Features

■ Continuous current (typ): 3.6 A

■ N-channel on-resistance (typ): 53 mΩ

■ Enable/Fault functions

■ Output clamp voltage (typ):15 V

■ Undervoltage lockout

■ Short-circuit limit

■ Overload current limit

■ Controlled output voltage ramp

■ Thermal latch (typ): 165 °C

■ Uses tiny capacitors

■ Operating junction temp. - 40 °C to 125 °C

■ Available in DFN10 (3x3 mm) package

Applications

■ Hard disk drives

■ Solid state drives (SSD)

■ Hard disk and SSD arrays

■ Set-top boxes

■ DVD and Blu-ray disc drivers

Description

The STEF12 is an integrated electronic fuse

optimized for monitoring output current and input

voltage. Connected in series to a 12 V rail, it is

capable of protecting the electronic circuitry on its

output from overcurrent and overvoltage. The

device has a controlled delay and turn-on time.

When an overload condition occurs, the STEF12

limits the output current to a predefined safe

value. If the anomalous overload condition

STEF12

Electronic fuse for 12 V line

Datasheet − production data

DFN10 (3x3 mm)

persists it goes into an open state, disconnecting

the load from the power supply. If a continuous

short-circuit is present on the board, when power

is re-applied the E-fuse initially limits the output

current to a safe value and then again goes into

an open state. The device is equipped with a

thermal protection circuit. The intervention of the

thermal protection is signalled to the board

monitoring circuits through a signal on the Fault

pin. Unlike the mechanical fuses, which must be

physically replaced after a single event, the Efuse does not degrade in its performance after

short-circuit/thermal protection interventions and

it is reset either by recycling the supply voltage or

using the Enable pin. The companion chip for the

5 V power rails is also available with part number

STEF05.

Table 1. Device summary

Order code Package Packaging

STEF12PUR DFN10 (3x3 mm) Tape and reel

March 2012 Doc ID 019056 Rev 4 1/20

This is information on a product in full production.

www.st.com

20

Contents STEF12

Contents

1 Device block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Typical application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 Turn-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.2 Normal operating condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.3 Output voltage clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.4 Current limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.5 Thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 R limit calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 C

5.4 Enable/Fault pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

dv/dt

6 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/20 Doc ID 019056 Rev 4

STEF12 Device block diagram

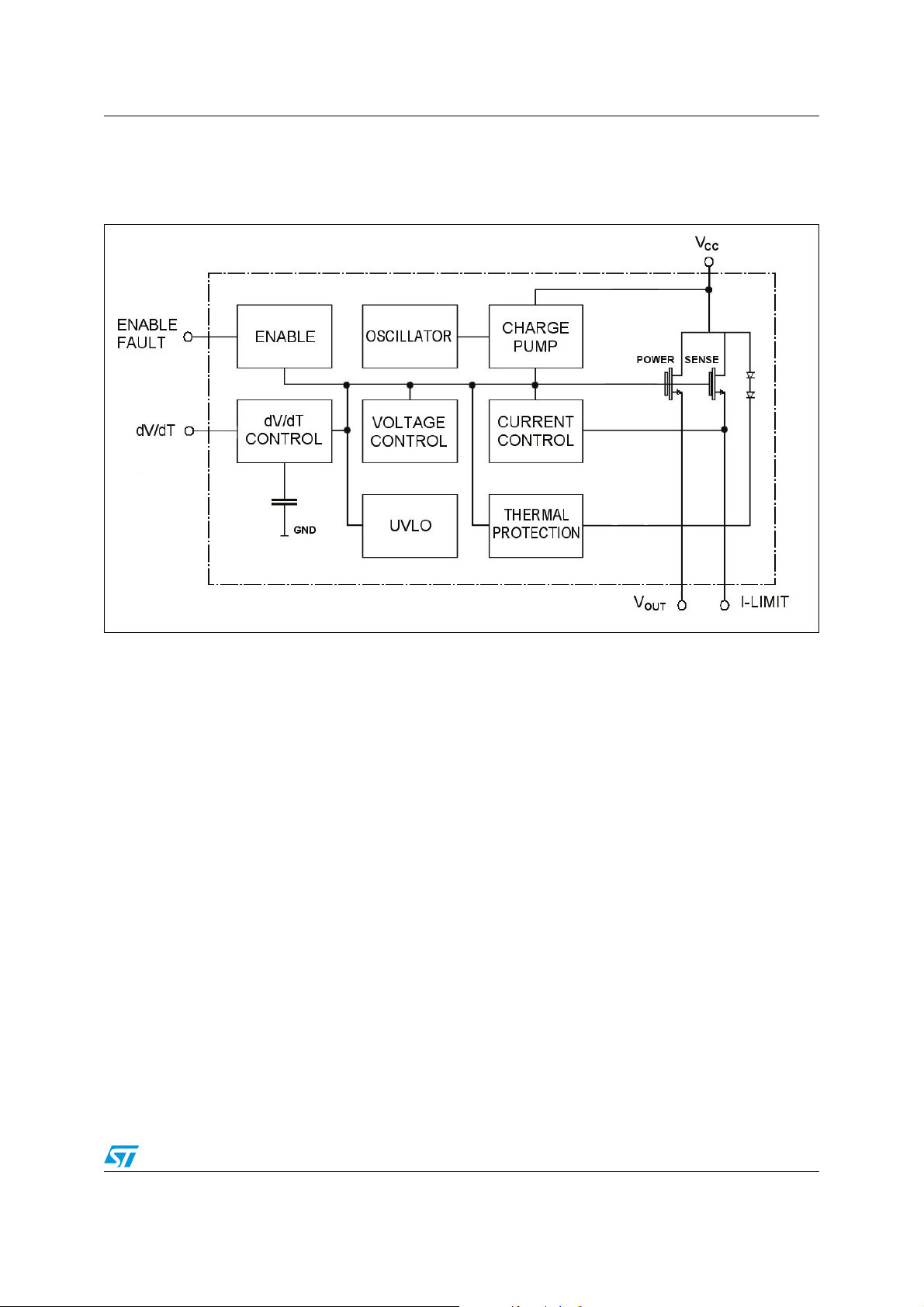

1 Device block diagram

Figure 1. STEF12 block diagram

AM09891v1

Doc ID 019056 Rev 4 3/20

Pin configuration STEF12

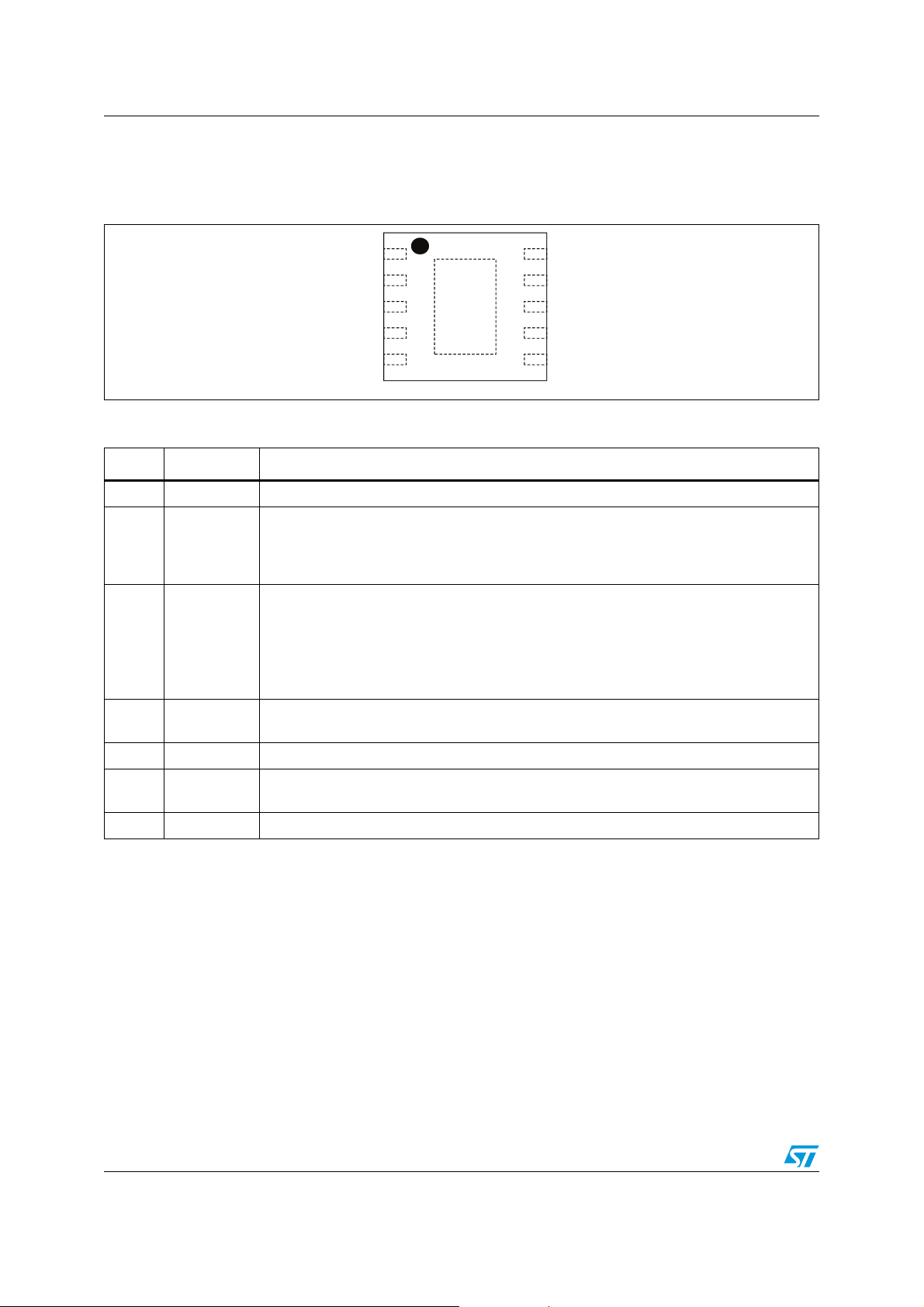

2 Pin configuration

Figure 2. Pin configuration (top view)

GND

dv/dt

V

En/fault

CC

I-Limit

N/C

AM09880v1

Table 2. Pin description

Pin n° Symbol Note

1 GND Ground pin

The internal dv/dt circuit controls the slew rate of the output voltage at turn-on. The

2dv/dt

3 En/Fault

internal capacitor allows a ramp-up time of around 1ms. An external capacitor can be

added to this pin to increase the ramp time. If an additional capacitor is not required, this

pin should be left open.

The Enable/Fault pin is a tri-state, bi-directional interface. During normal operation the pin

must be left floating, or it can be used to disable the output of the device by pulling it to

ground using an open drain or open collector device.

If a thermal fault occurs, the voltage on this pin goes into an intermediate state to signal a

monitor circuit that the device is in thermal shutdown. It can be connected to another

device of this family to cause a simultaneous shutdown during thermal events.

Source

Source

Source

Source

Source

4 I-Limit

5 NC Not connected

6 to 10 V

11 V

4/20 Doc ID 019056 Rev 4

OUT

/Source

CC

A resistor between this pin and the Source pin sets the overload and short-circuit current

limit levels.

Connected to the source of the internal power MOSFET and to the output terminal of the

fuse

Exposed pad. Positive input voltage must be connected to VCC.

STEF12 Maximum ratings

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

CC

/source (max 100ms) -0.3 to Vcc+0.3 V

V

OUT

Positive power supply voltage (max 100ms) -0.3 to 25

V

I-Limit (max 100ms) -0.3 to 25 V

En/Fault -0.3 to 7 V

dv/dt -0.3 to 7 V

Positive power supply voltage (steady state) -0.3 to 18

T

op

T

STG

T

LEAD

1. The thermal limit is set above the maximum thermal rating. It is not recommended to operate the device at temperatures

greater than the maximum ratings for extended periods of time.

Operating junction temperature range

Storage temperature range -65 to 150 °C

Lead temperature (soldering) 10 sec 260 °C

(1)

-40 to 125 °C

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied.

Table 4. Thermal data

Symbol Parameter Value Unit

R

R

thJA

thJC

Thermal resistance junction-ambient 52.7 °C/W

Thermal resistance junction-case 17.4 °C/W

Table 5. ESD performance

Symbol Parameter Test conditions Value Unit

HBM 1 kV

ESD ESD protection

Doc ID 019056 Rev 4 5/20

MM 200 V

CDM 500 V

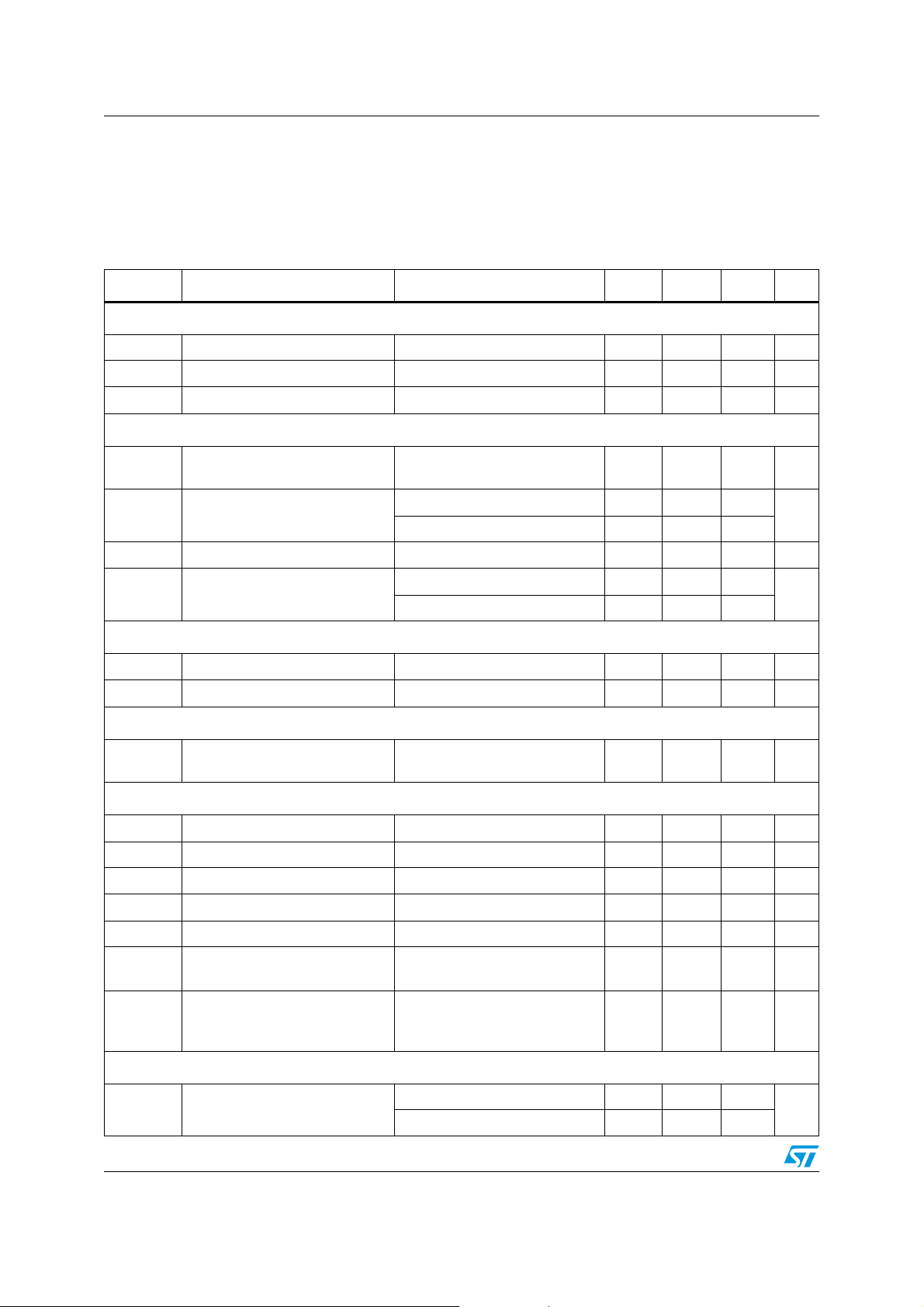

Electrical characteristics STEF12

4 Electrical characteristics

VCC = 12 V, V

= 3.3 V, CI = 10 µF, CO = 47 µF, TJ = 25 °C (unless otherwise specified).

EN

Table 6. Electrical characteristics for STEF12

Symbol Parameter Test Conditions Min. Typ. Max. Unit

Under/Overvoltage protection

V

Clamp

V

UVLO

V

Hyst

Power MOSFET

t

dly

R

DSon

V

OFF

I

Current limit

Output clamping voltage VCC = 18 V 13.8 15 16.2 V

Undervoltage lockout Turn-on, voltage rising 7.7 8.5 9.3 V

UVLO hysteresis 0.80 V

Delay time

On-resistance

Off state output voltage VCC = 18 V, V

Continuous current

D

Enabling of chip to I

with a 1 A resistive load

(1)

- 40 °C < TJ < 125 °C

GS

2

0.5in

pad, TA = 25 °C

Minimum copper, TA = 80 °C 1.7

= 100 mA

D

350 µs

35 53 70

(2)

= 0, RL = infinite 40 100 mV

(1)

3.6

82

mΩ

A

I

Short

I

Lim

Short-circuit current limit R

Overload current limit R

dv/dt circuit

dv/dt Output voltage ramp time

Enable/Fault

V

V

V

I(MAX)

V

I(INT)

I

Low level input voltage Output disabled 0.35 0.58 0.81 V

IL

Intermediate level input voltage Thermal fault, output disabled 0.82 1.4 1.95 V

High level input voltage Output enabled 1.96 2.64 3.3 V

IH

High state maximum voltage 3.4 4.3 5.4 V

Low level input current (sink) V

IL

High level leakage current for

I

I

external switch

Maximum fan-out for fault signal

Total device

I

Bias

Bias current

= 22 Ω 3.3 4.4 5.5 A

Limit

= 22 Ω 4.4 A

Limit

Enable to V

C

dv/dt

= 0 V -10 -30 µA

Enable

V

= 3.3 V 1 µA

Enable

= 11.7 V, No

OUT

0.5 0.9 2.6 ms

Total numbers of chips that can

be connected to this pin for

simultaneous shutdown

Device operational 1.5 2

Thermal shutdown 1

3Units

mA

6/20 Doc ID 019056 Rev 4

STEF12 Electrical characteristics

Table 6. Electrical characteristics for STEF12 (continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

min

Minimum operating voltage 7.6 V

Thermal latch

TSD Shutdown temperature

1. Pulse test: Pulse width = 300 µs, Duty cycle = 2%

2. Guaranteed by design, but not tested in production

(1)

165 °C

Doc ID 019056 Rev 4 7/20

Typical application STEF12

5 Typical application

Figure 3. Application circuit

Figure 4. Typical HDD application circuit

5.1 Operating modes

5.1.1 Turn-on

When the input voltage is applied, the Enable/Fault pin goes up to the high state, enabling

the internal control circuitry.

After an initial delay time of typically 350 µs, the output voltage is supplied with a slope

defined by the internal dv/dt circuitry. If no additional capacitor is connected to dv/dt pin, the

total time from the Enable signal going high and the output voltage reaching the nominal

value is around 1 ms (refer to

8/20 Doc ID 019056 Rev 4

Figure 5, 15

)

AM09869v1

STEF12 Typical application

5.1.2 Normal operating condition

The STEF12 E-fuse behaves like a mechanical fuse, buffering the circuitry on its output with

the same voltage shown at its input, with a small voltage fall due to the N-channel MOSFET

R

.

DSOn

5.1.3 Output voltage clamp

This internal protection circuit clamps the output voltage to a maximum safe value, typically

15 V, if the input voltage exceeds this threshold.

5.1.4 Current limiting

When an overload event occurs, the current limiting circuit reduces the conductivity of the

power MOSFET, in order to clamp the output current at the value selected externally by

means of the limiting resistor R

Limit

(

Figure 3

).

5.1.5 Thermal shutdown

If the device temperature exceeds the thermal latch threshold, typically 165 °C, the thermal

shutdown circuitry turns the power MOSFET off, thus disconnecting the load. The EN/Fault

pin of the device is automatically set at an intermediate voltage, in order to signal the

overtemperature event. In this condition the E-fuse can be reset either by cycling the supply

voltage or by pulling down the EN pin below the V

threshold and then releasing it.

il

5.2 R limit calculation

As shown in

monitor the output current and limit it at the level set by the user.

The R

following theoretical formula, together with the graph in

Equation 1

5.3 C

Connecting a capacitor between the C

output voltage ramp-up time.

Given the desired time interval Δt during which the output voltage goes from zero to its

maximum value, the capacitance to be added on the C

following theoretical formula:

Equation 2

dv/dt

Figure 3

value for achieving the requested current limitation can be estimated by using the

Limit

, the device uses an internal N-channel sense FET with a fixed ratio, to

calculation

RLimit

C

dvdt

Figure 13: Current limit vs. RLimit

95

--------------=

Short

I

pin and GND allows the modification of the

dv/dt

pin can be calculated using the

dv/dt

24 109–×Δt30x10

–=

12–

.

Where C

is expressed in Farads and the time in seconds.

dv/dt

Doc ID 019056 Rev 4 9/20

Typical application STEF12

The addition of an external C

between the Enable signal going high and the start of the V

influences also the initial delay time, defined as the time

dv/dt

OUT

slope (

Figure 5).

The contribution of the external capacitor to this time interval can be estimated by using the

following theoretical formula:

Equation 3

delay time 350 106–11.3 106×+× C

Figure 5. Delay time and V

12

10

delay

time

8

V

6

4

2

ramp-up time

OUT

ramp-up

time

×=

dvdt

AM09882v1

En/Fault

VOUT

0

5.4 Enable/Fault pin

The Enable/Fault pin has the dual function of controlling the output of the device and, at the

same time, of providing information about the device status to the application.

When it is used as a standard Enable pin, it should be connected to an external open-drain

or open-collector device. In this case, when it is pulled at low logic level, it turns the output of

the E-Fuse off.

If this pin is left floating, since it has internal pull-up circuitry, the output of the E-Fuse is kept

ON, in normal operating conditions.

In case of thermal fault, the pin is pulled to an intermediate state (

be provided to a monitor circuit, informing it that a thermal shutdown has occurred, or it can

be directly connected to the Enable/Fault pins of other STEFxx devices on the same

application in order to achieve a simultaneous enable/disable feature.

When a thermal fault occurs, the device can be reset either by cycling the supply voltage or

by pulling down the Enable pin below the V

Time

Figure 6

threshold and then releasing it.

il

). This signal can

10/20 Doc ID 019056 Rev 4

STEF12 Typical application

Figure 6. Enable/Fault pin status

5

Normal operating condition

4

3

2

EN/Fault voltage [V]

1

Thermal fault condition

Off/Reset

0

time

AM09871v1

Doc ID 019056 Rev 4 11/20

Typical performance characteristics STEF12

6 Typical performance characteristics

The following plots are referred to the typical application circuit and, unless otherwise noted,

= 25 °C.

at T

A

Figure 7. Clamping voltage vs. temperature Figure 8. UVLO voltage vs. temperature

16.5

16

15.5

15

Output Voltage (V)

14.5

14

13.5

V

= 18 V

CC

-40 -25 0 25 55 85 125 150

Temperature °C

AM09883v1

9.5

9.3

9.1

8.9

8.7

8.5

8.3

UVLO V oltage (V)

8.1

7.9

7.7

7.5

-40 -25 0 25 5 5 85125150

VCC= from 0 to 12 V, R

Temperature °C

LIMIT

= 15 Ω

AM09884v1

Figure 9. UVLO hysteresis vs. temperature Figure 10. Off-state voltage vs. temperature

1.4

1.2

VCCfrom 12 to 0 V, R

1

0.8

0.6

UVLO Hy steresys (V)

0.4

0.2

-40 -25 0 25 55 85125150

Temperature °C

Figure 11. Bias current (device operational) Figure 12. ON resistance vs. temperature

3

2.5

VCC= 12 V, R

2

1.5

Current (mA)

1

0.5

LIMIT

LIMIT

= 15 Ω

= 15 Ω

AM09885v1

AM09887v1

250

V

= 18 V, V

CC

200

150

100

Output Voltage (mV)

50

0

-40 -25 0 25 55 85 125 150

90

80

70

60

ON (mΩ)

50

DS

R

40

30

V

CC

= 12 V, R

= 0, RL = infi nite

GS

Temperature °C

= 15 Ω, I

LIMIT

LOAD

= 1 A

AM09886v1

AM09888v1

0

-40 -25 0 25 55 85 125 150

Temperature °C

20

12/20 Doc ID 019056 Rev 4

-40 -25 0 2 5 55 85 125

Temperature °C

STEF12 Typical performance characteristics

Figure 13. Current limit vs. R

9.00

8.00

7.00

6.00

5.00

4.00

3.00

Limit & Short Current (A)

2.00

1.00

0.00

01020304050607080

Figure 15. V

External Sensing Resistor (Ω)

ramp-up vs. Enable Figure 16. V

OUT

Limit

V

= 12 V, T = 25 °C

CC

ILIM

ISHORT

AM09889v1

Figure 14. Thermal latch delay vs. power

800

T=25 °C

80

8

Thermal Action Time (ms)

0.8

0102030405060

clamping

OUT

Power (W)

T=55 °C

T=85 °C

AM09890v1

V

= 12 V, C

CC

C

dv/dt,

Figure 17. Line transient Figure 18. Startup into output short-circuit

V

= from 12 to 18 V R

CC

= 100 µs

= 10 µF, C

IN

T = 25°C

OUT

LIMIT

= 10 µF, R

= 22 Ω; I

LIMIT

= 500 mA, T

OUT

= 22 Ω, No

RISE

V

CC

V

CC

= 18 V, C

= 12 V, R

= 10 µF, R

IN

= 22 Ω, V

LIMIT

= 22 Ω, No C

LIMIT

= Connected to GND

OUT

dv/dt

,T = 25°C

Doc ID 019056 Rev 4 13/20

Typical performance characteristics STEF12

Figure 19. Thermal latch from 2 A load to

short-circuit

Figure 20. Startup into output short-circuit

(fast rise)

V

= 12 V, R

CC

LIMIT

= 22 Ω, V

= Connected to GND

OUT

14/20 Doc ID 019056 Rev 4

STEF12 Package mechanical data

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at:

ECOPACK

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

www.st.com

.

Table 7. DFN10L (3x3 mm.) mechanical data

Dim.

Min. Typ. Max.

A 0.80 0.90 1.00

A1 0.02 0.05

A2 0.55 0.65 0.80

A3 0.20

b 0.18 0.25 0.30

D 2.85 3.00 3.15

D2 2.20 2.70

E 2.85 3.00 3.15

E2 1.40 1.75

e0.50

L 0.30 0.40 0.50

mm.

ddd 0.08

Doc ID 019056 Rev 4 15/20

Package mechanical data STEF12

Figure 21. DFN10L package outline

16/20 Doc ID 019056 Rev 4

7426335_G

STEF12 Package mechanical data

Tape & reel QFNxx/DFNxx (3x3) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A180 7.087

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N60 2.362

T 14.4 0.567

Ao 3.3 0.130

Bo 3.3 0.130

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

Doc ID 019056 Rev 4 17/20

Package mechanical data STEF12

Figure 22. DFN10L footprint - recommended data (dimensions in mm.)

7426335_G

18/20 Doc ID 019056 Rev 4

STEF12 Revision history

8 Revision history

Table 8. Document revision history

Date Revision Changes

15-Jul-2011 1 Initial release.

08-Aug-2011 2 Modified definition for Top in

14-Dec-2011 3 Removed V

06-Mar-2012 4

Updated: package mechanical data

Figure 22 on page 18

and

dv/dt

and I

rows from dv/dt circuit

dv/dt

Table 3: Absolute maximum ratings

Table 6 on page 6

Table 7 on page 15, Figure 21 on page 16

.

.

.

Doc ID 019056 Rev 4 19/20

STEF12

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

20/20 Doc ID 019056 Rev 4

Loading...

Loading...