

0x63 KPC_ctrl_msb Keypad control register Yes

0x64 KPC_ctrl_lsb Yes

0x68 KPC_data_byte0 Keypad data register No

0x69 KPC_data_byte1 No

0x6A KPC_data_byte2 No

41/55

Page 42

Keypad controller STMPE2401

13.2 KPC_col register

Table 38. KPC_col Register

Bit 76543210

Name Input Column 0 ~ 7

Read/Write WWWWWWWW

Reset Value 00000000

Bit Name Description

7 Input Column 7 ‘1’ to turn on scanning of column 7; ‘0’ to turn off

6 Input Column 6 ‘1’ to turn on scanning of column 6; ‘0’ to turn off

5 Input Column 5 ‘1’ to turn on scanning of column 5; ‘0’ to turn off

4 Input Column 4 ‘1’ to turn on scanning of column 4; ‘0’ to turn off

3 Input Column 3 ‘1’ to turn on scanning of column 3; ‘0’ to turn off

2 Input Column 2 ‘1’ to turn on scanning of column 2; ‘0’ to turn off

1 Input Column 1 ‘1’ to turn on scanning of column 1; ‘0’ to turn off

0 Input Column 0 ‘1’ to turn on scanning of column 0; ‘0’ to turn off

13.3 KPC_row_msb register

Table 39. KPC_row_msb register

Bit 7 6 543210

Name ScanPW1 ScanPW0 - - Output Row 8 ~ 11

Read/Write - - - - WWWW

Reset Value 1 1 000000

Bit Name Description

7 ScanPW1 Pulse width setting of keypad scanning. Use “11” at all

6 ScanPW0

5--

4--

3 Output Row 11 ‘1’ to turn on scanning of row 11; ‘0’ to turn off

2 Output Row 10 ‘1’ to turn on scanning of row 10; ‘0’ to turn off

1 Output Row 9 ‘1’ to turn on scanning of row 9; ‘0’ to turn off

0 Output Row 8 ‘1’ to turn on scanning of row 8; ‘0’ to turn off

times

42/55

Page 43

STMPE2401 Keypad controller

13.4 KPC_row_lsb register

Table 40. KPC_row_lsb register

Bit 76543210

Name output Row 0 ~ 7

Read/Write WWWWWWWW

Reset Value 00000000

Bit Name Description

7 output Row 7 ‘1’ to turn on scanning of row 7; ‘0’ to turn off

6 output Row 6 ‘1’ to turn on scanning of row 6; ‘0’ to turn off

5 output Row 5 ‘1’ to turn on scanning of row 5; ‘0’ to turn off

4 output Row 4 ‘1’ to turn on scanning of row 4; ‘0’ to turn off

3 output Row 3 ‘1’ to turn on scanning of row 3; ‘0’ to turn off

2 output Row 2 ‘1’ to turn on scanning of row 2; ‘0’ to turn off

1 output Row 1 ‘1’ to turn on scanning of row 1; ‘0’ to turn off

0 output Row 0 ‘1’ to turn on scanning of row 0; ‘0’ to turn off

13.5 KPC_ctrl_msb register

Table 41. KPC_ctrl_msb register

Bit 7 6543210

Name ScanCount0 ~ 3 DKey_0 ~ 3

Read/Write WWWWWWWW

Reset Value 00000000

Bit Name Description

7 ScanCount3 Number of key scanning cycles elapsed before a confirmed

6 ScanCount2

5 ScanCount1

4 ScanCount0

3 DKey_3 Set ‘1’ to use Input Column 3 as dedicated key

2 DKey_2 Set ‘1’ to use Input Column 2 as dedicated key

1 DKey_1 Set ‘1’ to use Input Column 1 as dedicated key

0 DKey_0 Set ‘1’ to use Input Column 0 as dedicated key

key data is updated into output data FIFO (0 ~ 15 cycles)

43/55

Page 44

Keypad controller STMPE2401

13.6 KPC_ctrl_lsb register

Table 42. KPC_ctrl_lsb register

Bit 76543210

Name DB_0 ~ 5 SCAN

Read/Write WWWWWWW W

Reset Value 00000000

Bit Name Description

7 DB_6 0-128ms of de-bounce time

6DB_5

5DB_4

4DB_3

3DB_2

2DB_1

1DB_0

0 SCAN ‘1’ to start scanning; ‘0’ to stop

13.7 Data registers

The KPC_DATA register contains three bytes of information. The first two bytes store the key

coordinates and status of any two keys from the normal key matrix, while the third byte store

the status of dedicated keys.

Table 43. KPC_data_byte0 register

Bit 7 6 5 432 1 0

Name Up/Down R3 R2 R1R0C2 C1 C0

Read/Write R R R RRR R R

Reset Value 1 1 1 110 0 0

Bit Name Description

7 Up/Down ‘0’ for key-down, ‘1’ for key-up

6 R3 row number of key 1 (valid range : 0-11)

5R2

4R1

3R0

2 C2 column number of key 1 (valid range : 0-7)

0x1111 for No Key

1C1

0C0

44/55

Page 45

STMPE2401 Keypad controller

Table 44. KPC_data_byte1 register

Bit 7 6543210

Name Up/DownR3R2R1R0C2C1C0

Read/Write R RRRRRRR

Reset Value 1 1111000

Bit Name Description

7 Up/Down ‘0’ for key-down, ‘1’ for key-up

6 R3 row number of key 2 (valid range : 0-11)

0x1111 for No Key

5R2

4R1

3R0

2 C2 column number of key 2 (valid range : 0-7)

1C1

0C0

Table 45. KPC_data_byte2 register

Bit 7 6543210

Name - - - - Dedicated Key 0 ~ 3

Read/Write R RRRRRRR

Reset

Val u e

Bit Name Description

7--

6--

5--

4--

3 Dedicated Key 3 ‘0’ for key-down, ‘1’ for key-up

2 Dedicated Key 2 ‘0’ for key-down, ‘1’ for key-up

1 Dedicated Key 1 ‘0’ for key-down, ‘1’ for key-up

0 Dedicated Key 0 ‘0’ for key-down, ‘1’ for key-up

00 001111

45/55

Page 46

Keypad controller STMPE2401

13.7.1 Resistance

Maximum resistance between keypad output and keypad input, inclusive of switch

resistance, protection circuit resistance and connection, must be less than 3.2 KΩ

13.7.2 Using the keypad controller

Before enabling the keypad controller operation, proper setup should be done by configuring

the input and output ports involved. This is achieved by programming the corresponding

GPIO control registers that determine the port direction and the necessary internal pull-up

or pull-down. For the GPIO ports that are used as keypad inputs, internal pull-up should be

enabled. For those that are used as keypad outputs, no internal pull-up or pull-down should

be enabled.

The scanning of column inputs should then be enabled for those GPIO ports that are

configured as keypad inputs by writing ‘1’s to the corresponding bits in the KPC_col register.

If any of the first three column inputs is to be used as dedicated key input, the corresponding

bits in the KPC_ctrl_msb register should be set to ‘1’. The bits in the KPC_row_msb and

KPC_row_lsb registers should also be set correctly to enable the row output scanning for

the corresponding GPIO ports programmed as keypad outputs.

The scan count and de-bounce count should also be programmed into the keypad control

registers before enabling the keypad controller operation. To enable the keypad controller

operation, the Enable_KPC bit in the system control register must be set to ‘1’ to provide the

required clock signals. The keypad controller will then start its operation by setting the

SCAN bit in the KPC_ctrl_lsb register to ‘1’.

The keypad controller operation can be disabled by setting the SCAN bit back to ‘0’. To

further reduce the power consumption, the clock signals can be cut off from the keypad

controller by setting the Enable_KPC bit to ‘0’.

ScanCount value is programmable to any value between 1-15 by writing into the scancount

register. If scan count is programmed to N, the Keypad Controller scans the entire matrix for

N times, collecting up to 2 matrix key and 4 dedicated keys, loads the keys into 1 set of

keypad data buffer and interrupts the host system.

46/55

Page 47

STMPE2401 Rotator controller

14 Rotator controller

Rotator controller consists of 3 terminal, each capable of becoming an input with internal

pull-up, or and output. At any moment, 2 terminals are inputs and one terminal is output.

Figure 10. Rotator controller

The Rotator Controller is responsible for the detection of the direction of rotator and the

reporting of these direction sequences. The direction of a rotator can be either up or down.

A rotator has 3 contacts and detection of shorts on these contacts is used to determine the

direction of rotation. Following diagram shows the definition of the direction of rotation and

how the FSM states and driven outputs correspond to rotation.

Table 46. 3 possible conditions: A-B short, B-C short, C-A short.

LO

Input

C1 A B C 2 B A CUp

B1 A B C 3 C A BDown

A2 B A C 3 C A BDown

C2 B A C 1 A B CUp

A3 C A B 2 B A CUp

B3 C A B 1 A B CDown

State Output Input Input State Output Input Input

Current State Next State

Figure 11. Possible conditions

Result

47/55

Page 48

Rotator controller STMPE2401

Table 47. Registers for rotator control

Address Register name Register Size

0x70 Rotator_Control 8

0x72 Rotator_Buffer 8

14.1 Rotator_Control

Bit 7 6543210

Start_FSM Reserved

Read/Write RW R R R R R R R

Reset Value0 0000000

Bits Name Description

7 Start_FSM Rotator FSM start bit.

‘1’ – Activate the FSM

‘0’ – Stop sampling rotator symbols

14.2 Rotator_Buffer

Bit 7 65432 1 0

Symbol_Type Symbol_Count

Read/Write R R R R R R R R

Reset Value 0 00000 0 0

Bits Name Description

7 Symbol_Type Symbol type to be reported

6~0 Symbol_Count Number of symbols of the type specified by bit 7

‘1’ – Down

‘0’ – Up

Minimum of 0 (b’0000000) to

Maximum of 127 (b’1111111)

48/55

Page 49

STMPE2401 Rotator controller

The host should do the following on the I2C bus to start the Rotator controller:

1. The host writes to GPIO Controller to configure the PU/PD bit and select the Rotator

Bits on the relevant IO.

2. Write Rotator_Control data register to start the rotator controller. A maximum of 2

rotations later, the correct initial state on the rotator FSM is obtained. Scanning for

rotator movement continues.

3. The host waits for interrupt from the rotator controller.

4. The host reads Rotator_Buffer

5. The host can stop rotator controller operation by writing to Rotator_Control register.

49/55

Page 50

Miscellaneous features STMPE2401

15 Miscellaneous features

15.1 Reset

STMPE2401 is equipped with an internal POR circuit that holds the device in reset state,

until the clock is steady and V

STMPE2401 by asserting Reset_N pin.

15.2 Under voltage lockout

STMPE2401 is equipped with an internal UVLO circuit that generates a RESET signal,

when the main supply voltage falls below the allowed threshold.

15.3 Clock output

STMPE2401 provides a buffered 32KHz clock output at one of the GPIO as alternate

function. This clock could be used for cascading of multiple port expander devices, using

just 1 XTAL unit.

input is valid. Host system may choose to reset the

CC

50/55

Page 51

STMPE2401 Mechanical data

16 Mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect . The category of

second level interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com

51/55

Page 52

Mechanical data STMPE2401

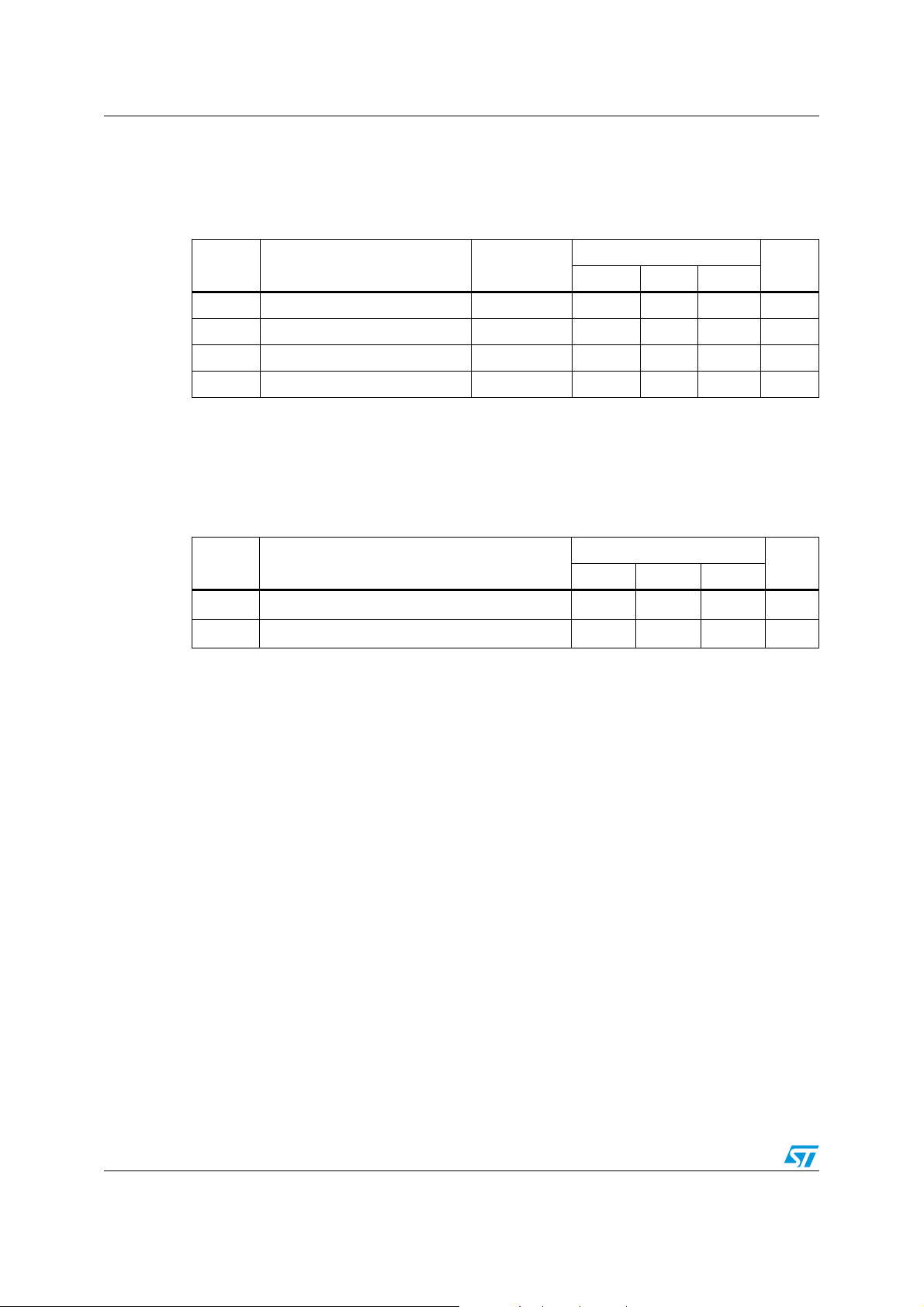

Table 48. TFBGA Mechanical data

mm. inch

Dim.

Min Typ Max Min Typ Max

A 1.1 1 1.16 0.043 0.039 0.046

A1 0.25 0.010

A2 0.78 0.86 0.031 0.034

b 0.30 0.25 0.35 0.012 0.010 0.014

D 3.60 3.50 3.70 0.142 0.138 0.146

D1 3.50 0.138

E 3.50 3.60 3.70 0.142 0.138 0.146

E1 2.50 0.098

e 0.50 0.020

F 0.55 0.022

Figure 12. Package dimensions

52/55

Page 53

STMPE2401 Mechanical data

Figure 13. Recommended footprint

Figure 14. Tape and reel information

53/55

Page 54

Revision history STMPE2401

17 Revision history

Table 49. Revision history

Date Revision Changes

08-Jan-2007 1 Initial release

29-May-2007 2 Cover page updated

54/55

Page 55

STMPE2401

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

55/55

Loading...

Loading...