Programmable single phase energy metering IC

Features

■ Active, reactive, apparent energies and RMS

values

■ Ripple free active energy pulsed output

■ Live and neutral monitoring for tamper

detection

■ Easy and fast digital calibration in only one

point over the whole current range

■ OTP for calibration and configuration

■ Integrated linear VREGs for digital and analog

supply

■ Selectable RC or crystal oscillator

■ Support 50 ÷ 60 Hz – IEC62052-11, IEC62053-

2x specification

■ Less than 0.1 % error

■ Precision voltage reference: 1.23 V and 30

ppm/°C max

Description

The STPM01 is designed for effective

measurement of active, reactive and apparent

energy in a power line system using Rogowski

coil, current transformer and shunt sensors. This

device can be implemented as a single chip

monophase energy meter or as a peripheral

measurement in a microcontroller based

monophase or 3-phase energy meter. The

STPM01 consists, essentially, of two parts: the

analog part and the digital part. The former, is

composed by preamplifier and 1

converter blocks, band gap voltage reference, low

drop voltage regulator, the latter, is composed by

system control, oscillator, hard wired DSP and

SPI interface. There is also an OTP block, which

is controlled through the SPI by means of a

st

order Δ ∑ A/D

STPM01

with tamper detection

TSSOP20

dedicated command set. The configured bits are

used for testing, configuration and calibration

purpose. From a pair of Δ

from analog section, a DSP unit computes the

amount of consummated active, reactive and

apparent energy, RMS and instantaneous values

of voltage and current. The results of computation

are available as pulse frequency and states on

the digital outputs of the device or as data bits in a

data stream, which can be read from the device

by means of SPI interface. This system bus

interface is used also during production testing of

the device and/or for temporary or permanent

programming of bits of internal OTP. In the

STPM01 an output signal with pulse frequency

proportional to energy is generated, this signal is

used in the calibration phase of the energy meter

application allowing a very easy approach. When

the device is fully configured and calibrated, a

dedicated bit of OTP block can be written

permanently in order to prevent accidental

entering into some test mode or changing any

configuration bit.

∑ output signals coming

Table 1. Device summary

Order code Temperature range Package Packaging

STPM01FTR - 40 to 85 °C TSSOP20 (tape and reel) 2500 parts per reel

June 2011 Doc ID 10853 Rev 8 1/60

www.st.com

60

Contents STPM01

Contents

1 Schematic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

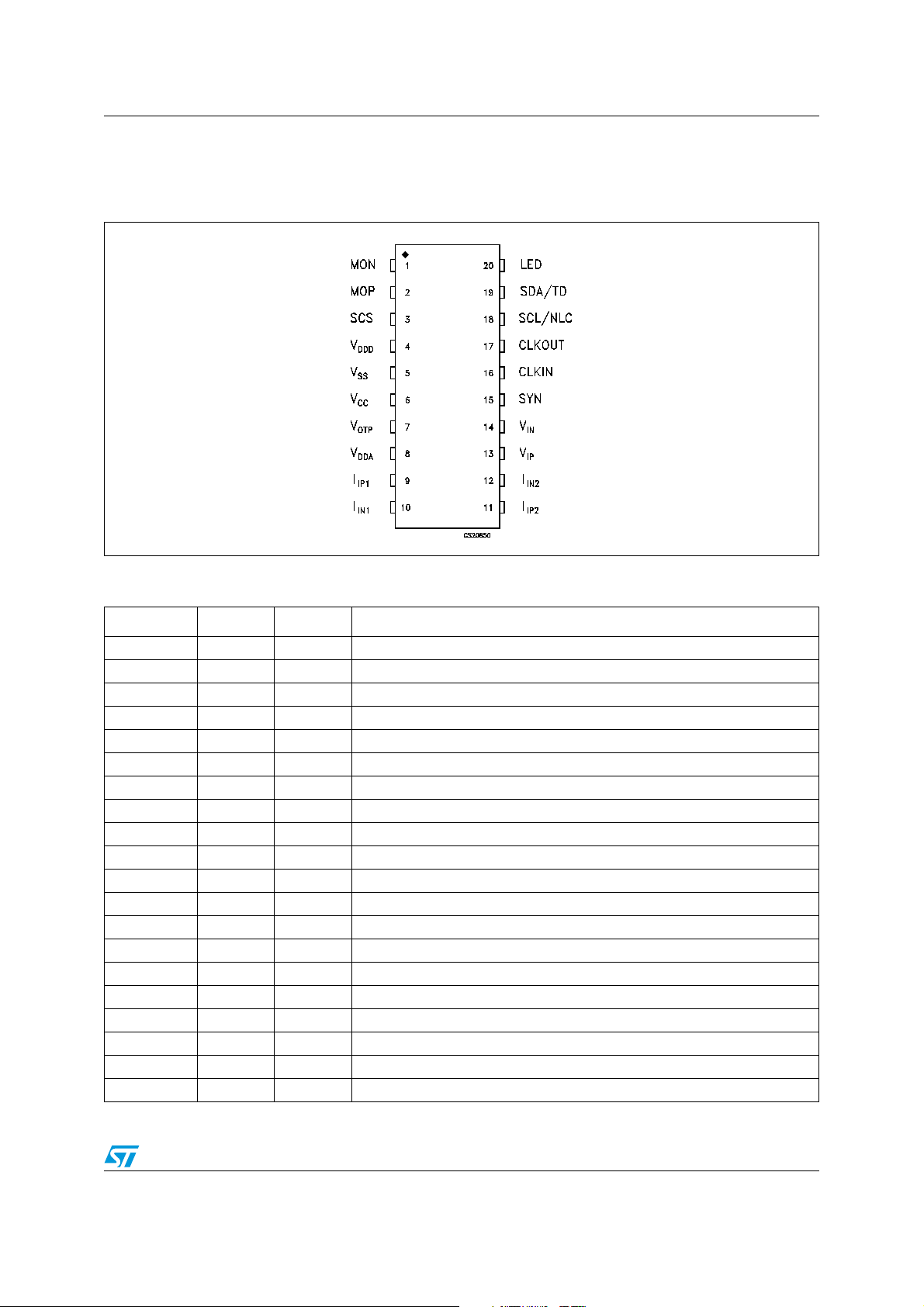

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

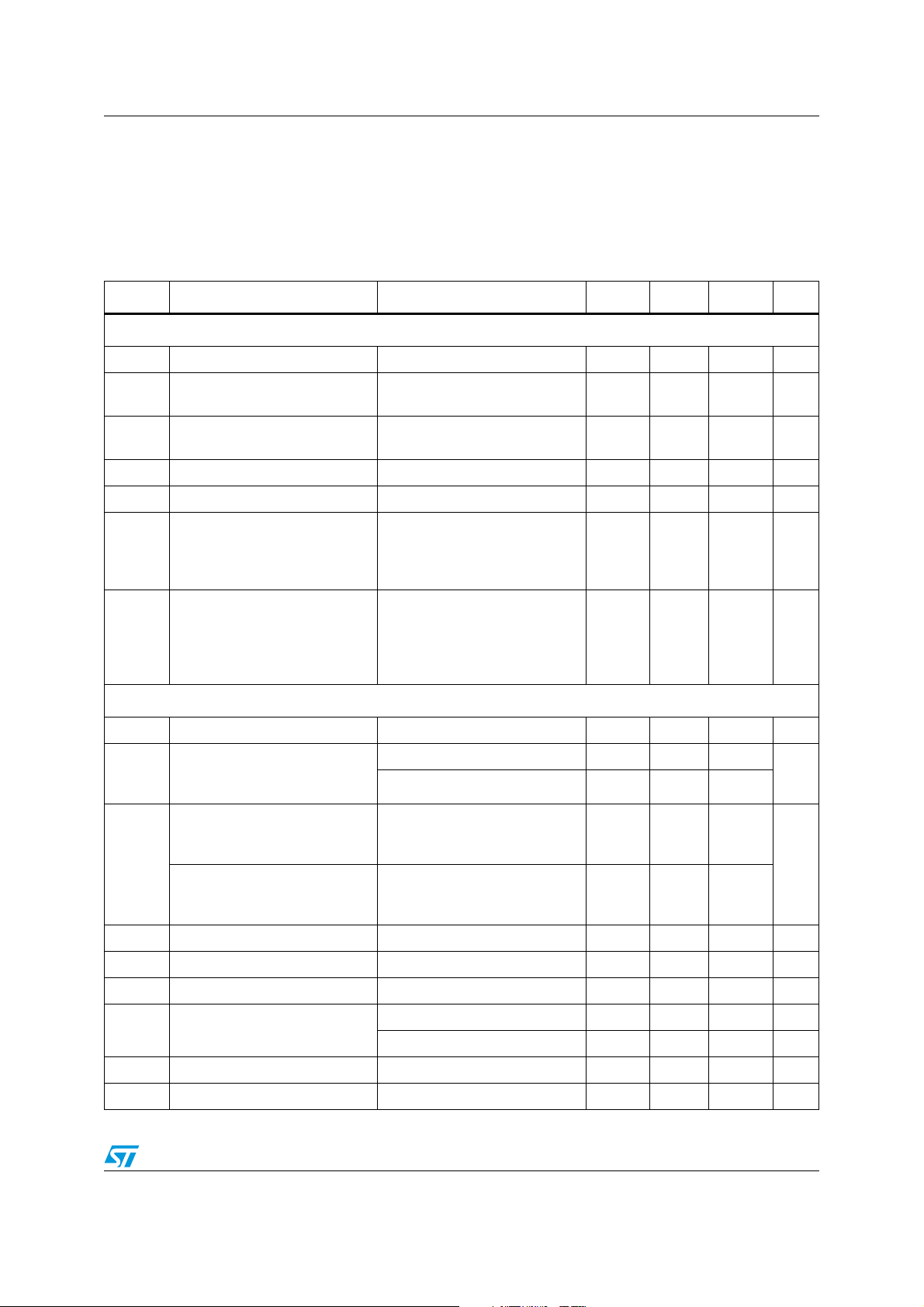

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Measurement error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 ADC offset error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Gain error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4 Power supply DC and AC rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1 General operation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.2 Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.3 ∑Δ A/D converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Zero crossing detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.5 Period and line voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.6 Single wire meter mode (only Rogowsky coil sensor) . . . . . . . . . . . . . . . 21

8.7 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.8 Load monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.9 Error detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.10 Tamper detection module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.10.1 Detailed operational description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.11 Phase compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.12 Clock generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/60 Doc ID 10853 Rev 8

STPM01 Contents

8.12.1 RC Startup procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.13 Resetting the STPM01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.14 Energy to frequency conversion (standalone) . . . . . . . . . . . . . . . . . . . . . 28

8.15 Driving a stepper motor (standalone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.16 Using STPM01 in microcontroller based meter (peripheral) . . . . . . . . . . 30

8.17 Status bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.18 Programming the STPM01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.19 Configuration bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.20 Mode signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.21 SPI interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.21.1 Remote reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.22 Reading data records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.23 Writing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.24 Energy calculation algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.24.1 Active power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.24.2 Reactive power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.24.3 Apparent power and RMS values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9 STPM01 calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Application design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Doc ID 10853 Rev 8 3/60

List of tables STPM01

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Programmable pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6. Internal signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 7. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Gain of voltage and current channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. Configuration of current sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 10. Nominal voltage values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 11. No load detection thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 12. Different settings for LED signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 13. Configuration of MOP and MON pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 14. LED pin configuration in peripheral mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 15. Status bit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 16. Configuration bits map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 17. Mode signals description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 18. Working point settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 19. Device constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 20. Resistor divider ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 21. Current channel typical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 22. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4/60 Doc ID 10853 Rev 8

STPM01 List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Pin connections (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Supply current vs. supply voltage, T

Figure 4. RC oscillator frequency vs. V

CC

Figure 5. RC oscillator: frequency jitter vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Analog voltage regulator: line - load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Digital voltage regulator: line - load regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8. Voltage channel linearity at different V

Figure 9. Power supply AC rejection vs. V

Figure 10. Power supply DC rejection vs. V

Figure 11. Error over dynamic range gain dependence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12. Primary current channel linearity at different V

Figure 13. Gain response of ΔΣ AD converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14. First order ∑ Δ A/D converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 15. ZCR signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 16. LIN and BFR signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 17. Bandgap temperature variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18. Timings of tamper module - Primary channel selected. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 19. Timings of tamper module - Secondary channel selected . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 20. Different oscillator circuits (a): with quartz; (b): internal oscillator; (c): with external source27

Figure 21. Positive energy stepper driving signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 22. Negative energy stepper driving signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 23. STPM01 data records map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 24. Timing for providing remote reset request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 25. Data records reconstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 26. Timing for data records reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 27. Timing for writing configuration and mode bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 28. Active energy computation diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 29. STPM01 reference schematic with one current transformer and one shunt. . . . . . . . . . . . 54

Figure 30. STPM01 with 3X charge pump DC-DC converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

= 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

A

, R = 12 kΩ, TA = 25 °C . . . . . . . . . . . . . . . . . . . . . . . . . . 15

voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CC

Doc ID 10853 Rev 8 5/60

Schematic diagram STPM01

1 Schematic diagram

Figure 1. Block diagram

6/60 Doc ID 10853 Rev 8

STPM01 Pin configuration

2 Pin configuration

Figure 2. Pin connections (top view)

Table 2. Pin description

Pin n° Symbol Type

1 MON P O Programmable output pin, see Ta bl e 5

2 MOP P O Programmable output pin, see Ta b l e 5

3 SCS D IN Digital input/output pin, see Ta b le 5

4V

5V

6V

7V

8V

9I

10 I

11 I

12 I

13 V

14 V

DDD

SS

CC

OTP

DDA

IP1

IN1

IP2

IN2

IP

IN

15 SYN D I/O Programmable input/output pin, see Ta bl e 5

16 CLKIN A IN Crystal oscillator input or resistor connection if RC oscillator is selected

17 CLKOUT A OUT Oscillator Output (RC or crystal)

18 SCL/NLC D I/O Programmable input/output pin, seeTa bl e 5

19 SDA/TD D I/O Programmable input/output pin, see Ta bl e 5

20 LED D O Programmable output pin, see Ta bl e 5

1. A: Analog, D: Digital, P: Power

(1)

Name and function

A OUT 1.5 V Output of internal low drop regulator which supplies the digital core

GND Ground

P IN Supply voltage

P INr Supply voltage for OTP cells

A OUT 3 V Output of internal low drop regulator which supplies the analog part

A IN Positive input of primary current channel

A IN Negative input of primary current channel

A IN Positive input of secondary current channel

A IN Negative input of secondary current channel

A IN Positive input of voltage channel

A IN Negative input of voltage channel

Doc ID 10853 Rev 8 7/60

Maximum ratings STPM01

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

V

I

V

V

CC

PIN

ID

IA

OTP

DC Input voltage -0.3 to 6 V

Current on any pin (sink/source) ± 150 mA

Input voltage at digital pins (SCS, MOP, MON, SYN, SDATD,

SCLNLC, LED)

Input voltage at analog pins (I

IP1

, I

, I

, I

IN1

, VIP, VIN) -0.7 to 0.7 V

IP2

IN2

-0.3 to V

+ 0.3 V

CC

Input voltage at OTP pin -0.3 to 25 V

ESD Human body model (all pins) ± 3.5 kV

Operating ambient temperature - 40 to 85 °C

Junction temperature - 40 to 150 °C

Storage temperature range - 55 to 150 °C

T

T

T

STG

OP

J

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these condition is not implied.

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

1. This value is referred to single-layer PCB, JEDEC standard test board.

Thermal resistance junction-ambient 114.5

(1)

°C/W

8/60 Doc ID 10853 Rev 8

STPM01 Functions

4 Functions

Table 5. Programmable pin functions

Programmable

pin

MON Output for Stepper’s node (MB)

MOP Output for Stepper’s node (MA)

If APL=2 then LED provides high frequency

pulses proportional to Active Energy with 50%

duty cycle.

LED

SCLNLC

SDATD

SYN

SCS

If APL=3 then LED provides pulses proportional

to Active Energy (internal signal AW). The

number of pulses per kWh can be selected

according to the value of KMOT configuration bit.

No-load indicator:

when low, a no-load condition is detected

Tamper indicator:

when low tamper condition is detected

Negative active power indicator:

when low a negative active power condition is

detected

Must be high to activate SCLNLC, SDATAD and

SYN indications

Stand-alone mode

(APL register=2 or 3)

Peripheral mode

(APL register=0 or 1)

If APL=0 then Watchdog signal.

If APL=1 then ΔΣ signal of current channel

If APL=0 then ZCR

If APL=1 then ΔΣ signal of voltage channel

If APL=0 then LED can provide Active,

Reactive or Apparent Energy according to

value of KMOT configuration bit.

If APL=1 then LED is connected to the MUX

signal generated from the tamper detection

circuit.

When LED=low then the primary current

channel is selected, if LED=high the

secondary current channel is selected.

Used for SPI interface (see SPI interface

section for details)

Doc ID 10853 Rev 8 9/60

Functions STPM01

Table 6. Internal signal description

Symbol Name Description

ZCR Zero crossing signal Provides positive pulse every time the line voltage crosses zero

AW Active energy Pulse frequency signal proportional to active energy

RW Reactive energy Pulse frequency signal proportional to reactive energy

SW Apparent energy Pulse frequency signal proportional to apparent energy

LIN Line frequency signal

BFR Base frequency range

MA

Stepper motor signals Signal available in MOP and MON to drive a stepper motor

MB

BIT Tamper flag

BIL No load condition

This signal is high when the voltage channel value is rising and it is low when

the voltage channel is falling. Basically this signal is the sign of dv/dt.

This signal is high when either the voltage line frequency is outside the

nominal band or the voltage register is below 64.

It is cleared when the voltage line frequency is inside the nominal band and

the voltage register goes above 128.

This signal provides the information on the tamper status. If low no tamper is

detected, when high a tamper condition has been detected. This signal is part

of the status register but is also available on the SDATD pin when in

standalone mode.

Provides information on the load condition. This signal is part of the status

register but is also available on the SCLNLC pin when in standalone mode.

BIL=1 no load condition, BIL=0 normal operation.

10/60 Doc ID 10853 Rev 8

STPM01 Electrical characteristics

5 Electrical characteristics

VCC = 5 V, TA = 25 °C, 100 nF to 1 uF between V

and V

Table 7. Electrical characteristics

, 100 nF to 1 uF between VCC and VSS unless otherwise specified.

SS

and VSS, 100 nF to 1 uF between V

DDA

Symbol Parameter Test conditions Min. Typ. Max. Unit

Energy measurement accuracy

f

e

e

e

Effective bandwidth Limited by digital filtering 5 400 Hz

BW

Accuracy of active power

AW

Accuracy of reactive power

RW

Accuracy of apparent power Over 1 to 500 of dynamic range 0.1 %

SW

Over 1 to 1000 of dynamic

range

Over 1 to 1000 of dynamic

range

0.1 %

0.1 %

SNR Signal to noise ratio Over the entire bandwidth 52 db

rms

rms

/50Hz

/50Hz

0.2 %

PSRR

Power supply DC rejection

DC

Voltage signal: 200 mV

Current signal: 10 mV

= 4.194 MHz

f

CLK

VCC=3.3V±10%, 5V±10%

PSRR

Power supply AC rejection

AC

Voltage signal: 200 mV

Current signal: 10 mV

f

= 4.194 MHz

CLK

VCC=3.3V+0.2V

=5.0V+0.2V

V

CC

rms

rms

/50Hz

rms

/50Hz

rms

1@100Hz

1@100Hz

0.1 %

General section

DDD

V

Operating supply voltage 3.165 5.5 V

CC

Supply current configuration

I

registers cleared or device

CC

locked (TSTD=1)

Increase of supply current per

configuration bit, during

programming

ΔI

CC

Increase of supply current per

configuration bit with device

locked

POR Power on reset on V

V

V

f

f

LINE

V

Analog supply voltage 2.85 3.0 3.15 V

DDA

Digital supply voltage 1.425 1.50 1.575 V

DDD

Oscillator clock frequency

CLK

Nominal line frequency 45 65 Hz

OTP programming voltage 14 20 V

OTP

CC

4 MHz, V

= 5V 3 4

CC

mA

8 MHz, V

4 MHz, V

= 5V 5 6

CC

= 5V 120

CC

µA/bit

4 MHz, V

= 5V 2

CC

2.5 V

MDIV bit = 0 4.000 4.194 MHz

MDIV bit = 1 8.000 8.192 MHz

Doc ID 10853 Rev 8 11/60

Electrical characteristics STPM01

Table 7. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

I

t

I

LATCH

OTP programming current per

OTP

bit

OTP programming time per bit 100 300 µs

OTP

Current injection latch-up

immunity

Analog Inputs (I

V

f

ADC

f

V

Z

G

I

LEAK

Maximum input signal levels

MAX

A/D Converter bandwidth 10 kHz

A/D Sampling frequency F

SPL

Amplifier offset ±20 mV

OFF

Z

VIP, VIN Impedance

IP

V

, V

IN

ERR

I

VL

IP1

Impedance

Current channels gain error ±10 %

Voltage channel leakage current -1 1 µA

Current channel leakage current

IP1

IN1

, I

, V

IN1

IP2

2.5 mA

300 mA

, I

, I

, VIP, VIN)

IP2

IN2

Voltage channel -0.3 0.3 V

Gain 8X -0.15 0.15

Current

channels

Gain 16X -0.075 0.075

V

Gain 24X -0.05 0.05

Gain 32X -0.035 0.035

/4 Hz

CLK

, V

IN2

Over the total operating voltage

range

Over the total operating voltage

range

100 400 kΩ

100 kΩ

Channel disabled (PST=0 to 3;

CH2 disabled if C

disabled if C

SEL

=0; CH1

SEL

=1) or device off

-1 1

µA

Input enabled -10 10

Digital I/O Characteristics (SDA, CLKIN, CLKOUT, SCS, SYN, LED)

SDA, SCS, SYN, LED 0.75V

V

Input high voltage

IH

CLKIN 1.5

SDA, SCS, SYN, LED 0.25V

V

Input low voltage

IL

V

V

I

Output high voltage IO = -2mA VCC-0.4 V

OH

Output low voltage IO = +2mA 0.4 V

OL

Pull up current 15 µA

UP

t

Transition time C

TR

CLKIN 0.8

= 50pF 10 ns

LOAD

Power I/O Characteristics (MOP, MON)

V

V

Output high voltage IO = -14mA VCC-0.5 V

OH

Output low voltage IO = +14mA 0.5 V

OL

t

Transition time C

TR

= 50pF 5 10 ns

LOAD

12/60 Doc ID 10853 Rev 8

CC

CC

V

V

STPM01 Electrical characteristics

Table 7. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

Crystal oscillator (see circuit Figure 20)

Input current on CLKIN 1 µA

I

I

R

External resistor 1 4 MΩ

P

External capacitors 22 pF

C

P

f

Nominal output frequency

CLK

RC oscillator (see circuit Figure 20)

44.194

MHz

88.192

I

CLKIN

R

t

Settling current

Settling resistor 12 kΩ

SET

Frequency jitter 1 ns

JIT

On chip reference voltage

Reference voltage 1.23 V

V

REF

Reference accuracy ±1 %

T

Temperature coefficient After calibration 30 50

C

SPI interface timing

F

SCLKr

F

SCLKw

t

t

t

t

t

Data read speed 32 MHz

Data write speed 100 kHz

Data setup time 20 ns

DS

Data hold time 0 ns

DH

Data driver on time 20 ns

ON

Data driver off time 20 ns

OFF

SYN active width 2/f

SYN

f

CLK

= 4 MHz

40 60 µA

ppm/

°C

CLK

s

Doc ID 10853 Rev 8 13/60

Terminology STPM01

6 Terminology

6.1 Measurement error

The error associated with the energy measurement made by the STPM01 is defined as:

Percentage error = [STPM01 (reading) - true energy] / true energy

6.2 ADC offset error

This is the error due to the DC component associated with the analog inputs of the A/D

converters. Due to the internal automatic DC offset cancellation the STPM01 measurement

is not affected by DC components in voltage and current channel. The DC offset

cancellation is implemented in the DSP.

6.3 Gain error

The gain error is gain due to the signal channel gain amplifiers. This is the difference

between the measured ADC code and the ideal output code. The difference is expressed as

percentage of the ideal code.

6.4 Power supply DC and AC rejection

This parameter quantifies the STPM01 measurement error as a percentage of reading when

the power supplies are varied. For the PSRRAC measurement, a reading at two nominal

supplies voltages (3.3 and 5 V) is taken. A second reading is obtained with the same input

signal levels when an ac (200 mV

error introduced by this ac signal is expressed as a percentage of reading.

For the PSRRDC measurement, a reading at two nominal supplies voltages (3.3 and 5V) is

taken. A second reading is obtained with the same input signal levels when the supplies are

varied ± 10 %. Any error introduced is again expressed as a percentage of the reading.

/100 Hz) signal is introduced onto the supplies. Any

RMS

6.5 Conventions

The lowest analog and digital power supply voltage is named VSS which represent the

system ground (GND). All voltage specifications for digital input/output pins are referred to

GND.

Positive currents flow into a pin. Sinking current means that the current is flowing into the pin

and then it is positive. Sourcing current means that the current is flowing out of the pin and

then it is negative.

Timing specifications of signal treated by a digital control part are relative to CLKOUT. This

signal is provided from the crystal oscillator of 4.194 MHz nominal frequency or from the

internal RC oscillator, eventually an external source of 4.194 MHz or 8.192 MHz can be

used.

Timing specifications of signals of the SPI interface are relative to the SCLNLC, there is no

direct relationship between the clock (SCLNLC) of the SPI interface and the clock of the

DSP block. A positive logic convention is used in all equations.

14/60 Doc ID 10853 Rev 8

STPM01 Typical performance characteristics

7 Typical performance characteristics

Figure 3. Supply current vs. supply voltage,

T

= 25 °C

A

Figure 5. RC oscillator: frequency jitter vs.

temperature

Figure 4. RC oscillator frequency vs. V

R = 12 kΩ, T

= 25 °C

A

CC

,

Figure 6. Analog voltage regulator: line - load

regulation

Figure 7. Digital voltage regulator: line - load

regulation

Doc ID 10853 Rev 8 15/60

Figure 8. Voltage channel linearity at

different V

voltages

CC

Typical performance characteristics STPM01

Figure 9. Power supply AC rejection vs. V

CC

Figure 11. Error over dynamic range gain

dependence

Figure 10. Power supply DC rejection vs. V

CC

Figure 12. Primary current channel linearity at

different V

CC

Figure 13. Gain response of ΔΣ AD converters

16/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

8 Theory of operation

8.1 General operation description

The STPM01 is able to perform active, reactive and apparent energy measurements, RMS

and instantaneous values for voltage and current, line frequency information.

Most of the functions are fully programmable using internal configuration bits accessible

through SPI interface. The most important configuration bits are the two application bits

(APL - see Ta bl e 1 6 for configuration register). Using these bits the STPM01 can be

programmed as peripheral (APL = 0 or APL = 1) in microcontroller based meter systems or

as standalone meter device (APL = 2 or APL = 3).

In standalone mode, the STPM01 is able to drive a stepper motor with the MOP and MON

pins, while some of the SPI pins (see Ta b le 5 ) are used to provide information on tamper, no

load and negative power.

In peripheral mode, due to the fact that the stepper motor is not used, the MOP and MON

pins are used to provide different information (see Ta bl e 5 ), while the SPI pins are used to

communicate with the microcontroller.

The STPM01 includes internal registers that hold the useful information for the meter

system. Two kinds of active energy are available: the total active energy that includes all

harmonic content called type 0 and the active energy limited to the 1st harmonic called type

1. This last energy value is obtained filtering the type 0 active energy. The resolution of both

the two active energies is 20-bit. Reactive and Apparent energies are also available with a

20-bit resolution.

STPM01 provides also the RMS values of voltage and current. Due to the modest dynamic

variation of the voltage, the RMS value is stored with a resolution of 11 bit. While the RMS

current value has a resolution of 16 bit. The momentary sampled value of voltage and

current are available also with a resolution of 11 and 16 bit respectively. The line frequency

value is stored with a resolution of 14 bits.

Due to the proprietary energy computation algorithm, STPM01 calibration is very easy and

fast allowing calibration in only one point over the whole current range. The calibration

parameters are stored permanently in the OTP (one time programmable) cells, preventing

calibration tampering.

8.2 Analog inputs

Input amplifiers

The STPM01 has one fully differential voltage input channel and two fully differential current

input channels.

The voltage channel consists of a differential amplifier with a gain of 4. The maximum

differential input voltage for the voltage channel is ± 0.3 V.

The two current channels are multiplexed (see tamper section for details) to provide a single

input to a preamplifier with a gain of 4. The output of this preamplifier is connected to the

input of a programmable gain amplifier (PGA) with possible gain selections of 2, 4, 6, 8. The

total gain of the current channels are then 8, 16, 24, 32. The gain selections are made by

writing to the gain register and it can be different for the two current channels. In case the

tamper function is not used, the secondary current can be disabled.

Doc ID 10853 Rev 8 17/60

Theory of operation STPM01

The maximum differential input voltage is dependent on the selected gain according to the

following table.

Table 8. Gain of voltage and current channels

Voltage channels Current channels

Gain Max Input voltage (V) Gain Max input voltage (V)

8X ±0.15

4 ±0.30

16X ±0.075

24X ±0.05

32X ±0.035

The gain register is included in the device configuration register with the address names

PST and ADDG. The table below shows the gain configuration according to the register

values:

Table 9. Configuration of current sensors

Primary Secondary Configuration Bits

Gain Sensor Gain Sensor PST (3 bits) ADDG (1 bit)

8

16 01

24 10

32 11

8CT 2 X

32 Shunt 3 X

8

16 16 4 1

24 24 5 0

32 32 5 1

8

8 32 Shunt 7 X

Rogowsky Coil

Rogowsky Coil

CT

Disabled (No Tamper)

8

Rogowsky Coil

8CT6 X

00

40

Note: If the device is used in configuration PST = 7 (primary channel with CT, secondary channel

with Shunt), the shunt Ks must always be equal to one fourth of the current transformer Ks.

Both the voltage and current channels implement an active offset correction architecture

which gives the benefit to avoid any offset compensation.

The analog voltage and current signals are processed by the ∑ Δ Analog to digital

converters that feed the hardwired DSP. The DSP implements an automatic digital offset

cancellation that make possible avoiding any manual offset calibration on the analog inputs.

18/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

8.3 ∑Δ A/D converters

The analog to digital conversion in the STPM01 is carried out using two first order ∑ Δ

converters. The device performs A/D conversions of analog signals on two independent

channels in parallel. The current channel is multiplexed as primary or secondary current

channel in order to be able to perform a tamper function, if it is enabled. The converted ∑ Δ

signals are supplied to the internal hardwired DSP unit, which filters and integrates those

signals in order to boost the resolution and to yield all the necessary signals for

computations.

A ∑ Δ modulator converts the input signal into a continuous serial stream of 1 s and 0 s at a

rate determined by the sampling clock. In the STPM01, the sampling clock is equal to f

The 1-bit DAC in the feedback loop is driven by the serial data stream. The DAC output is

subtracted from the input signal. If the loop gain is high enough, the average value of the

DAC output (and therefore the bit stream) can approach that of the input signal level. When

a large number of samples are averaged a very precise value of the analog signal is

obtained. This averaging is carried out in the DSP section which implements decimation,

integration and DC offset cancellation of the supplied ∑ Δ signals. The gain of the

decimation filters is 1.004 for the voltage channel and 0.502 for the current channel. The

resulting signal has a resolution of 11bits for voltage channel and 16 bits for current

channel.

CLK/4

.

Figure 14. First order ∑ Δ A/D converter

Integrator

+

Input analog signal

Σ

-

∫

8.4 Zero crossing detection

The STPM01 has a zero crossing detector circuit on the voltage channel which can be used

by application for synchronization of some utility equipment to event of zero crossing of line

voltage. This circuit produces the internal signal ZCR which has a rising edge every time the

line voltage crosses zero and a negative edge every time the voltage reaches its positive or

negative peak. The ZCR signal is then at twice the line voltage frequency. The ZCR signal is

available on the MOP pin only when STPM01 works as peripheral with the configuration bit

APL = 0.

DAC

f

CLK

/4

Output digital signal

Doc ID 10853 Rev 8 19/60

Theory of operation STPM01

Figure 15. ZCR signal

8.5 Period and line voltage measurement

The period module measures the period of the base frequency of the voltage channel and

checks if the voltage signal frequency is within the f

LIN signal is produced, which is low when the line voltage is rising, and high when the line

voltage is falling. This means that the LIN signal is the sign of dv/dt. With further elaboration,

the ZCR signal is also produced. On the trailing edge of LIN (line frequency) the period

counter starts counting up pulses of the f

/4 reference signal. The LIN signal is available

CLK

on the status bit register (see Tab le 1 5).

If the counted number of pulses between two trailing edges of LIN is higher than 2

the counting is never stopped (no LIN trailing edge) this means that the base frequency is

lower than f

/217 Hz and a BFR (base frequency range) error flag is set.

CLK

If the number of pulses counted between two trailing edges of LIN is lower than 2

base frequency exceeds the limit (means it is higher than f

must be repeated three consecutive times in order to set the BFR error flag.

For example, with a 4.194304 MHz oscillator frequency and MDIV bit clear (or 8.192 MHz

with MDIV set), f

/4 is 1048.576 MHz. If the line frequency is 30 Hz, the counted f

CLK

pulses between two LIN trailing edges are 34952, more than 2

low frequency limit is then:

f

/217 = 4194304/131072 = 32 Hz.

CLK

With the same clock frequency, if the line frequency is 130Hz, the f

LIN trailing edges are 8066, more than 2

13

(8192). The BFR high frequency limit is then:

CLK

/217 to f

CLK

/215 band. To do this, the

CLK

15

, or if

13

, the

/215. In this case, the error

15

(32768 pulses). The BFR

/4 pulses between two

CLK

CLK

/4

f

/215 = 4194304/32768 = 128 Hz.

CLK

When the line frequency re-enters the nominal band, the BFR flag is automatically reset.

This BFR error flag is also assembled as part of the 8-bit status register (see Ta b le 1 5 ).

20/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

Figure 16. LIN and BFR signal

The BFR flag is also set if the register value of the RMS voltage drops below 64. BFR is

cleared when the register value goes above 128. The BFR, then, also gives information

about the presence of the line voltage within the meter.

When the BFR error is set, the computation of power is zero unless the FRS bit is set or the

single wire mode operation is selected (see Section 8.6).

In fact, the effect of the BFR bit can be overridden by setting FRS configuration bit.

It means that if FRS is set and BFR is also set, all the energy computation is carried on as

BFR was cleared. In this case then p=u*i, where u could be zero or not (if BFR was set

because voltage RMS register value is below 64).

In standalone mode, the MOP, MON and LED provide the energy information, their

operation is not affected by FRS bit, it means that when BFR is set they stop switching

regardless the FRS value.

8.6 Single wire meter mode (only Rogowsky coil sensor)

STPM01 support single wire meter (SWM) operation when working with Rogowsky coil

current sensors. In SWM mode there is no available voltage information in the voltage

channel. It is possible that someone has disconnected one wire (live or neutral) of the meter

Doc ID 10853 Rev 8 21/60

Theory of operation STPM01

for tampering purposes or in case the line voltage is very stable, it is possible to use a

predefined value for computing the energy without sensing it.

In order to enable the SWM mode, the STPM01 must be configured with PST values of 4 or

5, (tamper enabled-Rogowsky coils). In this way, if the BFR error is detected, STPM01

enters in SWM. If BFR is cleared the energy calculation is performed normally, when BFR is

set (no voltage information is available) the energy computation is carried out using a

nominal voltage value according to the NOM configuration bits.

Since there is no more information on the phase shift between voltage and current, the

apparent rather than active power is used for tamper and energy computation. The

calculated apparent energy is the product between I

equivalent V

V

= VPK*K

RMS

where V

PK

that can be calculated as follows:

RMS

,

NOM

represents the maximum line voltage reading of the STPM01 and K

(effectively measured) and an

RMS

NOM

is a

coefficient that changes according to the following table:

Table 10. Nominal voltage values

NOM K

00.3594

10.3906

20.4219

30.4531

For example, if a R

= 783 kΩ and R2 = 475 Ω are used as resistor divider when the line

1

NOM

voltage is present, the positive voltage present at the input of the voltage channel of

STPM01 is:

VI

2

=

⋅

RR

+

21

RMS

2V

R

since the maximum voltage value applicable to the voltage channel input of STPM01 is +0.3

V, the equivalent maximum line voltage applicable is:

V

= R1+R2/R2 • 0.3 = 494.82

PK

considering the case of NOM=2, the correspondent RMS values used for energy

computation are:

V

= VPK • 0.4219 = 208.76 [V]

RMS

Usually the supply voltage for the electronic meter is taken from the line voltage, in SWM,

since the line voltage is not present any more, some other power source must be used in

order to provide the necessary supply to STPM01 and the other electronic components of

the meter.

8.7 Power supply

The main STPM01 supply pin is the VCC pin. From the VCC pin two linear regulators provide

the necessary voltage for the analog part V

The V

22/60 Doc ID 10853 Rev 8

pin represents the reference point for all the internal signals. 100 nF low ESR

SS

DDA

(3 V) and for the digital part V

DDD

(1.5 V).

STPM01 Theory of operation

capacitor should be connected between VCC and VSS, V

these capacitors must be located very close to the device.

The STPM01 contains a power on reset (POR) detection circuit. If the V

than 2.5 V then the STPM01 goes into an inactive state, all the functions are blocked

asserting a reset condition. This is useful to ensure correct device operation at power-up

and during power-down. The power supply monitor has built-in hysteresis and filtering,

which give a high degree of immunity to false triggering due to noisy supplies.

A bandgap voltage reference (VBG) of 1.23 V ±1 % is used as reference voltage level

source for the two linear regulators and for the A/D converters. Also, this module produces

several bias currents and voltages for all other analog modules and for the OTP module. The

bandgap voltage can be compensated regardless to the temperature variations with the

BGTC bits.

Figure 17. Bandgap temperature variation

and VSS, V

DDA

and VSS. All

DDD

supply is less

CC

8.8 Load monitoring

The STPM01 includes a no load condition detection circuit with adjustable threshold. This

circuit monitors the voltage and the current channels and, when the measured voltage is

below the set threshold, the internal signal BIL becomes high. The information about this

signal is also available in the status bit BIL.

The no load condition occurs when the product between V

below a given value. This value can be set with the LTCH configuration bits.

Four different no-load threshold values can be chosen according to the two configuration

bits LTCH (see Ta b le 1 1 ).

Table 11. No load detection thresholds

LTCH K

0800

1 1600

2 3200

3 6400

and I

RMS

LT CH

Doc ID 10853 Rev 8 23/60

register values is

RMS

Theory of operation STPM01

When a no load condition occurs (BIL=1) the integration of power is suspended and the

tamper module is disabled.

In standalone mode, if a no load condition is detected, the BIL signal blocks generation of

pulses for stepper and forces SCLNLC pin to be low. If APL = 2 (see Section 8.14) the LED

pin continues providing the high frequency pulses, while if APL = 3, the pulses are stopped

as happens for MOP and MON.

In peripheral mode, the BIL signal can be accessed only through the SPI interface.

8.9 Error detection

In addition to the no load condition and the line frequency band, the integration of power can

be suspended also due to detected error on the source signals.

There are two kinds of error detection circuits involved. The first checks all the ∑ Δ signals

from the analog part if any is stacked at 1 or 0 within the 1/128 of f

In case of detected error the corresponding ∑ Δ signal is replaced with an idle ∑ Δ signal,

which represents a constant value 0. All error and other resolved flags are treated as bits of

a device status and can be read out by means of SPI interface.

Another error condition occurs if the MOP, MON and LED pin outputs signals are different

from the internal signals that drive them. This can occur if some of this pin is forced to GND

or to some other imposed voltage value. In this case the internal status bit PIN is activated

providing the information that some hardware problem has been detected, for example the

stepper motor has been mechanically blocked.

period of observation.

CLK

8.10 Tamper detection module

The STPM01 is able to measure the current in both live and neutral wire with a time domain

multiplexing approach on a unique sigma delta modulator. This mechanism is adopted to

implement anti-tamper function. If this function is selected (see Ta bl e 9 ), the live and neutral

wire currents are monitored; when the difference between the two measurements exceeds a

rated threshold the STPM01 enters the "tamper state", while in "normal state" the two

measurements are below the threshold.

In particular, both channels are not observed all the time, rather a time multiplex mechanism

is used. During the observation time of each channel, its active energy is calculated. A

tamper condition occurs when the absolute value of the difference between the two active

energy values is greater than a certain percentage of the averaged energy during the

activated tamper module (see Equation 1: ).

This percentage value can be selected between two different values (12.5 % and 6.25 %)

according to the value of the configuration bit CRIT.

The tamper condition is detected when the following formula is satisfied:

Equation 1

EnergyCH1 - EnergyCH2 > K

where K

The detection threshold is much higher than the accuracy difference of the current channels,

which should be less than 0.2 %, but, some headroom should be left for possible transition

effect, due to accidental synchronism of actual load current change with the rhythm of taking

the energy samples.

can be 12.5 % or 6.25 %.

CRIT

(EnergyCH1 + EnergyCH2)/2;

CRIT

24/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

The tamper circuit works if the energies associated with the two current channels are both

positive or negative, if the two energies have different sign, the tamper is on all the time

however, the channel with the associated higher power is selected for the final computation

of energy.

In single wire mode, the apparent energy rather than the active is used for tamper detection.

When internal signals are not good enough to perform the calculations, i.e. line period is out

or range or ΔΣ signals from analog section are stacked at high or low logic level, or no load

condition is activated, the tamper module is disabled and its state is preset to normal.

8.10.1 Detailed operational description

The meter is initially set to normal state, i.e. tamper not detected.In this condition the

primary channel is selected for final integration of energy. In such state the values of both

load currents should not differ more than the accuracy difference of the channels does.

Sixty-four periods of line voltage is used as a tamper checking period.

After 24 periods of line voltage two internal signals MUX and INH are changed in order to

enable secondary current channel and to freeze the last power and RMS values of primary

current channel. The following 16 periods of line frequency are used for tamper detection

integration. During this gap, the final energy calculation does not use the signal from

selected channel but the frozen values.

Four line periods after the INH switch, the integration of power from secondary current

channel is started and lasts four periods. Additional four line periods later MUX signal is

switched back to primary current channel and the integration for tamper detection is started.

The timings of MUX and INH signals are shown in Figure 18 below.

Figure 18. Timings of tamper module - Primary channel selected

MUX Ch1Ch2Ch1Ch1

INH

Tampe rpowerintegrators B A

Cycles 444424 24

When the secondary channel is selected to be integrated by the final energy integrator, the

MUX and INH signals change according to Figure 19 below.

Figure 19. Timings of tamper module - Secondary channel selected

This means that energy of four periods from secondary channel followed by energy of four

periods from primary channel is sampled within the tamper module. From these two

Doc ID 10853 Rev 8 25/60

Theory of operation STPM01

samples, called B and A respectively, the criteria of tamper is calculated and the channel

with higher current is selected, resulting in a new tamper state. If four consecutive new

results of criteria happen, i.e. after elapsed 5.12 s at 50 Hz, the meter will enter into tamper

state. Thus, the channel with the higher current will be selected for the energy calculation. If

samples of power A and B would have different signs, the Tamper would be on all the time

but, the channel with bigger power would be still selected for the final integration of energy.

If a tamper status has been detected, the multiplex ratio will be 56:8 if the primary channel

energy is greater than the secondary one, otherwise it will be 8:56.

The detected tamper condition is stored in the BIT status bit. If BIT = 0 tamper is not

detected, if BIT = 1 a tamper condition has been detected. In standalone mode the BIT flag

is also available in the SDATD pin.

8.11 Phase compensation

The STPM01 is does not introduce any phase shift between voltage and current channel.

However, the voltage and current signals come from transducers, which could have inherent

phase errors. For example, a phase error of 0.1° to 0.3° is not uncommon for a current

transformer (CT). These phase errors can vary from part to part, and they must be corrected

in order to perform accurate power calculations. The errors associated with phase mismatch

are particularly noticeable at low power factors. The STPM01 provides a means of digitally

calibrating these small phase errors through a introducing delays on the voltage or current

signal. The amount of phase compensation can be set using the 4 bits of the phase

calibration register (CPH).

The default value of this register is at value of 0 which gives 0° phase compensation. When

the 4 bits give a CPH of 15 (1111) the introduced compensation is +0.576°. This

compensates the phase shift usually introduced by the current sensor, while the voltage

sensor, normally a resistor divider, does not introduce any delay. The resolution step of the

phase compensation is 0.038°.

8.12 Clock generator

All the internal timing of the STPM01 is based on the CLKOUT signal. This signal can be

generated in three different ways:

1. RC: this oscillator mode can be selected using the RC configuration bit. If RC = 1 the

STPM01 will run using the RC oscillator. A resistor connected between CLKIN and

ground will set the RC current. For 4 MHz operation the suggested settling resistor is

12 kΩ; The oscillator frequency can be compensated using the CRC configuration bit

(see Ta bl e 1 6 )

2. Quartz: If RC = 0 the oscillator will work with an external crystal. The suggested circuit

is depicted in Figure 20;

3. External clock: keeping RC=0, it is also possible to feed the CLKOUT pin with an

external oscillator signal

The clock generator is powered from analog supply and is responsible for two tasks. The

first one is to retard the turn on of some function blocks after POR in order to help smooth

start of external power supply circuitry by keeping off all major loads.

The second task of the clock generator is to provide all necessary clocks for analog and

digital parts. Within this task, the MDIV configuration bit is used to inform the device about

26/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

the nominal frequency value of CLKOUT. Two nominal frequency ranges are expected, from

4.000 MHz to 4.194 MHz (MDIV = 0) or from 8.000 MHz to 8.192 MHz (MDIV = 1).

Figure 20. Different oscillator circuits (a): with quartz; (b): internal oscillator; (c): with external

source

8.12.1 RC Startup procedure

To use the device with RC oscillator the configuration bit RC (see Ta bl e 1 6) must be set.

Since the default configuration is for a crystal oscillator, when a RC oscillator is used instead

and the device is supplied for the very first time it is not internally clocked and consequently

the DSP is inactive. In this condition it is not possible to set RC or any other configuration bit.

The following SPI procedure can be run in order to set the RC bit and provide the clock to

the device:

● Set the mode signal BANK;

● Perform a software reset;

● Read the registers: BANK mode signal should be checked and the records should

show something (not 000000F0);

● Set the mode signal RD;

● Read the registers through SPI just to check that RD mode signal has been set;

● Clear the mode signal BANK;

● DO NOT perform a reading, and write configuration bit RC;

In this way the RC oscillator is started. If the registers are read again, it can be seen that RD

and RC bits are set, and BANK is cleared.

Once the RC startup procedure is complete, the device is clocked and active and it is

possible to permanently write the RC bit.

For details on mode signals refer to Chapter 8.20, for SPI operations refer to Chapter 8.21.

Doc ID 10853 Rev 8 27/60

Theory of operation STPM01

8.13 Resetting the STPM01

The STPM01 has no reset pin. The device is automatically reset by the POR circuit when

the V

crosses the 2.5 V value but it can be reset also through the SPI interface giving a

CC

dedicated command (see SPI section for remote reset command details).

In case of reset caused by POR circuit all clocks and both DC buffers in the analog part are

kept off for about 30 ms and all blocks of digital part, except for SPI interface, which is hold

in a reset state for about 125 ms after a reset condition.

When the reset is performed through SPI no delayed turn on is generated.

Resetting the STPM01 causes all the functional modules of STPM01 to be cleared including

the OTP shadow latches (see paragraph 16 for OTP shadow latches description).

The reset through SPI (remote reset request) will normally take place during production

testing or in an application of meter with some on-board microprocessor when some

malfunction of metering device will be detected.

8.14 Energy to frequency conversion (standalone)

When used in standalone mode the STPM01 provides energy to frequency conversion both

for calibration and energy readout purposes. In fact one convenient way to verify the meter

calibration is to provide a pulse train signal with 50 % duty cycle whose frequency signal is

proportional to the active energy under steady load conditions. In this case the user will

choose a certain number of pulses on the LED pin that will corresponds to 1 kWh. We will

name this value as P.

The active energy frequency-based signal is available in the LED pin when APL = 2 or APL

= 3.

If APL = 2 the LED is driven from internal signal AW (active energy) whose frequency is

proportional to the active energy. The signal AW is taken from the 11

energy register, consequently a relationship between the LSB value of the active energy

register and the number of pulses provided per each kWh (P) can be defined as.

k

= 1000/(211•P) [Wh]

AW

If APL = 3 the LED pin provides active energy frequency-based signal dependent on the

value of the KMOT configuration bit according to the following table. In this case the pulses

will have a fixed width of 31.25 ms.

Table 12. Different settings for LED signal

KMOT (2 Bits)

0

1 P/128

2 P/32

3 P/256

th

bit of the active

APL=2 APL=3

Pulses Pulses

P/64

P

Due to the innovative and proprietary power calculation algorithm the frequency signal is not

affected by any ripple at twice the line frequency, this feature strongly reduces the

calibration time of the meter.

28/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

In a practical example where APL = 2, and the desired P is 64000 pulses/kWh (= 17.7

Hz*kW), we have:

K

= 7.63*10-6 Wh

AW

This means that the reading of 0x00001 in the active energy register represents 7.63 µWh,

while 0xFFFFF represents 8 Wh.

8.15 Driving a stepper motor (standalone)

When used in standalone mode (APL = 2 or APL = 3), the STPM01 is able to directly drive a

stepper motor. From signal AW, a stepper driving signals MA and MB are generated by

means of internal divider, mono-flop and decoder. The MA and MB signals are brought to

the MOP and MON pins that are able to drive the stepper motor. Several kinds of selections

are possible for the driving signals according to the configuration bits LVS and KMOT.

The numbers of pulses per kWh (PM) in the MOP and MON outputs are linked with the

number of pulses of the LED P (see previous paragraph) pin with the following relationship:

Table 13. Configuration of MOP and MON pins

LVS (1 Bit) KMOT (2 Bits) Pulses length PM

0 0 31.25 ms P/64

0 1 31.25 ms P/128

0 2 31.25 ms P/32

0 3 31.25 ms P/256

1 0 156.25 ms P/640

1 1 156.25 ms P/1280

1 2 156.25 ms P/320

1 3 156.25 ms P/2560

The mono-flop limits the length of the pulses according to the LVS bit value.

The decoder distributes the pulses to MA and MB alternatively, which means that each of

them has only a half of selected frequency.

Negative power is computed with its own sign, and the MOP and MON signals invert their

logic state in order to make the backward rotation direction of the motor. See the diagram

below.

Doc ID 10853 Rev 8 29/60

Theory of operation STPM01

Figure 21. Positive energy stepper driving signals

Hi

MON

Lo

Hi

MOP

Lo

Figure 22. Negative energy stepper driving signals

Hi

MON

Lo

Hi

MOP

Lo

When a no-load condition is detected MOP and MON are held low.

8.16 Using STPM01 in microcontroller based meter (peripheral)

The higher flexibility of STPM01 allows its use in very high end microcontroller based energy

meters. In this case the STPM01 must be programmed to work in peripheral mode, all the

SPI pins (SCS, SCLNCL, SDATD, SYN) are used only for communication purposes allowing

the microcontroller to write and read the internal STPM01 registers. The peripheral mode

has two further different configuration modes according to the status of the APL

configuration bit. The APL bit status changes the function of MOP, MON and LED pins

according to the description below.

APL = 0:

In the MOP pin, the ZCR signal is available (see paragraph 3 for details about ZCR signal);

The pin MON provides the DOG signal. The DOG signal generates a 16 ms long positive

pulse every 1.6 seconds. Generation of these pulses can be suspended if data are read in

intervals shorter than 1.6 s. The DOG signal is actually a watchdog reset signal which can

be used to control an operation of an on-board microcontroller. It is set to high whenever the

V

voltage is below 2.5 V, but after V

DDA

30/60 Doc ID 10853 Rev 8

goes above 2.5 V this signal starts to run.

DDA

STPM01 Theory of operation

It is expected that an application microcontroller should access the data in the metering

device on regular basis at least 1/s (recommended is 32/s). Every latching of results in the

metering device requested from the microcontroller also resets the watchdog. If latching

requests does not follow each other within 1.6 second, an active high pulse on MON is

produced, because device assumes that microcontroller does not operate properly. An

application can use this signal either to control the RESET pin of its microcontroller or it can

be tied to some interrupt pin. The last possibility is recommended for a battery backup

application which can enter some sleep mode due to power down condition and should not

be reset by metering device because it would exit from the sleep mode.

The LED pin can be driven from AW wide band (active energy as in standalone mode), AW

limited at fundamental, RW (reactive energy) or SW (apparent energy) according to the

value of KMOT bit.

Table 14. LED pin configuration in peripheral mode

KMOT (2 Bits) Signal available in LED pin # of Pulses

0 AW Type 0

1 AW Type 1

2RWP [kVARh]

3 SW P [kVAh]

1. * Type0 is the Wide band Active Energy and Type1 is the fundamental Active Energy if FUND=0, if FUND=1 they are

swapped.

(1)

(1)

P [kWh]

P [kWh]

In this case, since the LED pin is driven by signals different from AW, some other

relationship between the LSB of the register and must be defined:

K

AWFun d

K

RW

K

SW

= 4*KAW [Wh]

= 2*KAW [VARh]

= KAW [VAh]

APL = 1:

MOP provides the ∑ Δ signal generated from the analog voltage input;

MON provides the ∑ Δ signal generated from the analog current input, according to the

selection of the tamper module

LED provides the information about the selection of the current channel made by the tamper

module. If LED is low it means the primary channel is selected, if LED is high the secondary

channel is actually selected.

8.17 Status bits

The STPM01 includes 8 status bits that provide several information on the current meter

status. The status bits are the following:

Doc ID 10853 Rev 8 31/60

Theory of operation STPM01

Table 15. Status bit description

Bit # Name Description Condition

0 BIL No load condition

1BCF∑ Δ signals status

2 BFR Line frequency range

3 BIT Tamper condition

4 MUX Current channel selection

5 LIN Trend of the line voltage

6 PIN Output pins check

7 HLT Data Validity

BIL=0: No load condition not detected

BIL=1: No load detected

BCF=0: ∑ Δ signals alive

BCF=1: one or both ∑ Δ signals are stacked

BFR=0: Line frequency inside the 45Hz-65Hz range

BFR=1: Line frequency out of range

BIT=0: Tamper not detected;

BIT=1: Tamper detected;

MUX=0: Primary current channels selected by the tamper module;

MUX=1: Secondary current channels selected by the tamper

module;

LIN=0: line voltage is going from the minimum to the maximum value.

(Δv/Δt >0);

LIN=1: line voltage is going from the maximum to the minimum value.

(Δv/Δt < 0);

PIN=0: the output pins are consistent with the data

PIN=1: the output pins are different with the data, this means some

output pin is forced to 1 or 0.

HLT=0: the data records reading are valid.

HLT=1: the data records are not valid. A reset occurred and a restart

is in progress.

When STPM01 is used in peripheral mode all these signal can be read through the SPI

interface. See paragraph 16 for details on the Status bit location in the STPM01 data

records.

In standalone mode the BIL signal is available in SCLNLC pin and the BIT signal in the

SDATD pin. All the other signals can be read only through SPI interface.

8.18 Programming the STPM01

Data records

The STPM01 has 8 internal data records registers. Every data record consists of 4-bit parity

code and 28-bit data value where the parity code is computed from the data value, which

makes total of 32 bits or 4 bytes.

The figure below shows the data records structure with the name of the contained

information.

Each bit of parity nibble is defined as odd parity of all seven corresponding bits of data

nibbles.

32/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

The first 6 registers are read-only except for the 8 bit mode signals in the DFP register (the

mode signals will be described later in this paragraph). The last two registers CFL and CFH

can be also written because they contain the configuration bits. Among these last 64 bits (32

of CFL and 32 of CFH), 8 bits are used for parity nibbles, then only 56 bits are used for

configuring and programming the STPM01.

Figure 23. STPM01 data records map

20 bit

DAP

4 bit

parity

20 bit 8 bit

1bit

type0 active energy

1bit 1bit

6 bit

Status

DRP

DSP

DFP

DEV

DMV

CFL

CFH

parity

parity

parity

parity

parity

parity

parity

p

p

uMOM

msb lsb

8.19 Configuration bits

All the configuration bits that control the operation of the device (CFL and CFH data records)

can be written in a temporary or permanent way. In case of temporary writing the

configuration bits value are written in the so called shadow registers which are simple

latches that hold the configuration data. In case of permanent writing the configuration bits

are stored in the OTP (one time programmable) cells that keep the information for an

undefined period of time even if the STPM01 is without supply, but, once written, they

cannot be changed anymore.

reactive energy

apparent energy

type 1 energy

iRMSuRMS

iMOM

lower part of configurators

upper part of configurators

11 bit 16 bit

upper f(u)0 1

lower f(u)

mode signals

The shadow registers are cleared whenever a reset condition occurs (both POR and remote

reset).

As indicated in the data records table, the configuration bits are 56. Each of them consists of

paired elements, one is latch, the OTP shadow, and another is the OTP antifuse element.

When the STPM01 is released in the market, all antifuses represents logic low state but they

can be written by the user in order to configure the STPM01.This means that STPM01 can

retain 56 bits of information even if it has been unsupplied for an undefined time. That’s why

the CFG signals are used to keep certain configuration and calibration values of device.

Doc ID 10853 Rev 8 33/60

Theory of operation STPM01

The very first CFG bit, called TSTD, is used to disable any change of system signals after it

was permanently set. During the configuration phase, each bit set to logic level 1 will

increase the supply current of STPM01 of about 120 µA, until the TSTD bit is set to 1. The

residual increase of supply current is 2 µA per each bit set to 1. It is then recommended to

set the TSTD bit to 1 after the configuration procedure in order to keep the supply current as

low as possible.

The STPM01 can work either using the data stored in the OTP cells either the data available

in the shadow latches. This can be chosen according to the value RD Mode signal (see

mode signal paragraph for description). If the RD is set, the CFG bits originates from

corresponding OTP shadow latches otherwise, if the RD is cleared, the CFG bits originates

from corresponding OTP antifuses. This way one can temporary sets up certain

configuration or calibration of device then verify it and then change it, if it is necessary. For

example, this is extensively exercised during production tests.

Each configuration bit can be written sending a byte command to STPM01 through its SPI

interface. The procedure to write the configuration bits is described in the SPI section.

After the TSTD bit has been set, the only write commands accepted will be the precharge

and the remote reset, this implies that the shadow latches cannot be used as source of

configuration data anymore.

Table 16. Configuration bits map

Address

n. of

bits

(1)

Name

APL 2

6-bit

binary

000000 0 TSTD 1

000001 1 MDIV 1

000010 2 RC 1

000011 3

000100 4

DEC

Description

Test mode and OTP write disable:

- TSTD=0: testing and continuous pre-charge of OTP when in read mode,

- TSTD=1:normal operation and no more writes to OTP

Measurement frequency range selection:

- MDIV=0: 4.000MHz to 4.194MHz,

- MDIV=1: 8.000MHz to 8.192MHz

Type of internal oscillator selection:

- RC=0:crystal oscillator,

- RC=1:RC oscillator

Peripheral or Standalone mode:

- APL=0: peripheral, MON=WatchDOG; MOP=ZCR, LED=pulses,

- APL=1: peripheral, MOP=ΔΣ Voltage; MON=ΔΣ current; LED=Mux (current) APL=2: standalone, MOP,MON=stepper, LED=pulses, SCLNLC=no load

condition, SDATD=tamper detected, SYN=negative active power direction

- APL=3: standalone, MOP:MON=stepper, LED=pulses according to KMOT,

SCLNLC=no load condition, SDATD=tamper detected, SYN=negative active

power direction

(1)

34/60 Doc ID 10853 Rev 8

STPM01 Theory of operation

Table 16. Configuration bits map (continued)

Address

6-bit

binary

DEC

Name

n. of

bits

Description

(1)

000101 5

000110 6

Current channel sensor type, gain and tamper selection:

- PST=0: primary is coil x8 (x16 if ADDG=1), secondary is not used, no tamper

- PST=1: primary is coil x24 (x32 if ADDG=1), secondary is not used, no tamper

- PST=2: primary is CT x8, secondary is not used, no tamper

- PST=3: primary is shunt x32, secondary is not used, no tamper

000111 7

PST 3

(1)

- PST=4: primary is coil x8 (x16 if ADDG=1), secondary is coil x8 (x16 if

ADDG=1), tamper

- PST=5: primary is coil x24 (x32 if ADDG=1), secondary is coil x24 (x32 if

ADDG=1), tamper

- PST=6: primary is CT x8, secondary is CT x8, tamper

- PST=7: primary is CT x8, secondary is shunt x32, tamper

Power calculation when BFR=1 and PST

001000 8 FRS 1

- FRS=0: energy accumulation is frozen, power is set to zero;

- FRS=1: normal energy accumulation and power computation (p=u*i);

Bit sequence output during record data reading selection:

001001 9 MSBF 1

- MSBF=0: msb first

- MSBF=1: lsb first

This bit swap the information stored in the type0 (first 20 bits of DAP register)

and type1 (first 20 bits of DFP register) active energy.

001010 10 FUND 1

- FUND = 0: type 0 contains wide band active energy, type1 contains

fundamental active energy

- FUND = 1: type 0 contains fundamental active energy, type1 contains wide

band active energy

001011 11 1 RESERVED

001100 12

No load condition threshold as product between V

LTCH=0 800

001101 13

(1)

LT CH 2

LTCH=1 1600

LTCH=2 3200

LTCH=3 6400

Constant of stepper pulses/kWh (see par. 16) selection when APL=2 or 3:

If LVS=0,

KMOT=0 P/64

KMOT=1 P/128

KMOT=2 P/32

001110 14

KMOT=3 P/256

If LVS=1,

KMOT 2

KMOT=0 P/640

KMOT=1 P/1280

KMOT=2 P/320

KMOT=3 P/2560

≠4,5 (no single wire mode)

RMS

and I

RMS

:

001111 15

(1)

Selection of pulses for LED when APL=0:

KMOT=0 Type0 Active Energy

KMOT=1 Type1 Active Energy

KMOT=2 Reactive Energy

KMOT=3 Apparent Energy

Doc ID 10853 Rev 8 35/60

Theory of operation STPM01

Table 16. Configuration bits map (continued)

Address

6-bit

binary

DEC

Name

n. of

bits

Description

(1)

010000 16

010001 17

010010 18

010011 19

010100 20

010101 21

010110 22

010111 23

011000 24

011001 25

011010 26

011011 27

011100 28

011101 29

011110 30

011111 31

100000 32

100001 33

100010 34

100011 35

100100 36

100101 37

100110 38

100111 39

101000 40

101001 41

(1)

BGTC 2 Bandgap Temperature compensation bits. See Figure 17 for details.

(1)

2 RESERVED

4-bit unsigned data for compensation of phase error, 0°+0.576°.

CPH 4

16 values are possible with a compensation step of 0.0384°. When CPH=0 the

compensation is 0°, when CPH=15 the compensation is 0.576°.

(1)

8-bit unsigned data for voltage channel calibration.

CHV 8

256 values are possible. When CHV is 0 the calibrator is at -12.5 % of the

nominal value. When CHV is 255 the calibrator is at +12.5 %. The calibration

step is then 0.098%.

(1)

8-bit unsigned data for primary current channel calibration.

CHP 8

256 values are possible. When CHP is 0 the calibrator is at -12.5 % of the

nominal value. When CHP is 255 the calibrator is at +12.5 %. The calibration

step is then 0.098%.

(1)

101010 42

101011 43

CHS 8

101100 44

8-bit unsigned data for secondary current channel calibration.

256 values are possible. When CHS is 0 the calibrator is at -12.5 % of the