Page 1

8-bit MCU with 16 to 60K Flash/ROM, ADC, CSS,

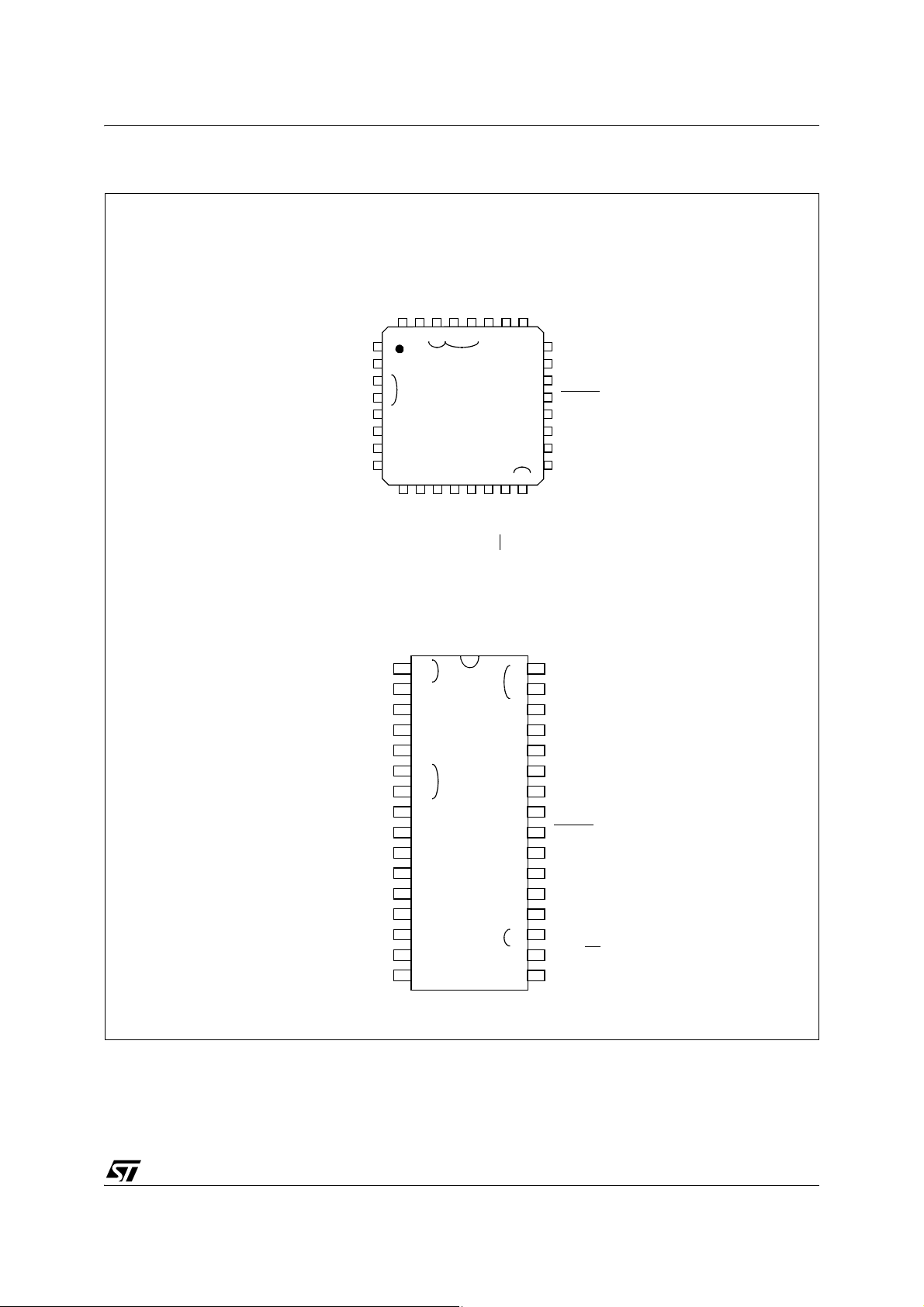

LQFP44

10 x 10

LQFP32

7 x 7

LQFP48

7 x 7

LQFP64

10 x 10

SDIP42

600 mil

SDIP32

400 mil

LQFP64

14 x 14

Features

■ Memories

– 16K to 60K dual voltage High Density Flash

(HDFlash) or up to 32K ROM with read-out

protection capability. In-Application Programming and In-Circuit Programming for HDFlash

devices

– 512 to 2048 bytes RAM

– HDFlash endurance: 100 cycles, data reten-

tion: 40 years at 85°C

■ Clock, reset and supply management

– Enhanced low voltage supervisor (LVD) for

main supply and auxiliary voltage detector

(AVD) with interrupt capability

– Clock sources: crystal/ceramic resonator os-

cillators, internal RC oscillator and bypass for

external clock

– PLL for 2x frequency multiplication

– Four Power Saving Modes: Halt, Active-Halt,

Wait and Slow

– Clock Security System

■ Interrupt management

– Nested interrupt controller

– 14 interrupt vectors plus TRAP and RESET

– Top Level Interrupt (TLI) pin on 64-pin devices

– 9/6 external interrupt lines (on 4 vectors)

■ Up to 48 I/O ports

– 48/36/32/24 multifunctional bidirectional I/O

lines

– 34/26/22/17 alternate function lines

– 16/13/12/10 high sink outputs

■ 5 timers

– Main Clock Controller with: Real time base,

Beep and Clock-out capabilities

ST72325xx

5 timers, SPI, SCI, I

– Configurable watchdog timer

– Two 16-bit timers with: 2 input captures, 2 out-

put compares, external clock input on one timer, PWM and pulse generator modes

– 8-bit PWM Auto-reload timer with: 2 input cap-

tures, 4 PWM outputs, output compare and

time base interrupt, external clock with event

detector

■ 3 Communication interfaces

– SPI synchronous serial interface

– SCI asynchronous serial interface

2

C multimaster interface

–I

■ 1 Analog peripheral (low current coupling)

– 10-bit ADC with up to 16 robust input ports

■ Instruction set

– 8-bit Data Manipulation

– 63 Basic Instructions

– 17 main Addressing Modes

– 8 x 8 Unsigned Multiply Instruction

■ Development tools

– Full hardware/software development package

– DM (Debug module)

2

C interface

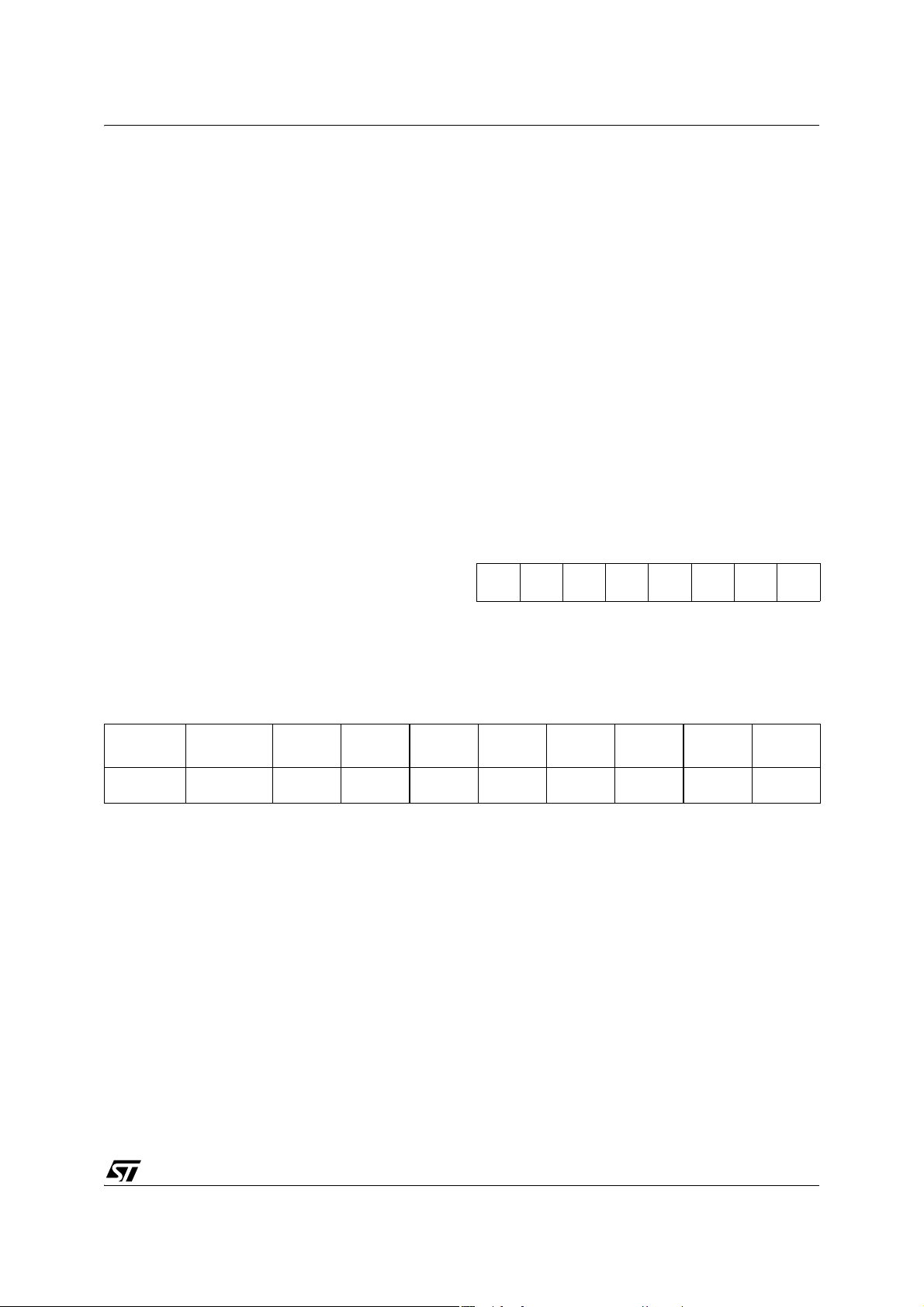

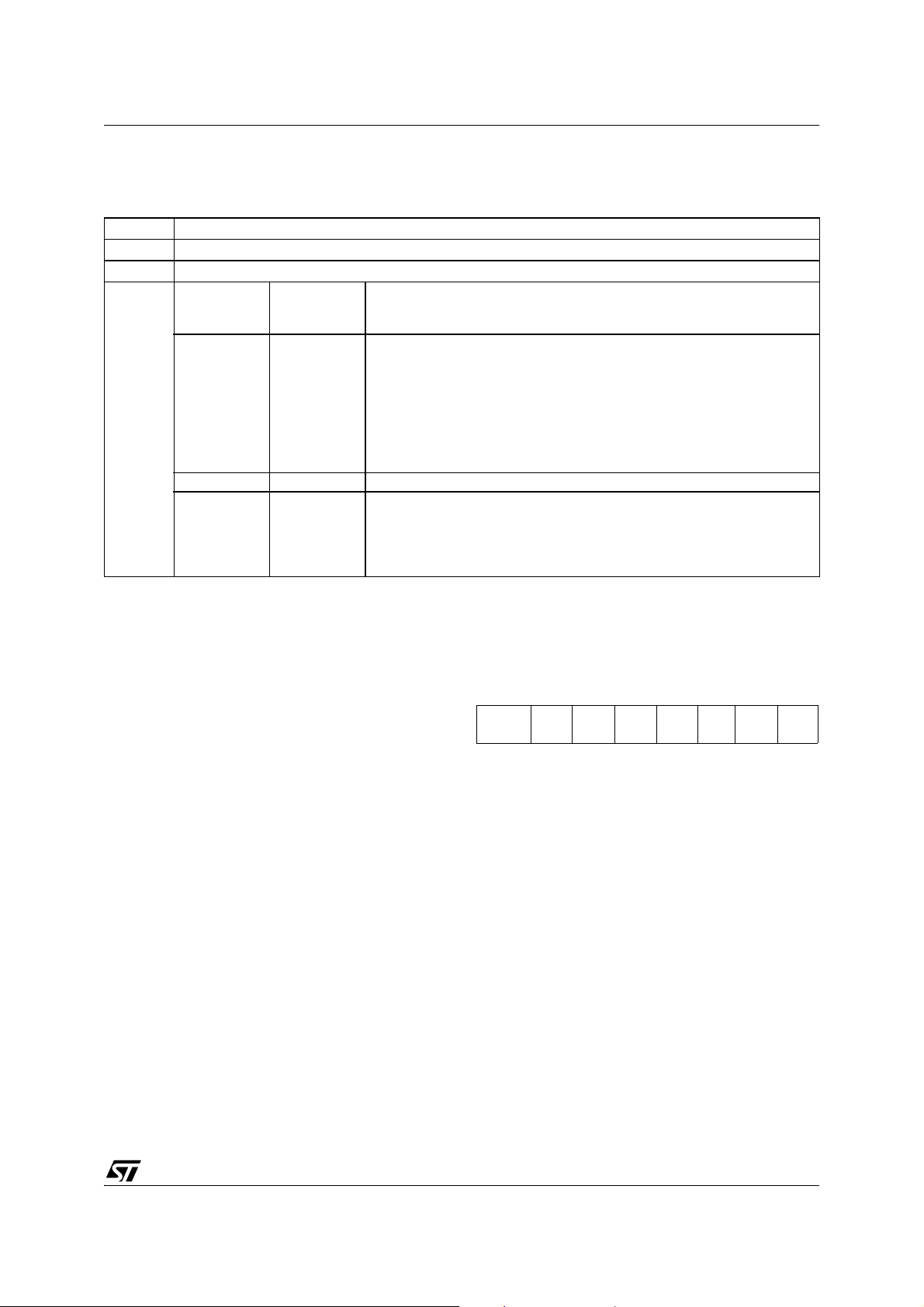

Table 1. Device summary

Features

Program memory - bytes Flash/ROM 16K Flash/ROM 32K Flash 48K Flash 60K

RAM (stack) - bytes 512 (256) 1024(256) 1536 (256) 2048(256)

Operating Voltage 3.8V to 5.5V

Temp. Range up to -40°C to +125°C

Package

October 2008 Rev 4 1/197

LQFP48(S), LQFP44/SDIP42 (J),

ST72325S4 /

ST72325J4 / ST72325K4

LQFP48(S) , LQFP44/ SDIP42 (J),

LQFP32/DIP32 (K)

ST72325S6 /

ST72325J6 / ST72325K6

LQFP32/DIP32 (K)

ST72325J7

LQFP44 (J)

ST72325R9 /

ST72325AR9 /

ST72325C9 /ST72325J9

LQFP64 14x14(R), LQFP64

10x10(AR), LQFP48(C),

LQFP44 (J)

1

Page 2

Table of Contents

1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 REGISTER & MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 Read-out Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 ICC INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 ICP (IN-CIRCUIT PROGRAMMING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 IAP (IN-APPLICATION PROGRAMMING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 RELATED DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7.1 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 PHASE LOCKED LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 MULTI-OSCILLATOR (MO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 RESET SEQUENCE MANAGER (RSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.2 Asynchronous External RESET pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.3 External Power-On RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.4 Internal Low Voltage Detector (LVD) RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.5 Internal Watchdog RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4 SYSTEM INTEGRITY MANAGEMENT (SI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.1 Low Voltage Detector (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2 Auxiliary Voltage Detector (AVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.3 Clock Security System (CSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.4 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2 MASKING AND PROCESSING FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 INTERRUPTS AND LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4 CONCURRENT & NESTED MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5 INTERRUPT REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.6 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.6.1 I/O Port Interrupt Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.7 EXTERNAL INTERRUPT CONTROL REGISTER (EICR) . . . . . . . . . . . . . . . . . . . . . . . . . 43

8 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

197

2/197

1

Page 3

Table of Contents

8.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.4 ACTIVE-HALT AND HALT MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.4.1 ACTIVE-HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.4.2 HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

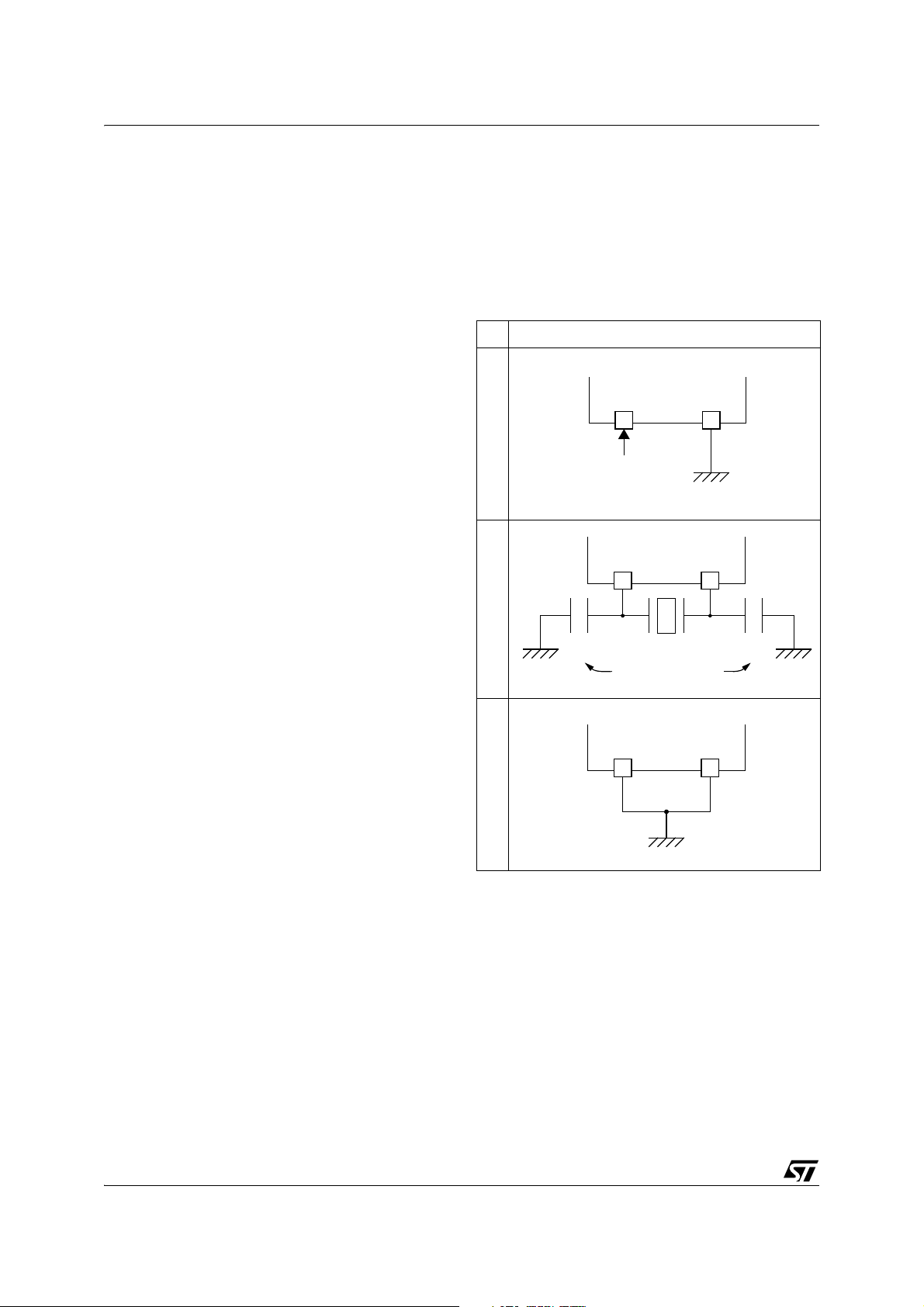

9.2.1 Input Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2.2 Output Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2.3 Alternate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.3 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.4 LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.5 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.5.1 I/O Port Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.4 How to Program the Watchdog Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.1.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.6 Hardware Watchdog Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.7 Using Halt Mode with the WDG (WDGHALT option) . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.8 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.1.9 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.2 MAIN CLOCK CONTROLLER WITH REAL TIME CLOCK AND BEEPER (MCC/RTC) . . 61

10.2.1 Programmable CPU Clock Prescaler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2.2 Clock-out Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2.3 Real Time Clock Timer (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2.4 Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.3 PWM AUTO-RELOAD TIMER (ART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.3.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.3.3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.4 16-BIT TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.4.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.4.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.4.4 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.4.5 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.4.6 Summary of Timer Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.4.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.5 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3/197

1

Page 4

Table of Contents

10.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.5.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.5.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.5.4 Clock Phase and Clock Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.5.5 Error Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.5.6 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.5.7 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.5.8 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.6 SERIAL COMMUNICATIONS INTERFACE (SCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.6.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.6.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.6.4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.6.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.6.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.6.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.7 I2C BUS INTERFACE (I2C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.7.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.7.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.7.4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.7.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

10.7.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

10.7.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

10.8 10-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.8.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.8.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.8.4 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.8.5 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

10.8.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

11 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11.1 CPU ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

11.1.1 Inherent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.1.2 Immediate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.1.3 Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.1.4 Indexed (No Offset, Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.1.5 Indirect (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

11.1.6 Indirect Indexed (Short, Long) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

11.1.7 Relative mode (Direct, Indirect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

11.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

12 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1.1 Minimum and Maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

12.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

197

4/197

Page 5

Table of Contents

12.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.2.1 Voltage Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.2.2 Current Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.2.3 Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

12.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

12.3.1 General Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

12.3.2 Operating Conditions with Low Voltage Detector (LVD) . . . . . . . . . . . . . . . . . . . 145

12.3.3 Auxiliary Voltage Detector (AVD) Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.3.4 External Voltage Detector (EVD) Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

12.4.1 CURRENT CONSUMPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

12.4.2 Supply and Clock Managers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12.4.3 On-Chip Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

12.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

12.5.1 General Timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

12.5.2 External Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

12.5.3 Crystal and Ceramic Resonator Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

12.5.4 RC Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

12.5.5 Clock Security System (CSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

12.5.6 PLL Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

12.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

12.6.1 RAM and Hardware Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

12.6.2 FLASH Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

12.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

12.7.1 Functional EMS (Electro Magnetic Susceptibility) . . . . . . . . . . . . . . . . . . . . . . . . 156

12.7.2 Electro Magnetic Interference (EMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

12.7.3 Absolute Maximum Ratings (Electrical Sensitivity) . . . . . . . . . . . . . . . . . . . . . . . 158

12.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

12.8.1 General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

12.8.2 Output Driving Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

12.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

12.9.1 Asynchronous RESET Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

12.9.2 ICCSEL/VPP Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

12.10TIMER PERIPHERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

12.10.1 8-Bit PWM-ART Auto-Reload Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

12.10.2 16-Bit Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

12.11COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . 166

12.11.1 SPI - Serial Peripheral Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

12.11.2 I2C - Inter IC Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

12.1210-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.12.1 Analog Power Supply and Reference Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

12.12.2 General PCB Design Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

12.12.3 ADC Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13 PACKAGE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

13.2 THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

5/197

Page 6

Table of Contents

13.3 SOLDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

14 ST72325 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . 181

14.1 FLASH OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.2 DEVICE ORDERING INFORMATION AND TRANSFER OF CUSTOMER CODE . . . . . 183

14.3 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.3.1 Starter kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.3.2 Development and debugging tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.3.3 Programming tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.3.4 Socket and Emulator Adapter Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

14.4 ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

15 KNOWN LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

15.1 ALL DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

15.1.1 Unexpected Reset Fetch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

15.1.2 External interrupt missed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

15.1.3 Clearing active interrupts outside interrupt routine . . . . . . . . . . . . . . . . . . . . . . . 193

15.1.4 SCI Wrong Break duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

15.1.5 16-bit Timer PWM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

15.1.6 TIMD set simultaneously with OC interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

15.1.7 I2C Multimaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

15.1.8 Pull-up always active on PE2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

15.1.9 ADC accuracy 16/32K Flash devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

16 REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

6/197

197

Page 7

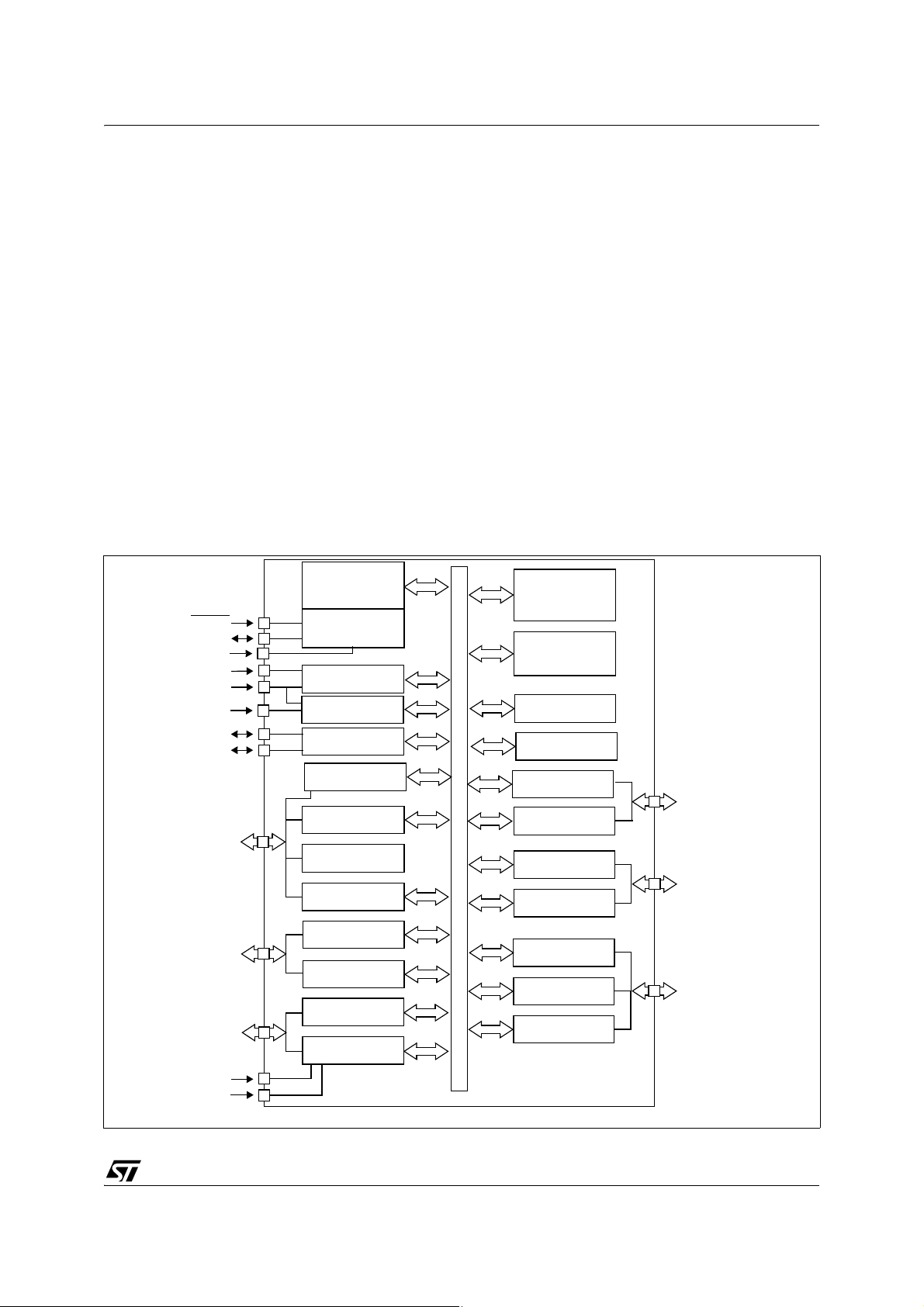

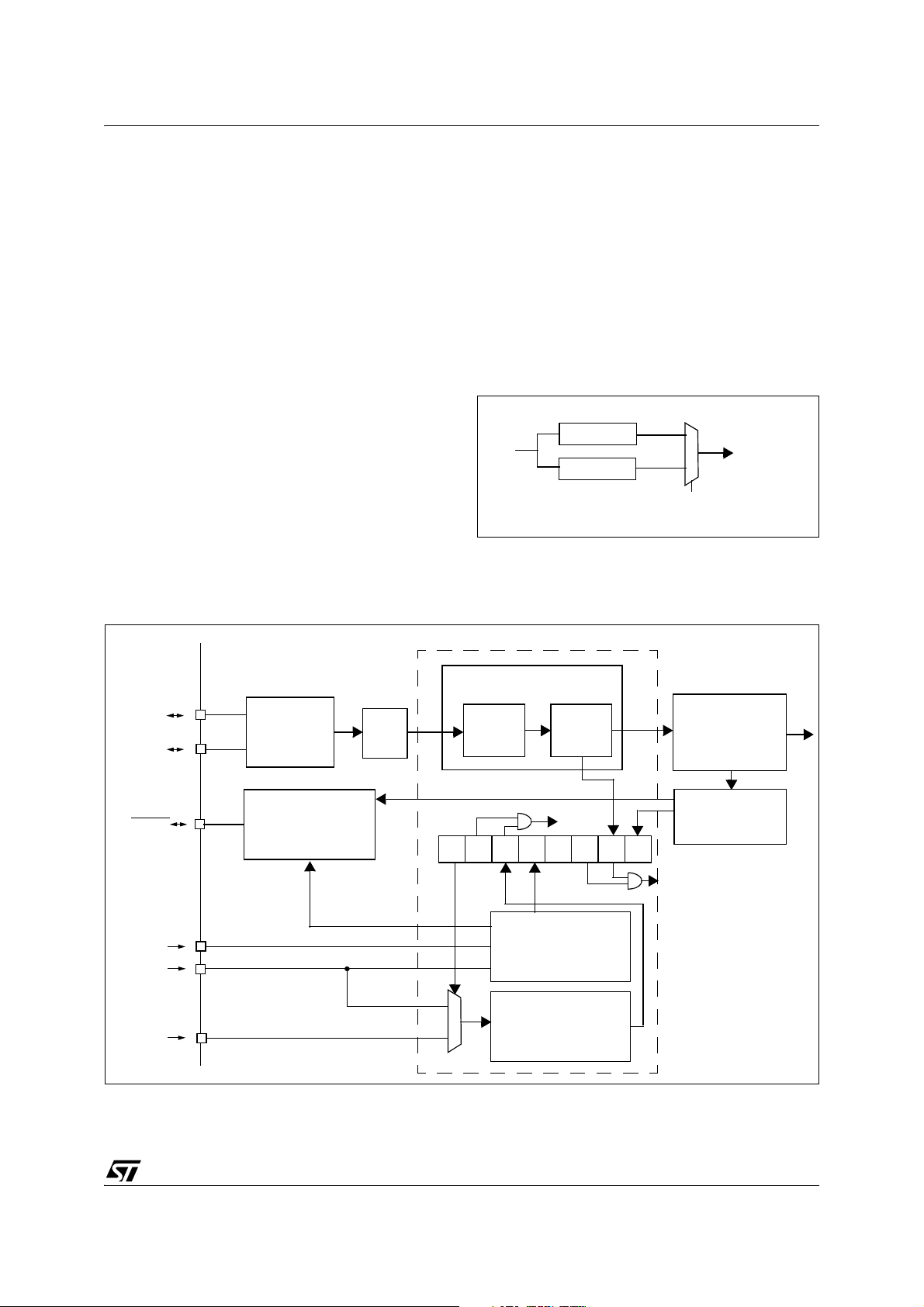

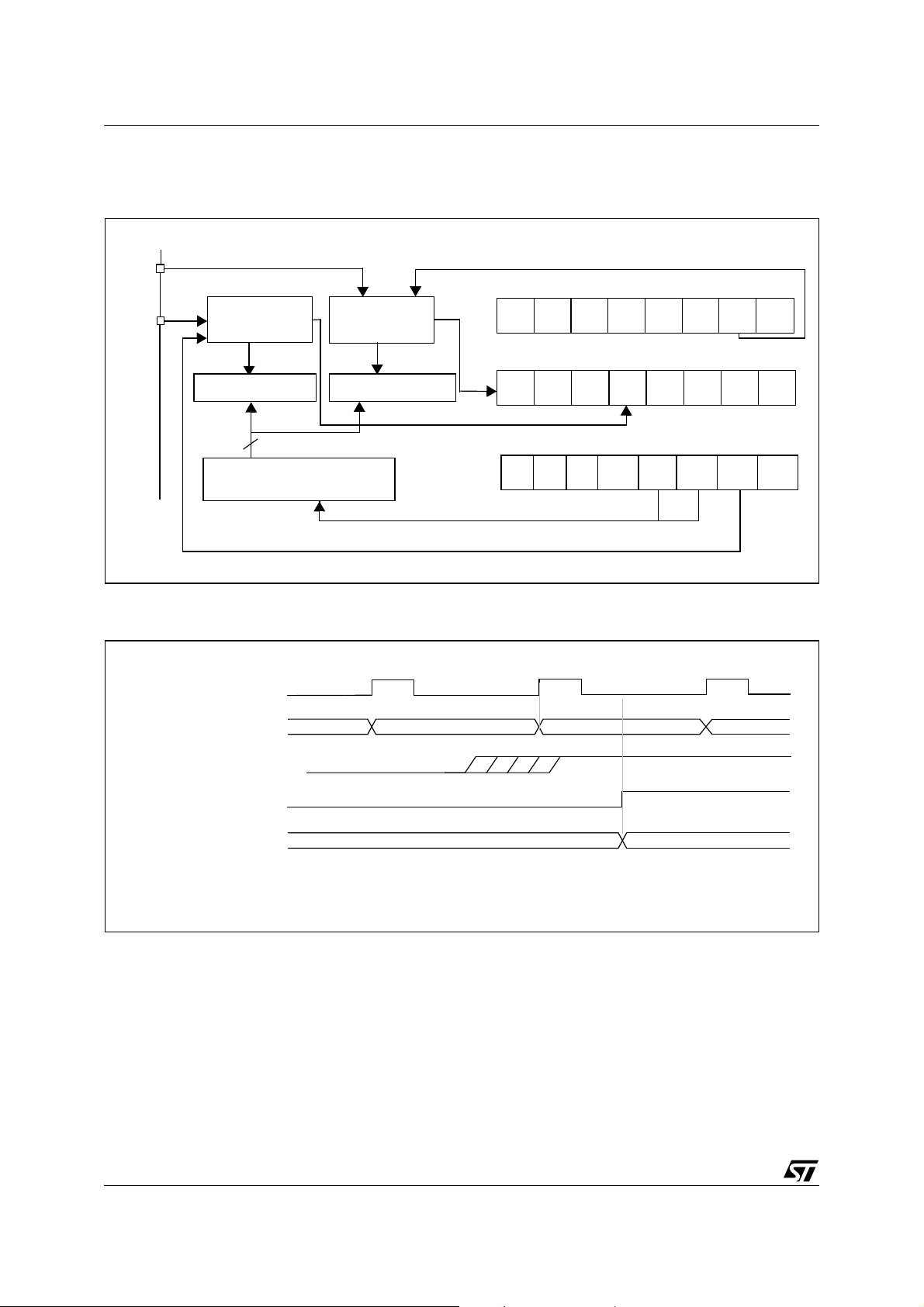

ST72325xx

8-BIT CORE

ALU

ADDRESS AND DATA BUS

OSC1

V

PP

CONTROL

PROGRAM

(16K - 60K Bytes1))

V

DD

RESET

PORT F

PF7:0

TIMER A

BEEP

RAM

(512 - 2048 Bytes1))

PORT C

10-BIT ADC

V

AREF

V

SSA

PB7:0

PORT E

PE7:0

(2 bits on C/J/K devices)

SCI

TIMER B

PA7:0

(5 bits on C/J devices)

PORT D

PD7:0

SPI

PC7:0

(8 bits)

V

SS

WATCHDOG

OSC

LVD

OSC2

MEMORY

MCC/RTC/BEEP

(4 bits on K devices)

(5 bits on C/J devices)

(3 bits on K devices)

(6 bits on C/J devices)

(2 bits on K devices)

(6 bits on C/J devices)

(5 bits on K devices)

PORT A

PORT B

PWM ART

I2C

EVD

AVD

(8 bits on AR devices)

(8 bits on AR devices)

(8 bits on AR devices)

(8 bits on AR devices)

(8 bits on AR devices)

TLI

1)

ROM devices have up to 32 Kbytes of program memory and up to 1 Kbyte of RAM.

DEBUG MODULE

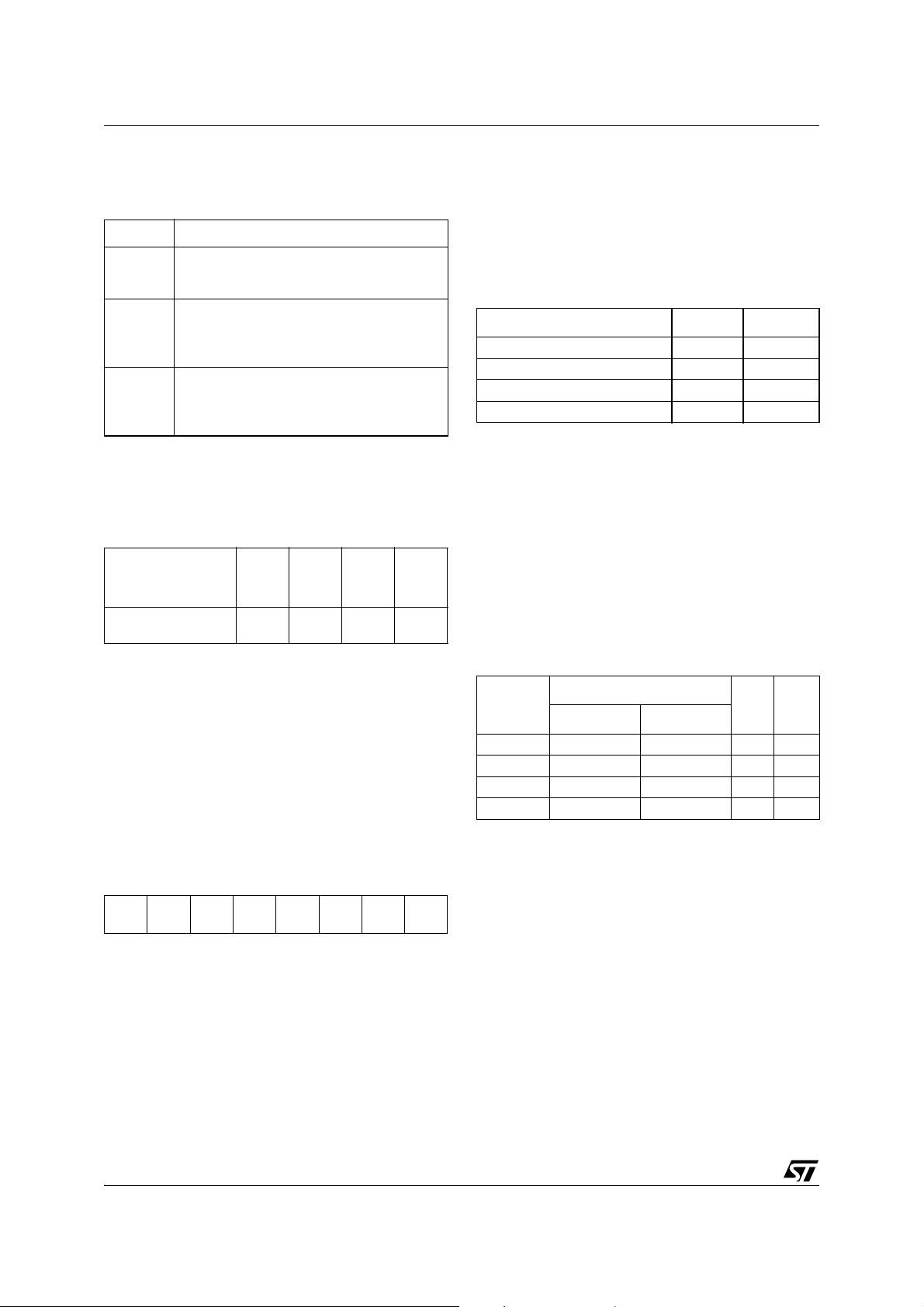

1 DESCRIPTION

The ST72F325 Flash and ST72325 ROM devices

are members of the ST7 microcontroller family designed for mid-range applications.

They are derivatives of the ST72321 and ST72324

devices, with enhanced characteristics and robust

Clock Security System.

All devices are based on a common industrystandard 8-bit core, featuring an enhanced instruction set and are available with Flash or ROM program memory. The ST7 family architecture offers

both power and flexibility to software developers,

enabling the design of highly efficient and compact

application code.

The on-chip peripherals include an A/D converter,

a PWM Autoreload timer, 2 general purpose tim-

2

C bus, SPI interface and an SCI interface.

ers, I

For power economy, microcontroller can switch

dynamically into WAIT, SLOW, ACTIVE-HALT or

Figure 1. Device Block Diagram

HALT mode when the application is in idle or

stand-by state.

Typical applications are consumer, home, office

and industrial products.

The devices feature an on-chip Debug Module

(DM) to support in-circuit debugging (ICD). For a

description of the DM registers, refer to the ST7

ICC Protocol Reference Manual.

Main Differences with ST72321:

– LQFP48 and LQFP32 packages

– Clock Security System

– Internal RC, Readout protection, LVD and PLL

without limitations

– Negative current injection not allowed on I/O port

PB0 (instead of PC6).

– External interrupts have Exit from Active Halt

mode capability.

7/197

Page 8

ST72325xx

V

AREF

V

SSA

V

DD_3

V

SS_3

MCO / AIN8 / PF0

BEEP / (HS) PF1

(HS) PF2

OCMP2_A / AIN9 / PF3

OCMP1_A / AIN10 / PF4

ICAP2_A / AIN11 / PF5

ICAP1_A / (HS) PF6

EXTCLK_A / (HS) PF7

AIN4 / PD4

AIN5 / PD5

AIN6 / PD6

AIN7 / PD7

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ei2

ei3

ei0

ei1

PWM3 / PB0

PWM2 / PB1

PWM1 / PB2

PWM0 / PB3

ARTCLK / (HS) PB4

ARTIC1 / PB5

ARTIC2 / PB6

PB7

AIN0 / PD0

AIN1 / PD1

AIN2 / PD2

AIN3 / PD3

(HS) PE4

(HS) PE5

(HS) PE6

(HS) PE7

PA1

PA0

PC7 / SS / AIN15

PC6 / SCK / ICCCLK

PC5 / MOSI / AIN14

PC4 / MISO / ICCDATA

PC3 (HS) / ICAP1_B

PC2 (HS) / ICAP2_B

PC1 / OCMP1_B / AIN13

PC0 / OCMP2_B / AIN12

V

SS_0

V

DD_0

V

SS_1

V

DD_1

PA3 (HS)

PA2

V

DD

_2

OSC1

OSC2

V

SS

_2

TLI

EVD

RESET

V

PP

/ ICCSEL

PA7 (HS) / SCLI

PA6 (HS) / SDAI

PA5 (HS)

PA4 (HS)

PE3

PE2

PE1 / RDI

PE0 / TDO

(HS) 20mA high sink capability

eix associated external interrupt vector

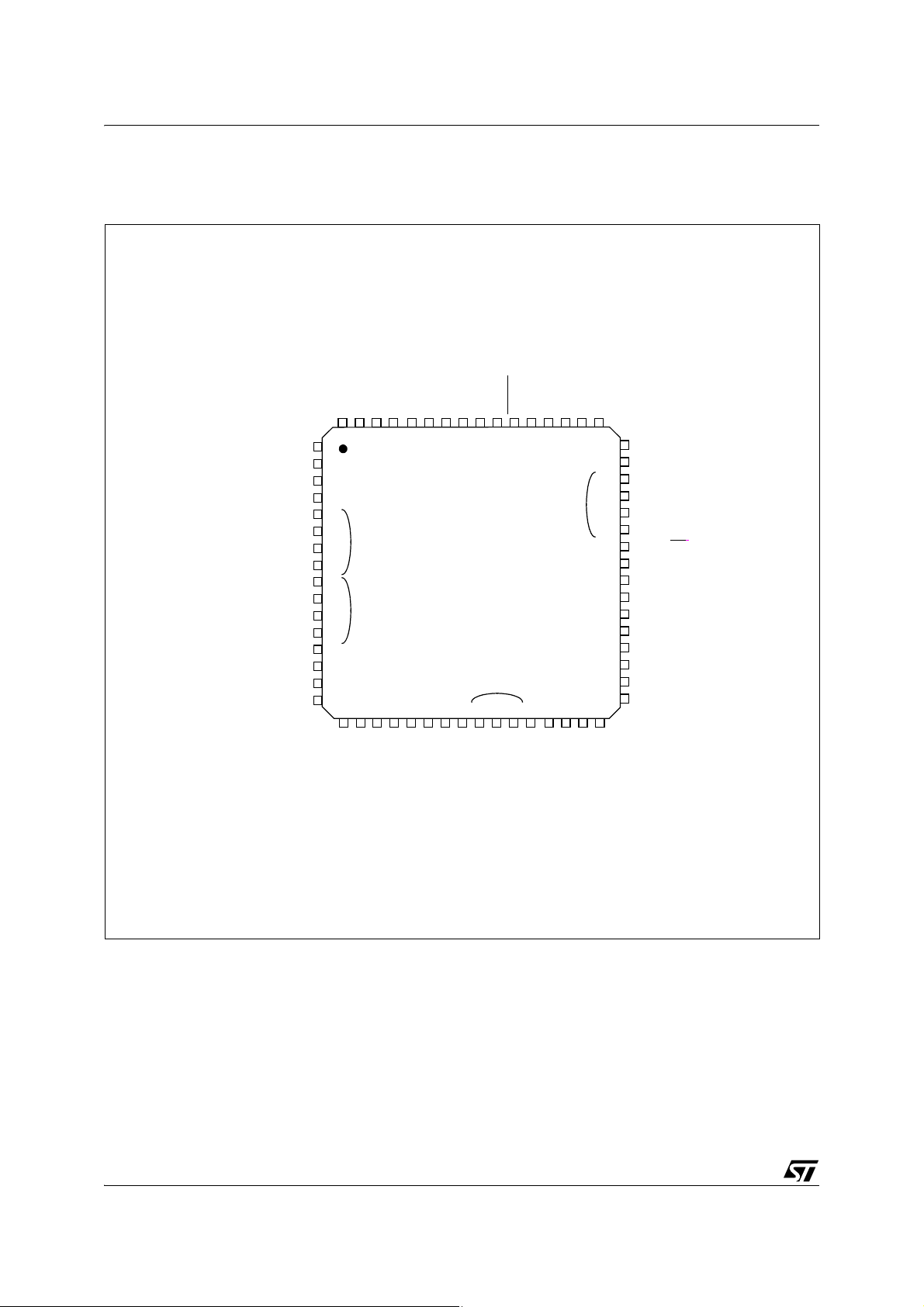

2 PIN DESCRIPTION

Figure 2. 64-Pin LQFP 14x14 and 10x10 Package Pinout

8/197

Page 9

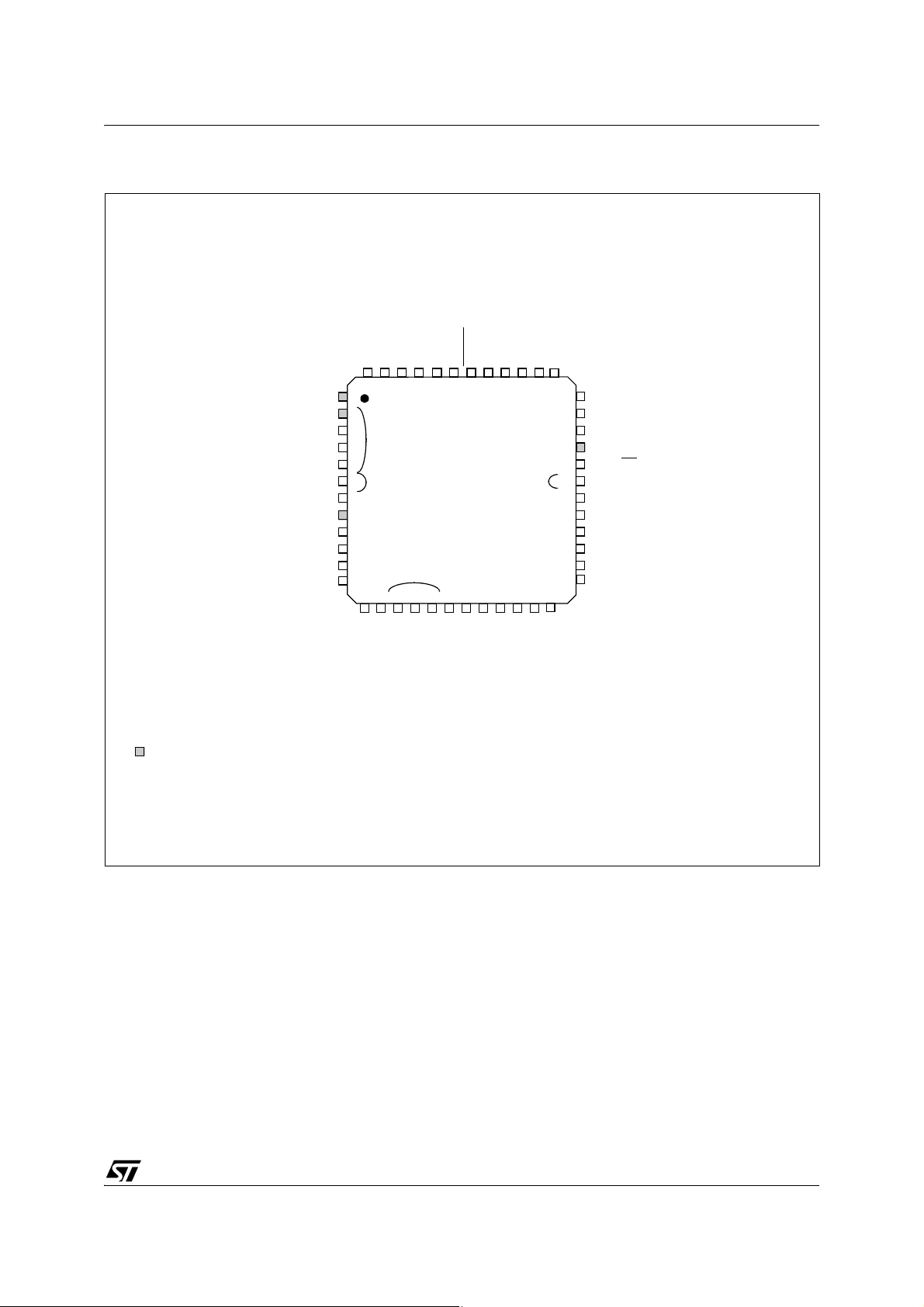

Figure 3. 48-Pin LQFP 7x7 Device Pinout

44 43 42 41 40 39 38 37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

12

13 14 15 16 17 18 19 20 21 22

1

2

3

4

5

6

7

8

9

10

11

48 47 46 45

AIN4 / PD3

V

DD_0

PC1 / OCMP1_B / AIN13

PC0 / OCMP2_B / AIN12

V

SS_1

V

SS_0

OSC2

V

SS

_2

PA7 (HS) / SCLI

PA6 (HS) / SDAI

PA5 (HS)

PA4 (HS)

PE1/ RDI

PE0 / TDO

V

DD

_2

OSC1

RESET

V

PP

/ICCSEL

PC6 / SCK / ICCCLK

PC5 / MOSI / AIN14

PC4 / MISO / ICCDATA

PC3 (HS) / ICAP1_B

PC2 (HS) / ICAP2_B

V

DD_1

PA3 (HS)

PA2

PC7 / SS / AIN15

V

AREF

V

SSA

MCO / AIN8 / PF0

BEEP / (HS) PF1

(HS) PF2

OCMP1_A / AIN10 / PF4

ICAP1_A / (HS) PF6

EXTCLK_A / (HS) PF7

AIN4 / PD4

AIN5 / PD5

PWM1 / PB2

PWM0 / PB3

ARTCLK / (HS) PB4

ARTIC1 / PB5

AIN0 / PD0

AIN1 / PD1

AIN3 / PD2

PE2

(HS) PE4

PWM3 / PB0

PWM2 / PB1

ei2

ei3

ei0

ei1

eix associated external interrupt vector

(HS) 20mA high sink capability

= Pin not connected in ST72325S devices

Legend

Caution: 48-pin ‘C’ devices have unbonded pins that require software initialization. Refer

to Note 4 on page 16 for details on initializing the I/O registers for these devices.

ST72325xx

9/197

Page 10

ST72325xx

MCO / AIN8 / PF0

BEEP / (HS) PF1

(HS) PF2

OCMP1_A / AIN10 / PF4

ICAP1_A / (HS) PF6

EXTCLK_A / (HS) PF7

V

DD_0

V

SS_0

AIN5 / PD5

V

AREF

V

SSA

44 43 42 41 40 39 38 37 36 35 34

33

32

31

30

29

28

27

26

25

24

23

12 13 14 15 16 17 18 19 20 21 22

1

2

3

4

5

6

7

8

9

10

11

ei2

ei3

ei0

ei1

PB3

(HS) PB4

AIN0 / PD0

AIN1 / PD1

AIN2 / PD2

AIN3 / PD3

AIN4 / PD4

RDI / PE1

PB0

PB1

PB2

PC6 / SCK / ICCCLK

PC5 / MOSI / AIN14

PC4 / MISO / ICCDATA

PC3 (HS) / ICAP1_B

PC2 (HS) / ICAP2_B

PC1 / OCMP1_B / AIN13

PC0 / OCMP2_B / AIN12

V

SS_1

V

DD_1

PA3 (HS)

PC7 / SS

/ AIN15

V

SS

_2

RESET

V

PP

/ ICCSEL

PA7 (HS) / SCLI

PA6 (HS) / SDAI

PA5 (HS)

PA4 (HS)

PE0 / TDO

V

DD

_2

OSC1

OSC2

38

37

36

35

34

33

32

31

30

29

28

27

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

39

40

41

42

(HS) PB4

AIN0 / PD0

AIN12 / OCMP2_B / PC0

EXTCLK_A / (HS) PF7

ICAP1_A / (HS) PF6

AIN10 / OCMP1_A / PF4

(HS) PF2

BEEP / (HS) PF1

MCO / AIN8 / PF0

AIN5 / PD5

AIN4 / PD4

AIN3 / PD3

AIN2 / PD2

AIN1 / PD1

V

SSA

V

AREF

PB3

PB2

PA4 (HS)

PA5 (HS)

PA6 (HS) / SDAI

PA7 (HS) / SCLI

V

PP

/ ICCSEL

RESET

VSS_2

V

DD

_2

PE0 / TDO

PE1 / RDI

PB0

PB1

OSC1

OSC2

ei3

ei0

ei2

ei1

21

20

17

18

19

AIN14 / MOSI / PC5

ICCDATA / MISO / PC4

ICAP1_B / (HS) PC3

ICAP2_B/ (HS) PC2

AIN13 / OCMP1_B / PC1

26

25

24

23

22

PC6 / SCK / ICCCLK

PC7 / SS

/ AIN15

PA3 (HS)

V

DD_1

V

SS_1

eix associated external interrupt vector

(HS) 20mA high sink capability

Figure 4. 44/42-Pin LQFP Package Pinouts

10/197

Page 11

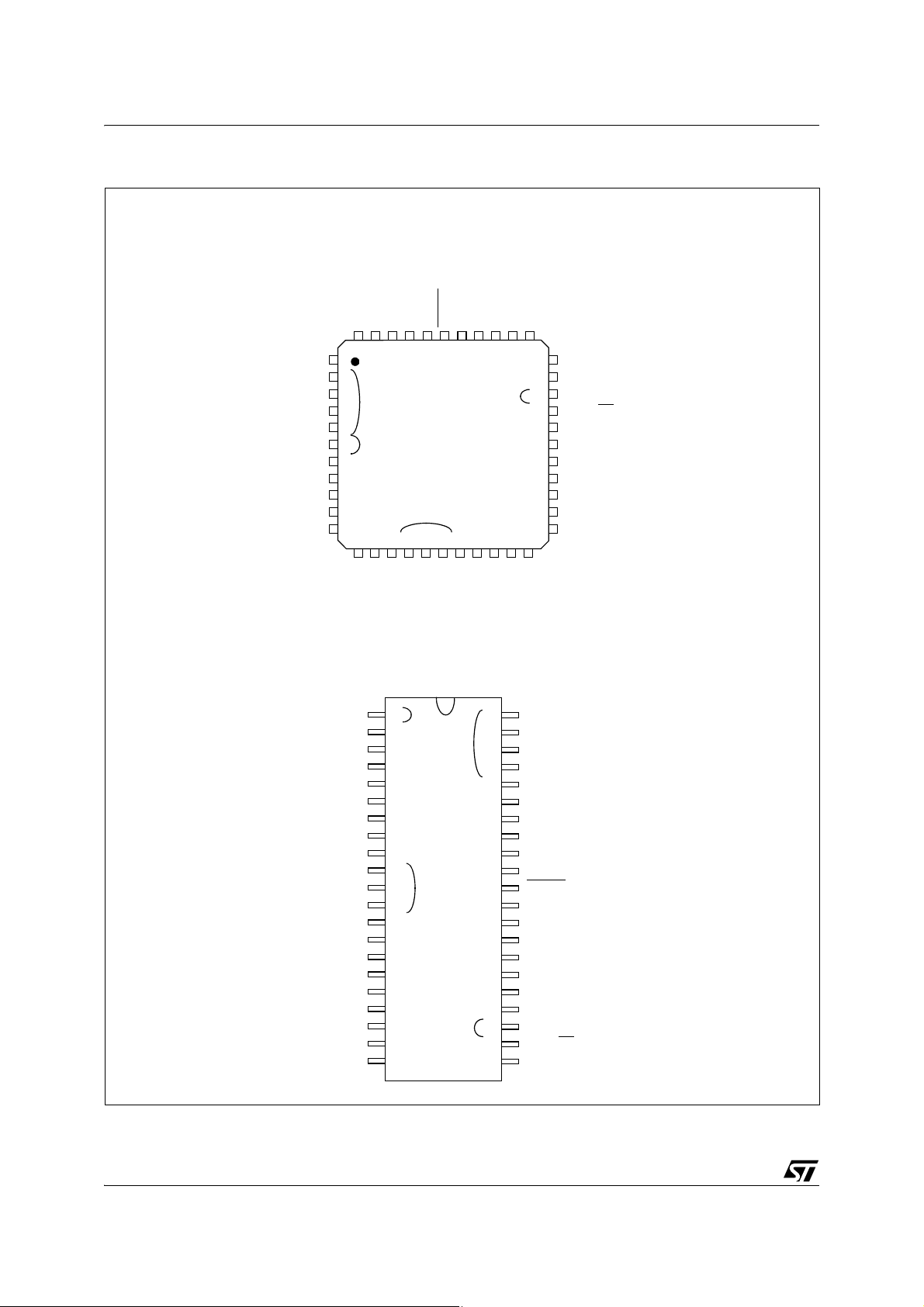

Figure 5. 32-Pin LQFP/DIP Package Pinouts

ICCDATA / MISO / PC4

AIN14 / MOSI / PC5

ICCCLK / SCK / PC6

AIN15 / SS / PC7

(HS) PA3

AIN13 / OCMP1_B / PC1

ICAP2_B / (HS) PC2

ICAP1_B / (HS) PC3

32 31 30 29 28 27 26 25

24

23

22

21

20

19

18

17

9 10111213141516

1

2

3

4

5

6

7

8

ei1

ei3

ei0

OCMP1_A / AIN10 / PF4

ICAP1_A / (HS) PF6

EXTCLK_A / (HS) PF7

AIN12 / OCMP2_B / PC0

V

AREF

V

SSA

MCO / AIN8 / PF0

BEEP / (HS) PF1

V

PP

/ ICCSEL

PA7 (HS)/SCLI

PA6 (HS) / SDAI

PA4 (HS)

OSC1

OSC2

V

SS

_2

RESET

PB0 / PWM3

PE1 / RDI

PE0 / TDO

V

DD

_2

PD1 / AIN1

PD0 / AIN0

PB4 (HS) / ARTCLK

PB3 / PWM0

ei2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

29

30

31

32

(HS) PB4

AIN0 / PD0

AIN14 / MOSI / PC5

ICCDATA/ MISO / PC4

ICAP1_B / (HS) PC3

ICAP2_B / (HS) PC2

AIN13 / OCMP1_B / PC1

AIN12 / OCMP2_B / PC0

EXTCLK_A / (HS) PF7

BEEP / (HS) PF1

MCO / AIN8 / PF0

V

SSA

V

AREF

AIN1 / PD1

ICAP1_A / (HS) PF6

OCMP1_A / AIN10 / PF4

PB3

PB0

PC6 / SCK / ICCCLK

PC7 / SS / AIN15

PA3 (HS)

PA4 (HS)

PA6 (HS) / SDAI

PA7 (HS) / SCLI

V

PP

/ ICCSEL

OSC2

OSC1

V

DD

_2

PE0 / TDO

PE1 / RDI

VSS_2

RESET

ei0

ei3

ei2

ei1

eix associated external interrupt vector

(HS) 20mA high sink capability

ST72325xx

11/197

Page 12

ST72325xx

PIN DESCRIPTION (Cont’d)

For external pin connection guidelines, refer to See “ELECTRICAL CHARACTERISTICS” on page 142.

Legend / Abbreviations for Table 2 and Table 3:

Type: I = input, O = output, S = supply

Input level: A = Dedicated analog input

In/Output level: C = CMOS 0.3V

CT= CMOS 0.3VDD/0.7VDD with input trigger

Output level: HS = 20mA high sink (on N-buffer only)

Port and control configuration:

– Input: float = floating, wpu = weak pull-up, int = interrupt

– Output: OD = open drain

Refer to “I/O PORTS” on page 50 for more details on the software configuration of the I/O ports.

The RESET configuration of each pin is shown in bold. This configuration is valid as long as the device is

in reset state.

= Pin not connected in ST72325S devices

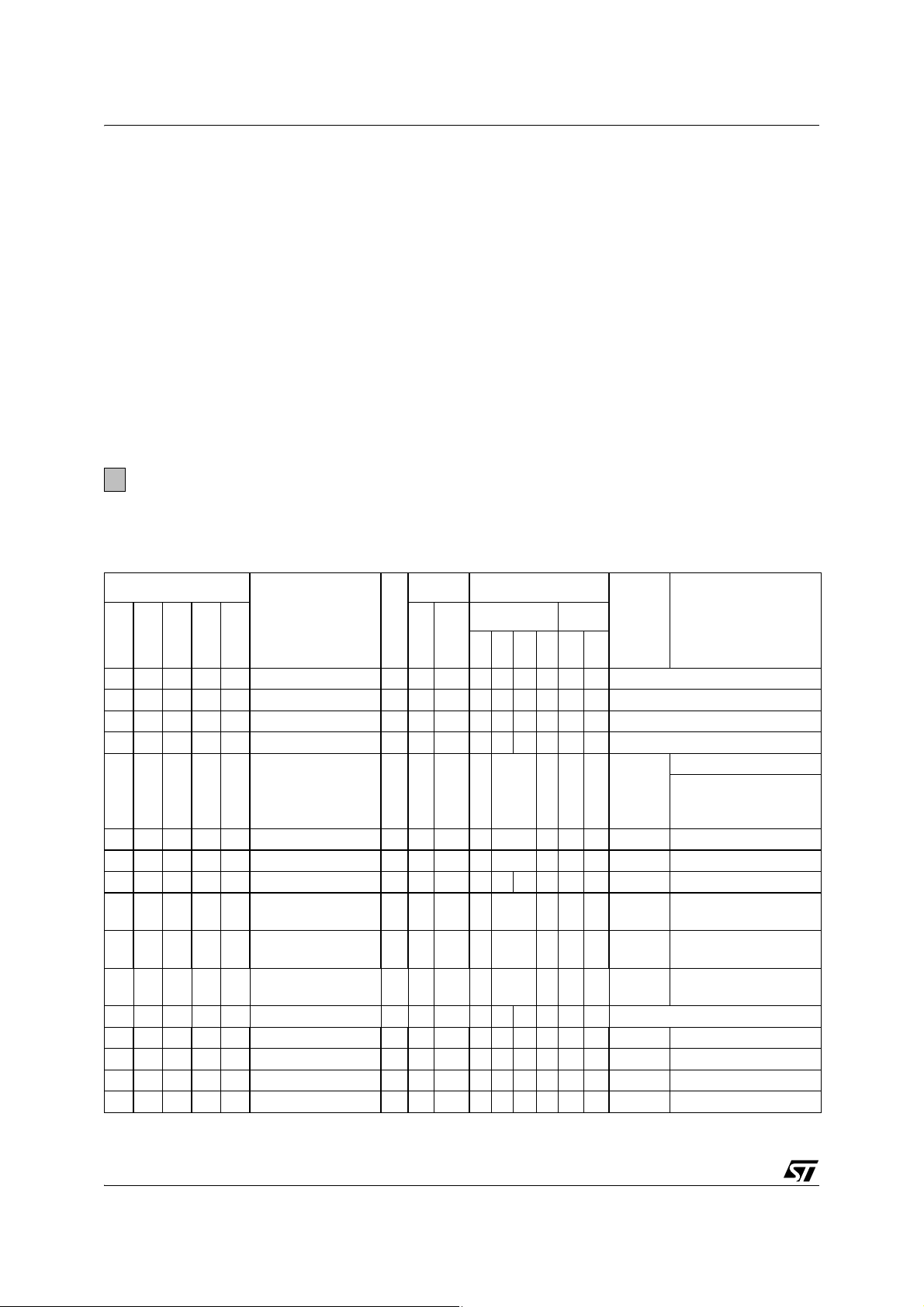

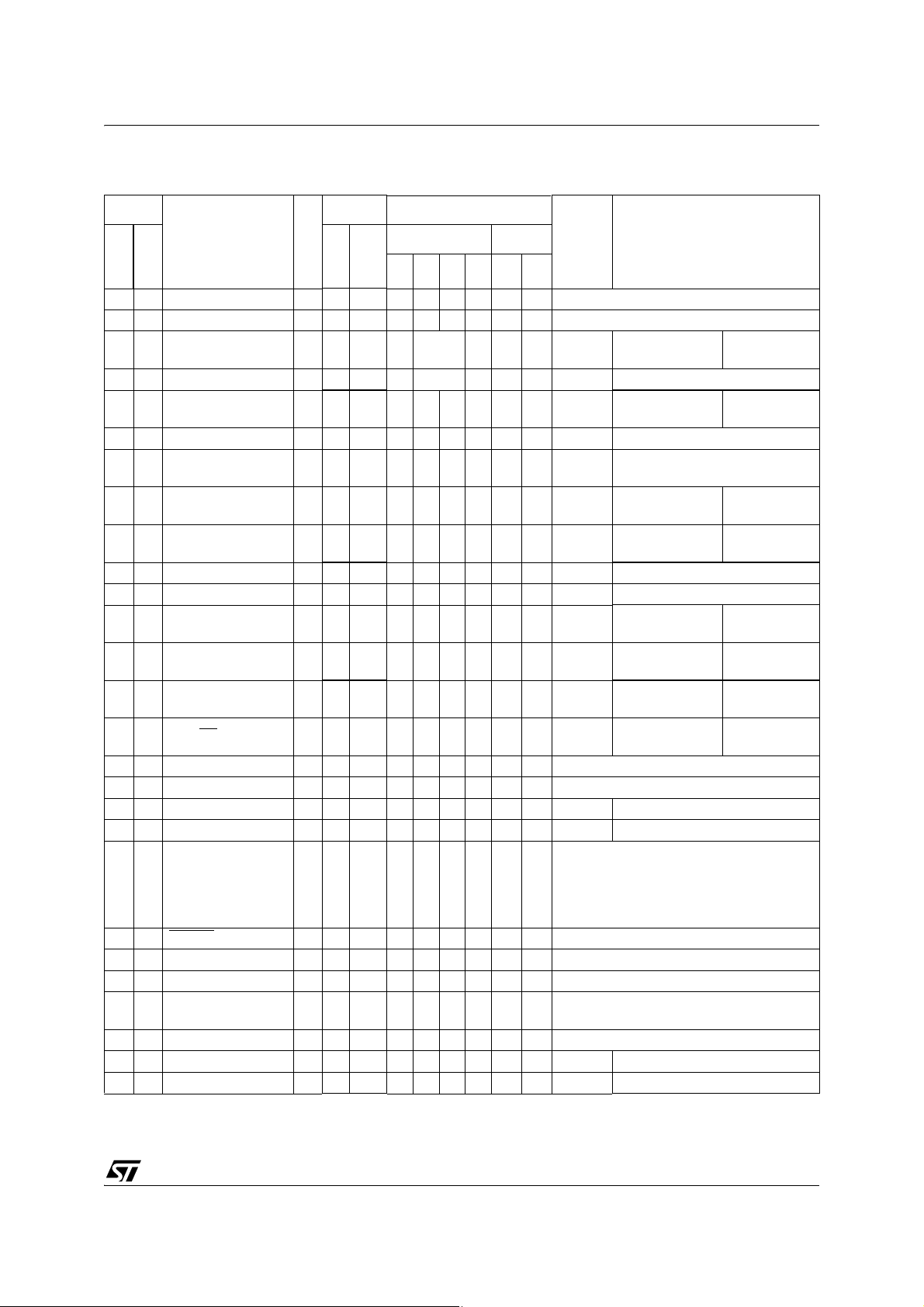

Table 2. LQFP64/48/44 and SDIP42 Device Pin Descriptions

/0.7V

DD

2)

DD

, PP = push-pull

1)

, ana = analog

LQFP64

Pin n°

LQFP48S

LQFP48C

Pin Name

SDIP42

LQFP44

Level Port

Type

Input

Output

float

Input Output

int

OD

ana

wpu

Main

function

(after

reset)

PP

Alternate function

12- - -PE4 (HS) I/OCTHS X XXXPort E4

4)

234-

---PE5 (HS) I/OCTHS X XXXPort E5

4)

---PE6 (HS) I/OCTHS X XXXPort E6

4)

---PE7 (HS) I/OCTHS X XXXPort E7

PWM Output 3

533239PB0/PWM3 I/OC

T

X ei2 X X Port B0

Caution: Negative cur-

rent injection not allowed on this pin

644340PB1/PWM2 I/OC

755441PB2/PWM1 I/OC

866542PB3/PWM0 I/OC

9 7 7 6 1 PB4 (HS)/ARTCLK I/O C

10 8 - - - PB5 / ARTIC1 I/O C

4)

11 -

12 -

- - - PB6 / ARTIC2 I/O C

4)

---PB7 I/OCTX ei3 X X Port B7

139972PD0/AIN0 I/OC

14 19 10 8 3 PD1/AIN1 I/O C

15 11 11 9 4 PD2/AIN2 I/O C

16 12 12 10 5 PD3/AIN3 I/O C

T

T

T

T

T

T

T

T

T

T

X ei2 X X Port B1 PWM Output 2

X ei2 X X Port B2 PWM Output 1

X ei2 X X Port B3 PWM Output 0

HS X ei3 X X Port B4

X ei3 X X Port B5

X ei3 X X Port B6

PWM-ART External

Clock

PWM-ART Input Capture 1

PWM-ART Input Capture 2

X X X X X Port D0 ADC Analog Input 0

X X X X X Port D1 ADC Analog Input 1

X X X X X Port D2 ADC Analog Input 2

X X X X X Port D3 ADC Analog Input 3

12/197

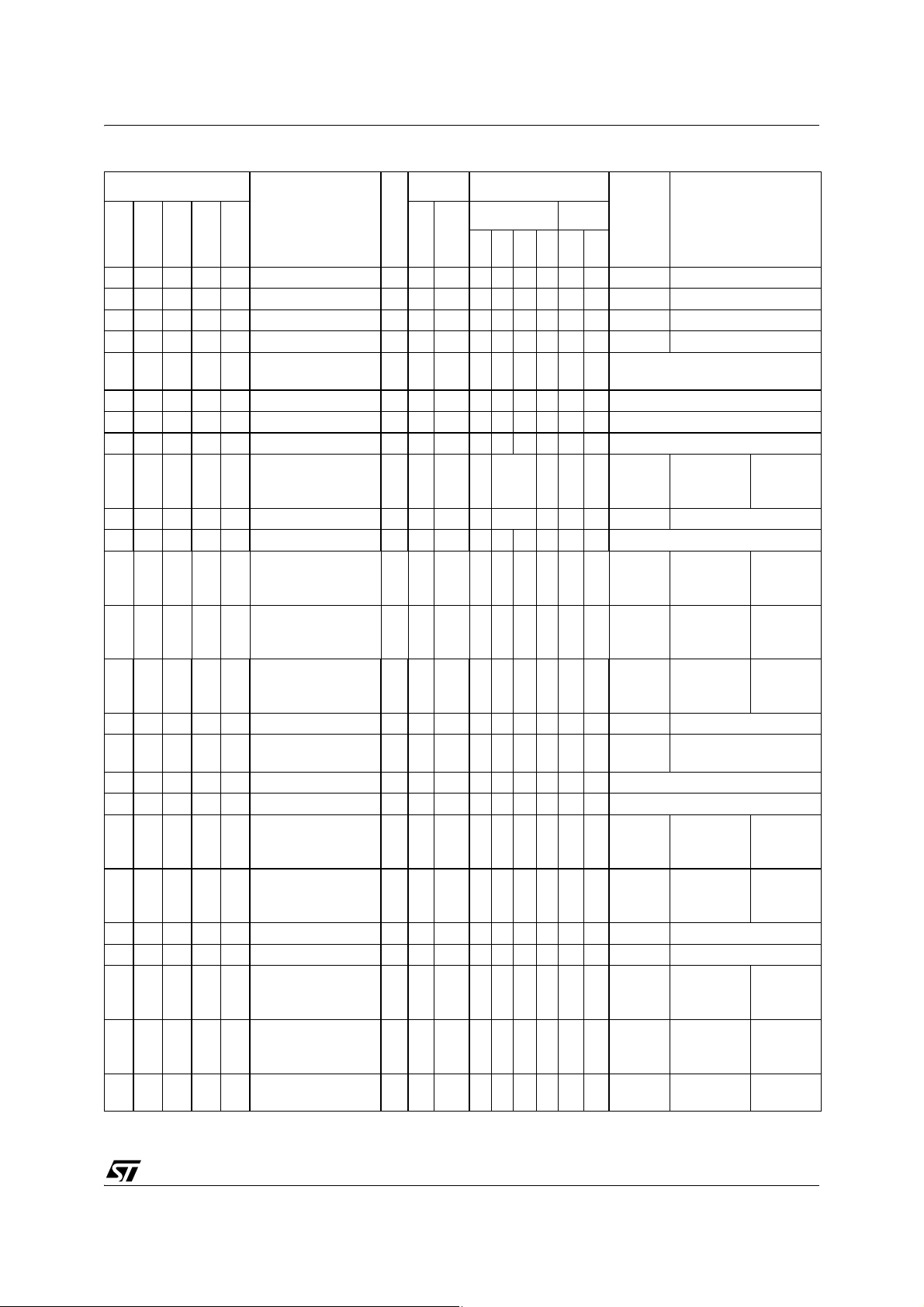

Page 13

ST72325xx

Pin n°

Pin Name

Type

LQFP64

LQFP48S

LQFP48C

SDIP42

LQFP44

17 13 13 11 6 PD4/AIN4 I/O C

18 14 14 12 7 PD5/AIN5 I/O C

4)

19 20 -

21 15 15 13 8 V

22 16 16 14 9 V

23----V

24----V

- - - PD6/AIN6 I/O C

4)

- - - PD7/AIN7 I/O C

6)

AREF

6)

SSA

6)

DD_3

6)

SS_3

I

S Analog Ground Voltage

S Digital Main Supply Voltage

S Digital Ground Voltage

25 17 17 15 10 PF0/MCO/AIN8 I/O C

26 18 18 16 11 PF1 (HS)/BEEP I/O C

27 19 19 17 12 PF2 (HS) I/O C

4)

28 -

---

29 20 20 18 13

4)

30 -

---

PF3/OCMP2_A/

AIN9

PF4/OCMP1_A/

AIN10

PF5/ICAP2_A/

AIN11

I/O C

I/O C

I/O C

31 21 21 19 14 PF6 (HS)/ICAP1_A I/O C

32 22 22 20 15

33 23 23 21 - V

34 24 24 22 - V

35 25 25 23 16

36 26 26 24 17

PF7 (HS)/

EXTCLK_A

6)

DD_0

6)

SS_0

PC0/OCMP2_B/

AIN12

PC1/OCMP1_B/

AIN13

I/O C

S Digital Main Supply Voltage

S Digital Ground Voltage

I/O C

I/O C

37 27 27 25 18 PC2 (HS)/ICAP2_B I/O C

38 28 28 26 19 PC3 (HS)/ICAP1_B I/O C

39 29 29 27 20

PC4/MISO/ICCDATA

I/O C

40 30 30 28 21 PC5/MOSI/AIN14 I/O C

41 31 31 29 22 PC6/SCK/ICCCLK I/O C

Level Port

Input Output

Input

Output

T

T

T

T

X X X X X Port D4 ADC Analog Input 4

X X X X X Port D5 ADC Analog Input 5

X X X X X Port D6 ADC Analog Input 6

X X X X X Port D7 ADC Analog Input 7

float

int

wpu

ana

OD

Main

function

(after

reset)

PP

Alternate function

Analog Reference Voltage for

ADC

/2)

ADC Analog

Input 8

ADC Analog

Input 9

ADC Analog

Input 10

ADC Analog

Input 11

ADC Analog

Input 12

ADC Analog

Input 13

ICC Data

Input

ADC Analog

Input 14

ICC Clock

Output

T

T

T

X ei1 X X X Port F0

HS X ei1 X X Port F1 Beep signal output

HS X ei1 X X Port F2

Main clock

out (f

OSC

Timer A

T

X XXXXPort F3

Output

Compare 2

Timer A

T

X XXXXPort F4

Output

Compare 1

Timer A In-

T

X XXXXPort F5

put Capture 2

HS X X X X Port F6 Timer A Input Capture 1

T

HS X XXXPort F7

T

Timer A External Clock

Source

Timer B

T

X XXXXPort C0

Output

Compare 2

Timer B

T

X XXXXPort C1

Output

Compare 1

HS X X X X Port C2 Timer B Input Capture 2

T

HS X X X X Port C3 Timer B Input Capture 1

T

SPI Master

T

X XXXPort C4

In / Slave

Out Data

SPI Master

T

X XXXXPort C5

Out / Slave

In Data

T

X XXXPort C6

SPI Serial

Clock

13/197

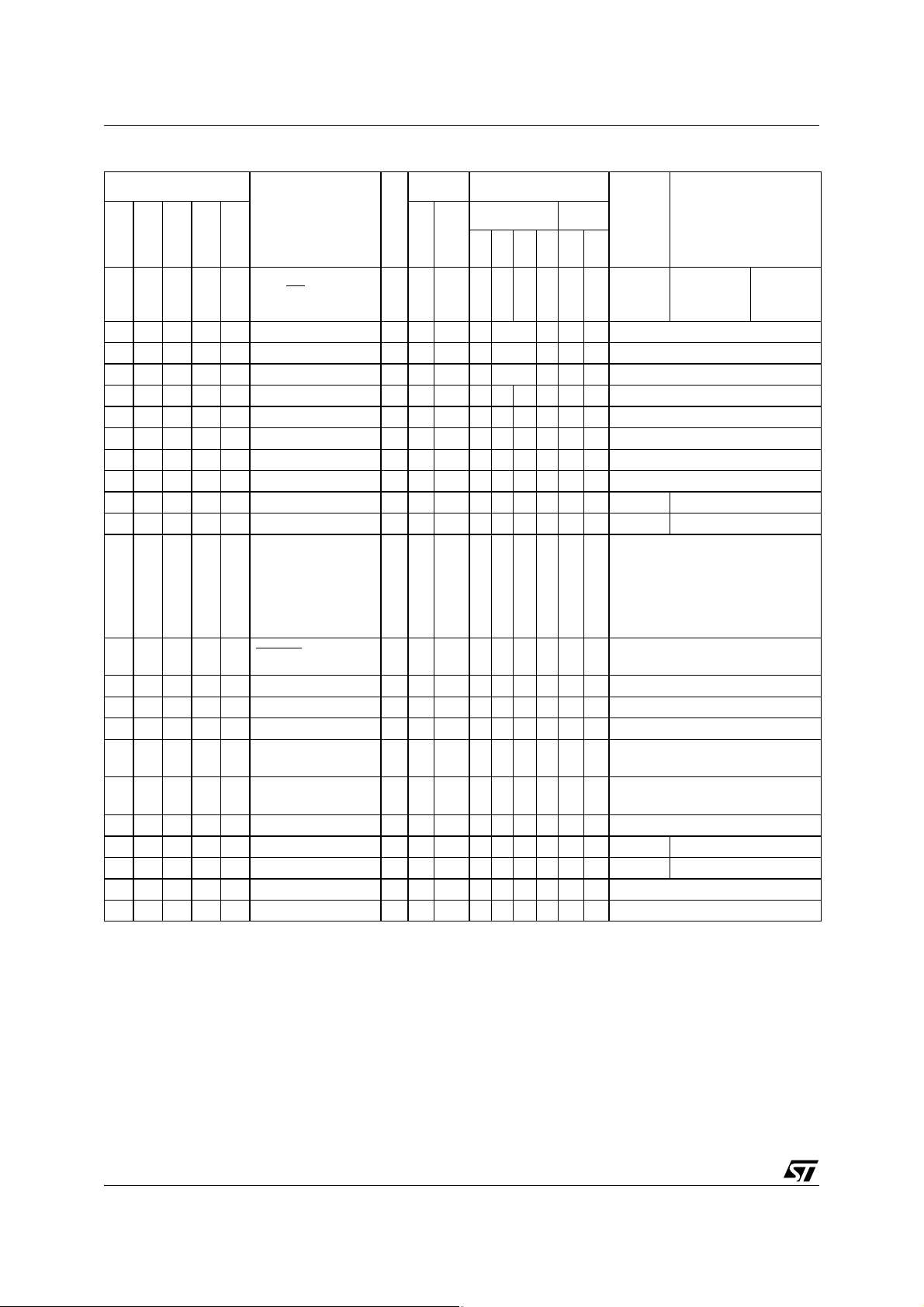

Page 14

ST72325xx

LQFP64

Pin n°

LQFP48S

LQFP48C

Pin Name

SDIP42

LQFP44

Level Port

Type

Input

Output

float

Input Output

int

OD

ana

wpu

Main

function

(after

reset)

PP

Alternate function

SPI Slave

42 32 32 30 23 PC7/SS/AIN15 I/O C

T

X XXXXPort C7

Select (active low)

4)

43 44 45 33 - - - PA2 I/O C

46 34 34 31 24 PA3 (HS) I/O C

47 35 35 32 25 V

48 36 36 33 26 V

49 37 37 34 27 PA4 (HS) I/O C

50 38 38 35 28 PA5 (HS) I/O C

51 39 39 36 29 PA6 (HS)/SDAI I/O C

52 40 40 37 30 PA7 (HS)/SCLI I/O CTHS X TPort A7 I

---PA0 I/OCTX ei0 X X Port A0

4)

---PA1 I/OCTX ei0 X X Port A1

X ei0 X X Port A2

HS X ei0 X X Port A3

HS X XXXPort A4

HS X XXXPort A5

HS X TPort A6 I

DD_1

SS_1

T

6)

6)

T

S Digital Main Supply Voltage

S Digital Ground Voltage

T

T

T

2

C Data

2

C Clock

1)

1)

Must be tied low. In flash programming mode, this pin acts as the

53 41 41 38 31 VPP/ ICCSEL I

programming voltage input V

See Section 12.9.2 for more details. High voltage must not be applied to ROM devices

54 42 42 39 32 RESET

I/O C

T

Top priority non maskable inter-

rupt.

55 - - - - EVD External voltage detector

56----TLI IC

57 43 43 40 33 V

58 44 44 41 34 OSC2

59 45 45 42 35 OSC1

60 46 46 43 36 V

SS_2

DD_2

6)

3)

3)

6)

61 47 47 44 37 PE0/TDO I/O C

62 48 48 1 38 PE1/RDI I/O C

63 1 - - - PE2 I/O C

4)

64 -

---PE3 I/OCTX XXXPort E3

T

S Digital Ground Voltage

I/O

I

S Digital Main Supply Voltage

T

T

T

X Top level interrupt input pin

Resonator oscillator inverter out-

put

External clock input or Resonator

oscillator inverter input

X X X X Port E0 SCI Transmit Data Out

X X X X Port E1 SCI Receive Data In

X XX

4)X4)

Port E2

ADC Analog

Input 15

.

PP

14/197

Page 15

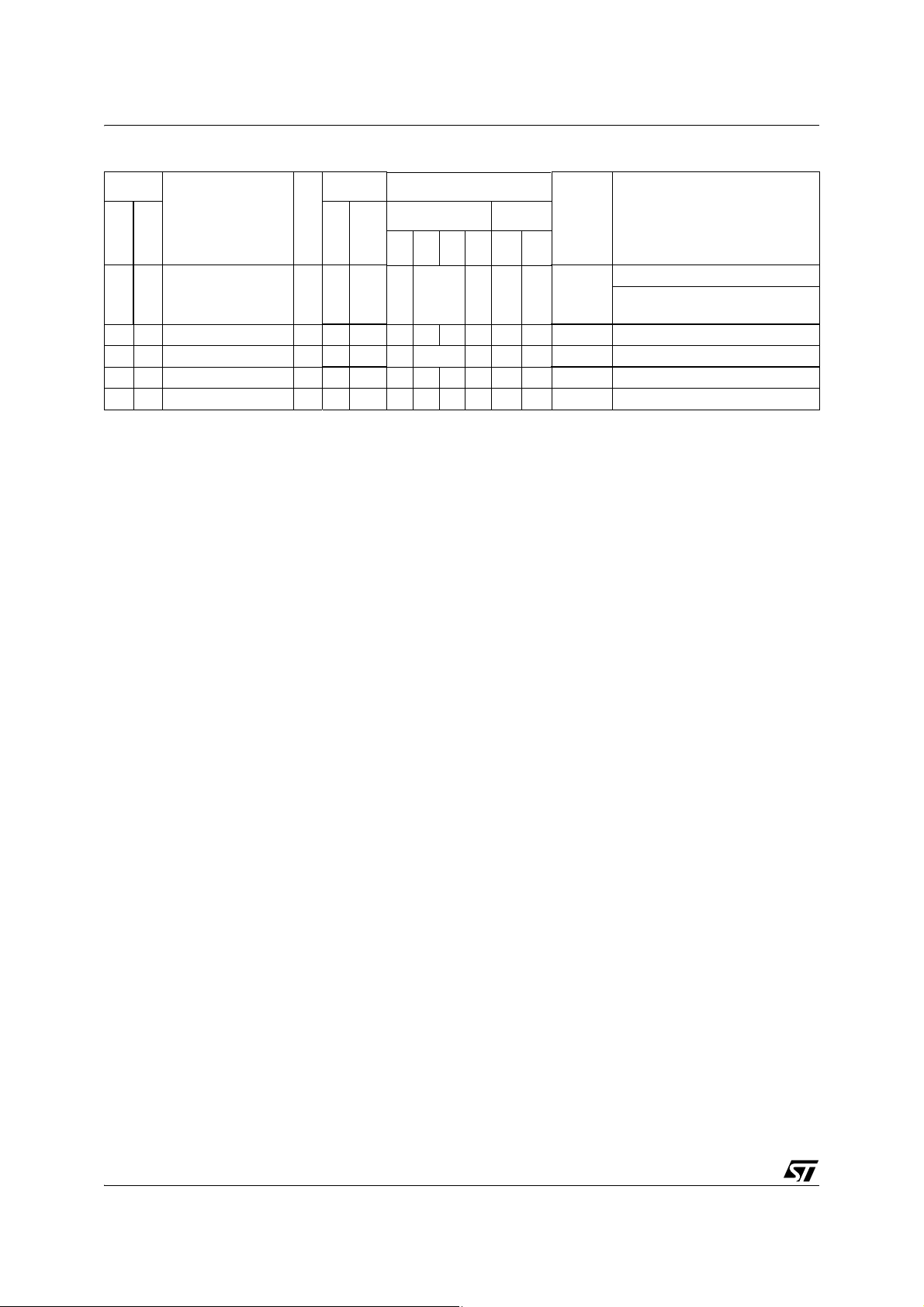

Table 3. LQFP32/DIP32 Device Pin Description

ST72325xx

Pin n°

Pin Name

DIP32

LQFP32

14V

25V

AREF

SSA

6)

6)

3 6 PF0/MCO/AIN8 I/O C

4 7 PF1 (HS)/BEEP I/O C

58

PF4/OCMP1_A/

AIN10

6 9 PF6 (HS)/ICAP1_A I/O C

710

811

912

PF7 (HS)/

EXTCLK_A

PC0/OCMP2_B/

AIN12

PC1/OCMP1_B/

AIN13

10 13 PC2 (HS)/ICAP2_B I/O C

11 14 PC3 (HS)/ICAP1_B I/O C

12 15

PC4/MISO/ICCDA-

TA

13 16 PC5/MOSI/AIN14 I/O C

14 17 PC6/SCK/ICCCLK I/O C

15 18 PC7/SS

/AIN15 I/O C

16 19 PA3 (HS) I/O C

17 20 PA4 (HS) I/O C

18 21 PA6 (HS)/SDAI I/O C

19 22 PA7 (HS)/SCLI I/O CTHS X TPort A7 I

Level Port

Type

Input

Output

float

Input Output

wpu

int

ana

OD

function

(after

reset)

PP

Main

Alternate function

I Analog Reference Voltage for ADC

S Analog Ground Voltage

Main clock out

/2)

(f

OSC

Timer A Output

Compare 1

Timer B Output

Compare 2

Timer B Output

Compare 1

SPI Master In /

Slave Out Data

SPI Master Out /

Slave In Data

SPI Slave Select

(active low)

2

C Data

2

C Clock

I/O C

I/O C

I/O C

I/O C

I/O C

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

X ei1 X X X Port F0

HS X ei1 X X Port F1 Beep signal output

X XXXXPort F4

HS X X X X Port F6 Timer A Input Capture 1

HS X X X X Port F7 Timer A External Clock Source

X XXXXPort C0

X XXXXPort C1

HS X X X X Port C2 Timer B Input Capture 2

HS X X X X Port C3 Timer B Input Capture 1

X XXXPort C4

X XXXXPort C5

X X X X Port C6 SPI Serial Clock

X XXXXPort C7

HS X ei0 X X Port A3

HS X XXXPort A4

HS X TPort A6 I

Must be tied low. In flash programming

mode, this pin acts as the programming

20 23 VPP/ ICCSEL I

voltage input VPP. See Section 12.9.2 for

more details. High voltage must not be ap-

plied to ROM devices

21 24 RESET

22 25 V

SS_2

23 26 OSC2

24 27 OSC1

25 28 V

DD_2

6)

3)

3)

6)

I/O C

S Digital Ground Voltage

I/O Resonator oscillator inverter output

I

S Digital Main Supply Voltage

26 29 PE0/TDO I/O C

27 30 PE1/RDI I/O C

T

T

T

X X X X Port E0 SCI Transmit Data Out

X X X X Port E1 SCI Receive Data In

Top priority non maskable interrupt.

External clock input or Resonator oscillator

inverter input

ADC Analog

Input 8

ADC Analog

Input 10

ADC Analog

Input 12

ADC Analog

Input 13

ICC Data Input

ADC Analog

Input 14

ICC Clock

Output

ADC Analog

Input 15

1)

1)

15/197

Page 16

ST72325xx

Pin n°

Pin Name

DIP32

LQFP32

28 31 PB0/PWM3 I/O C

29 32 PB3/PWM0 I/O C

30 1 PB4 (HS)/ARTCLK I/O C

31 2 PD0/AIN0 I/O C

32 3 PD1/AIN1 I/O C

Level Port

Type

Input

Output

float

T

T

T

T

T

X ei2 X X Port B0

X ei2 X X Port B3 PWM Output 0

HS X ei3 X X Port B4 PWM-ART External Clock

X X X X X Port D0 ADC Analog Input 0

X X X X X Port D1 ADC Analog Input 1

Input Output

wpu

int

ana

OD

function

(after

reset)

PP

Main

Alternate function

PWM Output 3

Caution: Negative current injec-

tion not allowed on this pin

Notes for Table 2 and Table 3:

1. In the interrupt input column, “eiX” defines the associated external interrupt vector. If the weak pull-up

column (wpu) is merged with the interrupt column (int), then the I/O configuration is pull-up interrupt input,

else the configuration is floating interrupt input.

2. In the open drain output column, “T” defines a true open drain I/O (P-Buffer and protection diode to V

are not implemented). See See “I/O PORTS” on page 50. and Section 12.8 I/O PORT PIN CHARACTER-

DD

ISTICS for more details.

3. OSC1 and OSC2 pins connect a crystal/ceramic resonator, or an external source to the on-chip oscillator; see Section 1 DESCRIPTION and Section 12.5 CLOCK AND TIMING CHARACTERISTICS for

more details.

4. On the chip, each I/O port may have up to 8 pads:

– In all devices except 48-pin ST72325C, pads that are not bonded to external pins are forced by hardware

in input pull-up configuration after reset. The configuration of these pads must be kept at reset state to

avoid added current consumption.

– In 48-pin ST72325C devices, unbonded pads PA0, PA1, PB6, PB7, PD6, PD7, PE3, PE5, PE6, PE7,

PF3 and PF5) are in input floating configuration after reset. To avoid added current consumption, the

application must force these ports in input pull-up state by writing to the OR and DDR registers after reset. This initialization is not necessary in 48-pin ST72325S devices.

5. Pull-up always activated on PE2 see limitation Section 15.1.8.

6. It is mandatory to connect all available V

pins to ground.

DD

and V

pins to the supply voltage and all VSS and V

REF

SSA

16/197

Page 17

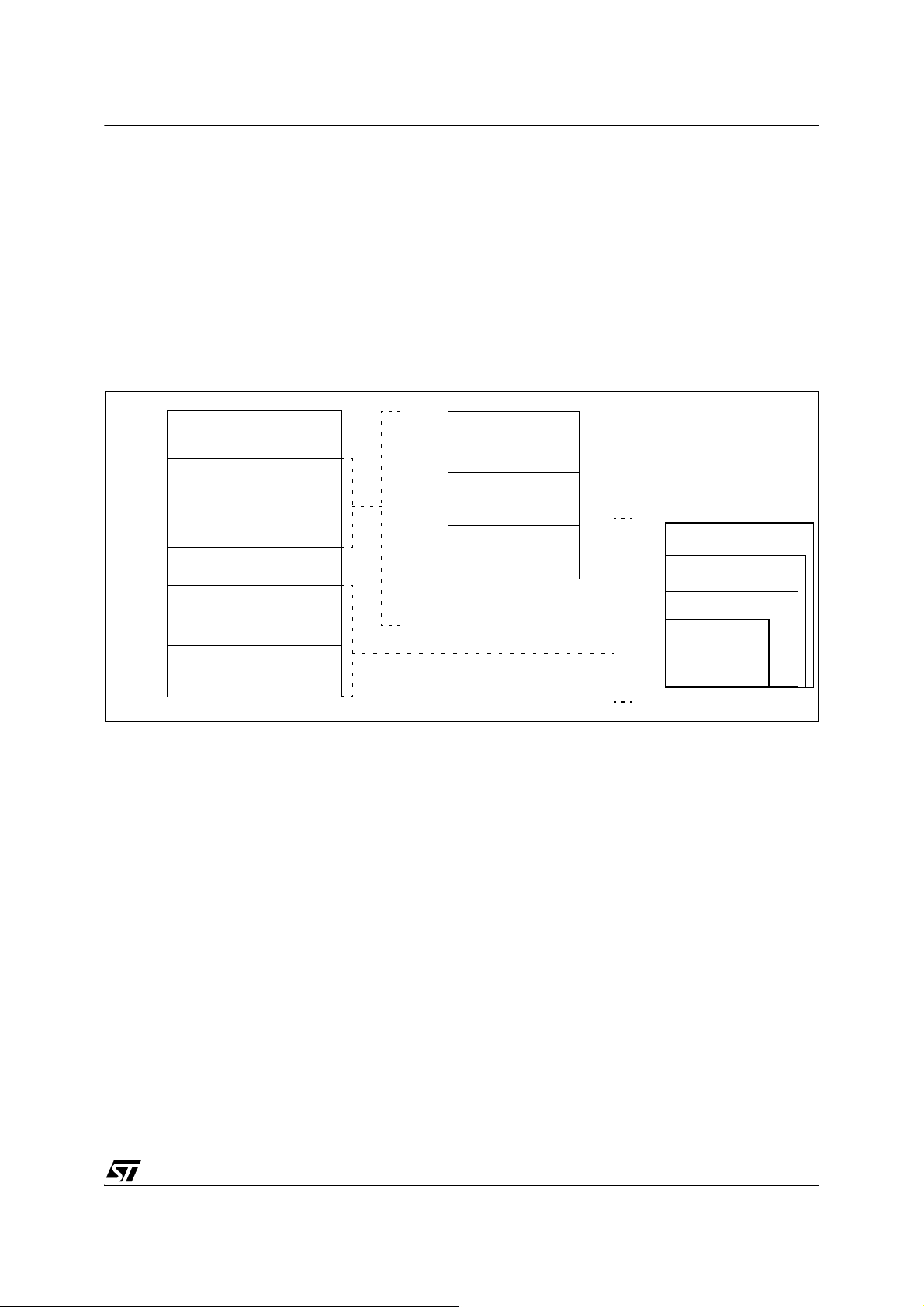

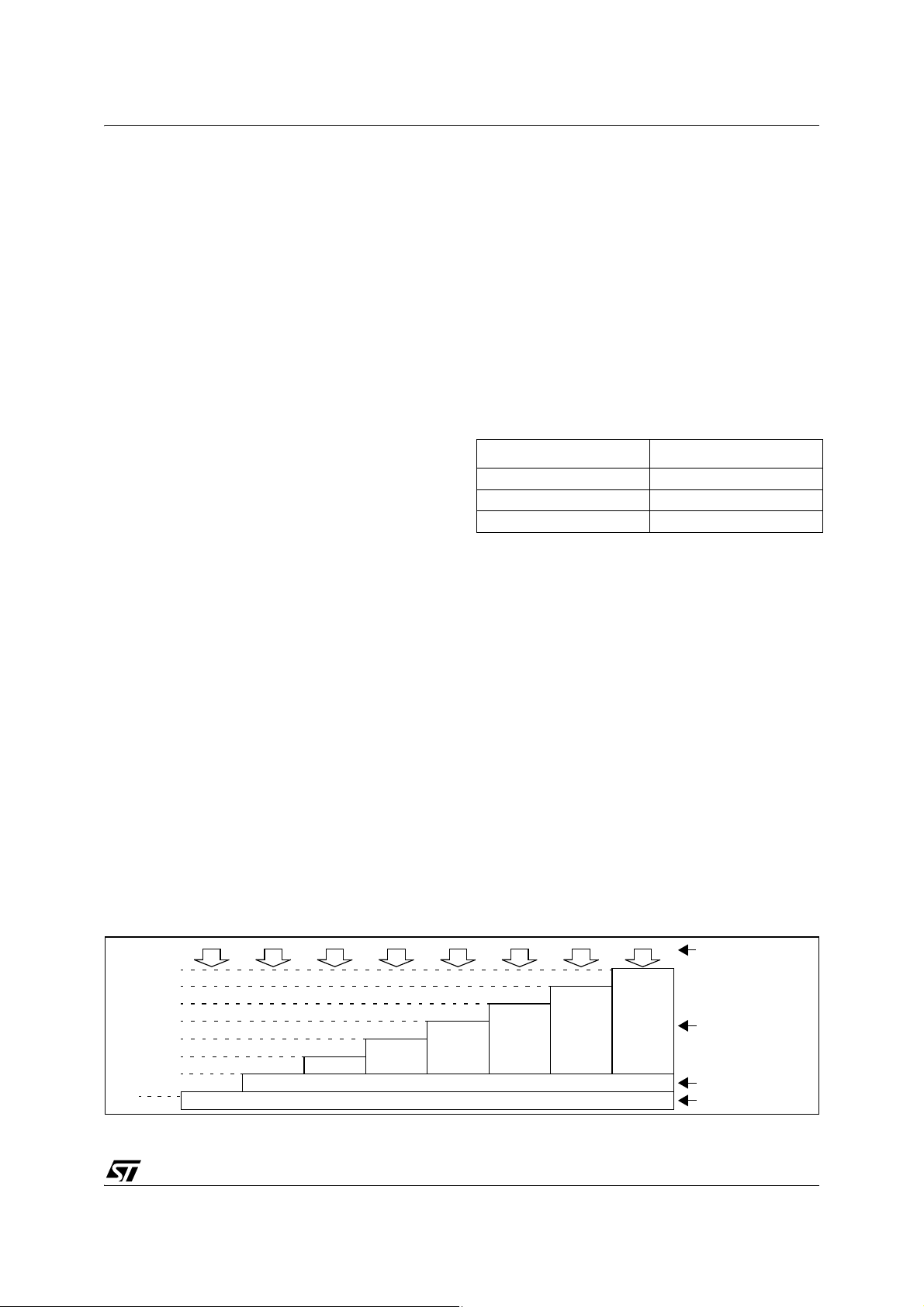

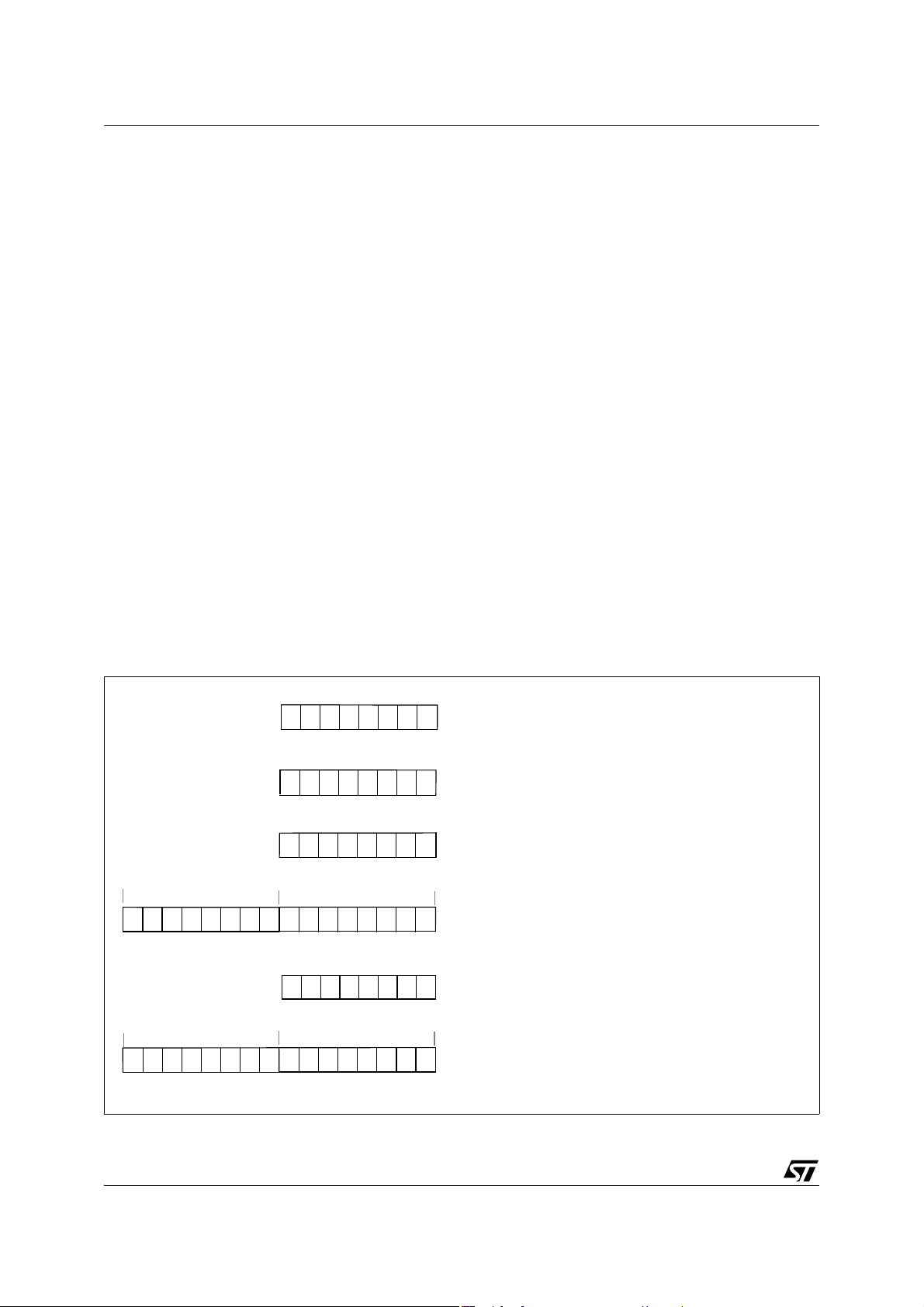

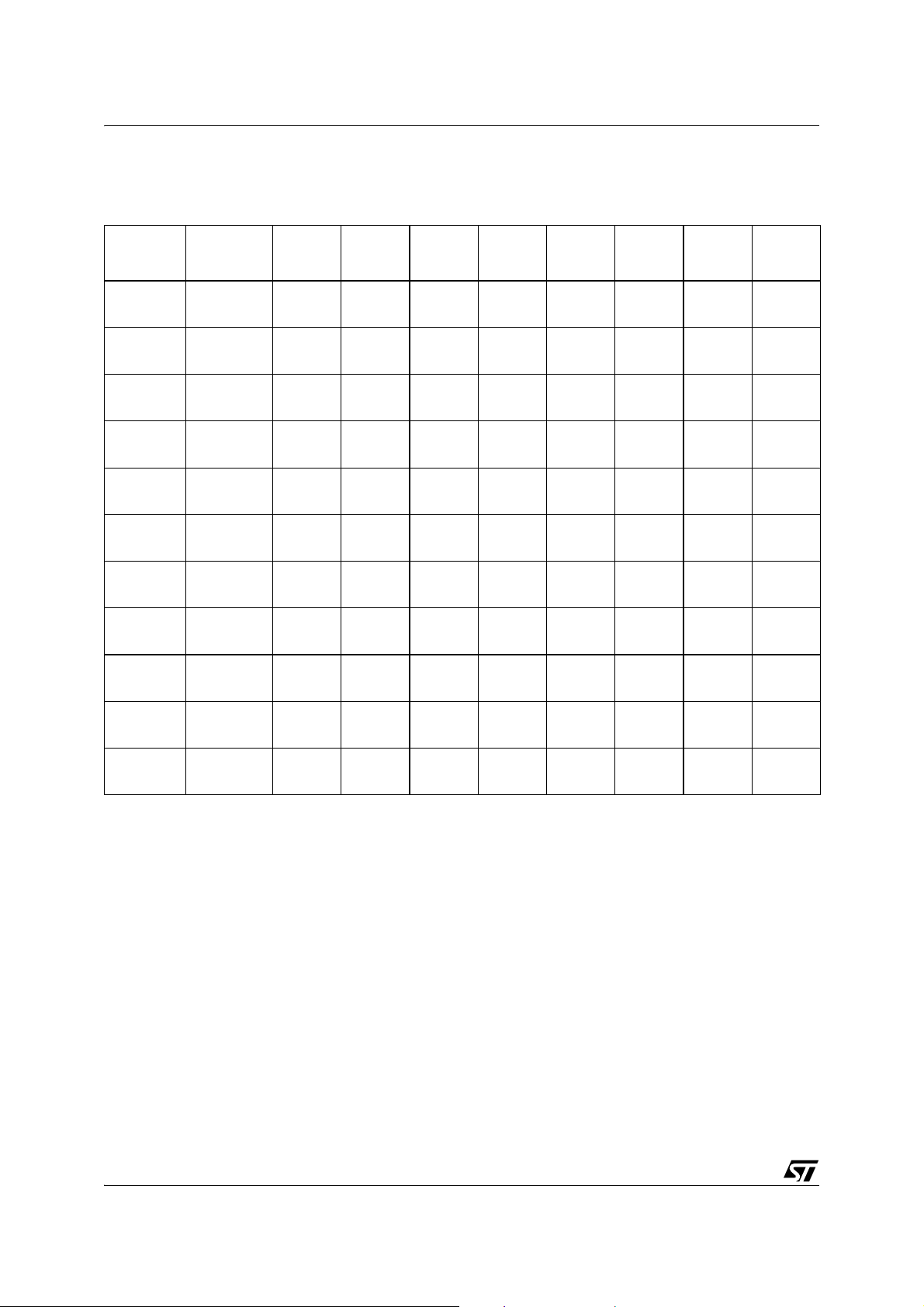

3 REGISTER & MEMORY MAP

0000h

RAM

Program Memory

(60,48, 32 or 16K)

Interrupt & Reset Vectors

HW Registers

0080h

007Fh

0FFFh

(see Table 4)

1000h

FFDFh

FFE0h

FFFFh

(see Table 9)

0880h

Reserved

087Fh

Short Addressing

RAM (zero page)

256 Bytes Stack

16-bit Addressing

RAM

0100h

01FFh

027Fh

0080h

0200h

00FFh

32 KBytes

8000h

FFFFh

(2048, 1536, 1024,

or 047Fh

16 KBytes

C000h

or 512 Bytes)

60 KBytes

48 KBytes

1000h

4000h

or 087Fh

or 067Fh

ST72325xx

As shown in Figure 6, the MCU is capable of addressing 64K bytes of memories and I/O registers.

The available memory locations consist of 128

bytes of register locations, up to 2Kbytes of RAM

and up to 60Kbytes of user program memory. The

RAM space includes up to 256 bytes for the stack

from 0100h to 01FFh.

The highest address bytes contain the user reset

and interrupt vectors.

Figure 6. Memory Map

IMPORTANT: Memory locations marked as “Re-

served” must never be accessed. Accessing a reseved area can have unpredictable effects on the

device.

Related Documentation

AN 985: Executing Code in ST7 RAM

17/197

Page 18

ST72325xx

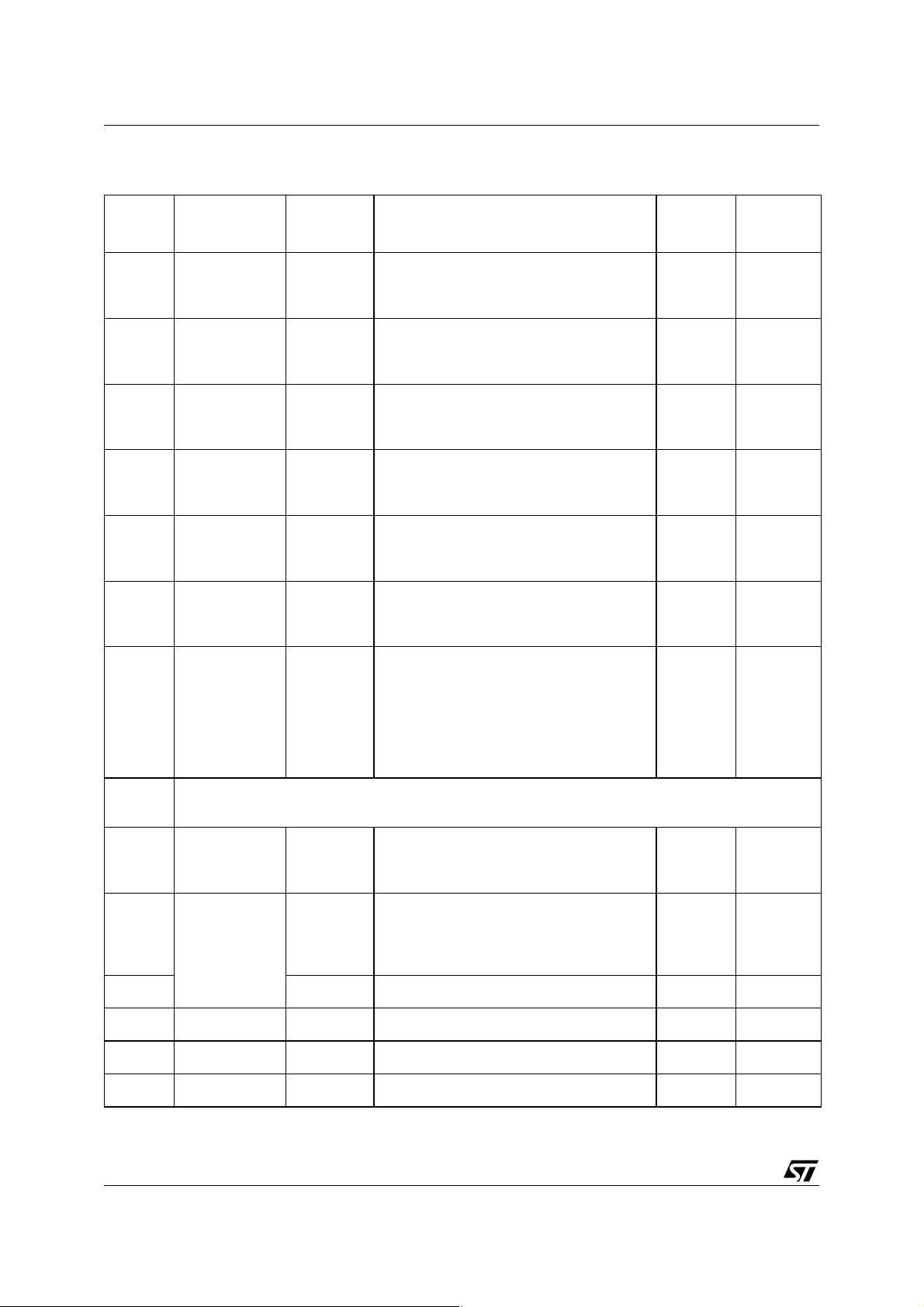

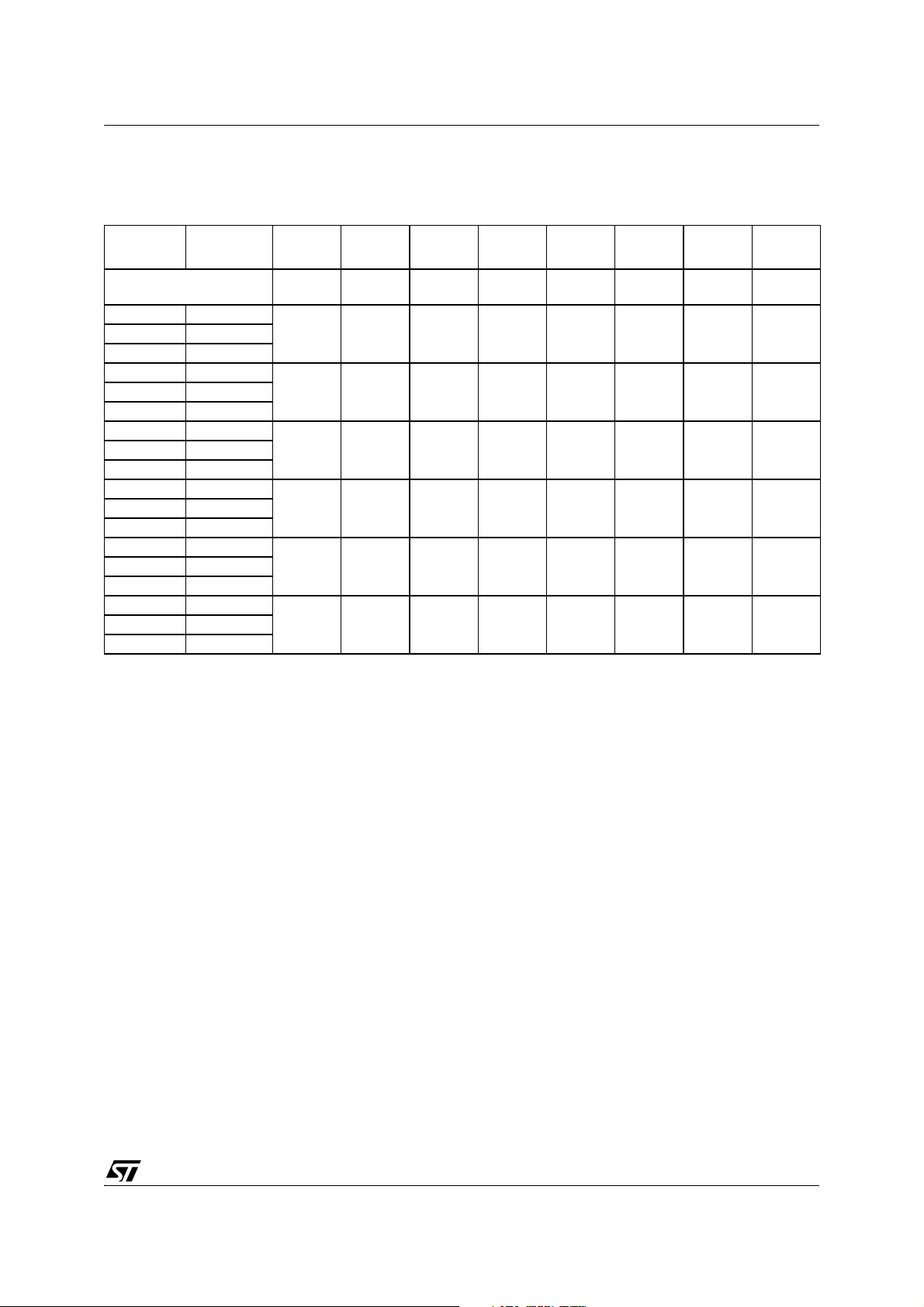

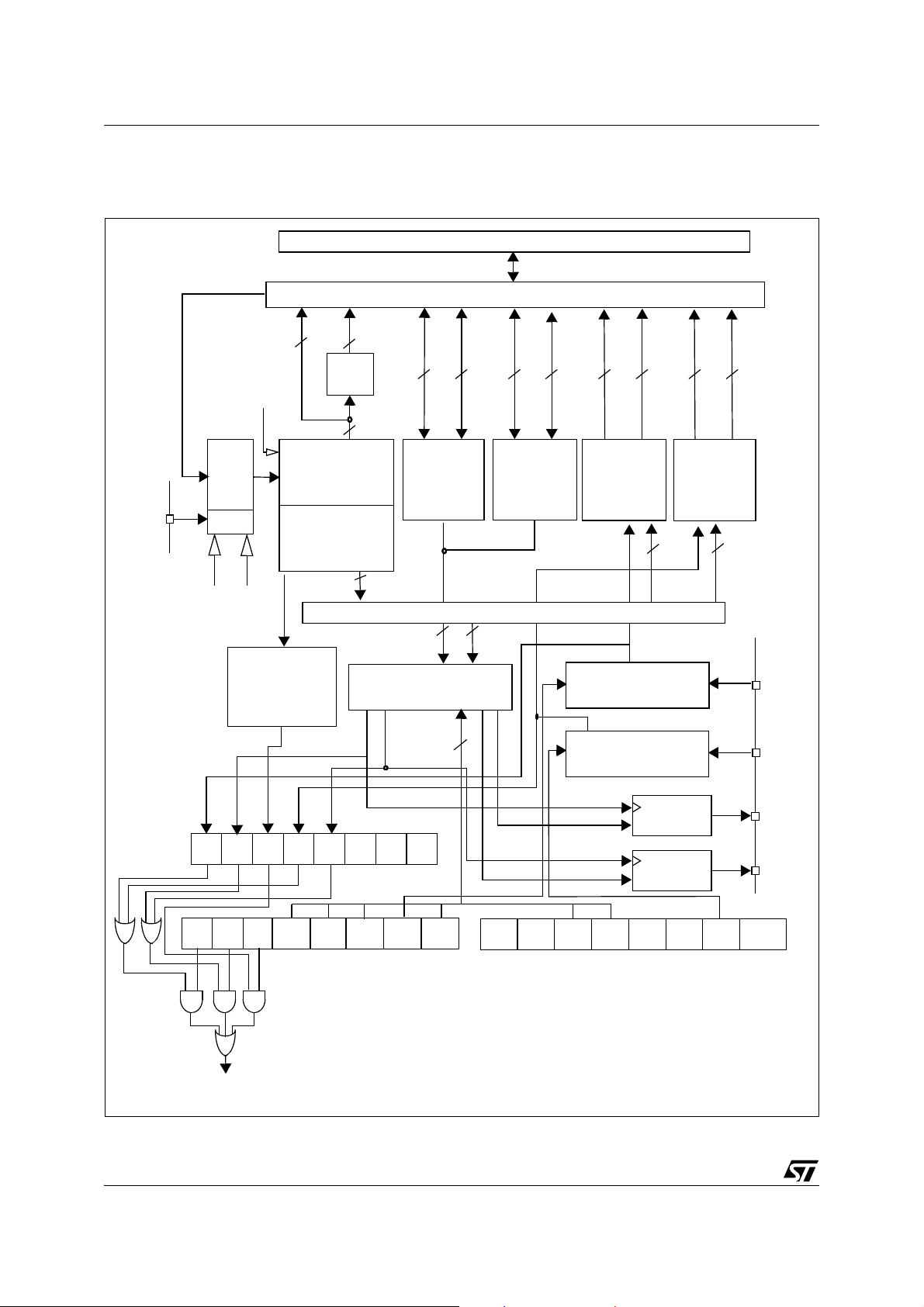

Table 4. Hardware Register Map

Address Block

0000h

0001h

Port A

0002h

0003h

0004h

Port B

0005h

0006h

0007h

Port C

0008h

0009h

000Ah

Port D

000Bh

000Ch

000Dh

Port E

000Eh

000Fh

0010h

Port F

0011h

0018h

0019h

001Ah

001Bh

2

C

I

001Ch

001Dh

001Eh

Register

Label

PADR

PADDR

PAOR

PBDR

PBDDR

PBOR

PCDR

PCDDR

PCOR

PDDR

PDDDR

PDOR

PEDR

PEDDR

PEOR

PFDR

PFDDR

PFOR

I2CCR

I2CSR1

I2CSR2

I2CCCR

I2COAR1

I2COAR2

I2CDR

Register Name

Port A Data Register

Port A Data Direction Register

Port A Option Register

Port B Data Register

Port B Data Direction Register

Port B Option Register

Port C Data Register

Port C Data Direction Register

Port C Option Register

Port D Data Register

Port D Data Direction Register

Port D Option Register

Port E Data Register

Port E Data Direction Register

Port E Option Register

Port F Data Register

Port F Data Direction Register

Port F Option Register

2

I

C Control Register

2

C Status Register 1

I

2

C Status Register 2

I

2

C Clock Control Register

I

2

C Own Address Register 1

I

2

C Own Address Register2

I

2

C Data Register

I

Reset

Status

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

1)

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

2)

R/W

2)

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

R/W

R/W

R/W

R/W

001Fh

0020h

0021h

0022h

0023h

0024h

0025h

0026h

0027h

SPI

ITC

SPIDR

SPICR

SPICSR

ISPR0

ISPR1

ISPR2

ISPR3

Reserved Area (2 Bytes)

SPI Data I/O Register

SPI Control Register

SPI Control/Status Register

Interrupt Software Priority Register 0

Interrupt Software Priority Register 1

Interrupt Software Priority Register 2

Interrupt Software Priority Register 3

xxh

0xh

00h

FFh

FFh

FFh

FFh

0028h EICR External Interrupt Control Register 00h R/W

0029h FLASH FCSR Flash Control/Status Register 00h R/W

002Ah WATCHDOG WDGCR Watchdog Control Register 7Fh R/W

002Bh SICSR System Integrity Control/Status Register 000x 000x b R/W

18/197

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Page 19

ST72325xx

Address Block

002Ch

002Dh

002Eh

to

0030h

0031h

0032h

0033h

0034h

0035h

0036h

0037h

0038h

0039h

003Ah

003Bh

003Ch

003Dh

003Eh

003Fh

0040h Reserved Area (1 Byte)

MCC

TIMER A

Register

Label

MCCSR

MCCBCR

TACR2

TACR1

TACSR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Register Name

Main Clock Control / Status Register

Main Clock Controller: Beep Control Register

Reserved Area (3 Bytes)

Timer A Control Register 2

Timer A Control Register 1

Timer A Control/Status Register

Timer A Input Capture 1 High Register

Timer A Input Capture 1 Low Register

Timer A Output Compare 1 High Register

Timer A Output Compare 1 Low Register

Timer A Counter High Register

Timer A Counter Low Register

Timer A Alternate Counter High Register

Timer A Alternate Counter Low Register

Timer A Input Capture 2 High Register

Timer A Input Capture 2 Low Register

Timer A Output Compare 2 High Register

Timer A Output Compare 2 Low Register

Reset

Status

00h

00h

00h

00h

xxxx x0xx b

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

0041h

0042h

0043h

0044h

0045h

0046h

0047h

0048h

0049h

004Ah

004Bh

004Ch

004Dh

004Eh

004Fh

0050h

0051h

0052h

0053h

0054h

0055h

0056h

0057h

TIMER B

SCI

TBCR2

TBCR1

TBCSR

TBIC1HR

TBIC1LR

TBOC1HR

TBOC1LR

TBCHR

TBCLR

TBACHR

TBACLR

TBIC2HR

TBIC2LR

TBOC2HR

TBOC2LR

SCISR

SCIDR

SCIBRR

SCICR1

SCICR2

SCIERPR

SCIETPR

Timer B Control Register 2

Timer B Control Register 1

Timer B Control/Status Register

Timer B Input Capture 1 High Register

Timer B Input Capture 1 Low Register

Timer B Output Compare 1 High Register

Timer B Output Compare 1 Low Register

Timer B Counter High Register

Timer B Counter Low Register

Timer B Alternate Counter High Register

Timer B Alternate Counter Low Register

Timer B Input Capture 2 High Register

Timer B Input Capture 2 Low Register

Timer B Output Compare 2 High Register

Timer B Output Compare 2 Low Register

SCI Status Register

SCI Data Register

SCI Baud Rate Register

SCI Control Register 1

SCI Control Register 2

SCI Extended Receive Prescaler Register

Reserved area

SCI Extended Transmit Prescaler Register

00h

00h

xxxx x0xx b

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

C0h

xxh

00h

x000 0000b

00h

00h

---

00h

R/W

R/W

R/W

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

19/197

Page 20

ST72325xx

Address Block

0058h

0059h

005Ah

005Bh

005Ch

005Dh

005Eh

to

006Fh

0070h

0071h

0072h

0073h

0074h

0075h

0076h

0077h

0078h

0079h

007Ah

007Bh

007Ch

007Dh

3)

DM

ADC

PWM ART

Register

Label

DMCR

DMSR

DMBK1H

DMBK1L

DMBK2H

DMBK2L

ADCCSR

ADCDRH

ADCDRL

PWMDCR3

PWMDCR2

PWMDCR1

PWMDCR0

PWMCR

ARTCSR

ARTCAR

ARTARR

ARTICCSR

ARTICR1

ARTICR2

Register Name

DM Control Register

DM Status Register

DM Breakpoint Register 1 High

DM Breakpoint Register 1 Low

DM Breakpoint Register 2 High

DM Breakpoint Register 2 Low

Reserved Area (18 Bytes)

Control/Status Register

Data High Register

Data Low Register

PWM AR Timer Duty Cycle Register 3

PWM AR Timer Duty Cycle Register 2

PWM AR Timer Duty Cycle Register 1

PWM AR Timer Duty Cycle Register 0

PWM AR Timer Control Register

Auto-Reload Timer Control/Status Register

Auto-Reload Timer Counter Access Register

Auto-Reload Timer Auto-Reload Register

AR Timer Input Capture Control/Status Reg.

AR Timer Input Capture Register 1

AR Timer Input Capture Register 1

Reset

Status

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

007Eh

007Fh

Reserved Area (2 Bytes)

Legend: x=undefined, R/W=read/write

Notes:

1. The contents of the I/O port DR registers are readable only in output configuration. In input configuration, the values of the I/O pins are returned instead of the DR register contents.

2. The bits associated with unavailable pins must always keep their reset value.

3. For a description of the Debug Module registers, see ICC Protocol Reference manual.

20/197

Page 21

4 FLASH PROGRAM MEMORY

4 Kbytes

4 Kbytes

2Kbytes

SECTOR 1

SECTOR 0

16 Kbytes

SECTOR 2

8K 16K 32K 60K

FLASH

FFFFh

EFFFh

DFFFh

3FFFh

7FFFh

1000h

24 Kbytes

MEMORY SIZE

8Kbytes 40 Kbytes

52 Kbytes

9FFFh

BFFFh

D7FFh

4K 10K 24K 48K

ST72325xx

4.1 Introduction

The ST7 dual voltage High Density Flash

(HDFlash) is a non-volatile memory that can be

electrically erased as a single block or by individual sectors and programmed on a Byte-by-Byte basis using an external V

supply.

PP

The HDFlash devices can be programmed and

erased off-board (plugged in a programming tool)

or on-board using ICP (In-Circuit Programming) or

IAP (In-Application Programming).

The array matrix organisation allows each sector

to be erased and reprogrammed without affecting

other sectors.

4.2 Main Features

■ Three Flash programming modes:

– Insertion in a programming tool. In this mode,

all sectors including option bytes can be programmed or erased.

– ICP (In-Circuit Programming). In this mode, all

sectors including option bytes can be programmed or erased without removing the device from the application board.

– IAP (In-Application Programming) In this

mode, all sectors except Sector 0, can be programmed or erased without removing the device from the application board and while the

application is running.

■ ICT (In-Circuit Testing) for downloading and

executing user application test patterns in RAM

■ Read-out protection

■ Register Access Security System (RASS) to

prevent accidental programming or erasing

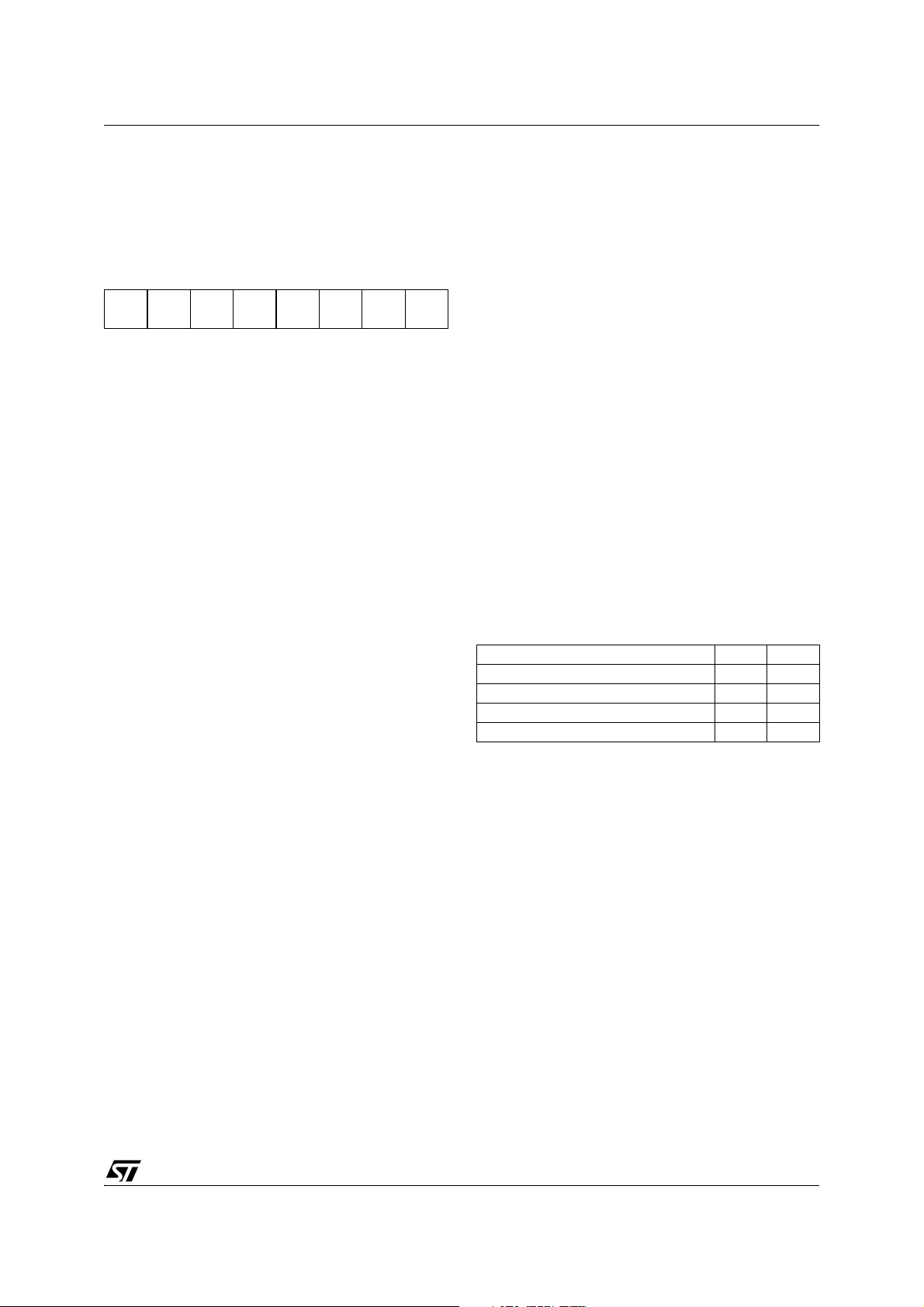

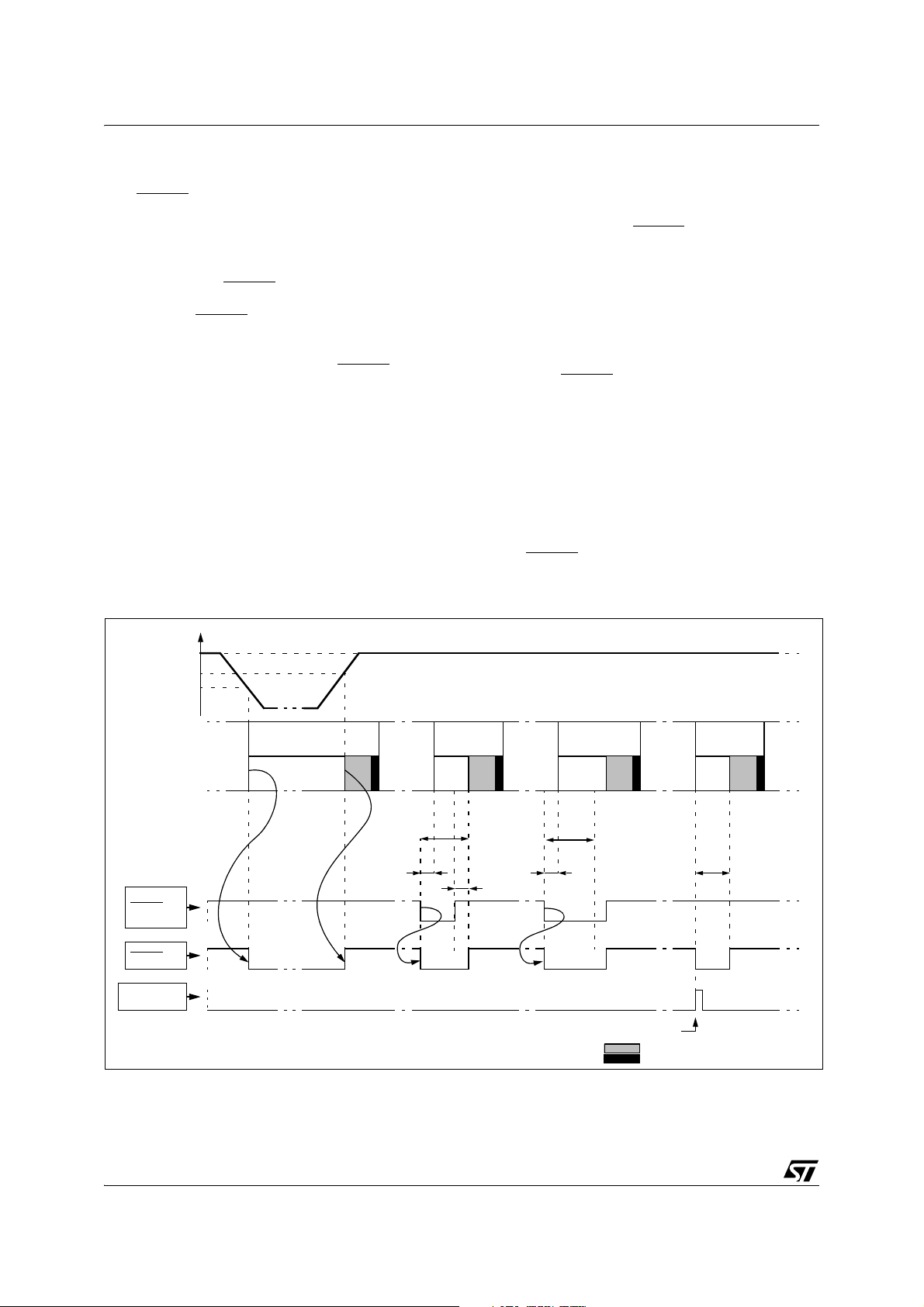

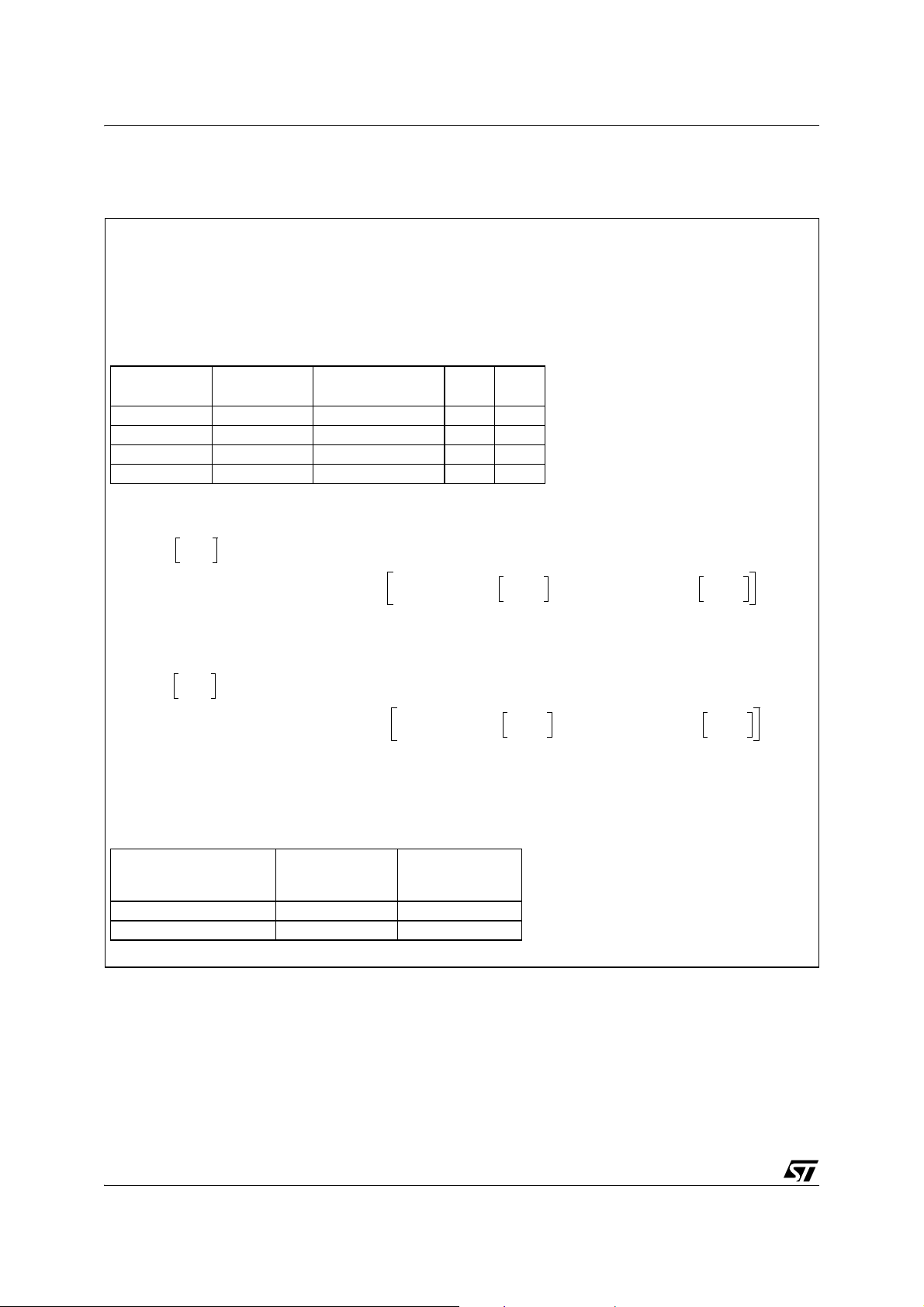

4.3 Structure

The Flash memory is organised in sectors and can

be used for both code and data storage.

Depending on the overall Flash memory size in the

microcontroller device, there are up to three user

sectors (see Table 5). Each of these sectors can

be erased independently to avoid unnecessary

erasing of the whole Flash memory when only a

partial erasing is required.

The first two sectors have a fixed size of 4 Kbytes

(see Figure 7). They are mapped in the upper part

of the ST7 addressing space so the reset and interrupt vectors are located in Sector 0 (F000hFFFFh).

Table 5. Sectors available in Flash devices

Flash Size (bytes) Available Sectors

4K Sector 0

8K Sectors 0,1

> 8K Sectors 0,1, 2

4.3.1 Read-out Protection

Read-out protection, when selected, provides a

protection against Program Memory content extraction and against write access to Flash memory. Even if no protection can be considered as totally unbreakable, the feature provides a very high

level of protection for a general purpose microcontroller.

In flash devices, this protection is removed by reprogramming the option. In this case, the entire

program memory is first automatically erased and

the device can be reprogrammed.

Read-out protection selection depends on the device type:

– In Flash devices it is enabled and removed

through the FMP_R bit in the option byte.

– In ROM devices it is enabled by mask option

specified in the Option List.

Figure 7. Memory Map and Sector Address

21/197

Page 22

ST72325xx

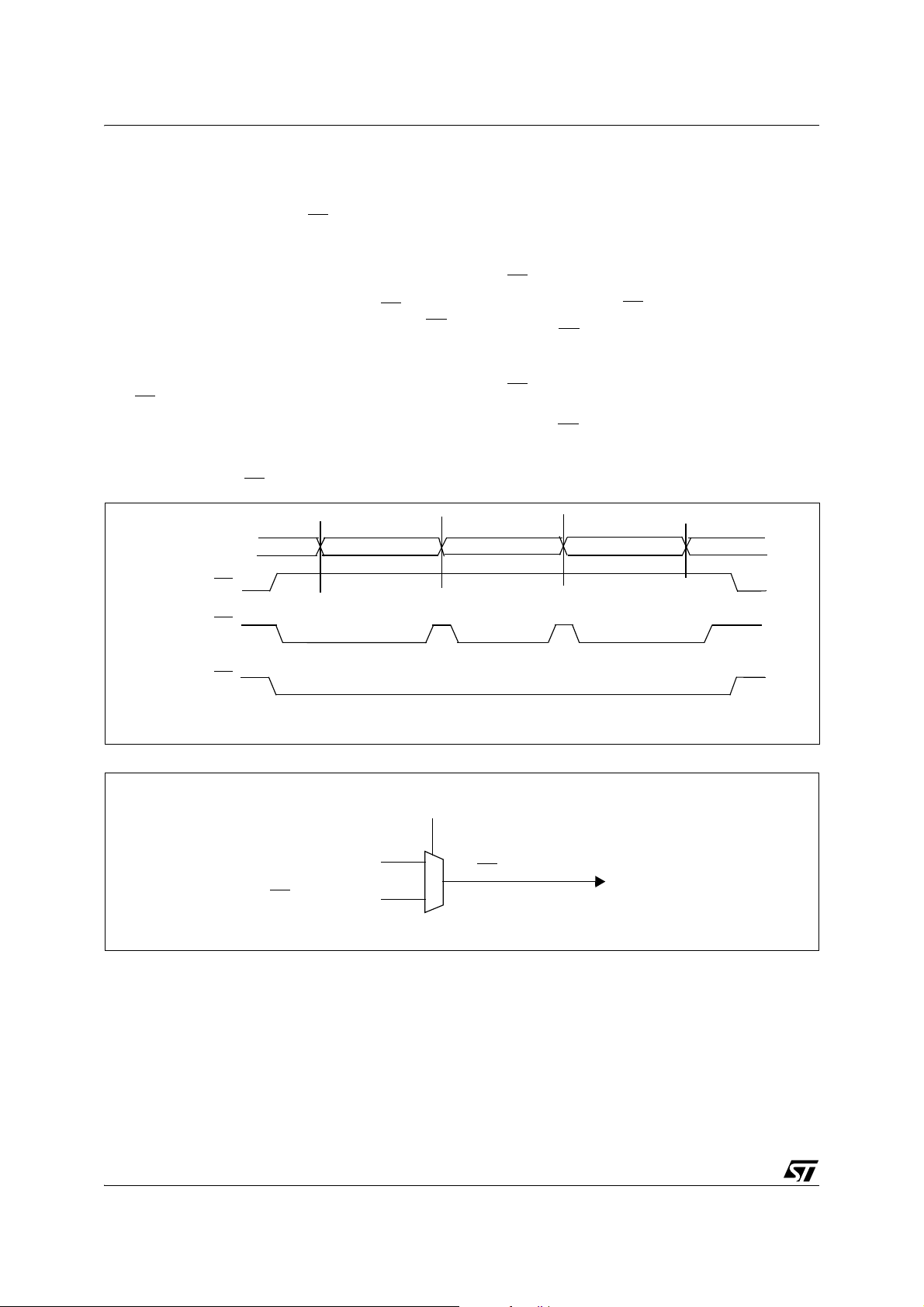

ICC CONNECTOR

ICCDATA

ICCCLK

RESET

V

DD

HE10 CONNECTOR TYPE

APPLICATION

POWER SUPPLY

1

246810

975 3

PROGRAMMING TOOL

ICC CONNECTOR

APPLICATION BOARD

ICC Cable

(See Note 3)

10kΩ

V

SS

ICCSEL/VPP

ST7

C

L2

C

L1

OSC1

OSC2

OPTIONAL

See Note 1

See Note 2

APPLICATION

RESET SOURCE

APPLICATION

I/O

(See Note 4)

FLASH PROGRAM MEMORY (Cont’d)

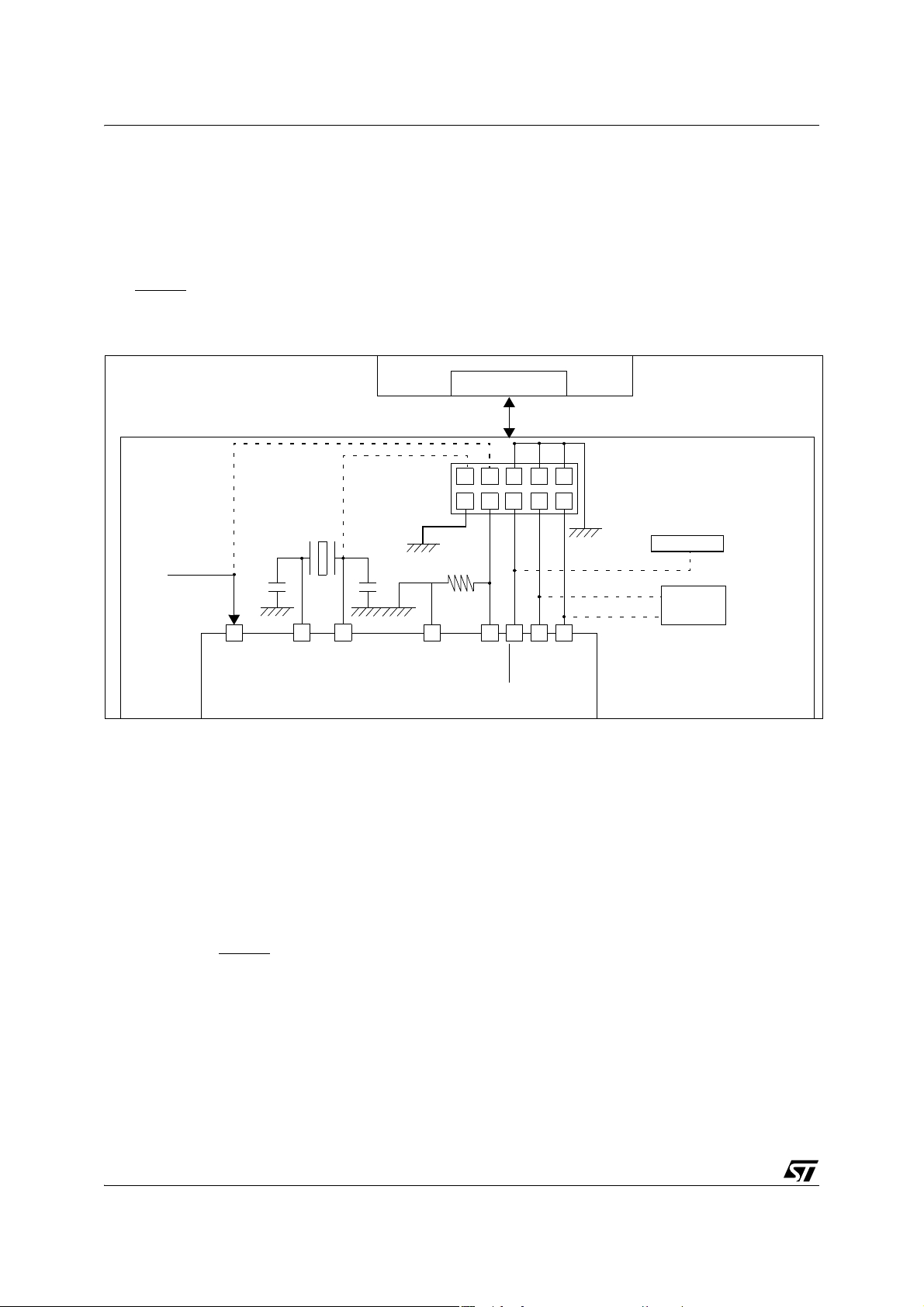

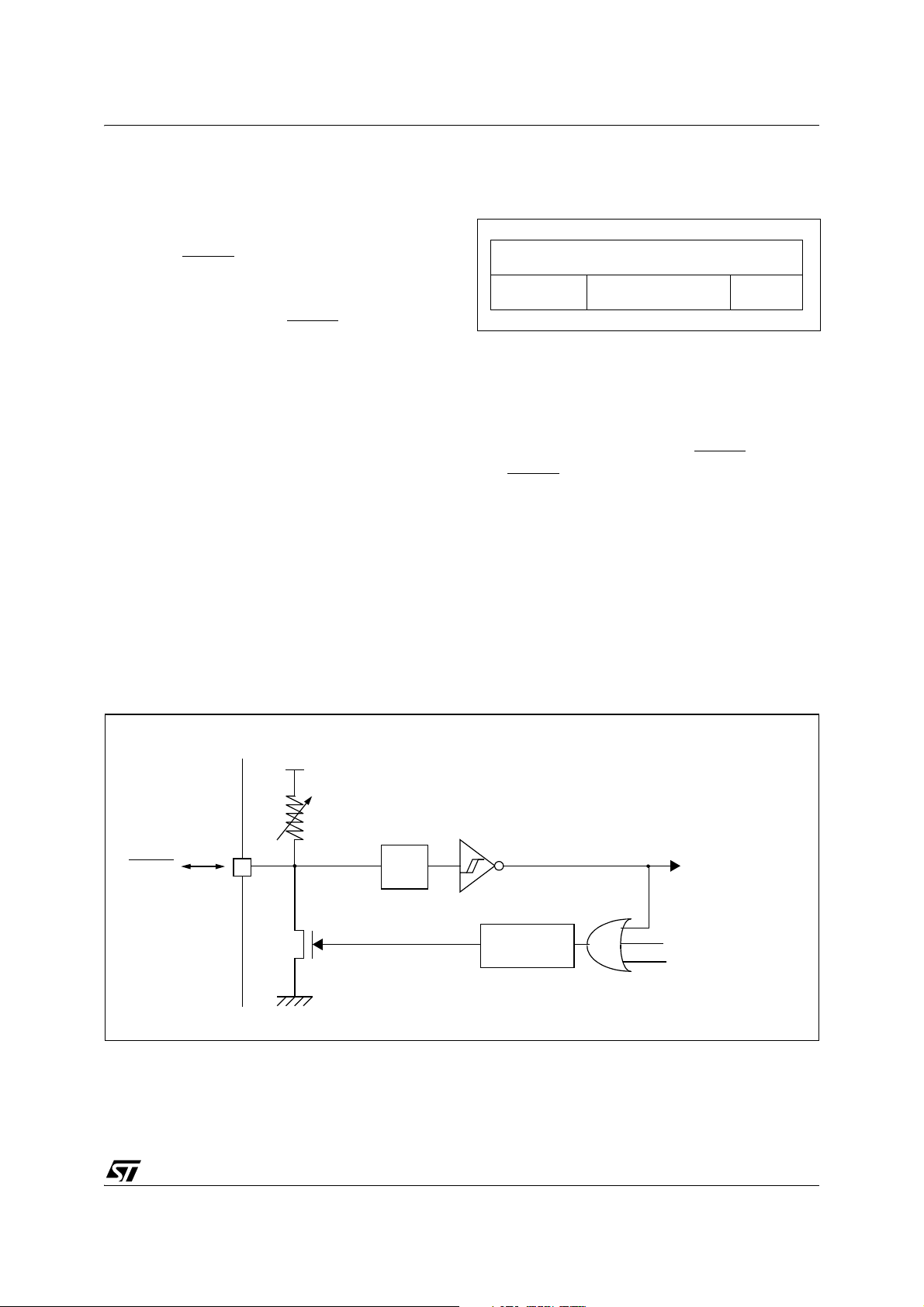

4.4 ICC Interface

ICC needs a minimum of 4 and up to 6 pins to be

connected to the programming tool (see Figure 8).

These pins are:

– RESET

–V

: device reset

: device power supply ground

SS

Figure 8. Typical ICC Interface

– ICCCLK: ICC output serial clock pin

– ICCDATA: ICC input/output serial data pin

– ICCSEL/V

: programming voltage

PP

– OSC1(or OSCIN): main clock input for exter-

nal source (optional)

: application board power supply (option-

–V

DD

al, see Figure 8, Note 3)

Notes:

1. If the ICCCLK or ICCDATA pins are only used

as outputs in the application, no signal isolation is

necessary. As soon as the Programming Tool is

plugged to the board, even if an ICC session is not

in progress, the ICCCLK and ICCDATA pins are

not available for the application. If they are used as

inputs by the application, isolation such as a serial

resistor has to implemented in case another device forces the signal. Refer to the Programming

Tool documentation for recommended resistor values.

2. During the ICC session, the programming tool

must control the RESET

flicts between the programming tool and the application reset circuit if it drives more than 5mA at

high level (push pull output or pull-up resistor<1K).

A schottky diode can be used to isolate the application RESET circuit in this case. When using a

classical RC network with R>1K or a reset man-

22/197

pin. This can lead to con-

agement IC with open drain output and pull-up resistor>1K, no additional components are needed.

In all cases the user must ensure that no external

reset is generated by the application during the

ICC session.

3. The use of Pin 7 of the ICC connector depends

on the Programming Tool architecture. This pin

must be connected when using most ST Programming Tools (it is used to monitor the application

power supply). Please refer to the Programming

Tool manual.

4. Pin 9 has to be connected to the OSC1 or OSCIN pin of the ST7 when the clock is not available

in the application or if the selected clock option is

not programmed in the option byte. ST7 devices

with multi-oscillator capability need to have OSC2

grounded in this case.

Page 23

FLASH PROGRAM MEMORY (Cont’d)

ST72325xx

4.5 ICP (In-Circuit Programming)

To perform ICP the microcontroller must be

switched to ICC (In-Circuit Communication) mode

by an external controller or programming tool.

Depending on the ICP code downloaded in RAM,

Flash memory programming can be fully customized (number of bytes to program, program locations, or selection serial communication interface

for downloading).

When using an STMicroelectronics or third-party

programming tool that supports ICP and the specific microcontroller device, the user needs only to

implement the ICP hardware interface on the application board (see Figure 8). For more details on

the pin locations, refer to the device pinout description.

4.6 IAP (In-Application Programming)

This mode uses a BootLoader program previously

stored in Sector 0 by the user (in ICP mode or by

plugging the device in a programming tool).

This mode is fully controlled by user software. This

allows it to be adapted to the user application, (user-defined strategy for entering programming

mode, choice of communications protocol used to

fetch the data to be stored, etc.). For example, it is

possible to download code from the SPI, SCI, USB

or CAN interface and program it in the Flash. IAP

mode can be used to program any of the Flash

sectors except Sector 0, which is write/erase protected to allow recovery in case errors occur during the programming operation.

4.7 Related Documentation

For details on Flash programming and ICC protocol, refer to the ST7 Flash Programming Reference Manual and to the ST7 ICC Protocol Reference Manual

.

4.7.1 Register Description FLASH CONTROL/STATUS REGISTER (FCSR)

Read/Write

Reset Value: 0000 0000 (00h)

70

00000000

This register is reserved for use by Programming

Tool software. It controls the Flash programming

and erasing operations.

Figure 9. Flash Control/Status Register Address and Reset Value

Address

(Hex.)

0029h

Register

Label

FCSR

Reset Value00000000

76543210

23/197

Page 24

ST72325xx

ACCUMULATOR

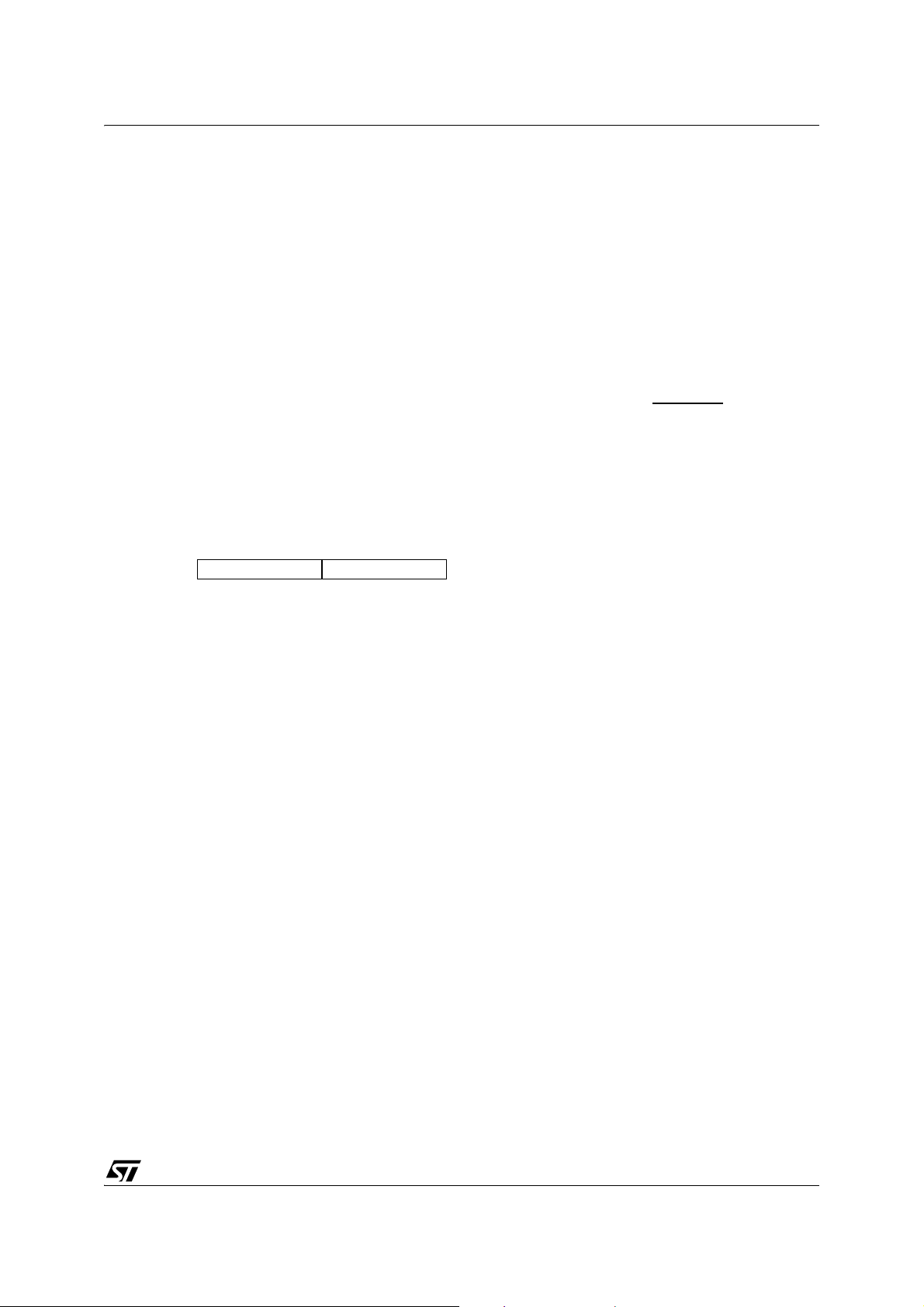

X INDEX REGISTER

Y INDEX REGISTER

STACK POINTER

CONDITION CODE REGISTER

PROGRAM COUNTER

70

1C1I1HI0NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

70

70

70

0

7

15 8

PCH

PCL

15

8

70

RESET VALUE = STACK HIGHER ADDRESS

RESET VALUE =

1X11X1XX

RESET VALUE = XXh

RESET VALUE = XXh

RESET VALUE = XXh

X = Undefined Value

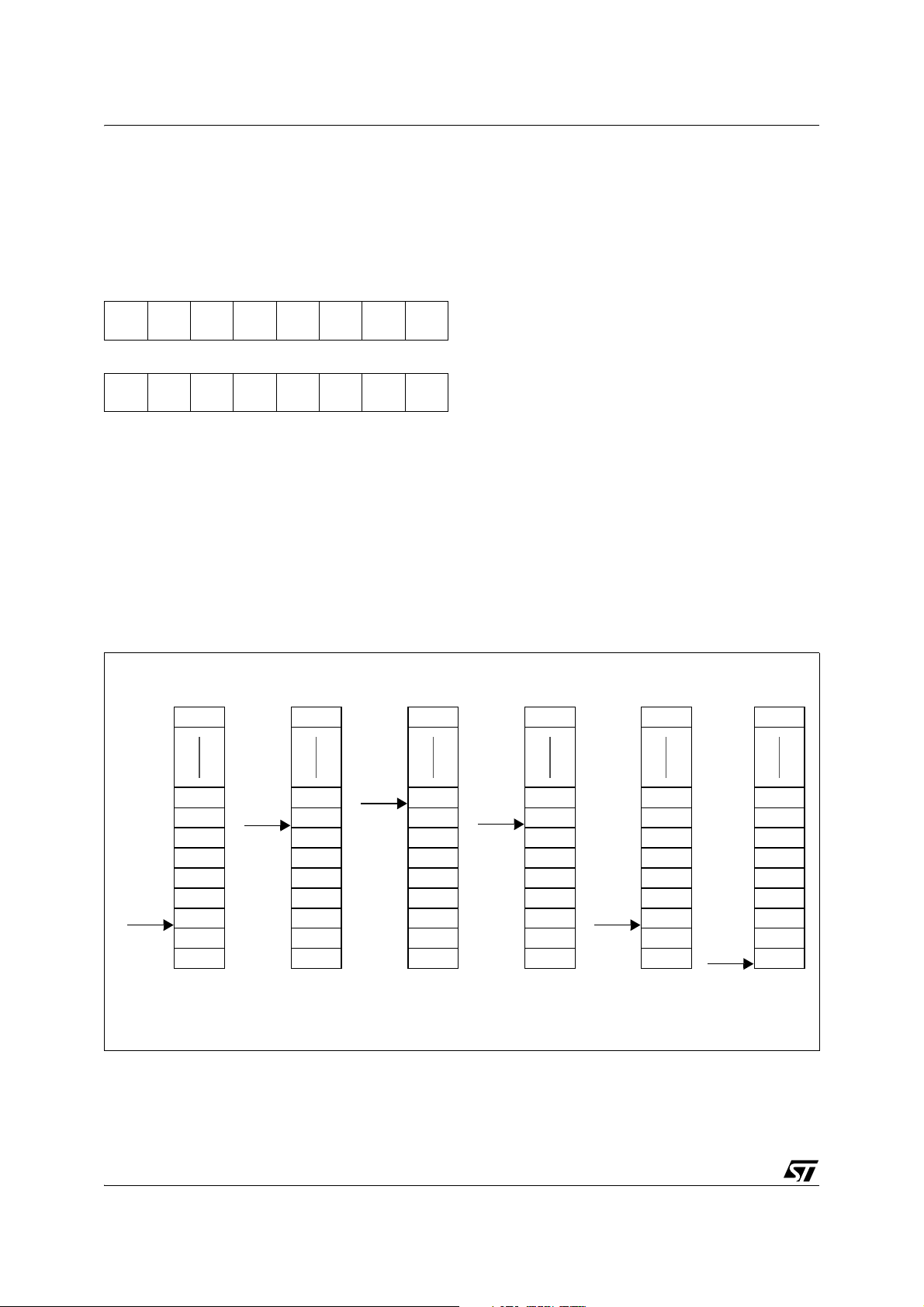

5 CENTRAL PROCESSING UNIT

5.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

5.2 MAIN FEATURES

■ Enable executing 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes (with indirect

addressing mode)

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power HALT and WAIT modes

■ Priority maskable hardware interrupts

■ Non-maskable software/hardware interrupts

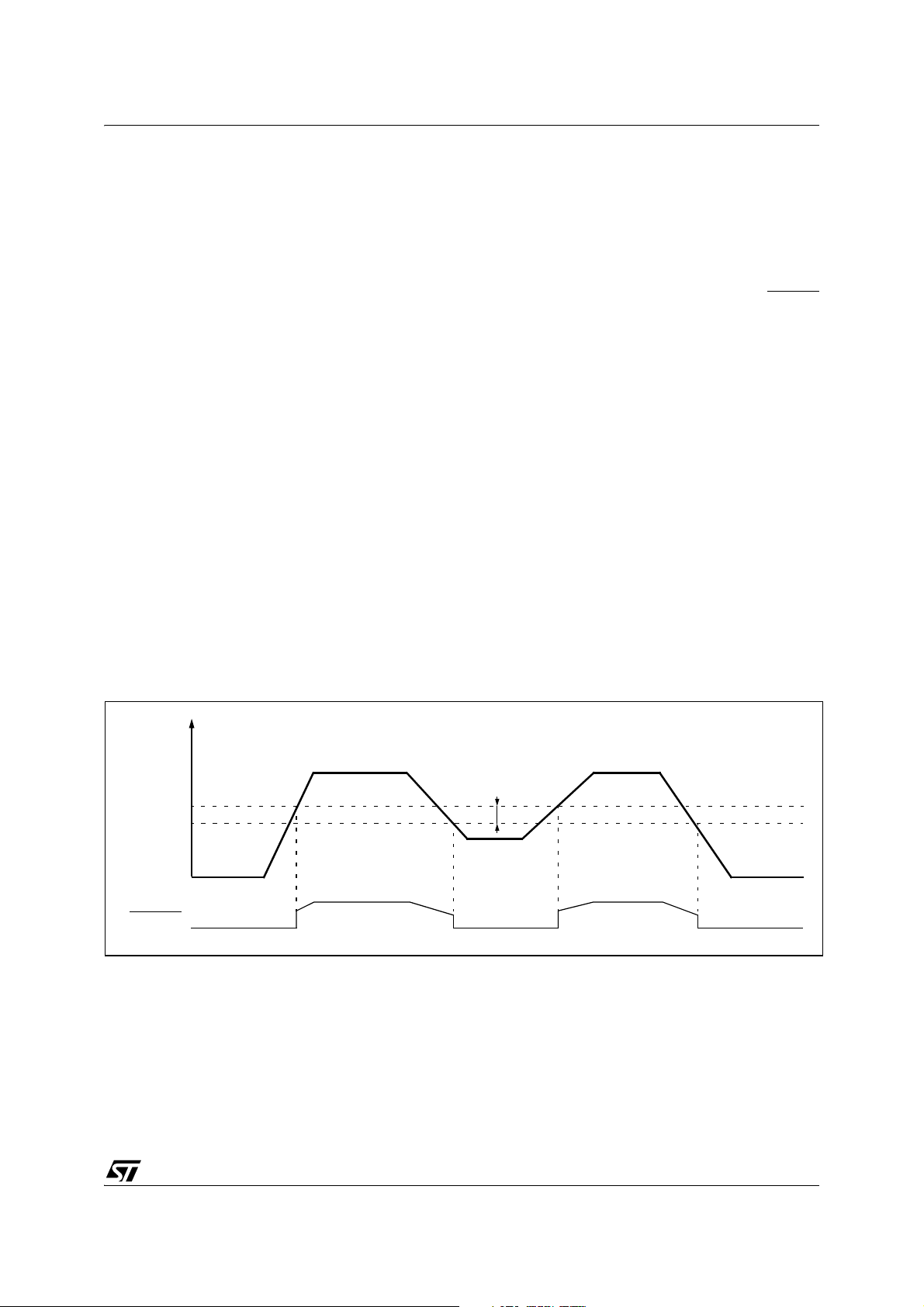

Figure 10. CPU Registers

5.3 CPU REGISTERS

The six CPU registers shown in Figure 1 are not

present in the memory mapping and are accessed

by specific instructions.

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

These 8-bit registers are used to create effective

addresses or as temporary storage areas for data

manipulation. (The Cross-Assembler generates a

precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures.

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

24/197

Page 25

CENTRAL PROCESSING UNIT (Cont’d)

Condition Code Register (CC)

Read/Write

Reset Value: 111x1xxx

70

Bit 1 = Z Zero.

This bit is set and cleared by hardware. This bit in-

dicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

11I1HI0NZ

C

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

The 8-bit Condition Code register contains the interrupt masks and four flags representative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Arithmetic Management Bits

Bit 4 = H Half carry.

This bit is set by hardware when a carry occurs be-

tween bits 3 and 4 of the ALU during an ADD or

ADC instructions. It is reset by hardware during

the same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 2 = N Negative.

This bit is set and cleared by hardware. It is repre-

sentative of the result sign of the last arithmetic,

logical or data manipulation. It’s a copy of the re-

th

sult 7

bit.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(that is, the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL instructions.

instructions.

Bit 0 = C Carry/borrow.

This bit is set and cleared by hardware and software. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.