查询ST72141供应商

8-BIT MCU WITH 8K ROM/OTP/EPROM, 256 BYTES RAM,

ELECTRIC-MOTOR CONTROL, ADC, WDG, SPI AND 2 TIMERS

■ User Program Memory (ROM/OTP/EPROM):

8K bytes

■ Data RAM: 256 bytes including 64 bytes of

stack

■ Master Reset and Power-On Reset

■ Run and Power Saving modes

■ Low Voltage Detector (LVD) Reset

■

14 multifunctional bidirectional I/O lines:

– 14 interrupt inputs on 2 independent lines

– 8 analog alternate inputs

– 3 high sink outputs

– 13 alternate functions

– EMI filtering

■ Software or Hardware Watchdog (WDG)

■ Motor Control peripheral featuring:

– 6 PWM output channels

– Emergency pin to force outputs to HiZ state

– 3 analog inputs for rotor position detection

with no need of additional sensors

– Comparator for current control or limitation

■ Two 16-bit Timers, each featuring:

– 2 Input Captures

– 2 Output Compares

– External Clock input

– PWM and Pulse Generator modes

■ Synchronous Serial Peripheral Interface (SPI)

■

8-bit ADC with 8 channels

■ 8-bit Data Manipulation

■ 63 basic Instructions

■ 17 main Addressing Modes

■

8 x 8 Unsigned Multiply Instruction

■ True Bit Manipulation

■ Complete Development Support on DOS/

WINDOWSTMReal-Time Emulator

■

Full Software Package on DOS/WINDOWS

(C-Compiler, Cross-Assembler, Debugger)

TM

ST72141

PRODUCT OVERVIEW

PSDIP32

CSDIP32W

SO34

Device Summary

Features ST72141K2

Program Memory - bytes 8K

RAM (stack) - bytes 256 (64)

Peripherals

Operating Supply 4.5 to 5.5 V

CPU Frequency

Temperature Range - 40°Cto+85°C

Package SO34 - PSDIP32

MotorControl, Watchdog,

Timers, SPI, ADC

8 or 4 MHz

(16 or 8MHz oscillator)

Rev. 1.1

July 1998 1/13

Thisispreliminary information onanewproduct in development orundergoing evaluation.Detailsaresubjecttochangewithout notice.

1

ST72141

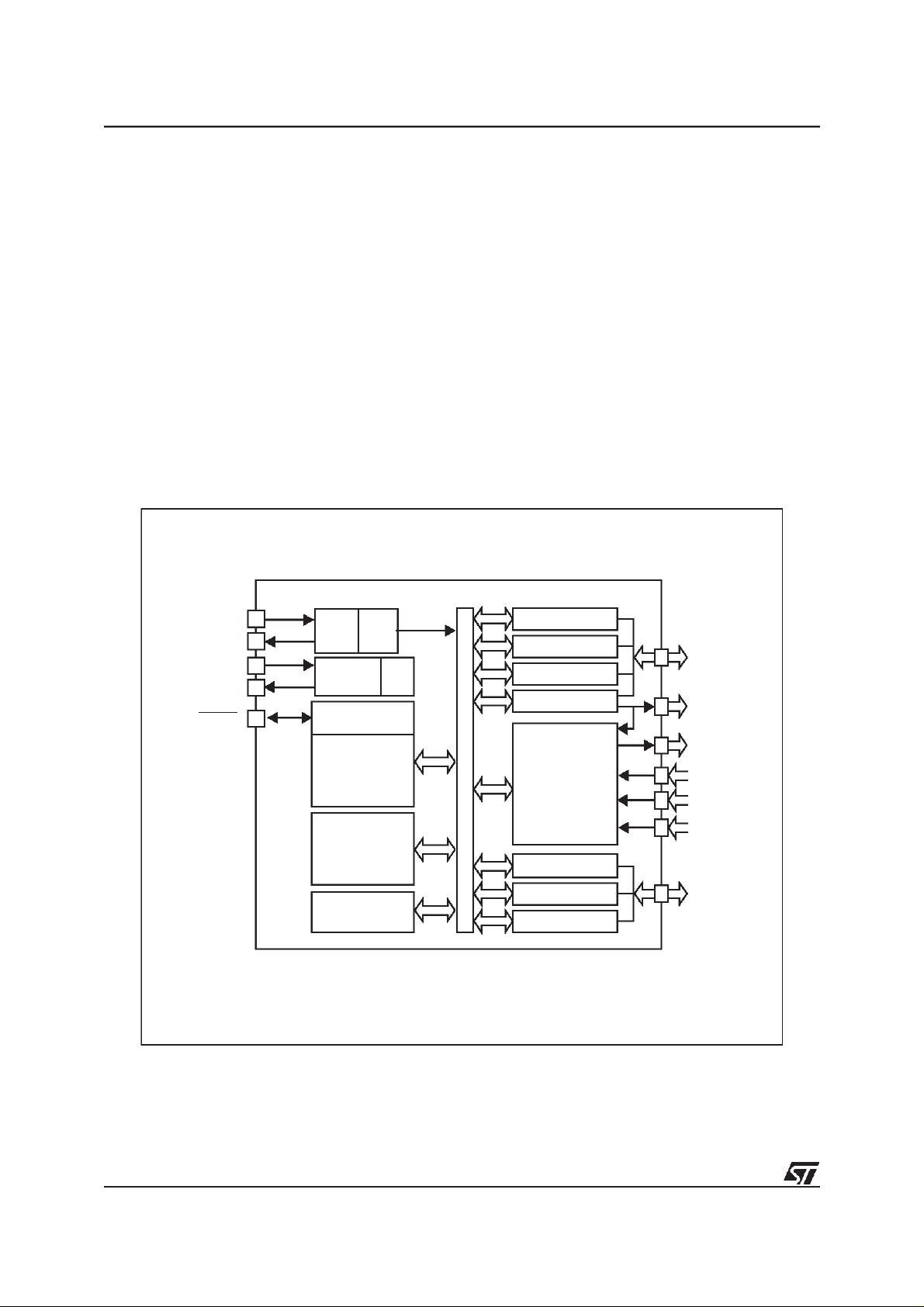

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST72141 Microcontroller Unit (MCU) is a

member of the ST7 family of Microcontrollers. The

device is based on an industry-standard 8-bit core

and features an enhanced instruction set. The device is operated at an 8 or 16MHz oscillator frequency. Under software control, the ST72141 may

be placed in either Wait, Slow or Halt modes, thus

reducing power consumption. The enhanced instruction set and addressing modes afford real

programming potential. In addition to standard 8bit data management, the ST72141 features true

bit manipulation, 8x8 unsigned multiplication and

indirect addressing modes. The device includes a

low consumption and fast start on-chip oscillator,

Figure 1.ST72E14 Block Diagram

Internal

OSCIN

OSCOUT

V

DD

V

RESET

SS

OSC

POWER

SUPPLY

CONTROL

CLOCK

DIV

LVD

CPU, ROM/OTP/EPROM, RAM, 14 I/O lines and

the following on-chip peripherals: Analog-to-Digital

converter (ADC) with 8 multiplexed analog inputs,

Motor Control (MTC) peripheral, industry standard

synchronous SPI serial interface, digital Watchdog, two independent 16-bit Timers featuring

Clock Inputs, Pulse Generator capabilities, 2 Input

Captures and 2 Output Compares.

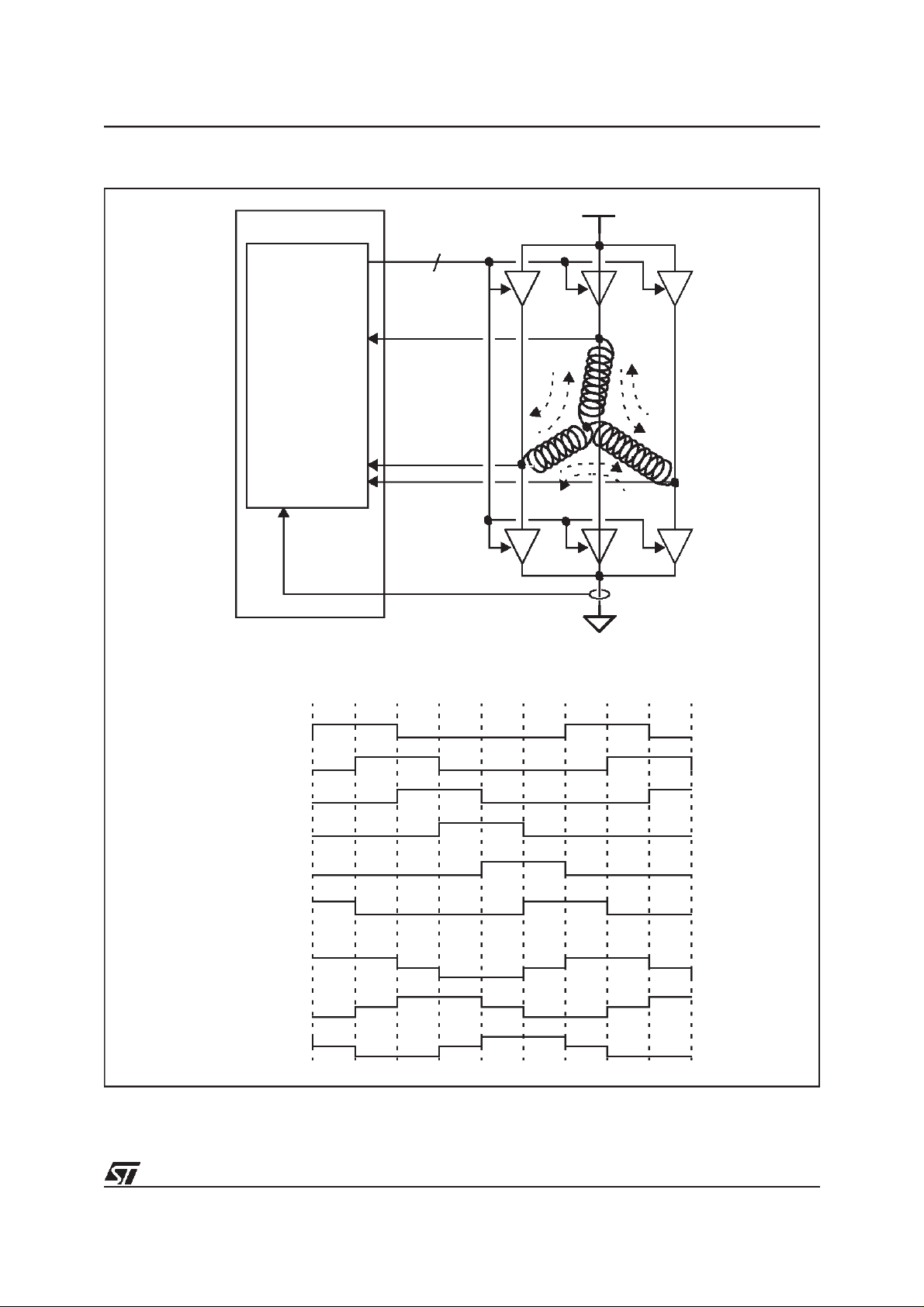

The MTC peripheral is designed to control electric

brushless motors, with or without sensors. An

example of application is givenFigure 2 for 6-step

control of Permanent Magnet Direct Current

(PMDC) motor.

PORT A

ADDRESS A ND DATA BUS

8-BIT ADC

TIMER B

TIMER A

PA7-PA0

(8 bits)

OC1A

2/13

8-BIT CORE

ALU

Program Memory

8KBytes

RAM

256 Bytes

MOTOR CTRL

PORT B

SPI

WATCHDOG

MCO5-MCO0

MCIA-C

MCES

MICCFI

PB5-PB0

(6 bits)

2

Figure 2.Example of a 6-step-controlled Motor

ST72141

ST7

MTC

MCCFI

MCO5-0

MCIB

MCIA

MCIC

6

Current feedback

300V

T0

T2

T4

B

I

T5

6

I

3

I

C

2

T1

I

1

I

4

A

I

5

T3

Step

Switch

T0

T1

T2

T3

T4

T5

Node

A

B

C

300V

150V

0

300V

150V

0

300V

150V

0

Σ

Σ

Σ

Σ

Σ

Σ

Σ

Σ

1

2

3

4

5

6

1

Σ

2

3

3/13

3

ST72141

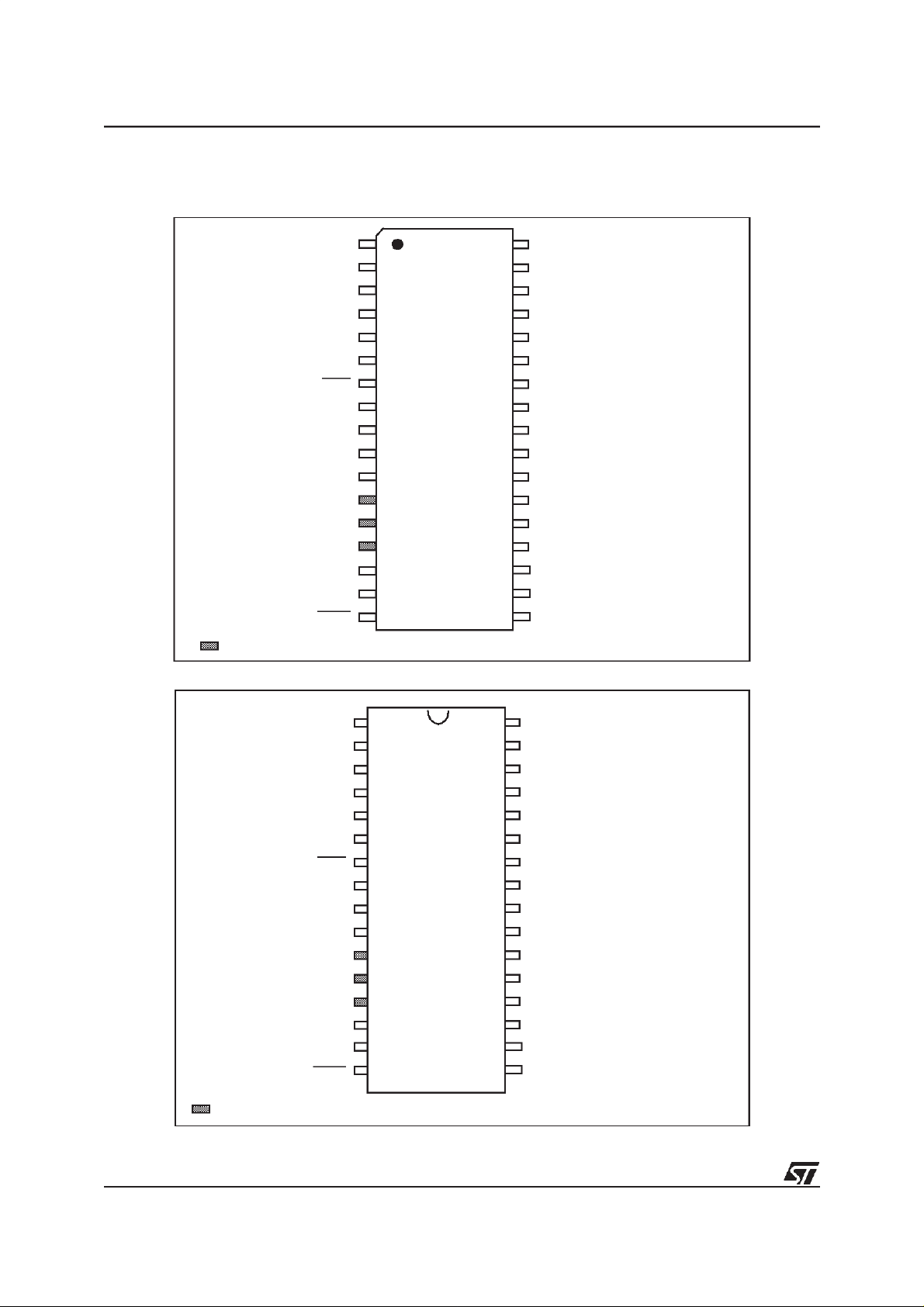

1.2 PIN DESCRIPTION

Figure 3.34-Pin SO Package Pinout

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

MCES

MISO / EI2 / PB5

NC

MOSI / EI2 / PB4

SCK/ EI2 /PB3

SS/ EI2 / PB2

EXTCLK_B/ EI2 /PB1

EXTCLK_A/ EI2 /PB0

OSCIN

OSCOUT

RESET

Factory fixed OpenDrain (Push-Pullprogramming notavailable) - HighSink

Figure 4.32-Pin SDIP Package Pinout

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

MCIA

34

MCIB

33

MCIC

32

MCCFI

31

V

30

29

28

27

26

25

24

23

22

21

20

19

18

DD

V

SS

TEST/V

OCP1A

NC

PA7 / AIN7 / EI1/ OCP2A

PA6 / AIN6 / EI1/ ICP1A

PA5 / AIN5 / EI1/ ICP2A

PA4 / AIN4 / EI1/ OCP1B

PA3 / AIN3 / EI1/ OCP2B

PA2 / AIN2 / EI1/ ICP1B

PA1 / AIN1 / EI1/ ICP2B

PA0 / AIN0 / EI1

PP

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

MCES

MISO / EI2/ PB5

MOSI / EI2/ PB4

SCK/ EI2 / PB3

SS/EI2 / PB2

EXTCLK_B/ EI2 /PB1

EXTCLK_A/ EI2 /PB0

OSCIN

OSCOUT

RESET

Factory fixedOpen Drain(Push-Pull programming not available) - High Sink

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

MCIA

31

MCIB

30

MCIC

29

MCCFI

28

V

27

V

26

TEST/V

25

OCP1A

24

PA7 / AIN7 /EI1 / OCP2A

23

PA6 / AIN6 /EI1 / ICP1A

22

PA5 / AIN5 /EI1/ ICP2A

21

PA4 / AIN4 /EI1/ OCP1B

20

PA3 / AIN3 /EI1/ OCP2B

19

PA2 / AIN2 /EI1/ ICP1B

18

PA1 / AIN1 /EI1/ ICP2B

17

PA0 / AIN0 /EI1

DD

SS

PP

4/13

4

Table 1.ST72E141 Pin Description

ST72141

Pin n°

Pin n°

SO34

SDIP32

1 1 MCO5 O C MTC Output Channel 5

2 2 MCO4 O C MTC Output Channel 4

3 3 MCO3 O C MTC Output Channel 3

4 4 MCO2 O C MTC Output Channel 2

5 5 MCO1 O C MTC Output Channel 1

6 6 MCO0 O C MTC Output Channel 0

7 7 MCES I C MTC Emergency Stop

8 8 MISO/EI2/PB5 I/O C C Port B5 or SPI Master In / Slave Out Data External Interrupt: EI2

9 NC Not Connected

10 9 MOSI/EI2/PB4 I/O C C Port B4 or SPI Master Out / Slave In Data External Interrupt: EI2

11 10 SCK/EI2/PB3 O C C Port B3 or SPI Serial Clock External Interrupt: EI2

12 11 SS/EI2/PB2 I/O C C Port B2 or SPI Slave Select (active low) Ext. Int.: EI2, High Sink

13 12 EXTCLK_B/EI2/PB1 I/O C C Port B1 or Timer B Input Clock Ext. Int.:EI2, High Sink

14 13 EXTCLK_A/EI2/PB0 I/O C C Port B0 or Timer A Input Clock Ext. Int.:EI2, High Sink

15 14 OSCIN I

16 15 OSCOUT O

17 16 RESET I/O C C Bidirectional. Active low. Top priority non maskable interrupt.

18 17 PA0/AIN0/EI1 I/O C/A C Port A0 or ADC Analog Input 0 External Interrupt: EI1

19 18

20 19

21 20

22 21

23 22

24 23

25 24

26 NC Not Connected

27 25 OCP1A O R TimerA Output Compare 1

28 26 TEST/V

29 27 V

30 28 V

31 29 MCCFI I A MTC Current Feed Back

32 30 MCIC I A MTC Input C

33 31 MCIB I A MTC Input B

34 32 MCIA I A MTC Input A

Pin Name Type

PA1/AIN1/EI1/

ICP2B

PA2/AIN2/EI1/

ICP1B

PA3/AIN3/EI1/

OCP2B

PA4/AIN4/EI1/

OCP1B

PA5/AIN5/EI1/

ICP2A

PA6/AIN6/EI1/

ICP1A

PA7/AIN7/EI1/

OCP2A

1)

PP

SS

DD

Levels

Description Remarks

In Out

Input/Output Oscillator pin. These pins connect a parallel-resonant

crystal, or an external source to the on-chip oscillator.

I/O C/A C

I/O C/A C

I/O C/A C

I/O C/A C

I/O C/A C

I/O C/A C

I/O C/A C

I/S

S Ground

S Main power supply

Port A1 or TimerB Input Capture 2 or ADC

Analog Input 1

Port A2 or TimerB Input Capture 1 or ADC

Analog Input 2

Port A3 or TimerB Output Compare 2 or

ADC Analog Input 3

Port A4 or TimerB Output Compare 1 or

ADC Analog Input 4

Port A5 or TimerA Input Capture 2 or ADC

Analog Input 5

Port A6 or TimerA Input Capture 1 or ADC

Analog Input 6

Port A7 or TimerA Output Compare 2 or

ADC Analog Input 7

Test mode pin (should be tied low in user mode). In the EPROM programming mode, this pin acts as the programming voltage input V

External Interrupt: EI1

External Interrupt: EI1

External Interrupt: EI1

External Interrupt: EI1

External Interrupt: EI1

External Interrupt: EI1

External Interrupt: EI1

PP

Note 1: VPPon EPROM/OTP only.

– C = CMOS levels (0.3V

/ 0.7VDD)

DD

– R = 70kΩ/100kΩ Ratio of CMOS Levels (0.2V

– A = Analog levels

/ 0.5VDD)

DD

5/13

5

ST72141

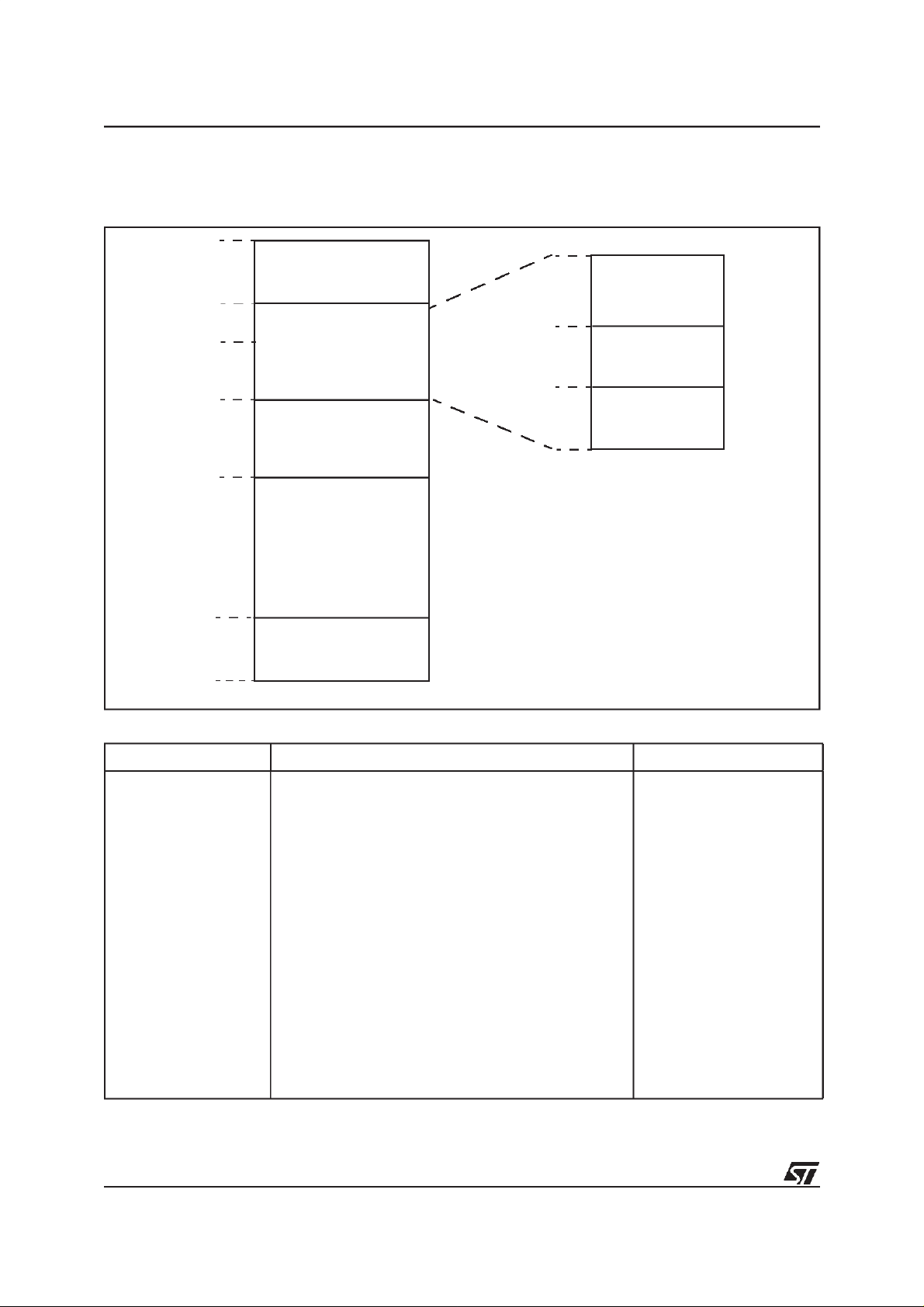

1.3 MEMORY MAP

Figure 5.Program Memory Map

0000h

HW Registers

007Fh

0080h

00FFh

017Fh

0180h

DFFFh

E000h

(see Table 3)

256 Bytes RAM

Reserved

8K Bytes

Program Memory

0080h

00FFh

0100h

013Fh

0140h

017Fh

Short Addressing

RAM (zero page)

16-bit Addressing

RAM

16-bit Addressing

64 Bytes Stack

FFDFh

FFE0h

FFFFh

Interrupt & Reset Vectors

(see Table 2)

Table 2. Interrupt Vector Map

Vector Address Description Remarks

FFE0-FFE1h

FFE2-FFE3h

FFE4-FFE5h

FFE6-FFE7h

FFE8-FFE9h

FFEA-FFEBh

FFEC-FFEDh

FFEE-FFEFh

FFF0-FFF1h

FFF2-FFF3h

FFF4-FFF5h

FFF6-FFF7h

FFF8-FFF9h

FFFA-FFFBh

FFFC-FFFDh

FFFE-FFFFh

TIMER B Interrupt Vector

TIMER A Interrupt Vector

MTC Interrupt Vector 3 (D, O, R & E events)

MTC Interrupt Vector 2 (C event)

MTC Interrupt Vector 1 (Z event)

External Interrupt Vector EI2 (PB0:PB5)

External Interrupt Vector EI1 (PA0:PA7)

TRAP (software) Interrupt Vector

Not Used

Not Used

Not Used

Not Used

Not Used

SPI Interrupt Vector

Not Used

RESET Vector

Internal Interrupt

Internal Interrupt

Internal Interrupt

Internal Interrupt

Internal Interrupt

Internal Interrupt

External Interrupt

External Interrupt

CPU Interrupt

6/13

6

Table 3.Hardware Register Memory Map

ST72141

Address Block

0000h

0001h

0002h

0003h Reserved Area (1 byte)

0004h

0005h

0006h

0007h to

001Fh

0020h MISCR Miscellaneous Register 00h

0021h

0022h

0023h

0024h

0025h

0026h to

0030h

0031h

0032h

0033h

0034h-0035h

0036h-0037h

0038h-0039h

003Ah-003Bh

003Ch-003Dh

003Eh-003Fh

0040h Reserved Area (1 byte)

Port A

Port B

SPI

WDG

Timer A

Register

Label

PADR

PADDR

PAOR

PBDR

PBDDR

PBOR

SPIDR

SPICR

SPISR

WDGCR

WDGSR

TACR2

TACR1

TASR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Register Name

Data Register

Data Direction Register

Option Register

Data Register

Data Direction Register

Option Register

Reserved Area (25 bytes)

SPI Data I/O Register

SPI Control Register

SPI Status Register

Watchdog Control Register

Watchdog Status Register

Reserved Area (11 bytes)

Control Register2

Control Register1

Status Register

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low Register

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

Reset

Status

00h

00h

00h

00h

00h

00h

xxh

0xh

00h

7Fh

x0h

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

R/W

Read Only

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

7/13

7

ST72141

Address Block

0041h

0042h

0043h

0044h-0045h

0046h-0047h

0048h-0049h

004Ah-004Bh

004Ch-004Dh

004Eh-004Fh

0050h to

005Fh

0060h

0061h

0062h

0063h

0064h

0065h

0066h

0067h

0068h

0069h

006Ah

006Bh

006Ch

006Dh

006Eh to

006Fh

0070h

0071h

0072h to

007Fh

Timer B

Motor

Control

ADC

Register

Label

TBCR2

TBCR1

TBSR

TBIC1HR

TBIC1LR

TBOC1HR

TBOC1LR

TBCHR

TBCLR

TBACHR

TBACLR

TBIC2HR

TBIC2LR

TBOC2HR

TBOC2LR

MCNT

MZPRV

MZREG

MCREG

MDREG

MWGHT

MPRSR

MIMR

MISR

MCRA

MCRB

MPHST

MPAR

MPOL

ADCDR

ADCCSR

Register Name

Control Register2

Control Register1

Status Register

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low Register

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

Reserved Area (16 bytes)

Counter Register

Zn-1 Capture Register

Zn Capture Register

C

Compare Register

n+1

D capture/Compare Register

Weight Register

Prescaler and Ratio Register

Interrupt Mask Register

Interrupt Status Register

Control Register A

Control Register B

Phase State Register

Output Parity Register

Output Polarity Register

Reserved Area (2 bytes)

Data Register

Control/ Status Register

Reserved Area (14 bytes)

Reset

Status

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

R/W

8/13

8

2 Motor Control peripheral overview

The Motor Control (MTC) peripheral can be seen

as a Pulse Width Modulator which can be multiplexed on six output channels, and a Back Electromotive Force (BEMF) zero-crossing detector

which enables a sensorless control of self commutated Permanent Magnet Direct Current (PMDC)

brushless motor.

This peripheral is particularly suited to driving synchronous motors and enables the implementation

of operating modes like

■ Commutation step control with motor voltage

regulation.

■

Commutation step control with motor current

regulation, i.e. direct torque control.

■ Sensor or sensorless motor phase commutation

control.

■

BEMF zero-crossing detection with high

sensitivity. The integrated phase voltage

comparator is directly referred to the full BEMF

voltage without any attenuation. So a BEMF

voltage down to 200mV can be detected,

providing high noise immunity and a selfcommutated operation in a large speed range.

■ Real time motor winding demagnetisation

detection enabling to fine-tune the phase

voltage masking time to be applied before

BEMF monitoring.

■ Automatic andprogrammable delaying between

BEMF zero-crossing detection and motorphase

commutation.

2.1 MTC peripheral main features

■ Two on-chip analog comparators, one for BEMF

zero-crossing detection with an 100mV

hysteresis, the other for current regulation or

limitation.

■ One of four selectableinternal voltage reference

values for the hysteresis comparator (0.2V,

0.6V, 1.2V, 2.5V).

■

One central 8-bit timer with two compare

registers and two capture features.

■ A “measurement window generator” allowing

BEMF zero-crossing detection.

ST72141

■ An auto-calibrated prescaler with 16 division

steps.

■ One 8-bit by 8-bit multiplier.

■ Phase input multiplexer.

■ Sophisticated output management:

– The six output channels can be split in two

groups (high side & low side).

– The PWM signal can be multiplexed on high,

low or both groups, alternatively or simultaneously.

– The output polarity is programmable channel

by channel.

– An output enable bit forces the outputs in HiZ

(active low).

– Anemergency stop pin input (MCES) immedi-

ately forces the outputs in HiZ when reset.

■ The MTC peripheral always operates at a4MHz

frequency, equal to f

the external clock frequency, and not affected

by slow mode selection.

2.2 General principle

The following example (Figure 6) relates to a six

step command sequence for a PMDC brushless

motor.

The commutation event [Cn] is automatically generated by the MTC peripheral after detecting the

zero-crossing of the BEMF induced in the non-exited coil by the rotor. The delay between this event

[Zn] and the commutation is computed by the MTC

peripheral. The BEMF zero-crossing detection is

enabled only after the end of demagnetization

event [Dn], also detected (or simulated) by the

MTC peripheral.

The speed regulation is managed by the microcontroller, by means of an adjustable reference

current level (current control), or by the PWM dutycycle adjustment (voltage control).

All the detection of [Zn] events is done during a

short measurement window while the high side

switch is turned off. The high side node (refer to

Table 4) is tied to 0V by the free-wheeling diode,

and the “zero-crossing” detection is then possible.

CPU

orf

/2depending on

CPU

9/13

ST72141

Figure 6.Example of command sequence for 6-step mode

Σ

Step

Switch

1Σ2Σ3Σ4Σ5Σ6Σ1Σ2Σ3

300V

T0

T1

T2

T3

T4

T5

Node

A

B

C

300V

150V

0

300V

150V

0

300V

150V

0

T0

T2

T4

B

T5

I

6

I

3

I

2

C

T1

I

1

I

4

A

I

5

T3

Note: Control & sampling PWM influence is not represented on these simplified chronograms.

superimposed voltage

(BEMF induced byrotor)

Demagnetization

10/13

300V

150V

0V

Wait for BEMF = 0

Σ

2

]

[D

2

]

[Z

2

Commutation delay

[C

Σ

3

]

2

[C

Σ

4

]

4

Σ

5

[Z

]

5

]

[D

5

t

Table 4.Step configuration summary

ST72141

Step

Σ

1

Σ

2

Σ

3

Σ

4

Σ

5

Current direction A(+)/B(-) A(+)/C(-) B(+)/C(-) B(+)/A(-) C(+)/A(-) C(+)/B(-)

High side active switch T0 T0 T2 T2 T4 T4

Low side active switch T5 T1 T1 T3 T3 T5

Measure done on

MCIC MCIB MCIA MCIC MCIB MCIA

Figure 7.Simplified MTC peripheral block diagram (without microcontroller interface)

DELAY MANAGER

DELAY

WEIGHT

CAPTURE Zn

DELAY = WEIGHT x Zn

TIMER

=?

COMMUTE [C]

BEMF ZERO-CROSSING

DETECTOR

BEMF=0

[Z]

Internal V

REF

MCIA

MCIB

MCIC

Σ

6

MEASUREMENT

WINDOW

GENRATOR

(I)

(V)

(V)

PWM (*)

(I)

PWM MANAGER

Note (*) : The PWM signal is generated by Timer A

[Z] : Back EMF Zero-crossing event

Z

: Time elapsed between two consecutive Z events

n

[C] : Commutation event

C

: Time delayed after Z event to generate C event

n

(I): Current mode

(V): Voltage mode

(I)

CURRENT

VOLTAGE

(V)

MODE

PHASE

CHANNEL MANAGER

MCO5

MCO4

MCO3

MCO2

MCO1

MCO0

MCES

MCCFI

OCP1A

C

ext

(I)

R

(V)

ext

11/13

ST72141

3 MTC Peripheral general description

The MTC peripheral can be split into four main

parts as described in the simplified block diagram

(Figure 7).

– The PWM MANAGER, including a “measure-

ment window generator”, a mode selector and

current control.

– The BEMF ZERO-CROSSING DETECTORwith

a comparator and an input multiplexer.

– The DELAY MANAGER with an 8 bit timer and

an 8x8 bit multiplier.

– The CHANNEL MANAGER with the PWM multi-

plexer, polarity programming capability and

emergency HiZ configuration input.

A pre-load register enables the CPU to asynchronously update the channel configuration for the

next step.

The multiplexer directs the PWM to the upper

channel, the lower channel or both of them alternatively or simultaneously, enabling to choose the

most appropriate reference potential when freewheeling the motor in order to improve system efficiency andspeed up the demagnetisation phase.

The polarity register is used to fit the polarity of the

power drivers keeping the same control logic and

software.

3.3 BEMF zero-crossing detector

3.1 PWM Manager

The PWM manager enables a voltage control or a

current control of the motor to beperformed via the

six output channels.

3.1.1 Voltage Mode

In voltage mode, the PWM provided by TimerA is

directed to the channel manager.

Its duty cycle is adjusted by software according to

the needs of the application (speed regulation for

example).

The current comparator is used for safety purpose

as a current limitation, with a limit fixed by means

of an internal resistor bridge, adjustable with an

external resistor (R

on OCP1A).

ext

3.1.2 Current Mode

In current mode, the PWM output signal is generated by a combination of the “measurement window generator” and the current comparator outputs, and is directed to the channel manager.

The “on state” of the resulting PWM starts at the

end of the “measurement window” (rising edge),

and ends either at the beginning of the next

“measurement window” (falling edge), or when the

current level in theexited coils reaches the current

reference.

This current reference is provided to the comparator by the PWM output of TimerA (0.25% resolution), filtered through a RC (integrated resistor and

external capacitor C

on OCP1A).

ext

3.2 Channel manager

The channel manager includes a channel state

register, a multiplexer with upper and lower channel differentiation, a polarity register and a tri-state

output buffer.

This detector is made of:

– a phase multiplexer for addressing thenon-excit-

ed motor winding

– an analog comparator referred to a selectable

voltage level for zero-crossing detection. This

voltage reference can be chosen between four

values, depending on the noise level and the

voltage supply of the application

– a latch to sample theBEMF zero-crossing detec-

tion.

This block is used for detecting BEMF zero-crossing and end of demagnetization events.

The BEMF detections are performed during the

“measurement window”, when free-wheeling

through the low side switches. The zero-crossing

sampling frequency is then defined by the “measurement window generator” frequency.

3.4 Delay manager

The delay manager computes in real time the delay between the BEMF zero-crossing detection

and the next step commutation.

It includes an 8 bit timer with two capture, two

compare registers and an 8x8 bit multiplier.

An auto-updated prescaler always configures the

timer in the best accuracy area.

Two BEMF zero-crossing consecutive events are

memorized by the capture registers. Starting from

those values, and using parameters preset by the

CPU, the delay manager calculates the value tobe

loaded in a compare register, which automatically

triggers the next commutation.

The second compare register is used for end of

demagnetization simulation when the event is not

detectable ([D2] on the example ofFigure 6).

12/13

Notes:

ST72141

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of suchinformation nor for anyinfringement of patents or otherrights ofthird partieswhich may result from its use. No license isgranted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in thispublication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without the express writtenapproval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2

Purchase of I

Australia - Brazil - Canada - China - France -Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use these components in an

2

C system is granted provided that the system conforms to the I2C Standard Specification asdefined by Philips.

I

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

1998 STMicroelectronics - AllRights Reserved.

STMicroelectronics Group of Companies

http://www.st.com

13/13

Loading...

Loading...