1/186

ST10F280

March 2003

■ HIGH PERFORMANCE CPU WITH DSP FUNCTIONS

- 16-BIT CPU WITH 4-STAGE PIPELINE.

- 50ns INSTRUCTION CYCLE TIME AT 40MHz CPU

CLOCK.

- MUL TIPLY/ACCUMULATE U NIT (MAC) 16 X 16-BIT

MULTIPLICATION, 40-BIT ACCUMULATOR

- REPEAT U NI T.

- ENHANCED BOOLEAN BIT MANIPULATION FACILITIES.

- ADDITIO NA L INSTRUC T ION S TO SUPPORT HLL

AND OPERATING SYSTEMS.

- SINGLE-CYCLE CONTEXT SWITCHING SUPPORT.

■ MEMORY ORGANIZATION

- 512K BYT E ON-CHIP FL AS H MEMORY SI NG LE

VOLTAG E WITH ER AS E/ PR O GRAM CONTR O L LER.

- 100K ERASING/PROGRAMMING CYCLES.

- 20 YEAR DAT A RETENTIO N TIME

- UP TO 16M BYTE LINEAR ADDRESS SPACE FOR

CODE AND DATA (5M BYTE WITH CAN).

- 2K BYTE ON -CH IP INT ER NAL RA M (IRA M).

- 16K BYTE EXT EN SI O N RAM (XRA M ).

■ FAST AND FLEXIBLE BUS

- PROGRAMMABLE EXTERNAL BUS CHARACTERISTICS FOR DIFFERENT ADDRESS RANGES.

- 8-BIT OR 16-BIT EXTERNAL DATA BUS.

- MULTIPLEXED OR DEMULTIPLEXED EXTERNAL

ADDRESS/DATA BUSES.

- FIVE PROGRAMMABLE CHIP-SELECT SIGNALS.

- HOLD-ACKNOWLEDGE BUS ARBITRATION SUPPORT.

■ INTERRUPT

- 8-CHANNEL PERIPHERAL EVENT CONTROLLER

FOR SINGLE CYCLE, INTERRUPT DRIVEN DATA

TRANSFER.

- 16-PRIORITY-LEVEL INTERRUPT SYSTEM WITH 56

SOURCES, SAMPLE-RATE DOWN TO 25ns.

■ TWO MULTI-FUNCTIONAL GENERAL PURPOSE

TIMER UNITS WITH 5 TIMERS.

■ TWO 16-CHANNEL CAPTURE/COMPARE UNITS

■ A/D CONVERTER

- 2X16-CHANNEL 10-BIT.

- 4.85µS CONVERSION TIME

- ONE TIMER FOR ADC CHANNEL INJEC TI ON

■ 8-CHANNEL PWM UNIT

■ SERIAL CHANNELS

- SYNCHRONOUS/ASYNC SERIAL CHANNEL

- HIGH-SPEED SYNCHRONOUS CHANNEL.

■ FAIL-SAFE PROTECTIO N

- PROGRAMMABLE WATCHDOG TIMER.

- OSCILLATOR WATCHDOG.

■ TWO CAN 2.0b INTERFACES OPERATING ON ONE

OR TWO CAN BUSSES (30 OR 2X15 MESSAGE

OBJECTS)

■ ON-CHIP BOOTSTRAP LOADER

■ CLOCK GENERA TION

- ON-CHIP PL L .

- DIRECT OR PRESCALED CLOCK INPUT.

■ UP TO 143 GENERAL PUR PO SE I/O LINES

- INDIVIDUALLY PROGRAMMABLE AS INPUT, OUTPUT OR SPECIAL FUNCTION.

- PROGRAMMABLE THRESHOLD (HYSTERESIS).

■ IDLE AND POWE R DOWN M OD ES

■ MAXIMUM CP U FR EQUE NC Y 40 MH z

■ PACKAGE PBGA 208 BALLS (23mm x 23mm x

1.96 mm - PITCH 1.27mm).

■ SINGLE VOLTAGE SUPPLY: 5V ±10% (EMBEDDED

REGULATOR FOR 3.3 V CORE SUPPLY).

■ TEMPERATURE RANGE: -40 +125

°

C

PBGA208 (23 x 23 x 1.96 - Pitch 1.27 mm)

(Plastic Bold Grid Array)

ORDER CO DE: ST10F280-JT3

P4.7 CA N2_TxD

P4.6 CA N1_TxD

P4.5 CA N1_R x D

P4.4 CA N2_R x D

Port 0Port 1Port 4

Port 6

Port 5

Port 3

Port 2

GPT1

GPT2

ASC usart

BRG

CPU-Core and MAC Unit

Internal

RAM

Watchdog

Interrupt Controller

8

32 16

PEC

16

16

CAN1

Port 7 Port 8

External Bus

10-Bit ADC

BRG

SSC

PWM

CAPCOM2

CAPCOM1

16

Oscillator

Controller

16

16

512K Byte

and PLL

Flash Memory

XTAL1 XTAL2

2K Byte

15

8

8

8

16

3.3V Voltage

Regulator

16K Byte

XRAM

CAN2

XPORT916XPWM4XTIMER

P7.7 T rigge r fo r A D C

16

XPORT10

16

16

cha nnel injection

XADCINJ

External connexion

16-BIT MCU WITH MAC UNIT, 512K BYTE FLASH MEMORY AND 18K BY TE RAM

PRODUCT PREVIEW

This is advance information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

ST10F280

2/186

TABLE OF CONTENTS

1 - INTRODUCTION ........... ................. ................ ........................ ................. ................... 6

2 - BALL DATA .. ................ ................. ....................... ................. ........................ ............ 7

3 - FUNCTIONAL DESCRIPTION ................ ................. ................ .......... ................ ........ 17

4 - MEMORY ORGANIZATION ....................................................................................... 18

5 - INTERNAL FLASH MEMORY ................ ................. ......... ................. ................ ........ 21

5.1 - OVERVIEW ................................................................................................................ 21

5.2 - OPERATIONAL OVERVIEW ...................................................................................... 21

5.3 - ARCHITECTURAL DESCRIPTION ............................................................................ 23

5.3.1 - Read Mode ................................................................................................................. 23

5.3.2 - Command Mode ......................................................................................................... 23

5.3.3 - Flash Status Register ................................................................................................. 23

5.3.4 - Flash Protection Register ........................................................................................... 25

5.3.5 - Instructions Description .............................................................................................. 25

5.3.6 - Reset Processing and Initial State .............................................................................. 29

5.4 - FLASH MEMORY CONFIGURATION ........................................................................ 29

5.5 - APPLICATION EXAMPLES ....................................................................................... 29

5.5.1 - Handling of Flash Addresses . ..................................................................................... 29

5.5.2 - Basic Flash Access Control ........................................................................................ 30

5.5.3 - Programming Examples ............................................................................................. 31

5.6 - BOOTSTRAP LOADER ............................................................................................ 34

5.6.1 - Entering the Bootstrap Loader .................................................................................... 34

5.6.2 - Memory Configuration After Reset ............................................................................. 35

5.6.3 - Loading the Startup Code ........................................................................................... 36

5.6.4 - Exiting Bootstrap Loader Mode .................................................................................. 36

5.6.5 - Choosing the Baud Rate for the BSL ......................................................................... 37

6 - CENTRAL PROCESSING UNIT (CPU) ..................................................................... 38

6.1 - MULTIPLIER-ACCUMULATOR UNIT (MAC) ............................................................. 39

6.1.1 - Features ..................................................................................................................... 40

6.1.1.1 - Enhanced Addressing Capab ilit ies.............................................................................. 40

6.1.1.2 - Multiply-Accumulate Unit............................................................................................. 40

6.1.1.3 - Program Control. ........................ ................. ....................... ................. ........................ 40

6.2 - INSTRUCTION SET SUMMARY ................................................................................ 41

6.3 - MAC COPROCESSOR SPECIFIC INSTRUCTIONS ................................................. 42

7 - EXTERNAL BUS CONTROLLER ............................ ......... ................. ................ ........ 46

7.1 - PROGRAMMABLE CHIP SELECT TIMING CONTROL ............................................ 46

7.2 - READY PROGRAMMABLE POLARITY ..................................................................... 47

8 - INTERRUPT SYSTEM ..... ................ ........................ ................ ........................ .......... 49

8.1 - EXTERNAL INTERRUPTS ......................................................................................... 49

ST10F280

3/186

8.2 - INTERRUPT REGISTERS AND VECTORS LOCATION LIST .................................. 50

8.3 - INTERRUPT CONTROL REGISTERS ....................................................................... 52

8.4 - EXCEPTION AND ERROR TRAPS LIST ................................................................... 53

9 - CAPTURE/COMPARE (CAPCOM) UNITS ................................................................ 54

10 - GENERAL PURPOSE TIMER UNIT .......................................................................... 57

10.1 - GPT1 .......................................................................................................................... 57

10.2 - GPT2 .......................................................................................................................... 58

11 - PWM MODULE .................. ........................ ................ ........................ ................ ........ 60

11.1 - STANDARD PWM MODULE ...................................................................................... 60

11.2 - NEW PWM MODULE : XPWM ................................................................................... 61

11.2.1 - Operating Modes ........................................................................................................62

11.2.1.1 - Mode 0: Standard PWM Generation (Edge Aligned PW M)......................................... 62

11.2.1.2 - Mode 1: Symmetrical PWM Generation (Ce nter Aligned PW M) ................................. 63

11.2.1.3 - Burst Mode ................................................................................................................ 64

11.2.1.4 - Single Shot Mode .... ........................ ................. ....................... ................. ................. 65

11.2.2 - XPWM Module Registers ........................................................................................... 66

11.2.3 - Interrupt Request Generation ..................................................................................... 68

11.2.4 - XPWM Output Signals ................................................................................................ 68

11.2.5 - XPOLAR Register (polarity of the XPWM channel) .................................................... 69

12 - PARALLEL PORTS ........... ................ ........................ ................. ....................... ........ 70

12.1 - INTRODUCTION ........................................................................................................ 72

12.1.1 - Open Drain Mode ....................................................................................................... 72

12.1.2 - Input Threshold Control ............................................................................................ 73

12.1.3 - Output Driver Control ................................................................................................73

12.1.4 - Alternate Port Functions ............................................................................................. 75

12.2 - PORT0 ........................................................................................................................ 76

12.2.1 - Alternate Functions of PORT0 .................................................................................... 77

12.3 - PORT1 ........................................................................................................................ 79

12.3.1 - Alternate Functions of PORT1 .................................................................................... 79

12.4 - PORT 2 ....................................................................................................................... 80

12.4.1 - Alternate Functions of Port 2 ..................................................................................... 81

12.5 - PORT 3 ....................................................................................................................... 84

12.5.1 - Alternate Functions of Port 3 ...................................................................................... 85

12.6 - PORT 4 ....................................................................................................................... 87

12.6.1 - Alternate Functions of Port 4 ...................................................................................... 88

12.7 - PORT 5 ....................................................................................................................... 92

12.7.1 - Port 5 Schmitt Trigger Analog Inputs .......................................................................... 93

12.8 - PORT 6 ....................................................................................................................... 93

12.8.1 - Alternate Functions of Port 6 ...................................................................................... 94

12.9 - PORT 7 ....................................................................................................................... 95

12.9.1 - Alternate Functions of Port 7 ...................................................................................... 96

ST10F280

4/186

12.10 - PORT 8 .......... ................ ................. ....................... ................. ........................ ............ 99

12.10.1 - Alternate Functions of Port 8 ...................................................................................... 99

12.11 - XPORT 9 .................................................................................................................... 101

12.12 - XPORT 10 .................................................................................................................. 103

12.12.1 - Alternate Functions of XPort 10 .................................................................................. 103

12.12.2 - New Disturb Protection on Analog Inputs ................................. ....... ..... ....... ....... ..... ... 104

13 - A/D CONVERTER ................... ....................... ................. ........................ ................ ... 105

13.1 - A/D CONVERTER MODULE ...................................................................................... 105

13.2 - MULTIPLEXAGE OF TWO BLOCKS OF 16 ANALOG INPUTS ................................ 106

13.3 - XTIMER PERIPHERAL (TRIGGER FOR ADC CHANNEL INJECTION) ................... 107

13.3.1 - Main Features ............................................................................................................. 107

13.3.2 - Register Description ...................................................................................................108

13.3.2.1 - TCR : Timer Control Register...................................................................................... 108

13.3.2.2 - XTSVR :Timer Start Value Register............................................................................ 109

13.3.2.3 - XTEVR : Timer End Value Regist e r.............. ........................ ................ ...................... 109

13.3.2.4 - XTCVR : Timer Current Value Register....................................................................... 109

13.3.2.5 - Registers Mapping....................................................................................................... 109

13.3.3 - Block Diagram ........................................................................................................... 110

13.3.3.1 - C l o cks........ ................ ........................ ................. ....................... ................. ....... .......... 110

13.3.3.2 - R e g i ste r s........ ....................... ................. ........................ ................ ............................. 110

13.3.3.3 - Timer output (XADCINJ).............................................................................................. 111

14 - SERIAL CHANNELS .............. ................ ........................ ........................ ................ ... 112

14.1 - ASYNCHRONOUS / SYNCHRONOUS SERIAL INTERFACE (ASCO) .................... 112

14.1.1 - ASCO in Asynchronous Mode .................................................................................... 112

14.1.2 - ASCO in Synchronous Mode ...................................................................................... 114

14.2 - HIGH SPEED SYNCHRONOUS SERIAL CHANNEL (SSC) .......... .......... ................. 116

15 - CAN MODULES ... ................ ........................ ................. ................ ........................ ..... 118

15.1 - MEMORY MAPPING .................................................................................................. 1 18

15.1.1 - CAN1 .......................................................................................................................... 118

15.1.2 - CAN2 .......................................................................................................................... 118

15.2 - CAN BUS CONFIGURATIONS .................................................................................. 118

15.3 - REGISTER AND MESSAGE OBJECT ORGANIZ AT IO N ........................... ............... 119

15.4 - CAN INTERRUPT HANDLING ................................................................................. 121

15.5 - THE MESSAGE OBJECT .......................................................................................... 124

15.6 - ARBITRATION REGISTERS ...................................................................................... 126

16 - WATCHDOG TIMER ............................. ................ ................. ........................ ............ 127

17 - SYSTEM RESET ........................................................................................................ 129

17.1 - ASYNCHRONOUS RESET (LONG HARDWARE RESET) ....................................... 129

17.2 - SYNCHRONOUS RESET (WARM RESET) .............................................................. 130

ST10F280

5/186

17.3 - SOFTWARE RESET .................................................................................................. 131

17.4 - WATCHDOG TIMER RESET ..................................................................................... 131

17.5 - RSTOUT PIN AND BIDIRECTIONAL RESET ............................................................ 131

17.6 - RESET CIRCUITRY ................................................................................................... 132

18 - POWER REDUCTION MODES ................................................................................. 135

18.1 - IDLE MODE ................................................................................................................135

18.2 - POWER DOWN MODE .............................................................................................. 135

18.2.1 - Protected Power Down Mode ..................................................................................... 136

18.2.2 - In terruptable Power Down Mode ................................................................................ 136

19 - SPECIAL FUNCTION REGISTER OVERVIEW ......................................................... 139

19.1 - IDENTIFICATION REGISTERS ................................................................................. 148

19.2 - SYSTEM CONFIGURATION REGISTERS ................................................................ 149

20 - ELECTRICAL CHARACTERISTICS ............. ................. ................ .......... ................. 155

20.1 - ABSOLUTE MAXIMUM RATINGS ............................................................................. 155

20.2 - PARAMETER INTERPRETATION ............................................................................. 155

20.3 - DC CHARACTERISTICS ........................................................................................... 155

20.3.1 - A/D Converter Characteristics .................................................................................... 158

20.3.2 - Conversion Timing Control ....................................................................................... 159

20.4 - AC CHARACTERISTICS ............................................................................................ 160

20.4.1 - Test Waveforms .......................................................................................................160

20.4.2 - Definition of Internal Timing ........................................................................................ 160

20.4.3 - Clock Generation Modes ............................................................................................ 1 61

20.4.4 - Prescaler Operation ....................................................................................................162

20.4.5 - Direct Drive ................................................................................................................. 162

20.4.6 - Osc illator Watchdog (OW D ) ....................................................................................... 162

20.4.7 - Phase Locked Loop .................................................................................................... 162

20.4.8 - External Clock Drive XTAL1 ....................................................................................... 163

20.4.9 - Memory Cycle Variables ............................................................................................. 164

20.4.10 - Multiplexed Bus .......................................................................................................... 165

20.4.11 - Demultiplexed Bus ...................................................................................................... 171

20.4.12 - CLKOUT and READY ................................................................................................. 177

20.4.13 - External Bus Arbitration ..............................................................................................179

20.4.14 - High-Speed Synchronous Serial Interface (SSC) Timing ........................................... 181

20.4.14.1 Master Mode................................................................................................................ 181

20.4.14.2 Slave mode.................................................................................................................. 182

21 - PACKAGE MECHANICAL DATA ...................... .......... ................ .......... ................. 183

22 - ORDERING INFORMATION ...................................................................................... 1 84

ST10F280

6/186

1 - INTRODUCTION

The ST10F280 is a new derivative of the ST

Microelectronics ST10 family of 16-bit single-chi p

CMOS microcontrollers. It combines high CPU

performance (up to 20 million instructions per

second) with high peripheral functionality and

enhanced I/O-capabilities. It also provides on-chip

high-speed single voltage FLASH memory,

on-chip high-speed RAM, and clock generation

via PLL.

ST10F280 is processed in 0.35µm CMOS

technology. The MCU core and the logic is

supplied with a 5V to 3.3V on chip voltage

regulator. The part is supplied with a single 5V

supply and I/Os work at 5V .

The device is upward compatible with the

ST10F269 device, with the following set of

differences:

– Two supply pins (DC1,DC2) on the PBGA-208

package are used for decoupling the internally

generated 3.3V core logic supply. Do not connect these two pins to 5. 0V external suppl y. Instead, these pins should be connected to a

decoupling capacitor (ceramic type, value

≥ 330nF).

– The A/D Converter characteristics stay identical

but 16 new input channel are added. A bit in a

new register (XADCMUX) control the multiplexage between the first b lock of 16 channel (on

Port5) and the second block (on XPort10). The

conversion result registers stay identical and the

software management can determine the block

in use. A new dedicated timer controls now the

ADC channel injection mode on the inp ut CC 31

(P7.7). The output of this timer is visible on a

dedicated pin (XADCINJ) to emulate this new

functionnality.

– A second XPWM peripheral (4 new channels) is

added. Four dedicated pins are reserved for the

outputs (XPWM[0:3])

– A new general purpose I/O port named XPORT9

(16 bits) is added. Due to the bit addressing

management, it will be different from other

standard general purpose I/O ports.

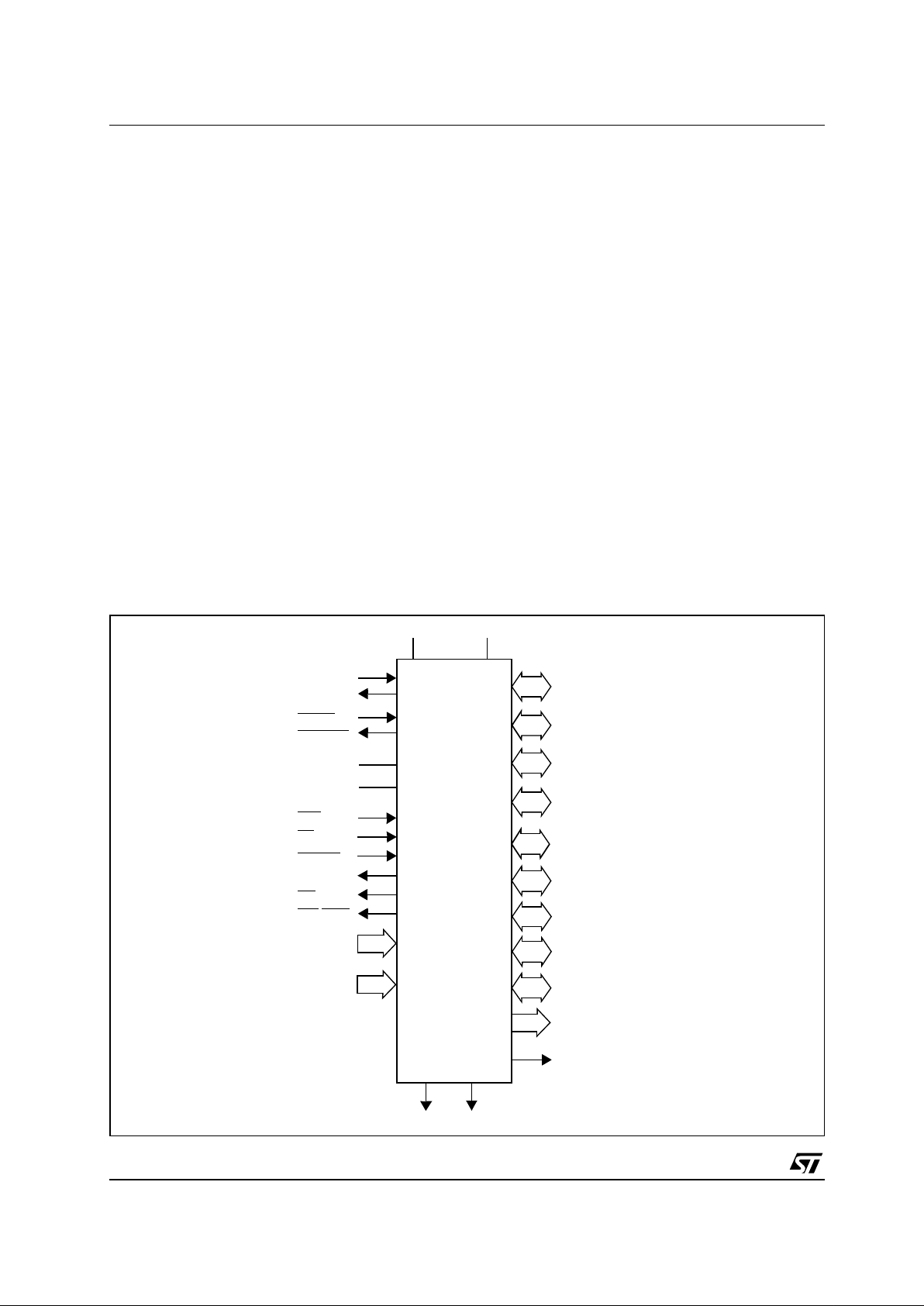

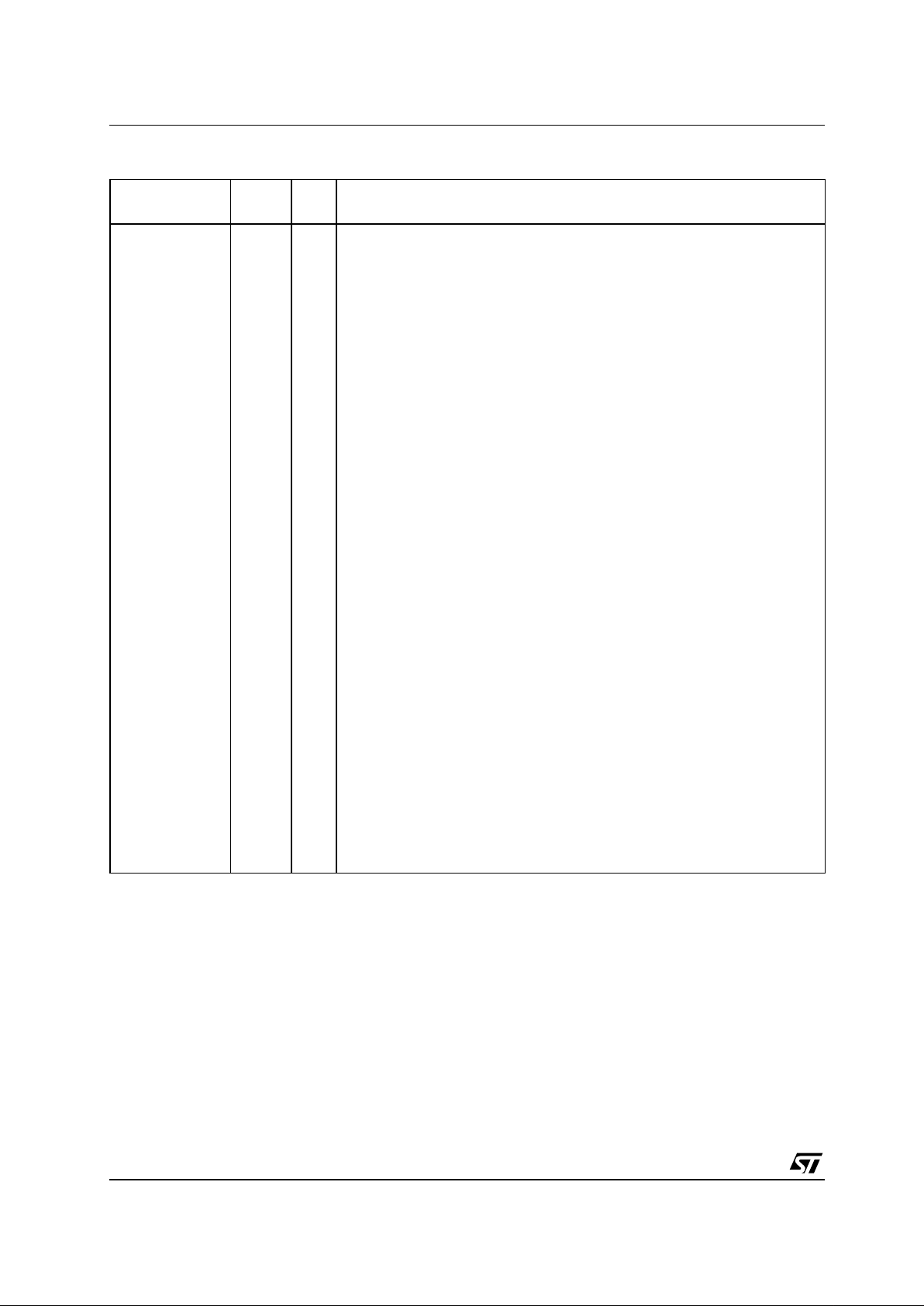

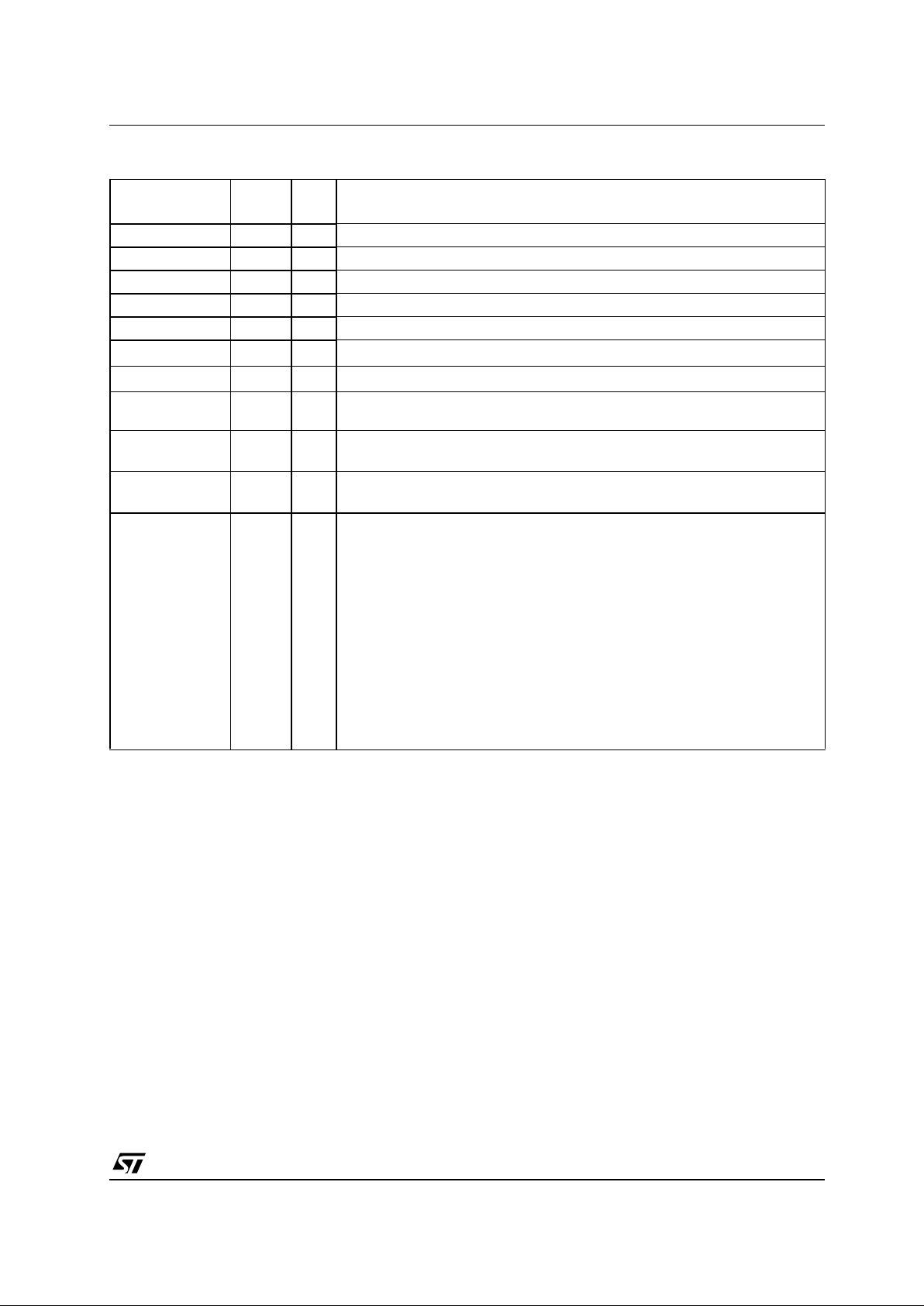

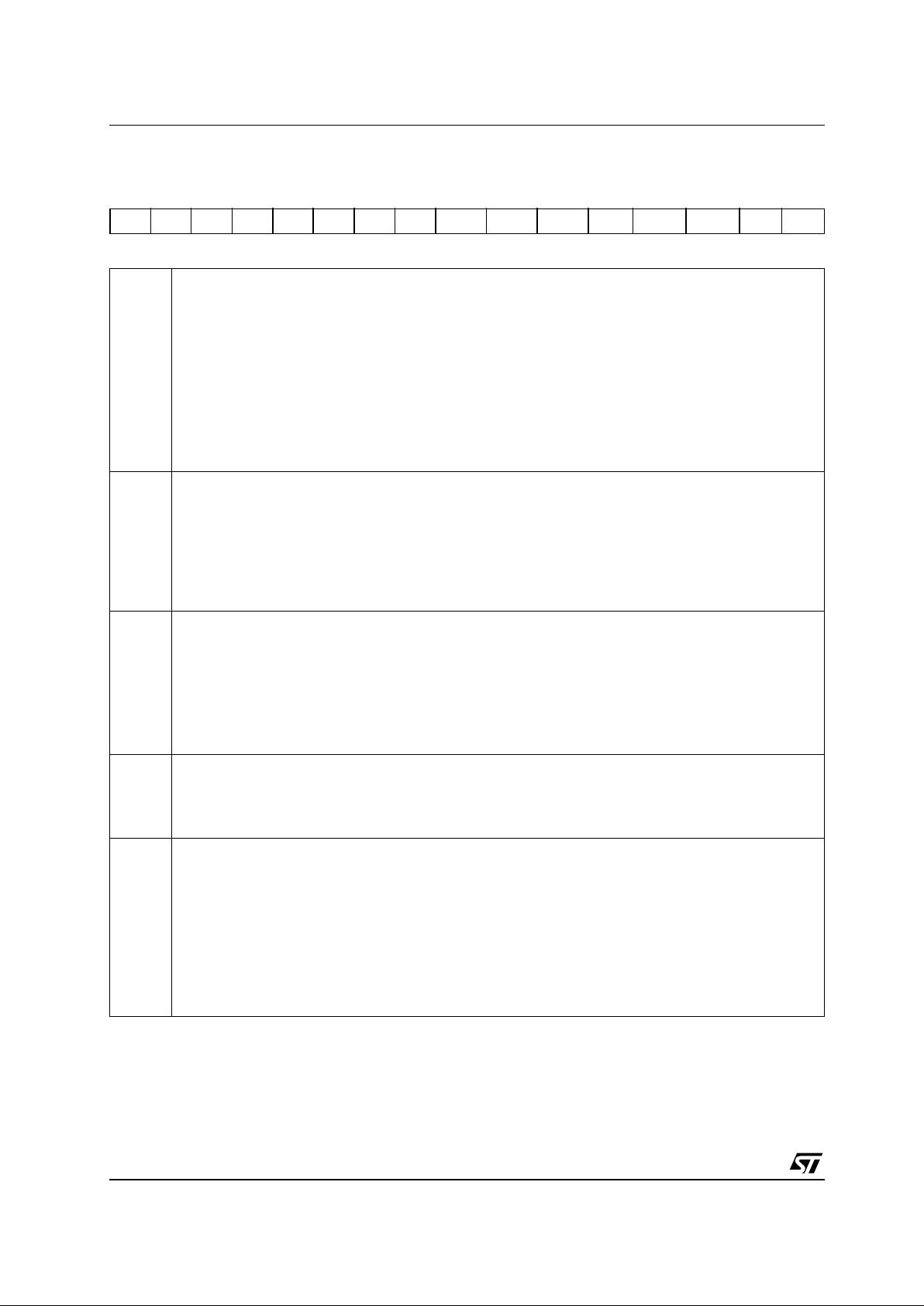

Figure 1 : Logic Symbol

XTAL1

RSTIN

XTAL2

RSTOUT

NMI

EA

READY

ALE

RD

WR/WRL

Port 5

16-bit

Port 6

8-bit

Port 4

8-bit

Port 3

15-bit

Port 2

16-bit

Port 1

16-bit

Port 0

16-bit

V

DD

V

SS

Port 7

8-bit

Port 8

8-bit

V

AREF

V

AGND

XPort 9

16-bit

XPWM

4-bit

XADCINJ

XPort10

16-bit

DC1

DC2

Decoupling capacitor for internal regulator

ST10F280

ST10F280

7/186

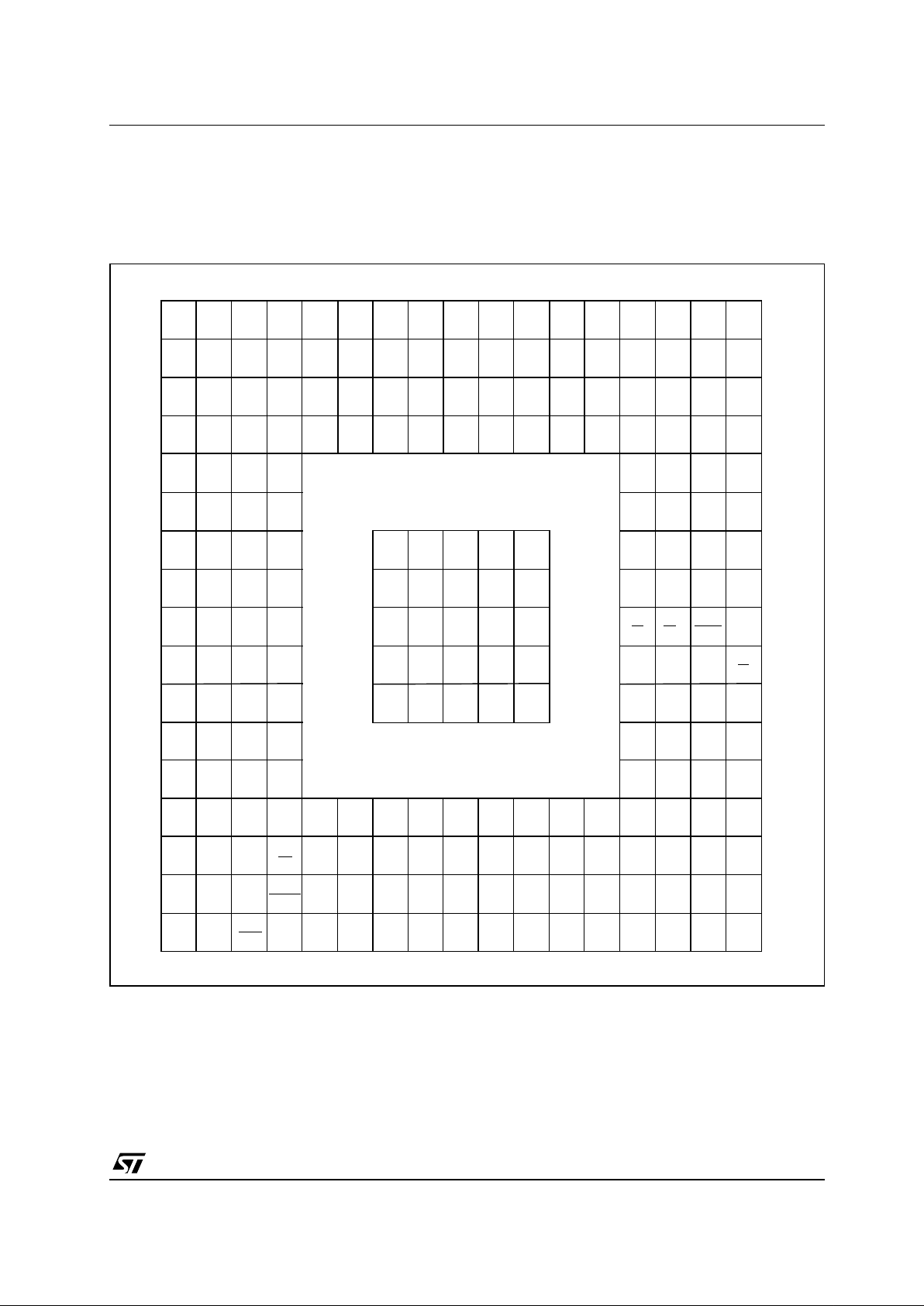

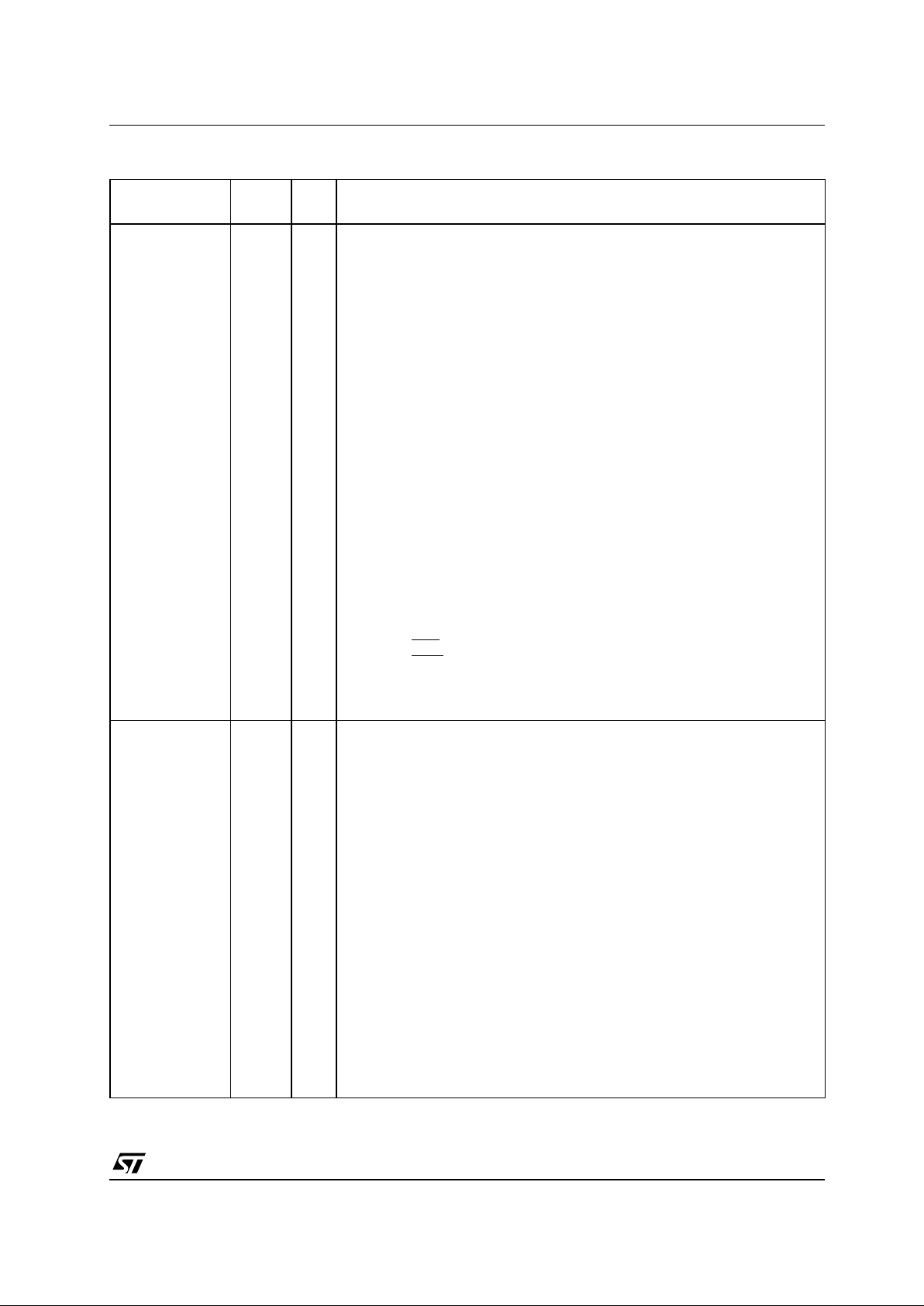

2 - BALL DATA

The ST10F280 package is a PB GA of 23 x 23 x 1.96 mm . The pitch of the balls is 1. 27 mm. The s ignal

assignment of the 208 balls is described in Figure 2 for the configuration and in Tabl e 1 for the ball signal

assignment. This package has 25 additional therm al balls.

Figure 2 : Ball Configuration (bottom view)

K7

V

SS

K8

V

SS

K9

V

SS

J7

V

SS

J8

V

SS

J9

V

SS

H7

V

SS

H8

V

SS

H9

V

SS

G7

V

SS

G8

V

SS

G9

V

SS

K10

V

SS

K11

V

SS

J10

V

SS

J11

V

SS

H10

V

SS

H11

V

SS

G10

V

SS

G11

V

SS

VSSVSSVSSVSSV

SS

U1 U2

V

AREF

U3

V

AGND

U4 U5 U6 U7 U8 U9 U1 0

V

SS

U11

DC2

U12 U13 U14 U15 U16

T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16

R1 R2 R3

R4

R14 R15 R16

M1 M2 M3

M15 M16 M17

L1

V

SS

L2 L3

L15 L16 L17

V

DD

K1

V

DD

K2 K3

K15 K16 K17

V

SS

J1 J2 J3

J15 J16 J17

H1 H2 H3

H15 H16 H17

G1 G2 G3

G15 G16 G17

F1 F2 F3

F15 F16 F17

E1 E2 E3

E15 E16 E17

V

SS

D1 D2 D3

D15 D16 D17

C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C1 1 C12 C13 C14 C15 C16

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 B13 B14 B15 B16

A1 A2 A3 A4

RSTIN

A5

XTAL1A6XTAL2

A7 A8 A9 A10 A11 A12 A13 A14 A15 A16

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

1716151413121110987654321

1716151413121110987654321

U17

T17

R17

C17

B17

A17

U

U

V

SS

DC1 V

DD

M4

L4

K4

J4

H4

G4

E4

D4

M14

L14

K14

J14

H14

G14

E14

D14

P15 P16 P17

P14

D5 D6 D7 D8 D9 D10 D11 D12 D13

P5 P6 P7 P8 P9 P10 P11 P12 P13

N1 N2 N3

N4

F4

F14

L7 L8 L9 L10 L11

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

VSSV

DD

VSSV

DD

P3.15

V

DD

V

SS

RPD

XP10.3 XP10.2 XP10.1 XP10.0

XP10.4XP10.5XP10.6XP10.7

XP10.11 XP10.8 P5.6 P5.10 P5.14XP10.9XP10.10

XP10.13 XP10.12 P5.1 P5.3 P5.7 P5.11 P5.15

XP10.14 P5.0 P5.2 P5.4 P5.8 P5.12

XP10.15 P5.5 P5.9 P5.13

xpwm.0

xpwm.1

xpwm.2

xpwm.3

P6.0

P6.1

P6.2

P6.3

P6.4

P6.5

P6.6

P6.7

P8.0

P8.1P8.2

P8.3P8.4

P8.5P8.6P8.7

P7.0P7.1P7.2P7.3

P7.4 P7.5 P7.6

P7.7 XADCINJ

P2.0

P2.1

P2.2

P2.3 P2.4

P2.5

P2.6

P2.7

P2.8

P2.9

P2.10

P2.11

P2.12

P2.13

P2.14

P2.15

P3.0

P3.1

P3.2

P3.3

P3.4

P3.5

P3.6

P3.7

P3.8 P3.9

P3.10

P3.11 P3.12

P3.13

P4.0

P4.1

P4.2

P4.3

P4.4 P4.5

P4.6 P4.7

RD WR READY ALE

EAP0.0P0.1P0.2

P0.3P0.4P0.5

P0.6

P0.7

P0.8

P0.9

P0.10

P0.11

P0.12

P0.13

P0.14

P0.15

XP9.0

XP9.1

XP9.2

XP9.3

XP9.4

XP9.5

XP9.6

XP9.7

XP9.8

XP9.9

XP9.10

XP9.11

XP9.12

XP9.13

XP9.14

XP9.15

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7P1.8

P1.9

P1.10

P1.11

P1.12

P1.13

P1.14 P1.15

V

SS

RSTOUT

NMI

V

SS

V

SS

V

SS

VSSV

SS

VSSV

SS

V

SS

V

SS

V

SS

V

SS

VSSV

SS

V

SS

V

SS

V

SS

VSSV

SS

V

SS

V

SSVSS

R5 R6 R7 R8 R9 R10 R11 R12 R13

N15 N16 N17

N14

P1 P2 P3 P4

ST10F280

8/186

Table 1 : Ball Descri pti o n

Symbol

Ball

Number

Type Function

P6.0 – P6.7 I/O Port 6 is an 8 -bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedance state. Port 6 outputs can be configured as push/pull or open

drain drivers.

The following Port 6 pins also serve for alternate functions:

E4 O P6.0 CS0

Chip Select 0 Output

D3 O P6.1 CS1 Chip Select 1 Output

B1 O P6.2 CS2

Chip Select 2 Output

C1 O P6.3 CS3 Chip Select 3 Output

D2 O P6.4 CS4

Chip Select 4 Output

E3 I P6.5 HOLD External Master Hold Request Input

F4 O P6.6 HLDA

Hold Acknowledge Output

D1 O P6.7 BREQ Bus Request Output

P8.0 – P8.7 I/O Port 8 is an 8 -bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedance state. Port 8 outputs can be configured as push/pull or open

drain drivers. The input threshold of Port 8 is selectable (TTL or special).

The following Port 8 pins also serve for alternate functions:

E2 I/O P8.0 CC16IO CAPCOM2: CC16 Capture Input / Compare Output

F3 I/O P8.1 CC17IO CAPCOM2: CC17 Capture Input / Compare Output

F2 I/O P8.2 CC18IO CAPCOM2: CC18 Capture Input / Compare Output

G3 I/O P8.3 CC19IO CAPCOM2: CC19 Capture Input / Compare Output

G2 I/O P8.4 CC20IO CAPCOM2: CC20 Capture Input / Compare Output

H4 I/O P8.5 CC21IO CAPCOM2: CC21 Capture Input / Compare Output

H3 I/O P8.6 CC22IO CAPCOM2: CC22 Capture Input / Compare Output

H2 I/O P8.7 CC23IO CAPCOM2: CC23 Capture Input / Compare Output

P7.0 – P7.7 I/O Port 7 is an 8 -bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedance state. Port 7 outputs can be configured as push/pull or open

drain drivers. The input threshold of Port 7 is selectable (TTL or special).

The following Port 7 pins also serve for alternate functions:

J4 O P7.0 POUT0 PWM Channel 0 Output

J3 O P7.1 POUT1 PWM Channel 1 Output

J2 O P7.2 POUT2 PWM Channel 2 Output

J1 O P7.3 POUT3 PWM Channel 3 Output

K2 I/O P7.4 CC28IO CAPCOM2: CC28 Capture Input / Compare Output

K3 I/O P7.5 CC29IO CAPCOM2: CC29 Capture Input / Compare Output

K4 I/O P7.6 CC30IO CAPCOM2: CC30 Capture Input / Compare Output

L2 I/O P7.7 CC31IO CAPCOM2: CC31 Capture Input / Compare Output

ST10F280

9/186

XP10.0 – XP10.15 I XPort 10 is a 16-bit input-only port with Schmitt-Trigger characteristics.

The pins of X Port10 also serve as the analo g input c hannels (up to 16) for the

A/D converter, where XP10.X equals ANx (Analog input channel x).

M4

M3

M2

M1

N4

N3

N2

N1

P4

P3

P2

P1

R2

R1

T1

U1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

XP10.0

XP10.1

XP10.2

XP10.3

XP10.4

XP10.5

XP10.6

XP10.7

XP10.8

XP10.9

XP10.10

XP10.11

XP10.12

XP10.13

XP10.14

XP10.15

P5.0 – P5.15 I Port 5 is a 16-bit input-only port with Schmitt-Trigger characteristics.

The pins of Port 5 also ser ve as the analog inp ut chann els (up to 16) for the A/D

converter, where P5.x equals ANx (Analog input channel x),

or they serve as timer inputs:

T2 I P5.0

R3 I P5.1

T3 I P5.2

R4 I P5.3

T4 I P5.4

U4 I P5.5

P5 I P5.6

R5 I P5.7

T5 I P5.8

U5 I P5.9

P6 I P5.10 T6EUD GPT2 Timer T6 External Up / Down Control Input

R6 I P5.11 T5EUD GPT2 Timer T5 External Up / Down Control Input

T6 I P5.12 T6IN GPT2 Timer T6 Count Input

U6 I P5.13 T5IN GPT2 Timer T5 Count Input

P7 I P5.14 T4EUD GPT1 Timer T4 External Up / Down Control Input

R7 I P5.15 T2EUD GPT1 Timer T2 External Up / Down Control Input

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

10/186

P2.0 – P2.15 I/O Port 2 is a 16 -bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedance state. Port 2 outputs can be configured as push/pull or open

drain drivers. The input threshold of Port 2 is selectable (TTL or special).

The following Port 2 pins also serve for alternate functions:

T7 I/O P2.0 CC0IO CAPCOM: CC0 Capture Input / Compare Output

P8 I/O P2.1 CC1IO CAPCOM: CC1 Capture Input / Compare Output

R8 I/O P2.2 CC2IO CAPCOM: CC2 Capture Input / Compare Output

T8 I/O P2.3 CC3IO CAPCOM: CC3 Capture Input / Compare Output

T9 I/O P2.4 CC4IO CAPCOM: CC4 Capture Input / Compare Output

P9 I/O P2.5 CC5IO CAPCOM: CC5 Capture Input / Compare Output

R9 I/O P2.6 CC6IO CAPCOM: CC6 Capture Input / Compare Output

U9 I/O P2.7 CC7IO CAPCOM: CC7 Capture Input / Compare Output

T10 I/OIP2.8 CC8IO CAPCOM: CC8 Capture Input / Compare Output,

EX0IN Fast External Interrupt 0 Input

R10 I/OIP2.9 CC9IO CAPCOM: CC9 Capture Input / Compare Output,

EX1IN Fast External Interrupt 1 Input

P10 I/OIP2.10 CC10IO CAPCOM: CC10 Capture Input / Compare Output,

EX2IN Fast External Interrupt 2 Input

T11 I/OIP2.11 CC11IO CAPCOM: CC11 Capture Input / Compare Output,

EX3IN Fast External Interrupt 3 Input

R11 I/OIP2.12 CC12IO CAPCOM: CC12 Capture Input / Compare Output,

EX4IN Fast External Interrupt 4 Input

U12 I/OIP2.13 CC13IO CAPCOM: CC13 Capture Input / Compare Output,

EX5IN Fast External Interrupt 5 Input

P11 I/OIP2.14 CC14IO CAPCOM: CC14 Capture Input / Compare Output,

EX6IN Fast External Interrupt 6 Input

T12 I/O

I

I

P2.15 CC15IO CAPCOM: CC15 Capture Input / Compare Output,

EX7IN Fast External Interrupt 7 Input

T7IN CAPCOM2 Timer T7 Count Input

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

11/186

P3.0 - P3.13,

P3.15

I/O Port 3 is a 15-bit (P 3.14 is missi ng) bidirecti onal I/O por t. It i s bit-wise pro gram-

mable for input or output via direction bits. For a pin configured as input, the out-

put driver is put in to high-imp edance st ate. Port 3 outputs ca n be config ured as

push/pull or open drain dri vers. The input threshold of Port 3 is select able (TTL

or special).

The following Port 3 pins also serve for alternate functions:

R12 I P3.0 T0IN CAPCOM Timer T0 Count Input

T13 O P3.1 T6OUT GPT2 Timer T6 Toggle Latch Output

P12 I P3.2 CAPIN GPT2 Register CAPREL Capture Input

R13 O P3.3 T3OUT GPT1 Timer T3 Toggle Latch Output

T14 I P3.4 T3EUD GPT1 Timer T3 External Up / Down Control Input

P13 I P3.5 T4IN GPT1 Timer T4 Input for Count / Gate /

Reload / Capture

R14 I P3.6 T3IN GPT1 Timer T3 Count / Gate Input

P14 I P3.7 T2IN GPT1 Timer T2 Input for Count / Gate /

Reload / Capture

R15 I/O P3.8 MRST SSC Master-Receive / Slave-Transmit I/O

R16 I/O P3.9 MTSR SSC Master-Transmit / Slave-Receive O/I

N14 I/O P3.10 TxD0 ASC0 Clock / Data Output (Asynchronous / Synchronous)

P15 O P3.11 RxD0 ASC0 Data Input (Asynchronous) or I/O (Synchronous)

P16 O P3.12 BHE

External Memory High Byte Enable Signal,

WRH

External Memory High Byte Write Strobe

M14 I/O P3.13 SCLK SSC Master Clock Output / Slave Clock Input

T17 O P3.15 CLKOUT System Clock Output (=CPU Clock)

P4.0 – P4.7 I/O Port 4 is an 8 -bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedance state. The input threshold is selectable (TTL or special).

P4.6 & P4.7 outputs can be configured as push-pull or open-drain drivers.

In case of an exter nal bus configuration, Por t 4 can be us ed to output the se g-

ment address lines:

N16 O P4.0 A16 Least Significant Segment Address Line

M15 O P4.1 A17 Segment Address Line

L14 O P4.2 A18 Segment Address Line

M16 O P4.3 A19 Segment Address Line

L15 OIP4.4 A20 Segment Address Line

CAN2_RxD CAN2 Receive Data Input

L16 OIP4.5 A21 Segment Address Line

CAN1_RxD CAN1 Receive Data Input

K14 OOP4.6 A22 Segment Address Line, CAN_TxD

CAN1_TxD CAN1 Transmit Data Output

K15 OOP4.7 A23 Most Significant Segment Address Line

CAN2_TxD CAN2 Transmit Data Output

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

12/186

RD

J14 O External Memory Read Strobe. RD is activated for every external instruction or

data read access.

WR

/WRL J15 O External Memory Write Strobe. In WR-mode this pin is activated for every

external data write access. In WRL

-mode this pin is activated for low byte data

write accesses on a 16-bit bus, and for every data write access on an 8-bit bus.

See WRCFG in register SYSCON for mode selection.

READY/

READY

J16 I Ready Input. The active level is programmable. When the Ready function is

enabled, the selected inactive level at this pin during an external memory access

will force the insertion of memory cycle time waitstates until the pin returns to the

selected active level.

ALE J17 O Address Latch Enable Output. Can be used for latching the address into external

memory or an address latch in the multiplexed bus modes.

EA

H17 I External Access Enable pin. A low level at this pin during and after Reset forces

the ST10F280 to begin instruction execution out of external memory. A high level

forces execution out of the internal Flash Memory.

PORT0:

P0L.0 - P0L.7,

P0H.0 - P0H.7

I/O PORT0 consists of the two 8-bit bidirectional I/O ports P0L and P0H. It is bit-wise

programmable for input or output via direction bits. For a pin configured as input,

the output driver is put into high-impedance state.

In case of an externa l bus configuration, PORT0 serves as the address (A) a nd

address/data (AD) bus in multiplexed bus modes and as the data (D) bus in

demultiplexed bus modes.

Demultiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: D0 - D7 D0 - D7

P0H.0 – P0H.7: I/O D8 - D15

Multiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: AD0 - AD7 AD0 - AD7

P0H.0 – P0H.7: A8 - A15 AD8 - AD15

H16 I/O P0L.0

H15 I/O P0L.1

H14 I/O P0L.2

G16 I/O P0L.3

G15 I/O P0L.4

G14 I/O P0L.5

F16 I/O P0L.6

E17 I/O P0L.7

F15 I/O P0H.0

E16 I/O P0H.1

F14 I/O P0H.2

D17 I/O P0H.3

E15 I/O P0H.4

D16 I/O P0H.5

C17 I/O P0H.6

E14 I/O P0H.7

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

13/186

XPORT9.0 XPORT9.15

I/O XPort 9 is a 16-bit bi directional I/O por t. It is bit- wise program mable for input or

output via direction bits. For a pin configured as input, the output driver is put into

high-impedanc e state. XPort 9 outputs ca n be configured as push/p ull or open

drain drivers.

D15 I/O XPORT9.0

C16 I/O XPORT9.1

D14 I/O XPORT9.2

C15 I/O XPORT9.3

B16 I/O XPORT9.4

D13 I/O XPORT9.5

C14 I/O XPORT9.6

B15 I/O XPORT9.7

A15 I/O XPORT9.8

B14 I/O XPORT9.9

C13 I/O XPORT9.10

D12 I/O XPORT9.11

B13 I/O XPORT9.12

C12 I/O XPORT9.13

D11 I/O XPORT9.14

B12 I/O XPORT9.15

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

14/186

PORT1:

P1L.0 - P1L.7,

P1H.0 - P1H.7

I/O PORT1 consists of the two 8-bit bidirectional I/O ports P1L and P1H. It is bit-wise

programmable for input or output via direction bits. For a pin configured as input,

the output driver is put into high-imped ance state. PORT1 is used as the 16-bit

address bus (A) in demultiplexed bus modes and also after switching from a

demultiplexed bus mode to a multiplexed bus mode. The following PORT1 pins

also serve for alternate functions:

C11 I/O P1L.0

B11 I/O P1L.1

D10 I/O P1L.2

C10 I/O P1L.3

B10 I/O P1L.4

A10 I/O P1L.5

D9 I/O P1L.6

C9 I/O P1L.7

C8 I/O P1H.0

D8 I/O P1H.1

A7 I/O P1H.2

B7 I/O P1H.3

C7 I P1H.4 CC24IO CAPCOM2: CC24 Capture Input

D7 I P1H.5 CC25IO CAPCOM2: CC25 Capture Input

C5 I P1H.6 CC26IO CAPCOM2: CC26 Capture Input

C6 I P1H.7 CC27IO CAPCOM2: CC27 Capture Input

XTAL1 A5 I XTAL1: Input to the oscillator amplifier and input to the internal clock generator

XTAL2 A6 O XTAL2: Output of the oscillator amplifier circuit.

To clock the device from an extern al source, drive XTAL1, while leaving XTAL2

unconnected. Minimum and maximum high/low and rise/fall times specified in

the AC Characteristics must be observed.

RSTIN

A3 I Reset Input with Schmitt-Trigger characteristics. A low level at this pin for a spec-

ified duration while the oscillator is running resets the ST10F280. An internal pullup resistor permits power-on reset using only a capacitor connected to V

SS

.

In bidirectiona l re set m ode (en abled by setting bit BDR STEN in SYS CON reg ister), the RSTIN line is pulled low for the duration of the internal reset sequence.

RSTOUT B4 O Internal Reset Indicati on Output. This pin is set to a low level when the part is

executing either a hardware, a software or a watchdog timer reset. RSTOUT

remains low until the EINIT (end of initialization) instruction is executed.

NMI C4 I Non-Maskable Interrupt Input. A high to low transition at this pin causes the CPU

to vector to the NMI trap routine. If bit PWDCFG = ‘0’ in SYSCON register, when

the PWRDN (power down) in struction is executed, the NMI

pin must be low in

order to force the ST10F280 to go into p ower down mode. If NMI

is high and

PWDCFG =’0’, when PWRDN is executed, the part will continue to run in normal

mode.

If not used, pin NMI

should be pulled high externally.

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

15/186

XPWM.0 D4 O XPWM Channel 0 Output

XPWM.1 C3 O XPWM Channel 1 Output

XPWM.2 B2 O XPWM Channel 2 Output

XPWM.3 C2 O XPWM Channel 3 Output

XADCINJ L3 O Output trigger for ADC channel injection

V

AREF

U2 - Reference voltage for the A/D converter.

V

AGND

U3 - Reference ground for the A/D converter.

RPD M17 I/O Timing pin for the return from powerdown circuit and synchronous/asynchronous

reset selection.

DC1 G1 O 3.3V Decoupling pin: a decoupling capacitor of ~330 nF must be connected

between this pin and nearest V

SS

pin.

DC2 U11 O 3.3V Decoupling pin: a decoupling capacitor of ~330 nF must be connected

between this pin and V

SS

nearest pin.

V

DD

A2

A9

A12

A14

E1

K1

U8

U15

P17

L17

G17

- Digital Supply Voltage: + 5 V during normal operation, idle mode and power

down mode

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

16/186

V

SS

A1

A4

A8

A11

A13

A16

A17

B3

B5

B6

B8

B9

B17

D5

D6

F1

F17

G4

H1

K16

K17

L1

L4

N15

N17

R17

T15

T16

U7

U10

U13

U14

U16

U17

- Digital Ground.

Table 1 : Ball Description (continued)

Symbol

Ball

Number

Type Function

ST10F280

17/186

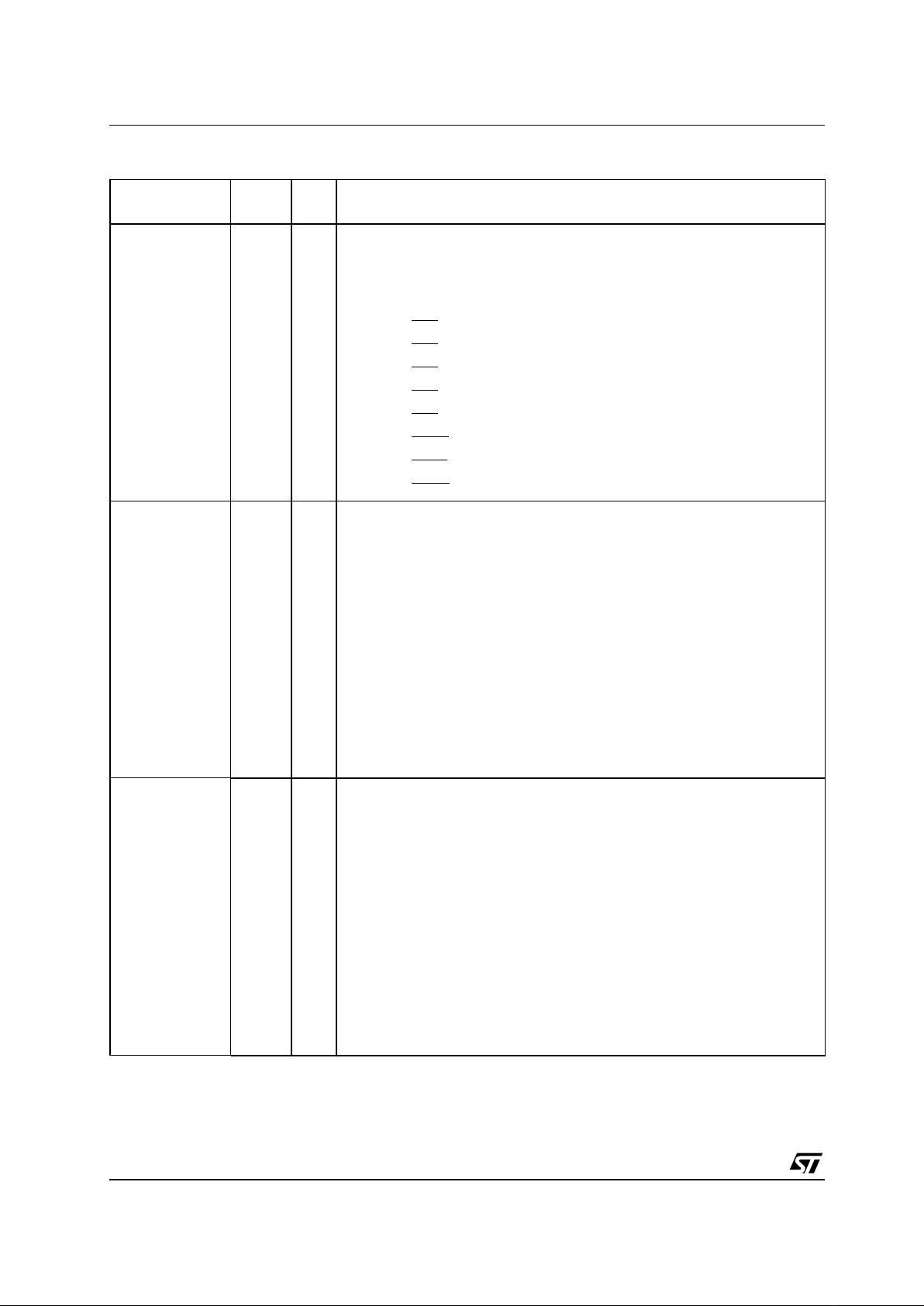

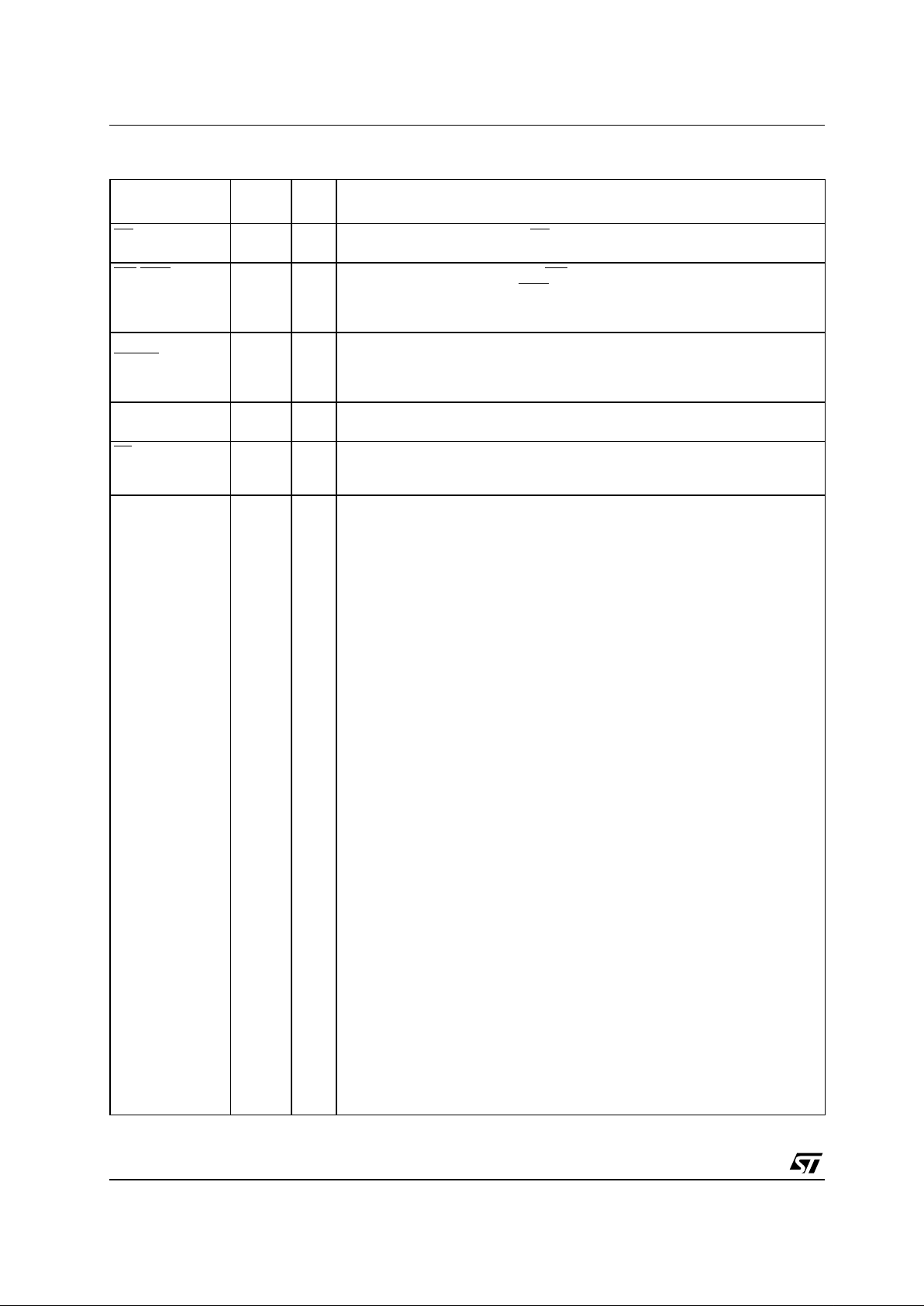

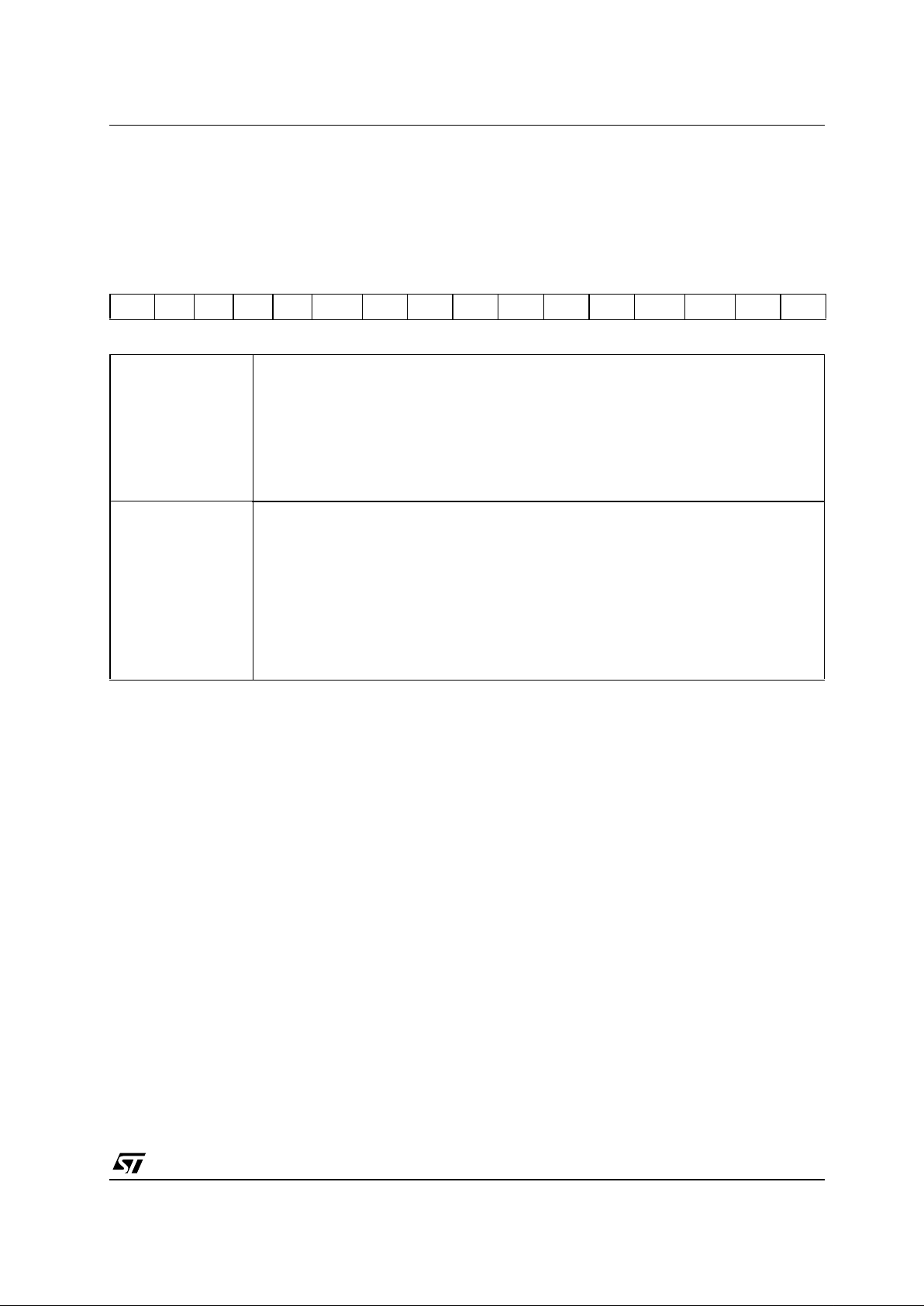

3 - FUNCTIONAL DESCRIPTION

The architecture of the ST10F280 combines

advantages of both RISC and CISC processors

and an advanced peripheral subsystem. The

block diagram g ives an overview of the different

on-chip components and the high bandwidth internal bus structure of the ST10F280.

Figure 3 : Block Diagram

P4.7 CAN2_TxD

P4.6 CAN1_TxD

P4.5 CAN1_RxD

P4.4 CAN2_RxD

Port 0

Port 1Port 4

Port 6

Port 5

Port 3

Port 2

GPT1

GPT2

ASC usart

BRG

CPU-Core and MAC Unit

Internal

RAM

Watch dog

Interrupt Controller

8

32 16

PEC

16

16

CAN1

Port 7

Port 8

External Bus

10-Bit ADC

BRG

SSC

PWM

CAPCOM2

CAPCOM1

16

Oscillator

Controller

16

16

512K Byte

and PLL

Flash Memory

XTAL1 XTAL2

2K Byte

15

8

8

8

16

3.3V Voltage

Regulator

16K Byte

XRAM

CAN2

XPORT916XPWM4XTIMER

P7.7 Trigger for ADC

16

XPORT10

16

16

XADCINJ

channel injection

External connexion

ST10F280

18/186

4 - MEMOR Y ORGA NI ZA T IO N

The memory space of the ST10F280 is configured

in a unified memory architecture. Code memory,

data memory, registers and I/O ports are organized within the same linear address space of

16M Bytes. The entire memory space can be

accessed bytewise or wordwise. Particular portions of the on-chip memory have additionally

been made directly bit addressable.

FLASH: 512K Bytes of on-chip single voltage

FLASH memory.

IRAM: 2K Bytes of on-chip internal RAM

(dual-port) is provided as a storage for data, system stack, general purpose register banks and

code. The register bank can con sist of up to 16

wordwide (R0 to R15) and/or bytewide (RL0, RH0,

…, RL7, RH7) general purpose registers. Base

address is 00’F600h, upper address is 00’FDFFh.

XRAM: 16K Bytes of on-chip extension RAM (single port XRA M) is provided as a storage for data,

user stack and cod e. The X RA M is a s ingle bank,

connected to the internal XBUS and are accessed

like an external memory in 16-bit demultiplexed

bus-mode without waitstate or read/write delay

(50ns access at 40MHz CPU clock). Byte and

word access is allowed.

The XRAM address range is 00’8000h - 00’BFFFh

if enabled (XPEN set bit 2 of SYSCON register-,

and XRAMEN set bit 2 of XPERCON register-). If

bit XRAMEN or XPEN is cleared, then any access

in the address range 00 ’8000h 00’BFFFh will be

directed to external memory interface, using the

BUSCONx register corresponding to address

matching ADDRSELx register

As the XRAM appears like external memory, it

cannot be used for the ST10F280’s system stack

or register banks. The XRAM is not provided for

single bit storage and therefore is not bit addressable.

SFR/ESFR: 1024 bytes (2 * 512 bytes) of address

space is reserved for the special func tion register

areas. SFRs are wordwide registers which are

used for controlling and monitoring functions of

the different on-chip units.

CAN1: Address range 00’EF00h 00’EFFFh is

reserved for the CAN1 Module access. The CAN1

is enabled by setting XPEN bit 2 of the SYSCON

register and bit 0 of the new XPERCON register.

Accesses to the CAN Module use demultiplexed

addresses and a 16-bi t data bus (byte accesses

are possible). Two waitstates give an access time

of 100 ns at 40MHz CPU clock. No tristate waitstate is used.

CAN2: Address range 00’EE00h 00’EEFFh is

reserved for the CAN2 Module access. The CAN2

is enabled by setting XPEN bit 2 of the SYSCON

register and bit 1 of the new XPERCON register.

Accesses to the CAN Module use demultiplexed

addresses and a 16-bi t data bus (byte accesses

are possible). Two waitstates give an access time

of 100 ns at 40MHz CPU clock. No tristate waitstate is used.

In order to meet the needs of designs where more

memory is required than is provided on chip, up to

16M Bytes of external RAM and/or ROM can be

connected to the microc ontroller. If one or the two

CAN modules are used, Port 4 can not be programmed to output all 8 segment address lines.

Thus, only 4 segment address li nes can be used,

reducing the external mem or y space to 5M Bytes

(1M Byte per CS

line).

XPWM: Address range 00’EC00h 00’ECFFh is

reserved for the XPWM Module access. The

XPWM is enabled by setting XPEN bit 2 of the

SYSCON register and bit 4 of the new XPERCON

register. Accesses to the XPWM Module use

demultiplexed addresses and a 16-bit data bus

(byte accesses are possible). Two waitstates give

an access time of 100 ns at 40MHz CPU clock. No

tristate waitstate is used.

XPORT9, XTIMER, XPORT10, XADCMUX :

Address range 00’C000h 00’C3FFh is reserved

for the XPORT9, XPORT10, XTIMER and

XADCMUX peripherals access. The XPORT9,

XTIMER, XPORT10, XADCMUX are enabled by

setting XPEN bit 2 of the SYSCON register and

the bit 3 of the new XPERCON register. Accesses

to the XPORT9, XTIMER, XPORT10 and

XADCMUX modules use a 16-bit demultiplexed

bus mode without waitstate or read/write delay

(50ns access at 40MHz CPU clock). Byte and

word access is allowed.

Visibi lity of X B U S Periphera ls

The XBUS peripherals can be separately selected

for being visible to the user by means of corresponding selection bits in the XP E RCON re gister.

If not selected (not activated with XPERCON bit)

before the global enabling with XPEN-bit in

SYSCON register, the corresponding address

space, port pins and interrupts are not occupied

by the peripheral, thus the peripheral is not visible

and not available. SYSCON register is described

in Section 19.2 - System Configuration Registers.

ST10F280

19/186

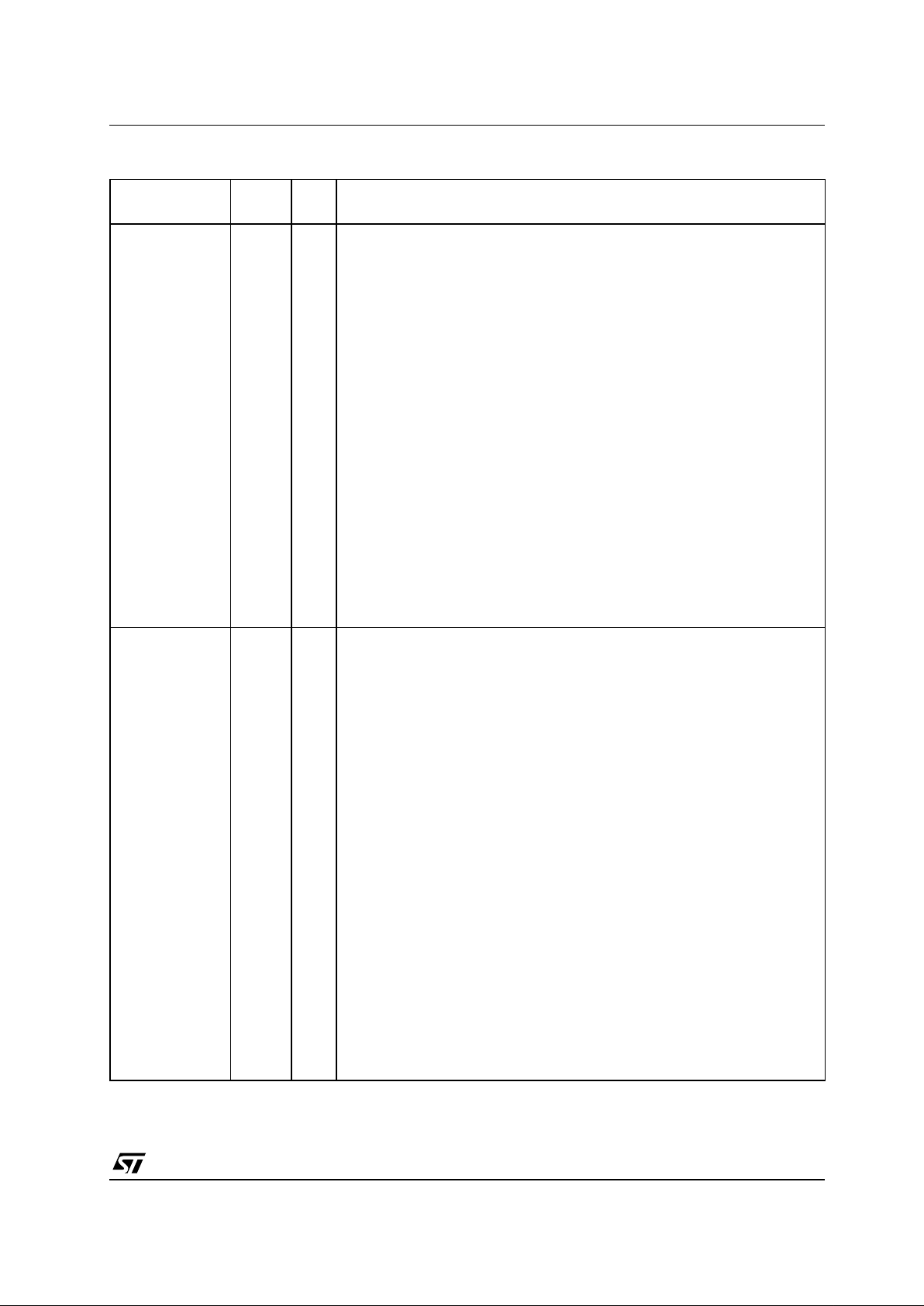

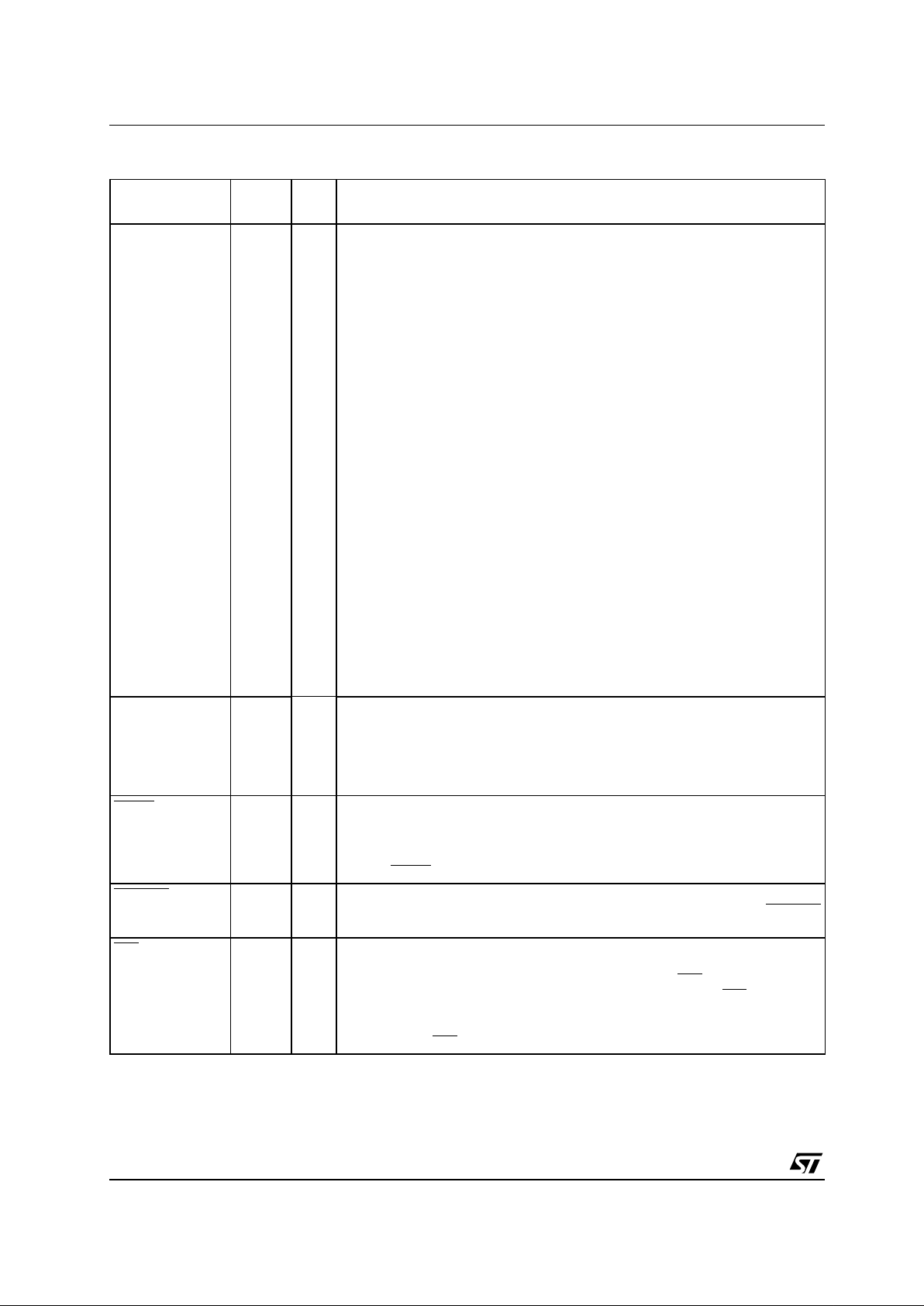

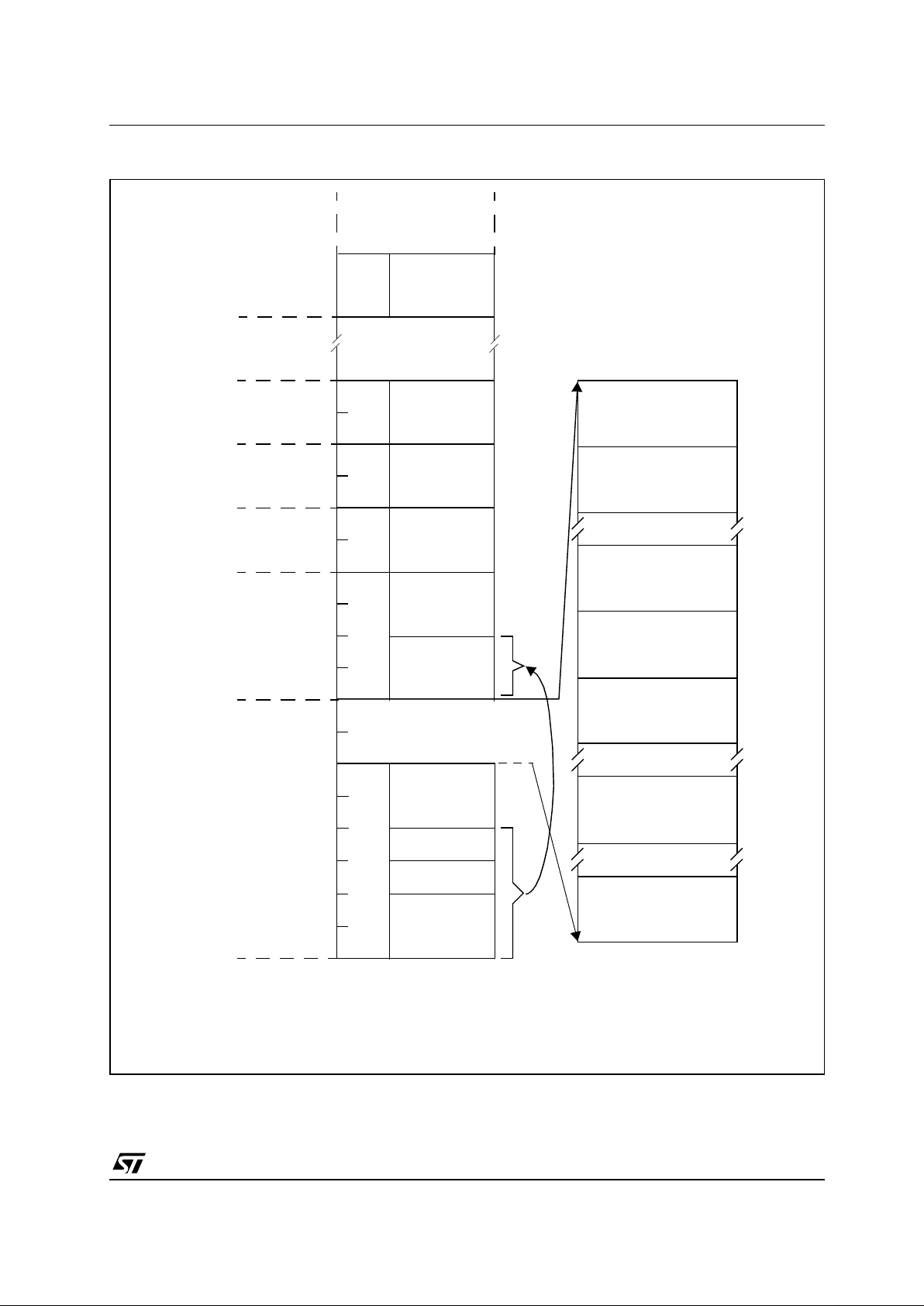

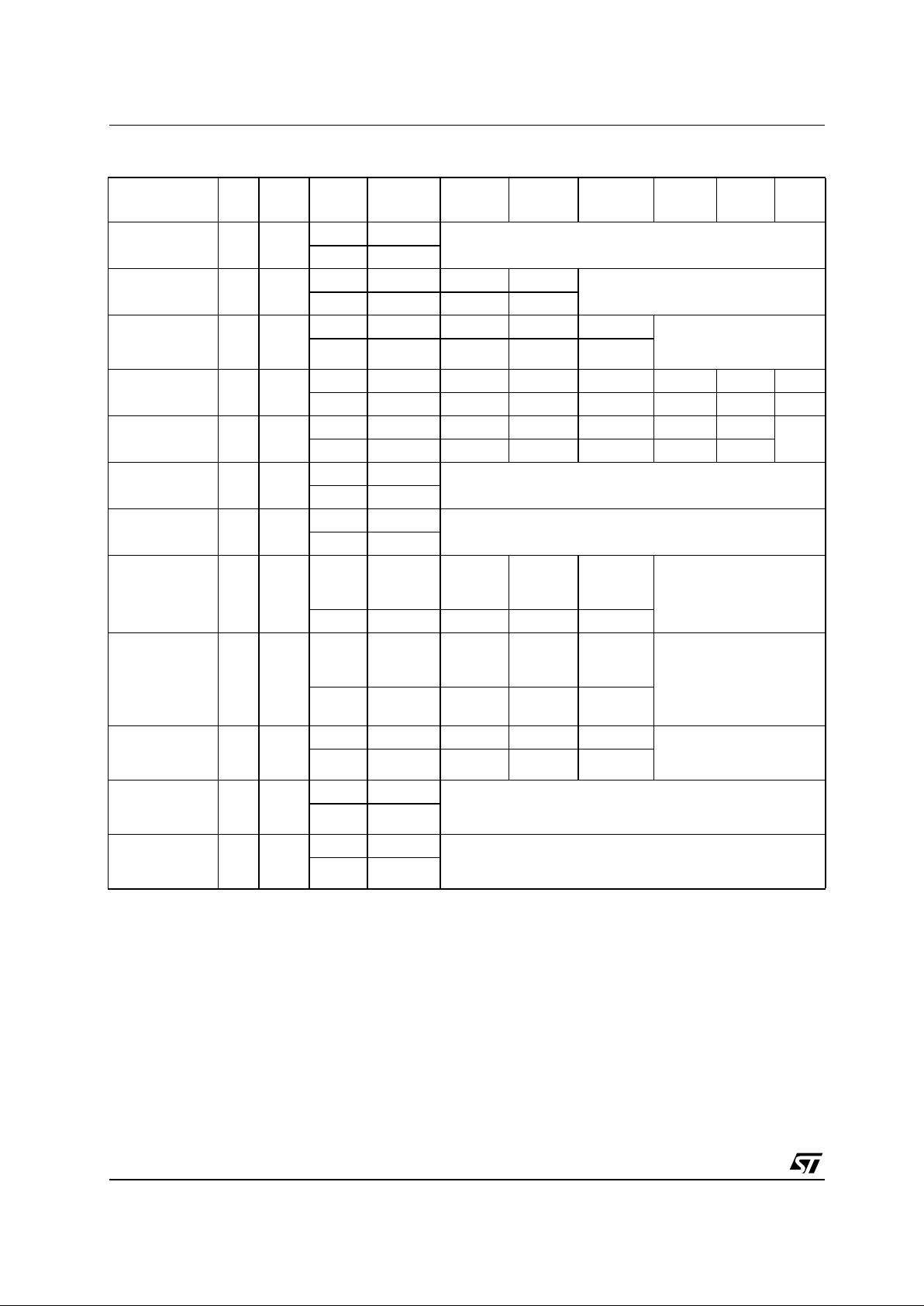

Figure 4 : ST10F280 On-chip Memo ry Mapping

14

07

06

05

04

00’4000

01

00

00’0000

02

00’C000

00’FFFF

SFR : 512 Bytes

00’FE00

00’FDFF

IRAM : 2K Bytes

00’F600

* Blocks 0, 1 and 2 may be remapped from segment 0 to segment 1 by setting SYSCON-ROMS1 (before EINIT)

RAM, SFR and X-pheripherals are

mapped into the address space.

Segment 4Segment 3Segment 2Segment 1Segment 0

Data

Page

Number

Absolute

Memory

Address

00’6000

00’F1FF

ESFR : 512 Bytes

00’F000

00’EFFF

CAN1 : 256 Byte s

00’EF00

00’EEFF

CAN2 : 256 Byte s

00’EE00

00’C3FF

XPORT9 XTIMER

00’C000

03

00’ECFF

XPWM

00’EC00

Block2 = 8K Bytes

Internal

Flash

Memory

Block1 = 8K Bytes

Block0 = 16K Bytes

01’0000

01’8000

02’0000

03’0000

0C

04’0000

10

05’0000

Block6 = 64K Bytes

Block5 = 64K Bytes

Block4 = 64K Bytes

Block3 = 32K Bytes

Block2*

Block1*

Block0*

Data Page Number and A bsolute Memory Address are hexadecim al values.

08

08’0000

20

Block10 = 64K Bytes

Segment 8

09’0000

00’8000

00’BFFF

XRAM = 16K Bytes

XPORT10

XADCMUX

ST10F280

20/186

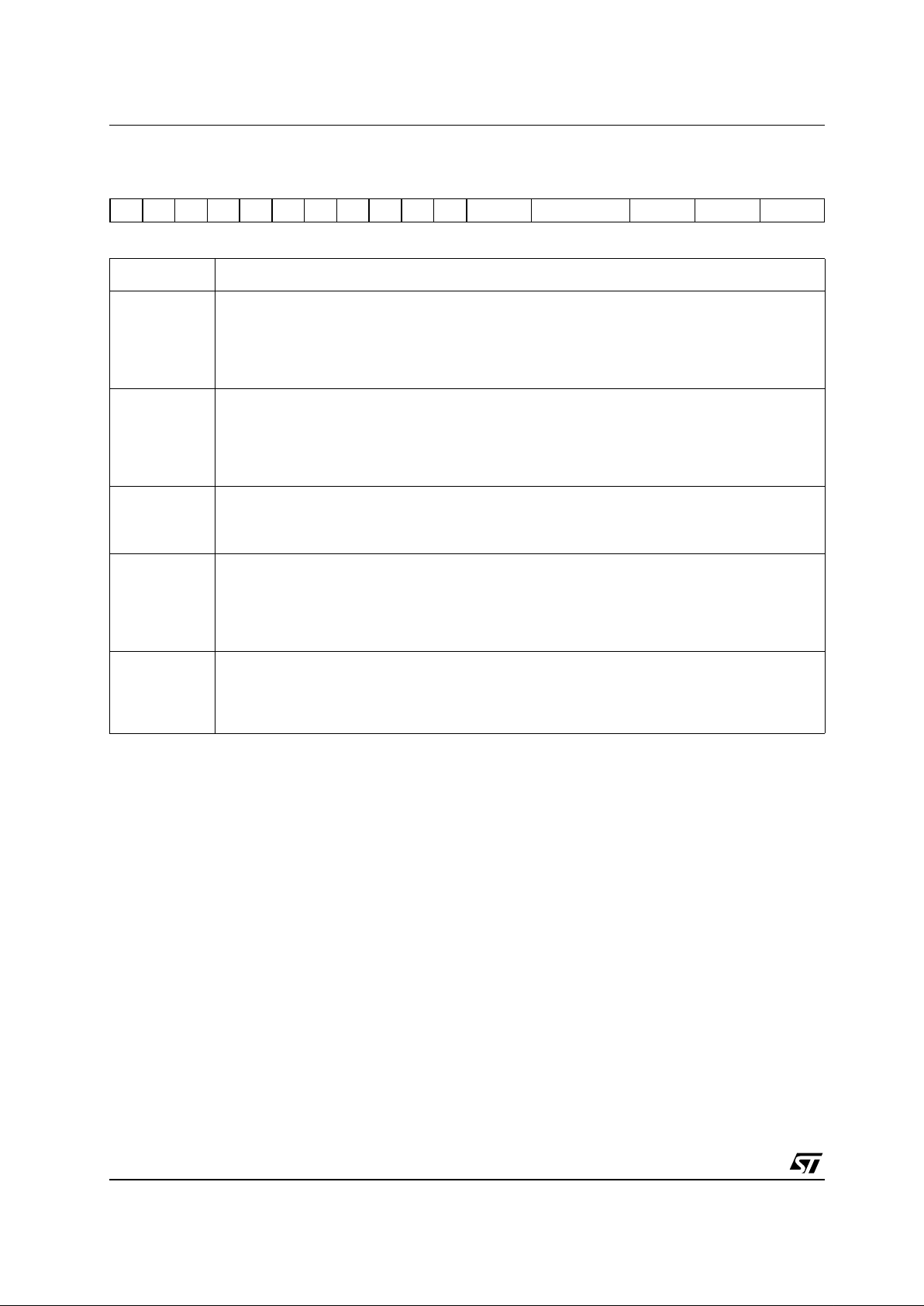

XPERCON (F024h / 12h) ESFR Reset Value: - - 05h

Note: - When both CAN and XPWM are disabled via XPERCON setting, then any access in the address

range 00’EC00h 00’EF FFh will be directed to external mem ory interface, using the BUSCONx

register corresponding to address matching ADDRSELx register. P4.4 and P4.7 can be used as

General Purpo se I/O when CAN2 is no t enabled, and P4.5 and P4. 6 can be used as G eneral

Purpose I/O when CAN1 is not enabled.

- The default XPER selection after Reset is : XCAN1 is enabled, XCAN2 is disabled, XRAM is

enabled, XPORT9, XTIMER, XPORT10, XPWM, XADCMUX are disabled.

- Register XPERCON cannot be changed after the global enabling of XPeripherals, i.e. after

setting of bit XPEN in SYSCON register.

15141312111098765 4 3 2 1 0

-----------XPWMENXPERCONEN3XRAMENCAN2ENCAN1EN

RW RW RW RW RW

Bit Function

CAN1EN

0

1

CAN1 Enable Bit

Accesses to the on- chip CAN 1 XPeripheral a nd its fu nctions are disabled. P4.5 a nd P4.6 pins

can be used as gen eral purpose I/Os. Addre ss range 00’EF00h-00’EF FFh is only directed to

external memory if CAN2EN and XPWM bits are cleared also.

The on-chip CAN1 XPeripheral is enabled and can be accessed.

CAN2EN

0

1

CAN2 Enable Bit

Accesses to the on- chip CAN 2 XPeripheral a nd its fu nctions are disabled. P4.4 a nd P4.7 pins

can be us ed as gene ral purpos e I/Os. Addres s range 00’E E00h-00’EEFFh is only di rected to

external memory if CAN1EN and XPWM bits are cleared also.

The on-chip CAN2 XPeripheral is enabled and can be accessed.

XRAMEN

0

1

XRAM Enable Bit

Accesses to the on-chip 16K Byte XRAM are disabled, external access performed.

The on-chip 16K Byte XRAM is enabled and can be accessed.

XPERCONEN3

0

1

XPORT9, XTIMER, XPORT10, XADCMUX Enable Bit

Accesses to the XPORT9, XTIMER, X PORT10, XADCMUX p eripherals are d isabled, external

access performed.

The on-chip XPORT9, XTIMER, XPORT10, XADCMUX peripherals are enabled and can be

accessed.

XPWMEN

0

1

XPWM Enable Bit

Accesses to the on-chip XPWM are disabled, external access performed. Address range

00’EC00h-00’ECFFh is only directed to external memory if CAN1EN and CAN2EN are ‘0’ also

The on-chip XPWM is enabled and can be accessed.

ST10F280

21/186

5 - INTERNAL FLASH MEMORY

5.1 - Overview

– 512K Byte on-chip Flash memory

– Two possibilities of Flash mapping into the CPU

address space

– Flash memory can be used for code and data

storage

– 32-bit, zero waitstate read ac cess (50ns cycle

time at f

CPU

= 40MHz)

– Erase-Program Controller (EPC) similar to

M29F400B STM’s stand-alone Flash memo ry

• Word-by-Word Programmable (16µs t ypic a l)

• Data polling and Toggle Protocol for EPC

Status

• Internal Power-On detection circuit

– Memory Erase in blocks

• One 16K Byte, two 8K Byte, one 32K Byte,

seven 64K Byte blocks

• Each block can be erased separately

(1.5 second typical)

• Chip erase (8.5 second typical)

• Each block can be separately protected

against programming and erasing

• Each protected block can be temporary unprotected

• When enabled, the read protection prevents

access to data in Flash memory using a program running out of the Flash memory space.

Access to data of internal Flash can only be performed with an inner protected program

– Erase Suspend and Res um e Modes

• Read and Program another Block during erase

suspend

– Single Voltage operat ion , no need of dedicat ed

supply pin

– Low Power Consumption:

• 45mA max. Read current

• 60mA max. Program or Erase current

• Automatic Stand-by-mode (50µA maximum)

– 100,000 Erase-Program Cycles per block,

20 y ea r data reten tion time

– Operating tempe rature: -40 to +125

o

C

5.2 - Operational Overview

Read M ode

In standard mode (the normal operating mode)

the Flash ap pears like an on-chip ROM with the

same timing and functiona lity. The Flash modul e

offers a fast access time, allowing zero waitstate

access with CPU frequency up to 40MHz.

Instruction fetches and data operand reads are

performed with all addressing modes of the

ST10F280 instruction set.

In order to optimize the programming tim e of the

internal Flash, blocks of 8K Bytes, 16K Bytes,

32K Bytes, 64K Bytes can be used. But the size of

the blocks does not apply to the whole memory

space, see details in Table 2.

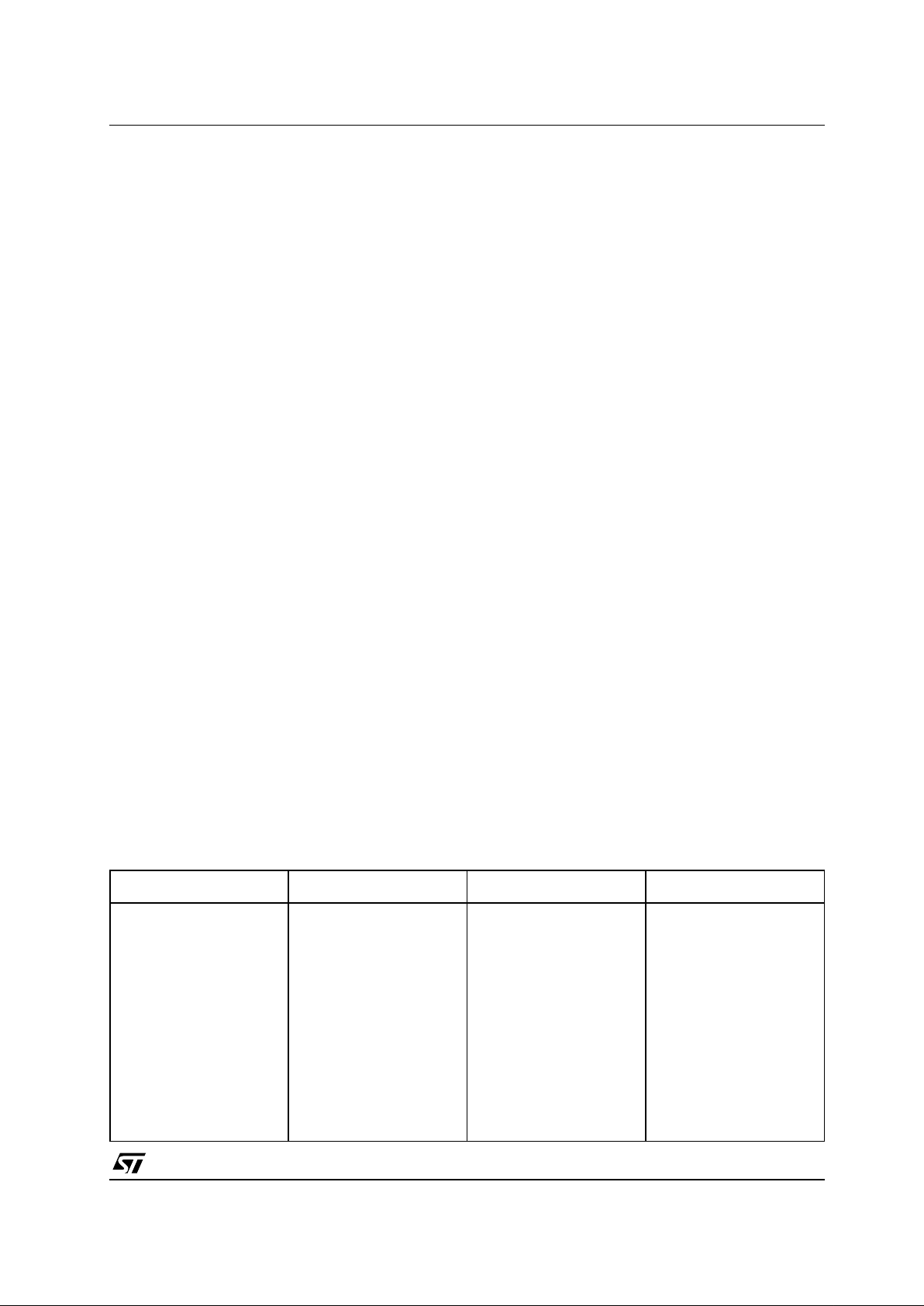

Table 2 : 512K Byte Flash Memory Block Organisation

Block Addresses (Segment 0) Addresses (Segment 1) Size (K Byte)

0

1

2

3

4

5

6

7

8

9

10

00’0000h to 00’3FFFh

00’4000h to 00’5FFFh

00’6000h to 00’7FFFh

01’8000h to 01’FFFFh

02’0000h to 02’FFFFh

03’0000h to 03’FFFFh

04’0000h to 04’FFFFh

05’0000h to 05’FFFFh

06’0000h to 06’FFFFh

07’0000h to 07’FFFFh

08’0000h to 08’FFFFh

01’0000h to 01’3FFFh

01’4000h to 01’5FFFh

01’6000h to 01’7FFFh

01’8000h to 01’FFFFh

02’0000h to 02’FFFFh

03’0000h to 03’FFFFh

04’0000h to 04’FFFFh

05’0000h to 05’FFFFh

06’0000h to 06’FFFFh

07’0000h to 07’FFFFh

08’0000h to 08’FFFFh

16

8

8

32

64

64

64

64

64

64

64

ST10F280

22/186

Instructions and Commands

All operations besides normal read operations are

initiated and controlled by command sequences

wri tte n to the Fla sh C om ma n d I nter fac e ( CI) . T h e

Command Interface (CI) interprets words written

to the Flash memory and enables one of the

following operations:

– Read memory array

– Program Word

– Block Erase

– Chip Erase

– Erase Suspend

– Erase Resume

– Block Protection

– Block Temporary Unprotection

– Code Protection

Commands are composed o f several write cycles

at specific addresses of the Flash memory. The

different write cycles of such command

sequences offer a fail-safe feature to protect

against an inadvertent write.

A command only starts when the Command

Interface has decoded the last write cycle of an

operation. Until that last write is performed, Flas h

memory rema ins in Read Mo de

Notes: 1. As it is not possible to perform write

operations in the Flash while fetching code

from Flash, the Flash commands must be

written by instructions executed from

internal RAM or ex ternal memo ry.

2. Command write c ycles do not need to

be consecutively received, pauses are

allowed, save for Block Erase command.

During this operation all Erase Confirm

commands mus t be sent to co mplete any

block erase operation before time-out

period expires (typically 96µs). Command

sequencing must be followed exactly. Any

invalid combination of commands will reset

the Command Interface to Read Mode.

Status R egister

This register is used to flag the status of the

memory and the result of an operation. This

register can be accessed by read cycles during

the Erase-Program Controller (EPC) operation.

Erase Operation

This Flash memory features a block erase

architecture with a chip erase capabi lity too. Erase

is accomplished by exec uting the six cycle erase

command sequence. Additional command write

cycles can then be performed to erase more than

one block in parallel . When a time-out period elaps

(96

µ

s) after the last cycle, the Erase-Program

Controller (EPC) automatically starts and times the

erase pulse and executes the erase operation.

There is no need to program the block to be

erased with ‘0000h’ before an erase operation.

Term ination of operation is indicated in the Flash

status register. After erase operation, the Flash

memory locations are read as 'FFFFh’ value.

Erase Suspend

A block erase operation is typically executed

within 1.5 second for a 64K Byte block. Erasure of

a memory block may be suspended, in order to

read data from another block or to program data in

another block, and then resumed.

In-System Programming

In-system programming is fully supported. No

special programming voltage is required. Because

of the automatic execution of erase and

programming algorithms, write operations are

reduced to transferring commands and data to the

Flash and reading the status. Any code that

programs or erases Flash memory lo cations (that

writes data to the Flash) must be executed from

memory out side the on-chip Flash memory its elf

(on-chip RAM or external memory).

A boot mechanism is provided to support

in-system programming. It wor ks using seria l link

via USART interface and a PC compatible or

other programming host.

Read/Write Protection

The Flash module supports read and write

protection in a very comfortable and advanced

protection functionality. If Read Protection is

installed, the whole Flash memory is protected

against any "external" read access; read

accesses are only possible with instructions

fetched directly from program Flash memory. For

update of the Flas h memor y a temporar y disable

of Flash Read Protection is supported.

The device also features a block write protection.

Software locking of selectable memory blocks is

provided to protect code and data. This feature

will disable both program and erase operations in

the selected block(s) of the memory. Block

Protection is accomplished by block specific

lock-bit which are programmed by executing a

four cycle command sequence. The locked state

of blocks is indicated by specific flags in the

according block status registers. A block may only

be temporarily unlocked for update (write)

operations.

ST10F280

23/186

With the two possibilities for write protection whole

memory or block specific a flexible installation of

write protection is suppor ted to protect the Flash

memory or parts of it from unauthorized

programming or erase accesses and to provide

virus-proof protection for all system code blocks.

All write protection also is enabled during boot

operation.

Power Supply, Reset

The Flash modul e uses a si ngle power supply for

both read and write functions. Internally generated and regulated voltages are provided for the

program and erase operations from 5V supply.

Once a program or erase cycle has been completed, the device resets to the standard read

mode. At power-on, the Flash memory has a

setup phase of some microseconds (dependent

on the power supply ramp-up). During this phase,

Flash can not be read. Thus, if EA

pin is high (execution will start from F lash m em or y ), the CP U will

remains in reset state until the Flash can be

accessed.

5.3 - Architectural Description

The Flash module distinguishes two basic

operating modes, the standard read mode and the

command mo de. The initial state after power-on

and after reset is the standard read mode.

5.3.1 - Read Mode

The Flash modul e enters the standard operating

mode, the read mode:

– After Reset command

– After every completed erase operation

– After every completed programming operation

– After every other completed command

execution

– Few microseconds after a CPU-reset has

started

– After incorrect address and data values of

command sequences or writing them in an

improper sequence

– After incorrect write access to a read protected

Flash memory

The read mode remains active until the last

command of a command sequence is decoded

which starts directly a Flash array operation, such

as:

– erase one or several blocks

– program a word into Flash array

– protect / temporary unprotect a block.

In the standard read mode read accesses are

directly controlled by the Flash memory array,

delivering a 32-bit double Word from the

addressed position. Read accesses are always

aligned to double Word boundaries. Thus, both

low order address bit A1 and A 0 are not used in

the Flash array for read accesses. The high order

address bit A18/A17/A16 define the physical

64K Bytes segment being accessed within the

Flash array.

5.3.2 - Command Mode

Every operation besides standard read operations

is initiated by commands written to the Flash

command register. The addresses used for

command cycles define in conjunction with the

actual state the specific step within command

sequences. With the last command of a command

sequence, the Erase-Program Controller (EPC)

starts the execution of the command. The EPC

status is indicated during comman d execution by:

– The Status Register,

– The Ready/Bu sy signal.

5.3.3 - Flash Status Register

The Flash Status register is used to flag the status

of the Flash memory and the result of an

operation. This register can be accessed by Read

cycles during the program-Erase Controller

operations. The program or erase operation can

be controlled by data polling on bit FSB.7 of

Status Register, detection of Toggle on FSB.6 and

FSB.2, or Error on FSB.5 and Erase Timeout on

FSB.3 bit. Any read attempt i n Flash during E PC

operation will a utomatic ally ou tput thes e five bits.

The EPC sets bit FSB.2, FSB.3, FSB.5, FSB.6

and FSB.7. Other bit are reserved for future use

and should be masked.

ST10F280

24/186

Flash Status (see note for address)

Note: The Address of Flash Status Register is the address of the word being programmed when

Programming operation is in progress, or an address w ithin block being erased when Erasing

operation is in progress.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-------- FSB.7 FSB.6 FSB.5 - FSB.3 FSB.2 - RRR R R

FSB.7 Flash Status bit 7: Data Polling Bit

Programming Operation: this bit outputs the complement of the bit 7 of the word being

programm ed , and after com ple t ion , w ill ou t pu t the b it 7 of the wo rd progr ammed.

Erasing Operation: outputs a ‘0’ during erasing, and ‘1’ after erasing completion.

If the block selected f or erasure is (are) protected, FSB.7 will be set to ‘0’ for about 100 µs, and

then return to the previous addressed memory data value.

FSB.7 will also flag t he Erase Suspend Mode by switching from ‘0’ to ‘1’ at the star t of the

Erase Suspend.

During Program operation in Erase Suspend Mode, FSB.7 will have the same behaviour as in

normal Program execution outside the Suspend mode.

FSB.6 Fl ash S t at us bit 6: Toggle Bit

Programming or Erasing Operations: successive read operations of Flash Status register will

deliver complementary values. FSB.6 will togg le each time the Flash Status register is read.

The Program operation is completed wh en two successive reads yield the same value. The

next read will output the bit last programmed, or a ‘1’ after Erase operation

FSB.6 will be set to‘1’ if a read operation is attempted on an Erase Suspended block. In

addition, an Erase Suspend/Resume command will cause FSB.6 to toggle.

FSB.5 Flash Status bit 5: Error Bit

This bit is set to ‘1’ when there is a failure of Program, block or chip erase operations.This bit

will also be set if a user tries to program a bit to ‘1’ to a Flash location that is currently

programmed with ‘0’.

The error bit resets after Read/Reset instruction.

In case of success, the Error bit w il l be set to ‘0’ during Program or Erase and then w ill o utpu t

the bit last programmed or a ‘1’ after erasing

FSB.3 Flash Status bit 3: Erase Time-out Bit

This bit is cleared by the EPC when the las t Block Erase command has been en tered to the

Command Interface and it is awaiting the Erase start. When the time-out period is finished,

after 96 µs, FSB.3 returns back to ‘1’.

FSB.2 Fl ash S t at us bit 2: Toggle Bit

This toggle bit, together with FSB.6, can be used to determine the chip status during the Erase

Mode or Erase Suspend Mode. It can be used also to identify the block being Erased

Suspended. A Read operation will cause FS B.2 to Toggle during the Erase Mode. If the Flash

is in Erase Suspend Mode, a Read operation from the Erase suspen ded block or a Program

operation into the Erase suspended block will cause FSB.2 to toggle.

When the Flash is in Program Mode during Erase Suspend, FSB.2 will be read as ‘1’ if address

used is the address of the word being programmed.

After Erase completion with an Error status, FSB.2 will toggle when reading the faulty sector.

ST10F280

25/186

5.3.4 - Flash Protection Register

The Flash Protection register is a non-volatile register that contains the protection status. This register

can be read by using the Read Protection St atus (RP) command, and programmed by using the de dicated Set Protection command.

Flash Protection Register (PR)

5.3.5 - Instructions Description

Twelve instructions dedicated to Flash memory

accesses are defined as follow:

Read/Reset (RD). The Read/Reset instruction

consist of one write cycle with data XXF0h . it can

be optionally preceded by two CI enable

coded

cycles (data xxA8h at address 1554h + data

xx54h at address 2AA8h). Any successive read

cycle following a Read/Reset instruction will read

the memory array. A Wait cycle of 10µs is

necessary after a Read/Reset command if the

memory was in program or Erase mode.

Program Word (PW). This instruction uses four

write cycles. After the two Cl enable coded cycles ,

the Program Word command xxA 0h is written at

address 1554h. The following write cycle will latch

the address and data of the word to be

programmed. Memor y p rogramming can be do ne

only by writing 0's instead of 1's, otherwise an

error occurs. During programming, the Flash

Status is checked by reading the Flash Status bit

FSB.2, FSB.5, FSB.6 and FSB.7 which show the

status of the EPC. FSB.2, FSB.6 and FSB.7

determine if programming is on going or has

completed, and FSB.5 allows a check to be made

for any possible error .

Block Erase (BE). This instruction uses a

minimum of six command cycles. The erase

enable command xx80h is written at address

1554h after the two-cycle CI enable sequence.

The erase confirm code xx30h must be written at

an address related to the block to be erased

preceded by the execution of a second CI enable

sequence. Additional erase confirm codes must

be given to erase m ore than on e block in parallel.

Additional erase confirm commands must be

written within a defined time-ou t perio d. The input

of a new Block Erase command will restart the

time -out period.

When this time-out period has elapsed, the erase

starts. The status of the internal timer can be

monitored through the level of FSB.3, if FSB.3 is

‘0’, the Block Erase command has been given and

the timeout is running ; if FSB.3 is ‘1’, the timeout

has expired and the EPC is erasing the block(s).

If the second command given is not an erase confirm or if the coded cycles are wrong, the instruction aborts, and the device is reset to Read Mode.

1514131211109876543 210

CP ----BP10 BP9 BP8 BP7 BP6 BP5 BP4 BP3 BP2 BP1 BP0

RW RW RW RW RW RW RW RW RW RW RW RW

BPx Block x Protection bit (x = 0...10)

‘0’: the Block Protection is enabled for block x. Programming or erasing the block is not

possible, unless a Block Temporary Unprotection command is issued.

1’: the Block Protection is disabled for block x.

Bit is ‘1’ by default, and can be programmed permanently to ‘0’ using the Set Protection

command but then cannot be set to ‘1’ again. It is therefore possible to temporally disable the

Block Protection using the Block Temporary Unprotection instruction.

CP Code Protection Bit

‘0’: the Flash Code Protection is enabled. Read accesses to the Flash for execution not

performed in the Flash itself are not allowed, the returned value will be 009Bh, whatever the

content of the Flash is.

1’: the Flash Code Protection is disabled: read accesses to the Flash from external or internal

RAM are allowed

Bit is ‘1’ by default, and can be programmed permanently to ‘0’ using the Set Protection

command but then cannot be set to ‘1’ again. It is therefore possible to temporarily disable the

Code Protection using the Code Temporary Unprotection instruction.

ST10F280

26/186

It is not necessary to program the block with

0000h as the EPC will do this automatically before

the erasing to FFFFh. Read operations after the

EPC has sta rted, output the Flash Status Register. During the execution of the erase by the EPC,

the device accepts only the Erase Suspend a nd

Read/Reset instructions. Data Polling bit FSB.7

returns ‘0’ while the erasure is in progress, and ‘1’

when it has completed. The To ggle bit FSB.2 and

FSB.6 toggle during the erase operation. They

stop when erase is completed. After completion,

the Error bit FSB.5 returns ‘1’ if there has been an

erase failure because erasure has not comp leted

even after the maximum number of erase cycles

have been executed by the EPC, in this case, it

will be necessary to input a Read/Reset to the

Command Interface in order to reset the EPC.

Chip Erase (CE). This instruction uses six write

cycles. The Erase Enable command xx80h, must