Turbo 2 ultrafast high voltage rectifier

Features

■ Ultrafast switching

■ Low reverse recovery current

■ Reduces switching and conduction losses

■ Low thermal resistance

Description

The STTH1L06/U/A, which is using ST Turbo 2

600 V technology, is specially suited as boost

diode in discontinuous or critical mode power

factor corrections.

The device is also intended for use as a free

wheeling diode in power supplies and other power

switching applications.

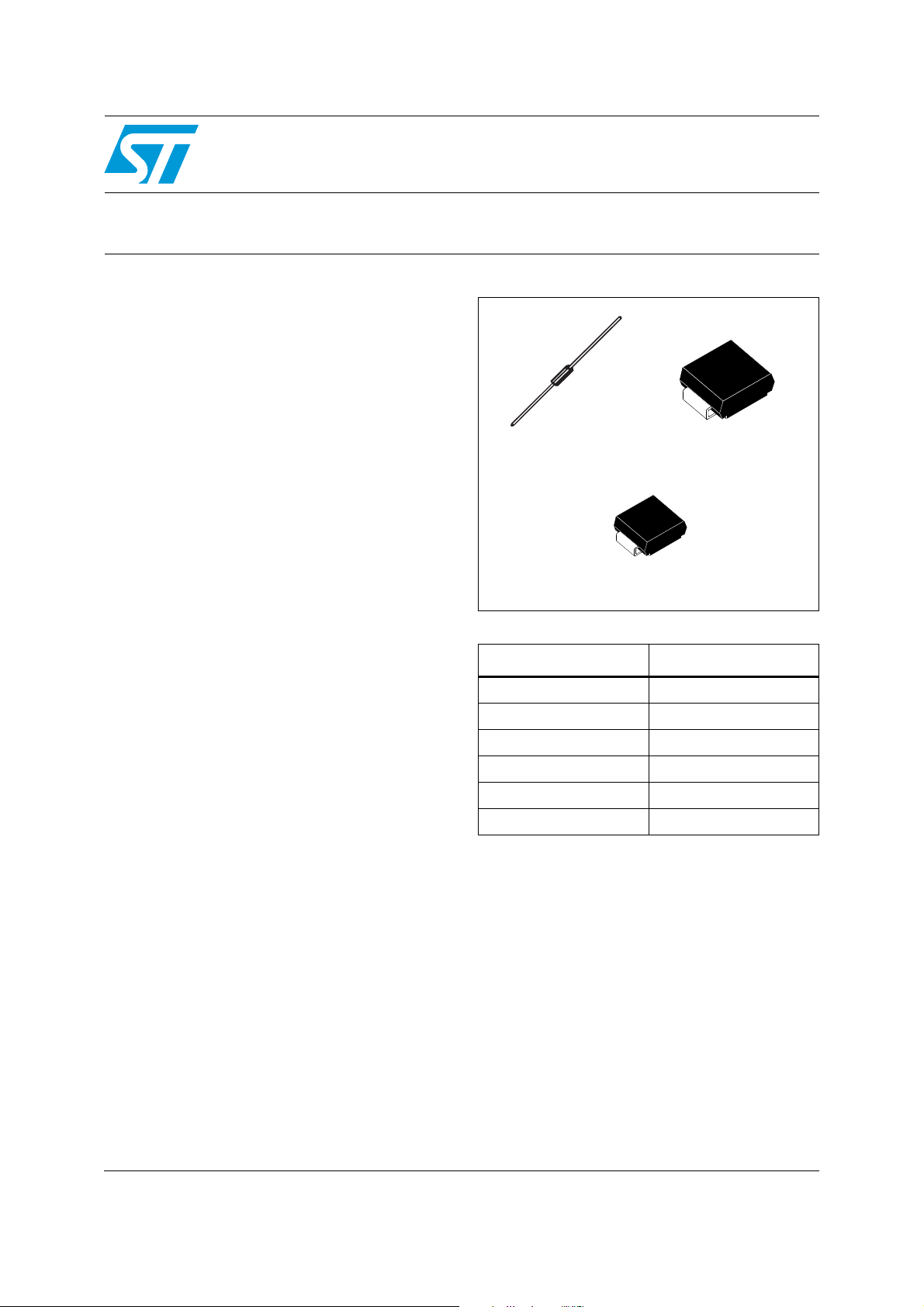

STTH1L06

DO-41

STTH1L06

SMA

STTH1L06A

Table 1. Device summary

SMB

STTH1L06U

Symbol Value

I

F(AV)

V

RRM

I

(max) 75 µA

R

(max) 175 °C

T

j

(max) 1.05 V

V

F

t

(max) 80 ns

rr

1 A

600 V

October 2009 Doc ID 8321 Rev 4 1/9

www.st.com

9

Characteristics STTH1L06

1 Characteristics

Table 2. Absolute ratings (limiting values)

Symbol Parameter Value Unit

V

Repetitive peak reverse voltage 600 V

RRM

DO-41 10

I

F(RMS)

I

F(AV)

I

T

Table 3. Thermal parameters

Forward rms voltage

SMA / SMB 7

DO-41 T

Average forward current δ = 0.5

SMB T

= 10 ms sinusoidal DO-41

t

Surge non repetitive forward current

FSM

Storage temperature range -65 to + 175 °C

stg

T

Maximum operating junction temperature 175 °C

j

p

= 10 ms sinusoidal SMA / SMB

t

p

= 120 °C

c

= 135 °C

c

= 145 °C

c

1ASMA T

30

20

Symbol Parameter Value (max) Unit

L = 10 mm DO-41 45

R

th(j-l)

Junction to lead

SMA 30

°C/W

SMB 25

R

1. Rth(j-a) is measured with a copper area S = 5 cm2 (see Figure 14.)

Table 4. Static electrical characteristics

Junction to ambient

th(j-a)

(1)

L = 10 mm DO-41 70

A

A

Symbol Parameter Test conditions Min. Typ. Max. Unit

I

Reverse leakage current

R

V

Forward voltage drop

F

T

j

= 150 °C 10 75

T

j

T

= 25 °C

j

= 150 °C 0.85 1.05

T

j

V

= 600 V

R

= 1 A

I

F

1

1.3

= 25 °C

To evaluate the conduction losses use the following equation:

P = 0.89 x I

2/9 Doc ID 8321 Rev 4

F(AV)

+ 0.165 I

F2(RMS)

µA

V

STTH1L06 Characteristics

0

00

03

Table 5. Dynamic characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

I

= 1 A, dIF/dt = -50, A/µs,

=tp/T

δ

=tp/T

F

VR = 30 V

= 1 A, dIF/dt = 100 A/µs

I

F

= 3.5 V

V

FR

Figure 2. Forward voltage drop versus

IFM(A)

100.0

δ = 1

T

tp

10.0

1.0

0.1

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

Figure 4. Relative variation of thermal

Zth(j-a)/Rth(j-a)

1.0

0.9

0.8

0.7

0.6

δ = 0.5

0.5

0.4

δ = 0.2

T

tp

0.3

δ = 0.1

0.2

0.1

Single pulse

0.0

1.E-

1 1.E+

55 80 ns

50 ns

forward current

Tj=150°C

Tj=150°C

(Maximum values)

(Maximum values)

Tj=150°C

Tj=150°C

(Typical values)

(Typical values)

Tj=25°C

(Maximum values)

VFM(V)

impedance junction ambient versus

pulse duration

SMB

epoxy FR4, S = 1 cm²

tp(s)

1.E+01 1.E+02 1.E+

δ

=tp/T

T

tp

t

Reverse recovery time Tj = 25 °C

rr

t

Forward recovery time Tj = 25 °C

fr

V

Forward recovery

FP

voltage

T

= 25 °C IF = 1 A, dIF/dt = 100 A/µs 10 V

j

Figure 1. Conduction losses versus

average current

P(W)

1.50

δ = 0.05

1.25

1.00

0.75

0.50

0.25

0.00

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

δ = 0.1

δ = 0.2

IF(av)(A)

δ = 0.5

Figure 3. Relative variation of thermal

impedance junction ambient versus

pulse duration

Zth(j-a)/Rth(j-a)

1.0

DO-41

Lleads = 10mm

0.9

0.8

0.7

0.6

δ = 0.5

0.5

0.4

0.3

δ = 0.2

0.2

δ = 0.1

0.1

Single pulse

0.0

1.E-01 1.E+00 1.E+01 1.E+02 1.E+03

epoxy FR4, Lead = 10 mm

tp(s)

δ

Doc ID 8321 Rev 4 3/9

Loading...

Loading...