查询ST72141K2B1供应商

8-BIT MCU WITH ELECTRIC-MOTOR CONTROL,

ADC, 16-BIT TIMERS, SPI INTERFACE

■ Memories

– 8K Program memory

(ROM/OTP/EPROM)

– 256 Bytes RAM

■ Clock, Reset and Supply Management

– Enhanced reset system

– Low voltage supply supervisor

– 3 Power saving modes

■ 14 I/O Ports

– 14 multifunctional bidirectional I/O lines with:

External interruptcapability (2 vectors), 13 alternate function lines, 3 high sink outputs

■ Motor Control peripheral

– 6 PWM output channels

– Emergency pin toforce outputs to HiZ state

– 3 analog inputs for rotor position detection

with no need for additional sensors

– Comparator for current limitation

■ 3 Timers

– Two 16-bittimers with: 2 input captures, 2out-

put compares,external clock input, PWM and

Pulse generator modes

– Watchdog timer for system integrity

■ Communications Interface

– SPI synchronous serial interface

■ Analog Peripheral

– 8-bit ADC with 8 input pins

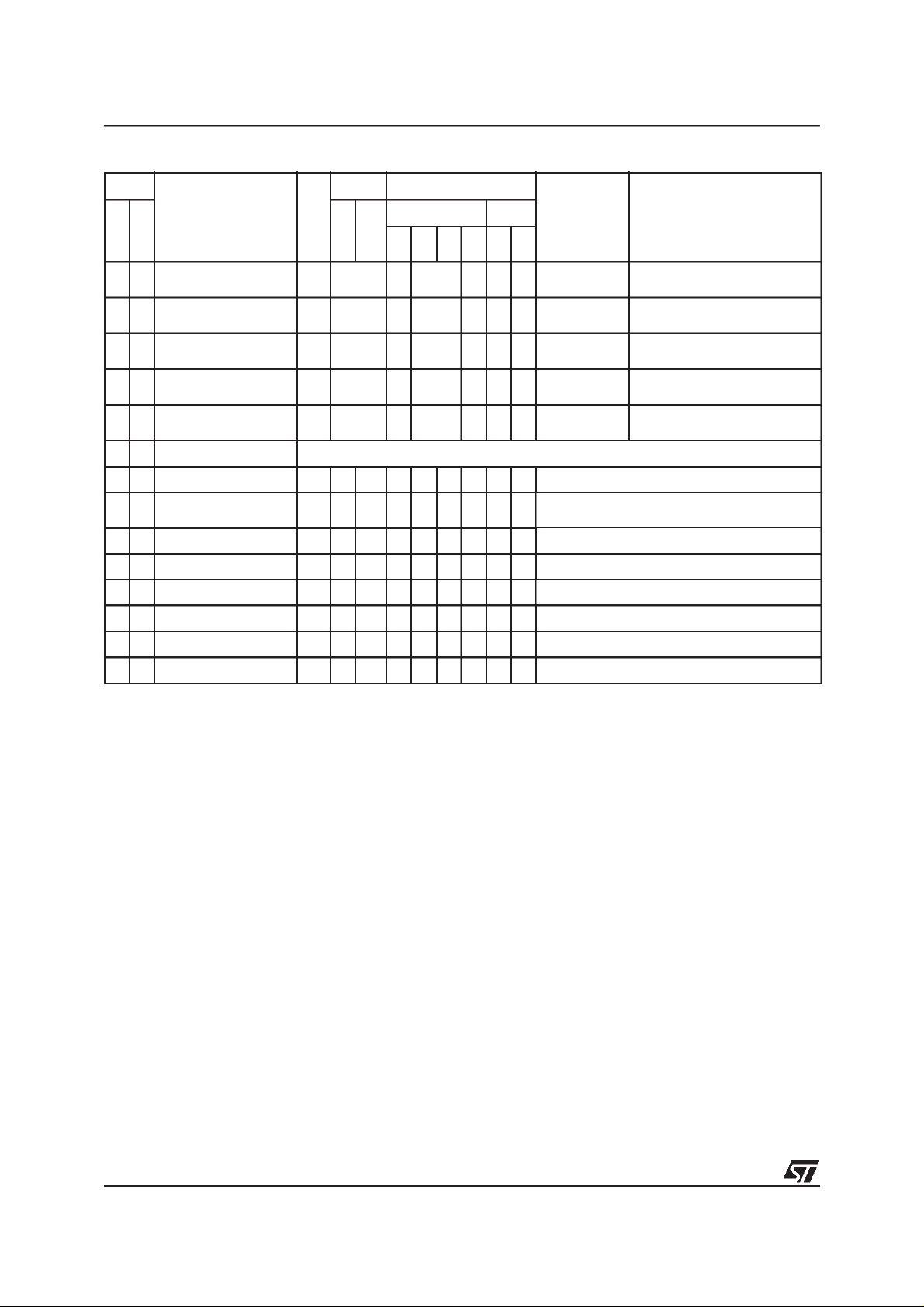

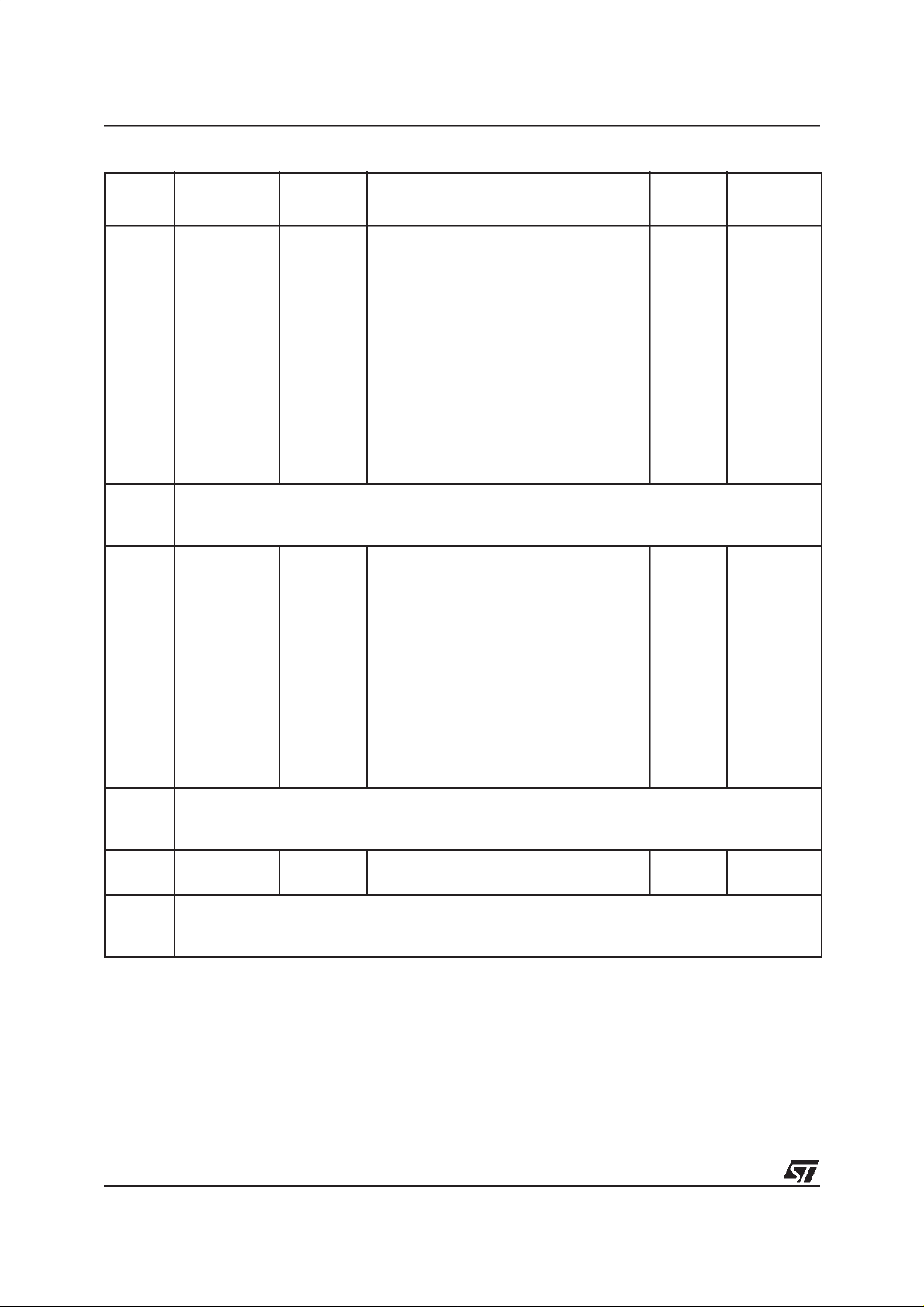

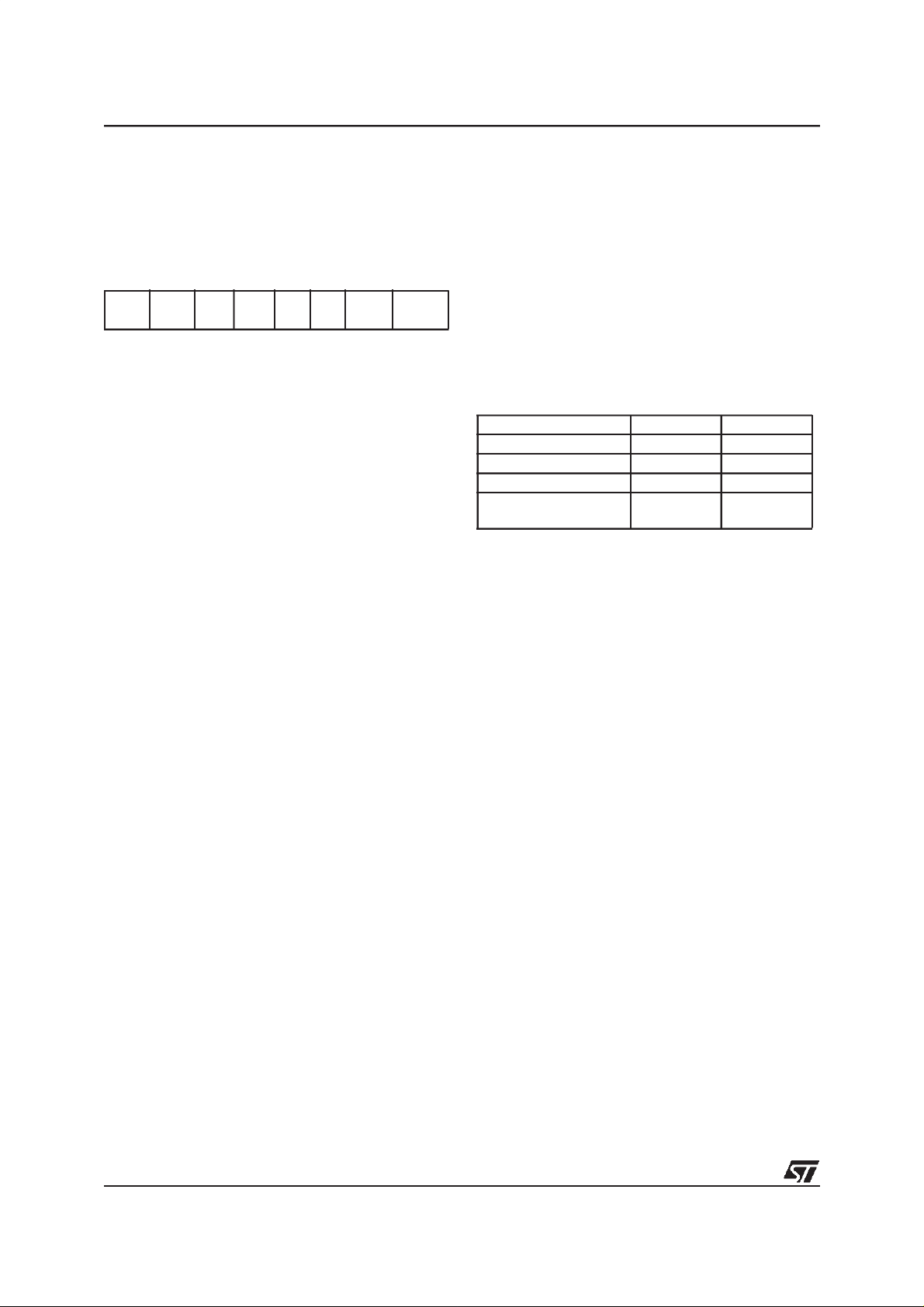

Device Summary

Features ST72141K2

Program memory - bytes 8K

RAM (stack) - bytes 256 (64)

Peripherals

Operating Supply 4V to 5.5V

CPU Frequency 4 or 8 MHz (with 8 or 16 MHz oscillator)

Operating Temperature -40°C to +85°C

Packages SO34 / SDIP32

■ Instruction Set

– 8-bit data manipulation

– 63 basic instructions

– 17 main addressing modes

– 8 x 8 unsigned multiply instruction

– True bit manipulation

■ Development Tools

– Full hardware/softwaredevelopment package

Motor control,

Watchdog, Two 16-bit timers,

SPI, ADC

ST72141K

PRELIMINARY DATA

SDIP32

SO34S

Rev. 1.6

September 2000 1/132

This ispreliminary information on anew product in development or undergoing evaluation. Details are subject tochange without notice.

1

Table of Contents

1 GENERAL DESCRIPTION . . . . . . ................................................ 5

1.1 INTRODUCTION . . . . . .. . . . . . ............................................. 5

1.2 PIN DESCRIPTION . . ..................................................... 6

1.3 EXTERNAL CONNECTIONS . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......... 9

1.4 REGISTER & MEMORY MAP . . ............................................10

1.5 EPROM PROGRAM MEMORY . . . . . . . . . . . . . . . . . . .. . . . . . .................... 13

2 CENTRAL PROCESSING UNIT . . ............................................... 14

2.1 INTRODUCTION . . . . . .. . . . . . ............................................14

2.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . .............................. 14

2.3 CPU REGISTERS . . . .................................................... 14

3 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . ................................17

3.1 LOW VOLTAGE DETECTOR (LVD) . . . . . . . . . . . . . . ........................... 18

3.2 RESET MANAGER . . .................................................... 19

3.3 LOW CONSUMPTION OSCILLATOR . . . . . . . .. . . . . . . . . . . . . . . . . . . . . ........... 23

3.4 MAIN CLOCK CONTROLLER (MCC) . . . . ....................................24

4 INTERRUPTS . . .............................................................25

4.1 NON MASKABLE SOFTWARE INTERRUPT .................................. 25

4.2 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . .............................. 25

4.3 PERIPHERAL INTERRUPTS ............................................... 25

5 POWER SAVING MODES . . . . . . . . . . ...........................................28

5.1 INTRODUCTION . . . . . .. . . . . . ............................................28

5.2 HALT MODE . . . . . . . . . . . . . . . . . . . ........................................ 29

5.3 WAIT MODE . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . ........ 30

5.4 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . ................................. 30

6 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . ........................................31

6.1 INTRODUCTION . . . . . .. . . . . . ............................................31

6.2 FUNCTIONAL DESCRIPTION . . . . . ......................................... 31

6.2.1 Input Modes . . . . . . . . . . . . . . . . . . . . . . ................................. 31

6.2.2 Output Modes . . . . . . ...............................................31

6.2.3 Alternate Functions . . ...............................................31

6.3 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.1 Register Description . . . . . ............................................36

7 MISCELLANEOUS REGISTER . . ...............................................38

7.1 I/O PORT INTERRUPT SENSITIVITY DESCRIPTION . . . . . .. . . . . . . . . . . . . . . . . . . . . 38

7.2 I/O PORT ALTERNATE FUNCTIONS . . . . . . . . ................................ 38

7.3 CLOCK PRESCALERSELECTION . . ........................................ 38

7.4 MISCELLANEOUS REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 ON-CHIP PERIPHERALS . . . . . . . . . . . ........................................... 40

8.1 MOTOR CONTROLLER (MTC) . . . . ......................................... 40

8.1.1 Introduction . . . .................................................... 40

8.1.2 Main Features . . . . . . ...............................................40

8.1.3 Application Example . . . . . . . . . . . . . . . . . . .............................. 40

8.1.4 Functional Description . . . . ...........................................44

132

2/132

2

Table of Contents

8.1.5 Low PowerModes . . . ...............................................66

8.1.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . ................................. 66

8.1.7 Register Description . . . . . ............................................67

8.2 WATCHDOG TIMER (WDG) . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2.1 Introduction . . . .................................................... 75

8.2.2 Main Features . . . . . . ...............................................75

8.2.3 Functional Description . . . . ...........................................76

8.2.4 Low PowerModes . . . ...............................................76

8.2.5 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . ................................. 76

8.2.6 Register Description . . . . . ............................................76

8.3 16-BIT TIMER . . . . . . . . . . . . . . . . . . ........................................78

8.3.1 Introduction . . . .................................................... 78

8.3.2 Main Features . . . . . . ...............................................78

8.3.3 Functional Description . . . . ...........................................78

8.3.4 Low PowerModes . . ............................................... 90

8.3.5 Interrupts . . . . . ....................................................90

8.3.6 Summary of Timer modes . . . . . . . . . . . . . . .............................. 90

8.3.7 Register Description . . . . . ............................................91

8.4 SERIAL PERIPHERAL INTERFACE (SPI) . . . .. . . . . . . . . . . . . .. . . . . . ............96

8.4.1 Introduction . . . .................................................... 96

8.4.2 Main Features . . . . . . ...............................................96

8.4.3 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.4.4 Functional Description . . . . ...........................................98

8.4.5 Low PowerModes . . . ..............................................105

8.4.6 Interrupts . . . . . ...................................................105

8.4.7 Register Description . . . . . ...........................................106

8.5 8-BIT A/D CONVERTER (ADC) . . . . . . . .. . . . . . .. . . .......................... 109

8.5.1 Introduction . . . ................................................... 109

8.5.2 Main Features . . . . . . .............................................. 109

8.5.3 Functional Description . . . . ..........................................110

8.5.4 Low PowerModes . . . ..............................................110

8.5.5 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . ................................ 110

8.5.6 Register Description . . . . . ...........................................111

9 INSTRUCTION SET . . . . . . . . . . . . . . . . . . .......................................112

9.1 ST7 ADDRESSING MODES . . . . . . . . . .. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

9.1.1 Inherent . . . . . . .. . . . .............................................. 113

9.1.2 Immediate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . 113

9.1.3 Direct . .......................................................... 113

9.1.4 Indexed (No Offset, Short, Long) . . . . . . . . . . . . .......................... 113

9.1.5 Indirect (Short, Long) . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.1.6 Indirect Indexed (Short, Long) . .......................................114

9.1.7 Relative Mode (Direct, Indirect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9.2 INSTRUCTION GROUPS . . .. . . . . . . . . . . . . ................................115

10 ELECTRICAL CHARACTERISTICS . . . . ........................................ 118

10.1ABSOLUTE MAXIMUM RATINGS . . . .......................................118

10.2RECOMMENDED OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . ..........119

10.3DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . .. . . . . . ........... 119

3/132

3

Table of Contents

10.4GENERAL TIMING CHARACTERISTICS . . . . . . . . . . . .. . . . . . . . . . . . . . . . . ....... 119

10.5I/O PORT CHARACTERISTICS . ........................................... 120

10.6SUPPLY, RESET AND CLOCK CHARACTERISTICS . . . . . . . . . . . . . . .. . . . . . . . . . . 121

10.6.1Supply Manager ...................................................121

10.6.2RESET Sequence Manager . . . . . . . . . . ................................121

10.6.3Clock System . . . . . . . . . . . .......................................... 121

10.7MEMORY AND PERIPHERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11 GENERAL INFORMATION ................................................... 128

11.1PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . .......................... 128

11.2ORDERING INFORMATION . . . . . . . . . . . . . ................................. 129

12 SUMMARY OF CHANGES . .................................................. 131

4/132

132

1

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

ST72141K

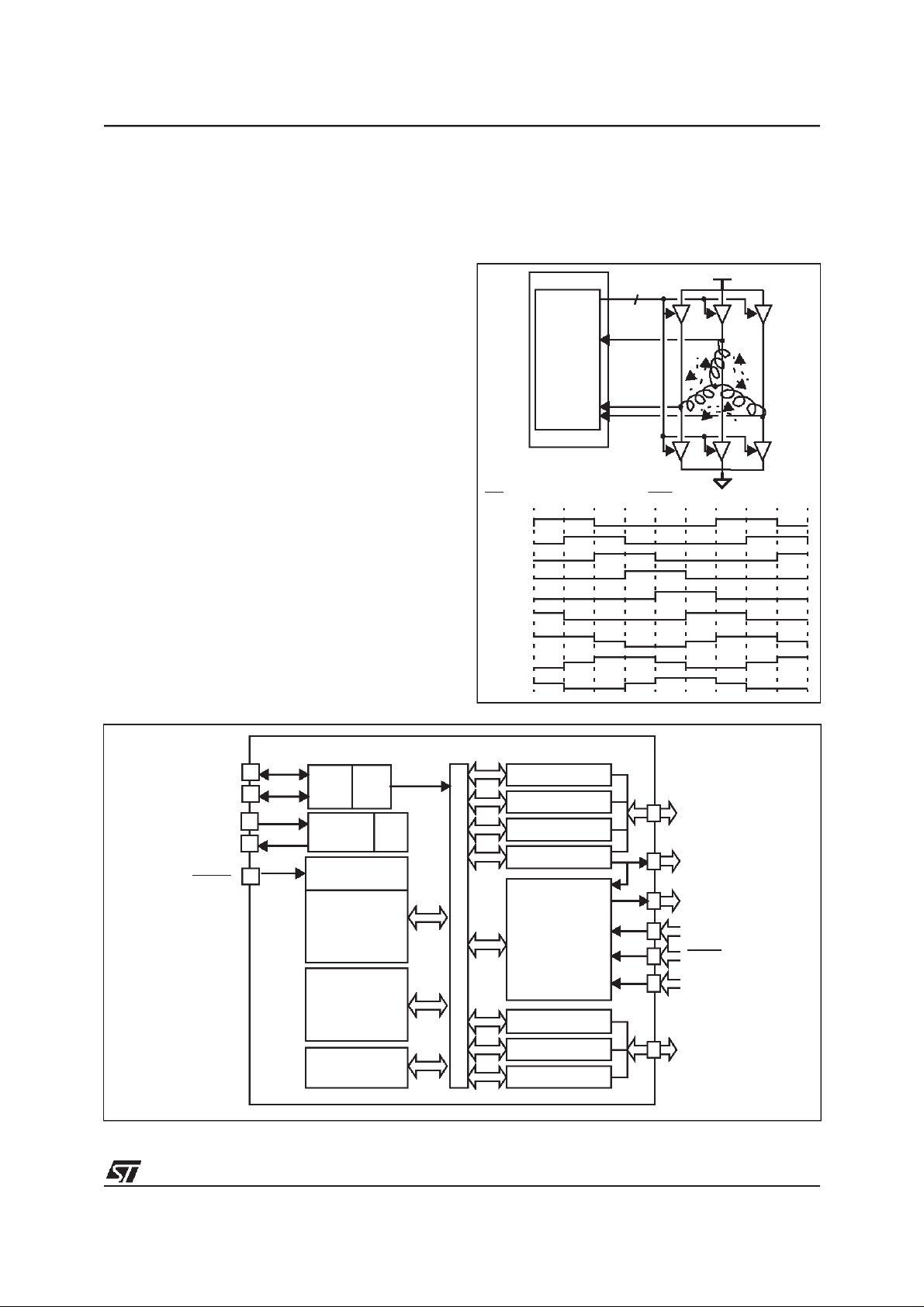

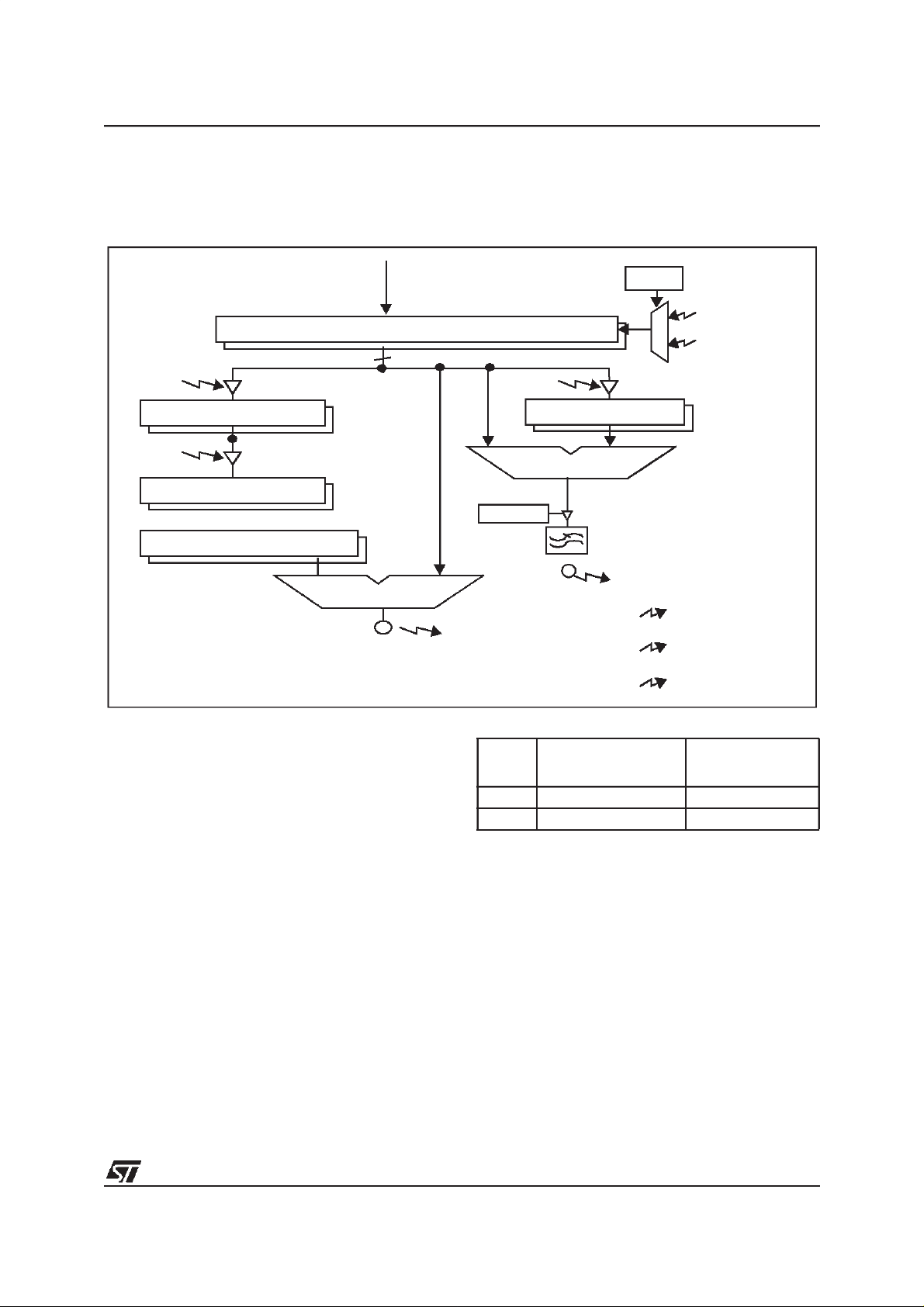

The ST72141K devices are members of the ST7

microcontroller family designed specifically for motor control applications and including A/D conversion and SPI interface capabilities. They include

an on-chip Moter Controller peripheral for control

of electric brushless moters with or without sensors. An example application, for 6-step control of

a Permanent Magnet DC motor, is shown in Figure

1.

The ST72141K devices are based on a common

industry-standard 8-bit core, featuring an enhanced instruction set.

Under software control, they can be placed in

WAIT, SLOW, or HALT mode, reducing power

consumption when the application is in idle or

standby state.

The enhanced instruction set and addressing

modes of the ST7 offer bothpower andflexibility to

software developers,enabling the design of highly

efficient and compact application code. In addition

to standard 8-bitdata management, all ST7microcontrollers feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing

modes.

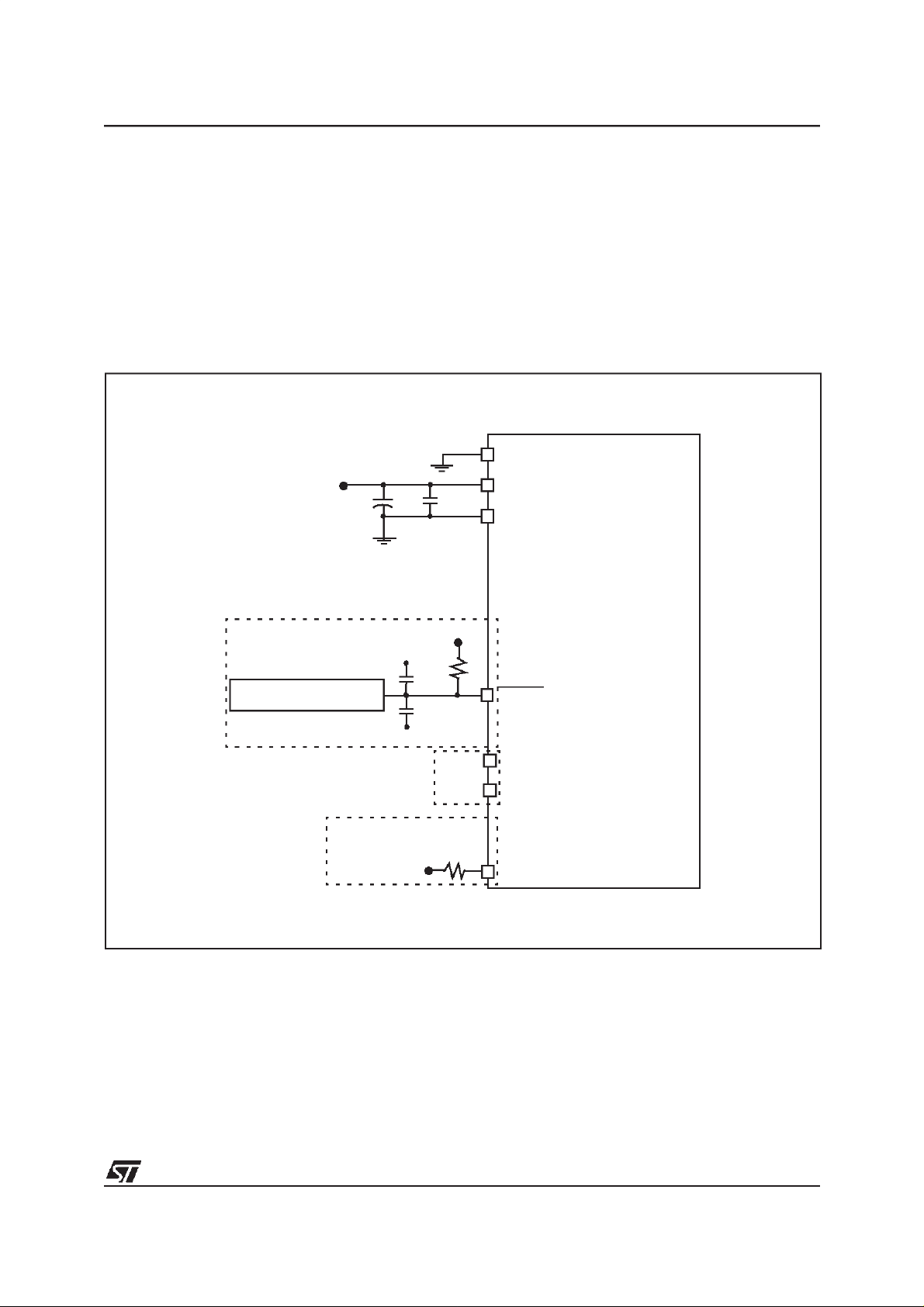

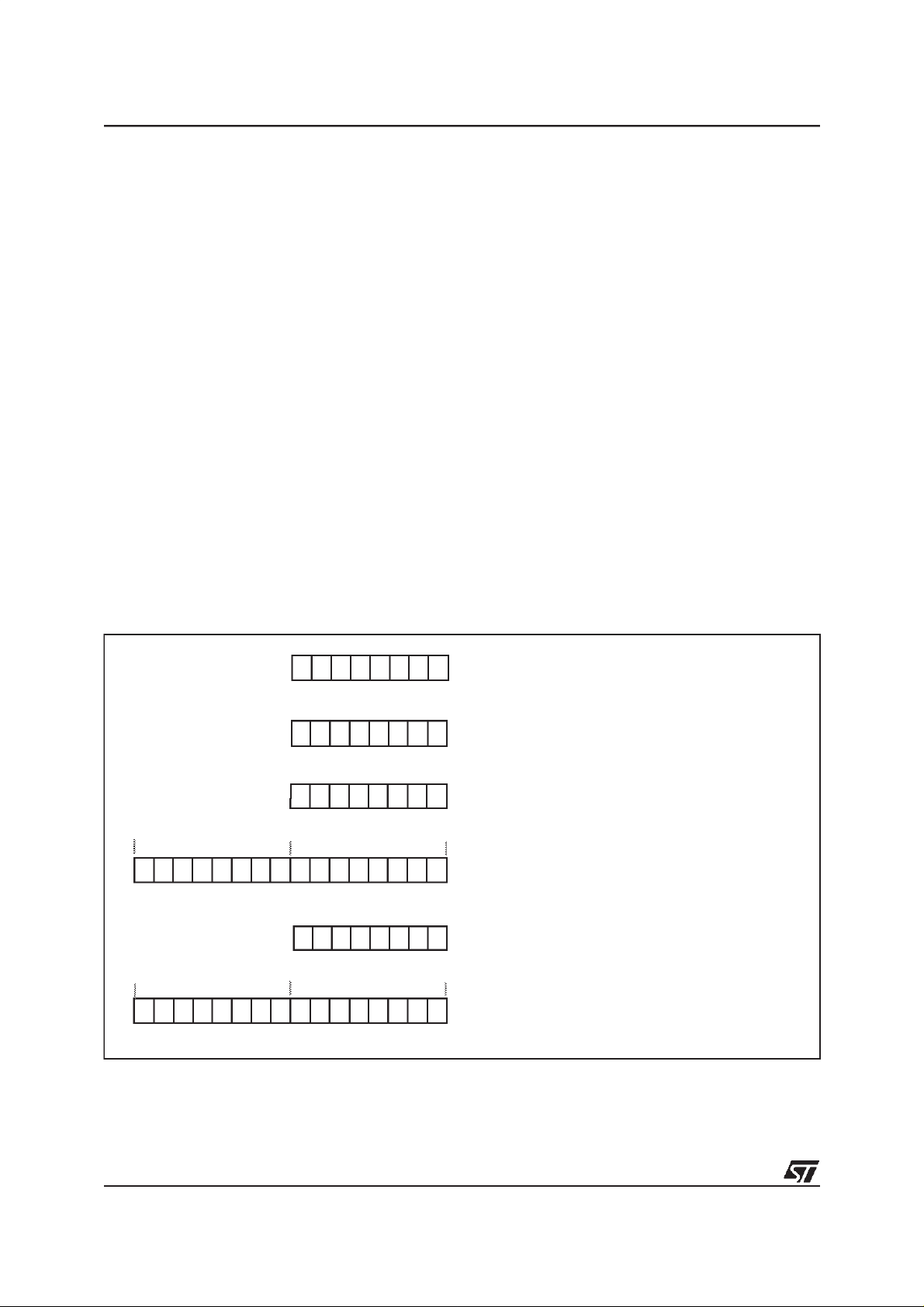

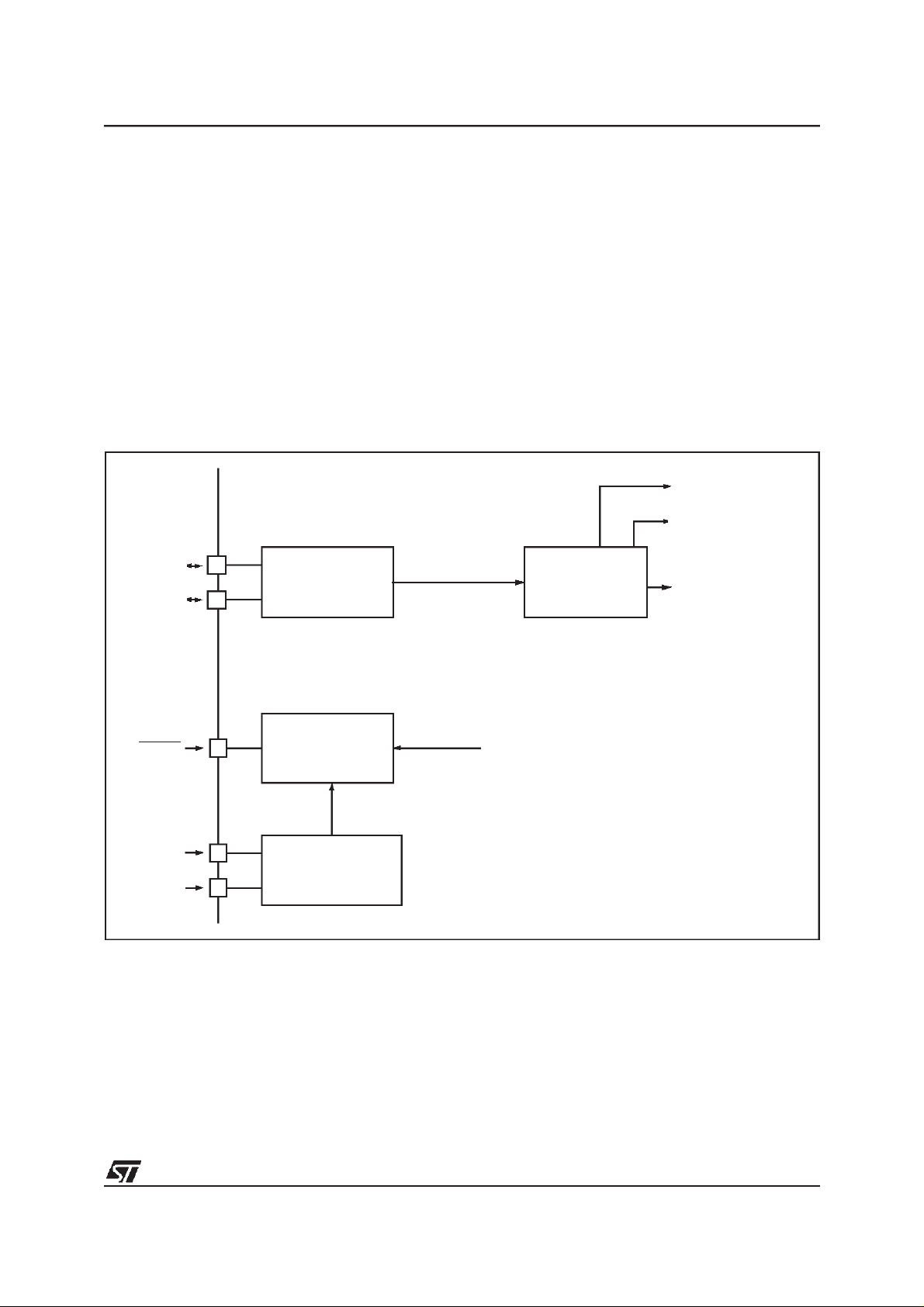

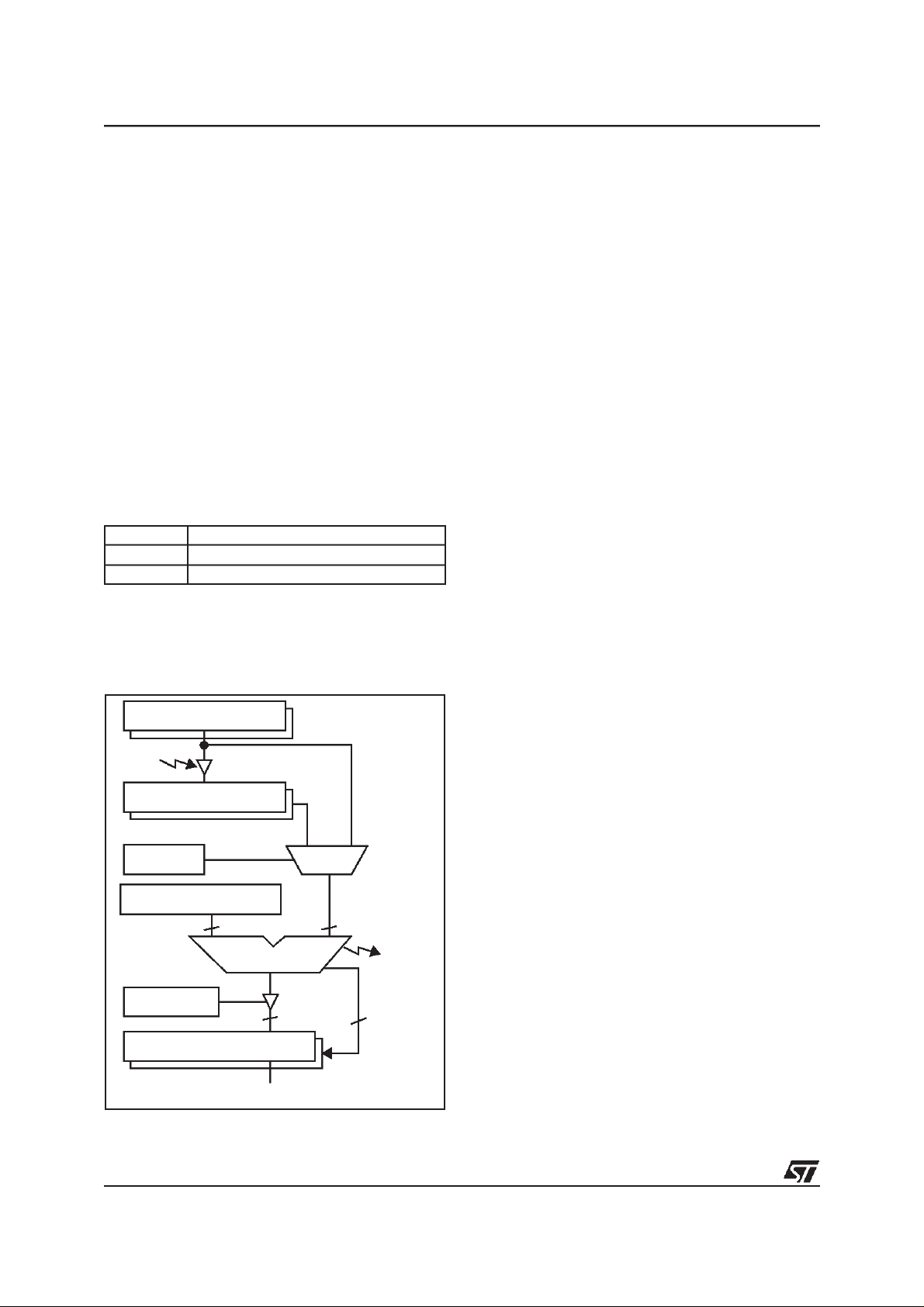

Figure 2. Device Block Diagram

Figure 1. Example of a 6-step-controlled Motor

ST7

MCO5 -0

6

MCIB

MTC

MCIA

MCIC

Net Step

Σ1Σ2Σ3Σ4Σ5Σ6Σ1Σ2Σ

0

1

2

3

4

5

300V

150V

A

0

300V

150V

B

0

300V

150V

0

C

0

I

4

A

I

35

300V

2

4

B

I

6

I

1

I

3

C

I

5

2

1

3

OSC1

OSC2

V

DD

V

SS

RESET

OSC

POWER

SUPPLY

CONTROL

8-BIT CORE

ALU

8K-EPROM

256b-RAM

DIV

LVD

Internal

CLOCK

ADDRESS AND DATA BUS

PORT A

8-BIT ADC

TIMER B

TIMER A

MOTOR CTRL

PORT B

SPI

WATCHDOG

PA7:0

(8-BIT)

OC1A

MCO5:0

MCIA:C

MCES

MCCFI

PB5:0

(6-BIT)

5/132

4

ST72141K

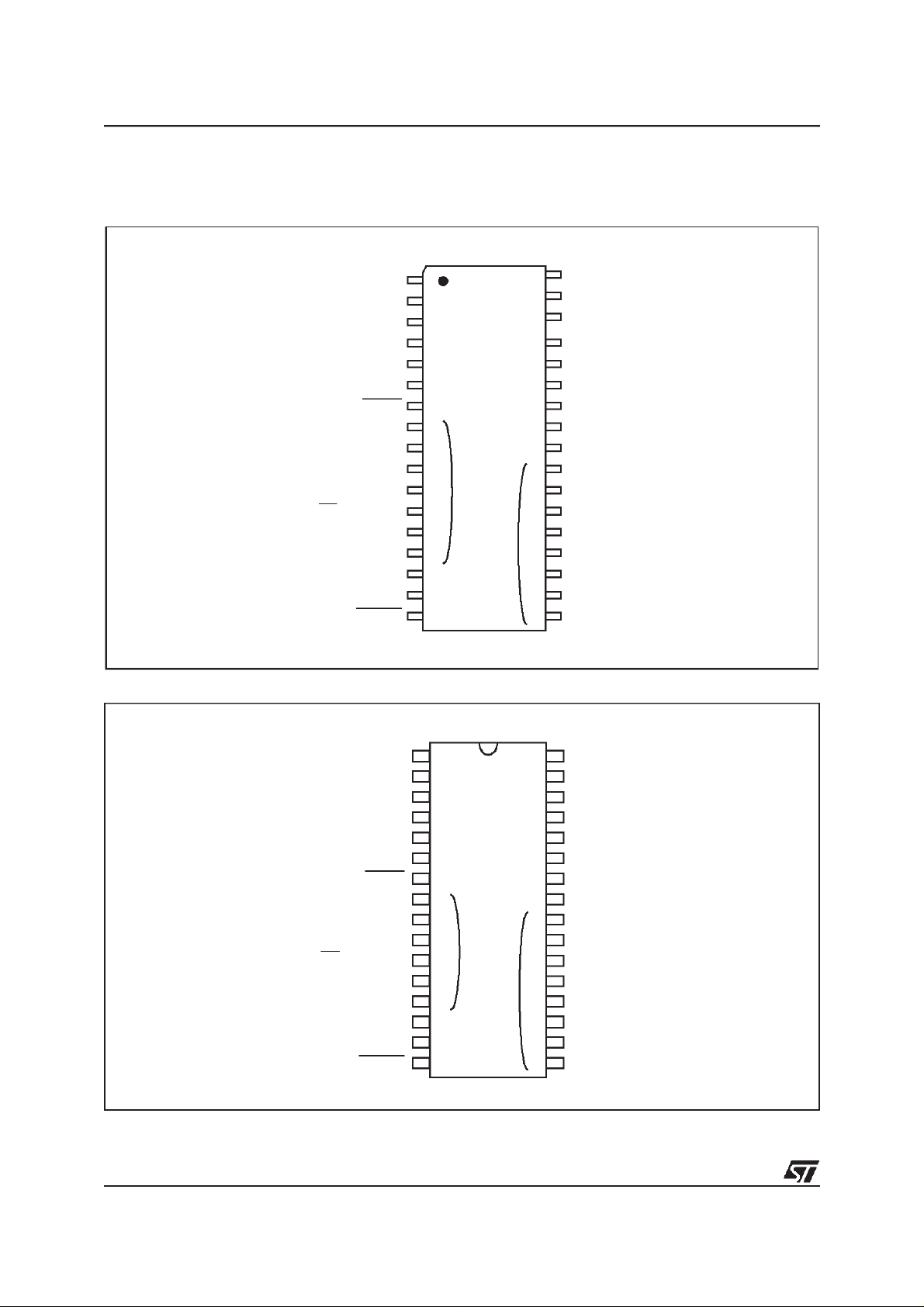

1.2 PIN DESCRIPTION

Figure 3. 34-Pin SO Package Pinout

MISO/PB5

MOSI/PB4

SCK/PB3

SS/ (HS) PB2

EXTCLK_B/ (HS) PB1

EXTCLK_A/ (HS) PB0

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

MCES

NC

OSC1

OSC2

RESET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

EI1

EI0

MCIA

34

MCIB

33

MCIC

32

MCCFI

31

V

30

DD

V

29

SS

V

28

PP

OCMP1_A

27

NC

26

PA7/AIN7/OCMP2_A

25

PA6/AIN6/ICAP1_A

24

23

PA5/AIN5/ICAP2_A

PA4/AIN4/OCMP1_B

22

PA3/AIN3/OCMP2_B

21

PA2/AIN2/ICAP1_B

20

PA1/AIN1/ICAP2_B

19

PA0/AIN0

18

Figure 4. 32-Pin SDIP Package Pinout

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

MCES

MISO/PB5

MOSI/PB4

SCK/PB3

SS/ (HS) PB2

EXTCLK_B/ (HS) PB1

EXTCLK_A/ (HS) PB0

OSC1

OSC2

RESET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

EI0

EI1

MCIA

32

MCIB

31

MCIC

30

MCCFI

29

V

28

27

26

25

24

23

22

21

20

19

18

17

DD

V

SS

V

PP

OCMP1_A

PA7/AIN7/OCMP2_A

PA6/AIN6/ICAP1_A

PA5/AIN5/ICAP2_A

PA4/AIN4/OCMP1_B

PA3/AIN3/OCMP2_B

PA2/AIN2/ICAP1_B

PA1/AIN1/ICAP2_B

PA0/AIN0

6/132

5

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations:

Type: I = input, O = output, S = supply

Input level: A = Dedicated analog input

In/Output level: C = CMOS 0.3VDD/0.7VDD,

CT= CMOS 0.3VDD/0.7VDDwith input trigger

Output level: HS = high sink (on N-buffer only),

R=70Ω/100Ω ratio of logical levels.

Analog level if used as PWM filtered with an external capacitor

Port configuration capabilities:

– Input: float = floating, wpu = weak pull-up, int = interrupt, ana = analog

– Output: OD = open drain, T = true open drain, PP = push-pull

Note: the Reset configuration of each pin is shown in bold.

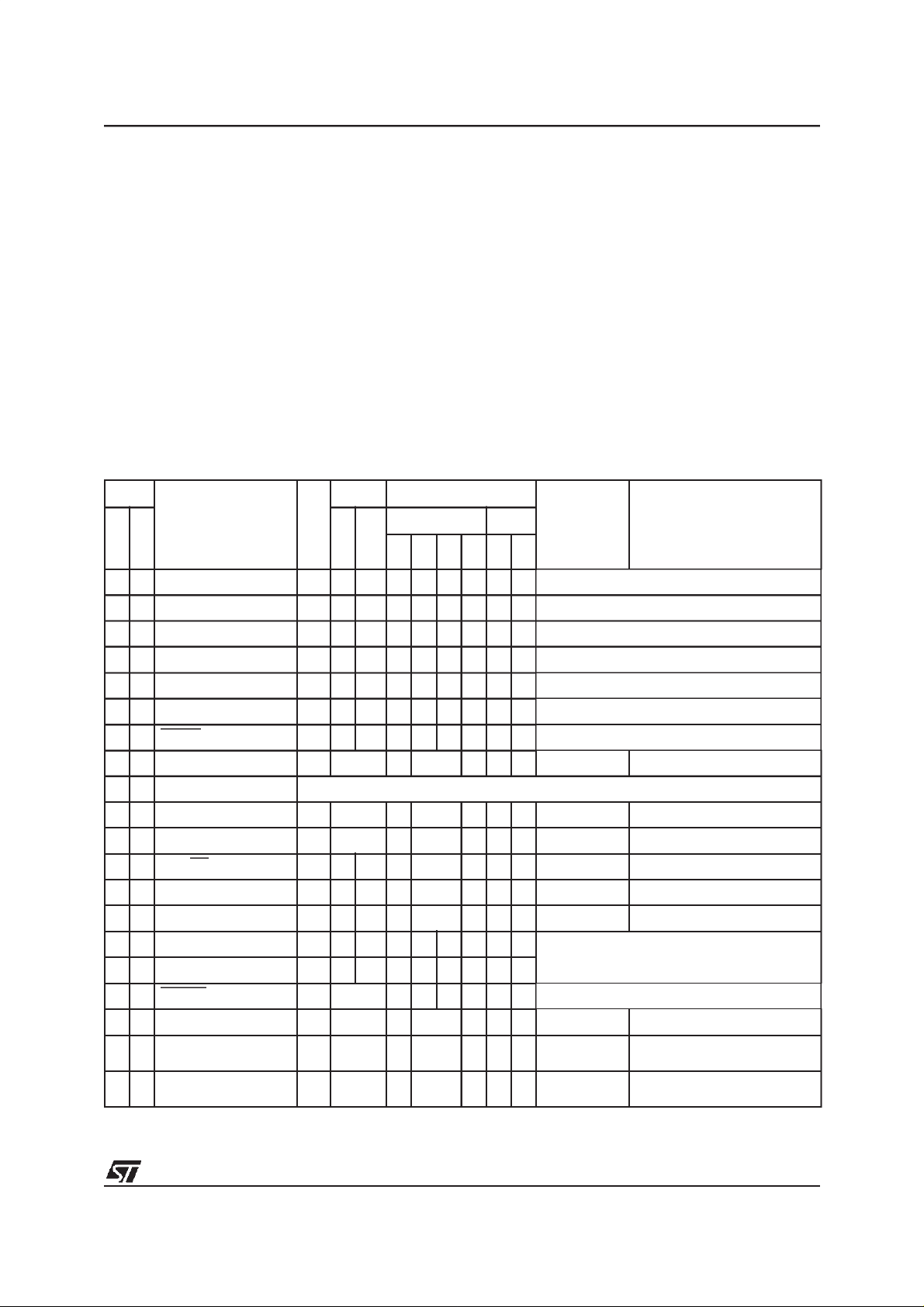

Table 1. Device Pin Description

ST72141K

Pin n°

Pin Name

SO34

SDIP32

1 1 MCO5 O C X Motor Control Output Channel 5

2 2 MCO4 O C X Motor Control Output Channel 4

3 3 MCO3 O C X Motor Control Output Channel 3

4 4 MCO2 O C X Motor Control Output Channel 2

5 5 MCO1 O C X Motor Control Output Channel 1

6 6 MCO0 O C X Motor Control Output Channel 0

7 7 MCES I C

8 8 PB5/MISO I/O C

9 NC Not Connected

9 10 PB4/MOSI I/O C

10 11 PB3/SCK I/O C

11 12 PB2/SS I/O C

12 13 PB1/EXTCLK_B I/O C

13 14 PB0/EXTCLK_A I/O C

14 15 OSC1

15 16 OSC2

16 17 RESET I/O C X X Toppriority nonmaskable interrupt (active low)

17 18 PA0/AIN0 I/O C

18 19 PA1/ICAP2_B/AIN1 I/O C

19 20 PA2/ICAP1_B/AIN2 I/O C

Level Port / Control

Input Output

Type

Input

Output

float

T

X EI1 X X Port B5 SPI Master In / Slave Out Data

T

X EI1 X X Port B4 SPI Master Out / Slave In Data

T

X EI1 X X Port B3 SPI Serial Clock

T

HS X EI1 T Port B2 SPI Slave Select (active low)

T

HS X EI1 T Port B1 Timer B Input Clock

T

HS X EI1 T Port B0 Timer A Input Clock

T

X EI0 X X X Port A0 ADC Analog Input 0

T

X EI0 X X X Port A1

T

X EI0 X X X Port A2

T

int

wpu

X Motor Control Emergency Stop Input

ana

OD

Main

Function

(after reset)

PP

These pins connect a crystal or ceramic

resonator, or an external RC, or an external

source to the on-chip oscillator

Alternate Function

Timer B Input Capture 2 or

ADC Analog Input 1

Timer B Input Capture 1 or

ADC Analog Input 2

7/132

6

ST72141K

Pin n°

Level Port / Control

Main

Pin Name

Type

SO34

SDIP32

Input

20 21 PA3/OCMP2_B/AIN3 I/O C

21 22 PA4/OCMP1_B/AIN4 I/O C

22 23 PA5/ICAP2_A/AIN5 I/O C

23 24 PA6/ICAP1_A/AIN6 I/O C

24 25 PA7/OCMP2_A/AIN7 I/O C

T

T

T

T

T

Input Output

Output

float

wpu

int

ana

OD

PP

X EI0 X X X Port A3

X EI0 X X X Port A4

X EI0 X X X Port A5

X EI0 X X X Port A6

X EI0 X X X Port A7

Function

(after reset)

Alternate Function

Timer B Output Compare 2 or

ADC Analog Input 3

Timer B Output Compare 1 or

ADC Analog Input 4

Timer A Input Capture 2 or

ADC Analog Input 5

Timer A Input Capture 1 or

ADC Analog Input 6

Timer A Output Compare 2 or

ADC Analog Input 7

26 NC Not Connected

25 27 OCMP1_A O R Timer A Output Compare 1

26 28 V

27 29 V

28 30 V

PP

SS

DD

I

S Ground

S Main power supply

Must be tied low during normal operating

mode,EPROM Programming voltage pin.

29 31 MCCFI I A Motor Control Current Feedback Input

30 32 MCIC I A Motor Control Input C

31 33 MCIB I A Motor Control Input B

32 34 MCIA I A Motor Control Input A

8/132

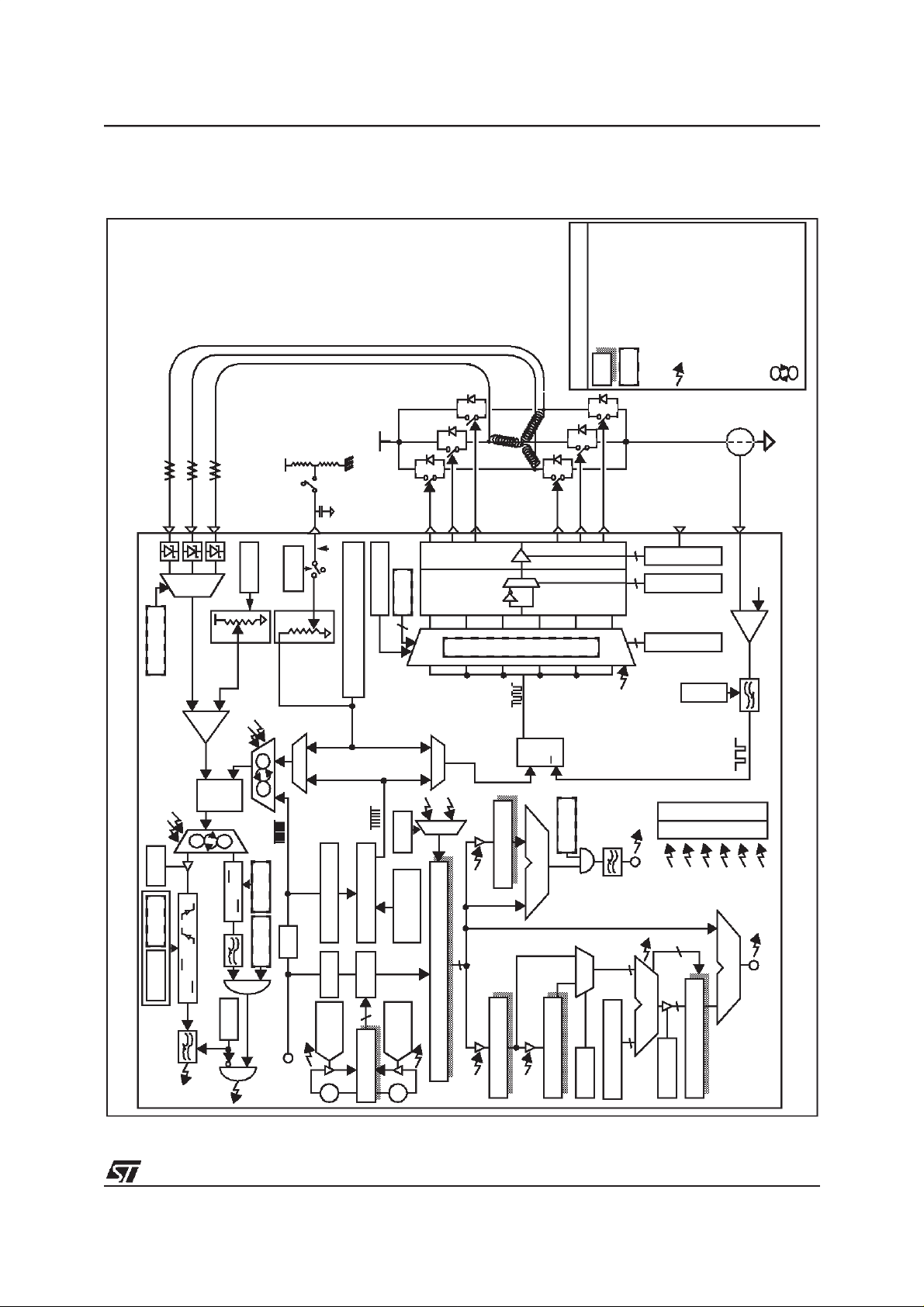

1.3 EXTERNAL CONNECTIONS

ST72141K

The following figure shows the recommended external connections for the device.

The VPPpin is only used for programming OTP

and EPROM devices and must be tied to ground in

user mode.

The 10 nF and 0.1 µF decoupling capacitors on

the power supply lines are a suggested EMC performance/cost tradeoff.

Figure 5. Recommended External Connections

V

DD

Optional if Low Voltage

Detector (LVD) isused

EXTERNAL RESET CIRCUIT

10µF

+

V

DD

0.1µF

0.1µF

V

SS

The external reset network is intended to protect

the device against parasitic resets, especially in

noisy environments.

Unused I/Os should be tied high to avoid any unnecessary power consumption on floating lines.

An alternative solution is to program the unused

ports as inputs with pull-up.

V

PP

V

V

4.7K

DD

DD

V

SS

RESET

OSC1

OSC2

0.1µF

See

Clocks

Section

Or configure unused I/O ports

by software as input with pull-up

V

10K

DD

Unused I/O

9/132

ST72141K

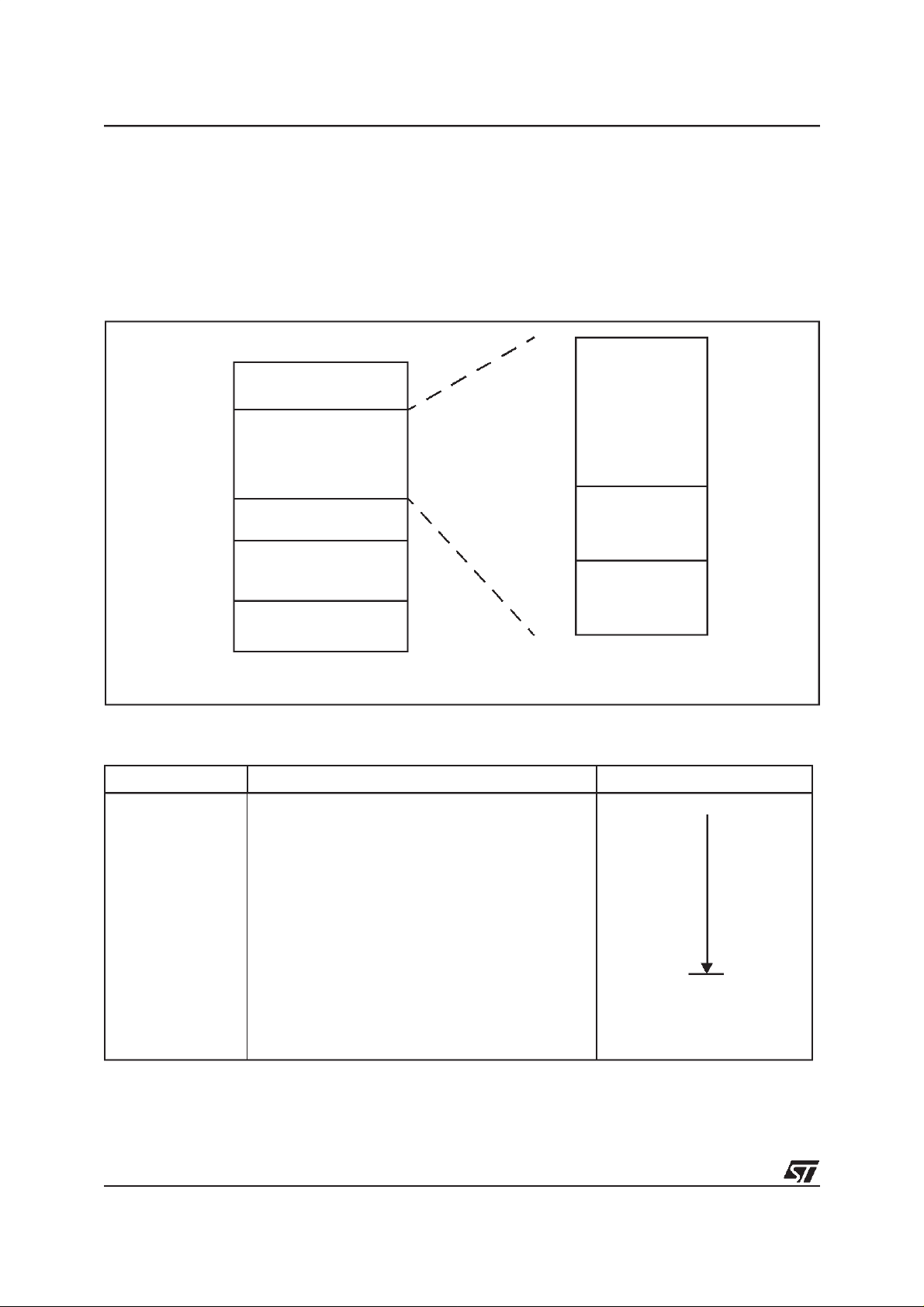

1.4 REGISTER & MEMORY MAP

As shown in Figure 6, the MCU is capable of addressing 64K bytes of memories and I/O registers.

The available memory locations consist of 128

bytes of register locations, 256 bytes of RAM and

8Kbytes of user program memory. The RAM

Figure 6. Memory Map

0000h

007Fh

0080h

017Fh

0180h

DFFFh

E000h

FFDFh

FFE0h

FFFFh

HW Registers

(see Table 3)

256 Bytes RAM

Reserved

Program Memory

(8K Bytes)

Interrupt & Reset Vectors

(see Table 2)

space includes up to 64 bytes for the stack from

0140h to 017Fh.

The highest address bytes contain the user reset

and interrupt vectors.

0080h

Short Addressing

RAM

“Zero page”

(128 Bytes)

00FFh

0100h

013Fh

0140h

017Fh

16-bit Addressing

RAM

(64 Bytes)

Stack or

16-bit Addressing

RAM

(64 Bytes)

Table 2. Interrupt Vector Map

Vector Address Description Remarks

FFE0-FFE1h

FFE2-FFE3h

FFE4-FFE5h

FFE6-FFE7h

FFE8-FFE9h

FFEA-FFEBh

FFEC-FFEDh

FFEE-FFEFh

FFF0-FFF1h

FFF2-FFF3h

FFF4-FFF5h

FFF6-FFF7h

FFF8-FFF9h

FFFA-FFFBh

FFFC-FFFDh

FFFE-FFFFh

10/132

Not used

Not used

Not used

Not used

Not used

TIMER B interrupt vector

TIMER A interrupt vector

SPI interrupt vector

Motor control interrupt vector (events: E, O)

Motor control interrupt vector (events: C, D)

Motor control interrupt vector (events: R, Z)

External interrupt vector EI1: port B7..0

External interrupt vector EI0: port A7..0

Not used

TRAP (software) interrupt vector

RESET vector

Internal Interrupt

External Interrupt

External Interrupt

CPU Interrupt

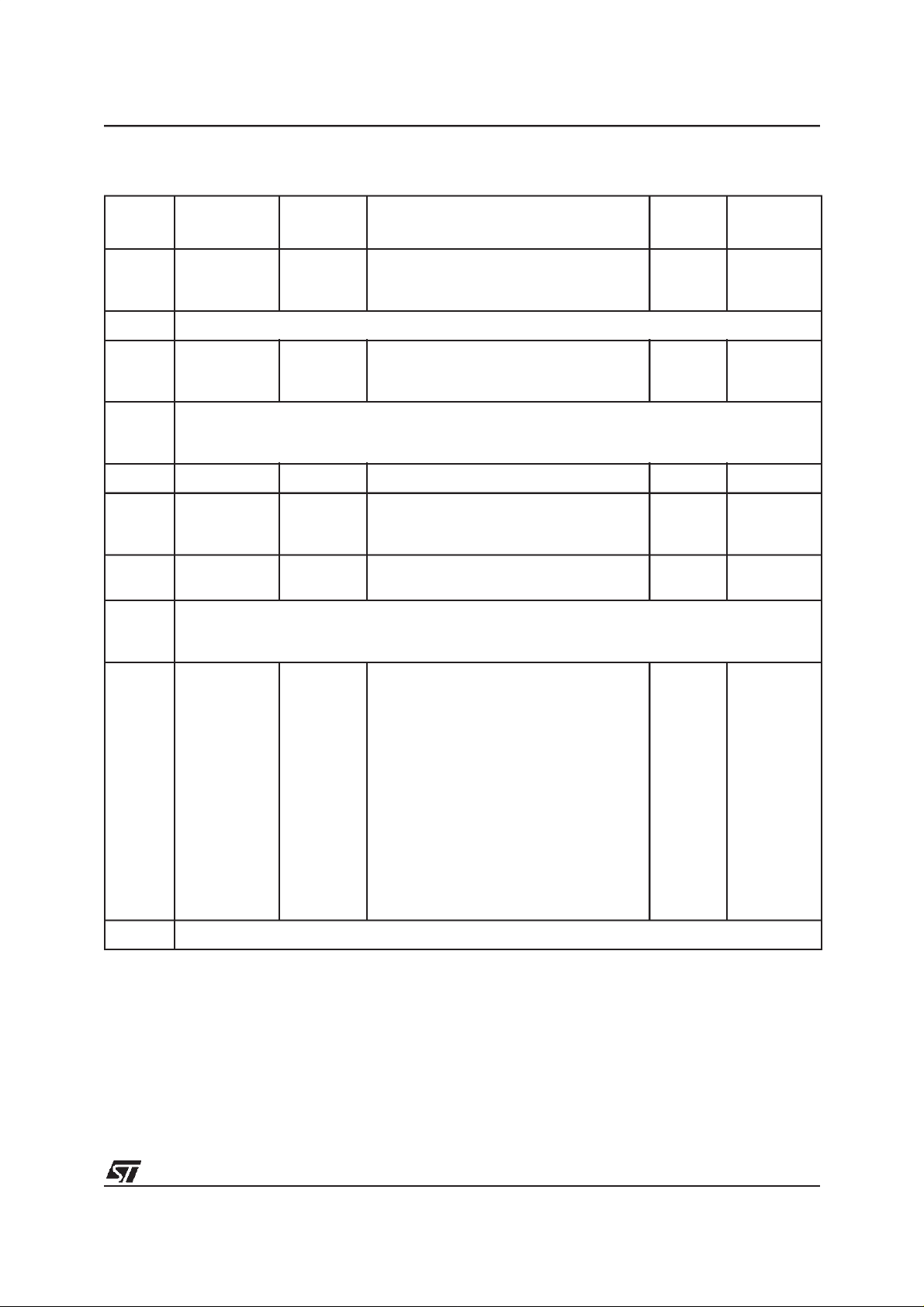

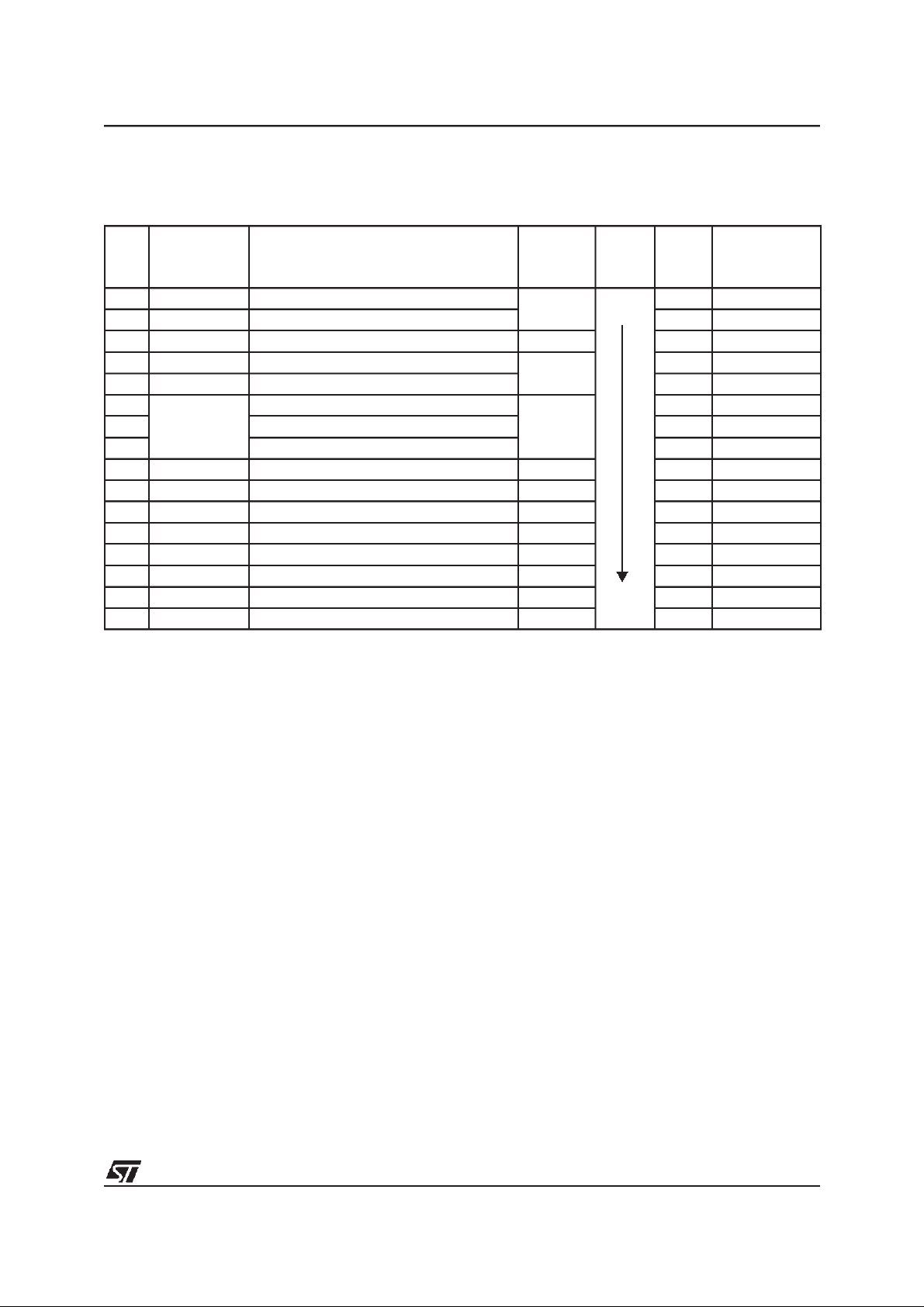

Table 3. Hardware Register Map

ST72141K

Address Block

0000h

0001h

0002h

0003h Reserved Area (1 Byte)

0004h

0005h

0006h

0007h

to

001F

0020h MISCR Miscellaneous Register 00h R/W

0021h

0022h

0023h

0024h

0025h

0026h

to

0030h

Port A

Port B

SPI

WATCHDOG

Register

Label

PADR

PADDR

PAOR

PBDR

PBDDR

PBOR

SPIDR

SPICR

SPISR

WDGCR

WDGSR

Register Name

Port A Data Register

Port A Data Direction Register

Port A Option Register

Port B Data Register

Port B Data Direction Register

Port B Option Register

Reserved Area (24 Byte)

SPI Data I/O Register

SPI Control Register

SPI Status Register

Watchdog Control Register

Watchdog Status Register

Reserved Area (11 Bytes)

Reset

Status

00h

00h

00h

00h

00h

00h

xxh

0xh

00h

7Fh

x0h

Remarks

R/W

R/W

R/W

R/W

R/W

R/W.

R/W

R/W

Read Only

R/W

Read Only

0031h

0032h

0033h

0034h

0035h

0036h

0037h

0038h

0039h

003Ah

003Bh

003Ch

003Dh

003Eh

003Fh

0040h Reserved Area (1 Byte)

TIMER A

TACR2

TACR1

TASR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Timer A Control Register 2

Timer A Control Register 1

Timer A Status Register

Timer A Input Capture 1 High Register

Timer A Input Capture 1 Low Register

Timer A Output Compare 1 High Register

Timer A Output Compare 1 Low Register

Timer A Counter High Register

Timer A Counter Low Register

Timer A Alternate Counter High Register

Timer A Alternate Counter Low Register

Timer A Input Capture 2 High Register

Timer A Input Capture 2 Low Register

Timer A Output Compare 2 High Register

Timer A Output Compare 2 Low Register

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

11/132

ST72141K

Address Block

0041h

0042h

0043h

0044h

0045h

0046h

0047h

0048h

0049h

004Ah

004Bh

004Ch

004Dh

004Eh

004Fh

0050h

to

005Fh

0060h

0061h

0062h

0063h

0064h

0065h

0066h

0067h

0068h

0069h

006Ah

006Bh

006Ch

006Dh

TIMER B

MOTOR

CONTROL

Register

Label

TBCR2

TBCR1

TBSR

TBIC1HR

TBIC1LR

TBOC1HR

TBOC1LR

TBCHR

TBCLR

TBACHR

TBACLR

TBIC2HR

TBIC2LR

TBOC2HR

TBOC2LR

MTIM

MZPRV

MZREG

MCOMP

MDREG

MWGHT

MPRSR

MIMR

MISR

MCRA

MCRB

MPHST

MPAR

MPOL

Register Name

Timer B Control Register 2

Timer B Control Register 1

Timer B Status Register

Timer B Input Capture 1 High Register

Timer B Input Capture 1 Low Register

Timer B Output Compare 1 High Register

Timer B Output Compare 1 Low Register

Timer B Counter High Register

Timer B Counter Low Register

Timer B Alternate Counter High Register

Timer B Alternate Counter Low Register

Timer B Input Capture 2 High Register

Timer B Input Capture 2 Low Register

Timer B Output Compare 2 High Register

Timer B Output Compare 2 Low Register

Reserved Area (16 Bytes)

Timer Counter Register

Zn-1 Capture Register

Zn Capture Register

Compare Register

C

n+1

D capture/Compare Register

Weight Register

Prescaler and Ratio Register

Interrupt Mask Register

Interrupt Status Register

Control Register A

Control Register B

Phase State Register

Output Parity Register

Output Polarity Register

Reset

Status

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

006Eh

006Fh

0070h

0071h

0072h

007Fh

12/132

to

ADC

to

ADCDR

ADCCSR

Data Register

Control/Status Register

Reserved Area (2 bytes)

Reserved Area (14 Bytes)

00h

00h

Read Only

R/W

1.5 EPROM PROGRAM MEMORY

ST72141K

The programmemory of the OTP and EPROMdevices can be programmed with EPROM programming tools available from STMicroelectronics.

EPROM Erasure

EPROM devices are erased by exposure to high

intensity UVlightadmitted through the transparent

window. This exposure discharges the floating

gate to its initial state through induced photo current.

It is recommended that the EPROM devices be

kept out of direct sunlight, since the UV content of

sunlight can be sufficient to cause functional failure. Extended exposure to room level fluorescent

lighting may also cause erasure.

An opaque coating (paint, tape, label, etc...)

should be placed over the package window if the

product is to be operated under theselighting conditions. Covering the window also reduces IDDin

power-saving modes due to photo-diode leakage

currents.

13/132

ST72141K

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

2.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low power modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

2.3 CPU REGISTERS

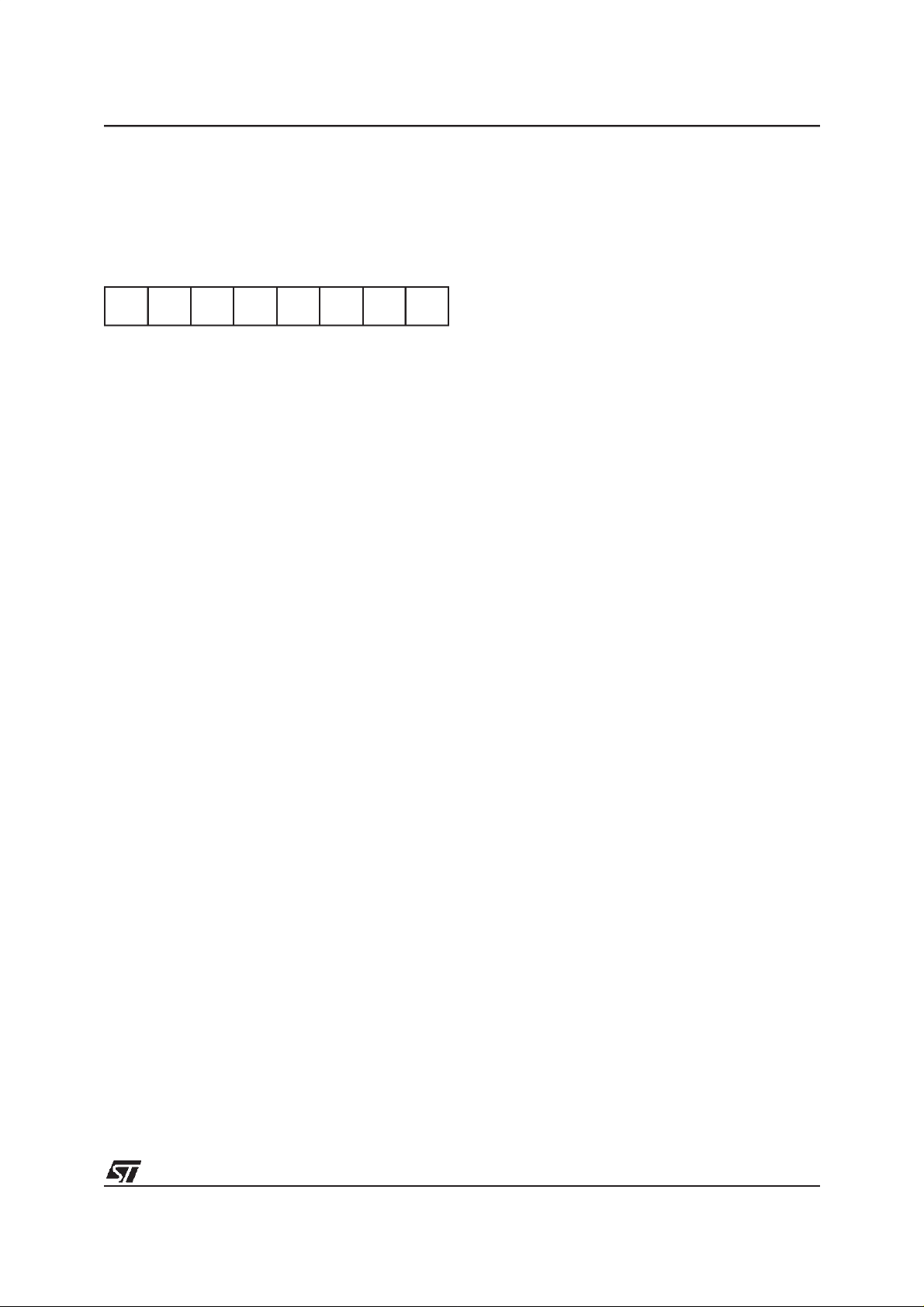

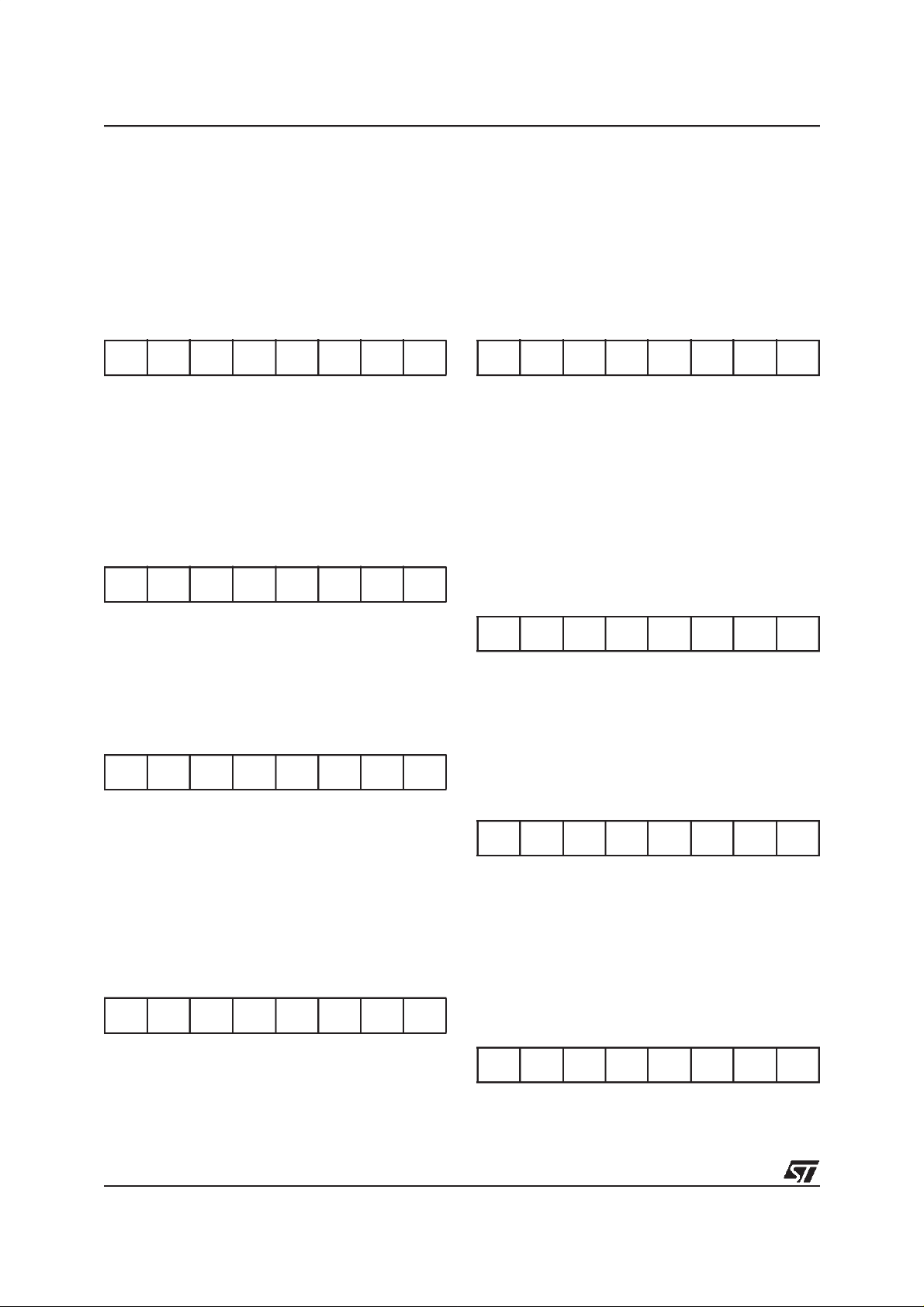

The 6 CPU registers shown in Figure 7 are not

present in the memory mapping and are accessed

by specific instructions.

Figure 7. CPU Registers

70

RESET VALUE = XXh

70

RESET VALUE = XXh

70

RESET VALUE= XXh

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bitregisters

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y registeris not affectedby the interrupt automatic procedures (notpushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) andPCH

(Program CounterHigh which is the MSB).

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

15 8

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

15

RESET VALUE = STACKHIGHER ADDRESS

14/132

PCH

RESET VALUE =

7

70

1C11HINZ

1X11X1XX

87 0

PCL

0

PROGRAM COUNTER

CONDITION CODE REGISTER

STACK POINTER

X = Undefined Value

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

70

111HINZC

The 8-bit Condition Code register contains the interrupt mask and four flags representative of the

result ofthe instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

because the I bit is set by hardware at the start of

the routine and reset by the IRET instruction at the

end of theroutine. If the I bit is cleared bysoftware

in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithmetic,

logical or data manipulation. It is a copy of the 7

bit of the result.

0:Theresultof the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit isaccessed bythe JRMI andJRPL instruc-

Bit 4 = H

Half carry

.

tions.

This bit is set by hardware whena carryoccursbetween bits 3 and 4 of the ALU during an ADD or

ADC instruction. It is resetby hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. Thisbit indicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 3 = I

This bit is set by hardware when entering in inter-

rupt or by software to disable all interrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlledby the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed when I is cleared.

Interrupt mask

.

Bit 0 = C

Carry/borrow.

This bit is set and cleared by hardware and software. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow hasoccurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

By default an interrupt routine is not interruptable

ST72141K

th

15/132

ST72141K

CENTRAL PROCESSING UNIT (Cont’d)

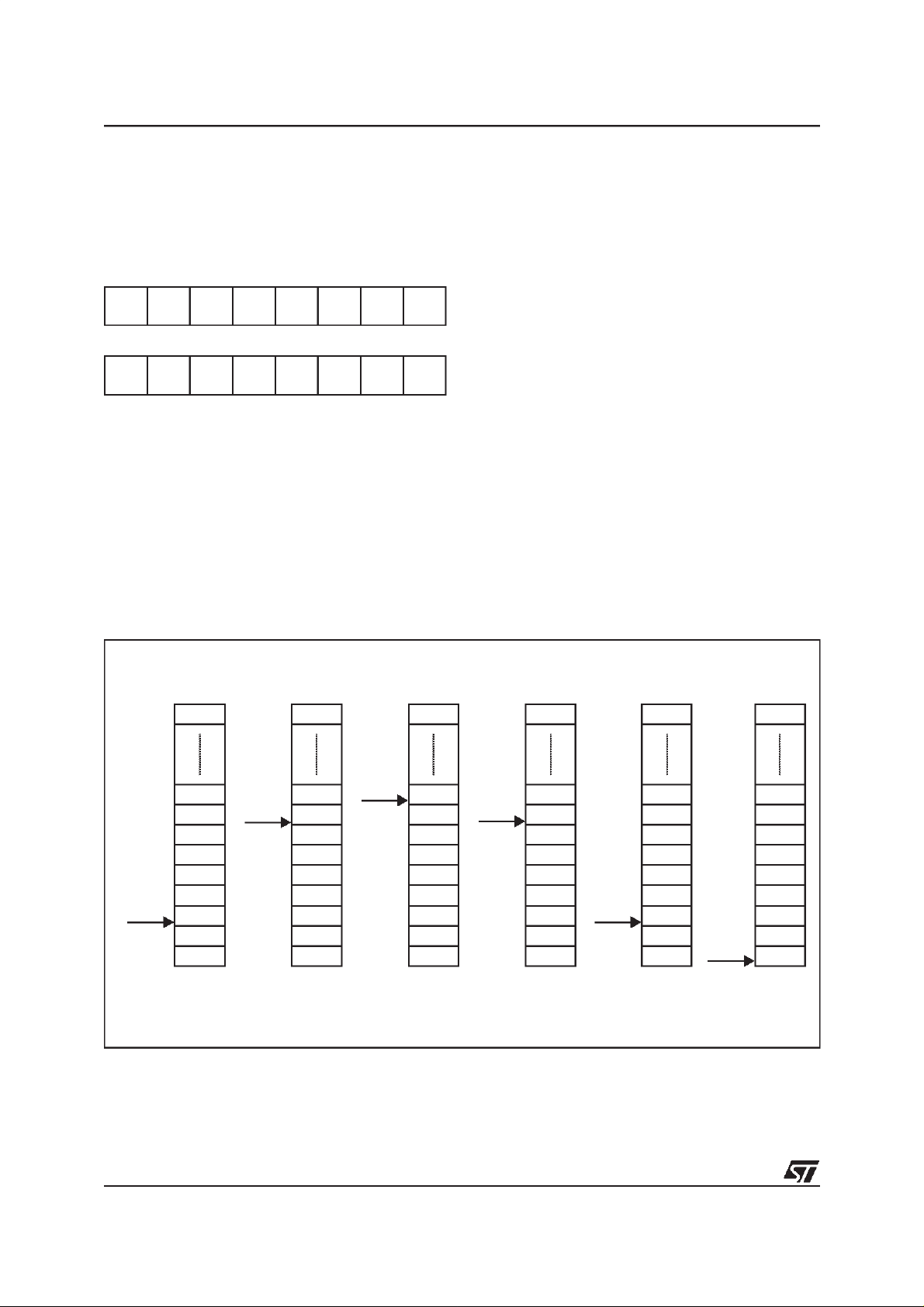

Stack Pointer (SP)

Read/Write

Reset Value: 01 7Fh

15 8

00000001

70

0 SP6 SP5 SP4 SP3 SP2 SP1 SP0

The Stack Pointer is a 16-bit register which is always pointingto the next free location in the stack.

It isthen decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 8).

Since the stack is 128 bytes deep, the 9th most

significant bits are forced by hardware. Following

an MCU Reset, or after a Reset Stack Pointer instruction (RSP), the Stack Pointer contains its reset value (the SP6 to SP0 bits areset) which is the

stack higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then overwritten and therefore lost. The stack also wrapsin case of anunderflow.

The stack is used to save the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by meansof the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location pointed to by the SP. Then the

other registers are stored in the next locations as

shown in Figure 8.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from thestack.

A subroutine call occupies twolocations and an interrupt five locations in the stack area.

Figure 8. Stack Manipulation Example

@ 0100h

SP

@ 017Fh

CALL

Subroutine

SP

PCH

PCL

Stack Higher Address = 017Fh

Stack Lower Address =

Interrupt

Event

SP

CC

A

X

PCH

PCL

PCH

PCL

0100h

PUSH Y POP Y IRET

SP

Y

CC

A

X

PCH

PCL

PCH

PCL

CC

A

X

PCH

PCL

PCH

PCL

SP

PCH

PCL

RET

or RSP

SP

16/132

3 SUPPLY, RESET AND CLOCK MANAGEMENT

The ST72141K includes a range of utility features

for securing the application in critical situations(for

example in case of a power brown-out), and reducing the number of external components. An

overview is shown in Figure 9.

Main Features

■ Main supply low voltage detection (LVD)

■ RESET Manager

■ Low consumption resonator oscillator

■ Main clock controller (MCC)

Figure 9. Clock, RESET, Option and Supply Management Overview

ST72141K

f

MOTOR_CONTROL

f

SPI

OSC2

OSC1

RESET

V

DD

V

SS

OSCILLATOR

RESET

LOW VOLTAGE

DETECTOR

(LVD)

f

OSC

MAIN CLOCK

CONTROLLER

FROM

WATCHDOG

PERIPHERAL

(MCC)

f

CPU

17/132

ST72141K

3.1 LOW VOLTAGE DETECTOR (LVD)

To allow the integration of power management

features in the application, the Low Voltage Detector function (LVD) generates a static reset when

the VDDsupply voltage is below a V

value. This means that it secures the power-up as

LVDf

reference

well as the power-down keeping the ST7 in reset.

The V

lower than the V

reference value for a voltage drop is

LVDf

reference value for power-on

LVDr

in order to avoid a parasitic reset when the MCU

starts running and sinks current on the supply

(hysteresis).

The LVD Reset circuitry generates a reset when

VDDis below:

–V

–V

when VDDis rising

LVDr

when VDDis falling

LVDf

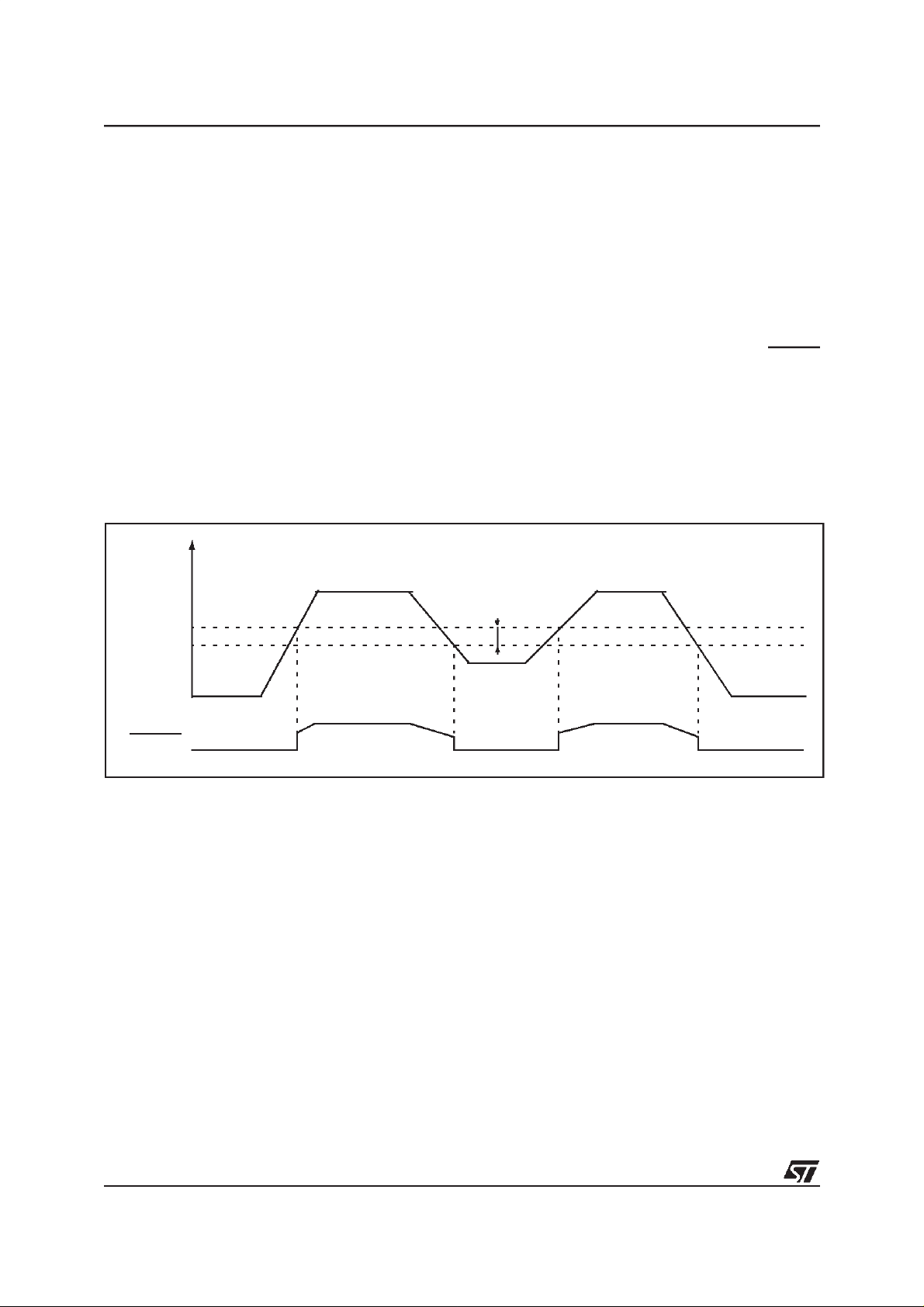

The LVD function is illustrated in Figure 10.

Figure 10. Low Voltage Detector vs Reset

V

DD

V

LVDr

V

LVDf

Provided the minimum VDDvalue (guaranteed for

the oscillator frequency) is below V

, the MCU

LVDf

can only be in two modes:

– under full software control

– in static safe reset

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During aLow Voltage Detector Reset, the RESET

pin is held low, thus permitting the MCU to reset

other devices.

Notes:

The LVDallows the device to be used without any

external RESET circuitry.

HYSTERISIS

V

LVDhyst

RESET

18/132

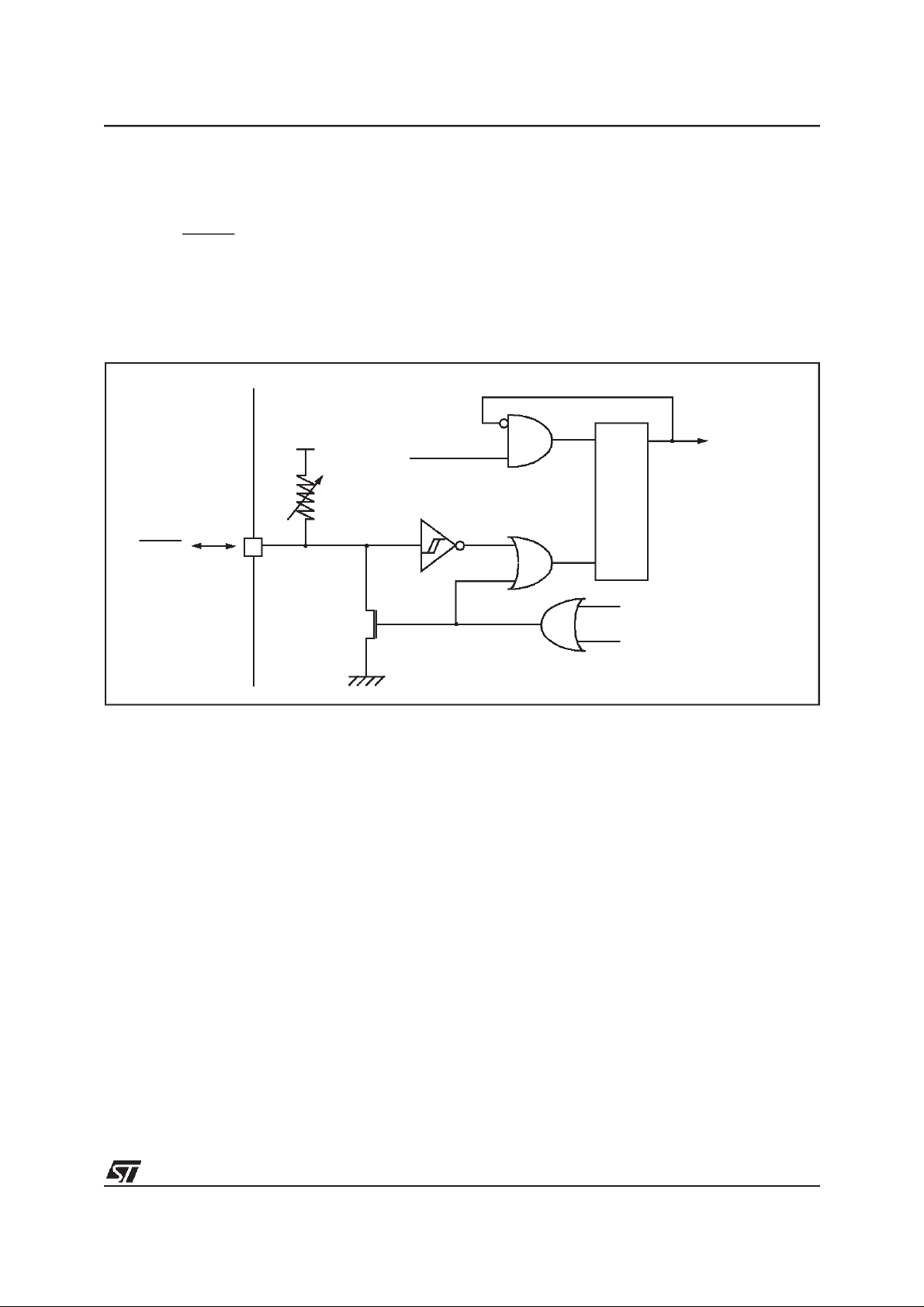

3.2 RESET MANAGER

ST72141K

The RESET block includes three RESET sources

as shown in Figure 11:

■ ExternalRESET source pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

Figure 11. Reset Block Diagram

V

RESET

DD

R

ON

f

CPU

The RESET service routine vector is fixed at addresses FFFEh-FFFFh in theST7 memory map.

A 4096 CPUclock cycle delay allows the oscillator

to stabilise and ensures that recovery has taken

place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

INTERNAL

RESET

COUNTER

WATCHDOG RESET

LVD RESET

19/132

ST72141K

RESET MANAGER (Cont’d)

External RESET pin

The RESETpin is both an input andan open-drain

output with integrated RONweak pull-up resistor

(see Figure11). This pull-up has no fixedvalue but

varies in accordance with the input voltage. Itcan

be pulled low by external circuitry to reset the device.

A RESET signal originating from an external

source must have a duration of at least t

PULSE

in

order to be recognized. Two RESET sequences

can be associated with this RESET source as

shown in Figure 12.

When the RESET is generated by a internal

source, during the two first phases of the RESET

sequence, the device RESET pin acts as an output that ispulled low.

Generic Power On RESET

The function of the POR circuit consists of waking

up the MCU by detecting (at around 2V) a dynamic

(rising edge) variation of the VDDSupply. At the

beginning of this sequence, the MCU is configured

in the RESET state. When the power supply voltage rises toa sufficient level, the oscillator starts to

operate, whereupon an internal 4096 CPU cycles

delay is initiated, in order to allow the oscillator to

fully stabilize before executing the first instruction.

The initialization sequence is executed immediately following the internal delay.

To ensure correct start-up, the user should take

care that the VDD Supply is stabilized at a sufficient level forthe chosen frequency (seeElectrical

Characteristics) before the reset signal is released. In addition, supply rising must start from

0V.

As a consequence, the POR does not allow to supervise static, slowly rising, or falling, or noisy (oscillating) VDDsupplies.

An external RC network connected to the RESET

pin, or the LVD reset can be used instead to get

the best performance.

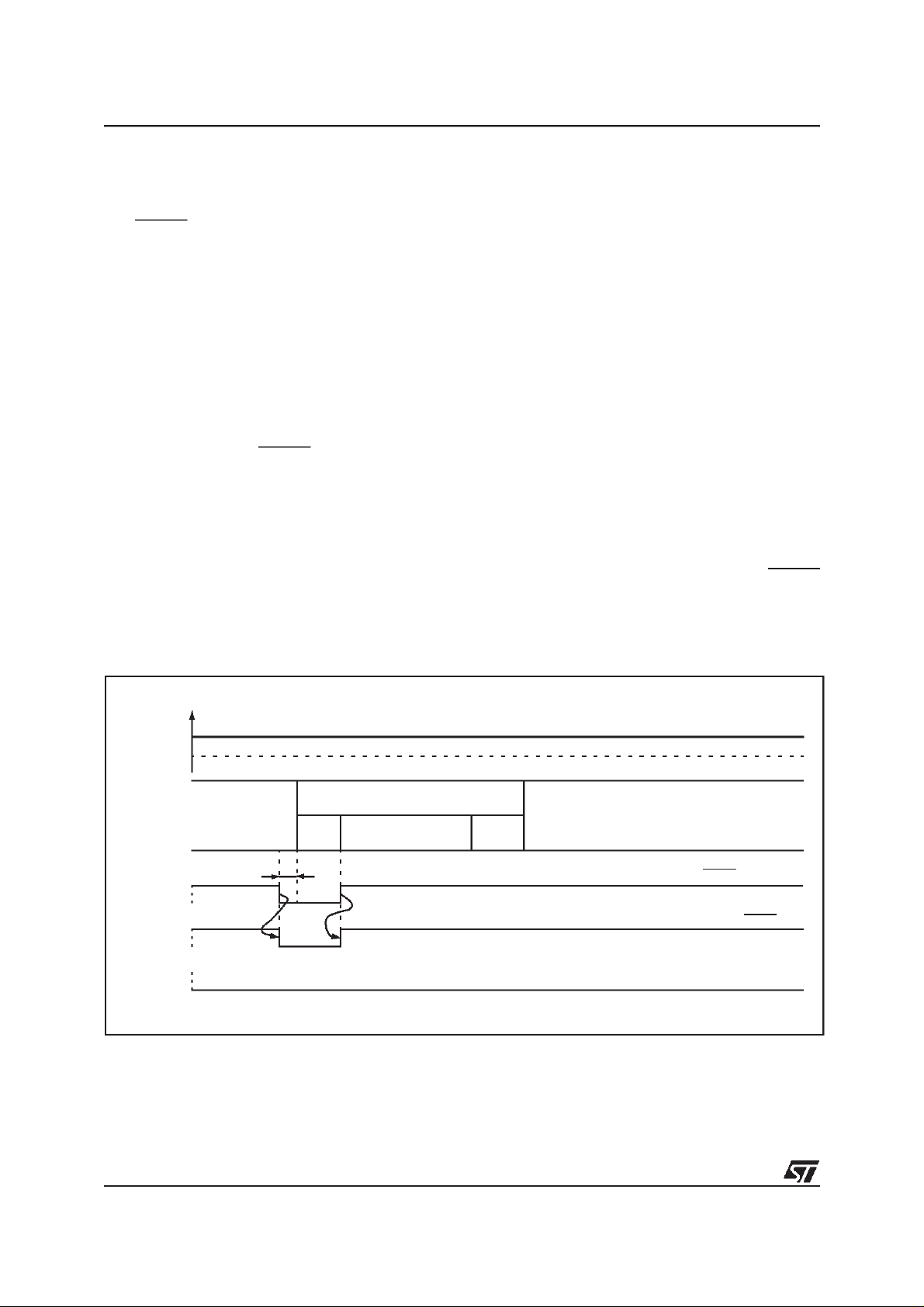

Figure 12. External RESET Sequences

V

DD

V

DD nominal

V

LVDf

RUN

t

DELAY

PULSE

INTERNAL RESET

4096 CLOCK CYCLES

RESET

FETCH

VECTOR

RUN

EXTERNAL RESET SOURCE

RESET PIN

WATCHDOG RESET

20/132

RESET MANAGER (Cont’d)

ST72141K

Internal Low VoltageDetection RESET (option)

Two different RESET sequences caused by the internal LVD circuitry can be distinguished:

- LVD Power-On RESET

- Voltage Drop RESET

Figure 13. LVD RESET Sequences

V

V

DDnominal

V

LVDr

LVD POWER-ON RESET

DD

POWER-

OFF

In the second sequence, a “delay” phase is used

to keep the device in RESET state until VDDrises

up to V

(see Figure 13).

LVDr

RESET

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

EXTERNAL RESET SOURCE

WATCHDOG RESET

RUN

RESET PIN

V

DDnominal

V

LVDr

V

LVDf

VOLTAGE DROP RESET

V

DD

RESET

RUN

DELAY

INTERNAL RESET

4096 CLOCK CYCLES

FETCH

VECTOR

EXTERNAL RESET SOURCE

RUN

RESET PIN

WATCHDOG RESET

21/132

ST72141K

RESET MANAGER (Cont’d)

Internal Watchdog RESET

The RESET sequence generated by a internal

Watchdog counter overflow has the shortest reset

phase (see Figure 14).

Figure 14. Watchdog RESET Sequence

V

DD

V

DDnominal

V

LVDf

RESET

RUN

INTERNAL RESET

4096 CLOCK CYCLES

t

WDGRST

FETCH

VECTOR

RUN

EXTERNAL RESET SOURCE

RESET PIN

WATCHDOG UNDERFLOW

WATCHDOG RESET

22/132

3.3 LOW CONSUMPTION OSCILLATOR

ST72141K

The main clock of the ST7 can be generated by

two differentsources:

■ an external source

■ a crystal or ceramic resonator oscillators

External Clock Source

In this mode, asquare clock signal with ~50% duty

cycle has to drive the OSC2 pin while the OSC1

pin is tied to VSS(see Figure 15).

Figure 15. External Clock

ST7

OSC1 OSC2

EXTERNAL

SOURCE

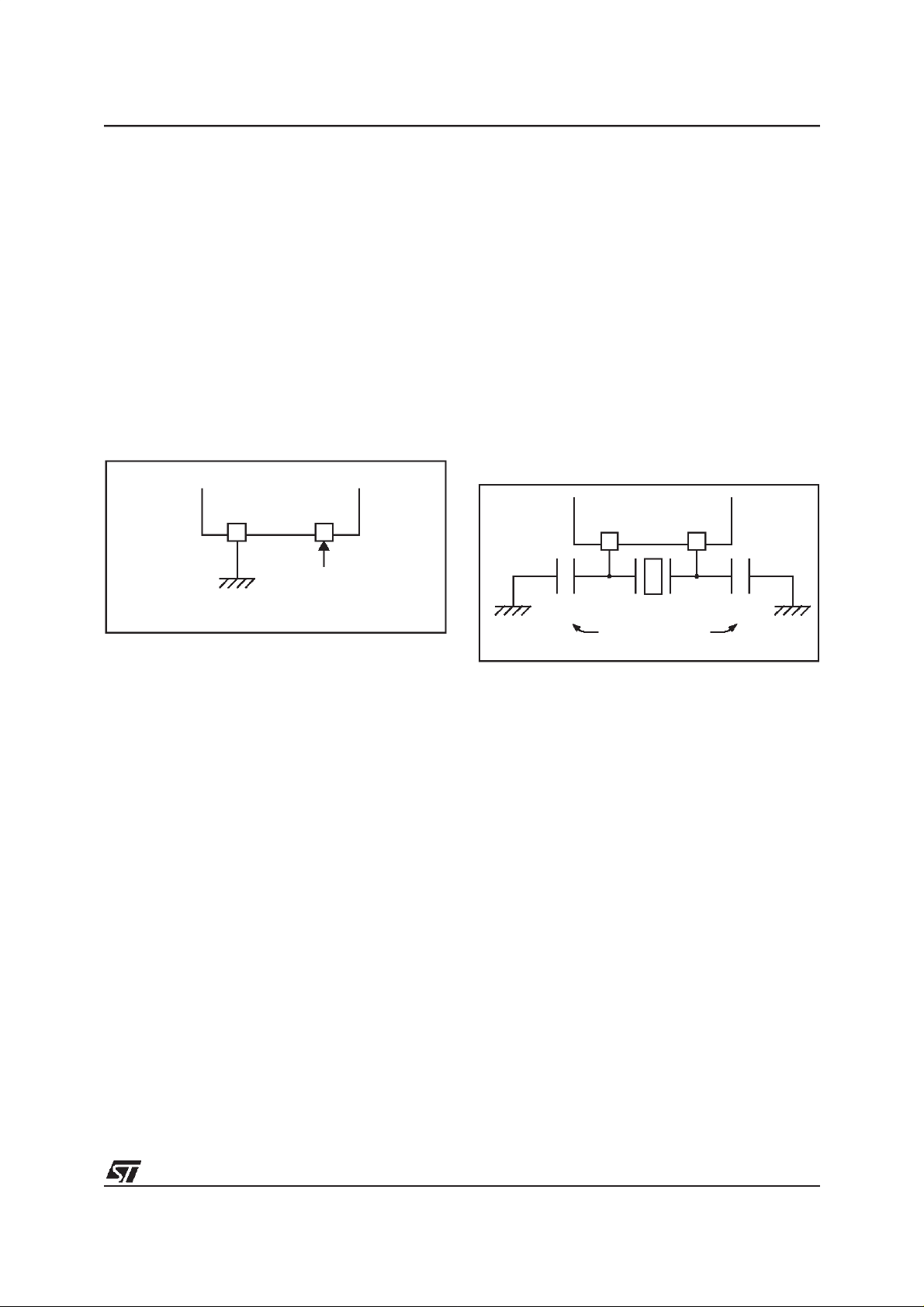

Crystal/Ceramic Oscillators

This oscillator (based on constant current source)

is optimized in terms of consumption and has the

advantage of producing a very accurate rate on

the main clock of the ST7.

When using this oscillator, the resonator and the

load capacitances have to be connected as shown

in Figure 16 and have to be mounted as close as

possible to the oscillator pins in order to minimize

output distortion and start-up stabilization time.

This oscillator is not stopped during the RESET

phase to avoid losing time in the oscillator start-up

phase.

Figure 16. Crystal/Ceramic Resonator

OSC1 OSC2

C

L0

ST7

LOAD

CAPACITANCES

C

L1

23/132

ST72141K

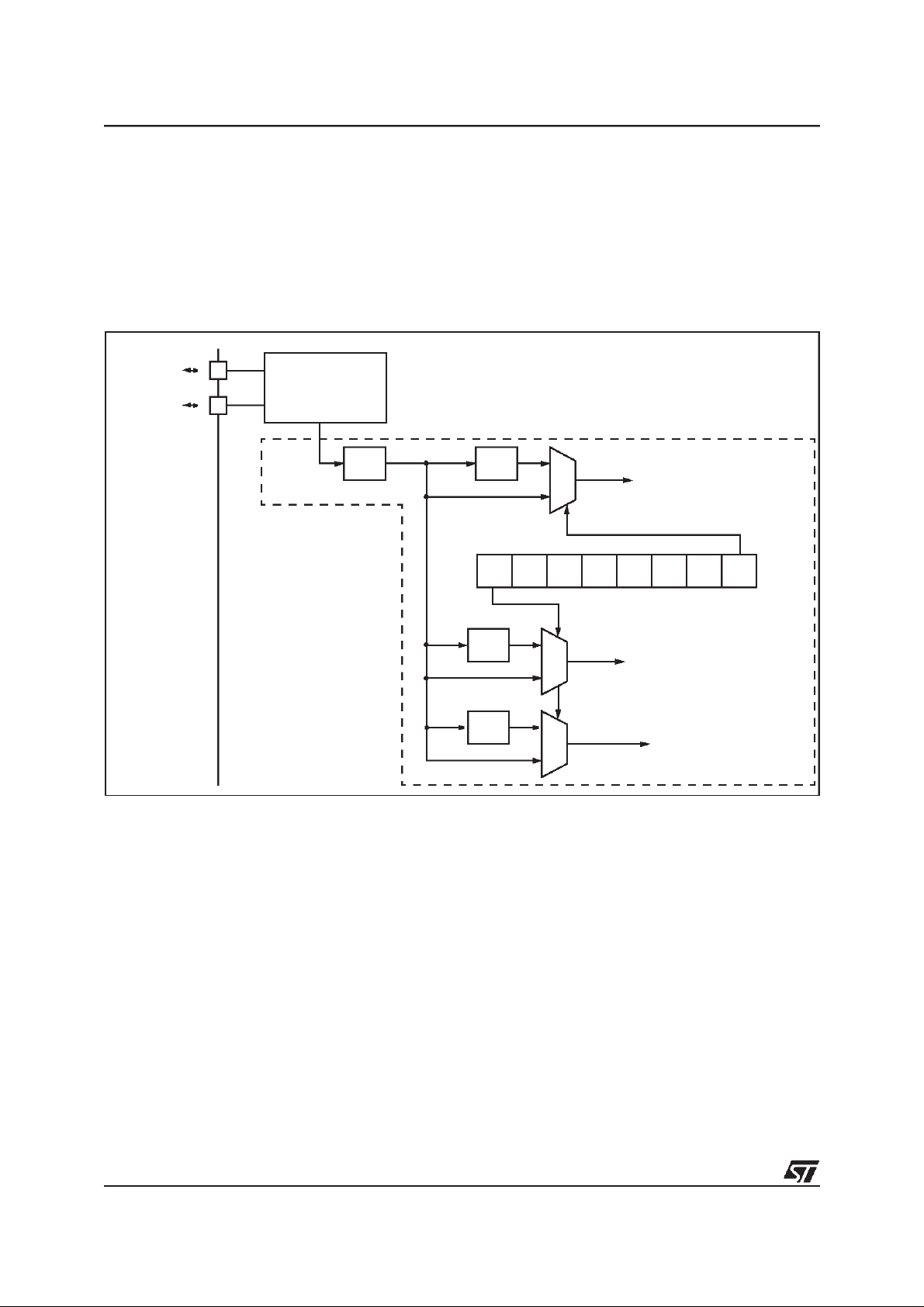

3.4 MAIN CLOCK CONTROLLER (MCC)

The MCC block supplies the clock for the ST7

CPU and its internal peripherals. It allows the

SLOW power saving mode and the Motor Contral

The XT16 bitacts on the clockof the motor control

and SPI peripherals while the SMS bit acts on the

CPU and the other peripherals.

and SPI peripheral clocks to be managed independently. The MCC functionality is controlled by

two bits of the MISCR register: SMS and XT16.

Figure 17. Main Clock Controller (MCC) Block Diagram

OSC2

OSCILLATOR

OSC1

f

OSC

DIV 2

DIV 16

DIV 2

MCC

f

CPU

----XT16

CPU CLOCK

TO CPU AND

PERIPHERALS

SMS--

4MHz

MOTOR CONTROL

PERIPHERAL

MISCR

24/132

DIV 2

4MHz

SPI

PERIPHERAL

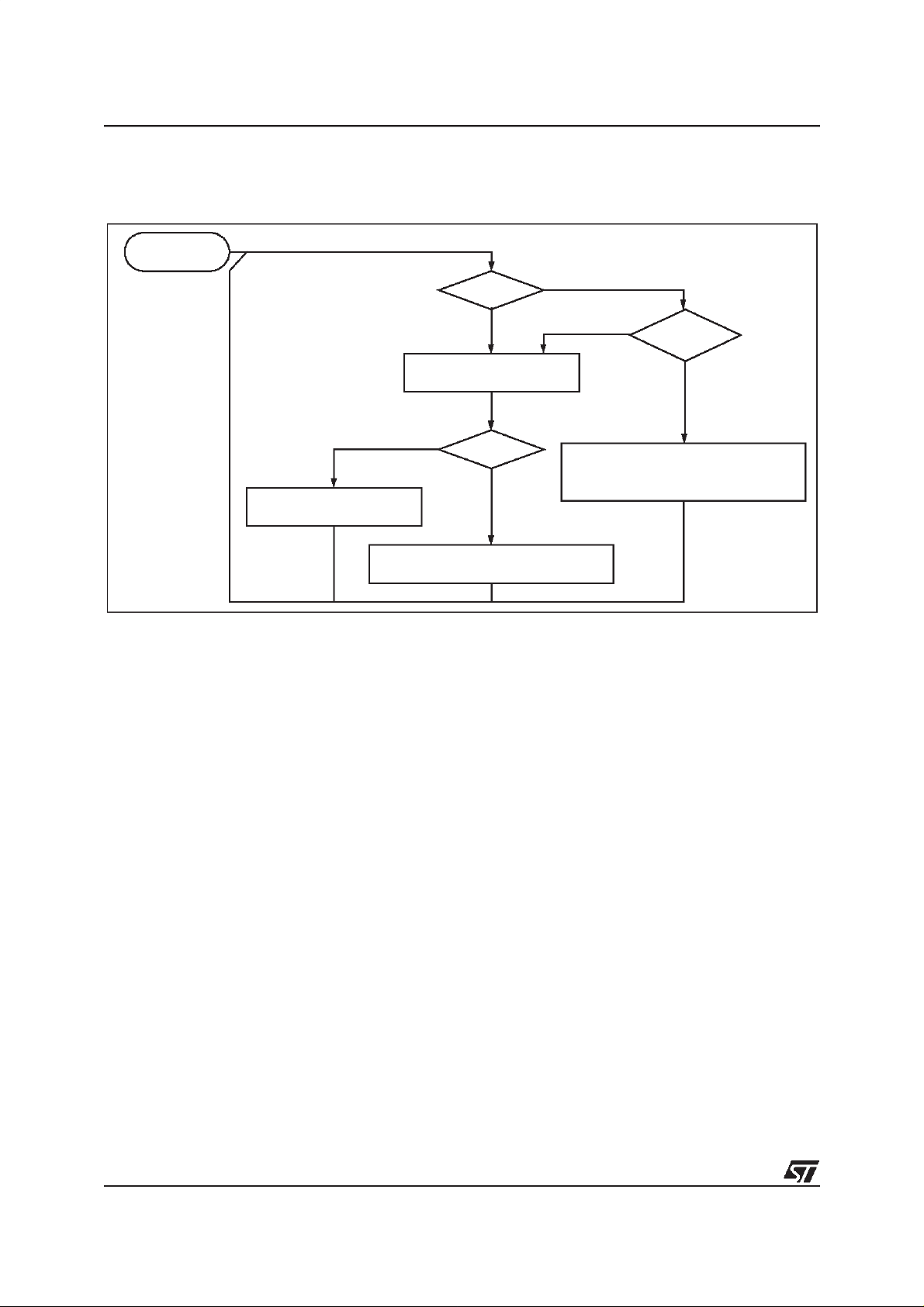

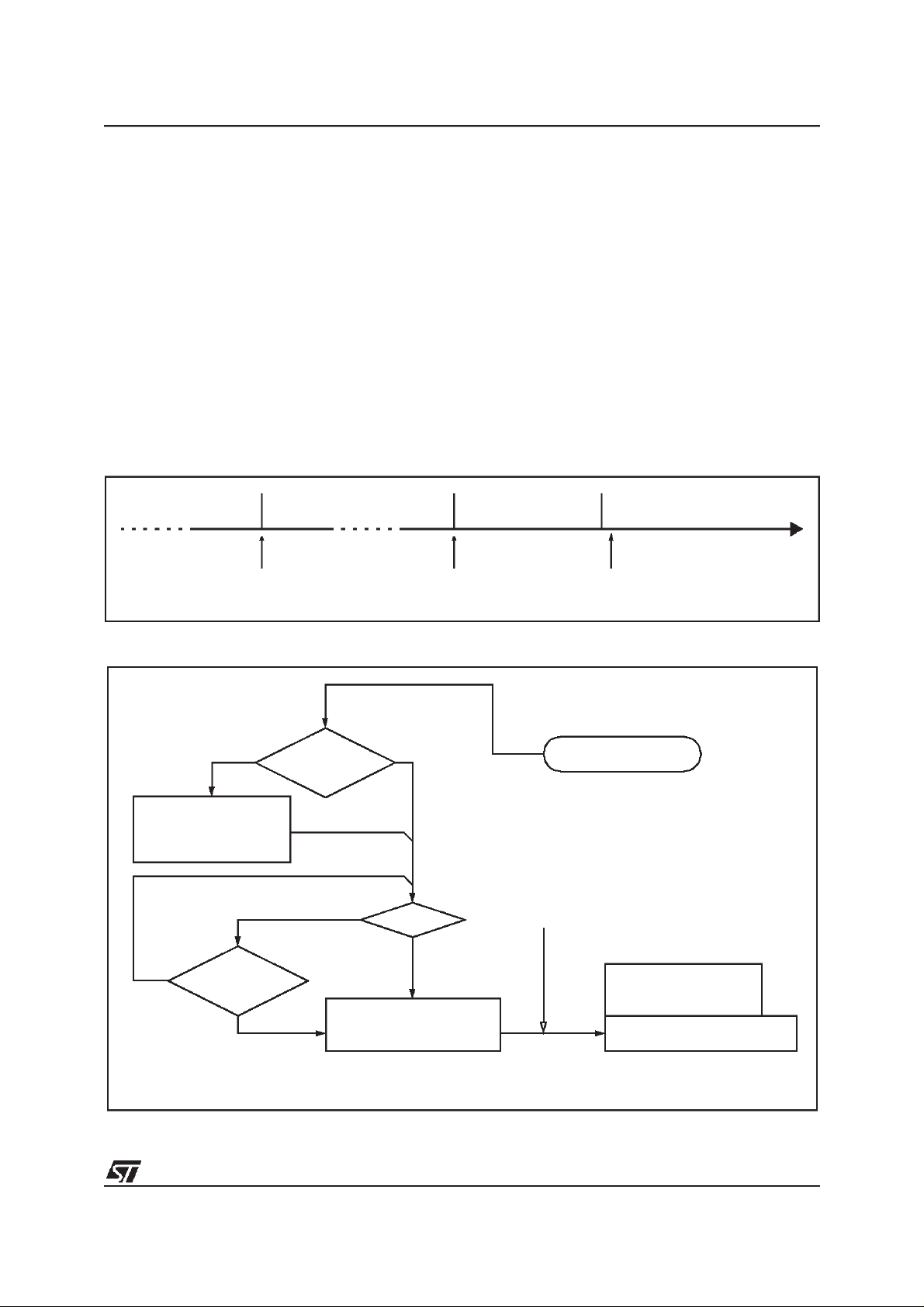

4 INTERRUPTS

ST72141K

The ST7 core may be interruptedby one oftwo different methods: maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

processing flowchart is shown in Figure 1.

The maskableinterrupts must be enabled clearing

the I bit in order to be serviced. However, disabled

interrupts may be latched and processed when

they are enabled (see external interrupts subsection).

When an interrupt has to be serviced:

– Normal processing is suspended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– ThePC isthenloaded with the interrupt vectorof

the interruptto service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Tablefor vector addresses).

The interrupt service routine should finish with the

IRET instruction which causes the contents of the

saved registers to be recovered from thestack.

Note: As a consequence of the IRET instruction,

the I bit will be cleared and the main program will

resume.

Priority Management

By default, a servicing interrupt cannot be interrupted because the I bit is set by hardware entering in interrupt routine.

In the case when severalinterrupts are simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low Power Mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the processor to

leave the HALT low power mode (refer to the “Exit

from HALT“ column in the Interrupt Mapping Table).

4.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the stateof theI bit.

It will be serviced according to the flowchart on

Figure 1.

4.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding external interrupt

occurred and if the I bit is cleared. Theseinterrupts

allow the processor to leave the Halt low power

mode.

The external interrupt polarity is selected through

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt serviceroutine.

If several input pins, connected to the same inter-

rupt vector, are configured as interrupts, their sig-

nals are logically ANDed beforeentering the edge/

level detection block.

Caution:The type of sensitivitydefinedin the Mis-

cellaneous or Interrupt register (if available) ap-

plies to the ei source. In case of an ANDedsource

(as described on the I/O ports section), a low level

on an I/O pin configured as input with interrupt,

masks the interrupt requesteven in case of rising-

edge sensitivity.

4.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– Thecorresponding enable bit is setin thecontrol

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0” to the corresponding bit in the status

register or

– Access tothe status registerwhile the flag isset

followed by a read or write of an associated register.

Note: the clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being en-

abled) will therefore be lost ifthe clear sequence is

executed.

25/132

ST72141K

INTERRUPTS (Cont’d)

Figure 18. Interrupt Processing Flowchart

FROM RESET

EXECUTEINSTRUCTION

RESTORE PC,X, A,CC FROM STACK

I BIT SET?

Y

FETCH NEXT INSTRUCTION

N

THIS CLEARS I BIT BY DEFAULT

IRET?

Y

N

N

INTERRUPT

PENDING?

Y

STACK PC, X, A, CC

SET I BIT

LOAD PC FROM INTERRUPT VECTOR

26/132

INTERRUPTS (Cont’d)

Table 4. Interrupt Mapping

ST72141K

N°

0 Not used FFFAh-FFFBh

1 EI0 External Interrupt Port A7..0 (C5..0*)

2 EI1 External Interrupt Port B7..0 (C5..0*) yes FFF8h-FFF9h

3

4 Motor Control Interrupt (events: C, D) no FFF2h-FFF3h

5 Motor Control Interrupt (events: E, O) no FFF0h-FFF1h

6 SPI SPI Peripheral Interrupts SPISR no FFEEh-FFEFh

7 TIMER A TIMER A Peripheral Interrupts TASR no FFECh-FFEDh

8 TIMER B TIMER B Peripheral Interrupts TBSR no FFEAh-FFEBh

9 Not used FFE8h-FFE9h

10 Not used FFE6h-FFE7h

11 Not used FFE4h-FFE5h

12 Not Used FFE2h-FFE3h

13 Not Used FFE0h-FFE1h

Source

Block

RESET Reset

TRAP Software Interrupt no FFFCh-FFFDh

Motor Control Interrupt (events: R, Z)

MTC

Description

Register

Label

N/A

N/A

MISR

Priority

Order

Highest

Priority

Lowest

Priority

Exit

from

HALT

yes FFFEh-FFFFh

yes FFFAh-FFFBh

no FFF4h-FFF5h

Address

Vector

27/132

ST72141K

5 POWER SAVING MODES

5.1 Introduction

To give a large measure of flexibilitytotheapplication in terms of power consumption, three main

power saving modes are implemented in the ST7

(see Figure 19).

After a RESET the normal operating mode is selected by default (RUN mode). This mode drives

the device (CPU and embedded peripherals) by

means of a master clock which is based on the

main oscillator frequency divided by 2 (f

From Run mode, the different power saving

modes may be selected by setting the relevant

register bits or by calling the specific ST7 software

instruction whose action depends on the the oscillator status.

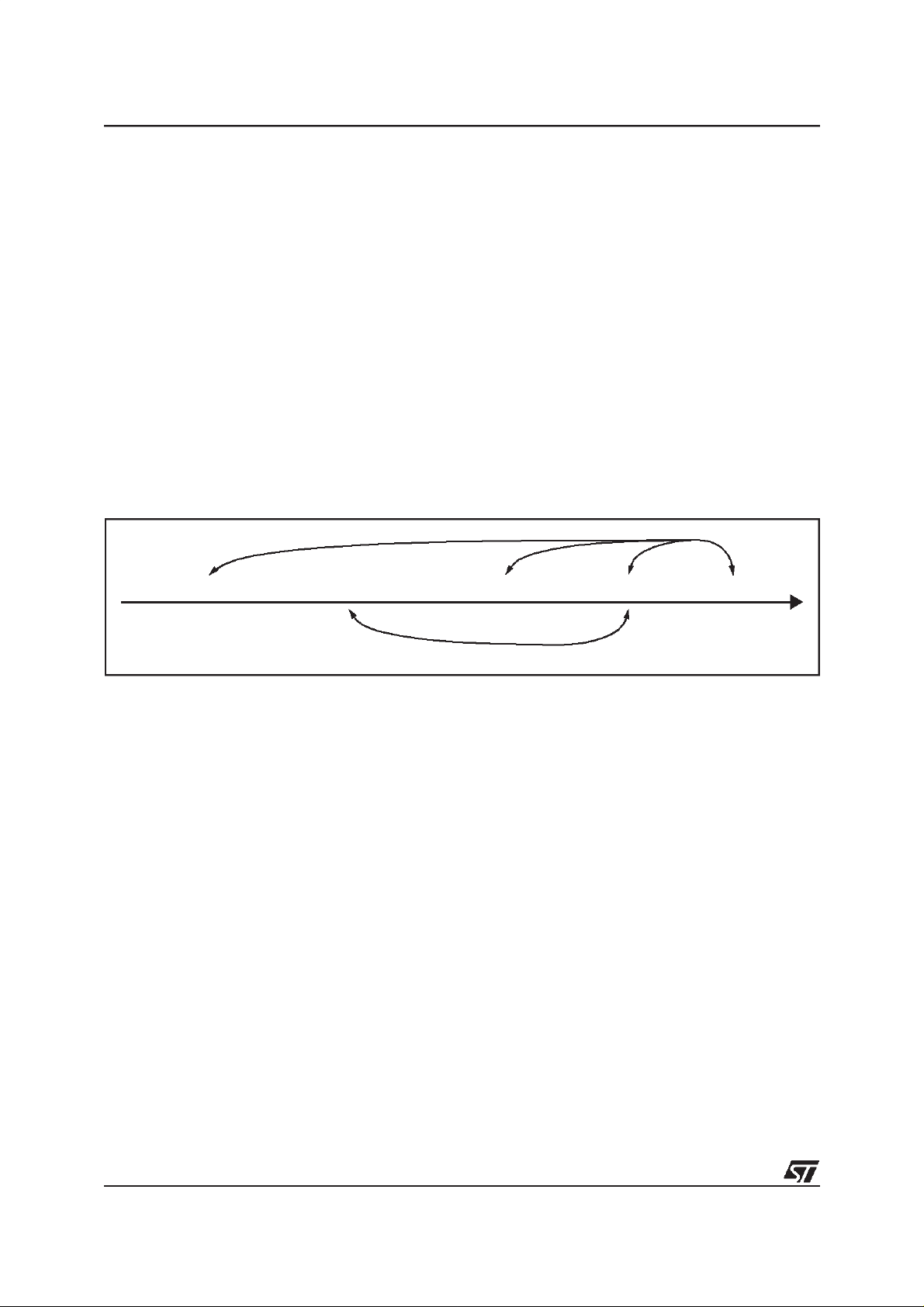

Figure 19. Power saving mode consumption / transitions

CPU

).

Low

POWERCONSUMPTION

SLOW WAIT

WAIT SLOW RUNHALT

High

28/132

POWER SAVING MODES (Cont’d)

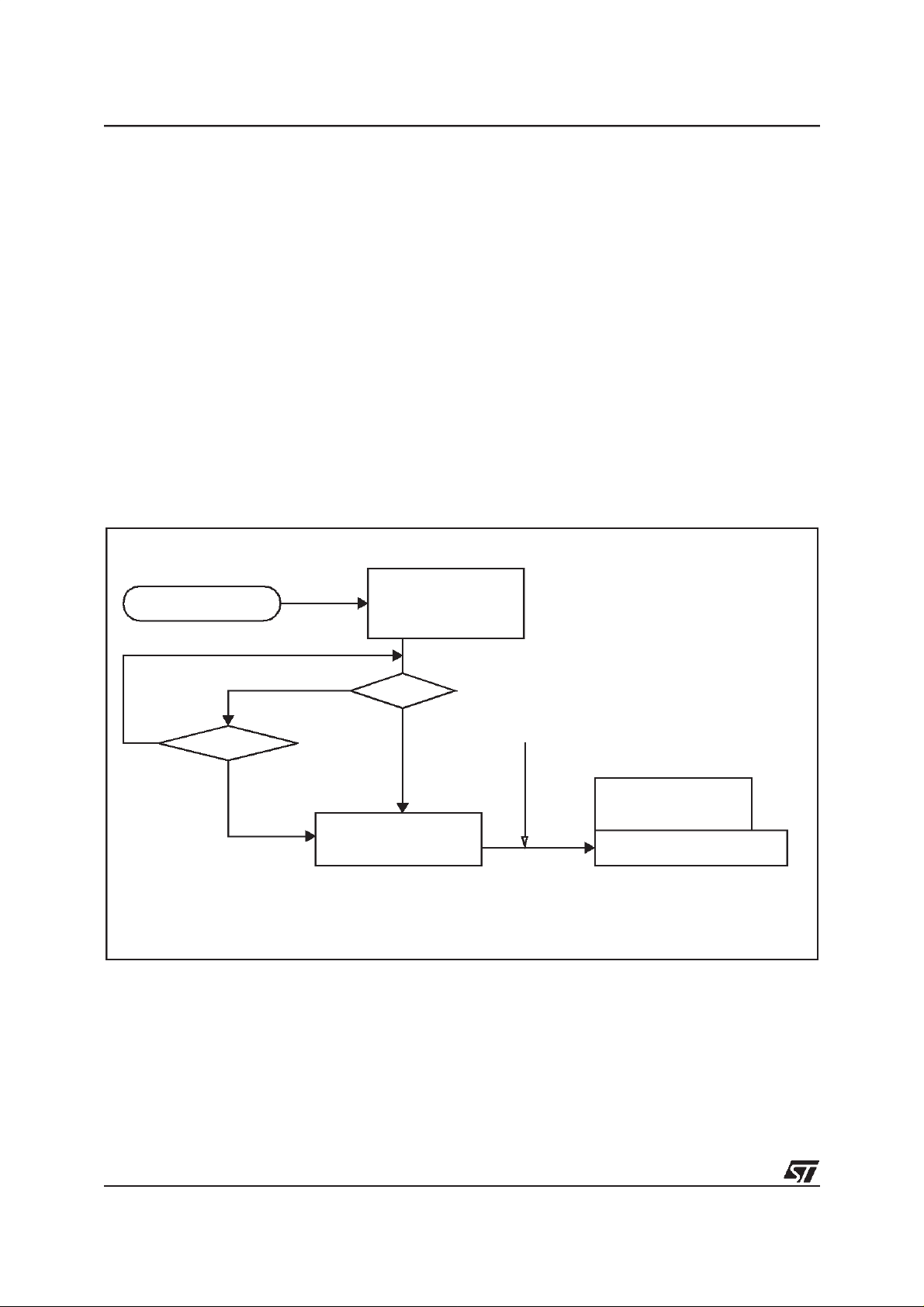

5.2 HALT Mode

The HALT mode is the lowest power consumption

mode of the MCU. It is entered by executing the

ST7 HALT instruction (see Figure 21).

The MCU can exit HALT mode on reception of either an external interrupt or a reset (see Table 2).

When exiting HALT mode by means of a RESET

or an interrupt, the oscillator is immediately turned

on and the 4096 CPU cycle delay is used to stabilize theoscillator. After the start up delay, the CPU

resumes operation by servicing the interrupt or by

fetching the reset vector which woke it up(see Figure 20).

Figure 20. HALT Mode timing overview

ST72141K

When entering HALT mode, the I bit in the CC

Register is forced to 0 to enable interrupts.

In the HALT mode the main oscillator is turned off

causing all internal processing to be stopped, including the operation of the on-chip peripherals.

All peripherals are not clocked except the ones

which get their clock supply from another clock

generator (such as an external or auxiliary oscillator).

RUN

HALT

HALT

INSTRUCTION

Figure 21. HALT modes flow-chart

WATCHDOG

HALT

OSCILLATOR

PERIPHERALS

CPU

I BIT

N

EXTERNAL*

INTERRUPT

Y

ENABLE

OFF

OFF

OFF

0

N

OSCILLATOR

PERIPHERALS

CPU

RESET

INTERRUPT

YN

RESET

Y

4096 CPU CYCLE

DELAY

OR

ON

OFF

OFF

FETCH

VECTOR

HALT INSTRUCTION

4096 clock cycles delay

OSCILLATOR

PERIPHERALS

CPU

FETCH RESET VECTOR

OR SERVICE INTERRUPT **

RUN

ON

ON

ON

Notes:

External interrupt or internal interrupts with Exit from Halt Mode capability

*

Before servicing an interrupt, the CC register is pushed on the stack.

**

29/132

ST72141K

POWER SAVING MODES (Cont’d)

5.3 WAIT Mode

WAIT mode places the MCU in a low power consumption mode by stopping the CPU.

This power saving mode is selectedby calling the

“WFI” ST7 software instruction.

All peripherals remain active. During WAIT mode,

the I bit of the CC register are forced to 0, to enable all interrupts. All other registers and memory

remain unchanged. The MCU remains in WAIT

mode until an interrupt or Reset occurs, whereupon the Program Counter branches to the starting

address of the interrupt or Reset serviceroutine.

The MCU will remain in WAIT mode until a Reset

or an Interrupt occurs, causing it to wake up.

Refer to Figure22.

Figure 22. WAIT mode flow-chart

OSCILLATOR

WFI INSTRUCTION

PERIPHERALS

CPU

I BIT

5.4 SLOW Mode

This mode has two targets:

– To reduce powerconsumption bydecreasingthe

internal clock in the device,

– To adapt the internal clock frequency (f

CPU

)to

the available supply voltage.

SLOW mode is controlled by the SMS bit in the

MISCR register. This bit enables or disables Slow

mode selecting the internal slow frequency (f

CPU

In this mode, the oscillator frequency can bedivided by 32 instead of 2 in normal operating mode.

The CPU and peripheralsare clocked atthis lower

frequency except the Motor Control and the SPI

peripherals which have their own clock selection

bit (XT16) in the MISCR register.

ON

ON

OFF

0

).

N

Note:

N

INTERRUPT

Y

OSCILLATOR

PERIPHERALS

CPU

The peripheral clock is stopped only when exit caused by RESET and not by an interrupt.

*

Before servicing an interrupt, the CC register is pushed on the stack.

**

RESET

Y

ON

OFF*

OFF

if exit caused by a RESET, a 4096 CPU

clock cycle delay is inserted.

OSCILLATOR

PERIPHERALS

CPU

ON

ON

ON

FETCH RESET VECTOR

OR SERVICE INTERRUPT**

30/132

6 I/O PORTS

ST72141K

6.1 INTRODUCTION

The I/O ports offer different functional modes:

– transferofdatathrough digitalinputs and outputs

and for specific pins:

– external interrupt generation

– alternate signal input/output for the on-chip pe-

ripherals.

An I/O port contains up to 8 pins.Each pin can be

programmed independently as digital input(with or

without interrupt generation)or digitaloutput.

6.2 FUNCTIONAL DESCRIPTION

Each port has 2 main registers:

– Data Register (DR)

– Data Direction Register (DDR)

and one optional register:

– Option Register (OR)

Each I/Opin may be programmed using thecorre-

sponding register bits in the DDR and OR registers: bit X corresponding to pin X of the port. The

same correspondence is used for the DR register.

The following description takes into account the

OR register, (for specific ports which do not provide this register refer to the I/O Port Implementation section). The generic I/O block diagram is

shown in Figure 23

6.2.1 Input Modes

The input configuration is selected by clearing the

corresponding DDR register bit.

In this case, reading the DR register returns the

digital value applied to the external I/O pin.

Different input modes can beselected bysoftware

through the OR register.

Notes:

1. Writing the DR register modifies the latch value

but does not affect the pin status.

2. When switching from input to output mode, the

DR register has to be written first to drive the correct level on the pin as soon as the port is configured as an output.

External interrupt function

When an I/O is configured as Input with Interrupt,

an event on this I/O can generate anexternal interrupt request to the CPU.

Each pin can independently generate an interrupt

request. The interrupt sensitivity is independently

programmable using the sensitivity bits in the Miscellaneous register.

Each external interrupt vector is linked to a dedicated group of I/O port pins (seepinout description

and interrupt section). If several input pins are selected simultaneously as interrupt source, these

are logically ANDed. For this reason if one of the

interrupt pins is tied low, it masks the other ones.

In case of a floating input with interrupt configuration, special care must be taken when changing

the configuration (see Figure 24).

The external interrupts are hardware interrupts,

which means that the request latch (not accessible

directly by the application)is automatically cleared

when the corresponding interrupt vector is

fetched. To clear an unwanted pending interrupt

by software, the sensitivity bits in the Miscellaneous register must be modified.

6.2.2 Output Modes

The output configuration is selected by setting the

corresponding DDR register bit. In this case, writing the DR register applies this digital value to the

I/O pin through the latch. Then readingthe DR register returns the previously stored value.

Two different output modes can be selected by

software through the OR register: Output push-pull

and open-drain.

DR register value and output pin status:

DR Push-pull Open-drain

0V

1V

SS

DD

Vss

Floating

6.2.3 Alternate Functions

When an on-chip peripheral is configured to use a

pin, the alternate function is automatically selected. This alternate function takes priority over the

standard I/O programming.

When the signal is coming froman on-chip peripheral, the I/O pin is automatically configured in output mode (push-pull or open drain according to the

peripheral).

When the signal is going to an on-chip peripheral,

the I/O pin must be configured in input mode. In

this case, the pin state is alsodigitally readableby

addressing theDR register.

Note: Input pull-up configuration can cause unexpected value attheinput ofthealternateperipheral

input. Whenan on-chip peripheral use a pin as input and output, this pin has to be configured in input floating mode.

31/132

ST72141K

I/O PORTS (Cont’d)

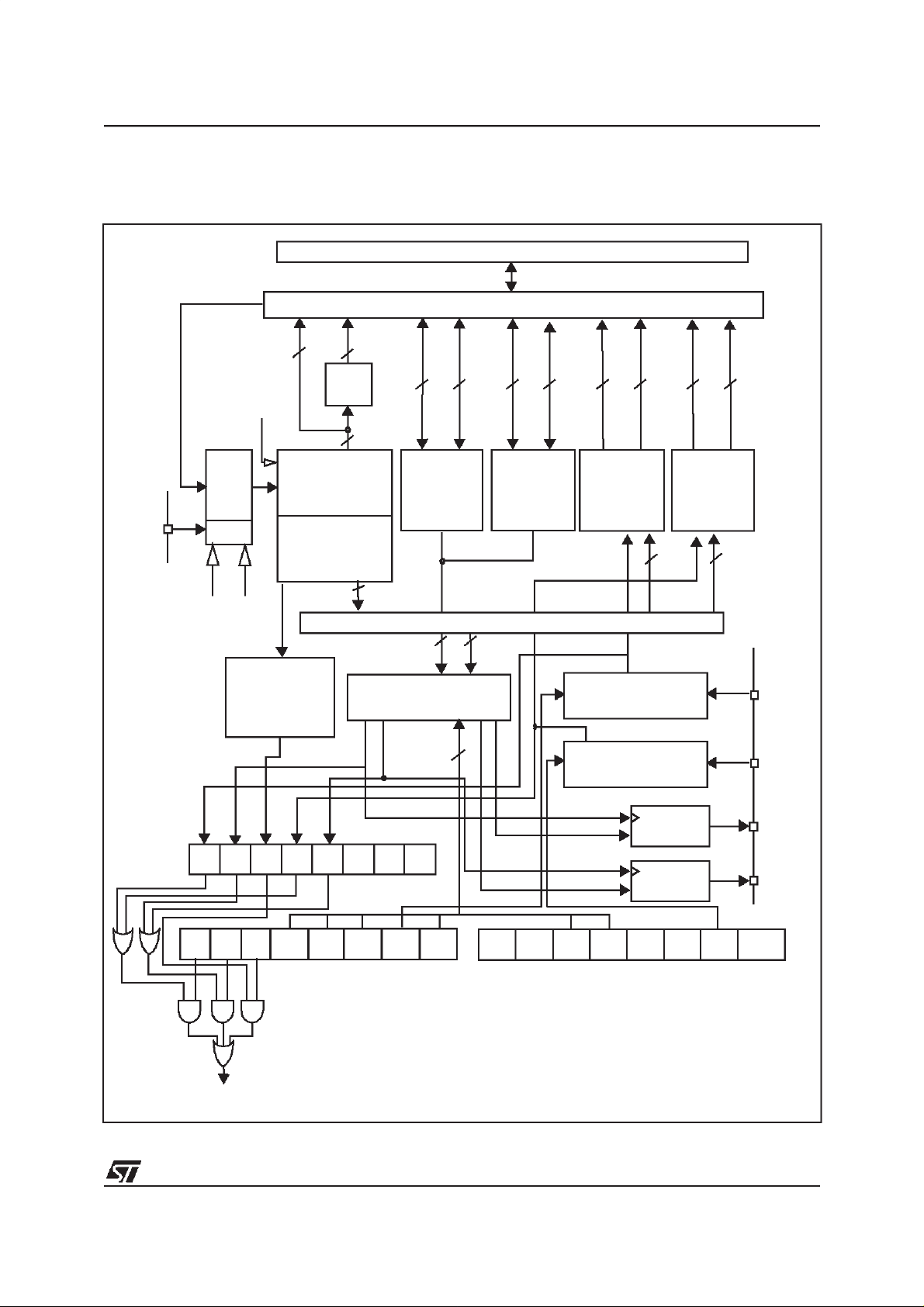

Figure 23. I/O Port General Block Diagram

REGISTER

ACCESS

DATA BUS

DDR SEL

DR

DDR

OR

OR SEL

DR SEL

ALTERNATE

OUTPUT

ALTERNATE

ENABLE

If implemented

1

1

0

PULL-UP

CONFIGURATION

N-BUFFER

V

DD

CMOS

SCHMITT

TRIGGER

P-BUFFER

(see table below)

PULL-UP

(see table below)

V

DD

PAD

DIODES

(see table below)

ANALOG

INPUT

0

EXTERNAL

INTERRUPT

SOURCE (ei

)

x

POLARITY

SELECTION

Table 5. I/O Port Mode Options

Configuration Mode Pull-Up P-Buffer

Input

Output

Floating with/without Interrupt Off

Pull-up with/without Interrupt On

Push-pull

Open Drain (logic level) Off

True Open Drain NI NI NI (see note)

Legend: NI - not implemented

Off - implemented not activated

On - implemented and activated

FROM

OTHER

BITS

ALTERNATE

INPUT

Diodes

to V

Off

Off

On

to V

On

DD

Note: The diode to VDDis not implemented in the

true open drain pads. A local protection between

the pad and VSSis implemented to protect the device against positive stress.

SS

On

32/132

I/O PORTS (Cont’d)

Table 6. I/O Port Configurations

ST72141K

Hardware Configuration

NOT IMPLEMENTED IN

TRUEOPEN DRAIN

I/O PORTS

1)

INPUT

NOT IMPLEMENTED IN

TRUE OPEN DRAIN

2)

I/O PORTS

OPEN-DRAIN OUTPUT

PAD

PAD

V

DD

R

PU

V

DD

R

PU

PULL-UP

CONFIGURATION

FROM

OTHER

PINS

INTERRUPT

CONFIGURATION

DR REGISTER ACCESS

DR

REGISTER

ENABLE OUTPUT

W

R

ALTERNATEINPUT

EXTERNAL INTERRUPT

SOURCE (ei

POLARITY

SELECTION

ANALOG INPUT

DR REGISTER ACCESS

DR

REGISTER

R/W

ALTERNATEALTERNATE

DATABUS

)

x

DATA BUS

NOT IMPLEMENTED IN

TRUE OPEN DRAIN

2)

I/O PORTS

PUSH-PULL OUTPUT

PAD

V

DD

R

PU

ENABLE OUTPUT

DR REGISTER ACCESS

DR

REGISTER

R/W

ALTERNATEALTERNATE

DATA BUS

Notes:

1. When the I/O port is in input configuration and the associated alternate function is enabled as an output,

reading the DR register will read the alternate function output status.

2. When the I/O port is in outputconfiguration and the associated alternate functionisenabledas an input,

the alternate function reads the pin status given by the DR register content.

33/132

ST72141K

I/O PORTS (Cont’d)

CAUTION: The alternate function must not be ac-

tivated as long as the pin is configured as input

with interrupt, in ordertoavoid generating spurious

interrupts.

Analog alternate function

When the pin is used as an ADC input, the I/O

must be configured as floating input. The analog

multiplexer (controlled by the ADC registers)

switches the analog voltage present on the selected pinto thecommon analog rail which is connected to the ADC input.

It is recommended not to change the voltage level

or loading on any port pin while conversion is in

progress. Furthermore it is recommended not to

have clocking pins located close to a selected analog pin.

WARNING: The analog input voltage level must

be within the limits stated in the absolute maximum ratings.

6.3 I/O PORT IMPLEMENTATION

The hardware implementation on each I/O port depends onthe settings in theDDRandORregisters

and specific feature of the I/O port such as ADCInput or true open drain.

Switching theseI/O ports from one state to another should be done in a sequence that prevents unwanted side effects. Recommended safe transitions are illustrated in Figure 24 Other transitions

are potentially risky and should beavoided, since

they are likely to present unwanted side-effects

such as spurious interrupt generation.

Figure 24. Interrupt I/O Port State Transitions

01

INPUT

floating/pull-up

interrupt

00

INPUT

floating

(reset state)

10

OUTPUT

open-drain

XX

11

OUTPUT

push-pull

= DDR, OR

The I/O port register configurations are summarized as follows.

34/132

I/O PORTS (Cont’d)

Interrupt Ports

PA7:0, PB5:3 (with pull-up)

MODE DDR OR

floating input 0 0

pull-up interrupt input 0 1

open drain output 1 0

push-pull output 1 1

True Open Drain Interrupt Ports

PA6, PA4 (without pull-up)

MODE DDR OR

floating input 0 0

floating interrupt input 0 1

true open drain (high sink ports) 1 X

Table 7. Port Configuration

ST72141K

Port Pin name

Port A PA7:0 floating pull-up interrupt open drain push-pull

Port B

PB5:3 floating pull-up interrupt open drain push-pull

PB2:0 floating floating interrupt true open drain

OR = 0 OR = 1 OR = 0 OR = 1

Input Output

35/132

ST72141K

I/O PORTS (Cont’d)

6.3.1 Register Description

DATA REGISTER (DR)

Port x Data Register

PxDR with x = A or B.

Read/Write

Reset Value: 0000 0000 (00h)

70

D7 D6 D5 D4 D3 D2 D1 D0

Bit 7:0 = D[7:0]

Data register 8 bits.

The DR register has a specific behaviour according to the selectedinput/output configuration. Writing the DR register is always taken into account

even ifthe pinis configured as an input; this allows

to always have the expected level on the pin when

toggling to output mode. Reading the DR register

returns either the DR register latch content (pin

configured asoutput) or the digital value applied to

the I/O pin (pin configured as input).

OPTION REGISTER (OR)

Port x Option Register

PxOR with x = A or B.

Read/Write

Reset Value: 0000 0000 (00h)

70

O7 O6 O5 O4 O3 O2 O1 O0

Bit 7:0 = O[7:0]

Option register 8 bits.

For specific I/O pins, this register is not implemented. In this case the DDR register is enough to select the I/O pin configuration.

The OR register allows to distinguish: in input

mode if the pull-up with interrupt capability or the

basic pull-up configuration is selected, in output

mode if the push-pull or open drainconfigurationis

selected.

Each bit is set and cleared by software.

DATA DIRECTION REGISTER (DDR)

Port x Data Direction Register

PxDDR with x = A or B.

Read/Write

Reset Value: 0000 0000 (00h)

Input mode:

0: floating input

1: pull-up input with or without interrupt

Output mode:

0: output open drain (with P-Buffer unactivated)

1: output push-pull (when available)

70

DD7 DD6 DD5 DD4 DD3 DD2 DD1 DD0

Bit 7:0 = DD[7:0]

Data direction register 8 bits.

The DDR register gives the input/output direction

configuration of the pins. Each bits is set and

cleared by software.

0: Input mode

1: Output mode

36/132

I/O PORTS (Cont’d)

Table 8. I/O Port Register Map andReset Values

ST72141K

Address

(Hex.)

Reset Value

of all IO port registers

0000h PADR

0002h PAOR

0004h PBDR

0006h PBOR

Register

Label

76543210

00000000

MSB LSB0001h PADDR

MSB LSB0005h PBDDR

37/132

ST72141K

7 MISCELLANEOUSREGISTER

The miscellaneous register allows control over

several different features such as the external interrupts or the I/O alternate functions.

7.1 I/O Port Interrupt Sensitivity Description

The external interrupt sensitivity is controlled by

the ISxx bits of the Miscellaneous register. This

control allows to have two fully independent external interrupt source sensitivities as shown in Figure 25.

Each external interrupt source can be generated

on four different events onthe pin:

■ Falling edge

■ Risingedge

■ Falling and rising edge

■ Falling edge and low level

To guaranty correct functionality, a modification of

the sensitivity in the MISCR registermust be done

only whenthe I bit of the CC register is set to 1 (interrupt masked). See I/O port register and Miscellaneous register descriptions for more details on

the programming.

Figure 25. External Interrupt Sensitivity

7.2 I/O Port Alternate Functions

The MISCR register manages the SPI SS pin alternate function configuration. Thismakesit possible to use the PB2 I/O port function while the SPI is

active.

These functions are described in detail in Section

7.4 Miscellaneous Register Description.

7.3 Clock Prescaler Selection

The MISCR register is used to select the SLOW

mode (see Section 5.4 SLOW Mode for more details) and the SPI and Motor Control peripheral

clock prescaler.

MISCR

IS00IS01

SENSITIVITY

CONTROL

MISCR

IS10IS11

SENSITIVITY

CONTROL

EI0

INTERRUPT

SOURCE

EI1

INTERRUPT

SOURCE

PA7

PA0

PB7

PB0

38/132

MISCELLANEOUS REGISTER (Cont’d)

ST72141K

7.4 Miscellaneous Register Description

Bits 4:3 = IS1[1:0]

EI1 sensitivity

The interrupt sensitivity defined using the IS1[1:0]

MISCELLANEOUS REGISTER (MISCR)

Read/Write

Reset Value: 0000 0000 (00h)

70

XT16 SSM SSI IS11 IS10 IS01 IS00 SMS

Bit 7 = XT16

MTC and SPI clock selection

This bit is set and cleared by software. The maximum allowed frequency is 4MHz.

0: MTC and SPI clock supplied with f

1: MTC and SPI clock supplied with f

Bit 6 = SSM

SS mode selection

OSC

OSC

/2

/4

This bit is set and cleared bysoftware.

0: Normal mode - the level of the SPI SS signal is

the external SS pin.

1: I/O mode, the level of the SPI SSsignal is read

from the SSI bit.

Bit 5 = SSI

SS internal mode

This bit replaces the SS pin of the SPI when the

SSM bit is set to 1. (see SPI description). It is set

and cleared by software.

bits combination is applied to the EI1 external interrupts. These two bits can be written only when

the I bit of the CC register is set to 1 (interrupt

masked).

EI1: Port B

IS11 IS10 External Interrupt Sensitivity

0 0 Falling edge & low level

0 1 Rising edge only

1 0 Falling edge only

1 1 Rising and falling edge

Bits 2:1 = IS0[1:0]

EI0 sensitivity

The interrupt sensitivity defined using the IS0[1:0]

bits combination is applied to the EI1 external interrupts. These two bits can be written only when

the I bit of the CC register is set to 1 (interrupt

masked).

EI0: Port A

IS01 IS00 External Interrupt Sensitivity

0 0 Falling edge & low level

0 1 Rising edge only

1 0 Falling edge only

1 1 Rising and falling edge

Bit 0 = SMS

This bit is set andcleared by software.

0: Normal mode. f

1: Slow mode. f

See sections on low power consumption mode

and MCC for more details.

Table 9. Miscellaneous Register Map and Reset Values

Address

(Hex.)

0020h

Register

Label

MISCR

Reset Value

76543210

XT16

0

SSM

0

SSI

0

IS11

0

Slow mode select

= f

= f

OSC

IS01

OSC

/32

0

CPU

CPU

IS10

0

/2

IS00

0

SMS

0

39/132

ST72141K

8 ON-CHIP PERIPHERALS

8.1 MOTOR CONTROLLER (MTC)

8.1.1 Introduction

The ST7Motor Controller (MTC) can be seenas a

Pulse Width Modulator multiplexed on six output

channels, and a Back Electromotive Force

(BEMF) zero-crossing detector for sensorless control of Permanent Magnet Direct Current (PMDC)

brushless motors.

The MTC is particularly suited to driving synchronous motors and supports operating modes like:

– Commutation step control with motor voltage

regulation and current limitation

– Commutation step control with motor current

regulation, i.e. direct torque control

– Sensoror sensorless motor phase commutation

control

– BEMFzero-crossingdetection with high sensitiv-

ity. The integrated phase voltage comparator is

directly referredto the full BEMF voltagewithout

any attenuation. A BEMF voltage down to

200 mV can be detected, providing high noise

immunity and self-commutated operation in a

large speed range.

– Realtime motor winding demagnetization detec-

tion for fine-tuning the phase voltage masking

time to be applied before BEMF monitoring.

– Automatic and programmable delay between

BEMF zero-crossing detection and motor phase

commutation.

8.1.2 Main Features

■ Two on-chipanalogcomparators,oneforBEMF

zero-crossing detection with 100 mV hysteresis,

the other for current regulation or limitation

■ Four selectable reference voltages for the

hysteresis comparator (0.2 V, 0.6 V, 1.2 V,

2.5 V)

■ 8-bit timer (MTIM) with two compare registers

and two capture features

■ Measurement window generator for BEMF

zero-crossing detection

■ Auto-calibrated prescaler with 16 division steps

■ 8x8-bit multiplier

■ Phase input multiplexer

■ Sophisticated output management:

– The six output channels can be split into two

groups (odd & even).

– The PWM signal can be multiplexed on even,

odd or both groups, alternatively or simultaneously.

– The output polarity is programmable channel

by channel.

– An softwareenabled bit (activelow) forcesthe

outputs in HiZ.

– An “emergency stop” input pin (active low)

asynchronously forces the outputs in HiZ.

Table 10. MTC Registers

Register Description Page

MTIM Timer Counter Register 71

MZPRV Capture Z

MZREG Capture Z

MCOMP Compare C

MDREG Demagnetization Register 71

MWGHT A

MPRSR Prescaler & Sampling Register 71

MIMR Interrupt Mask Register 72

MISR Interrupt Status Register 72

MCRA Control Register A 73

MCRB Control Register B 74

MPHST Phase State Register 75

MPAR Parity Register 75

MPOL Polarity Register 75

Weight Register 71

n

Register 71

n-1

Register 71

n

Register 71

n+1

8.1.3 Application Example

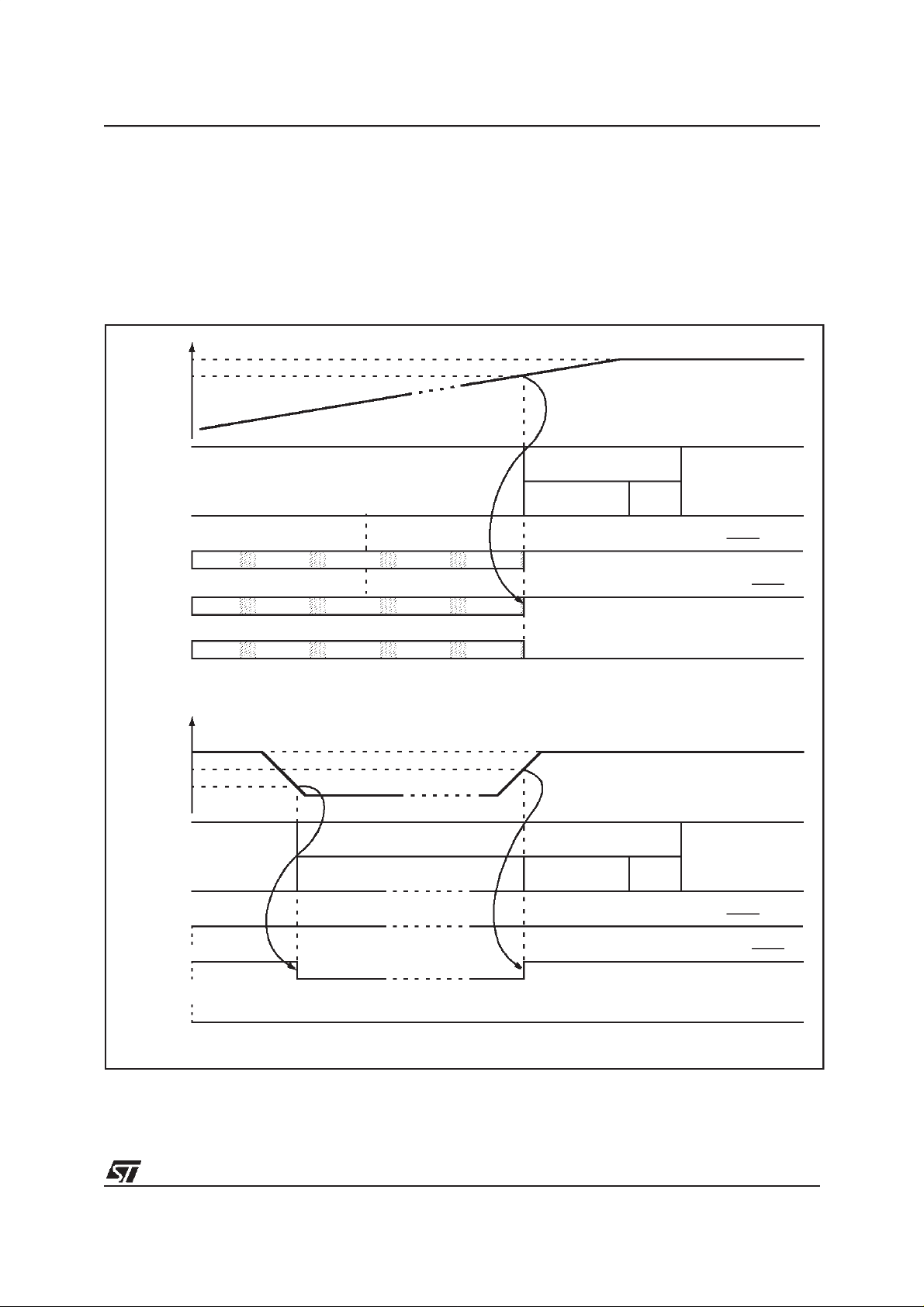

This example shows a six-step command sequence for a 3-phase permanent magnet DC

brushless motor (PMDC motor). Figure 27 shows

the phase steps and voltage, while Table 11

shows the relevant phase configurations.

To run this kind of motor efficiently, an autoswitching mode hasto be used, i.e. theposition of the rotor must self-generate the powered winding commutation. The BEMF zero crossing (Z event) on

the non-excited winding is used by the MTC as a

rotor position sensor. The delay between this

event and the commutation is computed by the

MTC and the commutation event Cnis automatically generated after this delay.

After the commutation occurs, the MTC waits until

the winding is completely demagnetized by the

free-wheeling diode: during thisphase the winding

is tied to 0V or to the HV high voltage rail and no

BEMF can be read. At theend of this phase a new

BEMF zero-crossing detection is enabled.

The end of demagnetization event (D), is also detected by the MTC or simulated with a timer compare feature when no detection is possible.

40/132

MOTOR CONTROLLER (Cont’d)

The MTC manages these three events always in

the same order: Z generates C after a delay computed in realtime, then waits for D in order to enable the peripheral todetect another Z event.

The speed regulation is managed by the microcontroller, by means of an adjustable reference

current level in case of current control, or by direct

PWM duty-cycle adjustment in case of voltage

control.

All detections of Znevents are doneduring a short

measurement window while the high side switch is

turned off. For this reason the PWM signal is applied on the high side switches.

When the high side switch is off, the high side