SPC564A74B4, SPC564A74L7,

SPC564A80B4, SPC564A80L7

32-bit MCU family built on the embedded Power Architecture

Features

■ 150 MHz e200z4 Power Architecture

– Variable length instruction encoding (VLE)

– Superscalar architecture with 2 execution

units

– Up to 2 integer or floating point instructions

per cycle

– Up to 4 multiply and accumulate operations

per cycle

■ Memory organization

– 4 MB on-chip flash memory with ECC and

Read While Write (RWW)

– 192 KB on-chip RAM with standby

functionality (32 KB) and ECC

– 8 KB instruction cache (with line locking),

configurable as 2- or 4-way

– 14 + 3 KB eTPU code and data RAM

–5× 4 crossbar switch (XBAR)

– 24-entry MMU

– External Bus Interface (EBI) with slave and

master port

■ Fail Safe Protection

– 16-entry Memory Protection Unit (MPU)

– CRC unit with 3 sub-modules

– Junction temperature sensor

■ Interrupts

– Configurable interrupt controller (with NMI)

– 64-channel DMA

■ Serial channels

–3× eSCI

–3× DSPI (2 of which support downstream

Micro Second Channel [MSC])

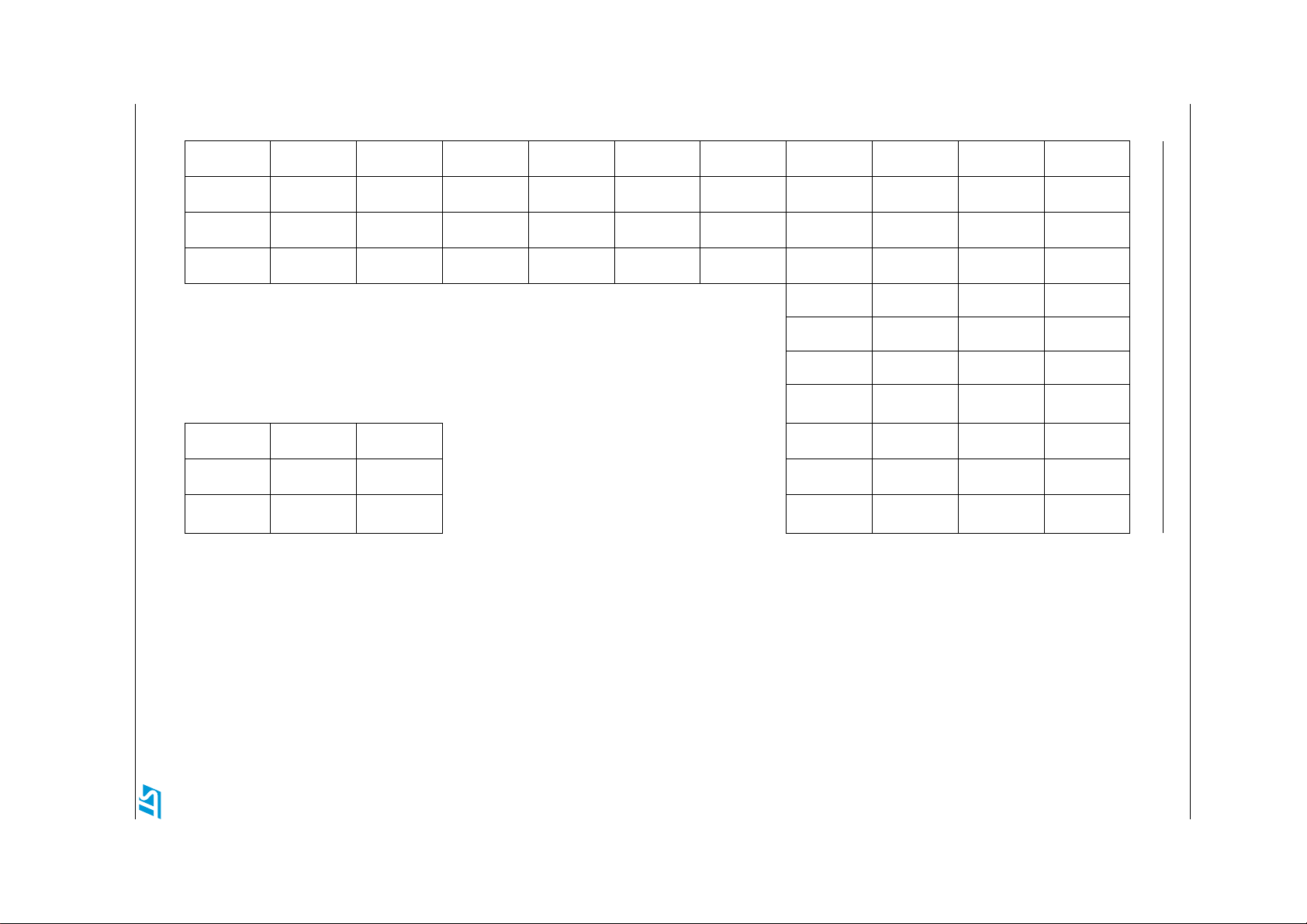

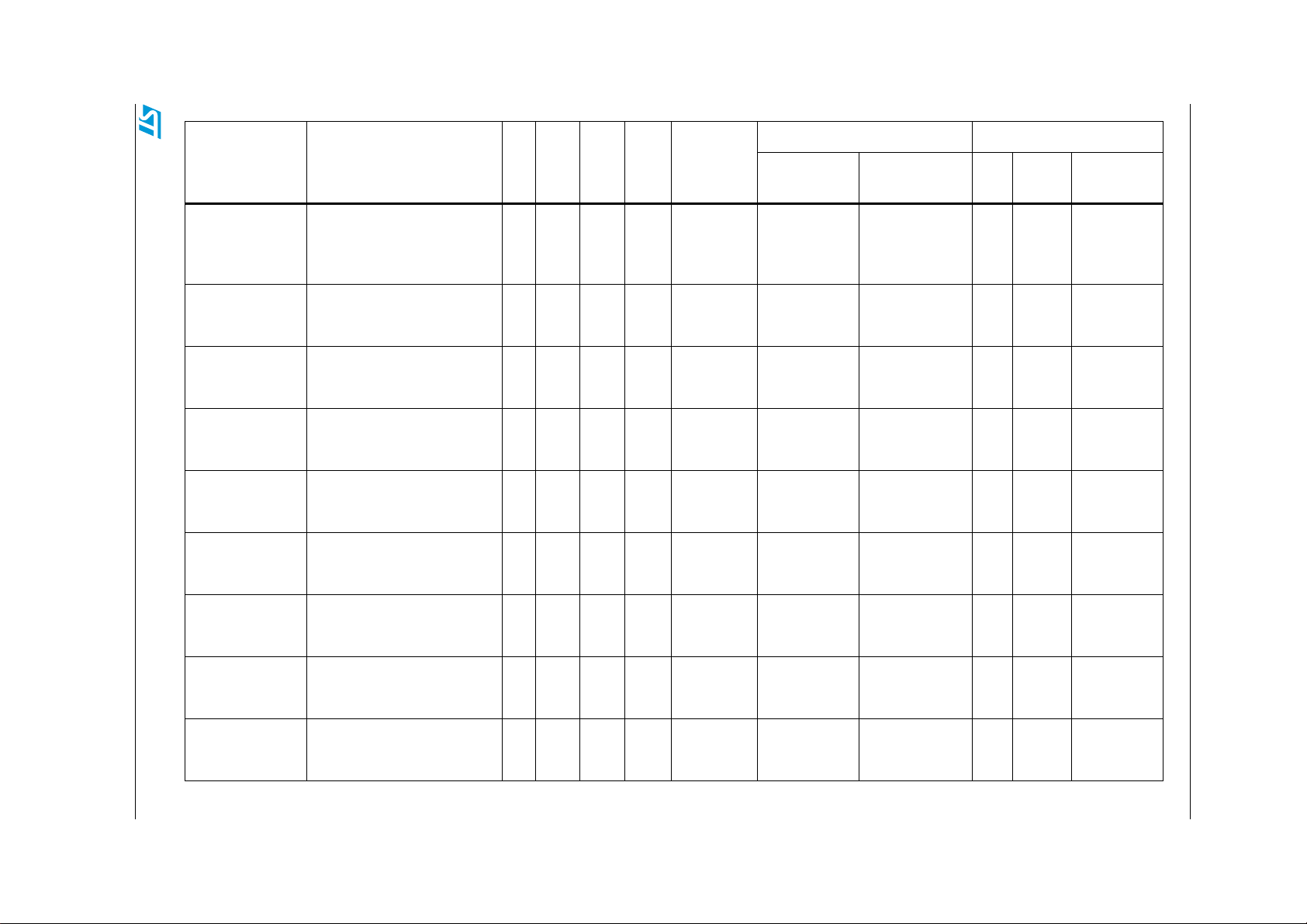

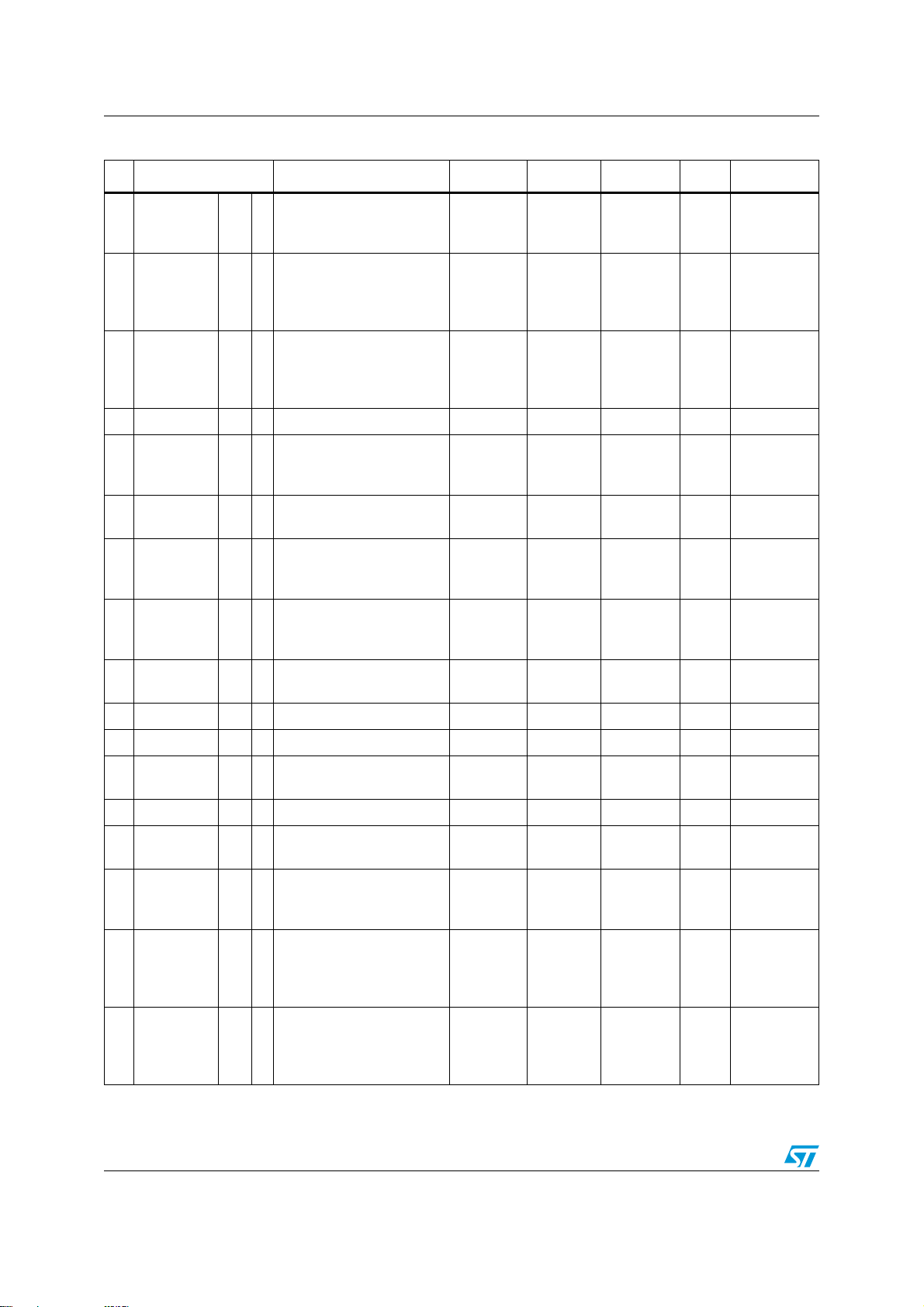

Table 1. Device summary

Memory Flash

size

Package LQFP176 Package: LBGA208 Package: PBGA324 KGD

®

core

®

LBGA208

–3× FlexCAN with 64 messages each

–1× FlexRay module (V2.1) up to 10 Mbit/s

with dual or single channel and 128

message objects and ECC

■ 1 × eMIOS

■ 1 × eTPU2 (second generation eTPU)

■ 2 enhanced queued analog-to-digital

converters (eQADCs)

■ On-chip CAN/SCI/FlexRay Bootstrap loader

with Boot Assist Module (BAM)

■ Nexus: Class 3+ for core; Class 1 for the eTPU

■ JTAG (5-pin)

■ Development Trigger Semaphore (DTS)

■ Clock generation

– On-chip 4–40 MHz main oscillator

– On-chip FMPLL (frequency-modulated

phase-locked loop)

■ Up to 120 general purpose I/O lines

■ Power reduction mode: slow, stop and stand-

by modes

■ Flexible supply scheme

– 5 V single supply with external ballast

– Multiple external supply: 5 V, 3.3 V and

1.2 V

■ Designed for LQFP176, LBGA208, PBGA324

and Known Good Die (KGD)

Part number

PBGA324

LQFP176

4MB SPC564A80L7 - SPC564A80B4 -

3MB SPC564A74L7 - SPC564A74B4 -

March 2012 Doc ID 15399 Rev 8 1/157

www.st.com

1

Contents SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 Document Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Device comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 SPC564A80 feature list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Feature details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.1 e200z4 core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.2 Crossbar Switch (XBAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.3 eDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.4 Interrupt controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.5 Memory protection unit (MPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5.6 FMPLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.7 SIU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5.8 Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5.9 BAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.10 eMIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.5.11 eTPU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.5.12 Reaction module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.5.13 eQADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.5.14 DSPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.5.15 eSCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.5.16 FlexCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.5.17 FlexRay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.5.18 System timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.5.19 Software watchdog timer (SWT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.5.20 Cyclic redundancy check (CRC) module . . . . . . . . . . . . . . . . . . . . . . . . 27

1.5.21 Error correction status module (ECSM) . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.5.22 External bus interface (EBI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.5.23 Calibration EBI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.5.24 Power management controller (PMC) . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.5.25 Nexus port controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.5.26 JTAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.5.27 Development Trigger Semaphore (DTS) . . . . . . . . . . . . . . . . . . . . . . . . 29

1.6 SPC564A80 series architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Contents

1.6.1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.6.2 Block summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 Pinout and signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.1 LQFP176 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2 LBGA208 ballmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 PBGA324 ballmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4 Signal summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.5 Signal details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.1 Parameter classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.3 Thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.3.1 General notes for specifications at maximum junction temperature . . . 85

3.4 EMI (electromagnetic interference) characteristics . . . . . . . . . . . . . . . . . 88

3.5 Electrostatic discharge (ESD) characteristics . . . . . . . . . . . . . . . . . . . . . 88

3.6 Power management control (PMC) and power on reset (POR) electrical

specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.6.1 Regulator Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.6.2 Recommended power transistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.7 Power up/down sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.8 DC electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.9 I/O pad current specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.9.1 I/O pad V

3.9.2 LVDS pad specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

current specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 102

RC33

3.10 Oscillator and PLLMRFM electrical characteristics . . . . . . . . . . . . . . . . 104

3.11 Temperature sensor electrical characteristics . . . . . . . . . . . . . . . . . . . . 106

3.12 eQADC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.13 Configuring SRAM wait states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.14 Platform flash controller electrical characteristics . . . . . . . . . . . . . . . . . 109

3.15 Flash memory electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.16 AC specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3.16.1 Pad AC specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

3.17 AC timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Doc ID 15399 Rev 8 3/157

Contents SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

3.17.1 Reset and configuration pin timing . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.17.2 IEEE 1149.1 interface timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

3.17.3 Nexus timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.17.4 External Bus Interface (EBI) and calibration bus interface timing . . . . 122

3.17.5 External interrupt timing (IRQ pin) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.17.6 eTPU timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.17.7 eMIOS timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.17.8 DSPI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.17.9 eQADC SSI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.17.10 FlexCAN system clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4 Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.1 ECOPACK

4.2 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.2.1 LQFP176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.2.2 BGA208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

‚ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.2.3 PBGA324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

5 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

6 Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

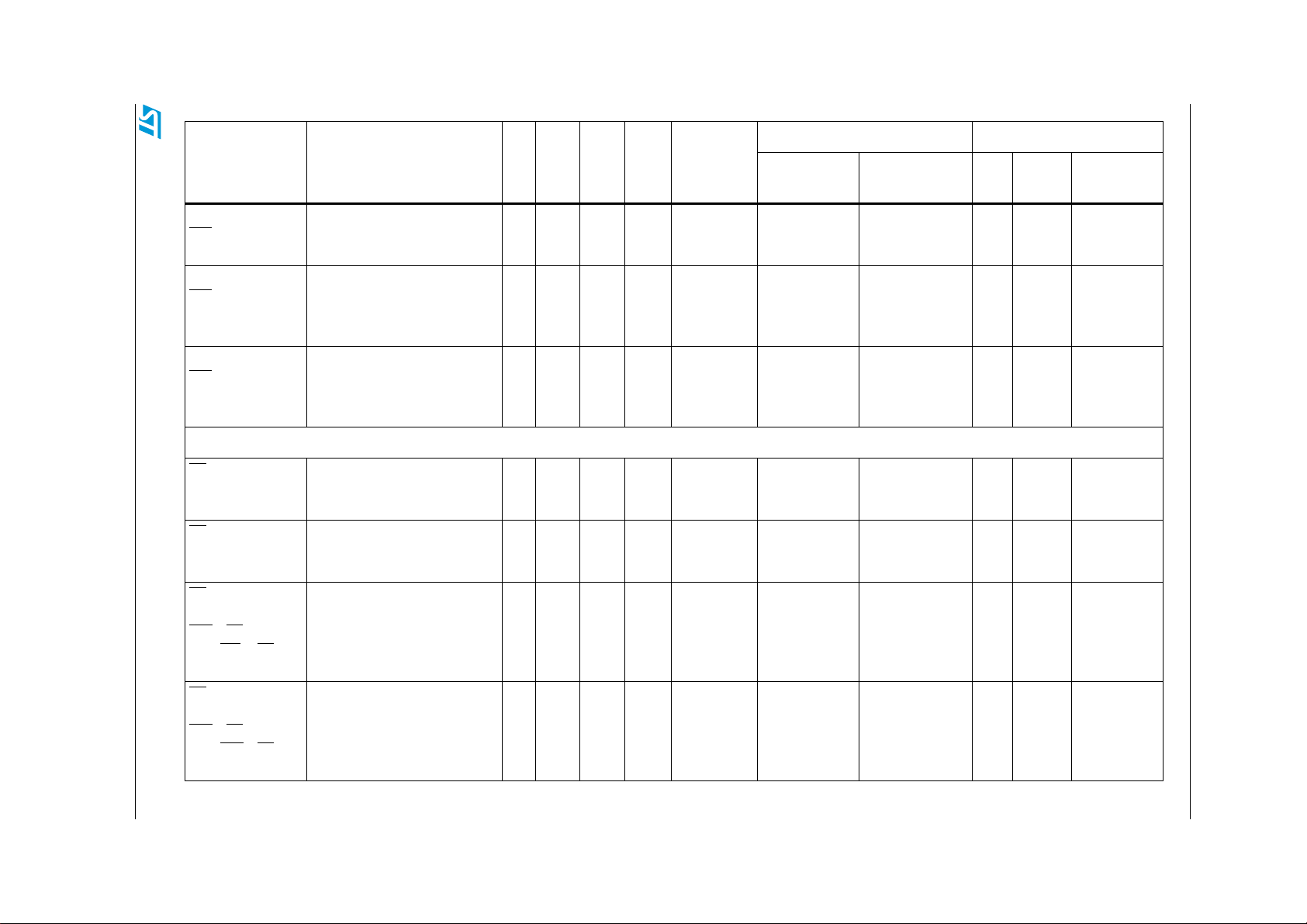

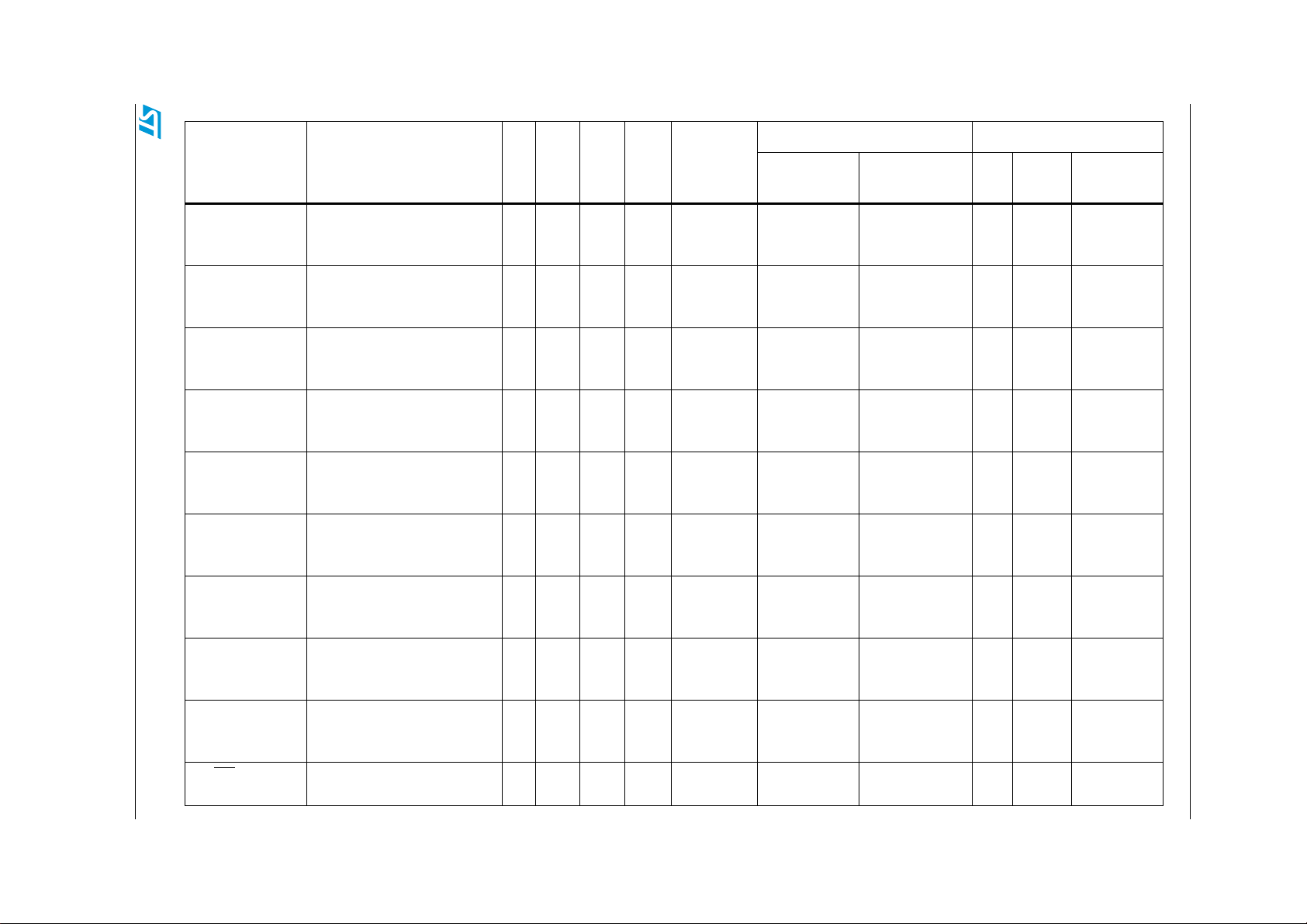

Table 2. SPC564A80, SPC563M64 and SPC564A70 comparison . . . . . . . . . . . . . . . . . . . . . . . . . . 9

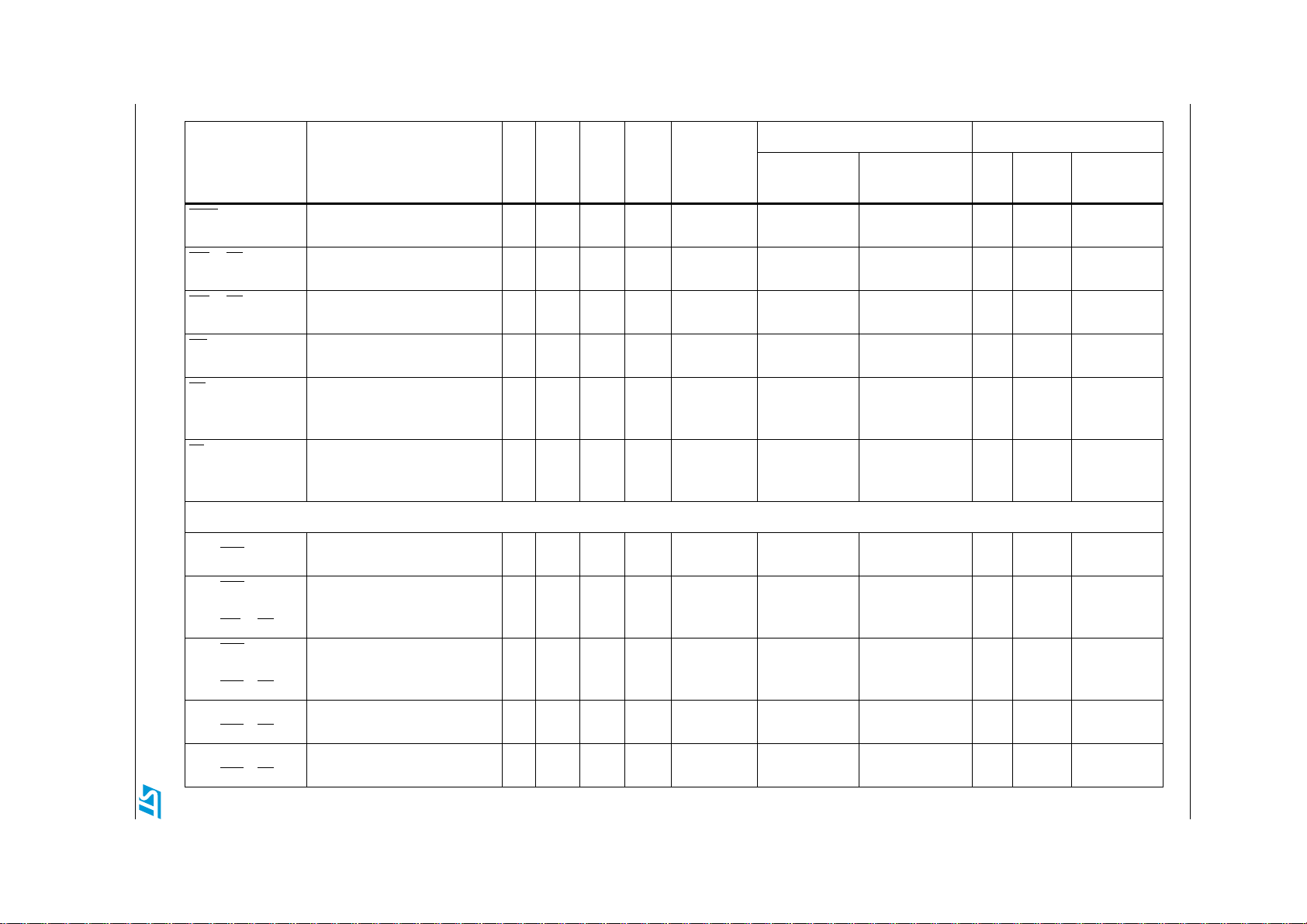

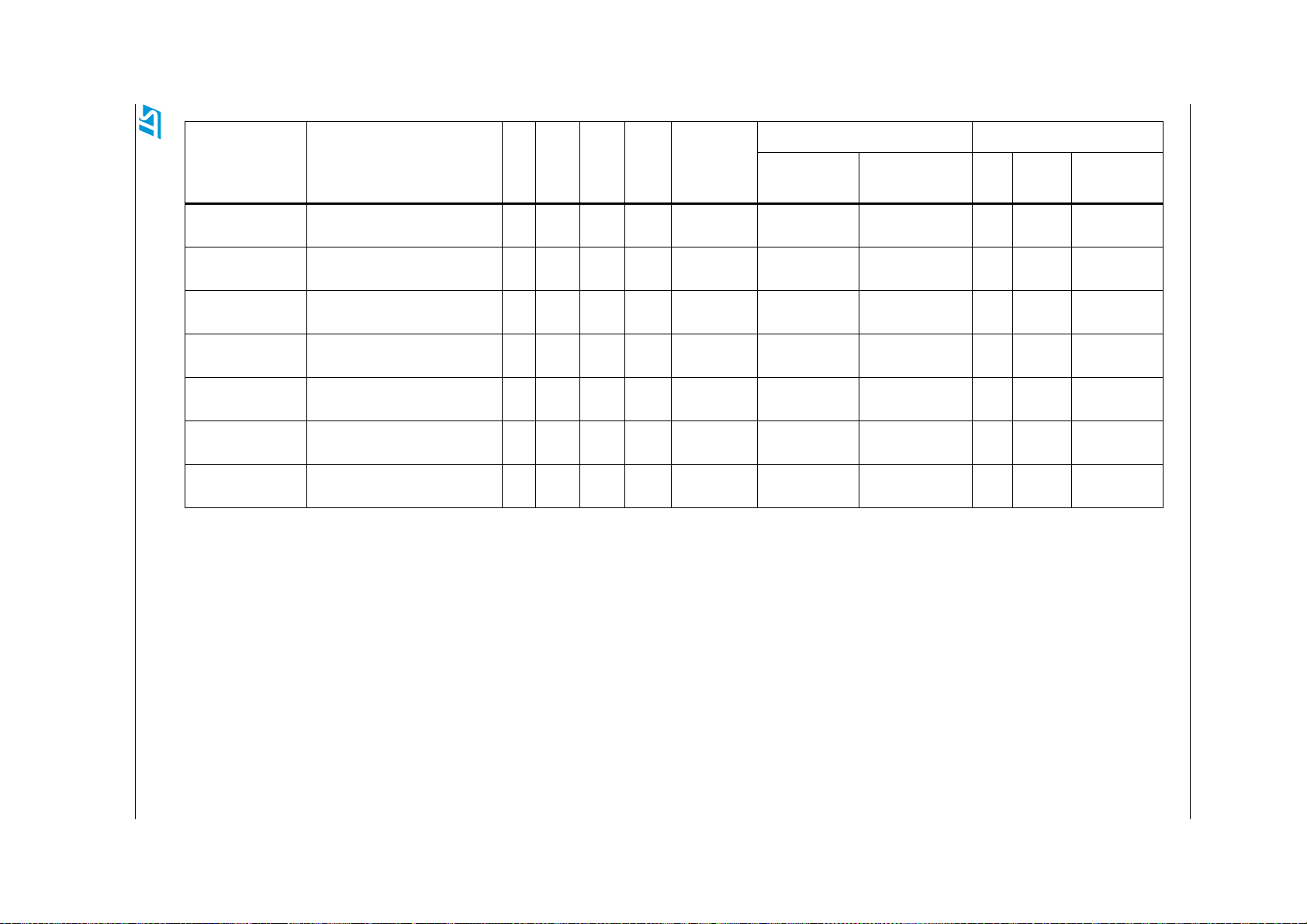

Table 3. SPC564A80 series block summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4. SPC564A80 signal properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5. Pad types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 6. Signal details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 7. Power/ground segmentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 8. Parameter classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 9. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 10. Thermal characteristics for 176-pin QFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 11. Thermal characteristics for 208-pin LBGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 12. Thermal characteristics for 324-pin PBGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 13. EMI Testing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 14. ESD ratings, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 15. PMC Operating Conditions and External Regulators Supply Voltage . . . . . . . . . . . . . . . . 89

Table 16. PMC Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 17. SPC564A80 External network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 18. Recommended operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 19. Power sequence pin states (fast pads). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 20. Power sequence pin states (medium, slow, and multi-voltage pads) . . . . . . . . . . . . . . . . . 94

Table 21. DC electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 22. I/O pad average I

Table 23. I/O pad V

Table 24. V

pad average DC current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

RC33

RC33

average I

Table 25. DSPI LVDS pad specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 26. PLLMRFM electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table 27. Temperature sensor electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 28. eQADC conversion specifications (operating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 29. eQADC single ended conversion specifications (operating). . . . . . . . . . . . . . . . . . . . . . . 107

Table 30. eQADC differential ended conversion specifications (operating) . . . . . . . . . . . . . . . . . . . 107

Table 31. Cutoff frequency for additional SRAM wait state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 32. APC, RWSC, WWSC settings vs. frequency of operation

Table 33. Flash program and erase specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 34. Flash module life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 35. Pad AC specifications (5.0 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 36. Pad AC specifications (V

Table 37. Reset and Configuration Pin Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 38. JTAG pin AC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 39. Nexus debug port timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 40. Nexus debug port operating frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table 41. External Bus Interface maximum operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table 42. Calibration bus interface maximum operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table 43. External bus interface (EBI) and calibration bus operation timing . . . . . . . . . . . . . . . . . 122

Table 44. External interrupt timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 45. eTPU timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 46. eMIOS timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table 47. DSPI channel frequency support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table 48. DSPI timing

,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

DDE

specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

DDE

,

. . . . . . . . . . . . . . . . . . . . . . . . 109

= 3.3 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

DDE

Doc ID 15399 Rev 8 5/157

List of tables SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

Table 49. eQADC SSI timing characteristics (pads at 3.3 V or at 5.0 V) . . . . . . . . . . . . . . . . . . . . . 135

Table 50. FlexCAN engine system clock divider threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 51. FlexCAN engine system clock divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 52. LQFP176 package mechanical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table 53. LBGA208 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Table 54. PBGA324 package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Table 55. Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Table 56. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

6/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 List of figures

List of figures

Figure 1. SPC564A80 series block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2. 176-pin LQFP pinout (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 3. 208-pin LBGA package ballmap (viewed from above) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 4. 324-pin PBGA package ballmap (northwest, viewed from above) . . . . . . . . . . . . . . . . . . . 37

Figure 5. 324-pin PBGA package ballmap (southwest, viewed from above) . . . . . . . . . . . . . . . . . . . 38

Figure 6. 324-pin PBGA package ballmap (northeast, viewed from above) . . . . . . . . . . . . . . . . . . . 39

Figure 7. 324-pin PBGA package ballmap (southeast, viewed from above) . . . . . . . . . . . . . . . . . . . 40

Figure 8. Core voltage regulator controller external components preferred configuration. . . . . . . . . 93

Figure 9. Pad output delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 10. Reset and Configuration Pin Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 11. JTAG test clock input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 12. JTAG test access port timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 13. JTAG JCOMP timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 14. JTAG boundary scan timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 15. Nexus output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 16. Nexus event trigger and test clock timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 17. Nexus TDI, TMS, TDO timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 18. CLKOUT timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 19. Synchronous output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 20. Synchronous input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 21. ALE signal timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 22. External Interrupt Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 23. DSPI classic SPI timing — master, CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 24. DSPI classic SPI timing — master, CPHA = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 25. DSPI classic SPI timing — slave, CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 26. DSPI classic SPI timing — slave, CPHA = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 27. DSPI modified transfer format timing — master, CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 28. DSPI modified transfer format timing — master, CPHA = 1 . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 29. DSPI modified transfer format timing — slave, CPHA =0 . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 30. DSPI modified transfer format timing — slave, CPHA =1 . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 31. DSPI PCS strobe (PCSS) timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 32. eQADC SSI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 33. LQFP176 package mechanical drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 34. PBGA324 package mechanical drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 35. Product code structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Doc ID 15399 Rev 8 7/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

1 Introduction

1.1 Document Overview

This document provides electrical specifications, pin assignments, and package diagrams

for the SPC564A80 series of microcontroller units (MCUs). For functional characteristics,

refer to the SPC564A80 Microcontroller Reference Manual.

1.2 Description

The microcontroller’s e200z4 host processor core is built on Power Architecture technology

and designed specifically for embedded applications. In addition to the Power Architecture

technology, this core supports instructions for digital signal processing (DSP).

The SPC564A80 has two levels of memory hierarchy consisting of 8 KB of instruction

cache, backed by 192 KB on-chip SRAM and 4 MB of internal flash memory. The

SPC564A80 includes an external bus interface, and also a calibration bus that is only

accessible when using the calibration tools.

This document describes the features of the SPC564A80 and highlights important electrical

and physical characteristics of the device.

8/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

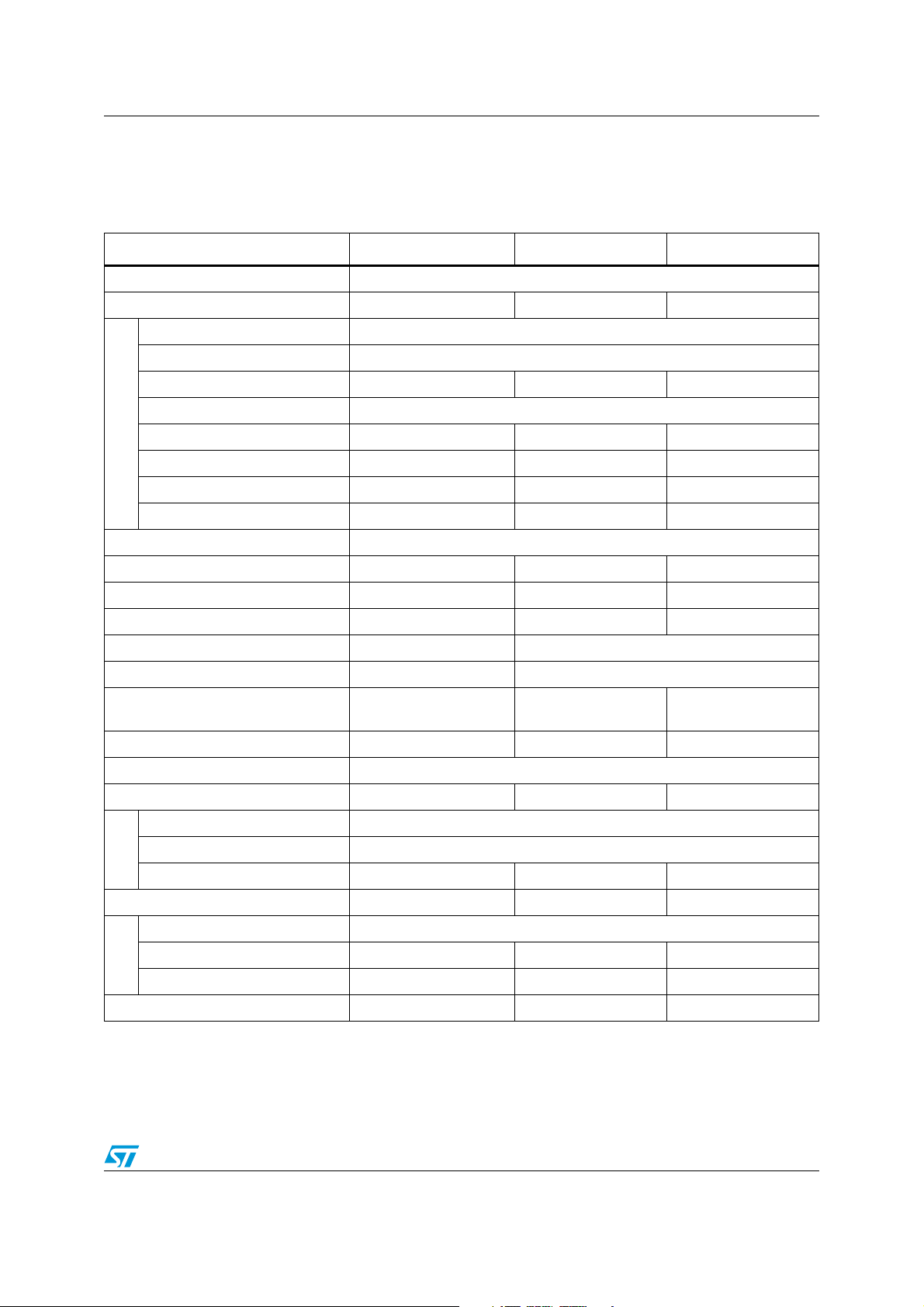

1.3 Device comparison

Ta bl e 2 summarizes the SPC564A80 and compares it to the SPC563M64.

Table 2. SPC564A80, SPC563M64 and SPC564A70 comparison

Process 90 nm

Core e200z4 e200z3 e200z4

SIMD Yes

VLE Yes

Cache 8 KB instruction No 8 KB instruction

Non-Maskable Interrupt (NMI) NMI & Critical Interrupt

MMU 24 entry 16 entry 24 entry

MPU 16 entry No 16 entry

Crossbar switch 5 × 43× 44× 4

Core performance 0–150 MHz 0–80 MHz 0–150 MHz

Windowing software watchdog Yes

Feature SPC564A80 SPC563M64 SPC564A70

Core Nexus Class 3+ Class 2+ Class 3+

SRAM 192 KB 94 KB 128 KB

Flash 4 MB 1.5 MB 2 MB

Flash fetch accelerator 4 × 256-bit 4 × 128-bit

External bus 16-bit (incl 32-bit muxed) None

Calibration bus 16-bit (incl 32-bit muxed) 16-bit

DMA 64 ch. 32 ch. 64 ch.

DMA Nexus None

Serial 3 2 3

eSCI_A Yes (MSC Uplink)

eSCI_B Yes (MSC Uplink)

eSCI_C Yes No Yes

CAN 3 2 3

CAN_A 64 buf

CAN_B 64 buf No 64 buf

CAN_C 64 buf 32 buf 64 buf

SPI 3 2 3

16-bit (incl 32-bit

muxed)

Doc ID 15399 Rev 8 9/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

Table 2. SPC564A80, SPC563M64 and SPC564A70 comparison (continued)

Feature SPC564A80 SPC563M64 SPC564A70

Micro Second Channel (MSC)

bus downlink

Ye s

DSPI_A No

DSPI_B Yes (with LVDS)

DSPI_C Yes (with LVDS)

DSPI_D Yes No Yes

FlexRay Yes No Yes

5 PIT channels

System timers

4 STM channels

1 Software Watchdog

eMIOS 24 ch. 16 ch. 24 ch.

eTPU 32 ch. eTPU2

Code memory 14 KB

Data memory 3 KB

Interrupt controller 486 ch.

(1)

307 ch. 486 ch.

ADC 40 ch. 34 ch. 40 ch.

ADC_A Yes

ADC_B Yes

Temp sensor Yes

(1)

Variable gain amp. Yes

Decimation filter 2 1 2

Sensor diagnostics Yes

CRC Yes No Yes

FMPLL Yes

VRC Yes

Supplies 5 V, 3.3 V

(2)

Low-power modes

LQFP176

LBGA208

Packages

(4)

(4)

PBGA

Known Good Die (KGD)

496-pin CSP

1. 199 interrupt vectors are reserved.

2. 5 V single supply only for LQFP176.

3. 5 V single supply only for LQFP144 and LQFP100.

4. Pinout compatible with STMicroelectronics’ SPC563M64 devices.

5. For ST calibration tool only.

(5)

5V, 3.3V

Stop Mode

Slow Mode

LQFP100

LQFP144

LQFP176

LBGA208

496-pin CSP

(3)

(5)

5V, 3.3V

LQFP176

LBGA208

PBGAKnown Good

Die (KGD)

496-pin CSP

(2)

(4)

(4)

(5)

10/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

1.4 SPC564A80 feature list

● 150 MHz e200z4 Power Architecture core

– Variable length instruction encoding (VLE)

– Superscalar architecture with 2 execution units

– Up to 2 integer or floating point instructions per cycle

– Up to 4 multiply and accumulate operations per cycle

● Memory organization

– 4 MB on-chip flash memory with ECC and Read While Write (RWW)

– 192 KB on-chip SRAM with standby functionality (32 KB) and ECC

– 8 KB instruction cache (with line locking), configurable as 2- or 4-way

– 14 + 3 KB eTPU code and data RAM

–5× 4 crossbar switch (XBAR)

– 24-entry MMU

– External Bus Interface (EBI) with slave and master port

● Fail Safe Protection

– 16-entry Memory Protection Unit (MPU)

– CRC unit with 3 sub-modules

– Junction temperature sensor

● Interrupts

– Configurable interrupt controller (with NMI)

– 64-channel DMA

● Serial channels

–3× eSCI

–3× DSPI (2 of which support downstream Micro Second Channel [MSC])

–3× FlexCAN with 64 messages each

–1× FlexRay module (V2.1) up to 10 Mbit/s with dual or single channel and 128

message objects and ECC

● 1 × eMIOS:

● 1 × eTPU2 (second generation eTPU)

– 32 standard channels

–1× reaction module (6 channels with three outputs per channel)

● 2 enhanced queued analog-to-digital converters (eQADCs)

– Forty 12-bit input channels (multiplexed on 2 ADCs); expandable to 56 channels

with external multiplexers

– 6 command queues

– Trigger and DMA support

– 688 ns minimum conversion time

● On-chip CAN/SCI/FlexRay Bootstrap loader with Boot Assist Module (BAM)

● Nexus

– Class 3+ for the e200z4 core

– Class 1 for the eTPU

● JTAG (5-pin)

24 unified channels

Doc ID 15399 Rev 8 11/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

● Development Trigger Semaphore (DTS)

– Register of semaphores (32-bits) and an identification register

– Used as part of a triggered data acquisition protocol

– EVTO pin is used to communicate to the external tool

● Clock generation

– On-chip 4–40 MHz main oscillator

– On-chip FMPLL (frequency-modulated phase-locked loop)

● Up to 120 general purpose I/O lines

– Individually programmable as input, output or special function

– Programmable threshold (hysteresis)

● Power reduction mode: slow, stop and stand-by modes

● Flexible supply scheme

– 5 V single supply with external ballast

– Multiple external supply: 5 V, 3.3 V and 1.2 V

● Packages

–LQFP176

– LBGA208

– PBGA324

– Known Good Die (KGD)

– 496-pin CSP (calibration tool only)

12/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

1.5 Feature details

1.5.1 e200z4 core

SPC564A80 devices have a high performance e200z448n3 core processor:

● Dual issue, 32-bit Power Architecture embedded category CPU

● Variable Length Encoding Enhancements

● 8 KB instruction cache: 2- or 4- way set associative instruction cache

● Thirty-two 64-bit general purpose registers (GPRs)

● Memory management unit (MMU) with 24-entry fully-associative translation look-aside

buffer (TLB)

● Harvard Architecture: Separate instruction bus and load/store bus

● Vectored interrupt support

● Non-maskable interrupt input

● Critical Interrupt input

● New ‘Wait for Interrupt’ instruction, to be used with new low power modes

● Reservation instructions for implementing read-modify-write accesses

● Signal processing extension (SPE) APU

● Single Precision Floating point (scalar and vector)

● Nexus Class 3+ debug

● Process ID manipulation for the MMU using an external tool

1.5.2 Crossbar Switch (XBAR)

The XBAR multiport crossbar switch supports simultaneous connections between five

master ports and four slave ports. The crossbar supports a 32-bit address bus width and a

64-bit data bus width.

The crossbar allows three concurrent transactions to occur from the master ports to any

slave port but each master must access a different slave. If a slave port is simultaneously

requested by more than one master port, arbitration logic selects the higher priority master

and grants it ownership of the slave port. All other masters requesting that slave port are

stalled until the higher priority master completes its transactions. Requesting masters are

treated with equal priority and are granted access to a slave port in round-robin fashion,

based upon the ID of the last master to be granted access. The crossbar provides the

following features:

● 5 master ports

– CPU instruction bus

– CPU data bus

–eDMA

–FlexRay

– External Bus Interface

Doc ID 15399 Rev 8 13/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

● 4 slave ports

–Flash

– Calibration and EBI bus

–SRAM

– Peripheral bridge

● 32-bit internal address, 64-bit internal data paths

1.5.3 eDMA

The enhanced direct memory access (eDMA) controller is a second-generation module

capable of performing complex data movements via 64 programmable channels, with

minimal intervention from the host processor. The hardware micro-architecture includes a

DMA engine which performs source and destination address calculations, and the actual

data movement operations, along with an SRAM-based memory containing the transfer

control descriptors (TCD) for the channels. This implementation is utilized to minimize the

overall block size. The eDMA module provides the following features:

● All data movement via dual-address transfers: read from source, write to destination

● Programmable source and destination addresses, transfer size, plus support for

enhanced addressing modes

● Transfer control descriptor organized to support two-deep, nested transfer operations

● An inner data transfer loop defined by a “minor” byte transfer count

● An outer data transfer loop defined by a “major” iteration count

● Channel activation via one of three methods:

– Explicit software initiation

– Initiation via a channel-to-channel linking mechanism for continuous transfers

– Peripheral-paced hardware requests (one per channel)

● Support for fixed-priority and round-robin channel arbitration

● Channel completion reported via optional interrupt requests

● One interrupt per channel, optionally asserted at completion of major iteration count

● Error termination interrupts optionally enabled

● Support for scatter/gather DMA processing

● Ability to suspend channel transfers by a higher priority channel

1.5.4 Interrupt controller

The INTC (interrupt controller) provides priority-based preemptive scheduling of interrupt

requests, suitable for statically scheduled hard real-time systems.

For high priority interrupt requests, the time from the assertion of the interrupt request from

the peripheral to when the processor is executing the interrupt service routine (ISR) has

been minimized. The INTC provides a unique vector for each interrupt request source for

quick determination of which ISR needs to be executed. It also provides an ample number of

priorities so that lower priority ISRs do not delay the execution of higher priority ISRs. To

allow the appropriate priorities for each source of interrupt request, the priority of each

interrupt request is software configurable.

When multiple tasks share a resource, coherent accesses to that resource need to be

supported. The INTC supports the priority ceiling protocol for coherent accesses. By

14/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

providing a modifiable priority mask, the priority can be raised temporarily so that all tasks

which share the resource cannot preempt each other.

The INTC provides the following features:

● 9-bit vector addresses

● Unique vector for each interrupt request source

● Hardware connection to processor or read from register

● Each interrupt source can assigned a specific priority by software

● Preemptive prioritized interrupt requests to processor

● ISR at a higher priority preempts executing ISRs or tasks at lower priorities

● Automatic pushing or popping of preempted priority to or from a LIFO

● Ability to modify the ISR or task priority to implement the priority ceiling protocol for

accessing shared resources

● Low latency—three clocks from receipt of interrupt request from peripheral to interrupt

request to processor

This device also includes a non-maskable interrupt (NMI) pin that bypasses the INTC and

multiplexing logic.

1.5.5 Memory protection unit (MPU)

The Memory Protection Unit (MPU) provides hardware access control for all memory

references generated in a device. Using preprogrammed region descriptors, which define

memory spaces and their associated access rights, the MPU concurrently monitors all

system bus transactions and evaluates the appropriateness of each transfer. Memory

references with sufficient access control rights are allowed to complete; references that are

not mapped to any region descriptor or have insufficient rights are terminated with a

protection error response.

The MPU has these major features:

● Support for 16 memory region descriptors, each 128 bits in size

– Specification of start and end addresses provide granularity for region sizes from

32 bytes to 4 GB

– MPU is invalid at reset, thus no access restrictions are enforced

– Two types of access control definitions: processor core bus master supports the

traditional {read, write, execute} permissions with independent definitions for

supervisor and user mode accesses; the remaining non-core bus masters (eDMA,

FlexRay, and EBI

1

) support {read, write} attributes

– Automatic hardware maintenance of the region descriptor valid bit removes issues

associated with maintaining a coherent image of the descriptor

– Alternate memory view of the access control word for each descriptor provides an

efficient mechanism to dynamically alter the access rights of a descriptor only

(a)

– For overlapping region descriptors, priority is given to permission granting over

access denying as this approach provides more flexibility to system software

● Support for two XBAR slave port connections (SRAM and PBRIDGE)

– For each connected XBAR slave port (SRAM and PBRIDGE), MPU hardware

monitors every port access using the pre-programmed memory region descriptors

Doc ID 15399 Rev 8 15/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

– An access protection error is detected if a memory reference does not hit in any

memory region or the reference is flagged as illegal in all memory regions where it

does hit. In the event of an access error, the XBAR reference is terminated with an

error response and the MPU inhibits the bus cycle being sent to the targeted slave

device

– 64-bit error registers, one for each XBAR slave port, capture the last faulting

address, attributes, and detail information

1.5.6 FMPLL

The FMPLL allows the user to generate high speed system clocks from a 4 MHz to 40 MHz

crystal oscillator or external clock generator. Further, the FMPLL supports programmable

frequency modulation of the system clock. The PLL multiplication factor, output clock divider

ratio are all software configurable. The PLL has the following major features:

● Input clock frequency from 4 MHz to 40 MHz

● Reduced frequency divider (RFD) for reduced frequency operation without forcing the

PLL to relock

● Three modes of operation

– Bypass mode with PLL off

– Bypass mode with PLL running (default mode out of reset)

– PLL normal mode

● Each of the three modes may be run with a crystal oscillator or an external clock

reference

● Programmable frequency modulation

– Modulation enabled/disabled through software

– Triangle wave modulation up to 100 kHz modulation frequency

– Programmable modulation depth (0% to 2% modulation depth)

– Programmable modulation frequency dependent on reference frequency

● Lock detect circuitry reports when the PLL has achieved frequency lock and

continuously monitors lock status to report loss of lock conditions

● Clock Quality Module

– Detects the quality of the crystal clock and causes interrupt request or system

reset if error is detected

– Detects the quality of the PLL output clock; if error detected, causes system reset

or switches system clock to crystal clock and causes interrupt request

● Programmable interrupt request or system reset on loss of lock

● Self-clocked mode (SCM) operation

1.5.7 SIU

The SPC564A80 SIU controls MCU reset configuration, pad configuration, external

interrupt, general purpose I/O (GPIO), internal peripheral multiplexing, and the system reset

operation. The reset configuration block contains the external pin boot configuration logic.

The pad configuration block controls the static electrical characteristics of I/O pins. The

a. EBI not available on all packages and is not available, as a master, for customer.

16/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

GPIO block provides uniform and discrete input/output control of the I/O pins of the MCU.

The reset controller performs reset monitoring of internal and external reset sources, and

drives the RSTOUT

pin. Communication between the SIU and the e200z4 CPU core is via

the crossbar switch. The SIU provides the following features:

● System configuration

– MCU reset configuration via external pins

– Pad configuration control for each pad

– Pad configuration control for virtual I/O via DSPI serialization

● System reset monitoring and generation

– Power-on reset support

– Reset status register provides last reset source to software

– Glitch detection on reset input

– Software controlled reset assertion

● External interrupt

– Rising or falling edge event detection

– Programmable digital filter for glitch rejection

– Critical Interrupt request

– Non-Maskable Interrupt request

● GPIO

– Centralized control of I/O and bus pins

– Virtual GPIO via DSPI serialization (requires external deserialization device)

– Dedicated input and output registers for setting each GPIO and Virtual GPIO pin

● Internal multiplexing

– Allows serial and parallel chaining of DSPIs

– Allows flexible selection of eQADC trigger inputs

– Allows selection of interrupt requests between external pins and DSPI

1.5.8 Flash memory

The SPC564A80 provides up to 4 MB of programmable, non-volatile, flash memory. The

non-volatile memory (NVM) can be used to store instructions or data, or both. The flash

module includes a Fetch Accelerator that optimizes the performance of the flash array to

match the CPU architecture. The flash module interfaces the system bus to a dedicated

flash memory array controller. For CPU ‘loads’, DMA transfers and CPU instruction fetch, it

supports a 64-bit data bus width at the system bus port, and 128- and 256-bit read data

interfaces to flash memory. The module contains a prefetch controller which prefetches

sequential lines of data from the flash array into the buffers. Prefetch buffer hits allow no-wait

responses.

The flash memory provides the following features:

● Supports a 64-bit data bus for instruction fetch, CPU loads and DMA access. Byte,

halfword, word and doubleword reads are supported. Only aligned word and

doubleword writes are supported.

● Fetch Accelerator

– Architected to optimize the performance of the flash

– Configurable read buffering and line prefetch support

Doc ID 15399 Rev 8 17/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

– Four-entry 256-bit wide line read buffer

– Prefetch controller

● Hardware and software configurable read and write access protections on a per-master

basis

● Interface to the flash array controller pipelined with a depth of one, allowing overlapped

accesses to proceed in parallel for interleaved or pipelined flash array designs

● Configurable access timing usable in a wide range of system frequencies

● Multiple-mapping support and mapping-based block access timing (0-31 additional

cycles) usable for emulation of other memory types

● Software programmable block program/erase restriction control

● Erase of selected block(s)

● Read page size of 128 bits (four words)

● ECC with single-bit correction, double-bit detection

● Program page size of 128 bits (four words) to accelerate programming

● ECC single-bit error corrections are visible to software

● Minimum program size is two consecutive 32-bit words, aligned on a 0-modulo-8 byte

address, due to ECC

● Embedded hardware program and erase algorithm

● Erase suspend, program suspend and erase-suspended program

● Shadow information stored in non-volatile shadow block

● Independent program/erase of the shadow block

1.5.9 BAM

The BAM (Boot Assist Module) is a block of read-only memory that is programmed once by

ST and is identical for all SPC564A80 MCUs. The BAM program is executed every time the

MCU is powered-on or reset in normal mode. The BAM supports different modes of booting.

They are:

● Booting from internal flash memory

● Serial boot loading (A program is downloaded into RAM via eSCI or the FlexCAN and

● Booting from external memory on external bus

The BAM also reads the reset configuration half word (RCHW) from internal flash memory

and configures the SPC564A80 hardware accordingly. The BAM provides the following

features:

● Sets up MMU to cover all resources and mapping of all physical addresses to logical

● Sets up MMU to allow user boot code to execute as either Power Architecture

● Location and detection of user boot code

● Automatic switch to serial boot mode if internal flash is blank or invalid

● Supports user programmable 64-bit password protection for serial boot mode

● Supports serial bootloading via FlexCAN bus and eSCI using standard protocol

● Supports serial bootloading via FlexCAN bus and eSCI with auto baud rate sensing

● Supports serial bootloading of either Power Architecture code (default) or VLE code

then executed)

addresses with minimum address translation

embedded category (default) or as VLE code

18/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

● Supports booting from calibration bus interface

● Supports censorship protection for internal flash memory

● Provides an option to enable the core watchdog timer

● Provides an option to disable the system watchdog timer

1.5.10 eMIOS

The eMIOS timer module provides the capability to generate or measure events in

hardware.

The eMIOS module features include:

● Twenty-four 24-bit wide channels

● 3 channels’ internal timebases can be shared between channels

● 1 Timebase from eTPU2 can be imported and used by the channels

● Global enable feature for all eMIOS and eTPU timebases

● Dedicated pin for each channel (not available on all package types)

Each channel (0–23) supports the following functions:

● General-purpose input/output (GPIO)

● Single-action input capture (SAIC)

● Single-action output compare (SAOC)

● Output pulse-width modulation buffered (OPWMB)

● Input period measurement (IPM)

● Input pulse-width measurement (IPWM)

● Double-action output compare (DAOC)

● Modulus counter buffered (MCB)

● Output pulse width and frequency modulation buffered (OPWFMB)

1.5.11 eTPU2

The eTPU2 is an enhanced co-processor designed for timing control. Operating in parallel

with the host CPU, the eTPU2 processes instructions and real-time input events, performs

output waveform generation, and accesses shared data without host intervention.

Consequently, for each timer event, the host CPU setup and service times are minimized or

eliminated. A powerful timer subsystem is formed by combining the eTPU2 with its own

instruction and data RAM. High-level assembler/compiler and documentation allows

customers to develop their own functions on the eTPU2.

SPC564A80 devices feature the second generation of the eTPU, called eTPU2.

Enhancements of the eTPU2 over the standard eTPU include:

● The Timer Counter (TCR1), channel logic and digital filters (both channel and the

external timer clock input [TCRCLK]) now have an option to run at full system clock

speed or system clock / 2.

● Channels support unordered transitions: transition 2 can now be detected before

transition 1. Related to this enhancement, the transition detection latches (TDL1 and

TDL2) can now be independently negated by microcode.

● A new User Programmable Channel Mode has been added: the blocking, enabling,

service request and capture characteristics of this channel mode can be programmed

via microcode.

Doc ID 15399 Rev 8 19/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

● Microinstructions now provide an option to issue Interrupt and Data Transfer requests

selected by channel. They can also be requested simultaneously at the same

instruction.

● Channel Flags 0 and 1 can now be tested for branching, in addition to selecting the

entry point.

● Channel digital filters can be bypassed.

The eTPU2 includes these distinctive features:

● 32 channels; each channel associated with one input and one output signal

– Enhanced input digital filters on the input pins for improved noise immunity

– Identical, orthogonal channels: each channel can perform any time function. Each

time function can be assigned to more than one channel at a given time, so each

signal can have any functionality.

– Each channel has an event mechanism which supports single and double action

functionality in various combinations. It includes two 24-bit capture registers, two

24-bit match registers, 24-bit greater-equal and equal-only comparators.

– Input and output signal states visible from the host

● 2 independent 24-bit time bases for channel synchronization:

– First time base clocked by system clock with programmable prescale division from

2 to 512 (in steps of 2), or by output of second time base prescaler

– Second time base counter can work as a continuous angle counter, enabling

angle based applications to match angle instead of time

– Both time bases can be exported to the eMIOS timer module

– Both time bases visible from the host

● Event-triggered microengine:

– Fixed-length instruction execution in two-system-clock microcycle

– 14 KB of code memory (SCM)

– 3 KB of parameter (data) RAM (SPRAM)

– Parallel execution of data memory, ALU, channel control and flow control sub-

instructions in selected combinations

– 32-bit microengine registers and 24-bit wide ALU, with 1 microcycle addition and

subtraction, absolute value, bitwise logical operations on 24-bit, 16-bit, or byte

operands, single-bit manipulation, shift operations, sign extension and conditional

execution

– Additional 24-bit Multiply/MAC/Divide unit which supports all signed/unsigned

Multiply/MAC combinations, and unsigned 24-bit divide. The MAC/Divide unit

works in parallel with the regular microcode commands.

● Resource sharing features support channel use of common channel registers, memory

and microengine time:

– Hardware scheduler works as a “task management” unit, dispatching event

service routines by predefined, host-configured priority

– Automatic channel context switch when a “task switch” occurs, that is, one function

thread ends and another begins to service a request from other channel: channelspecific registers, flags and parameter base address are automatically loaded for

the next serviced channel

20/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

– SPRAM shared between host CPU and eTPU2, supporting communication either

between channels and host or inter-channel

– Hardware implementation of four semaphores support coherent parameter

sharing between both eTPU engines

– Dual-parameter coherency hardware support allows atomic access to two

parameters by host

● Test and development support features:

– Nexus Class 1 debug, supporting single-step execution, arbitrary microinstruction

execution, hardware breakpoints and watchpoints on several conditions

– Software breakpoints

– SCM continuous signature-check built-in self test (MISC - multiple input signature

calculator), runs concurrently with eTPU2 normal operation

1.5.12 Reaction module

The reaction module provides the ability to modulate output signals to manage closed loop

control without CPU assistance. It works in conjunction with the eQADC and eTPU2 to

increase system performance by removing the CPU from the current control loop.

The reaction module has the following features:

● Six reaction channels

● Each channel output is a bus of three signals, providing ability to control 3 inputs.

● Each channel can implement a peak and hold waveform, making it possible to

implement up to six independent peak and hold control channels

Target applications include solenoid control for direct injection systems and valve control in

automatic transmissions

1.5.13 eQADC

The enhanced queued analog to digital converter (eQADC) block provides accurate and fast

conversions for a wide range of applications. The eQADC provides a parallel interface to two

on-chip analog to digital converters (ADC), and a single master to single slave serial

interface to an off-chip external device. Both on-chip ADCs have access to all the analog

channels.

The eQADC prioritizes and transfers commands from six command conversion command

‘queues’ to the on-chip ADCs or to the external device. The block can also receive data from

the on-chip ADCs or from an off-chip external device into the six result queues, in parallel,

independently of the command queues. The six command queues are prioritized with

Queue_0 having the highest priority and Queue_5 the lowest. Queue_0 also has the added

ability to bypass all buffering and queuing and abort a currently running conversion on either

ADC and start a Queue_0 conversion. This means that Queue_0 will always have a

deterministic time from trigger to start of conversion, irrespective of what tasks the ADCs

were performing when the trigger occurred. The eQADC supports software and external

hardware triggers from other blocks to initiate transfers of commands from the queues to the

on-chip ADCs or to the external device. It also monitors the fullness of command queues

and result queues, and accordingly generates DMA or interrupt requests to control data

movement between the queues and the system memory, which is external to the eQADC.

The ADCs also support features designed to allow the direct connection of high impedance

acoustic sensors that might be used in a system for detecting engine knock. These features

Doc ID 15399 Rev 8 21/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

include differential inputs; integrated variable gain amplifiers for increasing the dynamic

range; programmable pull-up and pull-down resistors for biasing and sensor diagnostics.

The eQADC also integrates a programmable decimation filter capable of taking in ADC

conversion results at a high rate, passing them through a hardware low pass filter, then

down-sampling the output of the filter and feeding the lower sample rate results to the result

FIFOs. This allows the ADCs to sample the sensor at a rate high enough to avoid aliasing of

out-of-band noise; while providing a reduced sample rate output to minimize the amount

DSP processing bandwidth required to fully process the digitized waveform.

The eQADC provides the following features:

● Dual on-chip ADCs

–2 × 12-bit ADC resolution

– Programmable resolution for increased conversion speed (12-bit, 10-bit, 8-bit)

12-bit conversion time: 938 ns (1 M sample/sec)

10-bit conversion time: 813 ns (1.2 M sample/second)

8-bit conversion time: 688 ns (1.4 M sample/second)

– Up to 10-bit accuracy at 500 KSample/s and 8-bit accuracy at 1 MSample/s

– Differential conversions

– Single-ended signal range from 0 to 5 V

– Variable gain amplifiers on differential inputs (×1, ×2, ×4)

– Sample times of 2 (default), 8, 64 or 128 ADC clock cycles

– Provides time stamp information when requested

– Allows time stamp information relative to eTPU clock sources, such as an angle

clock

– Parallel interface to eQADC CFIFOs and RFIFOs

– Supports both right-justified unsigned and signed formats for conversion results

● 40 single-ended input channels, expandable to 56 channels with external multiplexers

(supports four external 8-to-1 muxes)

● 8 channels can be used as 4 pairs of differential analog input channels

● Differential channels include variable gain amplifier for improved dynamic range

● Differential channels include programmable pull-up and pull-down resistors for biasing

and sensor diagnostics (200 kΩ, 100 kΩ, 5kΩ)

● Additional internal channels for monitoring voltages (such as core voltage, I/O voltage,

LVI voltages, etc.) inside the device

● An internal bandgap reference to allow absolute voltage measurements

● Silicon die temperature sensor

– Provides temperature of silicon as an analog value

– Read using an internal ADC analog channel

– May be read with either ADC

● 2 Decimation Filters

– Programmable decimation factor (1 to 16)

– Selectable IIR or FIR filter

– Up to 4th order IIR or 8th order FIR

– Programmable coefficients

22/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

– Saturated or non-saturated modes

– Programmable Rounding (Convergent; Two’s Complement; Truncated)

– Prefill mode to precondition the filter before the sample window opens

– Supports Multiple Cascading Decimation Filters to implement more complex filter

designs

– Optional Absolute Integrators on the output of Decimation Filters

● Full duplex synchronous serial interface to an external device

– Free-running clock for use by an external device

– Supports a 26-bit message length

● Priority based queues

– Supports six queues with fixed priority. When commands of distinct queues are

bound for the same ADC, the higher priority queue is always served first

– Queue_0 can bypass all prioritization, buffering and abort current conversions to

start a Queue_0 conversion a deterministic time after the queue trigger

– Supports software and hardware trigger modes to arm a particular queue

– Generates interrupt when command coherency is not achieved

● External hardware triggers

– Supports rising edge, falling edge, high level and low level triggers

– Supports configurable digital filter

1.5.14 DSPI

The deserial serial peripheral interface (DSPI) block provides a synchronous serial interface

for communication between the SPC564A80 MCU and external devices. The DSPI supports

pin count reduction through serialization and deserialization of eTPU and eMIOS channels

and memory-mapped registers. The channels and register content are transmitted using a

SPI-like protocol. This SPI-like protocol is completely configurable for baud rate, polarity and

phase, frame length, chip select assertion, etc. Each bit in the frame may be configured to

serialize either eTPU channels, eMIOS channels or GPIO signals. The DSPI can be

configured to serialize data to an external device that implements the Microsecond Bus

protocol. There are three identical DSPI blocks on the SPC564A80 MCU. The DSPI pins

support 5 V logic levels or Low Voltage Differential Signalling (LVDS) to improve high speed

operation.

DSPI module features include:

● Selectable LVDS pads working at 40 MHZ for SOUT and SCK pins for DSPI_B and

● 3 sources of serialized data: eTPU_A, eMIOS output channels and memory-mapped

● 4 destinations for deserialized data: eTPU_A and eMIOS input channels, SIU external

● 32-bit DSI and TSB modes require 32 PCR registers, 32 GPO and GPI registers in the

● The DSPI Module can generate and check parity in a serial frame

DSPI_C

register in the DSPI

Interrupt input request, memory-mapped register in the DSPI

SIU to select either GPIO, eTPU or eMIOS bits for serialization

Doc ID 15399 Rev 8 23/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

1.5.15 eSCI

Three enhanced serial communications interface (eSCI) modules provide asynchronous

serial communications with peripheral devices and other MCUs, and include support to

interface to Local Interconnect Network (LIN) slave devices. Each eSCI block provides the

following features:

● Full-duplex operation

● Standard mark/space non-return-to-zero (NRZ) format

● 13-bit baud rate selection

● Programmable 8-bit or 9-bit, data format

● Programmable 12-bit or 13-bit data format for Timed Serial Bus (TSB) configuration to

support the Microsecond bus standard

● Automatic parity generation

● LIN support

– Autonomous transmission of entire frames

– Configurable to support all revisions of the LIN standard

– Automatic parity bit generation

– Double stop bit after bit error

– 10- or 13-bit break support

● Separately enabled transmitter and receiver

● Programmable transmitter output parity

● 2 receiver wake-up methods:

– Idle line wake-up

– Address mark wake-up

● Interrupt-driven operation with flags

● Receiver framing error detection

● Hardware parity checking

● 1/16 bit-time noise detection

● DMA support for both transmit and receive data

– Global error bit stored with receive data in system RAM to allow post processing of

errors

1.5.16 FlexCAN

The SPC564A80 MCU includes three controller area network (FlexCAN) blocks. The

FlexCAN module is a communication controller implementing the CAN protocol according to

Bosch Specification version 2.0B. The CAN protocol was designed to be used primarily as a

vehicle serial data bus, meeting the specific requirements of this field: real-time processing,

reliable operation in the EMI environment of a vehicle, cost-effectiveness and required

bandwidth. Each FlexCAN module contains 64 message buffers.

24/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

The FlexCAN modules provide the following features:

● Full Implementation of the CAN protocol specification, Version 2.0B

– Standard data and remote frames

– Extended data and remote frames

– Zero to eight bytes data length

– Programmable bit rate up to 1 Mbit/s

● Content-related addressing

● 64 message buffers of zero to eight bytes data length

● Individual Rx Mask Register per message buffer

● Each message buffer configurable as Rx or Tx, all supporting standard and extended

messages

● Includes 1088 bytes of embedded memory for message buffer storage

● Includes 256-byte memory for storing individual Rx mask registers

● Full featured Rx FIFO with storage capacity for six frames and internal pointer handling

● Powerful Rx FIFO ID filtering, capable of matching incoming IDs against 8 extended, 16

standard or 32 partial (8 bits) IDs, with individual masking capability

● Selectable backwards compatibility with previous FlexCAN versions

● Programmable clock source to the CAN Protocol Interface, either system clock or

oscillator clock

● Listen only mode capability

● Programmable loop-back mode supporting self-test operation

● 3 programmable Mask Registers

● Programmable transmit-first scheme: lowest ID, lowest buffer number or highest priority

● Time Stamp based on 16-bit free-running timer

● Global network time, synchronized by a specific message

● Maskable interrupts

● Warning interrupts when the Rx and Tx Error Counters reach 96

● Independent of the transmission medium (an external transceiver is assumed)

● Multi-master concept

● High immunity to EMI

● Short latency time due to an arbitration scheme for high-priority messages

● Low power mode, with programmable wake-up on bus activity

Doc ID 15399 Rev 8 25/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

1.5.17 FlexRay

The SPC564A80 includes one dual-channel FlexRay module that implements the FlexRay

Communications System Protocol Specification, Version 2.1 Rev A. Features include:

● Single channel support

● FlexRay bus data rates of 10 Mbit/s, 8 Mbit/s, 5 Mbit/s, and 2.5 Mbit/s supported

● 128 message buffers, each configurable as:

– Receive message buffer

– Single buffered transmit message buffer

– Double buffered transmit message buffer (combines two single buffered message

buffer)

● 2 independent receive FIFOs

– 1 receive FIFO per channel

– Up to 255 entries for each FIFO

● ECC support

1.5.18 System timers

The system timers include two distinct types of system timer:

● Periodic interrupts/triggers using the Periodic Interrupt Timer (PIT)

● Operating system task monitors using the System Timer Module (STM)

Periodic interrupt timer (PIT)

The PIT provides five independent timer channels, capable of producing periodic interrupts

and periodic triggers. The PIT has no external input or output pins and is intended to provide

system ‘tick’ signals to the operating system, as well as periodic triggers for eQADC queues.

Of the five channels in the PIT, four are clocked by the system clock and one is clocked by

the crystal clock. This one channel is also referred to as Real-Time Interrupt (RTI) and is

used to wake up the device from low power stop mode.

The following features are implemented in the PIT:

● 5 independent timer channels

● Each channel includes 32-bit wide down counter with automatic reload

● 4 channels clocked from system clock

● 1 channel clocked from crystal clock (wake-up timer)

● Wake-up timer remains active when System STOP mode is entered; used to restart

system clock after predefined time-out period

● Each channel optionally able to generate an interrupt request or a trigger event (to

trigger eQADC queues) when timer reaches zero

System timer module (STM)

The System Timer Module (STM) is designed to implement the software task monitor as

defined by AUTOSAR

(b)

. It consists of a single 32-bit counter, clocked by the system clock,

b. AUTOSAR: AUTomotive Open System ARchitecture (see www.autosar.org)

26/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

and four independent timer comparators. These comparators produce a CPU interrupt when

the timer exceeds the programmed value.

The following features are implemented in the STM:

● One 32-bit up counter with 8-bit prescaler

● Four 32-bit compare channels

● Independent interrupt source for each channel

● Counter can be stopped in debug mode

1.5.19 Software watchdog timer (SWT)

The Software Watchdog Timer (SWT) is a second watchdog module to complement the

standard Power Architecture watchdog integrated in the CPU core. The SWT is a 32-bit

modulus counter, clocked by the system clock or the crystal clock, that can provide a system

reset or interrupt request when the correct software key is not written within the required

time window.

The following features are implemented:

● 32-bit modulus counter

● Clocked by system clock or crystal clock

● Optional programmable watchdog window mode

● Can optionally cause system reset or interrupt request on timeout

● Reset by writing a software key to memory mapped register

● Enabled out of reset

● Configuration is protected by a software key or a write-once register

1.5.20 Cyclic redundancy check (CRC) module

The CRC computing unit is dedicated to the computation of CRC off-loading the CPU. The

CRC features:

● Support for CRC-16-CCITT (x25 protocol):

16

–X

● Support for CRC-32 (Ethernet protocol):

–X

● Zero wait states for each write/read operations to the CRC_CFG and CRC_INP

+ X12 + X5 + 1

32

+ X26 + X23 + X22 + X16 + X12 + X11 + X10 + X8 + X7 + X5 + X4 + X2 + X + 1

registers at the maximum frequency

1.5.21 Error correction status module (ECSM)

The ECSM provides a myriad of miscellaneous control functions regarding program-visible

information about the platform configuration and revision levels, a reset status register, a

software watchdog timer, wakeup control for exiting sleep modes, and information on

platform memory errors reported by error-correcting codes and/or generic access error

information for certain processor cores.

Doc ID 15399 Rev 8 27/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

The Error Correction Status Module supports a number of miscellaneous control functions

for the platform. The ECSM includes these features:

● Registers for capturing information on platform memory errors if error-correcting codes

(ECC) are implemented

● For test purposes, optional registers to specify the generation of double-bit memory

errors are enabled on the SPC564A80.

The sources of the ECC errors are:

● Flash

● SRAM

● Peripheral RAM (FlexRay, CAN, eTPU2 Parameter RAM)

1.5.22 External bus interface (EBI)

The SPC564A80 device features an external bus interface that is available in PBGA324 and

calibration packages.

The EBI supports operation at frequencies of system clock /1, /2 and /4, with a maximum

frequency support of 80 MHz. Customers running the device at 120 MHz or 132 MHz will

use the /2 divider, giving an EBI frequency of 60 MHz or 66 MHz. Customers running the

device at 80 MHz will be able to use the /1 divider to have the EBI run at the full 80 MHz

frequency.

Features include:

● 1.8 V to 3.3 V ± 10% I/O (1.6 V to 3.6 V)

● Memory controller with support for various memory types

● 16-bit data bus, up to 22-bit address bus

● Pin muxing included to support 32-bit muxed bus

● Selectable drive strength

● Configurable bus speed modes

● Bus monitor

● Configurable wait states

1.5.23 Calibration EBI

The Calibration EBI controls data transfer across the crossbar switch to/from memories or

peripherals attached to the calibration tool connector in the calibration address space. The

Calibration EBI is only available in the calibration tool.

Features include:

● 1.8 V to 3.3 V ± 10% I/O (1.6 V to 3.6 V)

● Memory controller supports various memory types

● 16-bit data bus, up to 22-bit address bus

● Pin muxing supports 32-bit muxed bus

● Selectable drive strength

● Configurable bus speed modes

● Bus monitor

● Configurable wait states

28/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

1.5.24 Power management controller (PMC)

The power management controller contains circuitry to generate the internal 3.3 V supply

and to control the regulation of 1.2 V supply with an external NPN ballast transistor. It also

contains low voltage inhibit (LVI) and power-on reset (POR) circuits for the 1.2 V supply, the

3.3 V supply, the 3.3 V/5 V supply of the closest I/O segment (VDDEH1) and the 5 V supply

of the regulators (VDDREG).

1.5.25 Nexus port controller

The NPC (Nexus Port Controller) block provides real-time Nexus Class3+ development

support capabilities for the SPC564A80 Power Architecture-based MCU in compliance with

the IEEE-ISTO 5001-2003 and 2010 standards. MDO port widths of 4 pins and 12 pins are

available in all packages.

1.5.26 JTAG

The JTAGC (JTAG Controller) block provides the means to test chip functionality and

connectivity while remaining transparent to system logic when not in test mode. Testing is

performed via a boundary scan technique, as defined in the IEEE 1149.1-2001 standard. All

data input to and output from the JTAGC block is communicated in serial format. The JTAGC

block is compliant with the IEEE 1149.1-2001 standard and supports the following features:

● IEEE 1149.1-2001 Test Access Port (TAP) interface 4 pins (TDI, TMS, TCK, and TDO)

● A 5-bit instruction register that supports the following IEEE 1149.1-2001 defined

instructions:

– BYPASS, IDCODE, EXTEST, SAMPLE, SAMPLE/PRELOAD, HIGHZ, CLAMP

● A 5-bit instruction register that supports the additional following public instructions:

– ACCESS_AUX_TAP_NPC

– ACCESS_AUX_TAP_ONCE

– ACCESS_AUX_TAP_eTPU

– ACCESS_CENSOR

● 3 test data registers to support JTAG Boundary Scan mode

– Bypass register

– Boundary scan register

– Device identification register

● A TAP controller state machine that controls the operation of the data registers,

instruction register and associated circuitry

● Censorship Inhibit Register

– 64-bit Censorship password register

– If the external tool writes a 64-bit password that matches the Serial Boot password

stored in the internal flash shadow row, Censorship is disabled until the next

system reset.

1.5.27 Development Trigger Semaphore (DTS)

SPC564A80 devices include a system development feature, the Development Trigger

Semaphore (DTS) module, that enables software to signal an external tool by driving a

persistent (affected only by reset or an external tool) signal on an external device pin. There

Doc ID 15399 Rev 8 29/157

Introduction SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7

is a variety of ways this module can be used, including as a component of an external realtime data acquisition system

1.6 SPC564A80 series architecture

1.6.1 Block diagram

Figure 1 shows a top-level block diagram of the SPC564A80 series.

30/157 Doc ID 15399 Rev 8

SPC564A74B4, SPC564A74L7, SPC564A80B4, SPC564A80L7 Introduction

Interrupt

Controller

eDMA

64 Channel

S0

4 MB

Flash

Power Architecture

e200z4

TM

JTAG

Nexus Class 3+

SPE

VLE

MMU

8 KB I-cache

M4 M0 M6 M7

M1

Nexus

IEEE-ISTO

5001-2003/2010

FlexRay

Crossbar Switch

S1

Voltage Regulator

S2 S7

192 KB

MPU

Analog PLL

SRAM

RCOSC

Standby

Regulator

XOSC

with Switch

Ext. Bus InterfaceCal Bus Interface

ECSM

eMIOS

24

Channel

ADC – Analog to Digital Converter

ADCi – ADC interface

AMux – Analog Multiplexer

BAM – Boot Assist Module

CRC – Cyclic Redundancy Check unit

DEC – Decimation Filter

DTS – Development Trigger Semaphore

DSPI – Deserial/Serial Peripheral Interface

EBI – External Bus Interface

ECSM – Error Correction Status Module

eDMA – Enhanced Direct Memory Access

eMIOS – Enhanced Modular Input Output System

eSCI – Enhanced Serial Communications Interface

eTPU2 – Second gen. Enhanced Time Processing Unit

FlexCAN– Controller Area Network (FlexCAN)

FMPLL – Frequency-Modulated Phase Locked Loop

RAM

14 KB Code

RAM

3 KB Data

eTPU2

32

Channel

Nexus

Class 1

REACM