500 mA, 6 MHz synchronous step-down converter

Features

■ 85% typical efficiency

■ 500 mA output current capability

■ 45 µA typical quiescent current

■ PFM or PWM operation for best efficiency over

whole load range

■ Ultra-fast load and line transient

■ Short-circuit and thermal protection

■ Tiny external components

■ Auto or forced PWM selection with dedicated

pin

■ Available in Flip Chip 6 and DFN6 (2 x 2 mm)

packages

Applications

■ DSP and multimedia processors core supply

■ Cell phones

■ PDAs

ST1S15

Datasheet − preliminary data

Flip Chip 6

inductor and 4.7 µF for the output capacitor,

providing, at the same time, very good

performance in terms of load and line transients.

It is possible to select a PFM mode for high

efficiency under light load conditions or PWM

mode for tight regulation and best dynamic

performance. Short-circuit and thermal protection

are also included.

DFN6 (2 x 2 mm)

Description

The ST1S15 is a high efficiency miniaturized

step-down converter able to provide 500 mA

output current from an input voltage from 2.3 to

5.5. This converter is specifically designed for

applications where high efficiency and small a

application area are the key factors. With an

output voltage as low as 0.6 V the device

supports low voltage DSPs and processors core

supply. Due to the 6 MHz switching frequency the

ST1S15 can use nominal values of 470 nH for the

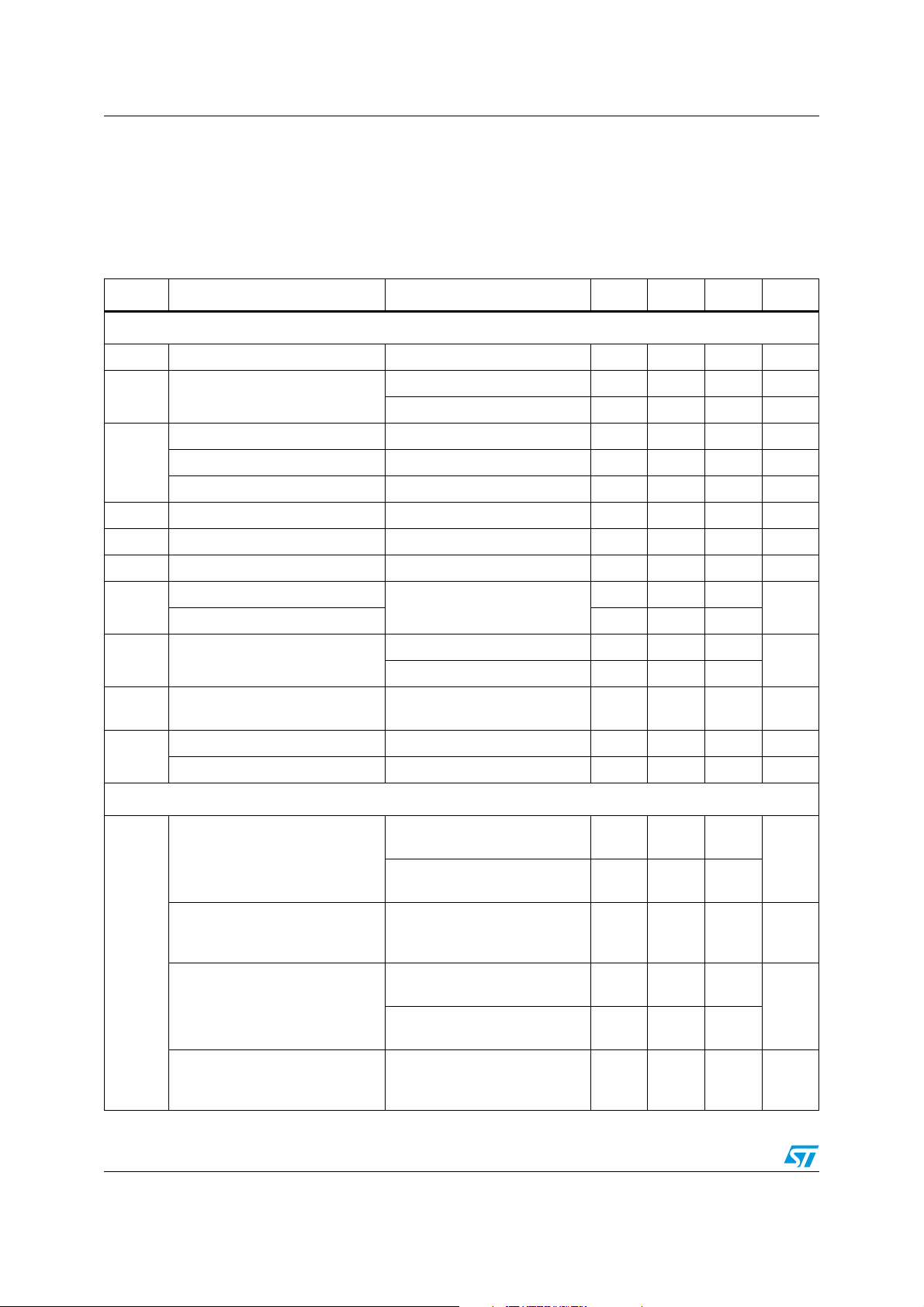

Table 1. Device summary

Order codes Output voltages (V) Packages

ST1S15J18R 1.82 Flip Chip 6

ST1S15J28R 2.8 Flip Chip 6

ST1S15TPU18R 1.82 DFN6 (2 x 2 mm)

June 2012 Doc ID 023280 Rev 1 1/27

This is preliminar y information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

27

Contents ST1S15

Contents

1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Block schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.2 Mode transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.4 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.5 Undervoltage lockout (UVLO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.6 Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.7 Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.8 Enable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 Input and output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2 Inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.3 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Different output voltage versions of the ST1S15

available on request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27 Doc ID 023280 Rev 1

ST1S15 Application schematic

1 Application schematic

Figure 1. ST1S15 application schematic

V

IN

VIN

C

IN

ST1S15

EN

MODE

SW

FB

GND

L

C

OUT

Table 2. Typical external components

Component Manufacturer Part number Value Size

Murata GRM155R60J475ME87 4.7 µF 0402

Murata

GRM155R60G475ME87

GRM155R60J475ME87

(1)

4.7 µF 0402

C

1. For V

C

IN

OUT

L Murata LQM21PNR47MC0D 470 nH 2.0 x 1.25 x 0.5 mm

≤ 1.82 V.

OUT

V

OUT

AM11904v1

Note: All the above components refer to a typical application. Operation of the ST1S15 is not

limited to the choice of these external components.

Doc ID 023280 Rev 1 3/27

Pin configuration ST1S15

2 Pin configuration

Figure 2. Pin connections (top view)

MARKING VIEW

A1 A2

B1 B2

C1 C2

BUMPS VIEW

A2 A1

B2 B1

C2 C1

AM11909v1

Table 3. Pin description

Pin name Flip Chip DFN6 Description

V

IN

EN B2 2

GND C2 3 Power and IC supply ground.

FB C1 4 Feedback input.

SW B1 5 Inductor connection to internal PFET and NFET.

MODE A1 6

A2 1 High-side switch connection and IC supply.

ENABLE pin with positive logic. The IC goes into shutdown if pulled

low. Do not leave this pin floating.

Operation mode selection:

- LOW => Automatic operation PFM or PWM according to output

load;

- HIGH => Forced PWM operation.

Do not leave this pin floating.

AM11911v1

Epad - Epad Exposed pad to be connected to ground

4/27 Doc ID 023280 Rev 1

ST1S15 Maximum ratings

3 Maximum ratings

Table 4. Absolute maximum ratings

Symbol Parameter Value Unit

V

IN

EN, MODE Logic input pins - 0.3 to + 6.0 V

FB, SW Feedback and switching pins -0.3 to V

T

AMB

T

J

T

STG

Power and signal supply voltage - 0.3 to + 6.0 V

+ 0.3 V

IN

Operating ambient temperature - 40 to 85 °C

Junction temperature - 40 to 150 °C

Storage temperature - 65 to 150 °C

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied.

Table 5. Thermal data

Symbol Parameter DFN6 Flip Chip Unit

R

thJA

Thermal resistance junction-ambient 80 130 °C/W

Table 6. ESD performance

Symbol Parameter Value Unit

ESD

Human body model ±

Machine model ± 100

2000

V

Doc ID 023280 Rev 1 5/27

Electrical characteristics ST1S15

4 Electrical characteristics

- 40 °C < TA < 85 °C, CIN = 4.7 µF nominal, C

values are at T

Table 7. Electrical characteristics

= 25 °C, V

A

= VIN unless otherwise specified.

EN

= 4.7 µF nominal, L = 470 nH, typical

OUT

Symbol Parameter Test conditions Min. Typ. Max. Unit

General section

V

V

UVLO

Operating input voltage range 2.3 5.5 V

IN

V

rising 2.1 2.2 V

Undervoltage lockout threshold

IN

V

falling 1.8 1.9

IN

PFM mode quiescent current No load 45 60 µA

I

PWM mode quiescent current No load 15 mA

Q

f

SW

I

OUT

I

SC

I

PFM-

PWM

η

t

ON

Shutdown current V

Switching frequency 5.4 6 6.6 MHz

Continuous output current

Short-circuit current

(1)

(2)

PFM to PWM transition

PWM to PFM transition 100

Efficiency (V

= 3.6 V, V

IN

OUT

=

1.82 V)

Startup time

= 0 0.5 5 µA

EN

VIN ≥ V

+ 0.40 V 500 mA

OUT

1200 mA

200

= 3.6V, V

V

IN

I

= 10 mA PFM mode 80

OUT

I

= 150 mA 83

OUT

from low to high, V

V

EN

OUT

= 1.82 V

V, V

OUT

= 1.82 V

IN

= 3.6

260 µs

Thermal shutdown 125 °C

T

SHDN

Hysteresis 30 °C

mA

%

Output voltage

V

Accuracy (ST1S15x18R)

Load regulation

OUT

Accuracy (ST1S15x28R)

Load regulation

2.3 ≤ VIN ≤ 5.5 V, I

PWM mode, -40 ≤ T

2.3 ≤ V

≤ 5.5 V, I

IN

PFM mode, -40 ≤ T

2.3 ≤ VIN ≤ 5.5 V, V

= 0 to 500 mA, PWM

I

OUT

mode, -40 ≤ T

3.2 ≤ VIN ≤ 5.5 V, I

PWM mode, -40 ≤ T

3.2 ≤ V

≤ 5.5 V, I

IN

PFM mode, -40 ≤ T

3.2 ≤ V

I

OUT

≤ 5.5 V, V

IN

= 0 to 500 mA, PWM

mode, - 40 ≤ T

OUT

OUT

≤ 85 °C

A

OUT

OUT

≤ 85 °C

A

A

A

OUT

A

A

OUT

6/27 Doc ID 023280 Rev 1

= 10 mA,

≤ 85 °C

= 10 mA,

≤ 85 °C

=1.82 V,

= 10 mA,

≤ 85 °C

= 10 mA,

≤ 85 °C

= 2.8 V,

1.78 1.82 1.86

V

1.78 1.82 1.86

-1.5 %

2.74 2.8 2.86

V

2.74 2.8 2.86

-1.5 %

ST1S15 Electrical characteristics

Table 7. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

OUT_Rip

I

LKFB

Peak-to-Peak output voltage

ripple

ple

FB pin leakage current V

Line transient response.

Output voltage variation over

V

IN_TR

nominal DC level.

t

R

Case 1: V

Case 2: V

Load transient response

t

R=tF

I

OUT_TR

Case 1: V

Case 2: V

Case 3: V

Logic Inputs

V

V

Low-level input voltage (EN,

IL

MODE pins)

High-level input voltage (EN,

IH

MODE pins)

= tF = 10 µs

IN

IN

=0.1µs.

=2.5 V

IN

=3.6 V

IN

=4.5 V

IN

= 2.5 to 3.1 V

= 3.9 to 4.5 V

PWM mode, I

= 3.6 V, V

V

IN

PFM mode, I

= 3.6 V, V

V

IN

= 5.5 V 9 µA

FB

I

= 50 mA, V

OUT

OUT

OUT

= 150 mA,

OUT

OUT

OUT

= 150 mA,

= 1.82 V

= 1.82 V

= 1.82 V

10 mV

30 mV

±50 mV

I

= 250 mA, V

OUT

= 0 to 150 mA,

I

OUT

= 1.82 V

V

OUT

= 50 to 250 mA,

I

OUT

V

= 1.82 V

OUT

= 150 to 400 mA,

I

OUT

= 1.82 V

V

OUT

OUT

= 1.82 V

±50

±70

±70

0.4 V

1.2 V

mV

I

Input leakage current (EN, MODE

LK-I

pins)

= V

V

EN

= 5.5 V 0.01 1 µA

MODE

Power Switches

P-channel MOSFET onresistance

R

DSON

N-channel MOSFET onresistance

I

LPEAK

I

LKG-P

I

LKG-N

1. Not tested in production. This value is guaranteed by correlation with R

2. Not tested in production. This parameter is guaranteed by peak current limit.

P-channel peak current limit Over input voltage range 900 1000 1200 mA

P-channel leakage current V

N-channel leakage current V

= 5.5 V, VEN= 0 1 µA

IN

= 5.5 V, VEN= 0 1 µA

SW

DSON

300 400

mΩ

350 450

, peak current limit and operating input voltage.

Doc ID 023280 Rev 1 7/27

Typical performance characteristics ST1S15

5 Typical performance characteristics

Figure 3. Efficiency vs. output current

100

90

80

70

60

50

40

30

Efficiency [%]

20

10

0

1 10 100 1000

VEN = VIN, I

(V

= 1.82 V)

OUT

= 1 mA to 500 mA

OUT

Figure 4. Efficiency vs. output current

(V

= 2.8 V)

100

90

80

Vin= 2.5V PWM Mode

Vin= 2.5V PFM Mode

Vin= 3.6V PWM Mode

Vin= 3.6V PFM Mode

Vin= 4.5V PWM Mode

Vin= 4.5V PFM Mode

Vin= 5.5V PWM Mode

Vin= 5.5V PFM Mode

I

[mA]

OUT

70

60

50

40

30

Efficiency [%]

20

10

0

1 10 100 1000

VEN = VIN, I

OUT

= 1 mA to 500 mA

OUT

Vin= 3.2V PWM Mode

Vin= 3.2V PFM Mode

Vin= 3.6V PWM Mode

Vin= 3.6V PFM Mode

Vin= 4.2V PWM Mode

Vin= 4.2V PFM Mode

Vin= 5.0V PWM Mode

Vin= 5.0V PFM Mode

I

[mA]

OUT

Figure 5. Output voltage vs. input voltage Figure 6. Supply current vs. input voltage in

2.00

1.80

1.60

1.40

1.20

1.00

0.80

0.60

0.40

Output Voltage [V]

0.20

0.00

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

T=85°C

T=55°C

T=25°C

T=0°C

T= -25°C

T= -40°C

Input Voltage [V]

65

60

55

50

ISupply [µA]

45

40

35

2 2.5 3 3.5 4 4.5 5 5.5 6

auto mode

T= 85°C

T= 25°C

T= 0°C

T= -40° C

Input Voltage [V]

VIN = 0 to 5.5 V (step 0.1 V), I

= V

V

EN

IN

= 500 mA, Mode = GND,

OUT

Figure 7. Supply current vs. input voltage in

100

10

ISupply [mA]

1

2 2.5 3 3.5 4 4.5 5 5.5 6

VIN = 2.3 V to 5.5 V, Mode = VIN, V

PWM mode

Input Voltage [V]

= 1.82 V, VEN = V

OUT

T= 85°C

T= 25°C

T= 0°C

T= -40 °C

VIN = 2.5 V to 5.5 V, Mode = GND, V

Figure 8. Output voltage vs. output current

1.85

1.84

1.83

1.82

1.81

Output Voltage [V]

1.8

1.79

0 50 100 150 200 250 300 350 400 450 500 550

VEN = VIN, Mode = VIN, V

IN

8/27 Doc ID 023280 Rev 1

Output Current [mA ]

= 1.82 V

OUT

= 1.82 V, VEN = V

OUT

IN

Vin = 2.5 V

Vin = 3.6 V

Vin = 4.5 V

ST1S15 Typical performance characteristics

Figure 9. Frequency vs. input voltage Figure 10. Output voltage vs. output current

7.5

7

6.5

T= 85°C

T= 25°C

T= 0°C

T= - 40°C

6

5.5

Frequency [MHz]

5

4.5

22.5 33.5 44.5 55.5 6

Inp ut Voltage [V]

VIN = 2.3 V to 5.5 V, I

Figure 11. Mode transition vs. input voltage Figure 12. Mode transition PFM to PWM

250

200

150

100

Output Current [ mA ]

50

0

2 2.5 3 3.5 4 4.5 5 5.5 6

= 10 mA, Mode = V

OUT

IN, VEN

= V

PFM t o PWM

PWM to PFM

IN

1.89

1.87

1.85

1.83

1.81

1.79

Output Voltage [V]

1.77

1.75

0 50 100 150 200 250 300 350 400 450 500 550

Output Cur rent [ mA ]

VIN = 3.6 V, I

= 0 to 500 mA, Mode = GND, VEN = V

OUT

Mode

V

IN

V

OUT

I

L

Inpu t Voltage [V]

T= 85°C

T= 25°C

T= 0°C

T= - 40°C

IN

VIN = Enable, V

Figure 13. Mode transition PWM to PFM Figure 14. Output voltage ripple

= 1.82 V, Mode = GND

OUT

VIN = 3.6 V, V

= 1.82 V, Mode = 0 to 3.6 V, Load = 180 Ω

OUT

Mode

V

IN

V

OUT

I

L

VIN = 3.6 V, V

= 1.82 V, Mode = 3.6 to 0 V, Load = 180 Ω

OUT

VIN = 3.6 V, V

load

= 1.82 V, Mode = GND, VEN = V

OUT

Doc ID 023280 Rev 1 9/27

IN,

No

Typical performance characteristics ST1S15

Figure 15. Output voltage ripple Figure 16. Line transient

V

OUT

I

OUT

VIN = 3.6 V, V

Figure 17. Load transient I

,

V

OUT

I

OUT

VIN = 3.6 V, tr = 100 ns, I

Mode = GND

Figure 19. Enable startup Figure 20. VIN startup

= 1.82 V, I

OUT

= 500 mA, VEN = V

OUT

= 50 to 250 mA Figure 18. Load transient I

OUT

= 50 mA to 250 mA, VEN = V

OUT

IN

VIN = 3.9 to 4.5 V, tr = tf = 10 µs, I

V

OUT

I

OUT

VIN = 3.6 V, tf = 100 ns, I

IN,

Mode = GND

= 250 mA to 50 mA, VEN = V

OUT

EN

I

OUT

V

IN

= 50 mA, VEN = V

OUT

= 250 to 50 mA

OUT

IN

IN,

V

OUT

I

L

VIN = 3.6 V, Enable = 0 to 3.6 V, Mode = VIN, V

Load = 3.6 Ω

= 1.82 V,

OUT

V

IN

V

OUT

VIN = 0 to 2.5 V, Enable = VIN, Mode = GND, V

Load = 3.3 Ω

10/27 Doc ID 023280 Rev 1

= 1.82 V,

OUT

ST1S15 Block schematic

6 Block schematic

Figure 21. Block schematic

V-I Refer ence

EN

MODE

Enable & Soft Start

&

Prereg + UVLO

Cur rent Li mi t & Shor t Protec t.

V

IN

GND

PFM - Analog timing

Oscill.

&

Sawtooth

Swi tch Cont rol Log ic

PWM Comparator

PFM - PW M

Driver

&

Anti X- Cond

Ther mal Protec t.

Err or Amp & Comp.

Vref_PW M

SW

Vref_PF M

FB

R1

R2

AM11905v1

Doc ID 023280 Rev 1 11/27

Detailed description ST1S15

7 Detailed description

7.1 General description

The ST1S15 is a fixed voltage mode PWM step-down DC-DC converter which operates with

typically 6 MHz fixed frequency pulse width modulation (PWM) at moderate to heavy load

currents. At light load currents the converter can automatically enter PFM (pulse frequency

mode) mode.

To make the device work, few components are required: an inductor and two capacitors. It

has been designed to work properly with X5R or X7R SMD ceramic capacitors both at the

input and at the output. These kinds of capacitors, thanks to their very low series resistance

(ESR), minimize the output voltage ripple. In addition, the chosen inductor must be able to

not saturate at the peak current level.

7.2 Mode transition

The ST1S15 can work in PWM mode or in PFM mode according to the different operating

conditions. If the MODE pin is pulled high, the device works only in PWM mode even at light

or no load. If the MODE pin is low, the operation changes according to the average input

current handled by the device. At low output current the device works in PFM mode in order

to obtain very low power consumption and very good efficiency. When the output current

increases, the device automatically switches to PWM mode in order to deliver the power

needed by the load.

The ST1S15 passes from PFM to PWM when 3 consecutive PFM pulses occur. This means

that the PFM has reached its maximum current capability and the device needs to go into

PWM mode. The whole PWM circuitry starts after a transition time. During this time the

duration of the PFM pulses are increased to about 350 ns so as to provide higher current

capability. After startup of the PWM circuitry, the ST1S15 switches to PWM operation.

Figure 22. PFM to PWM transition

I

L

MODE

LOAD

I

PWM

PFM

500 mA

Consecutive 3 PFM pulses

t

Transition

Time

t

High Load

Light Load

AM11906v1

12/27 Doc ID 023280 Rev 1

t

ST1S15 Detailed description

The transition from PWM to PFM mode occurs when the load current decreases and the coil

current becomes negative. After the zero-crossing output goes up for 127 consecutive times

the device switches to PFM mode.

Figure 23. PWM to PFM transition

I

L

127 Zero-C rossing output pulses

t

PWM

MODE

PFM

t

LOAD

500 mA

I

High Load

AM11907v1

7.3 Soft-start

The internal soft-start is enabled after VIN reaches the UVLO threshold and the EN pin is

high or for startup after enable. An overtemperature shutdown event or over short-circuit

event also activates the soft-start sequence.

It eliminates the in-rush current problem during the startup phase. During the soft-start the

device works always in PWM regardless of the status of the Mode pin.

7.4 Short-circuit protection

The short-circuit protection begins when there is a short between the device output and

ground. In this case the output voltage value is lower than the voltage reference and the

overcurrent protection comparator output is high. When this happens the power stage (Pch

and Nch) turns off and a soft-start phase starts. The device repeats the soft-start sequence

during the short-circuit condition.

7.5 Undervoltage lockout (UVLO)

Light Load

t

The UVLO circuit prevents the device from malfunctioning when the input voltage is not high

enough. The device is in shutdown mode, when the input voltage is below the UVLO

threshold. The hysteresis of 200 mV prevents unstable operation when the input voltage is

close to the UVLO threshold.

Doc ID 023280 Rev 1 13/27

Detailed description ST1S15

7.6 Thermal protection

The device also has thermal shutdown protection, which is active when the junction

temperature reaches 125 °C. In this case both the high and low-side MOSFETs are turned

off.

Once the junction temperature goes back below 95 °C, the device resumes normal

operation.

7.7 Overcurrent protection

The overcurrent protection is used to limit the maximum inductor current. This current

flowing through the Pch of the power stage causes a voltage drop, across its RDSON, at the

switching node. A comparator compares the switching node voltage with a reference voltage

VR. To generate the VR voltage a current generator is used, which causes a drop across a

Pch of the same kind as the power stage. When the switching node voltage is lower than

VR, the comparator output goes high and the power Pch turns off.

7.8 Enable function

The ST1S15 features an enable function (pin 2 or B2). When the EN voltage is higher than

1.2 V the device is ON, and if it is lower than 0.4 V the device is OFF. In shutdown mode the

consumption is lower than 5 µA.

The EN pin does not have an internal pull-up, which means that the EN pin cannot be left

floating.

If the enable function is not used, the EN pin must be connected to V

IN

.

14/27 Doc ID 023280 Rev 1

ST1S15 Application Information

8 Application Information

8.1 Input and output capacitor

It is recommended to use ceramic capacitors with X5R or X7R dielectric and low ESR. The

input capacitor is used to filter any disturbance present in the input line and to obtain stable

operation. The output capacitor is very important to satisfy the output voltage ripple

requirement.

The output voltage ripple (V

Equation 1

where ΔI

is the ripple current and fSW is the switching frequency.

L

The use of ceramic capacitors with voltage ratings in the range higher than 1.5 times the

maximum input or output voltage is recommended.

8.2 Inductor

The inductor is the key passive component for switching converters. The internal

compensation is optimized to operate with an output filter of L = 0.47 µH and C

In addition to the inductance value, in order to avoid saturation, the maximum saturation

current of the inductor must be higher than that of the I

The peak current of the inductor must be calculated as:

Equation 2

OUT_RIPPLE

), in continuous mode, must be calculated:

⎡

+×Δ=

ESRIV

⎢

LRIP PLE_OUT

⎣

1

××

fC8

SWOUT

PEAK

⎤

×

ESLV

IN

+

⎥

L

⎦

.

= 4.7 µF.

OUT

)VV(V

II

+=

OU TPEAK

−×

OUTMAX_INOUT

LfV2

×××

SWMAX_IN

The following inductor p/ns from different suppliers have been tested in the ST1S15

converters.

Table 8. Inductors

Manufacturers p/ns Dimensions (in mm)

LQM21PNR47MC0D 2.0 x 1.25 x 0.5

Murata

TDK

Doc ID 023280 Rev 1 15/27

LQM21PNR54MG0D 2.0 x 1.25 x 0.5

LQH32PNR47NN0L 3.2 x 2.7 x 1.55

MLP2012SR47T 2.0 x 1.25 x 0.5

VLS2010ET-1R0N 2.0 x 2.0 x 1.0

Application Information ST1S15

8.3 Layout guidelines

Due to the high switching frequency and peak current, the layout is an important design step

for all switching power supplies. If the layout is not done carefully, important parameters

such as stability, efficiency, line and load regulation and output voltage ripple may be

compromised.

Short, wide traces must be implemented for main current and for power ground paths. The

input capacitor must be placed as close as possible to the device pin as well as the inductor

and output capacitor.

The FEEDBACK pin (FB) is a high impedance node, so the interference can be minimized

by placing the routing of the feedback node as far as possible from the high current paths.

A common ground node minimizes ground noise.

The exposed pad of the DFN package must be connected to the common ground node.

Figure 24. DFN layout recommended (not to scale)

V

OUT

C

OUT

GND

L

EN

AM11908v1

C

MODE

IN

V

IN

Figure 25. Flip-Chip layout recommended (not to scale)

V

OUT

C

OUT

L

AM11910v1

EN

GND

C

IN

V

IN

MODE

EN

16/27 Doc ID 023280 Rev 1

ST1S15 Package mechanical data

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at:

packages, depending on their level of environmental compliance. ECOPACK

www.st.com

. ECOPACK

is an ST trademark.

Table 9. DFN6 (2 x 2 mm) mechanical data

(mm)

Dim.

Min. Typ. Max.

A 0.51 0.55 0.60

A1 0 0.02 0.05

b 0.18 0.25 0.30

D2.00

D2 1.30 1.45 1.55

E2.00

E2 0.85 1.00 1.10

e0.50

L 0.15 0.25 0.35

Doc ID 023280 Rev 1 17/27

Package mechanical data ST1S15

Figure 26. DFN6 (2 x 2 mm) package dimensions

18/27 Doc ID 023280 Rev 1

8128232_B

ST1S15 Package mechanical data

Figure 27. DFN6 footprint recommended data (dimensions in mm)

8128232_B

Doc ID 023280 Rev 1 19/27

Package mechanical data ST1S15

Table 10. Flip Chip 6 mechanical data

(mm)

Dim.

Min. Typ. Max.

A 0.52 0.56 0.6

A1 0.17 0.20 0.23

A2 0.35 0.36 0.37

b 0.23 0.25 0.29

D 0.905 0.935 0.965

D1 0.4

e0.4

E 1.16 1.19 1.22

E1 0.8

f

D

f

E

ccc 0.075

0.272

0.200

20/27 Doc ID 023280 Rev 1

ST1S15 Package mechanical data

Figure 28. Flip Chip 6 package dimensions

7504896_R

Doc ID 023280 Rev 1 21/27

Package mechanical data ST1S15

Figure 29. Flip Chip 6 footprint recommended data (dimensions in mm)

7504896_R

22/27 Doc ID 023280 Rev 1

ST1S15 Package mechanical data

Tape & reel QFNxx/DFNxx (2x2 mm) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A1807.087

C12.8 13.2 0.504 0.519

D 20.2 0.795

N60 2.362

T14.40.567

Ao 2.1 2.2 2.3 0.083 0.0870.091

Bo 2.1 2.2 2.3 0.083 0.0870.091

Ko 0.65 0.75 0.85 0.026 0.0300.033

Po 4 0.157

P4 0.157

Doc ID 023280 Rev 1 23/27

Package mechanical data ST1S15

Tape & reel Flip-Chip 6 mechanical data

mm.

Dim.

Min. Typ. Max.

A 180

C12.8 13.2

D20.2

N60

T 14.4

Ao 1.01 1.06 1.11

Bo 1.26 1.311.36

Ko 0.61 0.66 0.71

Po 3.9 4.1

P 3.9 4.1

24/27 Doc ID 023280 Rev 1

ST1S15 Different output voltage versions of the ST1S15 available on request

10 Different output voltage versions of the ST1S15

available on request

Table 11. Options available on request

Order codes Output voltages (V)

ST1S15x08R 0.8

ST1S15x10R 1

ST1S15x11R 1.05

ST1S15x12R 1.2

ST1S15x13R 1.25

ST1S15x15R 1.5

ST1S15x17R 1.8

ST1S15x19R 1.85

ST1S15x20R 1.875

ST1S15x25R 2.5

ST1S15x30R 3

ST1S15x33R 3.3

Doc ID 023280 Rev 1 25/27

Revision history ST1S15

11 Revision history

Table 12. Document revision history

Date Revision Changes

07-Jun-2012 1 First release.

26/27 Doc ID 023280 Rev 1

ST1S15

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 023280 Rev 1 27/27

Loading...

Loading...