STE2004S

102 X 65 SINGLE CHIP LCD CONTROLLER / DRIVER

1 FEATURES

■ 102 x 65 bits Display Data RAM

■ Programmable MUX rate

■ Programmable Frame Rate

■ X,Y Programmable Carriage Return

■ Dual Partial Display Mode

■ Row by Row Scrolling

■ N-line Inversion

■ Automatic data RAM Blanking procedure

■ Selectable Input Interface:

• I2C Bus Fast and Hs-mode (read and write)

• 68000 & 8080 Parallel Interfaces (read and write)

• 3-lines and 4-lines SPI Interface (read and write)

• 3-lines 9 bit Serial Interface (read and write)

■ Fully Integrated Oscillator requires no external

components

■ CMOS Compatible Inputs

■ Fully Integrated Configurable LCD bias voltage

generator with:

• Selectable

• Effective sensing for High Precision Output

• Eight selectable temperature compensation

coefficients

■ Designed for chip-on-glass (COG) applications.

multiplication factor (up to 5X)

■ Low Power Consumption, suitable for battery

operated systems

■ Logic Supply Voltage range from 1.7 to 3.6V

■ High Voltage Generator Supply Voltage range

from 1.75 to 4.5V

■ Display Supply Voltage range from 4.5 to 14.5V

■ Backward Compatibility with STE2001/2/4

2 DESCRIPTION

The STE2004S is a low power CMOS LCD controller driver. Designed to drive a 65 rows by 102

columns graphic display, it provides all necessary

functions in a single chip, including on-chip LCD

supply and bias voltages generators, resulting in a

minimum of externals components and in a very

low power consumption.

STE2004S features six standard interfaces (3lines Serial, 3-lines SPI, 4-lines SPI, 68000 Parallel, 8080 parallel & I

the host micro-controller.

Table 1. Order Codes

Part Numbers Type

STE2004S DIE2

2

C) for ease of interfacing with

Bumped Dice on Waffle Pack

Figure 1. Block Diagram

OSC_IN

OSC_OUT

FR_IN

FR_OUT

VSENSE SLAVE

VLCD

VLCDSENSE

VSSAUX

VDD1,2

V

SS

September 2005

RES

OSC

MASTER

SLAVE SYNC

BIAS VOLTAGE

GENERATOR

HIGH VOLTAGE

GENERATOR

RESET

I2C BUS

SAO SDIN/SDA_IN SDA_OUTSCLK/SCL

DATA

REGISTER

9 Bit SERIAL

GENERATOR

TIMING

CLOCK

INSTRUCTION

REGISTER

3 & 4 Line SPI

CO to C101 R0 to R64

COLUMN

DRIVERS

DATA

LATCHES

65 x 102

DRIVERS

REGISTER

SCROLL

RAM

DISPLAY

CONTROL

LOGIC

Parallel 8080

DB0

to

DB7

Parallel 68K

ROW

SHIFT

LOGIC

TEST

D/C CSSA1 SDOUT E/WR R/W- RD

TEST_MODE

TEST_VREF

ICON_MODE

EXT

SEL 3

SEL 2

SEL 1

LR0047

Rev. 1

1/66

STE2004S

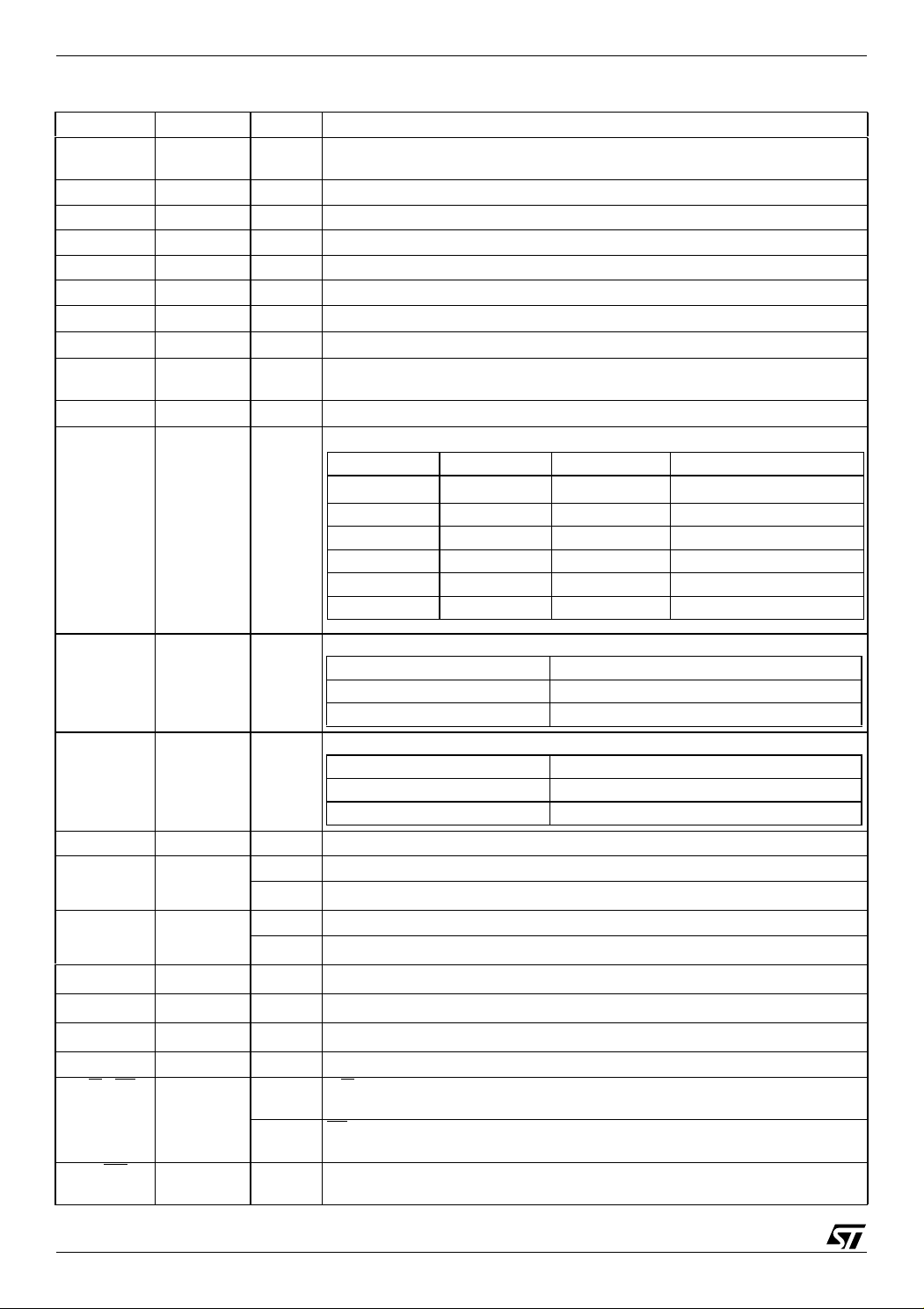

Table 2.

PIN DESCRIPTION

N° Pad Type Function

R0 to R64 1-6

O LCD Row Driver Output

109-141

C0 to C101 6-107 O LCD Column Driver Output

V

SS 192-203 GND Ground pads.

DD1 156-163 Supply IC Positive Power Supply

V

DD2 164-171 Supply Internal Generator Supply Voltages.

V

LCD 205-209 Supply Voltage Multiplier Output

V

V

LCDSENSE

V

SENSE_SLAVE

V

SSAUX

204 Supply

Voltage Multiplier Regulation Input. V

145 Supply Voltage reference for SLAVE CHARGE PUMP

190-177-

O Ground Reference for Pins Configuration

147

V

DD1AUX

SEL1,2,3 152

142 O VDD1 Reference for Pins Configuration

153

154

I Interface Mode Selection

SEL3 SEL2 SEL1 Interface

GND / VSSAUX GND / VSSAUX GND / VSSAUX

- CANNOT BE LEFT FLOATING

GND / VSSAUX GND / VSSAUX VDD1

GND / VSSAUX VDD1 GND / VSSAUX

GND / VSSAUX VDD1 VDD1

VDD1 GND / VSSAUX GND / VSSAUX

VDD1 GND / VSSAUX VDD1

Sensing for Output Voltage Fine Tuning

LCDOUT

SPI 4-Lines 8 bit

SPI 3-Lines 8 bit

Serial 3-Lines 9 bit

Parallel 8080-series

Parallel 68000-series

I2C

EXT_SET 151 I Extended Instruction Set Selection

- CANNOT BE LEFT FLOATING

EXT PAD CONFIG INSTRUCTION SET SELECTED

GND or VSSAUX BASIC

VDD1 EXTENDED

ICON_MODE

155 I Extended Instruction Set Selection

- CANNOT BE LEFT FLOATING

ICON MODE PAD CONFIG ICON MODE STATUS

GND or VSSAUX DISBLED

VDD1 ENABLED

SDOUT 180 O Serial & SPI Data Output - IF UNUSED MUST BE LEFT FLOATING

SDIN - SDAIN 179 I SDIN - Serial & SPI Interface Data Input - CANNOT BE LEFT FLOATING

I

SDAIN - I

2

C Bus Data In - CANNOT BE LEFT FLOATING

SCLK - SCL 181 I SCLK - Serial & SPI Interface Clock - CANNOT BE LEFT FLOATING

I

SDA_OUT 178 O

SA0 149 I

SA1 148 I

2

C bus Clock - CANNOT BE LEFT FLOATING

SCL - I

2

C Bus Data Out IF UNUSED MUST BE LEFT FLOATING

I

2

C Slave Address BIT 0 - CANNOT BE LEFT FLOATING

I

2

C Slave Address BIT 1- CANNOT BE LEFT FLOATING

I

DB0 to DB7 182-189 I/O Parallel Interface 8 Bit Data Bus - CANNOT BE LEFT FLOATING

- RD 175 I R/W - 68000 Series Parallel Interface Read & Write Control Input

R/W

- CANNOT BE LEFT FLOATING

IRD

- 8080 Series Parallel Interface Read enable Clock Input

- CANNOT BE LEFT FLOATING

E / WR

176 I E - 68000 Series Parallel Interface Read & Write Clock Input

- CANNOT BE LEFT FLOATING

2/66

STE2004S

Table 2.

TEST_MODE 191 I Test Pad - 50 kohm internal Pull-down MUST BE CONNECTED TO VSS/VSSAUX

TEST_VREF 146 O Test Pad - MUST BE LEFT FLOATING

OSCOUT 210 O Internal/External Oscillator Out - IF UNUSED MUST BE LEFT FLOATING

PIN DESCRIPTION

N° Pad Type Function

E / WR 176 I WR - 8080 Series Parallel Interface - Write enable clock input

RES

D/C

CS

OSCIN 144 I

FR_OUT 211 O Master Slave Frame Inversion Synchronization.

FR_IN 143 I Master Slave Frame Inversion Synchronization.

M/S 100 I Master/

172 I Reset Input. Active Low.

174 I Interface Data/Command Selector- CANNOT BE LEFT FLOATING

173 I Serial & Parallel Interfaces ENABLE. When Low the Incoming Data are Clocked In.

(continued)

- CANNOT BE LEFT FLOATING

CANNOT BE LEFT FLOATING

Oscillator Input:

OSC_IN Configuration

High Internal Oscillator Enabled

Low Internal Oscillator Disabled

External Oscillator Internal Oscillator Disabled

IF UNUSED MUST BE LEFT FLOATING

CANNOT BE LEFT FLOATING

Slave Configuration Bit:- CANNOT BE LEFT FLOATING

M/S PIN OSC_OUT FR_OUT FR_IN Charge Pump

High ENABLED Enabled Disabled AuxVsense Disabled

Low ENABLED Enabled Enabled Charge Pump in Slave Mode or Ext

Power

3/66

STE2004S

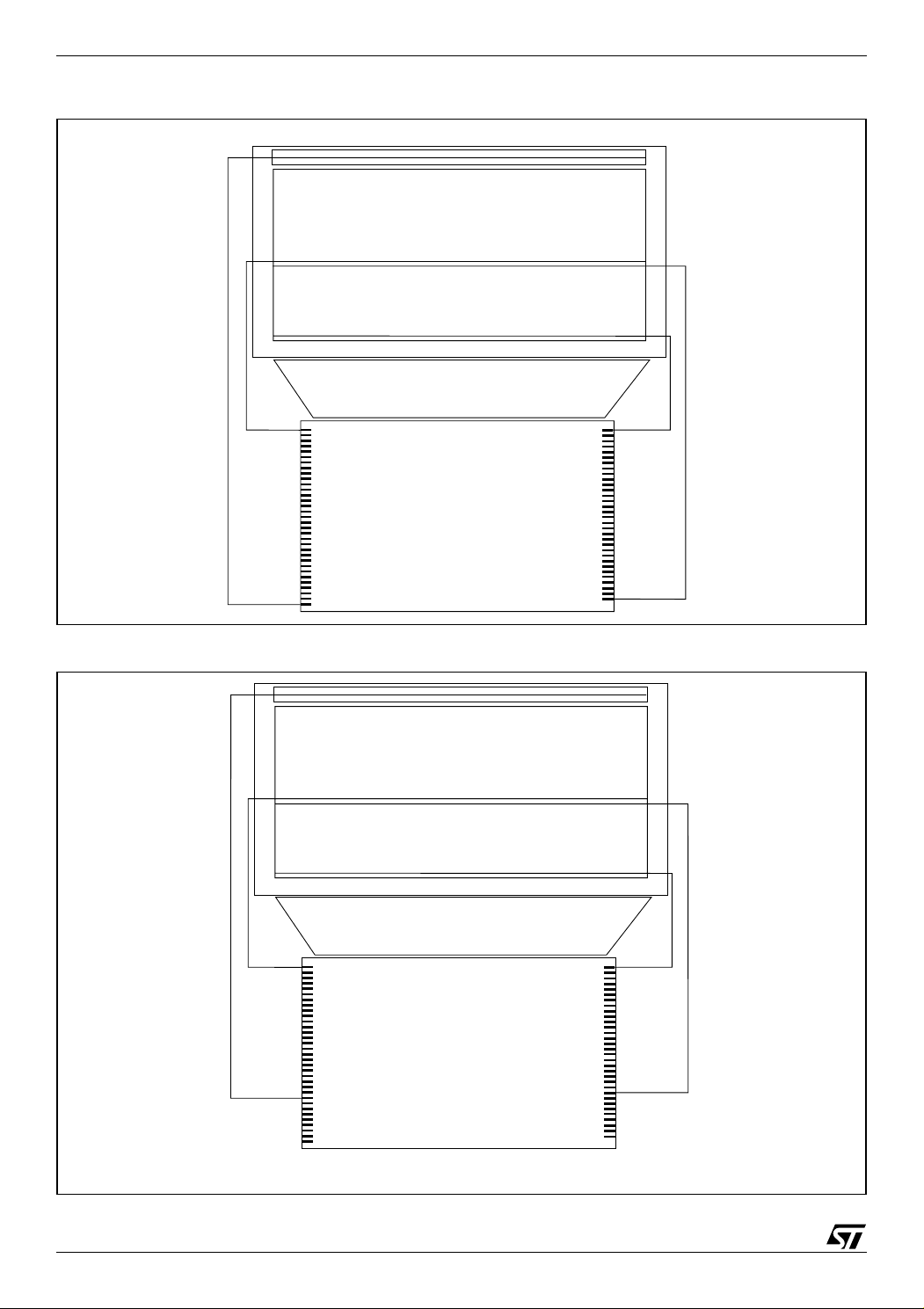

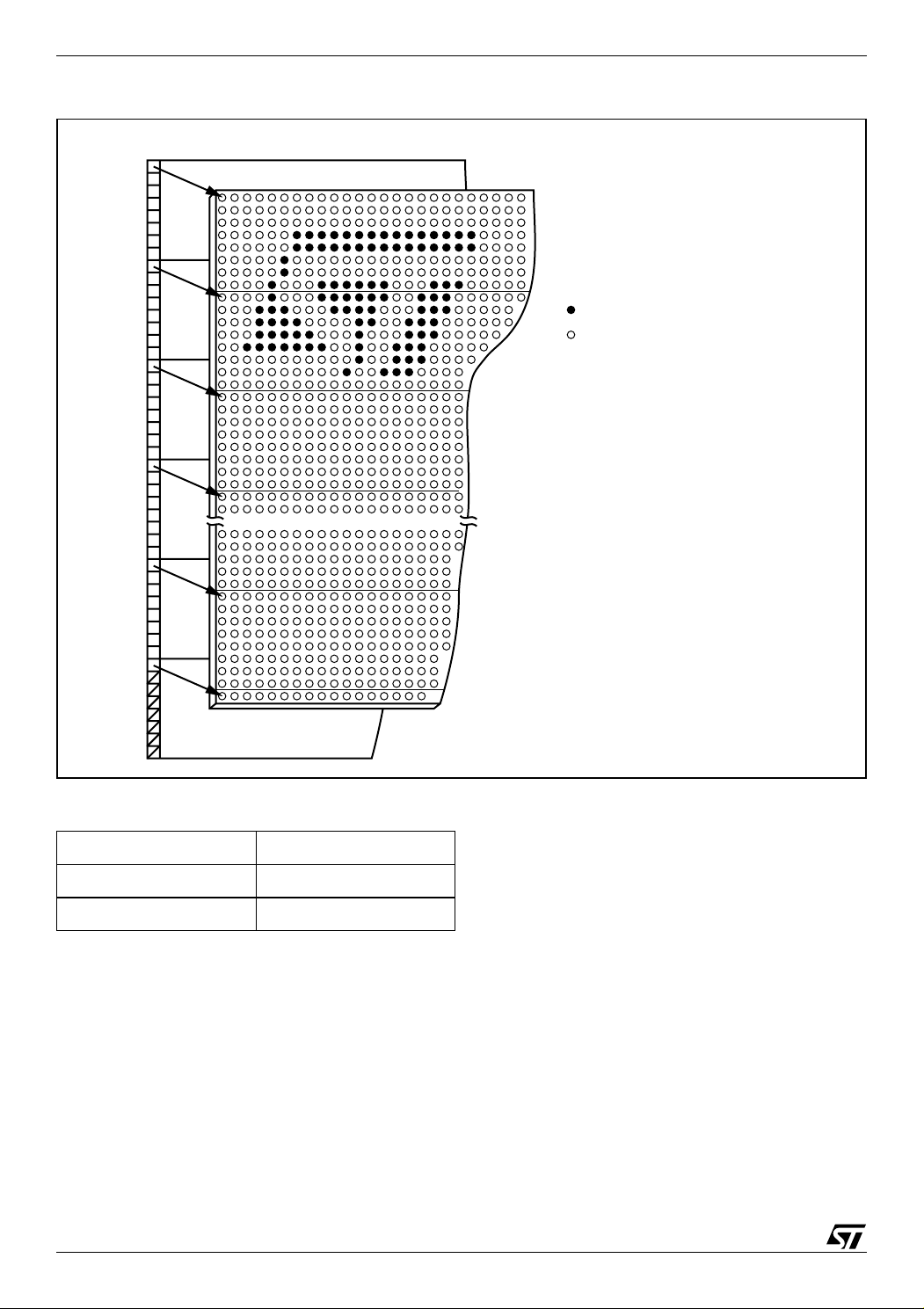

Figure 2. Chip Mechanical Drawing

ROW 5

ROW 0

COL 0

COL 50

COL 51

ROW 6

MARK_1

MARK_3

STE2004S

(0,0)

X

Y

MARK_4

ROW 27

ROW28

ROW31

FR_OUT

OSC_OUT

VLCD

VLCDSENSE

VSS

TEST_MODE

VSSAUX

D0

D1

D2

D3

D4

D5

D6

D7

SCLK - SCL

SDOUT

SDIN - SDAIN

SDAOUT

VSSAUX

E - WR

R/W - RD

D/C

CS

RES

4/66

COL 101

ROW 32

ROW 37

MARK_2

ROW 38

ROW 59

VDD2

VDD1

ICON

SEL1

SEL2

SEL3

EXT_SET

M/S

SA0

SA1

VSSAUX

TEST VREF

VSENSE_SLAVE

OSC_IN

FR_IN

VDD1_AUX

ROW64/ICON

ROW63

ROW60

LR0048

Figure 3. Improved ALTH & PLESKO Driving Method

V

LCD

V

2

V

3

ROW 0

R0 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

ROW 1

R1 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

COL 0

C0 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

COL 1

C1 (t)

V

4

V

5

V

SS

V

- V

LCD

SS

V3 - V

SS

STE2004S

∆V1(t)

∆V

(t)

2

V

V

state1

state2

V

- V

LCD

(t)

V3 - V

V

- V

LCD

V3 - V

V

- V

LCD

(t)

V3 - V

(t) = C1(t) - R0(t)

∆V

1

(t) = C1(t) - R1(t)

∆V

2

2

0V

SS

SS

SS

2

0V

SS

0 1 2 3 4 5 6 7 8 9 64

.......

FRAME n FRAME n + 1

0 1 2 3 4 5 6 7 8 9 64

.....

.......

.....

V

4 - V5

0V

V

SS - V5

V4 - V

VSS - V

V

4 - V5

0V

V

SS - V5

V4 - V

VSS - V

D00IN1154

LCD

LCD

LCD

LCD

5/66

STE2004S

3 CIRCUIT DESCRIPTION

3.1 Supplies Voltages and Grounds

is supply voltages to the internal voltage generator (see below). If the internal voltage generator is

V

DD2

not used, this should be connected to V

could be different form V

DD2

.

3.2 Internal Supply Voltage Generator

The IC has a fully integrated (no external capacitors required) charge pump for the Liquid Crystal Display

supply voltage generation. The multiplying factor can be programmed to be: Auto, X5, X4, X3, X2, using

the ’set CP Multiplication’ Command. If Auto is set, the multiplying factor is automatically selected to have

the lowest current consumption in every condition. This make possible to have an input voltage that changes over time and a constant V

CDSENSE

pad. For this voltage, eight different temperature coefficients (TC, rate of change with

voltage. The output voltage (V

LCD

temperature) can be programmed using TC1 & TC0 or T2, T1 and T0 bits. This will ensure no contrast

degradation over the LCD operating range.

An external supply could be connected to V

such event the internal voltage generator must be programmed to zero (PRS = [0;0], Vop = 0 - Reset condition) and the Charge pump (CP[0;0]) set to 5x or Auto Mode.

V

DD1

DD2

pad. V

2VLCD⋅

------------------------- 200mV+≥

n4+()

to supply the LCD without using the internal generator. In

LCD

supplies the rest of the IC. V

DD1

) is tightly controlled through the V

LCD

supply voltage

DD1

L-

3.3 Oscillator

A fully integrated oscillator (requires no external components) is present to provide the clock for the Display System. When used the OSC pad must be connected to V

pad. An external oscillator could be

DD1

used and fed into the OSC pin.If an external oscillator is used, it must be always present when STE2004S

is not in power down mode. An oscillator out is provided on the OSCOUT Pad to cascade two or more

drivers.

3.4 Master/Slave Mode

STE2004S support the Master Slave working Mode for Both Control Logic and Charge Pump. This function allows to drive matrix such as 204x65 or 102x130 using two synchronized STE2004S and the internal

Charge Pump of both device.

If M/S

is connected to VDD1, the driver is configured to work in Master Mode. When STE2004S is in Master Mode the Vsense_Slave Pin is disabled and is possible to control the VLCD value using Vop Bits. The

Master Time Generator outputs on FR_OUT and on OSC_OUT the relevant timing references.

If M/S

is connected to GND, the driver is configured to work in Slave Mode. When STE2004S is in Slave

Mode, the VLCD configuration set by Vop registers and the thermal compensation slope set by TC register

are neglected. The VLCD Value generated is equal to the Voltage value present on Vsense_Slave Pin so

the slave configuration can follow the master configuration. The only recognized configuration is Vop=0

that forces the Charge Pump to be in off state whatever is the value of Vsense_aux.

To Synchronize the Master & Slave timing circuits, the slave driver FR_IN pad must be connected to Master Driver FR_OUT pad and Slave Driver OSC_IN pad must be connected to the master driver OSC_OUT

Pad (Fig. 4). This connection ensure a synchronization at both Frame level (R0 on the master is driven

together with the Slave R0 driver) and at Oscillator Level (same Frame frequency on the master and on

the slave). If the Synchronization at Frame level is not required, FR_IN pin must be connected toVDD1 or

to VDD1_aux (Fig. 5).

During Power Up Procesure, Master device must be forced to exit from power down before the slave device. To enter in PowerDown Mode, Slave Device must be forced in Power Down state before Master Device.

6/66

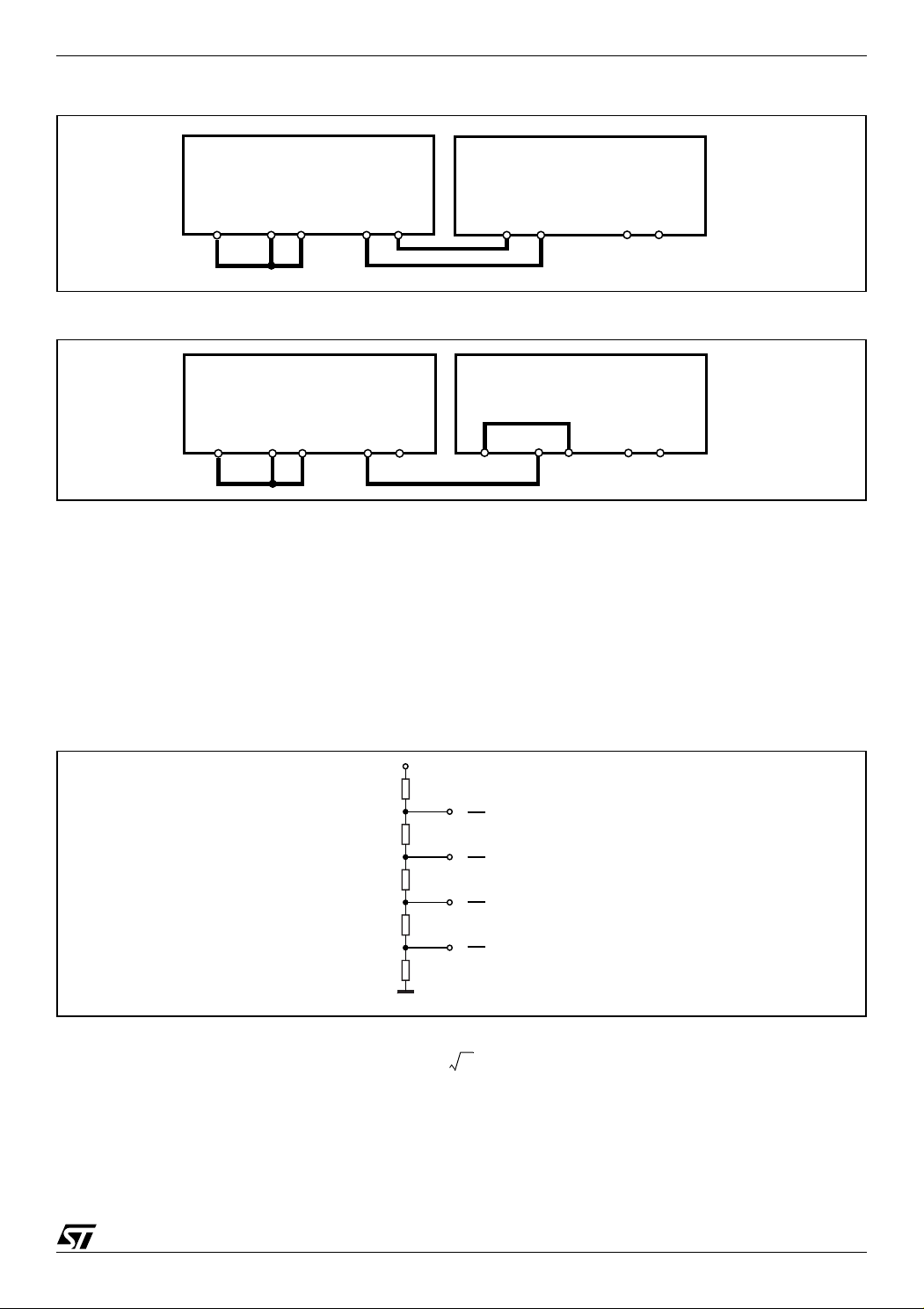

Figure 4. Master Slave Logic Connection with frame Synchronization

0

0

STE2004S

STE2004S

VDD1AUX

OSCOUT

FROUT OSCINFRINOSCIN FRIN

STE2004S

OSCOUT FROUT

LR0219

Figure 5. Master Slave Logic Connection without frame Synchronization

STE2004S

VDD1AUX

OSCOUT

FROUTOSCIN FRIN

STE2004S

OSCIN

VDD1AUX

FRIN

OSCOUT FROUT

LR022

3.5 Bias Levels

To properly drive the LCD, six (Including VLCD and VSS) different voltage (Bias) levels are generated.

The ratios among these levels and VLCD, should be selected according to the MUX ratio (m). They are

established to be (Fig. 6):

V

LCD

n3+

-------------

,

n4+

V

LCD

n2+

-------------

,

n4+

V

LCD

-------------

,

n4+

2

V

LCD

-------------

,

n4+

1

V

LCD,VSS

Figure 6. Bias level Generator

V

R

R

nR

R

R

LCD

n + 3

n + 4

n + 2

n + 4

n + 4

n + 4

V

2

1

SS

·V

LCD

·V

LCD

·V

LCD

·V

LCD

D00IN115

thus providing an 1/(n+4) ratio, with n calculated from:

nm3–=

For m = 65, n = 5 and an 1/9 ratio is set.

For m = 49, n =4 and an 1/8 ratio is set.

The STE2004S provides three bits (BS0, BS1, BS2) for programming the desired Bias Ratio as shown below:

7/66

STE2004S

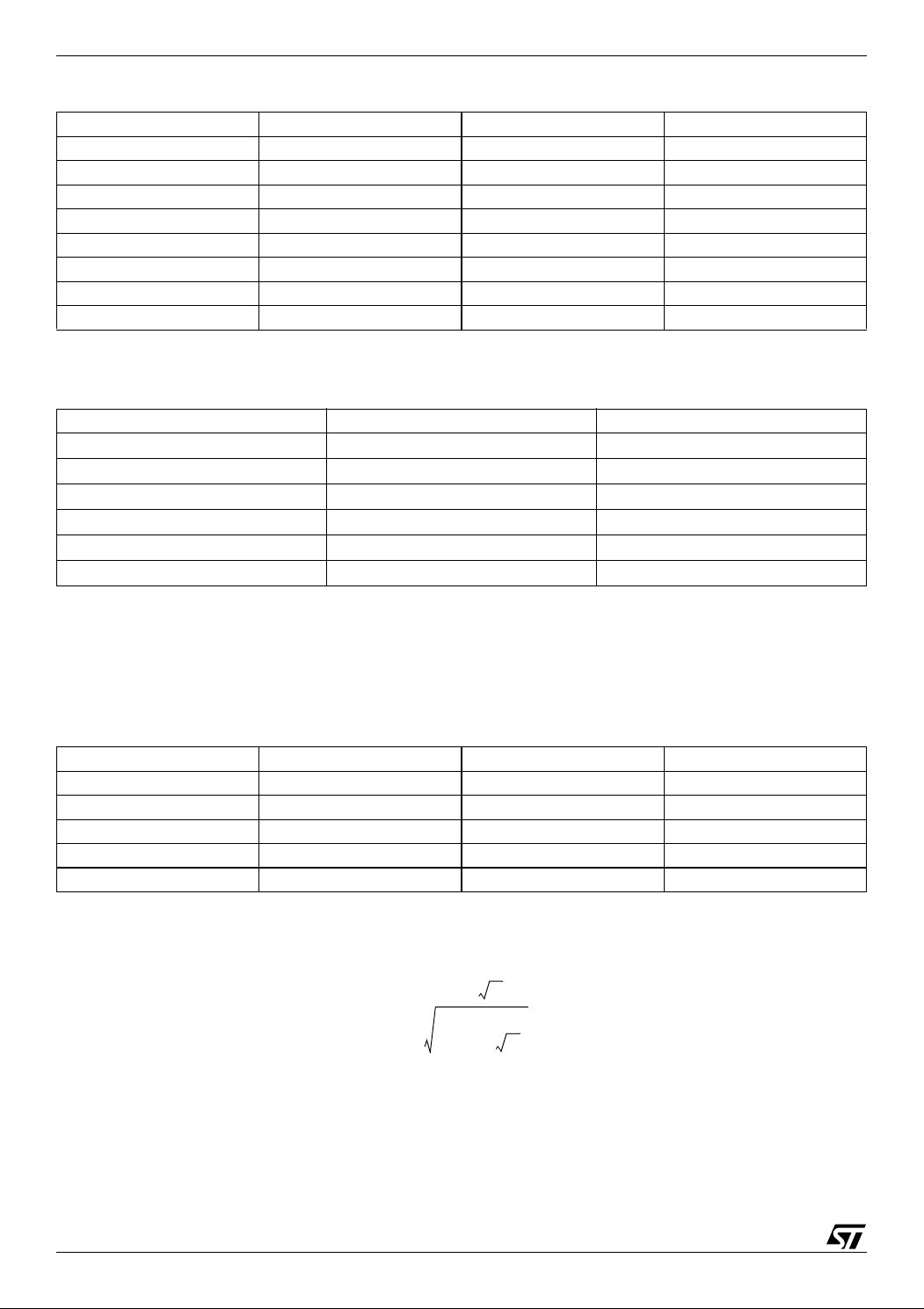

Table 3.

BS2 BS1 BS0 n

0007

0016

0105

0114

1003

1012

1101

1110

The following table Bias Level for m = 65 and m = 49 are provided:

Table 4.

Symbol m = 65 (1/9) m = 49 (1/8)

V1 V

V2 8/9*V

V3 7/9*V

V4 2/9*V V

V5 1/9 *V

V6 V

LCD

LCD

LCD

LCD

LCD

SS

V

7/8*V

6/8*V

2/8*V

1/8*V

V

LCD

LCD

LCD

LCD

LCD

SS

3.6 LCD Voltage Generation

The LCD Voltage at reference temperature (To = 27°C) can be set using the VOP register content according to

the following formula:

V

(T=To) = V

LCD

o = (Ai+VOP · B) (i=0,1,2)

LCD

with the following values:

Symbol Value Unit Note

Ao 2.95 V PRS = [0;0]

A1 6.83 V PRS = [0;1]

A2 10.71 V PRS = [1;0]

B 0.0303 V

To 2 7 ° C

Note that the three PRS values produce three adjacent ranges for VLCD. If the VOP register and PRS bits

are set to zero the internal voltage generator is switched off.

The proper value for the VLCD is a function of the Liquid Crystal Threshold Voltage (Vth) and of the Multiplexing Rate. A general expression for this is:

1m+

------------------------------------

21

V

LCD(to)

⋅=

V

1

⎛⎞

---------–

⋅

⎝⎠

m

= 6.85 · V

th

th

For MUX Rate m = 65 the ideal V

LCD

is:

V

LCD

than:

6.85 VthAi–⋅()

V

op

-----------------------------------------=

0.03

8/66

STE2004S

3.7 Temperature Coefficients

As the viscosity, and therefore the contrast, of the LCD are subject to change with temperature, there's

the need to vary the LCD Voltage with temperature. STE2004S provides the possibility to change the

VLCD in a linear fashion against temperature with eight different Temperature Coefficient selectable

through T2, T1 and T0 bits. Only four of them are available through basic instruction set.

Table 5.

NAME TC1 TC0 Value Unit

TC0 0 0

TC2 0 1

TC3 1 0

TC6 1 1

-0.7 · 10

-1.05· 10

-2.1 · 10

-0.0· 10

-3

-3

-3

-3

Table 6.

NAME T2 T1 T0 Value Unit

TC0 0 0 0

TC1 0 0 1

TC2 0 1 0

TC3 0 1 1

TC4 1 0 0

TC5 1 0 1

TC6 1 1 0

TC7 1 1 1

-0.35 · 10

-0.7 · 10

-1.05· 10

-1.4 · 10

-1.75· 10

-2.1 · 10

-0.0· 10

-2.3· 10

-3

-3

-3

-3

-3

-3

-3

-3

Figure 7.

1/ °C

1/°C

1/°C

1/°C

1/ °C

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

LCD

V

1

A

00h 01h 02h 03h 04h 05h …. 7Fh 00h 01h 02h7Ch 7Dh 7Eh 03h 04h 7Dh 7Eh 7Fh05h …. 7Ch

Finally, the V

B

1

0

A

+ B

A

PRS = [0;0] PRS = [0;1]

voltage at a given (T) temperature can be calculated as:

LCD

V

LCD

(T) = V

o · [1 + (T-To) · TC]

LCD

2

A

00h 01h 02h 03h 04h

PRS = [1;0]

05h 7Ch

….

7Dh 7Eh 7Fh

O

V

9/66

STE2004S

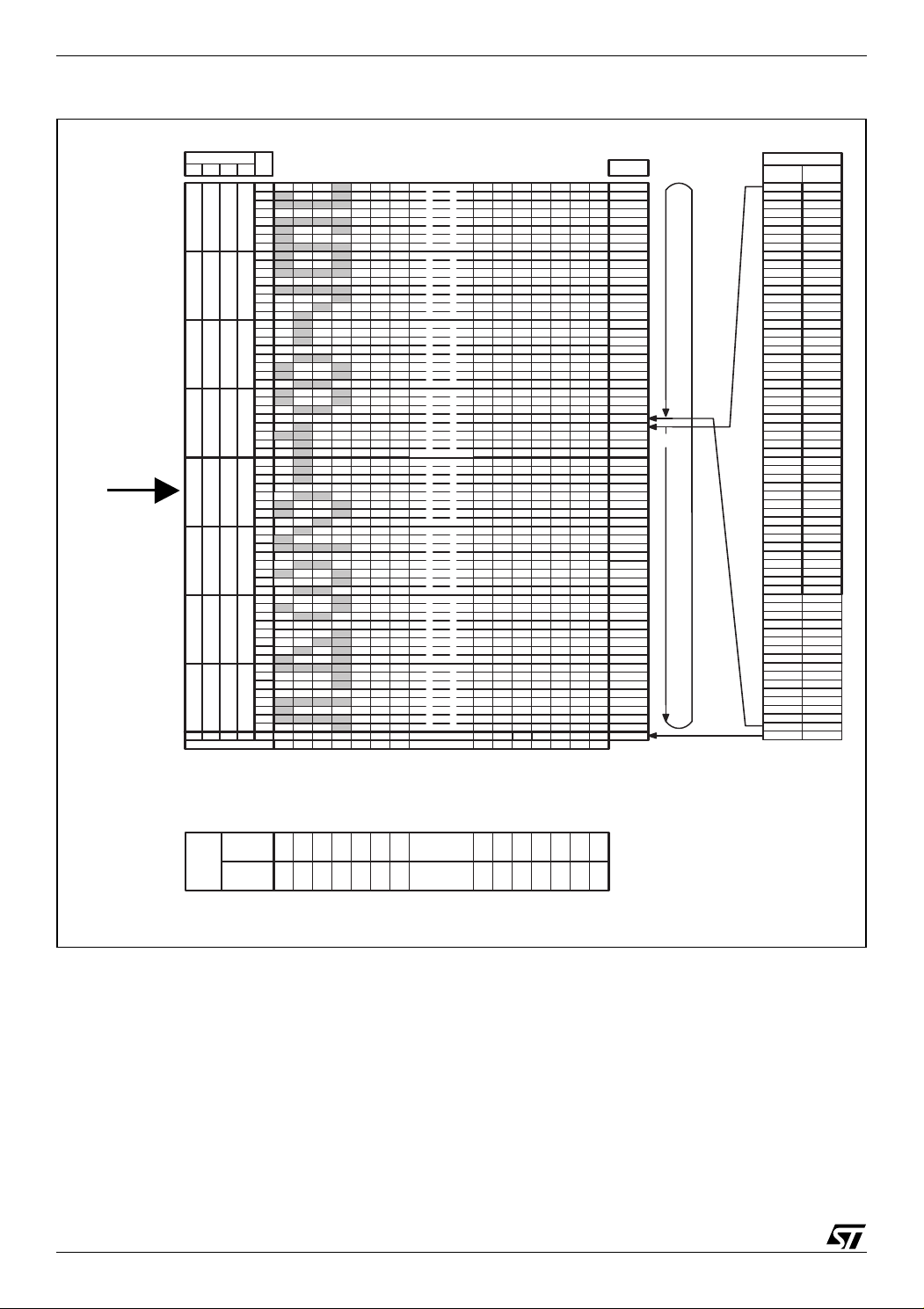

3.8 Display Data RAM

The STE2004S, provides an 102X65 bits Static RAM to store Display data. This is organized into 9 (Bank0

to Bank8) banks with 102 Bytes. One of these Banks can be used for Icons. RAM access is accomplished

in either one of the Bus Interfaces provided (see below). Allowed addresses are X0 to X101 (Horizontal)

and Y0 to Y8 (Vertical).

When writing to RAM, four addressing mode are provided:

• Normal Horizontal (MX=0 and V=0), having the column with address X= 0 located on the left of the mem-

ory map. The X pointer is increased after each byte written. After the last column address (X=X-Carriage), Y address pointer is set to jump to the following bank and X restarts from X=0. (Fig. 8)

• Normal Vertical (MX=0 and V=1), having the column with address X= 0 located on the left of the memory

map. The Y pointer is increased after each byte written. After the last Y bank address (Y=Y-Carriage),

X address pointer is set to jump to next column and Y restarts from Y=0 (Fig. 9).

• Mirrored Horizontal (MX=1 and V=0), having the column with address X= 0 located on the right of the

memory map. The X pointer is increased after each byte written. After the last column address (X=XCarriage), Y address pointer is set to jump to the next bank and X restarts from X=0 (fig. 10).

• Mirrored Vertical (MX=1 and V=1), having the column with address X= 0 located on the right of the mem-

ory map. The Y pointer is increased after each byte written. After the last Y bank address (Y=Y-Carriage), the X pointer is set to jump to next column and Y restarts from Y=0 (fig. 11).

After the last allowed address (X;Y)=(X-Carriage; Y-Carriage), the address pointers always jump to the

cell with address (X;Y) = (0;0) (Fig. 12,13,14 & 15).

Data bytes in the memory could have the MSB either on top (D0 = 0, Fig.16) or on the bottom (D0=1, Fig.

17).

The STE2004S provides also means to alter the normal output addressing. A mirroring of the Display

along the X axis is enabled setting to a logic one MY bit.This function doesn't affect the content of the

memory map. It is only related to the memory read process.

When ICON MODE=1 the Icon Row is not mirrored with MY and is not scrolled.

When ICON MODE=0 the Icon Row is like an other graphic line and is mirrored and scrolled.

Three are the multiplex ratio available when the partial display mode is disabled (MUX 33, MUX 49 and

MUX 65). Only a subset of writable rows are output on Row drivers in MUX 33,49 & 65 Mode.

When Y-Carriage<MUX/8, if Mux 49 is selected only the first 49 memory rows are visualized; if Mux 33 is

selected only the first 33 memory rows are visualized. The unused output row & column drivers must be

left floating.

When Y-Carriage<=MUX/8 the icon Bank is located to BANK 8 in MUX 65 Mode, to BANK6 in MUX 49

Mode and to BANK 4 in MUX 33 Mode.

In Mux 33 & 49 Mode, when Y-Carriage>MUX/8 lines only 33, 49 lines are visualized.

It is possible to select which lines of DDRAM are connected on the output drivers using the scrolling function (Range: 0-Y-Carriage*8). When Y-Carriage>MUX/8 lines, the icon row is moved in DDRAM to the

first row of the Bank correspondant to Y-CARRIAGE Return value, being always connected on the same

output Driver.

When MY=0, the icon Row is output on R64 in mux 65 mode, on R56 in MUX 49 and on R48 in MUX33.

When MY=1, and ICON MODE=0, the icon Row is output on R0 whatever is the MUX Rate.

10/66

STE2004S

2

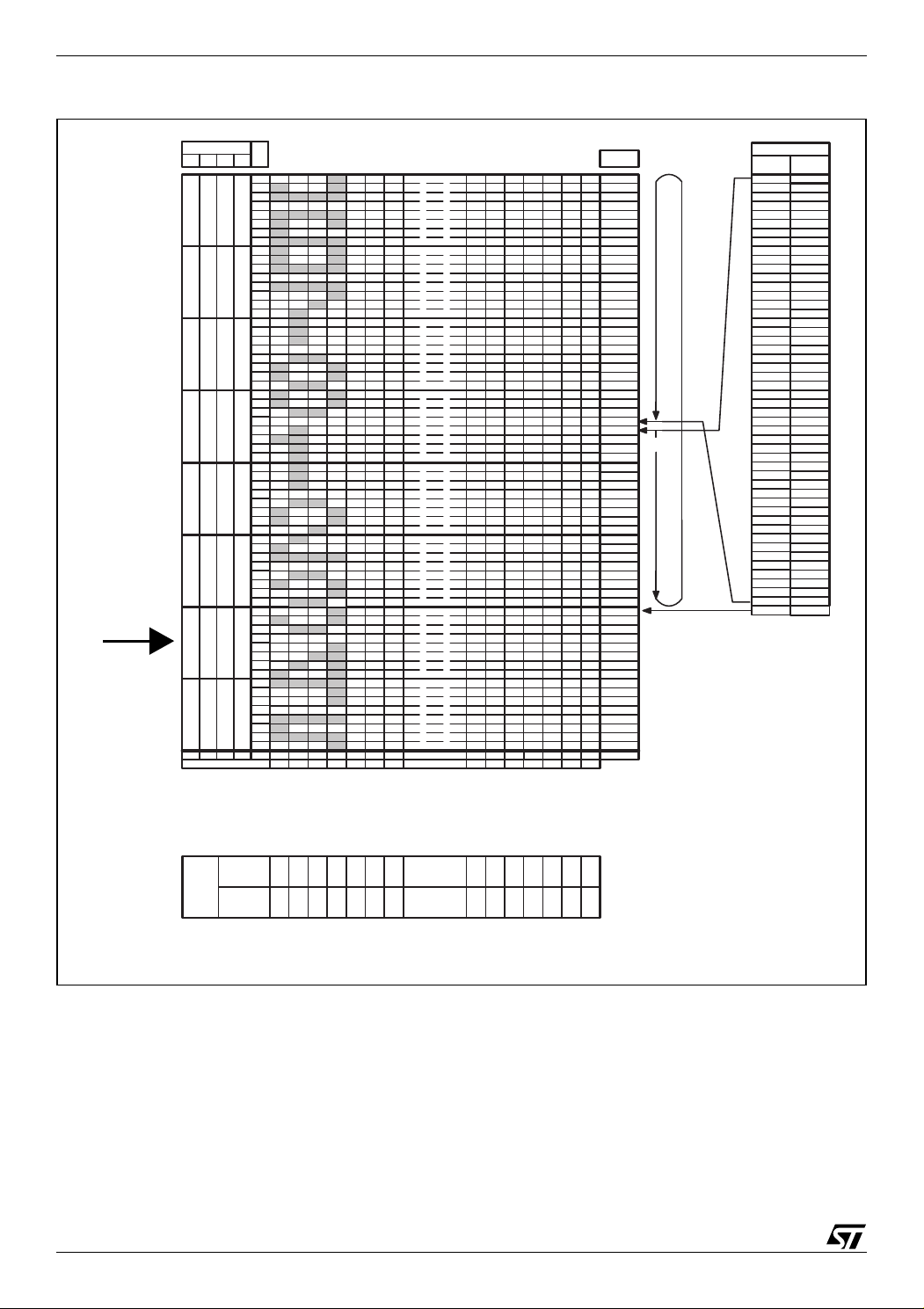

Figure 8. Automatic data RAM writing sequence with V=0 and Data RAM Normal Format (MX=0)1

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

0123 9899100101

LR0049

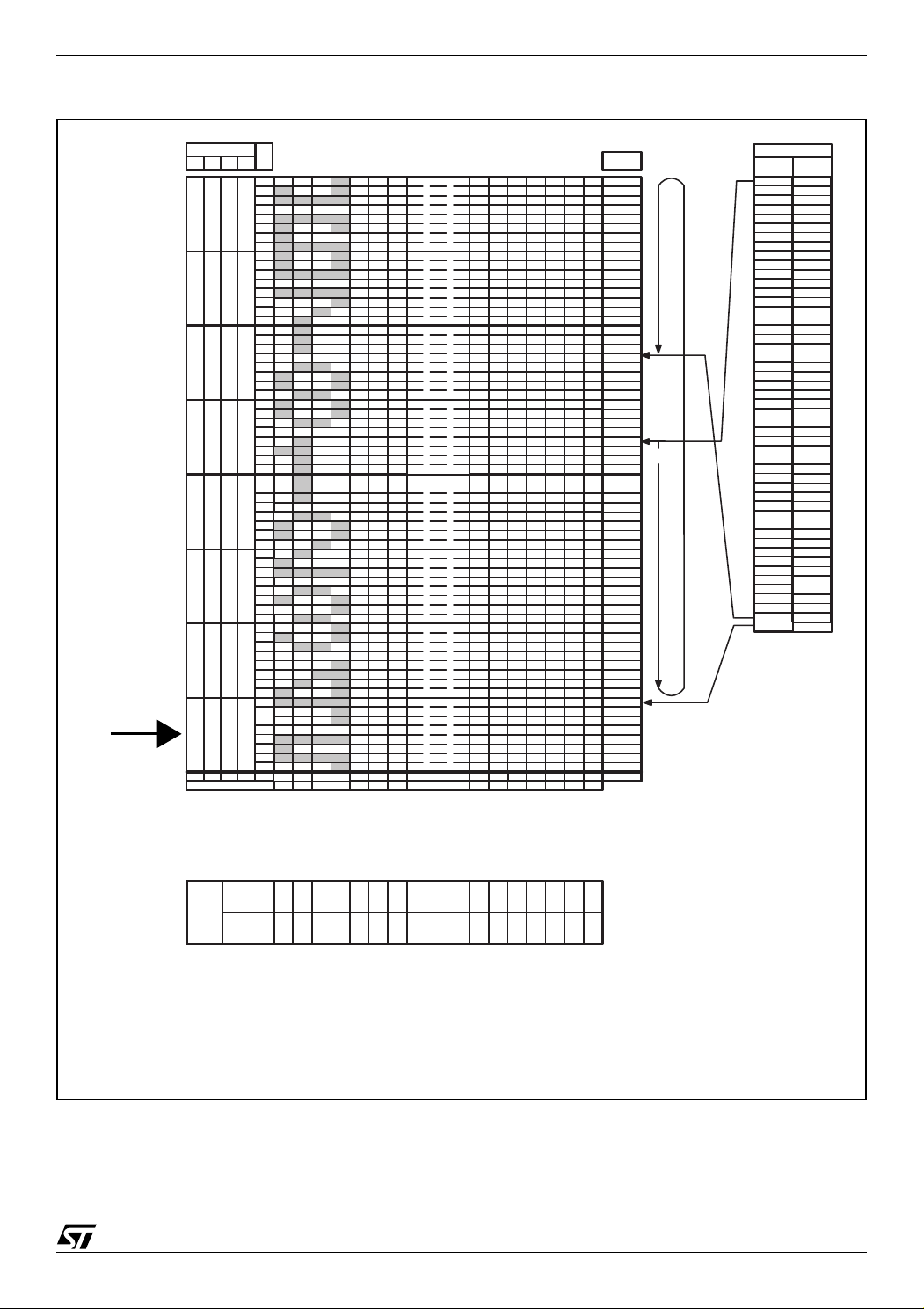

Figure 9. Automatic data RAM writing sequence with V=1 and Data RAM Normal Format (MX=0)

0123 9899100101

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

01

LR0050

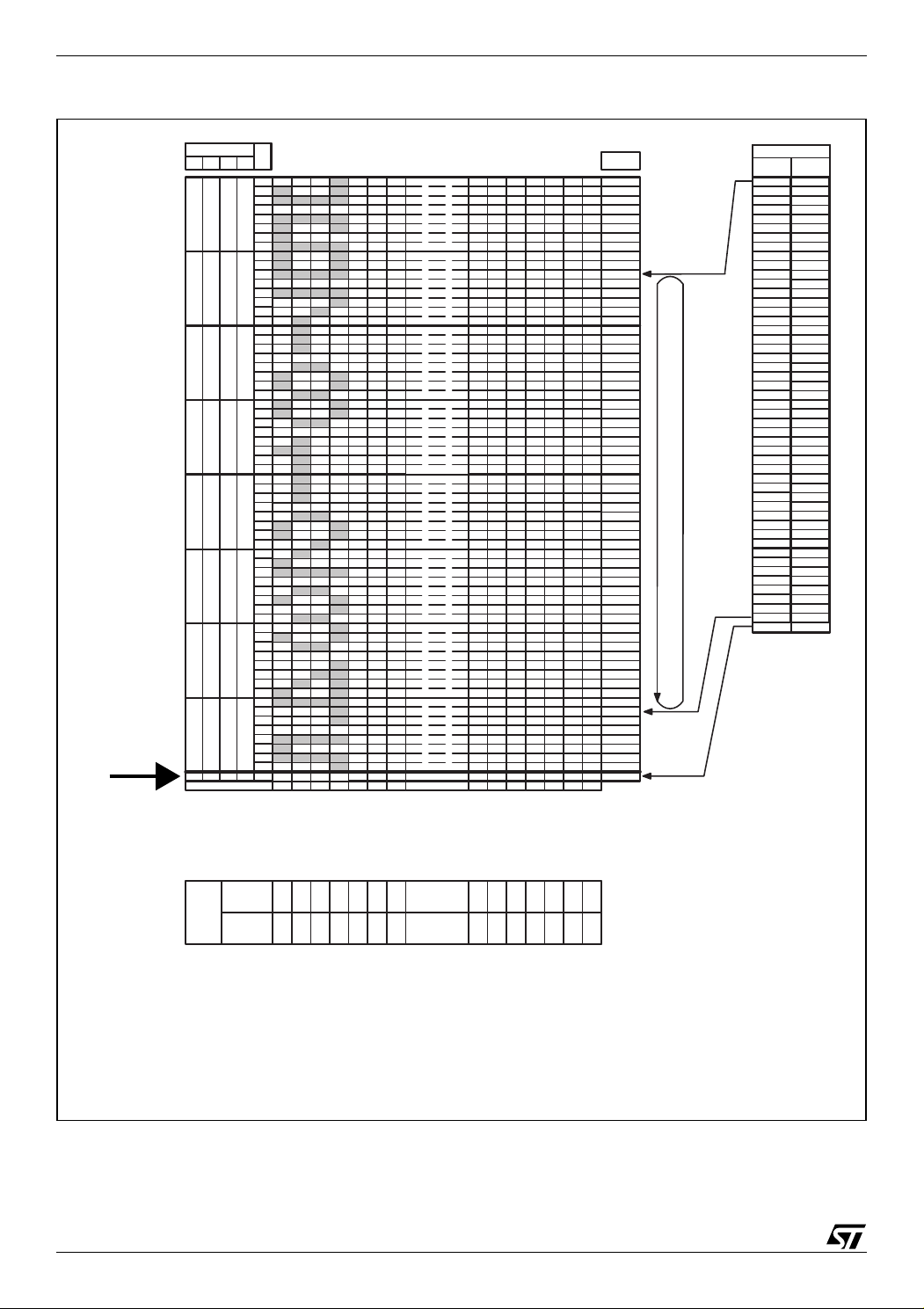

Figure 10. Automatic data RAM writing sequence with V=0 and Data RAM Mirrored Format (MX=1)

1

1

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

32109899100101

LR0051

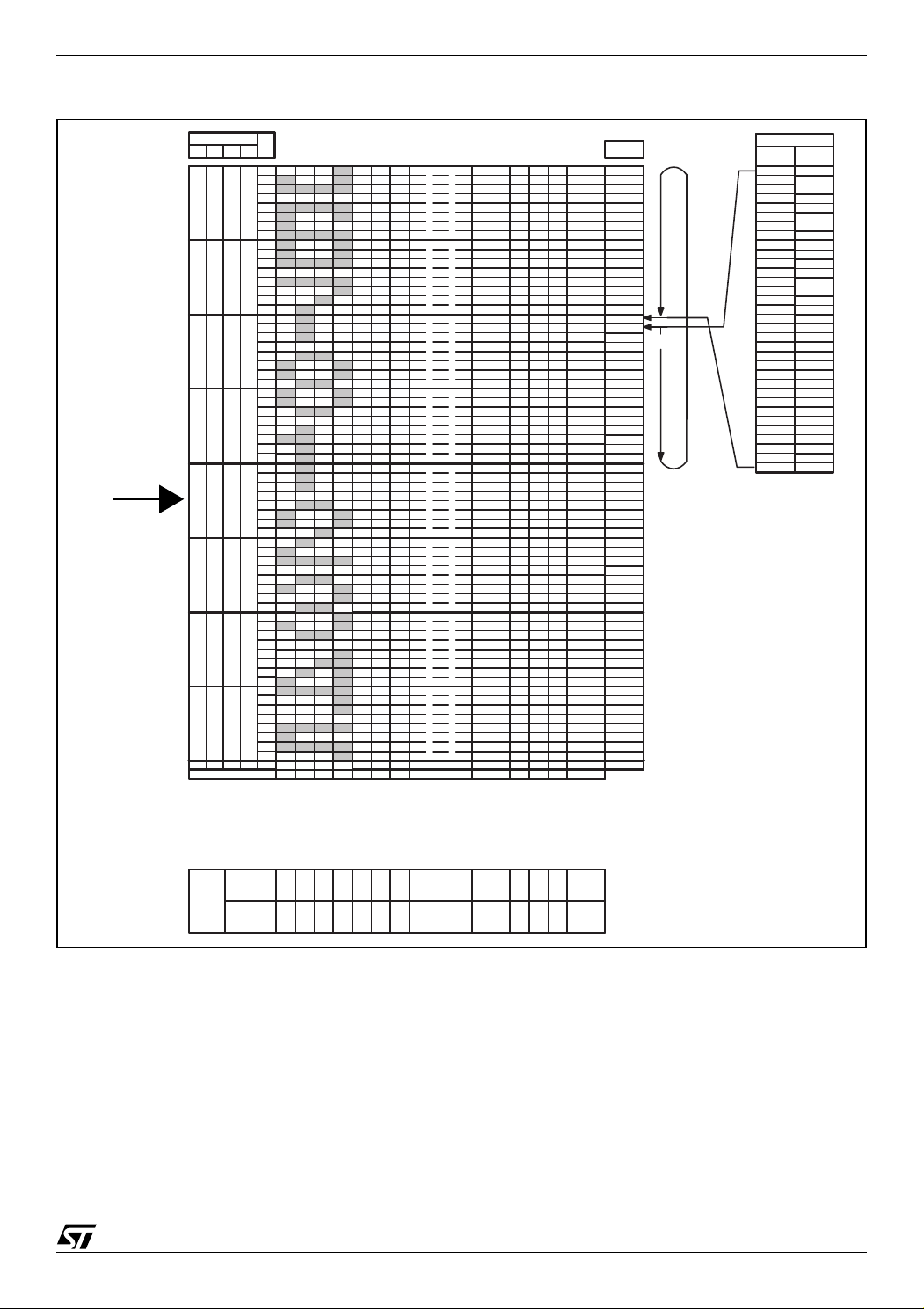

Figure 11. Automatic data RAM writing sequence with V=1 and Data RAM Mirrored Format (MX=1)1

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

1. X Carriage=101; Y-Carriage = 8

10329899100101

LR005

11/66

STE2004S

3

4

6

Figure 12. Automatic data RAM writing sequence with X-Y Carriage Return (V=0; MX=0)

BANK 0

0123

BANK 1

BANK 2

Y CARR

BANK 7

BANK 8

X CARR

98 99 100 101

LR005

Figure 13. Automatic data RAM writing sequence with X-Y Carriage Return (V=1; MX=0)

0123

X CARR

BANK 0

BANK 1

BANK 2

Y CARR

BANK 7

BANK 8

98 99 100 101

LR005

Figure 14. Automatic data RAM writing sequence with X-Y Carriage Return (V=0; MX=1)

X CARR

BANK 0

BANK 1

BANK 2

Y CARR

BANK 7

BANK 8

1239899100101

0

LR0055

Figure 15. Automatic data RAM writing sequence with X-Y Carriage Return (V=1; MX=1)

X CARR

BANK 0

9899100101

BANK 1

BANK 2

Y CARR

BANK 7

BANK 8

0

123

LR005

12/66

Figure 16. Data RAM Byte organization with D0 = 0

7

8

MSB

0

1 2 3 98 99 100 101

LSB

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

Figure 17. Data RAM Byte organization with D0 = 1

LSB

0123 9899100101

MSB

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

STE2004S

LR005

LR005

13/66

STE2004S

Figure 18. Memory Rows vs. Row Drivers Mapping ICON_MODE=1 and MUX 65

Y-CARRIAGE

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

0

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

0

D4

D5

D6

D7

D0

D1

D2

D3

0

0

1

D4

D5

D6

D7

D0

D1

D2

D3

0

1

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

1

1

D4

D5

D6

D7

0

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

ROW Output

Normal

Reverse

direction

direction

R0

R63

R1

R62

R2

R61

R3

R60

R4

R59

R5

R58

R6

R57

R7

R56

R8

R55

R9

R54

R10

R53

R11

R52

R12

R51

R13

R50

R14

R49

R15

R48

R16

R47

R17

R46

R18

R45

R19

R44

R20

R43

R21

R42

R22

R41

R23

R40

R24

R39

R25

R38

R26

R37

R27

R36

R28

R35

R29

R34

R30

R33

R31

R32

R32

R31

R33

R30

R34

R29

R35

R28

R36

R27

R37

R26

R38

R25

R39

R24

R40

R23

R41

R22

R42

R21

R43

R20

R44

R19

R45

R18

R46

R17

R47

R16

R48

R15

R49

R14

R50

R13

R51

R12

R52

R11

R53

R10

R54

R9

R55

R8

R56

R7

R57

R6

R58

R5

R59

R4

R60

R3

R61

R2

R62

R1

R63

R0

R64 R64

lr0268

14/66

COL

Output

Normal

Direction

Reverse

Direction

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

101

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

Figure 19. Memory Rows vs. Row Drivers Mapping ICON_MODE=0 and MUX 65

STE2004S

Y-CARRIAGE

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

0

1

0

1

0

1

0

1

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

D4

D5

D6

D7

D0

D1

D2

D3

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

D4

D5

D6

D7

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

40H

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

R57

R58

R59

R60

R61

R62

R63

R64

Reverse

direction

R64

R63

R62

R61

R60

R59

R58

R57

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R31

R30

R29

R28

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

COL

Output

Normal

Direction

Reverse

Direction

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

101

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

lr0269

15/66

STE2004S

Figure 20. Memory Rows vs. Row Drivers Mapping ICON_MODE=1,

D2 D1 D0

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

0

0

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

60H

61H 65H62H 63H 64H

Line

Address

Y-CARRIAGE

Y Address

D3

0

0

0

0

0

0

0

0

1

X address

Y-Carriage<=6

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Scrolling Pointer

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

and MUX 49

ROW Output

Normal

Reverse

direction

direction

R0

R55

R1

R54

R2

R53

R3

R52

R4

R51

R5

R50

R6

R49

R7

R48

R8

R47

R9

R46

R10

R45

R11

R44

R12

R43

R13

R42

R14

R41

R15

R40

R16

R39

R17

R38

R18

R37

R19

R36

R20

R35

R21

R34

R22

R33

R23

R32

R23

R32

R22

R33

R21

R34

R20

R35

R19

R36

R18

R37

R17

R38

R16

R39

R15

R40

R14

R41

R13

R42

R12

R43

R11

R44

R10

R45

R9

R46

R8

R47

R7

R48

R6

R49

R5

R50

R4

R51

R3

R52

R2

R53

R1

R54

R0

R55

R56

R56

16/66

COL

Output

Normal

Direction

Reverse

Direction

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

101

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

lr0270

STE2004S

Figure 21. Memory Rows vs. Row Drivers Mapping ICON_MODE=0,

D2 D1 D0

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

0

0

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Y-CARRIAGE

Y Address

D3

0

0

0

0

0

0

0

0

1

X address

Y-Carriage<=6

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

Scrolling Pointer

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

and MUX 49

ROW Output

Normal

Reverse

direction

direction

R0

R56

R1

R55

R2

R54

R3

R53

R4

R52

R5

R51

R6

R50

R7

R49

R8

R48

R9

R47

R10

R46

R11

R45

R12

R44

R13

R43

R14

R42

R15

R41

R16

R40

R17

R39

R18

R38

R19

R37

R20

R36

R21

R35

R22

R34

R23

R33

R32

R32

R23

R33

R22

R34

R21

R35

R20

R36

R19

R37

R18

R38

R17

R39

R16

R40

R15

R41

R14

R42

R13

R43

R12

R44

R11

R45

R10

R46

R9

R47

R8

R48

R7

R49

R6

R50

R5

R51

R4

R52

R3

R53

R2

R54

R1

R55

R0

R56

COL

Output

Normal

Direction

Reverse

Direction

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

101

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

lr0271

17/66

STE2004S

Figure 22.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=0, Y-Carriage=7, Scrolling Pointer>07h and MUX 49

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

0

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

0

D4

D5

D6

D7

D0

D1

D2

D3

0

0

1

D4

D5

D6

D7

D0

D1

D2

D3

0

1

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

1

1

D4

D5

D6

D7

0

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

60H

61H 65H62H 63H 64H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

Reverse

direction

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

18/66

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

lr0275

STE2004S

Figure 23.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=1, Y-Carriage=7, Scrolling Pointer>07h and MUX 49

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

0

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

0

D4

D5

D6

D7

D0

D1

D2

D3

0

0

1

D4

D5

D6

D7

D0

D1

D2

D3

0

1

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

1

1

D4

D5

D6

D7

0

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

Reverse

direction

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

R56

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

lr0276

19/66

STE2004S

Figure 24.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=1, Y-Carriage=8, Scrolling Pointer<10h and MUX 49

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

0

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

0

D4

D5

D6

D7

D0

D1

D2

D3

0

0

1

D4

D5

D6

D7

D0

D1

D2

D3

0

1

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

1

1

D4

D5

D6

D7

0

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

60H

61H 65H62H 63H 64H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

Reverse

direction

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

R56

20/66

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

LR0273

STE2004S

Figure 25.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=0, Y-Carriage=8, Scrolling Pointer<10h and MUX 49

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

0

1

0

1

0

1

0

1

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

D4

D5

D6

D7

D0

D1

D2

D3

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

D4

D5

D6

D7

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

60H

61H 65H62H 63H 64H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

Reverse

direction

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

LR0274

21/66

STE2004S

Figure 26.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=1, Y-Carriage<=4 and MUX33

D2 D1 D0

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

0

0

D

a

t

a

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

D0

D1

D2

D3

0

D4

D5

D6

D7

D0

D1

D2

D3

1

D4

D5

D6

D7

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

Scrolling Pointer

Y Address

D3

0

0

0

0

0

0

0

0

1

X address

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

Reverse

direction

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

R48

22/66

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

LR0272

STE2004S

Figure 27.

Y-CARRIAGE

Memory Rows vs. Row Drivers Mapping ICON_MODE=0,

Y Address

D2 D1 D0

D3

0

0

0

0

0

0

0

0

1

X address

D

a

t

a

D0

D1

D2

D3

0

0

0

D4

D5

D6

D7

D0

D1

D2

D3

0

1

0

D4

D5

D6

D7

D0

D1

D2

D3

1

0

0

D4

D5

D6

D7

D0

D1

D2

D3

1

1

0

D4

D5

D6

D7

D0

D1

D2

D3

0

0

1

D4

D5

D6

D7

D0

D1

D2

D3

0

1

1

D4

D5

D6

D7

D0

D1

D2

D3

1

0

1

D4

D5

D6

D7

D0

D1

D2

D3

1

1

1

D4

D5

D6

D7

0

0

0

D0

00H

02H 06H03H 04H 05H

01H

Page 0

Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

5FH

61H 65H62H 63H 64H

60H

Y-Carriage<=4

Line

Address

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1CH

1DH

1EH

1FH

20H

21H

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

33H

34H

35H

36H

37H

38H

39H

3AH

3BH

3CH

3DH

3EH

3FH

and MUX 33

Scrolling Pointer

ROW Output

Normal

direction

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

Reverse

direction

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R34

R33

R32

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

R0

COL

Output

Normal

Direction

Reverse

Direction

101

C

C

O

L

C

O

L

100 99

C

O

O

L

L

C

C

O

O

L

L

98 979695

C

O

L

0

C

O

L

C

C

C

O

O

O

L

L

L

C

C

C

O

O

O

L

L

L

C

C

O

O

L

L

C

C

O

O

L

L

5

6

C

C

C

C

O

O

L

L

C

C

O

O

L

L

4

C

O

O

O

L

L

L

1011 2 3 4 5 6 1009998979695

C

C

C

O

O

O

L

L

L

0

123

LR0272

23/66

STE2004S

Figure 28. Row Drivers vs. LCD Panel Interconnection in MUX65 Mode

ICON

MUX 65

COLUMN DRIVERS

ROW DRIVERS

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

STE2004S

R50

R51

R52

R53

R54

R55

R56

R57

R58

R59

R60

R61

R62

R63

R64

R 0

R 1

R 2

R 3

R 4

R 5

R 6

R 7

R 8

R 9

R10

R11

R12

R13

R14

R15

R16

ROW DRIVERS

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

Figure 29. Row Drivers vs. LCD Panel Interconnection in MUX49 Mode

ICON

MUX 49

COLUMN DRIVERS

LR0109

24/66

ROW DRIVERS

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

R50

STE2004S

R51

R52

R53

R54

R55

R56

R57

R58

R59

R60

R61

R62

R63

R64

R 0

R 1

R 2

R 3

R 4

R 5

R 6

R 7

R 8

R 9

R10

R11

R12

ROW DRIVERS

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

LR0108

Figure 30. Row Drivers vs. LCD Panel Interconnection in MUX33 Mode

ICON

MUX 33

COLUMN DRIVERS

STE2004S

ROW DRIVERS

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49

STE2004S

R50

R51

R52

R53

R54

R55

R56

R57

R58

R59

R60

R61

R62

R63

R64

R 0

R 1

R 2

R 3

R 4

R 5

R 6

R 7

ROW DRIVERS

R 8

R 9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

LR0107

4 BUS INTERFACES

To provide the widest flexibility and ease of use the STE2004S features Six different methods for interfacing the host Controller. To select the desired interface the SEL1, SEL2 and SEL3 pads need to be connected to a logic LOW (connect to GND) or a logic HIGH (connect to VDD). All the I/O pins of the unused

interfaces must be connected to GND.

All interfaces are working while the STE2004S is in Power Down.

Table 7.

SEL3 SEL2 SEL1 Interface Note

000

2

C

I

0 0 1 SPI 4 lines 8 bit Read and Write

0 1 0 SPI 3 lines 8 bit Read and Write

0 1 1 Serial 3 lines 9 bit Read and Write

1 0 0 Parallel 8080-series Read and Write

1 0 1 Parallel 68000-series Read and Write

Read and Write; Fast and

High Speed Mode

2

4.1 I

C Interface

2

C interface is a fully complying I2C bus specification, selectable to work in both Fast (400kHz Clock)

The I

and High Speed Mode (3.4MHz).

This bus is intended for communication between different Ics. It consists of two lines: one bi-directional for

data signals (SDA) and one for clock signals (SCL). Both the SDA and SCL lines must be connected to a

positive supply voltage via an active or passive pull-up.

25/66

STE2004S

The following protocol has been defined:

- Data transfer may be initiated only when the bus is not busy.

- During data transfer, the data line must remain stable whenever the clock line is high. Changes in the

data line while the clock line is high will be interpreted as control signals.

Accordingly, the following bus conditions have been defined:

BUS not busy: Both data and clock lines remain High.

Start Data Transfer: A change in the state of the data line, from High to Low, while the clock is High, de-

fine the START condition.

Stop Data Transfer: A Change in the state of the data line, from low to High, while the clock signal is High,

defines the STOP condition.

Data Valid: The state of the data line represents valid data when after a start condition, the data line is

stable for the duration of the High period of the clock signal. The data on the line may be changed during

the Low period of the clock signal. There is one clock pulse per bit of data.

Each data transfer is initiated with a start condition and terminated with a stop condition. The number of

data bytes transferred between the start and the stop conditions is not limited. The information is transmitted byte-wide and each receiver acknowledges with the ninth bit.

By definition, a device that gives out a message is called "transmitter", the receiving device that gets the

signals is called "receiver". The device that controls the message is called "master". The devices that are

controlled by the master are called "slaves"

Acknowledge. Each byte of eight bits is followed by one acknowledge bit. This acknowledge bit is a low

level put on the bus by the receiver, whereas the master generates an extra acknowledge related clock

pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of each byte. Also,

a master receiver must generate an acknowledge after the reception of each byte that has been clocked

out of the slave transmitter. The device that acknowledges has to pull down the SDA_IN line during the

acknowledge clock pulse. Of course, setup and hold time must be taken into account. A master receiver

must signal an end-of-data to the slave transmitter by not generating an acknowledge on the last byte that

has been clocked out of the slave. In this case, the transmitter must leave the data line High to enable the

master to generate the STOP condition.

Connecting SDA_IN and SDA_OUT together the SDA line become the standard data line. Having the acknowledge output (SDAOUT) separated from the serial data line is advantageous in Chip-On-Glass

(COG) applications. In COG applications where the track resistance from the SDAOUT pad to the system

SDA line can be significant, a potential divider is generated by the bus pull-up resistor and the Indium Tin

Oxide (ITO) track resistance. It is possible that during the acknowledge cycle the STE2004S will not be

able to create a valid logic 0 level. By splitting the SDA input from the output the device could be used in

a mode that ignores the acknowledge bit. In COG applications where the acknowledge cycle is required,

it is necessary to minimize the track resistance from the SDACK pad to the system SDA line to guarantee

a valid LOW level.

To be compliant with the I

quence "S00001xxx". After this sequence no acknowledge pulse is generated.

Since no internal modification are applied to work in Hs-mode, the device is able to work in Hs-mode without detecting the master code.

2

C-bus Hs-mode specification the STE2004S is able to detect the special se-

26/66

Figure 31. Bit transfer and START,STOP conditions definition

9

0

DATA LINE

STABLE

DATA VALID

CLOCK

DATA

STE2004S

START

CONDITION

Figure 32. Acknowledgment on the

SCLK FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

START

I2C-bus

1

MSB LSB

CHANGE OF

DATA ALLOWED

289

STOP

CONDITION

CLOCK PULSE FOR

ACKNOWLEDGEMENT

LR006

LR007

4.1.1 Communication Protocol

The STE2004S is an I

2

C slave. The access to the device is bi-directional since data write and status read

are allowed.

Four are the device addresses available for the device. All have in common the first 5 bits (01111). The

two least significant bit of the slave address are set by connecting the SA0 and SA1 inputs to a logic 0 or

to a logic 1.

To start the communication between the bus master and the slave LCD driver, the master must initiate a

START condition. Following this, the master sends an 8-bit byte, on the SDA bus line (Most significant bit

first). This consists of the 7-bit Device select Code, and the 1-bit Read/Write Designator (R/W

All slaves with the corresponding address acknowledge in parallel, all the others will ignore the I

).

2

C-bus

transfer.

4.1.1.1 Writing Mode.

If the R/W bit is set to logic 0 the STE2004S is set to be a receiver. After the slaves acknowledge one or

more command word follows to define the status of the device.

A command word is composed by three bytes. The first is a control byte which defines the Co and D/C

values, the second and third are data bytes. The Co bit is the command MSB and defines if after this command will follow two data bytes and an other command word or if will follow a stream of data (Co = 1 Command word, Co = 0 Stream of data). The D/C

= 1 RAM Data, D/C = 0 Command).

(D/C

If Co =1 and D/C

= 0 the incoming data byte is decoded as a command, and if Co =1 and D/C =1, the

bit defines whether the data byte is a command or RAM data

following data byte will be stored in the data RAM at the location specified by the data pointer.

Every byte of a command word must be acknowledged by all addressed units.

After the last control byte, if D/C

is set to a logic 1 the incoming data bytes are stored inside the STE2004S

Display RAM starting at the address specified by the data pointer. The data pointer is automatically updated after every byte written and in the end points to the last RAM location written.

Every byte must be acknowledged by all addressed units.

4.1.1.2 Reading Mode.

If the R/W bit is set to logic 1 the chip will output data immediately after the slave address. If the D/C bit

27/66

STE2004S

during the last write access, is set to a logic 0, the byte read is the status byte.

Figure 33. Communication Protocol

WRITE MODE

DRIVER ACK

S

SS011110A0A

SLAVE ADDRESS

READ MODE

SS011110A1A

A

1

R/W

DRIVER ACK MASTER ACK

S

A

1

Co

DRIVER ACK

A1 DC Control Byte DATA Byte

COMMAND WORD CONTROL BYTE MSB........LSB

P

DRIVER ACK DRIVER ACK DRIVER ACK

ADC Control ByteA 0 DATA Byte A P

Co LAST N> 0 BYTE

S

S

011110AR/

A

1

W

CoD

000 A

C

H

[1]H[0]HE

R/W

DRIVER

SLAVE ADDRESS

CONTROL BYTE

LR0008

4.2 SERIAL INTERFACES

STE2004S can feature three different serial synchronized interfaces with the host controller. It is possible to select a 3-lines SPI, a 4-lines SPI or 3-line 9 bits Serial Interface.

4.2.1 4-lines SPI interface

STE2004S 4-lines serial interface is a bidirectional link between the display driver and the application supervisor.