16-channel LED driver with 16-bit PWM,

8-bit gain and full LED error detection

Features

■ 16 constant current output channels

■ Supply voltage: 3.3 V or 5 V

■ Two PWM selectable counters 12/16-bit of

grayscale

■ Selectable enhanced PWM for ghost effect

reduction

■ Open and short LED detection

■ 8-bit current gain control by means of 256

steps in two selectable ranges

■ Single resistor to set the current from 3 mA to

60 mA

■ Programmable progressive output delay

■ Thermal protection and thermal flag

■ UVLO

■ Schmitt trigger input

■ Selectable 16-bit or 256-bit serial data-in

format

■ Max clock frequency: 30 MHz

■ ESD protection 2.5 kV HBM, 200 V MM

■ Drop-in compatible with STP16CP\S\DP05

series

■ Available in high thermal efficiency TSSOP

exposed pad

Applications

■ Video display LED panels

■ RGB backlighting

■ Special lighting

Table 1. Device summary

STP1612PW05

Preliminary data

QFN-24

TSSOP24 TSSOP24

Description

The STP1612PW05 is a 16-channel constant

current sink LED driver. The maximum output

current value for all the 16 channels is set by a

single resistor from 3 mA to 60 mA. The device

features 8-bit gain (256 steps) for global LED

brightness adjustment with two selectable ranges.

This function is accessible via a serial interface.

The device has an individual adjustable PWM

brightness control for each output channel. The

PWM counters are selectable via a serial

interface with 4096 or 65536 steps (12 or 16 bit).

The STP1612PW05 also provides enhanced

pulse-width modulation counting algorithms called

e-PWM to reduce flickering effects (ghost visual

effects) improving the overall image quality. The

device has a dual size 16-bit or 256-bit shift

register. All the control and the shift register read

back data are accessible via serial interface. The

STP1612PW05 has the capability to detect open

and short LED failure and overtemperature,

reporting the status through SPI line. The device

guarantees a 20 V output driving capability,

allowing the user to connect more LEDs in series.

SO-24

exposed pad

STP1612PW05QTR QFN-24 4000 parts per reel

STP1612PW05MTR SO-24 1000 parts per reel

STP1612PW05TTR TSSOP24 2500 parts per reel

STP1612PW05XTTR TSSOP24 exposed pad 2500 parts per reel

February 2011 Doc ID 15819 Rev 5 1/41

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

Order code Package Packaging

www.st.com

41

Contents STP1612PW05

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Summary description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Pin connection and description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

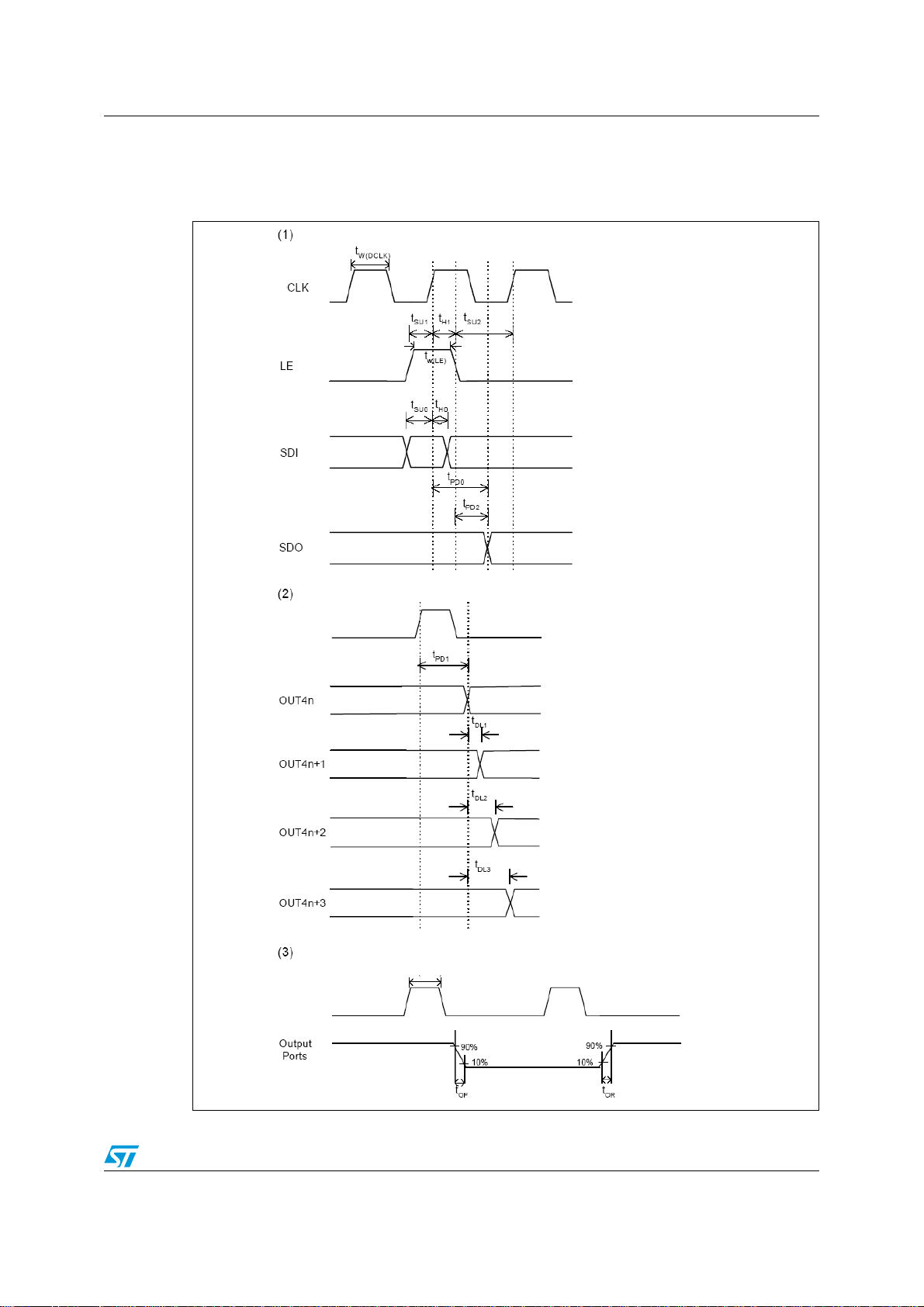

5 Timing waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Configuration register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Grey scales data loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 Setting the PWM gray scale counter . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.1 PWM data synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.2 Synchronization for PWM counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 Error detection conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Setting output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12 Constant current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13 Current gain adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14 Delay time of staggered output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

15 Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/41 Doc ID 15819 Rev 5

STP1612PW05 Contents

16 Time-out alert of GCLK disconnection . . . . . . . . . . . . . . . . . . . . . . . . . 26

17 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

17.1 LED supply voltage (VLED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

17.2 Setting grayscale brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

17.3 Multi device application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

18 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

19 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Doc ID 15819 Rev 5 3/41

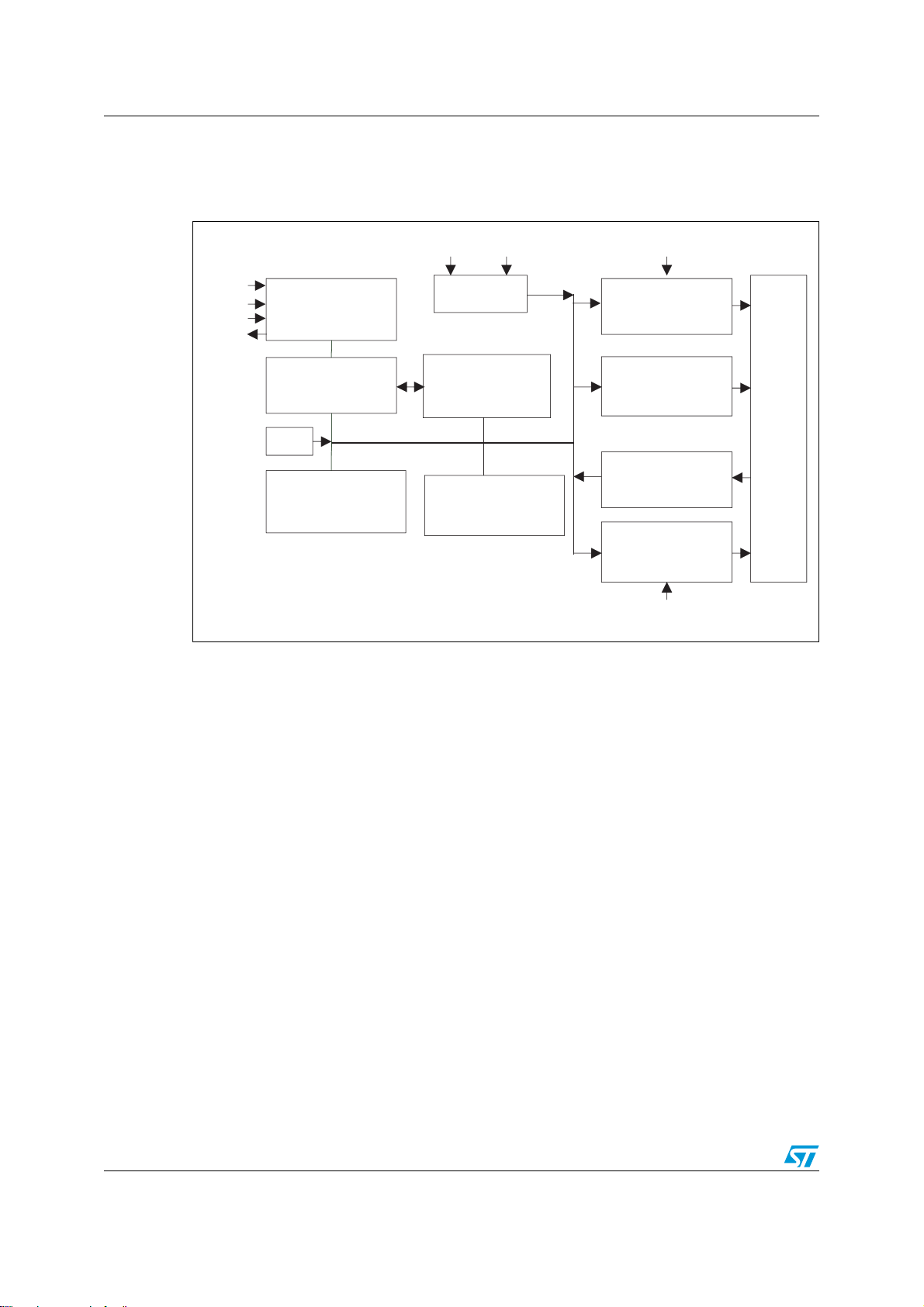

Block diagram STP1612PW05

1 Block diagram

Figure 1. Block diagram

SDI

CLK

LE

SDO

Serial interface

CTRL command

and

CTRL logic

TSD

Shift register

dual size mode

(16 or 256 bit)

GND

VDD

UVLO & POR

16-bit

Configuration

Register

PWM data buffer

(16x16 bit)

R-EXT

Dual range gain

7-bit DAC

Gradual outputs

delay

Open/short

error detection

PWM and e-PWM

12/16 bit counter

and SYNC control

PWCLK

1----------16

Constant current output channels

4/41 Doc ID 15819 Rev 5

STP1612PW05 Summary description

2 Summary description

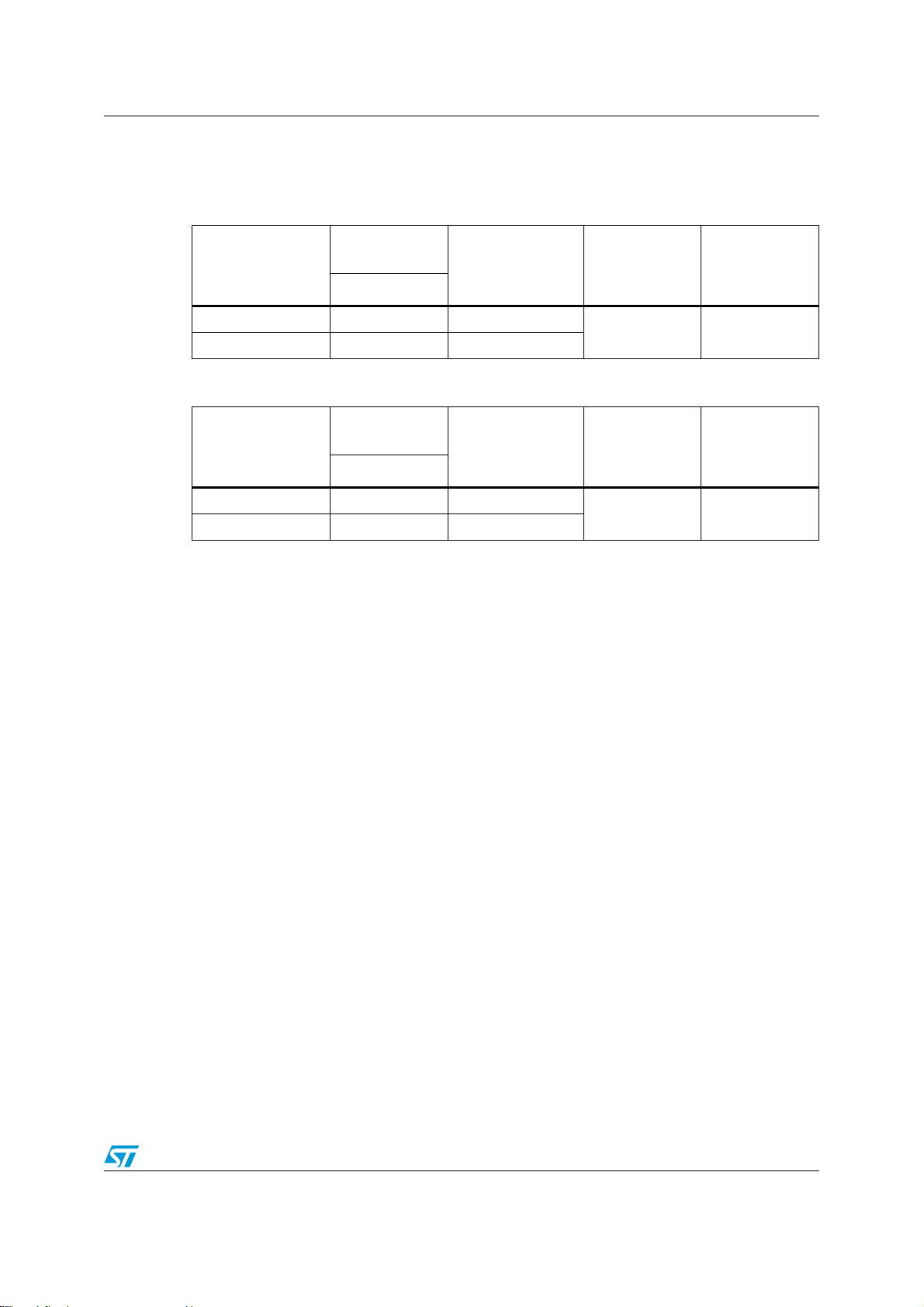

Table 2. Typical current accuracy at 5 V

Current

Output voltage

accuracy

Between ICs

Output current V

DD

temp.

≥ 1.0 ± 6% 15 to 60

≥ 0,2 ± 6% 3 to 15

Table 3. Typical current accuracy at 3.3 V

Current

Output voltage

accuracy

Output current V

Between ICs

≥ 1.0 ± 6% 15 to 60

≥ 0,3 ± 6% 3 to 15

5 V 25 °C

DD

temp.

3.3 V 25 °C

Doc ID 15819 Rev 5 5/41

Summary description STP1612PW05

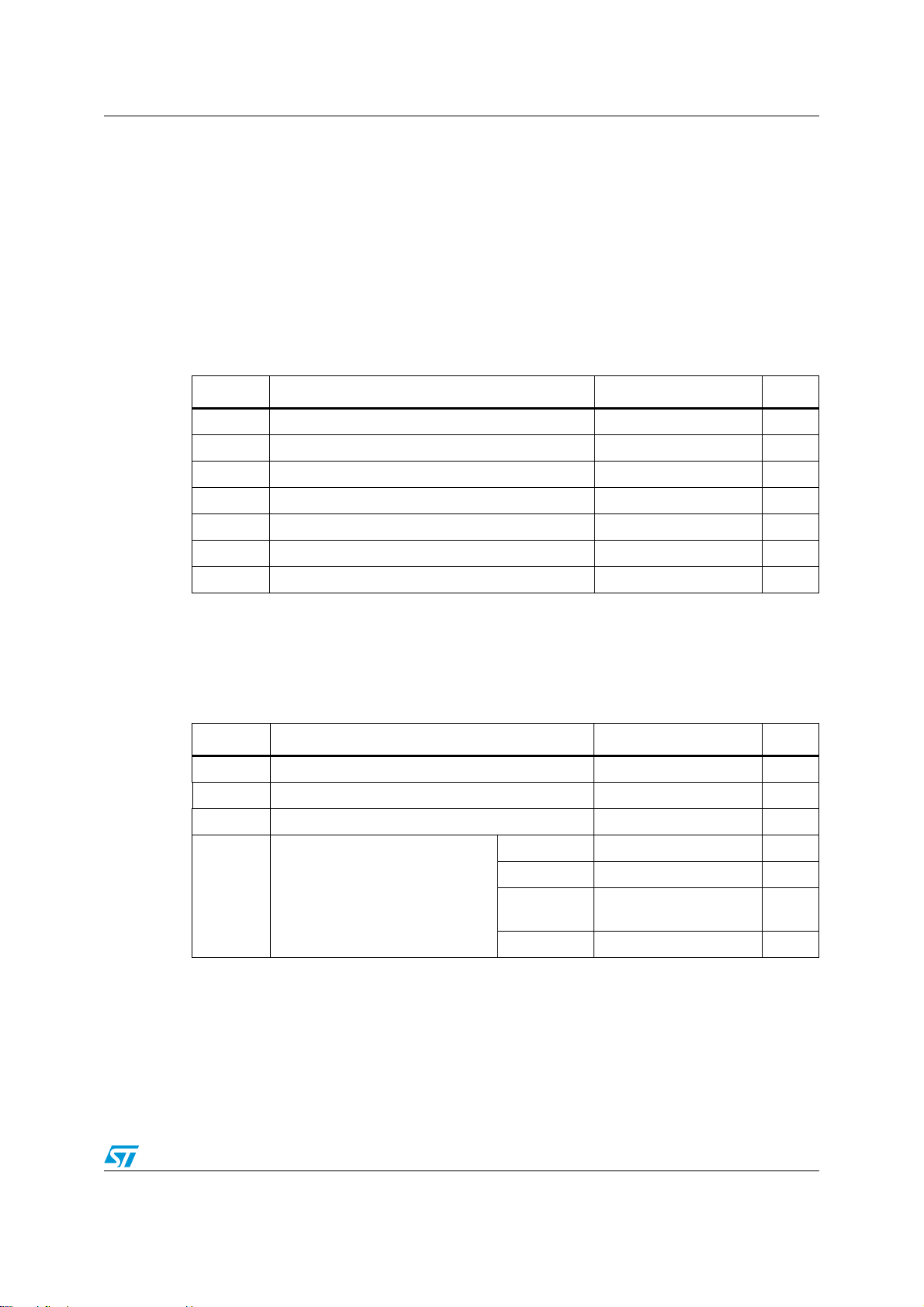

2.1 Pin connection and description

Figure 2. Pin connection

SDI

SDI

SDI

R-EXT

R-EXT

R-EXT

VDD

VDD

GND

GND

GND

SDI

SDI

SDI

CLK

CLK

CLK

LE

LE

LE

OUT0

OUT0

OUT0

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

OUT3

OUT3

OUT3

OUT4

OUT4

OUT4

OUT5

OUT5

OUT5

OUT6

OUT6

OUT6

OUT7

OUT7

OUT7

VDD

VDD

VDD

R-EXT

R-EXT

R-EXT

SDO

SDO

SDO

PWCLK

PWCLK

PWCLK

OUT15

OUT15

OUT15

OUT14

OUT14

OUT14

OUT13

OUT13

OUT13

OUT12

OUT12

OUT12

OUT11

OUT11

OUT11

OUT10

OUT10

OUT10

OUT9

OUT9

OUT9

OUT8

OUT8

OUT8

LE

LE

LE

OUT0

OUT0

OUT0

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

OUT3

OUT3

OUT3

OUT4

OUT4

OUT4

CLK

CLK

CLK

OUT5

OUT5

OUT5

OUT6

OUT6

OUT6

VDD

OUT7

OUT7

OUT7

SDO

PWCLK

SDO

PWCLK

SDO

PWCLK

OUT15

OUT15

OUT15

OUT14

OUT14

OUT14

OUT13

OUT13

OUT13

OUT12

OUT12

OUT12

OUT11

OUT11

OUT11

OUT10

OUT10

OUT10

GND

GND

GND

OUT9

OUT8

OUT9

OUT8

OUT9

OUT8

Note: The exposed pad should be electrically connected to a metal land electrically isolated or

connected to ground

Table 4. Pin description

Pin n° Symbol Name and function

1 GND Ground terminal

2 SDI Serial data input terminal

3CLK

4 LE Data strobe terminal and controlling command with CLK

5-20 OUT 0-15 Output terminals

21 PWCLK

22 SDO Serial data out terminal

23 R-EXT Input terminal of an external resistor for constant current programing

24 V

DD

Clock input terminal used to shift data on rising edge and carries

command information when LE is asserted.

Gray scale clock terminal.

Reference clock for grey scale PWM counter.

Supply voltage terminal

6/41 Doc ID 15819 Rev 5

STP1612PW05 Electrical ratings

3 Electrical ratings

3.1 Absolute maximum ratings

Stressing the device above the rating listed in the Table 5 may cause permanent damage to

the device. These are stress ratings only and operation of the device at these or any other

conditions above those indicated in the operating sections of this specification is not implied.

Exposure to absolute maximum rating conditions for extended periods may affect device

reliability.

Table 5. Absolute maximum ratings

Symbol Parameter Value Unit

V

V

I

V

I

GND

f

CLK

T

1. Such absolute value is based on the thermal shutdown protection.

Supply voltage 0 to 7 V

DD

Output voltage -0.5 to 20 V

O

Output current 60 mA

O

Input voltage -0.4 to VDD V

I

GND terminal current 1300 mA

Clock frequency 50 MHz

Junction temperature range

J

3.2 Thermal data

Table 6. Thermal data

Symbol Parameter Value Unit

T

J-OPR

T

R

T

STG

thJA

Operating free-air temperature range -40 to +125 °C

A

Operating thermal junction temperature range -40 to +150 °C

Storage temperature range -55 to +150 °C

Thermal resistance junctionambient

(1)

(1)

-40 to + 170 °C

SO-24 42.7 °C/W

TSSOP24 55 °C/W

(2)

TSSOP24

Exposed pad

37.5 °C/W

QFN-24 55 °C/W

1. According to Jedec standard 51-7B

2. The exposed pad should be soldered directly to the PCB to realize the thermal benefits.

Doc ID 15819 Rev 5 7/41

Electrical ratings STP1612PW05

3.3 Recommended operating conditions

Table 7. Recommended operating conditions at 25 °C

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

V

I

OH,SDO

I

OL,SDO

V

V

t

wLAT

t

wCLK

t

wEN

t

SETUP(D)

t

HOLD(D)

t

SETUP(L)

f

CLK

Supply voltage 3.0 - 5.5 V

DD

Output voltage - 20 V

O

Output current, OUTn 3 - 60 mA

I

O

Output current, SDO - +1 mA

Output current, SDO - -1 mA

Input voltage 0.7 V

IH

Input voltage GND - 0.3 V

IL

LE pulse width

DD

20 - ns

-V

CLK pulse width 10 - ns

PWCLK pulse width 20 - ns

VDD = 3.3 V to 5.0 V

Setup time for DATA 5 - ns

Hold time for DATA 5 - ns

Setup time for LATCH 5 - ns

Clock frequency Cascade operation

(1)

-30MHz

V

DD

DD

1. If the device is connected in cascade, it may not be possible achieve the maximum data transfer. Please

considered the timings carefully.

V

8/41 Doc ID 15819 Rev 5

STP1612PW05 Electrical characteristics

4 Electrical characteristics

VDD = 3.3 V ± 10%, VDD = 5 V ± 10%, TA = 25 °C unless otherwise specified

Table 8. Electrical characteristics

Symbol Characteristics Test conditions Min. Typ. Max. Unit

V

O

I

OUT

OH,SDO

I

OL,SDO

V

IH

V

IL

I

OH

V

OL

V

OH

dI

OUT1

dI

OUT1

dI

OUT2

dI

OUT2

%/dV

%/dV

R

IN(down)

I

DD(off) 1

I

DD(off) 2

I

DD(off) 3

Maximum output voltage OUT0 ~ OUT15 20 V

OUT0~OUT115 VO = 2V 3 60

Output

current

SDO -8

mAI

SDO 8

Input voltage “H” level 0.7 * VDD V

Input voltage “L” level GND 0.3 * V

V

DD

V

DD

Output leakage current VO = 20 V 1 µA

I

= +8 mA 0.4 V

Output voltage SDO

Current skew (channel)

Current skew (IC)

Output current vs. output voltage

O

regulation

Output current vs. supply voltage

DD

regulation

OL

IOH = -8 mA V

I

= 3mA, VO = 0.3V,

OUT

= 238.2kΩ

R

EXT

I

= 20mA, VO = 1V,

OUT

R

= 34.7kΩ

EXT

I

= 3mA, VO = 0.3V,

OUT

R

= 238.2kΩ

EXT

I

= 20mA, VO = 1V,

OUT

= 34.7kΩ

R

EXT

VO within 1.0 V and 3.0 V,

R

= 34.7 kΩ @ 20 mA

ext

within 4.5 V and 5.5 V ± 1.0 ± 5.0 % / V

V

DD

- 0.4 V

DD

±1.5 ±3 %

±3 ±6 %

± 0.1 ± 0.5 % / V

Pull-down resistor LE 150 200 250 kΩ

Supply current “Off”

Rext = Open,

OUT0 ~ OUT15 = Off

IO = 3 mA,

~ OUT15 = Off

OUT0

= 60 mA,

I

O

OUT0 ~ OUT15 = Off

811

8.5 11

11 15

mA

I

= 3 mA,

I

DD(on) 1

O

OUT0 ~ OUT15 = On

811.5

Supply current “On”

= 60 mA,

I

I

DD(on) 2

O

~ OUT15 = On

OUT0

11.5 15

Doc ID 15819 Rev 5 9/41

Electrical characteristics STP1612PW05

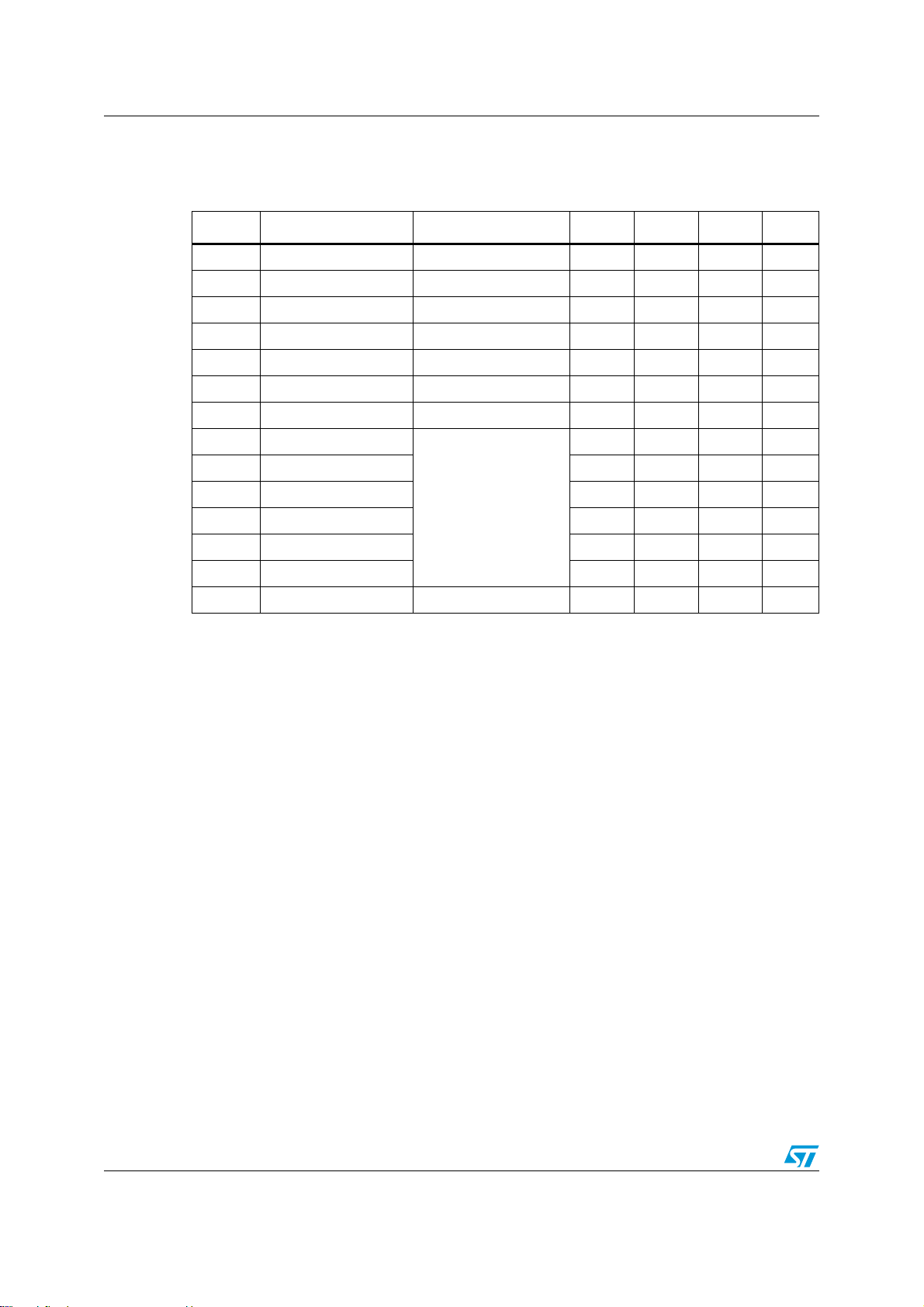

Figure 3. Test circuit for electrical characteristics

VIH=V

DD

VIL=GND

Function

Generator

inputLogic

waveform

VIH,V

DDI

IL

SDI

CLK

LE

PWCLK

R

ext

DDV

GND

EXT-R

V

DD

OUT0

OUT15

.

.

.

SDO

OUT

I

I

OL

I

OH

10/41 Doc ID 15819 Rev 5

STP1612PW05 Electrical characteristics

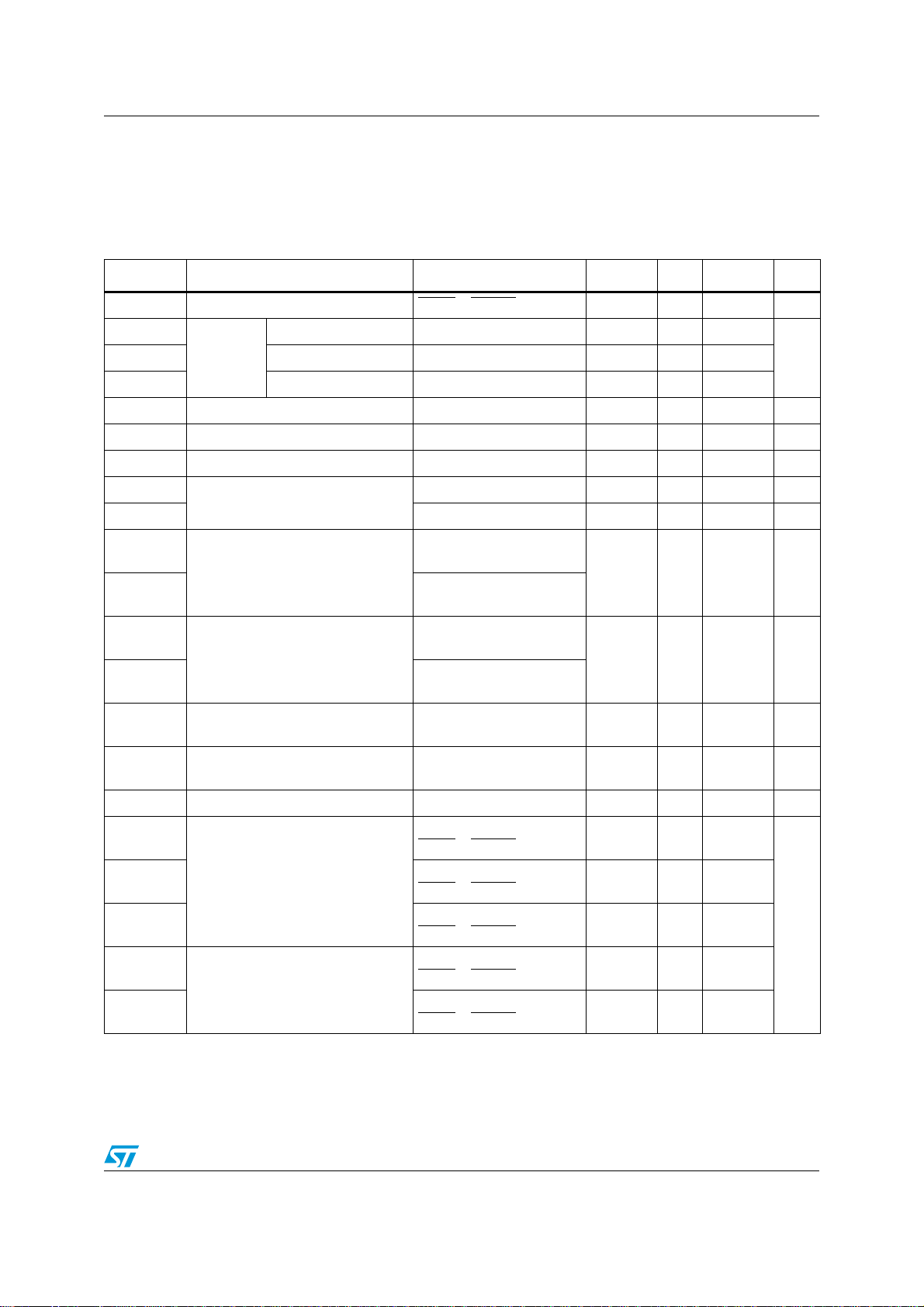

Table 9. Switching characteristics (VDD = 5.0 V) TA = -40 ~ 125 ° C

Symbol Characteristics Conditions Min. Typ. Max. Unit

t

SU0

t

SU1

t

SU2

t

H0

t

H1

t

PD0

t

PD1

t

PD2

t

DL1

t

DL2

t

DL3

t

w(L)

t

w( CLK)

t

w(PWCLK)

t

ON

t

OFF

t

EDD

Setup time

Hold time

Propagation

PWCLK-OUTn4

delay time

Stagger delay

time

Pulse width

Output rise time of output ports 10 ns

Output fall time of output ports 6 ns

Error detection minimum duration

SDI - CLK ↑

1 ns

LE ↑ – DCLK ↑ 1 ns

LE ↓ – DCLK ↑ 5 ns

CLK ↑ - SDI 3 ns

CLK ↑ - LE ↓ 7 ns

CLK - SDO 30 40 ns

LE – SDO

OUTn4

(2)

+ 1

OUTn4 + 2

OUTn4 +3

LE 5 ns

(1)

(1)

(1)

(1)

V

= 5.0 V

DD

VIH = VDD

VIL = GND

= 460 Ω

R

ext

V

= 4.5 V

LED

RL = 152 Ω

CL = 10 pF

C1 = 100 nF

C2 = 10 µF

= 20 mA

I

O

100 ns

30 40 ns

40 ns

80 ns

120 ns

CLK 20 ns

PWCLK 20 ns

(3)

1µs

1. Refer to the timing waveform, where n = 0, 1, 2, 3.

2. In timing of “read configuration” and “read error status code”, the next CLK rising edge should be t

the falling edge of LE.

3. Refer to Figure 5 on page 13.

PD2

after

Doc ID 15819 Rev 5 11/41

Electrical characteristics STP1612PW05

Table 10. Switching characteristics (V

= 3.3 V)

DD

Symbol Characteristics Conditions Min. Typ. M ax. Unit

t

SU0

t

SU1

t

SU2

t

H0

t

H1

t

PD0

t

PD1

t

PD2

t

DL1

t

DL2

t

DL3

t

w(L)

t

w(CLK)

t

w(PWCLK)

t

ON

t

OFF

t

DEC

Setup time

Hold time

Propagation delay

PWCLK-OUTn4

time

Stagger delay

time

Pulse width

Output rise time of output ports 11.6 ns

Output fall time of output ports 7 ns

Error detection duration 0.5 1 µs

1. Refer to the timing waveform Figure 4, where n = 0, 1, 2, 3.

2. In timing of “read configuration” and “read error status code”, the next CLK rising edge should be t

the falling edge of LE.

SDI - DCLK ↑

1 ns

LE ↑ – DCLK ↑ 1 ns

LE ↓ – DCLK ↑ 5 ns

CLK ↑ - SDI 3 ns

CLK ↑ - LE ↓ 7 ns

CLK - SDO 45 40 ns

LE – SDO

+ 1

OUTn4

OUTn4 + 2

OUTn4 +3

LE 5 ns

(1)

(2)

(1)

(1)

(1)

VDD = 3.3 V

VIH = VDD

= GND

V

IL

R

= 460 Ω

ext

= 4.5 V

V

LED

RL = 152 Ω

CL = 10 pF

C1 = 100 nF

C2 = 10 µF

120 ns

45 40 ns

40 ns

80 ns

120 ns

CLK 20 ns

PWCLK 20 ns

after

PD2

Figure 4. Test circuit for switching characteristics

VIH,V

IL

SDI

Function

Generator

inputLogic

VIH=V

DD

VIL=GND

12/41 Doc ID 15819 Rev 5

CLK

LE

PWCLK

V

DDV

GND

DD

OUT0

OUT15

SDO

1

C

OUT

I

.

.

.

R

L

C

L

R

L

C

L

V

C

LED waveform

C

L

2

DDI

EXT-R

R

ext

STP1612PW05 Timing waveform

5 Timing waveform

Figure 5. Timing waveform

PWCLK

PWCLK

PWCLK

Doc ID 15819 Rev 5 13/41

Principle of operation STP1612PW05

6 Principle of operation

Table 11. Control command

Signals combination Description

Number of CLK

Command name LE

Data latch High 1 Serial data are transferred to the buffers

Global latch High 2 or 3 Buffer data are transferred to the comparators

Read configuration High 4 or 5

rising edge when

LE is asserted

The action after a falling edge of LE

Move out “configuration register” to the shift

register

Enable “error

detection”

Read “error status

code”

High 6 or 7 Detect the status of each output’s LED

High 8 or 9

Write configuration High 10 or 11

Reset to 16-bit shift

register length

High 12 or 13 Set to 16-bit the shift register length

Move out “error status code” of 16 outputs to

the shift registers

Serial data are transferred to the

“configuration register”

14/41 Doc ID 15819 Rev 5

STP1612PW05 Principle of operation

Figure 6. Timing diagram

$ATA,ATCH

#,+

...

,%

3$)

3$/

-3"

$

$ $ $

$

$ $ $ $ $ $ $

$

0REVIOUS$ATA

$$

$

.EXT$ATA

$ $ $

'LOBAL,ATCH

#,+

...

,%

3$)

3$/

-3"

$

$ $ $

$

$ $ $ $ $ $ $

$

0REVIOUS$ATA

$$

$

.EXT$ATA

$ $ $

2EAD#ONFIGURATION

#,+

...

....

..

,%

3$/

0REVIOUS$ATA

&

$ #

%

!

"

7RITE#ONFIGURATION

#,+

,%

3$)

..

& %

#

$

" !

.

.EXT$ATA

%

3$/

0REVIOUS$ATA

&

$

Doc ID 15819 Rev 5 15/41

Configuration register STP1612PW05

7 Configuration register

Table 12. Configuration register

Bit Attribute Definition Value Function

15 Read/Write

14 Read

13 Read/Write

12-11 Read/Write

Shift register

length

Thermal error

flag

PWM counter

(12/16 bit)

PWM counting

mode

selection

0 16 bit shift register

1 256 bit shift register

0 Temperature OK

1 Over temperature (>150°C typ.)

0 12 bit Grayscale PWM counter

1 16 bit Grayscale PWM counter

(1)

00

01

10

64 times of MSB

(1)

of LSB

6-bit PWM

16 times of MSB 6-bit PWM counting by 1/4

PWCLK plus once of LSB 6-bit PWM counting

4 times of MSB 6-bit PWM counting by 1/16

PWCLK plus once of LSB 6-bit PWM counting

6-bit PWM counting plus once

11 PWM counting

10 Read/Write

9-2 Read/Write

PWM data

synchronizatio

n mode

Current gain

adjustment

0 Auto-synchronization

1 Manual synchronization

00000000

11111111

Adjust the current value set by R-EXT over 256

~

steps

Default

value

0

0

0

11

1

8b 10101011

Thermal

1 Read/Write

Shutdown

function

Time-out alert

0 Read/Write

for PWCLK

disconnection

1. Please refer to “setting the PWM counting mode” section.

2. Please refer to “TSD” thermal error flag and thermal shutdown “section.

3. Please refer to “time-out alert of PWCLK disconnection” section.

0 Disable

Enable

1

overcomes 150°C)

0 Enable

1 Disable

16/41 Doc ID 15819 Rev 5

(2)

(output channels OFF if temperature

(3)

0

0

STP1612PW05 Grey scales data loading

8 Grey scales data loading

The STP1612PW05 is able to manage a gray-scale depth of 12 or 16 bits for each output,

exploiting an e-PWM algorithm.

The bit D of the configuration register is used to select the grey-scale loading. Its value can

be set to “0” for 12 bits or “1” for 16 bits. By default, D is set to “0”.

Loading of the data is performed through the serial input on a dedicated buffer and two

different methods can be used.

With both methods, the first incoming data packet is relative to the output 15; the following

packet is relative to the output 14 and so on up to the output 0.

If F=”0”, when a data packet has been loaded, the latch signal (LE) must become active for

one CLK cycle (data latch). When the last data packet, relative to the output 0, has been

loaded, the latch signal must be active for two CLK cycles (global latch) and all the data will

be transferred to the e-PWM registers starting from the MSB.

If F=”1” all data packets (12 or 16 bits x16) are loaded and then the global latch signal must

be active and all the data will be transferred to the e-PWM registers starting from the MSB.

Figure 7. Full timing for data loading

Doc ID 15819 Rev 5 17/41

Setting the PWM gray scale counter STP1612PW05

9 Setting the PWM gray scale counter

STP1612PW05 provides a 12-bit or 16-bit PWM color depth. Each serial data input will be

implemented according to the e-PWM algorithm.

9.1 PWM data synchronization

STP1612PW05 defines the different counting algorithms that support e-PWM, technology,

(scrambled PWM). With e-PWM, the total PWM cycles can be broken down into MSB (most

significant bits) and LSB (least significant bits) of gray scale cycles, and the MSB

information can be dithered across many refresh cycles to achieve overall same high bit

resolution. STP1612PW05 also allows changing different counting algorithms and provides

the best output linearity when there are fewer transitions of output.

Figure 8. 12-bit e-PWM operation example

PWCLK

PWCLK

PWCLK

PWCLK

PWCLK

18/41 Doc ID 15819 Rev 5

STP1612PW05 Setting the PWM gray scale counter

9.2 Synchronization for PWM counting

The data synchronization between the incoming data flow and the output channels is

managed through the bit A within the configuration register.

If the bit A is set to “0” the device performs itself the data synchronization: when all the new

data are loaded with a “global latch”, the device wait until all the PWM counter completes

the counting cycle before updating them with the new data, at the next CLK rising edge.

Conversely, if bit A is set to “1” (default), the data synchronization is not performed by the

device and is managed by the microcontroller, which has to take care of the data and

signals. If this is not done, there might be artefacts on the output image.

Figure 9. Synchronization for PWM counting

CLK

PWCLK

Figure 10. Without synchronization for PWM counting

CLK

PWCLK

Doc ID 15819 Rev 5 19/41

Error detection conditions STP1612PW05

10 Error detection conditions

The STP1612PW05 can detect open channels (OD) and LED short-circuits (SD).

The detection circuitry performs open- and short-circuit detection simultaneously and needs

that all channels must be on. However the short test duration (0.5 µs typ) does not impact

the image quality.

According to Table 11, the command “Enable Error Detection” starts the diagnostic process.

After 0.5 µs (typ) the faults detection has already been carried out and, through the

command “Read Error Status Code”, the status is available on the serial output (SDO).

A bit set to "1" in the Error Status Code represents a channel considered good, whereas a

"0" represents a failed output (open/short).

Figure 11 describes the error detection process.

Figure 11. Error detection process

“Read Error Status Code”

“Enable Error Detection”

“Enable Error Detection”

command

command

“Read Error Status Code”

command

command

CLK

CLK

LE

LE

from SDI

SDO

SDO

from SDI

don’t care don’t care

don’t care don’t care

detection of faulty

detection of faulty

channels (typ 0.5µs)

channels (typ 0.5µs)

The Table 13 and Figure 12 explains the fault conditions detected by the diagnostic circuitry

and how the detection is performed.

Table 13. Detection conditions (V

SW-1 or

SW-3b

SW-2 or

SW-3a

Open line or output short to GND

detected

Short on LED or short to V-LED

detected

= 3.3 to 5 V temp. range -40 to 125 °C)

DD

Note: Where: IO = the output current programmed by the R

current in detection mode

EXT

==> I

==> V

, I

ODEC

ERROR STATUS CODE

ERROR STATUS CODE

≤ 0.5 x I

ODEC

≥ 2.3 V

O

O

= the detected output

20/41 Doc ID 15819 Rev 5

STP1612PW05 Error detection conditions

Figure 12. Detection circuit

16

STP1612PW05

Doc ID 15819 Rev 5 21/41

Setting output current STP1612PW05

11 Setting output current

The output current (I

) is set by an external resistor, R

OUT

ext

.

It is calculated from the equation:

V

Whereas R

and V

R-EXT

R-EXT

= 1.24 x G; I

is the resistance of the external resistor connected to R-EXT terminal

ext

OUT

= (V

R-EXT/Rext

) x 560

is its voltage. G is the digital current gain, which is set by the bit9 – bit2 of the

configuration register. The default value of G is 1. For your information, the output current is

about 20 mA when R

= 34.70 kΩ and 10 mA when R

ext

= 69.6 kΩ if G is set to

ext

default value 1. The formula and setting for G are described in next section.

Figure 13. Rext vs output current

275

250

225

200

175

150

125

100

Rex t (kO hm)

75

50

25

0

3 5 10 20 30 50 60 80

Iout (m A)

Table 14. Rext vs output current

Iout (mA) Rext (kΩ)

3 238.2

5 142.2

10 69.6

20 34.70

30 22.94

50 13.72

60 11.40

80 8.63

1. T

= 25 °C, Vdd = 3.3 V; 5.0 V, V

A

Led

(1)

= 3.0 V, V

= 1.5 V, HC = 0101011 (default)

drop

22/41 Doc ID 15819 Rev 5

STP1612PW05 Constant current

12 Constant current

The STP1612PW05 assures nearly no variation in current both from channel to channel and

from IC to IC.

The typical variation of the current between channels of the same IC is ±1.5%, whereas the

variation between ICs is around ±3%.

Moreover the current characteristic of the output stage is flat (see Figure 14 and Figure 15).

This contributes to keep the current constant regardless of the variation of the LEDs forward

voltage (V

) and consequently guarantees uniformity of brightness.

F

Figure 14. I

Figure 15. I

vs voltage drop across current generators (3.3 V supply voltage)

OUT

vs voltage drop across current generators (5 V supply voltage)

OUT

The typical characteristics in Figure 14 and Figure 15 also show the minimum voltage drop

required to assure that the current generators regulate the desired current.

This must be taken into account when choosing the suitable value of the LED supply voltage

(see dedicated section).

Doc ID 15819 Rev 5 23/41

Current gain adjustment STP1612PW05

13 Current gain adjustment

Figure 16. Gain vs DA6 - DA0

The bit 9 to bit 2 of the configuration register set the gain of output current, i.e., G. Being 8bit in total, ranging from 8’b00000000 to 8’b11111111, these bits allow the user to set the

output current gain up to 256 levels. These bits can be further defined in the configuration

register as follows:

Configuration register

MSB LSB

FEDCBA9876543210

------HCDA6DA5DA4DA3DA2DA1DA0--

1. Bit 9 is HC bit. The setting is in the low current range when HC=0, and in the high

current range when HC=1.

2. Bit 8 to bit 2 are DA6 ~ DA0.

The relationship between these bits and current gain G is:

HC = 1, D = (256G-128)/3

HC = 0, D = (1024G-128)/3

and D in the above decimal numeration can be converted to its equivalent in binary form by

the following equation:

D = DA6x2

6

+ DA5x25 + DA4x24 + DA3x23 + DA2x22 + DA1x21 + DA0x2

0

In other words, these bits can be looked as a floating number with 1-bit exponent HC and 7bit mantissa DA6~DA0.

24/41 Doc ID 15819 Rev 5

STP1612PW05 Delay time of staggered output

For example,

HC = 1, G = 1.25, D = (256x1.25-128)/3 = 64

the D in binary form would be:

D = 64 = 1x2

6

+0x25+0x24+0x23+0x22+0x21+0x2

0

The bit 9 to bit 2 of the configuration register are set to 8’b1100,0000.

14 Delay time of staggered output

This feature prevents large inrush current from the power line and reduces the bypass

capacitors.

The outputs are organized in four groups OUT4n, OUT4n+1, OUTn4+2, OUT4n+3 and each

group has 40 ns delay between the previous one.

E.g.: OUT4n has no delay, OUTn4+1 has 40ns delay, OUTn4+2 has 80ns delay, OUTn4+3

has 120 ns delay.

15 Thermal protection

Thermal flag provides an indication about the status of the junction temperature. When the

junction temperature reaches 150 °C the bit E of the configuration register is set to “1”,

signaling dangerous operating condition. This flag is useful when thermal shutdown function

is disabled.

The thermal shutdown function, if activated by configuration register (bit “1” set to 1), turnsoff all output channels if the junction exceeds 150 °C. As soon as the junction temperature is

below 140 °C the outputs channels will be turned ON. In thermal shutdown mode, the digital

core is active and data flow is guaranteed.

Doc ID 15819 Rev 5 25/41

Time-out alert of GCLK disconnection STP1612PW05

16 Time-out alert of GCLK disconnection

When the PWCLK signal is disconnected for around 1 second, all output ports will be turned

off automatically. This function will protect the LED display system from staying ON

indefinitely and prevent excessive current from damaging the power system. The default is

set to ‘enable” when bit “0” of the Configuration Register is 0. When the PWCLK is active

again and new serial data are moved in, the driver resumes to work after resetting the

internal counters and comparators.

Figure 17. Time-out alert application scheme

PWCLK

500K

STP1612PW05 STP1612PW05 STP1612PW05 STP1612PW05

26/41 Doc ID 15819 Rev 5

STP1612PW05 Application information

+

(

)

17 Application information

17.1 LED supply voltage (VLED)

The choice of the LED supply voltage (VLED) must be carried out considering several

parameters:

● The voltage drop across current generators (V

the desired current (see Figure 14 and Figure 15)

● The maximum LED forward voltage (V

● The maximum power that can be dissipated by the package under the application

F, m a x

ambient conditions

● The accuracy of the supply voltage itself (VLED can vary in a range and the minimum

value should be considered)

Therefore the minimum LED supply voltage can be calculated as:

), which must be enough to guarantee

O

)

=

The LED supply voltage should be higher than V

VVV

max,Ftyp,Omin,LED

(to consider any fluctuation of the

LED,min

involved parameters) but not too high in order to keep low the power dissipation:

16

DIVIVP ⋅⋅+⋅=

i

CHii,ODDDDD

1i

where D

is the duty cycle of the channel i.

i

∑

=

In particular the power dissipation should be kept below the maximum power dissipation,

defined as:

TT

−

P

=

max,D

aj

θ

ja

To summarize, the choice of the proper power supply must be a trade-off between the

correct value that assures the desired LED current and low power dissipation.

In RGB application, there can be a significant variability of the LEDs forward voltage (e.g.

red LEDs have a lower forward voltage compared to green and blue ones).

In this case the supply voltage must be chosen high enough to correctly switch on the LEDs

with the highest forward voltage (green or blue). However this supply voltage is higher than

the voltage required by red LEDs. Thus, the excess of voltage in the lines with red LEDs

drops on the current generators, bringing to an increase of the power dissipation and loss of

efficiency.

Moreover the extra-voltage across the red LEDs driving generators could cause an

erroneous shorted LED condition detection.

Doc ID 15819 Rev 5 27/41

Application information STP1612PW05

To avoid these drawbacks, two different approaches are possible:

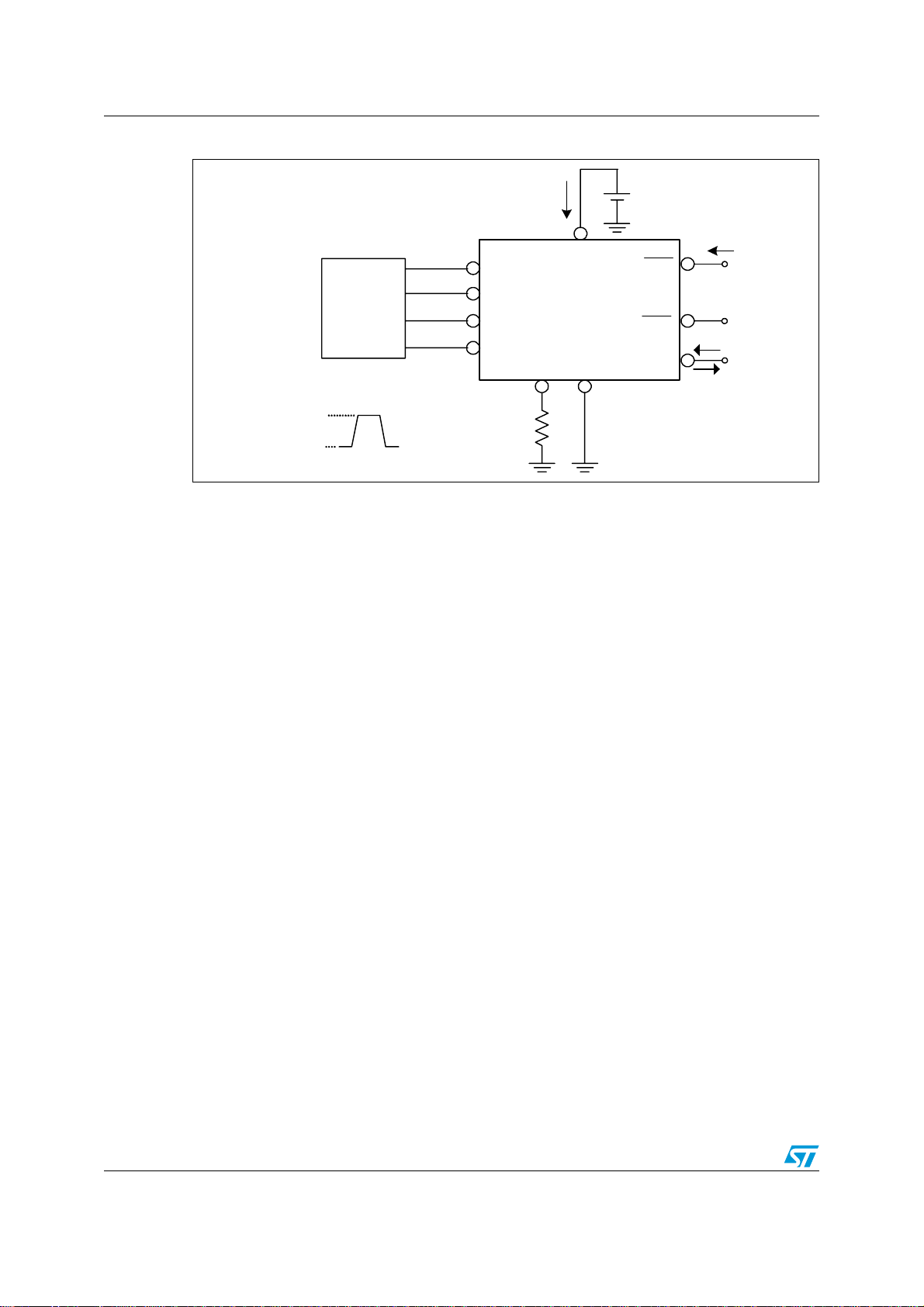

● Figure 18 shows an application with only one voltage rail (VLED). A resistor in series to

each red LEDs is added. In this way, the voltage excess drops across the resistor

instead of dropping across the current generators. This solution implies a significant

reduction of the power dissipated by the chip. However the total power dissipation does

not change and a remarkable part of the power is still wasted on the series resistor.

This not only affects the efficiency, but also raises the cost of the system due to the need to

dissipate the generated heat.

Figure 18. Solution with single supply voltage

VLED

VLED

VLED

VLED

VLED

VLED

5V

5V

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

the next

the next

the next

the next

the next

the next

device

device

device

device

device

device

SDO

SDO

SDO

SDO

SDO

SDO

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

the next

the next

the next

the next

the next

the next

device

device

device

device

device

device

SDO

SDO

SDO

SDO

SDO

SDO

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

to SDI of

the next

the next

the next

the next

the next

the next

device

device

device

device

device

device

SDO

SDO

SDO

SDO

SDO

SDO

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

red

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

the previous

the previous

the previous

the previous

the previous

the previous

device

device

device

device

device

device

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

OUT15

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

SDI

SDI

SDI

SDI

SDI

SDI

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

the previous

the previous

the previous

the previous

the previous

the previous

device

device

device

device

device

device

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

SDI

SDI

SDI

SDI

SDI

SDI

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

V

V

V

V

V

V

V

V

V

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

O,green

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

VLED

VLED

VLED

VLED

VLED

VLED

VLED

VLED

VLED

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

F,green

V

V

V

V

V

V

V

V

V

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

F,red

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

V

V

V

V

V

V

V

V

V

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

SDI

SDI

SDI

SDI

SDI

SDI

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

from SDO of

the previous

the previous

the previous

the previous

the previous

the previous

device

device

device

device

device

device

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

V

V

V

V

V

V

V

V

V

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

O,red

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

……

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

+ V

+ V

+ V

+ V

+ V

+ V

+ V

+ V

+ V

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

Rred

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

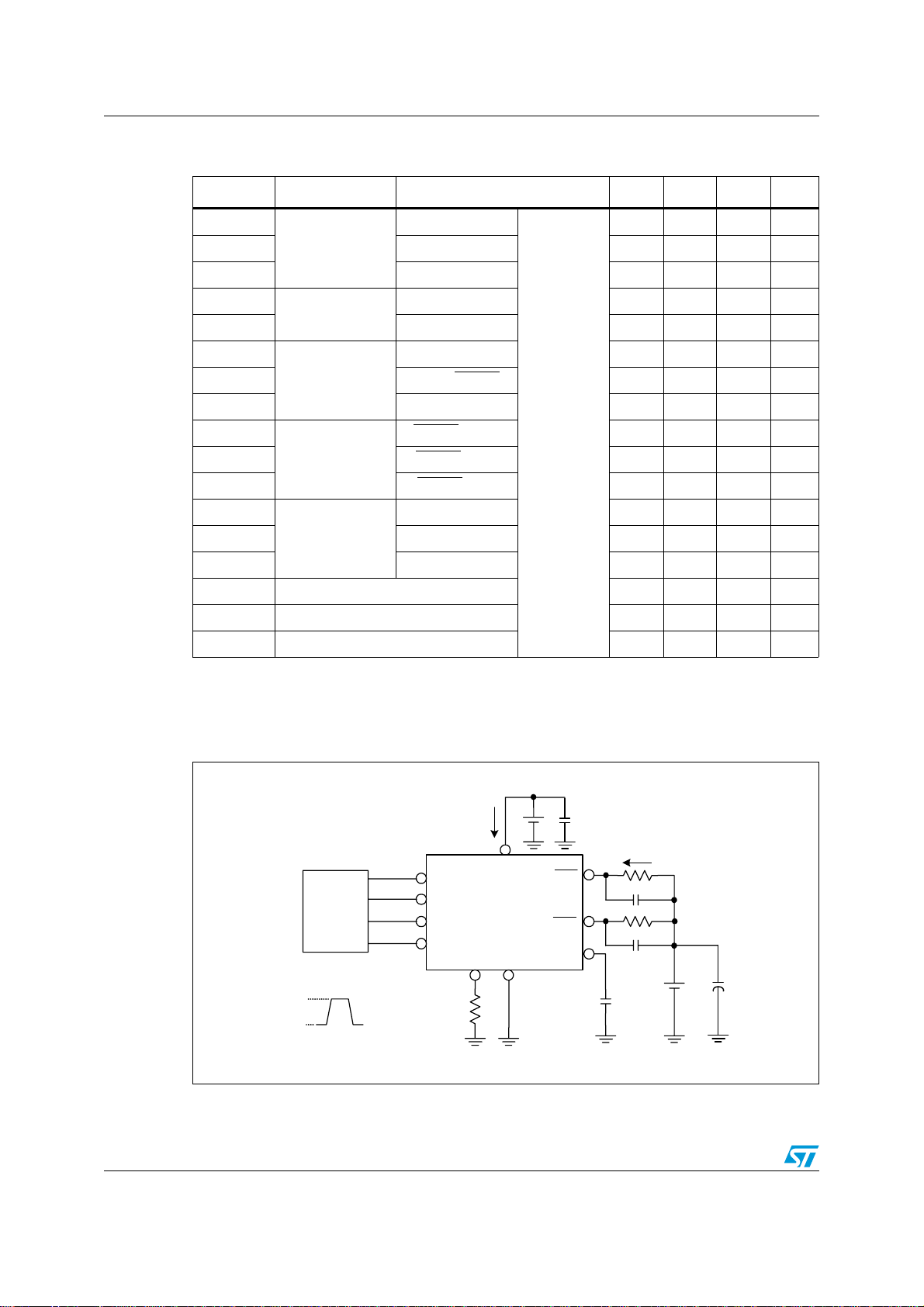

● Figure 19 shows a solution with two separate voltage rails: one for blue and green

LEDs (VLED) and one for red LEDs (VLED_RED), which can be derived from the

former (e.g. simply using a voltage regulator). This solution is by far the most

advantageous in terms of power dissipation. Voltage rails are tailored to the type of

LEDs they drive and the wasted power is significantly reduced as well as the heat

produced.

28/41 Doc ID 15819 Rev 5

STP1612PW05 Application information

Figure 19. Solution with separated supply voltage for red LEDs

to SDI of

to SDI of

the ne xt

the ne xt

device

device

from SDO of

from SDO of

the previous

the previous

device

device

V

V

V

O,g reen

O,g reen

O,g reen

V

V

V

O,blue

O,blue

O,blue

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

voltage

voltage

regulator

regulator

VLED = 5V

VLED = 5V

VLED_RED

VLED_RED

3.3V

3.3V

VLED _ RED = 3.3 V

VLED _ RED = 3.3 V

……

……

……

……

V

V

V

V

F,red

F,red

F,red

F,red

OUT15

OUT15

OUT15

OUT0

OUT0

OUT0

OUT0

SDO

SDO

OUT0

OUT0

OUT0

OUT0

SDI

SDI

OUT15

V

V

V

V

O,red

O,red

O,red

O,red

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

V

V

V

V

F,red

F,red

F,red

F,red

OUT15

OUT15

OUT15

OUT15

V

V

V

V

O,red

O,red

O,red

O,red

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

V

V

V

F,greenVF,blue

F,greenVF,blue

F,greenVF,blue

V

V

V

F,red

F,red

F,red

to SD I o f

to SD I o f

the next

the next

device

device

from SDO of

from SDO of

the previous

the previous

device

device

SDO

SDO

SDI

SDI

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

……

……

……

……

……

……

V

V

V

V

V

V

F,green

F,green

F,green

F,green

F,green

F,green

V

V

V

V

V

V

O,green

O,green

O,green

O,green

O,green

O,green

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

……

……

V

V

V

V

V

V

F,green

F,green

F,green

F,green

F,green

F,green

V

V

V

V

V

V

O,green

O,green

O,green

O,green

O,green

O,green

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

VLED

VLED

VLED

VLED_RED

VLED_RED

VLED_RED

V

V

V

O,re d

O,re d

O,re d

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

OUT15

to SDI of

to SDI of

the next

the next

device

device

from SDO of

from SDO of

the pr evious

the pr evious

device

device

SDO

SDO

SDI

SDI

……

……

……

……

……

……

V

V

V

V

V

V

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

OUT0

OUT0

OUT0

OUT0

OUT0

OUT0

V

V

V

V

V

V

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

……

……

……

……

……

……

……

……

V

V

V

V

V

V

F,blue

F,blue

F,blue

F,blue

F,blue

F,blue

OUT0 OUT15

OUT0 OUT15

OUT0 OUT15

OUT0 OUT15

OUT0 OUT15

OUT0 OUT15

V

V

V

V

V

V

O,blue

O,blue

O,blue

O,blue

O,blue

O,blue

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

STP1612PW05

VLED

VLED

5V

5V

17.2 Setting grayscale brightness

As explained in section 8, the brightness of each channel can be adjusted using 12 or 16 bit

per channel PWM control scheme, resulting in respectively 4095 or 65535 steps, from 0% to

100% brightness.

The brightness level of each output can be calculated as:

Where GS

up to 4095 or 65535, whereas GS

(12bit) or 65535 (16bit).

So, once the brightness level for the channel n is defined, according to the bit “D” of the

configuration register (see section 8), the GS

value into a binary word, the correct string to load into the register is achieved (see

Figure 20).

is the programmed grayscale value for OUTn (n from 0 to 15), which can be

value,n

Doc ID 15819 Rev 5 29/41

GS

%Brightness

is the maximum grayscale value programmable: 4095

max

value,n

n,value

100

GS

⋅=

max

can be calculated. Then, converting this

Application information STP1612PW05

Figure 20. Example of brightness setting

GS

= 65535

GS

= 65535

max

max

GS

= 45875

GS

= 45875

value, n

value, n

70% 100%

70% 100%

Brightness%

Brightness%

Word = 1011 0011 0011 0010

Word = 1011 0011 0011 0010

GS word

GS word

GS word

chann el 1 5

chann el 1 5

GS word

channel14

channel14

GS word

GS word

……. …….

……. …….

channeln

channeln

GS word

GS word

channel 1

channel 1

GS w ord

GS w ord

channel 0

channel 0

17.3 Multi device application

In a typical application several devices are used to drive the LEDs.

In this case more STP1612PW05 can be connected together in a daisy chain configuration

as shown in

Figure 21. STP1612PW05 in daisy chain configuration

Figure 21.

VLED

VLED

µC

µC

OUT0

OUT0

SDI

SDI

CLK

CLK

LE

LE

PWCLK

PWCLK

VDD

VDD

STP1612PW05

STP1612PW05

3

3

….

….

IC#1

IC#1

OUT15

OUT15

SDO

SDO

R-EXT

R-EXT

GND

GND

….

….

….

….

OUT0

OUT0

SDI

SDI

CLK

CLK

LE

LE

PWCLK

PWCLK

VDD

VDD

STP1612PW05

STP1612PW05

….

….

IC#n

IC#n

OUT15

OUT15

R-EXT

R-EXT

GND

GND

30/41 Doc ID 15819 Rev 5

STP1612PW05 Package mechanical data

18 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at:

packages, depending on their level of environmental compliance. ECOPACK®

www.st.com.

ECOPACK is an ST trademark.

Table 15. TSSOP24 mechanical data

mm. inch

Dim.

Min. Typ Max. Min. Typ. Max.

A 1.1 0.043

A1 0.05 0.15 0.002 0.006

A2 0.9 0.035

b 0.19 0.30 0.0075 0.0118

c 0.09 0.20 0.0035 0.0079

D 7.7 7.9 0.303 0.311

E 4.3 4.5 0.169 0.177

e 0.65 BSC 0.0256 BSC

H 6.25 6.5 0.246 0.256

K 0° 8° 0° 8°

L 0.50 0.70 0.020 0.028

Figure 22. TSSOP24 package dimensions

Doc ID 15819 Rev 5 31/41

Package mechanical data STP1612PW05

Table 16. TSSOP24 tape and reel

mm. inch

Dim.

Min. Typ Max. Min. Typ. Max.

A - 330 - 12.992

C 12.8 - 13.2 0.504 - 0.519

D 20.2 - 0.795 -

N 60 - 2.362 -

T - 22.4 - 0.882

Ao 6.8 - 7 0.268 - 0.276

Bo 8.2 - 8.4 0.323 - 0.331

Ko 1.7 - 1.9 0.067 - 0.075

Po 3.9 - 4.1 0.153 - 0.161

P 11.9 - 12.1 0.468 - 0.476

Figure 23. TSSOP24 reel dimensions

32/41 Doc ID 15819 Rev 5

STP1612PW05 Package mechanical data

Table 17. SO-24 mechanical data

mm. inch

Dim.

Min. Typ Max. Min. Typ. Max.

A 2.35 2.65 2.36 2.5

A1 0.1 0.3 0.12 0.15 0.18

B 0.33 0.51 0.375 0.4 0.425

C 0.23 0.32 0.292

(1)

D

E 7.4 7.6 7.52 7.55 7.58

e 1.27 1.27

H 10 10.65 10.2 10.3 10.4

h 0.25 0.75 0.35

L 0.4 1.27 0.6 0.75

k 0 8 2 4 6

ddd 0.1 0.06

15.2 15.6 15.43 15.46 15.49

1. Dimension “D” does not include mold flash, protrusions or gate burrs. Mold flash, protrusions or gate burrs

shall not exceed 0.15mm per side.

Doc ID 15819 Rev 5 33/41

Package mechanical data STP1612PW05

Figure 24. SO-24 package dimensions

34/41 Doc ID 15819 Rev 5

STP1612PW05 Package mechanical data

Table 18. SO-24 tape and reel

mm. inch

Dim.

Min. Typ Max. Min. Typ. Max.

A - 330 - 12.992

C 12.8 - 13.2 0.504 - 0.519

D 20.2 - 0.795 -

N 60 - 2.362 -

T - 30.4 - 1.197

Ao 10.8 - 11.0 0.425 - 0.433

Bo 15.7 - 15.9 0.618 - 0.626

Ko 2.9 - 3.1 0.114 - 0.122

Po 3.9 - 4.1 0.153 - 0.161

P 11.9 - 12.1 0.468 - 0.476

Figure 25. SO-24 reel dimensions

Doc ID 15819 Rev 5 35/41

Package mechanical data STP1612PW05

Table 19. TSSOP24 exposed pad

mm inch

Dim.

Min. Typ. Max. Min. Typ. Max.

A 1.2 0.047

A1 0.15 0.004 0.006

A2 0.8 1 1.05 0.031 0.039 0.041

b 0.19 0.30 0.007 0.012

c 0.09 0.20 0.004 0.0089

D 7.7 7.8 7.9 0.303 0.307 0.311

D1 4.7 5.0 5.3 0.185 0.197 0.209

E 6.2 6.4 6.6 0.244 0.252 0.260

E1 4.3 4.4 4.5 0.169 0.173 0.177

E2 2.9 3.2 3.5 0.114 0.126 0.138

e 0.65 0.0256

K 0° 8° 0° 8°

L 0.45 0.60 0.75 0.018 0.024 0.030

Figure 26. TSSOP24 package dimensions

36/41 Doc ID 15819 Rev 5

STP1612PW05 Package mechanical data

Table 20. QFN24 (4x4) mechanical data

mm. mils

Dim.

Min. Typ Max. Min. Typ. Max.

A 1.00 39.4

A1 0.00 0.05 0.0 2.0

b 0.18 0.30 7.1 11.8

D 3.9 4.1 153.5 161.4

D2 2.6 2.8 76.8 88.6

E 3.9 4.1 153.5 161.4

E2 2.6 2.8 76.8 88.6

e 0.50 19.7

L 0.40 0.60 15.7 23.6

Doc ID 15819 Rev 5 37/41

Package mechanical data STP1612PW05

Figure 27. QFN24 (4x4) mechanical drawing

38/41 Doc ID 15819 Rev 5

STP1612PW05 Package mechanical data

Tape & Reel QFNxx/DFNxx (4x4) MECHANICAL DATA

DIM.

mm. inch

MIN. TYP MAX. MIN. TYP. MAX.

A 330 12.992

C 12.8 13 .2 0 .504 0.519

D 20.2 0.795

N 99 101 3.898 3.976

T 14.4 0.567

Ao 4.35 0.171

Bo 4.35 0.171

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

Doc ID 15819 Rev 5 39/41

Revision history STP1612PW05

19 Revision history

Table 21. Document revision history

Date Revision Changes

17-Jun-2009 1 Initial release.

10-Aug-2009 2 Updated Section 9.2 on page 19 and Table 11 on page 14

29-Oct-2009 3

18-Dec-2009 4 Updated Section 11 on page 22

08-Feb-2011 5 Updated Table 17 on page 33 and Figure 24 on page 34

Updated: Figure 2 on page 6 and Table 20 on page 37

Added: Figure 17 on page 26

40/41 Doc ID 15819 Rev 5

STP1612PW05

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15819 Rev 5 41/41

Loading...

Loading...