查询STE2001DIE1供应商

65 X 128 SINGLE CHIP LCD CONTROLLER / DRIVER

STE2001

PRODUCT PREVIEW

■

65 x 128 bits Display Data RAM

■

Configurable matrix: 65 x 128 or 33 x 128

■

Programmable (65/33) MUX rate

■

Row byRow Scrolling

■ Automatic data RAM Blanking procedure

■

Selectable Input Interface:

• I2C Bus Fast and Hs-mode (read and write)

• Parallel Interface (write only)

• Serial Interface (write only)

■

Fully Integrated Oscillator requires no external

components

■

Fully IntegratedConfigurable LCD biasvoltages

generator with:

•Selectable (5X, 4X, 3X, 2X) multiplication factor

• Effective sensing for High Precision Output

• Four selectable temperature compensation

coefficients

■

Designed for chip-on-glass (COG) applications

■ Programmable bottom row pads mirroring and

top row pads mirroring for compatible with both

TCP and COG applications

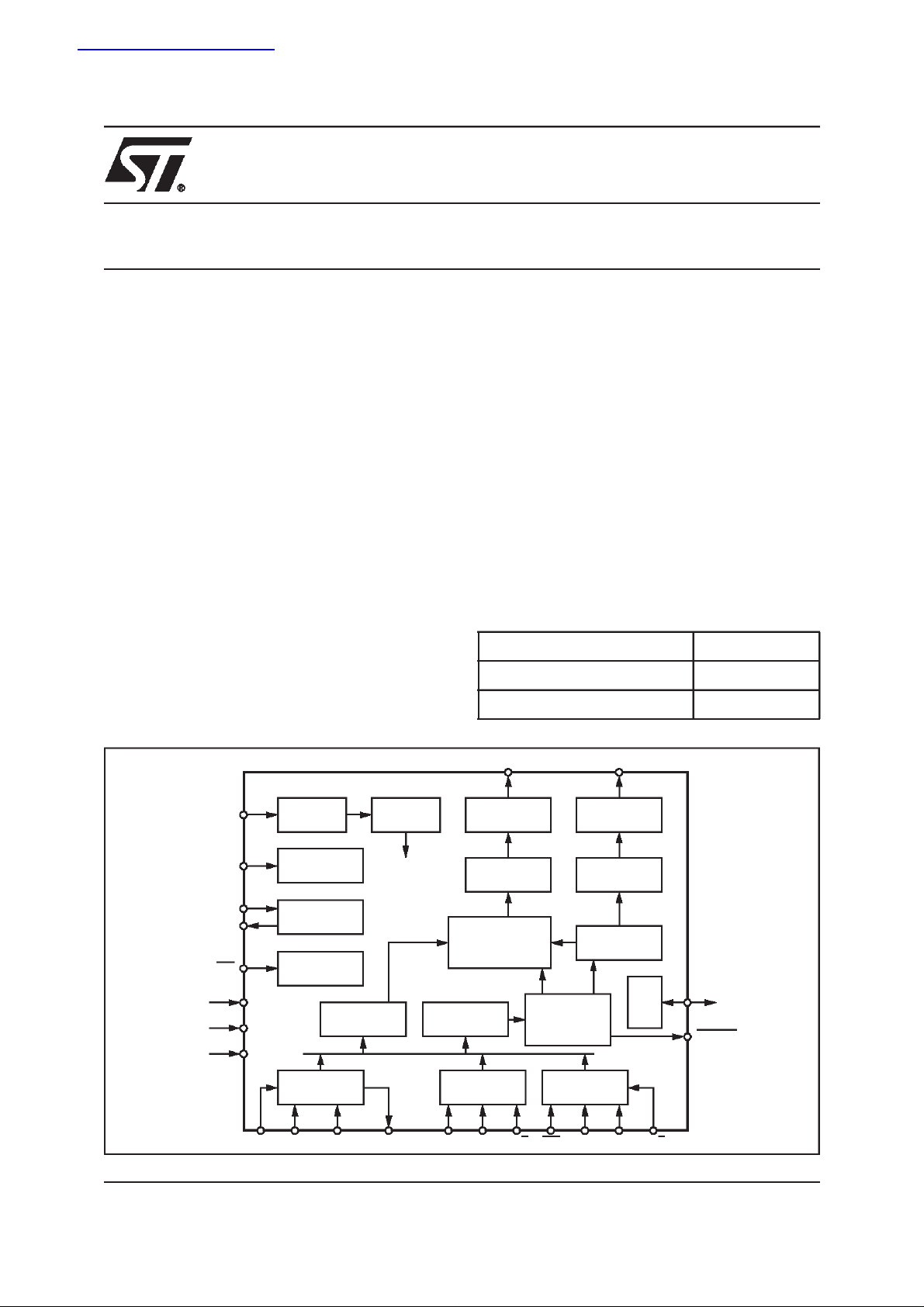

Figure 1. Block Diagram

■

Low Power Consumption, suitable for battery

operated systems

■

Logic Supply Voltage range from 1.9 to 5V

■

High Voltage Generator Supply Voltage range

from 2.4 to 4.5V

■

Display Supply Voltage range from 4.5 to 9V

DESCRIPTION

The STE2001 is a low power CMOS LCD controller

driver. Designed to drive a 65 rows by 128 columns

graphic display, provides all necessary functions in a

single chip, including on-chip LCD supply and bias

voltages generators, resulting in a minimum of externals components and in a very low power consumption. TheSTE2001 features three standard interfaces

(Serial, parallel, I

host

µcontroller.

Bumped Wafers STE2001DIE1

Bumped Dice on WafflePack STE2001DIE2

2

C) for ease of interfacing with the

Type Ordering Number

CO to C127 R0 to R64

OSC

VLCDIN

VLCDSENSE

VLCDOUT

RES

VDD1,2,3

V

1,2

SS

SEL1,2

SAO

DATA

TIMING

GENERATOR

CLOCK

INSTRUCTION

REGISTER

OSC

VOLTAGE

BIAS

GENERATOR

VOLTAGE

HIGH

GENERATOR

RESET

REGISTER

I2CBUS

SDA_IN SDA_OUTSCL DB0 to DB7 E PD/C

COLUMN

DRIVERS

LATCHES

65 x

RAM

PARALLEL

DATA

128

DISPLAY

CONTROL

LOGIC

SCE SDIN SCLK SD/C

SERIAL

ROW

DRIVERS

SHIFT

REGISTER

SCROLL

LOGIC

October 2001

This ispreliminary information on a new product now in development. Details are subject to change without notice.

TEST

TEST_0_13

BSY_FLG

D00IN1137

1/36

STE2001

PIN DESCRIPTION

N° Pad Type Function

R0 to R64 1 to 16

O LCD Row Driver Output

145 to 177

257 to 272

C0 to C127 17 to 144 O LCD Column Driver Output

V

SS1,2

V

DD1

V

DD2,3

V

LCDIN

V

LCDOUT

V

LCDSENSE

227 to 238 GND Ground pads. V

186 to 191 Supply IC Positive Power Supply

192 to 201 Supply Internal Generator Supply Voltages.

246 to 251 Supply LCD Supply Voltages forthe Column and Row Output Drivers.

239 to 244 Supply Voltage Multiplier Ouput

245 Supply Voltage Multiplier Regulation Input. V

is GND for V

SS1

Tuning

SEL1,2 183, 184 I Interface Mode Selection

SDA_IN 223 I

SDA_OUT 222 O

SCL 224 I

SA0 225 I

2

C Bus Data In

I

2

C Bus Data Out

I

2

C bus Clock

I

2

C Slave Address LSB

I

OSC 185 I External Oscillator Input

DD1,VSS2

LCDOUT

for V

DD2

and V

DD3

Sensing for Output Voltage Fine

RES 221 I Reset Input. Active Low.

DB0 to

211 to 218 I Parallel Interface 8 BitData Bus

DB7

E 220 I Parallel Interface Data Latch Signal. Data are Latched on the Falling EDGE.

PD/C 219 I Parallel Interface Data/Command Selector

SDIN 207 I Serial InterfaceData Input

SCLK 210 I Serial InterfaceClock

SCE 209 I Serial Interface ENABLE. When Low the Incoming Dataare Clocked In.

SD/C 208 I Serial InterfaceData/Command selection

BSYFLG 206 O Active Procedure Flag. Notice if There is an ongoing Internal Operation. Active

Low.

T1 to T13 178 to 181

I/O Test Pads.

202 to 205

226

252 to 256

2/36

STE2001

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

DD2,3

V

P

T

DD1

LCD

I

SS

V

I

I

out

P

T

in

tot

stg

Supply Voltage Range - 0.5 to + 6.5 V

Supply Voltage Range - 0.5 to + 5 V

LCD Supply Voltage Range - 0.5 to + 10 V

Supply Current - 50 to +50 mA

Input Voltage(all input pads) -0.5 to V

i

DD2,3

DC Input Current - 10 to + 10 mA

DC Output Current - 10 to + 10 mA

Total Power Dissipation (Tj=85°C) 300 mW

Power Dissipation per Output 30 mW

o

Operating Junction Temperature -40 to + 85 °C

j

Storage Temperature - 65 to150 °C

+ 0.5 V

ELECTRICAL CHARACTERISTICS

DC OPERATION

(V

DD1

= 1.9to V

DD2,3

+ 0.5V; V

= 2.4 to 4.5 V; V

DD2,3

ss1,2

= 0V; V

= 4.5to 9V; T

LCD

=-40to 85°C; unless otherwise

amb

specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Supply Voltages

V

DD1

V

DD2,3

V

LCDIN

V

LCDOUT

I(V

I(V

DD2,3

Supply Voltage 1.9

Supply Voltage LCD Voltage Internally

LCD Supply Voltage LCD Voltage Supplied externally 4.5 9 V

LCD Supply Voltage Internally generated; note 1 4.5 9 V

) Supply Current VDD= 2.8V;V

DD1

) Voltage Generator Supply

Current

T

=-20 to 85°C

amb

generated

= 7.6V; 4x

LCD

charge pump; f

=25°C; note 3.

T

amb

sclk

=0;

with VOP = 0 and PRS= 0

with external V

V

=7.6V; VDD=2.8V;

LCD

=0;T

f

sclk

amb

= 7.6V

LCD

=25°C; no display

load; 4x charge pump; note 3,6

F

=0

osc

V

DD2,3

+0.5

1.8

V

DD2,3

+0.5

2.4 4.5 V

815µA

10 15

70 115 µA

V

V

A

µ

3/36

STE2001

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

I(V

) TotalSupply Current V

DD1,2,3

= 7.6V; VDD=2.8V;

LCD

4x charge pump; f

sclk

=0;T

amb

80 125 µA

=25°C; no displayload; note 3,6

F

=0

osc

I(V

) External LCD Supply Voltage

LDCIN

Current

VDD=2.8V; V

display load; f

=25°C; note 3. F

T

amb

LCD

sclk

=7.6V;no

=0;

osc

=0

15 25 µA

Logic Inputs

V

V

I

Logic LOW voltage level VIN=Vih(tp<10µs) V

IL

Logic HIGH Voltage Level VIN=Vil(tp<10µs) 0.7

IH

Input Current Vin=V

in

SS1

or V

DD1

SS

V

DD

0.3

V

DD

V

DD2,3

+0.5

-1 1 µA

Columnand Row Driver

R

R

V

V

ROWOutput Resistance 12 20 kohm

row

Column Output resistance 12 20 kohm

col

Column Bias voltage accuracy No load -100 100 mV

col

Row Bias voltage accuracy -100 100 mV

row

LCD Supply Voltage

V

LCD

LCD Supply Voltage accuracy;

Internally generated

VDD= 2.8V;V

LCD

= 7.6V;

fsclk=0; Tamb=25 C;

-300 300 mV

no display load; note 2, 3, 6 & 7

TC Temperature coefficient 00 -550

PPM/°C

01 -1350 PPM/°C

10 -1650 PPM/°C

11 -2650 PPM/°C

Notes: 1. The maximum possible V

2. Internalclock

3. When f

4. Power-down mode. During power-down all static currents are switched-off.

5. If external V

6. Tolerance depends on the temperature; (typically zero at T

ature range limit.

7. ForTC0 to TC3

= 0 there is no interface clock.

sclk

, the display load current is not transmitted to I

LCD

voltage that can be generated is dependent on voltage, temperature and (display) load.

LCD

DD

=27°C), maximum tolerance values are measured at the temper-

amb

V

V

AC OPERATION

(V

DD1

= 1.9to V

DD2,3

+ 0.5V; V

= 2.4 to 4.5 V; V

DD2,3

ss1,2

= 0V; V

= 4.5to 9V; T

LCD

=-40to 85°C; unless otherwise

amb

specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

INTERNAL OSCILLATOR

F

F

OSC

EXT

Internal Oscillator frequency VDD= 2.8V; 20 38 70 kHz

External Oscillator frequency 20 38 100 kHz

4/36

STE2001

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

F

FRAME

T

VHRL

T

w(RES)

Frame frequency fosc or fext = 38 kHz; note 1 73 Hz

Vdd1 to RES Low note 2 and 10; C

=1µF0 5ms

VLCD

RES LOW pulse width note 3 600 ns

Reset Pulse Rejection T

=25°C; note 11 370 µs

amb

Reset Pulse Rejection note 11 200

T

START

T

VDD

2

I

C BUS INTERFACE (See note 4)

F

SCL

T

SCLL

T

SCLH

T

SCLL

T

SCLH

T

SU;DAT

T

HD;DAT

T

SU;DAT

T

HD;DAT

T

SU;STA

T

SU;STA

T

HD;STA

T

HD;STA

T

SU;STO

T

SU;STO

T

T

T

rCL1

T

rCL1

T

T

T

T

Reset Pulse vs. Device Ready 1 ms

0

SCL Clock Frequency Fast Mode ;V

=18V; T

V

DD1

High Speed Mode; Cb=100pF

(max); note 6; V

High Speed Mode; Cb=400pF

(max); note 6 ; V

=4.5V DC 400 kHz

DD1

= -20 to 70°C 400 kHz

amb

DC 3.4 MHz

=4.5V

DD1

DC 1.7 MHz

=4.5V

DD1

Cb=100pF 160 ns

Cb=100pF 160 ns

Cb=400pF 320 ns

Cb=400pF 320 ns

Cb=100pF 30 ns

Cb=100pF 30 ns

Cb=400pF 30 ns

Cb=400pF 30 ns

Cb=100pF Note 8 170 ns

Cb=400pF Note 8 330 ns

Cb=100pF Note 8 170 ns

Cb=400pF Note 8 330 ns

Cb=100pF Note 8 170 ns

Cb=400pF Note 8 330 ns

Cb=100pF Note 5, 8 25 ns

rCL

Cb=400pF Note 5, 8 50 ns

rCL

Cb=100pF Note 5, 8 30 ns

Cb=400pF Note 5, 8 120 ns

Cb=100pF Note 5, 8 30 ns

rDA

Cb=400pF Note 5, 8 120 ns

rDA

Cb=100pF Note 5, 8 25 ns

fCL

Cb=400pF Note 5, 8 50 ns

fCL

s

µ

5/36

STE2001

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

T

T

C

Cb=100pF 25 ns

fDA

Cb=400pF 120 ns

fDA

Capacitive load for SDAH and

b

100 400 pF

SCLH

C

Capacitive load for SDAH + SDA

b

400 pF

line and SCLH + SCL line

T

SW

note 5 10 ns

PARALLEL INTERFACE

T

CY(EN)

T

W(EN)

T

SU(A)

T

H(A)

T

SU(D)

T

H(D)

Enable Cycle Time VDD= 4.5V;Write 125 ns

Enable Pulse width VDD= 4.5V;Write 60 ns

Address Set-up Time VDD= 4.5V;Write 30 ns

Address Hold Time VDD= 4.5V;Write 50 ns

Data Set-Up Time VDD= 4.5V;Write 30 ns

Data Hold Time VDD= 4.5V;Write 50 ns

SERIAL INTERFACE

F

SCLK

T

T

PWH1

T

PWL1

T

T

T

PWH2

T

T

T

T

T

CYC

Clock Frequency VDD= 4.5V 8 MHz

V

= 1.8V 5 MHz

DD1

Clock Cycle SCLK VDD= 4.5V 125 ns

SCLK pulse width HIGH VDD= 4.5V 70 ns

SCLK Pulse width LOW VDD= 4.5V 70 ns

SCE setup time 50 ns

S2

SCE hold time 50 ns

H2

SCE minimum high time 60 ns

SCE start hold time Note 8 60 ns

H5

SD/C setup time 60 ns

S3

SD/C hold time 40 ns

H3

SDIN setup time 40 ns

S4

SDIN hold time 40 ns

H4

f

Notes: 1.

F

frame

2. RES may be LOW or HIGH before V

3. If T

w(RES)

4. All timing values are valid within the operatingsupply voltage and ambient temperature ranges and referenced toV

an inputvoltage swing of V

5. Therise and fall times specified here refer to the driver device and arepart of general Hs-mode specification.

6. Thedevice inputs SDA and SCLare filtered and will reject any spike on the bus-lines of with T

7. Cb is thecapacitive load for each bus line.

8. T

H5

9. Forbus line loads Cb between 100 and 400pF the timing parameters must be linearly interpolated

10.C

VLCD

11.If T

w(RES)

osc

----------=

520

goes HIGH.

to V

DD1

DD

is longer than 500ns (typical) a reset may be generated.

SS

is the time from theprevious SCLK positive edge to the negative edge of SCE

is the filteringcapacitor on VLCDOUT

is shorter than max.value a reset pulse is rejected.

SW

6/36

and VIHwith

IL

STE2001

CIRCUITDESCRIPTION

SuppliesVoltages and Grounds

V

andV

DD2

If the internal voltagegenerator is not used, these should be connectedto V

This supply voltage could be different form V

InternalSupply Voltage Generator

The IC has a fullyintegrated (no external capacitorsrequired)charge pump for the Liquid CrystalDisplay supplyvoltage generation. The multiplyingfactor can be programmed to be: X5; X4; X3; X2, using the ’set CP Multiplication’

Command. The output voltage (V

ferent temperaturecoefficients(TC, rateof changewithtemperature) can beprogrammedusing the bitsTC1 and TC0.

This will ensure no contrast degradation over theLCD operating range. Using the internal charge pump, the V

and V

LCDOUT

without using the internal generator. In such event the V

internal voltagegenerator must be programmed to zero (PRS = 0, Vop = 0 - Reset condition).

Oscillator

A fully integrated oscillator (requires no externalcomponents) is present to provide the clock for the DisplaySystem.

Whenused theOSCpadmustbeconnectedtoVDD1pad. Anexternaloscillatorcouldbeused andfedintotheOSCpin.

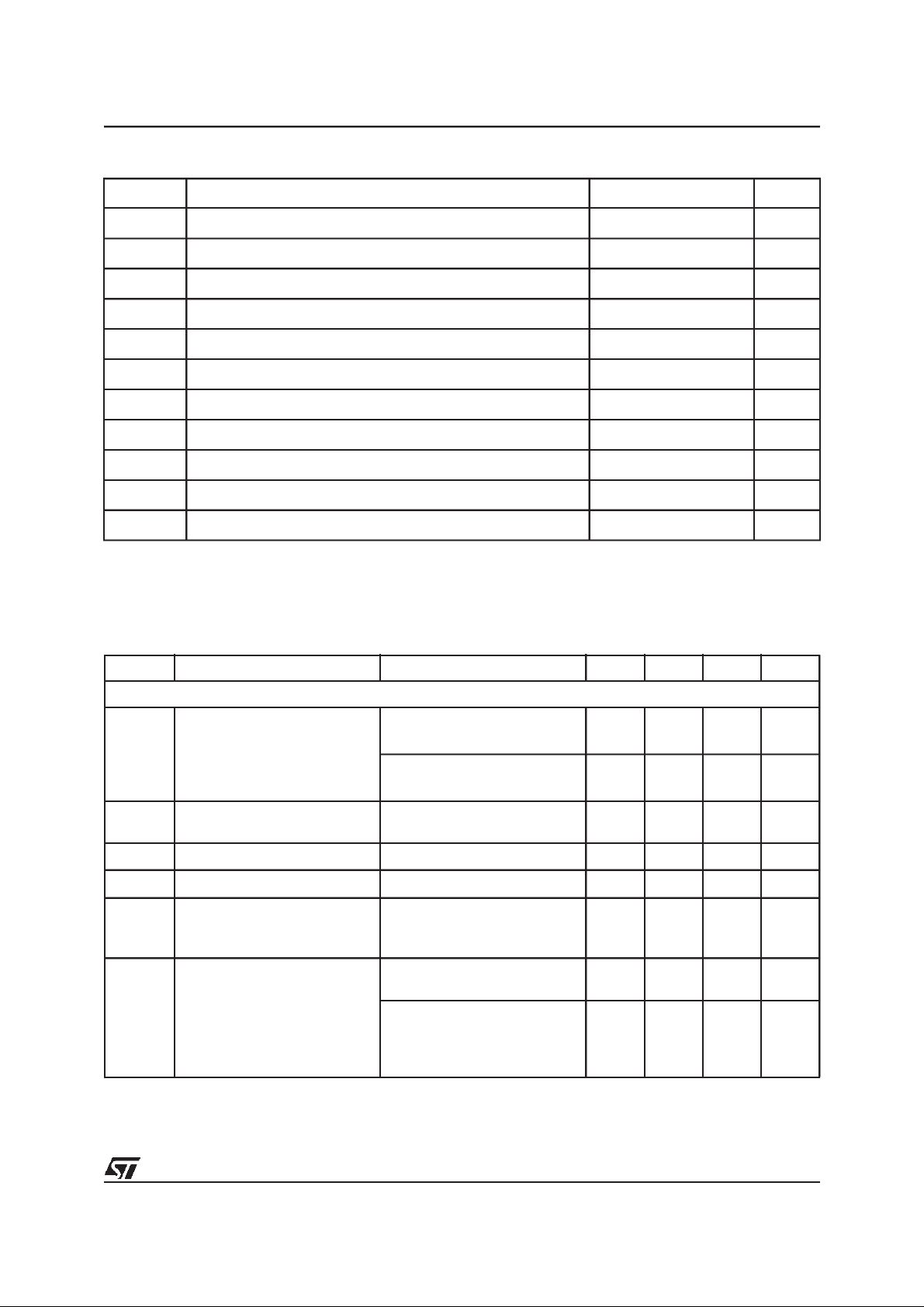

DisplayData RAM

The STE2001, provides an 65X128 bits Static RAM to store Display data. This is organized into 8 (Bank0 to

Bank7) banks with 128 Bytes and one Bank (Bank8) with 128 Bits to be used for icons. RAM access is accomplished in either one of the Bus Interfaces provided (seebelow). Allowed addresses are X0 to X127 (Horizontal)

and Y0 to Y8 (Vertical). When writing to RAM, four addressing mode are provided:

• NormalHorizontal (MX = 0 and V = 0), having the column with address X = 0 locatedon the left ofthe memorymap.

The Xpointerisincreased after each byte written. After the lastcolumnaddress(X = 127), Yaddress pointer is modified to jump to nextrow. X restarts fromX = 0 (Fig.2).

• Normal Vertical (MX = 0 and V = 1), having the column with address X = 0 located on the left of the memory map.

The Y pointeris increased after each byte written. After the last row address (Y = 8), the X pointer is modified to

jump to next column and Y restarting from Y = 0. (Fig. 3).

• Mirrored Horizontal (MX = 1 and V = 0), having the column with address X = 0 located on the right of the memory

map. The X pointer is increased after each byte written. After the last column address (X = 127), Y address pointer

is modified to jump to nextrow. X restarts from X = 0 (fig. 4).

• Mirrored Vertical (MX =1 andV = 1), havingthe columnwith address X = 0 located onthe rightof the memory map.

The Y pointeris increased after each byte written. After the last row address (Y = 8), the X pointer is modified to

jump to next column and Y restarting from Y = 0. (Fig. 5).

After the last allowed address (X;Y) = (128;8), the address pointers always jump to the cell with address (X;Y)= (0;0). Data

bytes in the memory couldhave the MSB either on top (D0 = 0, Fig. 6) oron the bottom (D0 = 1, Fig. 7).

are supply voltagesto the internalvoltagegenerator(see below). Theymust be externally connected.

DD3

and V

DD2

) is tightlycontrolled through the V

LCDOUT

DD3.VDD1

must be lower than V

pads must beconnected together. An external supply couldbeconnected to V

LDCOUT

and V

LCDSENSE

pad. V

DD1

LCDSENSE

supplies the rest of the IC.

DD1

+ 0.5V.

DD2,3

pad. For this voltage, four dif-

to supply the LCD

LCDIN

must be connected to GND and the

LCDIN

Mux 65 Mode

The STE2001 provides also means to alter the normal output addressing.A mirroring of the Display along the X axis

is enabled setting to a logic one the MY bit. This function is achievedreading the matrix from physical row 63 to 0,

since the relation between the physical memory rows and the output row drivers is only dependent on the memory

reading sequence (1st row read output on R0, 2nd on R1... last on R65). This function doesn’t affect the content of

the memory map. It is only related to the visualizationprocess (Fig. 8 & Fig. 9).

It is also possible to modify thewhywith whichrow driversare connected withDDRAM memory.A flip along y-axisof

each sub-block can be appliedon both the Row Pads located onthe Interface Side(the edge of the chip where the

Interface Padsare located),setting the TRS bitto a logic one, andon the Row Pads located onthe otheredge,setting

the BRS bitto a logic one.

Figure 2 Automatic data RAM writing sequence with V=0 and Data RAM Normal Format (MX=0) Figure 3 Automatic

data RAM writing sequence with V=1 and Data RAM Normal Format (MX=0)

7/36

STE2001

Figure 2. Automatic data RAM writing sequence with V=0 and Data RAM Normal Format (MX=0)

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

0123 124125126127

D00IN1138

Figure 3. Automatic data RAM writing sequence with V=1 and Data RAM Normal Format (MX=0)

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

0 1 2 3 124 125 126 127

D00IN1139

Figure 4. Automatic data RAM writing sequence with V=0 and Data RAM Mirrored Format (MX=1)

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

127126125124 3210

D00IN1140

Figure 5. Automatic data RAM writing sequence with V=1 and Data RAM Mirrored Format (MX=1)

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

8/36

127 126 125 124 3 2 1 0

D00IN1141

Figure 6. Data RAM Byte organization with D0 = 0

MSB

0

1 2 3 124 125 126 127

BANK 0

BANK 1

BANK 2

BANK 3

LSB

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

Figure 7. Data RAM Byte organization with D0 = 1

LSB

0

1 2 3 124 125 126 127

MSB

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

STE2001

D00IN1142

D00IN1143

Figure 8. Output drivers rows and physical memory rows correspondence with MY =0

PHYSICAL MEMORY ROWROW DRIVER

0

R0

R1

R2

R3

R4

R5

R60

R61

R62

R63

R64

ROW 0

ROW 1

ROW 2

ROW 3

ROW 4

ROW 5

ROW 60

ROW 61

ROW 62

ROW 63

ROW 64

1 2 3 124 125 126 127

D00IN1144

Figure 9. Output drivers rows and physical memory rows correspondence with MY =1

PHYSICAL MEMORY ROWROW DRIVER

0

R63

R62

R61

R60

R59

R58

R3

R2

R1

R0

R64

ROW 0

ROW 1

ROW 2

ROW 3

ROW 4

ROW 5

ROW 60

ROW 61

ROW 62

ROW 63

ROW 64

1 2 3 124 125 126 127

D00IN1145

9/36

STE2001

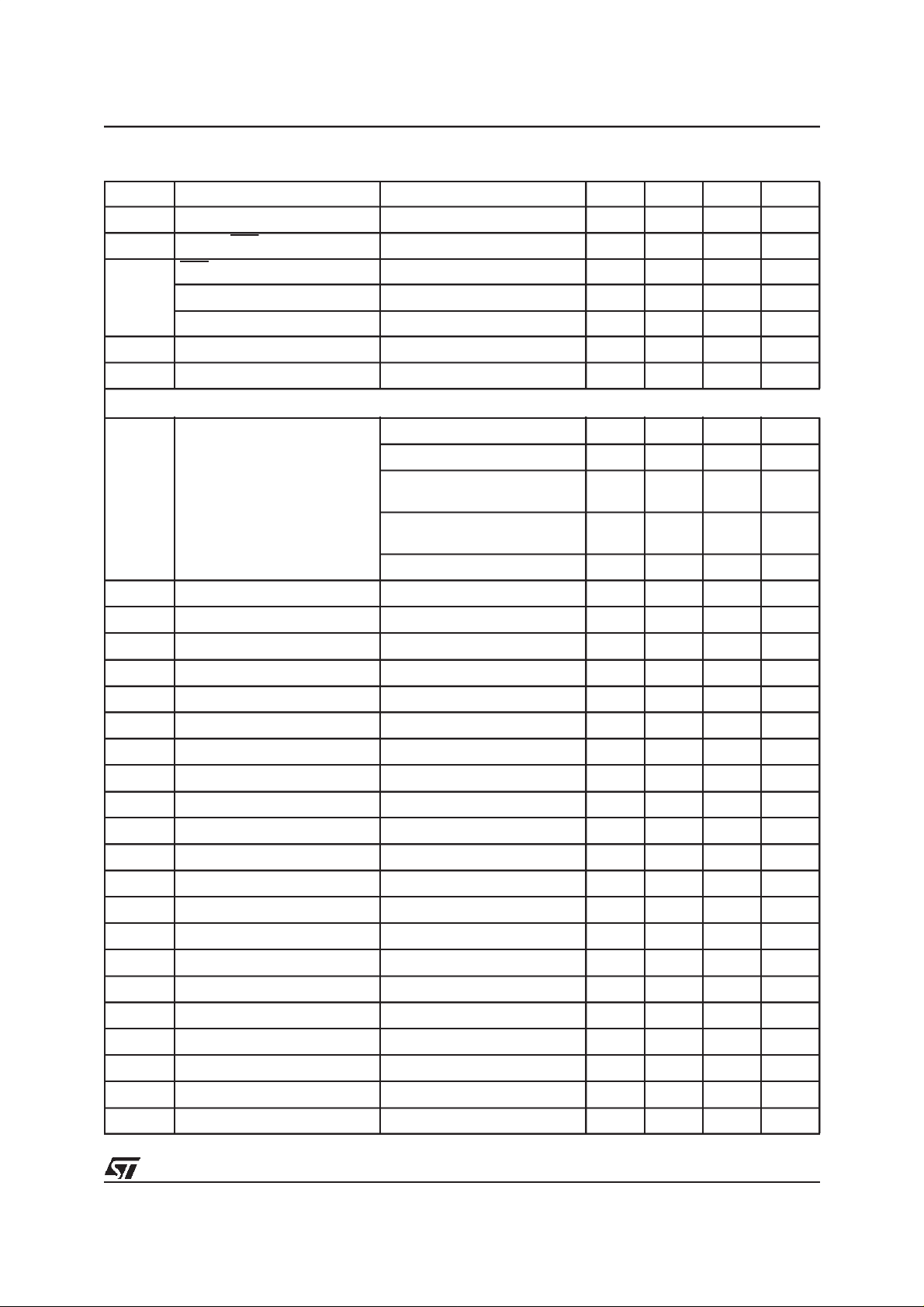

MUX 33 Mode

When using the 1:33 MUX ratio (MUX bit Set), the memory map is changed so that the only”active” row drivers

are the ones related to Bank4 to Bank7.

When writing data RAM, as for Mux 65, four addressing mode are provided. The memory matrix is written as in

mux 65 mode so the user must take care of updating X and Y pointers to fill the memory matrix in the correct

way.

In MUX 33 mode only the MUX 33 memory logic matrix is read. The MY bit control the reading process. If MY

is set to a logic zero the row reading sequence is 0-1-2..........33 (fig.11). If MY is set to a logic one the reading

sequence is 32....1-33 (Fig12).

The icon row (BANK8) is always the last being output either MY bit is a logic one or zero.

The functions relatedto bit TRS is the same as in MUX 65 mode.

In fig. 11 is shown the output drivers pad connection for MUX 33 mode. Note that the unused BANK 0-3 row

drivers become columns drivers.

If a 33x128 LCD matrix is driven, the output row drivers R0-R15and R32-R47 must be floating.

Figure 10. Physical 65x128 memory matrix and 33x128 correspondence

0 1 14 15 16 17 18 112 113110 111109 126127

BANK 0

BANK 1

BANK 2

BANK 3

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

NOT USED

D00IN1146

10/36

R16-R23

R24-R31

R48-R55

R56-R63

R64

C1

C0C3C2C5C4C7C6

C121

C120

C123

C122

C124

C125

C126

D00IN1147

C127

Figure 11. Output drivers rows and logical memory rows correspondence with MY = 0

ROW DRIVER MUX 33PHYSICAL MEMORY ROW

STE2001

R16

R23

R24

R31

R48

R55

R56

R63

R64 Row 32

Row 0

to

Row 7

Row 8

to

Row15

Row 16

to

Row 23

Row 24

to

Row 31

01234567 123 124 125121 122120 126127

to

to

to

to

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

D00IN1148

Figure 12. Output drivers rows and logical memory rows correspondence with MY = 1

ROW DRIVER MUX 33PHYSICAL MEMORY ROW

R16

R23

R24

R31

R48

R55

R56

R63

R64 Row 32

Row 0

to

Row 7

Row 8

to

Row15

Row 16

to

Row 23

Row 24

to

Row 31

01234567 123 124 125121 122120 126127

to

to

to

to

BANK 4

BANK 5

BANK 6

BANK 7

BANK 8

D00IN1148

InstructionSet

Two different instructions formats are provided:

- With D/C set to LOW

commands are sent to the Control circuitry.

- With D/C set to HIGH

the Data RAM is addressed Instructions have the syntax summarized in Table.1.

Reset (RES)

At power-on, all internal registers and RAM content are not defined. A Reset pulse mustbe applied on RES pad

(active low) toinitialize the internal registers content (see Tables 3,4,5,&6). Every on-going communication with

the host controller is interrupted. The IC after the reset pulse is programmed in Power Down mode.

The Default configurations is:

- Horizontaladdressing (V = 0)

- Normal instruction set (H = 0)

- Normal display (MX = MY = TRS =BRS = 0)

- MUX 65 mode (MUX= 0)

11/36

STE2001

- Displayblank (E = D = 0)

- Address counter X[6: 0] = 0 and Y[3 : 0] = 0

- Temperature coefficient (TC[1 : 0] = 0)

- Bias system (BS[2 : 0] = 0)

=0

-V

OP

- Power Down(PD = 1)

To clear the RAM content a MEMORY BLANK instruction should be executed.

PowerDown (PD = 1)

When atPowerDown, all LCD outputs are kept at VSS(display off). Biasgenerator and V

(V

LCDOUT

output is discharged to VSS, andthen is possible to disconnect V

LCDOUT

). The internal Oscillator is in

off state. An external clock can be provided. The RAM contents is not cleared.

ChargePump Factor

The desired Charge Pump Multiplication Factor can be programmedthough the S1 and S0 bits, as follows:

S1 S0 Multiplication Factor

002X

013X

104X

115X

generator are OFF

LCD

At Reset the X2 factor is selected.

Bias Levels

To properly drive the LCD, six (Including VLCD and VSS) different voltage (Bias)levels are generated. The ratios among these levels and VLCD, shouldbe selected according to the MUX ratio (m).They are established to

be (Fig. 14):

LCD

------------ -

,

+

n4

V

V

+

n3

LCD

+

n2

-------------

,

+

n4

V

LCD

2

------------ -

,

+

n4

V

LCD

1

------------ -

,

+

n4

V

LCD,VSS

Figure 13. Bias level Generator

V

R

R

nR

R

R

LCD

n+3

n+4

n+2

n+4

2

n+4

1

n+4

V

SS

·V

LCD

·V

LCD

·V

LCD

·V

LCD

D00IN1150

12/36

STE2001

thus providing an 1/(n+4) ratio, with n calculated from:

nm3

For m = 65, n = 5 and an 1/9 ratio is set.

For m = 33, n =3 and an 1/7 ratio is set.

The STE2001 provides three bits (BS0, BS1, BS2) for programming the desired Bias Ratio as shown below:

BS2 BS1 BS0 n

0007

0016

0105

0114

1003

1012

1101

1110

–=

The following table Bias Level for m = 65 and m = 33 are provided:

Symbol m = 65 (1/9) m = 33 (1/7)

V1 V

LCD

V2 8/9*V

V3 7/9*V

V4 2/9*V V

V5 1/9 *V

V6 V

SS

LCD

LCD

LCD

LCD

V

LCD

6/7* V

5/7* V

2/7* V

1/7* V

V

LCD

LCD

LCD

LCD

SS

LCD Voltage Generation

The LCD Voltage at reference temperature (To = 35°C) can be set using the VOP register content according to

the following formula:

V

LCD

(T=To) = V

o = (Ai+VOP· B) (i=0,1)

LCD

with the following values:

Symbol Value Unit Note

Ao 2.90 V PRS = 0

A1 6.91 V PRS = 1

B 0.034 V

To 35 °C

Note that the two PRS value produces two adjacent ranges for VLCD. If the register and PRS bit are set to zero

13/36

STE2001

the internal voltage generator is switched off.

The proper value for the VLCD is a function of the Liquid Crystal Threshold Voltage (Vth) and of the Multiplexing

Rate. A general expression for this is:

+

1m

------------------------ ----------- - V

V

LCD(to)

op

----------------------- ------------------=

V

⋅

21

= 6.85 · V

6.85 VthA

⋅()

0.03

For MUX Rate m = 65 the ideal V

than:

LCD

is:

V

LCD

TemperatureCoefficient

As theviscosity, and therefore the contrast, of theLCD are subjecttochange with temperature, there’s the need

to vary the LCD Voltage with temperature. The STE2001 provides the possibility to change the VLCD in a linear

fashion against temperature with four different Temperature Coefficient selectable through the TC0 and TC1

bits.

TC1 TC0 Value Unit

0 0 -550 PPM/°C

---------–

1

m

th

–

⋅=

th

i

0 1 -1350 PPM/°C

1 0 -1650 PPM/°C

1 1 -2650 PPM/°C

Figure 14. VLCD Slopes Cross Point with Different TC

V

LCD

D01IN1256/mod

35ºC

TEMP

14/36

Figure 15.

V

A

LCD

0

STE2001

B

A

1

A0+B

D01IN1257

V

O

Finally, the V

01h00h 03h 05h02h 04h 7Dh 7Eh 7Fh 00h 01h 02h 03h 04h 05h7Ch 7Dh7Eh 7Fh7Ch

voltage at a given (T) temperature can be calculated as:

LCD

PRS=0

V

LCD

(T) = V

o · [1 + (T-To) · TC]

LCD

PRS=1

MemoryBlanking Procedure

This instruction allows to fill the memory with ”blank” patterns, in order to delete patterns randomly generated

in memory when starting up the device. This instruction substitutes (128X9) single ”write” instructions. It is possible to program ”MemoryBlanking Procedure” only under the following conditions:

- X address = 0

- Y address = 0

-Vbit =0

- PD bit = 0

- MX bit = 0

The end of the procedure will be notified on the BSY_FLG pad going HIGH (while LOW the procedure is running). Any instruction programmed with BSY_FLG LOW will be ignored that is, no instruction can be programmed for a period equivalent to 128X9 internal write cycles (128X9X1/fclock). The start of Memory blanking

procedure will be between one and two fclock cycles from the last active edge (E rising edge for the parallel

interface, last SCLK rising edge for the Serial interface, last SCLrising edge for the I

2

C interface).

CheckerBoard Procedure

This instruction allows to fill the memory with ”checker-board” pattern. It is mainly intended to developers, who

can now simply obtain complexmodule test configuration by means of a single instruction. It is possible to program ”Checker Board Procedure” only under the following conditions:

- X address = 0

- Y address = 0

-Vbit =0

- PD bit = 0

- MX bit = 0

15/36

STE2001

The end ofthe procedure will be notified ontheBSY_FLG pad going HIGH, while LOW the procedure is running.

Any instruction programmed withBSY_FLG LOW will be ignored, that is, no instructioncan be programmed for

a period equivalent to 128X9 internal write cycles (128X9X1/fclock). The start of Memory blanking procedure

will be between one and two fclock cycles fromthe last active edge (Erisingedge for the parallel interface, last

SCLK rising edge for the Serial interface, last SCL risingedge for the I

Scroll

The STE2001 can scrollthe graphics display in units of raster-rows. The scrolling function is achieved changing

the correspondence between the rows of the logical memory map and the output row drivers.The scroll function

doesn’t affect the data ram content. It is only related to the visualization process. The information output on the

drivers is related to the row reading sequence (the 1st row read is output on R0, the 2nd on R1 and so on).

Scrolling means reading the matrix starting from a row that is sequentially increased or decreased. After every

scrolling command the offset between the memory address and the memory scanning pointer is increased or

decreased by one. The offset range is between 0 to 63 in mux 65 mode and 0-31 in mux 33 mode. After the

64th scrolling command in mux 65 mode and after the 32th in mux 33 mode, the offset between the memory

address and the memory scanning pointer is again zero (Cyclic Scrolling). Bank8 is always accessed last in

each frame, and so isn’t scrolled.

If the DIR Bitis set to a logic zero the offset register is increased by one and the raster is scrolled from top down. If

the DIR Bit is setto a logic one the offset register is decreased by one and the raster is scrolled from bottom-up.

Bus Interfaces

To provide the widest flexibility and ease of use the STE2001 features three different methods for interfacing

the host Controller. To select the desired interface the SEL1 and SEL2 pads need to be connected to a logic

LOW (connect to GND) or a logic HIGH (connect to VDD). All the I/O pins of the unused interfaces must be

connected to GND. If I/O pins voltage is lower than VDD interfaces could sink more current than expected.

All interfaces are working while the STE2001 is in Power Down.

SEL2 SEL1 Interface Note

00

0 1 Serial Write only

1 1 Parallel Write only

1 0 Not Used

2

C interface).

2

C

I

Read and Write; Fastand

High Speed Mode

I2C Interface

The I2C interface is a fully complying I2C bus specification, selectable to work in both Fast (400kHz Clock) and

High Speed Mode (3.4MHz).

This bus isintended for communication between different Ics. It consists of twolines: one bi-directional for data

signals (SDA) and one for clock signals (SCL). Both the SDA and SCL lines must be connected to a positive

supply voltage via an active or passive pull-up.

The following protocol has been defined:

- Data transfer may be initiated only when the bus is not busy.

- During data transfer, thedata line mustremainstable whenever the clock line is high. Changes in the data line

while the clock line is high will be interpreted as control signals.

Accordingly, the following bus conditions have been defined:

BUS not busy: Both data and clock lines remain High.

StartData Transfer: Achange in the state of the data line, from High to Low, while the clock is High,define the

START condition.

16/36

STE2001

Stop Data Transfer:

A Change in the state of the data line, from low to High, while the clock signal is High,

defines the STOP condition.

Data Valid: The state of the data line represents valid data when after a start condition, the data line is stable

for the duration of the High periodof theclock signal. The data on the linemay be changed during the Low period

of the clock signal. There is one clock pulse per bit of data.

Each data transfer is initiated with a start condition and terminated with a stop condition. The number of data

bytes transferred between the start and the stop conditions is not limited. The information is transmitted bytewide and each receiver acknowledges with the ninth bit.

By definition, adevice that gives outa message is called ”transmitter”, the receivingdevice that gets the signals

is called ”receiver”. The device that controls the message is called ”master”. The devices that are controlled by

the master are called ”slaves”

Acknowledge. Each byte of eight bits is followed by one acknowledge bit. This acknowledge bit is a low level

put on the bus by the receiver, whereas the master generates an extra acknowledge related clock pulse.

A slave receiver which is addressed must generate an acknowledge after the reception of each byte. Also, a

master receiver must generate an acknowledge after the reception of each byte that has been clocked out of

the slave transmitter. The device that acknowledges has to pull down the SDA_IN line during the acknowledge

clock pulse. Of course, setup and hold time must be taken into account. A master receiver must signal an endof-data to the slavetransmitter by not generating an acknowledge on the last byte that has been clocked out of

the slave. In this case, the transmitter must leave the data line High to enable themaster to generate the STOP

condition.

Connecting SDA_IN and SDA_OUT together the SDA line become the standard data line. Having the acknowledge output (SDAOUT) separated from the serial data line is advantageous in Chip-On-Glass

(COG) applications. In COG applications where thetrack resistance from the SDAOUT pad to thesystem

SDA line can be significant, a potential divider is generated by the bus pull-up resistor and the Indium Tin

Oxide (ITO) track resistance. It is possible that during the acknowledge cycle theSTE2001 will not be able

to create a valid logic 0 level. Bysplitting the SDAinput fromthe outputthe device could be usedin a mode

that ignores the acknowledge bit. In COG applications where the acknowledge cycle is required, it is necessary to minimize the track resistance from the SDACK pad to the system SDA line to guarantee a valid

LOW level.

To be compliant with the I2C-bus Hs-mode specification the STE2001 is able to detect the special sequence

”S00001xxx”. After this sequence no acknowledge pulse is generated.

Since no internal modification are applied to work in Hs-mode, the device is able to work in Hs-mode without

detecting the master code.

Figure 16. Bit transfer and START,STOP conditions definition

DATA

LINE

STABLE

DATA VALID

CLOCK

DATA

START

CONDITION

CHANGE

DATA ALLOWED

OF

D00IN1151

STOP

CONDITION

17/36

STE2001

Figure 17. Acknowledgment on theI

START

SCLK

FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

Figure 18. I

2

C-bustimings

SDAH

SCLH

RES

t

SU;STA

t

fDA

t

START

Sr

2

C-bus

1

MSB LSB

t

rDA

t

HD;DAT

t

HD;STA

t

t

rCL

t

HIGH

289

D00IN1152

t

SU;DAT

fCL

t

LOW

= MCScurrent source pull-up = Rp resistor pull-up

t

rCL1

(1) (1)

t

t

LOW

HIGH

CLOCK PULSE

ACKNOWLEDGEMENT

t

rCL1

D00IN1153

FOR

Sr P

CommunicationProtocol

The STE2001 is an I2C slave. The accesstothe device is bi-directional sincedata write and status read are allowed.

Two are the device addresses available for the device. Both have in commonthe first 6 bits (011110). The leastsignificantbit of the slave address is set by connectingthe SA0 inputto a logic 0 or to a logic 1.

To start the communication betweenthe bus masterand the slave LCD driver, the master must initiate a START condition.Followingthis,the mastersends an 8-bit byte, shown in Fig. 18, on the SDAbus line (Most significant bitfirst).

This consists of the 7-bit Device selectCode, andthe 1-bitRead/Write Designator (R/W).

All slaves with the corresponding address acknowledge in parallel,all the others willignore the I2C-bus transfer.

WritingMode.

If the R/W bit is set to logic 0 the STE2001 is set to be a receiver. After the slaves acknowledge one or more

command word follows to define the status of the device.

A command word is composed by two bytes. The first is a control byte which defines the Co and D/C values,

the second is a data byte (fig 18). The Co bitis the command MSB and defines if after this command willfollow

one data byte and an other command word or if will follow a stream of data (Co = 1 Command word, Co = 0

Stream of data). The D/C bit defines whether the data byte is a command or RAM data (D/C = 1 RAM Data, D/

C = 0 Command).

If Co =1 and D/C = 0 the incoming data byte isdecoded as a command, and if Co =1 and D/C =1, the following

data byte will be stored in the data RAM at the location specified by the data pointer.

E very byte of a command word must be acknowledged by all addressed units.

After the last control byte, if D/Cis set to alogic 1the incoming data bytes are stored inside theSTE2001 Display

RAM starting at the address specified by the data pointer. The data pointer is automatically updated after every

byte writtenand in the end points to the last RAM location written.

Every byte must be acknowledged by all addressed units.

ReadingMode.

If the R/W bit is set to logic 1 the chip will output data immediately after the slave address. If the D/C bit sent

during the last write access, is set to a logic 0, the byte read is the status byte.

18/36

Figure 19. communication protocol

WRITE MODE

STE2001 ACK

STE2001 ACK

STE2001

STE2001 ACK STE2001 ACK STE2001 ACK

SS0111100A0A

R/W

SLAVE ADDRESS

READ MODE

STE2001 ACK MASTER

SS0111100A1A

R/W

Co

COMMAND WORD CONTROL BYTE MSB........LSB

D01IN1247

A1 DC Control Byte DATA Byte ADC ControlByteA 0 DATA Byte A P

Co LAST N> 0 BYTE

P

0111100AR/

STE2001

SLAVE ADDRESS

S

W

C oD

000000A

C

CONTROL BYTE

SERIALINTERFACE

The STE2001 serial Interface is a unidirectional link between the display driver and the application supervisor.

It consists of four lines: one for data signals (SDIN), one forclock signals (SCLK), one for the peripheral enable

(SCE) and one for mode selection (SD/C).

The serial interface is active only if the SCE line is set to a logic 0. When SCE line is high the serial peripheral

power consumption is zero.

The STE2001is alwaysa slave on the bus and receive the communication clockon the SCLK pin from the mas-

ter. The STE2001 is only able to receive data.

Information are exchanged byte-wide. Duringdata transfer, the data line issampled on the positive SCLK edge.

While SCE pin is high the serial interface is kept in reset.

SD/C line status indicates whether the byte is a command (SD/C =0) or RAM data (SD/C =1);it is read on the

eighth SCLK clock pulse during every byte transfer.

If SCEstays low after the last bit of a command/data byte, the serial interface expects the MSB of thenext byte

at the next SCLK positive edge.

A reset pulse onRES pin interrupts the transmission. No data is written into the data RAM and all the internal

registers are cleared.

If SCE is low after the positive edge ofRES, the serial interface is readyto receive data.

19/36

STE2001

Figure 20. Serial bus protocol - one byte transmission

SCE

D/C

SCLK

SDIN

MSB LSB

Figure 21. Serial bus protocol - several byte transmission

SCE

D/C

SCLK

SDIN

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DB7 DB6 DB5

Figure 22. RESET effect on the serial interface

t

S2

D00IN1159

D00IN1160

t

H2

t

PWH2

20/36

SCE

D/C

SCLK

SDIN

RES t

START

t

S3

t

PWL1

t

H5

t

H3

t

WH1

t

S4

t

H4

t

CYC

t(

H5)

t

S2

D00IN1161

STE2001

ParallelInterface

The STE2001 parallel Interface isa unidirectional linkbetween the display driver and the application supervisor.

It consists of ten lines: eight data lines (from DB7 to DB0) and two control lines. The control lines are: enable

(E) for data latch and PD/C for mode selection.

The data lines and the control line values are internally latched on E rising edge (fig. 23).

Figure 23. Parallel interface timing

PD/C

t

SU(D)

t

HO(D)

t

W(en)

t

h(A)

t

CY(en)

D00IN1162

E

DB0-DB7

RES t

START

t

SU(A)

Table 1. Instruction Set

Instruction D/C R/W Description

B7 B6 B5 B4 B3 B2 B1 B0

H=0 or H=1

NOP 0000000000 NoOperation

Function Set 0 0 0 0 1 MX MY PD V H PowerDown Management; Entry

Mode; Extended Instruction Set

Read Status Byte 0 1 PD

TRS BRS D E MX MY DO

Write Data 1 0 D7 D6 D5 D4 D3 D2 D1 D0 Writes data to RAM

H=0

Memory Blank 0 0 0 0000001Starts Memory Blank Procedure

Scroll 0 0 0 000001DIRScrolls by one RowUP or DOWN

Range Setting 000000010PRS V

V

LCD

Display Control 0 0 0 0001D0E Select Display Configuration

Set CP Factor 0 0 0 00100S1S0Charge Pump Multiplication Factor

Set RAM Y 0 0 0 1 0 0 Y3 Y2 Y1 Y0 Set Horizontal (Y) RAM Address

Set RAM X 0 0 1 X6 X5 X4 X3 X2 X1 X0 Set Vertical (X) RAM Address

H=1

Checker Board 0 0 0 0000001Starts Checker Board Procedure

Multiplex Select 0 0 0 000001

TC Select 0 0 0 00001TC1TC0

MUX Selects MUX factor

SetTemperatureCoefficientforV

Output Address 0 0 0 0001DOTRS BRS Set Row Order on Output Pads

BiasRatios 0000010BS2BS1BS0 Setdesired Bias Ratios

Reserved 0 0 0 1 X X X X X X Not to be used

Set V

OP

001OP6 OP5 OP4 OP3 OP2 OP1 OP0 VOPregister Write instruction

2

(I

C interface only )

programmingrangeselection

LDC

LDC

21/36

STE2001

Table 2. Explanations of Table 6 symbols

BIT 0 1

DIR Scroll by one down Scroll by one up

H Use basic instruction set Use extended instruction set 0

PD Device fully working Devicein power down 1

V Horizontal addressing Vertical addressing 0

MX Normal X axis addressing X axis address is mirrored. 0

MY Image is displayed not vertically mirrored Image is displayed vertically mirrored 0

TRS No top rows mirroring Toprows mirroring (row pads 16-31 & 48-64) 0

BRS No bottom rows mirroring Bottom rows mirroring (row pads 0-15 & 32-47) 0

DO MSB on TOP MSB on BOTTOM 0

RESET

STATE

PRS V

MUX 1:65 multiplexing ratio 1:33 multiplexing ratio 0

= 2.94V V

LCD

= 6.75V 0

LCD

Table 3.

D E DESCRIPTION RESET STATE

0 0 displayblank

1 0 normal mode D=0

0 1 all display segments on E=0

1 1 inverse video mode

Table 4.

S1 S0 DESCRIPTION RESET STATE

0 0 Multiplication Factor 2X

0 1 Multiplication Factor 3X 0

1 0 Multiplication Factor 4X

1 1 Multiplication Factor 5X

Table 5.

TC1 TC0 DESCRIPTION RESET STATE

0 0 VLCD temperature Coefficient 0

0 1 VLCD temperature Coefficient 1 00

1 0 VLCD temperature Coefficient 2

1 1 VLCD temperature Coefficient 3

22/36

Table 6.

BS2 BS1 BS0 DESCRIPTION RESET STATE

0 0 0 Bias Ratio equal to 7

0 0 1 Bias Ratio equal to 6

0 1 0 Bias Ratio equal to 5

0 1 1 Bias Ratio equal to 4 000

1 0 0 Bias Ratio equal to 3

1 0 1 Bias Ratio equal to 2

1 1 0 Bias Ratio equal to 1

1 1 1 Bias Ratio equal to 0

Figure 24. Application Schematic Using an External LCD Voltage Generator

I/O

VDD2,3

V

DD

100nF

V

SS

VDD1

VSS2

VSS1

32

128

65 x 128

DISPLAY

STE2001

1µF

V

LCD

VLCDSENSE

VLCDOUT

VLCDIN

33

D00IN1157

Figure 25. Application Schematicusing the Internal LCD VoltageGenerator and two separatesupplies

I/O

V

DD2

V

100nF 100nF

V

SS

1µF

DD1

VLCDSENSE

VLCDOUT

VDD2,3

VDD1

VSS2

VSS1

VLCDIN

32

128

33

65 x 128

DISPLAY

D00IN1158

23/36

STE2001

Figure 26. Application Schematic using the Internal LCD Voltage Generator and a single supply

I/O

V

DD

VDD2,3

VDD1

100nF

V

SS

VSS2

VSS1

1µF

VLCDSENSE

VLCDOUT

VLCDIN

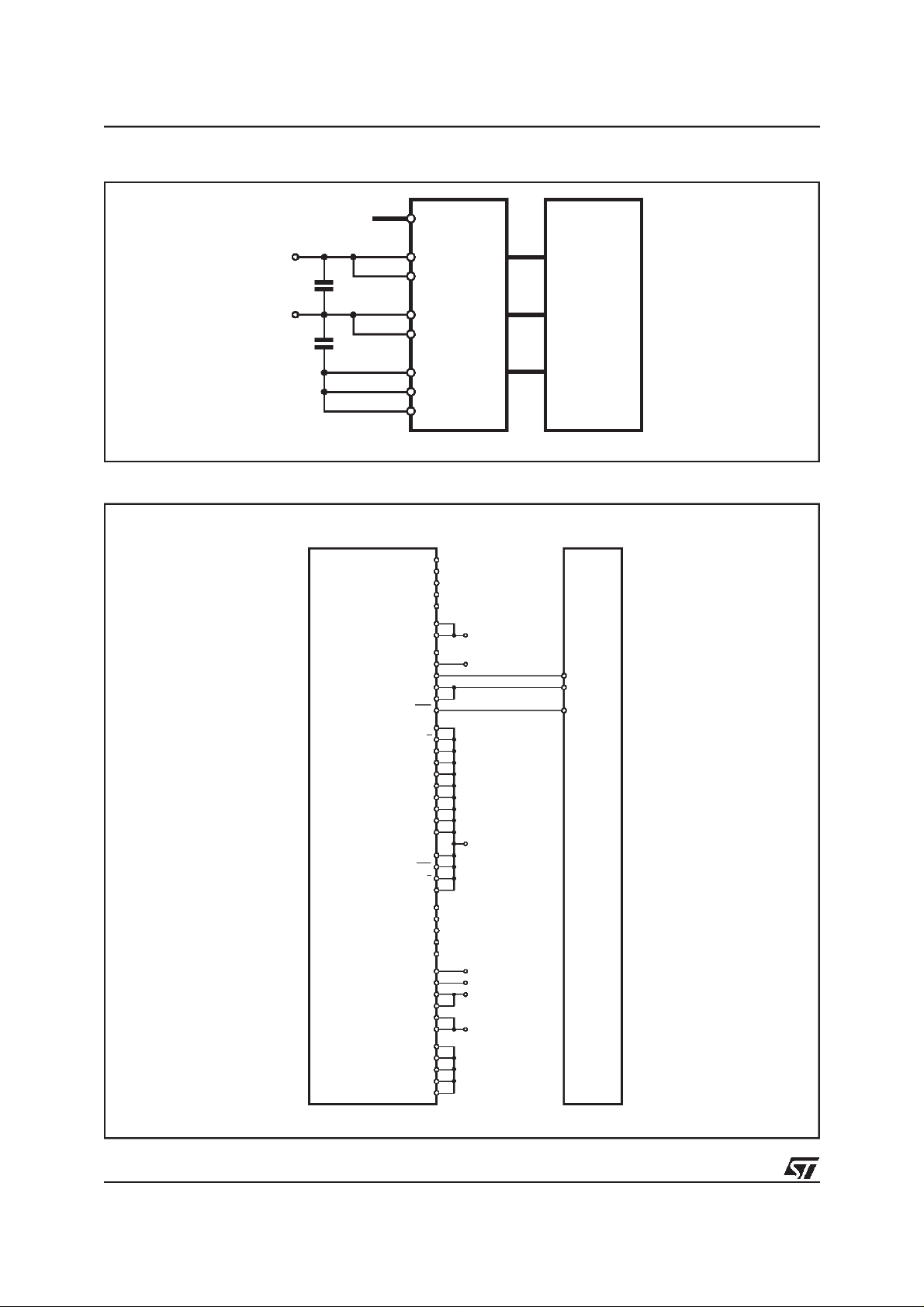

Figure 27. Pad Configuration with I2C interface

TEST_13

TEST_12

TEST_11

TEST_10

TEST_8

VSS2

VSS1

TEST 9

SA0

SCL

SDAIN

SDAOUT

STE2001 µP

RES

PD/C

SCLK

SCE

SD/C

SDIN

BSY_FLG

TEST_7

TEST_6

TEST_5

TEST_4

VDD3

VDD2

VDD1

OSCIN

SEL1

SEL2

VSSOUT

TEST_3

TEST_2

TEST_1

TEST_0

E

D0

D1

D2

D3

D4

D5

D6

D7

32

128

33

GND

VDD1/GND/VSSOUT

VDD1

GND/VSSOUT

D01IN1261

65 x 128

DISPLAY

D00IN1156

24/36

Figure 28. Pad Configuration with Parallel interface

TEST_13

TEST_12

TEST_11

TEST_10

TEST_8

VSS2

VSS1

SA0

SCL

RES

PD/C

SCLK

SCE

SD/C

SDIN

VDD3

VDD2

VDD1

OSC

SEL1

SEL2

E

D0

D1

D2

D3

D4

D5

D6

D7

GND

VDD1/GND/VSSOUT

VDD1

VDD1

GND/VSSOUT

VDD1

TEST 9

SDAIN

SDAOUT

STE2001 µP

BSY_FLG

TEST_7

TEST_6

TEST_5

TEST_4

VSSOUT

TEST_3

TEST_2

TEST_1

TEST_0

STE2001

D01IN1262

Figure 29. Pad Configuration with Serial interface

TEST_13

TEST_12

TEST_11

TEST_10

TEST_8

VSS2

VSS1

TEST 9

SA0

SCL

SDAIN

SDAOUT

STE2001 µP

RES

PD/C

SCLK

SCE

SD/C

SDIN

BSY_FLG

TEST_7

TEST_6

TEST_5

TEST_4

VDD3

VDD2

VDD1

OSCIN

SEL1

SEL2

VSSOUT

TEST_3

TEST_2

TEST_1

TEST_0

E

D0

D1

D2

D3

D4

D5

D6

D7

GND

VDD1/GND/VSSOUT

VDD1

VDD1

VDD1

GND/VSSOUT

D01IN1263

25/36

STE2001

Figure 30. Power OFF Timing Diagram

VDD2/3

VDD1

RES

INPUTS

Figure 31. Power OFF Sequence

POWER OFF SEQUENCE

t

VDD

D01IN1264

SET by Software (PD=0) or (Vop=0& PRS=[0;0])

Force Active Input Lines Low

REMOVE VDD1

REMOVEVDD2/3

END OF POWEROFF SEQUENCE

D01IN1265

26/36

Figure 32. Power-Up & RESET timing diagram

STE2001

VDD2/3

VDD1

RES

INPUTS

t

VDD

Figure 33. Power-Up & RESET timing diagram

VDD2/3

t

VDD1

RES

INPUTS

VDD

t

W(RES)

t

VHRL

t

W(RES)

D01IN1189

D01IN1190

Figure 34. Power Up Sequence

POWER UP SEQUENCE

Set Active Input lines low

Apply a RESET Pulse

Apply VDD2/3

Apply VDD1

END OF POWER UP

(STE2001 in Reset State)

SEQUENCE

D01IN1266

27/36

STE2001

Figure 35. Chip Mechanical Drawing

ROW 0

ALIGNEMENT MARK

STE2001

ROW16

ROW 15

COL 0

COL 63

COL 64

ALIGNEMENT MARK

(0,0)

Y

X

ROW31

TEST

VLCDIN

VLCDSENSE

VLCDOUT

VSS2

VSS1

TEST

SA0

SCL

SDAIN

SDAOUT

RES

E

PD/C

D0

D1

D2

D3

D4

D5

D6

D7

SCLK

SCE

SD/C

SDIN

BSY_FLG

TEST

28/36

COL 127

ROW 47

ROW 32

ALIGNEMENT MARK

ALIGNEMENT MARK

D01IN1191

VDD2

VDD3

VDD1

OSC

SEL1

SEL2

VSSOUT

TEST

ROW64

ROW48

Figure 36. Improved ALTH & PLESKO Driving Method

V

LCD

V

2

V

3

ROW 0

R0 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

ROW 1

R1 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

COL 0

C0 (t)

V

4

V

5

V

SS

V

LCD

V

2

V

3

COL 1

C1 (t)

V

4

V

5

V

SS

V

LCD-VSS

V

3-VSS

STE2001

∆V1(t)

(t)

∆V

2

V

V

state1

state2

V

LCD-V2

(t)

V

3-VSS

V

LCD-VSS

V

3-VSS

V

LCD-V2

(t)

V3-V

∆V

(t) = C1(t) - R0(t)

1

(t) = C1(t) - R1(t)

∆V

2

0V

0V

SS

0123456789 64

.......

FRAME n FRAME n + 1

0123456789 64.....

.....

.......

V

4-V5

0V

VSS-V

V4-V

VSS-V

V

4-V5

0V

VSS-V

V4-V

VSS-V

D00IN1154

5

LCD

LCD

5

LCD

LCD

29/36

STE2001

Figure 37. DATA RAM to display Mapping

DISPLAYDATA RAM

bank

0

bank

1

bank

2

bank

3

bank

7

bank

8

GLASS

TOPVIEW

DISPLAYDATA RAM = ”1”

DISPLAYDATA RAM = ”0”

LCD

ICOR ROW

Table 7. Test Pin Configuration

Test Numb. Pin

TEST_0

TEST_1

TEST_2

TEST_3

TEST_4

TEST_5

TEST_6

TEST_7

T8

T9

TEST_10

TEST_11

TEST_12

TEST_13

30/36

D00IN1155

GND

GND

GND

GND

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

OPEN

STE2001

Table 8. Mechanical Dimensions

Die Size 2.12mmX12.5mm

Pad Pitch

Pad Size

Bump Dimensions

WFS Thickness

70 µm

62µmX100µm

50µmX88µmX17.5

500µm

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

R0 1 -5,994 -898.2

R1 2 -5,924 -898.2

R2 3 -5,854 -898.2

R3

R4 5 -5,714 -898.2

R5

R6 7 -5,574 -898.2

R7 8 -5,504 -898.2

R8 9 -5,434 -898.2

R9 10 -5,364 -898.2

R10

R11 12 -5,224 -898.2

R12

R13 14 -5,084 -898.2

R14 15 -5,014 -898.2

R15 16 -4,944 -898.2

C0 17 -4,591.8 -898.2

C1

C2 19 -4,451.8 -898.2

C3

C4 21 -4,311.8 -898.2

C5 22 -4,241.8 -898.2

C6 23 -4,171.8 -898.2

C7 24 -4,101.8 -898.2

C8

C9 26 -3,961.8 -898.2

C10

C11 28 -3,821.8 -898.2

C12 29 -3,751.8 -898.2

4 -5,784 -898.2

6 -5,644 -898.2

11 -5,294 -898.2

13 -5,154 -898.2

18 -4,521.8 -898.2

20 -4,381.8 -898.2

25 -4,031.8 -898.2

27 -3,891.8 -898.2

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

C13 30 -3,681.8 -898.2

C14 31 -3,611.8 -898.2

C15 32 -3,541.8 -898.2

C16 33 -3,471.8 -898.2

C17

C18 35 -3,331.8 -898.2

C19

C20 37 -3,191.8 -898.2

C21 38 -3,121.8 -898.2

C22 39 -3,051.8 -898.2

C23 40 -2,981.8 -898.2

C24

C25 42 -2,841.8 -898.2

C26

C27 44 -2,701.8 -898.2

C28 45 -2,631.8 -898.2

C29 46 -2,561.8 -898.2

C30 47 -2,491.8 -898.2

C31

C32 49 -2,351.8 -898.2

C33

C34 51 -2,211.8 -898.2

C35 52 -2,141.8 -898.2

C36 53 -2,071.8 -898.2

C37 54 -2,001.8 -898.2

C38

C39 56 -1,861.8 -898.2

C40

C41 58 -1,721.8 -898.2

C42 59 -1,651.8 -898.2

C43 60 -1,581.8 -898.2

C44 61 -1,511.8 -898.2

C45

C46 63 -1,371.8 -898.2

C47

C48 65 -1,231.8 -898.2

C49 66 -1,161.8 -898.2

34 -3,401.8 -898.2

36 -3,261.8 -898.2

41 -2,911.8 -898.2

43 -2,771.8 -898.2

48 -2,421.8 -898.2

50 -2,281.8 -898.2

55 -1,931.8 -898.2

57 -1,791.8 -898.2

62 -1,441.8 -898.2

64 -1,301.8 -898.2

(continued)

31/36

STE2001

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

C50 67 -1,091.8 -898.2

C51 68 -1,021.8 -898.2

C52 69 -951.8 -898.2

C53 70 -881.8 -898.2

C54

C55 72 -741.8 -898.2

C56

C57 74 -601.8 -898.2

C58 75 -531.8 -898.2

C59 76 -461.8 -898.2

C60 77 -391.8 -898.2

C61

C62 79 -251.8 -898.2

C63

C64 81 175.44 -898.2

C65 82 245.44 -898.2

C66 83 315.44 -898.2

C67 84 385.44 -898.2

C68

C69 86 525.44 -898.2

C70

C71 88 665.44 -898.2

C72 89 735.44 -898.2

C73 90 805.44 -898.2

C74 91 875.44 -898.2

C75

C76 93 1,015.44 -898.2

C77

C78 95 1,155.44 -898.2

C79 96 1,225.44 -898.2

C80 97 1,295.44 -898.2

C81 98 1,365.44 -898.2

C82

C83 100 1,505.44 -898.2

C84

C85 102 1,645.44 -898.2

C86 103 1,715.44 -898.2

71 -811.8 -898.2

73 -671.8 -898.2

78 -321.8 -898.2

80 -181.8 -898.2

85 455.44 -898.2

87 595.44 -898.2

92 945.44 -898.2

94 1,085.44 -898.2

99 1,435.44 -898.2

101 1,575.44 -898.2

(continued)

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

C87 104 1,785.44 -898.2

C88 105 1,855.44 -898.2

C89 106 1,925.44 -898.2

C90 107 1,995.44 -898.2

C91

C92 109 2,135.44 -898.2

C93

C94 111 2,275.44 -898.2

C95 112 2,345.44 -898.2

C96 113 2,415.44 -898.2

C97 114 2,485.44 -898.2

C98

C99 116 2,625.44 -898.2

C100

C101 118 2,765.44 -898.2

C102 119 2,835.44 -898.2

C103 120 2,905.44 -898.2

C104 121 2,975.44 -898.2

C105

C106 123 3,115.44 -898.2

C107

C108 125 3,255.44 -898.2

C109 126 3,325.44 -898.2

C110 127 3,395.44 -898.2

C111 128 3,465.44 -898.2

C112

C113 130 3,605.44 -898.2

C114

C115 132 3,745.44 -898.2

C116 133 3,815.44 -898.2

C117 134 3,885.44 -898.2

C118 135 3,955.44 -898.2

C119

C120 137 4,095.44 -898.2

C121

C122 139 4,235.44 -898.2

C123 140 4,305.44 -898.2

108 2,065.44 -898.2

110 2,205.44 -898.2

115 2,555.44 -898.2

117 2,695.44 -898.2

122 3,045.44 -898.2

124 3,185.44 -898.2

129 3,535.44 -898.2

131 3,675.44 -898.2

136 4,025.44 -898.2

138 4,165.44 -898.2

(continued)

32/36

STE2001

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

C124 141 4,375.44 -898.2

C125 142 4,445.44 -898.2

C126 143 4,515.44 -898.2

C127 144 4,585.44 -898.2

R47

R46 146 5,013.84 -898.2

R45

R44 148 5,153.84 -898.2

R43 149 5,223.84 -898.2

R42 150 5,293.84 -898.2

R41 151 5,363.84 -898.2

R40

R39 153 5,503.84 -898.2

R38

R37 155 5,643.84 -898.2

R36 156 5,713.84 -898.2

R35 157 5,783.84 -898.2

R34 158 5,853.84 -898.2

R33

R32 160 5,993.84 -898.2

R48

R49 162 5,951.92 898.2

R50 163 5,881.92 898.2

R51 164 5,811.92 898.2

R52 165 5,741.92 898.2

R53

R54 167 5,601.92 898.2

R55

R56 169 5,461.92 898.2

R57 170 5,391.92 898.2

R58 171 5,321.92 898.2

R59 172 5,251.92 898.2

R60

R61 174 5,111.92 898.2

R62

R63 176 4,971.92 898.2

R64 177 4,901.92 898.2

145 4,943.84 -898.2

147 5,083.84 -898.2

152 5,433.84 -898.2

154 5,573.84 -898.2

159 5,923.84 -898.2

161 6,021.92 898.2

166 5,671.92 898.2

168 5,531.92 898.2

173 5,181.92 898.2

175 5,041.92 898.2

(continued)

Table 9. Pad Coordinates

NAME PAD X (µm) Y(µm)

TEST_3 178 4,640.52 898.2

TEST_2 179 4,500.68 898.2

TEST_1 180 4,360.84 898.2

TEST_0 181 4,221 898.2

VSSOUT

SEL2 183 4,011.16 898.2

SEL1

OSC 185 3,731.48 898.2

VDD1_1 186 3,661.48 898.2

VDD1_2 187 3,591.48 898.2

VDD1_3 188 3,521.48 898.2

VDD1_4

VDD1_5 190 3,381.48 898.2

VDD1_6

VDD3_1 192 3,223.08 898.2

VDD3_2 193 3,153.08 898.2

VDD3_3 194 3,083.08 898.2

VDD2_1 195 2,994.68 898.2

VDD2_2

VDD2_3 197 2,854.68 898.2

VDD2_4

VDD2_5 199 2,714.68 898.2

VDD2_6 200 2,644.68 898.2

VDD2_7 201 2,574.68 898.2

TEST_7 202 2,033.84 898.2

TEST_6

TEST_5 204 1,754.16 898.2

TEST_4

BSY_FLAG 206 1,474.48 898.2

SDIN 207 1,333.2 898.2

SD/C 208 1,193.36 898.2

SCE 209 1,053.52 898.2

SCLK

D7 211 773.84 898.2

D6

D5 213 494.16 898.2

D4 214 354.32 898.2

182 4,151 898.2

184 3,871.32 898.2

189 3,451.48 898.2

191 3,311.48 898.2

196 2,924.68 898.2

198 2,784.68 898.2

203 1,894 898.2

205 1,614.32 898.2

210 913.68 898.2

212 634 898.2

(continued)

33/36

STE2001

Table 9. Pad Coordinates

(continued)

NAME PAD X (µm) Y(µm)

D3 215 214.48 898.2

D2 216 74.64 898.2

D1 217 -65.2 898.2

D0 218 -205.04 898.2

PD/C

219 -344.88 898.2

E 220 -484.72 898.2

RES

SDA_OUT 222 -764.4 898.2

221 -624.56 898.2

SDA_IN 223 -904.24 898.2

SCL 224 -1,044.08 898.2

SA0 225 -1,183.92 898.2

TEST9

226 -1,722.04 898.2

VSS1_1 227 -1,795.48 898.2

VSS1_2

228 -1,865.48 898.2

VSS1_3 229 -1,935.48 898.2

VSS1_4 230 -2,075.88 898.2

VSS1_5 231 -2,145.88 898.2

VSS1_6 232 -2,215.88 898.2

VSS2_1

233 -2,356.28 898.2

VSS2_2 234 -2,426.28 898.2

VSS2_3

235 -2,496.28 898.2

VSS2_4 236 -2,636.68 898.2

VSS2_5 237 -2,706.68 898.2

VSS2_6 238 -2,776.68 898.2

VLCDOUT1 239 -3,545.64 898.2

VLCDOUT2

VLCDOUT3 241 -3,685.64 898.2

VLCDOUT4

VLCDOUT5 243 -3,825.64 898.2

VLCDOUT6 244 -3,895.64 898.2

VLCSENSE 245 -3,968.08 898.2

VLCDIN_1 246 -4,040.48 898.2

VLCDIN_2

VLCDIN_3 248 -4,180.48 898.2

VLCDIN_4

VLCDIN_5 250 -4,320.48 898.2

VLCDIN_6 251 -4,390.48 898.2

240 -3,615.64 898.2

242 -3,755.64 898.2

247 -4,110.48 898.2

249 -4,250.48 898.2

Table 9. Pad Coordinates

(continued)

NAME PAD X (µm) Y(µm)

TEST_12 252 -4,460.48 898.2

TEST_13 253 -4,540.48 898.2

TEST_10 254 -4,620.48 898.2

TEST_11 255 -4,700.48 898.2

TEST_8

256 -4,780.48 898.2

R31 257 -4,971.92 898.2

R30

258 -5,041.92 898.2

R29 259 -5,111.92 898.2

R28 260 -5,181.92 898.2

R27 261 -5,251.92 898.2

R26 262 -5,321.92 898.2

R25

263 -5,391.92 898.2

R24 264 -5,461.92 898.2

R23

265 -5,531.92 898.2

R22 266 -5,601.92 898.2

R21 267 -5,671.92 898.2

R20 268 -5,741.92 898.2

R19 269 -5,811.92 898.2

R18

270 -5,881.92 898.2

R17 271 -5,951.92 898.2

R16

272 -6,021.92 898.2

Table 10. Alignment marks coordinates

X Y MARKS

4806.2 901.8 mark1

-4876.2 901.8 mark2

-6092.6 -901.8 mark3

6092.6 -901.8 mark4

Figure 38. Alignment marks dimensions

34/36

Figure 39.

Figure 40. Tray Information

DIE IDENTIFICATION

R16

STE2001

D01IN1249

PAD

WIDE

CENTERLINE

STE2001

SHRINK

50.6±0.25

45.90

X

DETAIL

MASSTAB5:1

SCHNITT B-B

2 x 14.59 = 29.18±0.25

10.75

2.54 x 45?

PACK

STATPRO150

NOTES: ENGRAVING TOBE 20 CHAIR x 0.3

x 0.05 RAISED CENTER ON

KNOCKDUTS NOT TO EXCEED 0.08

MATERIAL:

BUILD TOOL TO 0.009 MM/MM

TRAYOR WAFFLE

OF STE2000/STE2001

SCHNITT A-A

10º

1

+0.08

0.3

12.80

-0.10

2.46

-0.13

+0.08

3.94

2.18

D01IN1248

Y

DETAIL

MASSTAB5:1

1

2.39

10º

DETAILX

B

4.60

0.90

AA

B

-0.25

+0.13

45.59

STATPROT.150

FLUOROWARE GmbH

13 x 3.19 = 41.47±0.25

DETAILY

35/36

STE2001

Information furnished is believed tobe accurate and reliable. However,STMicroelectronics assumes no responsibility for the consequences

of useof such information nor for any infringementof patents or other rightsof third partieswhich may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products arenot

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMicroelectronics - All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta- Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden- Switzerland - United Kingdom - U.S.A.

http://www.st.com

36/36

Loading...

Loading...