Page 1

February 1998 1/49

R

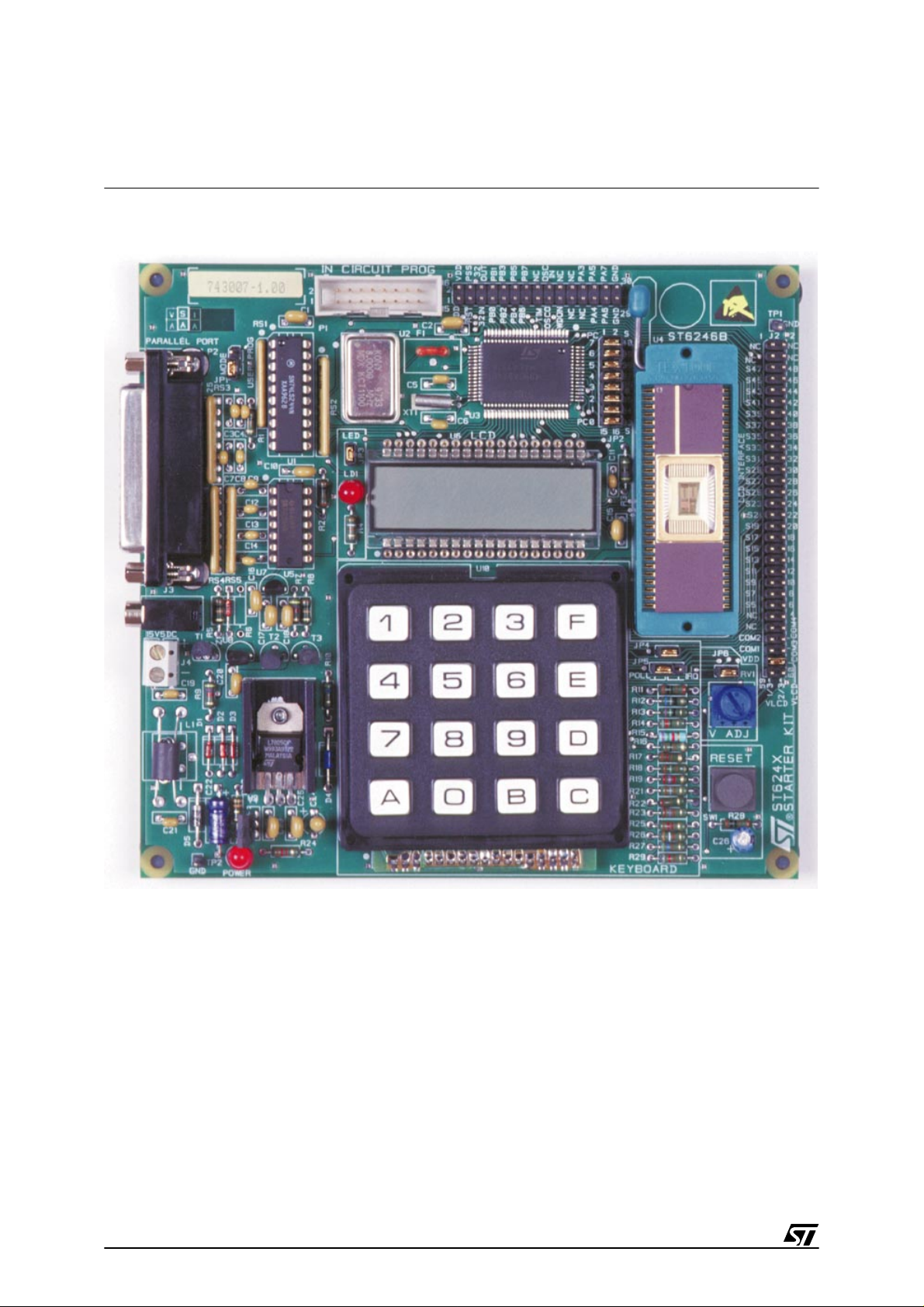

ST624x-KIT

STARTER KIT FOR ST624x MCU FAMILY

HARDWARE FEATURES

■

Immediate evaluation of ST6240 with

demonstration examples

■

Program debugging within the user’s real

application environment

■

On board programming of ST62E46 and

ST62T46

■

In-circuit programming of ST62E4x and

ST62T4x devices on the user’s application

board

SOFTWARE FEATURES

■

Software simulator including LCD display and

I/O read/write

■

Assembler, linker, debugger

■

EPROM/OTP programming utilities

■

Application examples

5

查询ST624x-KIT供应商 捷多邦,专业PCB打样工厂,24小时加急出货

Page 2

2/49

Table of Contents

6

ST624x -KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Where to go from here... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 THE STARTER KIT HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 The ST6 Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 The Starter Kit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 8 MHz and 32 KHz Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 8-alphanumeric Digit LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Hexadecimal Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Resistance trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9 Combi-ports PC0-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 INSTALLING THE STARTER KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Hardware and Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 I ns ta llin g the Softwar e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 RUNNING THE DEMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 What the Demos Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Demo 1 - Key Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.2 Demo 2 - Voltmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Running the Demonstration Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 CONNECTING EXTERNAL RESOURCES TO THE STARTER KIT BOARD . . . . . . . . . . . . . . 19

6 USING THE STARTER KIT BOARD AS A HARDWARE SIMULATOR . . . . . . . . . . . . . . . . . . 22

6.1 The Data Transmission Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Technical Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4 Troublesho oting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 EXERCISES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Exercise 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Exercise 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 PROGRAMMING ST6 MICROCONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1 Setting Up the Starter Kit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.2 In-Circuit Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2.1 Application B oard Connect ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3 Setting Up the Starter Kit Board for In-Circuit Programming . . . . . . . . . . . . . . . . . . . . . . . 35

Page 3

3/49

Table of Contents

9 LCD INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1 ST6240 LCD DRIVER OVERVIE W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.2 STARTER KIT LCD PANEL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.3 Interfacing The LCD Panel with the ST6240 LCD Driver . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.4 Character Definition Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.4.1 Character A Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.4.2 Character 3 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.5 Starter Kit LCD Panel Character Set Software Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.5.1 Direct Code LCD RAM Patching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.5.2 Indexed Data ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.5.3 Complete Message Displa y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10 HARDWARE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.1Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.2Starter Kit Board Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7

Page 4

4/49

Introduction

1 INTRODUCTION

The ST624x Starter Kit provides you with all you need to start designing, developing and evaluating programs for ST624x microcontrollers immediately.

The ST624x Starter Kit includes:

• The ST6 assembler and linker, AST6 and LST6.

• The ST6 Windows debugger, WGDB6.

• The Windows ST6 microcontroller programmer, Epromer.

• The ST6 Starter Kit board, w hich serves as a demonstration board and low-cost debugging tool.

• Some demonstration programs that show how ST6 microcontrollers use the Starter Kit

board resources.

• Some example programs.

• Two ST62E46BF1 microcontro llers.

• A complete set of paper documentation and online help.

The demonstration programs, that come pre-loaded on the ST62T40B microcontroller, show

how the powerful features of ST6 microcontrollers operate in a real environment. The demonstration programs use the hardware resources provided on the Starter Kit board, which include an LCD, hexadecimal keyboard, a resistance trimmer and an 8 MHz and a 32 KHz oscillator.

Using the ST6 assembler and linker, AST6 and LST6, you can assemble and link ST6 programs. The "ST6 Family Software development tools AST6, LST6, WGDB6" User Manual will

guide you through the steps of developing, assembling and linking programs for the ST6. The

Starter Kit software includes a set of example programs of typical ST6 applications. These are

installed in the directory C:\st6tools\sk624Xi1\examples.

For a fast-track solution for developing bug-free programs for the ST6, without the hassle of

writing assembler code, try out the ST6-Realizer program.

Once you have developed your ST6 program, you can use the Windows-based ST6 program

debugger, WGDB6/SIMULATOR, together with the Starter Kit board, as a low-cost but powerful debugging tool. WGDB6 includes an ST6 simulator, that simulates the execution of your

program, and uses the ST6 that is plugged into the Starter Kit board to emulate all transactions that are performed with the data space. Thus, using the Starter Kit board with WGDB6,

you can view how the microcontroller peripherals behave when your program is executed.

WGDB6 includes powerful debugging features, such as source-level debugging, instruction

and conditional memory access breakpoints and selective trace recording. The "ST 6 Family

8

Page 5

5/49

Introduction

Software development tools AST6, LST6, WGDB6" User Manual and online help will lead you

through the debugging process using WGDB6.

When your program is ready, Epromer provides you with an easy-to-use Windows interface,

which lets you prepare executable code, then write it to the ST62E46B microcontroller that

can be plugged into the SDIP56 ZIF socket on the Starter Kit board, or your own in-circuit application board that is connected to the Starter Kit board.

The ST62T40B can’t be erased or programmed, it is already programmed and contains the

demonstrations program.

To observe and evaluate the consequences of your program on the resources it controls, you

can run it on the ST62T40B microcontroller that is s oldered on the Starter K it board in Hardware Simulation mode. If it controls a resource that is not included on the Starter Kit board,

you can connect your own resource to the board.

Instructions for use - Warning

This product conforms with the 89/336/EEC directive; it also complies with the EN55022 emissions standard for ITE, as well as with generic 50082-1 immunity standards.

The product is a

Class A apparatus

. In a residential environment this device may cause ra-

dioelectrical disturbances which may require that the user adopt appropriate precautions.

The product is not contained in an outer c asing, and cannot therefore be immune against elec-

trostatic discharge (ESD):

it should therefore only be handled at static safe work stations.

9

Page 6

6/49

Introduction

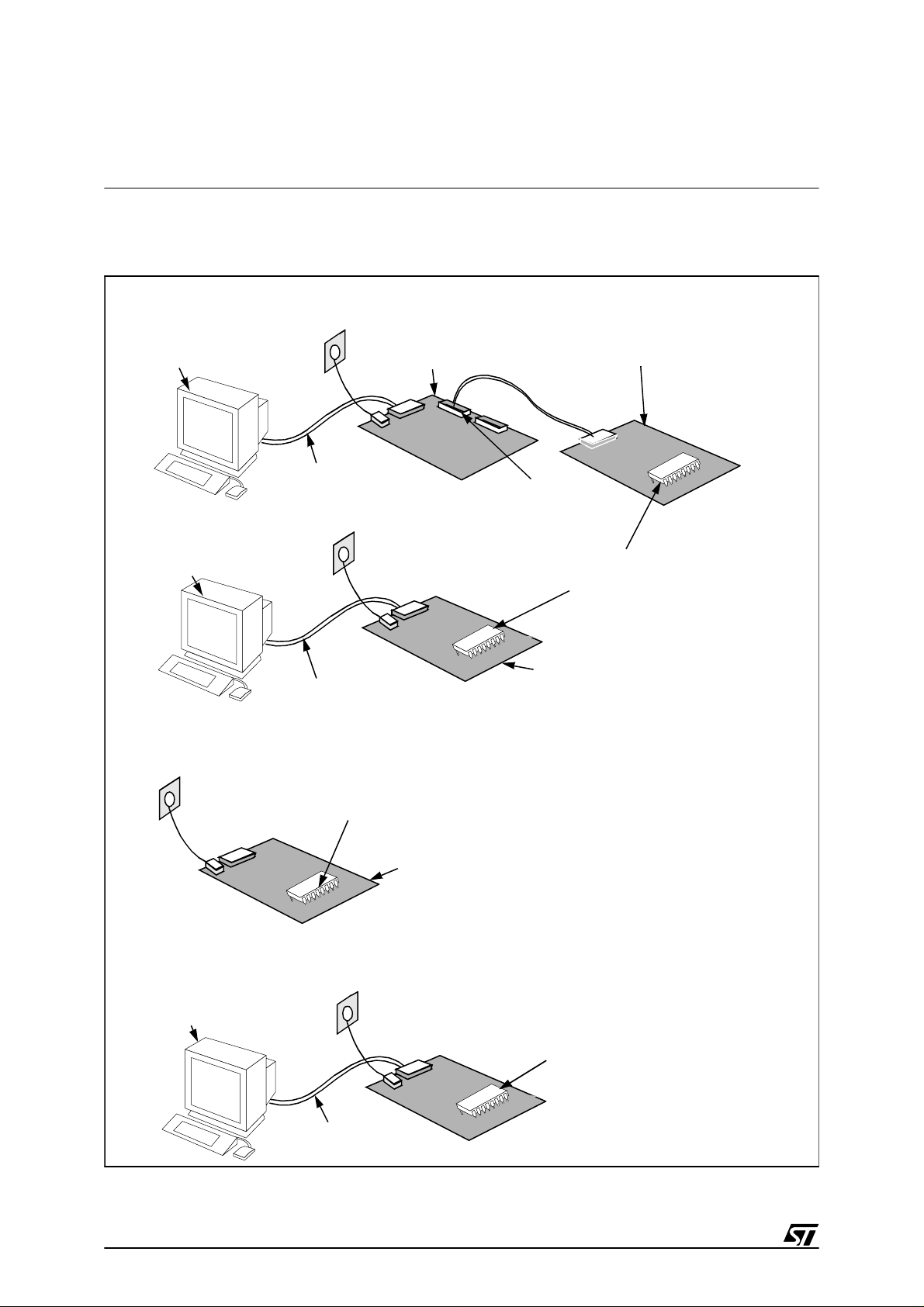

The following diagram summarises the possible uses of the Starter Kit board and the hardware setup required for each one.

To program ST6s on your own in-circuit programming board:

To run the demonstrations:

To use the Starter Kit board as a hardware simulator:

To program ST6s using the Starter Kit board:

PC running

Epromer

Starter Kit

board

In-circuit

programming board

Parallel port

connected to P2

Parallel port

connected to P2

P1 connector

ST6 to be

programmed

PC running

Epromer

ST62T40B Programmed with

DEMOKIT2.HEX

Starter Kit board

Starter Kit board

PC running

WGDB6 Simulator

ST62T40B Programmed with

DEMOKIT2.HEX

Parallel port

connected to P2

10

Page 7

7/49

Introduction

1.1 Where to go from here...

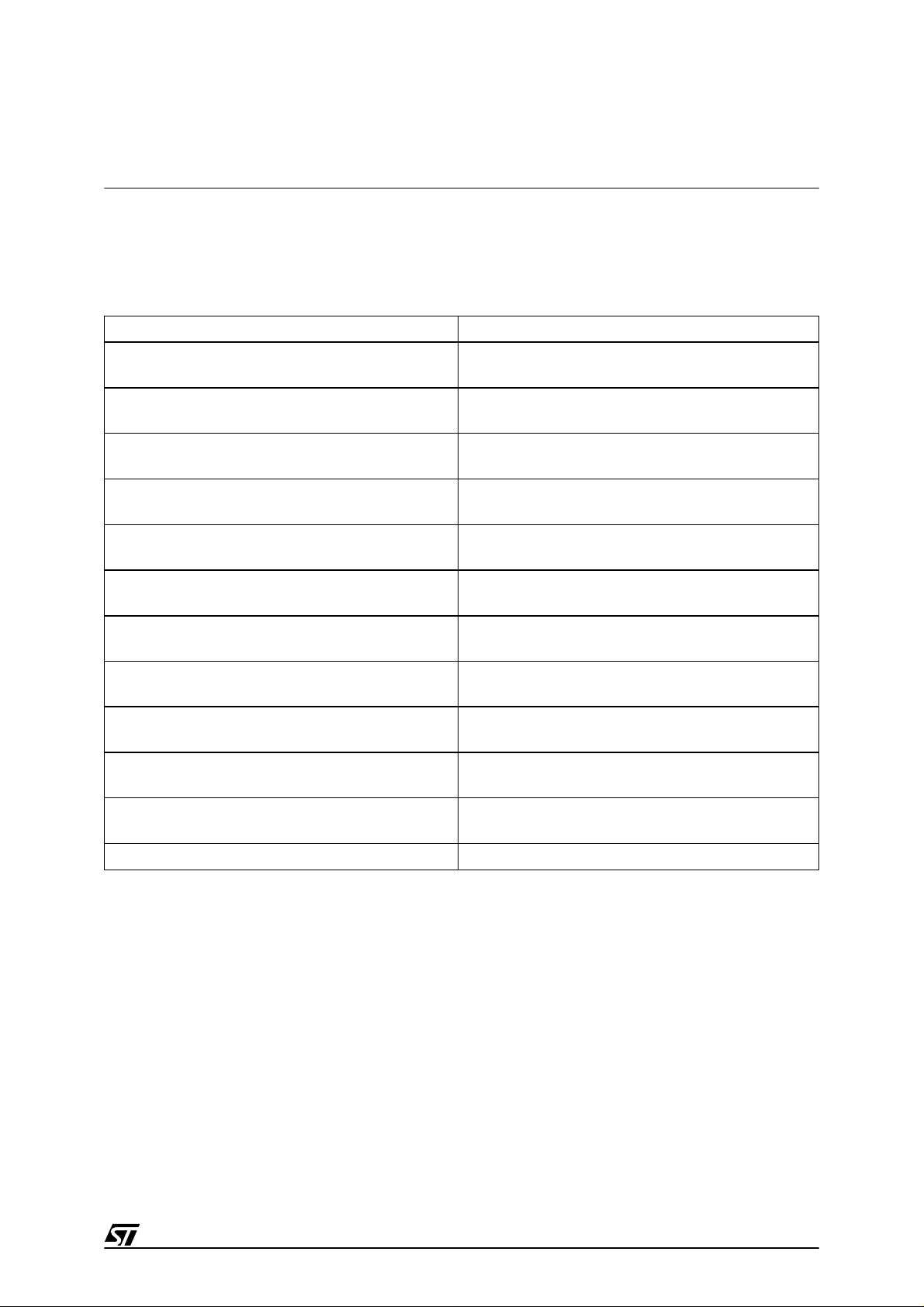

The following table directs you to where you should look for further information about using the

ST6 Starter Kit

To: Refer to:

Find out about the Starter Kit board and ST6

microcontrollers provided with the kit.

“The Starter Kit Hardware” on page 8 of this book.

Install the Starter Kit software, and connect the

power supply to th e board.

“Installing the Starter Kit” on page 15 of this book.

Find out what the demonstration applications do,

and run them.

“Running the Demos” on page 17 of this book.

Learn how to develop source code for AST6 and

LST6.

"ST6 Family Software development tools AST 6,

LST6, WGDB6" User Manual.

Prepare the Starter Kit board for use as an ST6

hardware simulator with WGDB6.

“Using The Starter Kit Board as a Hardware

Simulator” on page 22 of this book.

Learn how to use WGDB6 for debugging your

programs.

"ST6 Family Software development tools AST 6,

LST6, WGDB6" User Manual.

Prepare the Starter Kit board for programming

ST6 microcontrollers using Epromer.

“Programming ST6 Microcontrollers” on page 32 of

this book.

Prepare the Starter Kit board for connecting your

own in-circuit programming board.

“In-Circuit Programming” on page 33 of this book.

Learn how to use Eprommer for programming

ST6 microcontrollers.

The Epromer online help.

Connect your own hardware resource or LCD to

the Starter Kit board.

“Connecting External Resources to the Starter Kit

Board” on page 19 of this book.

Perform some introductory excercises using

WGDB6.

“Exercises” on page 26.

Learn how the LCD interface works. “LCD Interface” on page 36.

11

Page 8

8/49

The Starter Kit Hardware

2 THE STARTER KIT HARDWARE

This section describes the ST6 microcontrollers and the Starte r Kit board that come w ith the

ST6 Starter Kit. A full schematic of the Starter Kit board is provided in “Hardware Information”

on page 47.

2.1 The ST6 Microcontroller

The Starter Kit includes two ST62E46BF1 microcontrollers.

The ST62T40B microcontroller is pre-loaded with the c ode

DEMOKIT2.HEX

, which includes

the demonstration programs (see “Running the Demos” on page 17), as well as the communications protocol program, that enables you to use the Starter Kit board as a sim ulator (see

“Using The Starter Kit Board as a Hardware Simulator” on page 22).

2.2 The Starter Kit Board

The Starter Kit board includes the following resources:

• A Reset button.

• An 8-alphanumeric digit LCD.

• A hexadecimal keyboard.

• A LED indicator.

• A resistance trimmer.

• One 8 MHz and one 32 KHz oscillator.

• A SDIP56 ZIF socket to program the ST62E46B or ST62T46B.

It comes with its own power supply unit that can be plugged i nto an AC mains source, or a DC

source with the following characteristics:

• Voltage: 16V min./20V max.

• Current: 100 mA min.

12

Page 9

9/49

The Starter Kit Hardware

It includes the following connectors:

• A parallel port connector (P2) for connection to the host PC when it is used as a hardware

simulator or for programming.

• A remote resource I/O interface (J1).

• An in-circuit ST6 programming board connector (P1).

• A remote LCD connector (J2) to which you can connect your own LCD.

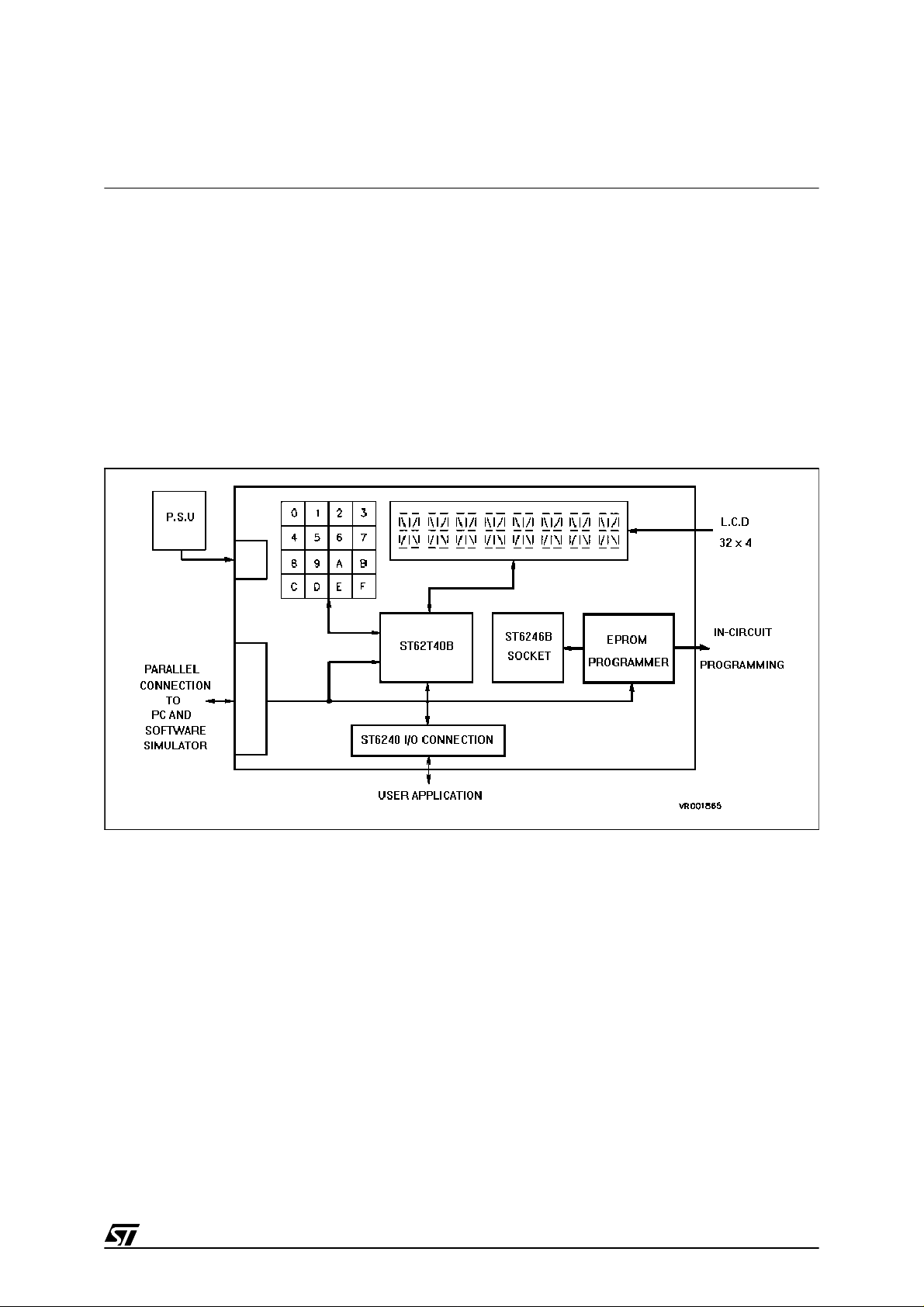

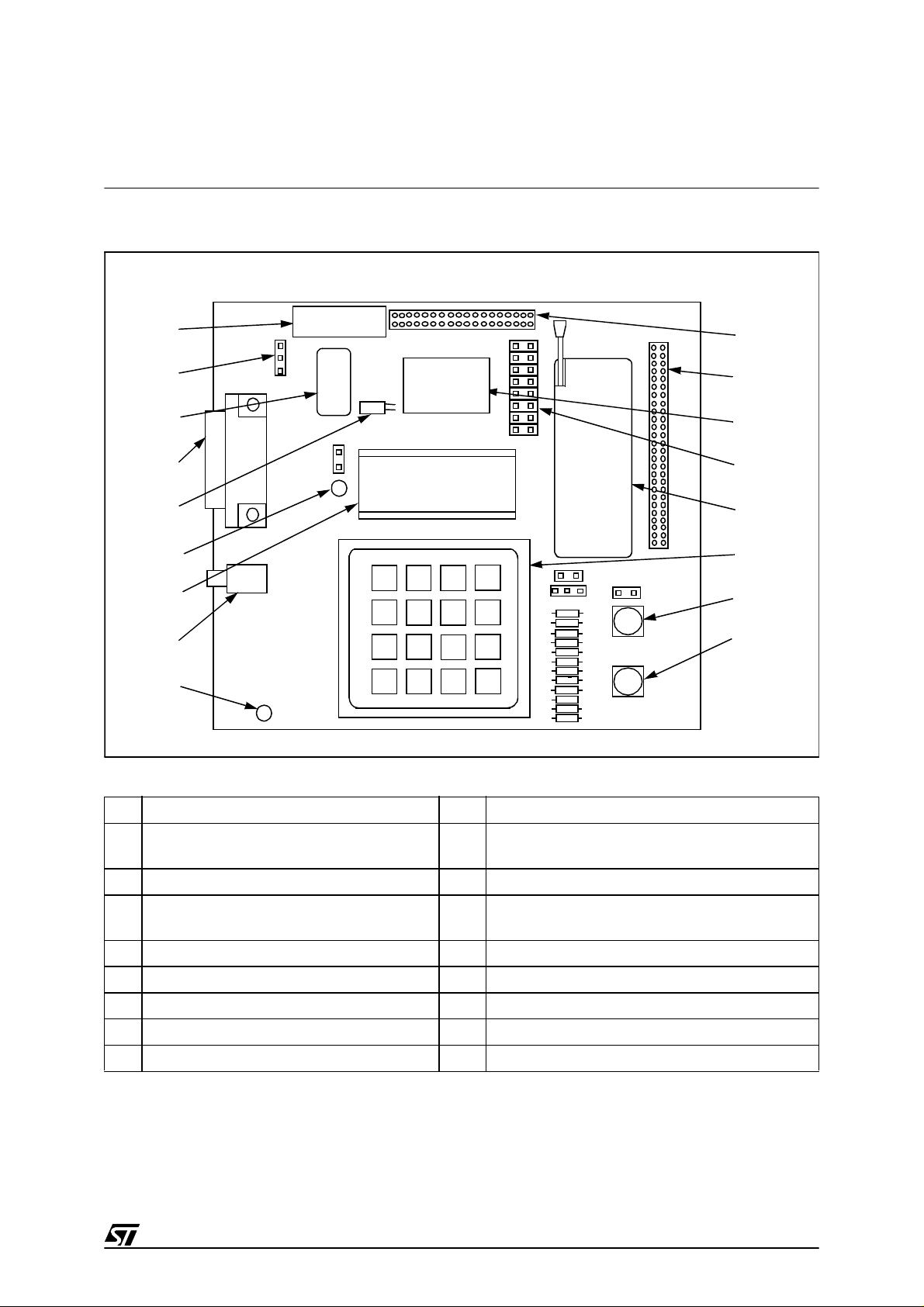

Below is a block diagram of the Starter Kit board:

13

Page 10

10/49

The Starter Kit Hardware

ST624x Starter Kit Board

14

Page 11

11/49

The Starter Kit Hardware

The following diagram shows the layout of the Starter Kit board.

1 In-circuit programming connector P1. 17 Remote resource I/O interface J1.

2 “Programming” or “User” operating mode

selection jumper JP1.

16 Remote LCD interface connector J2.

3 8 Mhz oscillator. 15 ST62T40B MCU

4 PC connector P2. 14 LCD protection with jumper JP2 if the combi-

port PC0-7 is used.

5 32.768 KHz oscillator. 13 SDIP56 ZIF MCU socket.

6 LED indicator LD1. 12 Keyboard

7 LCD display. 11 Voltage trimmer

8 Power supply JACK connector J3. 10 RESET button.

9 Power supply LED indicator LD2.

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

JP1

17

ST6246B

ST62T40B

SOCKET

DISPLAY

10

F

E654

789D

CB0A

321

15

Page 12

12/49

The Starter Kit Hardware

2.3 8 MHz and 32 KHz Oscillators

An oscillator feeds the ST62T40B OSCIN input with an 8 MHz clock signal.

A 32 KHz oscillator is delivered with the boar d. The required components: crystal XT1 and ca-

pacitors C5, C6 are connected to the ST62T40B as described in the ST6240 Data Book.

2.4 8-alphanumeric Digit LCD

An 8-alphanumeric digit LCD is connected to the ST62T40B LCD driver outputs. It has 32 segments that are driven by 4 COM outputs. You can disconnect a part of the LCD by removing

jumper JP2 if you want to use the combi-port PC0-7 on the connector interface J2. For full details about the LCD see “LCD Interface” on page 36.

2.5 Reset Button

This activates the ST62T40B RESET input when pressed. A power-on reset circuit is also provided.

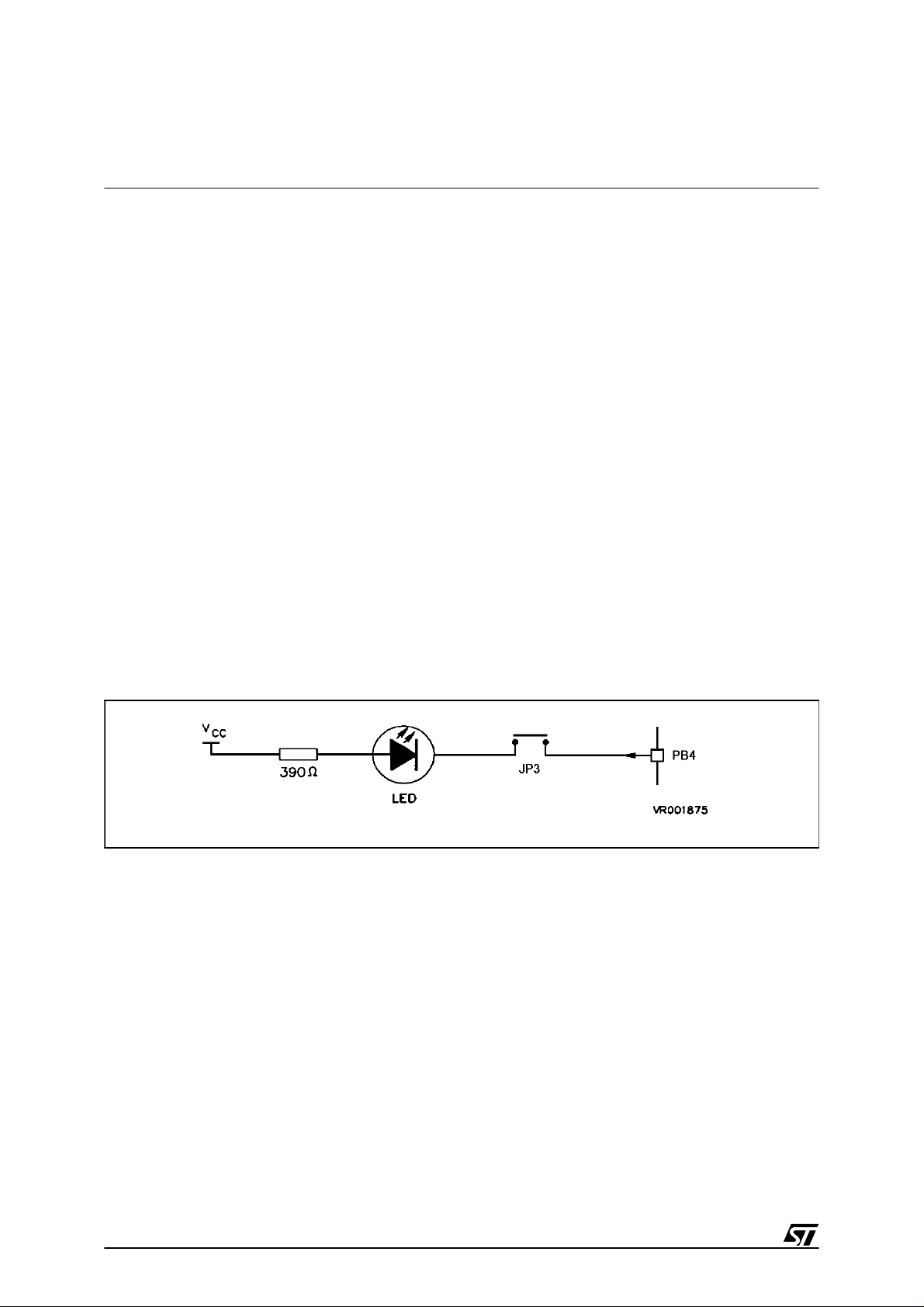

2.6 LED Indicator

A LED is connected to the ST62T40B PB4 I/O pin (which is defined as output) to demonstrate

the ST6 LED-driving capacity. It can be disconnected from PB4 by removing the jumper JP3.

2.7 Hexadecimal Keyboard

A hexadecimal keyboard is connected to the ST62T40B PB0 I/O pin (defined as A/D Converter input), via an analog interface resistor array.

The voltage value on the A/D converter input is equal to 5V/16 x the key number, thus giving

an image of the pressed key.

16

Page 13

13/49

The Starter Kit Hardware

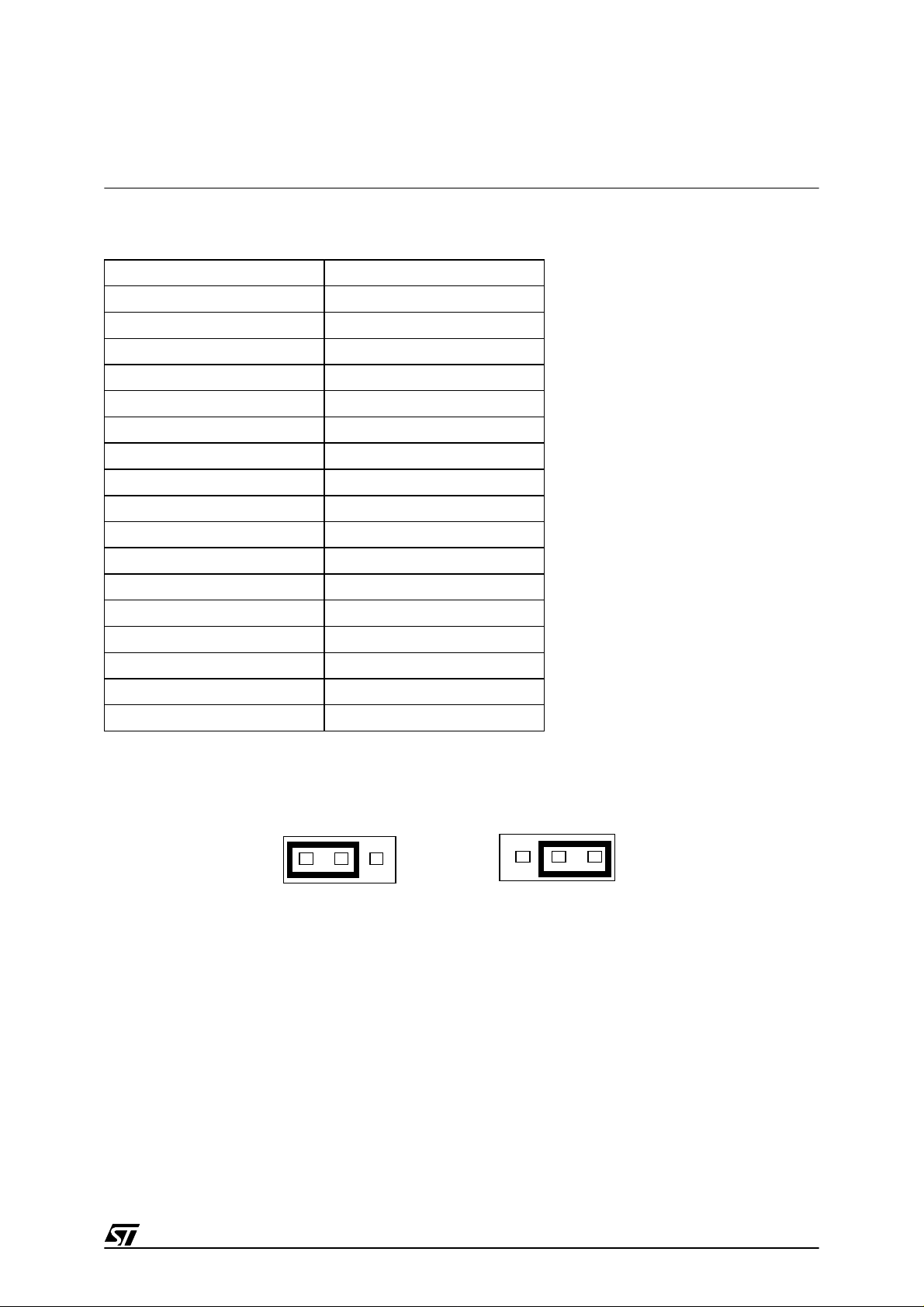

The following table lists the Resistor array values and their corresponding voltage/key values:

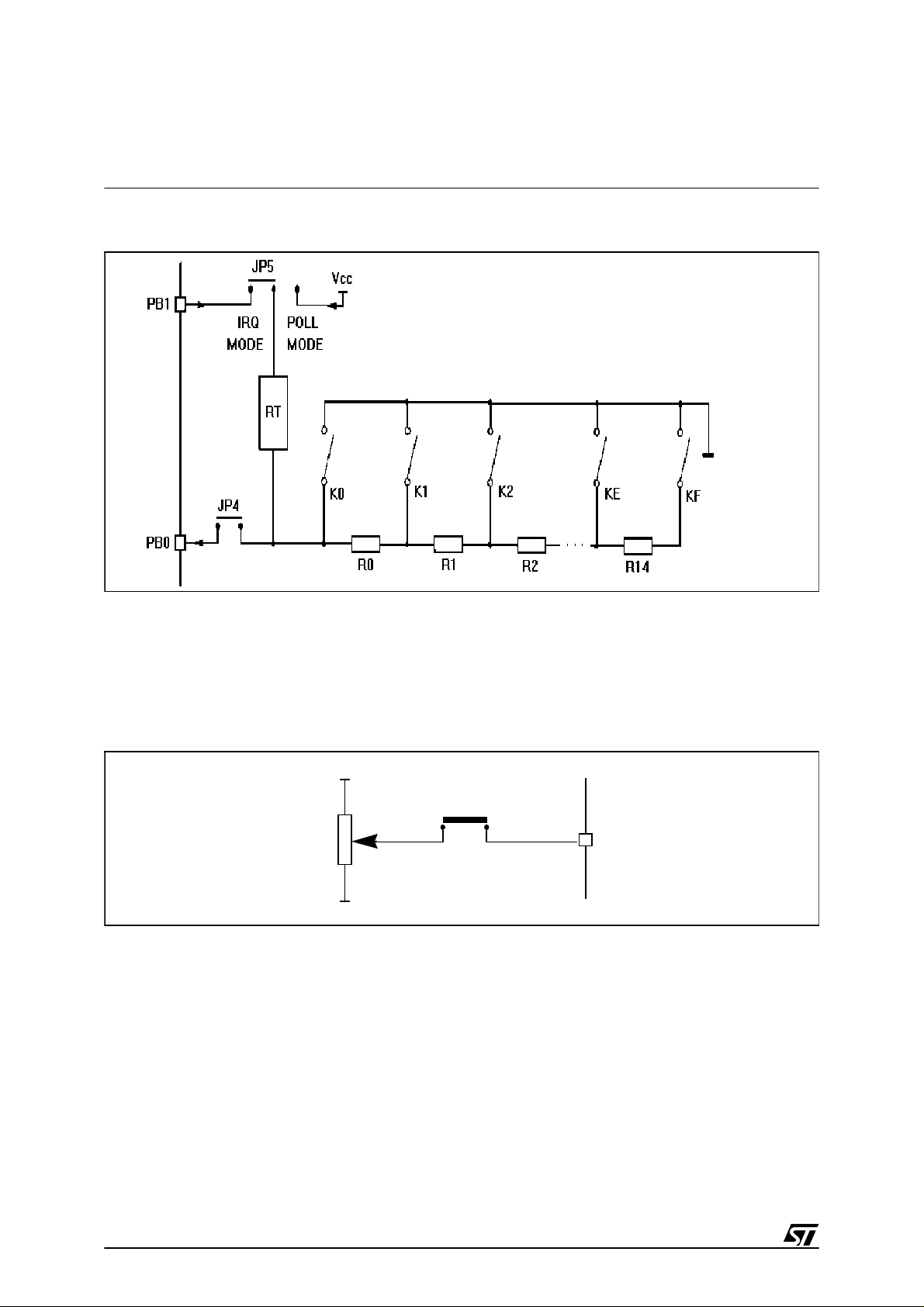

Jumper JP5 sets the keyboard operation mode: polling or IRQ, according to the following diagram.

Jumper JP4 disconnects the keyboard output from PB0 when it is removed, enabling you to

connect your own external source to PB0 via the J1 connector.

For an example of the analog keyboard application, refer to the SGS-Thomson application

note AN431: Using ST6 Analog Inputs for Multiple Key decoding.

Resistor Array Values Theoretical Voltage Values

RT: 1K

Ω

NO KEY: 5V

R0: 68

Ω

K0: 0V

R1: 75

Ω

K1: 0.312V

R2: 82

Ω

K2: 0.625V

R3: 100

Ω

K3: 0.937V

R4: 120

Ω

K4: 1.250V

R5: 150

Ω

K5: 1.562V

R6: 180

Ω

K6: 1.875V

R7: 220

Ω

K7: 2.187V

R8: 270

Ω

K8: 2.500V

R9: 390

Ω

K9: 2.812V

R10: 560

Ω

KA: 3.125V

R11: 820

Ω

KB: 3.437V

R12: 1.2K

Ω

KC: 3.750V

R13: 2.7K

Ω

KD: 4.062V

R14: 7.5K

Ω

KE: 4.375V

KF: 4.687V

JP5

This pos it io n

selects polling.

This position

selects IRQ.

JP5

17

Page 14

14/49

The Starter Kit Hardware

Analog Keyboard diagram:

2.8 Resistance trimmer

A 10 KΩ resistance trimmer feeds the ST62T40B PA4 I/O pin (when programmed as an A/D

Converter input) with a variable voltage (0 to 5V DC). It is used for A/D conversion demonstration/evaluation.

The trimmer can be disconnected from the PA4 I/O pin by removing the JP6 jum per.

2.9 Combi-ports PC0-7

The port C of the ST6240B is used for the LCD segments. It can be used as a normal port in

hardware simulation mode.

The port PC0-7 can be accessed on J2, prior to use it, remove the 8 jumpers on JP2 (marked

14 on the Starter Kit board diagram on page 11). Thus, the LC D won’t be aff ected by the inputs on the port PC0-7 and won’t be damaged.

TRIMMER

V

DD

PB4

JP6

JUMPER

ST62T40B

RV1

GND

18

Page 15

15/49

Installing the Starter Kit

3 INSTALLING THE STARTER KIT

3.1 Hardware and Software Requirements

To be able to install and run the ST6 Starter Kit, you need a PC with:

• A 3 1/2” Floppy Disk Drive

• A free Centronics compatible parallel port connector

• MS-Windows

TM

3.11, NT or 95.

• A CD-ROM Disk Drive

3.2 Installing the Software

If diskettes are provided, you must install the software with them in order to have the latest release:

1

Place the SK624XI1 diskette into your floppy disk drive.

2

In Windows Explorer or File Manager, view the contents of the diskette, then double-click

the

Setup

file or icon.

3

Follow the instructions as they appear on screen.

If only the ST62 CDROM is provided, then:

1

Place the ST62 CDROM provided into your CDROM disk drive.

2

In Windows Explorer or File Manager, view the contents of the CDROM, browse to

st62oncd\ftools\sk624Xi1 and double-click the

Setup

file or icon.

3

Follow the instructions as they appear on screen.

3.3 Connecting the Power Supp ly

If you have AC mains supply, connect the Jack plug on the power supply cable provided to the

J3 input socket, then connect the mains plug to a mains source.

If you have DC mains supply, connect the male plug on the power supply cable provi ded to the

J3 input socket, then connect the mains plug to a mains source with the following characteristics:

• Voltage: 16V min./20V max.

• Current: 100 mA min.

To avoid a short circuit, always connect the power input cable to the starter kit board before

connecting it to a mains power supply.

19

Page 16

16/49

Installing the Starter Kit

If you use your own 3.5 mm power supply plug, its polarity must be as follows:

JACK P LUG

-

+

20

Page 17

17/49

Running the Demos

4 RUNNING THE DEMOS

This section describes the demonstration programs that are provided with the Starter Kit and

explains how to run them.

4.1 What the Demos Do

The following paragraphs describe the demos that come pre-loaded with the ST6 Starter Kit

demos. See “Running the Demonstration Programs” on page 18 below for details on how to

select and run a demo.

The source files of these demos are provided with the Starter Kit software in the file

C:\st6tools\sk624Xi1\sk624Xli\DEMOKIT2.ASM.

4.1.1 Demo 1 - Key Display

1

Initialises the pin PB0 (which is connected to the keyboard) as an analog input.

2

Polls the A/D converter to detect whether a key is pressed.

3

When a key is pressed, it shifts the contents of the LCD one place to the left and displays

the value of the pressed key on the right side of the LCD.

To stop the demonstration, press the Reset button. To quit the demonstration routine and bypass the presentation message, press and r elease the Reset button while pressing any key on

the Starter Kit keyboard.

4.1.2 Demo 2 - Voltmeter

1

Initialises the pins as follows:

2

Reads digital value of the voltage present on PA4 from the A/D converter data register.

3

Displays the read voltage value on the LCD panel. When the read value reaches 4 volts,

the LD1 LED is switched on indicating that the voltage value is reaching its upper limit.

You can adjust the voltage value using the voltage trimmer (marked 11 on the Starter Kit

board diagram on page 11).

To stop the demonstration, press the Reset button. To quit the demonstration routine and bypass the presentation message, press and r elease the Reset button while pressing any key on

the Starter Kit keyboard.

The LED flickers when around 4 volts is reached. This is because of the power s upply voltage

noise >20 mV or instability of the resistor trimmer.

This pin: Is initialised as:

PA4 Analog input. Connected to the trimmer RV1.

PB4 20 mA direct LED drive output.

21

Page 18

18/49

Running the Demos

4.2 Running the Demonstration Programs

The ST62T40B microcontroller labelled DEMOKIT2 is programmed with the demonstration

software.

To run the demonstrations:

1

Power down the Starter Kit board.

2

Make sure that the ST62E46B is not plugged into the SDIP56 ZIF MCU socket.

3

Select the USER mode using the jumpers marked JP1 (marked 2 on the Starter Kit board

diagram on page 11), as shown in the diagram below:

4

Disconnect the cable from the parallel port (P2) connection, if it is connected.

5

Power up the Starter Kit board.

6

Press and release the Reset button on the Starter Kit board. When the message “Press key

1\2” is displayed on the LCD, press either 1 to run the Keyboard demonstration or 2 to run

the Voltmeter demo.

To stop the current demonstration and view the other demonstration, repeat s tep 6 above. Or,

to avoid the display of the presentation message, press any key on the Starter Kit keyboard

then, while keeping the key pressed, press and release the Reset button.

USER

PROG

22

Page 19

19/49

Connecting External Resources to the Starter Kit Board

5 CONNECT ING EXTERNAL RESOUR CES TO THE STARTER KIT BOARD

You can connect your own external resources to the pre-programmed ST62T40B to debug or

evaluate your programs, using the connector J1 (marked 17 on the Star ter K it board diagram

on page 11).

You can also connect your own LCD to the ST62T40B LCD driver using the connector J2

(marked 16 on the Starter Kit board diagram on page 11).

To be able to use either of these connectors, y ou must disconnect the resources that are already connected to the ST62T40B, to avoid external resource/Starter Kit board resource conflicts.

The following tables list the Starter Kit board resources and the corresponding J1 and J2 connections, and indicates the jumper that disconnects each resource

Table 1. J1 User’s I/O Interface Connector

NOTE:

1. The 5V supply is available up to 200mA max current.

2. 32KHz oscillator is mounted on PCB at XT1, C5 and C6 locations.

Signal Pin Number Pin Number Signal

5V supply

(1)

125V supply

(1)

RESET 3 4 PSS

OSC32in

(2)

5 6 OSC32out

(2)

PB0

(3)

7 8 PB1

(4)

PB2 9 10 PB3

PB4

(5)

11 12 PB5

PB6 13 14 PB7

TIMER 15 16 NMI

OSCout 17 18 OSCin

WDON 19 20 Unused

Unused 21 22 Unused

Unused 23 24 PA3

PA4

(6)

25 26 PA5

(7)

PA6

(7)

27 28 PA7

(7)

GND 29 30 GND

23

Page 20

20/49

Connecting External Resources to the Starter Kit Board

3. PB0 is connected to Analog Keyboard Array output. It c an be disconnected by removing

jumper JP4.

4. PB1 may be connected to Analog Keyboard reference voltage input (for interrupt mode). It

can be disconnected by removing jumper JP5.

5. PB4 is connected to LED LD1. It can be disconnected by removing jumper JP3.

6. PA4 is connected to the trimmer RV1. It can be disconnected by removing jumper JP6.

7. PA5, PA6, PA7 are used to perform data transfer in programming mode (PROG c onfiguration). In case these signals are connected to external user’s sources, those sources

must be disconnected (or set to High Z state) during programming operations.

PA0, PA1, PA2 are used to perform data transfer with PC simulator software. They are not

available for external usage in this operating mode. Thus, they are not present on J1 connector.

Table 2. J2 User’s LCD Interface Connector

Signal Pin Number Pin Number Signal

Unused 1 2 Unused

Unused 3 4 Unused

S47 5 6 S48

S45 7 8 S46

S43 9 10 S44

S4111 12S42

S39/PC6

(1)

13 14 S40/PC7

(1)

S37PC4

(1)

15 16 S38/PC5

(1)

S35PC2

(1)

17 18 S36/PC3

(1)

S33/PC0

(1)

19 20 S34/PC1

(1)

S3121 22S32

S2923 24S30

S2725 26S28

S2527 28S26

S2329 30S24

S2131 32S22

S1933 34S20

S1735 36S18

S1537 38S16

S1339 40S14

S1141 42S12

24

Page 21

21/49

Connecting External Resources to the Starter Kit Board

NOTE:

1. The combi-port PC0-7 can be accessed on J2. It is normally connected to the LCD pins

but, however, these LCD pins can be disconnected with JP2 jumper in order to use the

combi-port. After Reset, these pins are configured automatically as LCD segment.

2. The VLCD input pin is connected to 5V supply voltage through a jumper between pins 57

and 58. To connect another voltage source, first remove this jumper and then feed pin 58

with the new VLCD voltage.

3. For the Starter Kit LCD, VLCD1/3 and VLCD2/3 are generated by the ST62T40B internal

resistor divider. If needed, an external di vider can be connec ted to these two pi ns as described in ST6240 data book, especially if VLCD < 4.5V.

S9 43 44 S10

S7 45 46 S8

S5 47 48 S6

Unused 49 50 S4

Unused 51 52 Unused

COM2 53 54 COM4

COM1 55 56 COM3

5V

(2)

57 58 VLCD

(2)

VLCD1/3

(3)

59 60 VLCD2/3

(3)

Signal Pin Number Pin Number Signal

25

Page 22

22/49

Using The Starter Kit Board as a Hardware Simulator

6 USING TH E STARTER KIT BOAR D AS A HARDWARE SIMUL AT OR

WGDB6, the ST6 debugger that runs under Windows, lets you test your programs without

having to program the EPROM of your target ST6. Depending how much information you

want, and how close to real life you want your test environment to be, you can use WGDB6 in

one of three ways:

• As a software simulator. If you use WGDB6 as a simulator, you need not attach any additional hardware to your PC. The ST6 simulator program, that comes with WGDB6 and i s

run when you run WGDB6/Simulator, simulates the execution of your program, letting you

step through the code and see what happens as the program runs. WGDB6 simulator

includes Wave Form Editor, which simulates the output of the pins on your target ST6 in

relation to inputs that you define, enabli ng you to see how its peripherals react to the inupts

they receive.

• With an ST6 hardware emulator. Emulators are hardware systems that act as your target

microcontroller, at the same time capturing detailed information, such as which areas of

memory are accessed by the program and what happens when they are accessed. In this

case, WGDB6/Emulator provides an interface between the emulator and your PC, displaying data captured by the emulator and letting you implement the WGDB6 features in the

emulator, such as software or hardware breakpoints.

• With the Starter Kit board as a hardware simulator. This is a cross between the abov e two.

The WGDB6 software simulator simulates the execution of your program, but each time

the data space is accessed, it accesses that of the ST6 that is plugged into your Starter Kit

board. Thus, using the Starter Kit board with WGDB6, you can view how the real microcontroller peripherals behave when your program is executed.

This section describes the third option, how to use the Starter Kit board as a hardware simulator.

You can use the Starter Kit board to emulate any ST624x microcontroller.

When simulating programs designed for other microcontrollers, make sure that you do not use

resources that are not available on the microcontroller your application is designed for.

26

Page 23

23/49

Using The Starter Kit Board as a Hardware Simulator

6.1 The Data Transmission Driver

Data is transferred between the simulated peripheral registers and the ST62T40B registers

via the host PC’s parallel port. The D EMO KIT2.HEX pr ogram, w hich is in the ST62T40B microcontroller that is soldered on the Starter Kit board includes the transmission driver.

The data transfer driver uses the following pins:

Note

: Do not connect any external r esources to the corresponding J1 c onnector pins when us-

ing the Starter Kit board as a peripheral emulator.

6.2 Technical Limitations

The Starter Kit board has the following limitations when used with WGDB6 as a hardware simulator:

• Real-time program execution is not supported. The program execution speed depends on

your PC.

• Resetting the ST62T40B by power up, pressing the Reset button or external reset does

not reset the simulated ST6 core. To perform a complete simulated reset, use the WGDB6

reset command instead.

• Interrupts sent by the ST62T40B microcontroller are not supported by the WGDB6 simulator.

• The pins: NMI, PA0, PA1 and PA2 on the ST62T40B microcontroller are used for communications with the host PC, and are thus not available for simulation.

PC

parallel port

ST62T40B SIMULATOR USAGE

D2 PA2 Synchronisation

D3 PA0 Write data to MCU

D4 RESET Hardware reset of peripherals

D6 NMI Initiates data transfer

SDOP PA1 Read data from MCU

27

Page 24

24/49

Using The Starter Kit Board as a Hardware Simulator

To use the Starter Kit board as a hardware simulator:

1

Power down the Starter Kit board.

2

Make sure that the ST62E46BF1 is not plugged into the SDIP56 ZIF MCU socket.

3

Select the USER mode using the jumper JP1 (marked 2 on the Starter Kit board diagram on

page 11), as shown in the diagram below:

4

Connect the Parallel port P2 on the Starter Kit board to a spare parallel port on your PC using the cable provided with the Starter Kit.

5

Power up the Starter Kit board.

To run WGDB6:

• If you are using Windows 95, click the

Start

button, point to

Programs

, then

ST6 Tools

,

then click

WGDB6/Simulator

.

• If you are using Windows 3.x, double-click the appropriate

WGDB6/Simulator

icon in the

ST6 Tools

program group.

Refer to "WGDB6 User Guide" in the "ST6 Family Software Development Tools AST6, LST6,

WGDB6" User Manual for full instructions on how to use WGDB6.

USER

PROG

28

Page 25

25/49

Using The Starter Kit Board as a Hardware Simulator

6.3 Error Messages

The following table lists the error messages you may encounter when using WGDB6 with the

Starter Kit board:

6.4 Troubleshooting

If there is a communication problem between WGDB6 and the Starter kit board, the title

“WGDB6 Simulator” appears in the WGDB6 title bar. In this case, you shoud check the following:

• That the Starter Kit board is correctly powered up.

• That the parallel port cable is correctly connected.

• That the device jumper JP1 is in the USER position.

• That no ST62E46B is plugged into the Starter Kit board.

Error message Description

Error 116 Port A protected when using board. This means that WGDB6 tried to access the PORT A

registers. These are used for communications with

the board.

Error 117 Communication error with ST624x

board.

This means that a problem occurred during

communications between the host PC and the board.

Perform the checks listed below.

29

Page 26

26/49

Exercises

7 EXERCISES

This section describes two exercises, in whi ch y ou use your ST6 Starter Kit board as a hardware simulator with WGDB6:

• In the first excercise, you’re going to learn how to use WGDB6 to reset the LCD on your

Starter Kit board then display the letter A on it.

• In the second excercise, you’re going to use WGDB6 to step through the instructions that

display messages on the keyboard.

7.1 Exercise 1

1

Connect your Starter Kit board as a Hardware Si m u lator following the instructions given in

“Using The Starter Kit Board as a Hardware Simulator” on page 22.

Press the Reset button on the Starter Kit.

2

Run WGDB6 Simulator:

If you are using Windows 95, c lick the

Start

button, point to

Programs

, then

ST6 Tools

,

then click

WGDB6/Simulator

.

If you are using Windows 3.x, doubl e-click the appropriate

WGDB6/Simulator

icon in th e

ST6 Tools

program group.

The message ‘REMOTE’ is displayed on the LCD of the Starter K it board.

The WGDB6 main window opens:

3

Load the file

Stktrain.hex

:

i

In WGDB6, on the

File

menu, click

Open

.

ii

Browse to the director

y

c:\st6tools\sk624Xi1

iii

Select the file

stktrain.hex

, then click OK.

4

The Disassembler window now opens, displaying the source code of

stktrain.hex

.

30

Page 27

27/49

Exercises

5

Reset the simulated program: on the

Commands

menu, click

Reset

.

The disassembler window opens, displaying the line

0xffe

, which is set by the reset vector.

The LCD panel on the Starter Kit board is now clear, indicating that the WGDB6 simulator

performed a physical reset of the ST62T40B plugged into the starter kit board. When the

reset was performed, all segment outputs were set to OFF by setting the HFE bits 2, 1 and

0 of the LMCR register to 0. The LMCR register sets the LCD control mode. For full details

about the LMCR, see the ST6240 Data Book.

31

Page 28

28/49

Exercises

You are now going to locate the register LMCR, an d change its value:

1

In the WGDB6 main window, on the

Windows

menu, click

Browser

.

The Browser dialog box opens:

2

From the

Type

drop down list, choose data, as shown above (LMCR is a data address).

3

In the

Filter

field, type

LMCR

, as shown above.

4

Click

Apply

.

LMCR

is now displayed in the

Symbols

matching box, as shown above.

5

Select LMCR in the

Symbols matching

box, then click

Inspect

.

The Inspect window opens, displaying the value of LMCR (which is 0):

32

Page 29

29/49

Exercises

You are now going to change the value of LMCR to 36:

1

In the Inspect window, select the value ‘0’, then on the

Edit

menu, click

Modify

, and over-

type the value 0 with 36, and click

Set

. The contents of the inspect window are now

36

‘$’

, indicating that the new LMCR value is 36. The value 36 corresponds to the following

configuration:

bits DS1-0 = hold the values 0 0, defining 1/4 duty.

bits HF2-0 = hold the values 1 1 0, setting %256 main osc.

bits LF2-1 = hold the values 1 1 0, setting the LCD frequency to 512 Hz.

2

Look at the LCD on the Starter Kit board, it now displays the message ‘

REMOTE

’.

(If you already used the program, the message may not be ‘REMOTE’. It depends on what

is in the memory)

You are now going to manually build the character ‘A’ that will be displayed on the LCD:

1

In the

Inspect

window, on the

Edit

menu, click

Dump

. The dump window opens, cl ick on

‘Data’ to display the contents of the data space starting at the address

0d0

.

2

In the

Address

field in the Dump window, type the address

0e0

, then press the Enter key

on your keyboard. This moves the cursor to the beginning of the LC D RAM area. Observe

the values from

0E0

to

0F7

: these correspond to the letters ‘R EMOTE’ that ar e displayed

on the LCD. Overtype all these values with the value ‘00’, by repeatedly pressing the 0 key

on your keyboard: you will note that all LCD panel segments are turned off.

33

Page 30

30/49

Exercises

3

To build the letter A, in the Dump window overtype the values 00 with the following values:

Look at the LCD: the character ‘A’ is now displayed at digit 0. Now try writing some of your own

characters, using the information provided in “LCD Interface” on page 36.

7.2 Exercise 2

1

With

stktrain.hex

still loaded in WGDB6, in the WGDB6 main window, on the

Commands

menu, click

Reset

to reset the program.

The Disassembler window opens, with the l ine

jp init

highlighted: this is the line pointed

to by the reset vector.

2

In the WGDB6 main window, click the

Cont

button. The program counter jumps to the init

address, which is the beginning of the program.

Look at the Starter Kit LCD: it is first cleared, then the word ‘

DISPLAY

’, followed by ‘

KEY

’ is

displayed on it. Press some keys on the starter kit keyboard, and note the result: the keys

you press are displayed on the right side LCD. Bear in mind that the program is being simulated, and thus is not running i n real time mode, so you may have to keep keys pressed for

several seconds until they are displayed on the LCD.

3

In the WGDB6 main window, click the

Stop

button.

4

In the Disassembler window, type

m_disp

in the top right field, next to the

Page

field, and

press the Enter key on your PC keyboard.

The disassembled code around the address

m_disp

is displayed, with the

m_disp

ad-

dress highlighted. Click the

Break

button in the Disassembler window to set a breakpoint

At this address: Which corresponds to this

value:

Type this value:

0e1 COM1 02

0e7 COM2 0e

0ed COM3 07

0f3 COM4 00

34

Page 31

31/49

Exercises

on the

m_disp

address: program execution will now stop when the PC reaches this ad-

dress.

5

In the Disassembler window, on the

Commands

menu, click

Reset

.

6

Type

init

in the top right field, next to the

Page

field, and press the Enter key on your PC

keyboard. The program counter now jumps to the beginning of the program.

7

On the

Commands

menu, click

Conti nue

. This continues running the program, until the

breakpoint you placed on the line of

m_disp

is reached. Wait for program execution to

stop.

8

Click th e

Next

button to execute the next line of the program, and look at the LCD : it dis-

plays one segment, that has been turned on by the instruction:

ldi E1, 80

. Keep press-

ing the

Next

button to execute each instruction in turn, watching the effects each one has

on the LCD. You will notice that each time you press the

Next

button, a few more segments

are turned on, until the word ‘

DISPLAY

’ appears on the LCD.

Now that you are familiar with WGDB6, try stepping through the program yourself, observing

the effects each command has on the LCD, and modifying data to see the effect it has on the

LCD.

35

Page 32

32/49

Programming S T6 Microcontr ol lers

8 PROGRAMMING ST6 MI CROCONTRO LL E RS

You can use the Starter Kit board, in conjunction with the program Epromer, to program

ST62E46B or ST62T46B microcontrollers. You can also perform in-circuit programming of

ST62E4X or ST62T4X OTP/EPROM microcontrollers using your own board, connected to the

Starter Kit board via the c onnector P1 (marked 1 on the Starter Kit board di agram on page 11).

NOTE:

The PA5, PA6, PA7 and RESET pins are used to perform programmi ng operations. If these

pins are connected to an external resource via J1, y ou must either disconnect them (see “Connecting External Resources to the Starter Kit Board” on page 19) or set them to high impedance state during programming operations.

This section describes how to set up the Starter Kit board for programming microcontrollers,

and lists the connection requirements for in-circuit application boards.

8.1 Setting Up the Starter Kit Board

1

Power down the Starter Kit board.

2

Plug the ST62E46B/T46B microcontroller you want to program into the MCU socket on the

Starter Kit board.

3

Select the PROG mode using the jumper JP1(marked 2 on the Starter Ki t board diagram on

page 11), as shown in the diagram below:

USER

PROG

36

Page 33

33/49

Programming ST6 Microcontrollers

4

Connect the Parallel port P2 on the Starter Kit board to a spare parallel port on your PC using the cable provided with the starter kit.

5

Power up the Starter Kit board.

You can now use E promer to progr am the microcontroller that is plugge d into the Starter Kit

board.

NOTE :

Epromer does not work under Windows NT.

To run Epromer from Windows 3.x, double-click the Epromer icon in the ST6 Tools group.

To run Epromer from Windows 95, click

Start, Programs, ST6 Tools

, then

Epromer

.

For instructions on how to operate Epromer, click

Help

in the Epromer main window.

8.2 In-Circuit Programmin g

You can perform in-circuit programming of ST 62E4x and ST62T4x EPROM/OT P microcontrollers using your own board, connected to the Starter Kit board via the connector P1 (marked

1 on the Starter Kit board diagram on page 11).

8.2.1 Application Board Connections

The following paragraphs specify the connection requirements between your application

board and the Starter Kit board.

The application board must have a suitable 16-way connector (8x2 header HE10) to be connected via a 16-way cable to connector P1 ( marked 1 on the Starter Kit board diagram on

page 11) on the Starter Kit board.

The following table shows the required pin connections:

Table 3. Signal interconnectio n to different ST6 families

8x2 Connector I/O S T6 21X /2X ST624X ST626X/9X

Pin 1 O PB6 PA6 PB3

Pin 3 O PB5 PA5 PB0

Pin 5 O OSCin OSCin OSCin

Pin 7 I PB7 PA7 PB2

Pin 9 O RESET RESET RESET

Pin 11 I OSCout OSCout OSCout

Pin 13 O VPP/TM VPP/TM VPP/TM

Pin 14+16 Power VDD VDD VDD

Pin 2+4+8 Power VSS VSS VSS

37

Page 34

34/49

Programming S T6 Microcontr ol lers

V

DD

Use of the

V

DD

connection is optional, depending on whether the application board supply can

or cannot be disconnected. If the application board supply is disconnected, you can supply it

through pins 14 and 16 of the connector, as long as the total load current does not exceed 100

mA, and the capacitive load is less than 50 µF.

If the application board has its own power supply, its voltage must be set to 5V, so that logic

levels are compatible with those of the Starter Kit board.

OSCin

Synchronises the programming operations using a clock generated by the programming tool.

OSCin is located on the application board, and must be directly connected to Pin 5 on the 16way connector. No isolation is needed as long as a quartz crystal or ceramic resonator is used

in the application. If an external clock generator is used in the application, it mus t be disconnected during in-circuit programming.

RESET

Controls the programming mode entry. To prevent signal level contention, RESET must be di rectly connected to Pin 9 on the 16-way connector, and must be isolated from other nodes on

the application board. Any direct connection to V

DD

, V

SS

or an output must b e avoided. This

pin can be connected to a CMOS input, a 2 KΩ pull-up, a 10 KOhm pull-down or left open (Internal pull-up). The capacitive load of the RESET pin should not exceed 1

µ

F.

Pins 1 and 7

on the 16-way connector are used to establish communications between the

programming tool and the microcontroller.

To prevent signal-level contention, Pins 1 and 7 must be directly connected to PA6 and PA7

on the 16-way connector, and must be isolated from other nodes on the application board. Any

direct connection to V

DD

, V

SS

or an output must be avoided. These pins may be connected to

a CMOS input, a 2 KΩ pull-up, a 10 KOhm pull-down or left open (Internal pull-up).

If

pin 3

on the 16-pin connector is connected to the target device, the same applies. Connec-

tion to pin 3 is not necessary if a high voltage level is guaranteed by the board design.

Some

I/O pins

are not connected to the 16-way connector and must be set to a high level during programming. This is normally achieved by the RESET signal sent by the programming

tool through the 16-way cable, setting the I/O pins as inputs with an internal 300 KΩ pull-up.

To keep these I/O lines high, direct connection of these pins to GND or to any other signal at

low level (even temporarily) must be avoided. Only connections to another CMOS input, to an

external pull-up or a 10 MΩ pull-down is allowed.

The

Vpp/TM

pin must not be directly connected to GND/V

SS

on the application board, to avoid

any conflict with the programming voltage provided by the programming tool via pin 13 on the

38

Page 35

35/49

Programming ST6 Microcontrollers

connector. This pin should be pulled down by a resistor with minimum value of 10 KΩ. You must

add a 100 nF ceramic capacitor between Vpp/Test and V

SS.

8.3 Setting Up the Starter Kit Board for In-Circu it Programming

1

Power down the Starter Kit board.

2

Select the PROG mode using the jumpers JP1 (marked 2 on the Starter Kit board diagram

on page 11), as shown in the diagram below:

3

Connect the Parallel port P2 on the Starter Kit board to a spare parallel port on your PC using the cable provided with the starter kit.

4

Connect your application board to the connector P1 (marked 1 on the Starter Kit board diagram on page 11) on the Starter Kit board.

5

Power up your Starter Kit board.

You can now use Epromer to program the microcontroller that is on your own board.

NOTE:

Epromer does not work under Windows NT.

To run Epromer from Windows 3.x, double-click the Epromer icon in the ST6 Tools group.

To run Epromer from Windows 95, click

Start, Programs, ST6 Tools

, then

Epromer

.

For instructions on how to operate Epromer, click

Help

in the Epromer main window.

If your application board is not powered by the Starter Kit, you must connect it to a 5V DC power supply before you start programming.

PROG

39

Page 36

36/49

LCD Interface

9 LCD INTERFACE

9.1 ST6240 LCD DRIVER OVERVIEW

This is a quick summary of the features of the ST6240 LCD driver. Refer to the ST6240 data

book for more detailed information.

The ST6240 LCD driver comprises LCD control logic, a programmable prescaler, a 24-byte

wide dedicated LCD RAM, 45 segments and 4 c ommon outputs. This drives up to 180 LCD

segments.

The LCD control logic operates automatically and without interrupting the processor.

The LCD driver configuration is defined by the following ST6240 registers:

• LMCR (LCD Mode Control Register), which defines the LCD backplanes (duty cycle) and

the frame frequencies used by the LCD.

• LCD RAM (24 bytes), which sets each segment to O N or OFF by setting or resetting the

corresponding bit. According to the contents of the LCD RAM, the drivers generate the

segments and common signals which can directly drive an LCD panel.

Hardware configuration requirements are reduced to minimum:

• The VLCD input pin must be fed with VLCD voltage (independently of VMVDD), according

to your LCD panel specifications.

• The VLCD1/3, VLCD2/3 pins are connected to interm ediate VLCD voltages, to enable

external capacitive buffering or resistive shunting. An internal resistor network is implemented so that in most cases, thus no additional components are necessary.

To interface with the LCD panel, all you have to do is:

• Determine the operating LMCR register value according to the LCD panel specifications.

• Generate the correct VLCD v oltage and, i f needed, connect an external resistor network to

the VLCD1/3 and VLCD2/3 pins.

• Determine the most suitable mapping between the LCD panel segments and the LCD

RAM bits.

Once you’ve completed the above s teps, c ontrolling the LCD panel becomes as easy as modifying software bits.

40

Page 37

37/49

LCD Interface

9.2 STARTER KIT LCD PANEL INTERFACE

The following paragraphs describe how the starter kit LCD panel interfaces with the

ST62T40B microcontroller.

The LCD panel used on ST62T40B Starter Kit board has 8 alphanumeric digits.

Each digit is based on a 16-segment m atrix operating in mul tiplexed mode (1/4 duty) so that

only 4 segment pins are required per digit.

Thus the following pins are required for the 8 digits:

• 32 segment (SEG) pins

• 4 common (COM) pins

VLCD operating mode is 5V.

Digits are annotated from 0 to 7 respectively from right to left as s hown by th e fol lowing dia-

gram:

X

B

D

F

E

C

GK

LN

H

J

DP

I

M

VR0A1879

E

D

M

G

L

C

DP

N

K

H

F

I

A

B

J

E

D

M

G

L

E

C

DP

N

K

D

M

L

GNK

X

H

F

I

A

BJF

X

H

I

J

A

C

DP

B

digit digit

digit digit

7

6

54

digit

D

digit

3

DP

E

X

F

NL

M

GK

L

C

E

G

A

H

J

I

X

BF

H

DDD

2

DP

digit

1

DP

0

digit

DP

N

M

C

E

K

NL

M

GK

X

J

I

A

BF

H

J

I

A

L

C

E

G

N

M

C

K

X

BF

H

J

I

A

B

A

X

8 ALPHANUMERIC DIGI TS LCD

41

Page 38

38/49

LCD Interface

Each digit is made up of 16 segments (A,B,C,D and so on) as shown by the following diagram:

Each segment can be set to ON or OFF, depending on the state of its dedicated Segment and

Common lines, according to the boolean equation:

segment ON = Seg_line and Com_line active

Each DIGIT requires 4 SEG lines X 4 COM lines to be completely defined. The following diagram shows the graphic segments that are switched on according to each active COM:

X

A

B

D

F

E

C

GK

LN

H

J

DP

I

M

VR001879

X

A

B

D

F

E

C

GK

LN

H

J

DP

I

M

VR0B1879

E

D

M

G

L

C

DP

N

K

X

H

F

I

A

B

J

E

D

M

G

L

E

C

DP

N

K

D

M

L

G

N

K

X

H

F

I

A

B

J

F

X

H

I

J

A

C

DP

B

COM1 COM2 COM3 COM4

42

Page 39

39/49

LCD Interface

The following table shows the mapping between graphic elements set and the segment/common pins.

Table 4. Digit Matrix to Segment/COM Pins Mapping

For example, the graphic element 7J (J of digit 7) is driven by SEG l ine S2 (pin 2) and COM

line C2 (pin 19). For digit 2, pin 12 drives segments I,J,K,N when COM lines C1,C2,C3,C4 respectively are active.

PIN SEGMENTS PIN SEGMENTS PIN SEGMENTS

1

7X

7F 7E 7D 13 1X 1F 1E 1D 25 2A 2B 2C 2DP

27I7J7K7N141I1J1K1N262H2G2L2M

36X6F6E6D150X0F0E0D273A3B3C3DP

46I6J6K6N160I0J0K0N283H3G3L3M

5 5X5F5E5D 17 . . . C04 29 4A4B4C4DP

65I5J5K5N18 . .C03. 304H4G4L4M

7 4X4F4E4D 19 . C02 . . 31 5A5B5C5DP

8 4I 4J 4K 4N 20 C01 . . . 32 5H 5G 5L 5M

9 3X 3F 3E 3D 21 0A 0B 0C 0DP 33 6A 6B 6C 6DP

10 3I 3J 3K 3N 22 0H 0G 0L 0M 34 6H 6G 6L 6M

11 2X 2F 2E 2D 23 1A 1B 1C 1DP 35 7A 7B 7C 7DP

12 2I 2J 2K 2N 24 1H 1G 1L 1M 36 7H 7G 7L 7M

COM C1 C2 C3 C4 COM C1 C2 C3 C4 COM C1 C2 C3 C4

43

Page 40

40/49

LCD Interface

9.3 Interfacing The LCD Panel with the ST6240 LCD Driver

When assigning the LCD panel segments to the LCD RAM bits, the mapping used will depend

on the LCD you are using. It is recommended that you define the character mapping after defining your software architecture. Make sure, however that this mapping is kept as si mple as

possible. For example, the description map of each character in LCD RAM should be the

same for all the 8 digits on the LCD.

The LCD panel requires 32 segment lines multiplexed through 4 common lines. This is less

than the capabilities of the ST6240. Segments S9 to S39 and outputs COM1,2,3,4 of ST6240

LCD driver are connected to the LCD panel inputs as described in the following diagram.

VR001880

digit 6

digit 5

digit 4

digit 3

digit 2

digit 1

digit 0

digit 7

COM4

COM3

COM1

COM2

36

35

S40

S38

1

2

S39

S37

ST6240

OUTPUTS

S33

S35

3

4

S36

S34

33

34

S29

S31

5

6

S32

S30

31

32

S25

S27

7

8

S28

S26

29

30

S21

S23

9

10

S24

S22

27

28

S17

S19

11

12

S20

S18

25

26

S13

S15

13

14

S16

S14

23

24

S9

S11

15

16

S12

S10

21

22

COM4

COM3

COM1

COM2

ST6240

OUTPUTS

LCD PANEL

20

19

17

18

44

Page 41

41/49

LCD Interface

The following table lists the location of each digit definition in the ST6 RAM. Note that the

memory is not entirely used.

Table 5. Digit Locations in LCD RAM

Each digit is represented by 4 bits (MSB for odd digits, LSB for even digits) in each COM

memory area. Each set of 4 bits x 4 COMs are assigned to the 16 bits defined above as shown

in the following table.

Table 6. LCD RAM Bits Mapping

LCD RAM Address D7 D6 D5 D4 D3 D2 D1 D0

COM1

E1h Digit 1 Digit 0

E2h Digit 3 Digit 2

E3h Digit 5 Digit 4

E4h Digit 7 Digit 6

COM2

E7h Digit 1 Digit 0

E8h Digit 3 Digit 2

E9h Digit 5 Digit 4

EAh Digit 7 Digit 6

COM3

EDh Digit 1 Digit 0

EEh Digit 3 Digit 2

EFh D ig it 5 Digit 4

F0h Digit 7 Digit 6

COM4

F3h Digit 1 Digit 0

F4h Digit 3 Digit 2

F5h Digit 5 Digit 4

F6h Digit 7 Digit 6

Bit 7/3 Bit 6/2 Bit 5/1 Bit 4/0

COM1 H X A I

COM2 G F B J

COM3 L E C K

COM4 M D DP N

45

Page 42

42/49

LCD Interface

9.4 Character Definition Examples

The following examples show the defi nition of character s using the previously des cribed method.

9.4.1 Character A Definition

The following diagram represents the ‘A’ character to be displayed on the LCD panel.

The following table gives the corresponding bit pattern to be set in the LCD RAM to display the

character ‘A’ on the LCD panel. The bits set to 0 are left blank, and the bits set to 1 are shaded.

The right column provides the corresponding hexadecimal value.

This description is valid for all characters. The position of the displayed character depends

only on the addresses and the position (LS/MS nibble).

D3 D2 D1 D0

Hex

value

COM1

HX

AI2

COM2

G F BJE

COM3

L

E C K7

COM4

MDDPN0

X

A

B

D

F

E

C

GK

LN

H

J

DP

I

M

VR0C1879

46

Page 43

43/49

LCD Interface

9.4.2 Character 3 Definition

The following diagram shows the character 3 to be displayed on the LCD.

The following table gives the corresponding bit pattern to be set in the LCD RAM to display the

character ‘3’ on the LCD panel.

The set of 4 x 4 bits (representing the character set) can be stored in the ST624x DATA ROM

and easily used by display software through indexed accesses.

D3 D2 D1 D0

Hex

value

COM1

H X A I2

COM2

G F B JA

COM3

L E C K3

COM4

M D DP N4

X

A

B

D

F

E

C

GK

LN

H

J

DP

I

M

VR0D1879

47

Page 44

44/49

LCD Interface

9.5 Starter Kit LCD Panel Character Set Software Model

As described in the previous paragraphs, LCD connection and character mapping drive a software model of the LCD-displayable objects. These objects are available for DISPLAY routines

to drive LCD panel display during program execution.

The following paragraphs describe three methods of displaying characters on the LCD.

9.5.1 Direct Code LCD RAM Patching

This is the most simple way to display digits on an LCD. The mapped character values are directly patched into the corresponding LCD RAM locations. The bit map values are contained

in the immediate values of write instructions.

This method should only be used for very simple applications (few characters, displayed few

times) or for rapid evaluation.

The following block of code shows how to use direct code LCD RAM patching to display the

character ‘A’ at digit 0, where x is the value of the MSB (digit 1):

disp_A_0 ldi E1, x2 ;value 2 to digit 0 COM1 addr (E1, LSB)

ldi E7, xE ;value E to digit 0 COM2 addr (E7, LSB)

ldi ED, x7 ;value 7 to digit 0 COM3 addr (ED, LSB)

ldi F3, x0 ;value 0 to digit 0 COM4 addr (F3, LSB)

9.5.2 Indexed Data ROM

The mapped values of character sets are defined into ST6240 Data ROM area (refer to

ST6240 databook). The AST6/LST6

.byte

directive and .w and .d labels define and access

the Data ROM area.

A generic display call subroutine accesses the character definition map through the parameter

passed by the calling program. The

disp_0

subroutine (see below) displays a character at

digit 0 and clears digit 1 (MSB of the same LCD RAM locations).

An efficient generic display subroutine should manage the digit number (as input par ameter)

and perform the read/modify/write only on the concerned nibble in the LCD RAM byte (MSB or

LSB). This is done by the display subroutine delivered with the ST6240 Starter Kit library

(please read the README file provided in the SK6240LIB directory).

A character is defined by 4 x 4 bit words = 16 bits. To optimize the character set size in Data

ROM, it is useful to compact these 16 bits into 2 bytes, however this method increases the display routine complexity.

48

Page 45

45/49

LCD Interface

For the ST6240 Starter Kit demo routines, the character set is defined as follows (for example

character A):

CHAR_A. .byte 22

.byte EE

.byte 77

.byte 00

The character is displayed using the following routine:

disp_A_0 ldi RWSR, CHAR_A.w;set Data ROM Window register

ldi X, CHAR_A.d ;X set to point to CHA R_A

call disp_0 ;subroutine that displays digit 0

disp_0 ld E1, (X) ; output value 2 to digit 0 COM1

;(E1, LSB)

inc X ;X set to second byte of CHAR_A

ld E7, (X) ;output value E to digit 0 COM2

;(E7, LSB)

inc X ;X set to third byte of CHAR_A

ld ED, (X) ;output value 7 to digit 0 COM3

;(ED, LSB)

inc X ;X set to fourth byte of CHAR_A

ld F3, (X) ;output value 0 to digit 0 COM4

;(F3, LSB)

Four bytes are used to define a character, with MSB and LSB equal to the 4 bit definition values. In this way, MSB and LSB are easily distinguished using the AND instruction for masking

the non-relevant nibble.

9.5.3 Complete Message Display

You can simplify the definition of complete messages using the AST6 .ASCIZ directive. This

directive returns the ASCII code pattern of the characters indicated ended by NULL). To enable you to use the .ASCIZ directive, the ST6240 character set is pre-defined in the Data ROM

so that it becomes simple to access a mapped character definition through the character’s ASCII code.

One Data ROM window contains 64 bytes. As a character definition map requires 4 bytes, 16

characters can be defined in a whole window. This corresponds to a page of ASCII codes

(represented by the MSB of the ASCII code).

49

Page 46

46/49

LCD Interface

For example characters @, A, B through O, whose ASCII codes are 40,41,42 through 4F

(Hex) respectively, represent the ASCII code page 4, and fill a Data ROM window as shown

below:

.ORG x00;beginning of a wind ow

0 CHAR_@.byte 22;address 0 in the window

.byte AA

.byte BB

.byte 44

1 CHAR_A.byte 22;address 3 in the window

.byte EE

.byte 77

.byte 00

through

F CHAR_O.byte 22;address 3 C in the window

.byte 66

.byte 66

.byte 44;last address (3F) i n the window

For example, the ASCII code of character A is 41 (hex):

• 4 specifies the Data ROM window number

• 1 indexes the number of the character in the Data ROM window

The available LCD character set that is delivered with the ST6240 Starter Kit library is defined

using this method. This allows the

asci_dis

subroutine to display a character defined by its

ASCII code and

Mdis_mes

subroutine to display a complete message, built using the ASCIZ

AST6 directive, on the LCD panel.

Refer to the files SK6240LI.INI and SK6240LI.ASM in the SK624XLI directory for a description

of these subroutines.

50

Page 47

47/49

Hardware Information

10 HARDWARE INFORMATION

10.1 Part List

10.2 Starter Kit Board Schematic

See next page

Part Device Part Device

U1 74LS244 R1, R16 100

Ω

U2 8M Hz os cillator R2, R11, R28 1K

Ω

U3 S T 62T40 B MCU R3 47

Ω

U4 ST 62E 46B MCU socket R4, R26 39 0

Ω

U5 74LS04 R5, R8 10K

Ω

U6 LCD panel R6 Not connected

U7, U8 78L05 Voltage Regulator R7, R9 4.7K

Ω

U9 7805 Voltage Regulator R10, R27 560

Ω

U10 Keyboard R12 68

Ω

XT1 32.768 KHz crystal R13 75

Ω

RV1 10KΩ resistor trimmer R14 82

Ω

D1, D2, D3 1N4148 diode R15 7.5K

Ω

D4 BYV 10-20 Schottky R17 120

Ω

D5 1N4004 diode R18 150

Ω

Z1 8.2V Zener diode R19 2.7K

Ω

LD1, LD2 Red LED R20 3.3

Ω

T1, T3 BC547B transistor R21 180

Ω

T2 BC557B transistor R22 220

Ω

T4 BD236 transistor R23 270

Ω

L1 Sel f 2x2µH R24, R25 1.2K

Ω

C1, C2, C10, C15 100nF (Cd) R29 820

Ω

C16,C17,C18,C20,C23,C25 100nF RS1, RS5 3.3KΩ SIL8 Array

C3, C4, C7, C8, C9, C11, 100pF RS2 10 KΩ SIL9 Array

C12, C13, C14 100pF RS3, RS4 150Ω SIL8 Array

C5, C6 15pF RV1 10KΩ resistor trimmer

C19, C21 1.0nF P1 Header 2x8

C22 22µF P2 SUBD25-M Connector

C24 10µF J1 2x15 pins connector

C26 1µF J2 2x30 pins connector

SW1 Push-button J3 Female Jack plug

JP1 to JP6 jumpers J4 2nd power supply conn.

51

Page 48

48/49

Hardware Information

TO- 220

TO-92

USER'S I/O INTERFA C E

I N SI TU PROG. CONNECTOR

( enabl es VDD)

(disables RESET/)

( d i sab l es VPP)

PROG

IRQ POLL

USER

Not used

USER' S LCD INTERFACE

SDI P5 6

SOCKET

(SDOP 46B)

LCD Pi ns Prot ect i on i f

Combi -Port PC0- 7 i s used

14 femal e j umpers 2.54

(SDOP 40B)

TO-92

ENVPP Lev el c ompat ibi l i t y

ENVPP Lev el c ompat ibi l i t y

Reset Push

PC i nt erf ace connect or

Parallel Port

Solder Bri dge

Solder Bri dge

Solder Bri dge

Solder Bri dge

Solder Bri dge

Sol der Bri dge

Solder Bri dge

D0

S6

VPP

PA7/SDOP

PB3

OSCP

S22

S25

COM2

S8

OSCOUT

S10

COM1

D1

S21

S15

S44

PPINT

S26

S27

PB3

PA5/TM 2

S14

OSC32O

PA7/SDOP

PA7/SDO P

D2

S7

PB0

SDOP

S16

OSC32I

S18

PB4

PB0

PA6/TR O

PA1

PROG/

TROMIN

VLCD2/3

TM2

D0

D3

S19

PB2

PB7

S23

OSCIN

S24

D4

PB2

PB5

TROMIN

TIMER

VLCD1/3

SIM/

D6

PB4

RESET/

S20

D7

D4

OSCPI

PA5/TM2

S47

PA3

PSS

S5

PA4

OSC32I

PA7/SDOP

REM/

S12

PB6

PA4

VLCD

OSC32I

PB1

S17

RESETP/

RESETP

OSCPI

SDOP

TROMIN

AKEY

OSCPI

S11

PA0

WDON

S13

PA6/TRO

S42

PSS

RESETP/

OSCOUT

PB1

S48

TM2

PA3

S43

D5

PA5/TM 2

PA2

COM3

S45

COM4

REM/

PA0

PA6/TR O

S46

TIMER

PPINT

D1

OSC32O

PB5

ENVPP

SDOP

PA1

COM3

S6S5

S12

S17

S21

S24S23

S29

PC5/S38

S8

S32

PC1/S34

S43

S45

PC2/S35

S9

S25

S46

S47

VLCD2/3VLCD1/3

S13

S20

S22

VLCD

COM1

S15

S18

PC2/S35

PC5/S38

PC3/S36

S30

S31

PC6/S39

PC4/S37

VDD

S26

PC6/S39

S42

S14

S41

PC7/S40

COM2

S10

S16

S19

PC3/S36

PC7/S40

S44

S7

S11

S27

S41

PC4/S37

COM4

S28

S48

PC1/S34S4PC0/S33

PC0/S33

NMI

NMI

PA2

PC0/S33

PC1/S34

PC2/S35

PC3/S36

PC4/S37

PC5/S38

PC6/S39

PC7/S40

S33

S34

S35

S37

S36

S38

S39

S40

S9

S4

PB7

PB6

ENVDD

WDON

OSC32O

OSCP

VPP6240

OSCIN

RESET/

RESET/

PA7/SDOP

PA6/TR O

OSCIN46B

VPP

VPP

PA5/TM 2

PA5/TM2

VDD

OSCIN46B

PA6/TRO

S28

S30

S36

S29

S24

S19

S21

COM3

S37

S31

S40

S34

S18

S10

COM2

S15

S35

S28

S23

S14

S32

S27

S11

S39

S22

S30

COM4

S9

S16

S13

S17

S20

S32

S12

S26

S33

S25

COM1

S29

S31

S38

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

VCC

VCC

GND GND

GND GND

GND

GND

GND

GND

GND

GND

GND

VCC

GND

GND GND

GND

VDD

VDD

VDD

VDD

GND GND

VDD

VDDVDD

VDD

VDD

VDD

VDD

VDD

GND

VCC

VDD

GND

GND

GND

GND

GND

GND

GND

GND

VDD

U4

ST6246B

PC3/S361PC4/S372PC5/S383PC6/S394PC7/S405S416S427S438COM49COM310COM211COM112VLCD1/313VLCD2/3

14

VSS22VDD21TEST/Vpp20Ain/PA419Ain/PA518Ain/PA617Ain/PA716VLCD

15

RESET23OSCout24PB6/Sin28PB7/Sout27NMI26OSCin

25

PB5/Scl

29

PB4

30

S1342S1241S1140S10

39S938

PSS

37

OSC32in

36

OSC32out

35

PB0/Ain34PB1/Ain33PB2/Ain32PB3/Ain

31

S1443S1544S1645S2546S2647S2748S2849S2950S3051S3152S32

53

PC0/S3354PC1/S3455PC2/S35

56

SW1

5 4

21

3

P2

SUBD25C-F-COUDE

13251224112310229218207196185174163152141

U3

ST62T40B

PB0/Ai n

38

PB1/Ai n

37

PB2/Ai n

36

PB3/Ai n

35

PB4

34

PB5/Scl

33

PB6/Sin

32

PB7/Sout

31

TIMER

30

PA0/Ain22PA1/Ain21PA2/Ain20PA3/Ain19PA4/Ain17PA5/Ain16PA6/Ain15PA7/Ain14COM110COM29COM38COM47S486S475S464S453S442S43

1

S26

64

S42

80

S25

63

S41

79

S24

62

PC7/S4 0

78

S23

61

PC6/S3 9

77

S22

60

PC5/S3 8

76

S21

59

PC4/S3 7

75

S20

58

PC3/S3 6

74

S19

57

PC2/S35

73

S18

56

PC1/S3 4

72

S17

55

PC0/S3 3

71

S16

54

S32

70

S15

53

S31

69

S14

52

S30

68

S13

51

S29

67

S12

50

S28

66

S11

49

S27

65

S10

48S947S846S745S644S543S442

PSS

41

OSC32in

40

OSC32out

39

NMI

29

WDON

28

OSCIN

27

OSCOUT

26

RS

25

VSS24VDD

23

VPP/TM

18

VLCD13VLCD2/312VLCD1/3

11

L1

SELF 2x2.2ÿH

2

43

1

JP2

MW2X8C

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

J2

MW2X30 C

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

51 52

53 54

55 56

57 58

59 60

JP6

MW2X1C

1 2

JP4

MW2X1C

1 2

JP3

MW2X1C

1 2

J1

MW2X15C

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

JP5

MW1X3C

1

2

3

JP1

MW1X3C

123

TP1

MW1X1C

TP2

MW1X1C

I

GND

O

U9

LM7805

1

2

3

LD2

LED-RED-5 MM

12

LD1

LED-RED-5MM

1 2

U6

LCD VIM878

D8.C1D8.A2D7.C3D7.A4D6.C5D6.A6D5.C7D5.A8D4.C9D4.A10D3.C11D3.A12D2.C13D2.A14D1.C15D1.A16COM417COM3

18

D8.D

36

D8.B

35

D7.D

34

D7.B

33

D6.D

32

D6.B

31

D5.D

30

D5.B

29

D4.D

28

D4.B

27

D3.D

26

D3.B

25

D2.D

24

D2.B

23

D1.D

22

D1.B

21

COM120COM2

19