Page 1

查询STE2007DIE2供应商

STE2007

96 x 68 Single Chip LCD Controller/Driver

Features

■ 68 x 96 bits Display Data RAM

■ 33,49, 65 and 68 Lines Mode

■ Row by Row Scrolling

■ Interfaces

– 3-lines Serial Interface (read and write)

2

C (read and write)

–I

– 4-Line Serial (read and write)

■ Partial Display Mode (33,25,17,9 Lines Mode)

■ Fully Integrated Oscillator requires no external

components

■ CMOS Compatible Inputs

■ Programmable ID-Number

■ Programmable Bias Ratio

■ Programmable Columns Organization

■ Fully Integrated Configurable LCD bias voltage

generator with:

– Selectable multiplication factor (3x, 4X and

5X)

– Effective sensing for High Precision Output

– Eight selectable temperature compensation

coefficients

■ Designed for chip-on-glass (COG) applications

■ Low Power Consumption, suitable for battery

operated systems

■ Interfaces Supply Voltage range from 1.6 to

3.6V

■ High Voltage Generator Supply Voltage range

from 2.4 to 3.6V

■ Display Supply Voltage range from 3 to 13.2V

= 25°C)

(T

amb

Description

The STE2007 is a low power LCD driver, capable

to drive 96 columns and up to 68 lines, designed

for monochrome displays.

The STE2007 includes fully integrated bias

voltage generator (up to 5x multiplication factor),

and internal oscillator, thus reducing to minimum

the number of external components required and

the current consumption.

The STE2007 features the three standard serial

interfaces (3 and 4 lines serial, I

2

C interface).

Order codes

Type Ordering Number

Bumped Dice on Waffle Pack STE2007DIE2

Rev 1

November 2005 1/62

www.st.com

62

Page 2

STE2007

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Driver Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 CPU Interface Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Power Supply Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Configuration Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Test Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Display Driver Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 MCU Tx Data Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.1 Driver TxData Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2 Reset Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 3-lines 9 bit Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.1 MCU TxData Mode (Write Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.2 Driver TxData Mode (Read Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 4-Line SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 MCU TxData Mode (Write Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Driver TxData Mode (Read Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.2 Starting the Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.3 MCU TxData Mode (Write Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.4 Driver TxData Mode (Read Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Reading Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 IIdentification byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Display Data RAM (DDRAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 DDRAM and Page/column address circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/62

Page 3

STE2007

5.2 Line address circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 Partial Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.1 33 Line Partial Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.2 25 Line Partial Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3.3 17 Line Partial Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.4 9 Line Partial Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4 Command Parameters Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . 38

6 Instruction Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Initialization (Power ON Sequence) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2 Display Data Writing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3 Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Power ON/Power OFF timing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

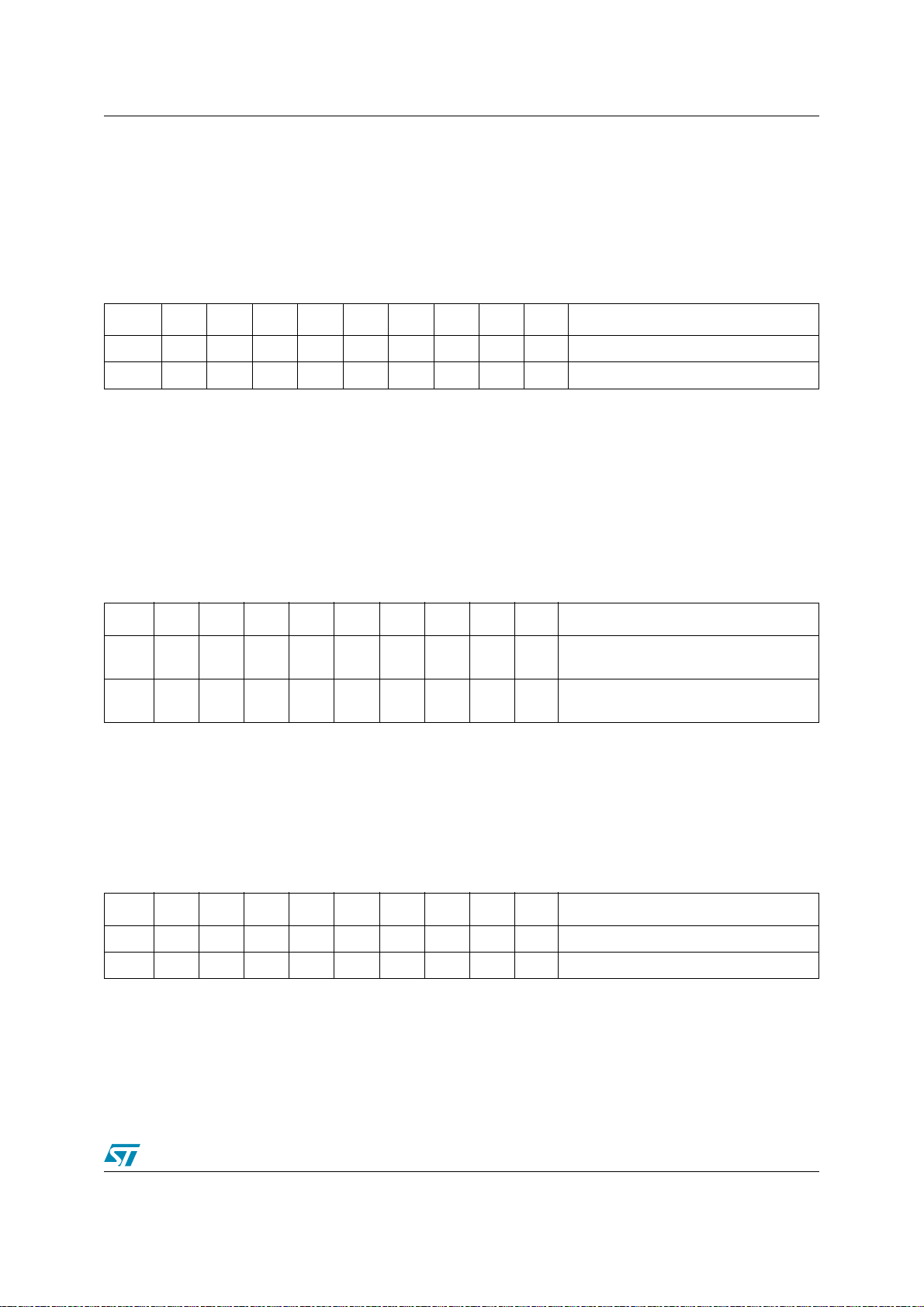

8.1 Display ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Display normal/reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.3 Display all points ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4 Page address set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.5 Column address set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.6 Display start line address set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.7 Segment driver direction select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.8 Common driver direction select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.9 Display data write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.10 Data reading from driver (Driver TxData–mode) . . . . . . . . . . . . . . . . . . . . . . 46

8.11 Power Control Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.12 VLCD set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.12.1 V0R - Voltage Range Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.12.2 VOP Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.12.3 Electronic volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.13 Power saver mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.14 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.15 NOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.16 Image Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3/62

Page 4

STE2007

8.17 Bias Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.18 Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.19 Charge Pump Multiplication Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.20 Refresh Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.21 Icon Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.22 N- Line Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.23 Number of Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9 Chip Mechanical Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4/62

Page 5

STE2007 1 Introduction

1 Introduction

In this document is specified LCD driver for Black&White full graphic displays with a resolution

of 96x68, 96x65, 96x49, and 96x33 (ColumnsXRows).

Abbreviations

LCD Liquid Crystal Display

COG Chip On Glass –technology

MCU Micro Controller Unit

DDRAM Display Data Random Access Memory

MSB Most Significant Bit

LSB Least Significant Bit

T.B.D. To Be Defined

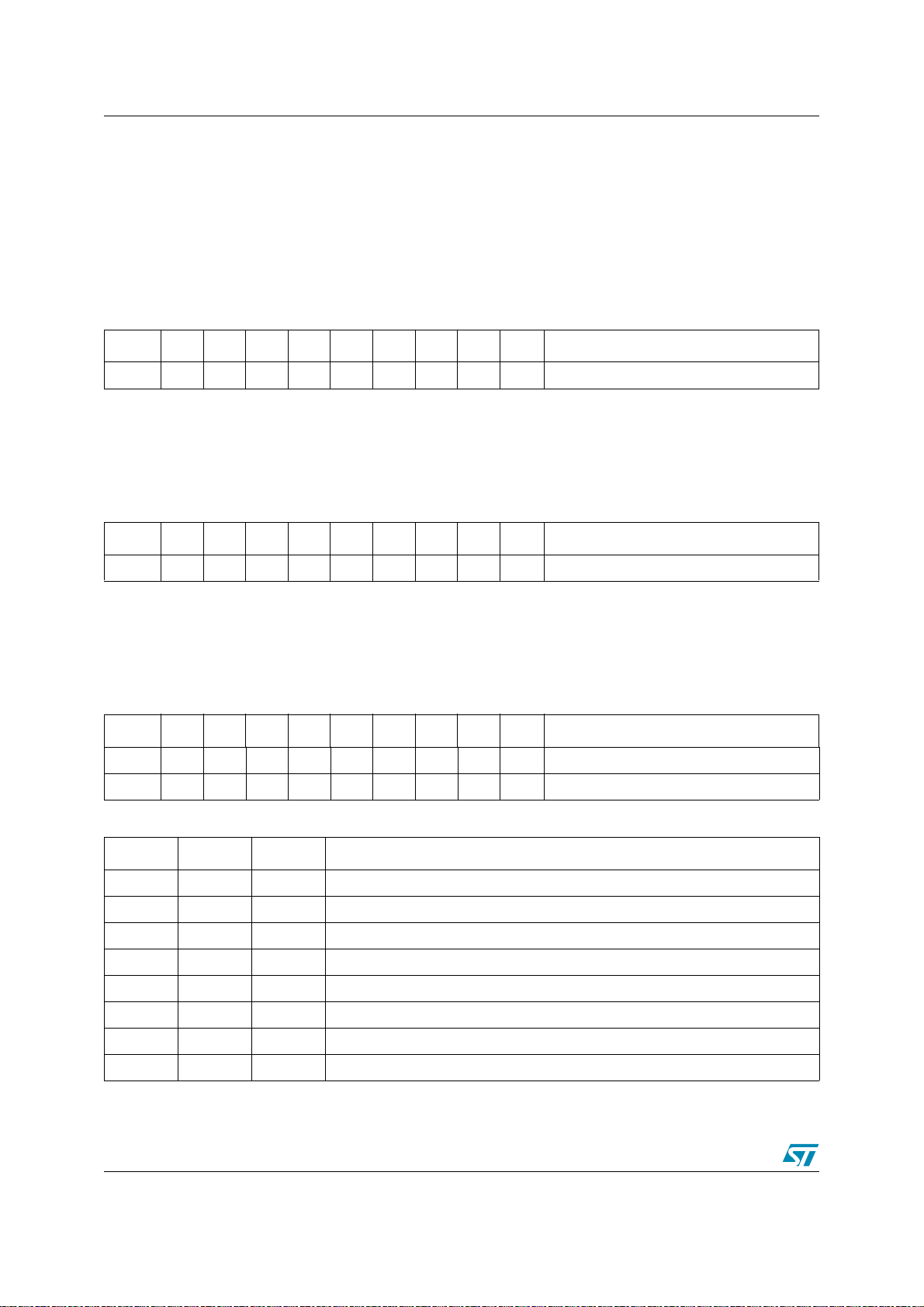

Table 1. General Driver Parameters

Driver assembly technology

Chip On Glass (COG)

Memory Size

(Columns x Rows)

96x68

DDRAM capacity:

6528 bits

Mux

1:68

1:65

1:49

1:33

Frame frequency (Hz)

65

70

75

80

5/62

Page 6

1 Introduction STE2007

Figure 1. Chip Mechanical Drawing

R66

STE2007

45µm

(0,0)

X

BUMP SIDE

Y

72µm

! /

!

!

VSS_AUX

VSS_AUX

VSS_AUX

VSS_AUX

R67

R65

6/62

Page 7

STE2007 2 Driver Pin Description

2 Driver Pin Description

2.1 CPU Interface Pins

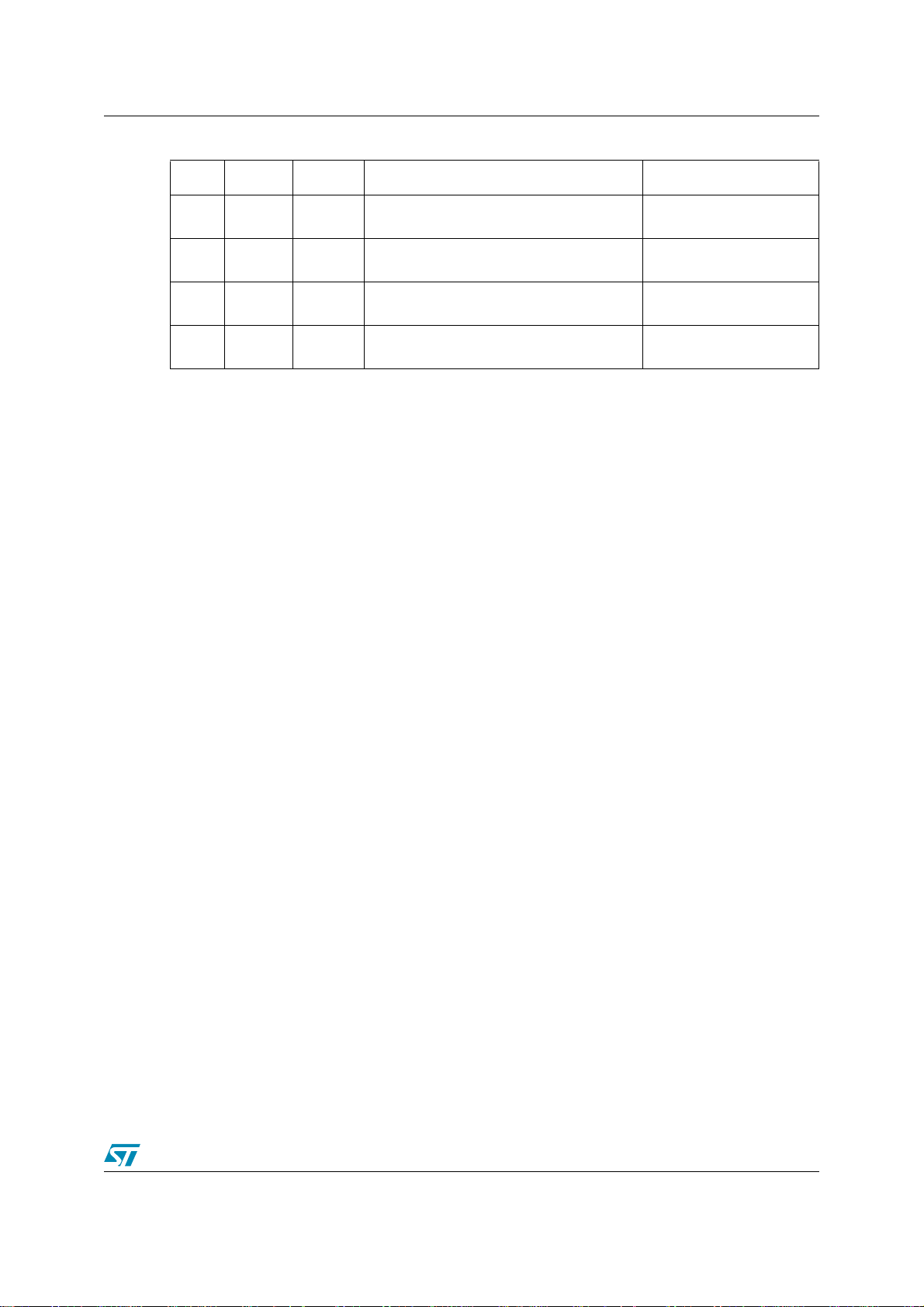

Table 2. CPU Interface Logic

PIN Signal Type Description Note

!RES I Reset Input

When Low the

!CS I Chip Select Input

SDOUT 0 Serial Data Output

SDAIN I

SCLK I

SDA_OUT 0

SA1 I

SA0 I

!D/C I 4 Line SPI Data/Command Selector

Serial Data Input /I

Serial Clock Input/I

2

C Bus Data Out

I

2

C Slave Address

I

2

C Slave Address

I

2

C Interface Data Input

2

C Interface Clock

communication port is

enabled

Must be connected to

SDAIN at Module

Level

Must be left floating

when I2C Interface is

not is use

Cannot be left floating

Cannot be left floating

Must be connected to

VSSAUX at Module

Level when 4-Line SPI

is not in USE

2.2 Power Supply Pins

Table 3. Power Supply Pins

PIN Signal Type Description Note

VSS Power Analog & Digital Grounds

VSS_LCD Power Drivers Analog Ground

VSS_CP Power Booster Ground

VDDI Power Digital Power

VDD Power Analog Supply

VDD_CP Power Booster Power Supply

VSSAUX Power Auxiliar Vss Output

Table 4. High Voltage Pins

PIN Signal Type Description Note

V

LCD

V

LCD_SENSE

High

Voltage

High

Voltage

Booster Output

Booster Sense Input

Cext = 0.1-1µF

Connected to Vss

Must be connected to

Vlcd at module level

7/62

Page 8

2 Driver Pin Description STE2007

Table 4. High Voltage Pins (continued)

PIN Signal Type Description Note

COM0 to

COM67

COMS

SEG0 to

SEG95

High

Voltage

High

Voltage

High

Voltage

2.3 Configuration Pins

Table 5. Configuration Pin Description

PIN Signal Type Config Description Note

OSCIN I

SEL0 -SEL1 I

LCD Row Driver Output

LCD Row Driver Output

LCD Column Driver Output

VSS/VSSAUX Internal Oscillator Stopped

VDDI Internal Oscillator Active

SEL1 SEL0 Interface

VSS/VSSAUX VSS//VSSAUX

VSS/VSSAUX VDD1 SPI 4-Lines 8 bit

VDD1 VSS/VSSAUX Serial 3-Lines 9 bit

VDD1 VDD1 Not Used

Unused lines must be

left floating

Unused lines must be

left floating

Unused lines must be

left floating

2

C

I

2.4 Test Pins

Table 6. Test Pin Description

PIN Signal Type Description Note

T2 I Test Input. Enable Test Mode.

T1 I Test Input. Enable Test Mode.

T0 I Test Input.

T3 O Test Output.

IDA I

VSS/VSSAUX IDA=”0”

VDDI IDA=”1”

VSS/VSSAUX IDB=”0”

IDB I

VDDI IDB=”1”

Must Be connected to VSS

in Normal Working Mode

Must Be connected to VSS

in Normal Working Mode

Must Be connected to VSS

in Normal Working Mode

Must Be OPEN in Normal

Working Mode

8/62

Page 9

STE2007 2 Driver Pin Description

Table 6. Test Pin Description (continued)

PIN Signal Type Description Note

T4 O Test Output.

T5 O Test Output.

T6 O Test Output.

VREF_B

UFF

O Analog Test Output Must be left floating

Must Be OPEN in Normal

Working Mode

Must Be OPEN in Normal

Working Mode

Must Be OPEN in Normal

Working Mode

9/62

Page 10

3 Display Driver Electrical Characteristics STE2007

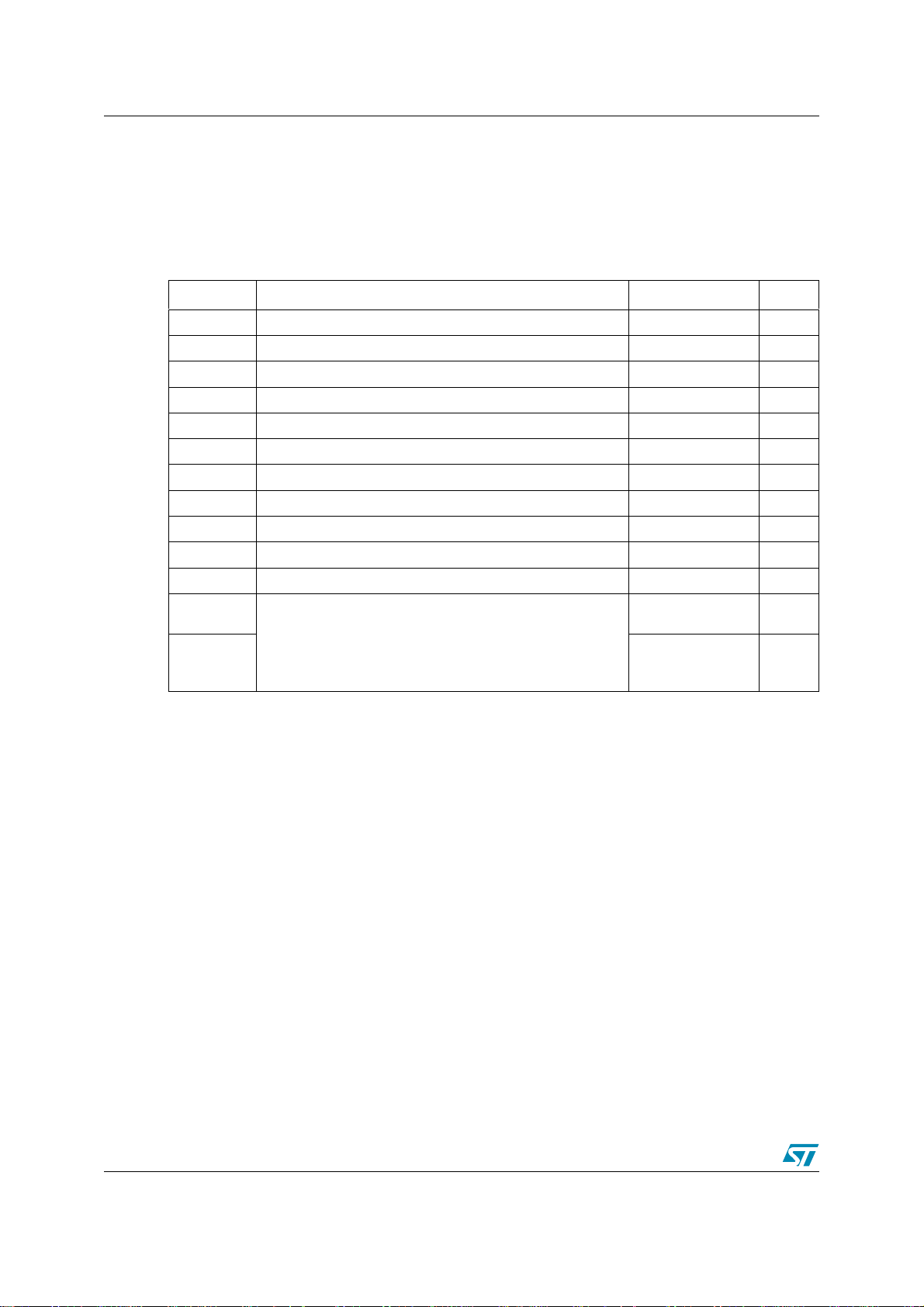

3 Display Driver Electrical Characteristics

3.1 Absolute maximum ratings

Table 7. Absolute maximum ratings

Symbol Parameter Value Unit

V

DDI

V

DD

V

LCD

I

SS

V

I

in

I

out

P

tot

P

o

T

T

stg

All pins vs

VDDI (*) ESD Maximum Withstanding Voltage Range

All other

pins / pin

Supply Voltage Range - 0.5 to + 5 V

Supply Voltage Range - 0.5 to + 5 V

LCD Supply Voltage Range - 0.5 to + 14.0 V

Supply Current - 50 to +50 mA

Digital Inputs Voltage

i

-0.5 to V

DDI

DC Input Current - 10 to + 10 mA

DC Output Current - 10 to + 10 mA

Total Power Dissipation (Tj = 85°C)

300 mW

Power Dissipation per Output 30 mW

Operating Junction Temperature -40 to + 85 °C

j

Storage Temperature - 65 to 150 °C

±1750 V

Test Condition: CDF-AEC-Q100-002- “Human Body Model”

Acceptance Criteria: “Normal Performance”

±2000 V

+ 0.5

combination

Note: (*) ESD tests have been performed with VSS, VSS_LCD and VSS_CP shorted together

V

10/62

Page 11

STE2007 3 Display Driver Electrical Characteristics

3.2 DC Characteristics

Table 8. DC characteristics

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

DD,VDDCP

V

DDI

V

LCD

V

LCD_SENSE

V

LCD

I(V

)

DDI

I(VDD+V

DDCP

)

Logic Inputs

V

IH

V

IL

I

IH

I

lL

Logic Outputs

V

OH

V

OL

Power Supply Voltage Operating Voltage 2.4 3.6 V

Power Supply Voltage(Logic) I/O supply Voltage 1.6 3.6 V

Booster Output 13.5 V

Booster Sense Input 13.5 V

LCD Supply Voltage Accuracy

Logic Supply Current

LCD=10V; VDD=2.6V; T

V

25°C; No display Load;

f

=0Hz

SCLK

Power Saver Mode ON

(Interfaces quiescent)

Power Saver Mode OFF

(Interfaces quiescent)

amb

=

-2 2 %

13µA

620µA

Write Mode 120 250 µA

=10V;Booster= 5X;

V

LCD

f

=0Hz; VDD=2.4V

Analog Supply Current

Logic High level input voltage

Logic Low level input voltage Vss

SCLK

Refresh Rate=75Hz;

no display load;T

amb

= 25°C

0.7V

90 180 µA

DD

I

V

0.3V

DDI

I

DD

V

V

Logic High level input current 1 µA

Logic Low level input current -1 µA

0.8V

Logic High level output voltage

Logic Low level output voltage

= -500µA; VDDI=1.6V

l

OUT

= 500µA; VDDI=1.6V

l

OUT

I

Vss

DD

V

0.2V

DDI

DDl

V

V

Note: 1 T

= -40 to 85°C, unless otherwise specified.

amb

11/62

Page 12

3 Display Driver Electrical Characteristics STE2007

3.3 AC Characteristics

Table 9. AC Operation - Internal Oscillator

Symbol Parameter Test Condition Min. Typ. Max. Unit

VDDI= 1.6; VDD= 2.9V

F

FRAME

Frame Frequency Default

Rafresh Rate = 75Hz

Tamb = -20°C to +70°C

68 75 82 Hz

3.4 MCU Tx Data Mode

Table 10. AC Characteristics for Serial interface

Description Signal Symbol Notes Min. Typ. Max. Unit

tcss 60 ns

Chip Select !CS

Input Serial Data Interface SDAIN

Output Serial Data interface SDAOUT

Serial clock input SCLK

tcsh 100 ns

tchw 50 ns

tsds Data setup time 100 ns

tsdh Data hold time 100 125 ns

tac Access Time 0 100 ns

tod

Output Disable

Time

25 100 ns

tscyc Serial clock cycle 250 ns

tshw

tslw

Serial clock H

pulse width

Serial clock L

pulse width

100 ns

100 ns

Note: 1 The input signal rise and fall times must be within 10ns.

2 Every timing is specified on the basis of 30% and 70% of VDDI.

3T

= -40 to 85°C, unless otherwise specified.

amb

Figure 2. MCU TxData timing

tchw

!CS

SCLK

tf

SDA/MCU TxData

tcss tcsh

tslw

tscyc

tr

tsdhtsds

tchw

tshw

12/62

Page 13

STE2007 3 Display Driver Electrical Characteristics

Table 11. Input Signals Change Time

Signal Symbol Parameter Minimum

Inputs tr,tf 10 ns / to 30% & 70% levels

Typical/

Nominal

Maximum Unit / Notes

3.4.1 Driver TxData Mode

Table 12. Timings based on 4 MHz SCLK Speed

Item Symbol Condition Rating Units

Min. Max.

Data hold time T1 Note 1 100 125 ns

Access time T2 – 10 100 ns

Output disable time T3 – 25 100 ns

Data setup time T4 – 100 – ns

!CS pulse width high T5 – 250 ns

Note: 1 Data Hold Time T1 depends on SCLK high time and Max Data Hold time. It is Always 3-8ns

before SCLK pulse falling edge

2 The input signal rise and fall times must be within 10ns.

3 Every timing is specified on the basis of 30% and 70% of VDDI.

4T

= -40 to 85°C, unless otherwise specified.

amb

Table 13. Timings based on 1 MHz SCLK Speed

Item Symbol Condition Rating Units

Min. Max.

Data hold time *) T1 – 100 125 ns

Access time T2 – 10 450 ns

Output disable time T3 – 25 450 ns

Data setup time T4 – 100 – ns

1CS pulse width high T5 – 250 ns

Note: 1 The input signal rise and fall times must be within 10ns.

2 Every timing is specified on the basis of 30% and 70% of VDDI.

3T

= -40 to 85°C, unless otherwise specified.

amb

13/62

Page 14

3 Display Driver Electrical Characteristics STE2007

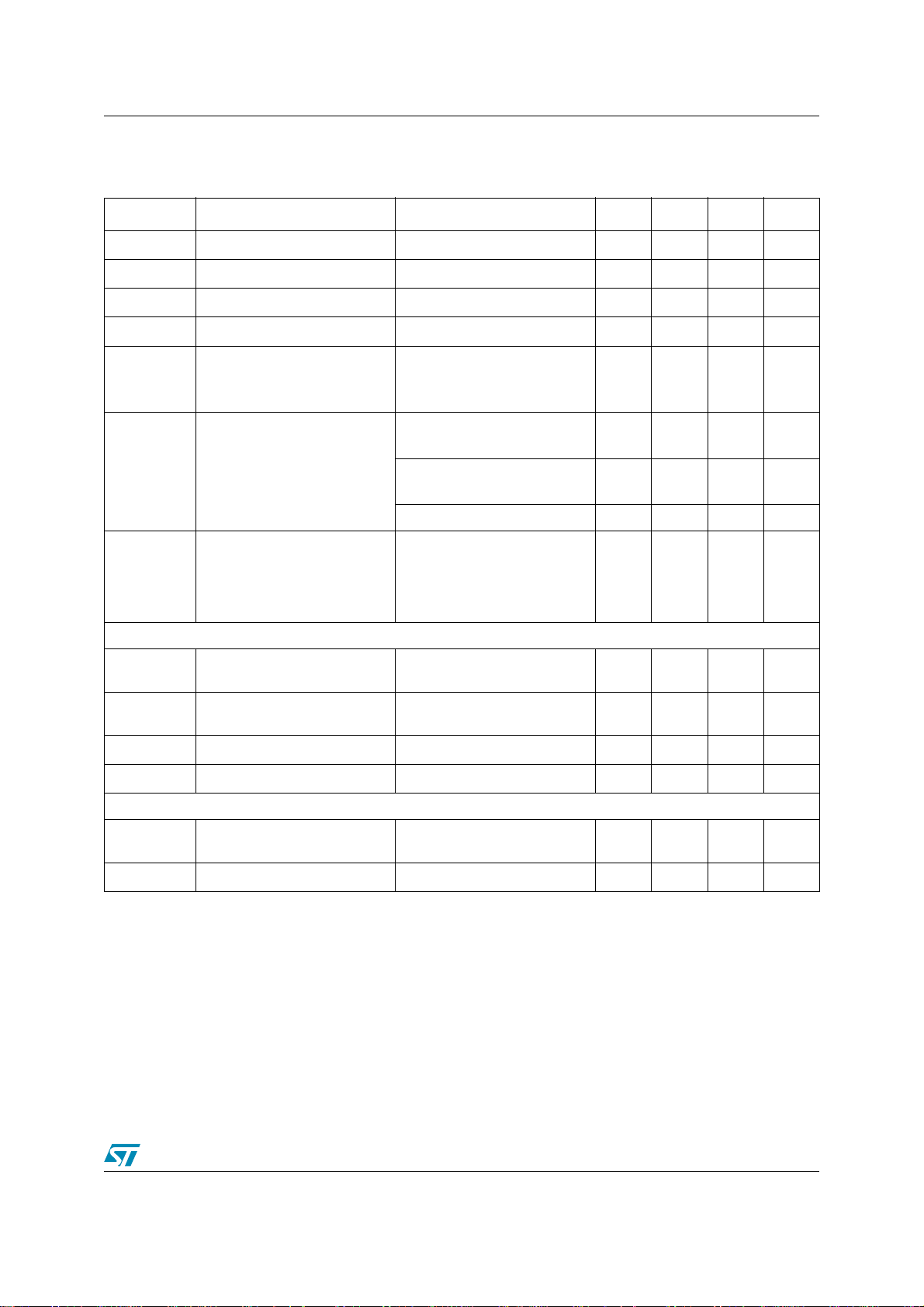

Figure 3. Driver TxData Mode AC timing characteristics

Timing BTiming A

SCLK

MCU TxData

MCU Data direction

Driver TxData

Timing A

SCLK

MCU TxData

Driver TxData

Driver SDA direction

!CS

Timing B

SCLK

MCU TxData

Command

Tx TxRx

Hi±Z

Hi±Z Status

in out

Hi±Z

T1 T2

T3 T4

Command

Hi±Z

D/C

Driver TxData

out inDriver SDA direction

T5

!CS

1/2 SCLK

1/2 SCLK

3.4.2 Reset Timing

Table 14. Reset Timing

Description Signal Symbol Min. Max. Unit

Reset time !RES trs 2500

Reset rejection (for noise spike) !RES trj 1000

Note: 1 The input signal rise and fall times must be within 10ns.

2 Every timing is specified on the basis of 30% and 70% of VDDI.

3T

= -40 to 85°C, unless otherwise specified.

amb

nsReset low pulse width (for valid reset) !RES trw 2500

14/62

Page 15

STE2007 3 Display Driver Electrical Characteristics

Figure 4.

!RES

Internal circuit status

trj

trw

During reset

trs

Normal operation

15/62

Page 16

4 INTERFACE STE2007

4 INTERFACE

4.1 3-lines 9 bit Serial Interface

STE2007 3-lines 9 bits serial interface is a bidirectional link between the display driver and the

host processor.

It consists of three lines:

– SDAIN/SDAOUT Serial Data

– SCLK Serial Clock

– !CS Peripheral enable: - Active Low- Enables and Disables the serial interface

The serial interface is active only if the !CS line is low. If !CS is low after the positive edge of

!RES, the serial interface is ready to receive data after the internal reset time. Serial data must

be input to SDA in the sequence D/!C, D7 to D0. STE2007 read data on SCLK rising edge. The

first bit of serial data D/!C is data/command flag. When D/!C =”1” D7 to D0 bits are display RAM

data or Command Parameters. When D/!C=”0” D7 to D0 bits identify a command

4.1.1 MCU TxData Mode (Write Mode)

STE2007 is always a slave device on the communication bus and receive the communication

clock on the SCLK pin from the master. Information are exchanged word-wide. Every word is

composed by 9 bit. The first bit is named D/!C and indicates whether the following byte is a

command (D/!C =0) or a Display Data Byte (D/!C =1).

During data transfer, the data line is sampled by the receiver unit on the SCLK rising edge.

The data/command received is transferred to DDRAM or Executed on the first falling edge after

the latching rising edge or on the !CS rising edge.

If !CS stays low after the last bit of a command/data byte, the serial interface expects the D/!C

bit of the next data byte on the next SCLK positive edge.

A reset pulse on !RES pin interrupts any transmission.

Figure 5.

!CS

SDA

SCLK

D/C D7 D6 D5 D4 D3 D2 D1 D0 D/C

123456789

4.1.1.1 Data/Command Transfer break

If the Host processor generates an break condition (!CS Line HIGH before having received Bit

D0) while transferring a Data byte to the Frame Memory or a Command identifier or a command

parameter, the not complete received byte is discarded, the communication is interrupted and

the interface is forced in reset state.

D7 D6 D5 D4

1110 12 13 14

When !CS line becomes low again to start a new communication session STE2007 is ready to

receive the same byte interrupted re-transmitted or a new command identifier.

16/62

Page 17

STE2007 4 INTERFACE

3

Figure 6. 3-lines SPI Data Transfer break condition

Break

!CS

SCL

SDA

D7 D6 D5 D4 D3 D7 D6 D5 D4

COMMAND/PARAMETER COMMAND/PARAMETER

4.1.1.2 Data/Command Transfer pause

It is possible while transferring Frame Memory Data, Commands or Command Parameters to

insert a pause in the data transmission (!CS Line HIGH after 8 Bits Received). When !CS is

forced high after a whole byte received, the received byte is processed. Then STE2007 is

forced in a wait state ready to restart processing incoming data from the point where the

communication has been paused

If a new command identifier is transferred after a pause condition the previous communication

session is definitively closed.

Four are the possible conditions:

– Command-Pause-Command

– Command-Pause-Parameter

– Parameter-Pause-Command

– Parameter-Pause-Parameter

D/!C

LR0204

Figure 7. 3-lines SPI Data Transfer Pause

Pause

!CS

SCL

SDA

D3 D2 D1 D0 D7 D6 D5 D4 D3

COMMAND/PARAMETER COMMAND/PARAMETER

4.1.2 Driver TxData Mode (Read Mode)

The Driver TxData–mode is a method to check the electrical interconnection between LCD

driver and baseband, to identify the driver and for VDD Intercfonnection electrical self testing.

D/!C

D2 D1 D0

LR020

17/62

Page 18

4 INTERFACE STE2007

Self Testing of the electrical contacts is based on the monitoring of VLCD. The improper

electrical contact on VDD can be noted from a too low level of VLCD.

The serial interface Driver TxData–mode is controlled by three input signals.

The serial data output (SDAOUT/Driver TxData) and serial clock input (SCLK) are enabled

when !CS is low after having received one Reading Command.

To access Driver TxData–mode a Reading command must be sent to STE2007 driver. The first

bit (D/C) is low to indicates next 8–bits are for command. The data is read to the driver on the

rising edge of SCLK (see section ”MCU TxData–mode”). After last command bit (bit 0) is read

SDAOUT becomes active (Low impedance) and MCU is able to read data from driver.

SDAOUT is forced in high impedence when !CS line is forced high or after the eight SCLK rising

edges from the last SCLK rising edge of teh reading command transfer (Figure 8).

After sending out all 8 bits the driver release automatically the bus and go back to the MCU

TxData–mode. MCU Txdata line changes from high–z to active low or high in the falling edge of

8th SCLK pulse. !CS must be set high and low again before !D/C writing can continue.

If !CS is forced high during the Driver TxDAta-mode, the Driver Tx data session is aborted and

SDAOUT is forced in high impedance Mode.

SDAOUT and SDAIN line can be short circuited in normal working conditions.

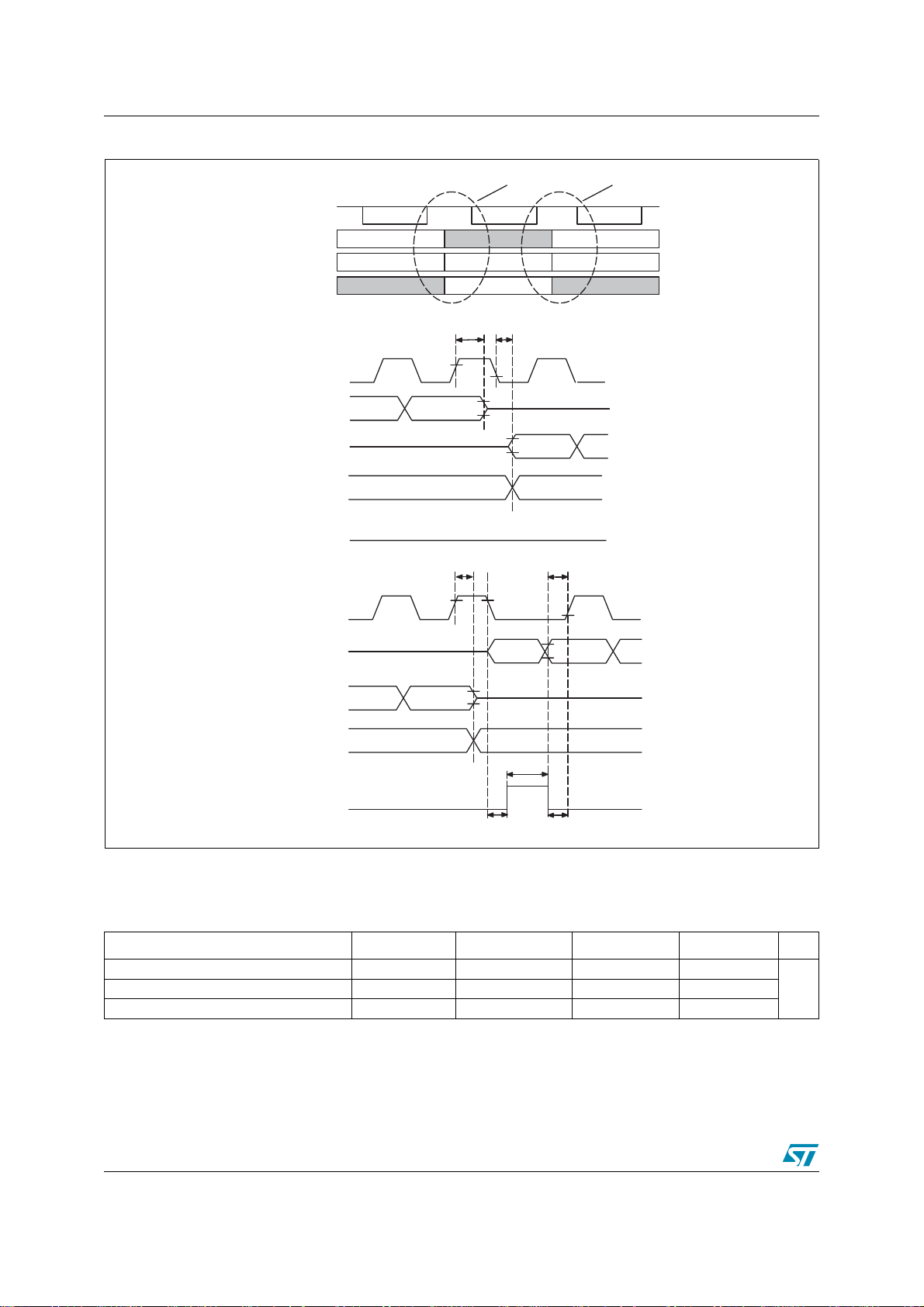

Figure 8. AC timing characteristics

Timing BTiming A

SCLK

MCU TxData

MCU Data direction

Driver TxData

Command

Tx TxRx

Hi±Z

Hi±Z Status

Hi±Z

Command

Hi±Z

Timing A

SCLK

MCU TxData

Driver TxData

Driver SDA direction

!CS

Timing B

SCLK

MCU TxData

Driver TxData

!CS

T1 T2

in out

T3 T4

out inDriver SDA direction

1/2 SCLK

D/C

T5

1/2 SCLK

18/62

Page 19

STE2007 4 INTERFACE

Figure 9. Timing chart for start and stop of data reading from driver

Self Test command writing Reading of status D/C writing

SCLK

MCU TxData

0

Driver TxData

!CS

MCU TxData begins

1

D/C='0' 7

4.2 4-Line SPI

STE2007 4-lines serial interface is a bidirectional link between the display driver and the host

processor.

It consists of four lines:

– SDA Serial Data

– SCL Serial Clock

– !CS Peripheral enable: - Active Low- Enables and Disables the serial interface

– Mode selection (D/!C).

28912

...

...

High Z

...

1

0

Driver TxData begins

7

...

High Z

...

...

6

...

8

7

0

1

MCU TxData begins

1

2

D/C

7

The serial interface is active only if the !CS line is low. If !CS is low after the positive edge of

!RES, the serial interface is ready to receive data after the internal reset time.

4.2.1 MCU TxData Mode (Write Mode)

STE2007 is always a slave device on the communication bus and receive the communication

clock on the SCL pin from the master. Information are exchanged byte-wide. During data

transfer, the data line is sampled by the receiver unit on the SCL rising edge.

D/!C line status set whether the byte is a command (D/!C =0) or a data (D/!C =1); D/!C line is

read on the eighth SCL clock pulse during every byte transfer.

If !CS stays low after the last bit of a command/data byte, the serial interface expects the MSB

of the next data byte on the next SCL positive edge.

If !CS line is forced high in the middle of a data transfer, not complete Data bytes and

Commands bytes are discarded.

A reset pulse on !RES pin interrupts any transmission.

19/62

Page 20

4 INTERFACE STE2007

9

0

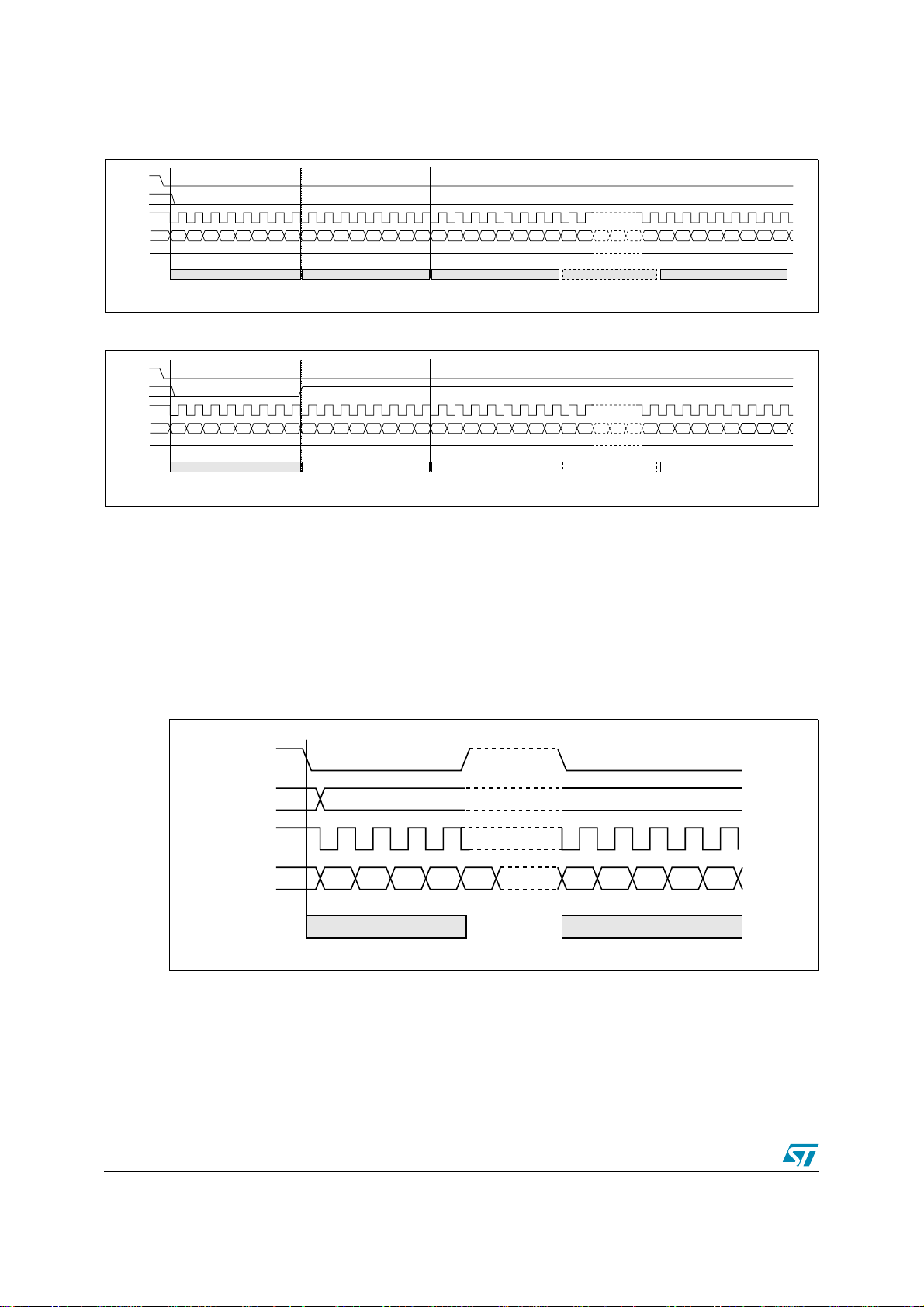

Figure 10. 4-lines SPI Commands Transfe

!CS

D/!C

SCL

SDA

(input)

SDA

(output)

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0 D7

Hi-Z

COMMAND COMMAND

D6 D5 D4 D3 D2 D1 D0 D7 D6

COMMAND COMMAND

D0 D7 D6 D5 D4 D3 D2 D1 D0

LR018

Figure 11. 4-lines SPI Video Data Write Cycle

!CS

D/!C

SCL

SDA

(input)

SDA

(output)

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0 D7

Hi-Z

COMMAND

DATA to VIDEO RAM

D6 D5 D4 D3 D2 D1 D0 D7 D6

DATA to VIDEO RAM

D0 D7 D6 D5 D4 D3 D2 D1 D0

DATA to VIDEO RAM

LR019

4.2.1.1 Data/Command Transfer break

If the Host processor generates an break condition (!CS Line HIGH before having received Bit

D0) while transferring a Data byte to the Frame Memory or a Command identifier or a command

parameter, the not complete received byte is discarded, the communication is interrupted and

the interface is forced in reset state.

When !CS line becomes low again to start a new communication session STE2007 is ready to

receive the same byte interrupted re-transmitted or a new command identifier.

Figure 12. 4-lines SPI Data Transfer break condition

!CS

D/!C

SCL

SDA

D7 D6 D5 D4 D3 D7 D6 D5 D4 D3

COMMAND/PARAMETER COMMAND/PARAMETER

4.2.1.2 Data/Command Transfer pause

Break

LR0192

It is possible while transferring Frame Memory Data, Commands or Command Parameters to

insert a pause in the data transmission (!CS Line HIGH after 8 Bits Received). When !CS is

forced high after a whole byte received, the received byte is processed. Then STE2007 is

forced in a wait state ready to restart processing incoming data from the point where the

communication has been paused

20/62

Page 21

STE2007 4 INTERFACE

5

If a new command identifier is transferred after a pause condition the previous communication

session is definitively closed.

Four are the possible conditions:

– Command-Pause-Command

– Command-Pause-Parameter

– Parameter-Pause-Command

– Parameter-Pause-Parameter

Figure 13. 4-lines SPI Data Transfer Pause

Pause

!CS

D/!C

SCL

SDA

D3 D2 D1 D0 D7 D6 D5 D4 D3

COMMAND/PARAMETER COMMAND/PARAMETER

4.2.2 Driver TxData Mode (Read Mode)

Throughout SDA line is possible to read some registers value (ID Numbers, Status byte,

temperature).

SDA (output Driver) is in High impedance in steady state and during data write.

Figure 14. 4-lines SPI 8Bit Read Cycle

DATA

High Z

!CS

D!C

SCL

SDA

(Input)

SDA

(Output)

MCU Data Tx Start

Read Command

D7 D6 D5 D4 D3 D2 D1 D0

High Z

LCD Driver Data Tx Start

D7 D6 D5 D4 D3 D2 D1

D2 D1 D0

LR0191

Next Command

D7 D6 D5 D4 D3 D2 D1 D0

D0

LR025

MCU Data Tx Start

4.3 I2C Bus

The I2C interface is a fully complying I2C bus specification, selectable to work in both Fast

(400kHz Clock) and High Speed Mode (3.4MHz).

This bus is intended for communication between different ICs. It consists of two lines: one bidirectional for data signals (SDA) and one for clock signals (SCL). Both the SDA and SCL lines

must be connected to a positive supply voltage via an active or passive pull-up.

The following protocol has been defined:

21/62

Page 22

4 INTERFACE STE2007

– Data transfer may be initiated only when the bus is not busy.

– During data transfer, the data line must remain stable whenever the clock line is high.

Changes in the data line while the clock line is high will be interpreted as a Start or

Stop Data Transfer condition (see below).

Accordingly, the following bus conditions have been defined:

BUS not busy: Both data and clock lines remain High.

Start Data Transfer: A change in the state of the data line, from High to Low, while the clock is

High, define the START condition.

Stop Data Transfer: A Change in the state of the data line, from low to High, while the clock

signal is High, defines the STOP condition.

Data Valid: The state of the data line represents valid data when after a start condition, the

data line is stable for the duration of the High period of the clock signal. The data on the line

may be changed during the Low period of the clock signal. There is one clock pulse per bit of

data.

Each data transfer starts with a start condition and terminated with a stop condition. The

number of data bytes transferred between the start and the stop conditions is not limited. The

information is transmitted byte-wide and each receiver acknowledges with the ninth bit.

By definition, a device that gives out a message is called "transmitter", the receiving device that

gets the signals is called "receiver". The device that controls the message is called "master".

The devices that are controlled by the master are called "slaves"

Acknowledge. Each byte of eight bits is followed by one acknowledge bit. This acknowledge

bit is a low level put on the bus by the receiver, whereas the master generates an extra

acknowledge related clock pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of each

byte. Also, a master receiver must generate an acknowledge after the reception of each byte

that has been clocked out of the slave transmitter. The device that acknowledges has to pull

down the SDA_IN line during the acknowledge clock pulse. Of course, setup and hold time

must be taken into account. A master receiver must signal an end-of-data to the slave

transmitter by not generating an acknowledge on the last byte that has been clocked out of the

slave. In this case, the transmitter must leave the data line High to enable the master to

generate the STOP condition.

Connecting SDA_IN and SDA_OUT together the SDA line become the standard data line.

Having the acknowledge output (SDAOUT) separated from the serial data line is advantageous

in Chip-On-Glass (COG) applications. In COG applications where the track resistance from the

SDAOUT pad to the system SDA line can be significant, a potential divider is generated by the

bus pull-up resistor and the Indium Tin Oxide (ITO) track resistance. It is possible that during

the acknowledge cycle the STE2007 will not be able to create a valid logic 0 level. By splitting

the SDA input from the output the device could be used in a mode that ignores the

acknowledge bit. In COG applications where the acknowledge cycle is required, it is necessary

to minimize the track resistance from the SDACK pad to the system SDA line to guarantee a

valid LOW level.

2

To be compliant with the I

C-bus Hs-mode specification the STE2007 is able to detect the

special sequence "S00001xxx". After this sequence no acknowledge pulse is generated.

Since no internal modification are applied to work in Hs-mode, the device is able to work in Hsmode without detecting the master code.

22/62

Page 23

STE2007 4 INTERFACE

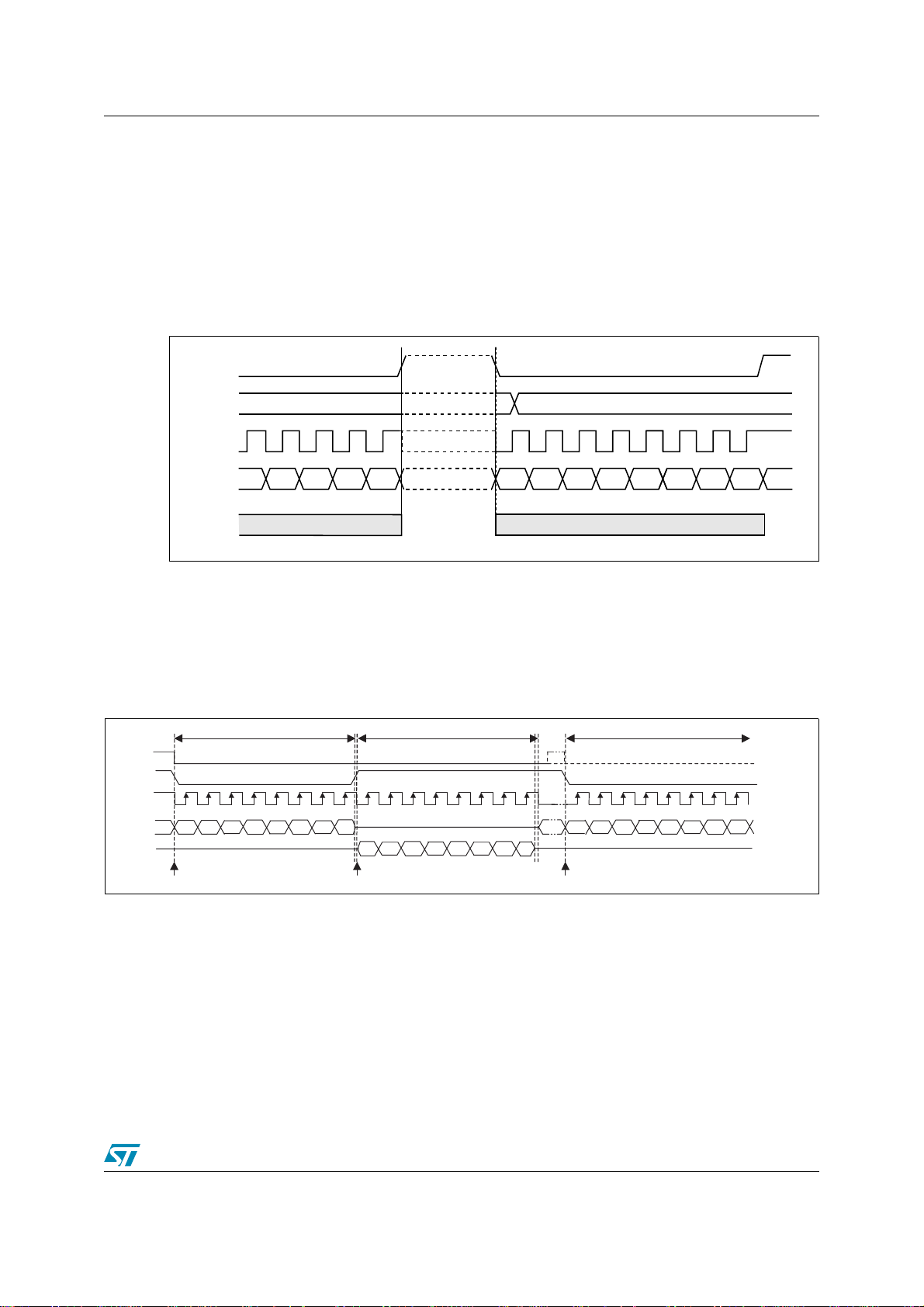

Figure 15. Bit transfer and START,STOP conditions definition

DATA LINE

STABLE

DATA VALID

CLOCK

DATA

START

CONDITION

Figure 16. Acknowledgment on the I

START

SCLK FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

1

MSB LSB

4.3.1 Communication Protocol

The STE2007 is an I2C slave. The access to the device is bi-directional since data write and

status read are allowed.

Four are the device addresses available for the device. All have in common the first 5 bits

(01111). The two least significant bit of the slave address are set by connecting the SA0 and

SA1 inputs to a logic 0 or to a logic 1.

CHANGE OF

DATA ALLOWED

2

C-bus

289

D00IN1151

D00IN1152

STOP

CONDITION

CLOCK PULSE FOR

ACKNOWLEDGEMENT

4.3.2 Starting the Communication

To start the communication between the bus master and the slave LCD driver, the master must

initiate a START condition. Following this, the master sends an 8-bit byte, on the SDA bus line

(Most significant bit first). This consists of the 7-bit Device Address Code, and the 1-bit Read/

Write Designator (R/W

communication (read or write).

All slaves with the corresponding address acknowledge in parallel, all the others will ignore the

2

I

C-bus transfer.

). The R/W bit has to be set to logic 1 to logic 0 according to the type of

ADDRESS BYTE

STE2007

SLAVE ADDRESS

S

011110AR/

S

A

W

1

READ or WRITE

DESIGNATOR

23/62

Page 24

4 INTERFACE STE2007

4.3.3 MCU TxData Mode (Write Mode)

If the R/W bit is set to logic 0 the STE2007 is set to be a receiver and the master can send

commands or data.

After the communication has started and slaves have acknowledged, the master sends a

control byte defined as follows and waits for its acknowledgement:

CONTROL BYTE

Co

DC

000

000

The Co bit is the control byte MSB and defines if after this control byte will follow a single byte

sequence (Co = 1) or a multiple bytes sequence (Co = 0). The D/C

following byte (if Co = 1) or the following stream of bytes (if Co = 0) are command (D/C

DDRAM data (D/C

= 1).

bit defines whether the

= 0) or

Depending on state of flags Co and D/C, four writing sequences are possible:

SINGLE COMMAND BYTE SEQUENCE (Co = 1, D/C

= 0): a single byte interpreted as a

command will follow the control byte;

SINGLE DATA BYTE SEQUENCE (Co = 1, D/C

= 1): a single byte interpreted as a data to be

written in DDRAM will follow the control byte;

MULTIPLE COMMAND BYTES SEQUENCE (Co = 0, D/C

= 0): a stream of bytes will follow the

control byte, with each single byte interpreted as a command;

MULTIPLE DATA BYTES SEQUENCE (Co = 0, D/C

= 1): a stream of bytes will follow the

control byte, with each byte interpreted as a data byte to be written in DDRAM.

Every single byte of a sequence must be acknowledged by all addressed units.

A multiple data sequence is terminated only by sending a STOP condition on the I

When a sequence is terminated, another sequence of any type can follow or a I

2

C bus.

2

C STOP

condition can be sent to close the communication.

In a single or multiple data bytes sequence, every data byte received is stored in the DDRAM at

the location specified by the current values of data pointers. Data pointers are automatically

updated after each single data byte written.

24/62

Page 25

STE2007 4 INTERFACE

4.3.4 Driver TxData Mode (Read Mode)

If the R/W bit is set to logic 1 the chip will output data immediately after the slave address. If the

D/C bit during the last write access, is set to a logic 0, the byte read is the status byte.

Figure 17. Communication Protocol

WRITE MODE

COMMUNICATION

START

SINGLE COMMAND

SEQUENCE

MULTIPLE COMMAND

SEQUENCE

SINGLE DATA

SEQUENCE

I2C START

COND

Co

D/C

Control Byte

Co

D/C

Control Byte

Co

D/C

Control Byte

111

0

SLAVE ADDRESS

STE2007 ACK

00010

000

STE2007 ACK STE2007 ACK

000

00000

STE2007 ACK

00011

000

1

A

COMMAND Byte

Command Byte

A

COMMAND Byte

First Command Byte

DATA Byte A

A

Data Byte

STE2007 ACK

SA1

SA2

STE2007 ACK

STE2007 ACK

R/W

0

A

A

STE2007 ACK

COMMAND Byte A

A

Last Command Byte

MULTIPLE DATA

SEQUENCE

COMMUNICATION

STOP

READ MODE

STATUS BYTE READ

SEQUENCE

Co

D/C

Control Byte

I2C STOP

COND

I2C START

COND

STE2007 ACK STE2007 ACK

000

A

00001

01111 0A

DATA Byte

First Data Byte

SA1

SLAVE ADDRESS

25/62

A

STE2007 ACK

SA2

R/W

Last Data Byte

STATUS Byte

STE2007 ACK

DATA Byte A

MASTER ACK

I2C START

A

COND

LR0008d

Page 26

4 INTERFACE STE2007

4.4 Reading Mode

STE2007 features a reading Command to transmitt data from the LCD driver to Host

Processor. After the reading command STE2007 transfers 8 bits to the Host controller:

– Identification Byte (Command Code DB

4.4.1 IIdentification byte

Identification byte is an 8 Bit code that identify the module revision Number.

Table 15. ID byte format

Bit nr D7(MSB) D6 D5 D4 D3 D2 D1 D0(LSB)

0 0 I DB PAD I DA PA D 0 0 0 0

Figure 18.

ASIC(MCU)

8 bit register

Power IC

VDD

VDDI

GND

MCU TxData

Driver TxData

VDDCP

VDD

VDDI

VSS

VSSCP

RESET

SDA

XCS

SCLK

test

Auto

return

)

hex

STE2007

Command decoder

Multi

plexer

ID

VLCD

Voltage booster

BaseBand side

Driver side

Figure 19.

Identification Information

Send rading command (DBh)

Read status(ID data)

Send reset command

26/62

LCD Power

Supply circuit

Command:E2H

Page 27

STE2007 5 Display Data RAM (DDRAM)

5 Display Data RAM (DDRAM)

5.1 DDRAM and Page/column address circuit

The DDRAM stores pixel data for LCD. It is a 68–row (8 page by 8 bits +4) by 96–column

addressable array. D7 to D0 display data from MCU corresponds to the LCD common direction.

”0” bit in DDRAM is a OFF–dot on display and ”1” bit in DDRAM is displayed as ON–dot on

display.

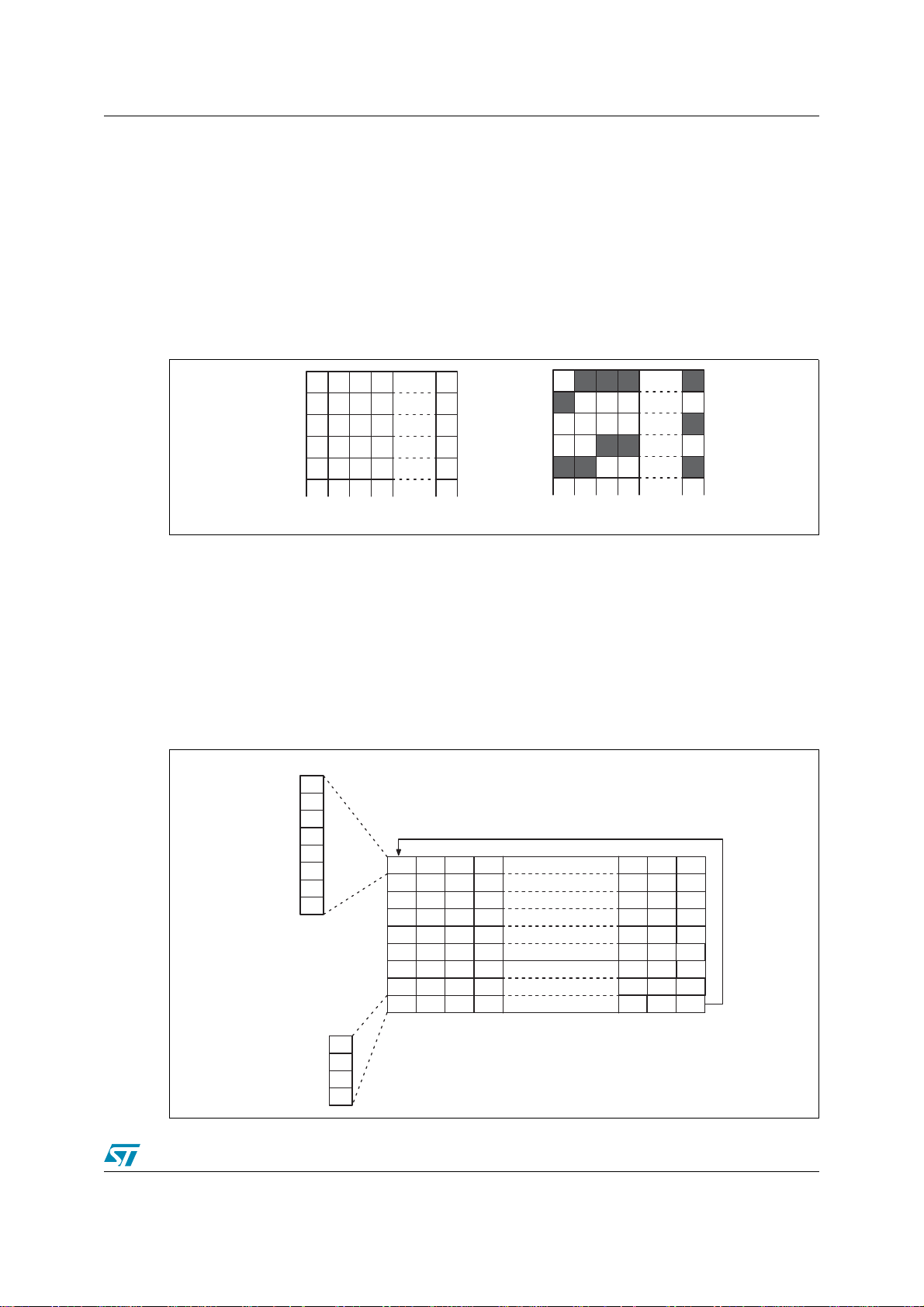

Figure 20. DDRAM vs. display on LCD

011 1 1D0

100 0 0D1

000 0 1D2

001 1 0D3

110 0 1D4

±± ±±

DDRAM Display on LCD

COM0

COM1

COM2

COM3

COM4

Each pixel can be selected when page address and column address are specified. The MCU

issues Page address set command to change the page and access to another page. In

DDRAM page address 8 (D3,D2,D1,D0=1,0,0,0) only display data D0,D1,D2 & D3 are valid.

The DDRAM column address is specified by Column address set command.

The specified column address is automatically incremented by +1 when a Display data write

command is entered. After the last column address (5Fh), column address returns to 00h and

page address incremented by +1. After the very last address (column=5Fh, page=8h), both

column address and page address return to 00h (column address=00h, page address=0h).

Figure 21. Column address in normal mode

Data

LSBit

MSBit

Page address

Data for page address 0H to 07H

D0

D1

D2

D3

D4

D5

D6

D7

D0

D1

D2

D3

0 1 2 94 95

0H

96 97 98

1H

192 193 194

2H

3H

288 289 290

4H

384 385 386

5H

480 481 482

576 577 578

6H

672 673 674

7H

768 769 770

8H

00H 01H

Data for page address 8H

02H

Column address

190 191

286 287

382 383

478 479

574 575

670 671

766 767

862 863

5EH 5FH

27/62

Page 28

5 Display Data RAM (DDRAM) STE2007

Figure 22. Column address in reversed mode

Data for page address 0H to 07H

Data

D0

LSBit

D1

D2

D3

95

191

287

383

479

575

671

767

863

5FH

190

286

382

478

574

670

766

862

5EH

94

Column address

02H

0H

96

9798

1H

2H

192193194

3H

288289290

4H

384385386

5H

480481482

576577578

6H

672673674

7H

8H

768769770

00H01H

Data for page address 8H

D4

D5

D6

D7

Page address

D0

D1

D2

D3

MSBit

Data can be written to the DDRAM at the same time as data is being displayed, without causing

the LCD to flicker.

Segment driver direction command can be used to reverse the relationship between the

DDRAM column address and segment output. This function is achieved writing data into

DDRAM in reverse order (from Right to left).

Table 16. Column address direction

Column

address

Normal

Direction

Reverse

Direction

00H 01H 02H 5DH 5EH 5FH 5DH

SEG0 SEG1 SEG2 _ _ _ _ _ _ SEG93 SEG94 SEG95

SEG95 SEG94 SEG93 _ _ _ _ _ _ SEG2 SEG1 SEG0

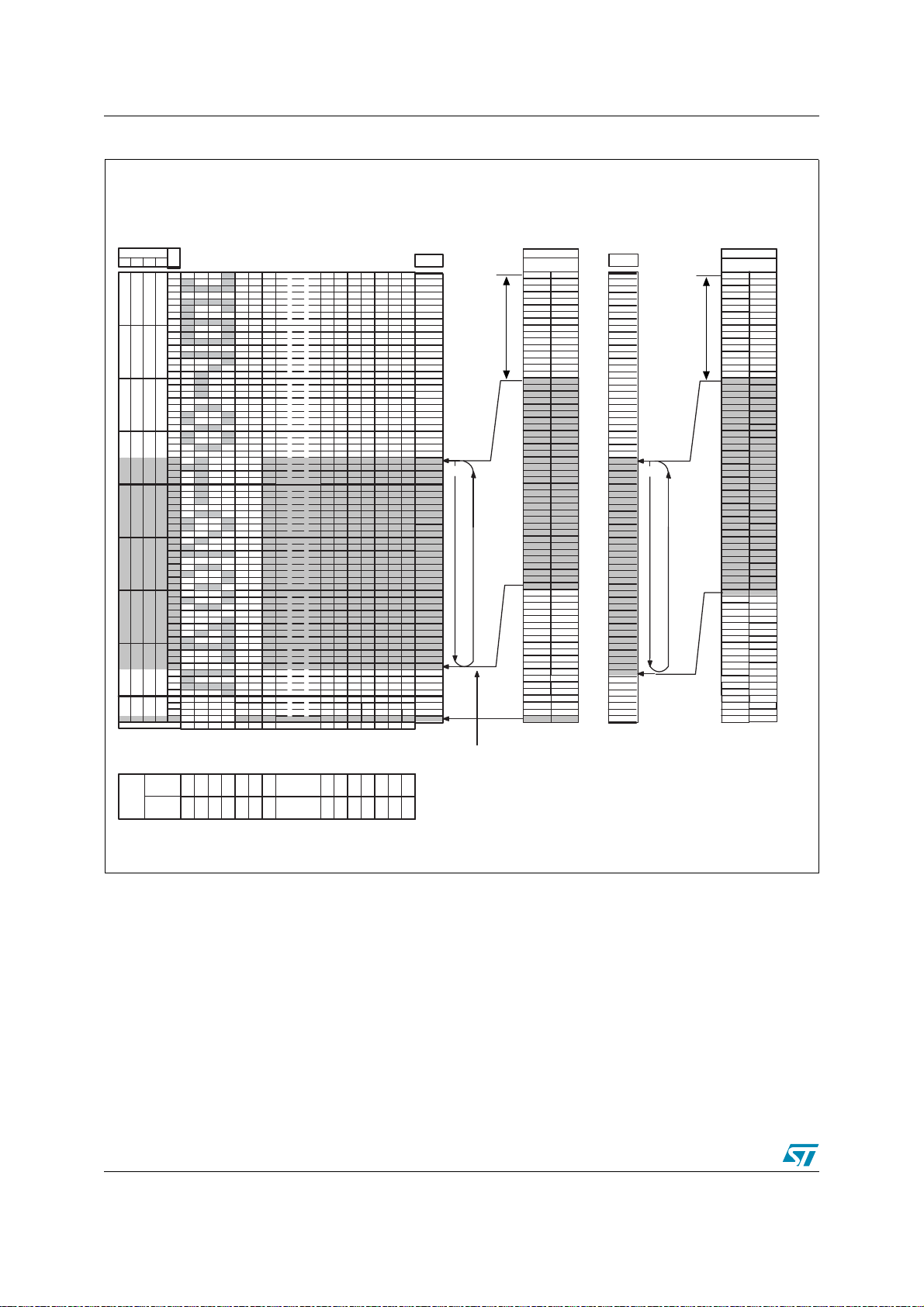

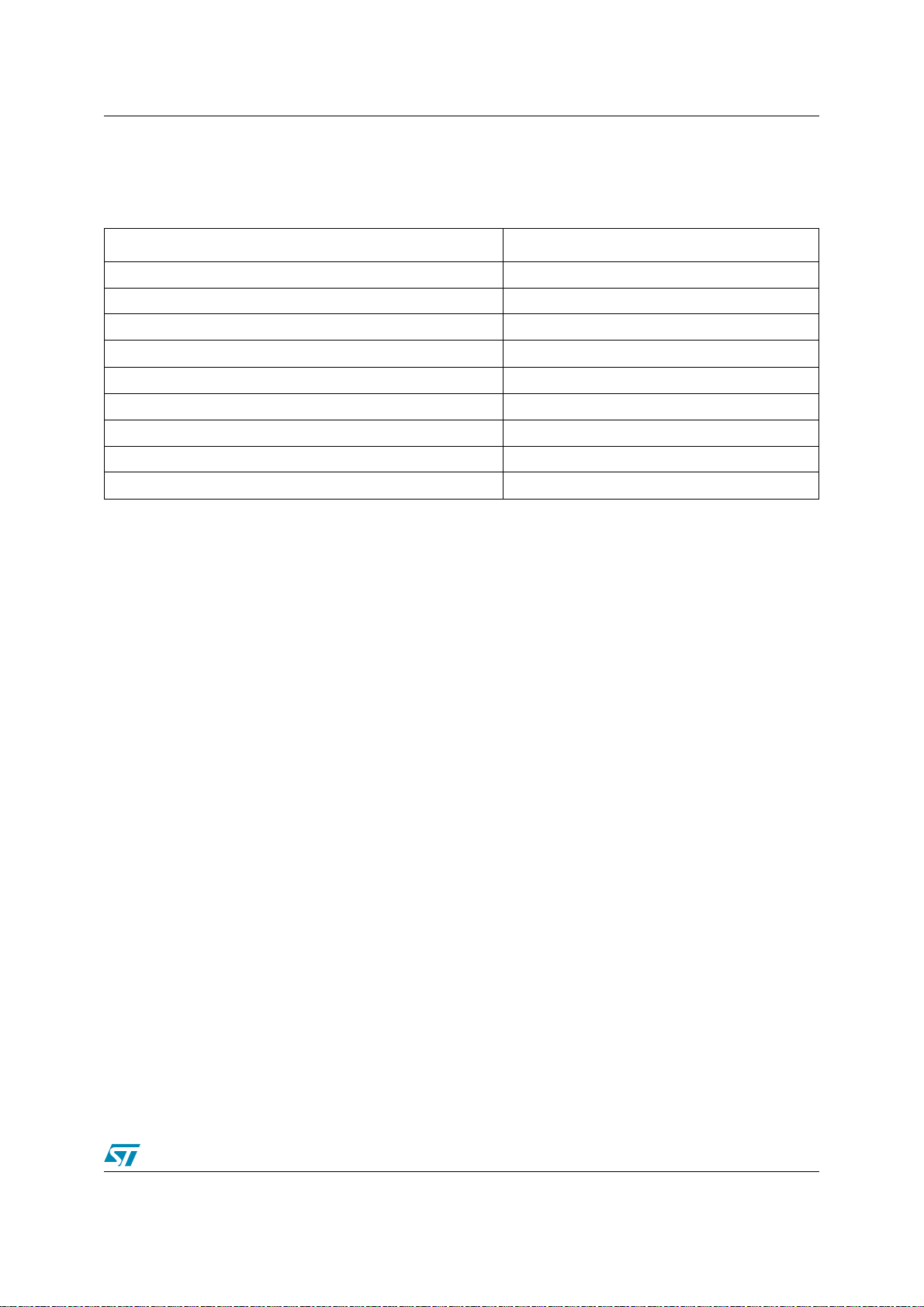

5.2 Line address circuit

The line address circuit specifies the line address relating to the COM output when the contents

of the DDRAM are displayed. The display start line that is normally the top line of the display,

can be specified by Display start line address set command.

STE2007 features Four different Multiplexing Mode to fine tune the duty ratio on the display

size:

– 68 Lines Display

– 65 Lines Display

– 49 Lines Display

– 33 Lines Display

28/62

Page 29

STE2007 5 Display Data RAM (DDRAM)

Figure 23. 68–line Mode

Page address

D2 D1 D0

D3

0

0

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

1

0

1

1

0

1

0

0

1

Column address

ICONMODE="1"

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

0

D2

D3

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

59H

5AH

5BH 5FH5CH 5DH 5EH

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Start

COM Output

Normal

Reverse

direction

direction

COM66

COM0

COM65

COM1

COM64

COM2

COM3

COM63

COM4

COM62

COM5

COM61

COM6

COM60

COM7

COM59

COM8

COM58

COM9

COM57

COM10

COM56

COM11

COM55

COM12

COM54

COM13

COM53

COM14

COM52

COM15

COM51

COM16

COM50

COM17

COM49

COM18

COM48

COM19

COM47

COM20

COM46

COM21

COM45

COM22

COM44

COM23

COM43

COM24

COM42

COM25

COM41

COM26

COM40

COM27

COM39

COM28

COM38

COM29

COM37

COM30

COM36

COM31

COM35

COM32

COM34

COM33

COM33

COM34

COM32

COM35

COM31

COM36

COM30

COM37

COM29

COM38

COM28

COM39

COM27

COM40

COM26

COM41

COM25

COM42

COM24

COM43

COM23

COM44

COM22

COM45

COM21

COM46

COM20

COM47

COM19

COM48

COM18

COM49

COM17

COM50

COM16

COM51

COM15

COM52

COM14

COM53

COM13

COM54

COM12

COM55

COM1

COM56

COM10

COM57

COM9

COM58

COM8

COM59

COM7

COM60

COM6

COM61

COM5

COM62

COM4

COM63

COM3

COM64

COM2

COM65

COM1

COM66

COM0

COMS COMS

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Start

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

1

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

ICONMODE="0"

COM Output

Normal

Reverse

direction

direction

COM0

COMS

COM66

COM1

COM65

COM2

COM3

COM64

COM4

COM63

COM5

COM62

COM6

COM61

COM7

COM60

COM8

COM59

COM9

COM58

COM10

COM57

COM11

COM56

COM12

COM55

COM13

COM54

COM14

COM53

COM15

COM52

COM16

COM51

COM17

COM50

COM18

COM49

COM19

COM48

COM20

COM47

COM21

COM46

COM22

COM45

COM23

COM44

COM24

COM43

COM25

COM42

COM26

COM41

COM27

COM40

COM28

COM39

COM29

COM38

COM30

COM37

COM31

COM36

COM32

COM35

COM33

COM34

COM34

COM33

COM35

COM32

COM36

COM31

COM37

COM30

COM38

COM29

COM39

COM28

COM40

COM27

COM41

COM26

COM42

COM25

COM43

COM24

COM44

COM23

COM45

COM22

COM46

COM21

COM47

COM20

COM48

COM19

COM18

COM49

COM50

COM17

COM16

COM51

COM52

COM15

COM53

COM14

COM54

COM13

COM55

COM12

COM56

COM11

COM57

COM10

COM58

COM9

COM59

COM8

COM60

COM7

COM6

COM61

COM5

COM62

COM63

COM4

COM3

COM64

COM2

COM65

COM1

COM66

COM0

COMS

SEG

Output

Normal

Direction

Reverse

Direction

Display start line does not access 65th, 66th, 67th, 68th line

S

S

S

S

S

S

E

E

E

G

G

G

0

1

2

S

S

S

E

E

E

G

G

G

95

94

93

S

E

E

E

E

G

G

G

G

3

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

92

91

90

89

S

S

S

E

E

E

G

G

G

91

90

89

S

S

S

E

E

E

G

G

G

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

95

94

93

92

S

S

S

S

E

E

E

E

G

G

G

G

0

1

2

3

Display start line does not access 65th, 66th, 67th, 68th line

29/62

Page 30

5 Display Data RAM (DDRAM) STE2007

Figure 24. 65–line Mode

Page address

D2 D1 D0

D3

0

0

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

1

0

1

1

0

1

0

0

1

Column address

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

0

D2

D3

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5AH

59H

5BH 5FH5CH5DH 5EH

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Start

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Display start line does not access 65th, 66th, 67th, 68th line

COM Output

Normal

Reverse

direction

direction

COM0

COM63

COM1

COM62

COM2

COM61

COM3

COM60

COM4

COM59

COM5

COM58

COM6

COM57

COM7

COM56

COM8

COM55

COM9

COM54

COM10

COM53

COM11

COM52

COM12

COM51

COM13

COM50

COM14

COM49

COM15

COM48

COM16

COM47

COM17

COM46

COM18

COM45

COM19

COM44

COM20

COM43

COM21

COM42

COM22

COM41

COM23

COM40

COM24

COM39

COM25

COM38

COM26

COM37

COM27

COM36

COM28

COM35

COM29

COM34

COM30

COM33

COM31

COM32

COM32

COM31

COM33

COM30

COM34

COM29

COM35

COM28

COM36

COM27

COM37

COM26

COM38

COM25

COM39

COM24

COM40

COM23

COM41

COM22

COM42

COM21

COM43

COM20

COM44

COM19

COM45

COM18

COM46

COM17

COM47

COM16

COM48

COM15

COM49

COM14

COM50

COM13

COM51

COM12

COM52

COM11

COM53

COM10

COM54

COM9

COM55

COM8

COM56

COM7

COM57

COM6

COM58

COM5

COM59

COM4

COM60

COM3

COM61

COM2

COM1

COM62

COM63

COM0

COM64 COM64

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Start

ICONMODE="1"

ICONMODE="0"

COM Output

Normal

Reverse

direction

direction

COM64

COM0

COM1

COM63

COM2

COM62

COM3

COM61

COM4

COM60

COM5

COM59

COM6

COM58

COM7

COM57

COM8

COM56

COM9

COM55

COM10

COM54

COM11

COM53

COM12

COM52

COM13

COM51

COM14

COM50

COM15

COM49

COM16

COM48

COM17

COM47

COM18

COM46

COM19

COM45

COM20

COM44

COM21

COM43

COM22

COM42

COM23

COM41

COM24

COM40

COM25

COM39

COM26

COM38

COM27

COM37

COM28

COM36

COM29

COM35

COM30

COM34

COM31

COM33

COM32

COM32

COM33

COM31

COM34

COM30

COM35

COM29

COM36

COM28

COM37

COM27

COM38

COM26

COM39

COM25

COM40

COM24

COM41

COM23

COM42

COM22

COM43

COM21

COM44

COM20

COM45

COM19

COM46

COM18

COM47

COM17

COM48

COM16

COM49

COM15

COM50

COM14

COM51

COM13

COM52

COM12

COM53

COM11

COM54

COM10

COM55

COM9

COM56

COM8

COM57

COM7

COM58

COM6

COM59

COM5

COM60

COM4

COM61

COM3

COM62

COM2

COM63

COM1

COM64

COM0

SEG

Output

Normal

Direction

Reverse

Direction

S

S

S

S

S

S

E

E

E

G

G

G

0

1

2

S

S

S

E

E

E

G

G

G

95

94

93

S

E

E

E

E

G

G

G

G

3

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

92

91

90

89

S

S

S

E

E

E

G

G

G

91

90

89

S

S

S

E

E

E

G

G

G

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

95

94

93

92

S

S

S

S

E

E

E

E

G

G

G

G

0

1

2

3

30/62

Page 31

STE2007 5 Display Data RAM (DDRAM)

Figure 25. 49–line Mode

Page address

D2 D1 D0

D3

0

0

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

1

0

1

1

0

1

0

0

1

Column address

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

0

D2

D3

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

59H

5AH

5BH 5FH5CH5DH 5EH

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Start

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Display start line does not access 65th, 66th, 67th, 68th line

COM Output

Normal

Reverse

direction

direction

COM0

COM47

COM1

COM46

COM2

COM45

COM3

COM44

COM4

COM43

COM5

COM42

COM6

COM41

COM7

COM40

COM8

COM39

COM9

COM38

COM10

COM37

COM11

COM36

COM12

COM35

COM13

COM34

COM14

COM33

COM15

COM32

COM16

COM31

COM17

COM30

COM18

COM29

COM19

COM28

COM20

COM27

COM21

COM26

COM22

COM25

COM23

COM24

COM24

COM23

COM25

COM22

COM26

COM21

COM27

COM20

COM28

COM19

COM29

COM18

COM30

COM17

COM31

COM16

COM32

COM15

COM33

COM14

COM34

COM13

COM35

COM12

COM36

COM11

COM37

COM10

COM38

COM9

COM39

COM8

COM40

COM7

COM41

COM6

COM42

COM5

COM43

COM4

COM44

COM3

COM45

COM2

COM46

COM1

COM47

COM0

COM64 COM64

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Start

ICONMODE="1"

ICONMODE="0"

COM Output

Normal

Reverse

direction

direction

COM0

COM48

COM47

COM1

COM46

COM2

COM45

COM3

COM44

COM4

COM43

COM5

COM42

COM6

COM41

COM7

COM40

COM8

COM39

COM9

COM38

COM10

COM37

COM11

COM36

COM12

COM35

COM13

COM34

COM14

COM33

COM15

COM32

COM16

COM31

COM17

COM30

COM18

COM29

COM19

COM28

COM20

COM27

COM21

COM26

COM22

COM25

COM23

COM24

COM24

COM23

COM25

COM22

COM26

COM21

COM27

COM20

COM28

COM19

COM29

COM18

COM30

COM17

COM31

COM16

COM32

COM15

COM33

COM14

COM34

COM13

COM35

COM12

COM36

COM11

COM37

COM10

COM38

COM9

COM39

COM8

COM40

COM7

COM41

COM6

COM42

COM5

COM43

COM4

COM44

COM3

COM45

COM2

COM46

COM1

COM47

COM0

COM48

SEG

Output

Normal

Direction

Reverse

Direction

S

S

S

S

S

S

E

E

E

G

G

G

0

1

2

S

S

S

E

E

E

G

G

G

95

94

93

S

E

E

E

E

G

G

G

G

3

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

92

91

90

89

S

S

S

E

E

E

G

G

G

91

90

89

S

S

S

E

E

E

G

G

G

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

95

94

93

92

S

S

S

S

E

E

E

E

G

G

G

G

0

1

2

3

31/62

Page 32

5 Display Data RAM (DDRAM) STE2007

Figure 26. 33–line Mode

Page address

D2 D1 D0

D3

0

0

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

1

0

1

1

0

1

0

0

1

Column address

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

1

D3

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

D4

1

D5

D6

D7

D0

D1

0

D2

D3

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

59H

5AH

5BH 5FH5CH5DH 5EH

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Start

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Display start line does not access 65th, 66th, 67th, 68th line

COM Output

Normal

Reverse

direction

direction

COM0

COM31

COM1

COM30

COM2

COM29

COM3

COM28

COM4

COM27

COM5

COM26

COM6

COM25

COM7

COM24

COM8

COM23

COM9

COM22

COM10

COM21

COM11

COM20

COM12

COM19

COM13

COM18

COM14

COM17

COM15

COM16

COM16

COM15

COM17

COM14

COM18

COM13

COM19

COM12

COM20

COM11

COM21

COM10

COM22

COM9

COM23

COM8

COM24

COM7

COM25

COM6

COM26

COM5

COM27

COM4

COM28

COM3

COM29

COM2

COM30

COM1

COM31

COM0

COM64 COM64

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

41H

42H

43H

Start

ICONMODE="1"

ICONMODE="0"

COM Output

Normal

Reverse

direction

direction

COM32

COM0

COM31

COM1

COM30

COM2

COM29

COM3

COM28

COM4

COM27

COM5

COM26

COM6

COM25

COM7

COM24

COM8

COM23

COM9

COM22

COM10

COM21

COM11

COM20

COM12

COM19

COM13

COM18

COM14

COM17

COM15

COM16

COM16

COM17

COM15

COM18

COM14

COM19

COM13

COM20

COM12

COM21

COM11

COM22

COM10

COM23

COM9

COM24

COM8

COM25

COM7

COM26

COM6

COM27

COM5

COM28

COM4

COM29

COM3

COM30

COM2

COM31

COM1

COM0

COM32

SEG

Output

Normal

Direction

Reverse

Direction

S

S

S

S

S

S

E

E

E

G

G

G

0

1

2

S

S

S

E

E

E

G

G

G

95

94

93

S

E

E

E

E

G

G

G

G

3

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

92

91

90

89

S

S

S

E

E

E

G

G

G

91

90

89

S

S

S

E

E

E

G

G

G

4

5

6

S

S

S

S

E

E

E

E

G

G

G

G

95

94

93

92

S

S

S

S

E

E

E

E

G

G

G

G

0

1

2

3

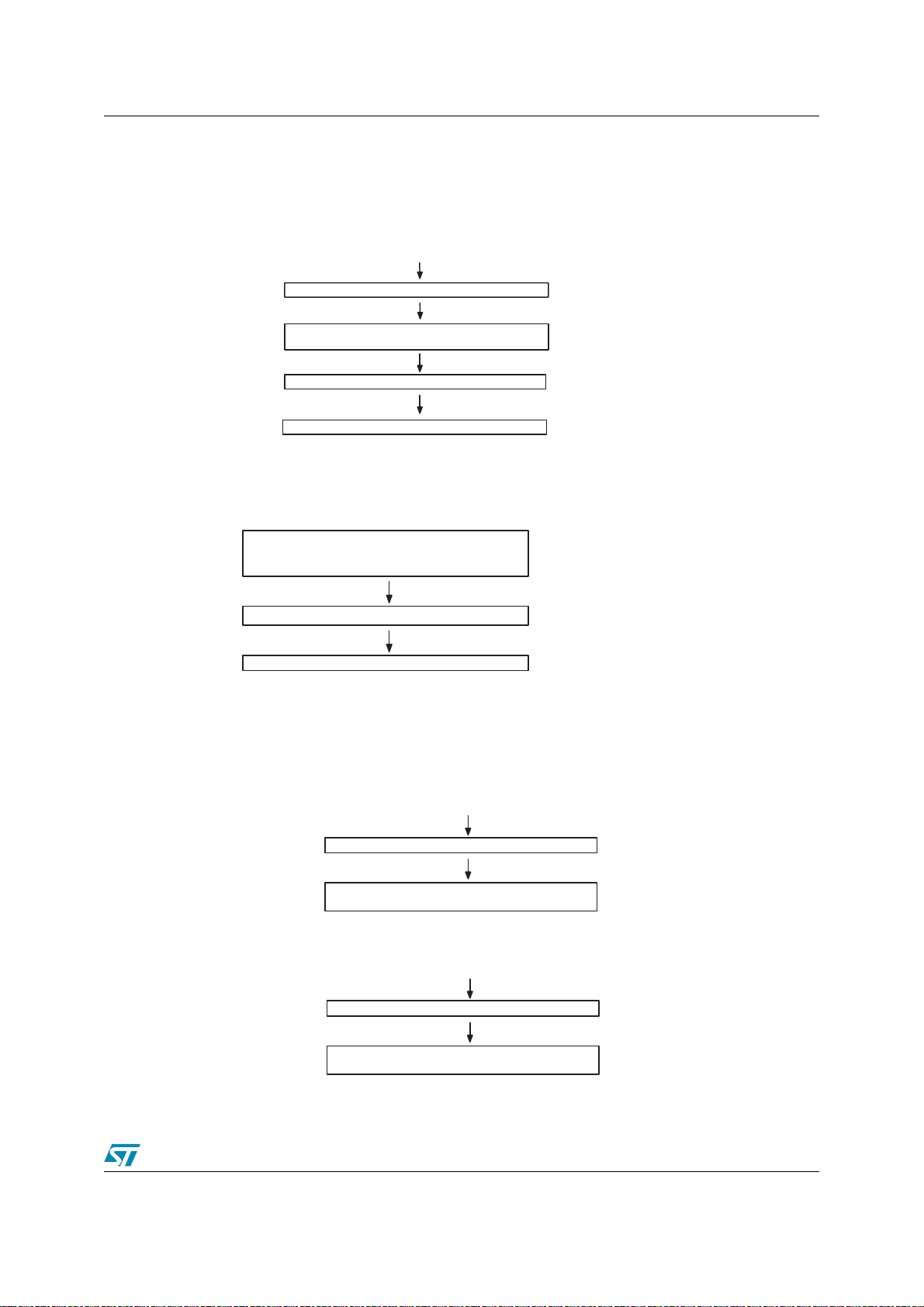

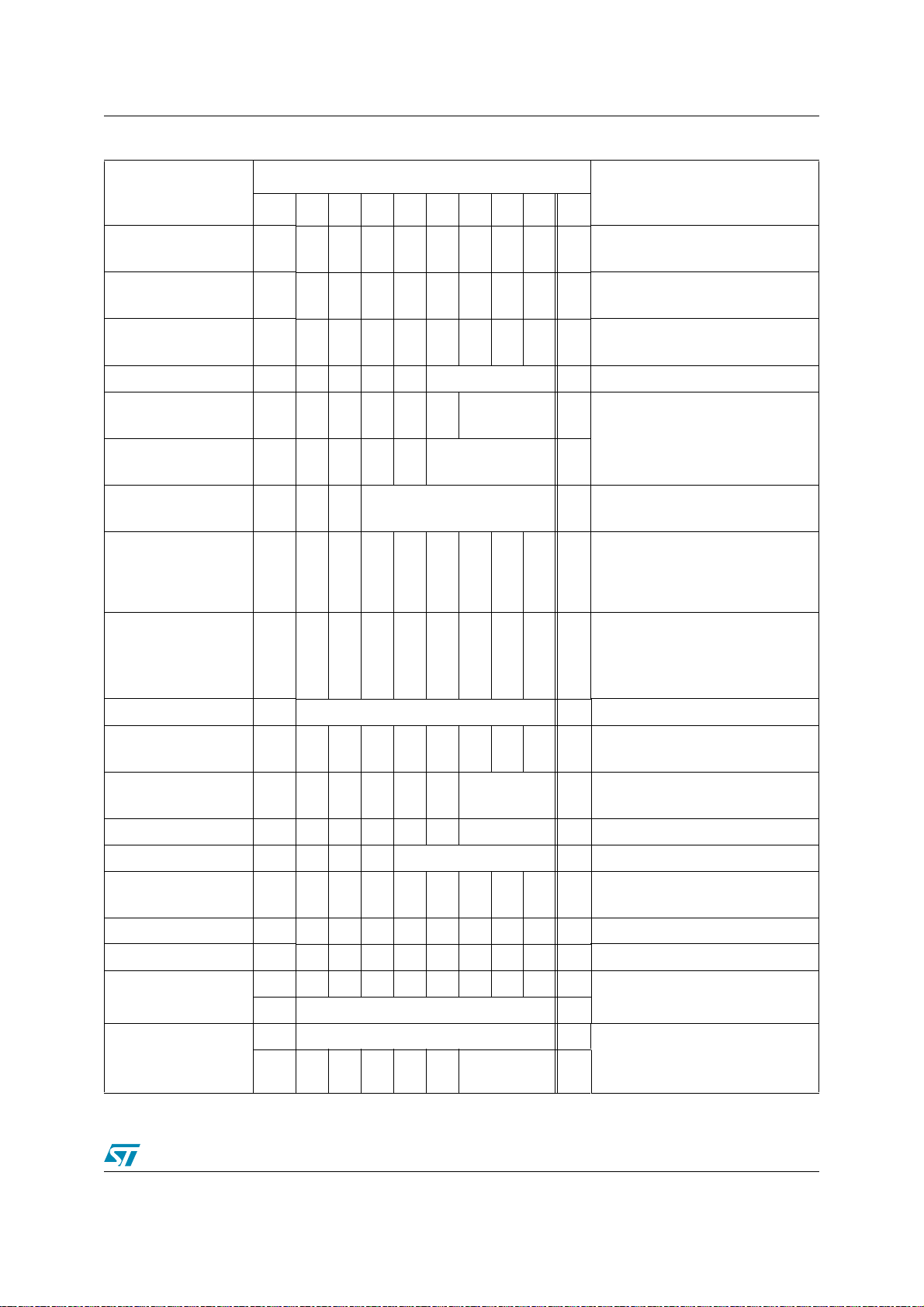

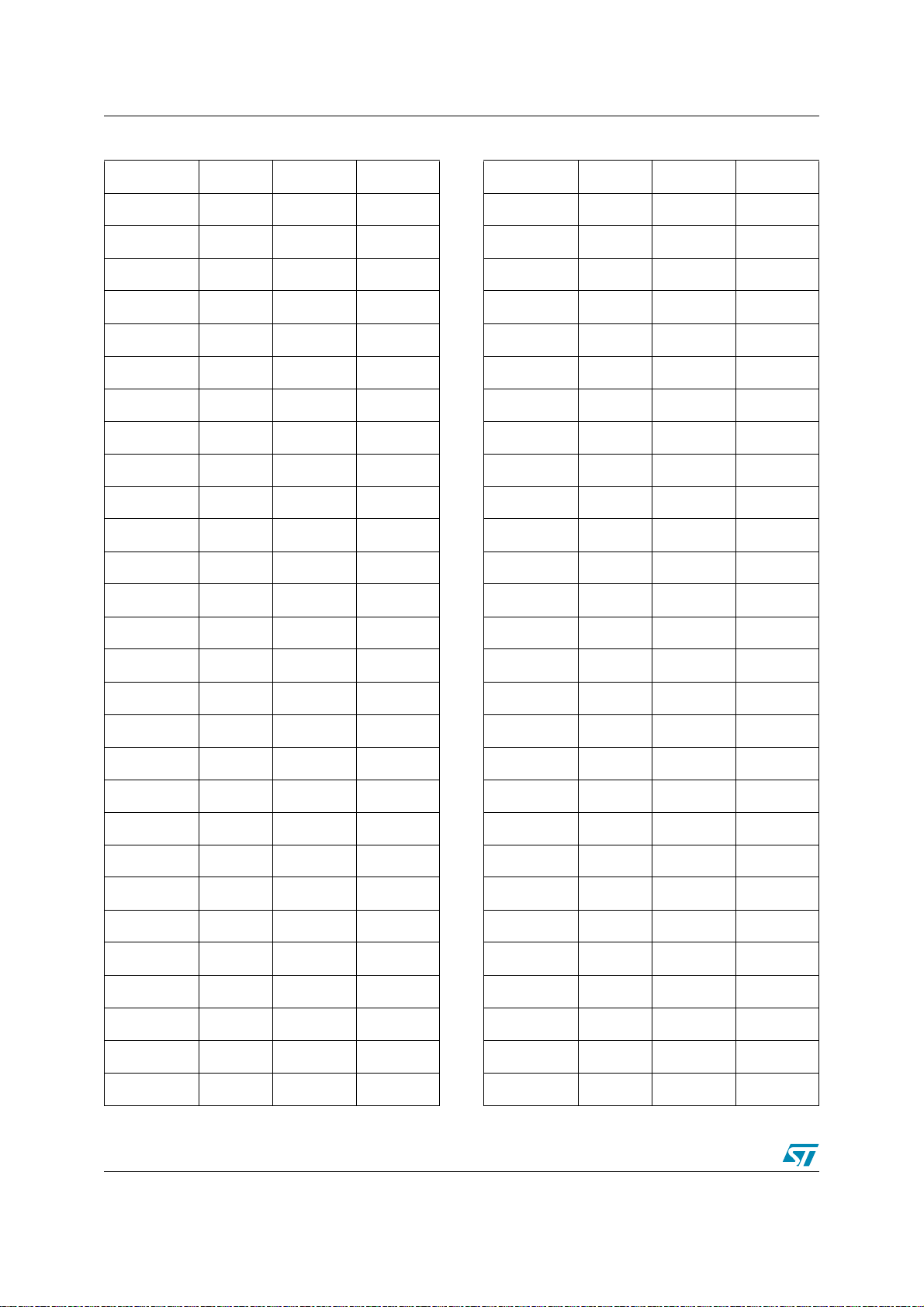

5.3 Partial Display

STE2007 feature four configuration for Partial Display function:

– 33 Line Partial Display

– 25 Line Partial display

– 16 Line Partial Display

– 9 Line Partial Display

Partial display Area location on the screen is defined by Image Location Parameter.

Image Location + Partial display area > Multiplexing rate.

32/62

Page 33

STE2007 5 Display Data RAM (DDRAM)

Figure 27.

Display

Image Location + Partial display area width <= Multiplexing rate Image Location + Partial display area width > Multiplexing rate

When Partial Display Mode is enabled the user has to Update the Operative Voltage, Bias Ratio

and Charge Pump Setting to match the new working conditions.

5.3.1 33 Line Partial Display Mode

Partial Display Area is composed of 33 Lines. Memory vs. Row Drivers Mapping is defined

according to the following parameters:

– Multiplexing Value

– IL[2:0]

Figure 28. Example: Partial Display 33 lines & MUX65

D

Page address

D2 D1 D0

D3

0

0

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

1

0

1

1

0

1

0

0

1

Column address

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

0

D2

D3

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

59H

5AH

5BH 5FH5CH 5DH 5EH

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

IL[2:0]

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH