Page 1

8-bit microcontroller with single voltage

Flash memory, data EEPROM, ADC, timers, SPI

■ Memories

– 1K or 1.5 Kbytes single voltage Flash Pro-

gram memory with read-out protection, In-Circuit and In-Application Programming (ICP and

IAP). 10 K write/erase cycles guaranteed,

data retention: 20 years at 55 °C.

– 128 bytes RAM.

– 128 bytes data EEPROM with read-out pro-

tection. 300K write/erase cycles guaranteed,

data retention: 20 years at 55 °C.

■ Clock, Reset and Supply Management

– 3-level low voltage supervisor (LVD) and aux-

iliary voltage detector (AVD) for safe power-

on/off procedures

– Clock sources: internal 1MHz RC 1% oscilla-

tor or external clock

– PLL x4 or x8 for 4 or 8 MHz internal clock

– Four Power Saving Modes: Halt, Active-Halt,

Wait and Slow

■ Interrupt Management

– 10 interrupt vectors plus TRAP and RESET

– 4 external interrupt lines (on 4 vectors)

■ I/O Ports

– 13 multifunctional bidirectional I/O lines

– 9 alternate function lines

– 6 high sink outputs

■ 2 Timers

– One 8-bit Lite Timer (LT) with prescaler in-

cluding: watchdog, 1 realtime base and 1 in-

put capture.

ST7LITE0xY0, ST7LITESxY0

SO16

DIP16

QFN20

– One 12-bit Auto-reload Timer (AT) with output

compare function and PWM

■ 1 Communication Interface

– SPI synchronous serial interface

■ A/D Converter

– 8-bit resolution for 0 to V

– Fixed gain Op-amp for 11-bit resolution in 0 to

250 mV range (@ 5V V

DD

– 5 input channels

■ Instruction Set

– 8-bit data manipulation

– 63 basic instructions with illegal opcode de-

tection

– 17 main addressing modes

– 8 x 8 unsigned multiply instruction

■ Development Tools

– Full hardware/software development package

150”

DD

)

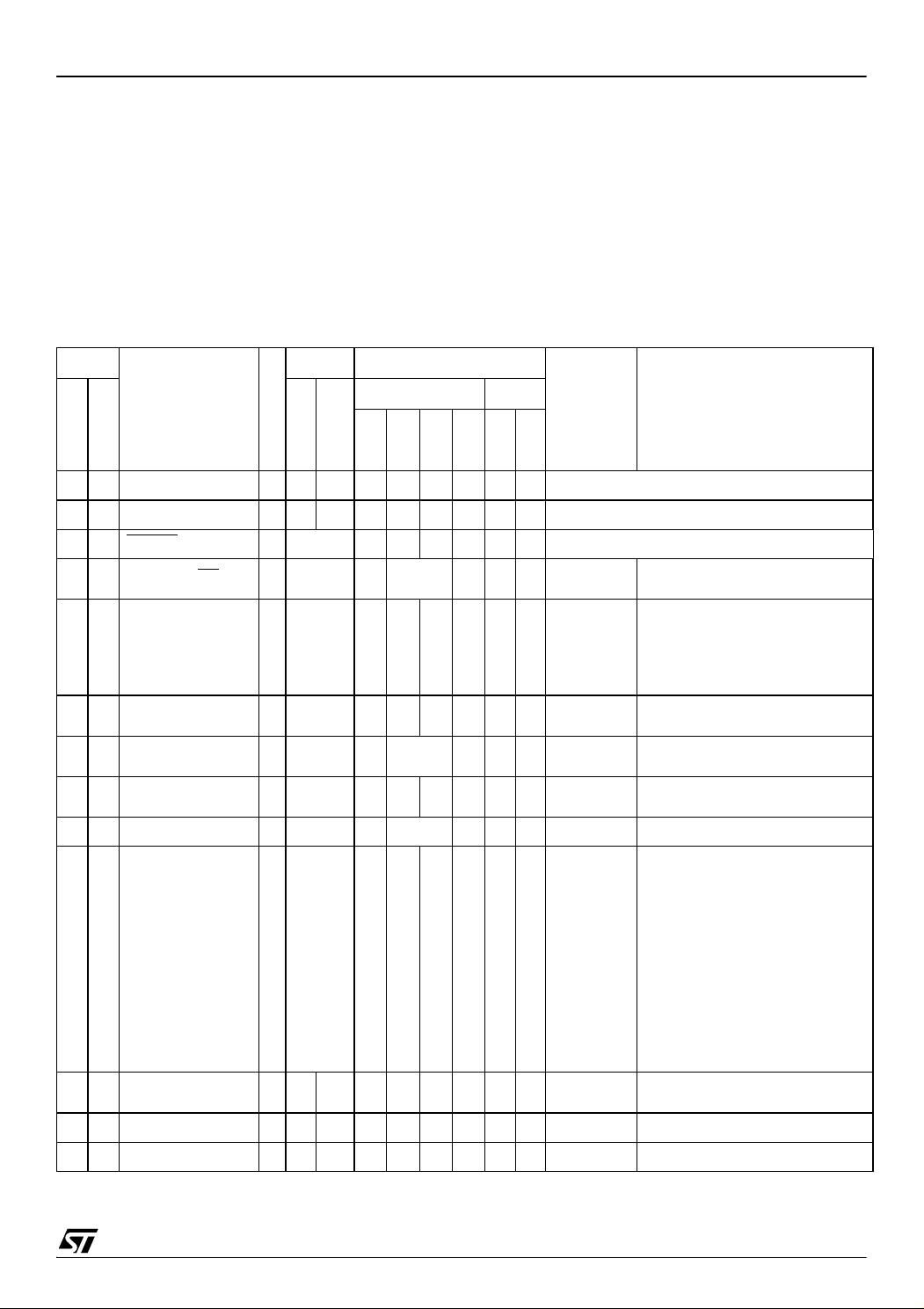

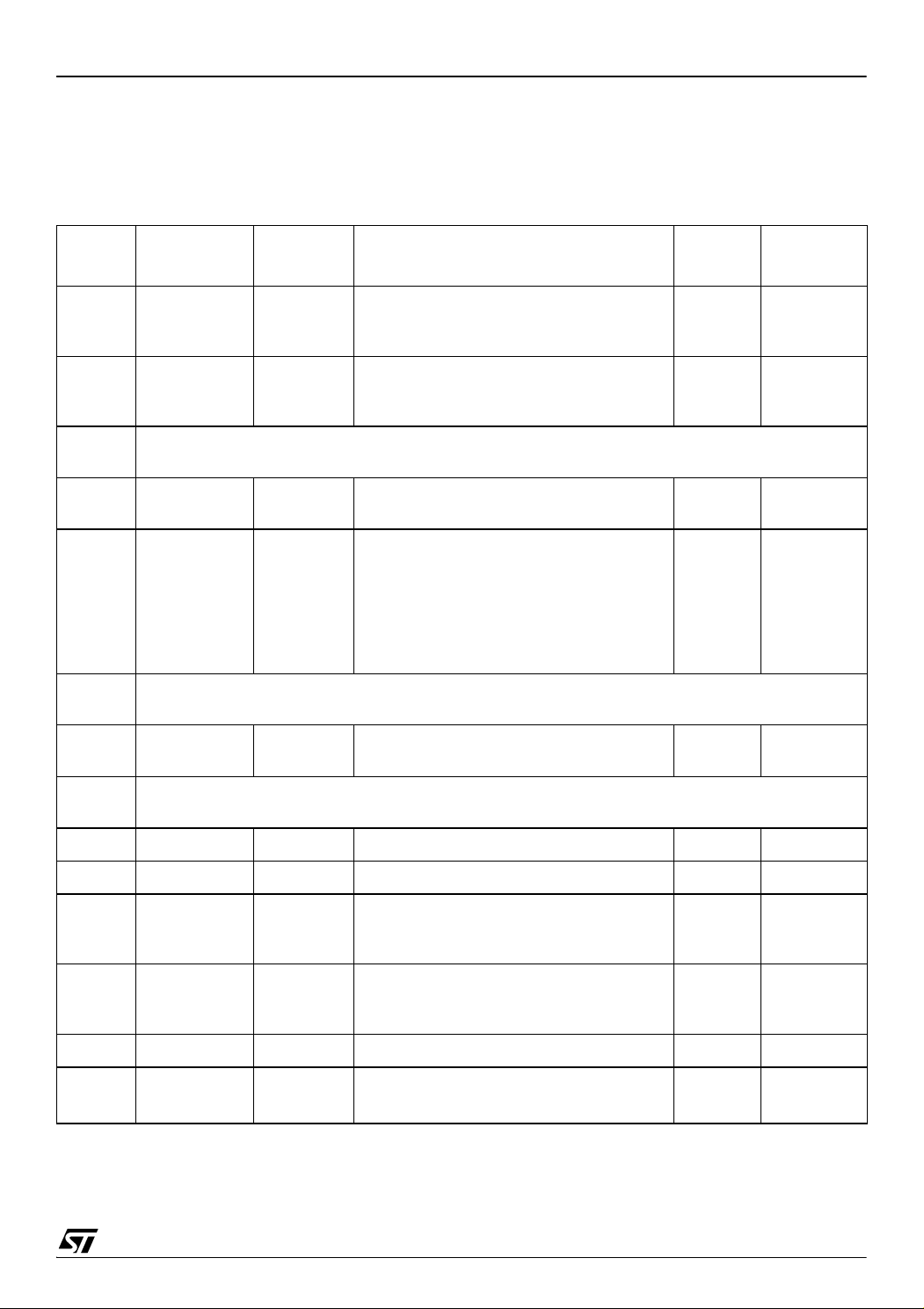

Device Summary

Features

Program memory - bytes 1K 1K 1.5K 1.5K 1.5K

RAM (stack) - bytes 128 (64) 128 (64) 128 (64) 128 (64) 128 (64)

Data EEPROM - bytes----128

Peripherals

Operating Supply 2.4V to 5.5V

CPU Frequency 1MHz RC 1% + PLLx4/8MHz

Operating Temperature -40°C to +85°C

Packages SO16 150”, DIP16, QFN20

ST7LITESxY0 (ST7SUPERLITE) ST7LITE0xY0

ST7LITES2Y0 ST7LITES5Y0 ST7LITE02Y0 ST7LITE05Y0 ST7LITE09Y0

LT Timer w/ Wdg,

AT Timer w/ 1 PWM,

SPI

LT Timer w/ Wdg,

AT Timer w/ 1 PWM,

SPI, 8-bit ADC

LT Timer w/ Wdg,

AT Timer w/ 1 PWM,

SPI

LT Timer w/ Wdg,

AT Timer w/ 1 PWM, SPI,

8-bit ADC w/ Op-Amp

Rev 6

November 2007 1/124

1

Page 2

Table of Contents

ST7LITE0xY0, ST7LITESxY0 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 REGISTER & MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 PROGRAMMING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 ICC INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 MEMORY PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 RELATED DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 DATA EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 MEMORY ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5 ACCESS ERROR HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 DATA EEPROM READ-OUT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.7 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 INTERNAL RC OSCILLATOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 PHASE LOCKED LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4 RESET SEQUENCE MANAGER (RSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1 NON MASKABLE SOFTWARE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.3 PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.4 SYSTEM INTEGRITY MANAGEMENT (SI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.4 ACTIVE-HALT AND HALT MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

124

2/124

2

Page 3

Table of Contents

10 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.3 UNUSED I/O PINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.4 LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.5 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.6 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.1 LITE TIMER (LT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.2 12-BIT AUTORELOAD TIMER (AT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.3 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.4 8-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

13 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

13.7 EMC (ELECTROMAGNETIC COMPATIBILITY) CHARACTERISTICS . . . . . . . . . . . . . 93

13.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

13.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

13.10 COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . 102

13.11 8-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

14 PACKAGE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.2 THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

15 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 112

15.1 OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

15.2 DEVICE ORDERING INFORMATION AND TRANSFER OF CUSTOMER CODE . . . . 114

15.3 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

15.4 ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

16 KNOWN LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

16.1 EXECUTION OF BTJX INSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

16.2 IN-CIRCUIT PROGRAMMING OF DEVICES PREVIOUSLY PROGRAMMED WITH HARDWARE WATCHDOG OPTION 121

16.3 IN-CIRCUIT DEBUGGING WITH HARDWARE WATCHDOG . . . . . . . . . . . . . . . . . . . 121

16.4 RECOMMENDATIONS WHEN LVD IS ENABLED . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

16.5 CLEARING ACTIVE INTERRUPTS OUTSIDE INTERRUPT ROUTINE . . . . . . . . . . . . 121

17 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

3/124

3

Page 4

Table of Contents

To obtain the most recent version of this datasheet,

please check at www.st.com

Please also pay special attention to the Section “KNOWN LIMITATIONS” on page 121.

4/124

1

Page 5

1 DESCRIPTION

ST7LITE0xY0, ST7LITESxY0

The ST7LITE0x and ST7SUPERLITE

(ST7LITESx) are members of the ST7 microcontroller family. All ST7 devices are based on a common industry-standard 8-bit core, featuring an enhanced instruction set.

The ST7LITE0x and ST7SUPERLITE feature

FLASH memory with byte-by-byte In-Circuit Programming (ICP) and In-Application Programming

(IAP) capability.

Under software control, the ST7LITE0x and

ST7SUPERLITE devices can be placed in WAIT,

SLOW, or HALT mode, reducing power consumption when the application is in idle or standby state.

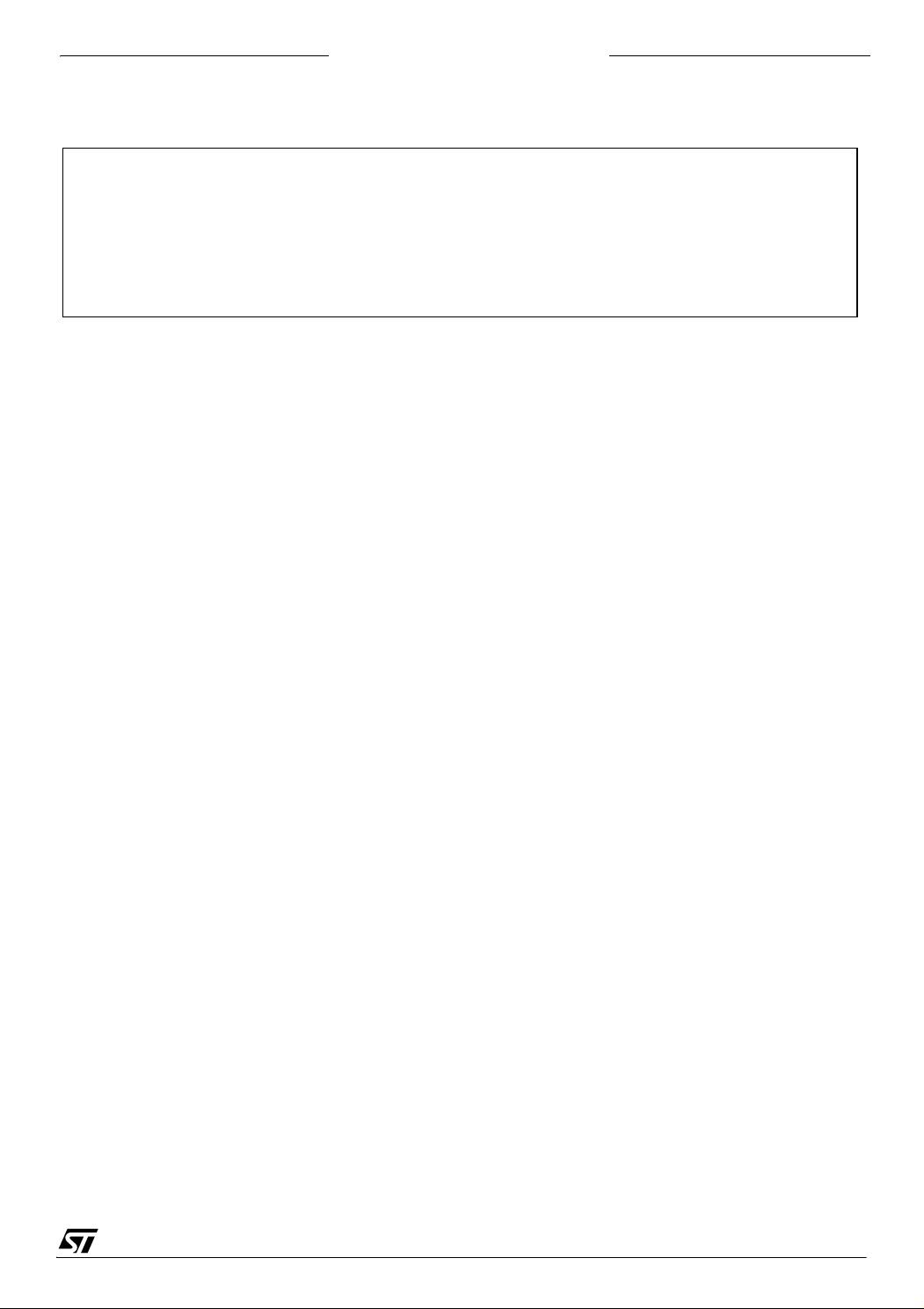

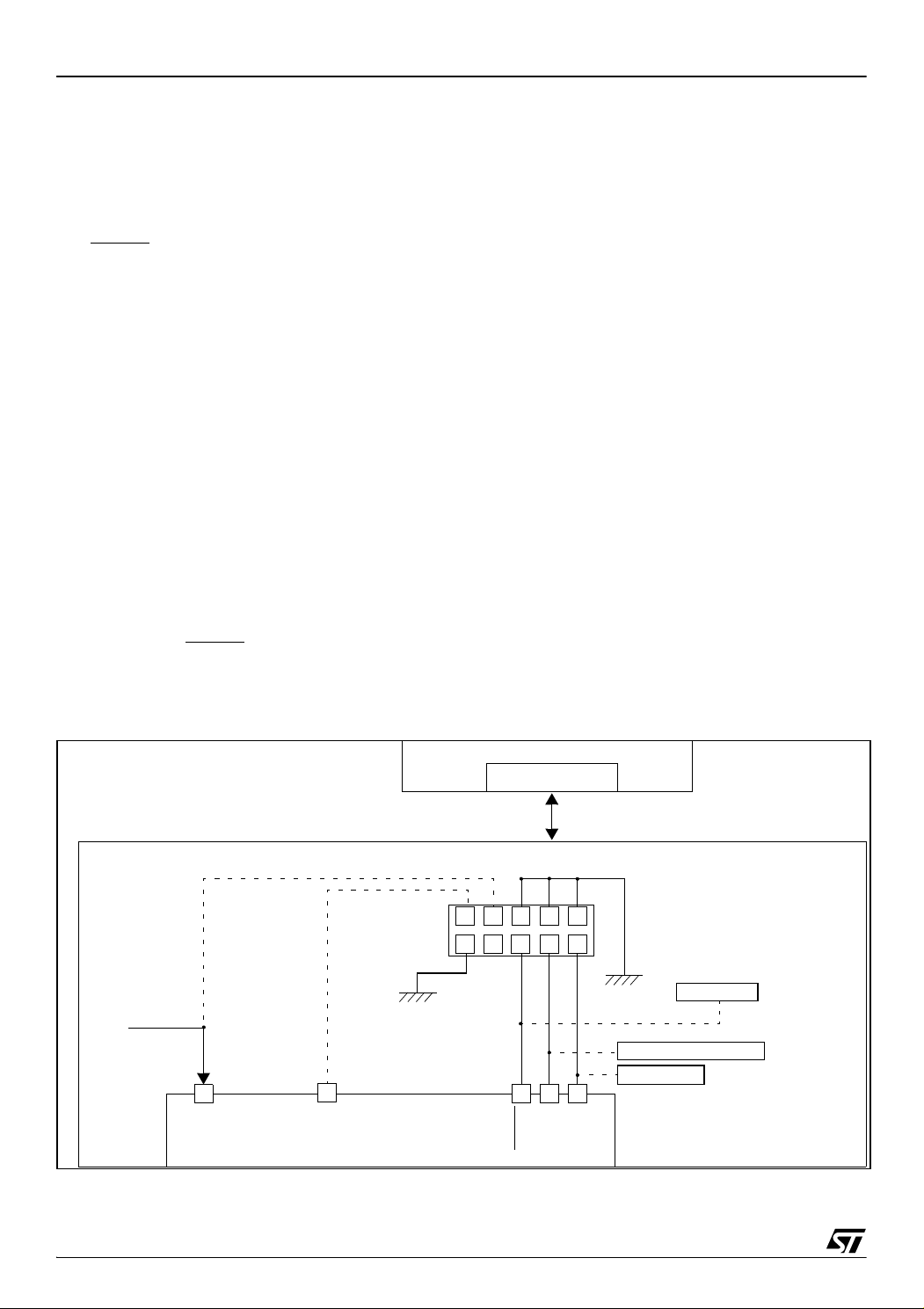

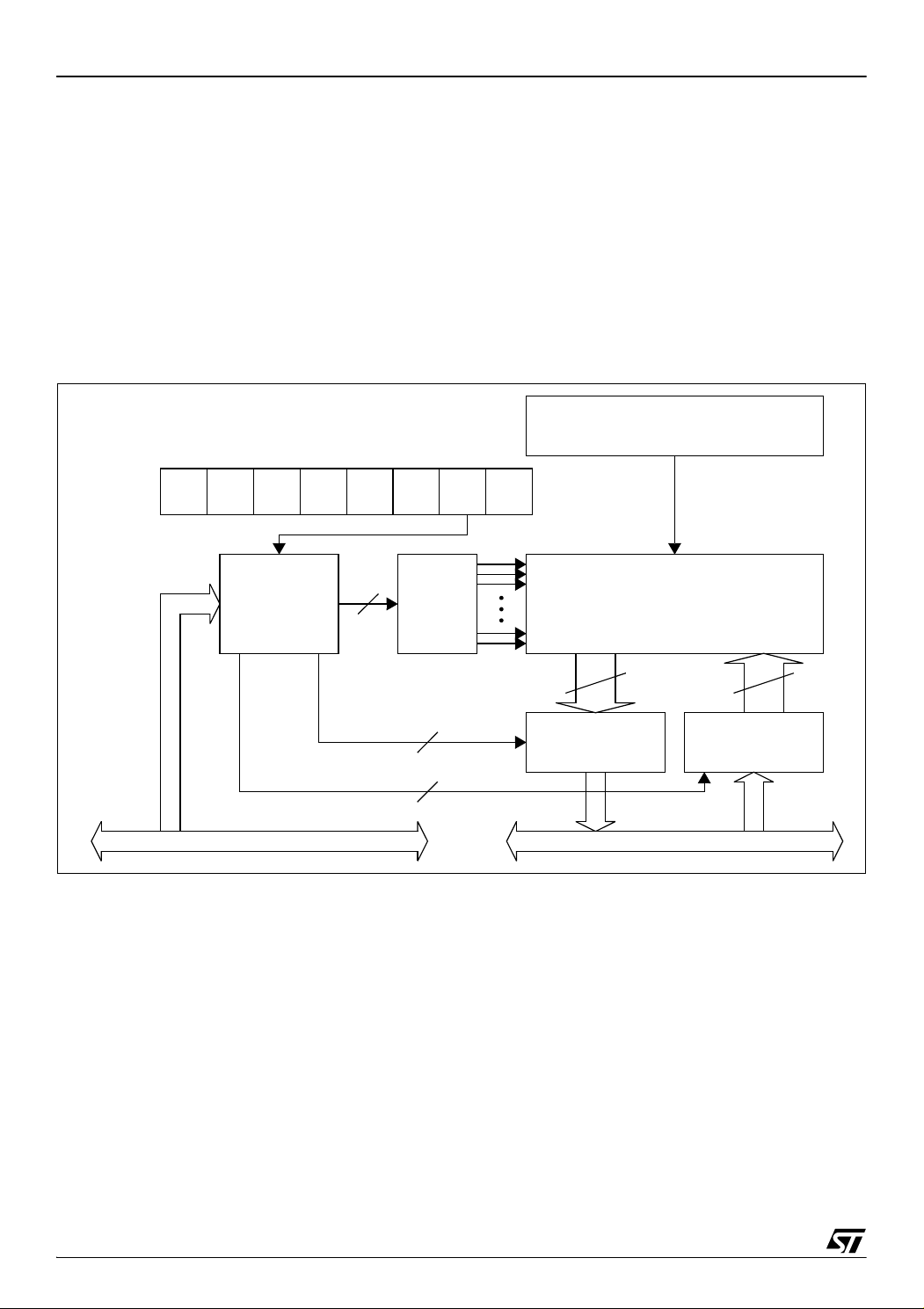

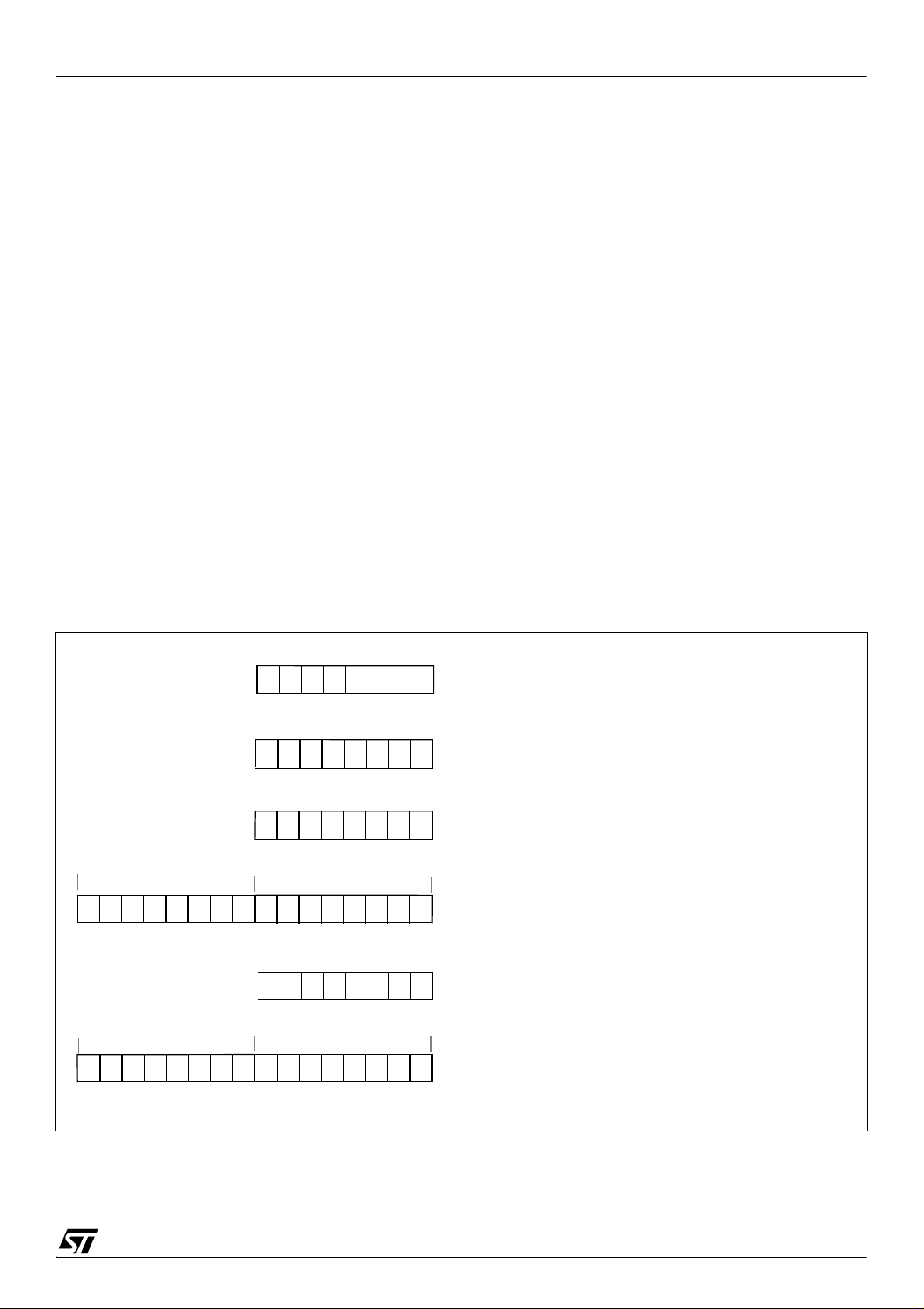

Figure 1. General Block Diagram

Internal

CLOCK

V

V

RESET

DD

SS

1 MHz. RC OSC

+

PLL x 4 or x 8

LVD/AVD

POWER

SUPPLY

CONTROL

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibility to

software developers, enabling the design of highly

efficient and compact application code. In addition

to standard 8-bit data management, all ST7 microcontrollers feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing

modes.

For easy reference, all parametric data are located

in section 13 on page 81.

LITE TIMER

w/ WATCHDOG

PORT A

ADDRESS AND DATA BUS

12-BIT AUTO-

RELOAD TIMER

PA7:0

(8 bits)

8-BIT CORE

ALU

FLASH

MEMORY

(1 or 1.5K Bytes)

RAM

(128 Bytes)

DATA EEPROM

(128 Bytes)

SPI

PORT B

8-BIT ADC

PB4:0

(5 bits)

5/124

1

Page 6

ST7LITE0xY0, ST7LITESxY0

2 PIN DESCRIPTION

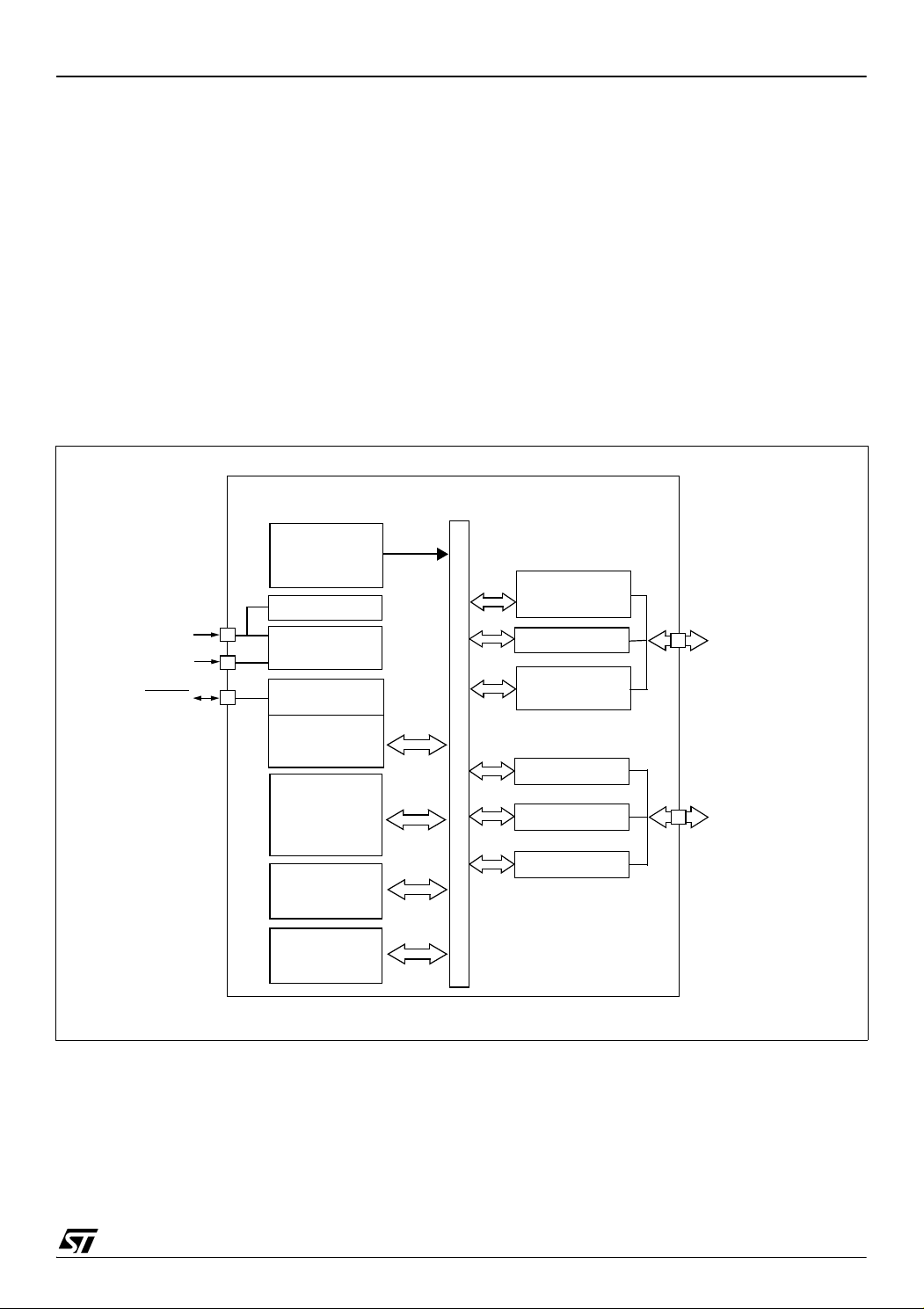

Figure 2. 20-Pin QFN Package Pinout

RESET

NC

NC

NC

MISO/AIN2/PB2

SCK/AIN1/PB1

DD

V

PB0/SS/AIN0

1

2

3

4

5

ei2

6

78 910

ei1

SS

PA0 (HS)/LTIC

V

17181920

16

e0e3

PA1 (HS)

15

PA2 (HS)/ATPWM0

PA3 (HS)

14

NC

13

12

PA4 (HS)

11

PA5 (HS)/ICCDATA

MOSI/AIN3/PB3

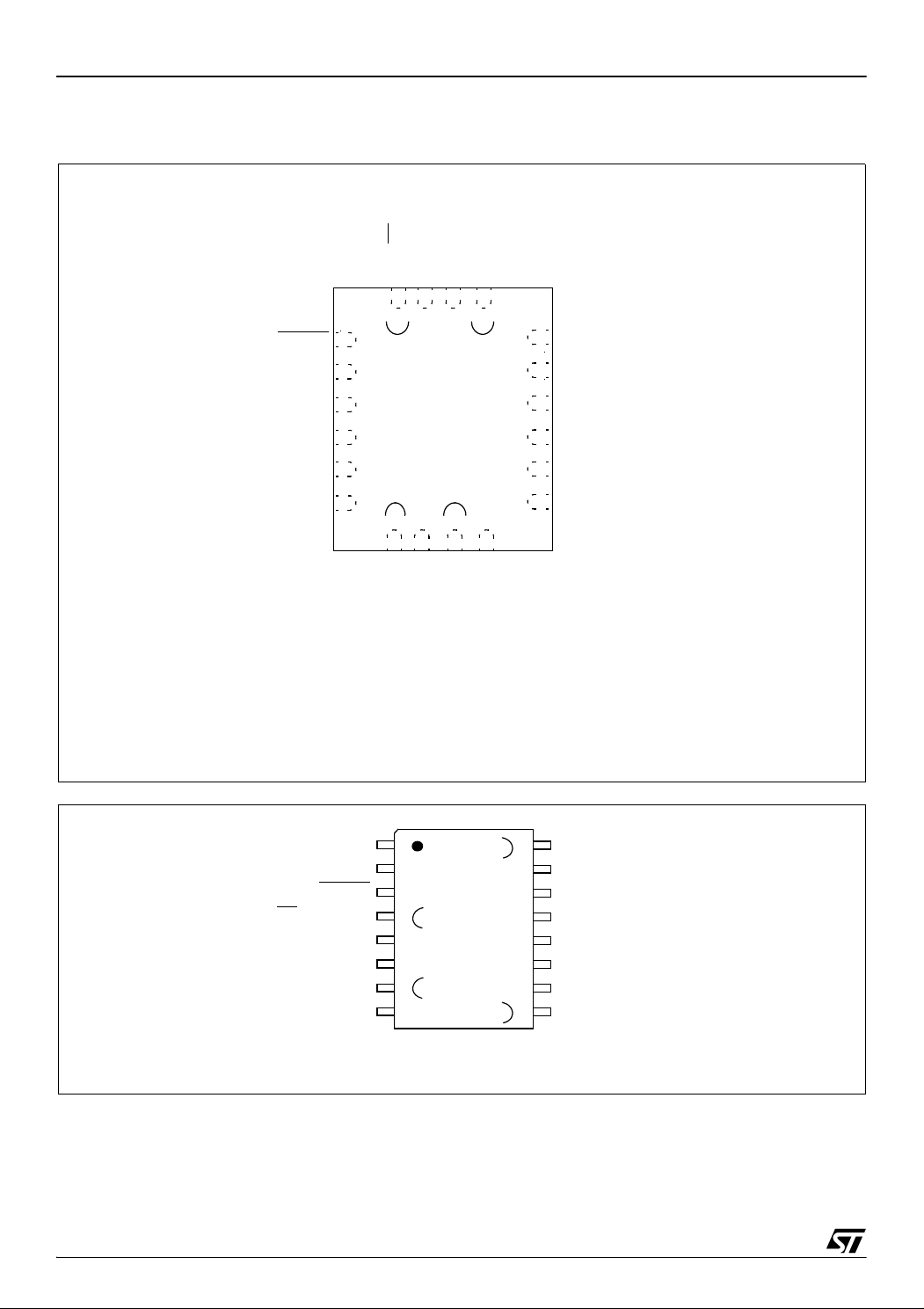

Figure 3. 16-Pin SO and DIP Package Pinout

k

V

V

RESET

SS/AIN0/PB0

SCK/AIN1/PB1

MISO/AIN2/PB2

MOSI/AIN3/PB3

CLKIN/AIN4/PB4

SS

DD

1

2

3

4

5

6

7

8

PA7

CLKIN/AIN4/PB4

ei3

ei2

MCO/ICCCLK/PA6

ei0

ei1

PA0 (HS)/LTIC

16

PA1 (HS)

15

PA2 (HS)/ATPWM0

14

PA3 (HS)

13

PA4 (HS)

12

PA5 (HS)/ICCDATA

11

PA6/MCO/ICCCLK

10

PA7

9

(HS) 20mA High sink capability

eix associated external interrupt vector

(HS) 20mA high sink capability

eixassociated external interrupt vector

6/124

1

Page 7

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations for Table 1:

Type: I = input, O = output, S = supply

In/Output level: C= CMOS 0.15V

= CMOS 0.3VDD/0.7VDD with input trigger

C

T

/0.85VDD with input trigger

DD

Output level: HS = 20mA high sink (on N-buffer only)

Port and control configuration:

– Input: float = floating, wpu = weak pull-up, int = interrupt

– Output: OD = open drain, PP = push-pull

Table 1. Device Pin Description

ST7LITE0xY0, ST7LITESxY0

1)

, ana = analog

Pin n°

Pin Name

Type

QFN20

SO16/DIP16

18 1 V

19 2 V

1 3 RESET

SS

DD

I/O C

20 4 PB0/AIN0/SS

S Ground

S Main power supply

I/O C

6 5 PB1/AIN1/SCK I/O C

5 6 PB2/AIN2/MISO I/O C

7 7 PB3/AIN3/MOSI I/O C

8 8 PB4/AIN4/CLKIN I/O C

9 9 PA7 I/O C

10 10

11 11

PA6 /MCO/

ICCCLK

PA5/

ICCDATA

I/O C

I/O C

12 12 PA4 I/O C

14 13 PA3 I/O C

Level Port / Control

Main

Function

(after reset)

PP

Alternate Function

ADC Analog Input 0 or SPI Slave

Select (active low)

Input

Input Output

Output

float

T

X ei3 X X X Port B0

T

wpu

int

ana

OD

X X Top priority non maskable interrupt (active low)

ADC Analog Input 1 or SPI Clock

Caution: No negative current in-

X XXXXPort B1

T

jection allowed on this pin. For

details, refer to section 13.2.2 on

page 82

X XXXXPort B2

T

X ei2 X X X Port B3

T

X XXXXPort B4

T

X ei1 X X Port A7

T

ADC Analog Input 2 or SPI Master In/ Slave Out Data

ADC Analog Input 3 or SPI Master Out / Slave In Data

ADC Analog Input 4 or External

clock input

Main Clock Output/In Circuit

Communication Clock.

Caution: During normal operation this pin must be pulled- up,

internally or externally (external

X X XXPort A6

T

pull-up of 10k mandatory in noisy

environment). This is to avoid entering ICC mode unexpectedly

during a reset. In the application,

even if the pin is configured as

output, any reset will put it back in

input pull-up

HS X XXXPort A5 In Circuit Communication Data

T

HS X XXXPort A4

T

HS X XXXPort A3

T

7/124

1

Page 8

ST7LITE0xY0, ST7LITESxY0

Pin n°

Pin Name

QFN20

SO16/DIP16

15 14 PA2/ATPWM0 I/O CTHS X XXXPort A2 Auto-Reload Timer PWM0

16 15 PA1 I/O C

17 16 PA0/LTIC I/O C

Level Port / Control

Input Output

Type

Input

Output

float

HS X XXXPort A1

T

HS X ei0 X X Port A0 Lite Timer Input Capture

T

int

wpu

OD

ana

Main

Function

(after reset)

PP

Alternate Function

Note:

In the interrupt input column, “ei

” defines the associated external interrupt vector. If the weak pull-up col-

x

umn (wpu) is merged with the interrupt column (int), then the I/O configuration is pull-up interrupt input,

else the configuration is floating interrupt input.

8/124

1

Page 9

3 REGISTER & MEMORY MAP

ST7LITE0xY0, ST7LITESxY0

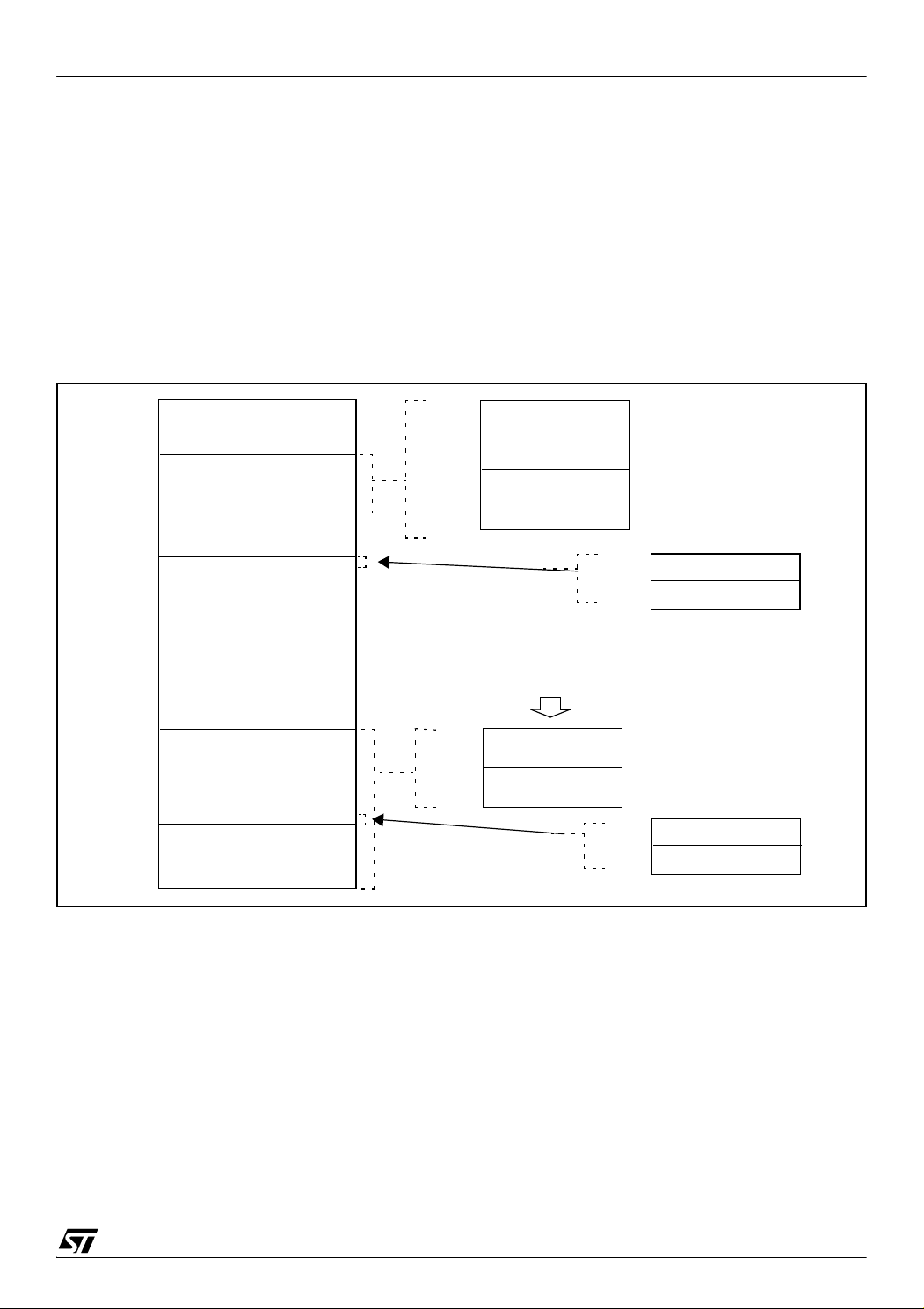

As shown in Figure 4 and Figure 5, the MCU is capable of addressing 64K bytes of memories and I/

O registers.

The available memory locations consist of up to

128 bytes of register locations, 128 bytes of RAM,

128 bytes of data EEPROM and up to 1.5 Kbytes

of user program memory. The RAM space includes up to 64 bytes for the stack from 0C0h to

0FFh.

Figure 4. Memory Map (ST7LITE0x)

0000h

007Fh

0080h

00FFh

0100h

0FFFh

1000h

107Fh

1080h

HW Registers

(see Table 2)

RAM

(128 Bytes)

Reserved

Data EEPROM

(128 Bytes)

0080h

00BFh

00C0h

00FFh

The highest address bytes contain the user reset

and interrupt vectors.

The size of Flash Sector 0 is configurable by Option byte.

IMPORTANT: Memory locations marked as “Reserved” must never be accessed. Accessing a reserved area can have unpredictable effects on the

device.

Short Addressing

RAM (zero page)

64 Bytes Stack

1000h

1001h

see section 7.1 on page 24

RCCR0

RCCR1

F9FFh

FA00h

FFDFh

FFE0h

FFFFh

Reserved

Flash Memory

(1.5K)

Interrupt & Reset Vectors

(see Table 6)

PROGRAM MEMORY

FA00h

FBFFh

FC00h

FFFFh

1.5K FLASH

0.5 Kbytes

SECTOR 1

1 Kbytes

SECTOR 0

FFDEh

RCCR0

FFDFh

RCCR1

see section 7.1 on page 24

9/124

1

Page 10

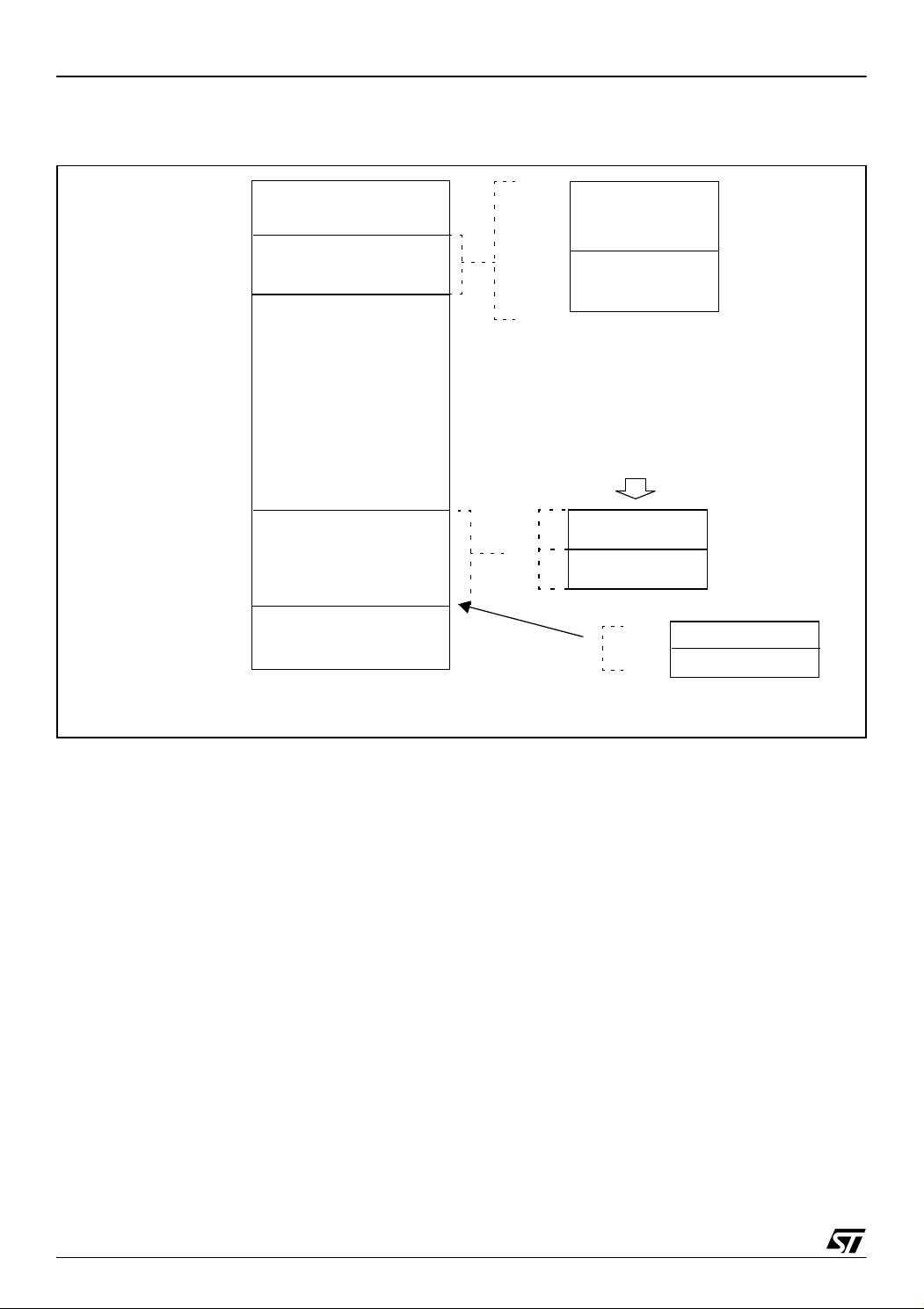

ST7LITE0xY0, ST7LITESxY0

REGISTER AND MEMORY MAP (Cont’d)

Figure 5. Memory Map (ST7SUPERLITE)

0000h

007Fh

0080h

00FFh

0100h

FBFFh

FC00h

FFDFh

FFE0h

FFFFh

HW Registers

(see Table 2)

RAM

(128 Bytes)

Reserved

Flash Memory

(1K)

Interrupt & Reset Vectors

(see Table 6)

FC00h

FDFFh

FE00h

FFFFh

0080h

00BFh

00C0h

00FFh

Short Addressing

RAM (zero page)

64 Bytes Stack

1K FLASH

PROGRAM MEMORY

0.5 Kbytes

SECTOR 1

0.5 Kbytes

SECTOR 0

FFDEh

FFDFh

see section 7.1 on page 24

RCCR0

RCCR1

10/124

1

Page 11

REGISTER AND MEMORY MAP (Cont’d)

Legend: x=undefined, R/W=read/write

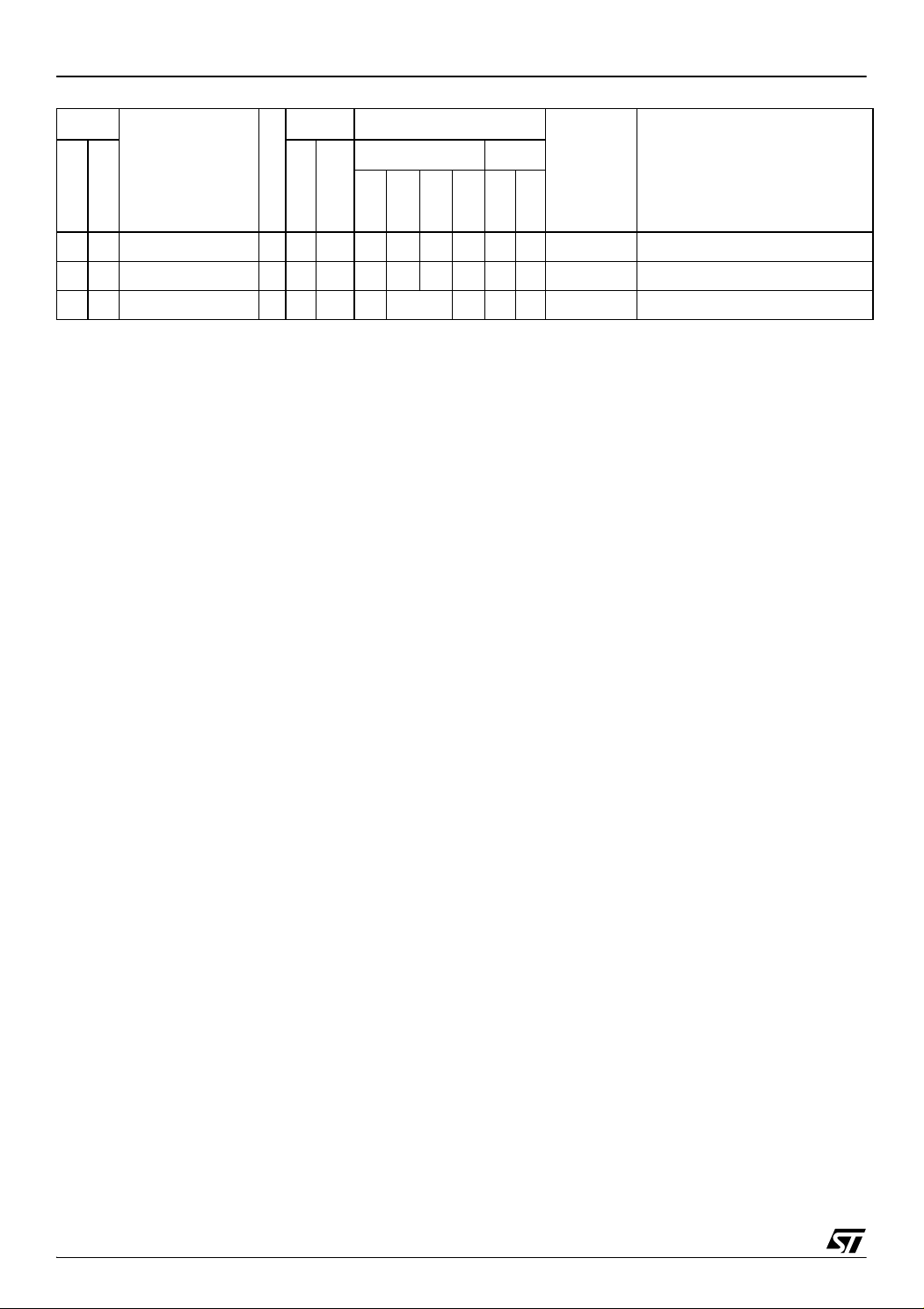

Table 2. Hardware Register Map

ST7LITE0xY0, ST7LITESxY0

Address Block

0000h

0001h

0002h

0003h

0004h

0005h

0006h to

000Ah

000Bh

000Ch

000Dh

000Eh

000Fh

0010h

0011h

0012h

0013h

0014h to

0016h

0017h

0018h

Port A

Port B

LITE

TIMER

AUTO-RELOAD

TIMER

AUTO-RELOAD

TIMER

Register

Label

PADR

PADDR

PAOR

PBDR

PBDDR

PBOR

LTCSR

LTICR

ATCSR

CNTRH

CNTRL

ATRH

ATRL

PWMCR

PWM0CSR

DCR0H

DCR0L

Register Name

Port A Data Register

Port A Data Direction Register

Port A Option Register

Port B Data Register

Port B Data Direction Register

Port B Option Register

Reserved area (5 bytes)

Lite Timer Control/Status Register

Lite Timer Input Capture Register

Timer Control/Status Register

Counter Register High

Counter Register Low

Auto-Reload Register High

Auto-Reload Register Low

PWM Output Control Register

PWM 0 Control/Status Register

Reserved area (3 bytes)

PWM 0 Duty Cycle Register High

PWM 0 Duty Cycle Register Low

Reset

Status

1)

00h

00h

40h

1)

E0h

00h

00h

xxh

xxh

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

2)

R/W

R/W

Read Only

R/W

Read Only

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

0019h to

002Eh

0002Fh FLASH FCSR Flash Control/Status Register 00h R/W

00030h EEPROM EECSR Data EEPROM Control/Status Register 00h R/W

0031h

0032h

0033h

0034h

0035h

0036h

0037h ITC EICR External Interrupt Control Register 00h R/W

0038h

0039h

SPI

ADC

CLOCKS

SPIDR

SPICR

SPICSR

ADCCSR

ADCDR

ADCAMP

MCCSR

RCCR

SPI Data I/O Register

SPI Control Register

SPI Control/Status Register

A/D Control Status Register

A/D Data Register

A/D Amplifier Control Register

Main Clock Control/Status Register

RC oscillator Control Register

Reserved area (22 bytes)

xxh

0xh

00h

00h

00h

00h

00h

FFh

R/W

R/W

R/W

R/W

Read Only

R/W

R/W

R/W

11/124

1

Page 12

ST7LITE0xY0, ST7LITESxY0

Address Block

003Ah SI SICSR System Integrity Control/Status Register 0xh R/W

003Bh to

007Fh

Register

Label

Register Name

Reserved area (69 bytes)

Reset

Status

Remarks

Notes:

1. The contents of the I/O port DR registers are readable only in output configuration. In input configura-

tion, the values of the I/O pins are returned instead of the DR register contents.

2. The bits associated with unavailable pins must always keep their reset value.

12/124

1

Page 13

4 FLASH PROGRAM MEMORY

ST7LITE0xY0, ST7LITESxY0

4.1 Introduction

The ST7 single voltage extended Flash (XFlash) is

a non-volatile memory that can be electrically

erased and programmed either on a byte-by-byte

basis or up to 32 bytes in parallel.

The XFlash devices can be programmed off-board

(plugged in a programming tool) or on-board using

In-Circuit Programming or In-Application Programming.

The array matrix organisation allows each sector

to be erased and reprogrammed without affecting

other sectors.

4.2 Main Features

■ ICP (In-Circuit Programming)

■ IAP (In-Application Programming)

■ ICT (In-Circuit Testing) for downloading and

executing user application test patterns in RAM

■ Sector 0 size configurable by option byte

■ Read-out and write protection

4.3 PROGRAMMING MODES

The ST7 can be programmed in three different

ways:

– Insertion in a programming tool. In this mode,

FLASH sectors 0 and 1, option byte row and

data EEPROM can be programmed or

erased.

– In-Circuit Programming. In this mode, FLASH

sectors 0 and 1, option byte row and data

EEPROM can be programmed or erased without removing the device from the application

board.

– In-Application Programming. In this mode,

sector 1 and data EEPROM can be programmed or erased without removing the device from the application board and while the

application is running.

4.3.1 In-Circuit Programming (ICP)

ICP uses a protocol called ICC (In-Circuit Communication) which allows an ST7 plugged on a printed circuit board (PCB) to communicate with an external programming device connected via cable.

ICP is performed in three steps:

Switch the ST7 to ICC mode (In-Circuit Communications). This is done by driving a specific signal

sequence on the ICCCLK/DATA pins while the

RESET pin is pulled low. When the ST7 enters

ICC mode, it fetches a specific RESET vector

which points to the ST7 System Memory containing the ICC protocol routine. This routine enables

the ST7 to receive bytes from the ICC interface.

– Download ICP Driver code in RAM from the

ICCDATA pin

– Execute ICP Driver code in RAM to program

the FLASH memory

Depending on the ICP Driver code downloaded in

RAM, FLASH memory programming can be fully

customized (number of bytes to program, program

locations, or selection of the serial communication

interface for downloading).

4.3.2 In Application Programming (IAP)

This mode uses an IAP Driver program previously

programmed in Sector 0 by the user (in ICP

mode).

This mode is fully controlled by user software. This

allows it to be adapted to the user application, (user-defined strategy for entering programming

mode, choice of communications protocol used to

fetch the data to be stored etc.)

IAP mode can be used to program any memory areas except Sector 0, which is write/erase protected to allow recovery in case errors occur during

the programming operation.

13/124

1

Page 14

ST7LITE0xY0, ST7LITESxY0

FLASH PROGRAM MEMORY (Cont’d)

4.4 ICC interface

ICP needs a minimum of 4 and up to 6 pins to be

connected to the programming tool. These pins

are:

– RESET

–V

: device reset

: device power supply ground

SS

– ICCCLK: ICC output serial clock pin

– ICCDATA: ICC input serial data pin

– CLKIN: main clock input for external source

: application board power supply (option-

–V

DD

al, see Note 3)

Notes:

1. If the ICCCLK or ICCDATA pins are only used

as outputs in the application, no signal isolation is

necessary. As soon as the Programming Tool is

plugged to the board, even if an ICC session is not

in progress, the ICCCLK and ICCDATA pins are

not available for the application. If they are used as

inputs by the application, isolation such as a serial

resistor has to be implemented in case another device forces the signal. Refer to the Programming

Tool documentation for recommended resistor values.

2. During the ICP session, the programming tool

must control the RESET

pin. This can lead to conflicts between the programming tool and the application reset circuit if it drives more than 5mA at

Figure 6. Typical ICC Interface

high level (push pull output or pull-up resistor<1K).

A schottky diode can be used to isolate the application RESET circuit in this case. When using a

classical RC network with R>1K or a reset management IC with open drain output and pull-up resistor>1K, no additional components are needed.

In all cases the user must ensure that no external

reset is generated by the application during the

ICC session.

3. The use of Pin 7 of the ICC connector depends

on the Programming Tool architecture. This pin

must be connected when using most ST Programming Tools (it is used to monitor the application

power supply). Please refer to the Programming

Tool manual.

4. Pin 9 has to be connected to the CLKIN pin of

the ST7 when the clock is not available in the application or if the selected clock option is not programmed in the option byte.

Caution: During normal operation, ICCCLK pin

must be pulled- up, internally or externally (external pull-up of 10K mandatory in noisy environment). This is to avoid entering ICC mode unexpectedly during a reset. In the application, even if

the pin is configured as output, any reset will put it

back in input pull-up.

APPLICATION

POWER SUPPLY

14/124

(See Note 3)

VDD

OPTIONAL

(See Note 4)

CLKIN

ST7

PROGRAMMING TOOL

ICC CONNECTOR

ICC Cable

ICC CONNECTOR

HE10 CONNECTOR TYPE

975 3

1

246810

RESET

ICCCLK

ICCDATA

APPLICATION BOARD

APPLICATION

RESET SOURCE

See Note 2

See Note 1 and Caution

See Note 1

APPLICATION

I/O

1

Page 15

FLASH PROGRAM MEMORY (Cont’d)

ST7LITE0xY0, ST7LITESxY0

4.5 Memory Protection

There are two different types of memory protection: Read Out Protection and Write/Erase Protection which can be applied individually.

4.5.1 Read out Protection

Readout protection, when selected provides a protection against program memory content extraction and against write access to Flash memory.

Even if no protection can be considered as totally

unbreakable, the feature provides a very high level

of protection for a general purpose microcontroller.

Both program and data E

2

memory are protected.

In flash devices, this protection is removed by reprogramming the option. In this case, both program and data E

2

memory are automatically

erased, and the device can be reprogrammed.

Read-out protection selection depends on the de-

vice type:

– In Flash devices it is enabled and removed

through the FMP_R bit in the option byte.

– In ROM devices it is enabled by mask option

specified in the Option List.

4.5.2 Flash Write/Erase Protection

Write/erase protection, when set, makes it impossible to both overwrite and erase program memory. It does not apply to E

2

data. Its purpose is to

provide advanced security to applications and prevent any change being made to the memory content.

Warning: Once set, Write/erase protection can

never be removed. A write-protected flash device

is no longer reprogrammable.

Write/erase protection is enabled through the

FMP_W bit in the option byte.

4.6 Related Documentation

For details on Flash programming and ICC protocol, refer to the ST7 Flash Programming Reference Manual and to the ST7 ICC Protocol Reference Manual

.

4.7 Register Description

FLASH CONTROL/STATUS REGISTER (FCSR)

Read/Write

Reset Value: 000 0000 (00h)

1st RASS Key: 0101 0110 (56h)

2nd RASS Key: 1010 1110 (AEh)

70

00000OPTLATPGM

Note: This register is reserved for programming

using ICP, IAP or other programming methods. It

controls the XFlash programming and erasing operations.

When an EPB or another programming tool is

used (in socket or ICP mode), the RASS keys are

sent automatically.

Table 3. FLASH Register Map and Reset Values

Address

(Hex.)

002Fh

Register

Label

FCSR

Reset Value

76543210

00000

OPT

0

LAT

0

PGM

0

15/124

1

Page 16

ST7LITE0xY0, ST7LITESxY0

5 DATA EEPROM

5.1 INTRODUCTION

The Electrically Erasable Programmable Read

Only Memory can be used as a non-volatile backup for storing data. Using the EEPROM requires a

basic access protocol described in this chapter.

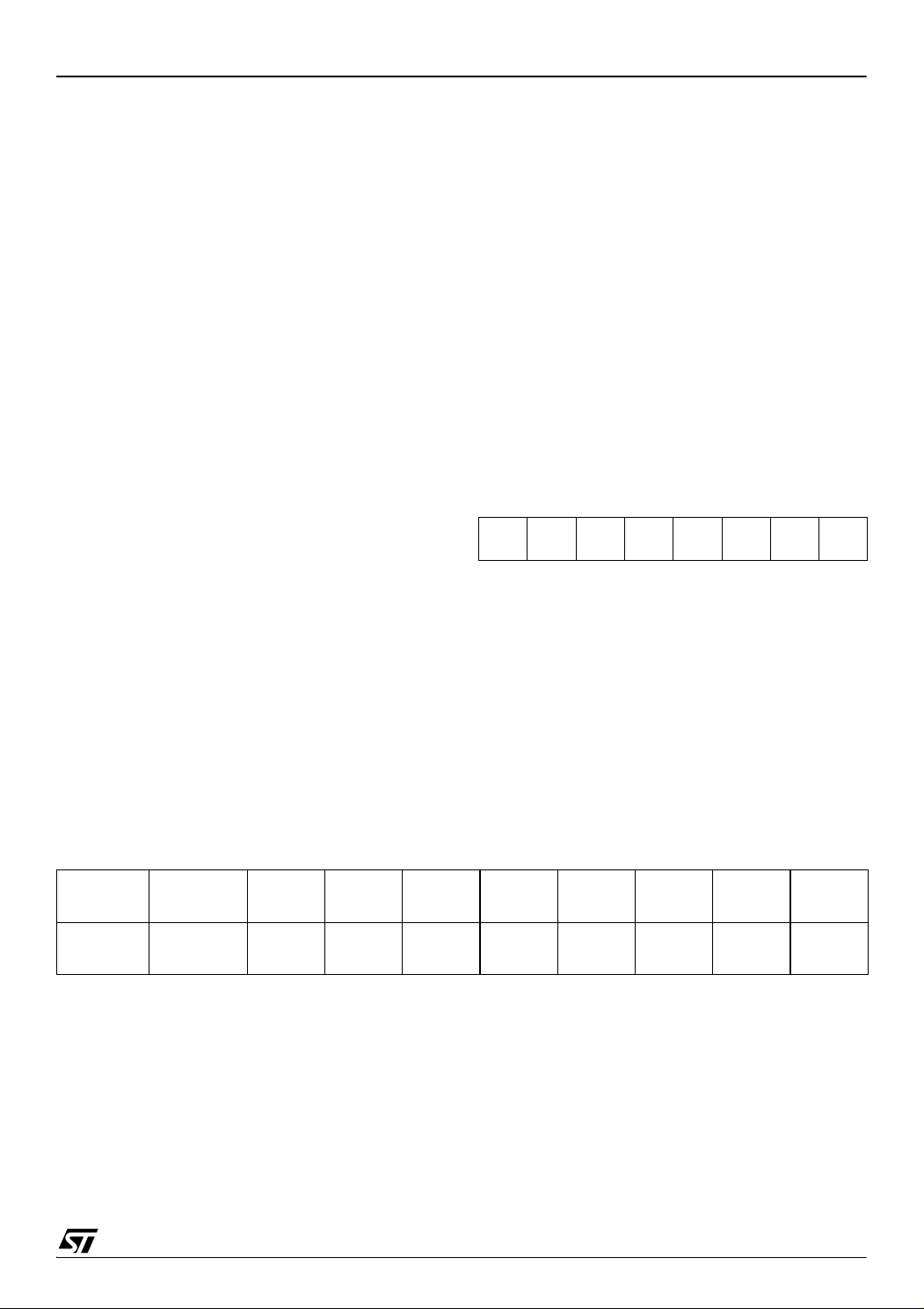

Figure 7. EEPROM Block Diagram

EECSR

ADDRESS

DECODER

0 E2LAT00 0 0 0 E2PGM

4

DECODER

ROW

5.2 MAIN FEATURES

■ Up to 32 bytes programmed in the same cycle

■ EEPROM mono-voltage (charge pump)

■ Chained erase and programming cycles

■ Internal control of the global programming cycle

duration

■ WAIT mode management

■ Read-out protection

HIGH VOLTAGE

PUMP

EEPROM

MEMORY MATRIX

(1 ROW = 32 x 8 BITS)

ADDRESS BUS

128128

4

4

DATA

MULTIPLEXER

DATA BUS

32 x 8 BITS

DATA LATCHES

16/124

1

Page 17

DATA EEPROM (Cont’d)

ST7LITE0xY0, ST7LITESxY0

5.3 MEMORY ACCESS

The Data EEPROM memory read/write access

modes are controlled by the E2LAT bit of the EEPROM Control/Status register (EECSR). The flowchart in Figure 8 describes these different memory

access modes.

Read Operation (E2LAT = 0)

The EEPROM can be read as a normal ROM location when the E2LAT bit of the EECSR register is

cleared.

On this device, Data EEPROM can also be used to

execute machine code. Take care not to write to

the Data EEPROM while executing from it. This

would result in an unexpected code being executed.

Write Operation (E2LAT = 1)

To access the write mode, the E2LAT bit has to be

set by software (the E2PGM bit remains cleared).

When a write access to the EEPROM area occurs,

Figure 8. Data EEPROM Programming Flowchart

READ MODE

E2LAT = 0

E2PGM = 0

the value is latched inside the 32 data latches according to its address.

When PGM bit is set by the software, all the previous bytes written in the data latches (up to 32) are

programmed in the EEPROM cells. The effective

high address (row) is determined by the last EEPROM write sequence. To avoid wrong programming, the user must take care that all the bytes

written between two programming sequences

have the same high address: Only the five Least

Significant Bits of the address can change.

At the end of the programming cycle, the PGM and

LAT bits are cleared simultaneously.

Note: Care should be taken during the programming cycle. Writing to the same memory location

will over-program the memory (logical AND between the two write access data result) because

the data latches are only cleared at the end of the

programming cycle and by the falling edge of the

E2LAT bit.

It is not possible to read the latched data.

This note is illustrated by the Figure 10.

WRITE MODE

E2LAT = 1

E2PGM = 0

READ BYTES

IN EEPROM AREA

CLEARED BY HARDWARE

WRITEUPTO32BYTES

(with the same 11 MSB of the address)

IN EEPROM AREA

START PROGRAMMING CYCLE

E2PGM=1 (set by software)

E2LAT=1

01

E2LAT

17/124

1

Page 18

ST7LITE0xY0, ST7LITESxY0

DATA EEPROM (Cont’d)

2

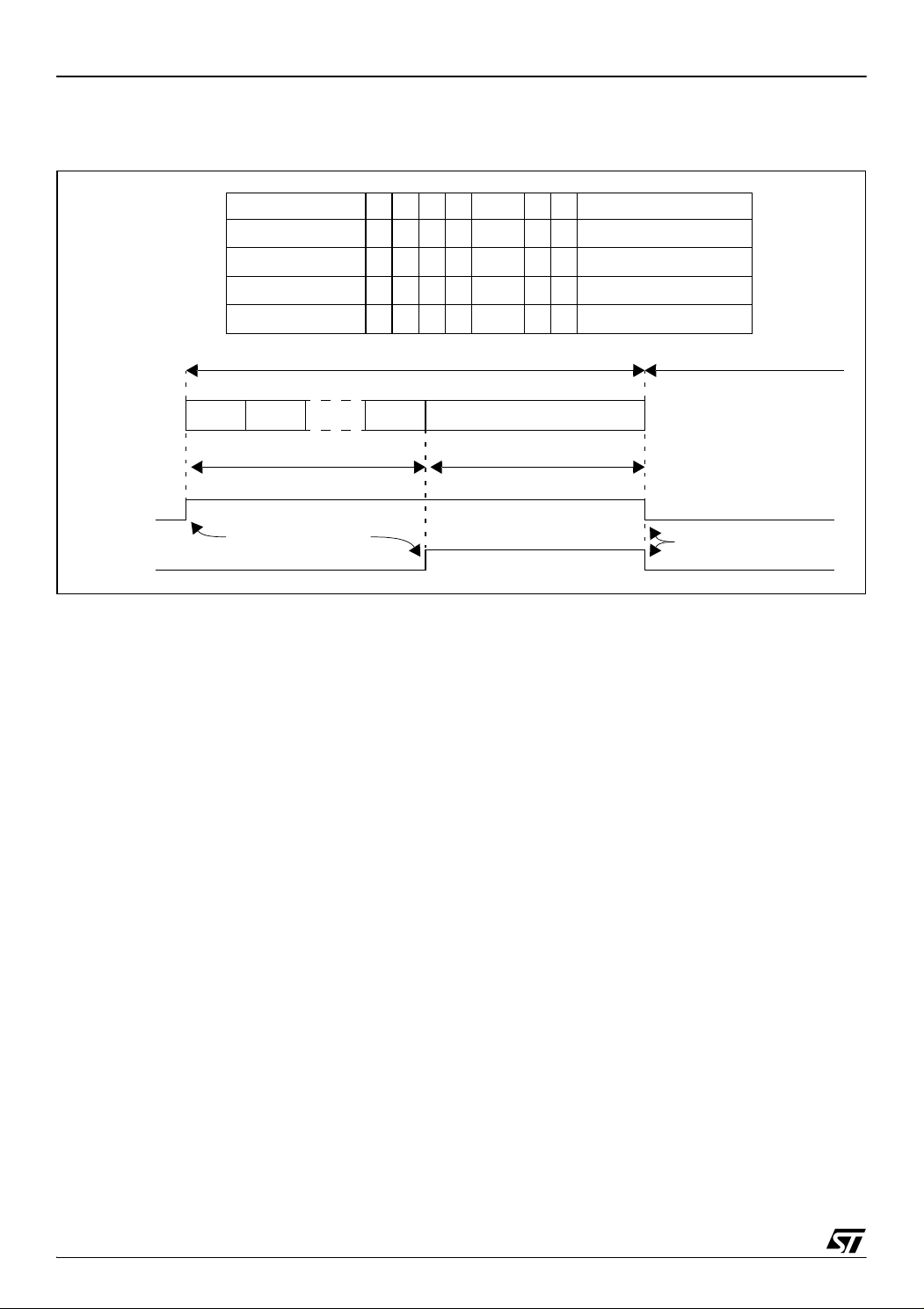

Figure 9. Data E

DEFINITION

PROM Write Operation

⇓ Row / Byte ⇒ 0 1 2 3 ... 30 31 Physical Address

ROW

0

1

...

N

00h...1Fh

20h...3Fh

Nx20h...Nx20h+1Fh

E2LAT bit

E2PGM bit

Read operation impossible

Byte 1 Byte 2 Byte 32

PHASE 1

Writing data latches Waiting E2PGM and E2LAT to fall

Set by USER application

Programming cycle

PHASE 2

Read operation possible

Cleared by hardware

Note: If a programming cycle is interrupted (by RESET action), the integrity of the data in memory will not

be guaranteed.

18/124

1

Page 19

DATA EEPROM (Cont’d)

ST7LITE0xY0, ST7LITESxY0

5.4 POWER SAVING MODES

Wait mode

The DATA EEPROM can enter WAIT mode on execution of the WFI instruction of the microcontroller or when the microcontroller enters Active Halt

mode.The DATA EEPROM will immediately enter

this mode if there is no programming in progress,

otherwise the DATA EEPROM will finish the cycle

and then enter WAIT mode.

Active Halt mode

Refer to Wait mode.

Halt mode

The DATA EEPROM immediately enters HALT

mode if the microcontroller executes the HALT instruction. Therefore the EEPROM will stop the

function in progress, and data may be corrupted.

5.5 ACCESS ERROR HANDLING

If a read access occurs while E2LAT = 1, then the

data bus will not be driven.

If a write access occurs while E2LAT = 0, then the

data on the bus will not be latched.

If a programming cycle is interrupted (by RESET

action), the integrity of the data in memory will not

be guaranteed.

5.6 DATA EEPROM READ-OUT PROTECTION

The read-out protection is enabled through an option bit (see option byte section).

When this option is selected, the programs and

data stored in the EEPROM memory are protected

against read-out (including a re-write protection).

In Flash devices, when this protection is removed

by reprogramming the Option Byte, the entire Program memory and EEPROM is first automatically

erased.

Note: Both Program Memory and data EEPROM

are protected using the same option bit.

Figure 10. Data EEPROM Programming Cycle

READ OPERATION NOT POSSIBLE

INTERNAL

PROGRAMMING

VOLTAGE

ERASE CYCLE WRITE CYCLE

WRITE OF

DATA

LATCHES

t

PROG

READ OPERATION POSSIBLE

LAT

PGM

19/124

1

Page 20

ST7LITE0xY0, ST7LITESxY0

DATA EEPROM (Cont’d)

5.7 REGISTER DESCRIPTION

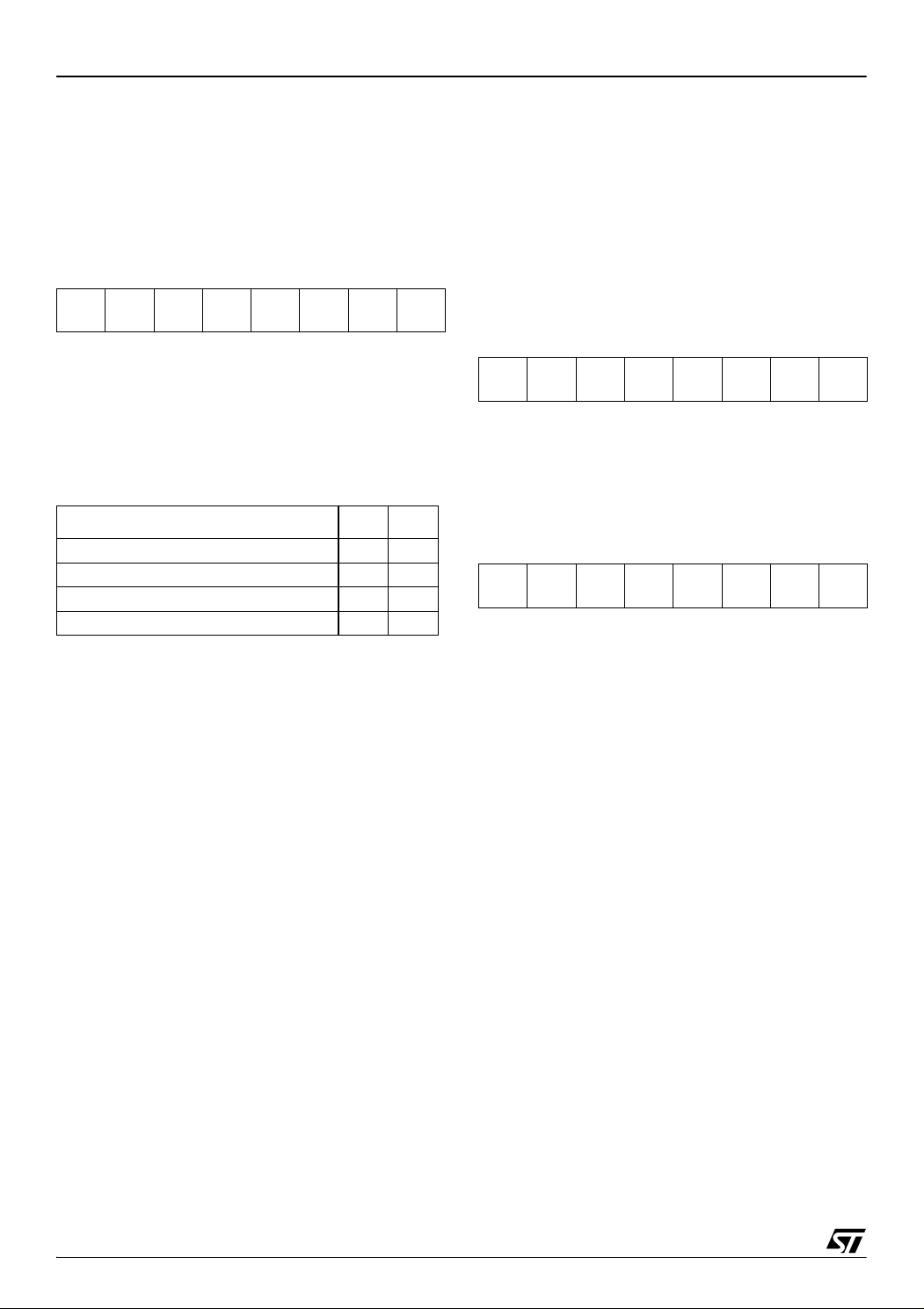

EEPROM CONTROL/STATUS REGISTER (EECSR)

Read/Write

Reset Value: 0000 0000 (00h)

70

000000E2LATE2PGM

Bits 7:2 = Reserved, forced by hardware to 0.

Bit 1 = E2LAT Latch Access Transfer

This bit is set by software. It is cleared by hardware at the end of the programming cycle. It can

only be cleared by software if the E2PGM bit is

cleared.

0: Read mode

1: Write mode

Bit 0 = E2PGM Programming control and status

This bit is set by software to begin the programming

cycle. At the end of the programming cycle, this bit

is cleared by hardware.

0: Programming finished or not yet started

1: Programming cycle is in progress

Note: If the E2PGM bit is cleared during the programming cycle, the memory data is not guaranteed.

Table 4. DATA EEPROM Register Map and Reset Values

Address

(Hex.)

0030h

Register

Label

EECSR

Reset Value

76543210

000000

E2LAT0E2PGM

0

20/124

1

Page 21

6 CENTRAL PROCESSING UNIT

ST7LITE0xY0, ST7LITESxY0

6.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

6.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

6.3 CPU REGISTERS

The six CPU registers shown in Figure 11 are not

present in the memory mapping and are accessed

by specific instructions.

Figure 11. CPU Registers

70

RESET VALUE = XXh

70

RESET VALUE = XXh

70

RESET VALUE = XXh

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures (not pushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

15 8

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

15

RESET VALUE = STACK HIGHER ADDRESS

PCH

RESET VALUE =

7

70

1C11HI NZ

1X11X1XX

70

8

PCL

0

PROGRAM COUNTER

CONDITION CODE REGISTER

STACK POINTER

X = Undefined Value

21/124

1

Page 22

ST7LITE0xY0, ST7LITESxY0

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

70

111HINZC

The 8-bit Condition Code register contains the interrupt mask and four flags representative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Bit 4 = H Half carry.

This bit is set by hardware when a carry occurs be-

tween bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 3 = I Interrupt mask.

This bit is set by hardware when entering in inter-

rupt or by software to disable all interrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlled by the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed when I is cleared.

By default an interrupt routine is not interruptible

because the I bit is set by hardware at the start of

the routine and reset by the IRET instruction at the

end of the routine. If the I bit is cleared by software

in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N Negative.

This bit is set and cleared by hardware. It is repre-

sentative of the result sign of the last arithmetic,

logical or data manipulation. It is a copy of the 7

bit of the result.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(that is, the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL instructions.

Bit 1 = Z Zero.

This bit is set and cleared by hardware. This bit in-

dicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C Carry/borrow.

This bit is set and cleared by hardware and soft-

ware. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

th

22/124

1

Page 23

ST7LITE0xY0, ST7LITESxY0

CPU REGISTERS (Cont’d)

Stack Pointer (SP)

Read/Write

Reset Value: 00 FFh

15 8

00000000

70

1 1 SP5 SP4 SP3 SP2 SP1 SP0

The Stack Pointer is a 16-bit register which is always pointing to the next free location in the stack.

It is then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 12).

Since the stack is 64 bytes deep, the 10 most significant bits are forced by hardware. Following an

MCU Reset, or after a Reset Stack Pointer instruction (RSP), the Stack Pointer contains its reset value (the SP5 to SP0 bits are set) which is the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then overwritten and therefore lost. The stack also wraps in case of an underflow.

The stack is used to save the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by means of the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location pointed to by the SP. Then the

other registers are stored in the next locations as

shown in Figure 12.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locations in the stack area.

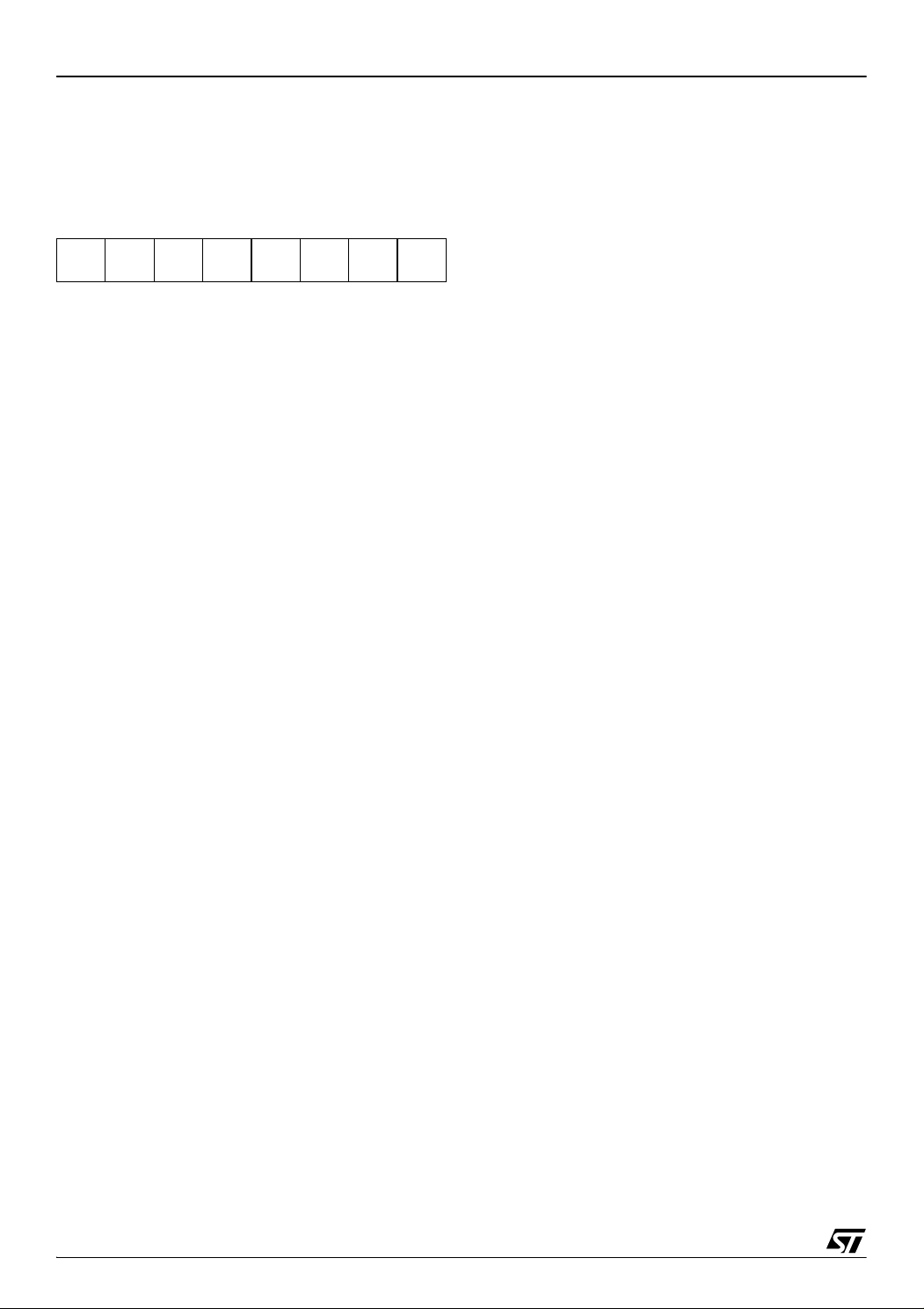

Figure 12. Stack Manipulation Example

@ 00C0h

SP

@ 00FFh

CALL

Subroutine

SP

PCH

PCL

Stack Higher Address = 00FFh

Stack Lower Address =

Interrupt

event

SP

CC

A

X

PCH

PCL

PCH

PCL

00C0h

PUSH Y POP Y IRET

SP

Y

CC

A

X

PCH

PCL

PCH

PCL

CC

A

X

PCH

PCL

PCH

PCL

SP

PCH

PCL

RET

or RSP

SP

23/124

1

Page 24

ST7LITE0xY0, ST7LITESxY0

7 SUPPLY, RESET AND CLOCK MANAGEMENT

The device includes a range of utility features for

securing the application in critical situations (for

example in case of a power brown-out), and reducing the number of external components.

Main features

■ Clock Management

– 1 MHz internal RC oscillator (enabled by op-

tion byte)

– External Clock Input (enabled by option byte)

– PLL for multiplying the frequency by 4 or 8

(enabled by option byte)

■ Reset Sequence Manager (RSM)

■ System Integrity Management (SI)

– Main supply Low voltage detection (LVD) with

reset generation (enabled by option byte)

– Auxiliary Voltage detector (AVD) with interrupt

capability for monitoring the main supply (en-

abled by option byte)

7.1 INTERNAL RC OSCILLATOR ADJUSTMENT

The ST7 contains an internal RC oscillator with an

accuracy of 1% for a given device, temperature

and voltage. It must be calibrated to obtain the frequency required in the application. This is done by

software writing a calibration value in the RCCR

(RC Control Register).

Whenever the microcontroller is reset, the RCCR

returns to its default value (FFh), i.e. each time the

device is reset, the calibration value must be loaded in the RCCR. Predefined calibration values are

stored in EEPROM for 3.0 and 5V V

ages at 25°C, as shown in the following table.

supply volt-

DD

Notes:

– See “ELECTRICAL CHARACTERISTICS” on

page 81. for more information on the frequency

and accuracy of the RC oscillator.

– To improve clock stability and frequency accura-

cy, it is recommended to place a decoupling capacitor, typically 100nF, between the V

pins as close as possible to the ST7 device.

V

SS

DD

and

ST7FLITE05/

ST7FLITES5

Address

FFDEh

FFDFh

RCCR Conditions

=5V

V

DD

=25°C

RCCR0

RCCR1

T

A

=1MHz

f

RC

V

DD

=25°C

T

A

=700KHz

f

RC

=3.0V

ST7FLITE09

Address

1000h and

FFDEh

1001h andFFDFh

– These two bytes are systematically programmed

by ST, including on FASTROM devices. Consequently, customers intending to us e FASTROM

service must not use these two bytes.

– RCCR0 and RCCR1 calibration values will be

erased if the read-out protection bit is reset after

it has been set. See “Read out Protection” on

page 15.

Caution: If the voltage or temperature conditions

change in the application, the frequency may need

to be recalibrated.

Refer to application note AN1324 for information

on how to calibrate the RC frequency using an external reference signal.

7.2 PHASE LOCKED LOOP

The PLL can be used to multiply a 1MHz frequency from the RC oscillator or the external clock by 4

or 8 to obtain f

of 4 or 8 MHz. The PLL is ena-

OSC

bled and the multiplication factor of 4 or 8 is selected by 2 option bits.

– The x4 PLL is intended for operation with V

DD

in

the 2.4V to 3.3V range

– The x8 PLL is intended for operation with V

DD

in

the 3.3V to 5.5V range

Refer to Section 15.1 for the option byte description.

If the PLL is disabled and the RC oscillator is enabled, then f

OSC =

1MHz.

If both the RC oscillator and the PLL are disabled,

is driven by the external clock.

f

OSC

24/124

1

Page 25

ST7LITE0xY0, ST7LITESxY0

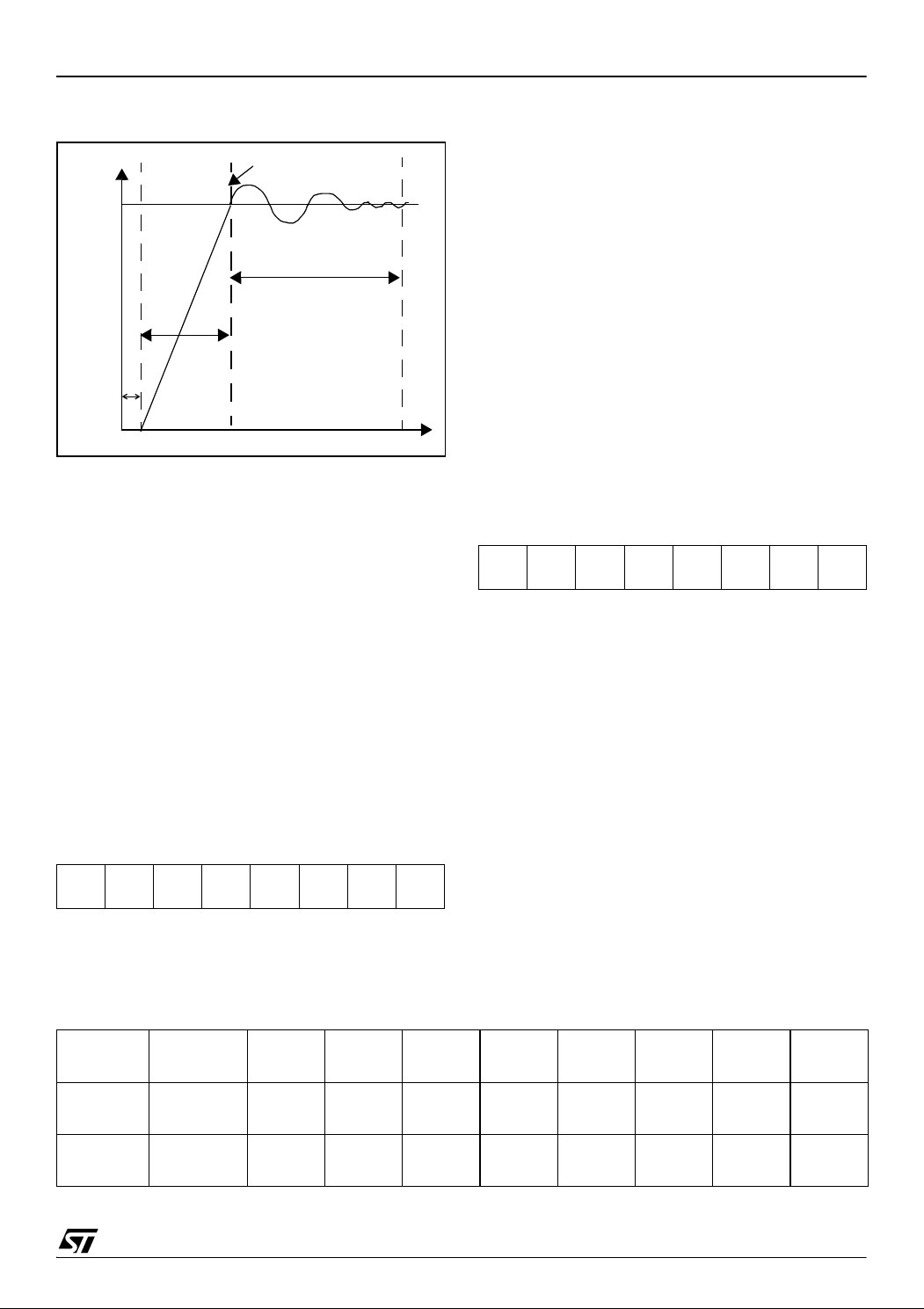

Figure 13. PLL Output Frequency Timing

Diagram

LOCKED bit set

4/8 x

input

freq.

t

STAB

Bit 1 = MCO Main Clock Out enable

This bit is read/write by software and cleared by

hardware after a reset. This bit allows to enable

the MCO output clock.

0: MCO clock disabled, I/O port free for general

purpose I/O.

1: MCO clock enabled.

Bit 0 = SMS Slow Mode select

This bit is read/write by software and cleared by

hardware after a reset. This bit selects the input

OSC

or f

clock f

0: Normal mode (f

1: Slow mode (f

/32.

OSC

CPU = fOSC

CPU = fOSC

/32)

RC CONTROL REGISTER (RCCR)

t

STARTUP

Output freq.

t

LOCK

t

Read / Write

When the PLL is started, after reset or wakeup

Reset Value: 1111 1111 (FFh)

from Halt mode or AWUFH mode, it outputs the

clock after a delay of t

STARTUP

.

70

When the PLL output signal reaches the operating

frequency, the LOCKED bit in the SICSCR register

is set. Full PLL accuracy (ACC

a stabilization time of t

STAB

) is reached after

PLL

(see Figure 13 and

13.3.4 Internal RC Oscillator and PLL)

Refer to section 8.4.4 on page 36 for a description

of the LOCKED bit in the SICSR register.

CR7 CR6 CR5 CR4 CR3 CR2 CR1 CR0

Bits 7:0 = CR[7:0] RC Oscillator Frequency Ad-

justment Bits

These bits must be written immediately after reset

to adjust the RC oscillator frequency and to obtain

an accuracy of 1%. The application can store the

7.3 REGISTER DESCRIPTION

MAIN CLOCK CONTROL/STATUS REGISTER

(MCCSR)

Read / Write

Reset Value: 0000 0000 (00h)

correct value for each voltage range in EEPROM

and write it to this register at start-up.

00h = maximum available frequency

FFh = lowest available frequency

Note: To tune the oscillator, write a series of differ-

ent values in the register until the correct frequen-

70

cy is reached. The fastest method is to use a di-

chotomy starting with 80h.

000000

MCO SMS

Bits 7:2 = Reserved, must be kept cleared.

Table 5. Clock Register Map and Reset Values

Address

(Hex.)

0038h

0039h

Register

Label

MCCSR

Reset Value

RCCR

Reset Value

76543210

000000

CR7

1

CR6

1

CR5

MCO

0

CR4

1

1

CR3

1

CR2

1

CR1

1

SMS

0

CR0

1

25/124

1

Page 26

ST7LITE0xY0, ST7LITESxY0

SUPPLY, RESET AND CLOCK MANAGEMENT (Cont’d)

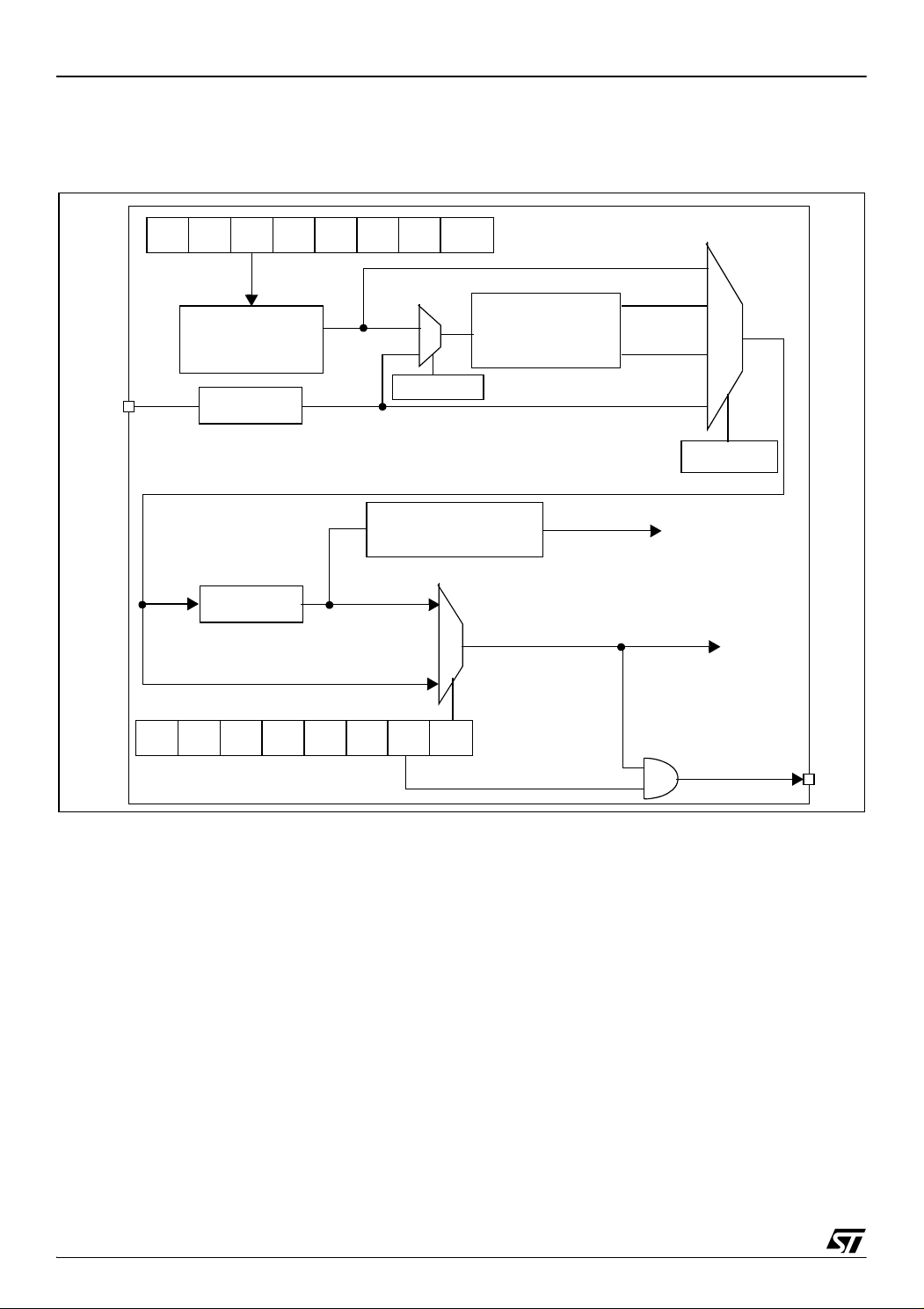

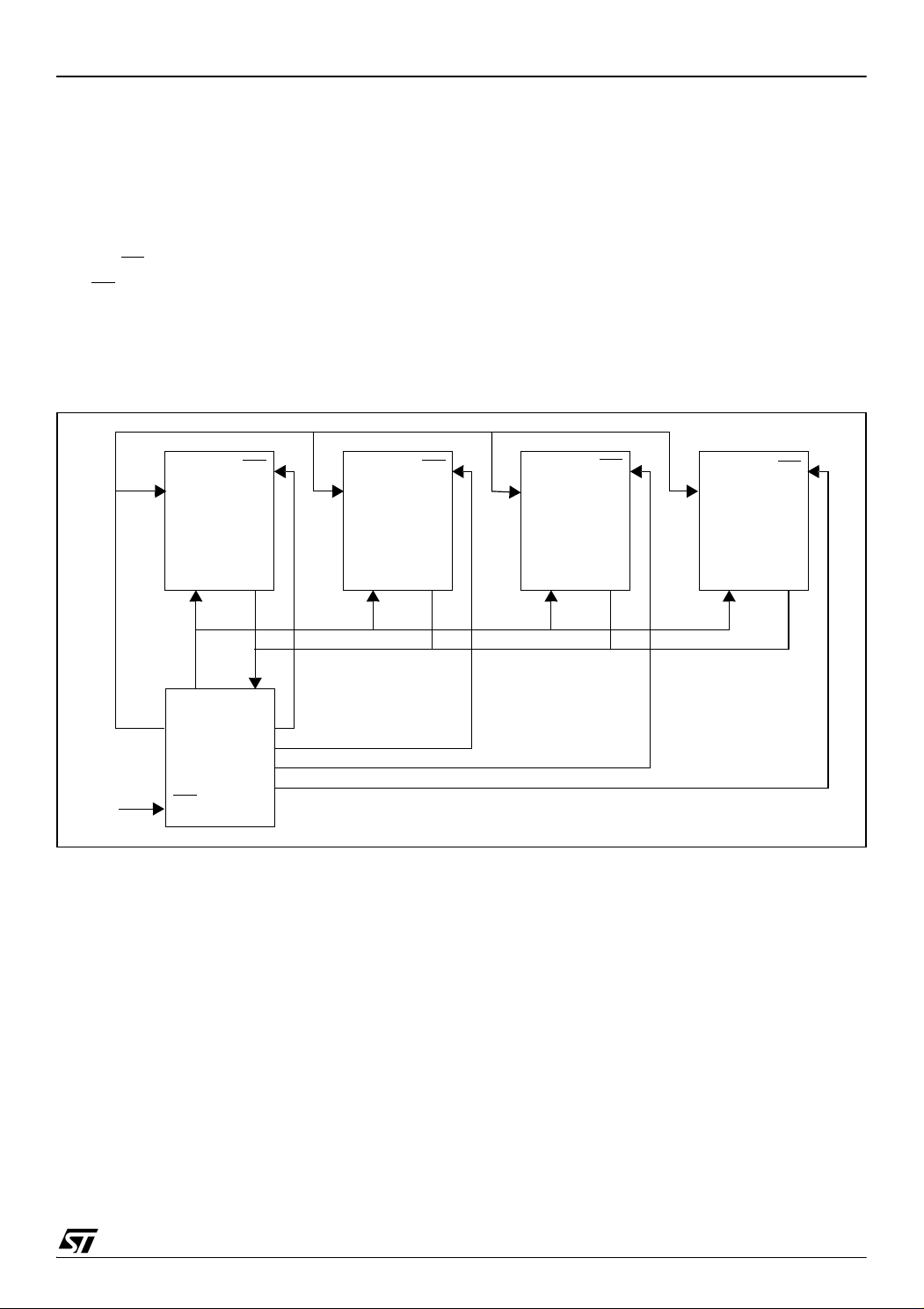

Figure 14. Clock Management Block Diagram

CR4CR7 CR0CR1CR2CR3CR6 CR5

Tunable

Oscillator1% RC

Option byte

CLKIN

/2 DIVIDER

LITE TIMER COUNTER

f

OSC

/32 DIVIDER

f

OSC

f

OSC

/32

MCO

7

PLL 1MHz -> 8MHz

PLL 1MHz -> 4MHz

8-BIT

1

0

MCCSR

SMS

0

RCCR

1MHz

8MHz

4MHz

0 to 8 MHz

Option byte

f

LTIMER

(1ms timebase @ 8 MHz f

f

CPU

TO CPU AND

PERIPHERALS

(except LITE

TIMER)

OSC

f

CPU

f

OSC

)

MCO

26/124

1

Page 27

7.4 RESET SEQUENCE MANAGER (RSM)

ST7LITE0xY0, ST7LITESxY0

7.4.1 Introduction

The reset sequence manager includes three RESET sources as shown in Figure 16:

■ External RESET source pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

Note: A reset can also be triggered following the

detection of an illegal opcode or prebyte code. Refer to section 11.2.1 on page 53 for further details.

These sources act on the RESET

pin and it is al-

ways kept low during the delay phase.

The RESET service routine vector is fixed at ad-

dresses FFFEh-FFFFh in the ST7 memory map.

The basic RESET sequence consists of 3 phases

as shown in Figure 15:

■ Active Phase depending on the RESET source

■ 256 CPU clock cycle delay

■ RESET vector fetch

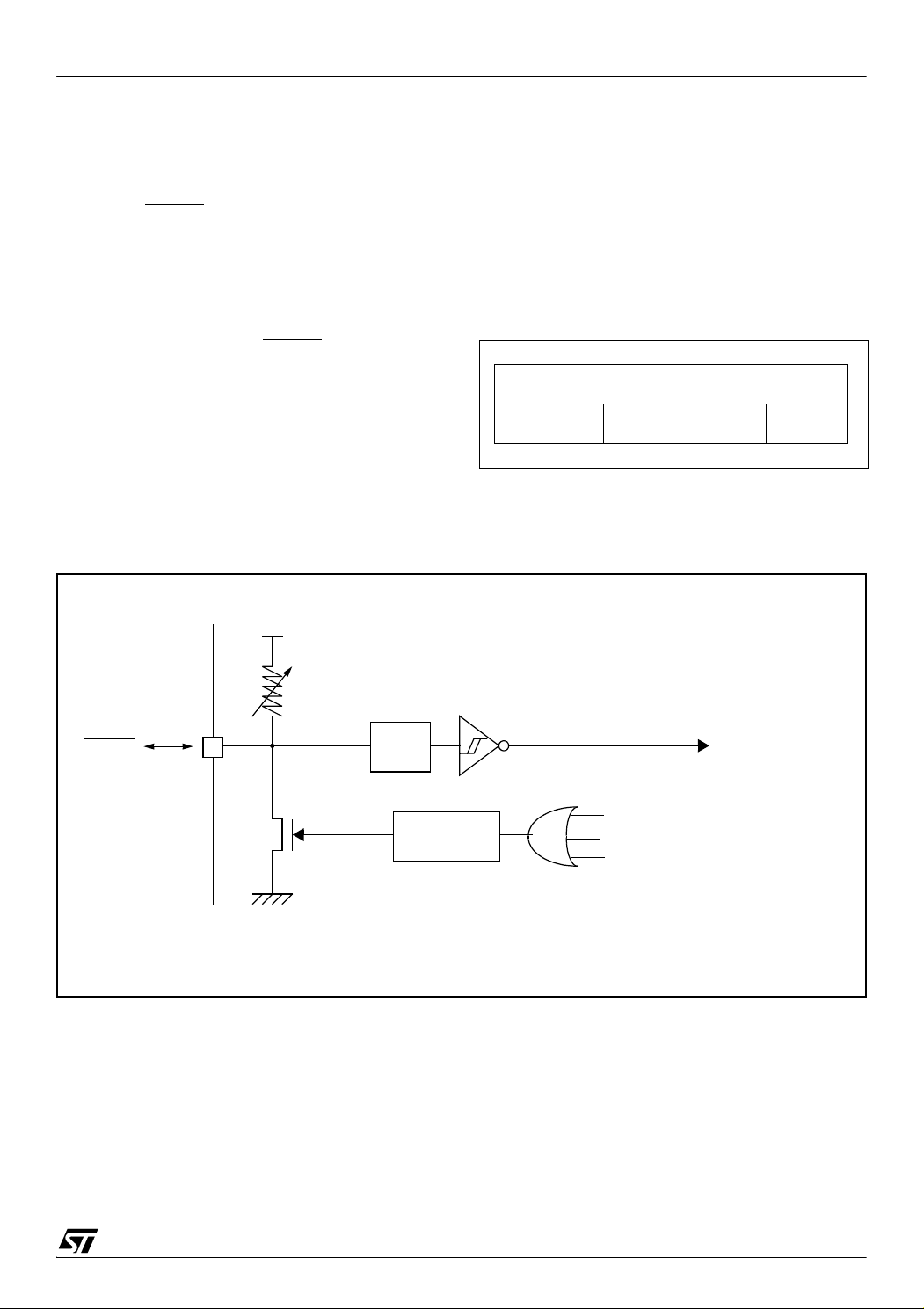

Figure 16.Reset Block Diagram

V

DD

The 256 CPU clock cycle delay allows the oscilla-

tor to stabilise and ensures that recovery has tak-

en place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

If the PLL is enabled by option byte, it outputs the

clock after an additional delay of t

STARTUP

(see

Figure 13).

Figure 15. RESET Sequence Phases

RESET

Active Phase

INTERNAL RESET

256 CLOCK CYCLES

FETCH

VECTOR

R

ON

RESET

Note 1: See “Illegal Opcode Reset” on page 78. for more details on illegal opcode reset conditions.

FILTER

PULSE

GENERATOR

WATCHDOG RESET

ILLEGAL OPCODE RESET

LVD RESET

INTERNAL

RESET

1)

27/124

1

Page 28

ST7LITE0xY0, ST7LITESxY0

RESET SEQUENCE MANAGER (Cont’d)

7.4.2 Asynchronous External RESET

The RESET

output with integrated R

pin is both an input and an open-drain

weak pull-up resistor.

ON

pin

This pull-up has no fixed value but varies in accordance with the input voltage. It

can be pulled

low by external circuitry to reset the device. See

Electrical Characteristic section for more details.

A RESET signal originating from an external

source must have a duration of at least t

h(RSTL)in

in

order to be recognized (see Figure 17). This detection is asynchronous and therefore the MCU

can enter reset state even in HALT mode.

The RESET

pin is an asynchronous signal which

plays a major role in EMS performance. In a noisy

environment, it is recommended to follow the

guidelines mentioned in the electrical characteristics section.

7.4.3 External Power-On RESET

If the LVD is disabled by option byte, to start up the

microcontroller correctly, the user must ensure by

means of an external reset circuit that the reset

signal is held low until V

level specified for the selected f

is over the minimum

DD

frequency.

OSC

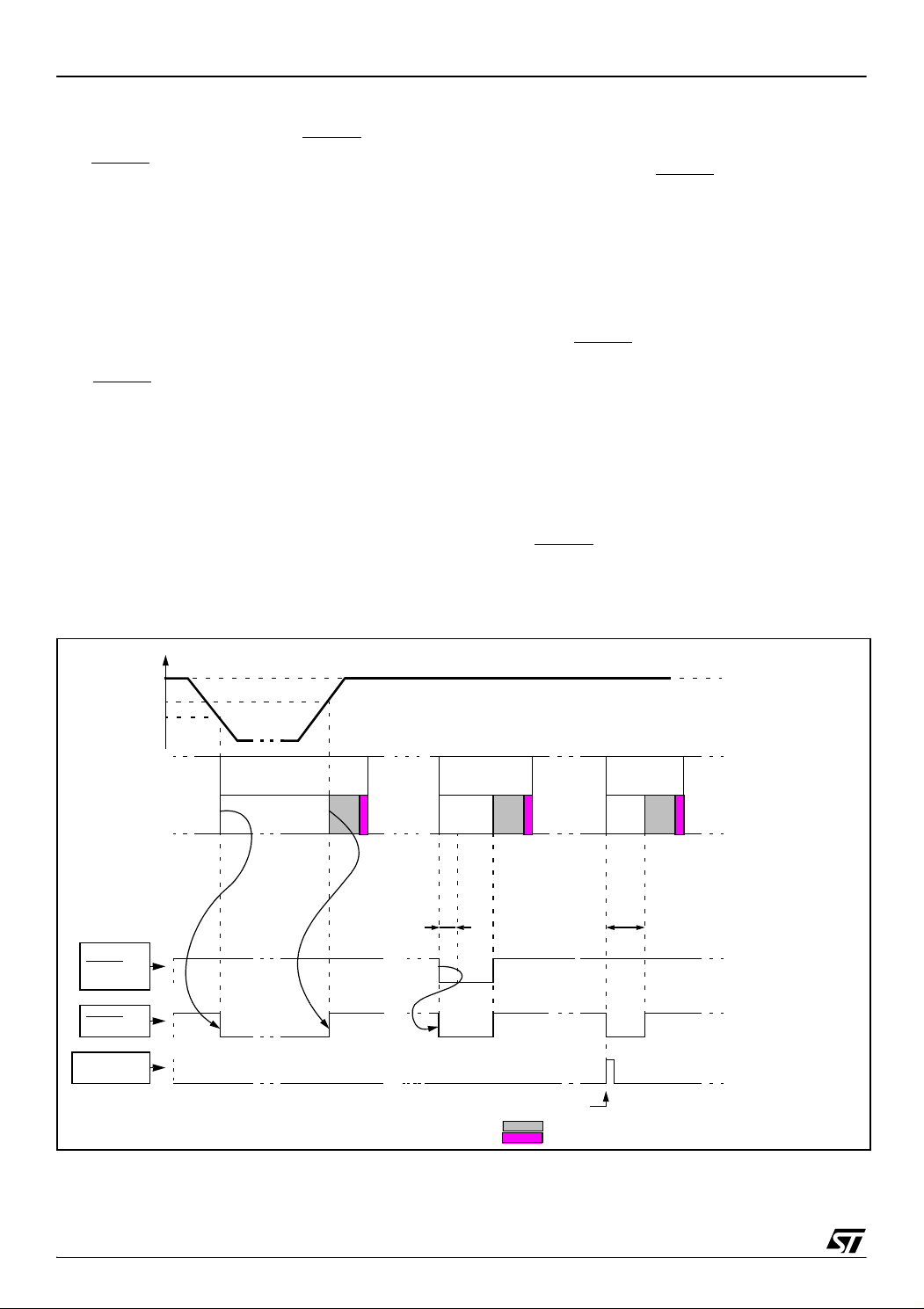

Figure 17. RESET Sequences

V

DD

A proper reset signal for a slow rising V

supply

DD

can generally be provided by an external RC network connected to the RESET

pin.

7.4.4 Internal Low Voltage Detector (LVD) RESET

Two different RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

The device RESET

pulled low when V

V

DD<VIT-

(falling edge) as shown in Figure 17.

The LVD filters spikes on V

pin acts as an output that is

DD<VIT+

(rising edge) or

larger than t

DD

g(VDD)

to

avoid parasitic resets.

7.4.5 Internal Watchdog RESET

The RESET sequence generated by a internal

Watchdog counter overflow is shown in Figure 17.

Starting from the Watchdog counter underflow, the

device RESET

low during at least t

pin acts as an output that is pulled

w(RSTL)out

.

V

IT+(LVD)

V

IT-(LVD)

EXTERNAL

RESET

SOURCE

RESET PIN

WATCHDOG

RESET

RUN

LVD

RESET

ACTIVE PHASE

RUN

t

h(RSTL)in

EXTERNAL

RESET

ACTIVE

PHASE

WATCHDOG UNDERFLOW

RUN RUN

INTERNAL RESET (256 T

VECTOR FETCH

WATCHDOG

RESET

ACTIVE

PHASE

t

w(RSTL)out

CPU

)

28/124

1

Page 29

8 INTERRUPTS

ST7LITE0xY0, ST7LITESxY0

The ST7 core may be interrupted by one of two different methods: Maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

processing flowchart is shown in Figure 18.

The maskable interrupts must be enabled by

clearing the I bit in order to be serviced. However,

disabled interrupts may be latched and processed

when they are enabled (see external interrupts

subsection).

Note: After reset, all interrupts are disabled.

When an interrupt has to be serviced:

– Normal processing is suspended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– The PC is then loaded with the interrupt vector of

the interrupt to service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Table for vector addresses).

The interrupt service routine should finish with the

IRET instruction which causes the contents of the

saved registers to be recovered from the stack.

Note: As a consequence of the IRET instruction,

the I bit is cleared and the main program resumes.

Priority Management

By default, a servicing interrupt cannot be interrupted because the I bit is set by hardware entering in interrupt routine.

In the case when several interrupts are simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low Power Mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the processor to

leave the HALT low power mode (refer to the “Exit

from HALT” column in the Interrupt Mapping Table).

8.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the state of the I bit.

It is serviced according to the flowchart in Figure

18.

8.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding external interrupt

occurred and if the I bit is cleared. These interrupts

allow the processor to leave the HALT low power

mode.

The external interrupt polarity is selected through

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt service routine.

Caution: The type of sensitivity defined in the Miscellaneous or Interrupt register (if available) applies to the ei source. In case of a NANDed source

(as described in the I/O ports section), a low level

on an I/O pin, configured as input with interrupt,

masks the interrupt request even in case of risingedge sensitivity.

8.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– The corresponding enable bit is set in the control

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0” to the corresponding bit in the status

register or

– Access to the status register while the flag is set

followed by a read or write of an associated register.

Note: The clearing sequence resets the internal

latch. A pending interrupt (that is, waiting for being

enabled) will therefore be lost if the clear sequence is executed.

29/124

1

Page 30

ST7LITE0xY0, ST7LITESxY0

INTERRUPTS (Cont’d)

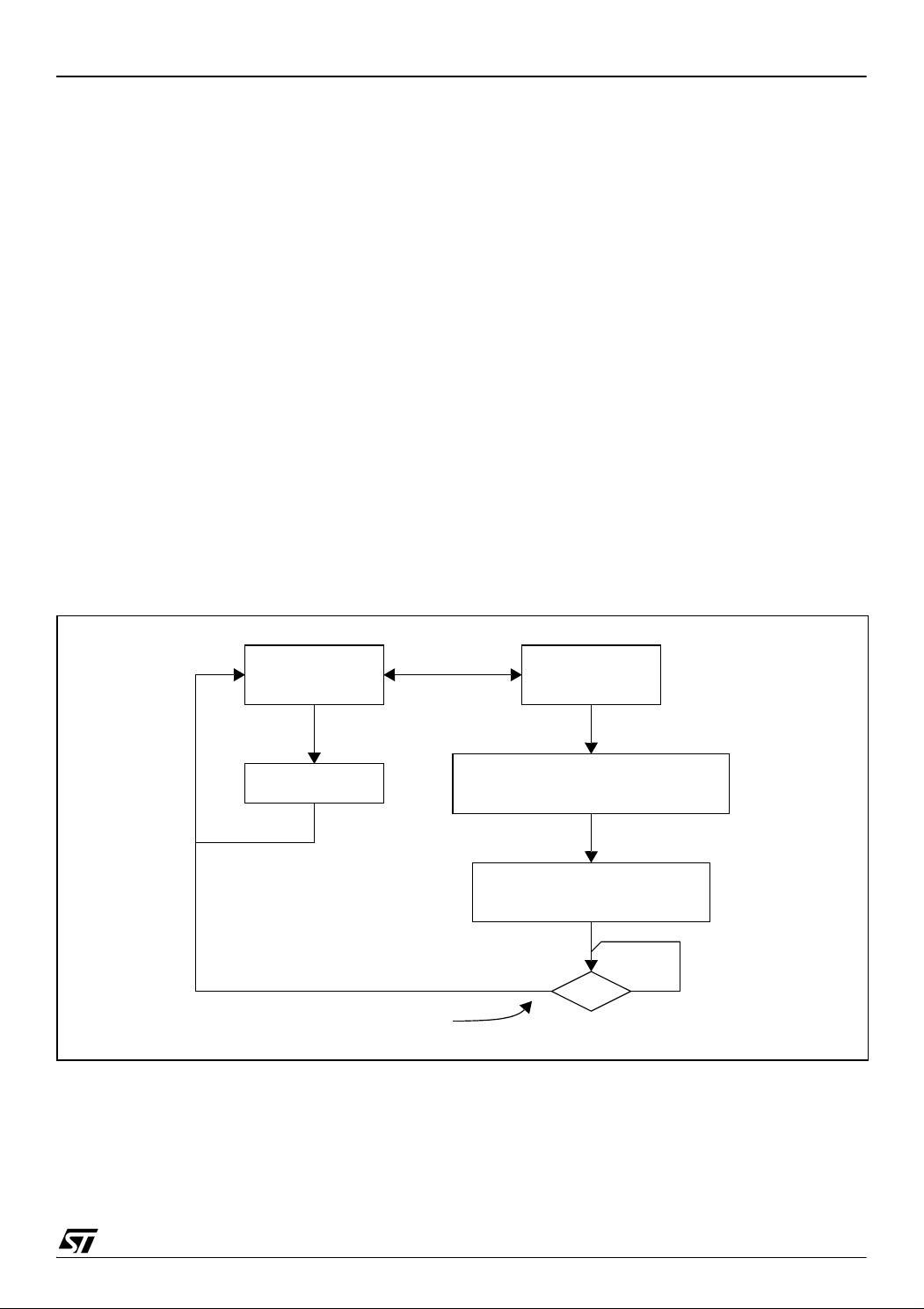

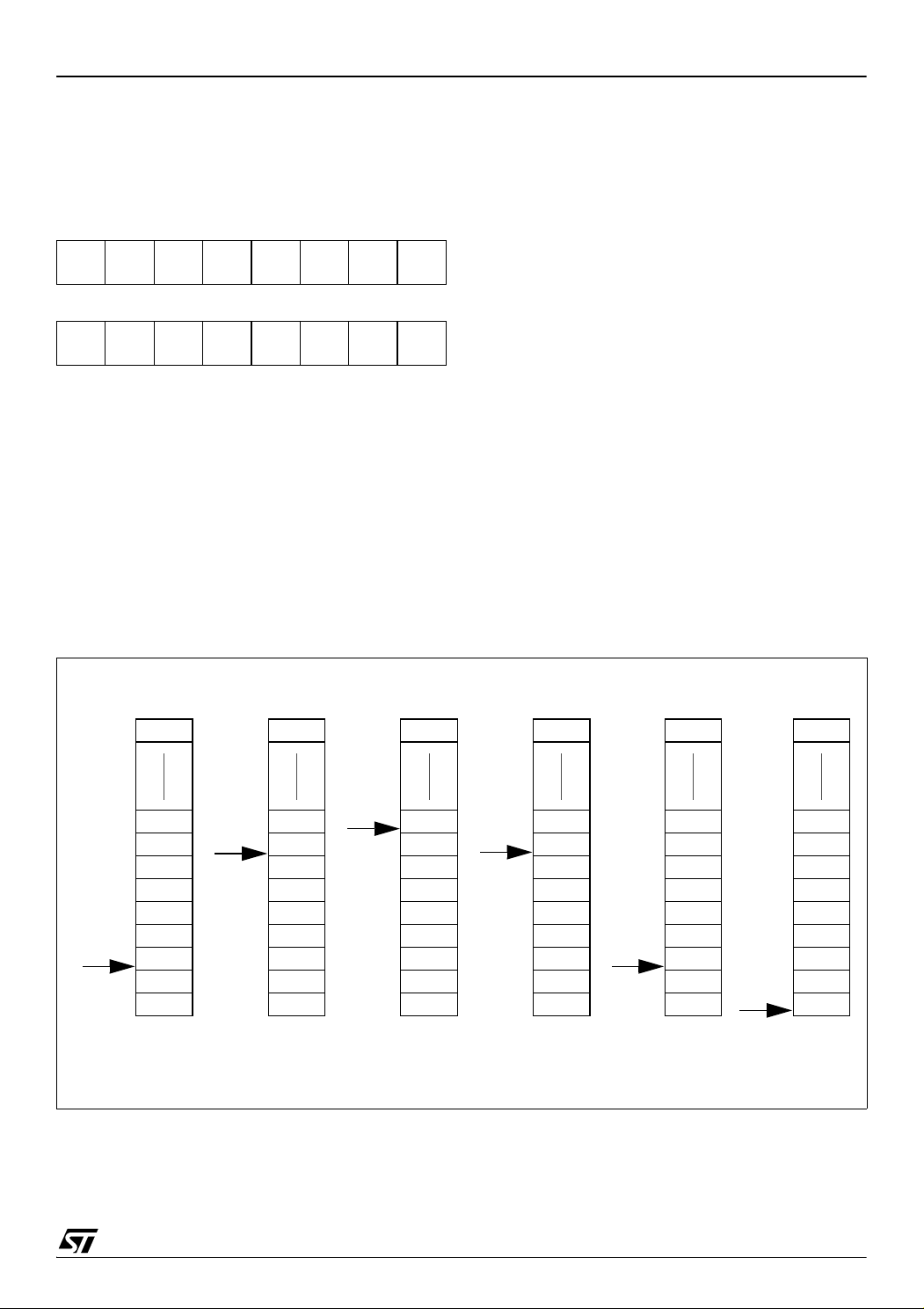

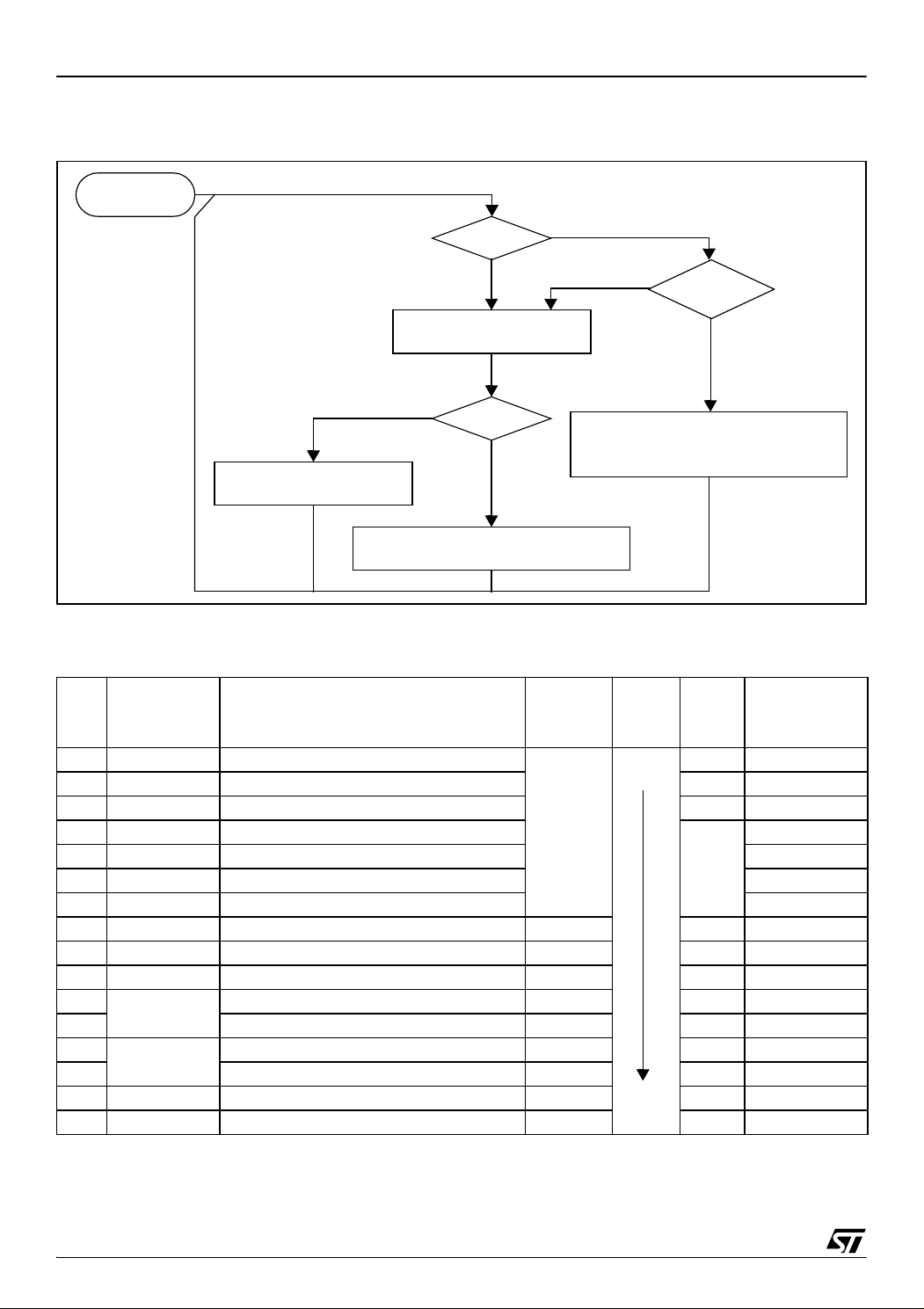

Figure 18. Interrupt Processing Flowchart

FROM RESET

N

N

INTERRUPT

PENDING?

Y

STACK PC, X, A, CC

SET I BIT

LOAD PC FROM INTERRUPT VECTOR

EXECUTE INSTRUCTION

RESTORE PC, X, A, CC FROM STACK

I BIT SET?

Y

FETCH NEXT INSTRUCTION

N

THIS CLEARS I BIT BY DEFAULT

IRET?

Y

Table 6. Interrupt Mapping

Exit

from

HALT

Address

Vector

yes FFFEh-FFFFh

FFF8h-FFF9h

yes

N°

Source

Block

Description

RESET Reset

TRAP Software Interrupt no FFFCh-FFFDh

Register

Label

Priority

Order

Highest

Priority

0 Not used FFFAh-FFFBh

1 ei0 External Interrupt 0

N/A

2 ei1 External Interrupt 1 FFF6h-FFF7h

3 ei2 External Interrupt 2 FFF4h-FFF5h

4 ei3 External Interrupt 3 FFF2h-FFF3h

5 Not used FFF0h-FFF1h

6 Not used FFEEh-FFEFh

7 SI AVD interrupt SICSR no FFECh-FFEDh

8

AT TIMER

9 AT TIMER Overflow Interrupt ATCSR yes FFE8h-FFE9h

10

LITE TIMER

11 LITE TIMER RTC Interrupt LTCSR yes FFE4h-FFE5h

12 SPI SPI Peripheral Interrupts SPICSR yes FFE2h-FFE3h

13 Not used FFE0h-FFE1h

AT TIMER Output Compare Interrupt PWM0CSR no FFEAh-FFEBh

LITE TIMER Input Capture Interrupt LTCSR no FFE6h-FFE7h

Lowest

Priority

30/124

1

Page 31

INTERRUPTS (Cont’d)

ST7LITE0xY0, ST7LITESxY0

EXTERNAL INTERRUPT CONTROL REGISTER

(EICR)

Read/Write

Reset Value: 0000 0000 (00h)

Notes:

1. These 8 bits can be written only when the I bit in

the CC register is set.

2. Changing the sensitivity of a particular external

interrupt clears this pending interrupt. This can be

70

used to clear unwanted pending interrupts. Refer

to section “External interrupt function” on page 42.

IS31 IS30 IS21 IS20 IS11 IS10 IS01 IS00

Table 7. Interrupt Sensitivity Bits

Bit 7:6 = IS3[1:0] ei3 sensitivity

These bits define the interrupt sensitivity for ei3

(Port B0) according to Table 7.

Bit 5:4 = IS2[1:0] ei2 sensitivity

These bits define the interrupt sensitivity for ei2

(Port B3) according to Table 7.

ISx1 ISx0 External Interrupt Sensitivity

0 0 Falling edge & low level

0 1 Rising edge only

1 0 Falling edge only

1 1 Rising and falling edge

Bit 3:2 = IS1[1:0] ei1 sensitivity

These bits define the interrupt sensitivity for ei1

(Port A7) according to Table 7.

Bit 1:0 = IS0[1:0] ei0 sensitivity

These bits define the interrupt sensitivity for ei0

(Port A0) according to Table 7.

31/124

1

Page 32

ST7LITE0xY0, ST7LITESxY0

8.4 SYSTEM INTEGRITY MANAGEMENT (SI)

The System Integrity Management block contains

the Low voltage Detector (LVD) and Auxiliary Voltage Detector (AVD) functions. It is managed by

the SICSR register.

Note: A reset can also be triggered following the

detection of an illegal opcode or prebyte code. Refer to section 12.2.1 on page 78 for further details.

8.4.1 Low Voltage Detector (LVD)

The Low Voltage Detector function (LVD) generates a static reset when the V

below a V

IT-(LVD)

reference value. This means that

supply voltage is

DD

it secures the power-up as well as the power-down

keeping the ST7 in reset.

The V

IT-(LVD)

lower than the V

reference value for a voltage drop is

IT+(LVD)

reference value for poweron in order to avoid a parasitic reset when the

MCU starts running and sinks current on the supply (hysteresis).

The LVD Reset circuitry generates a reset when

is below:

V

DD

–V

–V

IT+(LVD)

IT-(LVD)

when VDD is rising

when VDD is falling

The LVD function is illustrated in Figure 19.

The voltage threshold can be configured by option

byte to be low, medium or high. See section 15.1

on page 112.

Provided the minimum V

the oscillator frequency) is above V

value (guaranteed for

DD

IT-(LVD)

, the

MCU can only be in two modes:

– under full software control

– in static safe reset

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During a Low Voltage Detector Reset, the RESET

pin is held low, thus permitting the MCU to reset

other devices.

Notes:

The LVD is an optional function which can be se-

lected by option byte. See section 15.1 on page

112.

It allows the device to be used without any external

RESET circuitry.

If the LVD is disabled, an external circuitry must be

used to ensure a proper power-on reset.

It is recommended to make sure that the V

DD

supply voltage rises monotonously when the device is

exiting from Reset, to ensure the application functions properly.

Caution: If an LVD reset occurs after a watchdog

reset has occurred, the LVD will take priority and

will clear the watchdog flag.

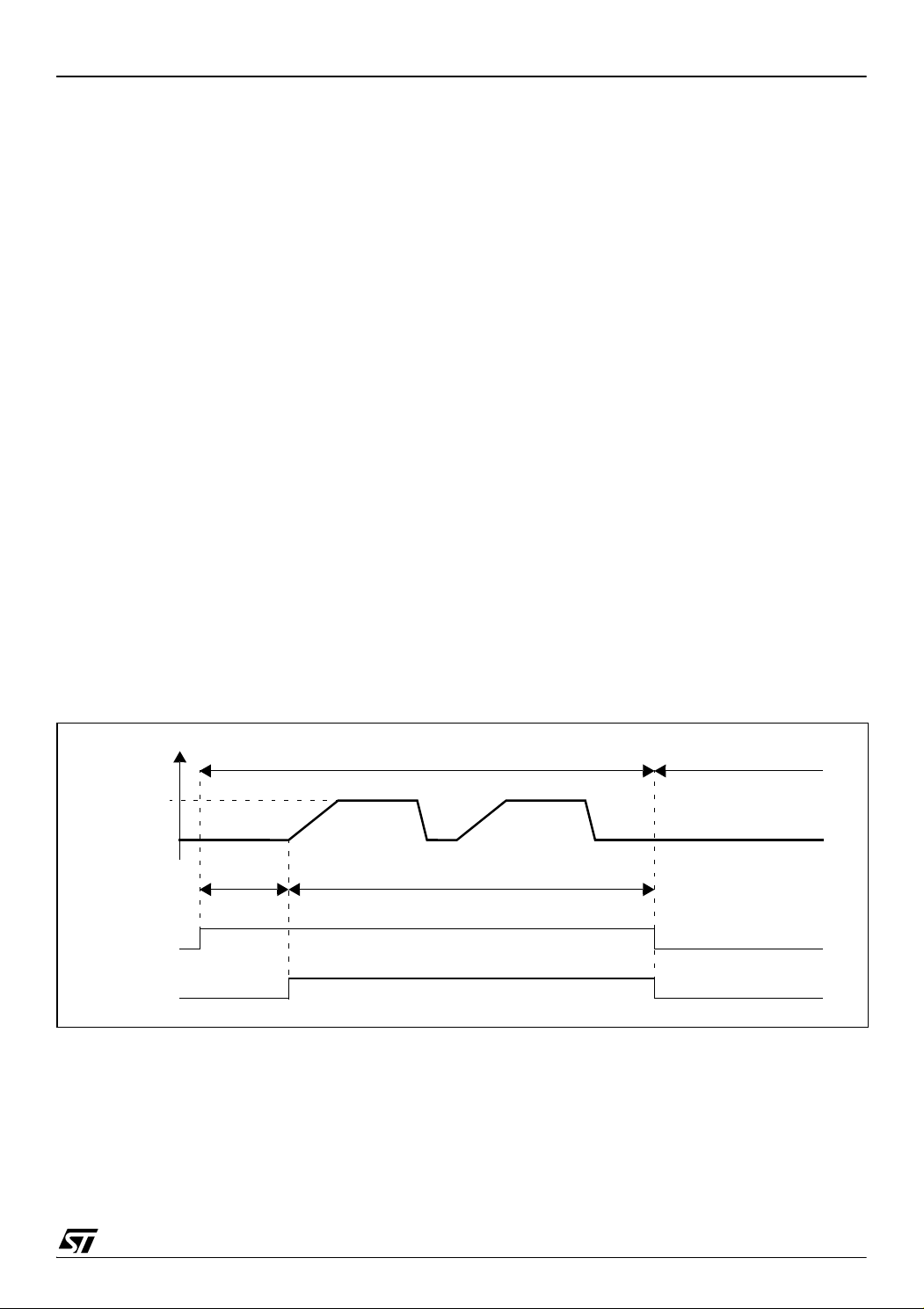

Figure 19. Low Voltage Detector vs Reset

V

DD

V

IT+

(LVD)

V

IT-

(LVD)

RESET

32/124

1

V

hys

Page 33

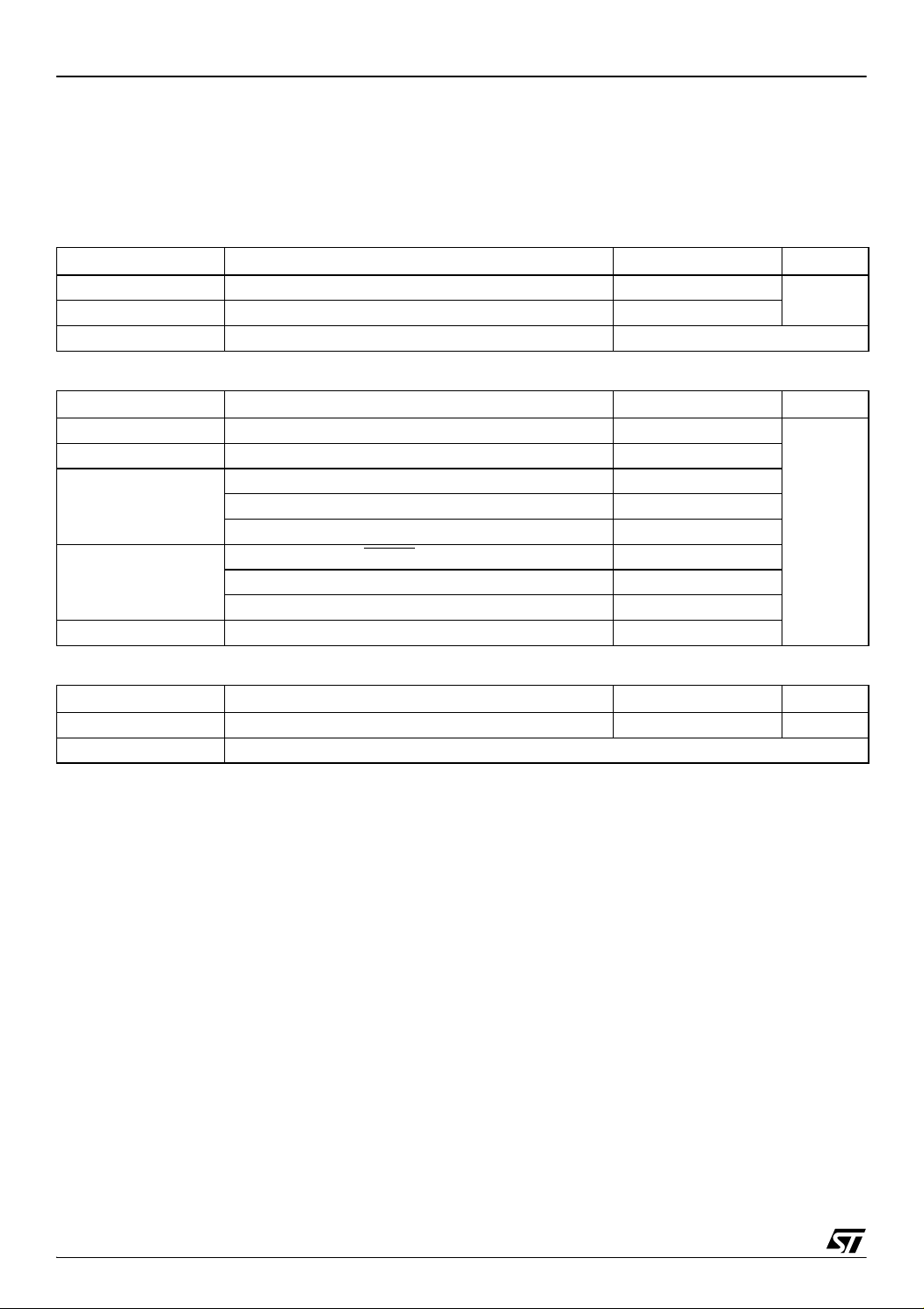

Figure 20. Reset and Supply Management Block Diagram

ST7LITE0xY0, ST7LITESxY0

RESET

V

SS

V

DD

RESET SEQUENCE

MANAGER

(RSM)

WATCHDOG

TIMER (WDG)

STATUS FLAG

SYSTEM INTEGRITY MANAGEMENT

SICSR

LOC

0

7

0

00

LOW VOLTAGE

DETECTOR

AUXILIARY VOLTAGE

DETECTOR

KED

(LVD)

(AVD)

RF IE

AVD Interrupt Request

AVDAVDLVD

F

0

33/124

1

Page 34

ST7LITE0xY0, ST7LITESxY0

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

8.4.2 Auxiliary Voltage Detector (AVD)

The Voltage Detector function (AVD) is based on

an analog comparison between a V

V

IT+(AVD)

ply voltage (V

reference value and the VDD main sup-

). The V

AVD

IT-(AVD)

for falling voltage is lower than the V

IT-(AVD)

reference value

IT+(AVD)

ence value for rising voltage in order to avoid parasitic detection (hysteresis).

The output of the AVD comparator is directly readable by the application software through a real

time status bit (AVDF) in the SICSR register. This

bit is read only.

Caution: The AVD functions only if the LVD is enabled through the option byte.

and

refer-

8.4.2.1 Monitoring the V

Main Supply

DD

The AVD voltage threshold value is relative to the

selected LVD threshold configured by option byte

(see section 15.1 on page 112).

If the AVD interrupt is enabled, an interrupt is generated when the voltage crosses the V

V

IT-(AVD)

threshold (AVDF bit is set).

IT+(LVD)

or

In the case of a drop in voltage, the AVD interrupt

acts as an early warning, allowing software to shut

down safely before the LVD resets the microcontroller. See Figure 21.

The interrupt on the rising edge is used to inform

the application that the V

warning state is over

DD

Figure 21. Using the AVD to Monitor V

V

DD

V

IT+(AVD)

V

IT-(AVD)

V

IT+(LVD)

V

IT-(LVD)

AVDF bit

AVD INTERRUPT

REQUEST

IF AVDIE bit = 1

LVD RESET

01

INTERRUPT Cleared by

DD

Early Warning Interrupt

(Power has dropped, MCU not

not yet in reset)

V

hyst

RESET

reset

01

INTERRUPT Cleared by

hardware

34/124

1

Page 35

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

8.4.3 Low Power Modes

Mode Description

WAIT

HALT

No effect on SI. AVD interrupts cause the

device to exit from Wait mode.

The SICSR register is frozen.

The AVD remains active but the AVD interrupt cannot be used to exit from Halt mode.

8.4.3.1 Interrupts

The AVD interrupt event generates an interrupt if

the corresponding Enable Control Bit (AVDIE) is

ST7LITE0xY0, ST7LITESxY0

set and the interrupt mask in the CC register is reset (RIM instruction).

Flag

Enable

Control

Bit

Interrupt Event

AVD event AVDF AVDIE Yes No

Event

Exit

from

Wait

Exit

from

Halt

35/124

1

Page 36

ST7LITE0xY0, ST7LITESxY0

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

8.4.4 Register Description SYSTEM INTEGRITY (SI) CONTROL/STATUS REGISTER (SICSR)

Read/Write

Reset Value: 0000 0x00 (0xh)

70

LOCK

0000

LVDRF AVDF AVDIE

ED

Bit 7:4 = Reserved, must be kept cleared.

Bit 3 = LOCKED PLL Locked Flag

This bit is set by hardware. It is cleared only by a

power-on reset. It is set automatically when the

PLL reaches its operating frequency.

0: PLL not locked

1: PLL locked

Bit 2 = LVDRF LVD reset flag

This bit indicates that the last Reset was generated by the LVD block. It is set by hardware (LVD reset) and cleared by software (writing zero). See

WDGRF flag description in Section 11.1 for more

details. When the LVD is disabled by OPTION

BYTE, the LVDRF bit value is undefined.

If the AVDIE bit is set, an interrupt request is generated when the AVDF bit is set. Refer to Figure

21 for additional details

over AVD threshold

0: V

DD

under AVD threshold

1: V

DD

Bit 0 = AVDIE Voltage Detector interrupt enable

This bit is set and cleared by software. It enables

an interrupt to be generated when the AVDF flag is

set. The pending interrupt information is automatically cleared when software enters the AVD interrupt routine.

0: AVD interrupt disabled

1: AVD interrupt enabled

Application notes

The LVDRF flag is not cleared when another RESET type occurs (external or watchdog), the

LVDRF flag remains set to keep trace of the original failure.

In this case, a watchdog reset can be detected by

software while an external reset can not.

Bit 1 = AVDF Voltage Detector flag

This read-only bit is set and cleared by hardware.

Table 8. System Integrity Register Map and Reset Values

Address

(Hex.)

003Ah

Register

Label

SICSR

Reset Value

76543210

0000

LOCKED0LVDRFxAVDF0AVDIE

0

36/124

1

Page 37

9 POWER SAVING MODES

ST7LITE0xY0, ST7LITESxY0

9.1 INTRODUCTION

To give a large measure of flexibility to the application in terms of power consumption, four main

power saving modes are implemented in the ST7

(see Figure 22): SLOW, WAIT (SLOW WAIT), ACTIVE HALT and HALT.

After a RESET the normal operating mode is selected by default (RUN mode). This mode drives

the device (CPU and embedded peripherals) by

means of a master clock which is based on the

main oscillator frequency (f

OSC

).

From RUN mode, the different power saving

modes may be selected by setting the relevant

register bits or by calling the specific ST7 software

instruction whose action depends on the oscillator

status.

Figure 22. Power Saving Mode Transitions

High

RUN

SLOW

9.2 SLOW MODE

This mode has two targets:

– To reduce power consumption by decreasing the

internal clock in the device,

– To adapt the internal clock frequency (f

CPU

) to

the available supply voltage.

SLOW mode is controlled by the SMS bit in the

MCCSR register which enables or disables Slow

mode.

In this mode, the oscillator frequency is divided by

32. The CPU and peripherals are clocked at this

lower frequency.

Notes:

SLOW-WAIT mode is activated when entering

WAIT mode while the device is already in SLOW

mode.

SLOW mode has no effect on the Lite Timer which

is already clocked at F

OSC/32

.

Figure 23. SLOW Mode Clock Transition

f

/32 f

f

CPU

OSC

OSC

WAIT

SLOW WAIT

ACTIVE HALT

HALT

Low

POWER CONSUMPTION

f

SMS

OSC

NORMAL RUN MODE

REQUEST

37/124

1

Page 38

ST7LITE0xY0, ST7LITESxY0

POWER SAVING MODES (Cont’d)

9.3 WAIT MODE

WAIT mode places the MCU in a low power consumption mode by stopping the CPU.

This power saving mode is selected by calling the

‘WFI’ instruction.

All peripherals remain active. During WAIT mode,

the I bit of the CC register is cleared, to enable all

interrupts. All other registers and memory remain