Dual USB/wall adapter Li-ion battery charger with gas gauge

Features

■ Constant current constant voltage (CCCV)

linear charger

■ Common or separate USB/wall adapter inputs

■ Fast charge current control up to 1 A for wall

adapter and up to 500 mA for USB

■ Support for currents higher than 1 A using

external components

■ Programmable charge voltage (4.1 V, 4.2 V,

4.3 V, 4.35 V) with 1% accuracy

■ Thermal regulation

■ Trickle charge mode at low battery voltage

■ Wall adapter voltage up to 16 V

■ Battery overvoltage protection at 4.7 V

■ Gas gauge with 13-bit AD converter

■ Battery voltage monitor with 7-12 bit AD

converter

2

■ I

C interface for device monitoring and control

■ Charge status output pin

■ Power detection output pin

■ Programmable watchdog security timer

■ 4.7 V LDO regulator (with external power

MOSFET)

Applications

■ Cellular phones (GSM, CDMA, WCDMA),

PDA, MP3 players, cordless phones

■ Digital camera, USB appliances, bluetooth

devices, portable navigation devices

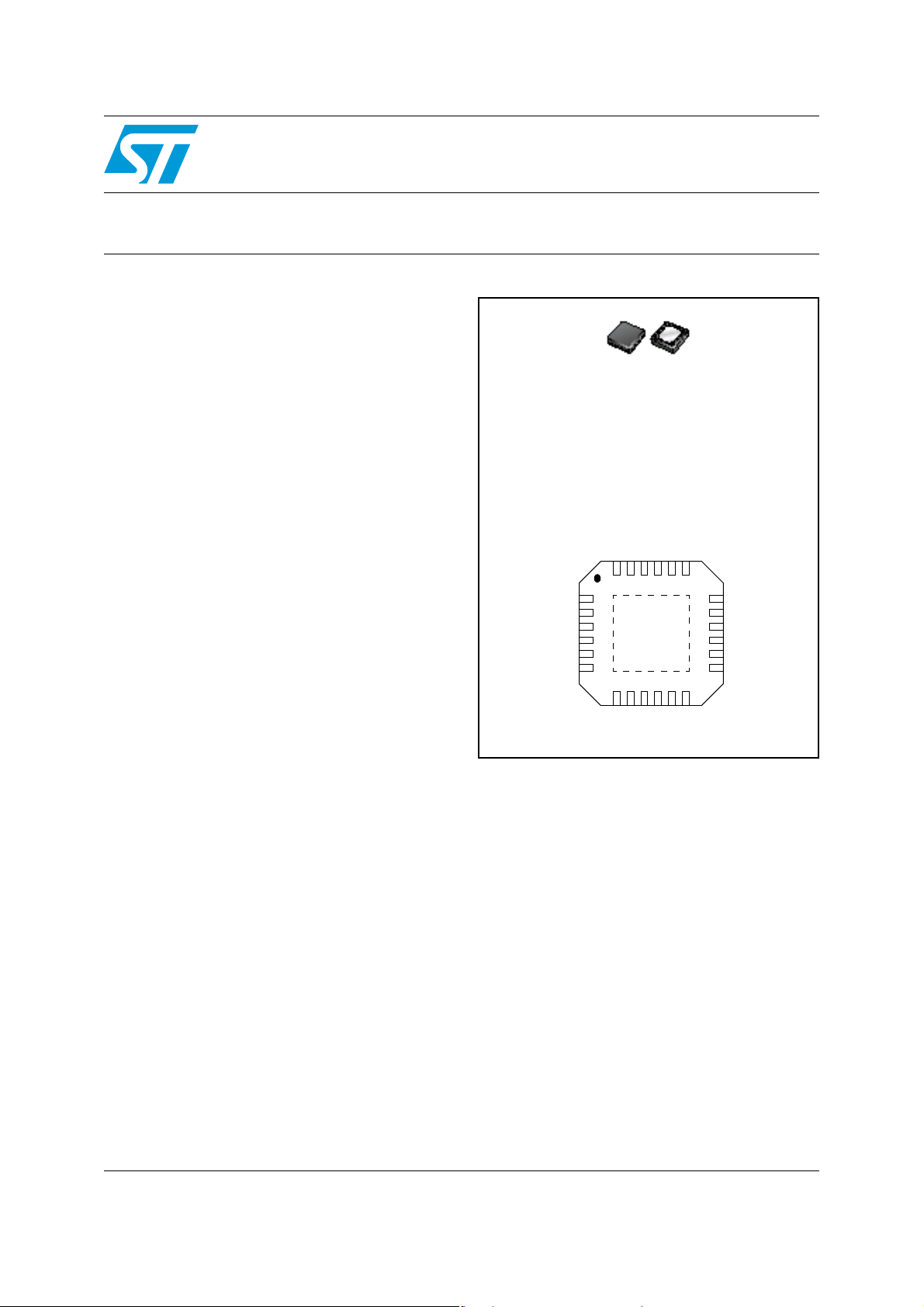

STw4102

QFN 24

(Plastic micropackage)

Pin connections

(top view)

BATT

SENSE

EOCHG

BATTSENSE

PWRDETECTN

TEST

24 23 22 21 20 19

MAIN

VOUT

USBPWR

DRIVER

LDODRV

LDOFB

1

2

3

4

5

6

789101112

ISET

CVREF

The STw4102 offers dual charging capability

using separate inputs for USB cable and wall

adapter, or a single input that accepts both.

The STw4102 also offers programmable fast

charge current using an ext ernal resistor. A

thermal regulation circuit limits the charge current

against the die high power dissipation or high

ambient temperature. An e nd of charge output pin

indicates the charge termination when the fast

charge current drops below 10% of the

programmed current value.

GND

ICG+

CVIS

18

VIO

17

SCL

16

SDA

15

RESETN

14

STDBY

13

C32KHZ

ICG-

Description

The STw4102 includes an accurate gas gauge

based on a 13-bit AD converter. An external

The STw4102 is a standalone constant current

constant voltage (CCCV) linear charger

specifically designed for Li-ion batteries.

March 2008 Rev 2 1/34

resistor is used between battery and ground to

sense a charge/discharge current. With a typical

30 mΩ resistor, current can be up to 2.5 A.

www.st.com

34

Contents STw4102

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Absolute maximum ratings and operating conditions . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

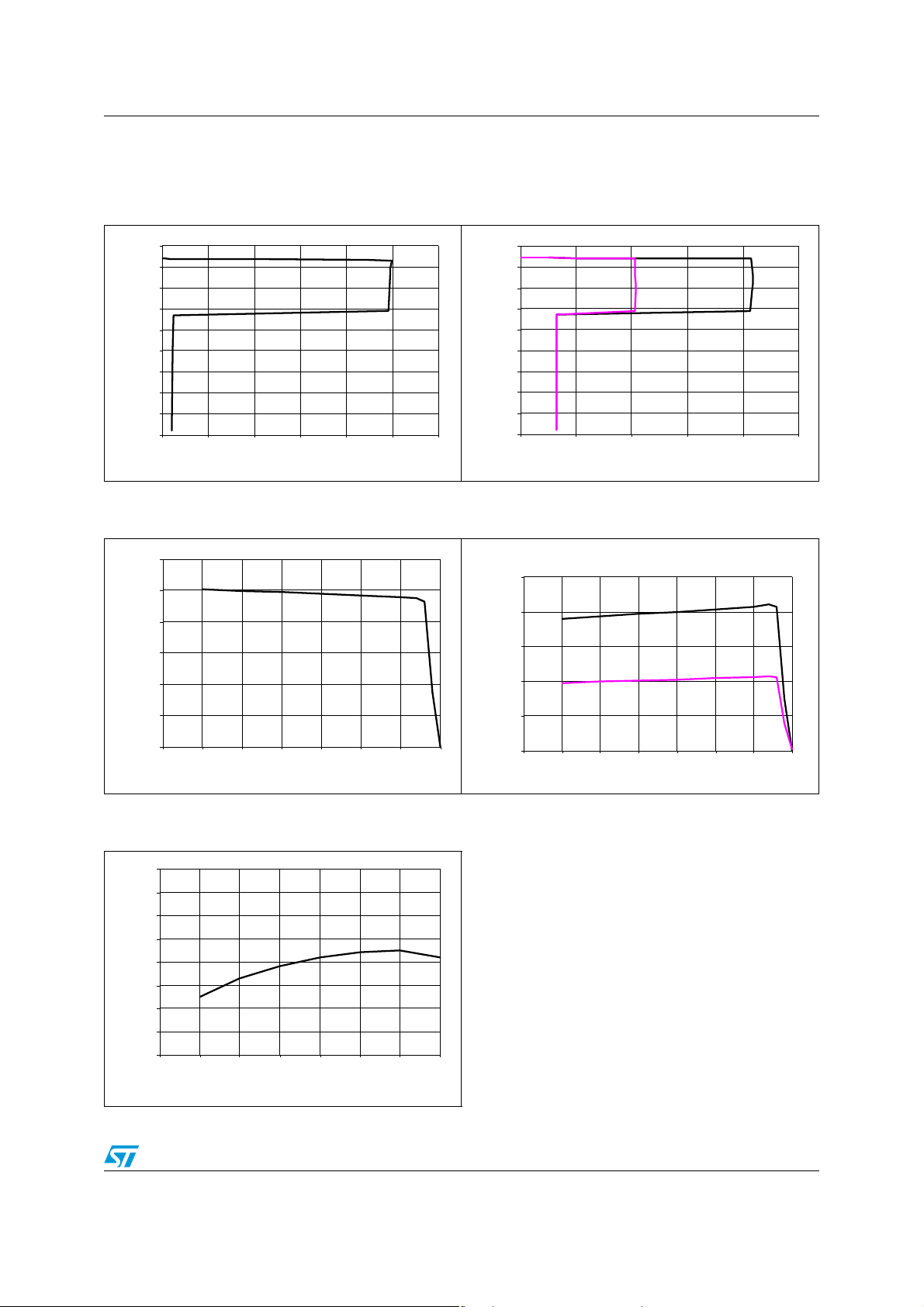

Typical performance curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Application schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Charge from USB or wall adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Charge currents higher than 1 Amp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Using LDO regulator to supply telephone from wall adapter . . . . . . . . . . 16

6 Battery charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Charge cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Trickle charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Charging from a wall adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Charging from a USB port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.5 Charging using external power devices . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.6 Charge mode summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 Watchdog timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.8 Thermal regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Low drop-out regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Battery monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1 Gas gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2 Battery voltage monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9 Factory OTP options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

10 I

2/34

C interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10.1 Read and write operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

STw4102 Contents

10.2 Register mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3/34

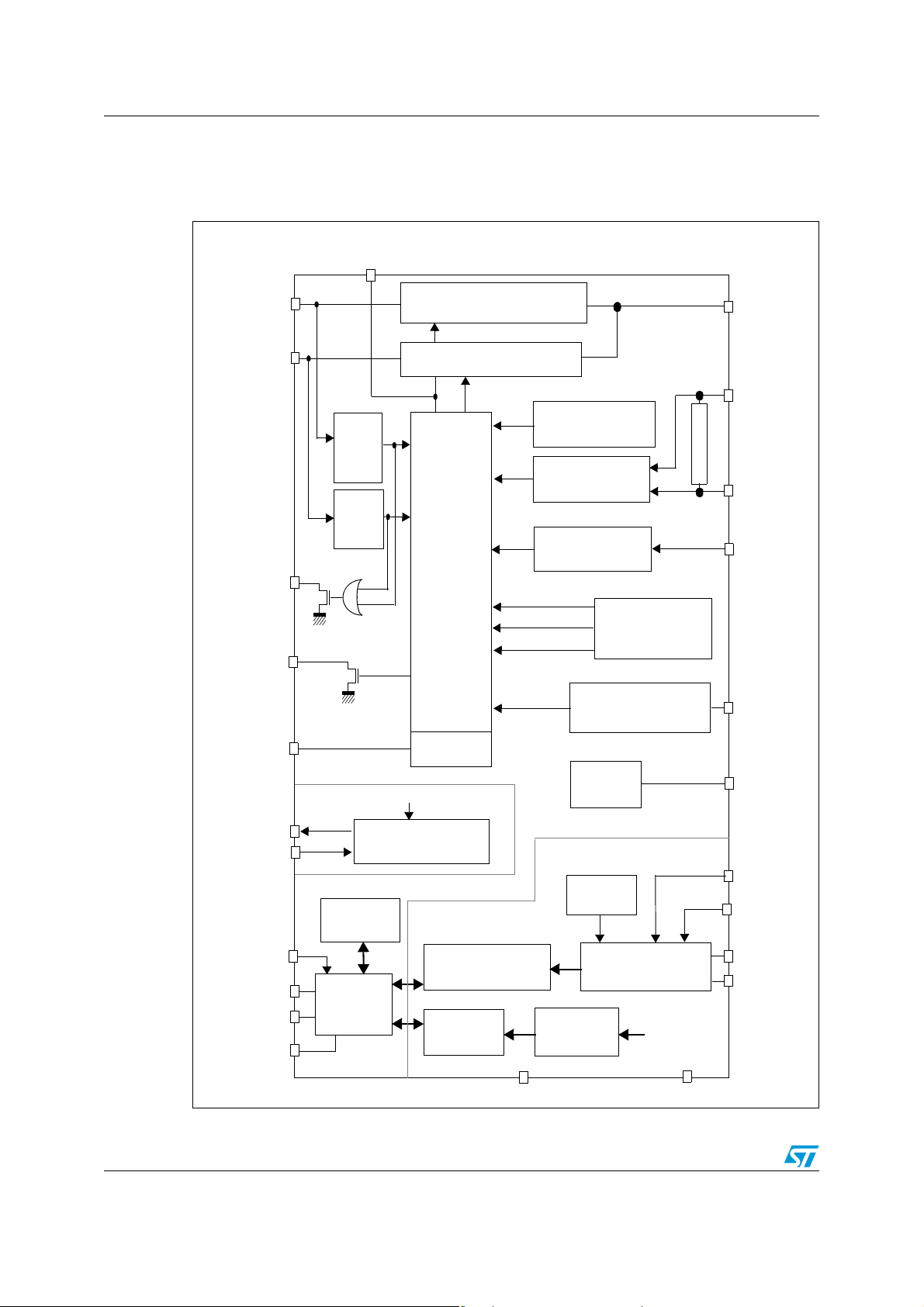

Block diagram STw4102

1 Block diagram

Figure 1. Internal block diagram

DRIVER

MAIN

USBPWR

PWRDETECTN

EOCHG

CVREF

Main

adapter

Detect

USB

Detect

Main Power Device (max 1A)

USB Power Device (max 500mA)

Driver

Thermal regulation

Voltage

Current

Regulation

CC/CV

Trickle threshold

Trickle current

Charge Voltage

Charge current

Vref

Current Sense

Voltage Sense

CC/CV

configuration

Current defined by

external resistor

VOUT

SENSE

Sense ressitor

BATT

BATTSENSE

ISET

LDO

LDODRV

LDOFB

Main supply

LDO driver 4.7V

Charge Control

Registers

VIO

24 bit accumulator

Control registers

SCL

SDA

RESETN

I2C interface

Control

Registers

4/34

Supply

Battery Monitoring

Power On

Reset

AD converter

7-12 bits

GND

Internal

AD converter

12 bits + sign bit

CVIS

STDBY

C32KHZ

ICG+

ICG-

Battery voltage

TEST

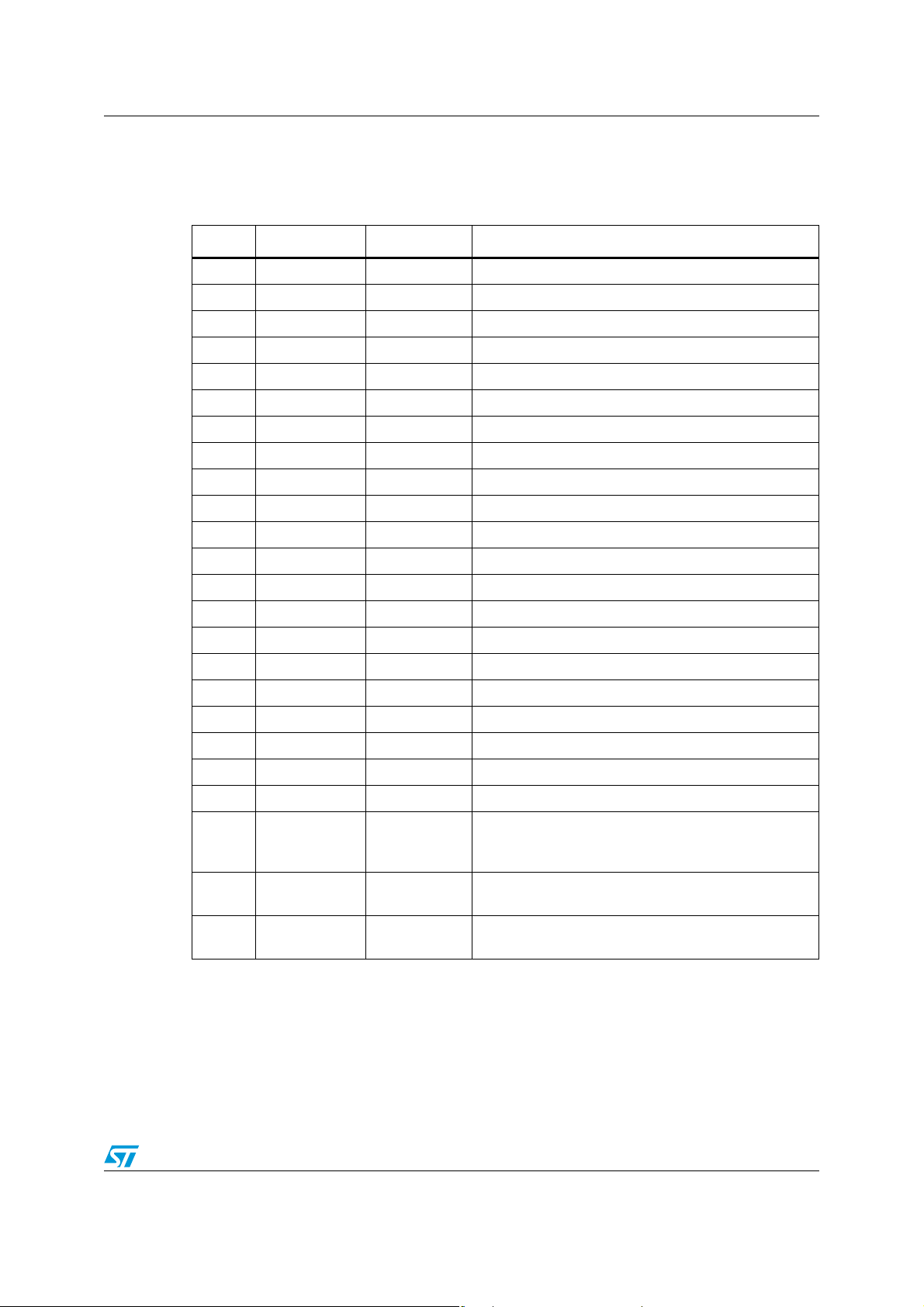

STw4102 Pin assignment

2 Pin assignment

P

Table 1. Pin descriptions

Pin # Pin name Type Function

1 MAIN Supply Main power input from wall adapter or USB charger

2 VOUT O_A Power path output

3 USBPWR Supply Power supply from USB cable

4 DRIVER O_A Driver for external power switch (PMOS or PNP)

5 LDODRV O_A LDO power PMOS driver

6 LDOFB I_A LDO feedback regulation

7 ISET O_A Resistor to program the main charge current

8 CVREF I_A Bypass capacitor for internal voltage reference

9 GND Ground Analog and digital ground

10 CVIS I_A Bypass capacitor for internal supply

11 ICG+ I_A Gas gauge sense resistor

12 ICG- I_A Gas gauge sense resistor

13 C32KHZ I_D External 32kHz clock input

14 STDBY I_D Gas gauge standby input (active low)

15 RESETN I_D Digital register reset (active low)

2

16 SD A IO_D I

17 SCL I_D I

18 VIO Supply Supply for I/O

19 SENSE I_A Sense resistor input to regulate the charge current

20 BATT Supply Battery power voltage

21 BATTSENSE I_A Battery sense voltage

22 EOCHG OD

23 TEST I_D

24 PWRDETECTN OD

C serial data.

2

C serial clock.

End of charge output status. Pulled low when the fast

charge current is above 10% of its programmed

maximum value.

Reserved pin for factory test. To be connected to

ground.

Main or USB plug-in detection. Pulled low when power

is detected, open when no power is detected.

In this table, the following conventions are used:

I: Input

O: Output

I/O: Bidirectional

OD: Open Drain

A: Analog

D: Digital

5/34

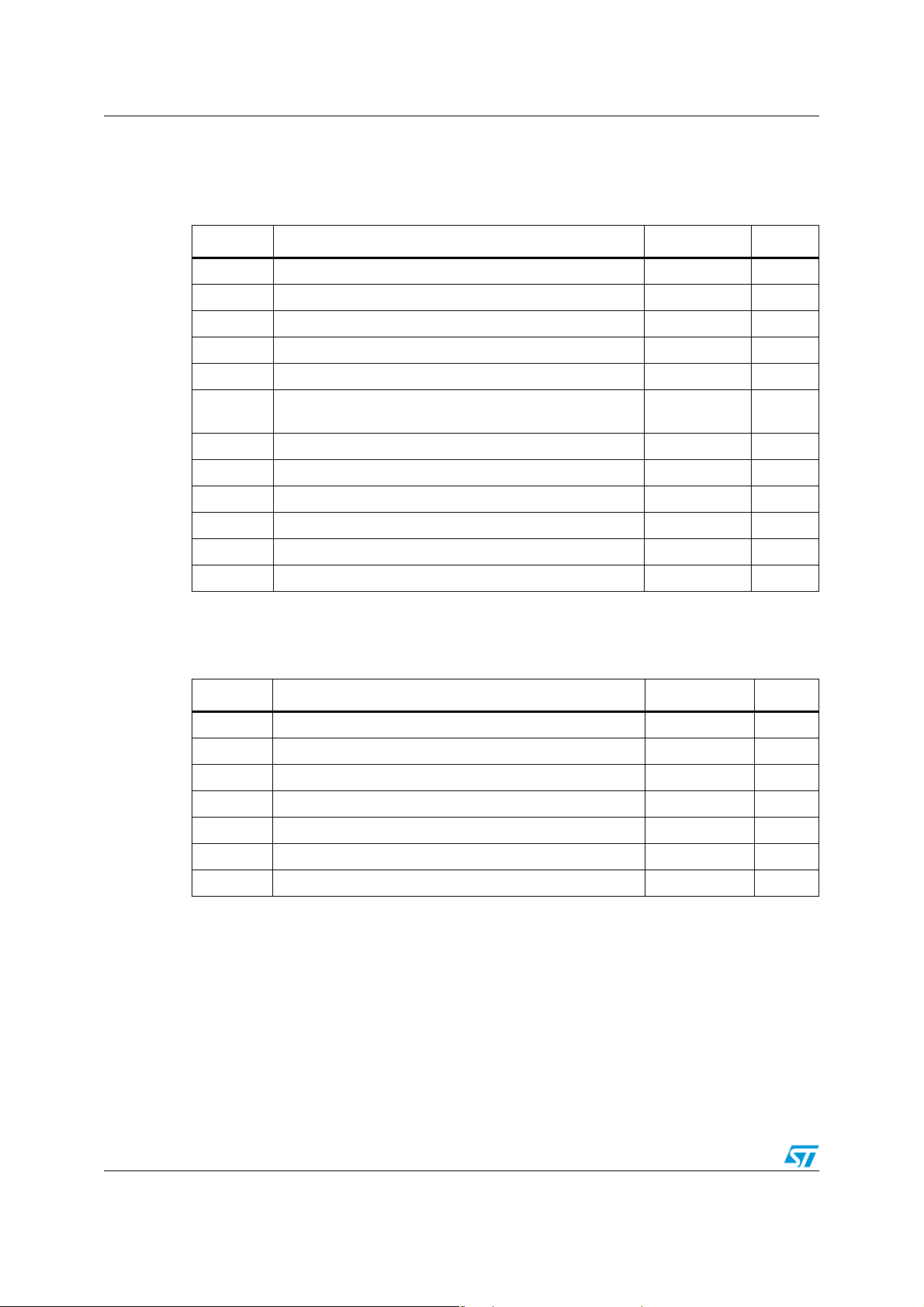

Absolute maximum ratings and operating conditions STw4102

3 Absolute maximum ratings and operating conditions

Table 2. Absolute maximum ratings (AMR)

Symbol Parameter Value Unit

V

MAIN

V

CC

V

USB

V

batt

V

V

DD

P

I

sense

T

stg

T

R

thja

ESD Electrostatic discha rg e (HBM human body model)

1. Package's exposed pad is soldered to a copper pad on the PCB with multiple vias to the ground plane.

2. Human body model: 100pF discharged through a 1.5 kΩ resistor between two pins of the device, done for

all couples of pin combinations with other pins floating.

Table 3. Operating conditions

Maximum supply voltage on MAIN input 20 V

Voltage on EOCHG, LDODRV, DRIVER pins -0.3 to V

Maximum supply voltage on USBPWR input 7 V

Maximum voltage on BATT, BATTSENSE, PWRDETECTN 7 V

Maximum supply voltage on VIO pin 7 V

IO

Voltage on I/O pins (SCL, SDA, RESETN, C32KHZ,

STDBY)

Pow er dissipation self-limited

d

-0.3 to V

Maximum current from SENSE to BATT 1 A

Storage temperature -55 to 150 ° C

Maximum junction temperature 150 ° C

j

Thermal resistance junction-ambient

(1)

(2)

MAIN

IO

V

V

45 ° C/W

2kV

Symbol Parameter Value Unit

V

V

T

V

V

V

V

main

CC

USB

batt

out

oper

Operating supply voltage on MAIN 4.25 to 16 V

Maximum voltage on EOCHG 16 V

Operating supply voltage on USBPWR 4.25 to 5.5 V

Operating supply voltage on VIO 1.45 to 3.0 V

IO

Max voltage on BATT, BATTSENSE, PWRDETECTN 5.0 V

Max voltage on VOUT BATT +0.7 V

Operating free air temperature range -30 to 85 ° C

6/34

STw4102 Electrical characteristics

4 Electrical characteristics

Table 4. CC/CV charger - V

oper

=5V, V

=3.6V, T

batt

= -30°C to 85° C (unless otherwise

amb

specified)

Symbol Parameter Conditions Min Typ Max Unit

Supply (V

I

charger

I

STBY

I

batt_sense

I

batt

POR_IS+ Power ON reset threshold+ CVIS internal supply 2.2 2.3 2.4 V

POR_IS- Po wer ON reset threshold- CVIS internal supply 2.1 2.2 2.3 V

Voltage regu lation

V

charge_acc

R

power

Battery

Battery

Current regulation

I

trickle

V

trickle

V

trickle_hyst

I

charge

I

charge_acc

I

USB

EOCHG

EOCHG

T

regulation

T

softstart

from MAIN or USB)

oper

Main or USB input operating current 2 mA

USBPWR input standby current Charge off 40 µA

BSENSE input current No charge 1 µA

BATT input current No charge 25 µA

Output voltage accuracy T

Power path resistance MAIN to BATT 0.6 Ω

ovv

ovv_hyst

Static battery overvoltage detection 4.55 4.7 4.8 V

Static battery overvoltage hysteresis 100 mV

Trickle charge current

Trickle to fast charge threshold Standard configuration 2.8 2.9 3.0 V

Trickle to fast charge threshold hysteresis 100 mV

Main charge current range Internal path 100 1000 mA

Main charge current accuracy I

USB charge current

ith

ith_hys

End of charge threshold % of current setting 10 %

End of charge threshold hysteresis % of current setting 5 %

Regulated junction temperature 125 ° C

Soft start from trickle to fast charge 100 µs

= 0°C to 85° C-1 +1%

amb

V

batt<Vtrickle

Standard configuration

Factory OTP option

> 500mA -15 +15 %

charge

306060

120

100

180mAmA

REG_CHG0[7..6]:

00

01

10

11

30 60

200

400

100

500

0

mA

mA

mA

mA

7/34

Electrical characteristics STw4102

Table 4. CC/CV charger - V

oper

=5V, V

=3.6V, T

batt

= -30°C to 85° C (unless otherwise

amb

specified) (continued)

Symbol Parameter Conditions Min Typ Max Unit

Watchdog

REG_WDOG[2,1]:

00

t

watchdog

Watchdog duration

01

10

11

Input/output pins

V

charger_det

V

charger_det_hys

V

USB_det

V

USB_det_hys

Vol

powerdetect

Vol

EOCHG

I

drv_sink

Table 5. LDO - V

Main charger supply voltage detection 2.4 2.5 2.6 V

Main charger supply voltage detection

hysterisis

USB supply voltage detection 2.4 2.5 2.6 V

USB supply voltage detection hysteresis 100 mV

POWERDETECTN output capability I

EOCHG output capability

= 10mA 0.45 V

sink

= 10mA

I

sink

= 20mA

I

sink

Driver sink current (If option enabled) 60 mA

main

=6V, T

= -30°C to 85° C (unless otherwise specified)

amb

Symbol Parameter Conditions Min Typ Max Unit

0.5

1

7.5

15

15

30

30

60

100 mV

1.5

22.5

45

90

0.5

1.1

min

min

min

min

V

V

LDO

LDO

LDO

LDO

V

power_th

power_th_hys

PSRR

Including line and load

LDO regulated output voltage

regulation (up to 1A),

V

>6V

main

4.47 4.7 4.93 V

LDO power turn off threshold 6.8 7.2 7.5 V

LDO power turn off threshold hysterisis 0.7 V

LDO power supply rejection ratio Up to 20kHz 50 dB

8/34

STw4102 Electrical characteristics

Table 6. Battery monitor - V

=3.6V, T

batt

= -30°C to 85° C (unless otherwise specified)

amb

Symbol Parameter Conditions Min Typ Max Unit

POR_IS2+ Power ON reset threshold+ CVIS internal supply 2.6 2.7 2.8 V

POR_IS2- Power ON reset threshold- CVIS internal supply 2.5 2.6 2.7 V

Gas gauge A/D converter

V

os_gg

V

in_gg

I

dd_gg

I

pdn_gg

I

in

LSB

Acc

gg

Tamb_gg

Input offset voltage 40 µV

Input voltage range -80 +80 mV

Current consumption CG_ENA=1 90 µA

Current consumption in off mode CG_ENA=0 1 µA

Input current for ICG+ and ICG- 500 nA

AD converter granularity (LSB value) 12 bits + 1 sign bit 23.5 µV

Accuracy at ambient temperature

External resistor at 1%

No calibration

3%

Battery voltage A/D converter

V

in_mon

I

dd_mon

I

pdn_mon

LSB

mon

Acc

Tamb_m on

Input voltage range BATT voltage 1 5 V

Current consumption ADPOWERON=1 190 µA

Current consumption in off mode ADPOWERON=0 1 µA

AD converter granularity (LSB value)

7 bits

12 bits

45.4

1.42

Accuracy at ambient temperature No calibration 3 %

Digital I/O pins (SCL, SDA, STDBY, C32KHZ, RESETN)

mV

mV

V

il

V

ih

V

ol

Input pin low voltage 0 0.3 x V

Input pin high voltage 0.7 x V

SDA output pin low voltage I

= 3mA 0.2 x V

sink

IO

V

IO

V

IO

V

V

IO

9/34

Electrical characteristics STw4102

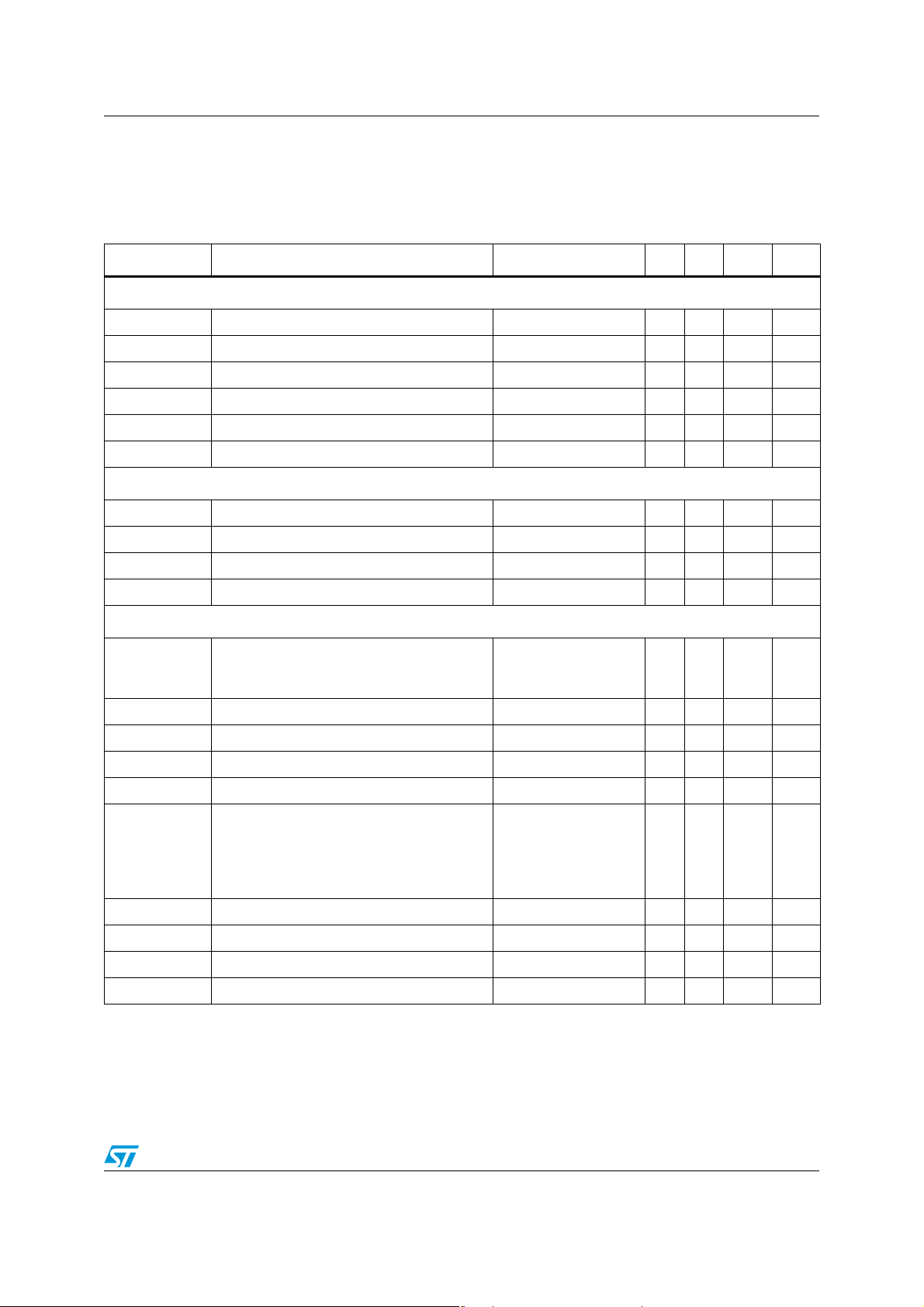

Table 7. I

Symbol Parameter Conditions Min Typ Max Unit

2

C timing - VIO= 2.8V, T

= -30°C to 85° C (unless otherwise specified)

amb

F

scl

t

hd,sta

t

low

t

high

t

su,dat

t

hd,dat

t

r

t

f

t

su,sto

C

b

SCL clock frequency 400 kHz

Hold time (repeated) START condition 0.6 µs

LOW period of the SCL clock 1.3 µs

HIGH period of the SCL clock 0.6 µs

Setup time for repeated START condition 0.6 µs

Data hold time 0 0.9 us

Rise time of both SDA and SCL signals

Fall time of both SDA and SCL signals

Setup time for STOP condition 0.6 µs

Capacitive load for each bus line 400 pF

Figure 2. I2C timing diagram

t

f

ih

il

t

hd,sta

SDA

V

V

20+

0.1C

20+

0.1C

b

b

300 ns

300 ns

SCL

t

low

t

hd,dat

t

su,dat

t

high

t

su,sta

t

r

10/34

STw4102 Electrical characteristics

Typical performance curves

Figure 3. Charger voltage vs. charge current

(Main charge, 4.2V and 1A settings)

4.5

4.0

3.5

3.0

2.5

2.0

Vba tt (V)

1.5

1.0

0.5

0.0

0 200 400 600 800 1000 1200

Icharge (mA)

Figure 5. Charge current vs. tempe rat u r e

(charge from MAIN, 1A setting)

1.2

1.0

0.8

0.6

Icharge (A)

0.4

Figure 4. Charger voltage vs. charge current

(USB charge, 4.2V setting)

4.5

4.0

3.5

3.0

2.5

2.0

Vba tt (V)

1.5

1.0

0.5

0.0

0 100 200 300 400 500

Iusb (mA)

Ich=400mAIch=200mA

Figure 6. Charge current vs. temperature

(charge from USBPWR)

500

400

300

200

Iusb (mA)

Ich=400mA

Ich=200mA

0.2

0.0

-50-250 255075100125

Temp (°C)

Figure 7. Charge voltage vs. temperature

(4.2V nominal setting)

4.24

4.23

4.22

4.21

4.20

4.19

Vcharge (V)

4.18

4.17

4.16

-50 -25 0 25 50 75 100 125

Temp (°C)

100

0

-50 -25 0 25 50 75 100 125

Temp (°C)

11/34

Electrical characteristics STw4102

Figure 8. USB standby input current vs.

temperature (charge disabled)

60

50

40

30

Iusb (µA)

20

10

0

-50 -25 0 25 50 75 100 125

Temp (°C)

Figure 10. Watchdog period vs. temperature

(normalized to value at 25°C)

1.4

1.2

Figure 9. Battery standby current vs

temperature (no MAIN, no

USBPWR, gas gauge disabled)

60

50

40

30

Ibat (µA)

20

10

0

-50 -25 0 25 50 75 100 125

Temp (°C )

Figure 11. LDO output voltage vs. temperature

(10 mA output current)

4.9

4.8

1.0

Twatchdog

0.8

0.6

-50-250 255075100125

Temp (°C)

Figure 12. LDO output voltage vs. output

current

5.0

4.9

4.8

4.7

LDOv (V)

4.6

4.5

4.4

0 500 1000 1500

LDOi (mA )

Vmain=6V

Vmain=5V

4.7

LDOv (V)

4.6

4.5

-50 -25 0 25 50 75 100 125

Temp (°C)

12/34

STw4102 Electrical characteristics

Figure 13. Waveforms at USB plug-in

Vusb

Vbatt

Ibatt

50µs/div

Figure 14. Switching from USB char ge to main

charge

Vmain

Vbatt

Ibatt

100µs/div

Figure 15. Switching from main char ge to USB

charge

Vmain

Vbatt

Ibatt

10ms/div

13/34

Application schematics STw4102

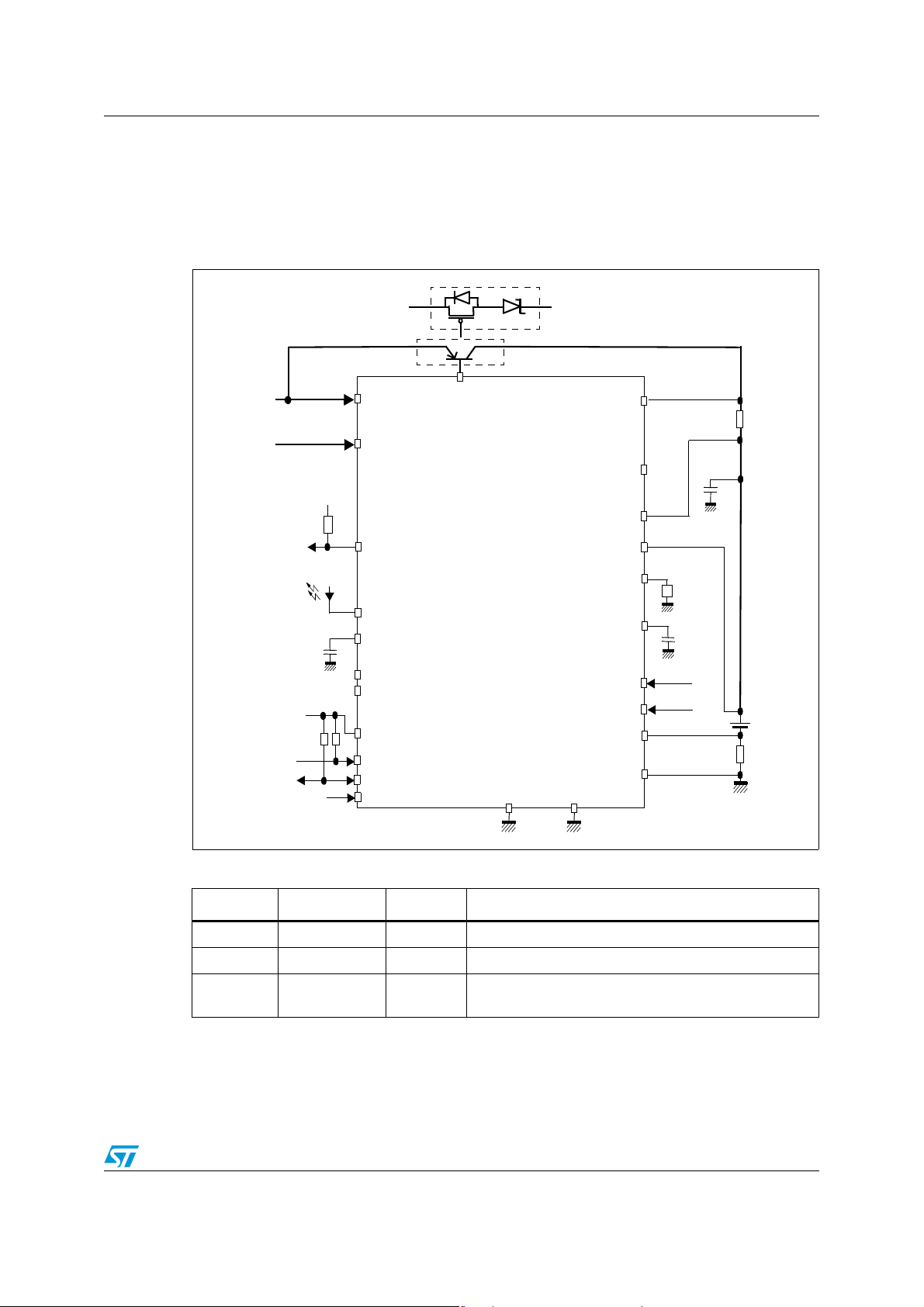

5 Application schematics

5.1 Charge from USB or wall adapter

The MAIN input is used with either a wall adapter or a USB charger. The charge current can

be programmed to 100 mA or 500 mA max for use with a USB 2.0 port, or programmed to

the value set by the R

The USBPWR input is used only for charging from a USB port (100 mA or 500 mA max).

Figure 16. Charge using internal power devices

resistor for use with a wall adapter or a dedicated USB charger.

set

from wall adapter

or USB port/charger

from USB port only

battery voltage

to power

management

Indicator LED

Reset

C4

C5

C2

IO voltage

MAIN

USBPWR

PWRDETECTN

EOCHG

CVREF

LDODRV

LDOFB

VIO

SCL

SDA

RESETN

DRIVER

STw4102

GND

VOUT

SENSE

BATTSENSE

C32KHZ

STDBY

TEST

BATT

ISET

CVIS

ICG+

ICG-

C3

Rset

C1

32kHz

StandBy

Rcg

Table 8. External component list

Name Typ. value Tolerance Comments

R

set

R

cg

12k to 120k 1% Main charge current setting

30mΩ 1% Gas gauge sense resistor

C1 1µF Internal supply decoupling capacitor

C2 1µF Internal voltage reference decoupling capacitor

C3 0.1 to 22µF

C4 0.1 to 1µF MAIN input decoupling capacitor

C5 0.1 to 1µF USBPWR input decoupling capacitor

14/34

When the battery is removed, a capacitor of at least

15µF is required for low ripple on the battery line.

STw4102 Application schematics

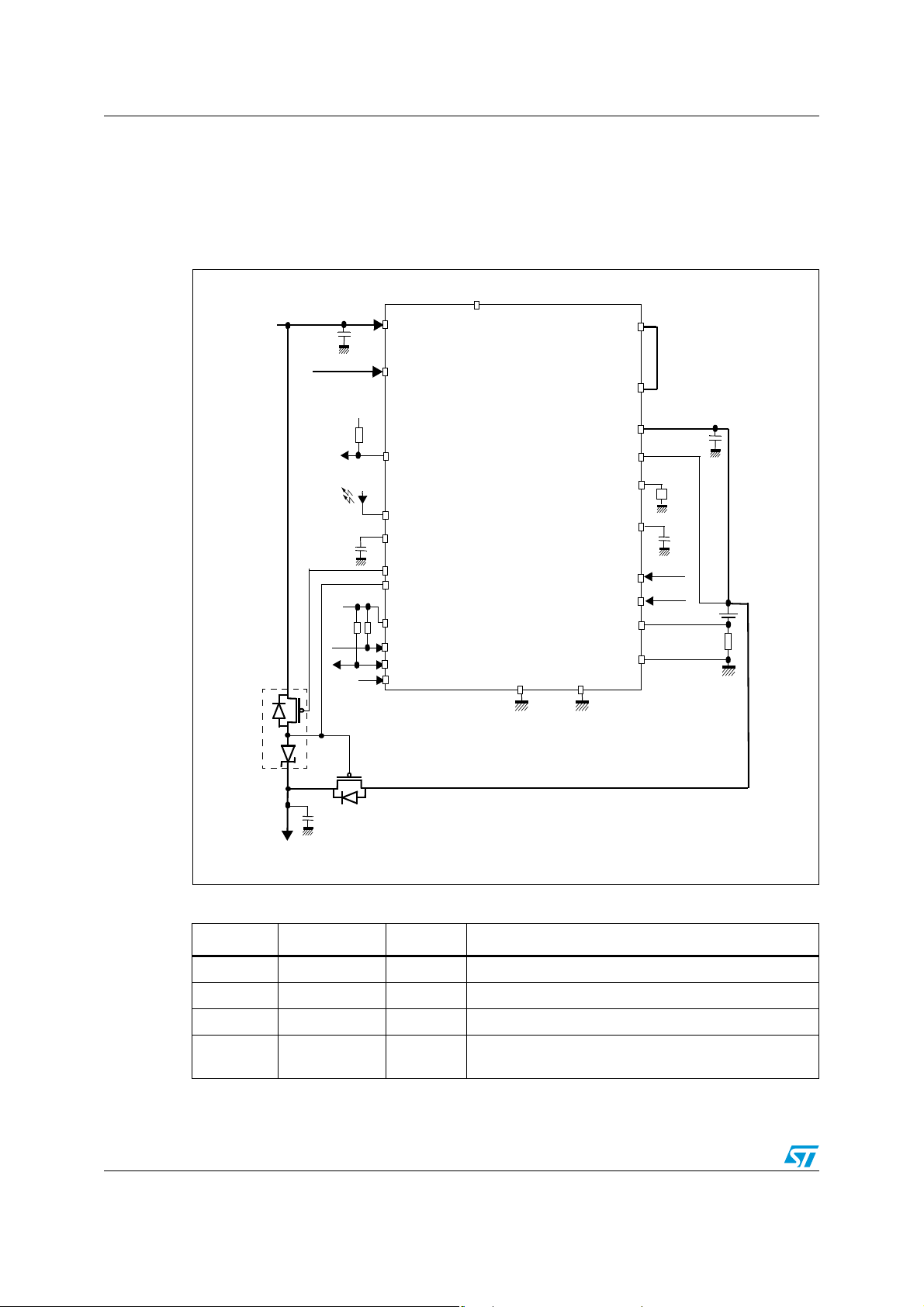

5.2 Charge currents higher than 1 Amp

One-time programming (OTP) options off er the ab ility to use an external power device or an

external sense resistor to handle charge currents higher than 1 A from the wall adapter.

These OTP options are set by STMicroelectronics at factory level.

Figure 17. Charge using e xternal power devices

D1

M1

T1

battery voltage

to power

management

Indicator LED

IO voltage

Reset

C2

MAIN

USBPWR

PWRDETECTN

EOCHG

CVREF

LDODRV

LDOFB

VIO

SCL

SDA

RESETN

DRIVER

STw4102

GND

VOUT

SENSE

BATT

BATTSENSE

ISET

CVIS

C32KHZ

STDBY

ICG+

ICG-

TEST

Rs

C3

Rset

C1

32kHz

StandBy

Rcg

Table 9. Component list for external power devices

Name Typ. value Tolerance Comments

R

set

R

s

T1 or

M1 + D1

8k to 12k 1% Main charge current setting

200mΩ 1% External current sense resistor

STT818B

STS2DPFS20V

PNP transistor

PMOS transistor with Schottky diode

15/34

Application schematics STw4102

5.3 Using LDO regulator to supply telephone from wall adapter

The regulator with external power PMOS (M1) supplies the telephone while the battery is

discharged or unplugged. When the charger is unplugged, the phone is supplied by the

battery through Power MOS M2. A Schottky diode (D1) avoids reverse current.

Figure 18. Charge power path and regulator

to power

management

M1

D1

C4

Battery voltage

Indicator LED

C2

IO voltage

Reset

MAIN

USBPWR

PWRDETECTN

EOCHG

CVREF

LDODRV

LDOFB

VIO

SCL

SDA

RESETN

DRIVER

STw4102

GND

VOUT

SENSE

BATT

BATTSENSE

ISET

CVIS

C32KHZ

STDBY

ICG+

ICG-

TEST

C3

Rset

C1

32kHz

StandBy

Rcg

M2

Co >= 15uF

To phone

Table 10. Component list for LDO regulator

Name Typ. value Tolerance Comments

M1 + D1 STS2DPFS20V PMOS transistor with Schottky diode

M2 STT5PF20V PMOS transistor

Co 10µF to 22µF An output capacitor Co of at least 10µF is required.

C4 Co

16/34

An input capacitor C4 equal to or larger than Co is

required on MAIN input.

STw4102 Battery charger

6 Battery charger

6.1 Charge cycle

The charge cycle is initiated when the presence of a power source on either the MAIN or

USBPWR inputs is detected (the PWRDETECTN pin goes low), while the charger is

enabled by the CHG_ENA bit of the REG_CHG1 control register. If both supplies are

connected, the MAIN input path is selected.

The EOCHG output pin is driven low as the charge begins. If the battery voltage is lower

than the trickle threshold, the charge cycle begins in t ric kle m ode wit h a low current (default

value: 60 mA) until the battery voltage reaches the trickle voltage threshold (default value:

2.9 V). Once the battery voltage rises above this threshold, the charger enters into fast

charge mode where the programmed charge current I

battery.

When the battery voltage approaches the programmable charge voltage (4.10V, 4.20V,

4.30V or 4.35V), the charger enters int o a constant v olta ge charging mode and the chargi ng

current decreases. When the current level reaches the end-of charge level (10% of I

the EOCHG status pin is switched off (open) to indicate that the battery is almost fully

charged, and the charger enters maintenance mode.

charge

or I

is supplied to the

USB

charge

),

In maintenance mode, the charger continues to monitor the battery voltage to maintain the

battery voltage level. The maintenance mode lasts until the charge is stopped by clearing

the CHG_ENA bit in the REG_CHG1 control register, or by removing the power source

(PWRDETECTN is opened).

Figure 19. Charge flow (simplified)

EOCH OPEN (LED OFF)

Power detected (PWRDETECTN LOW)

Trickle charge

EOCH LOW (LED ON)

V

< 2.8v

batt

CCCV charge

EOCH LOW (LED ON)

> 15%

I

charge

Maintenance charge

EOCH OPEN (LED OFF)

CCCV is still ON

Charge Off

60mA

V

batt

I

charge

> 2.9v

< 10%

Power removed (PWRDETECTN OPEN)

Charge Stopped

EOCH OPEN (LED OFF)

Battery overvoltage

or Watchdog event

Battery overvoltage

or Watchdog event

17/34

Battery charger STw4102

6.2 Trickle charge

The trickle charge mode is enabled when the battery voltage V

voltage threshold V

above V

, the trickle current generator is off and the battery is charged using the

trickle

. An internal current source charges the battery. When V

trickle

constant current method.

The trickle voltage threshold and trickle current are defined by OTP configuration bits and

are factory set to 2.9 V and 60 mA b y default. Other values are possible, see Section 9:

Factory OTP opt ions on page 24.

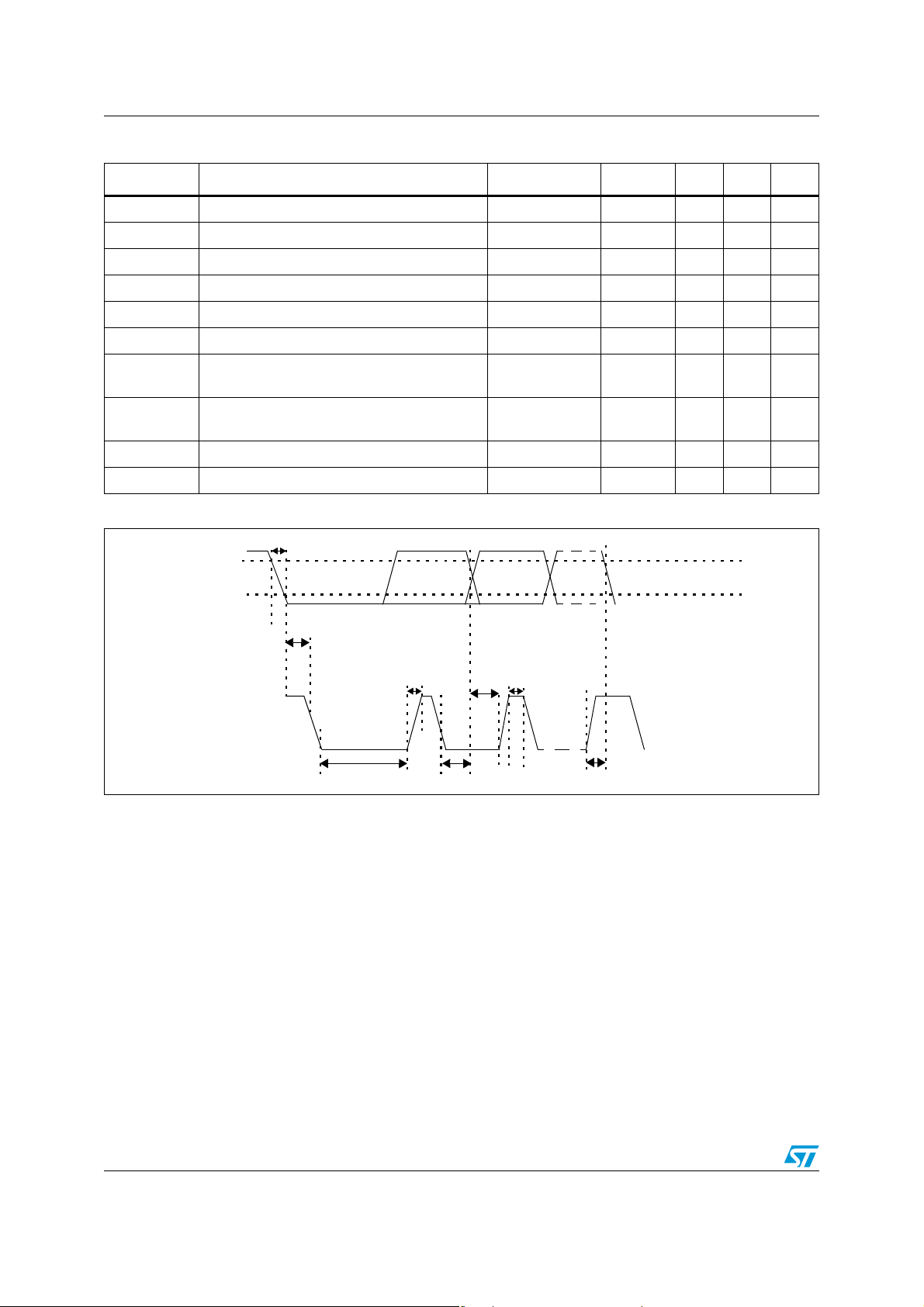

6.3 Charging from a wall adapter

The MAIN input is used for charging from a wall adapter or a dedicated USB charger. The

SEL_DC_USB bit (bit 5 of register REG_CHG0) must be set to 0. The fast charge current is

defined by the external resistor R

The value of the fast charge current is given by the following formula:

I

= 12000 / R

charge

set

In the constant voltage mod e, the ch arger output v oltag e is regulated with 1% accur acy. The

charger output voltage is programmable using the REG_CHG0 register, bits 3 and 4 (see

Table 11).

Table 11. Charger output vol tage

REG_CHG0[4] REG_CHG0[3] V

0 0 4.10V +/- 1%

connected to the ISET pin, and can be set up to 1 A.

set

is lower than the trickle

batt

batt

charge

is

0 1 4.20V +/- 1%

1 0 4.30V +/-1%

1 1 4.35V +/-1%

Figure 20. Main charge mode

I

batt

I

I

trickle

charge

set

(60mA)

)

Trickle

charge

Constant current

(defined by R

Battery Voltage

Charge current

Fast charge

Flag end of

charge (10% I

Constant voltage

charge

Maintenance

charge

V

batt

V

charge

)

V

(2.9v)

trickle

18/34

STw4102 Battery charger

6.4 Charging from a USB port

The MAIN or USBPWR input can be used to charge from a USB 2.0 port. When using the

MAIN input, bit SEL_DC_USB (bit 5 of register REG_CHG0) must be set to 1. Charging

from a USB port is similar to charging from a wall adapter, except the fast charge current

I

is set internally and depends on bits 6 and 7 of the control register REG_CHG0.

USB

Table 12. USB charge current

REG_CHG0[7] REG_CHG0[6] I

0 0 60mA (100 mA max)

0 1 200mA

1 0 400mA (500 mA max)

11 off

6.5 Charging using external power devices

To support charge currents higher than 1 A from the main supply adapter, the STw4102

provides the option to use an external power device and sense resistor. This OTP option is

factory set.

The STw4102 driver is able to drive an external PNP (STT818B or equivalent) or a PMOS

plus Schottky diode (STS2DPFS20V or equivalent). The driver maximum sink current is

60 mA.

The external current sensing device is usually a 200 mΩ shunt resistor. With this resistor

value, the trickle and USB charge currents are close to the nominal values.

6.6 Charge mode summary

Table 13 summarizes the different charge modes.

Table 13. Charge modes

USB

(typ)

V

batt

-

under

V

trickle

above

V

trickle

MAIN

detected

0 0 1 x No charge

1x

0 1 Trickle charge from USBPWR

1x

0 1 1 x

USBPWR

detected

x x 0 x Charge disabled

CHG_ENA

bit

1x

10

11

SEL_DC_USB

bit

19/34

Charge

Trickle charge from MAIN

Fast charge from MAIN input,

current set by Rset

Fast charge from MAIN input,

current set by USB_ICHG bits

Fast charge from USBPWR input,

current set by USB_ICHG bits

Battery charger STw4102

6.7 Watchdog timer

When the fast charge is active, a watchdog timer starts to prevent damage on the battery.

The system controller refreshes the watchdog periodically in order let the charge continue.

When the watchdog time elapses, the charge is stopped.

When the charge starts in trickle mode, to allow the battery to be charged although the

system controller is not running, the watchdog is disabled. However, if for any reason the

charger goes from fast charge mode to trickle mode, then the watchdog is not disabled to

protect against battery failure.

Watchdog timing ca n be 1 minute , 15 minutes , 30 minut es or 60 minutes . It is progr ammable

through the I

or by unplugging the charger (PWRDETECTN goes to low). The watchdog can also be

enabled and disab led through the I

In the standard configuration, t he default state at powerup is watchdog enabled and the

timing is one minute.

2

C interface. The w atc hdog ca n be rese t b y t he I2C interface (bit WDOG_RST)

6.8 Thermal regulation

A thermal regulation circuit limits the charge current in case of high po wer dissipation due to

high input voltage or high ambient temper ature. Th e charge current is prog ressively red uced

to maintain the die temperature in a safe area. This allows to charge the battery with the

highest possible current depending on the operating conditions, and protects the device

against any damage.

2

C interface.

20/34

STw4102 Low drop-out regulator

7 Low drop-out regulator

The purpose of the low drop-out regulator (LDO) is to supply t he phone directly from t he wall

adapter when the battery is low or not present. When the wall adapter is present, MOSFET

is off and the phone supply is regulated at 4.7 V minus the drop voltage across D1. When

the MAIN pin is not connected, MOSFET M2 is on (the gate is pulled down) and the D1

diode avoids any reverse current. The LDO output current is limited by The M1 MOSFET

and D1 diode current capabilities. An output capacitor C

schematics are illustrated in Figure 21.

When the battery is fully discharged, the regulator can charge the battery from the main

supply and at the same time supply the phone, which avoids waiting for the battery to be

charged up to the minimum operating voltage before using the phone.

Figure 21. Regulator

Wall adapter power supply

of at least 15 µF is required. The

o

M1

To phone

LDODRV

LDOFB

D1

M2

Co >= 15uF

When the main supply is abov e the low dropout threshold LDO

Main supply

LDO 4.7V

Battery power supply

power_th

(about 7.2 V), then

the LDO is turned off to protect the ext ernal PMOS against high po wer dissip ation as sho wn

in Figure 22. LDO

power_th

hysteresis is around 0.7 V. By default, this protection feature is

enabled, but can be disabled at factory level by OTP.

Figure 22. Supply voltage

Main supply voltage

7.2V

6.5V

4.7V

Main detect

ON

ON

21/34

Battery monitoring STw4102

8 Battery monitoring

8.1 Gas gauge

The gas gauge is designed to monitor the battery capacity. A current sensing resistor

(typically of 30 mΩ) is needed between the negative terminal of the battery and the ground.

The sensing resistor voltage drop is input to a 13-bit integrating AD converter. When a

conversion cycle is completed, depending on the output sign, the result is forwarded to the

charge or discharge 24-bit accumulator, and the number of conversions is incremented in a

12-bit counter.

One accumulator accumulates current fl owing into the batt ery during charging and the other

accumulates discharge current during system operation. The rema ining battery charge is

given by the difference between the charge and discharge accumu lators.

Figure 23. Gas gauge block diagram

ICG+

ICG-

AD converter

12 bits + sign bit

From 2’s

to binary

EOC

cg_clock

cg_enable

cg_calibration

sign

24 bit max

Σ

32kHz

12 bits Counter

Charge

accumulator

Control logic

Discharge

accumulator

Control

registers

Conv_number

registers

13

24

24

Conv_data

registers

Charge

registers

Discharge

registers

The Digital Base Band (DBB) can control, enable and read gas gauge data t hrough I

control registers. The DBB can read the value of the most recent conversion in two’s

complement format by reading the CONVDATA registers.

The RD_REQ bit enables the transfer of the charge/discharge accumulators and con v ersion

counter register. The transfer can take up to eight 32 kHz cycles, therefore a delay of

22/34

2

C

STw4102 Battery monitoring

approximately 250 microseconds must be respected between the time the RD_REQ bit is

set and the actual register reading. The RD_REQ bit is automatically cleared after the

transfer.

A high value written to the RST_CHRG, RST_DCHRG or RST_COUNTER bits of the

control register resets respectively the charge accumulator, discharge accumulator or

conversion counter. If these bits are set together with the RD_REQ bit, then the reset occurs

after the transfer to the charge, discharge or conversion counter register respectively. The

RST_CHRG, RST_DCHRG or RST_COUNTER bits are automatically cleared after the

reset.

The differential inputs are scaled to the full range of the AD converter, introducing a small

offset error. A high value written to the CG_CAL bit of the control register connects the

inputs of the AD converter together, allowing the DBB to measure the digital offset error.

Using this measurement, the gas gauge can be calibrated to reduce the offset error.

The conversion cycle of a 12- bit plus 1 sign-bit AD converter is 2

13

(8192) clock cycles.

Using the 32.768kHz RTC clock, the conversion cycle time is 250 ms. The LSB value is

23.54 µV, which corresponds to a current of 784.7 µA with a typical 30 mΩ sense resistor.

Given a 250 ms con v ersion cycle time, this LSB v alu e corresponds t o a charge of 54.5nAh.

Under these conditions, the 24-bit accumulator has a capacity of 914 mAh.

The gas gauge system is disabled when the battery voltage is below the Power On Reset

threshold (2.7 V), or when the RESETN pin is driven low (CG_ENA bit default value is 0).

During normal operation, either the STDBY pin or the CG_ENA bit can be used to disab le

the gas gauge function. When the STDBY pin is low, the gas gauge is disabled without

waiting for the end of the current conversion. When the CG_ENA bit is low, the current

gauge is disabled at the end of the current conversion.

8.2 Battery voltage monitoring

The battery voltage can be measured by mean s of a 7- or 12-bit A/D con v erter. This funct ion

is enabled and configured using the following bits of the ADCTRL register:

● The ADPOWERON bit enables battery voltage monitoring.

● The ADRESOLUTION bit allows to select 7- or 12-bit conversion.

● The ONSTATE bit is set when the ADC converter is ready.

● The ADSTART bit starts a conversion; it is automatically cleared after writing.

● The ADRUN bit indicates that a conversion is in progress. The result is available when

the ADRUN bit goes low, and it can be read in the ADDATA registers.

A high value written to the ADCAL bit of the control re gister connects the input of the A/D

converter to ground, allowing the DBB to measure the digital offset error. Using this

measurement, the AD converter can be calibrated to reduce the offset error.

The conversion cycle of a 7 (12) bit co nv ersion is 2

32.768kHz RTC clock, the conversion cycle time is 7.8 (250) ms. LSB va lue is 45 (1.4) mV.

When the battery voltage falls below the Power On Reset threshold, or when the RESETN

input is driven low, the battery voltage monitoring function is disabled.

8

=256 (213=8192) clock cycles. Using the

23/34

Factory OTP options STw4102

9 Factory OTP options

Table 14 summarizes the one-time programming (OTP) options offered by

STMicroelectronics to customize the STw4102 at factory level.

Table 14. Factory OTP options

Option Configuration bits Value

TRICKLE current (wall adapter

charge only)

TRICKLE threshold voltage

MAIN input mode at powerup

Watchdog state at powerup

Watchdog period at powerup

Power switch

Sense resistor

LDO overvoltage protection

OTP_TC=0 (default)

OTP_TC=1

OTP_TV1, OTP_TV 0 :

00

01

10

11 (default)

OTP_SEL_DC_USB=0 (default)

OTP_SEL_DC_USB=1

OTP_WD_ENA=0

OTP_WD_ENA=1 (default)

OTP_WD_TIME1, O T P_WD_TIME0 :

00 (default)

01

10

11

OPT_IEPD=0 (default)

OPT_IEPD=1

OPT_IERSENSE=0 (default)

OPT_IERSENSE=1

OPT_LDOEXT_PRO=0

OPT_LDOEXT_PRO=1 (default)

60 mA

120 mA

2.3 V

2.5 V

2.7 V

2.9 V

Wall adapter mode

USB mode

Disabled

Enabled

1 min

15 min

30 min

60 min

Internal

External

Internal

External

Disabled

Enabled

OTP_ID2, OTP_ID1, OTP_ID0 :

000 (default)

001

2

C ID address

I

010

011

100

101

110

111

For any option re quest other than the standard configuration (default values), contact

STMicroelectronics to get a specific order code.

24/34

70h

71h

72h

73h

74h

75h

76h

77h

STw4102 I2C interface

10 I2C interface

10.1 Read and write operations

The I2C interface is used to control the ch arging an d the ga s gauge system. I t is compatib le

with the I

2

C specification of Philips (version 2.1). It is a slave serial interface with a serial

data line (SDA) and a serial clock line (SCL):

SCL: input clock used to shift data

SDA: input/output bi-directional data transfers

A filter rejects the potential spikes on th e bus data line to preserve data integrity. The bidirectional data line supports transfers up to 400 kbit/s (fast-mode). The data is shifted into

and from the chip on the SDA line, MSB first.

The first bit must be high (START), followe d by the De vice ID an d Read/Write control bit (see

Table 15). The AddrID0 to AddrID2 bits are factory programmable, their default ID value is

70h (AddrID0 = AddrID1 = AddrID2 = 0). Then, the STw4102 sends an acknowledge at the

end of the 8-bit transmission.

The next 8 bits correspon d to the address register, followed by another acknowledge.

Table 16 shows the address register format.

The data field is sent last. It can be composed of several 8-bit data registers, each followed

by an acknowledge. Table 17 shows the data register for m at.

The STw4102 supports byte read, word read, block read, and byte write operations. The

transmission protocol is summarized in Figure 24 and Figure 25.

Table 15. Device ID and R/W bit format

b7 b6 b5 b4 b3 b2 b1 b0

1 1 1 0 AddrID2 AddrID1 AddrID0 R/W

Table 16. Address register format

b7 b6 b5 b4 b3 b2 b1 b0

RegAddr7 RegAddr6 RegAddr5 RegAddr4 RegAddr3 RegAddr2 RegAddr1 RegAddr0

Table 17. Data register format

r

b7 b6 b5 b4 b3 b2 b1 b0

DATA7 DATA6 DATA5 DATA4 DATA3 DATA2 DATA1 DATA0

Figure 24. Byte, word and block read operation

Master

Start Device id

7 bits 7 bits

Start bit = SDAfalling w h en SCL=1

Stop bit = SDArising when SCL=1

Restart bit = start after a start

Acknowledge = SDA force low during a SCL clock

Slave

W

Reg address

A

8bits

A

Restart Device id

Reg data

A

R

8bits

<-- byte read -->

<-- word read (2 bytes) ---------->

<-- block read (up to 10 bytes) ---------------------->

A

Reg data

8bits

address

n+1

A

Reg data

8bits

address

n+2

A/A

25/34

Stop

I2C interface STw4102

Figure 25. Byte write operati on

Start Device id

7 bits

Start bit = SDAfalling when SCL=1

Stop bit = SDArising when SCL=1

Restart bit = start after a start

W

A

10.2 Register mapping

The mapping of all registers is shown in Table 18. Individual register descriptions are sho wn

in Table 19 to Table 35. Power-up values are set at power startup, or at reset (RESETN pin

falling edge). Charge and discharge internal accumulators are not affected by RESETN.

Table 18. Register mapping

Name

REG_CHG0 0 Charge control and status

REG_CHG1 1 Charge enable

REG_WDOG 2 Watchdog control

REG_CG 3 Gas gauge control

REG_CHARGE_LOW 4 Gas gauge charge data, bits 0-7

Reg address

8bits

Address

(dec.)

A

Reg data

8bits

A

Stop

Description

REG_CHARGE_MID 5 Gas gauge charge data, bits 8-15

REG_CHARGE_HIGH 6 Gas gauge charge data, bits 16-23

REG_DISCHARGE_LOW 7 Gas gauge discharge data, bits 0-7

REG_DISCHARGE_MID 8 Gas gauge discharge data, bits 8-15

REG_DISCHARGE_HIGH 9 Gas gauge discharge data, bits 16-23

REG_CONVDATA_LOW 16 Gas gauge AD converter data, bits 0-7

REG_CONVDATA_HIGH 17 Gas gauge AD converter data, bits 8-12

REG_CONVNUMBER_LOW 18 Number of conversions, bits 0-7

REG_CONVNUMBER_HIGH 19 Number of conversions, bits 8-11

REG_ADCTRL 20 Battery voltage monitor control

REG_ADDATA_LOW 21 Battery voltage monitor AD converter data, bits 0-7

REG_ADDATA_HIGH 22 Battery voltage monitor AD converter data, bits 8-10

26/34

STw4102 I2C interface

Table 19. REG_CHG0. address 0 (00h)

Name Pos. Type

CHARGERUN 0 R 0

Power-

up

Description

0: Charge is below 10% of fast charge current.

1: Charge is above 10% of fast charge current.

MAINDETECT 1 R 0 Main input voltage detection.

USBDETECT 2 R 0 USB input voltage detection.

VCHG [4,3] R/W 00

Charge voltage

00=4.1V, 01=4.2V, 10=4.3V, 11=4.35V.

Wall adapter/USB selection for MAIN input

SEL_DC_USB 5 R/W 0

0: charge current set by Rset resistor

1: charge current set by USB_ICHG bits

USB_ICHG [7,6] R/W 00

Table 20. REG_CHG1. address 1 (01h)

Name Pos. Type

Power-

CHG_ENA 0 R/W 1

USB charge current

00=60mA, 01=200mA, 10=400mA, 11=off.

up

Description

0: Charger disabled.

1: Charger enabled.

Reserved [3,1] R/W 0 Reserved bits, to be set to zero.

FORCECHARGER

UN

4R/W0

0: no effect.

1: force EOCHG low independently of charge

state.

0: Internal supply from Main or USB input when

SEL_IS 5 R/W 0

available and charge enabled.

1: Internal supply always from Battery.

Unused [7,6] R/W

Table 21. REG_WDOG. address 2 (02h)

Name Pos. Type

WDOG_EN 0 R/W 1

WDOG_TIME [2,1] R/W 00

WDOG_RST 3 R/W 0

Power-

up

Description

0: Watchdog disabled.

1: Watchdog enabled.

00=1 minute, 01=15 minutes, 10=30 minutes,

11=60 minutes.

0: No effect.

1: Reset watchdog. Bit clear after watchdog reset.

Reserved [5,4] R/W 0 Reserved bits, to be set to zero

WDOG_INT 6 R x 1: Watchdog is elapsed.

Unused 7 R/W

27/34

I2C interface STw4102

Table 22. REG_CG. address 3 (03h)

Name Pos. Type

Power-

up

0: Gas gauge disabled. Charge/discharge

CG_ENA 0 R/W 0

accumulators are reset.

1: Gas gauge enabled.

0: No effect.

RST_CHRG 1 R/W 0

1: Resets the charge accumulator. This bit auto

clears after the charge register is reset.

0: No effect.

RST_DCHRG 2 R/W 0

1: Resets the discharge accumulator. This bit auto

clears after the discharge register is reset.

0: No effect.

RST_COUNTER 3 R/W 0

1: Resets the counter conversion. This bit auto

clears after the counter register is reset.

0: No effect.

1: Transfers the 24 bit charge/discharge

RD_REQ 4 R/W 0

accumulators and the conversion counter to the

charge/discharge and conversion number

registers. This bit auto clears after the transfer.

CG_CAL 5 R/W 0

CG_EOC 6 R 0

0: No effect.

1: Allows to calibrate AD converter.

Set high at the end of a conversion. Cleared after

read.

Unused 7 R/W

Table 23. REG_CHARGE_LOW. address 4 (04h)

Description

Name Pos. Type

Power-

up

Description

DATA[7..0] [7..0] R 00 Current charge data.

Table 24. REG_CHARGE_MID. address 5 (05h)

Name Pos. Type

Power-

up

Description

DATA[15..8] [7..0] R 00 Current charge data.

Table 25. REG_CHARGE_HIGH. address 6 (06h)

Name Pos. Type

Power-

up

Description

DATA[23..16] [7..0] R 00 Current charge data.

Table 26. REG_DISCHARGE_LOW. address 7 (07h)

Name Pos. Type

Power-

up

Description

DATA[7..0] [7..0] R 00 Current discharge data.

28/34

STw4102 I2C interface

Table 27. REG_DISCHARGE_MID. address 8 (08h)

Name Pos. Type

Power-

up

Description

DATA[15..8] [7..0] R 00 Current discharge data.

Table 28. REG_DISCHARGE_HIGH. address 9 (09h)

Name Pos. Type

Power-

up

Description

DATA[23..16] [7..0] R 00 Current discharge data.

Table 29. REG_CONVD ATA_LOW. address 16 (10h)

Name Pos. Type

Power-

up

Description

DATA[7..0] [7..0] R 00 AD converter data.

Table 30. REG_CONVDATA_HIGH. address 17 (11h)

Name Pos. Type

Power-

up

Description

DATA[12..8] [4..0] R 0 AD converter data.

Not used [7..5] R 0

Table 31. REG_CONVNUMBER_LOW. address 18 (12h)

Name Pos. Type

Power-

up

Description

DATA[7..0] [7..0] R 0 Number of conversions.

Table 32. REG_CONVNUMBER_HIGH. address 19 (13h)

Name Pos. Type

Power-

up

Description

DATA[11..8] [3..0] R 0 Number of conversions.

Reserved [7..4] R x Reserved bits.

29/34

I2C interface STw4102

Table 33. REG_ADCTRL. address 20 (14h)

Name Pos. Type

ADPOWERON 0 R/W 0

ONSTATE 1 R 0

Power-

up

0: Allows ADC shutdown.

1: Enables ADC operation.

0: ADC is not ready for operation.

1: ADC is ready for operation.

0: No effect.

ADSTART 2 R/W 0

1: Allows to start a conversion. Cleared upon

writing.

ADRUN 3 R 0

ADRESOLUTION 4 R/W 0

ADCAL 5 R/W 0

0: An AD conversion is not running.

1: An AD conversion is running.

0: 7 bits.

1: 12 bits.

0: No effect.

1: Allows to calibrate AD converter.

Not used [7,6] R 0

Table 34. REG_ADDATA_LOW. address 21 (15h)

Name Pos. Type

DATA[7..0]

DATA[6..0]

Table 35. REG_ADDATA_HIGH. address 22 (16h)

[7..0]

[6..0]

Power-

up

R00

AD converter data in 12 bit mode.

AD converter data in 7 bit mode (bit7=0).

Description

Description

Name Pos. Type

Power-

DATA[11..8] [3..0] R 0

Not used [7..4] R 0

up

Description

AD converter data in 12-bit mode (0 in 7-bit

mode).

30/34

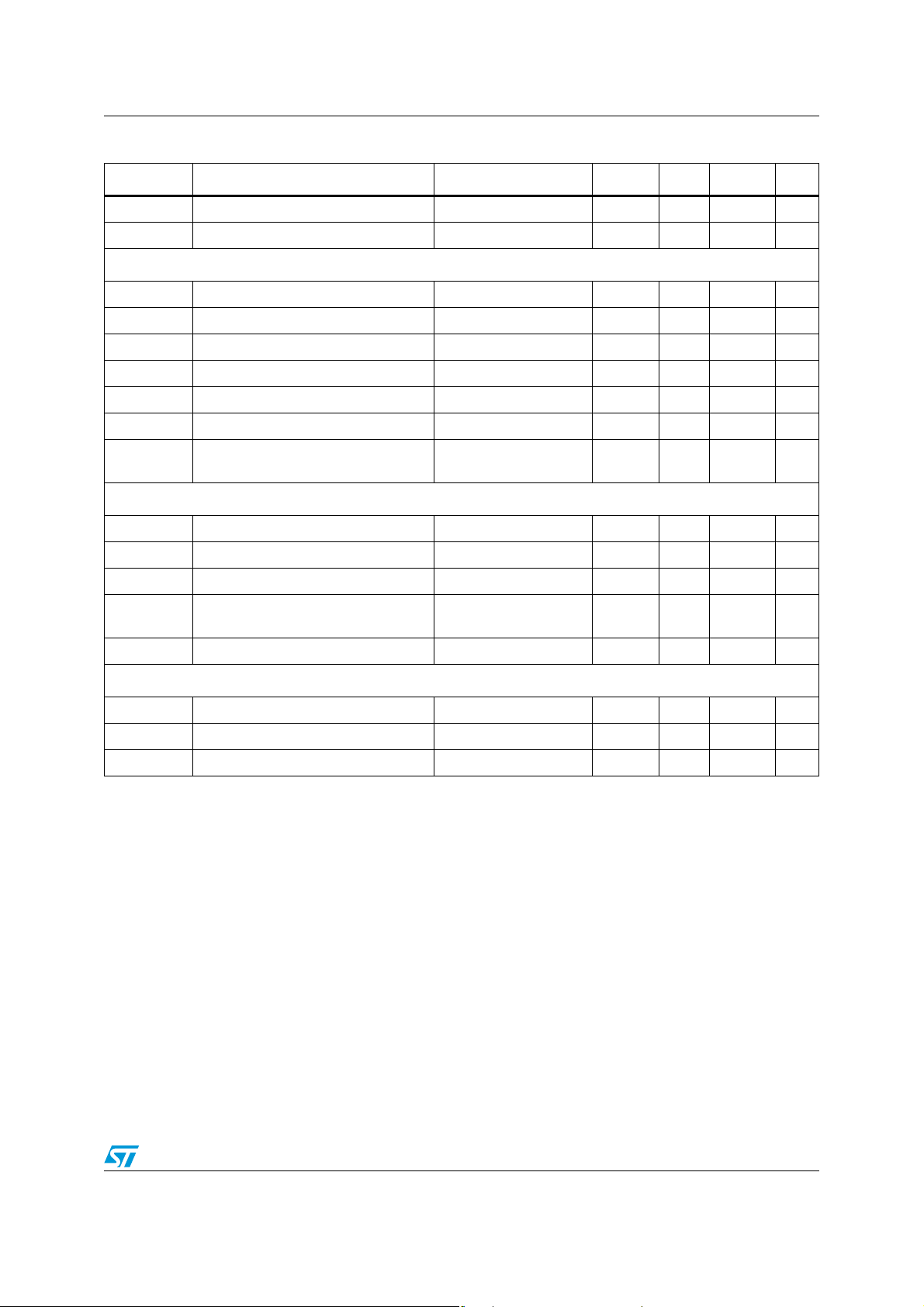

STw4102 Package information

11 Package information

In order to meet environmental requirements, STMicroelectronics offers these devices in

ECOPACK

®

packages. These packages have a lead-free second level interconnect. The

category of second level interconnect is marke d on the pa ckage and on the inner box label,

in compliance with JEDEC Standard JESD97. The maximum ratings related t o soldering

conditions are also marked on the inner box label. ECOPACK is an STMicroelectronics

trademark. ECOPACK specifications are available at: www.st.com

.

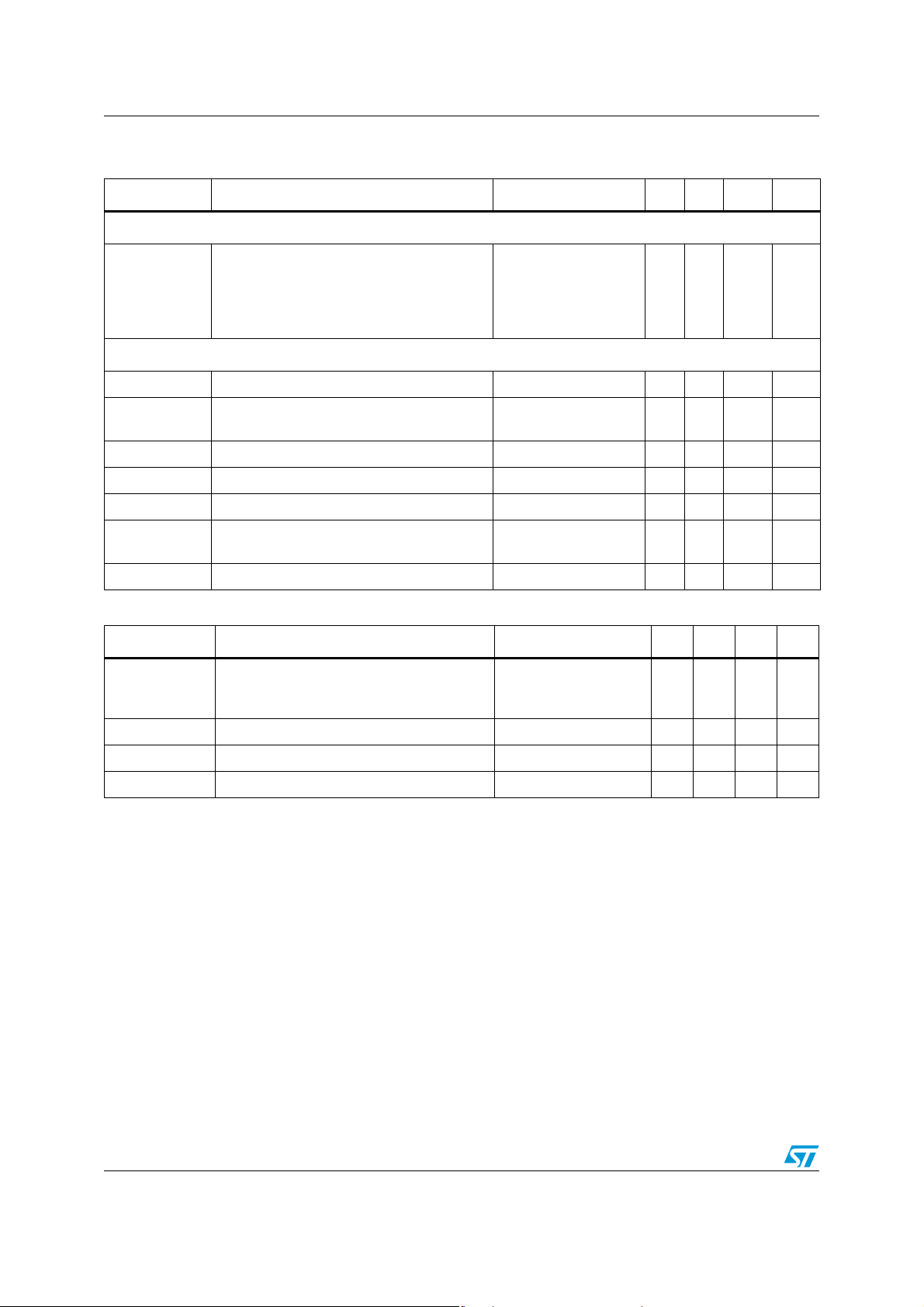

Table 36. QFN24 package mechanical data

Dimensions

Ref.

Typ. Min. Max. Typ. Min. Max.

A 0.80 1.00

A1 0.00 0.05

A2 0.65 0.80

D4.00

D1 3.75

E4.00

E1 3.75

Θ 12°

P 0.420.240.60

Millimeters Inches

R 0.170.130.23

e0.50

N 24.00

Nd 6.00

Ne 6.00

L 0.400.300.50

b 0.18 0.30

Q0.20 0.45

D2 2.10 1.95 2.25

E2 2.10 1.95 2.25

31/34

Package information STw4102

Figure 26. QFN24 package mechanical drawing

Figure 27. QFN24 footprint

32/34

STw4102 Ordering information

12 Ordering information

Table 37. Order code

Order code

(1)

Temperature range Package Packaging Marking

STw4102IQT -30

1. Order code for parts with standard configuration. Contact STMicroelectronics to get order codes for parts

with specific configurations.

° C, +85° C QFN24 Tape & reel W4102I

13 Revision history

Table 38. Document revision history

Date Revision Changes

17-Mar-2008 1 Initial release (preliminary data).

20-Mar-2008 2 Document status promoted from preliminary data to datashee t.

33/34

STw4102

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in vari ous countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - Fran ce - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

34/34

Loading...

Loading...