查询STW4141供应商

for Digital Base Band and Multimedia Processor Supply

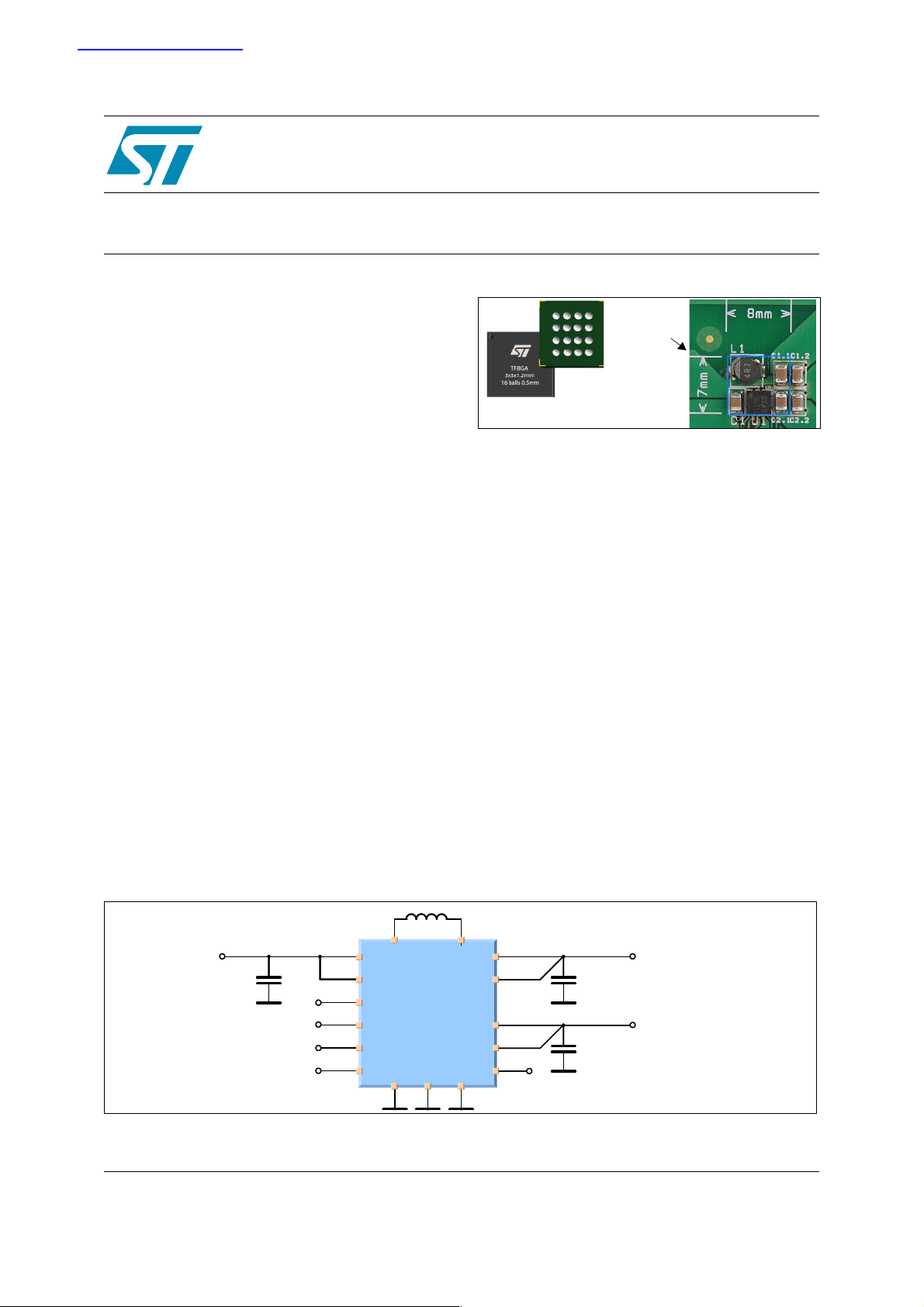

STw4141

Single Coil Dual Output Step Down DC/DC Converter

PRELIMINARY DATA

Features

■ Single coil dual output switc hi ng co nve r ter for

digital core supply & digital I/Os supply

– Digital I/O supply:V

– CPU CORE supply:V

■ Wide range of fixed output voltage

configurations availabl e

■ High efficiency synchronous step down

converter with up to 92 % for the entire device

■ Size and cost optimized application board

(7x8 mm, height 1.2mm) three capacitors and

only one inductor necessary for both outputs

■ 2.7 V to 5.5 V battery input range

■ ±100mV output voltage accuracy full range in

PWM (Including Line and Load Transients)

■ 900 kHz fixed frequency PWM oper ation

■ PFM mode operation at light load current

■ PWM/PFM switch can be done automatically or

forced by setting external pin s (AUTO and

MODE/SYNC)

■ MODE/SYNC input pin for external clock

synchronization from 600 kHz to 1.5 MHz

■ VSEL input pin for V

■ Ultra low shutdown current (Iq<1 µA)

■ Short circuit and thermal shutdown protections

OUT2/VOUT2(red.)

OUT1

OUT2

@ 200 mA

@ 400 mA

selection

Solution size

7 x 8 mm

TFBGA 3x3mm

16 bumps 0.5 mm pitch

Applications

■ Mobile phones

■ PDAs and hand held terminals

■ Portable media players

■ Digital still camera

■ WLAN and Bluetooth applications

Description

The STw4141 is a single coil dual output

synchronous step down DC/DC converter that

requires only four standard external components.

It operates at a fixed 900 kHz switching frequency

in PWM mode. The device can operate in PFM

mode to maintain high efficiency over the full

range of output currents.

The STw4141 application requires a very small

PCB area and offers a very efficient, accurate,

space and cost saving solution to fulfill the

requirements of digital baseband or multimedia

processor supply (CORE & I/O).

Application Test Circuit

L 4.7 µH

L 4.7 µH

VLX1 VLX2

VLX1 VLX2

=2.7V to 5.5V

=2.7V to 5.5V

V

V

IN

IN

C

C

IN

IN

10 µF

10 µF

6.3 V

6.3 V

MODE/SYNC

MODE/SYNC

PVDD

PVDD

VDD

VDD

EN

EN

AUTO

AUTO

VSEL

VSEL

A2 A3

A2 A3

B1

B1

D3

D3

D4

D4

STw4141

STw4141

C2

C2

C3

C3

C1

C1

A1B3C4

A1B3C4

PGND

PGND

GND

GND

A4

A4

D1

D1

B4

B4

D2

D2

B2

B2

T_MODE

T_MODE

VOUT1

VOUT1

FB1

FB1

VOUT2

VOUT2

FB2

FB2

STATE

STATE

C

C

OUT1

OUT1

22 µF

22 µF

6.3 V

6.3 V

C

C

OUT2

OUT2

22 µF

22 µF

6.3 V

6.3 V

December 2005 1/27

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

V

V

OUT1

OUT1

V

V

OUT2

OUT2

=1.8V

=1.8V

=1.0V/1.2V

=1.0V/1.2V

Rev 1

www.st.com

2

STw4141

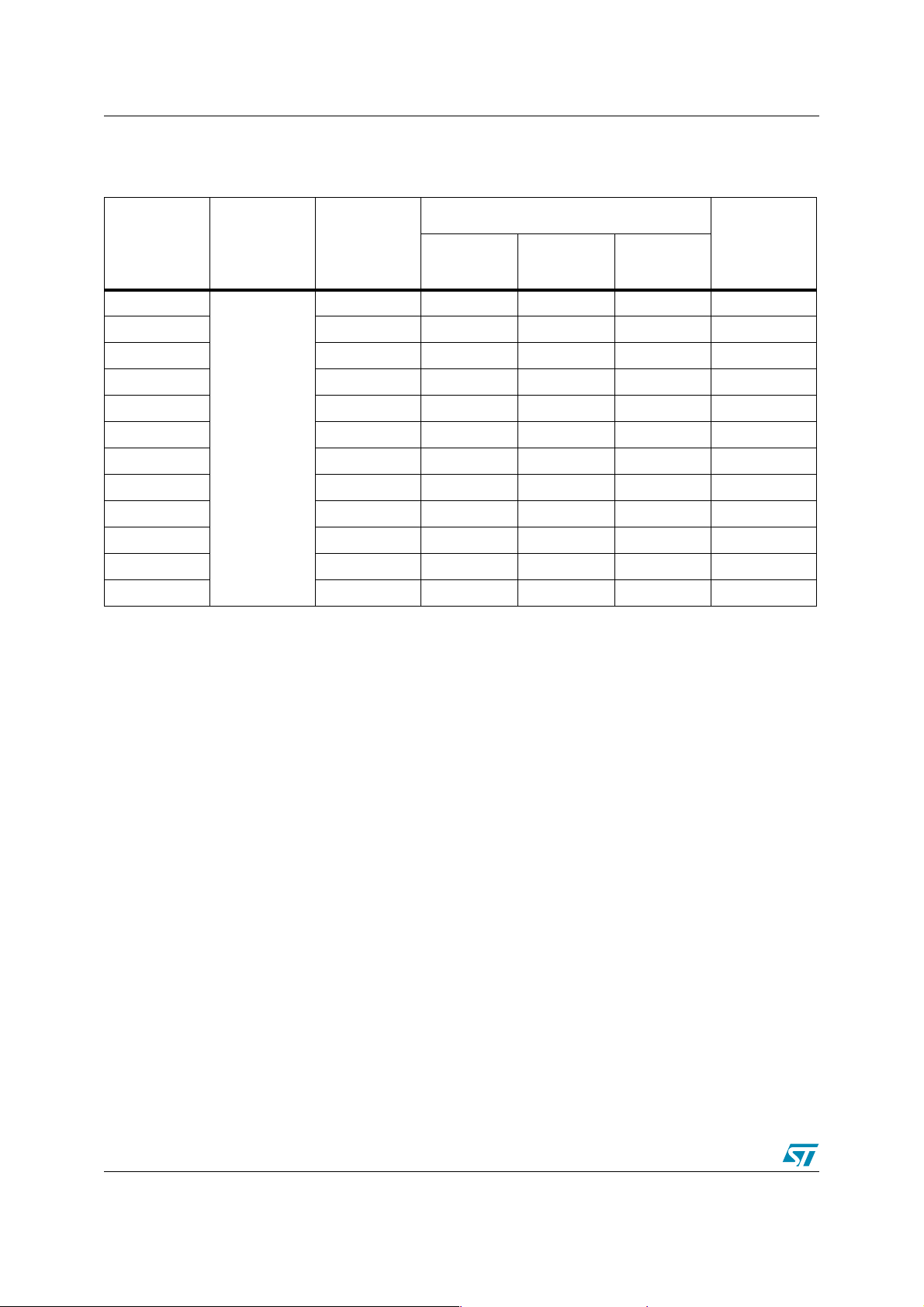

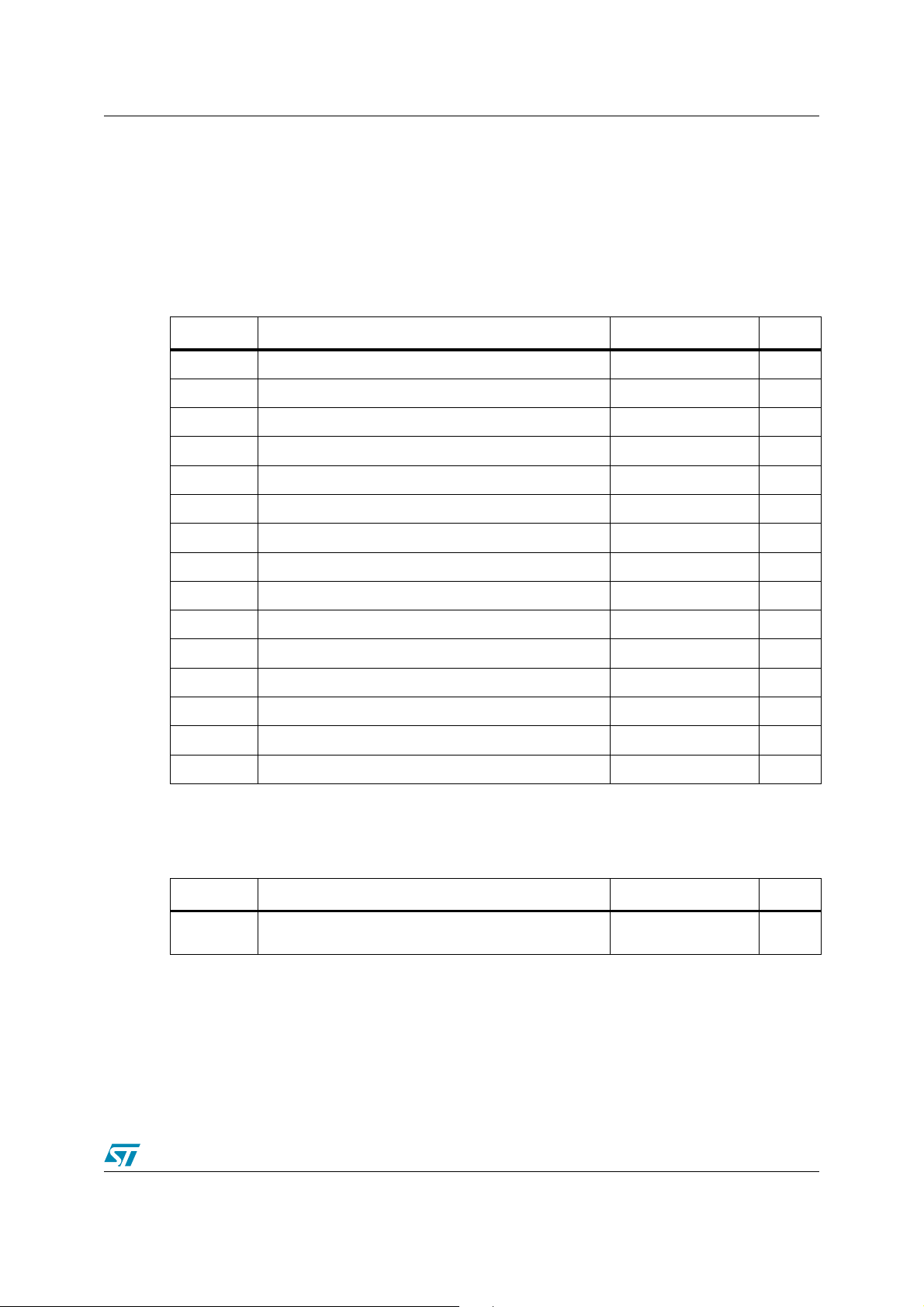

Order Codes

Table 1. STw4141 ordering information

(1)

V

OUT2reduced

(CORE)

Supplied as

Part number Package type

Package

marking

Output voltage options

(2)

V

OUT1

(I/O)

(CORE)

V

OUT2

STw41411

STA1 1.8 V 1.2 V 1.0 V Tray

STw41411/T STA1 1.8 V 1.2 V 1.0 V Tapes/Reels

STw41412 STA2 1.8 V 1.3 V 1.0 V Tray

STw41412/T STA2 1.8 V 1.3 V 1.0 V Tapes/Reels

STw41413 STA3 1.5 V 1.3 V 1.0 V Tray

STw41413/T STA3 1.5 V 1.3 V 1.0 V Tapes/Reels

TFBGA

3x3x1.2

STw41414 STA4 1.8 V 1.5 V 1.3 V Tray

16 balls

STw41414/T STA4 1.8 V 1.5 V 1.3 V Tapes/Reels

STw41415 STA5 1.8 V 1.35 V 1.0 V Tray

STw41415/T STA5 1.8 V 1.35 V 1.0 V Tapes/Reels

STw41416 STA6 1.8 V 1.25 V 1.0 V Tray

STw41416/T STA6 1.8 V 1.25 V 1.0 V Tapes/Reels

1. The output configuration which will be introduced in production will be only those related to customer design-in.

2. THIS CONDITION MUST BE ALWAYS VALID.

VOUT1 VOUT2≥

2/27

STw4141

Contents

1 STw4141 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Dynamic electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Soft start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Settling time of VOUT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Line transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Load transients in AUTO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.9 Load transients in PWM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.10 Switching between PFM and PWM in FORCED MODE . . . . . . . . . . . . . . . . 13

2.11 Efficiency in PWM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12 Efficiency in AUTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.13 Output voltages versus output currents in PWM and PFM . . . . . . . . . . . . . . 16

3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 PWM and PFM mode operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Current limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Short circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Thermal shutdown protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 User mode details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Aut omatic PWM/PFM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 User selected PWM/PFM mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 External clock synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Checking Transient response versus external components . . . . . . . . . . . . . 20

4.6 Bill of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3/27

STw4141

4.6.2 Input capacitor (CIN selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.3 Output capacitors (COUT selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.4 Capacitors selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7 PCB layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7.1 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7.2 TFBGA16 internal bumps access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Package Outline and Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4/27

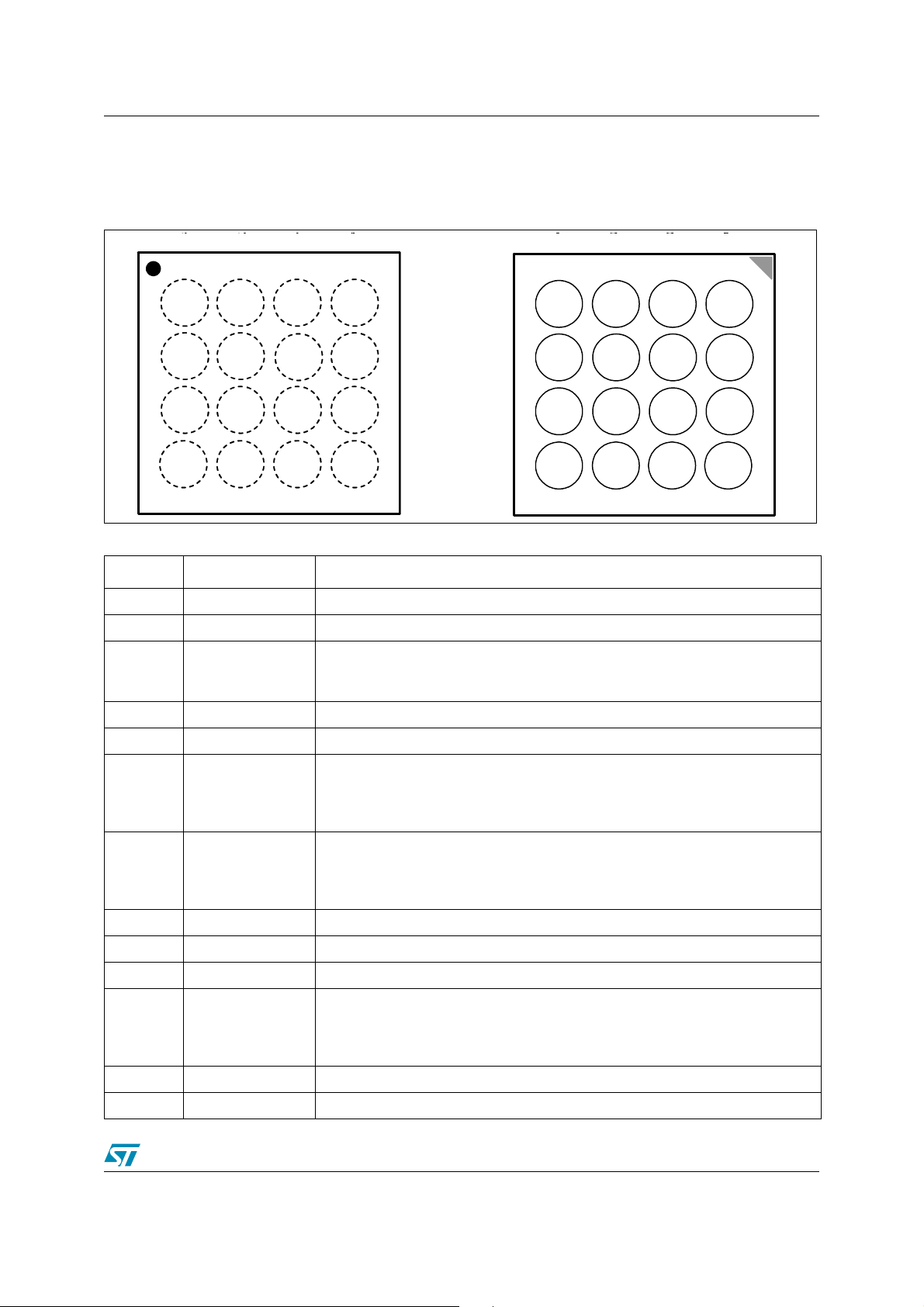

STw4141 1 STw4141 Pinout

1 2 3

4

/

1 2 3

4

1 STw4141 Pinout

Figure 1. Pin assignment in TFBGA 3x3 mm - 16 bumps 0.5 mm pitch

12 34

4321

A

B

C

D

PGND

PVDD

MODE/

SYNC

FB1

VLX1

STATE

AUTO

FB2

VLX2

T_MODE

VSEL

VDD

VOUT1

VOUT2

GND

EN

Top v i ew

Table 2. STw4141 pin description

Pin Symbol Description

A1 PGND Power ground

B1 PVDD Power supply voltage

MODE/SYNC = High to forced PWM mode

C1 MODE/SYNC

D1 FB1 Feedback 1

A2 VLX1 External inductor connection pin 1

B2 STATE

MODE/SYNC = Low to forced PFM mode

MODE/SYNC = 600 kHz - 1.5 MHz external clock synchronization in PWM

Output STATE pin allow the user to monitor operation mode of the product

STATE = High - PFM mode

STATE = Low - PWM mode

If not used must be left unconnected.

VOUT1

VOUT2

GND

EN

VLX2

T_MODE

VSEL

VDD

Bottom view

VLX1

STATE

AUTO

FB2

PGND

PVDD

MODE

SYNC

FB1

A

A

B

B

C

C

D

D

PWM/PFM automatic switch control pin

C2 AUTO

AUTO = High - PWM/PFM mode automatic switch ENABLED

AUTO = Low - PWM/PFM mode automatic switch DISABLED

PWM/PFM mode controlled by MODE/SYNC pin)

D2 FB2 Feedback 2

A3 VLX2 External inductor connection pin 2

B3 T_MODE Input signal for test mode selection. This pin must be connected to GND.

Voltage selection input

C3 VSEL

VSEL = High - VOUT1 = 1.8V, VOUT2 = 1.2V (valid for STA1)

VSEL = Low - VOUT1 = 1.8V, VOUT2 = 1.0V (valid for STA1)

(For other voltage options see

Table 1: STw4141 ordering information

)

D3 VDD Signal supply voltage

A4 VOUT1 Output voltage 1

5/27

1 STw4141 Pinout STw4141

Table 2. STw4141 pin description

Pin Symbol Description

B4 VOUT2 Output voltage 2

C4 GND Signal ground

Enable Input:

D4 EN

EN = Low - Device in shutdown mode,

EN = High - Enable device

This pin must be connected either to VDD or GND.

PGND pin

This is the ground pin related to power sign al. This pin should be connected to the board ground

plane by short and wide track or multiply vias to reduce impedance and EMI.

GND pins This is the ground pin related to analog signal.

PVDD pin

This pin is designed to provide power to the device. This path leads high currents. It should be

wide and short to minimize track impedance to reduce losses and EMI.

VDD pin

This pin is designed to provide signal supply voltage to the device. There is no specific

requirement for its related track design.

VLX1/VLX2 pins

External coil is connected on those pins. It should be placed as closed as possible to the device

in order minimize resistances which cause looses. These paths lead high currents.

VOUT1 pin3

It is the first output voltage of this device. This path leads high currents. It should be wide and

short to minimize track impedance to reduce losses and EMI.

VOUT2 pin

It is the second output v olta ge of t his d e vic e. This p ath le ads h igh c urrents . It shou ld be wide and

short to minimize track impedance to reduce losses and EMI.

FB1 pin Intended to measure VOUT1 voltage in order to ensure the regulation of this output.

FB2 pin Intended to measure VOUT2 voltage in order to ensure the regulation of this output.

ENABLE pin

This is the enable pin of the device. Pulling this pin to ground, forces the device into shutdown

mode. Pulling this pin to VDD enables the device. This pin must be terminated.

MODE/SYNC pin

The MODE/SYNC pin is a multipurpose pin which provides mode selection and frequency

synchronization.

The devic e c an al so be s yn chr onized to an external cl ock signal from 600 kHz to 1.5 MHz by the

MODE/SYNC pin. During synchronization, the mode is forced to PWM mode and the top switch

turn-on is synchronized to the rising edge of the external clock.

AUTO pin

This pin allows th e de vice to au tomatica lly s witch from PWM to PFM mo de f ollowi ng load on b oth

2 outputs.

STATE pin This output pin informs user in which state the device is working: PWM or PFM mode.

VSEL pin

This pin is used to reduce V

(CORE) output voltage in order to r edu ce the proc essor power

OUT2

consumption when entering into sleep mode.

6/27

STw4141 2 Electrical Characteristics

2 Electrical Characteristics

2.1 Absolute maximum ratings

Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied. All voltages are referenced to GND.

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

PV

DD

V

DD

V

EN

V

SEL

V

MODE/SYNC

V

AUTO

V

T_MODE

V

STATE

,FB

V

OUT1

V

OUT2, FB2

VLX

1

VLX

2

T

A

T

J

T

STG

Power Supply Voltage -0.3 to 6 V

Signal Supply Voltage -0.3 to 6 V

Enable Input

V oltage Selection

Operating Mode Selection/Synchronization Input

PWM/PFM automatic switch selection

Test mode select ion

Operating mode information

Output Voltage 1, Feedback 1 -0.3 to 3.3 V

1

-0.3 to V

-0.3 to V

-0.3 to V

-0.3 to V

-0.3 to V

-0.3 to V

DD

DD

DD

DD

DD

OUT1

Output Voltage 2, Feedback 2 -0.3 to 3.3 V

External Inductor Connection Pin 1

-0.3 to V

DD

External Inductor Connection Pin 2 -0.3 to 3.3 V

Operating Temperature Range -40 to 85 °C

Maximum Operating Junction Temperature 150 °C

Storage Temperature Range -65 to 150 °C

V

V

V

V

V

V

V

2.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

Thermal Resistance Junction-Ambient

TFBGA 3x3 mm – 16 bumps - 0.5 mm pitch

150 °C/W

7/27

2 Electrical Characteristics STw4141

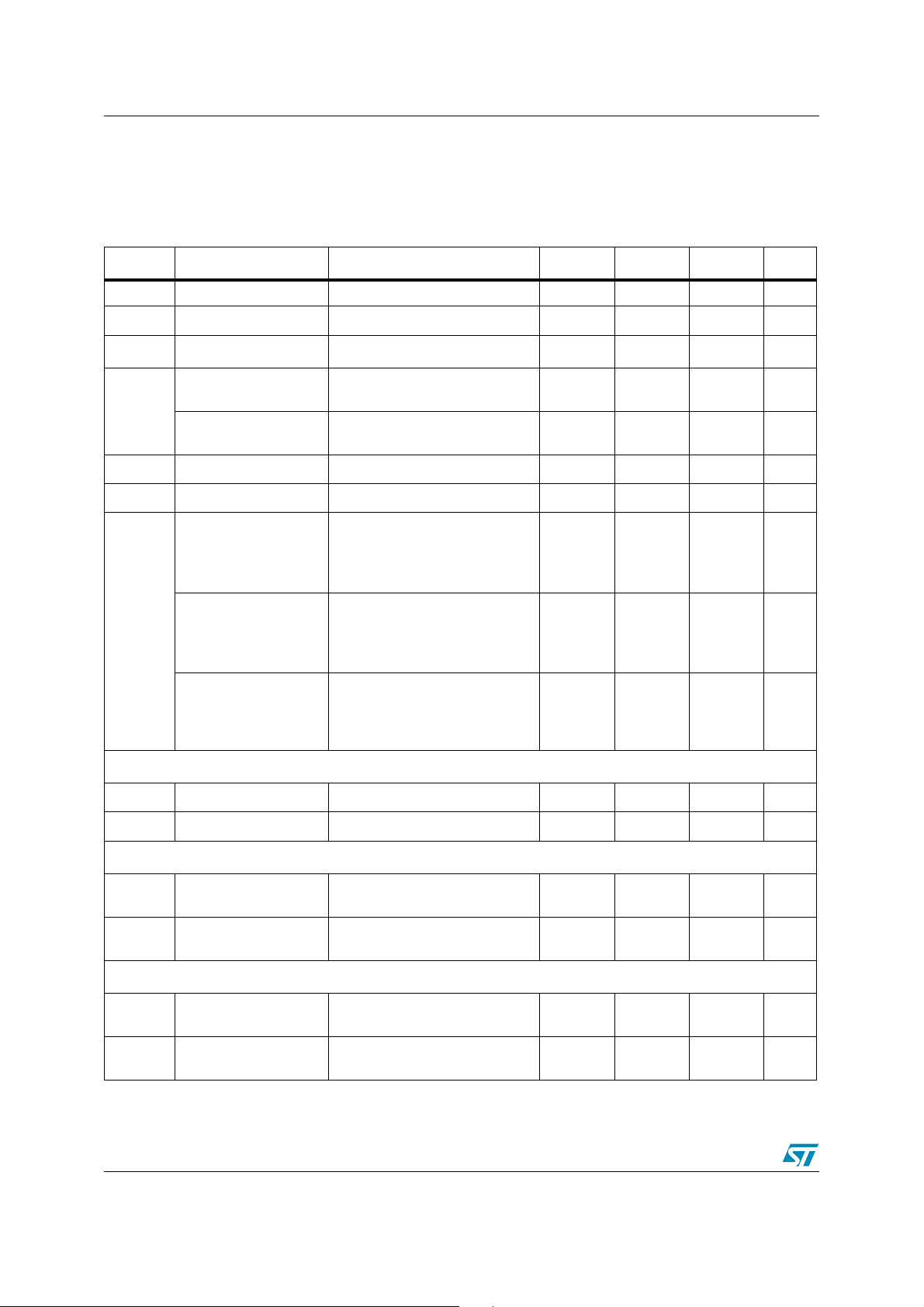

2.3 DC electrical characteristics

Characteristics measured over recommended operating conditions unless otherwise is noted.

All typical values are referred to T

Table 5. DC electrical characteristics

Symbol Parameter Test Conditions Min. Typ Max. Unit

PVDD Power supply voltage 2.7 5.5 V

I

LIM

V

OUT1

V

OUT2

Peak current limit 1.6 A

(1)

Output voltage 1

Output voltage 2

Output voltage 2

(2)

(2)

(2)

VSEL = VDD,

MODE/SYNC = VDD

VSEL = GND,

MODE/SYNC = VDD

= 25°C, PVDD = 3.6V, VDD = 3.6V.

A

-3 +3 %

-3 +3 %

-3 +3 %

I

OUT1

I

OUT2

Output current 1 200 mA

Output current 2 400 mA

Quiescent Current

(PWM)

I

q

Quiescent Current

(PFM)

Shutdown Current

Enable functions

H

V

EN

V

EN

Enable Threshold High 0.9 V

L

Enable Threshold Low 0.4 V

Mode/sync functions

H

L

MODE/SYNC

Threshold High

MODE/SYNC

Threshold Low

V

M/S

V

M/S

I

OUT1

= 0 mA, I

OUT2

= 0 mA

EN = VDD, VSEL = VDD

MODE/SYNC = VDD,

AUTO = GND

I

OUT1

= 0 mA, I

OUT2

= 0 mA

EN = VDD, VSEL = VDD

MODE/SYNC = GND,

AUTO = GND

EN = GND,

VSEL = GND

MODE/SYNC = GND,

AUTO = GND

600 µA

90 µA

15µA

0.9 V

0.4 V

VSEL functions

Voltage Selection

H

V

V

SEL

SEL

Threshold High

Voltage Selection

L

Threshold Low

8/27

0.9 V

0.4 V

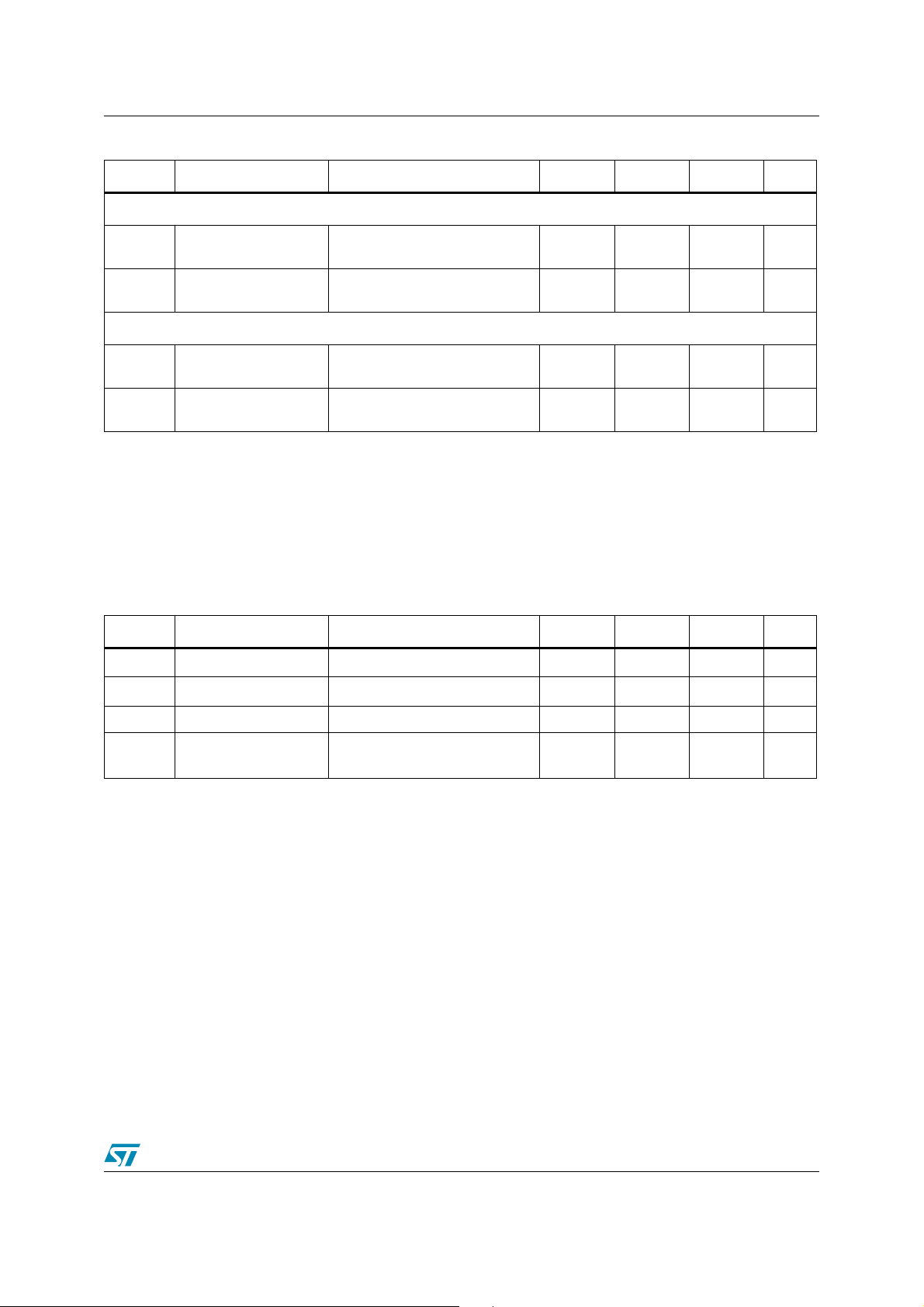

STw4141 2 Electrical Characteristics

Table 5. DC electrical characteristics

Symbol Parameter Test Conditions Min. Typ Max. Unit

Auto functions

Voltage Selection

H

V

AUTO

V

AUTO

Threshold High

Voltage Selection

L

Threshold Low

State functions

Voltage Selection

H

V

STATE

V

STATE

1. . This condition must always be valid.

VOUT1 VOUT2≥

2. Output voltage accuracy excludes line and load transients

Threshold High

Voltage Selection

L

Threshold Low

R

R

Lmax

Lmax

= 100k, C

= 100k, C

Lmax

Lmax

= 10pF 0.7V

= 10pF 0.3 V

0.9 V

0.4 V

OUT1

OUT1

V

V

2.4 Dynamic electrical characteristics

Characteristics measured over recommended operating conditions unless otherwise is noted.

All typical values are referred to T

= 25°C, PVDD = 3.6V, VDD = 3.6V.

A

Table 6. Dynamic electrical characteristics

Symbol Parameter Test Conditions Min. Typ Max. Unit

f

SW

f

SYNC

Ts Settling time (soft start) 400 µs

TS2

Switching frequency 900 kHz

Sync mode frequency 600 1500 kHz

Settling time

V

(reduced)/V

OUT2

VSEL change from GND to VDD 80 µs

OUT2

9/27

2 Electrical Characteristics STw4141

2.5 Soft start

To avoid spikes on battery during STw4141 start-up sequence, a smooth start-up is

implemented. Reference voltage grows up less than 600 µs until it achieves is final target.

Therefore, STw4141 start up is smooth and secure for the overall mobile phone.

Figure 2. Smooth start-up sequence V

V

=1.2V@400mA

OUT2

2.6 Settling time of V

OUT2

= 3.6V, V

IN

= 1.8V@ 200mA,

OUT1

Figure 3. Settling time of V

10/27

OUT2, IOUT1

= 200mA, I

OUT2

= 400mA

STw4141 2 Electrical Characteristics

2.7 Line transients

Figure 4. Line transient, V

= 1.8V @ 100mA, V

OUT1

2.8 Load transients in AUTO mode

Figure 5. Load transient in AUTO mode VIN = 3.6V, V

= 1.2V @ 100mA

OUT2

= 1.8V, V

OUT1

OUT2

= 1.2V

11/27

2 Electrical Characteristics STw4141

2.9 Load transients in PWM mode

Figure 6: Load transient in PWM mode, I

Load transient related to in-phase switching

VIN = 3.6V, V

Load transient output 2 leading output 1

= 3.6V, V

V

IN

OUT1

OUT1

= 1.8V, V

= 1.8V, V

OUT2

OUT2

= 1.2V

= 1.2V

= 1mA to 200mA, I

OUT1

= 1mA to 400mA

OUT2

Load transient output 1 leading output 2

= 3.6V, V

V

IN

OUT1

= 1.8V, V

OUT2

Load transient related to anti-phase switching

VIN = 3.6V, V

OUT1

= 1.8V, V

OUT2

= 1.2V

= 1.2V

12/27

STw4141 2 Electrical Characteristics

2.10 Switching between PFM and PWM in FORCED MODE

Figure 7. Switching between PFM to PWM operation modes VIN = 3.6V, I

= 10mA

I

OUT2

Figure 8. Switching between PWM to PFM operation modes V

I

= 10mA

OUT2

= 3.6V, I

IN

OUT1

OUT1

= 10mA,

= 10mA,

13/27

2 Electrical Characteristics STw4141

2.11 Efficiency in PWM

The efficiency of a switching regulator is equal to the total output power divided by the input.

STw4141 has high efficiency up to 92% (for the 2 outputs). Efficiency curve is flat over the

output current range.

Figure 9. Switching regulator efficiency in PWM mode

Efficiency in PWM mode @ VIN=2.7V, TA= 25°C

Efficiency in PWM mode @ VIN=3.6V, TA= 25°C

200

180

160

140

120

I

(mA)

OUT1

Efficiency vs I

60

50

40

30

20

10

0

100

80

60

40

20

1

1

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

OUT1@IOUT2

V

= 2.7V

IN

V

= 1.8V

OUT1

V

= 1.2V

OUT2

1 10 100 1000

200

160

120

80

40

PWM mode, TA=25°C

I

(mA)

OUT1

400

360

320

280

240

(mA)

I

OUT2

100

90

80

70

Efficiency (%)

90-100

80-90

70-80

60-70

50-60

40-50

30-40

20-30

10-20

0-10

I

= 0 mA

OUT2

I

= 200 mA

OUT2

I

= 400 mA

OUT2

200

180

160

140

120

I

(mA)

OUT1

Efficiency vs I

EFFICIENCY (%)

100

90

80

70

60

50

40

30

20

10

100

80

60

40

20

1

1

100

90

80

70

60

50

40

30

20

10

0

OUT1@IOUT2

V

= 3.6V

IN

V

= 1.8V

OUT1

V

= 1.2V

OUT2

1 10 100 1000

200

160

120

80

40

PWM mode, TA=25°C

I

(mA)

OUT1

0

400

360

320

280

240

I

(mA)

OUT2

I

OUT2

I

OUT2

I

OUT2

Effici ency (%)

90-100

80-90

70-80

60-70

50-60

40-50

30-40

20-30

10-20

0-10

= 0 mA

= 200 mA

= 400 mA

Efficiency vs I

100

V

90

80

70

V

60

V

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

IN

OUT1

OUT2

= 2.7V

= 1.8V

= 1.2V

OUT2@IOUT1

, PWM mode, TA=25°C

I

(mA)

OUT2

I

= 0 mA

OUT1

I

= 100 mA

OUT1

I

= 200 mA

OUT1

14/27

Efficiency vs I

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

V

IN

V

OUT1

V

OUT2

= 3.6V

= 1.8V

= 1.2V

OUT2@IOUT1

, PWM mode, TA=25°C

I

(mA)

OUT2

I

= 0 mA

OUT1

I

= 100 mA

OUT1

I

= 200 mA

OUT1

STw4141 2 Electrical Characteristics

)

)

)

2.12 Efficiency in AUTO

The efficiency of a switching regulator is equal to the total output power divided by the input.

STw4141 has high efficiency up to 92% (both outputs) and always higher than 70% for output

currents higher than 1mA.

Figure 10. Switching regulator efficiency in auto mode

Efficiency VS output currents I

180

150

120

90

I

OUT1

60

(mA)

30

1

Efficiency VS I

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

Efficiency VS I

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

V

IN

V

OUT1

V

OUT2

V

IN

V

OUT1

V

OUT2

= 2.7V

= 2.7V

= 1.8V

= 1.2V

= 1.8V

= 1.2V

OUT1@IOUT2

OUT2@IOUT1

OUT1

40

80

and I

120

, VIN = 2.7V, AUTO mode

OUT2

320

280

240

200

160

I

(mA)

OUT2

, AUTO mode, TA = 25°C

I

(mA

, AUTO mode, TA = 25°C

I

(mA)

OUT2

Efficiency VS output currents I

100

90

80

70

60

50

Efficiency (%

40

90-100

80-90

30

70-80

20

60-70

50-60

10

40-50

0

30-40

20-30

400

10-20

360

0-10

200

160

120

80

(mA)

I

OUT1

40

1

Efficiency VS IOUT1@I

100

V

= 3.6V

I

= 0 mA

OUT2

I

= 200 mA

OUT2

I

= 400 mA

OUT2

IN

90

80

70

V

= 1.8V

OUT1

V

= 1.2V

60

OUT2

50

40

EFFICIENCY (%)

30

20

10

0

1 10 100 1000

Efficiency VS I

100

V

= 3.6V

I

= 0 mA

OUT1

I

= 100 mA

OUT1

I

= 200 mA

OUT1

IN

90

80

70

60

V

= 1.8V

OUT1

V

= 1.2V

OUT2

50

40

EFFICIENCY (%)

30

20

10

0

1101001000

and I

OUT1

160

120

80

0

OUT2

I

OUT2@IOUT1

I

OUT2

, VIN = 3.6V, AUTO mode

OUT2

100

90

80

70

60

50

Efficiency (%)

40

30

20

10

0

400

360

320

280

240

200

I

(mA)

OUT2

, AUTO mode, TA = 25°C

I

= 0 mA

OUT2

I

= 200 mA

OUT2

I

= 400 mA

OUT2

(mA

, AUTO mode, TA = 25°C

I

= 0 mA

OUT1

I

= 100 mA

OUT1

I

= 200 mA

OUT1

(mA)

90-100

80-90

70-80

60-70

50-60

40-50

30-40

20-30

10-20

0-10

15/27

2 Electrical Characteristics STw4141

2.13 Output voltages versus output currents in PWM and PFM

Figure 11. Output voltages versus output currents in PWM and PFM

V

VS I

OUT1

1.830

V

= 3.6V

IN

1.820

1.810

(V)

1.800

OUT1

V

1.790

OUT1

@ I

- PWM mode

OUT1

I

I

I

OUT2

OUT2

OUT2

= 0 mA

= 200 mA

= 400 mA

V

VS I

OUT2

1.230

V

= 3.6V

IN

1.220

1.210

(V)

1.200

OUT2

V

1.190

OUT2

@ I

- PWM mode

OUT1

I

I

I

OUT1

OUT1

OUT1

= 0 mA

= 100 mA

= 200 mA

1.780

1.770

1 10 100 1000

V

OUT1

1.830

V

= 3.6V

IN

1.820

1.810

(V)

1.800

OUT1

V

1.790

1.780

1.770

110100

VS I

I

OUT1

I

OUT1

OUT1

(mA)

@ I

(mA)

- PFM mode

OUT2

I

= 0 mA

OUT2

I

= 20 mA

OUT2

I

= 40 mA

OUT2

1.180

1.170

1 10 100 1000

V

OUT2

1.230

V

= 3.6V

IN

1.220

1.210

(V)

1.200

OUT2

V

1.190

1.180

1.170

110100

VS I

OUT2

I

(mA)

OUT2

@ I

- PFM mode

OUT1

I

= 0 mA

OUT1

I

= 10 mA

OUT1

I

= 20 mA

OUT1

I

(mA)

OUT2

16/27

STw4141 3 Functional Description

3 Functional Description

3.1 Introduction

The STw4141 is an easy to use, single coil dual outputs step down DC/DC converter optimized

to supply low-voltage to CPUs or DSPs in cell phones and other miniature devices powered by

single cell lithium-ion or 3 cell NiMH/NiCd batteries. It provides two different output voltages

with high efficiency operation in a wide range of output currents. The device offers high DC

voltage regulation accuracy and load transient response to satisfy demanding processor core

supply. The converter is based on voltage mode buck architecture using PWM and PFM

operation modes.

At light load currents, the device can operate in PFM mode to maintain high efficiency over the

entire load current range. Switching between PWM and PFM modes can be done automatically

or can be forced by external pins (AUTO and MODE/SYNC). Externally synchronized or fixed

frequency (internal oscillator) PWM mode offers full output current capability while minimizing

interference to sensitive RF and data acquisition circuits.

3.2 PWM and PFM mode operation

PWM (Pulse Width Modulation) mode is intended for normal load to high load currents. Energy

is delivered to the load with an accurate and defined frequency of 900 kHz.

PFM (Pulse Frequency Modulation) mode is intended for low load currents to maintain high

efficiency conversion.

Forced mode: When AUTO pin is LOW, the operating mode is selectable by the user itself. It

means that system controls the behavior of the STw4141 according to processor needs.

STw4141 is switched from PWM to PFM mode using MODE/SYNC pin (refer to

details

” section).

Automatic PWM / PFM switch: When AUTO pin is HIGH, the operating mode is directly

controlled by internal digital circuit according to processor needs. The device switches from

PWM to PFM by itself if sum of output currents is lower than approximately 100 mA during at

least 16 clock cycles. The device can be forced to PWM mode connecting MODE/SYNC to

HIGH level. (see

Section 2.8

and

3.3 Current limiter

This protection limits the current flowing through coil. As soon as ILIM is detected, the duty

cycle is terminated and prevents the coil current against rising above peak current limit. There

is no reset of device.

3.4 Short circuit protection

Section 2.9

User mode

).

It protects the device against short-circuit at output terminals. When one or both output

voltages are decreased by 0.7 V below their nominal output values the device enters into reset

followed by soft start sequence.

17/27

4 Application information STw4141

3.5 Thermal shutdown protection

Thermal shutdown protects the device against damage due to overheating when maximum

operating junction temperature is exceeded. The device is kept in reset until junction

temperature decreases by 25°C approximately.

4 Application information

4.1 User mode details

The following table describes the different user modes available. Depending on the application

constraints (processor I/O pins available) and expected efficiency, PWM or PFM mode are

forced or automatically controlled by STw4141 internal digital gates.

Table 7. STw4141 available user modes

Mode User mode / pins EN AUTO

OFF Shutdown L X X

Forced PFM H L L

FORCED

AUTO

Forced PWM H L H

Forced PWM and synchronized external clock H L CLK

Auto mode H H L

Forced PWM H H H

Forced PWM and synchronized external clock H H CLK

MODE/

SYNC

Table 8. Operating mode information (STATE pin - digital output)

Operation mode State pin voltage level

PFM VOUT1

PWM GND

18/27

STw4141 4 Application information

4.2 Automatic PWM/PFM mode

This user mode is designed to allow STw4141 to switch automatically between PWM and PFM

modes. This feature improves the application efficiency because ST w4141 enters in PFM mode

according to application processor current consumption.

Figure 12. Automatic PWM/PFM switch schematic example

L 4.7 µH

L 4.7 µH

VLX1 VLX2

VLX1 VLX2

VIN=2.7V to 5.5V

=2.7V to 5.5V

V

IN

C

C

IN

IN

10 µF

10 µF

6.3 V

6.3 V

MODE/SYNC

MODE/SYNC

PVDD

PVDD

VDD

VDD

EN

EN

AUTO

AUTO

VSEL

VSEL

A2 A3

A2 A3

B1

B1

D3

D3

D4

D4

STw4141

STw4141

C2

C2

C3

C3

C1

C1

A1B3C4

A1B3C4

PGND

PGND

GND

GND

A4

A4

D1

D1

B4

B4

D2

D2

B2

B2

T_MODE

T_MODE

VOUT1

VOUT1

FB1 C

FB1 C

VOUT2

VOUT2

FB2 C

FB2 C

STATE

STATE

OUT1

OUT1

22 µF

22 µF

6.3 V

6.3 V

OUT2

OUT2

22 µF

22 µF

6.3 V

6.3 V

C

C

1

1

100 nF

100 nF

C

C

2

2

100 nF

100 nF

APE I/O

APE I/O

APE CORE

APE CORE

APPLICATION

APPLICATION

PROCESSOR

PROCESSOR

MODE_INFO

MODE_INFO

SLEEP

SLEEP

GND

GND

4.3 User selected PWM/PFM mode

STw4141 PWM/PFM mode can also be controlled by the application processor. This feature is

accessible through MODE/SYNC pin state. It is useful to users who want to use STw4141 with

the modem digital processor. Therefore, MODE/SYNC pin is connected to SLEEP mobile

phone signal.

Figure 13. PWM/PFM forced mode schematic example

L 4.7 µH

L 4.7 µH

VLX1 VLX2

VLX1 VLX2

VIN=2.7V to 5.5V

=2.7V to 5.5V

V

IN

C

C

IN

IN

10 µF

10 µF

6.3 V

6.3 V

MODE/SYNC

MODE/SYNC

PVDD

PVDD

VDD

VDD

EN

EN

AUTO

AUTO

VSEL

VSEL

A2 A3

A2 A3

B1

B1

D3

D3

D4

D4

STw4141

STw4141

C2

C2

C3

C3

C1

C1

A1B3C4

A1B3C4

PGND

PGND

GND

GND

A4

A4

D1

D1

B4

B4

D2

D2

B2

B2

T_MODE

T_MODE

VOUT1

VOUT1

FB1 C

FB1 C

VOUT2

VOUT2

FB2 C

FB2 C

STATE

STATE

OUT1

OUT1

22 µF

22 µF

6.3 V

6.3 V

OUT2

OUT2

22 µF

22 µF

6.3 V

6.3 V

C

C

1

1

100 nF

100 nF

C

C

2

2

100 nF

100 nF

APE I/O

APE I/O

APE CORE

APE CORE

APPLICATION

APPLICATION

PROCESSOR

PROCESSOR

MODE_INFO

MODE_INFO

PWR_EN

PWR_EN

SLEEP

SLEEP

GND

GND

19/27

4 Application information STw4141

4.4 External clock synchronization

Figure 14. Application using external clock synchronization

L 4.7 µH

L 4.7 µH

VLX1 VLX2

VLX1 VLX2

VIN=2.7V to 5.5V

VIN=2.7V to 5.5V

C

C

IN

IN

10 µF

10 µF

6.3 V

6.3 V

PVDD

PVDD

VDD

VDD

EN

EN

AUTO

AUTO

VSEL

VSEL

MODE/SYNC

MODE/SYNC

A2 A3

A2 A3

B1

B1

D3

D3

D4

D4

STw4141

STw4141

C2

C2

C3

C3

C1

C1

A1B3C4

A1B3C4

PGND

PGND

GND

GND

A4

A4

D1

D1

B4

B4

D2

D2

B2

B2

T_MODE

T_MODE

VOUT1

VOUT1

FB1 C

FB1 C

VOUT2

VOUT2

FB2 C

FB2 C

STATE

STATE

OUT1

OUT1

22 µF

22 µF

6.3 V

6.3 V

OUT2

OUT2

22 µF

22 µF

6.3 V

6.3 V

C

C

1

1

100 nF

100 nF

C

C

2

2

100 nF

100 nF

APE I/O

APE I/O

APE CORE

APE CORE

APPLICATION

APPLICATION

PROCESSOR

PROCESSOR

MODE_INFO

MODE_INFO

CLK

CLK

SLEEP

SLEEP

GND

GND

4.5 Checking Transient response versus external components

The regulator loop response can be checked by looking at the load transient response.

Switching regulators take several cycles to respond to a step in load current. When a load step

occurs, V

equivalent series resistance of C

generating a feedback error signal used by the regulator to return V

is immediately shifted by an amount equal to I

OUT

OUT

. I

also begins to charge or discharge C

LOAD

x ESR, wher e ESR is the

LOAD

to its steady-state

OUT

OUT

value. In order to improve the transient response, it is better to use two 10 µF ceramic

capacitors on each output to reduce ESR.

4.6 Bill of Material

4.6.1 Inductor selection

The choice of which inductor to use depends on the price and size versus performance

required with the STw4141 application.

that work well in STw4141 applications.

Table 9. Bill of material: inductor selection

Part number Supplier

VFL4012A-4R7M1R1 TDK 4.7 0.14 1100 3.5 x 3.7 x 1.2

VFL3012A-4R7MR74 TDK 4.7 0.16 740 2.6 x 2.8 x 1.2

Table 9

Val ue

(µH)

shows some typical surface mount inductors

DCR

( max)

Max DC

current (mA)

Size (mm)

W x L x H

744031004 WUERTH 4.7 0.085 900 3.8 x 3.8 x 1.8

20/27

STw4141 4 Application information

4.6.2 Input capacitor (CIN selection)

Input capacitor of 10 µF ceramic low ESR capacitor should be used to reduce switching losses.

It should be placed as close as possible to supply pins VDD and PVDD. The connection traces

should be wide and short to minimize impedance.

4.6.3 Output capacitors (COUT selection)

The selection of COUT is driven by the required ESR to minimize voltage ripple and load step

transients. There are two possibilities for output capacitors: either a 22 µF is connected to

ground or two 10 µF ceramic are used to reduce ESR and switching losses. The capacitor

should be placed as close as possible to V

pins. The connection traces should be wide and

OUTx

short to minimize impedance.

4.6.4 Capacitors selection

Table 10. Bill of Material: capacitor selection

Component Supplier Part number Valu e Case size

TDK C1608X5R0J106MT 10 µF, 6.3V 0603

C

IN

TDK C2012X5R0J106MT 10 µF, 6.3V 0805

TAIYO YUDEN JMK212BJ106MG-T 10 µF, 6.3V 0805

TDK

C

, C

OUT1

OUT2

TAIYO YUDEN

4.7 PCB layout considerations

The Printed Circuit Board layout must include the following consideration:

Current paths carrying high currents (bold lines in

minimize impedance in order to reduce looses and EMI.

Small currents flow through voltage paths. No specific care is requested about voltage paths

but it is recommended to follow the general rules for PCB routing to reduce influence of external

and internal interferences.

C1608X5R0J106MT 2 x 10 µF, 6.3V 2 x 0603

C2012X5R0J106MT 2 x 10 µF, 6.3V 2 x 0805

C2012X5R0J226MT 22 µF, 6.3V 0805

JMK212BJ106MG-T 2 x 10 µF, 6.3V 2 x 0805

JMK212BJ226MG-T 22 µF, 6.3V 0805

Figure 15

) must be wide and short to

21/27

4 Application information STw4141

Figure 15. Board layout track length and width

L 4.7 µH

HIGH CURRENT PATH

HIGH CURRENT PATH

=2.7V to 5.5V

=2.7V to 5.5V

V

V

IN

IN

C

C

IN

IN

10 µF

10 µF

6.3 V

6.3 V

MODE/SYNC

MODE/SYNC

PVDD

PVDD

VDD

VDD

EN

EN

AUTO

AUTO

VSEL

VSEL

B1

B1

D3

D3

D4

D4

C2

C2

C3

C3

C1

C1

L 4.7 µH

VLX1 VLX2

VLX1 VLX2

A2 A3

A2 A3

STw4141

STw4141

A1

C4

A1

C4

B3

B3

PGND

PGND

GND

GND

A4

A4

D1

D1

B4

B4

D2

D2

B2

B2

T_MODE

T_MODE

VOUT1

VOUT1

FB1

FB1

VOUT2

VOUT2

FB2

FB2

STATE

STATE

C

C

OUT1

OUT1

22 µF

22 µF

6.3 V

6.3 V

C

C

OUT2

OUT2

22 µF

22 µF

6.3 V

6.3 V

V

V

OUT1

OUT1

V

V

OUT2

OUT2

=1.8V

=1.8V

=1.0V/1.2V

=1.0V/1.2V

4.7.1 PCB layout

Figure 16

and

Figure 17

show the PCB layout. All components are on the top side of the board.

Figure 16. Demoboard top layer Figure 17. Demoboard assembled with 2x10µF

output capacitors

22/27

STw4141 4 Application information

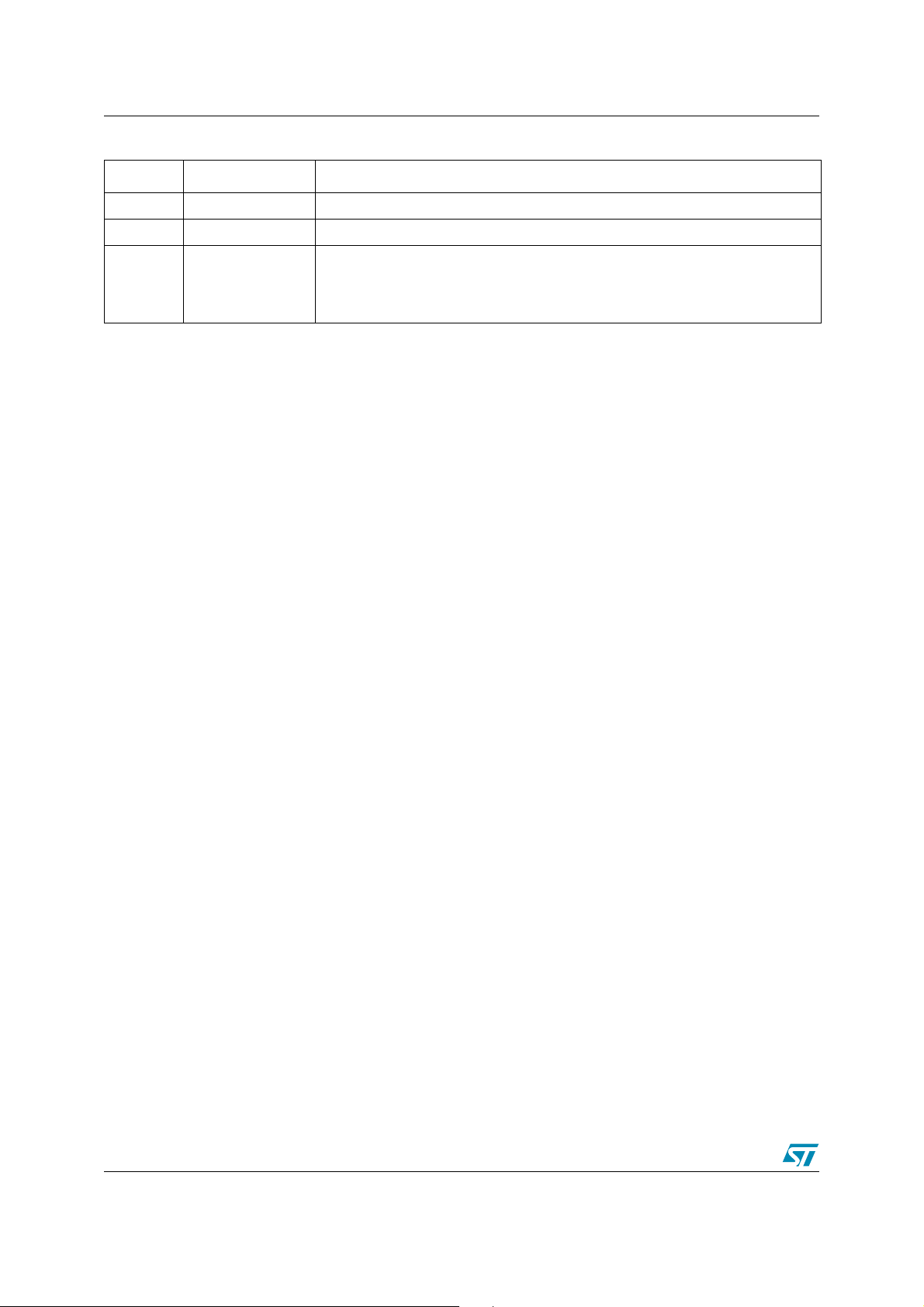

4.7.2 TFBGA16 internal bumps access

Pad centers are at 500 µm distance. Pad diameter is 275 µm. The distance between two

adjacent pad edges is only 225 µm. We recommend a distance for lead-out signals from the

center of pad matrix by 75 µm wide trace. Isolation distance in this case is 75 µm (see

Figure 18

Figure 18. TFBGA16 ball pad spacing and track parameters to internal pads

Figure 19. PCB routing example using TFBGA16

and

Figure 19

).

Grid dot distance : with

A = 500µm

B = 275µm

C = 75µm

23/27

5 Package Outline and Mechanical Data STw4141

5 Package Outline and Mechanical Data

Table 11: TFBGA 3x3x1.20 16 F4x4 0.50. Package code: L0 - JEDEC/EAIJ reference

number: N/A

Ref Min. Typ. Max.

Note 1

A 1.01 1.20 (

A1 0.15

A2 0.82

b 0.25 0.30 0.35

D 2.85 3.00 3.15

D1 1.50

E 2.85 3.00 3.15

E1 1.50

e0.50

ddd 0.85 0.08

)

eee 0.15

fff 0.05

Note: 1 Max mounted height is 1.12 mm. Based on a 0.28 mm ball pad diameter.

Solder paste is 0.15 mm thickness and 0.28 mm diameter.

2 TFBGA stands for Thin Profile Fine Pitch Ball Grid Array.

Thin profile: The total profile height (DIm A) is measured from the seating plane to the top of the

component.

A = 1.01 to 1.20 mm

Fine pitch < 1.00 mm pitch.

3 The tolerance of position that controls the location of the pattern of balls with respect to datums

A and B.

For each ball there is a cylindral tolerance zone eee perpendicular to datum C and located on

true position with respect to datums A and B as defined by e. The axis perpendicular to datum

C of each ball must lie within this tolerance zone.

4 The tolerance of position that controls the location of the balls within the matrix with respect to

each other. For each ball there is a cylindrical tolerance zone fff perpendicular to datum C and

located on true position as defined by e. The axis perpendicular to datum C of each ball must

lie within the tolerance zone.

Each tolerance zone fff in the array is contained entirely in the respective above eee zone

above.

The axis of each ball must be simultaneously in both tolerance zones.

5 Leadfree package according to JEDEC JESD-020-C

24/27

STw4141 5 Package Outline and Mechanical Data

Figure 20. TFBGA 3x3x1.20 16 F4x4 0.50

25/27

6 Revision history STw4141

6 Revision history

Date Revision Changes

8-Dec-2005 1 Initial release

26/27

STw4141

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility fo r the consequences

of use of such information no r for any infringement of patent s or other rights of third part ies which ma y result from its u se. No license is grant ed

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notic e. This publication supersedes and replaces all information previously supplied. STMicr oelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of the i r respective owners

© 2005 STMicroelectronics - All rights reserv ed

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

27/27

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...