Features

■ 1.5 A source/2.3 A sink (typ) gate drive

■ Active Miller clamp feature

■ Two-level turn-off with adjustable level and

delay

■ Desaturation detection

■ Fault status output

■ Negative gate drive capability

■ Input compatible with pulse transformer or

optocoupler

■ Separate sink and source outputs for easy gate

driving

■ UVLO protection

■ 2 kV ESD protection (HBM)

Applications

■ 1200 V, 3-phase inverters

■ Motor control

■ UPS systems

TD350E

Advanced IGBT/MOSFET driver

Description

This device is an advanced gate driver for IGBTs

and power MOSFETs. Control and protection

functions are included and allow the design of

high reliability systems.

The innovative active Miller clamp function

eliminates the need for negative gate drive in

most applications and allows the use of a simple

bootstrap supply for the high side driver.

The device includes a two-level turn-off feature

with adjustable level and delay. This function

protects against excessive overvoltage at turn-off

in case of overcurrent or short-circuit conditions.

The same delay set in the two-level turn-off

feature is applied at turn-on to prevent pulse width

distortion.

The device also includes IGBT desaturation

protection and a FAULT status output, and is

compatible with both pulse transformer and

optocoupler signals.

Table 1. Device summary

Order codes Temperature range Package Packaging

TD350E

-40, +125 °C SO-14

TD350ETR Tape and reel

September 2011 Doc ID 018539 Rev 2 1/17

Tube

www.st.com

17

Contents TD350E

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Desaturation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 Active Miller clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.5 Two-level turn-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.6 Minimum ON time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.7 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.8 Fault status output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.9 Undervoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Typical performance curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Application diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2/17 Doc ID 018539 Rev 2

TD350E Block diagram

1 Block diagram

Figure 1. TD350E functional block diagram

9UHI

0ULSE4RANSFORMER

9+

9UHI

9UHI

9+

).

62%&

&!5,4

.#

#/&&

.#

,6/&&

6REF

/FF

DELAY

/FF,EVEL

56,/

#ONTROL "LOCK

4$%

$ESAT

$%3!4

6(

/54(

/54,

6,

#,!-0

'.$

6

/PTIONNAL

6

".W

Doc ID 018539 Rev 2 3/17

Pin connections TD350E

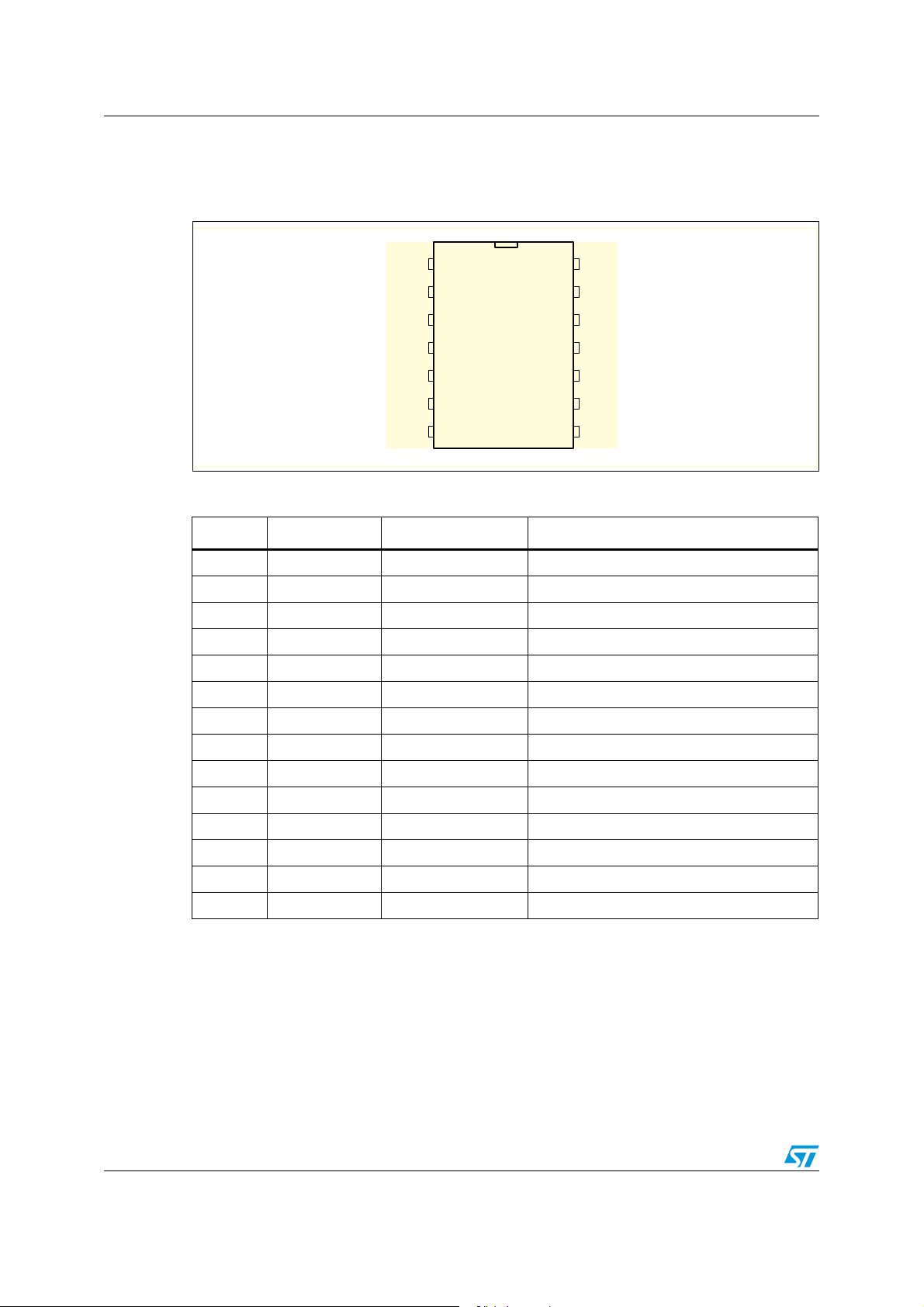

2 Pin connections

Figure 2. Pin connections (top view)

$%3!4

6(

(

/54

/54,

6,

#,!-0

'.$

62%

&!5, 4

.#

#/&&

.#

,6/&&

).

&

4$%

Table 2. Pin description

Name Pin number Type Function

IN 1 Analog input Input

VREF 2 Analog output +5 V reference voltage

FAULT 3 Digital output Fault status output

NC 4 Not connected

COFF 5 Timing capacitor Turn-off delay

NC 6 Not connected

LVOFF 7 Analog input Turn off level

GND 8 Power supply Signal ground

".W

CLAMP 9 Analog output Miller clamp

VL 10 Power supply Negative supply

OUTL 11 Analog output Gate drive output (sink)

OUTH 12 Analog output Gate drive output (source)

VH 13 Power supply Positive supply

DESAT 14 Analog input Desaturation protection

4/17 Doc ID 018539 Rev 2

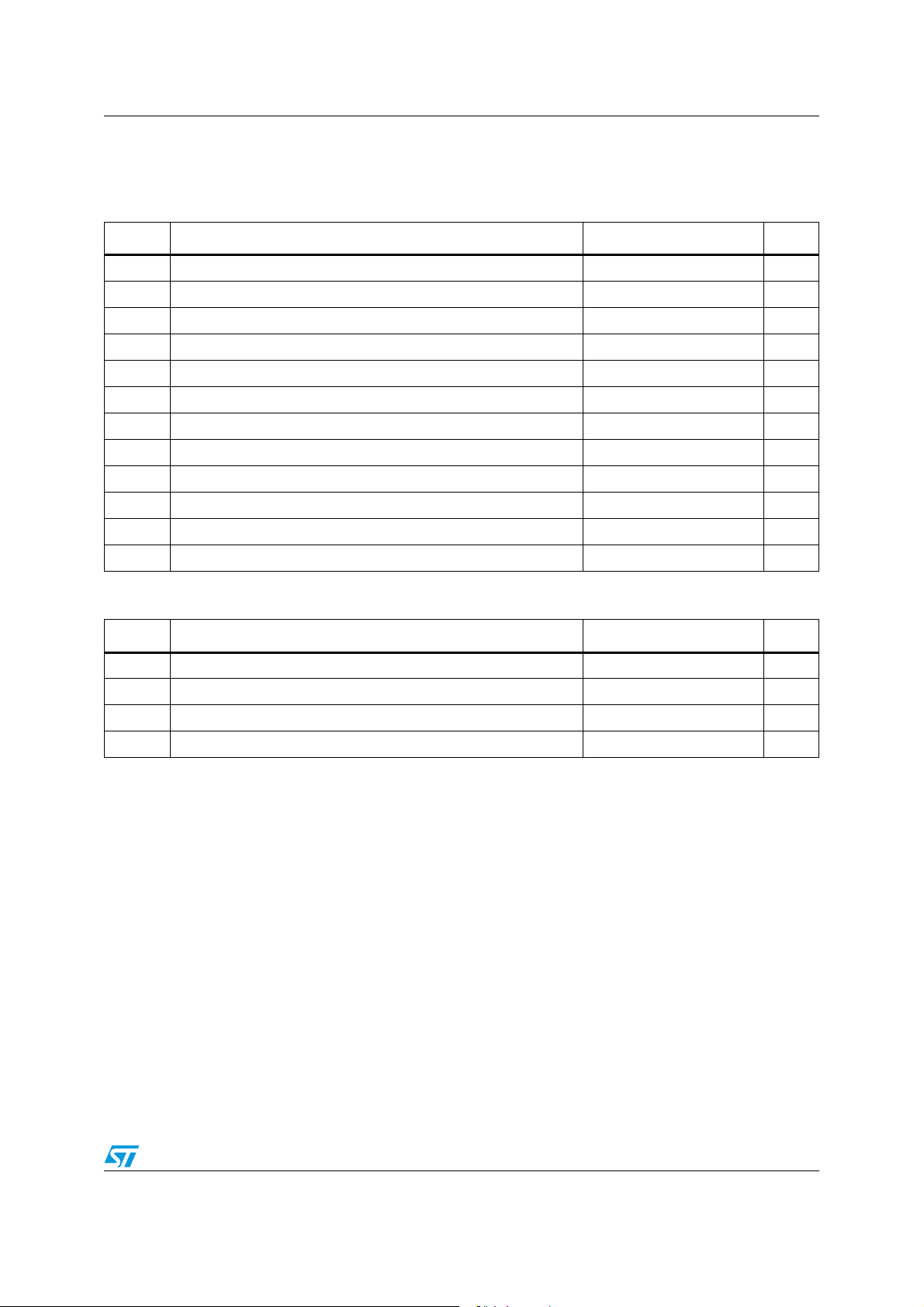

TD350E Absolute maximum ratings

3 Absolute maximum ratings

Table 3. Key parameters and their absolute maximum ratings

Symbol Parameter Value Unit

VHL Maximum supply voltage (VH - VL) 28 V

VH Maximum VH voltage vs. GND 28 V

VL Minimum VL voltage vs. GND -12 V

V

V

V

T

R

R

ESD Electrostatic discharge (HBM) 2 kV

Voltage on OUTH, OUTL, CLAMP pins VL-0.3 to VH+0.3 V

out

Voltage on DESAT, FAULT, LVOFF pin -0.3 to VH+0.3 V

des

Voltage on other pins (IN, COFF, VREF) -0.3 to 7 V

other

Power dissipation 500 mW

P

d

Storage temperature -55 to 150 °C

stg

T

Maximum junction temperature 150 °C

j

Thermal resistance junction-ambient 125 °C/W

thja

Thermal resistance junction-case 22 °C/W

thjc

Table 4. Operating conditions

Symbol Parameter Value Unit

VH Positive supply voltage vs. GND UVLO to 26 V

VL Negative supply voltage vs. GND 0 to -10 V

VH-VL Maximum total supply voltage 26 V

T

Operating free air temperature range -40 to 125 °C

oper

Doc ID 018539 Rev 2 5/17

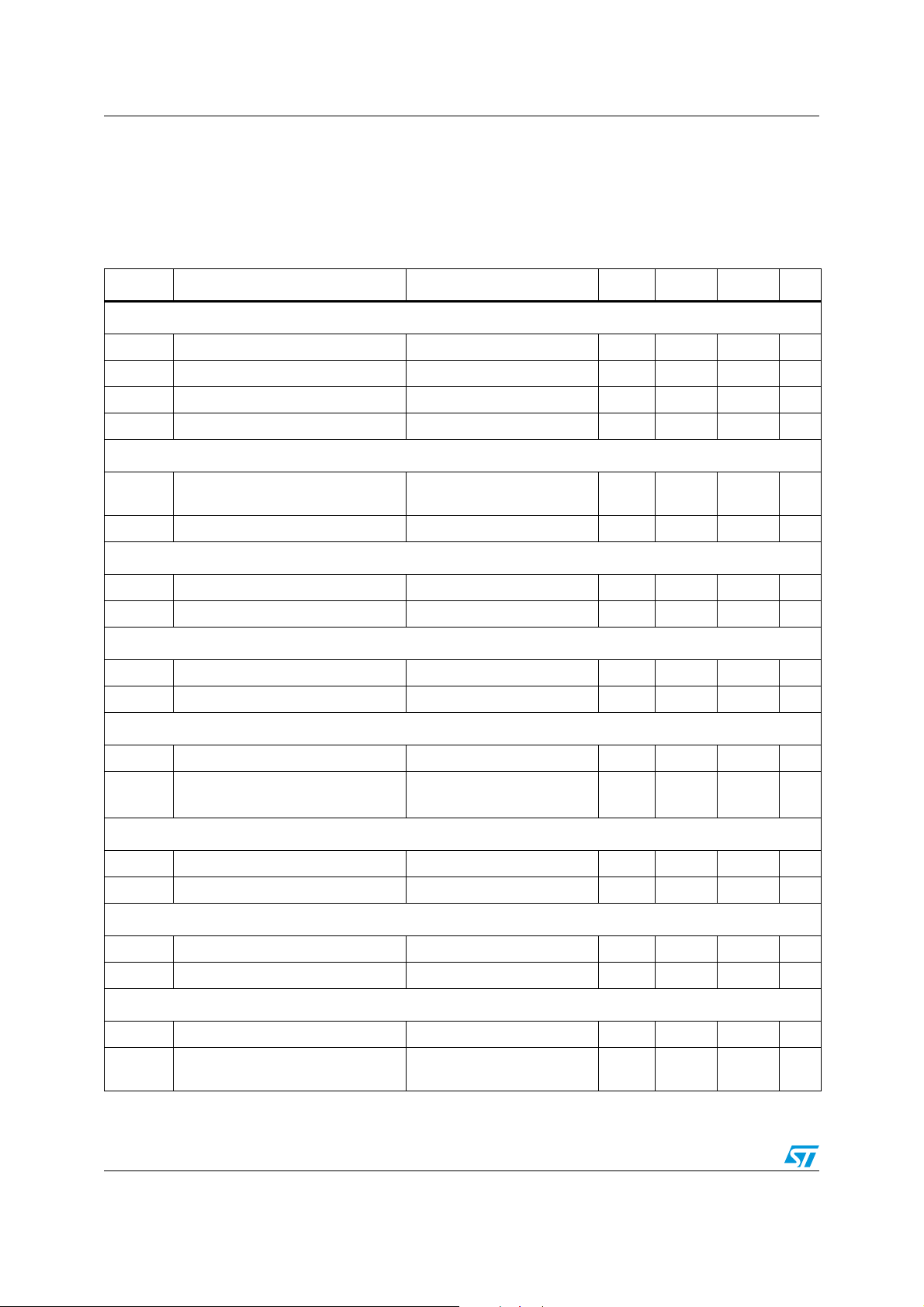

Electrical characteristics TD350E

4 Electrical characteristics

TA = -20 to 125 °C, VH=16 V, VL= -10 V (unless otherwise specified)

Table 5. Electrical characteristics

Symbol Parameter Test condition Min Typ Max Unit

Input

V

V

t

onmin

I

Voltage reference

V

I

IN turn-on threshold voltage 0.8 1.0 V

ton

IN turn-off threshold voltage 4.0 4.2 V

toff

Minimum pulse width 100 135 220 ns

IN input current 1 μA

inp

(1)

Voltage reference

ref

Maximum output current 10 mA

ref

Desaturation protection

V

I

Desaturation threshold 6.5 7.2 7.9 V

des

Source current 250 μA

des

Fault output

t

fault

V

Delay for fault detection 500 ns

FAULT low voltage I

FL

Clamp

V

tclamp

V

CLAMP pin voltage threshold 2.0 V

Clamp low voltage

CL

Off delay

T=25°C

T

<T<T

min

FLsink

T=25°C; I

T

min

max

=10mA 1 V

=500mA

CLsink

<T<T

max

; I

CLsink

=500mA

4.85

4.77

5.00 5.15

5.22

VL+2.5

VL+3.0VV

V

V

V

R

Voltage threshold 2.35 2.50 2.65 V

tdel

Discharge resistor I=1mA 500 Ω

del

Off levels

I

blvoff

V

LVOFF peak input current (sink) LVOFF=12V 120 200 μA

Offset voltage LVOFF=12V -0.3 -0.15 0 V

iolv

Outputs

V

V

Output low voltage at I

OL1

Output low voltage at I

OL2

=20mA VL+0.35 V

osink

osink

=200mA

T=25°C

<T<T

T

min

max

6/17 Doc ID 018539 Rev 2

VL+1.0

VL+1.5VV

TD350E Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min Typ Max Unit

V

V

V

V

Output low voltage at I

OL3

Output high voltage 1 I

OH1

Output high voltage 2 I

OH2

Output high voltage 3 I

OH3

osink

=500mA

T=25°C

<T<T

T

min

osource

osource

osource

max

=20 mA VH-2.5 V

=200 mA VH-3.0 V

=500 mA VH-4.0 V

VL+2.5

VL+3.0VV

CL=1nF, 10% to 90%

t

r

t

f

Rise time

Fall time

(2)

VL=0

VL=-10V

CL=1nF, 90% to 10%

VL=0

VL=-10V

10% output change;

130

175

75

90

400 500 600 ns

T=25°C

t

pd_on

Turn-on propagation delay

10% output change;

T

<T<T

min

max

10% output change;

350 650 ns

350 450 570 ns

T=25°C

t

pd_off

Turn-off propagation delay

10% output change;

<T<T

T

min

max

300 620 ns

Δtw Input to output pulse distortion 10% output change 25 50 120 ns

Undervoltage lockout (UVLO)

ns

ns

ns

ns

UVLOH UVLO top threshold 10 11 12 V

UVLOL UVLO bottom threshold 9 10 11 V

V

UVLO hysteresis UVLOH-UVLOL 0.5 1 V

hyst

Supply current

Quiescent current Output=0 V, no load 5 mA

I

in

1. Recommended capacitor range on VREF pin is 10 nF to 100 nF.

2. 2-step turn-off disabled

Doc ID 018539 Rev 2 7/17

Functional description TD350E

5 Functional description

5.1 Input

The input is compatible with optocouplers or pulse transformers. The input is triggered by

the signal edge and allows the use of a small-sized, low-cost pulse transformer. Input is

active low (output is high when input is low) to ease the use of the optocoupler. When driven

by a pulse transformer, the input pulse (positive and negative) width must be larger than the

minimum pulse width t

5.2 Voltage reference

A voltage reference is used to create accurate timing for the two-level turn-off with external

resistor and capacitor.

5.3 Desaturation protection

Desaturation protection ensures the protection of the IGBT in the event of overcurrent.

When the DESAT voltage goes higher than 7 V, the output is driven low (with 2-level turn-off,

if applicable). The FAULT output is activated. The FAULT state is exited at the next falling

edge of IN input.

onmin

.

A programmable blanking time is used to allow enough time for IGBT saturation. Blanking

time is provided by an internal current source and external capacitor.

DESAT input can also be used with an external comparator for overcurrent or

overtemperature detection.

5.4 Active Miller clamp

A Miller clamp allows the control of the Miller current during a high dV/dt situation and can

eliminate the need for a negative supply voltage.

During turn-off, the gate voltage is monitored and the clamp output is activated when gate

voltage goes below 2 V (relative to GND). The clamp voltage is VL+3 V max for a Miller

current up to 500 mA. The clamp is disabled when the IN input is triggered again.

5.5 Two-level turn-off

The two-level turn-off is used to increase the reliability of the application.

During turn-off, gate voltage can be reduced to a programmable level in order to reduce the

IGBT current (in the event of overcurrent). This action prevents both dangerous overvoltage

across the IGBT and RBSOA problems, especially at short-circuit turn-off.

Turn-off (T

timing.

) delay is programmable through an external resistor and capacitor for accurate

a

Turn-off delay (T

width.

8/17 Doc ID 018539 Rev 2

) is also used to delay the input signal to prevent distortion of input pulse

a

TD350E Functional description

5.6 Minimum ON time

In order to ensure the proper operation of the 2-level turn-off function, the input ON time

(T

) must be greater than the T

win

T

winmin=Ta

R

del

Input signals smaller than T

the output stage after the T

For an input signal width T

below T

+2*R

del*Coff

is the internal discharge resistor and C

are ignored. Input signals larger than T

a

delay with minimum width distortion (ΔTw=T

a

between Ta and T

(pulse distortion) and the IGBT could be partially turned on. These input signals

win

win

winmin

value:

is the external timing capacitor.

off

winmin

, the output width T

winmin

are transmitted to

wout-Twin

wout

).

is reduced

should be avoided during normal operation.

5.7 Output

The output stage is able to sink 2.3 A and source 1.5 A (typ) at 25 °C (1.2 A/0.75 A minimum

over the full temperature range). Separate sink and source outputs allow independent gate

charge and discharge control without an extra external diode.

5.8 Fault status output

Fault output is used to signal a fault event (desaturation, UVLO) to a controller. The fault pin

is designed to drive an optocoupler.

5.9 Undervoltage protection

Undervoltage detection protects the application in the event of a low VH supply voltage

(during startup or a fault situation). During undervoltage, the OUTH pin is open and the

OUTL pin is driven low (active pull-down for VH>2 V, passive pull-down for VH<2 V). Fault

output signals the undervoltage state and is reset only when undervoltage state disappears.

Figure 3. Undervoltage protection

6(

/54

&!5, 4

56(

56,

6CCMIN

6

".W

Doc ID 018539 Rev 2 9/17

Functional description TD350E

Figure 4. Detailed internal schematic

56,/

#/&&

,6 / & &

99

#OMP?)NPUT

$ELAY

6REF

U!

#OMP?$ESAT

9

62%&

9+

$%3!4

).

#ONTROL"LOCK

9UHI

#OMP?$ELAY/FF

9

6

#OMP?#LAMP

9

&!5,4

#,!-0

6(

/54(

9+

LEVEL/&&DRIVER

/54,

6,

10/17 Doc ID 018539 Rev 2

'.$

".W

TD350E Timing diagrams

6 Timing diagrams

Figure 5. Turn-on and turn-off

IN

COFF

Ta

OUT

CLAMP

Vge

VL level

Vce

Figure 6. Minimum ON time

Tin<Ta Tin>Twinmin

IN

Ta<Tin<Twinmin

Twin

VH level

Twout

Open

VH level

Miller plateau

Ta

LVOFF

VL level

Clamp threshold

2.5V

COFF

Ta

OUT

CLAMP

Figure 7. Desaturation fault

IN

COFF

OUT

DESAT

FAULT

Ta

Open

2.5V

Ta

Desat Blanking Time

Ta Ta

VH level

LVOFF

VL level

Ta

VH level

LVOFF

VL level

7V

open

Doc ID 018539 Rev 2 11/17

Typical performance curves TD350E

7 Typical performance curves

Figure 8. Supply current vs. temperature Figure 9. Low level output voltage vs. temp.

Figure 10. Desaturation threshold vs. temp. Figure 11. Voltage reference vs. temp.

5.0

4.0

3.0

In (mA)

2.0

1.0

0.0

-50 -25 0 25 50 75 100 125

Temp (°C)

10

9

8

Vdes (V)

7

3.0

3.0

2.0

2.0

Iosink=500mA

Iosink=500mA

VOL -VL ( V)

VOL -VL ( V)

1.0

1.0

Iosink=200mA

Iosink=200mA

Iosink=20mA

0.0

0.0

-50 -25 0 25 50 75 100 125

-50 -25 0 25 50 75 100 125

Temp (°C)

Temp (°C)

5.20

5.10

5.00

Vref ( V)

Iosink=20mA

6

5

-50 -25 0 25 50 75 100 125

Temp (°C)

4.90

4.80

-50 -25 0 25 50 75 100 125

Temp (°C)

Figure 12. High level output voltage vs. temp. Figure 13. Desaturation source current vs.

4.0

4.0

3.0

3.0

Iosource=500mA

Iosource=500mA

2.0

2.0

VH-VO H (V)

VH-VO H (V)

1.0

1.0

0.0

0.0

-50-250 255075100125

-50-250 255075100125

Temp (°C)

Temp (°C)

Iosource=200mA

Iosource=200mA

Iosource=20mA

Iosource=20mA

temp.

500

400

300

200

Ides (uA)

100

0

-50 -25 0 25 50 75 100 125

Temp (°C)

12/17 Doc ID 018539 Rev 2

TD350E Application diagrams

8 Application diagrams

Figure 14. Single supply IGBT drive with active Miller clamp and 2-level turn-off

6(

6REF

6(

9

6REF

).

62%&

&!5,4

.#

#/&&

.#

,6/&&

6REF

/FF,EVEL

/FF

DELAY

56,/

$%3!4

$ESAT

#ONTROL "LOCK

6(

/54(

/54,

6,

#,!-0

'.$

6

4$%

Figure 15. Large IGBT drive with negative gate drive and desaturation detection

6REF

6REF

/FF

DELAY

/FF,EVEL

56,/

"LOCK

#ONTROL

4$%

$ESAT

$%3!4

6(

/54(

/54,

6,

#,!-0

'.$

6

6

0ULSE4RANSFORMER

6(

6REF

6(

6REF

).

62%&

&!5,4

.#

#/&&

.#

,6/& &

Figure 16. Use of DESAT input for direct overcurrent detection

%

Doc ID 018539 Rev 2 13/17

Package mechanical data TD350E

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Table 6. SO-14 mechanical data

mm. inch

Dim.

Min Typ Max Min Typ Max

A 1.75 0.068

a1 0.1 0.2 0.003 0.007

a2 1.65 0.064

b 0.35 0.46 0.013 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.019

c1 45° (typ.)

D 8.55 8.75 0.336 0.344

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 7.62 0.300

F 3.8 4.0 0.149 0.157

G 4.6 5.3 0.181 0.208

L 0.5 1.27 0.019 0.050

M 0.68 0.026

S 8° (max.)

14/17 Doc ID 018539 Rev 2

TD350E Package mechanical data

Figure 17. Package dimensions

Doc ID 018539 Rev 2 15/17

Revision history TD350E

10 Revision history

Table 7. Document revision history

Date Revision Changes

08-Mar-2011 1 First release.

23-Sep-2011 2

– Updated Ta b l e 1

– Minor text changes throughout the document

16/17 Doc ID 018539 Rev 2

TD350E

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 018539 Rev 2 17/17

Loading...

Loading...