Page 1

Front panel controller/driver with standby

power management and real-time clock

Features

■ IC front panel VFD controller driver

■ Standby power management to the host

■ 3.3 V (V

supply for the IC

■ IR remote control decoder

(Philips, NEC, Thomson, Sony, Matsushita)

■ Multiple display modes

(12 seg. and 16 digits to 20 seg and 8 digits)

■ High voltage outputs (V

■ No additional external resistors required for

driver outputs (P-CH. open drain + pull-down

resistor outputs)

■ Key scanning (up to 12 x 2 matrix = 24 keys)

■ LED ports (4 channels 20 mA max each)

■ Serial I

communication protocol b

■ Operating speed: up to 400 kHz for I

■ Programmable hotkeys for IR remote con tr ol

command and KEYSCAN command

■ Low power consumption in standby mode

■ Dimming circuit (8 steps)

■ Real-time clock (accuracy ± 25 secs/month)

■ Wake-up alarm

■ Internal oscillator with external crystal for RTC

■ Available in PQFP-52 package (0.65 mm pitc h

Applications

) and down to -30 V (VSS)

DD

- 33.3 V max)

DD

2

C interface (SCL, SDA)

2

C

STFPC320

PQFP-52

Description

The STFPC320 is designed to integrate the VFD

driving, key-scan matrix, LED driving, infrared (I R)

remote control decoding and real-time clock

(RTC) into one integrated solution. All the

functions are programmable using the I

Low power consumpt ion is achieved during

standby operation. The STFPC320 provides the

standby power management to the main chipset.

The STFPC320 is housed in a 52-pin PQFP

package. The pin assignments and application

circuit are optimized for an easy PCB layout and

cost saving advantages.

2

C bus.

■ VCR, DVD and personal video recorders

■ Home theatre with clock feature, STB and HTiB

(home theater in a box)

Table 1. Device summary

Order code Operating temperature Package Packaging

STFPC320 -40°C to 85°C PQFP-52 Tape and reel

July 2008 Rev 2 1/78

www.st.com

78

Page 2

Contents STFPC320

Contents

1 Device block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Cold boot up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Entering standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Wake-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Interrupts/events handling by STFPC320 . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Ready pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 Mute pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.8 Keyscan matrix/front panel keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.9 LED ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.10 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.10.1 Normal display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.10.2 RTC display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.11 Remote control decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.12 PIN_AV8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.13 Default state upon power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.14 Initial state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

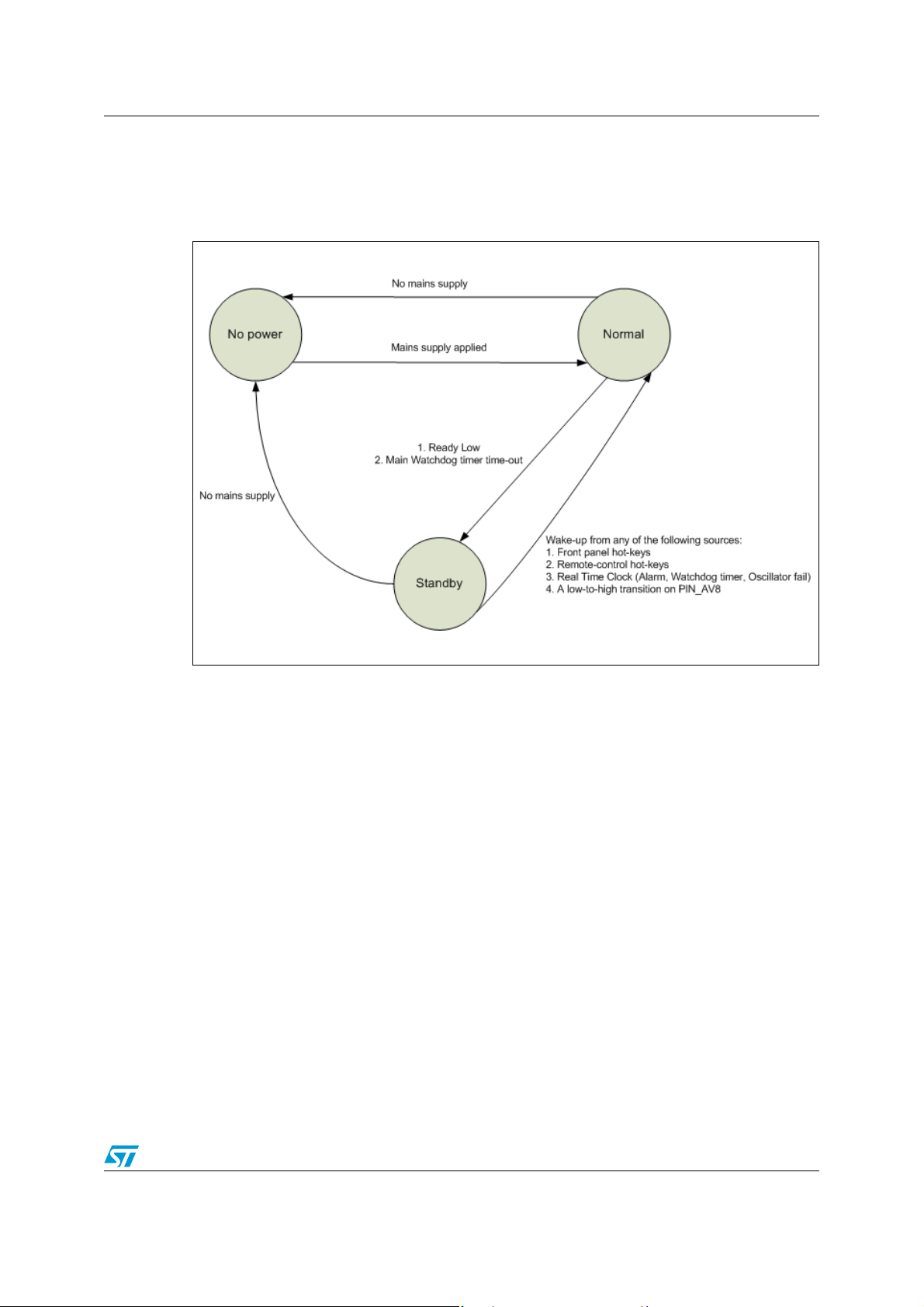

5 Operating state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Real-time clock (RTC) operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Real-time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 2-wire bus characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Watchdog timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/78

Page 3

STFPC320 Contents

6.4 Real-time clock (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Reading the real-time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.2 Writing to the real-time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 Register table for RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.6 Setting alarm clock registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.7 Calibrating the clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.8 Square wave output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.9 Century bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.10 Oscillator stop detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.11 Initial power-on defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Configuration mode setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Data setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Display control and hotkey setting command . . . . . . . . . . . . . . . . . . . . . . 38

7.4 Example for device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 Key matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1 Key read sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 LED port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 Writing to LED sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10 SW data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.1 Reading switch sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11 Address setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

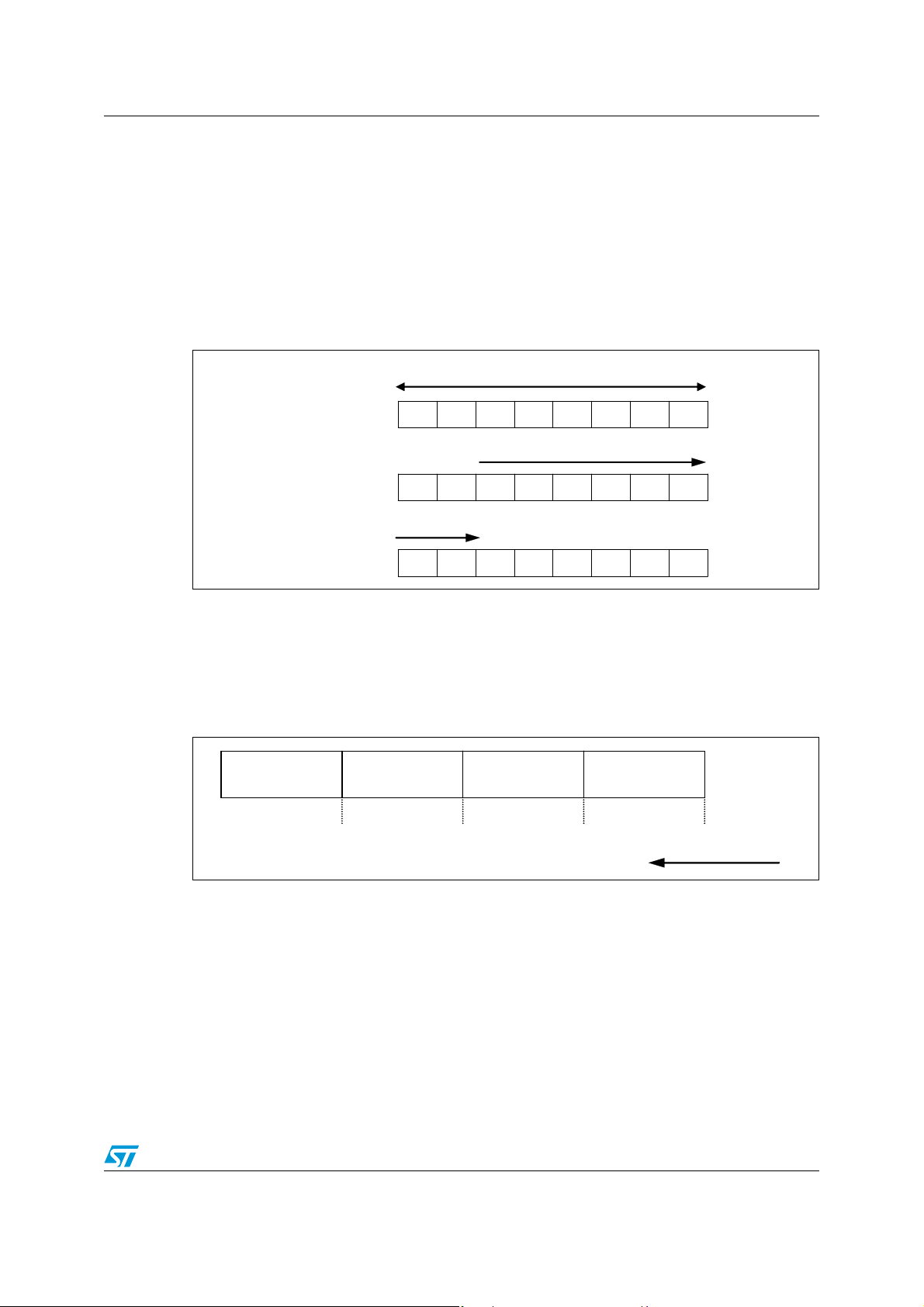

11.1 RTC display data read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.2 Display (normal & RTC) data write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12 Normal display memory locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13 Configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

14 Interrupt flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3/78

Page 4

Contents STFPC320

15 Remote control protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15.1 Decoded and RAW formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15.2 Sending IR data on I

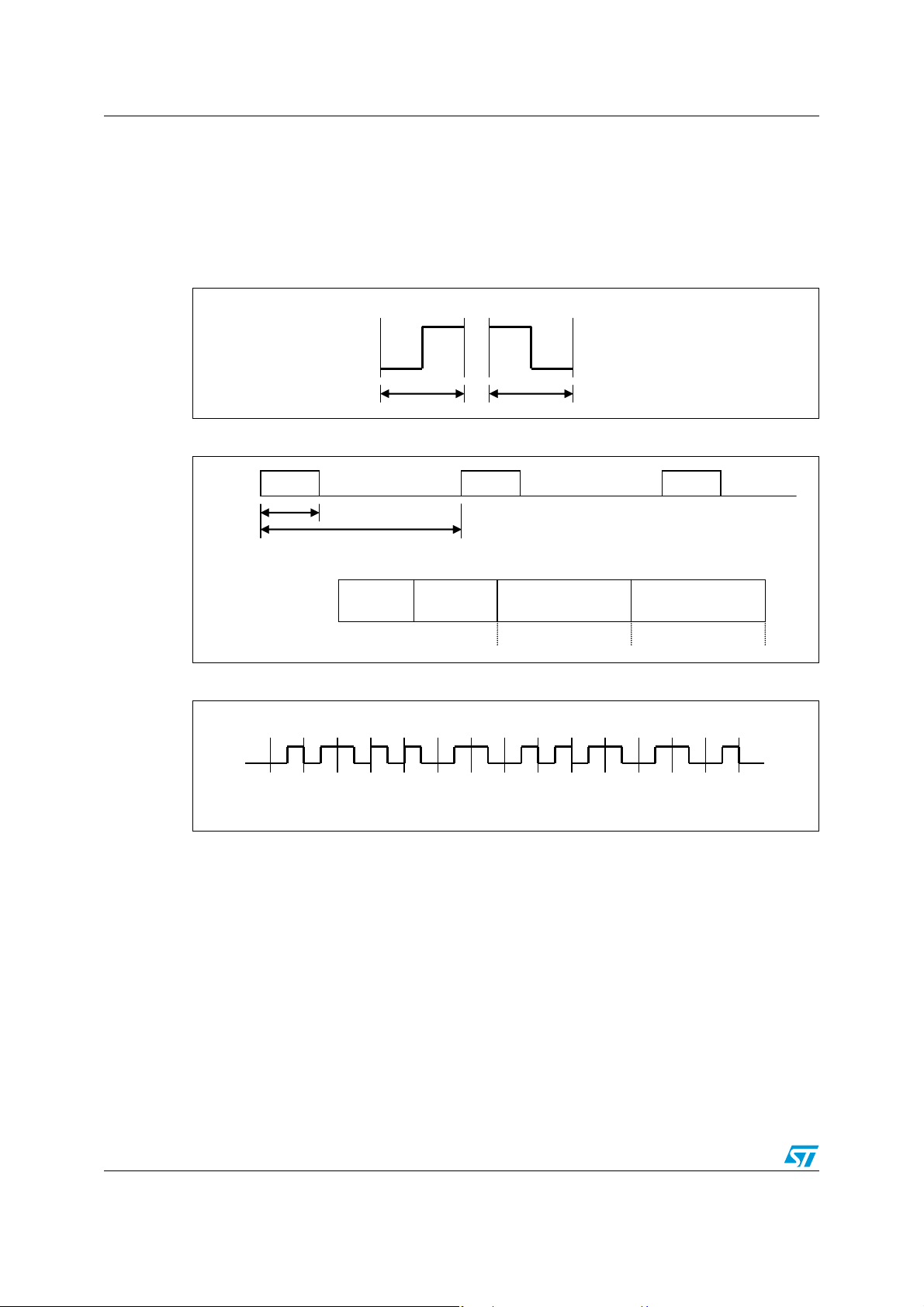

15.3 Philips RC-5 remote control protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

15.3.1 RC-5 data in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

15.3.2 RC-5 data in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

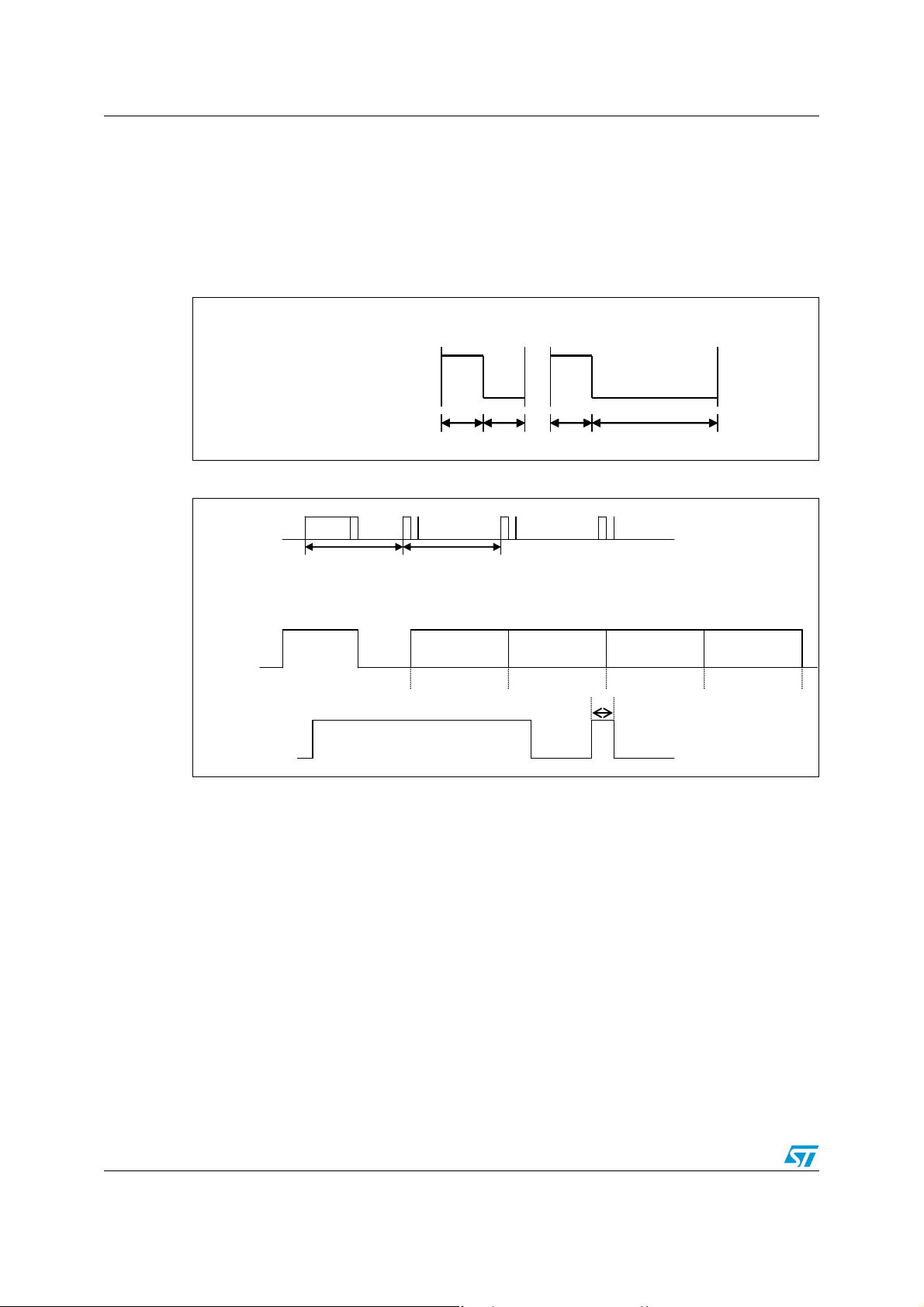

15.4 NEC remote control protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15.4.1 NEC in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

15.4.2 NEC in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

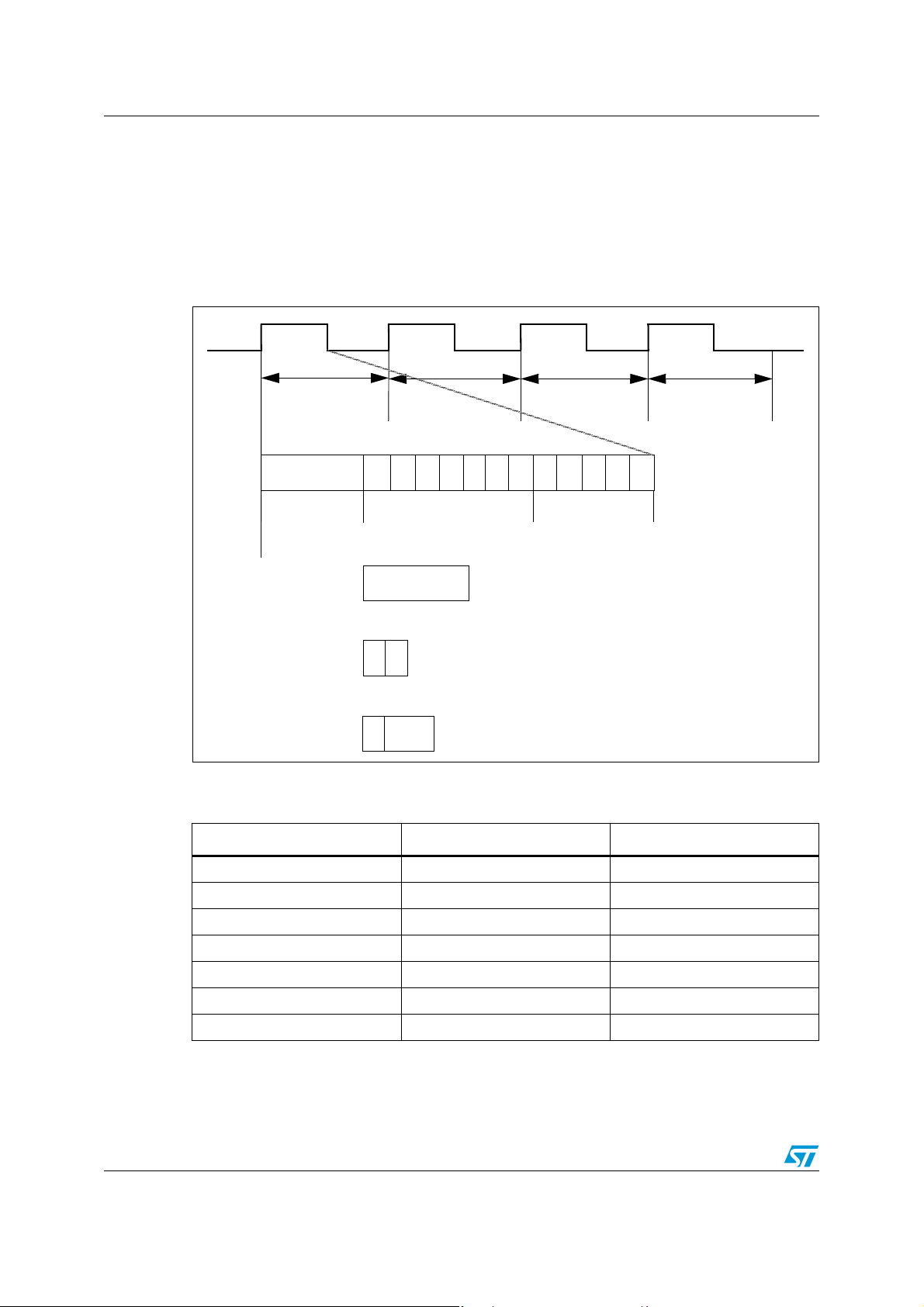

15.5 Sony remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

15.5.1 Sony in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

15.5.2 Sony in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

15.6 Matsushita remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

15.6.1 Matsushita in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

15.6.2 Matsushita in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2

C interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15.7 R2000 remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

15.7.1 R2000 in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15.7.2 R2000 in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15.8 RCA remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

15.8.1 RCA in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

15.8.2 RCA in RAW format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

16 Serial communication format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

17 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

17.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

17.2 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

17.3 Power consumption estimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

17.4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

17.5 Crystal electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

17.6 Oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

17.7 Timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

17.8 Switching characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

18 STFPC320 typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4/78

Page 5

STFPC320 Contents

19 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

20 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5/78

Page 6

List of tables STFPC320

List of tables

Table 1. Device summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3. Default state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 4. Register table for RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 5. Alarm repeat modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 6. Square wave output frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 7. Century bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 8. Initial power-on default values of the registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9. Data write command. b5 b4: 00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10. Data read 1 command. b5 b4: 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 11. Data read 2 command. b5 b4: 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 12. Display RAM address and display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 13. Sony remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 14. Matsushita remote control format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 15. Absolute maximum ratings (TA = 25°C, GND = 0 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 16. Recommended operating conditions (T

Table 17. Electrical specifications

(T

= -20 to +70 °C, VDD = 3.3 V, GND = 0 V, VSS = VDD – 33.3 V)70

A

Table 18. Crystal electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 19. Oscillator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 20. Switching characterist ics

(T

= -20 to +70 °C, VDD = 3.3V, VSS = -30V)73

Table 21. Switching characterist ics (T

A

= -20 to +70 °C, VDD = 3.3V, VSS = -30V) . . . . . . . . . . . . . . 73

A

Table 22. PQFP52 (10 x 10 x 2 mm) mechanical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 23. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

= -20 to +70°C, GND = 0V) . . . . . . . . . . . . . . . . 68

A

6/78

Page 7

STFPC320 List of figures

List of figures

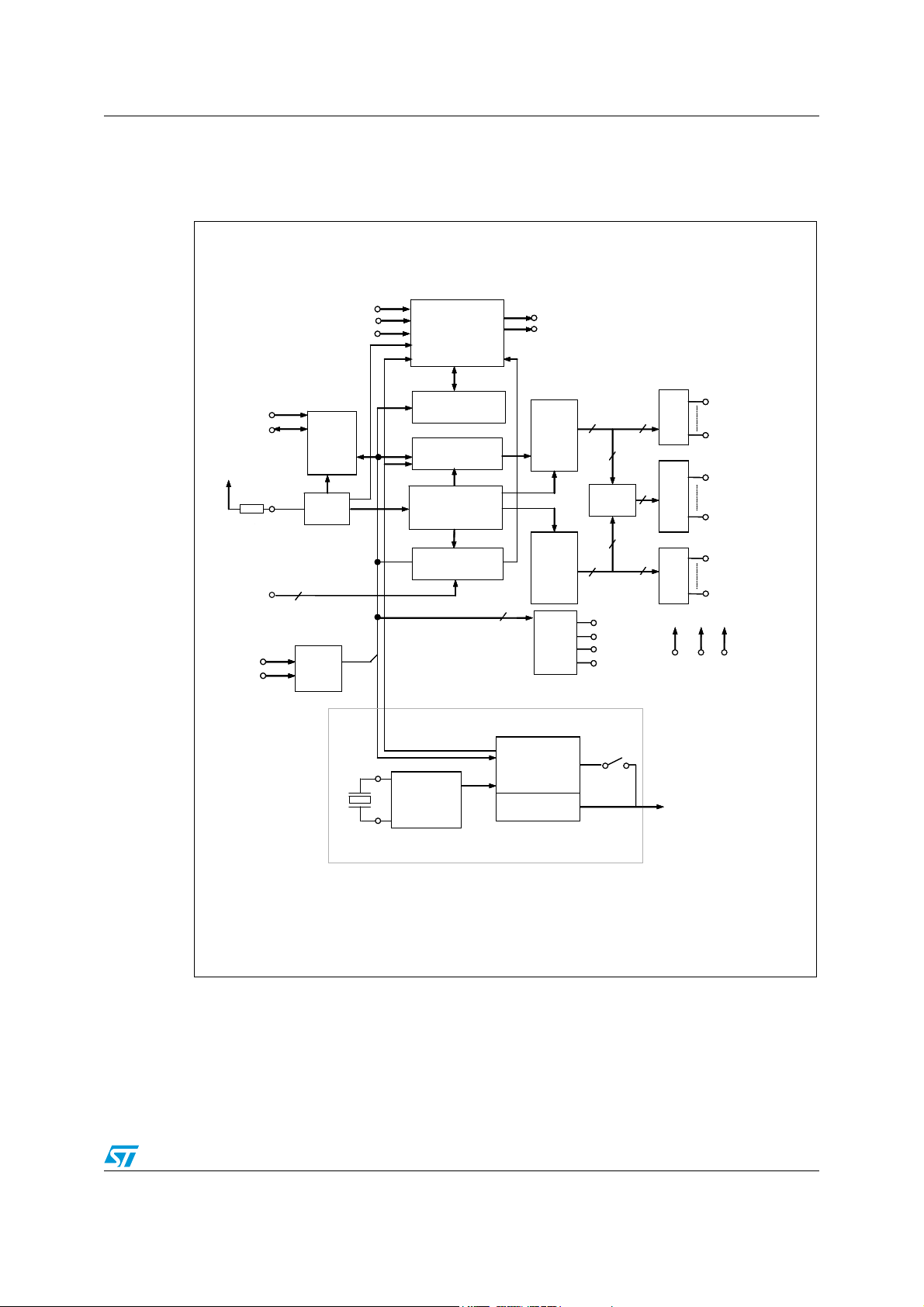

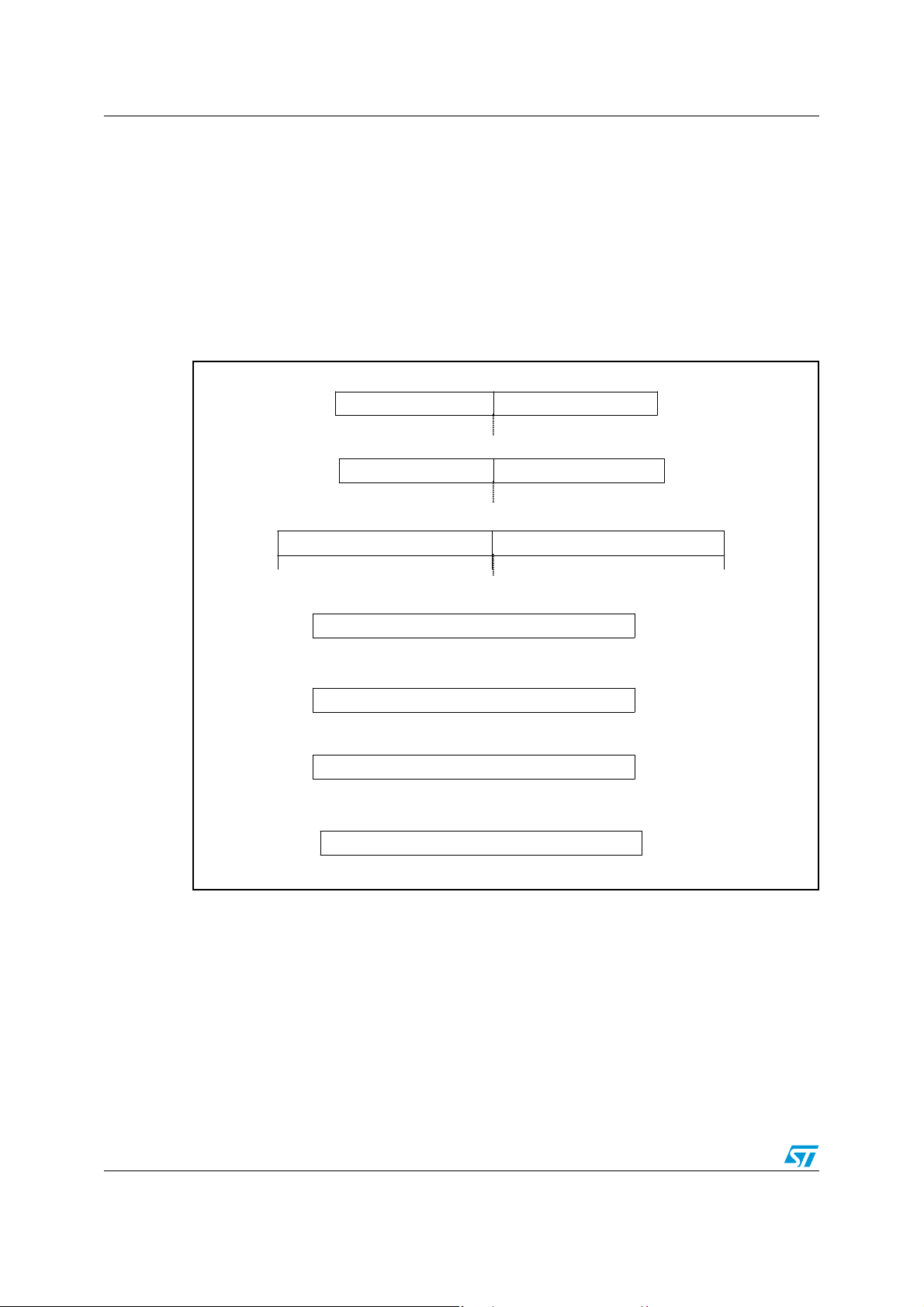

Figure 1. STFPC320 block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

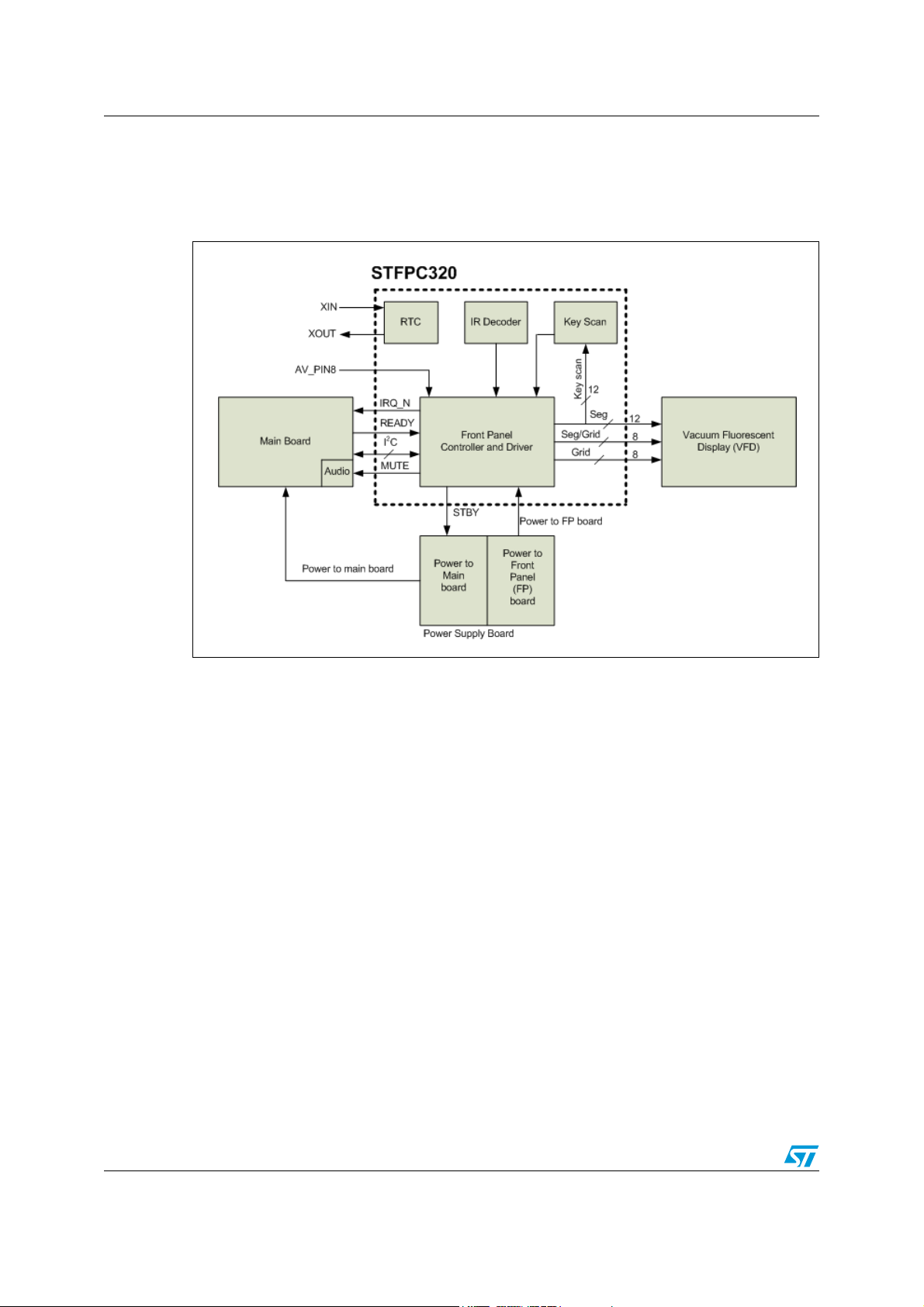

Figure 2. Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

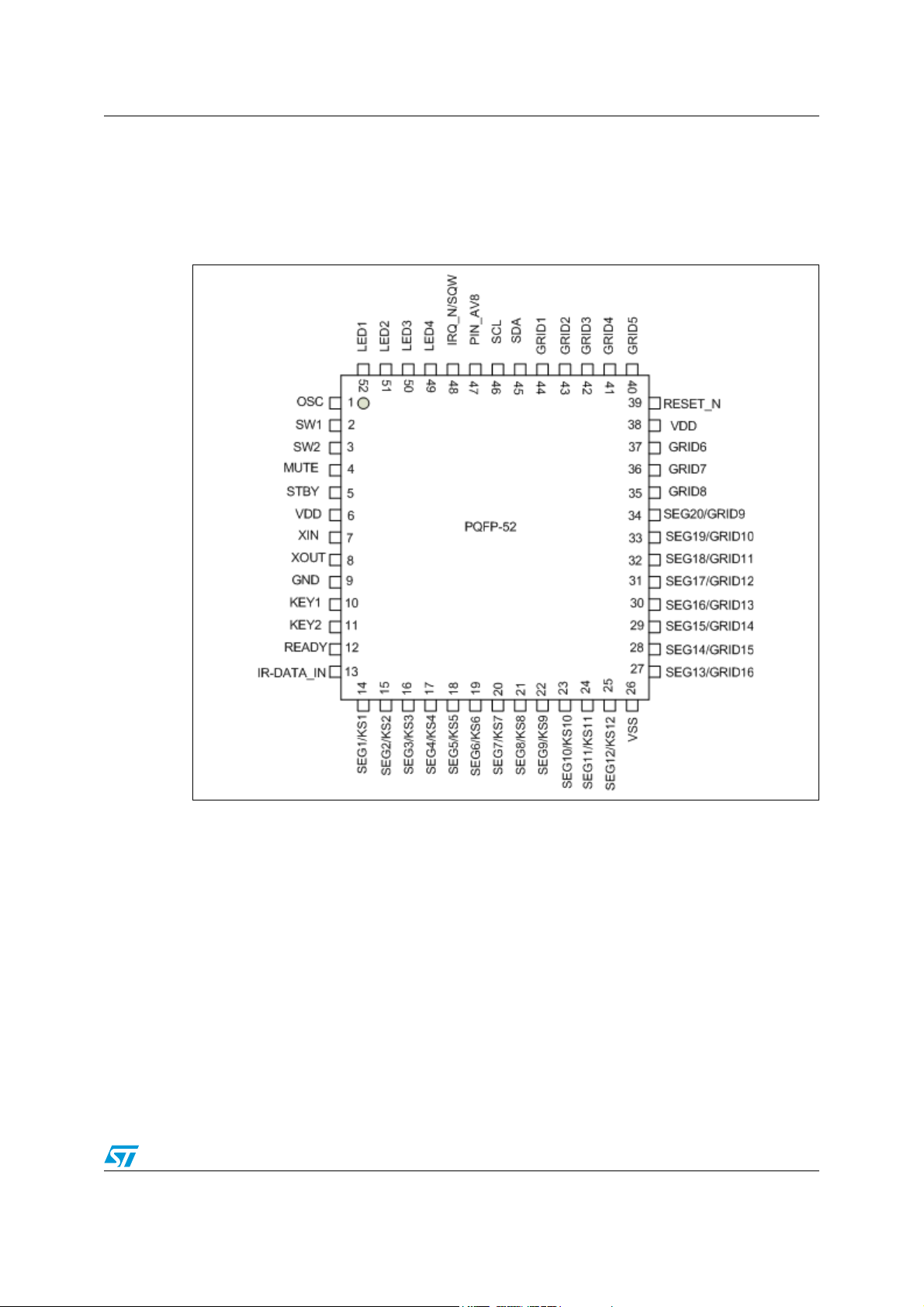

Figure 3. Pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Power-up behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 5. Standby mode behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 6. Wake-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Interrupts/events handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

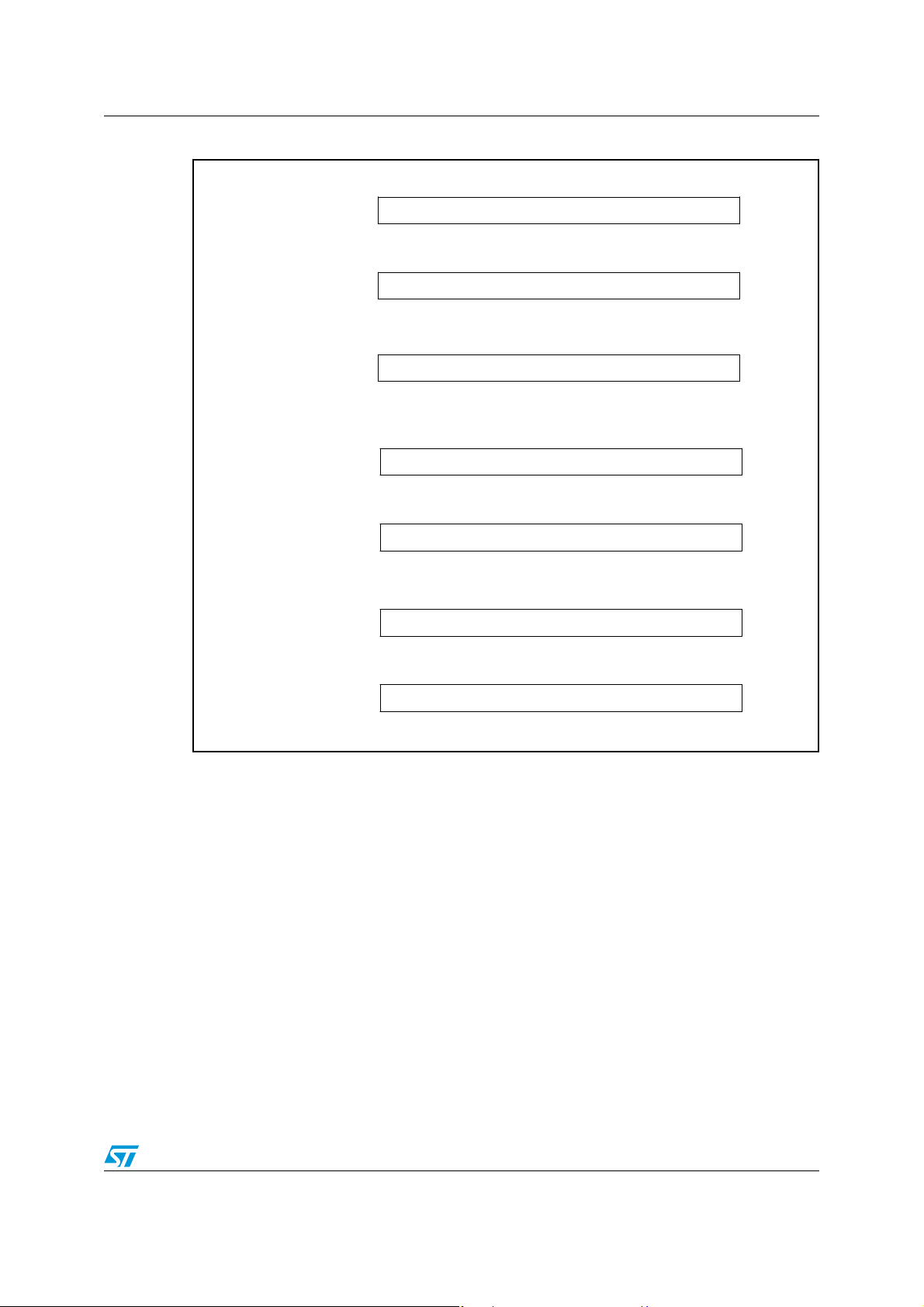

Figure 8. Operating state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

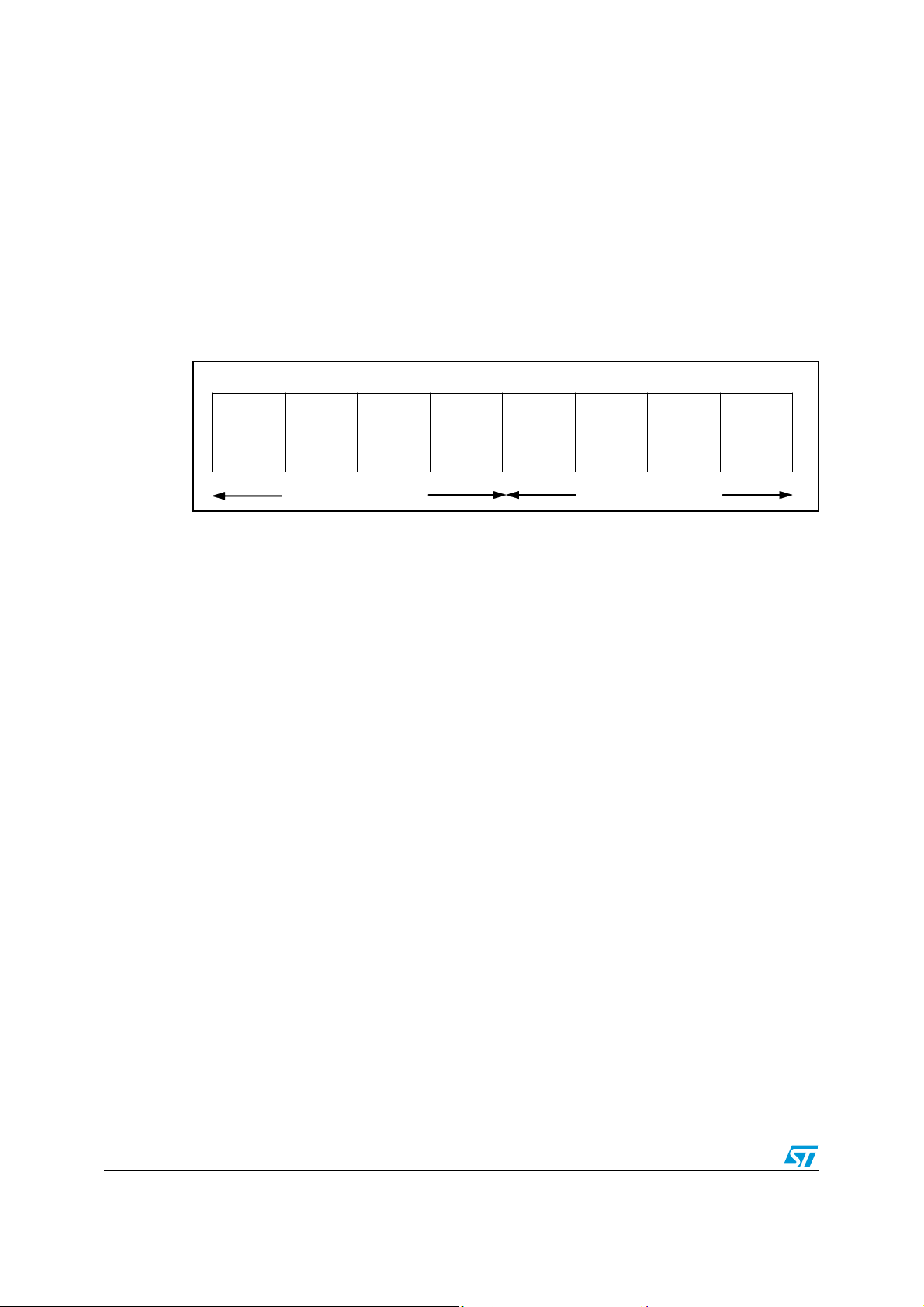

Figure 9. Serial bus data transfer sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2

Figure 10. Acknowledgement sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

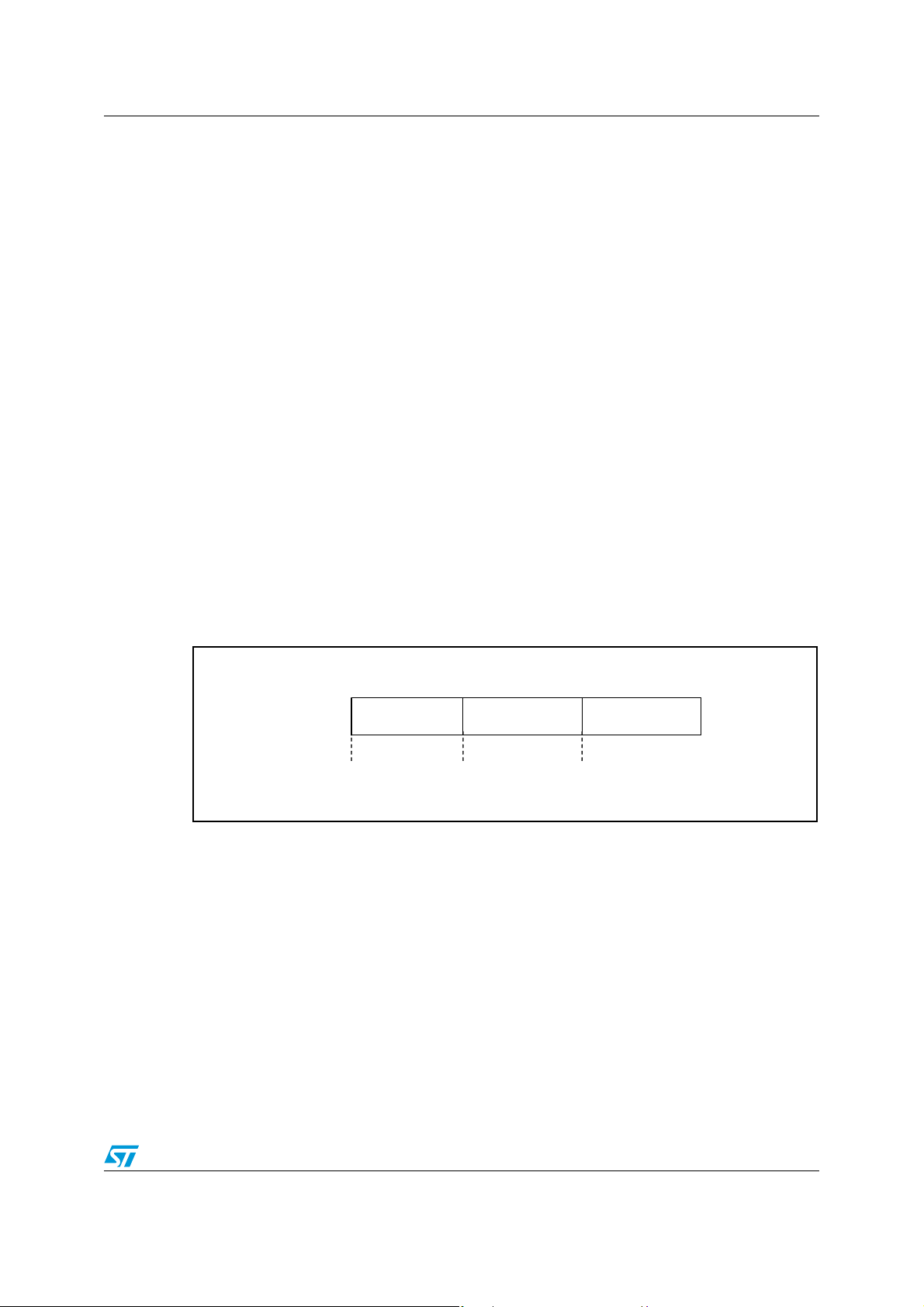

Figure 11. Alarm interrupt reset waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12. Crystal accuracy across temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13. Calibrating waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

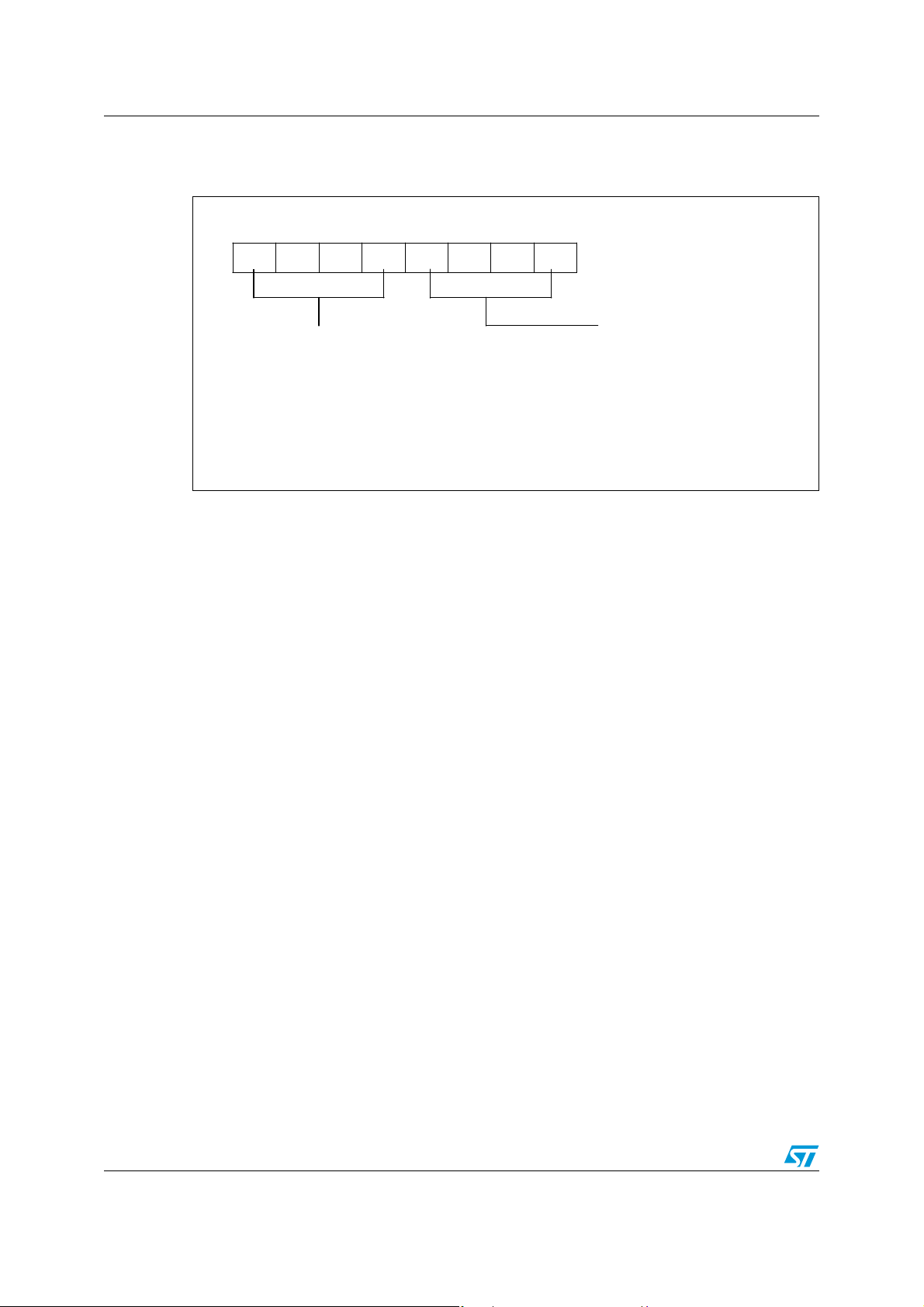

Figure 14. First byte format after configuration byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 15. Second byte format after configuration byte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 16. 14-segment + dotpoint display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 17. Front panel hotkeys configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 18. Key matrix and key-input data storage RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 19. LED byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 20. LED byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 21. Configuration data bytes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 22. Configuration data bytes (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 23. Interrupt byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 24. IR data format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 25. Bi-phase coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 26. RC-5 protocol frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 27. Example of RC-5 transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 28. RC-5 data structure in decoded format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 29. RC-5 data structure in raw format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 30. Pulse distance modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 31. The transmitted waveform for NEC protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 32. NEC data structure in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 33. NEC data structure in raw format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 34. Output code waveform timing definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 35. Sony data structure in decoded format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 36. Sony data structure in raw format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 37. Matsushita remote control protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 38. Matsushita data structure in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 39. Matsushita data structure in raw format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 40. Thomson R2000 remote control protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 41. R2000 data structure in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 42. R2000 data structure in raw format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 43. Thomson RCA remote control protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 44. RCA data structure in decoded format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 45. RCA data structure in raw format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 46. Complete data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 47. Valid data changes on the SDA bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 48. Valid start and stop conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7/78

Page 8

List of figures STFPC320

Figure 49. Acknowledge response from receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 50. Bus timing requirements sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 51. Slave address location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 52. Read mode sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 53. Alternative READ mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 54. WRITE mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

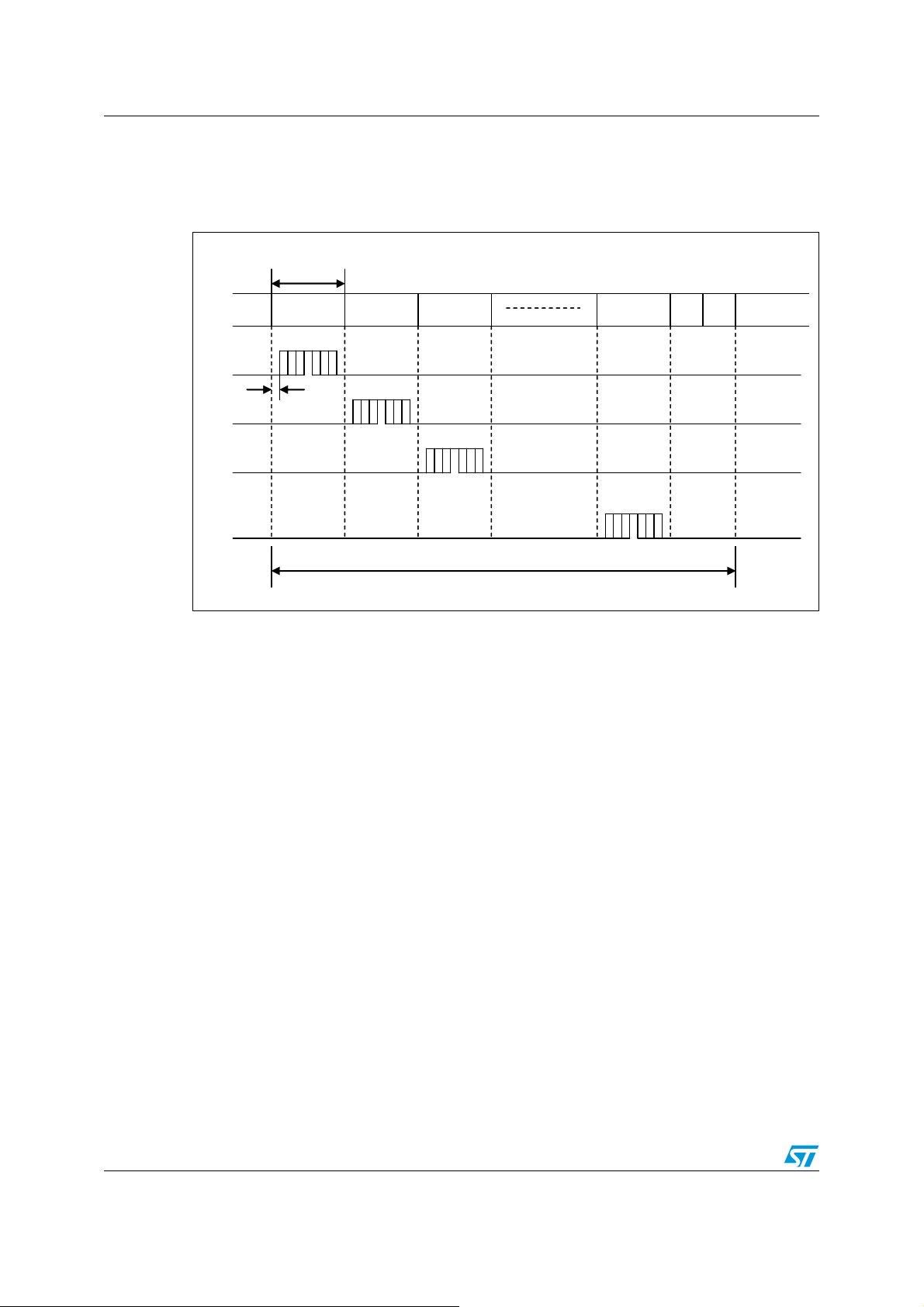

Figure 55. Key scanning and display timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 56. Typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 57. PQFP52L package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8/78

Page 9

STFPC320 Device block diagram

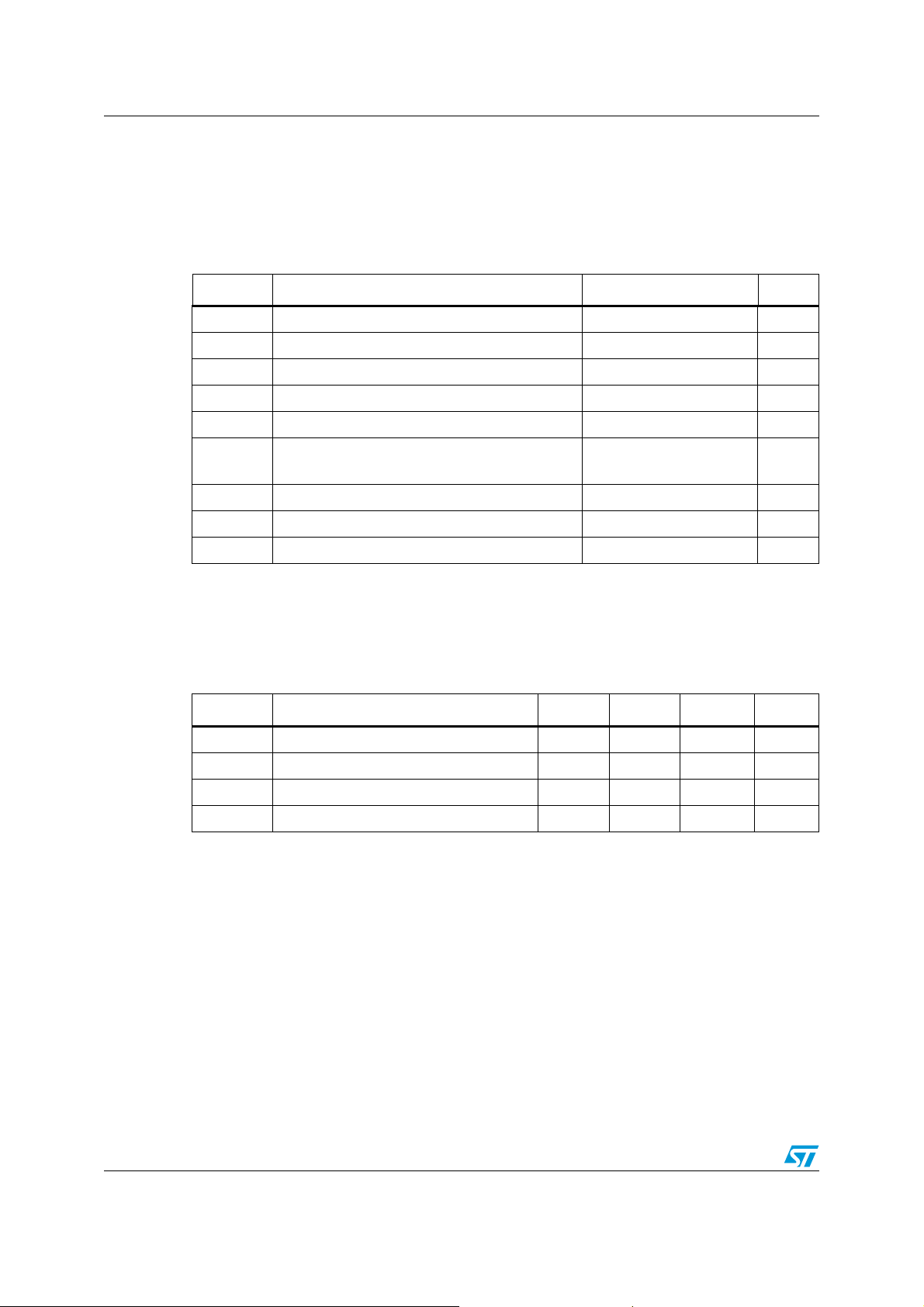

1 Device block diagram

Figure 1. STFPC320 block diagram

IR_DATA_IN

VDD

VDD

SW1

SW1

SW2

SW2

SCL

SCL

SDA

SDA

R

R

Key1

Key1

Key2

Key2

IR_DATA_IN

Serial

Serial

OSC

OSC

2

2

2-bit

2-bit

Latc h

Latc h

READY

READY

PIN_AV8

PIN_AV8

I2C

I2C

I/F

I/F

Remote Control

Remote Control

Decoder & Stand

Decoder & Stand

By Function

By Function

Command Decoder

Command Decoder

Display Memory

Display Memory

(20 x 16)

(20 x 16)

Timing Generator

Timing Generator

Key Scan and

Key Scan and

Dimming Circuit

Dimming Circuit

Key Data Mem ory

Key Data Mem ory

(2 x 12)

(2 x 12)

32 KHz

32 KHz

oscillator

oscillator

MUTE

MUTE

STBY

STBY

20-bit

20-bit

Output

Output

Latc h

Latc h

16-bit

16-bit

Shift

Shift

Register

Register

4

4

4-bit

4-bit

Latch

Latch

Real-time Clock

Real-time Clock

Real-time Clock

Real-time Clock

Calendar

Calendar

RTC wit h Alarm

RTC wit h Alarm

& Calibrat ion

& Calibrat ion

Watchdog

Watchdog

20 12

20 12

8

8

Data

Data

Selector

Selector

8

8

16

16

LED1

LED1

LED2

LED2

LED3

LED3

LED4

LED4

AFE

AFE

8

8

8

8

Drivers

Drivers

Segment

Segment

Drivers

Drivers

Multiplexed

Multiplexed

Grid

Grid

Drivers

Drivers

VDD

VDD

(+3.3V)

(+3.3V)

IRQ_N/SQW

IRQ_N/SQW

SEG1/KS1

SEG1/KS1

SEG12/KS12

SEG12/KS12

SEG13/GRID16

SEG13/GRID16

SEG20/GRID9

SEG20/GRID9

GRID8

GRID8

GRID1

GRID1

GND

GND

(0V)

(0V)

(-30V)

(-30V)

VSS

VSS

9/78

Page 10

Functional diagram STFPC320

2 Functional diagram

Figure 2. Functional diagram

10/78

Page 11

STFPC320 Pin settings

3 Pin settings

3.1 Pin connection

Figure 3. Pin connection (top view)

Note: For a description of each pin behaviour, please refer to the STFPC320 Table 2: Pin

description on page 12

11/78

Page 12

Pin settings STFPC320

3.2 Pin description

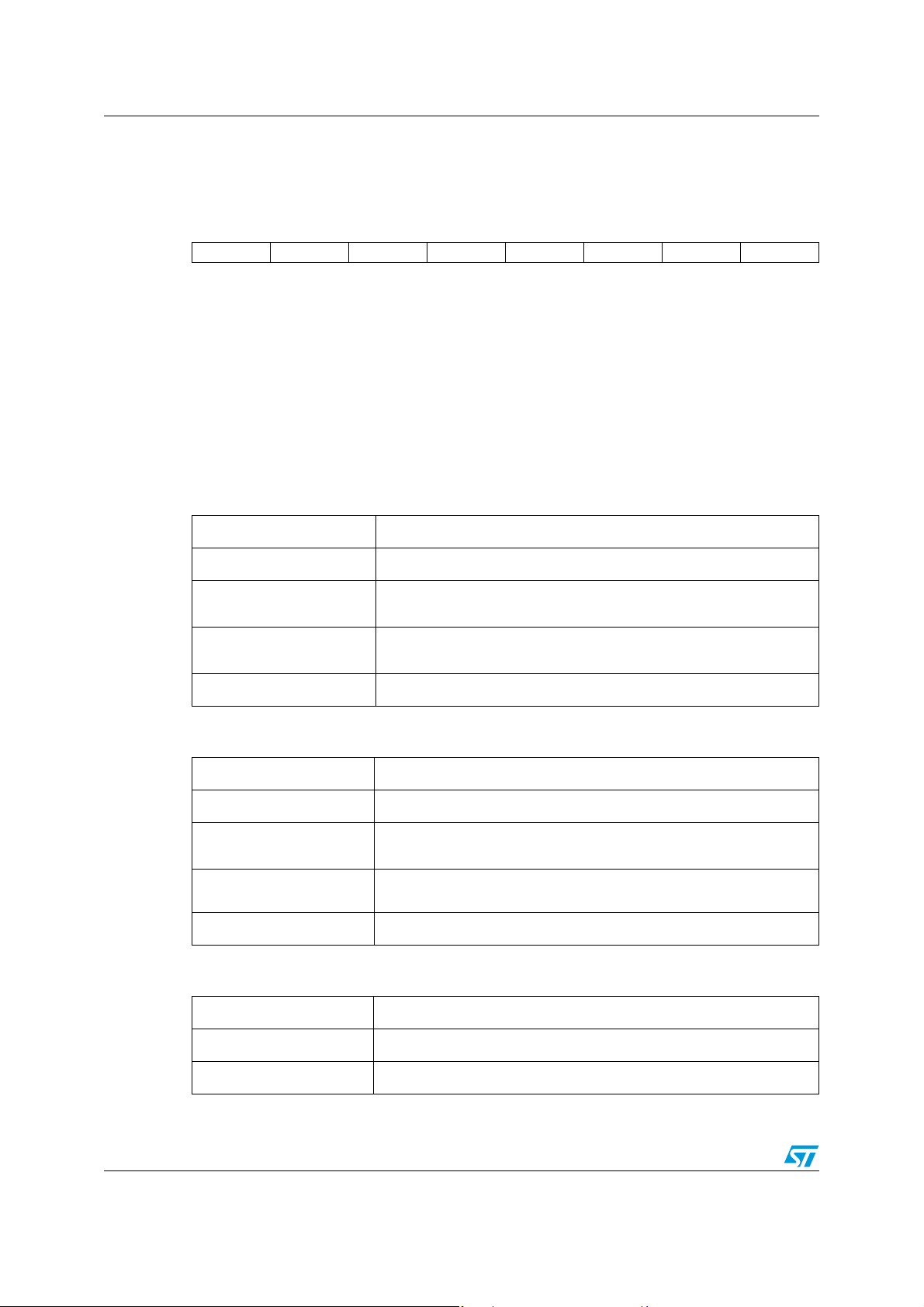

Table 2. Pin description

Pin N° Name Type Description

1 OSC IN Connect to an external resistor of value 33 kΩ ± 1%

2 SW1 IN General purpose switch input port.

3 SW2 IN General purpose switch input port.

4 MUTE OUT

5STBYOUT

6, 38 VDD SUPPLY 3.3 V ± 10%. Core main supply voltage.

7 XIN IN Oscillator input pin. 32.768 KHz crystal.

8 XOUT OUT Oscillator output pin. 32.768 KHz crystal.

9 GND SUPPLY Connect this pin to system GND.

10,11 KEY1, KEY2 IN

12 READY IN

13 IR_DATA_IN IN Remote control input. Connect to IR photodiode.

14 to 25

26 VSS SUPPLY VFD outputs high voltage pull-down level. VDD- 33.3 V max.

27 to 34

35-37 GRID8 to GRID6 OUT Grid output pins.

39 RESET_N IN Active low reset input.

SEG1/KS1 to

SEG12/KS12

SEG13/GRID16

to SEG20/GRID9

OUT Segment output pins (dual function as key source).

OUT These pins are selectable for segment or grid driving.

High level means mute status for audio.

Low level stands for normal working.

Pin to control power to the main board. High level means standby status.

Low level stands for normal working. Active high.

Input data to these pins from external keyboard are latched at end of the

display cycle (maximum keyboard size is 12 x 2).

High level on this pin means that main board chip has been working

normally. Connect an external pull down resistor of 10kΩ on this pin.

40-44 GRID5 to GRID1 OUT Grid output pins.

45 SDA IN/OUT Serial data in/out. Connect to 3.3 V through an external pull-up resistor.

46 SCL IN Serial clock input. Connect to 3.3 V through an external pull-up resistor.

A rising edge transition on this input will signal wake-up operation. This

47 PIN_AV8 IN

48 IRQ_N/SQW OUT

49, 50,

51, 52

12/78

LED4, LED3,

LED2, LED1

OUT CMOS sink outputs (20 mA max).

signal comes from the SCART interface. The micro processor can use this

signal to start the recording or take other actions.

Interrupt/square wave output (open drain). A pull up resistor of 10 kΩ must

be connected on this pin.

Page 13

STFPC320 Functional description

4 Functional description

The STFPC320 integrates the supply standby management functionality, remote control

decoder, a 2 8-bit VFD driver and a real-time cloc k (R TC). This d e vice is meant to reduce the

standby power consumption of the whole front panel application and also to reduce

hardware/cost by integrating the above mentioned functions in a single chip.

By utilizing the standby function, the host processor and other ICs could be turned off, thus

reducing the system power consumption. The STFPC 32 0 is able to wake-up the system

when programmed hotkeys are detected to signal that the full operation of the system is

required. The hotkeys could be entered to the system through the front panel keys or

through the infrared (IR) remote control. STFPC320 supports multiple remote control

protocols decoding by setting the appropriate register.

The integrated 28-bit VFD driver can drive up to 16 digits of display. Controlling of the

display is done through writing to a internal RAM. The 4 LED drivers allow indication of

operation of the system. 2-wire serial interface (I

host processor and STFPC320.

The STFPC320 integrates a a low-power serial RTC with a built-in 32.768kHz oscillator

(external crystal controlled). Eight bytes of the SRAM are used for the clock/calendar

function and are configured in bin ary coded decimal (BCD) f ormat. An additio nal 12 b ytes of

SRAM provide status/ control of alarm, watchdog and square wave functions. Addresses

and data are transf erred serially via a two line, bidirectional I

address register is incremented automatically after each WRITE or READ data byte.

2

C) completes the interfacing part between

2

C interface. The built-in

Functions available to the user include a non-volatile, time-of-day clock/calendar, alarm

interrupts, watchdog timer a nd progr ammab le Square W a v e output. T he eight cloc k address

locations contain the century, year, month, date, day, hour, minute, second and

tenths/hundredths of a second in 24 hour BCD format. Corrections for 28, 29 (leap year valid until year 2100), 30 and 31 day months are made automatically.

4.1 Reset

Reset is an active low input signal to the STFPC320. A negative pulse input on RESET_N

pin resets the STFPC320. Electrical specifications of this pin are identical to that of the logic

input pin.

Upon power-up, an internal power on reset circuit resets the whole chip. This occurs when

V

is ramping up (at appro xim ately 2.7 V) and the whole chip is initialized within 4 µs. This

DD

time is much lesser than the typical V

RESET_N pin permanently by a pull-up resistor to V

during normal operation. For an initia lization on po wer-up, a power-on-reset in STFPC320 is

sufficient to reset the entire STFPC320.

As soon as the 3.3 V supply to the chip is stable, the I

communication.

ramp-up time. It is recommended to tie the

DD

if reset to STFPC320 is not desired

DD

2

C bus of the STFPC320 is ready for

13/78

Page 14

Functional description STFPC320

4.2 Cold boot up

When power is first applied to the system, the STFPC320 will be reset. It will then manage

the power to the main board by bringing the STBY pin to a low level. This will wake-up the

main processor which will assert the READY pin to a high lev el to indicate to STFPC320 of a

proper boot-up sequence.

If the microprocessor does not assert the READY pin to a high within 10s, the STFPC320

will cut off the power to the Host by asserting the STBY pin. The high level on READY pin

signifies that the processor is ready. After this, the processor can configure the STFPC320

by sending the v arious I

mapping, hot-keys.

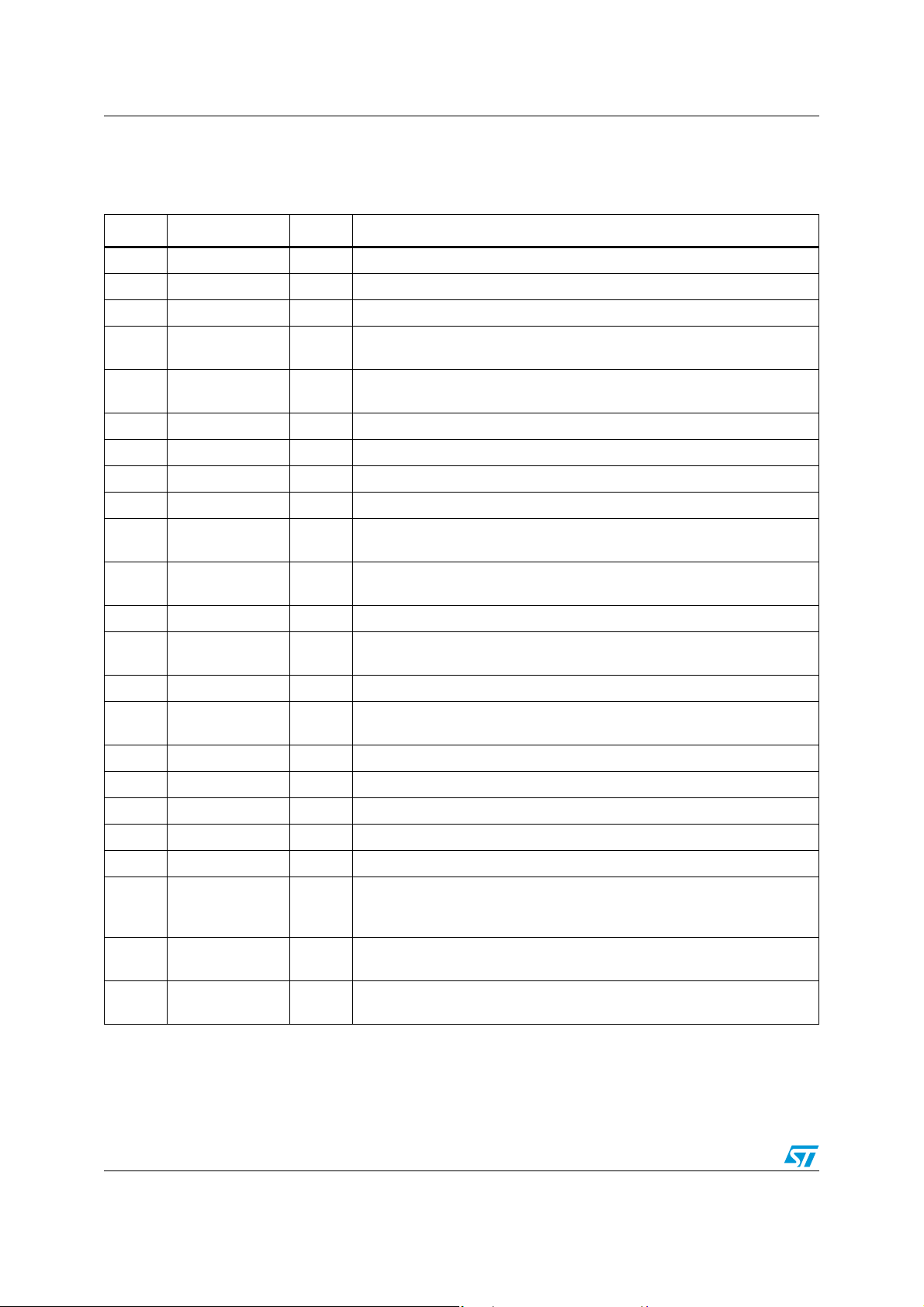

The power-up behavior in 2 conditions is shown in the Figure 4.

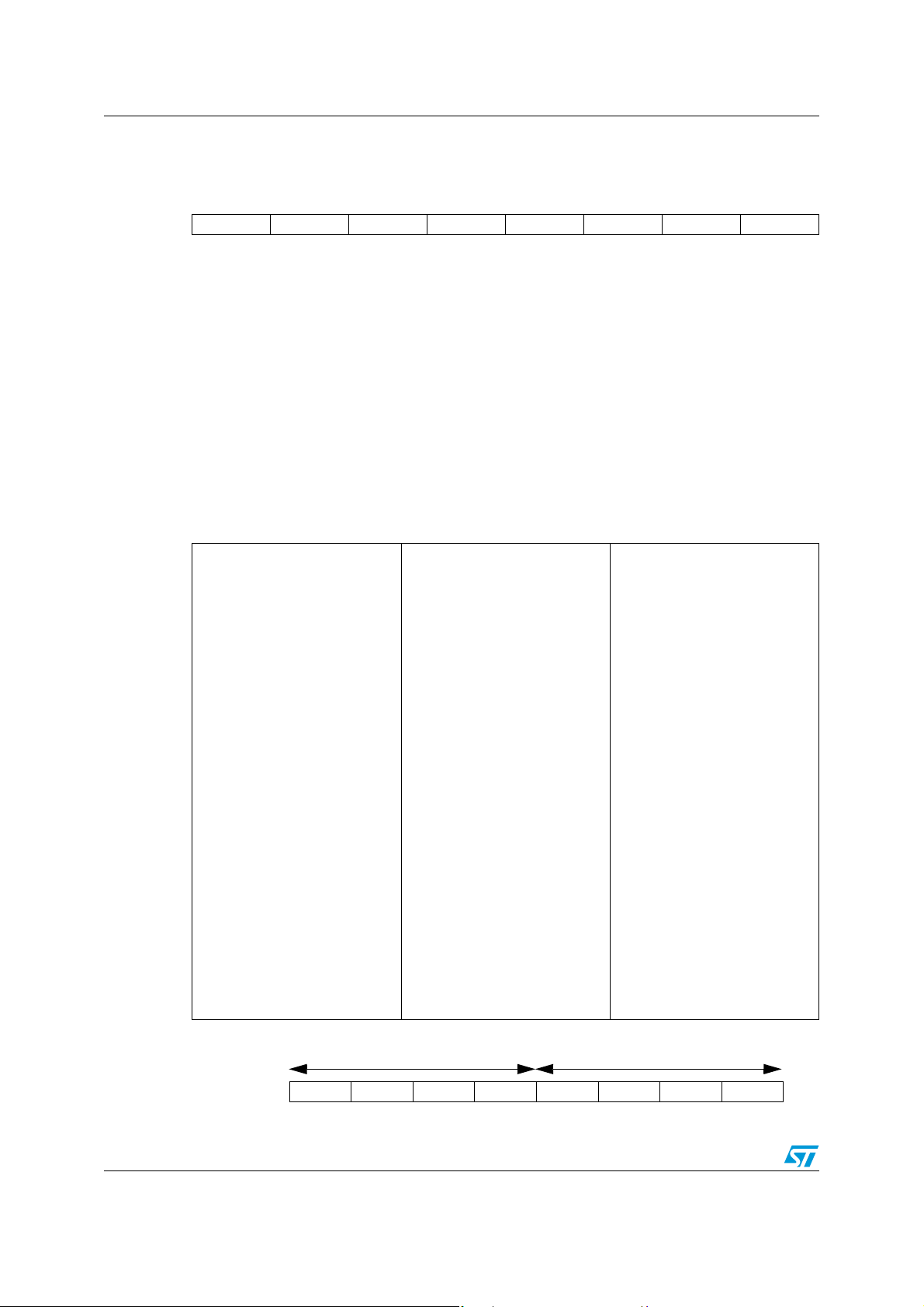

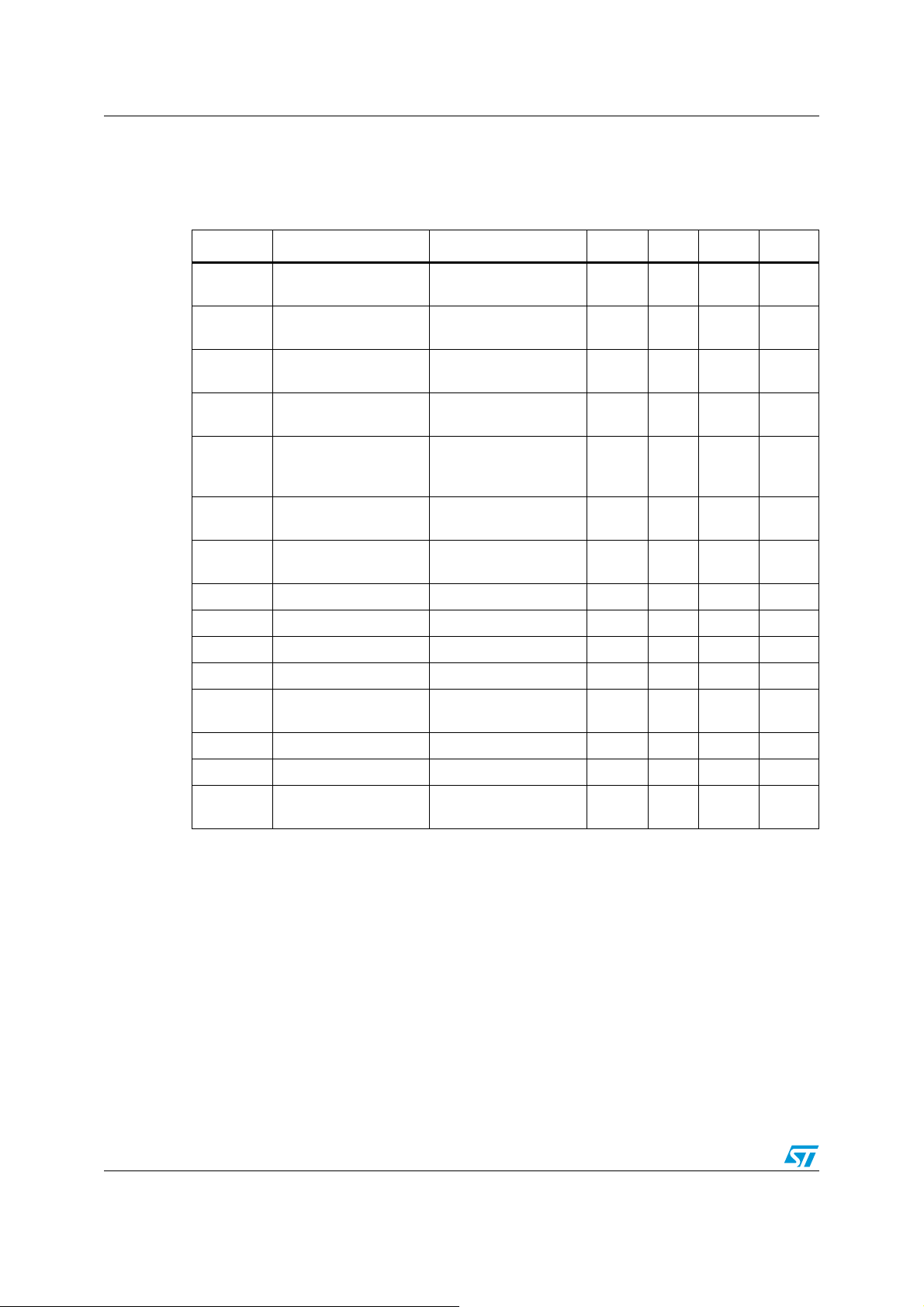

Figure 4. Power-up behaviour

2

C commands for configuration o f displa y, RC protocol, R TC displa y

Note: 1 Guard timer is turned off by default upon READY assertion.

2 If the guard timer is to be kept on during READY high condition, the guard timer registers

must be set accordingly by proper commands through I

2

C bus.

3 In this power-up condition, the guard timer is triggered by internal POR pulse.

4 During power-up, the guard timer value is 10s.

14/78

Page 15

STFPC320 Functional description

4.3 Entering standby mode

The STFPC320 will control the power to the main board using the STBY pin. During normal

operation, the STBY pin is at a low level which externally controls a power MOS switch to

enable power to the main board. The STFPC320 asserts the STBY pin to a high when any

one of the following condit ions occur:

● Processor fails to respond by enabling the READY pin within 10 s upon first power-up

(cold boot up)

● Guard timer counts down to 0 s

● Processor makes the READY pin to low (can happen in various conditions, such as

user presses STBY key on front panel, STBY key on remote control, etc.)

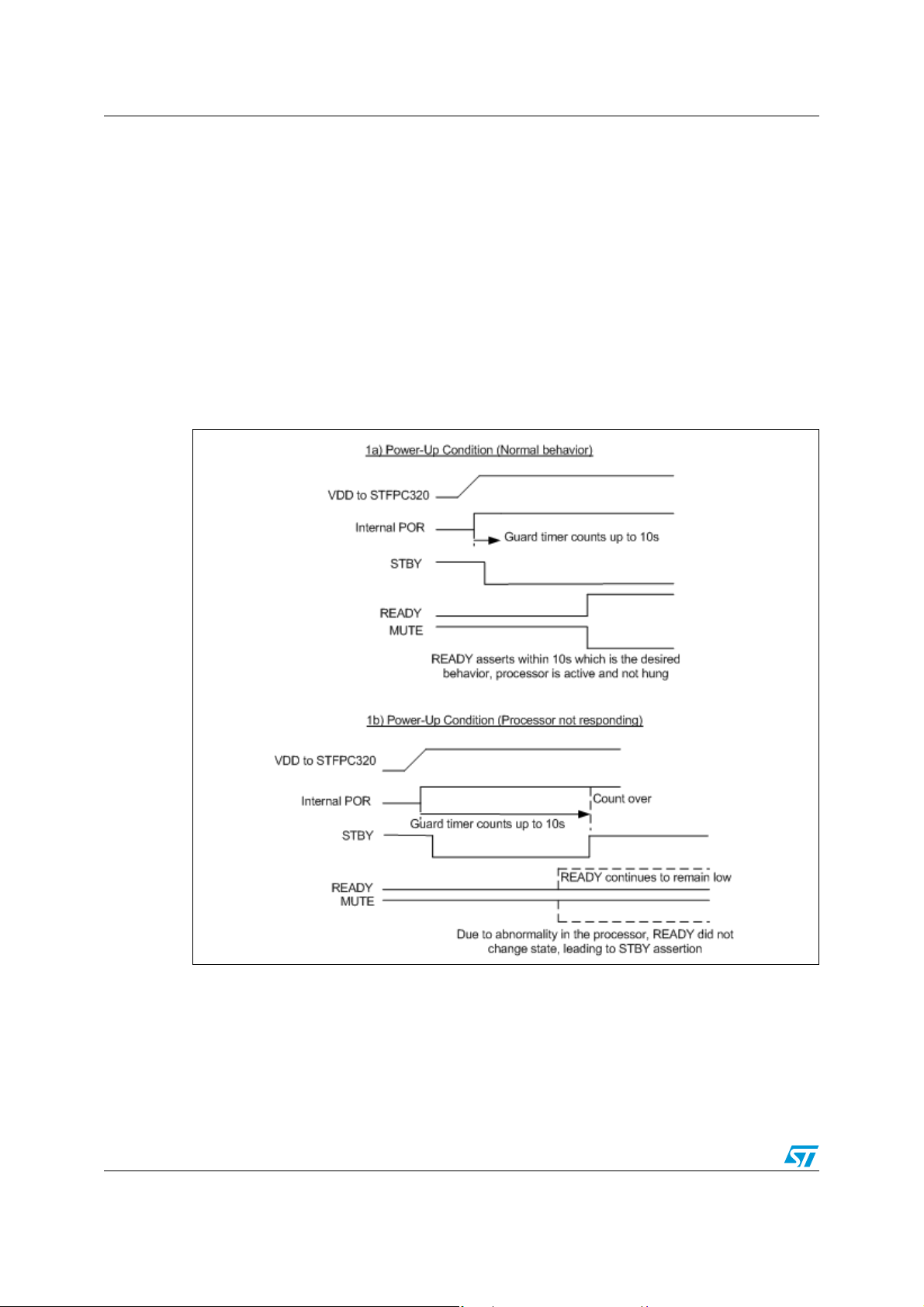

Figure 5. Standby mode behaviour

Note: 1 Guard timer can be kept on during normal condition when READY is high (depending on the

user).

2 In this condition, the guard timer can be disabled or enabled. If the guard timer is enabled,

the timer needs to be cleared before the programmed count o f the timer is reached. If the

programmed count is reached, the STBY will be asserted.

3 It is advisable not to enable the guard timer during normal operation.

15/78

Page 16

Functional description STFPC320

4.4 Wake-up

The STFPC320 can wake-up f rom any one of the fo llowing sources:

● Front-panel keys

● Remote-control keys

● Real-time clock (RTC) in 3 conditions (alarm, watchdog timer, oscillator fail)

● External pin PIN_AV8 (only by a low-to-high transition on this pin)

Figure 6. Wake-up

Note: 1 When the hot-key is detect ed either fr om front-pane l or remote cont rol or RTC or from a low-

to-high transition on PIN_AV8 pin during standby, the STBY pin de-asserts.

2 The de-assertion of the STBY triggers the guard timer.

3 The timer value is the progr am med value by the user (1-1 5s). If t he u ser did not chan ge the

value before entering standby, then it remains 10s.

4 Also note that the guard timer is off when the STFPC320 is in the standby mode.

Guard timer is thus triggered by a de-assertion of the STBY signal or by internal power on

reset signal.

16/78

Page 17

STFPC320 Functional description

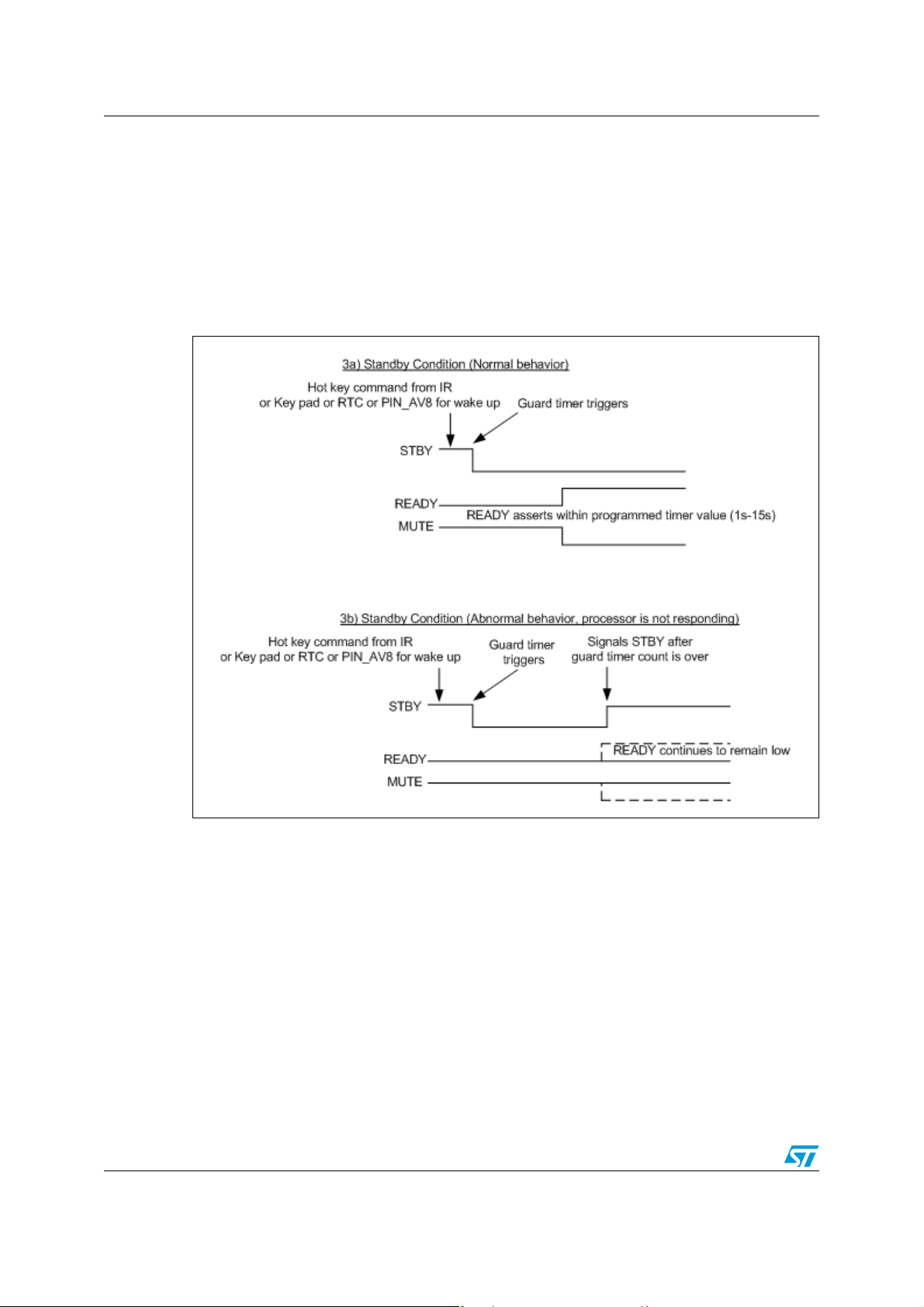

4.5 Interrupts/events handling by STFPC320

The STFPC320 interrupts the Host by pulling the IRQ_N/SQW pin to a low-level both in

normal mode of operation and during wak e-up . The int errupt is enable d by ST FPC320 when

any of the conditions occur:

● Front panel key press in normal operation or during system standb y state

● Remote control key press in normal operation or during system standby state

● A low-to-high transition on the external pin, PIN_AV8

● Real-time clock triggers (alarm, watchdog timer, oscillator fail)

The IRQ_N/SQW is an active low level signal and is cleared only after the interrupt b u ffer is

read. After reading the interrupt buffer, the Host will know the actual source of the interrupt.

This allows the Host to exact ly kno w the event which caused the interrupt (e.g STBY key on

the front panel). The interrupt signal is used to inf orm the Host of any events detected by the

STFPC320. Note that the IRQ_N/SQW pin is an open-drain pin which requires an external

pull-up resistor.

Figure 7. Interrupts/events handling

4.6 Ready pin

The STFPC320 supports cutting-off power to the main board for standby operation for good

power management. STBY will be set to high when the READY transitions from high to low.

During a cold boot up or wakeup from standby, if the READY pin stays low, the STFPC320

will assert the STBY when the guard timer has finished counting down to 0.

When the READY drops to a low, MUTE goes high immediately and soon after (2 µs) the

STBY is asserted.

In the normal mode of operation, when READY is a high, the STBY is asserted only when

the guard timer is enabled and has finished counting down to 0. This is meant to put the

system into standby as the READY pin was stuck at high and the guard timer regi ster was

not cleared before it finished counting down to 0. It is advised to disable the guard timer

during normal operation.

17/78

Page 18

Functional description STFPC320

4.7 Mute pin

The MUTE pin is set to logic high to mute the audio output before power is cut to the host

processor. In wakeup mode, the MUTE pin is set to logic low to enable the audio output

immediately after the high assertion of the READY pin. In general, MUTE f ollows READY pin

with an inverted polarity. This pin is used to prevent pop-up sound during power-up and

power-down states.

4.8 Keyscan matrix/front panel keys

The key scan matrix on the STFPC320 helps to pass command from the front panel to the

host processor through the SDA pin on STFPC320. The STFPC320 can be prog r a mme d to

wake-up the system from standby using any of the 24 keys pressed on the front panel.

These wake-up keys are also referred to as hot-keys.

4.9 LED ports

4 LED displays are supported by the STFPC320. Turning on or off of the LED is done by

issuing write command to the LED port. After reset, the LEDs are off. Note that the LED

outputs sink the current, so the cathode of the diode must be connected to the LED pins of

STFPC320.

4.10 Display

The display is divided into two sections, Normal and real-time clock (RTC).

4.10.1 Normal display

The VFD display is configurable for displays from 8 digits/20 segments to 16 digits/12

segments. The VFD displa y can be configured to be eith er in the normal VFD mode or in the

RTC mode. In the normal VFD mode, the display shows whatever is written in the VFD

display memory.

If the user desires to show normal display simultaneously with the RTC, then CPU must

read the time of RTC display memory and then write all the data to be displayed to the

normal display memory. After writing the values to the display memory, a display-on

command will show both the normal and RTC display on the front panel.

On first power on, the default configuration is 16-digit, 12-segment mode (with display

turned OFF).

4.10.2 RTC display

In RTC mode, th e display can be configured to show the time in two modes, either by dire ct

mapping of RTC to t he display or by using the CPU. If CPU is used, the CPU reads th e R T C

value from RTC registers and then writes the time to be displayed in the RTC display

memory.

18/78

Page 19

STFPC320 Functional description

4.11 Remote control decoder

Remote control (RC) decoder module decodes the signal coming from IR_DATA_IN. The list

of IR remote control protocols recognized by STFPC320 is Philips RC-5, SONY, NEC,

Thomson-RCA, Thomson-R2000 and Matsushita. The selection of remote control protocol

to use is done by setting the RC Protocols register. The commands from RC is used to

wake-up from standb y and resume n ormal operation. All RC ke ys can be pro grammed t o act

like RC hotkeys. Upon receiving any one of the designated hotkeys, wake-up operation will

begin.

4.12 PIN_AV8

External device (e.g. set-top box) could pull this pin high to wake-up the system. A low-to-

high transition on this pin will signal the STPFC320 to wake-up and provide power to the

system. This signal is considered high when it is in the range of 2.5 - 3.6 V (proper voltage

division must be done externally so that the STFPC320 PIN_ AV8 sees no more than 3.6 V).

No action is taken on the high-to-low transition on PIN_AV8. Also when the pin is already a

high, the current state of the system is maintained and it does not trigger anything.

4.13 Default state upon power-up

The Table 3 below shows the default state of the STFPC320 upon power-up.

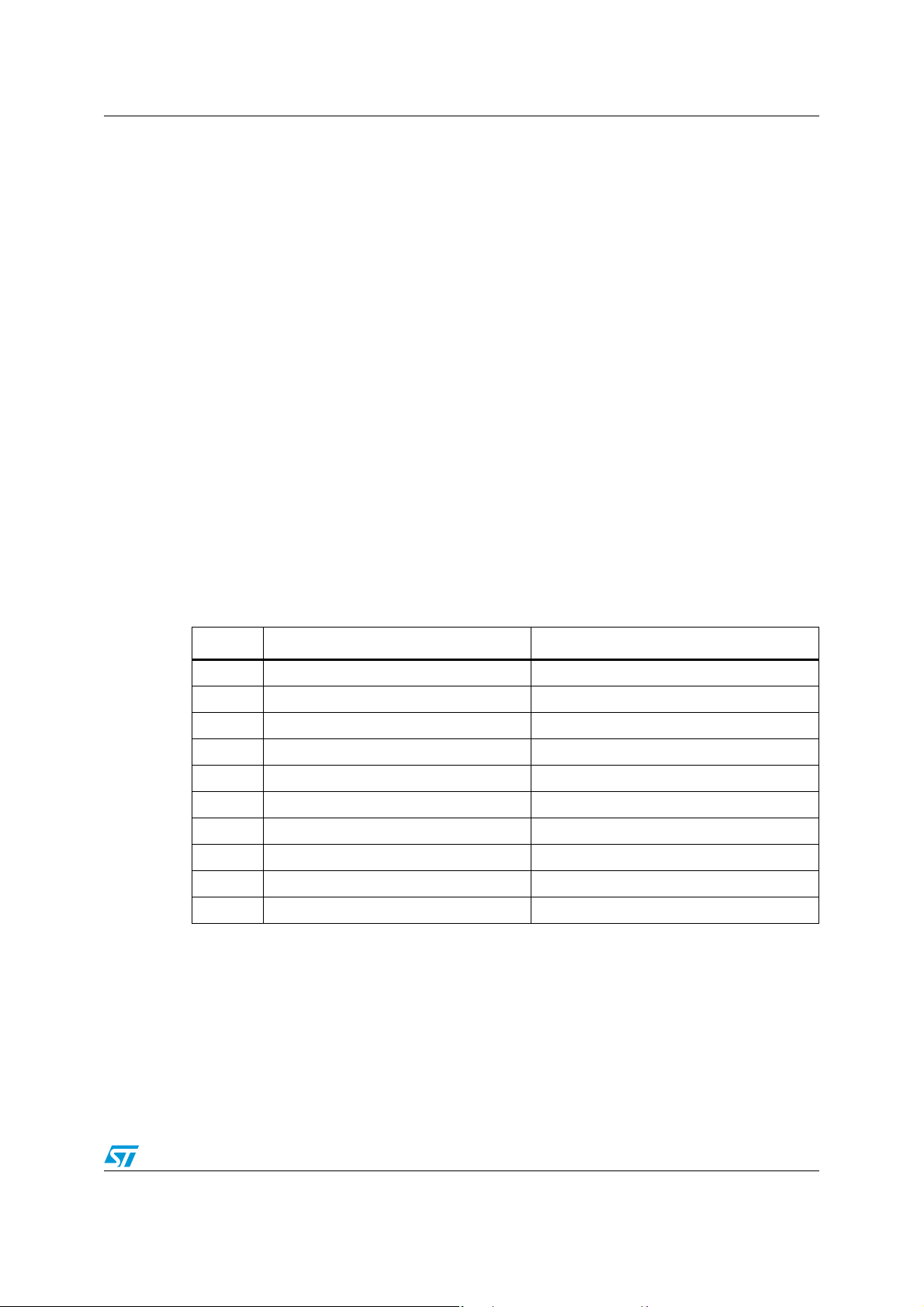

Table 3. Default state

S.No. Functions Default state

1 Display OFF

2Key-scan ON

3 IR (Remote Control) ON

4 Display mode 12 segment/16 digit

5 Display address 10H with Address increment mode

6 RC protocol RC-5 (Raw format)

7LED OFF

8 Dimming 1/16 duty factor

9 Hot Keys (IR and FP) Disabled

10 Guard timer 10s

19/78

Page 20

Functional description STFPC320

4.14 Initial state

On power application, the 1/16-pulse width is set and th e display shows the value

configured in the VFD display RAM before entering the standby mode. Thus if HELLO is

required to be shown on the VFD upon w ak e-up , then the user must write the cor responding

digit and segments locations in the VFD displa y memory before going in to the standby mo de

of operation. Note that t he V

value of the display changes only after user configuration.

If the user wishes to display t he RTC value during standby, then the user must configure the

STFPC320 by sending the appropriate command. If the user does not configure the

STFPC320 to display the RTC in standby, the VFD shows the same value as was written in

the VFD display memory location.

Note that all the hot keys are disabled on power-up. Only the hotkeys (FP or RC) or RTC or

the low to high transition on the PIN_AV8 pin can be detected to wake-up the system from

standby condition.

must be present in order to keep th e VFD displa y activ e . The

SS

20/78

Page 21

STFPC320 Operating state diagram

5 Operating state diagram

Figure 8. Operating state diagram

21/78

Page 22

Real-time clock (RTC) operation STFPC320

6 Real-time clock (RTC) operation

6.1 Real-time clock

The RTC operates as a slave device through the slave address of the STFPC320 on the

serial bus. Access is obtained by implementing a start condition followed by the correct

slave address (Write: 0x52H and Read: 0x53H). The 16 bytes contained in the device can

then be accessed sequentially in the following order:

1. Reserved

2. Seconds register

3. Minutes register

4. Hours register

5. Square wave/day register

6. Date register

7. Century/month register

8. Year register

9. Calibration register

10. Watchdog register

11 - 15. Alarm registers

16. Flags register

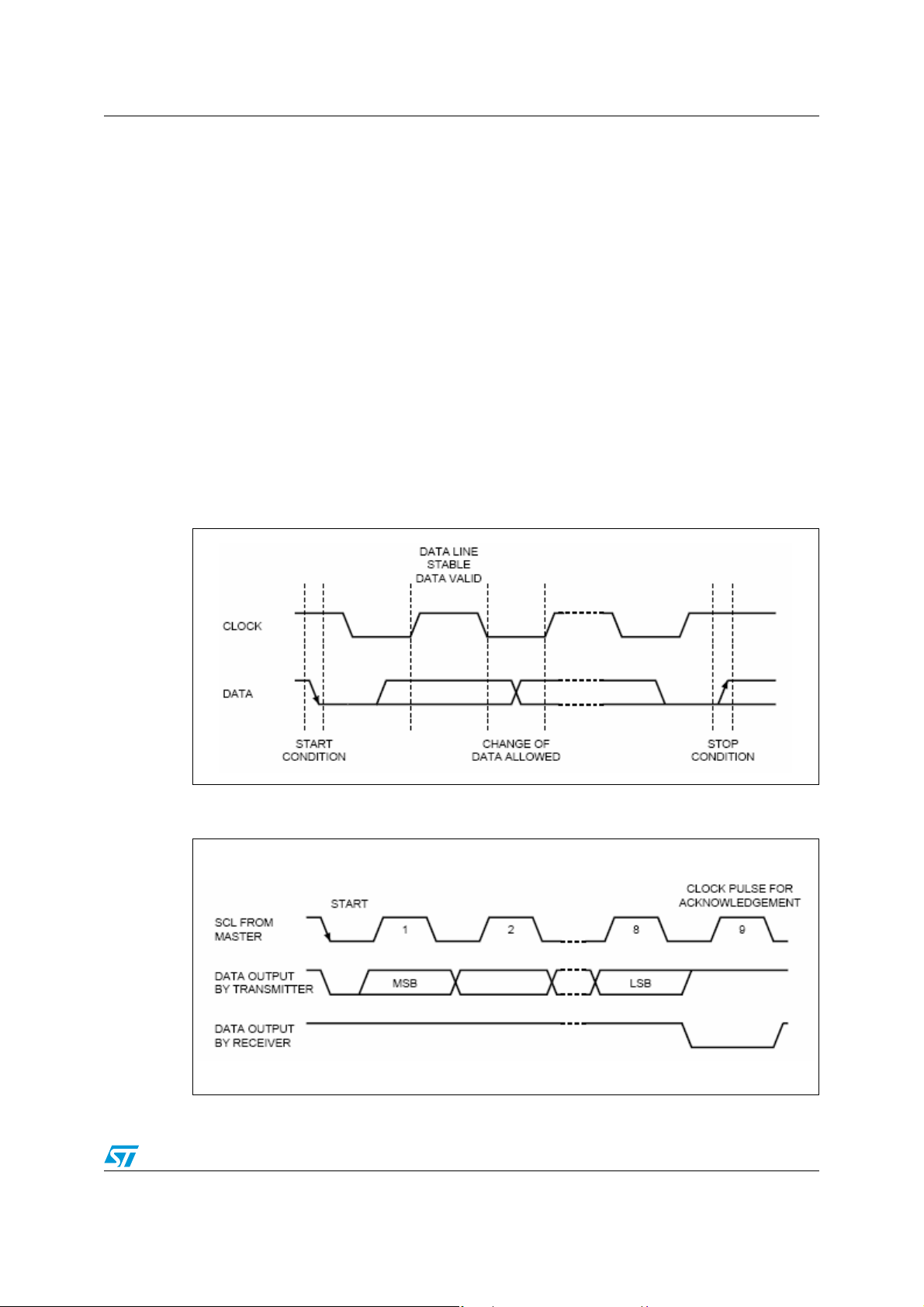

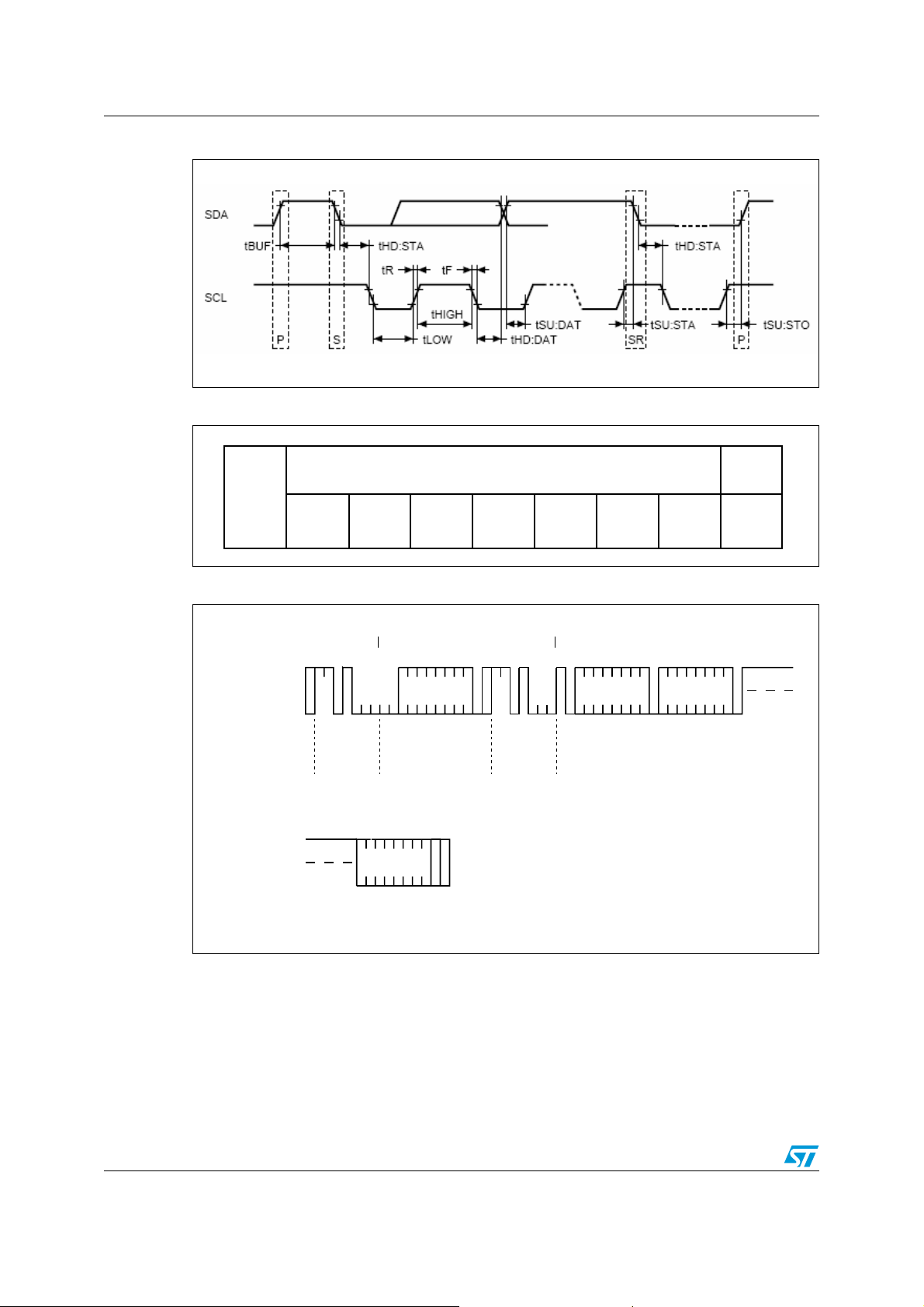

6.2 2-wire bus characteristics

The bus is intended for communication between different ICs. It consists of two lines: a

bidirectional data signal (SDA) and a clock signal (SCL). Both the SDA and SCL lines must

be connected to a positive supply voltage (typical voltage is 3.3 V) via a pull-up resistor

(typical value is 10 K). The following protocol has been defined:

● Data transfer may be initiated only when the bus is not busy.

● During data transfer, the data line must remain stable whenever the clock line is High.

● Changes in the data line, while the clock line is High, will be interpreted as control

signals.

Accordingly, the following bus conditions have been defined:

● Bus not busy: both data and clock lines remain High.

● Start data transfer: a change in the state of the data line, from high to Low, while the

clock is High, defines the START condition.

● Stop data transfer: a change in the state of the data line , from Low to High, while the

clock is High, defines the STOP condition.

● Data Valid: the st ate o f the data line represent s v a lid data when after a sta rt condition,

the data line is stable fo r the durat ion of the high period of the clo ck signal. The data on

the line may be changed during the Low pe riod of the clock signal. There is one clock

pulse per bit of data.

Each data transfer is initiated with a start condition and terminated with a stop

22/78

Page 23

STFPC320 Real-time clock (RTC) operation

condition. The number of data bytes transferred between the start and stop conditions

is not limited. The information is transmitted byte-wide an d each receiver ac knowledges

with a ninth bit.

By definition a device that gives out a message is called “transmitter,” the receiving

device that gets the message is called “recei v er.” The de vice t hat controls t he message

is called “master.” The devices that are co ntrolled by the master are called “sla ves.”

● Acknowledge: each byte of eight bits is followed by one Acknowledge Bit. This

Acknowledge Bit is a low level put on the bus by the receiver whereas the master

generates an extra acknowledge related clock pulse. A slave receiver which is

addressed is obliged to generate an acknowledge afte r the reception of each byte that

has been clocked out of the master transmitter.

The device that acknowledges has to pull down the SDA line during the acknowledge

clock pulse in such a way th at the SD A line is a stable Lo w during the High period of the

acknowledge related clock pulse. Of course, set up and hold times must be taken into

account. A master receiver must signal an end of data to the slave transmitter by not

generating an acknowledge on the last byte that has been clocked out of the slave. In

this case the transmitter must lea v e t he data line High to enab le the master t o gener ate

the STOP condition.

Figure 9. Serial bus data transfer sequence

Figure 10. Acknowledgement sequence

23/78

Page 24

Real-time clock (RTC) operation STFPC320

6.3 Watchdog timer

The watchdog timer can be used to detect an out of control microprocessor. The user

programs the watchdog timer by setting the desired amou nt of time-out into the Watchdog

Register, address 09h. Bits BMB4-BMB0 store a binary multiplier and the three bits RB2-

RB0 select the resolution where:

● 000 = 1/16 second (16Hz)

● 001 = 1/4 second (4Hz)

● 010 = 1 second (1Hz)

● 011 = 4 seconds (1/4Hz)

● 100 = 1 minute (1/60Hz)

Note: Invalid combinations (101, 110, and 111) do NOT enable a watchdog time-out. Setting the

BMB4-BMB0 = 0 with any combination of RB2-RB0, other than 000, will result in an

immediate watchdog time-out. The amount of time-out is then determined to be the

multiplication of the five-bit multiplier value with the resolution. (For example: writing

00001110 in the Watch dog reg ist er = 3*1 or 3 second s). If the pro ces so r do es not reset th e

timer within the specified period, the STFPC320 generates a watchdog output pulse on the

IRQ_N/SQW pin.

The watchdog timer can only be reset b y having the microprocessor perf orm a WRITE of the

Watchdog register. The time-out period then starts over. Should the watchdog timer time-

out, any value may be written to the Watchdog Register in order to clear the IRQ_N/SQW

pin. A value of 00h will disable the watchdog function until it is again programmed to a new

value. A READ of the Flags Register will reset the W atchdog flag (Bit D7; Register 0Fh). The

watchdog function is automatically disabled upon power-up, and the Watchdog Register is

cleared.

6.4 Real-time clock (RTC)

The RTC keeps track of the date and time. Once the date and time are set, the clock works

when the STFPC320 is in normal operation and standby operation. The wake-up alarm

feature is included in the RTC module. The accuracy of the RTC is approximately 10 ppm

(±25 secs/month).

The wakeup alarm is programmed to wake up once the date and time set are met. This

feature is present in normal and standby mode of operation. Only one date and time is

available for setting.

The real-time clock (RTC) uses an external 32.768 kHz quartz crystal to maintain an

accurate internal representation of the second, minute, hour, day, date, month, and year.

The RTC has leap-year correction. The clock also corrects for months having fewer than 31

days.

24/78

Page 25

STFPC320 Real-time clock (RTC) operation

6.4.1 Reading the real-time clock

The real-time clock (R TC) is read by specifying the address correspondin g to the r egist er of

the real-time clock and then initiating a Read command. The RTC registers can then be

read in a sequential read mode. Since the clock runs continuously and a read takes a finite

amount of time, there is the possibility that the clock could change during the course of a

read operation. In this device, the time is latched by the read command (falling edge of the

clock on the ACK bit prior to RTC data output) into a separate latch to avoid time changes

during the read operation. The clock cont inues to run. Alarms occurring during a read are

unaffected by the read operation.

6.4.2 Writing to the real-time clock

The time and date may be set b y writing to t he R TC r egisters . To av oid ch anging th e current

time by an uncompleted write operation, the current time value is loaded into a separate

buffer at the falling edge of the clock on the ACK bit before the RTC data input bytes, the

clock continues to run. The new serial input data replaces the values in the buff er. This new

RTC value is loaded back into the RTC register by a stop bit at the end of a valid write

sequence. An invalid write operation aborts the time update procedure and the contents of

the buffer are discarded. After a valid write operation the RTC will reflect the newly loaded

data beginning with the next “one second” clock cycle after the stop bit is written. The RTC

continues to update the time while an RTC register write is in progress and the RTC

continues to run during any nonvolatile write sequences. A single b yte may be written to the

RTC without affecting the other bytes.

25/78

Page 26

Real-time clock (RTC) operation STFPC320

6.5 Register table for RTC

Table 4. Register table for RTC

Addr D7 D6 D5 D4 D3 D2 D1 D0 Function/range BCD format

00h Reserved Reserved - -

01h ST 10 seconds Seconds Seconds 00-59

02h OFIE 10 minutes Minutes Minutes 00-59

03h 0 0 1 0 hours Hours (24-hour format) Hours 00-23

04h RS3 RS2 RS1 RS0 0 Day of week Day 01-7

05h 1 0 10 date Date: day of month Date 01-31

06h CB0 CB1 0 10M Month Century/month 0-3/01-12

07h 10 Years Year Year 00-99

08h 1 0 S Calibration Calibration

09h RB2 BMB4 BMB3 BMB2 BMB1 BMB0 RB1 RB0 Watchdog

0Ah AFE SQWE 1 Al 10M Alarm month Al month 01-12

0Bh RPT4 RPT5 Al 10 date Alarm date Al date 01-31

0Ch RPT3 0 Al 10 Hour Alarm Hour Al hour 00-23

0Dh RPT2 Alarm 10 minutes Alarm minutes Al min 00-59

0Eh RPT1 Alarm 10 seconds Alarm seconds Al sec 00-59

0Fh WDF AF 0 0 0 Flags

Keys: S = sign bit

ST = stop bit

OFIE = oscillator fail interrupt enable bit

BMB0 – BMB4 = watchdog multiplier bits

CEB = century enable bit

CB = century bit

OUT = output level

AFE = Alarm flag enable flag

RS0-RS3 = SQW frequency bits

RB0 – RB2 = watchdog resolution bits

RPT1 – RPT5 = alarm repeat mode bits

WDF = watchdog flag (read only)

AF = alarm flag (read only)

OF = Oscillator fail bit

SQWE = square wave enable bit

It is recommended to fill the unused bits in the register map to ‘0’ upon a cold boot up.

26/78

Page 27

STFPC320 Real-time clock (RTC) operation

6.6 Setting alarm clock registers

The address locations 0Ah-0Eh contain the alarm settings. The alarm can be configured to

go off at a prescribed time on a specific month, date, hour, minute, or second or repeat

every year, month, day, hour, minute, or second. It can also be programmed to go off while

the STFPC320 is in the standby mode to serve as a system wake-up call.

The bits RPT5-RPT1 put the alarm in the repeat mode of operation. Table 5 shows the

possible configurations . Codes not list ed in the ta ble def ault to the once p er second mode to

quickly alert the user of an incorrect ala rm setting.

When the clock information matches the alarm clock sett ings based on the match criteria

defined by RPT5-RPT1, the AF (Alarm Flag) is set. If AFE (alarm flag enable) is also set

(and SQWE is '0.'), the alarm condition activates the IRQ_N/SQW pin.

Note: Note that by default, the alarm repeat mode is enabled and by default the repeat fre quency

is set to “once per year”.

Note: If the address pointer is allow ed to increment to the flag re gister address , an alarm condition

will not cause the Interrupt/Flag to occur until the address pointer is moved to a different

address. It should also be noted that if the last address written is the “Alarm Seconds,” the

address pointer will increment to the Flag address, causing this situation to occur.

The IRQ_N/SQW output is cleared b y a READ to the f lags register as sho wn in Figure 11. A

subsequent READ of the flags register is necessary to see that the value of the alarm flag

has been reset to '0’.

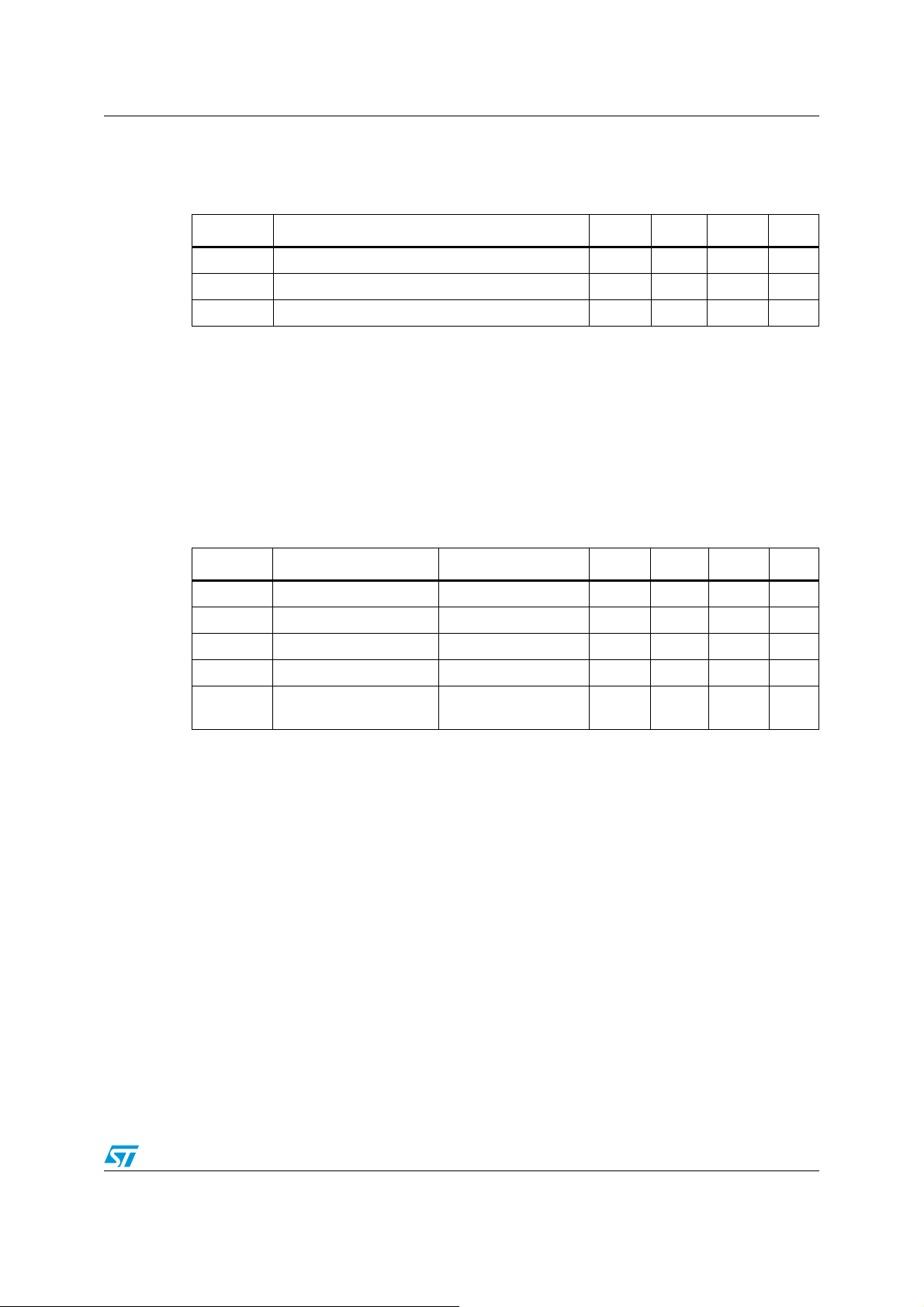

Figure 11. Alarm interrupt reset waveform

Table 5. Alarm repeat modes

RPT5 RPT4 RPT3 RPT2 RPT1 Alarm se ttings

1 1 1 1 1 Once per second

1 1 1 1 0 Once per minute

1 1 1 0 0 Once per hour

1 1 0 0 0 Once per day

1 0 0 0 0 Once per month

0 0 0 0 0 Once per year

Note: The “Once Per Year” is the default.

27/78

Page 28

Real-time clock (RTC) operation STFPC320

6.7 Calibrating the clock

The STFPC320 is driven by a quartz controlled oscillator with a nominal frequency of

32.768 kHz. The accuracy of the RTC depends on the frequency of the quartz crystal that is

used as the time-base for the RTC. The accuracy of the clock is dependent upon the

accuracy of the crystal, and the match between the capacitive load of the oscillator circuit

and the capacitive load for which the crystal was trimmed. The STFPC320 crystal is

designed for use with a 6 pF crystal load capacitance. When the calibration circuit is

properly employed, accuracy improves to better than ±2 ppm at 25 deg C.

The oscillation rate of crystals changes with temperature. Therefore, the STFPC320 design

employs periodic counter correction. The calibration circuit adds or subtracts counts fro m

the oscillator divider circuit at the divide by 256 stage. The number of times pulses which are

blanked (subtr acted, negat ive calib ration) or split (added, p ositive calibration) depends upon

the value loaded into the five calibration bits found in the calibration register. Adding counts

speeds the clock up, subtracting counts slows the clock down.

The calibration bits occup y the five lower or der bit s (D4- D0 ) in th e calibration register (08h).

These bits can be set to represent any value between 0 and 31 in binary form. Bit D5 is a

sign bit; ‘1’ indicates positive calibration and ‘0’ indicates negative calibration. Calibration

occurs within a 64-minute cycle. The first 62 minutes in the cycle may, once per minute,

have one second either shortened by 128 or lengthened by 256 oscillator cycles . If a binary

‘1’ is loaded into the register, only the first 2 minutes in the 64 minute cycle will be modified;

if a binary 6 is loaded, the first 12 will be affected, and so on.

Therefore, each calibration step has the effect of adding 512 or subtracting 256 oscillator

cycles for every 125,829,120 actual oscillator cycles, that is +4.068 or -2.034 PPM of

adjustment per calibration step in the calibration register.

Assuming that the oscillator is running at exactly 32.768 KHz, each of the 31 increments in

the calibration byte w ould repre sent +10.7 or - 5.35 seconds per day which corresponds to a

total range of +5.5 or -2.75 minutes per month.

Two methods are available for ascertaining how much calibration a given STFPC320 may

require:

● The first involves setting the clock, letting it run for a month and comparing it to a known

accurate reference and recor ding deviation over a fixed period of time. Calibration

values, including the number of seconds lost or gained in a given period allows the

designer to give the end user the ability to calibrate the clock as the environment

requires, e v en if the fina l product is pac kaged in a non-user serviceable en closure . The

designer could provide a simple utility that accesses the calibration byte.

● The second approach is better suited to a manuf acturing environment, an d inv olve s the

use of IRQ_N/SQW pin. This pin will toggle at 512Hz when RS3 = ‘0’, RS2 = ‘1’, RS1 =

‘1’, RS0 = ‘0’, SQWE = ‘1’ and ST = ‘0’. In normal mode, it is always advised to keep the

SQWE to a ‘0’.

Any deviation from 512 Hz indicates the degree and direction of oscillator frequency shift at

the test temperature. For example, a reading of 512.010124 Hz would indicate a +20ppm

oscillator frequency error, requiring a -10 (XX001010) to be loaded into the Calibration Byte

for correction. Note that setting or changing the calibration b yte does not affect the

frequency test or square wave output frequency.

28/78

Page 29

STFPC320 Real-time clock (RTC) operation

Figure 12. Crystal accuracy across temperature

Figure 13. Calibrating waveform

29/78

Page 30

Real-time clock (RTC) operation STFPC320

6.8 Square wave output

The STFPC320 offers t he user a progr ammab le square w av e function which is output on the

IRQ_N/SQW pin. RS3-RS0 bits located in 04h register establish the square wave output

frequency. These frequencies are listed in Table 6. Once the selection of the SQW

frequency has been completed, the IRQ_N/SQ W pin can be turned on or off under sof tw are

control with the square wav e enab le bit (SQWE) located in reg ister 0Ah. The initial po wer-up

default for the IRQ_N/SQW output is 32 KHz.

Table 6. Square wave output frequency

Square wave bits Square wave

RS3 RS2 RS1 RS0 Frequency Units

0000None-

000132.768kHz

00108.162kHz

00114.096kHz

01002.048kHz

01011.024kHz

0110512Hz

0111256Hz

1000128Hz

100164Hz

101032Hz

101116Hz

11008Hz

11014Hz

11102Hz

11111Hz

30/78

Page 31

STFPC320 Real-time clock (RTC) operation

6.9 Century bits

These two bits will increment in a binary fashion at the turn of the century, and handle all

leap years correctly. See Table 7 below for additional explanation.

Table 7. Century bits

CB1 CB0 Leap Year? Example

0 0 Yes 2000

0 1 No 2100

1 0 No 2200

1 1 No 2300

1. Leap year occurs every four years (for years evenly divisible by 4), except for years evenly divisible by

100. The only exceptions are those years evenly divisible by 400 (the year 2000 was a leap year, year

2100 is not).

(1)

6.10 Oscillator stop detection

If the oscillator fail (OF) bit is internally set to a ‘1’, this indicates that the oscillator has either

stopped, or was stopped f or some period of time a nd can be used to judge the v alid ity of the

clock and date data. This bit will be set to ‘1’ any time the oscillator stops.

In the event the OF bit is found to be set to ‘1’ at any time other than the initial power-up, the

STOP bit (ST) should be written to a ‘1’, then immediately reset to a ‘0’. This will restart the

oscillator.

The following conditions can cause the OF bit to be set:

● The first time power is applied (defaults to a ‘1’ on power-up).

Note: If the OF bit cannot be written to ‘1’ four (4) seconds after the initial power-up, the STOP bit

(ST) should be written to a ‘1’, then immediately reset to a ‘0’.

● The voltage present on Vcc is insufficient to support oscillation.

● The ST bit is set to a ‘1’.

● External interference of the crystal

If the oscillator fail interrupt enable bit (OFIE) is set to a ‘1’, the IRQ_N/SQW pin will also be

activated. The IRQ_N/SQW output is cleared by resetting the OFIE or OF bit to ‘0’ (NOT by

reading the Flag register).

The OF bit will remain set to ‘1’ until written to logic ‘0’. The oscillator must start and have

run for at least 4 seconds before attempting to reset the OF bit to ‘0’. If the trigger event

occurs during the power-down condition, this bit will be set correctly.

31/78

Page 32

Real-time clock (RTC) operation STFPC320

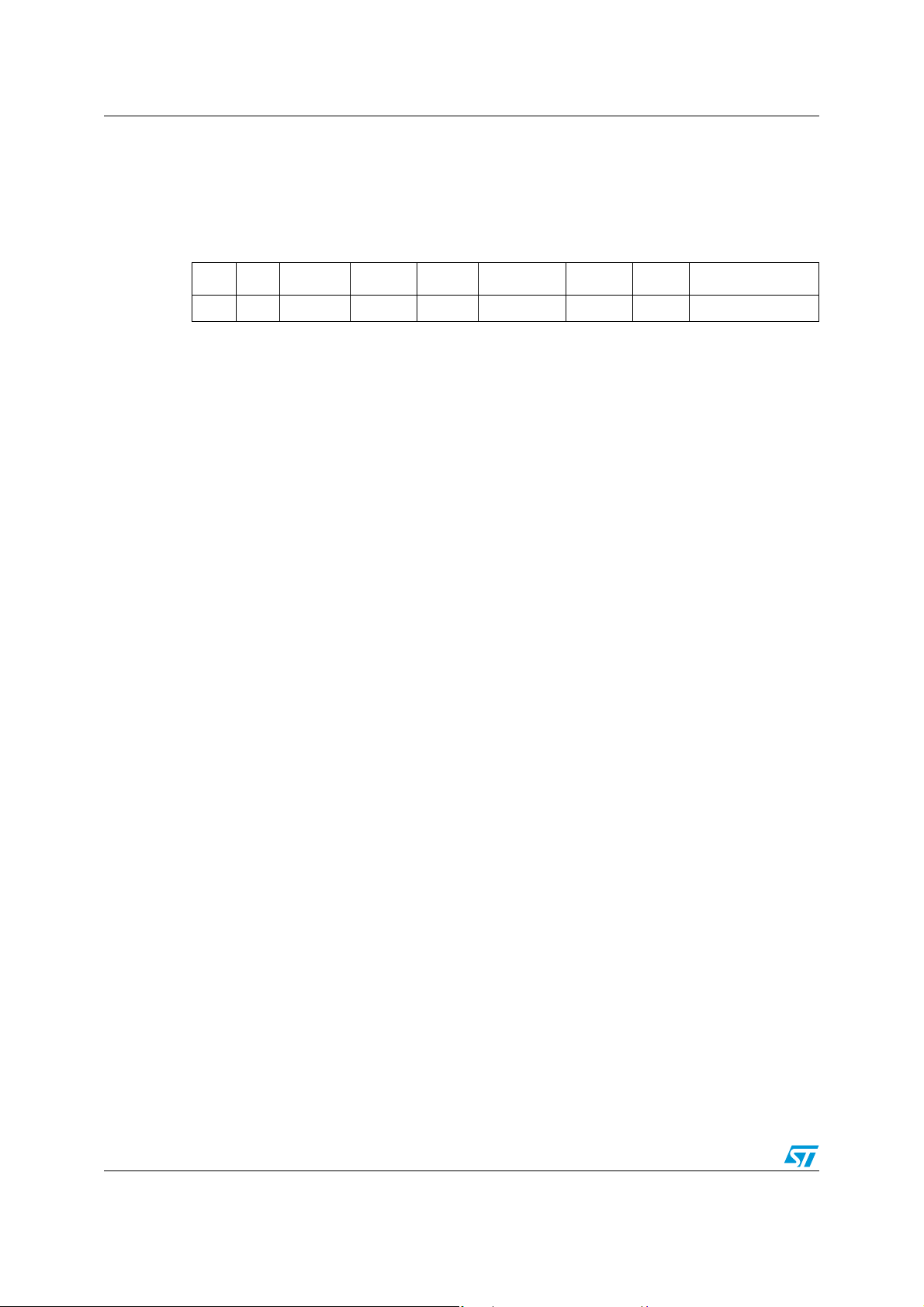

6.11 Initial power-on defaults

Upon application of power to the device, the register bits in the RTC will initially power-on in

the state indicated in Table 8.

Table 8. Initial power-on default values of the registers

ST OF OFIE OUT AFE SQWE RS3-1 RS0 Watchdog

01 0 1 0 0 0 1 0

Note: All other control bits power- up in an undet ermined state. The user sho uld write the OF bit to

a 0 after 4s (after the oscillator has started up and the clock is stable). If the OFIE is to be

enabled, then write a ‘1’ to the OFIE bit in the RTC register.

32/78

Page 33

STFPC320 Commands

7 Commands

A command sets the display mode and status of the VFD driver.

The first 1 byte input to the STFPC320 through the SDA pin after the slave address is

regarded as a command. If slave address is not transmitted before the commands/data are

transmitted, the commands/data being transmitted are invalid (howev er , the commands/data

already transmitted remain valid).

7.1 Configuration mode setting command

This command initializes the STFPC320 and performs any one of the following functions:

1. Selects the number of segments and num ber of g rids (1/8 to 1/16 duty, 12 segments to

20 segments). When this command is executed, display is turned off. To resume

display, the display ON command must be executed. If the same mode is selected,

nothing is performed.

2. Selects the remote control protocol to use.

3. Sets the guard timer. The guard timer is configurable from 1 to 15s or turned off

completely.

4. Sets the guard timer action to perform when the guard timer counts. Two actions are

allowed: no action, set STBY to high level.

MSB LSB

0 0 b5 b4 b3 b2 b1 b0

Description: Bits b7-b6 = 00 is decoded as a configuration mode setting command. The

subsequent bits are decoded as follows:

b5: Reserved

b4: Normal display setting

b3: RTC display setting (during normal or STBY modes)

b2: enables all RC keys as hot-keys

b1: Reserved

b0: enables the guard timer to issue STBY

Note: When displaying the RTC during normal mode, if the µP is writing data to STFPC320 using

2

I

C bus, the RTC display on VFD momentarily turns OFF.

33/78

Page 34

Commands STFPC320

The first byte after the configuration command is in the following format:

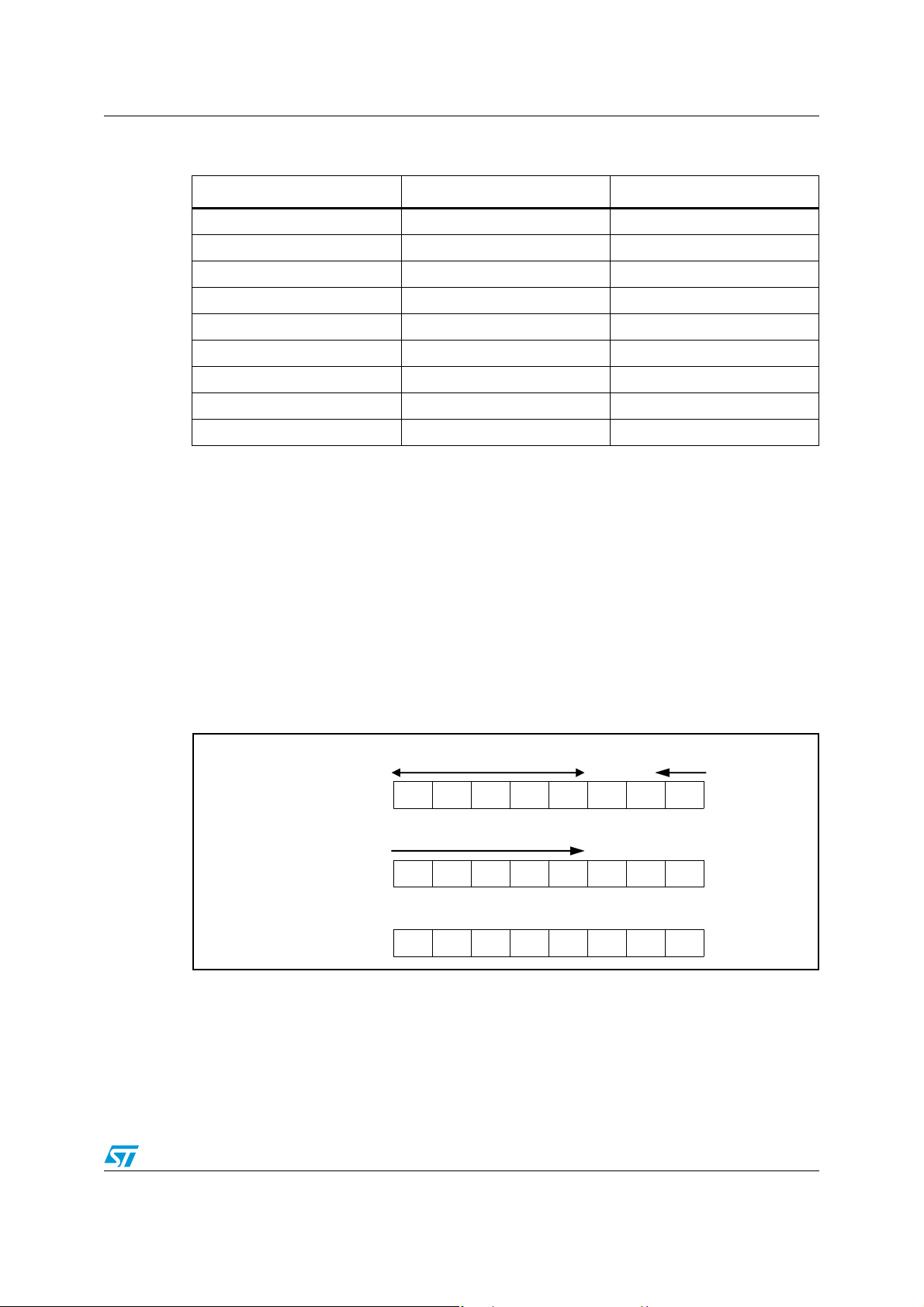

Figure 14. First byte format after configuration byte

MSB LSB

MSB LSB

MSB LSB

b0b1b2b3b4b5b6b7

b0b1b2b3b4b5b6b7

b0b1b2b3b4b5b6b7

GUARD TIMER SETTING

GUARD TIMER SETTING

GUARD TIMER SETTING

0000 : Turned off

0000 : Turned off

REMOTE CONTROL PROTOCOL

REMOTE CONTROL PROTOCOL

REMOTE CONTROL PROTOCOL

SETTING

SETTING

SETTING

(Decoded format since b7=‘0’)

(Decoded format since b7=‘0’)

(Decoded format since b7=‘0’)

0110 : R2000

0110 : R2000

0111 : RCA

0000 : RC Disable

0000 : RC Disable

0000 : RC Disable

0010 : RC-5

0010 : RC-5

0010 : RC-5

0011 : Reserved

0011 : Reserved

0011 : Reserved

0100 : NEC

0100 : NEC

0100 : NEC

0111 : RCA

0101 : Sony

0101 : Sony

0001: Matsushita

0001: Matsushita

0000 : Turned off

0001 : 1 seconds

0001 : 1 seconds

0001 : 1 seconds

1111 : 15 seconds

1111 : 15 seconds

1111 : 15 seconds

xxxx : No. of seconds in BCD

xxxx : No. of seconds in BCD

xxxx : No. of seconds in BCD

format

format

format

When b7 = ‘0’, incoming RC data is output on SDA in decoded format where the Device

Address, Start Bit, Toggle Bit and Data Bits are sent. Note that the default location is 0x00

for the first device address. This order of the bits sent is in the same f o rmat as the incoming

RC data.

When b7 = ‘1’, incoming raw data (no header information) is output on SDA.Address

decoding is still performed to decode the corresponding RC protocol. The format of the data

on SDA corresponds to the format of the respective RC f rame.

For details, refer to the RC protocol section of the datasheet.

Upon power application, the following modes are selected:

● Normal display setting: 16-digit, 12-segment mode is selected (default: display off and

keyscan on).

● Remote control protocol setting: RC-5 with raw format.

● Guard timer setting: turned on with 10s. After the fi rst command is processed by

STFPC320, the guard timer is turned off until it is turned on by the host.

● Guard timer action: issue standby.

34/78

Page 35

STFPC320 Commands

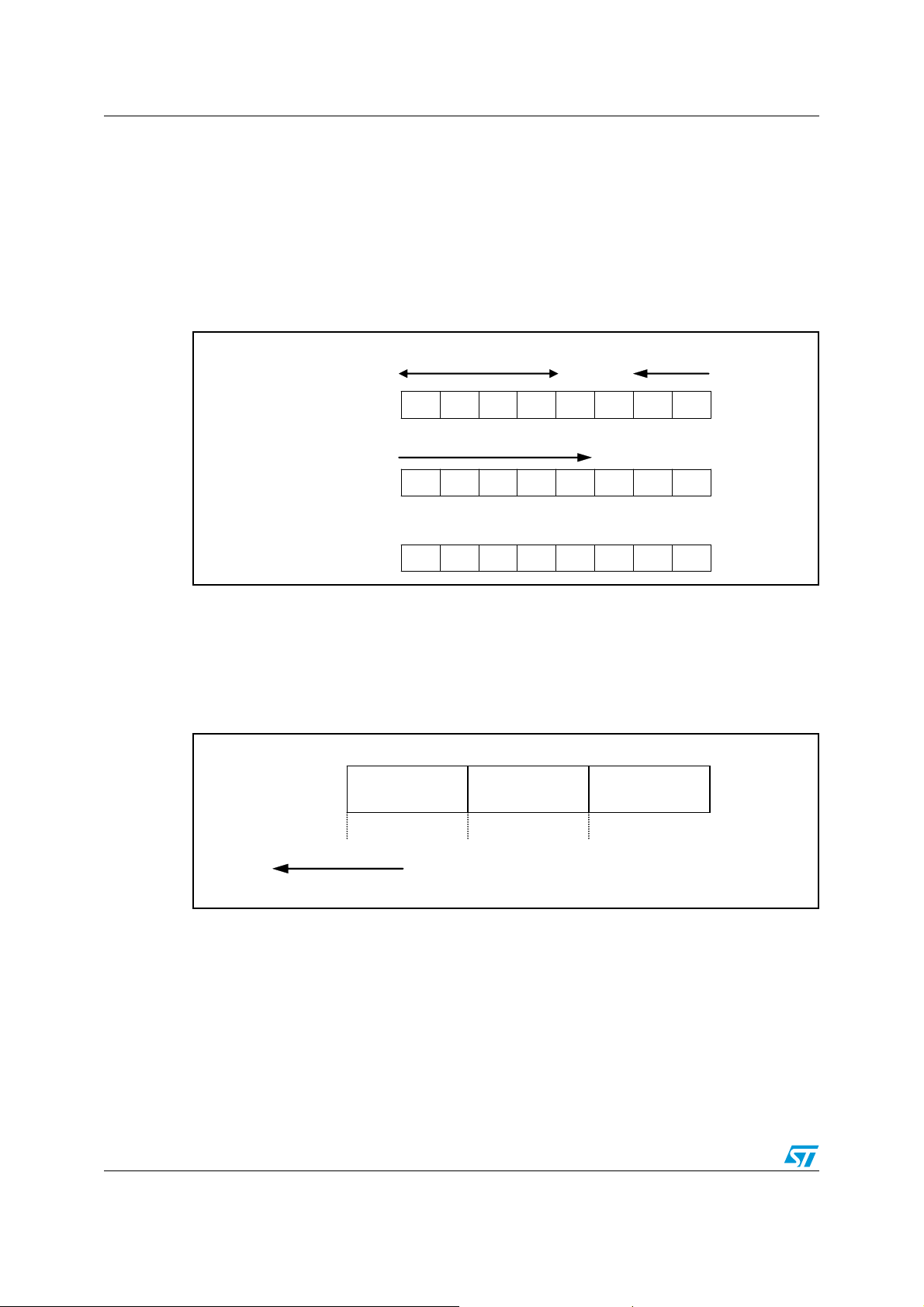

The second byte after the configuration command is in the format displayed in Figure 15

Figure 15. Second byte format after configuration type

MSB LSB

MSB LSB

b0b1b2b3b4b5b6b7

b0b1b2b3b4b5b6b7

RTC DISPLAY MODE

RTC DISPLAY MODE

SETTING

SETTING

0000: RTC digit 1 (default)

0000: RTC digit 1 (default)

0001: RTC digit 2

0001: RTC digit 2

0010: RTC digit 3

0010: RTC digit 3

0011: RTC digit 4

0011: RTC digit 4

0100: RTC digit 5

0100: RTC digit 5

0101: RTC digit 6

0101: RTC digit 6

0110: RTC digit 7

0110: RTC digit 7

Note that the RTC digit 1 is the

Note that the RTC digit 1 is the

default setting.

default setting.

VFD DISPLAY MODE SETTING

VFD DISPLAY MODE SETTING

0111 : 8 digits, 20 segments

0111 : 8 digits, 20 segments

1000 : 9 digits, 19 segments

1000 : 9 digits, 19 segments

1001 : 10 digits, 18 segments

1001 : 10 digits, 18 segments

1010 : 11 digits, 17 segments

1010 : 11 digits, 17 segments

1011 : 12 digits, 16 segments

1011 : 12 digits, 16 segments

1100 : 13 digits, 15 segments

1100 : 13 digits, 15 segments

1101 : 14 digits, 14 segments

1101 : 14 digits, 14 segments

1110 : 15 digits, 13 segments

1110 : 15 digits, 13 segments

1111 : 16 digits, 12 segments

1111 : 16 digits, 12 segments

HHMMSS

Dig 1 Dig 2 Dig 3 Dig 4 Dig 5 Dig 6 Dig 7 Dig 8 Dig 9 Dig 10

The above example shows the HH, MM, SS digits on a 10-digit display panel when RTC

digit 1 is configured (Bits b7 - b4= “0000”) & HH:MM:SS format is selected with separator

being a part of the same digit. The MSB of Hour corresponds to Digit 1 when

b7 - b4= “0000”.

When b7-b4=“0001” is configured, the MSB of Hour starts from the Digit 2.

Note: The Digit 1 must start from the left.

35/78

Page 36

Commands STFPC320

7.2 Data setting command

This command sets the data-write and data-read modes.

MSB LSB

0 1 b5 b4 b3 b2 b1 b0

Description: Bits b7-b6 = 01 is decoded as a data setting command. The subsequent bits are

decoded as follows:

b5 b4 = 00: data write command (see bits b1-b0)

b5 b4 = 10: data read 1 command (see bits b1-b0)

b5 b4 = 11: data read 2 command (see bits b1-b0)

b5 b4 = 01: reserved

b3: clear the guard timer (no change in guard time)

b2: ‘1’ implies fixed address of display RAM/ ‘0’ implies auto increments the address

after data has been written.

Table 9. Data write command. b5 b4: 00

b1-b0

00 Write memory (display or RTC) – See Note Note: on page 37

01

10

11 Write LED (see Section 9: LED port on page 44)

Enter Test mode (only used for production test)

Do not use this in normal operatio n.

Clear Test mode

Do not use this in normal operatio n.

Table 10. Data read 1 command. b5 b4: 10

b1-b0

00 Read Key (Section 8: Key matrix on page 42)

01

10

11 Read Interrupt (refer to Section 14: Interrupt flags on page 50)

Read Switch + Address Pointer

(see Section 10: SW data on page 45)

Read RC data (following two bytes are the address + command from

RC); Refer to Section 15: Remote control protocols on page 51

Table 11. Data read 2 command. b5 b4: 11

b1-b0

00 Reserved

01 Read Configuration (see Section 13: Configuration data on page 48)

36/78

Page 37

STFPC320 Commands

Table 11. Data read 2 command. b5 b4: 11

10 Reserved

11

Read RTC Registers

(see Section 11.1: RTC display data read on page 46)

On power application, the normal display mod e and address incremen t mode is set with the

default display memory address set to 10H.

In the auto increment address mode, the address command is sent only once followed by

the data bytes.

Note: This command is seldom used. For writing to memory (normal or RTC), the address se tting

command is sufficient.

37/78

Page 38

Commands STFPC320

7.3 Display control and hotkey setting command

MSB LSB

1 0 b5 b4 b3 b2 b1 b0

Description: Bits b7-b6 = 10 is decoded as a display control and hotkey setting command. The

subsequent bits are decoded as follows:

b5 = 0: sets display control for dimming setting as shown in the table on the next

page.

When b5 = 1, the decoding is based on bits b2-b0 as illustrated below:

b2 b1 b0 = XX1: RC hotkeys and address configuration.

b2 b1 b0 = X1X: front panel hotkeys configuration.

b2 b1 b0 = 1XX: sets the RTC segments loca tion. Refer to the table below for the

configuration.

b4, b3: reserved (the bits can be set to ‘0’)

Note: XXX on the bit values means don’t care. The bits can be set to ‘0’.

RTC segments configuration

Remote control hotkeys

When b5 = 0

b2.b0: Sets dimming quantity.

000: Sets pulse width to 1/16.

001: Sets pulse width to 2/16.

010: Sets pulse width to 4/16.

011: Sets pulse width to 10/16.

100: Sets pulse width to 11/16.

101: Sets pulse width to 12/16.

110: Sets pulse width to 13/16.

111: Sets pulse width to 14/16.

b3: Turns on/off display

0: Display off (key scan

continues)

1: Display on

When b5 = 1

b2 b1 b0: 1XX

This command is followed by

sending 7 bytes of configuration

data for RTC segments (byte1-

6) and format configuration

(byte7).

Read 12.3.1 for details.

When b5 = 1

b2 b1 b0: XX1

Following this command is

16bytes configuration data for 8

RC hotkeys configuration.

Read 12.3.3 for details.

Front panel hotkeys

When b5 = 1

b2 b1 b0: X1X

This command is followed by

sending 3 bytes (24 keys) of

configuration data to set any ke y

as hotkey.

Section : Thus, if the a

Read

segment is located on

segment 1, the bits b3-b0 are

“0000”. If b segment is

located on segment 2, the

bits b3-b0 are “0001” and so

on. on page 39

for details.

MSB Segment b Segment a LSB

BYTE1b7b6b5b4b3b2b1b0

38/78

Page 39

STFPC320 Commands

Description: Byte2 to byte6 will follow the same pattern as shown for byte1 above:

BYTE2: segment d, segment c

BYTE3: segment f, segment e

BYTE4: segment m, segment g

BYTE5: segment k, segment h

BYTE6: segment p/col, segment j/col

Segments r and n are never used for RTC display.

Byte7 is for RTC format configuration:

BYTE7 0 b6 b5 b4 0 0 0 b0

MSB LSB

When b6 is set to a ‘0’, it implies that the dot point/column is a part of the same digit as the

LSB of the HH or LSB of the MM. When b6 is set to a ‘1’, it means that a separate digit is

used for the separator between the hour/minute and minute/second.

When b5 is set to a ‘0’, HH:MM display format of RTC is chosen and when it is set to a ‘1’,

the HH:MM:SS format is chosen.

When b4 is set to a ‘0’, the AM/PM is not displayed and when it is set to a ‘1’, the AM/PM is

displayed on the VFD.

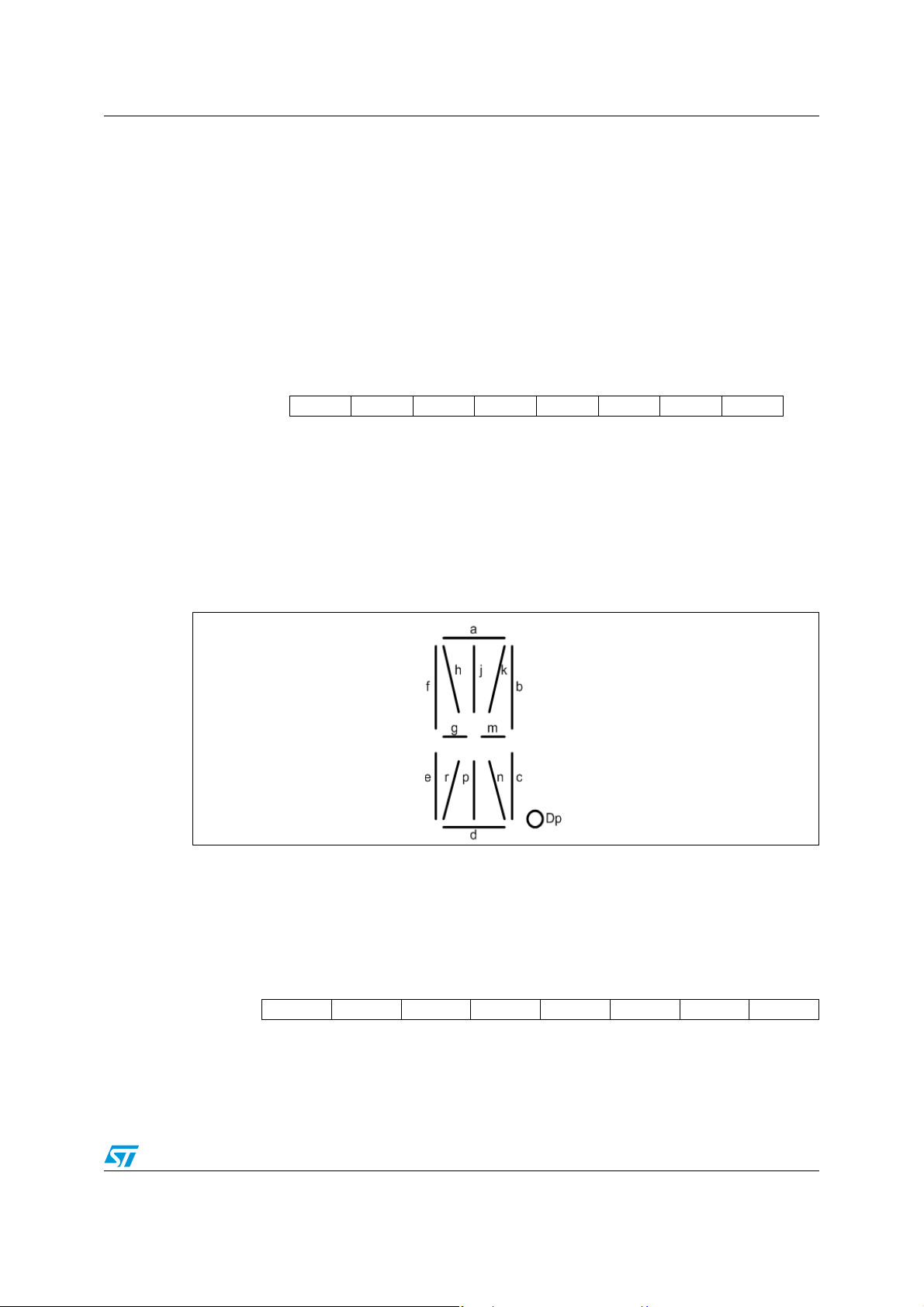

Figure 16. 14-segment + dotpoint display

For a display with segment configuration as in Figure 16, the location of “a” segment

represented by bits b3-b0 corresponds to “0000”. Location of b segment corresponds to

“0001”. Location of c segment correspo nd s to “00 10” an d so on.

Thus, if the a segment is located on segment 1, the bits b3-b0 are “0000”. If b segment is

located on segment 2, the bits b3-b0 are “0001” and so on.

BYTE1 b7 b6 b5 b4 b3 b2 b1 b0

MSB LSB

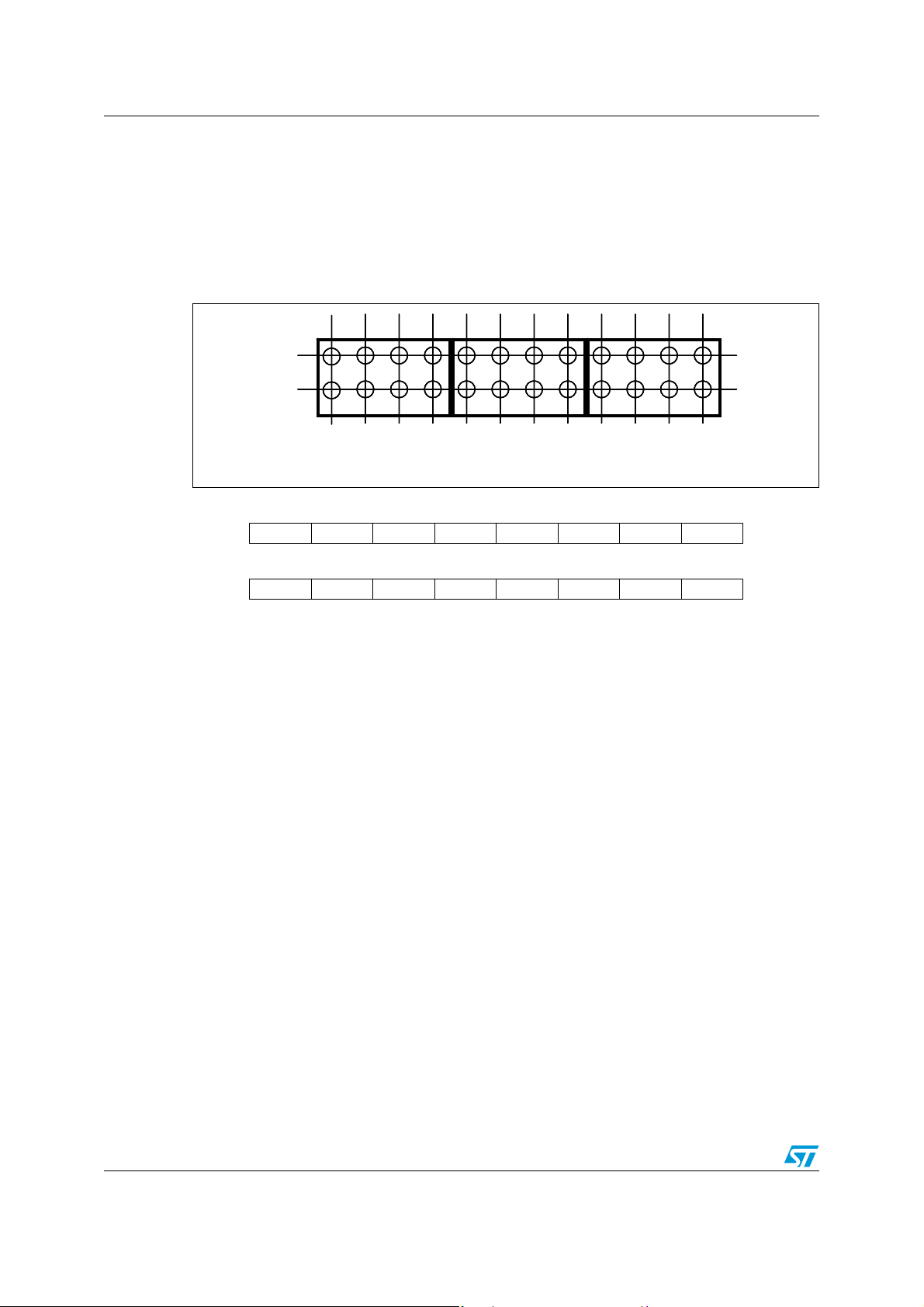

Description: b0: KS1 KEY1

b1: KS1 KEY2

b2: KS2 KEY1

b3: KS2 KEY2

39/78

Page 40

Commands STFPC320

b4: KS3 KEY1

b5: KS3 KEY2

b6: KS4 KEY1

b7: KS4 KEY2

Byte2 and Byte3 follow the same pattern as above for the hotkey configuration. To

select any one of the key as hotkey, the bit value is set to ‘1’.

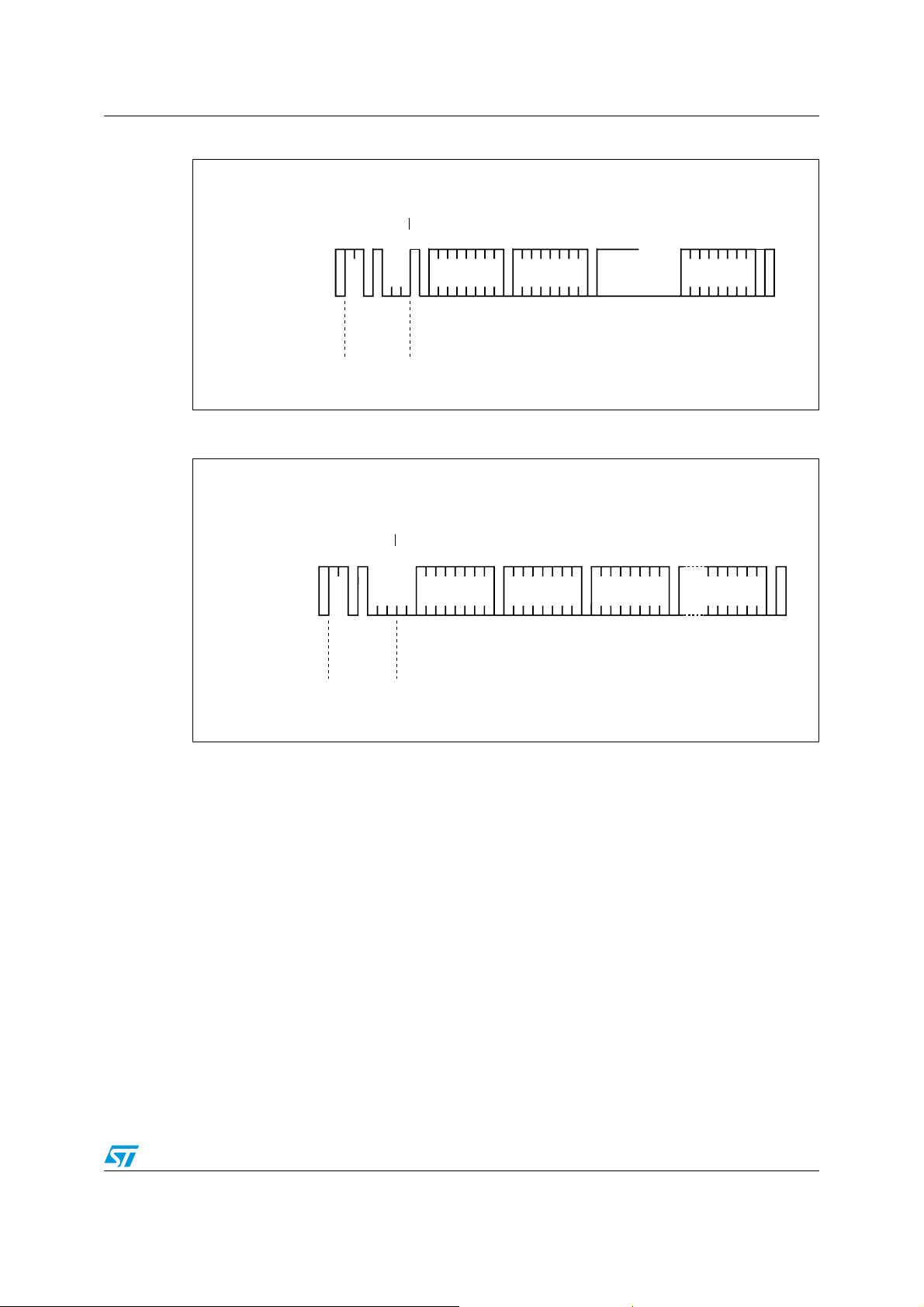

Figure 17. Front panel hotkeys configuration

BYTE1 BYTE2 BYTE3

BYTE1 BYTE2 BYTE3

KEY

KEY

KEY

KEY

1

1

1

1

b0

b2 b4

b0

b2 b4

b1 b3

b1 b3

b1 b3

1

1

1

1

/KS

/KS

/KS

/KS

1

1

1

1

Seg

Seg

Seg

Seg

b2 b4

2

2

2

2

/KS

/KS

/KS

/KS

2

2

2

2

Seg

Seg

Seg

Seg

KEY

KEY

KEY

KEY

2

2

2

2

MSB LSB

BYTE1 b7 b6 b5 b4 b3 b2 b1 b0 RC address 1

b5 b7

b5 b7

b5 b7

3

3

3

3

/KS

/KS

/KS

/KS

3

3

3

3

Seg

Seg

Seg

Seg

b6 b0

b6b0

b6 b0

4

4

4

4

/KS

/KS

/KS

/KS

4

4

4

4

Seg

Seg

Seg

Seg

b1 b3

b1 b3

b1 b3

5

5

5

5

/KS

/KS

/KS

/KS

5

5

5

5

Seg

Seg

Seg

Seg

b2 b4

b2 b4

b2 b4

6

6

6

6

/KS

/KS

/KS

/KS

6

6

6

6

Seg

Seg

Seg

Seg

b5 b7

b5 b7

b5 b7

7

7

7

7

/KS

/KS

/KS

/KS

7

7

7

7

Seg

Seg

Seg

Seg

b6 b0

b6b0

b6 b0

8

8

8

8

/KS

/KS

/KS

/KS

8

8

8

8

Seg

Seg

Seg

Seg

b1 b3

b1 b3

b1 b3

9

9

9

9

/KS

/KS

/KS

/KS

9

9

9

9

Seg

Seg

Seg

Seg

b2 b4

b2 b4

b2 b4

10

10

10

10

/KS

/KS

/KS

/KS

10

10

10

10

Seg

Seg

Seg

Seg

b5 b7

b5 b7

b5 b7

11

11

11

11

/KS

/KS

/KS

/KS

11

11

11

11

Seg

Seg

Seg

Seg

b6

b6b0

b6

12

12

12

12

/KS

/KS

/KS

/KS

12

12

12

12

Seg

Seg

Seg

Seg

MSB LSB

BYTE2b7b6b5b4b3b2b1b0RC hotkey 1

Description: To configure an RC hotkey two bytes are required. The first byte is used to specify the

RC address and the second byte is used to specify the hotkey command. Hence

there is the option of having 8 hot ke ys fro m the same RC addr ess or one hotk e y each

for 8 different RC address.

byte1, byte2: RC hotkey1

byte3, byte4: RC hotkey2

byte5, byte6: RC hotkey3

byte7, byte8: RC hotkey4

byte9, byte 10: RC hotkey5

byte11, byte12: RC hotkey6

byte13, byte14: RC hotkey7

byte15, byte16: RC hotkey8

If less than 8 RC hotkeys are required, there is no need to fill all the 16 bytes . The number of

configuration bytes sent will depends on how many hotkeys.