ST STTH30W03C User Manual

Features

■ Ultrafast switching

■ Low reverse recovery current

■ Low thermal resistance

■ Reduces switching losses

■ ECOPACK

®

2 compliant component

STTH30W03C

Turbo 2 ultrafast high voltage rectifier

Datasheet − production data

A1

K

A2

Description

The STTH30W03C uses ST Turbo 2 300 V

technology. It is especially suited to be used for

DC/DC and DC/AC converters in secondary stage

of MIG/MMA/TIG welding machine. Housed in

ST's TO-247, this device offers high power

integration for all welding machines and industrial

applications.

A1

TO-247

STTH30W03CW

Table 1. Device summary

Symbol Value

I

F(AV)

V

RRM

(typ) 20 ns

t

rr

T

j

V

(typ) 0.90 V

F

A2

K

2 x 15 A

300 V

175 °C

May 2012 Doc ID 023116 Rev 1 1/8

This is information on a product in full production.

www.st.com

8

Characteristics STTH30W03C

1 Characteristics

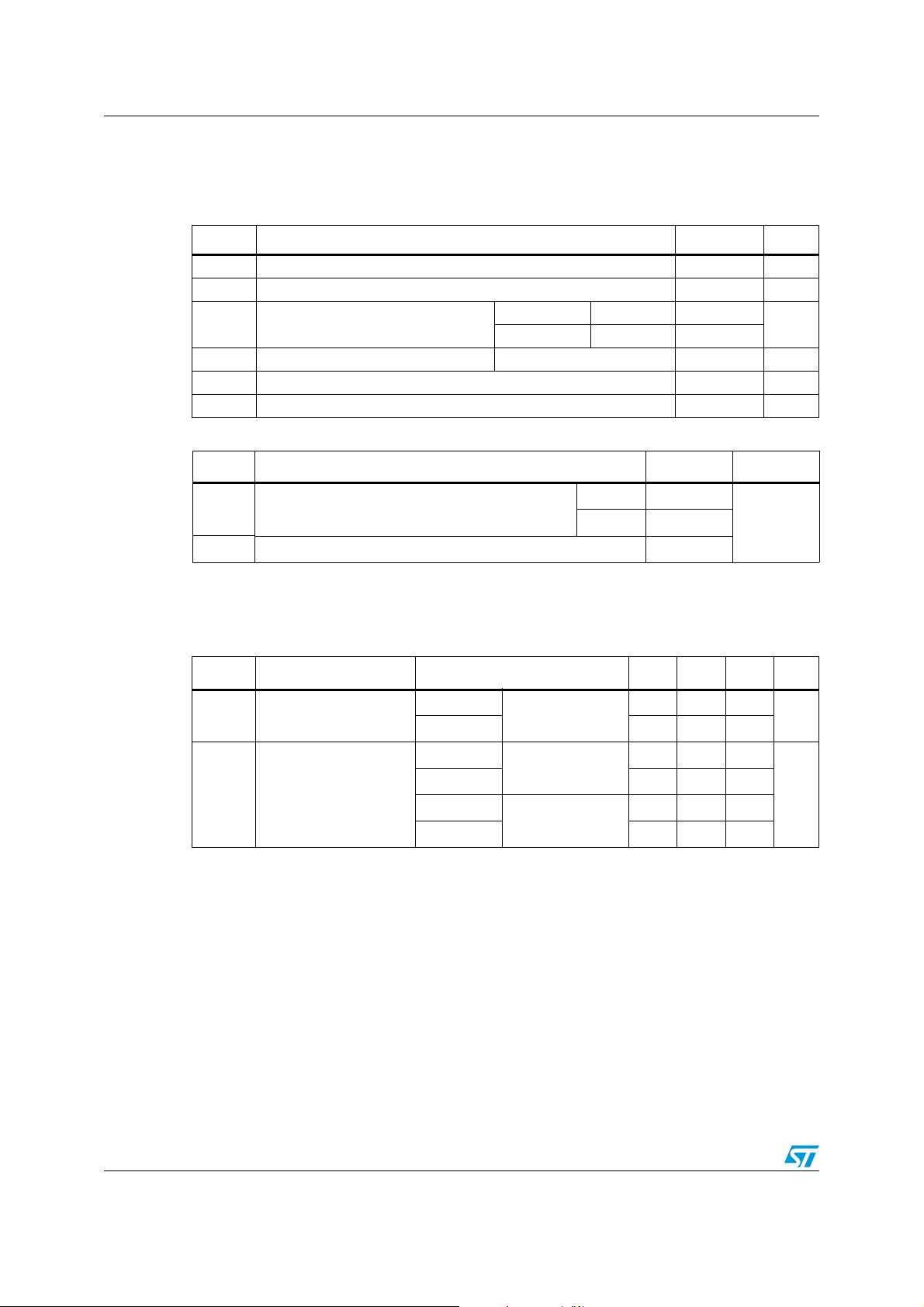

Table 2. Absolute ratings (limiting values, at 25 °C, unless otherwise specified)

Symbol Parameter Value Unit

V

I

F(RMS)

I

F(AV)

I

FSM

T

Table 3. Thermal resistance

Symbol Parameter Value Unit

Repetitive peak reverse voltage 300 V

RRM

RMS forward current 30 A

= 140 °C Per diode 15

T

Average forward current, δ = 0.5

c

T

= 130 °C Per device 30

c

Surge non repetitive forward current tp = 10 ms sinusoidal 150 A

Storage temperature range -65 to + 175 °C

stg

Maximum operating junction temperature + 175 °C

T

j

A

R

R

Junction to case

th(j-c)

Coupling 0.3

th(c)

Total

1.0

°C / W

When diodes 1 and 2 are used simultaneously:

Per diode 1.7

T

j(diode 1)

Table 4. Static electrical characteristics

Symbol Parameter Test conditions Min. Typ Max. Unit

1. Pulse test: tp = 5 ms, δ < 2%

2. Pulse test: tp = 380 µs, δ < 2%

IR

V

= P

(diode 1)

(1)

Reverse leakage current

(2)

Forward voltage drop

F

x R

(Per diode) + P

th(j-c)

VR = V

= 15A

I

F

= 30 A

I

F

x R

RRM

th(c)

(diode 2)

T

= 25 °C

j

= 125 °C 10 100

T

j

= 25 °C

T

j

T

= 150 °C 0.90 1.10

j

= 25 °C

T

j

T

= 150 °C 1.1 1.35

j

10

1.40

1.6

To evaluate the conduction losses use the following equation:

P = 0.85 x I

+ 0.0167 I

F(AV)

F2(RMS)

µA

V

2/8 Doc ID 023116 Rev 1

STTH30W03C Characteristics

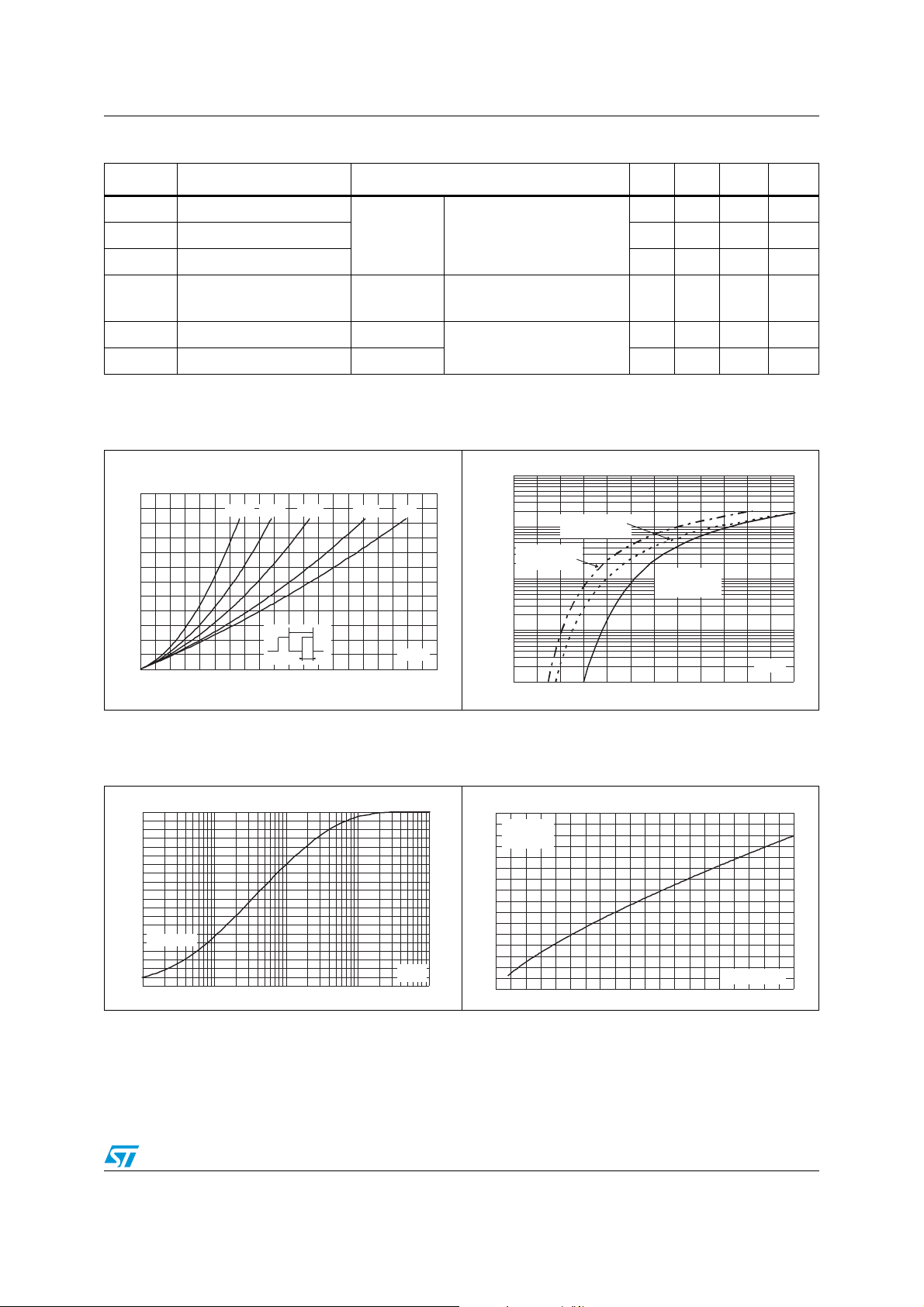

Table 5. Dynamic electrical characteristics

Symbol Parameter Test conditions Min. Typ Max. Unit

Q

S

I

RM

factor

t

V

Reverse recovery current

Reverse recovery charge 160 nC

RR

= 125 °C

T

j

Softness factor 0.3

Reverse recovery time Tj = 25 °C

rr

t

Forward recovery time Tj = 25 °C

fr

Forward recovery voltage Tj = 25 °C 2.0 3.0 V

FP

Figure 1. Average forward power dissipation

versus average forward current

IF = 15 A, VR = 200 V

dIF/dt = -200 A/µs

IF = 1 A, VR = 30 V

dIF/dt = -100 A/µs

IF = 15 A, VFR = 1.2 V

/dt = 100 A/µs

dI

F

Figure 2. Forward voltage drop versus

forward current (per diode)

79 A

20 25 ns

230 ns

(per diode)

IFM(A)

P(W)

F(AV)

24

20

δ = 0.05

16

12

8

4

0

02468101214161820

δ1= 0.

δ

= tp/T

δ = 0.2

T

tp

δ = 0.5

δ = 1

I

F(AV)

(A)

1000.0

100.0

Tj=150 °C

(Typical values)

10.0

1.0

0.1

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Tj=150°C

(Maximum values)

T

°C

= 25

j

(Maximum values)

VFM(V)

Figure 3. Relative variation of thermal

impedance junction to case versus

pulse duration

Z

th(j-c)/Rth(j-c)

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Single pulse

0.2

0.1

0.0

1.E-04 1.E-03 1.E-02 1.E-01 1.E+00

Figure 4. Peak reverse recovery current

versus dI

/dt (typical values, per

F

diode)

IRM(A)

16

IF=I

F(AV)

VR=200 V

14

T

=125 °C

j

12

10

8

6

4

tp(s)

Doc ID 023116 Rev 1 3/8

2

0

0 50 100 150 200 250 300 350 400 450 500

dIF/dt(A/µs)

Loading...

Loading...