Page 1

Smart Reset

™

with push-button controlled output delay

Features

■ Dual Smart Reset™ push-button inputs, with

user-selectable extended reset setup delay

(by two-state input logic): t

■ Push-button controlled reset pulse duration

(no fixed nor minimum pulse width guaranteed)

■ No power-on reset

■ Dual reset outputs

–RST1

- active-low, open-drain

– RST2 - active-high, push-pull

■ Fixed Smart Reset™ input logic voltage levels

■ Broad operating voltage range 1.65 V to 5.5 V,

inactive reset output levels valid down to 1.0 V

■ Low supply current 1.5 µA

■ Operating temperature: –30 °C to +85 °C

■ TDFN8 package: 2 mm x 2 mm x 0.75 mm

■ RoHS compliant

= 6, 10 s (min.)

SRC

STM6520

Dual push-button

TDFN8 (DG)

2 mm x 2 mm

Applications

■ Mobile phones, smartphones

■ e-books

■ MP3 players

■ Games

■ Portable navigation devices

■ Any application that requires delayed reset

push-button(s) response for improved system

stability

January 2011 Doc ID15953 Rev 6 1/23

www.st.com

1

Page 2

Contents STM6520

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Power supply (VCC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Ground (V

3.3 Smart Reset™ inputs (SR0

3.4 User-selectable Smart Reset™ delay (DSR) . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Reset outputs (RST1

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SS

, SR1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

, RST2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Typical application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Typical operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9 Package footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Tape and reel information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12 Package marking information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/23 Doc ID 15953 Rev 6

Page 3

STM6520 List of tables

List of tables

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Operating and measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. DC and AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5. TDFN – 8-lead 2 x 2 x 0.75 mm, 0.5 mm package mechanical data . . . . . . . . . . . . . . . . . 15

Table 6. Parameter for landing pattern - TDFN – 8-lead 2 x 2 mm package . . . . . . . . . . . . . . . . . . 16

Table 7. Carrier tape dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 8. Reel dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 10. Package marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 11. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Doc ID 15953 Rev 6 3/23

Page 4

List of figures STM6520

List of figures

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. RST1

Figure 5. RST2 used for interrupting system power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. Timing waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. Undervoltage condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 8. Supply current (I

Figure 9. Smart Reset™ delay (t

Figure 10. AC testing input/output waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. TDFN - 8-lead, 2 x 2 mm package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 12. Landing pattern - TDFN – 8-lead 2 x 2 mm without thermal pad . . . . . . . . . . . . . . . . . . . . 16

Figure 13. Carrier tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14. Reel dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 15. Tape trailer/leader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 16. Pin 1 orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 17. Package marking area, top view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

output used for microcontroller reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

) vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CC

) vs. temperature, DSR = VSS . . . . . . . . . . . . . . . . . . . . . . . . . 10

SRC

4/23 Doc ID 15953 Rev 6

Page 5

STM6520 Description

1 Description

The Smart Reset™ devices provide a useful feature that ensures inadvertent short reset

push-button closures do not cause system resets. This is done by implementing extended

Smart Reset™ input delay time (t

ensures a safe reset and eliminates the need for a specific dedicated reset button.

This reset configuration provides versatility and allows the application to discriminate

between a software generated interrupt and a hard system reset. When the input pushbuttons are connected to microcontroller interrupt inputs, and are closed for a short time, the

processor can only be interrupted. If the system still does not respond properly, continuing

to keep the push-buttons closed for the extended setup time t

processor through the reset outputs.

) and combined push-button inputs, which together

SRC

causes a hard reset of the

SRC

The STM6520 has two combined delayed Smart Reset™ inputs (SR0

selectable delayed Smart Reset™ setup time (t

) options of 7.5 s and 12.5 s typ.,

SRC

, SR1) with two user-

selected by a dual-state Smart Reset™ DSR input pin. When DSR is connected to ground,

t

= 7.5 s, when connected to VCC, t

SRC

= 12.5 s (typ.). There are two reset outputs, both

SRC

going active simultaneously after both of the Smart Reset™ inputs were held active for the

selected t

delay time. The outputs remain asserted until either or both inputs go to

SRC

inactive logic level (for this device the output reset pulse duration is fully push-button

controlled, meaning neither fixed nor minimum reset pulse width, nor power-on reset pulse

is implemented). The first reset output, RST1

output, RST2, is active-high, push-pull. The device fully operates over a broad V

, is active-low, open-drain; the second reset

range

CC

1.65 to 5.5 V. Below 1.575 V typ. the inputs are ignored and outputs are deasserted; the

deasserted reset output levels are then valid down to 1.0 V.

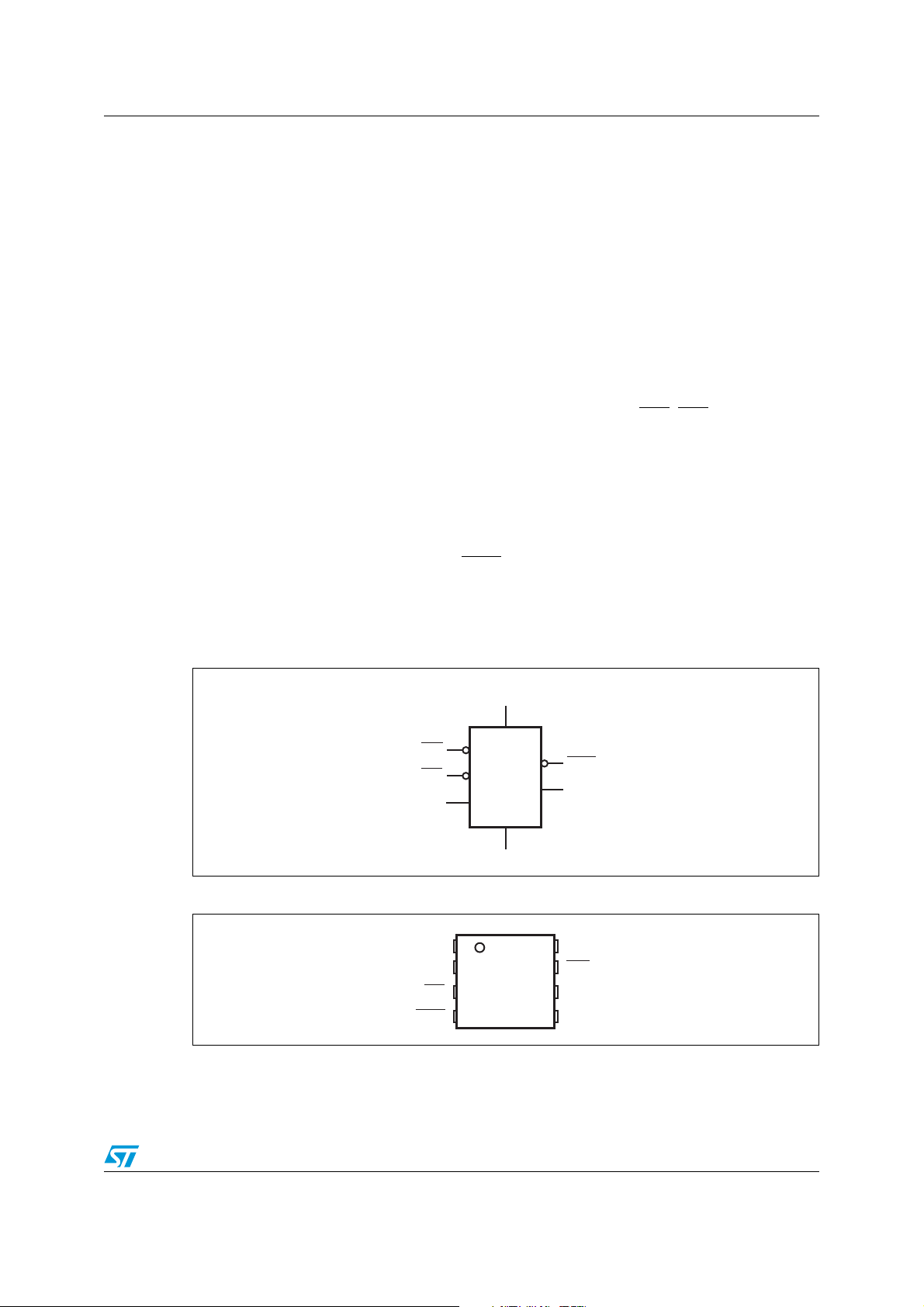

Figure 1. Logic diagram

V

CC

SR0

SR1

DSR

STM6520

V

SS

RST1

RST2

AM00434

Figure 2. Pin connections

RST2

V

SS

SR1

RST1

1

2

STM6520

3

4

8

V

CC

SR0

7

NC

6

5

DSR

AM00435

Doc ID 15953 Rev 6 5/23

Page 6

Device overview STM6520

2 Device overview

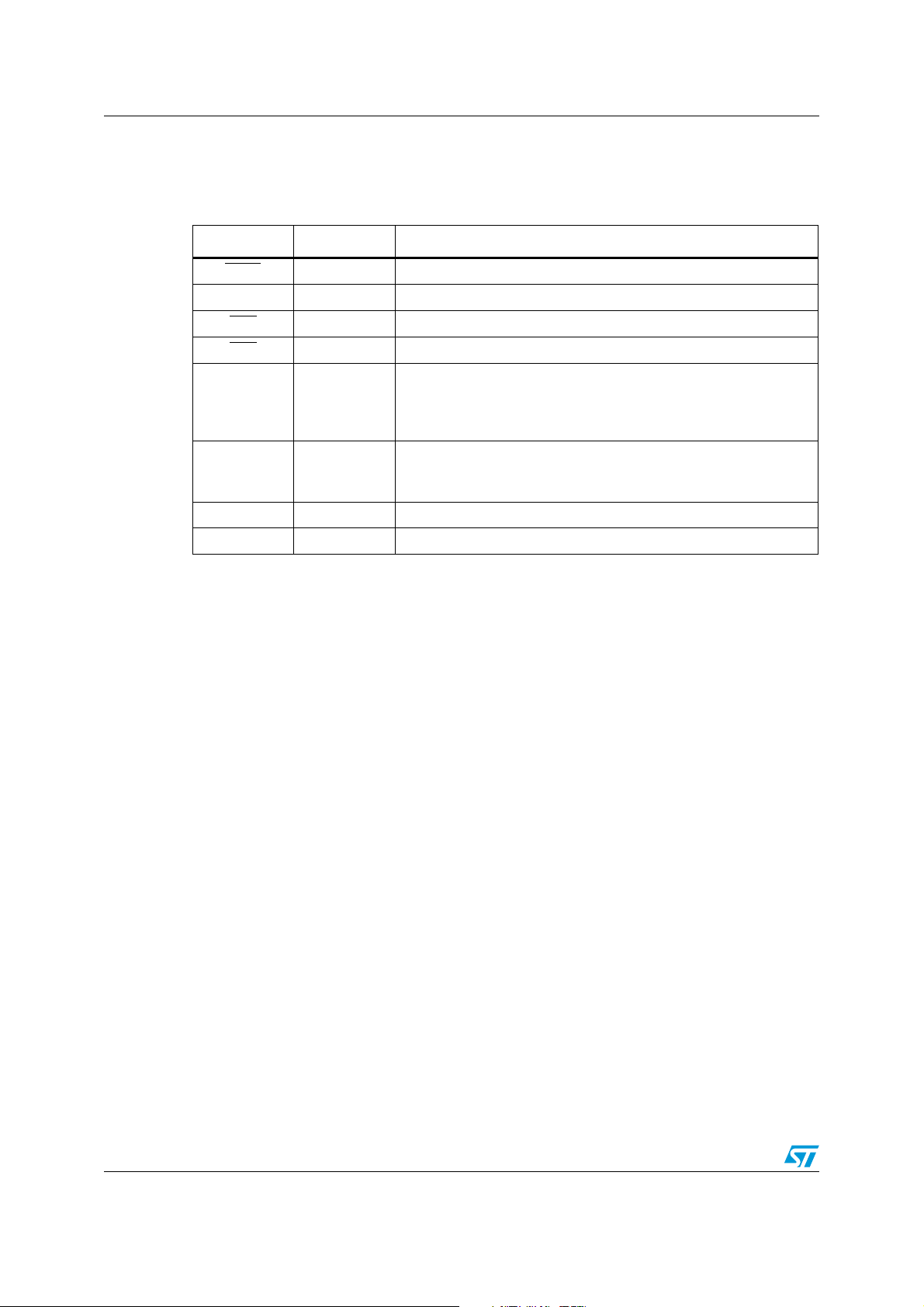

Table 1. Signal names

Symbol Input/output Description

RST1

Output First reset output, active-low, open-drain.

RST2 Output Second reset output, active-high, push-pull.

SR0

SR1

Input Primary push-button Smart Reset™ input. Active-low.

Input Secondary push-button Smart Reset™ input. Active-low.

A dual-state Smart Reset™ input delay selection pin. When

DSR Input

connected to ground, t

t

= 12.5 s (typ.). DSR is a DC-type input, intended to be either

SRC

= 7.5 s; when connected to VCC,

SRC

permanently grounded or permanently connected to V

Positive supply voltage for the device. A 0.1 µF decoupling ceramic

V

CC

Supply voltage

capacitor is recommended to be connected between VCC and VSS

pins.

V

SS

Supply ground Ground

NC No connect (not bonded; should be connected to V

SS

.

CC

).

6/23 Doc ID 15953 Rev 6

Page 7

STM6520 Pin descriptions

3 Pin descriptions

3.1 Power supply (VCC)

This pin is used to provide power to the Smart Reset™ device. A 0.1 µF ceramic decoupling

capacitor is recommended to be connected between the V

STM6520 device as possible.

3.2 Ground (VSS)

This is the ground pin for the device.

3.3 Smart Reset™ inputs (SR0, SR1)

Push-button Smart Reset™ inputs, active-low. Both inputs need to be asserted

simultaneously for at least t

to activate the reset outputs.

SRC

3.4 User-selectable Smart Reset™ delay (DSR)

and VSS pins, as close to the

CC

An input that allows the user to program the setup time (t

buttons need to be pressed to activate the reset outputs. Controlled by different voltage

levels on the DSR pin: when connected to ground, t

t

= 12.5 s (typ.). DSR is a DC-type input, intended to be either permanently grounded or

SRC

permanently connected to V

CC

.

3.5 Reset outputs (RST1, RST2)

RST1 is active-low, open-drain, RST2 active-high, push-pull. Neither fixed nor minimum

output reset pulse duration, nor power-on reset is implemented. Releasing any of the pushbuttons while reset outputs are active, causes both outputs to deassert.

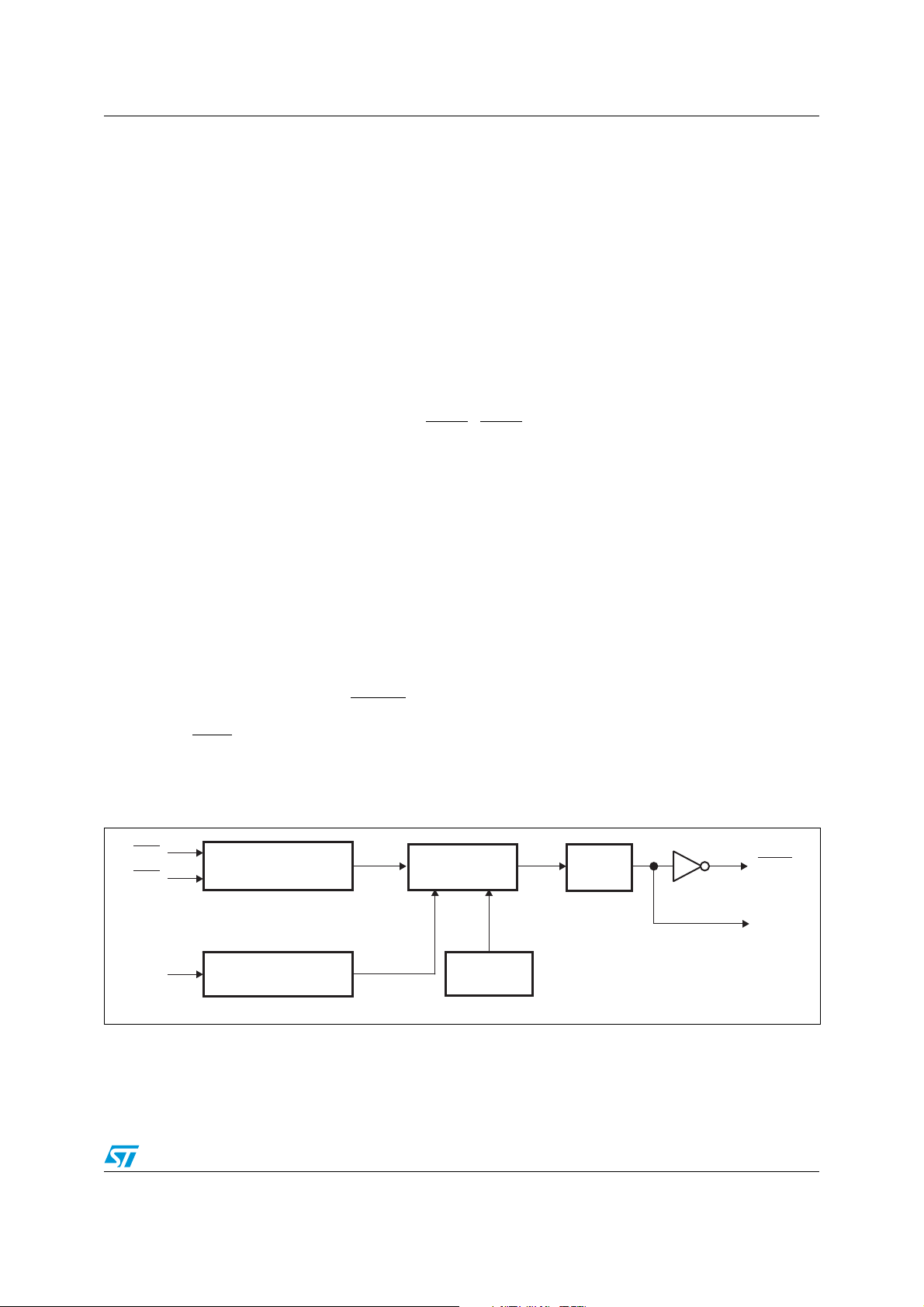

Figure 3. Block diagram

SR0

SR0

SR1

SR1

DSR

DSR

Smart ResetTM

Smart ResetTM

reset logic

reset logic

t

selector

t

selector

SRC

SRC

two-state logic

two-state logic

t

t

SRC

SRC

Oscillator

Oscillator

) for which both the push-

SRC

= 7.5 s, when connected to VCC,

SRC

Output

Output

logic

logic

RST1

RST1

RST2

RST2

AM00436V2

AM00436V2

Doc ID 15953 Rev 6 7/23

Page 8

Typical application diagram STM6520

4 Typical application diagram

Figure 4. RST1 output used for microcontroller reset

V

BAT

C1

0.1 µF

STM6520

(1)

DSR

SR0

SR1 RST1

(2)

RST2

Sys_Reset

Reset

Power_on

Powerkey

System ASIC MCU

1. DSR pin (pin 5) must be tied to VCC or VSS.

2. When only one Smart Reset™ input is used, connect the unused one permanently to V

Figure 5. RST2 used for interrupting system power

System power

output

V

SYS

C1

0.1 µF

V

BAT

Regulator

EN

STM6520

(1)

DSR

SR0

SR1 RST1

(2)

RST2

Sys_Reset

Power_on

Powerkey

System ASIC MCU

SS

AM00440c

.

V

SYS

AM00439c

1. DSR pin (pin 5) must be tied to VCC or VSS.

2. When only one Smart Reset™ input is used, connect the unused one permanently to V

8/23 Doc ID 15953 Rev 6

SS

.

Page 9

STM6520 Typical application diagram

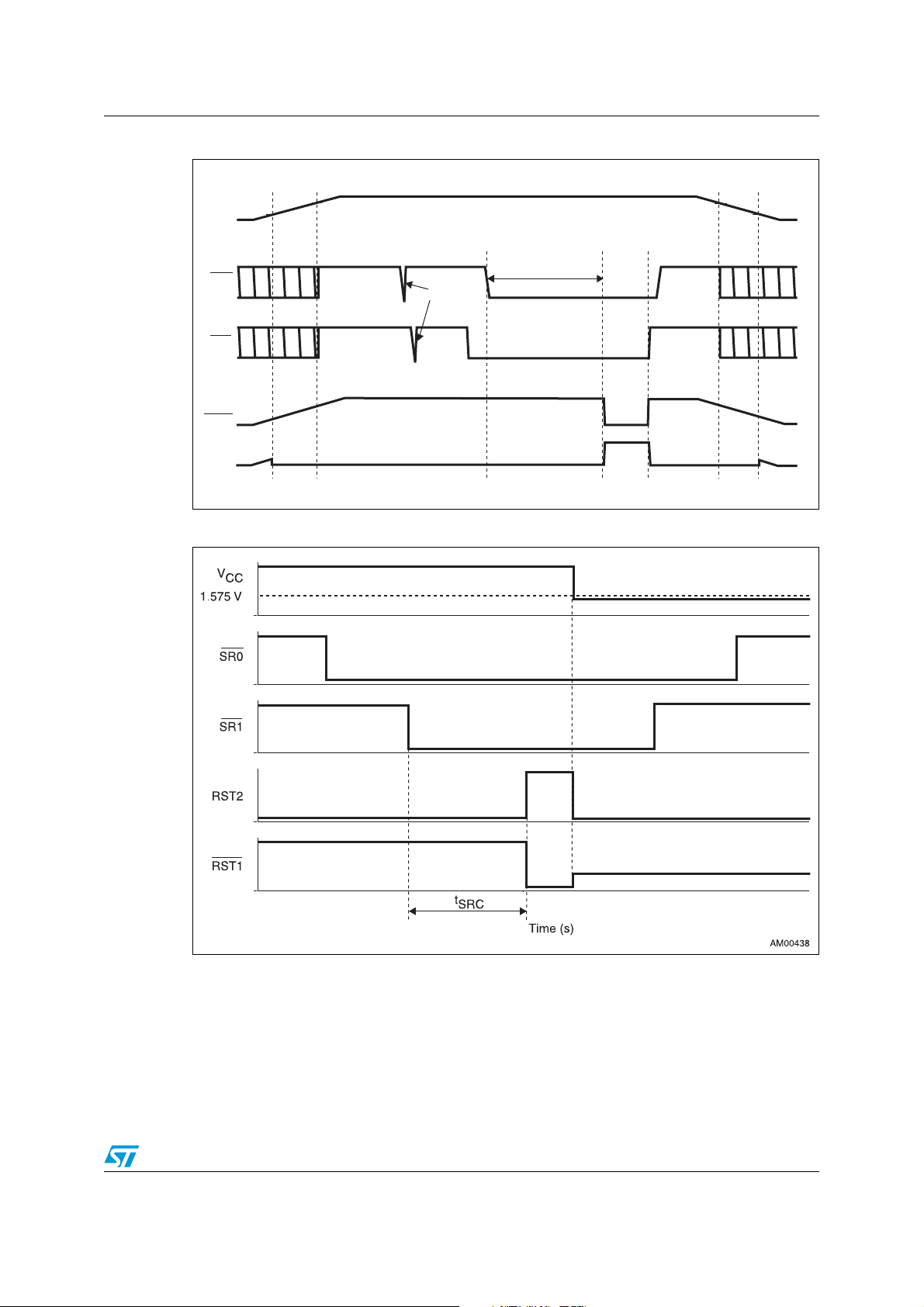

Figure 6. Timing waveforms

1.65 V

1.0 V

V

BAT

SR0

immunity

SR1

RST1

RST2

Figure 7. Undervoltage condition

5 V

0 V

5 V

Glitch

Start

timer

N seconds

t

SRC

End

timer

controlled output

1.65 V

1.0 V

Push-button

AM00437

0 V

5 V

0 V

5 V

0 V

5 V

0 V

Note: If undervoltage occurs (V

outputs are released and go inactive.

drops below 1.575 V typ.) while reset outputs are active, both

CC

Doc ID 15953 Rev 6 9/23

Page 10

Typical operating characteristics STM6520

5 Typical operating characteristics

Figure 8. Supply current (ICC) vs. temperature

3

2.5

2

ICC [µA]

1.5

1

0.5

0

–40 –20 0 20 40 60 80 100 120 140

Figure 9. Smart Reset™ delay (t

9

8.5

8

Temperature [˚C]

5.5 V 3.3 V 2 V

) vs. temperature, DSR = VSS

SRC

AM00624

t

[s]

SRC

–40 –20 0 20 40 60 80 100 120 140

7.5

7

6.5

6

Temperature [˚C]

5.5 V 3.3 V 2 V

10/23 Doc ID 15953 Rev 6

AM00625

Page 11

STM6520 Maximum rating

6 Maximum rating

Stressing the device above the rating listed in the “Absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality documents.

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

T

T

SLD

θ

V

V

STG

Storage temperature (VCC off) –55 to +150 °C

(1)

Lead solder temperature for 10 seconds 260 °C

Thermal resistance (junction to ambient) TDFN8 149.0 °C/W

JA

Input or output voltage –0.3 to 5.5

IO

Supply voltage –0.3 to 7 V

CC

ESD

V

HBM

V

RCDM

V

MM

1. Reflow at peak temperature of 260 °C. The time above 255 °C must not exceed 30 seconds.

2. For RST2 –0.3 to V

Electrostatic discharge protection, human body model,

all pins (JESD22-A114-B level 2)

Electrostatic discharge protection, charged device model,

all pins

Electrostatic discharge protection, machine model, all pins

(JESD22-A115-A level A)

Latch-up (V

pin, reset input pins) EIA/JESD78

CC

+0.3 V only.

CC

2kV

1kV

200 V

(2)

V

Doc ID 15953 Rev 6 11/23

Page 12

DC and AC parameters STM6520

7 DC and AC parameters

This section summarizes the operating measurement conditions, and the DC and AC

characteristics of the device. The parameters in the DC and AC characteristics table that

follow, are derived from tests performed under the Measurement Conditions summarized in

Table 3: Operating and measurement conditions. Designers should check that the operating

conditions in their circuit match the operating conditions when relying on the quoted

parameters.

Table 3. Operating and measurement conditions

Parameter Value Unit

V

supply voltage 1.65 to 5.5 V

CC

Ambient operating temperature (T

Input rise and fall times ≤

Input pulse voltages 0.2 to 0.8 V

Input and output timing ref. voltages 0.3 to 0.7 V

) –30 to +85 °C

A

5ns

CC

CC

V

V

Figure 10. AC testing input/output waveforms

0.8 V

CC

0.2 V

CC

0.7 V

0.3 V

CC

CC

AM00478

12/23 Doc ID 15953 Rev 6

Page 13

STM6520 DC and AC parameters

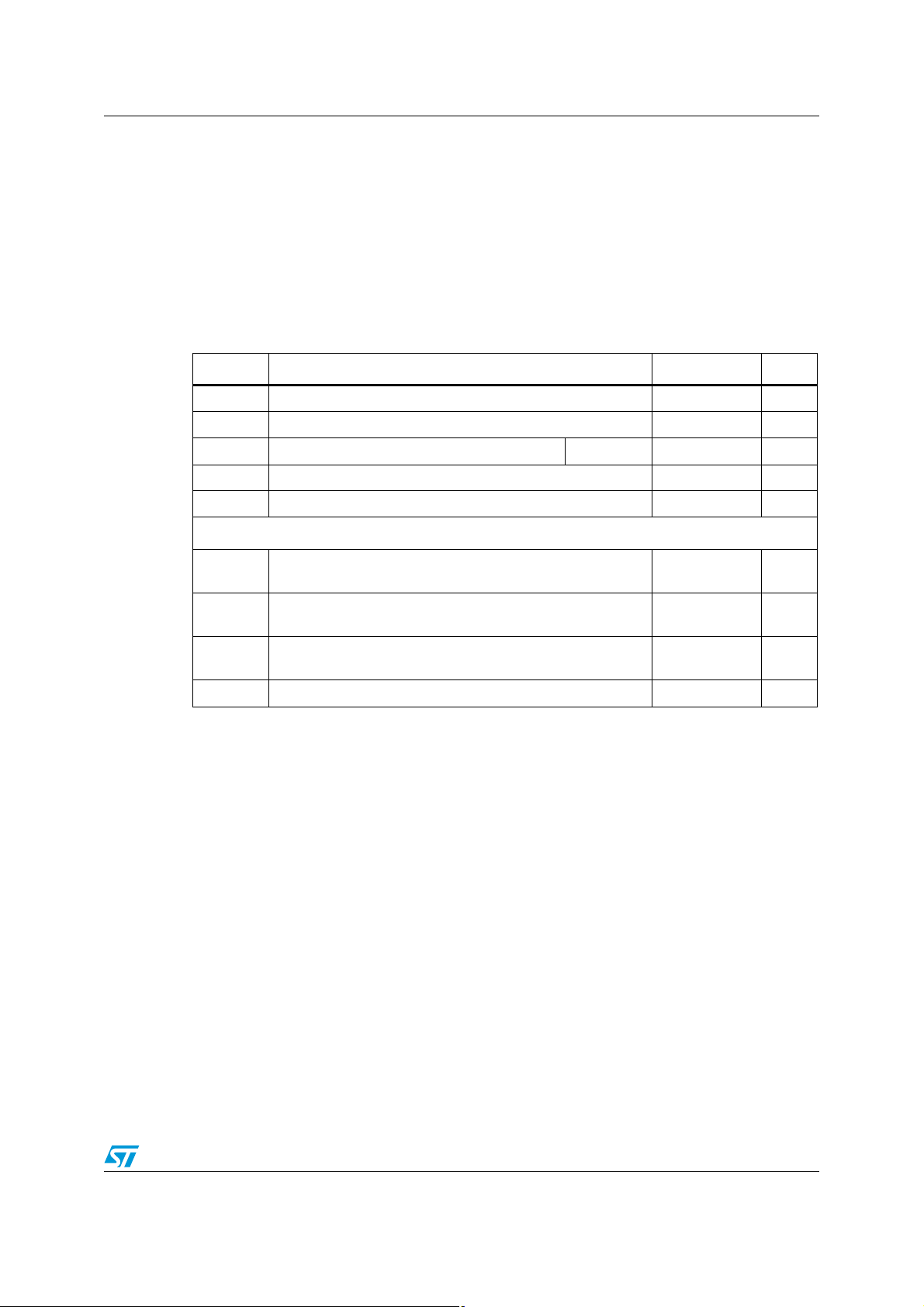

Table 4. DC and AC characteristics

Symbol Parameter Test conditions

V

CC

I

CC

V

OL

V

OH

I

LO

Smart Reset

t

SRC

V

IL

V

IH

I

LI

1. Valid for ambient operating temperature: TA = –30 to +85 °C; VCC = 1.65 to 5.5 V (except where noted).

2. Typical value is at 25 °C and V

3. Reset outputs are deasserted below 1.575 V typ. and remain deasserted down to V

4. Input glitch immunity is equal to t

Supply voltage range Operating voltage

= 3.0 V, t

V

CC

V

= 5.0 V, t

Supply voltage

Reset output voltage low

Reset output voltage high,

RST2

CC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

V

CC

= 3.0 V, t

= 5.0 V, t

≥

≥

≥

≥

≥

≥

Output leakage current, RST1 Open-drain, V

™

Smart Reset™ delay

DSR = V

DSR = V

SRC

SRC

SRC

SRC

4.5 V, sinking 3.2 mA 0.3 V

3.3 V, sinking 2.5 mA 0.3 V

1.65 V, sinking 1 mA 0.3 V

4.5 V, I

SOURCE

2.7 V, I

SOURCE

1.65 V, I

RST1

SS

CC

SR0, SR1 input voltage low

(1)

(3)

counter is inactive 1.5 2.5 µA

counter is inactive 2.0 3.0 µA

counter is active 3.5 µA

counter is active 4.7 µA

= 0.8 mA 0.8 V

= 0.5 mA 0.8 V

SOURCE

= 0.25 mA 0.8 V

= 5.5 V –0.1 0.1 µA

Min. Typ.

1.65 5.5 V

CC

CC

CC

67.59s

10 12.5 15 s

V

SS

– 0.3

SR0, SR1 input voltage high 0.85 5.5 V

Input leakage current (SR0,

SR1

, DSR pins)

Input glitch immunity

(4)

= 3.3 V unless otherwise noted.

CC

(when both SR inputs are low), otherwise infinite.

SRC

Corresponds to the actual t

SRC

–1 1 µA

= 1 V.

CC

t

SRC

(2)

Max. Units

0.3 V

V

V

V

s

Doc ID 15953 Rev 6 13/23

Page 14

Package mechanical data STM6520

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Figure 11. TDFN - 8-lead, 2 x 2 mm package outline

PIN 1 INDEX AREA

0.10 C

0.10

C

A

0.08 C

PIN 1 INDEX AREA

D

2x

0.10 C

2x

TOP VIEW

SIDE VIEW

e

1

A

B

E

C

A1

SEATING

PLANE

b

4

0.10 C A B

Pin#1 ID

8

BOTTOM VIEW

14/23 Doc ID 15953 Rev 6

L

5

8070540_A

Page 15

STM6520 Package mechanical data

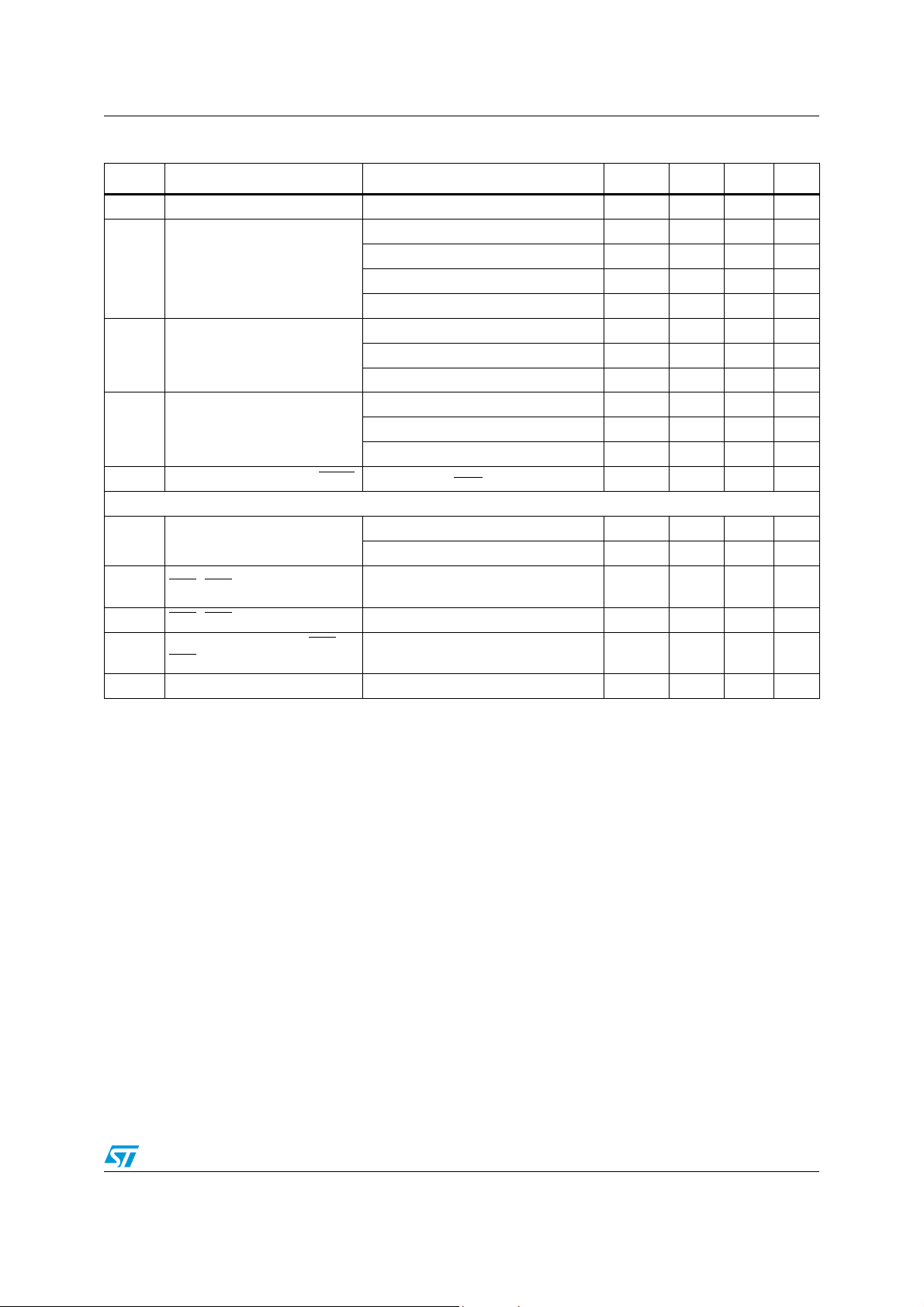

Table 5. TDFN – 8-lead 2 x 2 x 0.75 mm, 0.5 mm package mechanical data

Dimension (mm) Dimension (inches)

Symbol

Min. Nom. Max. Min. Nom. Max.

A 0.70 0.75 0.80 0.028 0.030 0.031

A1 0.00 0.02 0.05 0.000 0.001 0.002

b 0.15 0.20 0.25 0.006 0.008 0.010

D

BSC

E

BSC

1.9 2.00 2.1 0.075 0.079 0.083

1.9 2.00 2.1 0.075 0.079 0.083

e 0.50 0.020

L 0.45 0.55 0.65 0.018 0.022 0.026

Doc ID 15953 Rev 6 15/23

Page 16

Package footprint STM6520

9 Package footprint

Figure 12. Landing pattern - TDFN – 8-lead 2 x 2 mm without thermal pad

D

P

E1E

L

b

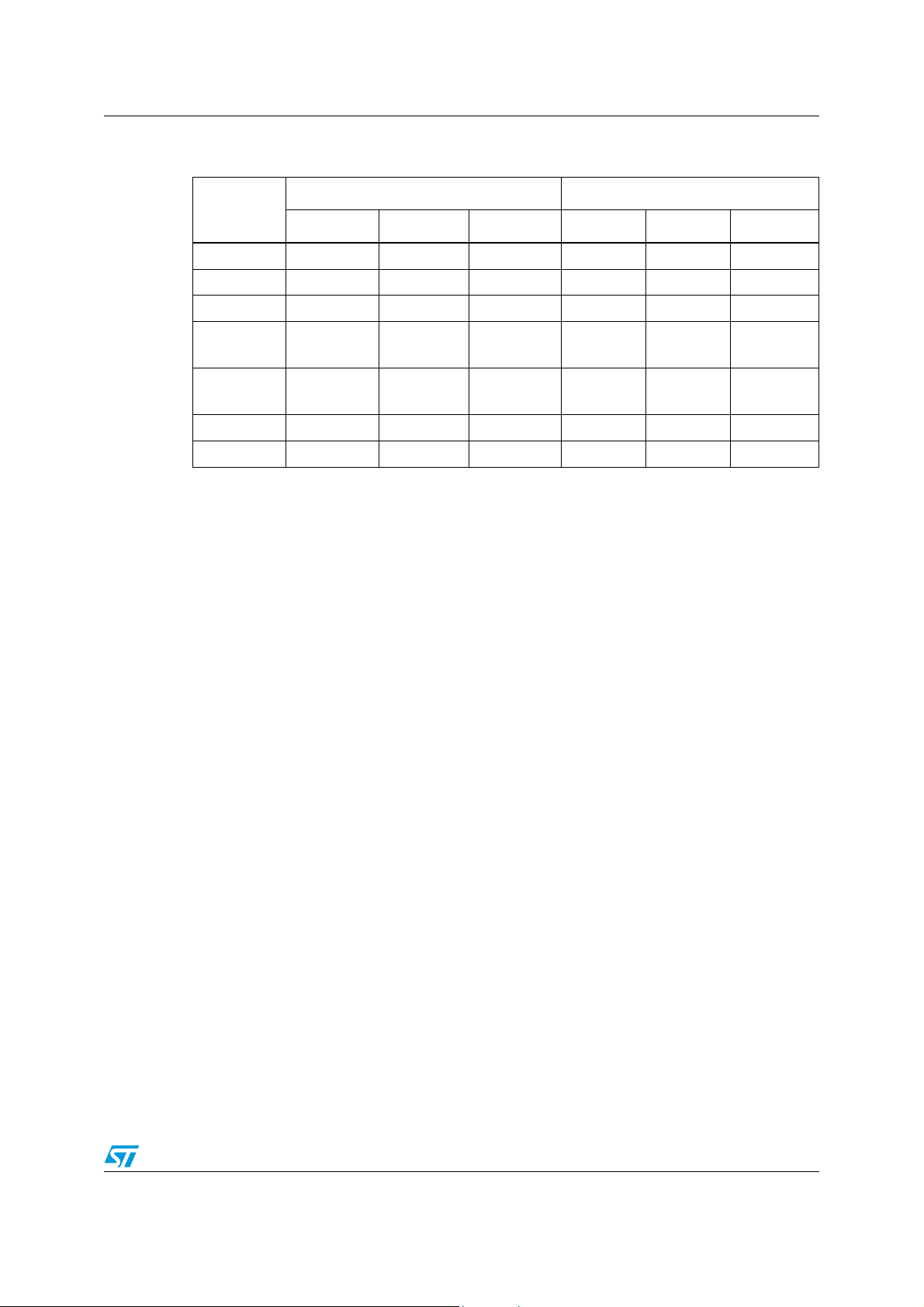

Table 6. Parameter for landing pattern - TDFN – 8-lead 2 x 2 mm package

Dimension (mm)

Parameter Description

Min. Nom. Max.

L Contact length 1.05

b Contact width 0.25

E Max. land pattern Y-direction

— 2.85 —

—

— 0.30

E1 Contact gap spacing — 0.65 —

D Max. land pattern X-direction — 1.75 —

P Contact pitch — 0.5 —

AM00441

1.15

16/23 Doc ID 15953 Rev 6

Page 17

STM6520 Tape and reel information

10 Tape and reel information

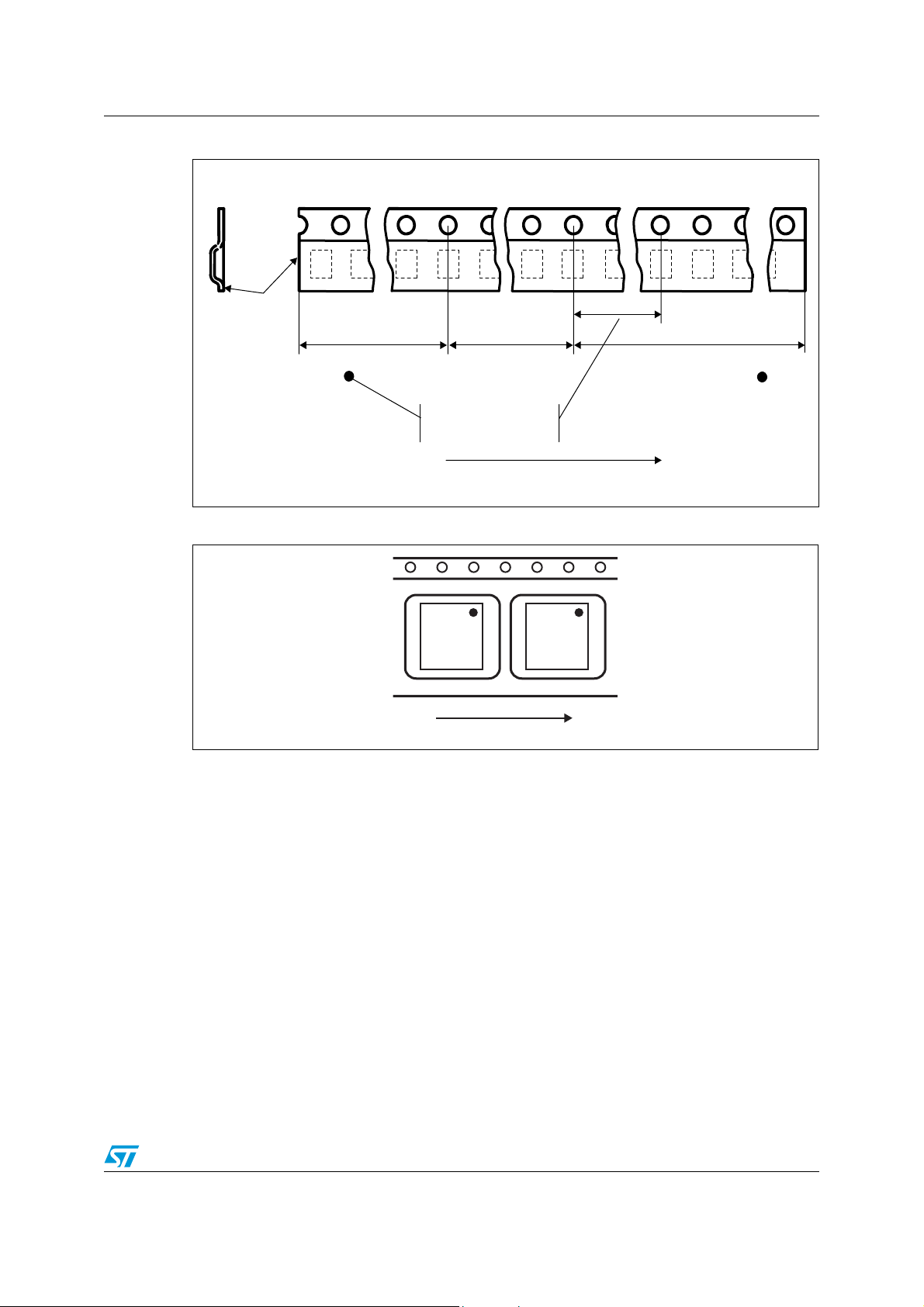

Figure 13. Carrier tape

P

0

D

T

Top cover

tape

K

0

Center lines

of cavity

Table 7. Carrier tape dimensions

Package W D E P

1.50

+0.10/

–0.00

1.75

±0.10

TDFN8

8.00

+0.30

–0.10

0

4.00

±0.10

P

2

User direction of feed

P

2.00

±0.10

FA0B

2

3.50

±0.05

±0.05

2.30

E

A

0

B

0

P

1

K

0

2.30

±0.05

1.00

±0.05

F

W

AM03073v2

P

0

4.00

±0.10

1

TUnit

0.250

±0.05

Bulk

qty.

mm 3000

Doc ID 15953 Rev 6 17/23

Page 18

Tape and reel information STM6520

Figure 14. Reel dimensions

T

40 mm min.

acces hole

at slot location

B

D

A

Full radius

C

N

Tape slot

in core for

tape start

25 mm min width

G measured

at hub

AM00443

Table 8. Reel dimensions

Tape sizes A max. B min. C D min. N min. G T max.

8 mm 180 (7 inches) 1.50 13.0 +/– 0.20 20.20 60 8.4 +2/–0 14.40

18/23 Doc ID 15953 Rev 6

Page 19

STM6520 Tape and reel information

Figure 15. Tape trailer/leader

End

To p

cover

tape

No components No componentsComponents

TRAILER

160 mm min.

Figure 16. Pin 1 orientation

Sealed with cover tape

User direction of feed

10 0 mm min.

LEADE

400 mm min.

Start

R

AM00444

Note: 1 Drawings are not to scale.

2 All dimensions are in mm, unless otherwise noted.

User direction of feed

AM00442

Doc ID 15953 Rev 6 19/23

Page 20

Ordering information STM6520

11 Ordering information

Table 9. Ordering information scheme

Example: STM6520 A Q R R DG 9 F

Device type

STM6520

Reset (V

monitoring threshold) voltage V

CC

A = no VCC monitoring feature

Smart Reset™ setup delay (t

SRC

)

Q = 7.5 or 12.5 s typ., user-selected (two-state);

input comparator on SR0

, SR1, no input pull-ups

Outputs type

R = RST1

Reset pulse timeout period (t

R = push-button controlled (no defined t

active-low, open-drain, no pull-up; RST2 active-high, push-pull

)

REC

, no power-on reset)

REC

Package

DG = TDFN8 2 x 2 x 0.75 mm, 0.5 mm pitch

Temperature range

9 = –30 °C to +85 °C

RST

Shipping method

F = ECOPACK

®

package, tape and reel

For other options, voltage threshold values etc. or for more information on any aspect of this

device, please contact the ST sales office nearest you.

20/23 Doc ID 15953 Rev 6

Page 21

STM6520 Package marking information

12 Package marking information

Table 10. Package marking

Part number Package Topmark

STM6520AQRRDG9F TDFN8 2 x 2 x 0.75 mm, 0.5 mm pitch DRM

STM6520AQRRDG9F TDFN8 2 x 2 x 0.75 mm, 0.5 mm pitch ERM

Figure 17. Package marking area, top view

A

BC

E

D

Topmark

A = dot (pin 1 reference)

B = assembly plant (P)

C = assembly year (Y, 0-9): 9 = 2009 etc.

D = assembly work week (WW, 01 to 52): 20 = WW20 etc.

E = marking area (topmark)

AM00479

Doc ID 15953 Rev 6 21/23

Page 22

Revision history STM6520

13 Revision history

Table 11. Document revision history

Date Revision Changes

08-Jul-2009 1 Initial release.

Document reformatted, updated Section 1: Description,

20-Oct-2009 2

20-Jan-2010 3 Updated Section 1: Description, Ta b l e 1 .

06-May-2010 4 Updated title, Features, Applications, Ta b l e 5 .

31-May-2010 5

Ta ble 1 , Figure 4, Figure 5, Tab le 4 , renamed Section 2:

Device overview, added Section 5: Typical operating

characteristics, updated supply voltage range in Ta bl e 4 .

Replaced “smart reset” by “Smart Reset™”, updated

Applications, Section 1, Section 3.1, Section 3.5, Figure 4,

Figure 5, Ta b le 2 , Ta bl e 4 , Ta b l e 6 and Tab le 1 0.

06-Jan-2011 6 Updated I

- supply voltage in Ta b l e 4 .

CC

22/23 Doc ID 15953 Rev 6

Page 23

STM6520

y

Please Read Carefully:

Informatio n in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at an

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 15953 Rev 6 23/23

Loading...

Loading...