Full-speed USB MCU with smartcard firmware

Features

■ Clock, reset and supply management

– Low voltage reset

– Halt power saving mode

– PLL for generating 48 MHz USB clock

using a 4 MHz crystal

■ USB (Universal Serial Bus) interface

– USB 2.0 compliant

– CCID V1.0

– Full speed, hubless

– Bus-powered, low consumption

■ Serial RS232 interface

– Transmission rate: 9.6 Kbps to 115 Kbps

– Format: 8-bit, no parity

– Auto baud rate

– CCID V1.0 on ser ial TTL link

■ ISO 7816-3 UART interface

– 4 Mhz clock generation

– Synchronous/Asynchronous protocols

(T=0, T=1)

– Automatic retry on parity error

– Programmable baud rate from 372 to

11.625 clock pulses (D=32/F=372)

– Card insertion/removal detection

■ Smartcard power supply

– Selectable card V

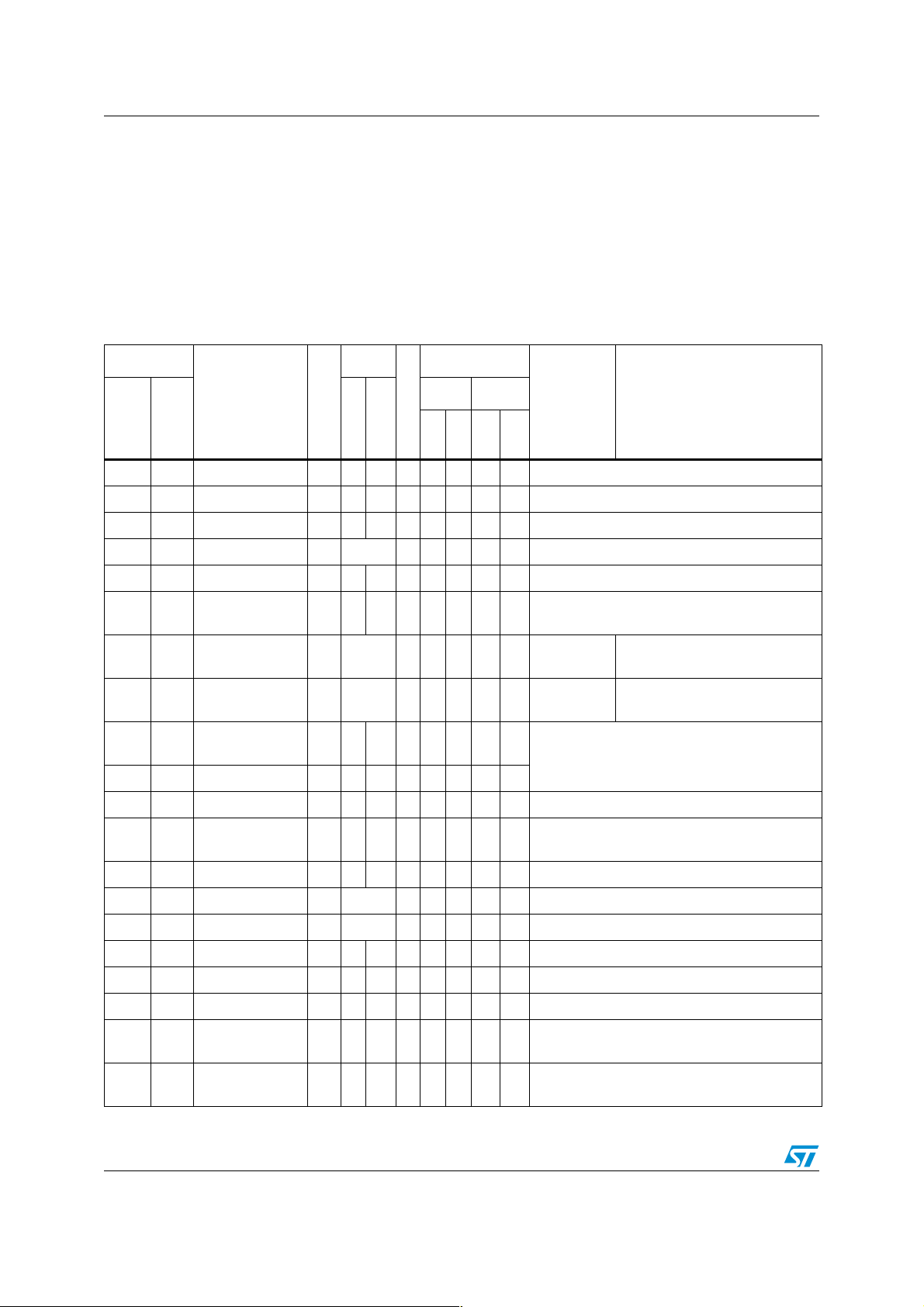

Table 1. Device summary

Features

: 1.8 V, 3 V, and 5 V

CC

ST7GEME4

and EMV/non-EMV interface

24

1

VFQFPN24

– Internal Step-up converter for 5V supplied

Smartcards (with a cu rr en t of up to 55mA)

using only two external components.

– Programmable smartcard internal voltage

regulator (1.8 to 3.0 V) with current

overload protection and 4 kV ESD

protection (Human Body Model) for all

smartcard interface I/Os

■ Development tools

– Application note on PCB recommendations

and component bill of materials

– Full hardware/software kit for pe rformance

evaluation

Description

The ST7GEME4 is an 8-bit microcontroller

dedicated to smartcard reading applications. It

has been developed to be the core of smartcard

readers communicating through a serial or USB

link. It is pre-programmed using Gemplus

software, and offers a single integrated circuit

solution with very few external components.

Order codes

ST7GEME4M1 ST7GEME4U1

SO24(9U)

Program memory 16K ROM

User RAM + USB data buffer (bytes) 512 + 256

Peripherals USB Full-Speed (7 Ep), TBU, Watchdog timer, ISO 7816-3 Interface

Operating Supply 4.0 to 5.5V

Package SO24 VFQFPN24

CPU Frequency 4 or 8 MHz

Operating temperature 0 to +70 °C

September 2007 Rev 2.0 1/28

www.st.com

1

Contents ST7GEME4

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 ST7GEME4 implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Smartcard interface features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 EMV versus PC/SC-ISO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Supply and reset characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Clock and timing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.1 General timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.2 Crystal resonator oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 Memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Smartcard supply supervisor electrical characteristics . . . . . . . . . . . . . . 19

4.7 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7.1 Functional EMS (electromagnetic susceptibility) . . . . . . . . . . . . . . . . . . 21

4.7.2 Electromagnetic interference (EMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7.3 Absolute maximum ratings (electrical sensitivity) . . . . . . . . . . . . . . . . . 23

4.8 Communication interface characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Package characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/28

ST7GEME4 List of tables

List of tables

Table 1. Device summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Technical features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6. General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Current injection on I/O port and control pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8. Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. I/O port pins characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 10. LED pins characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 11. Low voltage detector and supervisor characteristics (LVDS) . . . . . . . . . . . . . . . . . . . . . . . 16

Table 12. General timings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 13. External clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 14. Crystal resonator oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 15. Typical crystal resonator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 16. Recommended values for 4 MHz crystal resonator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 17. RAM and hardware registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 18. Smartcard supply supervisor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 19. EMS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 20. EMI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 21. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 22. Electrical sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 23. USB DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 24. USB full speed electrical characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 25. 24-lead very thin fine pitch quad flat no-lead 5x5mm,0.65mm pitch, mechanical data. . . . 25

Table 26. 24-pin plastic small outline package- 300-mil width, mechanical data . . . . . . . . . . . . . . . . 26

Table 27. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3/28

List of figures ST7GEME4

List of figures

Figure 1. ST7GEME4 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. 24-lead VFQFPN package pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. 24-pin SO package pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Smartcard interface reference application - 24-pin SO package . . . . . . . . . . . . . . . . . . . . . 9

Figure 5. Typical application with an external clock source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6. Typical application with a crystal resonator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. USB data signal rise and fall time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 8. 24-lead very thin fine pitch quad flat no-lead 5x5 mm 0.65 mm pitch, package outline . . . 25

Figure 9. 24-pin plastic small outline package- 300-mil width, package outline. . . . . . . . . . . . . . . . . 26

4/28

ST7GEME4 Introduction

1 Introduction

The ST7GEME4 device is a member of the ST7 microcont roller family designed for USB

applications. All devices are based on a common industry-standard 8-bit core, featuring an

enhanced instruction set.

The ST7GEME4 is factory-programmed ROM devices and as such ar e not

reprogrammable.

It operates at a 4 MHz external oscillator frequency.

Under software control, all devices can be placed in Halt mode, reducing power

consumption when the application is in idle or stand-by state.

The enhanced instruction set and addressing modes of the ST7 offer both power and

flexibility to software developers, enabling the design of highly efficient and compact

application code. In addition to standard 8-bit data management, all ST7 microcontrollers

feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing modes.

The ST7GEME4 includes an ST7 Core, up to 16 Kbytes of program memory, up to 512

bytes of user RAM and the following on-chip peripherals:

● USB full speed interface with 7 endpoints, programmable in/out configuration and

embedded 3.3 V voltage regulator and transceivers (no external components are

needed).

● ISO 7816-3 UART interface with programmable baud rate from 372 clock pulses up to

11.625 clock pulses

● Smartcard supply block able to provide programmable supply voltage and I/O voltage

levels to the smartcards

● Low voltage reset ensuring proper power-on or power-off of the device (selectable by

option)

● 8-bit timer (TBU)

5/28

Introduction ST7GEME4

Figure 1. ST7GEME4 block diagram

OSCIN

OSCOUT

USBDP

USBDM

USBVCC

PA6

V

4MHz

OSCILLATOR

PLL

48 MHz

PP

DIVIDER

USB

DATA

BUFFER

(256 bytes)

USB

8-BIT TIMER

CONTROL

8-BIT CORE

ALU

LVD

RAM

(512 Bytes)

PROGRAM

MEMORY

(16K Bytes)

8 MHz

or 4 MHz

ADDRESS AND DATA BUS

PORT A

LED

ISO 7816 UART

SUPPLY

MANAGER

DC/DC

CONVERTER

3V/1.8V Vreg

PA[1:0]

LED0

DIODE

SELF

CRDVCC

CRDDET

CRDIO

CRDC4

CRDC8

CRDRST

CRDCLK

6/28

ST7GEME4 Pin description

2 Pin description

Figure 2. 24-lead VFQFPN package pinout

GND

GNDA

DIODE

SELF

VDD

VDDA

2324

7 8 11 12

CRDVCC

CRDRST

CRDCLK

C4

CRDIO

C8

1

2

3

4

5

6

CRDDET

ICCDATA/WAKUP2/

Figure 3. 24-pin SO package pinout

DIODE

GNDA

GND

CRDVCC

CRDRST

CRDCLK

CRDIO

CRDDET

ICCDATA/WAKUP2/

ICCCLK/WAKUP2/P

910

NC

ICCCLK/WAKUP2

1

2

3

4

5

6

7

C4

8

9

C8

10

11

12

OSCIN

19202122

18

17

16

15

14

13

OSCOUT

24

23

22

21

20

19

18

17

16

15

14

13

USBV

DP

DM

LED0

PA6

VPP

SELF

V

DD

V

DDA

USBVcc

DP

DM

LED0

PA6

V

PP

OSCOUT

OSCIN

NC

CC

7/28

Pin description ST7GEME4

Legend / Abbreviations

● Type: I = input, O = output, S = supply

● In/Output level: CT = CMOS 0.3VDD/0.7VDD with input trigger

● Output level: HS = 10mA high sink (on N-buffer only)

● Port and control configuration:

– Input: float = floating, wpu = weak pull-up, int = interrupt, ana = analog

– Output: OD = open drain, PP = push-pull

Table 2. Pin description

Pin number

Pin name

SO24

VFQFPN24

Type

Level

Input

supplied

Output

CARD

V

Port / Control

Input Output

int

wpu

OD

Main

function

(after reset)

PP

2 5 CRDRST O CTX X Smartcard reset

3 6 CRDCLK O C

47C4 O C

5 8 CRDIO I/O C

69C8 O C

7 10 CRDDET I

811

912

PA0/WAKUP2/

ICCDATA

PA1/WAKUP2/

ICCCLK

11 14 OSCIN

C

T

I/O C

I/O C

C

T

12 15 OSCOUT C

13 16 V

PP

14 17 PA6 I

S Must be held low in normal operating mode.

C

T

X X Smartcard clock

T

X X Smartcard C4

T

X X X Smartcard I/O

T

X X Smartcard C8

T

X Smartcard detection

T

T

XXX XPort A0

XXX XPort A1

Input/output oscillator pins. These pins

connect a 4 MHz parallel-resonant crystal, or

T

an external source to the on-chip oscillator.

PA6

Interrupt, In-circuit

communication data input

Interrupt, In-circuit

communication clock input

15 18 LED0 O HS X Constant current output

16 19 DM I/O C

17 20 DP I/O C

T

T

18 21 USBVCC O C

19 22 V

20 23 V

DDA

DD

S Power Supply voltage 4-5.5 V

S Power Supply voltage 4-5.5 V

21 24 SELF O C

T

T

USB Data Minus line

USB Data Plus line

3.3 V output for USB

An external inductance must be connected to

these pins for the step up converter

Alternate function

22 1 DIODE S C

T

8/28

An external diode must be connected to this

pin for the step up converter

ST7GEME4 Pin description

Table 2. Pin description (continued)

Pin number

Pin name

SO24

VFQFPN24

Type

Level

Input

Output

supplied

CARD

V

Port / Control

Input Output

int

wpu

OD

Main

function

(after reset)

PP

23 2 GNDA S

Ground

24 3 GND S

1 4 CDRVCC O C

X Smartcard supply pin

T

Figure 4. Smartcard interface reference application - 24-pin SO package

V

DD

C1

L1

D1

C4

C3

C5

C6

DIODE

GNDA

GND

CRDVCC

CRDRST

CRDCLK

C4

CRDIO

C8

CRDDET

PA0

PA1

SELF

V

DD

V

DDA

USBVcc

DP

DM

LED0

PA6

V

PP

OSCOUT

OSCIN

NC

R

LED

V

DD

C2

D+

D-

V

DD

C

L1

C

L2

Alternate function

1. Mandatory values for the external components:

C1 = 4.7 µF; C2 = 100 nF. C1 and C2 must be located close to the chip (refer to Section 4.4.2.).

C3 = 1 nF;

C4 = 4.7 µF ESR 0.5 Ω.

C5 : 470 pF;

C6 :

100 pF;

R : 1.5kΩ;

L1 : 10 µH, 2 Ω;

Crystal 4.0 MHz; Impedance max100 Ω

D1: BAT42 SHOTTKY.

9/28

ST7GEME4 implementation ST7GEME4

3 ST7GEME4 implementation

The ST7GEME4 has been developed to offer a complete ready-to-use firmware solution

which allows fast development and rapid time-to-market of smartcard reader applications.

It offers a single IC solution and simplifies the integration of smartcard interfaces into

electronic devices such as computer s , POS terminals, mobile phones , PDAs, home routers,

and set-top boxes. Pre-programmed with communication software from our partner

GEMPLUS, the ST7GEME4 is a complete firmware solution controlling the communication

between ISO 7816 1-2-3-4 cards an d a ho st syste m. An evaluation kit and reference design

with a complete bill of materials and PCB recommendations are available. The ST7GEME4

complies with EMVCo/EMV2000 standards. Software support and engineering expertise in

system integration and PCB design are available as additional services.

3.1 Functionality

The core functionality of ST7GEME4 resides in its pre-programmed software embedded in

ROM memory. GemCore

host computer and the external card. Basic features and compliance are described in the

features section and in Table 3 on page 11.

A dedicated analog block provides smartcard power supplies 1.8 V, 3 V, and 5 V necessary

to interface with different card voltages available on the market. Voltages are selected by

software. External LEDs can also be directly connected to dedicated I/Os.

A dedicated UART interface provides an ISO 7816 communication port for connection with

the smartcard connector. A full-speed USB interface port allows external connection to a

host computer. An optional RS232 connection is also available on dedicated I/Os.

TM

technology manages the commu nication protocol to/from the

3.2 Smartcard interface features

The ST7GEME4 firmware includes the following features:

● Compatibility with asynchronous cards

● Compatibility with T=0 and T=1 protocols

● Compatibility with EMV and PC/SC modes.

● Compatibility with ISO 7816-3 and 4 and ability to supply the cards with 5V, 3V or 1.8V

(class A, B or C cards, respectively)

● Resume/wake-up mode upon smartcard inser tion/removal

Further details on smartcard management can be found in "Gemcore USB Pro reference

manual" from Gemplus.

The reader is able to communicate with smartcards up to the maximum baud rate allowed,

namely 344 086 bps (TA1=16) for a clock frequency of 4 MHz. Because the size of the

smartcard buffer is 261 bytes, care must be taken not to exceed this size during APDU

exchanges when the protocol in use is T=1.

10/28

ST7GEME4 ST7GEME4 implementation

3.3 EMV versus PC/SC-ISO mode

The ST7GEME4 supports two operating modes:

● An EMV mode, based on the EMV4.1 specifications

● A PC/SC-ISO mode which allows to manage of a smartcard according to the PC/SC

and ISO 7816-3 standards

The default mode is PC/SC, however, the reader can switch between EMV and PC/SC-ISO

modes.

GemCore2000 is a utility in charge of managing the switching between the two modes.

When the utility is activated, the reader attempts EMV mode management whenever a

smartcard is inserted. If reading is successful, PC/SC mode will not be available.

Caution: The activation of the GemCore2000 utility must be done before any card command. Any

activation of the GemCore2000 utility is not recommended unless the reader is reset.

The EMV mode fails if:

● The smartcard has not sent an EMV-compliant answer to reset (ATR)

● Negotiation of the buffer size with a T=1 card has failed

Using PC/SC-ISO mode with GemCore2000

The reader switches to PC/SC mode after the application or the driver has sent the

appropriate dedicated command to the reader (with a pro prietary Escape command). In this

case, the reader remains in PC/SC mode as long as the card remains in the reader.

Whenever the EMV mode fails, the sm artcard is powered off. After the host application has

sent the PC/SC switch (proprietary) Escape command, the application must send a new

Card Power On command.

When the reader deals with an EMV card, the data exchanged between the reader and the

host consists of short APDU messages. When the card is not EMV-compliant and the reader

is set to PC/SC-ISO mode, the reader exchanges TPDU messages with the host.

Restriction: character level and the extended APDU are not implemented in ST7GEME4

solution.

Table 3. Technical features

Features Description Characteristics

– Microprocessor cards

Supported

smartcards

Smartcard

electrical interface

Asynchronous

Synchronous – Through a comprehensive API

Smartcard power supply

Smartcard management – Card insertion/extraction detection

ESD protection on card I/O – 4 kV Human Body Model

– T=0, T=1 protocols

– Transmission rate: 2 Kbps to 344 Kbps

– 5V/55mA and 3V/50mA and 1.8V/20mA

– Short circuit current limitation

– Power up/power down control sequences

11/28

ST7GEME4 implementation ST7GEME4

Table 3. Technical features (continued)

– Microsoft Windows 2000/XP/Server 2003

– Microsoft Windows CE 4.1/4.2/5.0

– Linux Red Hat/SUSE/Debian

USB and serial versions

Drivers

Compliance with class drivers

USB interface USB 2.0 compliant

Serial host

interface

Other features

Serial asynchronous link

Communication protocol – CCID V1.0 on serial TTL link

Temperature range

Environmental standard – RoHS compliant

– Microsoft Windows XP 64-bit on AMD64 and

EMT64

– Microsoft Windows Server 2003 64-bit

– Mac OS 10.3/10.4

– Microsoft Windows 2000/XP/Server 2003

– Microsoft Windows Vista (beta version)

– Mac OS 10.3/10.4

– CCID V1.0

– Full speed, hubless

– Bus powered, low consumption

– Transmission rate: 9.6 Kbps to 115 Kbps

– Format: 8-bit, no parity

– Auto baud rate

– Operating range: 0 to +70°C

– Storage: -65 to +150°C

12/28

ST7GEME4 Electrical characteristics

4 Electrical characteristics

4.1 Absolute maximum ratings

The ST7GEME4 contains circuitry to protect the inputs against damage due to high static

voltages. However it is advisable to take normal precautions to avoid applying any voltage

higher than the specified maximum rated voltages .

For proper operation it is recommended that V

V

. Reliability is enhanced if unused inputs are connected to an appropriate logic voltage

DD

level (V

or VSS).

DD

and VO be higher than VSS and lower than

I

Power considerations

The average chip-junction temperature, TJ, in Celsius can be obtained by the following

equation:

TJTAPD RthJA×+=

where:

T

= Ambient temperature

A

RthJA = Package thermal resistance (junction-to ambient)

P

= P

D

P

INT

P

PORT

Stresses above those listed as “absolute maximum ratings” may cause permanent damage

to the device. This is a stress rating only and functional operation of the device at these

conditions is not implied. Exposure to maximum rating for extended periods may affect

device reliability.

Table 4. Absolute maximum ratings

+ P

INT

PORT

= IDD x VDD (chip internal power)

= Port power dissipation determined by the user

Symbol Ratings Value Unit

- V

V

DD

SS

V

IN

V

OUT

ESD ESD susceptibility 2000 V

ESDCard ESD susceptibility for card pads 4000 V

I

VDD_i

I

VSS_i

Supply voltage 6.0 V

Input voltage VSS - 0.3 to VDD + 0.3 V

Output voltage VSS - 0.3 to VDD + 0.3 V

Total current into V

Total current out of V

(source) 250

DD_i

(sink) 250

SS_i

mA

Warning: Direct connection to VDD or VSS of the I/O pins could damage

the device in case of program counte r corruption (due to

unwanted change of the I/O configuration). To guarantee safe

conditions, this connection has to be done through a typical

10kΩ pull-up or pull-down resistor.

13/28

Electrical characteristics ST7GEME4

Table 5. Thermal characteristics

Symbol Ratings Value Unit

R

T

T

PD

thJA

Jmax

STG

max

Package thermal resistance

Max. junction temperature 150 °C

Storage temperature range -65 to +150 °C

Power dissipation

VFQFPN24 42 °C/W

SO24 80 °C/W

VFQFPN24 600 mW

SO24 500 mW

4.2 Recommended operating conditions

Table 6. General operating conditions

Symbol Parameter Conditions Min Typ Max Unit

V

f

OSC

Operating conditions are given for TA = 0 to +70 °C unless ot he rwise specified.

Table 7. Current injection on I/O port and control pins

Symbol Parameter Conditions Min Typ Max Unit

I

INJ+

I

1. When several inputs are submitted to a current injection, the maximum injected current is the sum of the

positive (resp. negative) currents (instantaneous values).

2. Positive injection. The I

3. For SmartCard I/Os, V

4. The negative injected current, I

substrate of the die. The drawback is a small leakage (few µA) induced inside the die when a negative

injection is performed. This leakage is tolerated by the digital structure. The effect depends on the pin

which is submitted to the injection. Of course, external digital signals applied to the component must have

a maximum impedance close to 50kΩ.

5. Location of the negative current injection: Pure digital pins can tolerate 1.6mA. In addition, the best choice

is to inject the current as far as possible from the analog input pins.

Supply voltage 4.0 5.5 V

DD

External clock source 4 MHz

T

Ambient temperature range 0 70 °C

A

V

Total positive injected

(2)(3)

current

T otal negative injected current

(4)(5)

INJ-

INJ+

CRDVCC

is done through protection diodes insulated from the substrate of the die.

has to be considered.

, passes through protection diodes which are NOT INSULATED from the

INJ-

EXTERNAL>VDD

V

EXTERNAL>VCRDVCC

V

EXTERNAL<VSS

V

EXTERNAL<VSS

I/Os)

(1)

(Standard I/Os)

(Smartcard

Digital pins

Analog pins

20 mA

20 mA

14/28

ST7GEME4 Electrical characteristics

Table 8 characteristics are measured at TA=0 to +70oC, and VDD-VSS=5.5V unless

otherwise specified.

Table 8. Current consumption

Symbol Parameter Conditions Min Typ. Max Unit

Supply current in RUN mode

Supply current in suspend mode

I

DD

Supply current in Halt mode

(1)

(2)

f

= 4MHz 10 15 mA

OSC

External I

(USB transceiver

enabled)

External I

(USB transceiver

disabled)

LOAD

LOAD

= 0mA

500

µA

= 0mA

50 100

1. All I/O pins are in input mode with a static value at V

square wave.

2. CPU running with memory access, all I/O pins in input mode with a static value at VDD or VSS; clock input

(OSCIN) driven by external square wave.

or VSS; clock input (OSCIN) driven by external

DD

Table 9 characteristics are measured at TA=0 to +70oC. Voltage are referred to VSS unless

otherwise specified.

Table 9. I/O port pins characteristics

Symbol Parameter Conditions Min Typ Max Unit

V

Input low level voltage VDD=5V 0.3V

IL

Input high level voltage VDD=5V 0.7V

V

V

V

V

R

IH

Schmidt trigger voltage

HYS

hysteresis

Output low level volt a ge for

OL

Standard I/O port pins

Output high level voltage I=3mA

OH

Input leakage current VSS<V

I

L

Pull-up equivalent resistor 50 90 170 kΩ

PU

(1)

I=-5mA 1.3

I=-2mA 0.4

PIN<VDD

V

DD

0.8

DD

400 mV

-

Output high to low level fall time

t

OHL

for high sink I/O port pins (Port

(2)

D)

6813

Output high to low level fall time

t

t

t

t

ITEXT

1. Hysteresis voltage between Schmitt trigger switching levels. Based on characterization results, not tested.

2. Guaranteed by design, not tested in production.

for standard I/O port pins (Port A,

OHL

OLH

OLH

(2)

B or C)

Output L-H rise time (Port D)

Output L-H rise time for standard

I/O port pins (Port A, B or C)

(2)

(2)

Cl=50pF

External interrupt pulse time 1 t

18 23

7914

19 28

DD

V

V

1µA

ns

CPU

15/28

Electrical characteristics ST7GEME4

Table 10. LED pins characteristics

Symbol Parameter Conditions Min Typ Max Unit

I

Lsink

I

Lsink

Low current V

High current V

PAD

> VDD-2.4 2 4

PAD

> VDD-2.4 for ROM 5 6 8.4

4.3 Supply and reset characteristics

Table 11 characteristics are measured at T = 0 to +70oC, VDD - VSS = 5.5 V unless

otherwise specified.

Table 11. Low voltage detector and supervisor characteristics (LVDS)

Symbol Parameter Conditions Min Typ Max Unit

V

V

V

V

1. Hysteresis voltage between Schmitt trigger switching levels. Based on characterization results, not tested.

Reset release threshold

IT+

IT-

hys

tPORVDD

rising)

(V

DD

Reset generation threshold

falling)

(V

DD

Hysteresis V

rise time rate

IT+

- V

(1)

IT-

1)

4.4 Clock and timing characteristics

mA

3.7 3.9 V

3.3 3.5 V

200 mV

20 ms/V

4.4.1 General timings

Table 12 characteristics are measured at T = 0 to +70oC unless otherwise specified.

Table 12. General timings

Symbol Parameter Conditions Min Typ

t

c(INST)

t

v(IT)

1. Data based on typical application software.

2. Time measured between interrupt event and interrupt vector fetch. ∆t

needed to finish the current instruction execution.

3.

∆t

Instruction cycle time

Interrupt reaction time

t

= ∆t

v(IT)

is the number of t

INST

+ 10

c(INST)

to finish the current instruction execution.

CPU

(3)

(2)

(1)

Max Unit

2312t

f

=4 MHz 500 750 3000 ns

CPU

10 22 t

f

=4 MHz 2.5 5.5 µs

CPU

is the number of t

c(INST)

CPU

CPU

CPU

cycles

16/28

ST7GEME4 Electrical characteristics

Table 13. External clock source

Symbol Parameter Conditions Min Typ Max Unit

V

OSCINH

V

OSCINL

t

w(OSCINH)

t

w(OSCINL)

t

r(OSCIN)

t

f(OSCIN)

I

OSCIN input pin high level

voltage

OSCIN input pin low level voltage V

OSCIN high or low time

OSCIN rise or fall time

OSCx Input leakage current VSS≤VIN≤V

L

(1)

(1)

see Figure 5

DD

0.7V

15

DD

SS

1. Data based on design simulation and/or technology characteristics, not tested in production.

Figure 5. Typical application with an external clock source

90%

V

OSCINH

V

OSCINL

EXTERNAL

CLOCK SOURCE

t

r(OSCIN)

t

f(OSCIN)

10%

OSCOUT

OSCIN

t

w(OSCINH)

I

L

t

w(OSCINL)

f

OSC

ST7XXX

V

DD

0.3V

DD

15

±1 µA

V

ns

17/28

Electrical characteristics ST7GEME4

4.4.2 Crystal resonator oscillators

The ST7 internal clock is supplied with one Crystal resonator oscillator. All the information

given in this paragraph are based on characterization results with specified typical external

components. In the application, the resonator and the load capacitors have to be placed as

close as possible to the oscillator pins in order to minimize output distortion and start-up

stabilization time. Refer to the crystal resonator manufacturer for more details (frequency,

package, accuracy...).

Table 14. Crystal resonator oscillator characte ristics

Symbol Parameter Conditions Min Typ Max Unit

f

OSC

R

F

C

L1

C

L2

i

2

1. The oscillator selection can be optimized in terms of supply current using an high quality resonator with small RS value.

Refer to crystal resonator manufacturer for more details.

Oscillator Frequency

(1)

MP: Medium power oscillator 4 MHz

Feedback resistor 90 150 kΩ

Recommended load

capacitances versus equivalent

serial resistance of the crystal

resonator (R

)

S

See Table 16 (MP oscillator) 22 56 pF

OSCOUT driving current VDD=5V, VIN=VSS(MP oscillator) 1.5 3.5 mA

Table 15. Typical crystal resonator characteristics

Oscillator Reference Freq. Characteristic

MP JAUCH

Crystal

1. Resonator characteristics given by the crystal resonator manufacturer.

2. t

Table 16. Recommended values for 4 MHz crystal resonator

is the typical oscillator start-up time measured between VDD=2.8 V and the fetch of the first instruction (with a quick

SU(OSC)

VDD ramp-up from 0 to 5 V (<50 µs).

SS3-400-3030/30

4MHz

Symbol Min Typ Max Unit

(1)

R

SMAX

C

OSCIN

C

OSCOUT

1. R

is the equivalent serial resistor of the crystal (see crystal specification).

SMAX

∆f

=[±30ppm

OSC

25°C

Typ. RS=60Ω

20 25 70 Ω

56 47 22 pF

56 47 22

(1)

,±30ppm

∆Ta

CL1

[pF]

],

33 33 7~10

CL2

[pF]

tSU(osc)

(2)

[ms]

18/28

ST7GEME4 Electrical characteristics

Figure 6. Typical application with a crystal resonator

WHEN RESONATOR WITH

INTEGRATED CAPACITORS

C

L1

C

L2

RESONATOR

4.5 Memory characteristics

Subject to general operating conditions for VDD, f

Table 17. RAM and hardware registers

Symbol Parameter Conditions Min Typ Max Unit

V

1. Minimum VDD supply voltage without losing data stored in RAM (in Halt mode or under Reset) or in

hardware registers (only in Halt mode). Not tested in production.

Data retention mode

RM

(1)

i

2

f

OSCIN

OSCOUT

OSC

R

F

, and TA unless otherwise specified.

OSC

ST7XXX

Halt mode (or Reset) 2 V

4.6 Smartcard supply supervisor electrical characteristics

Table 18 characteristics are measured at TA = 0 to +70oC, 4.0 V < VDD - VSS < 5.5 V unless

otherwise specified.

Table 18. Smartcard supply supervisor characteristics

Symbol Parameter Conditions Min Typ Max Unit

5 V regulator output (for IEC 7816-3 Class A Cards)

V

CRDVCC

I

SC

I

OVDET

t

IDET

t

OFF

t

ON

V

CRDVCC

I

VDD

SmartCard power supply

voltage

4.6 5.00 5.4 V

SmartCard supply current 55 mA

Current overload de t e c ti o n 120

Detection time on current

overload

V

CRDVCC

V

CRDVCC

V

CARD

turn-off time C

turn-on time C

above minimum supply

voltage

VDD supply current

LOADmax

LOADmax

(2)

≤ 4.7µF 750 µs

≤ 4.7µF 150 500 µs

170

4.52

(1)

(1)

(1)

(1)

1400

(1)

4.76

100 mA

mA

µs

V

19/28

Electrical characteristics ST7GEME4

Table 18. Smartcard supply supervisor characteristics (continued)

Symbol Parameter Conditions Min Typ Max Unit

3 V regulator output (for IEC 7816-3 Class B Cards)

V

CRDVCC

I

I

OVDET

t

IDET

t

OFF

t

SmartCard power supply

voltage

SmartCard supply current 50 mA

SC

Current overload de t e c ti o n 100

Detection time on current

overload

ON

V

V

turn-off time C

CRDVCC

turn-on time C

CRDVCC

LOADmax

LOADmax

1.8V regulator output (for IEC 7816-3 Class C Cards)

V

CRDVCC

I

I

OVDET

t

IDET

t

OFF

t

SmartCard power supply

voltage

SmartCard supply current 20 mA

SC

Current overload de t e c ti o n 100

Detection time on current

overload

ON

V

V

turn-off time C

CRDVCC

turn-on time C

CRDVCC

LOADmax

LOADmax

Smartcard CLKPin

V

V

T

OHL

T

OLH

F

VAR

F

DUTY

P

P

I

SGND

Output low level vo ltage I = -50 µA - - 0.4

OL

Output high level voltage I = 50 µA V

OH

(1)

(1)

(1)

(1)

(1)

(1)

Cl = 30 pF - 20 ns

Cl = 30 pF - 20 ns

Output high to low fall time

Output low to high rise time

Frequency variation

Duty cycle

Signal low perturbation

OL

Signal high perturbation

OH

(1)

Short-circuit to ground

Smartcard I/O Pin

V

V

V

V

I

RPU

Input low level voltage - - 0.5

IL

Input high level voltage 0.6V

IH

Output low Level Voltage I = -0.5 mA - - 0.4

OL

Output high level voltage I = 20 µA 0.8V

OH

I

Input leakage current

L

(1)

VSS<VIN<V

Pull-up equivalent resistance VIN=V

2.7 3.3 V

170

(1)

1400

(1)

(1)

mA

µs

≤ 4.7µF 750 µs

≤ 4.7µF 150 500 µs

1.65 1.95 V

170

(1)

1400

(1)

(1)

mA

µs

≤ 4.7µF 750 µs

≤ 4.7µF 150 500 µs

(3)

(3)

CRDVCC

-0.5

--V

-1%

45 55 %

-0.25 0.4 V

V

V

CRDVCC

-0.5

CRDVCC

+0.25

15 mA

(3)

(3)

--V

(3)

(3)

-V

CRDVCC

(3)

24 30 kΩ

SC_PWR

SS

CRDVCC

CRDVCC

-10 - 10 µA

V

V

V

V

V

20/28

ST7GEME4 Electrical characteristics

Table 18. Smartcard supply supervisor characteristics (continued)

Symbol Parameter Conditions Min Typ Max Unit

T

OHL

T

OLH

I

SGND

V

V

T

OHL

T

OLH

I

SGND

1. Guaranteed by design.

2. V

and CPU in WFI mode.

3. Data based on characterization results, not tested in production.

Output high to low fall time

Output low to high rise time

Short-circuit to ground

Output low Level Voltage I = -0.5 mA - - 0.4

OL

Output high level voltage I = 20 µAV

OH

Output high to low fall time

Output low to high rise time

Short-circuit to ground

= 4.75 V, Card consumption = 55mA, CRDCLK frequency = 4MHz, LED with a 3mA current, USB in reception mode

DD

(1)

(1)

(1)

Cl = 30 pF - 0.8 µs

Cl = 30 pF - 0.8 µs

Smartcard RST C4 and C8 Pin

(1)

(1)

(1)

Cl = 30 pF - 0.8 µs

Cl = 30 pF - 0.8 µs

CRDVCC

-0.5

15 mA

(3)

-V

CRDVCC

15 mA

(3)

(3)

V

V

4.7 EMC characteristics

Susceptibility tests are performed on a sample basis during product characterization.

4.7.1 Functional EMS (electromagnetic susceptibility)

Based on a simple running application on the product (toggling 2 LEDs through I/O ports),

the product is stressed by two e lectromagn etic e vents until a failure occurs (indicated by the

LEDs).

● ESD: electrostatic discharge (positive and negative) is applied on all pins of the device

until a functional disturbance occurs. This test conforms with the IEC 1000-4-2

standard.

● FTB: a burst of fast transient voltage (positive and negative) is applied to V

through a 100 pF capacitor, until a functional disturbance occurs. This test conforms

with the IEC 1000-4-4 standard.

A device reset allows normal operation s t o be resumed. The test results are given in the

table below based on the EMS levels and classes defined in application note AN1709.

Designing hardened software to avoid noise problems

EMC characterization and optimization are performed at component level with a typical

application environment and simplified MCU sof tware. It should be noted that good EMC

performance is highly dependent on the user application and the software in particular.

Therefore it is recommended that the user applies EMC software optimization and

prequalification tests in relation with the EMC level requested for his application.

and VSS

DD

21/28

Electrical characteristics ST7GEME4

Software recommendations

The software flowchart must include the management of runaway conditions such as :

● Corrupted program counter

● Unexpected reset

● Critical Data corruption (control registers...)

Prequalification trials

Most of the common failures (u nexpected reset and program counter corruption) can be

reproduced by manually forcing a low state on the RESET pin or the Oscillator pins for 1

second.

To complete these trials, ESD stress can be applied directly on the device , o v er the r ange of

specification values. When unexpected behavior is detected, the software can be hardened

to prevent unrecoverab le errors occurring (see application note AN1015).

Table 19. EMS characteristics

Symbol Parameter Conditions

V

Voltage limits to be applied on any I/O pin to

FESD

induce a functional disturbance

Fast transient voltage burst limits to be

V

applied through 100 pF on VDD and V

FFTB

to induce a functional disturbance

4.7.2 Electromagnetic interference (EMI)

Based on a simple application running on the product (toggling 2 LEDs through the I/O

ports), the product is monitored in terms of emission. This emission test is in line with the

norm SAE J 1752/3 which specifies the board and the loading of each pin.

Table 20. EMI characteristics

Symbol Parameter Conditions

V

=5V, TA=+25 °C,

S

EMI

Peak level

DD

conforming to SAE J 1752/3

DD

VDD=5V, TA=+25 °C, f

OSC

=8MHz

conforms to IEC 1000-4-2

=5V, TA=+25 °C, f

V

pins

DD

conforms to IEC 1000-4-4

OSC

=8MHz

Max vs.

Monitored

[f

OSC/fCPU

frequency band

4/8MHz 4/4MHz

0.1 MHz to

30 MHz

30 MHz to

130 MHz

130 MHz to

1GHz

19 18

32 27

31 26

SAE EMI Level 4 3.5 -

Level/

Class

2B

4B

(1)

]

Unit

dBµ

V

1. Data based on characterization results, not tested in production.

22/28

ST7GEME4 Electrical characteristics

4.7.3 Absolute maximum ratings (electrical sensitivity)

Based on three differe nt tests (ESD , LU and DLU) using specific measurement m ethods, the

product is stressed in order to determine its performance in terms of electrical sensitivity.

For more details, refer to the application note AN1 181.

Electrostatic discharge (ESD)

Electrostatic discharges (a positive then a negative pulse separated by 1 second) are

applied to the pins of each sample according to each pin combination. The sample size

depends on the number of supply pins in the device (3 parts*(n+1) supply pin). The Human

Body Model is simulated. This test conforms to the JESD22-A114A sta ndard.

Table 21. Absolute maximum ratings

Symbol Ratings Conditions

V

ESD(HBM)

1. Data based on characterization results, not tested in production.

Electrostatic discharge voltage

(Human Body Model)

=+25 °C 2000 V

T

A

Maximum

(1)

value

Unit

Static and dynamic latch-up

● LU: 3 complementary static tests are required on 10 parts to assess the latch-up

performance. A supply overvoltage (applied to each power supply pin) and a current

injection (applied to each input, output and configurable I/O pin) are performed on each

sample. This test conforms to the EIA/JESD 78 I C lat ch-u p standa rd . For more details,

refer to the application note AN1181.

● DLU: Electrostatic discharges (one positive then one negative test) are applied to e ach

pin of 3 samples when the micro is running to assess the latch-up performance in

dynamic mode. P o wer supplies are set to the typical values, the oscillator is connected

as near as possible to the pins of the micro and the component is put in reset mode.

This test conforms to the IEC1000-4-2 and SAEJ1752/3 standards. For more details,

refer to the application note AN1181.

Table 22. Electrical sensitivities

Symbol Parameter Conditions Class

LU Static latch-up class TA=+25 °C A

(1)

V

=5.5 V, f

DLU Dynamic latch-up class

1. Class description: A Class is an STMicroelectronics internal specification. All its limits are higher than the

JEDEC specifications, that means when a device belongs to Class A it exceeds the JEDEC standard. B

Class strictly covers all the JEDEC criteria (international standard).

DD

T

A

OSC

=+25 °C

=4MHz,

A

23/28

Electrical characteristics ST7GEME4

4.8 Communication interface characteristics

Table 23. USB DC electrical characteristics

(1)

Parameter Symbol Conditions Min. Max. Unit

Input Levels

Differential input sensitivity VDI I(D+, D-) 0.2 V

Differential common mode

range

Single ended receiver

threshold

VCM Includes VDI range 0.8 2.5 V

VSE 1.3 2.0 V

Output levels

Static output low V OL RL of 1.5 kΩ to 3.6 V 0.3 V

Static Output high VOH RL of 15 kΩ to V

USBVCC: voltage level USBV V

1. RL is the load connected on the USB drivers. All the voltages are measured from the local ground

potential.

DD

SS

=5 V 3.00 3.60 V

2.8 3.6 V

Figure 7. USB data signal rise and fall time

Differential

Data Lines

VCRS

Crossover

points

V

SS

tf

Table 24. USB full speed electrical characteristics

tr

Parameter Symbol Conditions Min Max Unit

Driver characteristics:

tr/t

(1)

(1)

f

420ns

420ns

90 110 %

Rise time t

Fall time t

Rise/ fall time

matching

Output signal

crossover Voltage

1. Measured from 10% to 90% of the data signal. For more detailed informations, please refer to Chapter 7

(Electrical) of the USB specification (version 1.1).

r

f

t

rfm

VCRS 1.3 2.0 V

CL = 50 pF

CL = 50 pF

24/28

ST7GEME4 Package characteristics

5 Package characteristics

5.1 Package mechanical data

Figure 8. 24-lead very thin fine pitch quad flat no-lead 5x5 mm 0.65 mm pitch, package outline

D

e

19

18

E2

b

13

12

Table 25. 24-lead very thin fine pitch quad flat no-lead 5x5mm,0.65mm pitch, mechanical data

24

1

e

E

6

7

b

D2

L

L

A1

mm inches

C

A

(1)

Dim.

Min Typ Max Min Typ Max

A 0.80 0.90 1.00 0.031 0.035 0.039

A1 0.02 0.05 0.001 0.002

b 0.25 0.30 0.35 0.010 0.012 0.014

D 5.00 0.197

D2 3.50 3.60 3.70 0.138 0.142 0.146

E 5.00 0.197

E2 3.50 3.60 3.70 0.138 0.142 0.146

e 0.65 0.026

L 0.35 0.45 0.55 0.014 0.018 0.022

ddd 0.08 0.003

Number of pins

N 24

1. Values in inches are converted from mm and rounded to 3 decimal digits.

25/28

Package characteristics ST7GEME4

Figure 9. 24-pin plastic small outline package- 300-mil width, package outline

D

12

1

h x 45˚

E

H

13 28

A

B

Table 26. 24-pin plastic small outline package- 300-mil width, mechanical data

e

A1

ddd

C

LA1 α

9U_ME

mm inches

Dim.

Min Typ Max Min Typ Max

A 2.35 2.65 0.093 0.104

A1 0.10 0.30 0.004 0.012

B 0.33 0.51 0.013 0.020

C 0.23 0.32 0.009 0.020

D 15.20 15.60 0.599 0.619

E 7.40 7.60 0.291 0.299

e 1.27 0.050

H 10.00 10.65 0.394 0.419

h 0.25 0.75 0.010 0.030

α 0° 8° 0° 8°

L 0.40 1.27 0.016 0.050

ddd 0.10 0.004

Number of pins

N 24

26/28

ST7GEME4 Revision history

6 Revision history

Table 27. Document revision history

Date Revision Changes

01-Aug-06 0.1 Initial release

10-May-2007 1 Root part number changed from ST7GEM to ST7GEME4.

Document reformatted.

Modified Figure 1 title.

USB host interface replaced by USB interface in Section 1:

Introduction and Table 3: Technical features.

21-Sep-2007 2

Updated Figure 9: 24-pin plastic small outline package- 300-mil

width, package outline. ddd tolerance and maximum values in inched

added in Table 26: 24-pin plastic small outline package- 300-mil

width, mechanical data.

QFN24 package renamed VFQFPN24. Figure 8: 24-lead very thin

fine pitch quad flat no-lead 5x5 mm 0.65 mm pitch, package outline

updated to remove A2 and A3 dimensions.

27/28

ST7GEME4

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely res ponsibl e fo r the c hoic e, se lecti on an d use o f the S T prod ucts and s ervi ces d escr ibed he rein , and ST as sumes no

liability whatsoever relati ng to the choice, selection or use of the ST products and services described he rein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third pa rty p ro duc ts or se rv ices it sh all n ot be deem ed a lice ns e gr ant by ST fo r t he use of su ch thi r d party products

or services, or any intellectua l property c ontained the rein or consi dered as a warr anty coverin g the use in any manner whats oever of suc h

third party products or servi ces or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICUL AR PURPOS E (AND THEIR EQUIVALE NTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJ URY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST fo r the ST pro duct or serv ice describe d herein and shall not cr eate or exten d in any manne r whatsoever , any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document su persedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of compan ie s

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Ger many - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

28/28

Loading...

Loading...