Battery charger with thermal regulation

Feature summary

■ Programmable charge current up to 800mA

■ No external MOSFET, sense resistors or

blocking diode required

■ Constant current / constant voltage operation

with thermal regulation to maximize charge

rate without risk of overheating

■ Charges single cell li-ion batteries directly from

USB port

■ Preset 4.2V charge voltage with 1% accuracy

■ Automatic recharge

■ Single charge status output pin

■ Charge current monitor output for gas gauging

■ C/10 Charge termination

■ 25µA supply current in shutdown mode

■ Low battery voltage detect for precharge

setting

■ Soft-start limits inrush current

■ TSOT23-5L package

Applications

■ Cellular telephones

■ PDAs

■ Bluetooth applications

■ Battery-powered devices

Description

The STC4054 is a constant current/constant

voltage charger for single cell Li-Ion batteries. No

external sense resistor or blocking diode is

STC4054

800mA Standalone linear Li-Ion

TSOT23-5L

required and its ThinSOT package make it ideally

suited for portable applications.

The STC4054 is designed to work within USB

power specifications. An internal block regulates

the current when the junction temperature

increases, in order to protect the device when it

operates in high power or high ambient

temperature.

The charge voltage is fixed at 4.2V, and the

charge current limitation can be programmed

using a single resistor connectd between PROG

pin and GND. The charge cycle is automatically

terminated when the current flowing to the battery

is 1/10 of the programmed value. If the external

adaptor is removed, the STC4054 turns off and a

2µA current can flow from the battery to the

device. The device can be put into Shutdown

Mode, reducing the supply current to 25µA. The

device also has a charge current monitor, under

voltage lockout, automatic recharge. The device is

packaged in TSOT23-5L.

Order code

Part number Package Packaging

STC4054GR TSOT23-5L 3000 parts per reel

September 2006 Rev. 1 1/17

www.st.com

17

STC4054

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Charge cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 V

6.3 Power ON pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.4 CHRG pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.5 PROG pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.6 Programming charge current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.7 BAT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.8 Charge termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.9 Automatic recharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.10 Soft start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.11 Thermal regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.12 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.13 Stability considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CC

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2/17

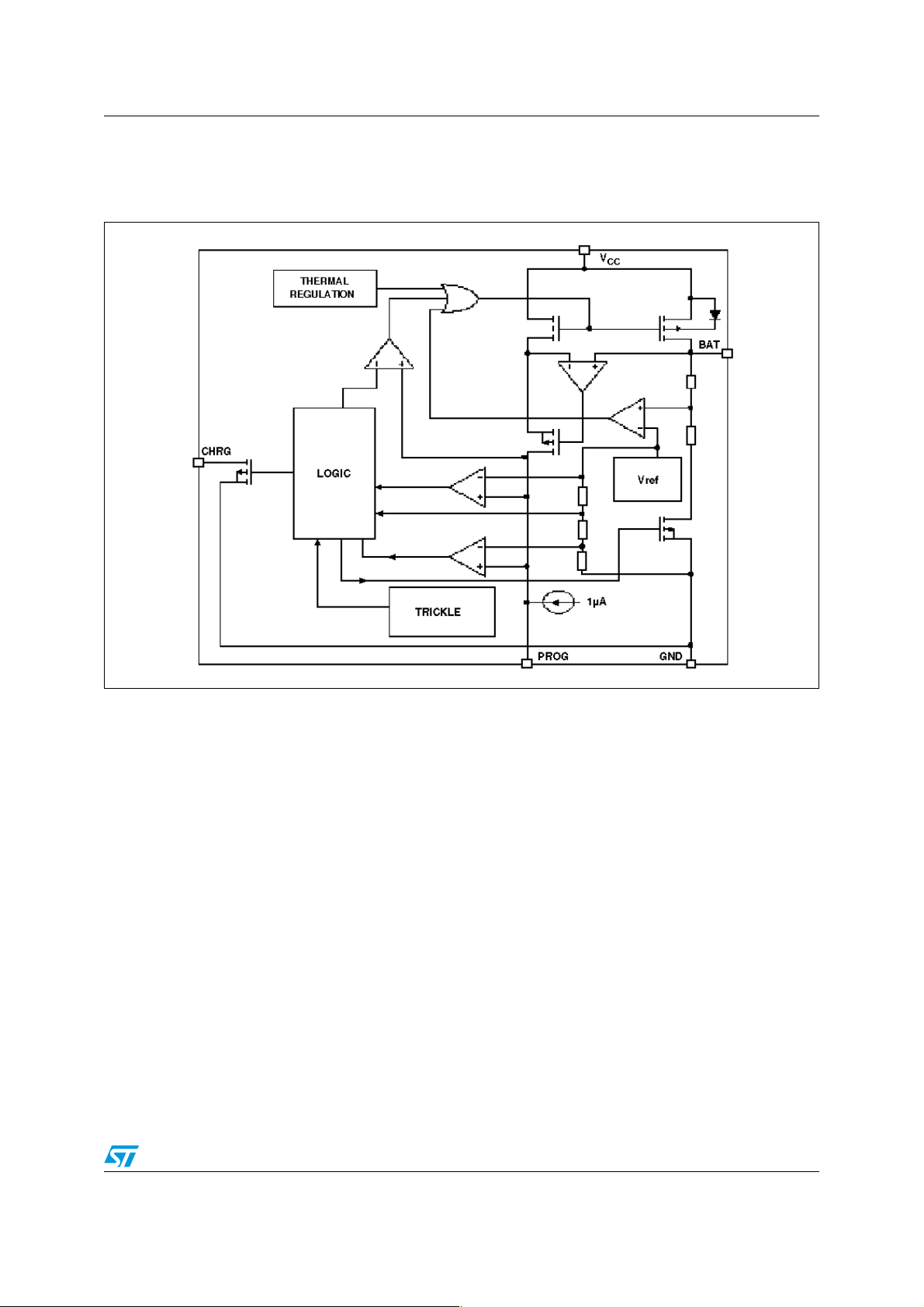

STC4054 Block diagram

1 Block diagram

Figure 1. Block diagram

3/17

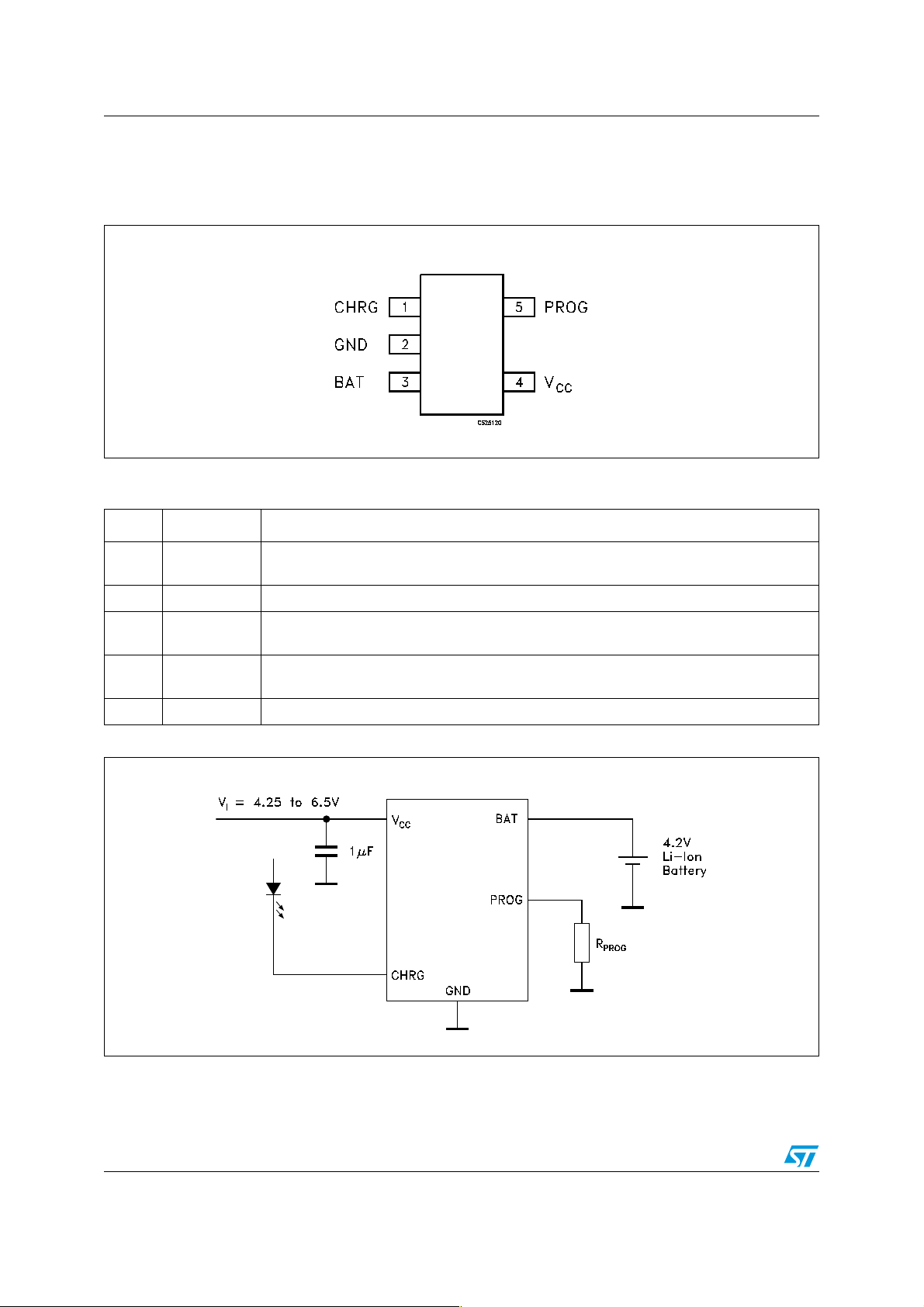

Pin configuration STC4054

2 Pin configuration

Figure 2. Pin connections (top view)

Table 1. Pin description

Pln N° Symbol Note

1 CHRG

2 GND Ground pin

3BAT

4V

5 PROG Charge current program. Charge Current monitor and Shutdown pin

CC

Open Drain. This pin goes in low impedance when the STC4054 is in precharge or

charge mode

This pin provides an accurate 4.2V output voltage and the charge current to the battery.

Only 2µA reverse current can flow in to the device when in Shutdown mode

Input Supply voltage. The input range is from 4.25V to 6.5V. If VCC<V

device enters Shutdown mode and the sinked I

is less than 2µA

BAT

Figure 3. Application circuit

+30mV the

BAT

4/17

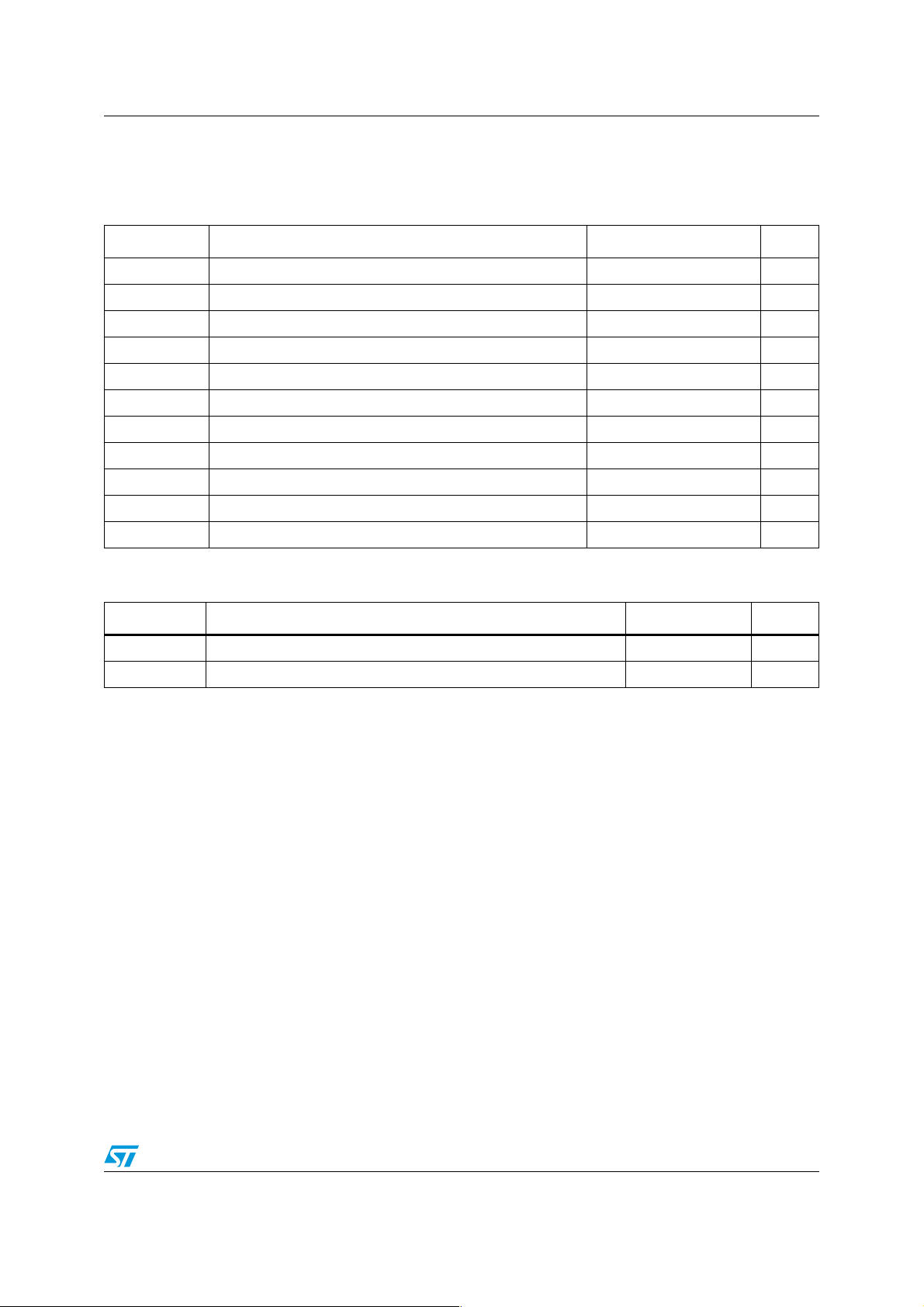

STC4054 Maximum ratings

3 Maximum ratings

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

V

V

V

PROG

V

CHRG

I

BAT

I

PROG

CC

BAT

Input supply voltage From -0.3 to 10 V

BAT pin voltage From -0.3 to 7 V

PROG pin voltage From -0.3 to VCC+0.3 V

CHRG pin voltage From -0.3 to 7 V

BAT pin current 800 mA

PROG pin current 800 µA

BAT short circuit duration Continuous

T

T

P

D

T

J

STG

OP

Power dissipation Internally Limited mW

Max junction temperature 125 °C

Storage temperature range -65 to 125 °C

Operating junction temperature range -40 to 85 °C

Table 3. Thermal Data

Symbol Parameter Value Unit

R

R

thJC

thJA

Thermal resistance junction-case 81 °C/W

Thermal resistance junction-ambient 255 °C/W

5/17

Electrical characteristics STC4054

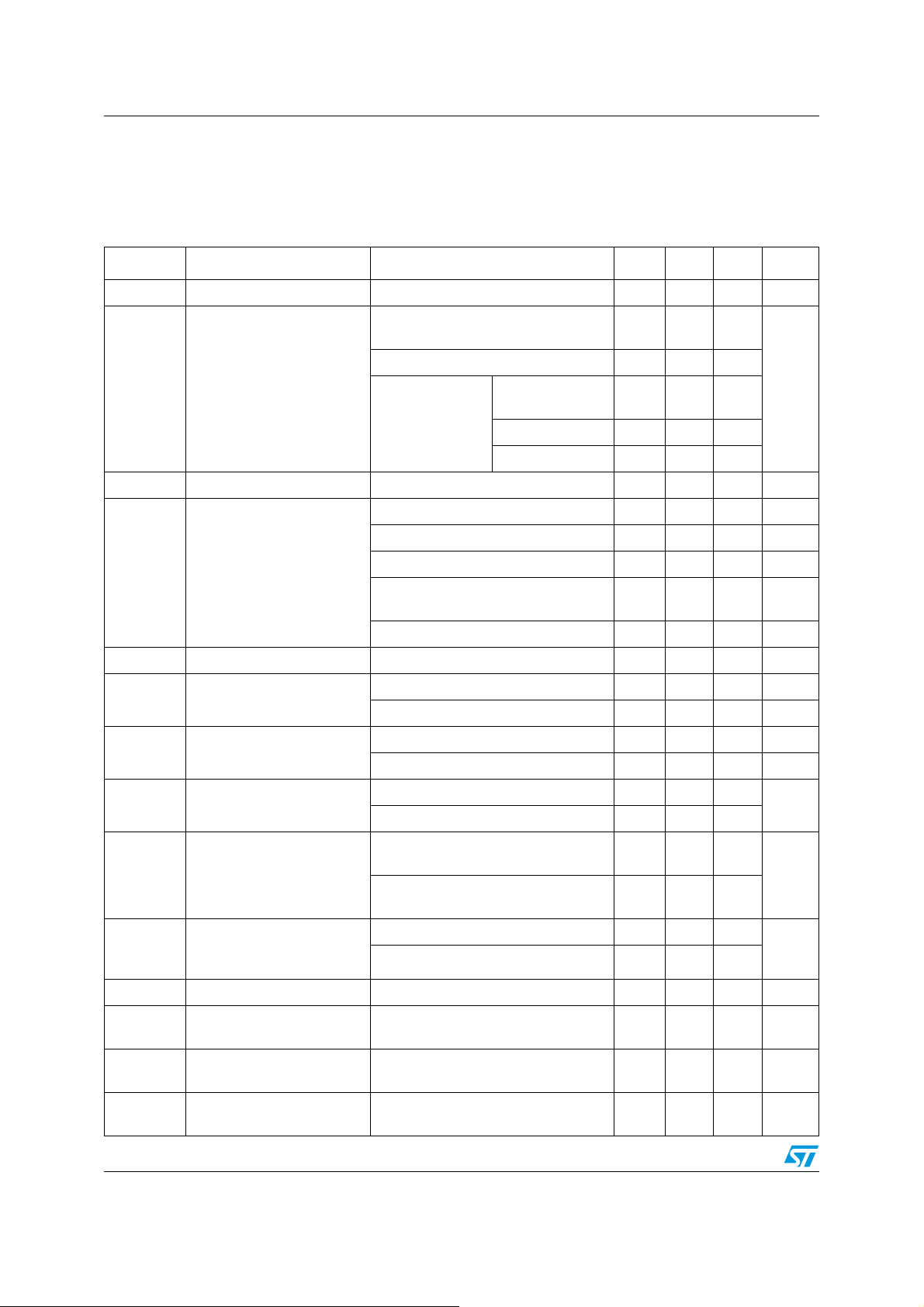

4 Electrical characteristics

Table 4. Electrical characteristics

(V

= 5V, CI = 1µF, TJ = -40 to 85° unless otherwise specified) (

CC

Symbol Parameter Test Min. Typ. Max. Unit

Note 1

).

V

V

V

V

I

I

BAT

I

PRE

V

MSD

CC

CC

BAT

PRE

UV

Supply voltage 4.25 6.5 V

Charge mode, R

= 3.5V

V

BAT

PROG

=10KΩ,

150 500

Standby mode (charge terminated) 150 300

Supply current (

Termination output voltage V

BAT pin current

Pre-charge current V

Pre-charge threshold

VCC Undervoltage lockout

Note 2

)

Shutdown mode

CC

Current mode R

Current mode R

Standby mode V

Shutdown mode (R

connected), T

Sleep mode, V

BAT

R

PROG

Hysteresis R

V

CC

Hysteresis R

= 4.3V to 6.5V, R

PROG

PROG

BAT

=25°C

J

=0V, TJ=25°C ±1 ±2µA

CC

<2.8V R

=10KΩ V

=2KΩ TJ=25°C 20 45 70 mA

PROG

BAT

=10KΩ 70 100 130 mV

PROG

Low to High R

=10KΩ 50 180 300 mV

PROG

not

R

PROG

connected

< V

V

CC

BAT

V

< V

CC

UV

=10KΩ 4.158 4.2 4.242 V

PROG

21 40

17 50

17 40

=10KΩ 90 100 110 mA

=2KΩ 465 500 535 mA

=4.2V 0 -2.5 -6 µA

not

PROG

±1 ±2µA

falling 2.8 2.9 3.0 V

=10KΩ 3.7 3.8 3.9 V

PROG

µA

PROG Pin Rising 1.15 1.21 1.30

Manual shutdown threshold

PROG Pin Falling 0.85 0.95 1.05

V

∆V

6/17

V

ASD

I

TERM

V

PROG

I

CHRG

V

CHRG

RECHRG

Low to High TJ=25°C

V

CC

=10KΩ

R

VCC-V

Lockout threshold

BAT

C/10 Termination current

threshold (I

Note 3

)

(

BAT/IBATC10

)

PROG

V

High to Low TJ=25°C

CC

=10KΩ

R

PROG

R

=10KΩ 0.1

PROG

R

=2KΩ 0.1

PROG

PROG pin voltage Current Mode R

CHRG Pin current weak

pull-down

CHRG Pin pull-down

voltage

Recharger battery threshold

voltage

V

=5V, V

CHRG

R

PROG

I

CHRG

V

FLOAT-VRECHRG

R

PROG

BAT

=10KΩ

=5mA 0.35 0.6 V

=10KΩ

50 85 120

53050

=10KΩ 0.93 1.0 1.07 V

PROG

=4.3V,

, TJ=25°C

82035µA

200 mV

mV

mA/mA

STC4054 Electrical characteristics

Table 4. Electrical characteristics

(V

= 5V, CI = 1µF, TJ = -40 to 85° unless otherwise specified) (

CC

Symbol Parameter Test Min. Typ. Max. Unit

Note 1

).

T

LIM

R

ON

t

SS

T

RECHARGE

t

TERM

I

PROG

Junction temperature in

constant current mode

Power Fet “ON” resistance

(Between V

and BAT)

CC

Soft-start time I

Recharge comparator filter

time

Note 4

Termination comparator

filter time

Note 4

=0 to I

BAT

V

High to Low 0.75 2 4.5 ms

BAT

I

Falling Below I

BAT

=1000V/R

BAT

100 µs

PROG

/10 400 1000 2500 µs

CHG

120 °C

600 mΩ

PROG pin pull-up current 1 µA

Note: 1 The STC4054 was tested using a battery simulator and an output capacitor value about

4.7µF

2 Supply current includes PROG pin current but not include any current delivered to the

battery through the V

3I

is expressed as a fraction of measured full charge current with indicated PROG

TERM

BAT

pin

resistor

4 Guaranteed by design

7/17

Typical performance characteristics STC4054

5 Typical performance characteristics

Figure 4. I

Figure 6. I

vs Supply voltage Figure 5. V

BAT

vs temperature Figure 7. V

BAT

vs V

BAT

PROG

CC

vs temperature

Figure 8. I

8/17

BAT/IPROG

vs temperature Figure 9. I

BAT

vs V

PROG

STC4054 Typical performance characteristics

Figure 10. I

Figure 12. I

BAT/IPROG

CHRG

vs V

CC

vs temperature (CHRG pin

weak pull down current)

Figure 11. V

vs temperature (CHRG pin

CHRG

output low voltage)

Figure 13. Power FET “ON” resistance

Figure 14. I

BAT

vs V

BAT

Figure 15. Recharge battery threshold voltage

vs. temperature

9/17

Application information STC4054

6 Application information

The STC4054 uses an internal P-Channel MOSFET to work in constant current and

constant voltage method. It is able to provide up to 800mA with a final regulated output

voltage of 4.2V

required. It is also possible to use an USB port as power supply voltage.

6.1 Charge cycle

A charge cycle begins when the voltage at the VCC pin rises above the UVLO threshold

level, the R

and when a battery is connected to the charger output. If the battery voltage is below 2.9V,

the charger enters in Trickle Charge mode. In this condition, the device supplies 1/10 of the

programmed charge current to bring the battery voltage up to safe level otherwise the life of

a battery is reduced. If the BAT pin voltage is higher than 2.9V the charger enters in

Constant Current Mode. When the BAT pin voltage is close to the final float voltage (4.2V)

the device enters in Constant Voltage Mode and the charge current begins to decrease. The

charge cycle is terminated when the current drops to 1/10 of the programmed value.

± 1% in full temperature range. No blocking diode and sensing resistor are

program resistor of 1% is connected between the PROG pin to GND pin

PROG

6.2 VCC Pin

Input Supply Voltage. This pin is used to supplie the device in the range from 4.25V to 6.5V

voltage. A bypass capacitor of 1µF is recommended for use. When V

30mV of the BAT pin voltage, the device enters in Shutdown Mode, dropping I

than 2µA.

6.3 CHRG pin

This is a flag open drain. It indicates three different status of the output. When the charge is

in progress this pin is pulled low instead at the end of the charge cycle, a weak pull down of

approximately 20µA is connected to the CHRG pin, indicating a present supply power; if the

flag is forced high impedance an under voltage condition is detected.

6.4 PROG pin

Charge Current Program, Charge Current Monitor and Shutdown Pin. The charge current is

programmed by connecting a 1% resistor, R

constant current, the value of voltage on this pin is 1.0V. In other conditions, the voltage on

this pin can be used to measure the charge current using the following formula:

The PROG pin is used to shut down the device, disconnecting the program resistor from

ground a 1µA current flows to pull the PROG pin high. If the value of this Pin is 1.21V

(shutdown threshold voltage), the device enters Shutdown mode and the input supply

current drops to 25µA. Driving this pin to voltage beyond 2.4V a current of 35µA flows into

the device from PROG pin.

I

BAT

= (V

PROG/RPROG

value drops of

CC

BAT

, to ground. When the device is charging in

PROG

)*1000

to less

10/17

STC4054 Application information

6.5 Programming charge current

The R

1000 times the Prog pin current value. The program resistor and the charge current are

calculated using the following formula:

R

PROG

The charge current out of the BAT pin can be monitored through the PROG pin voltage

using the following equation:

I

=(V

BAT

resistor is used to set the charge current value. The battery charge current is

PROG

=1000*V

PROG/RPROG

PROG/IBAT

;

)x1000

6.6 Charge status indicator (CHRG)

The charge status output has three different states: Strong pull-down (~10mA), weak pulldown (20µA) and high impedance. The strong pull-down indicates that the device is

charging the battery. Weak pull-down indicates that V

device is ready to charge. The last status high impedance indicates an insufficient voltage is

applied to the V

pin or the voltage on VCC is less than 100mV above the BAT pin voltage.

CC

6.7 BAT pin

Charge Current Output pin. It provides charge current to the battery and regulates the final

float voltage to 4.2V. An internal precision resistor is used as a feedback loop to compare

the V

with the reference.

O

meets the UVLO conditions and the

CC

6.8 Charge termination

A charge cycle is terminated when the final float voltage is reached consequently the charge

current falls to 1/10th of the programmed value. The charge is over when the PROG pin

voltage falls below 100mV for longer time than t

off, the device enters in standby mode and the input supply current drops to 200µA.

6.9 Automatic recharge

The device restarts the charge cycle when the battery voltage falls below 4.05V to maintain

the battery capacity value higher than 80%. During the recharge time, the CHRG pin goes

low state.

6.10 Soft start

When a charge cycle starts, a internal soft start circuit minimizes the inrush current. At

starting phase, the charge current ramps from zero to the full scale in a 100µs period time.

(~1ms). The charge current is latched

TERM

11/17

Application information STC4054

6.11 Thermal regulation

An internal thermal feedback loop reduces the output current if the die temperature attempts

to rise above a present value of approximately 120°C. This feature protects the device from

excessive temperature and allows the user to push the limits of the power handling

capability of a given circuit board without risk of damaging the device.

6.12 Power dissipation

It is very important to use a good thermal PC board layout to maximize the available output

current. The thermal path for the heat generated by the IC is from the die to the copper lead

frame through the package leads and exposed pad to the PC board copper. The PC board

copper is the heat sink. The footprint copper pads should be as wide as possible and

expand out to larger copper areas to spread and dissipate the heat to the surrounding

ambient. Feed through vias to inner or backside copper layers are also useful in improving

the overall thermal performance of the device. Other heat sources on the board, not related

to the device, must also be considered when designing a PC board layout because they will

affect overall temperature rise and the maximum output current.

6.13 Stability considerations

The STC4054 contains two control loops: constant voltage and constant current. The

constant-voltage loop is stable without any compensation when a battery is connected with

low impedance leads. Excessive lead length, however, may add enough series inductance

to require a bypass capacitor of at least 1µF from BAT to GND. Furthermore, a 4.7µF

capacitor with a 0.2Ω to 1Ω series resistor from BAT to GND is required to keep ripple

voltage low when the battery is disconnected.

12/17

STC4054 Package mechanical data

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect. The category of

second Level Interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com.

13/17

Package mechanical data STC4054

TSOT23-5L MECHANICAL DATA

mm. mils

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

A 1.1 43.3

A1 0 0.1 3.9

A2 0.7 1.0 27.6 39.4

b 0.3 0.5 11.8 19.7

C 0.08 0.2 3.1 7.9

D 2.9 114.2

E 2.8 110.2

E1 1.6 63.0

e0.95 37.4

e1 1.9 74.8

L 0.3 0.6 11.8 23.6

14/17

7282780B

STC4054 Package mechanical data

Tape & Reel SOT23-xL MECHANICAL DATA

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

A 180 7.086

C 12.8 13.0 13.2 0.504 0.512 0.519

D 20.2 0.795

N 60 2.362

T 14.4 0.567

Ao 3.13 3.23 3.33 0.123 0.127 0.131

Bo 3.07 3.17 3.27 0.120 0.124 0.128

Ko 1.27 1.37 1.47 0.050 0.054 0.0.58

Po 3.9 4.0 4.1 0.153 0.157 0.161

P 3.9 4.0 4.1 0.153 0.157 0.161

mm. inch

15/17

Revision history STC4054

8 Revision history

Table 5. Revision history

Date Revision Changes

04-Sep-2006 1 Initial release.

16/17

STC4054

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2006 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

17/17

Loading...

Loading...