Page 1

8 keys with individual key state outputs or I2C interface

LQFP32 (7x7 mm)

Features

■ Patented charge-transfer design

■ Up to 8 independent QTouch™ keys supported

■ Individual key state outputs or I

■ Fully “debounced” results

■ Patented AKS™ Adjacent Key Suppression

■ Self-calibration and auto drift compensation

■ Spread-spectrum bursts to reduce EMI

■ Up to 5 general-purpose outputs

■ ECOPACK® (RoHS compliant) package

Applications

This device specifically targets human interfaces

and front panels for a wide range of applications

such as PC peripherals, home entertainment

systems, gaming devices, lighting and appliance

controls, remote controls, etc.

QST devices are designed to replace mechanical

switching/control devices and the reduced

number of moving parts in the end product

provides the following advantages:

■ Lower customer service costs

■ Reduced manufacturing costs

■ Increased product lifetime

Table 1. Device summary

2

C interface

QST108

Capacitive touch sensor device

Not For New Design

Description

The QST108 is the ideal solution for the design of

capacitive touch sensing user interfaces.

Touch-sensitive controls are increasingly

replacing electromechanical switches in home

appliances, consumer and mobile electronics,

and in computers and peripherals. Capacitive

touch controls allow designers to create stylish,

functional, and economical designs which are

highly valued by consumers, often at lower cost

than the electromechanical solutions they

replace.

The QST108 QTouch™ sensor IC is a pure digital

solution based on Quantum's patented chargetransfer (QProx™) capacitive technology.

QTouch™ and QProx™ are trademarks of the

Quantum Research Group.

Order codes

Feature

QST108KT6

Operating supply voltage 2.4 to 5.5 V

Supported interfaces Individual key state outputs or I

Operating temperature -40° to +85° C

Package LQFP32 (7x7 mm)

July 2008 Rev 5 1/51

This is information on a product still in production but not recommended for new designs.

2

C Interface

www.st.com

1

Page 2

Contents QST108

Contents

1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 QST touch sensing technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Spread-spectrum operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Faulty and unused keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Detection threshold levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Detection integrator filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Self-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Fast positive recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Forced key recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.9 Max On-Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.10 Drift compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.11 Adjacent key suppression (AKS™) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Device operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Reset and power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Burst operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Low power mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Stand-alone mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5.1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5.2 KOUT outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.3 Option descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 I2C mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6.1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6.2 General-purpose outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.3 IRQ pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.4 Communication packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.5 I2C address selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7 Supported commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/51

Page 3

QST108 Contents

5 Design guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 CS sense capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Sensitivity tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.1 Increasing sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.2 Decreasing sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2.3 Key balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 Crosstalk precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 PCB layout and construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Parameter conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 Minimum and maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Functional EMS (electro magnetic susceptibility) . . . . . . . . . . . . . . . . . 32

6.3.2 Electro magnetic interference (EMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.3 Absolute maximum ratings (electrical sensitivity) . . . . . . . . . . . . . . . . . 33

6.4 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Supply current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6 Capacitive sensing characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7 KOUTn/OPTn/GPOn pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7.1 General characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7.2 Output pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8 RESET pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.9 I2C control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Soldering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9 Device revision information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3/51

Page 4

Contents QST108

9.1 Device revision identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2 Device revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.1 Revision 2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.2 Revision 2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4/51

Page 5

QST108 Device overview

1 Device overview

The QST108 capacitive touch sensor IC is a pure digital solution based on Quantum's

patented charge-transfer (QProx™) capacitive technology.

This technology allows users to create simple touch panel sensing electrode interfaces for

conventional or flexible printed circuit boards (PCB/FPCB). Sensing electrodes are part of

the PCB layout (copper pattern or printed conductive ink) and may be used in various

shapes (circle, rectangular, etc.).

By implementing the QProx™ charge-transfer algorithm, the QST108 detects finger

presence (human touch) near electrodes behind a dielectric (glass, plastic, wood, etc.). Only

one external sampling capacitor by channel is used in the measuring circuitry to control the

detection.

QST technology also incorporates advanced processing techniques such as drift

compensation, auto-calibration, noise filtering, and Quantum's patented Adjacent Key

Suppression™ (AKS™) to ensure maximum usability and control integrity.

In order to meet environmental requirements, ST offers this device in ECOPACK®

packages. These packages have a lead-free second level interconnect. The category of

second level interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97.

The maximum ratings related to soldering conditions are also marked on the inner box label.

ECOPACK is an ST trademark. ECOPACK specifications are available at: www.st.com.

5/51

Page 6

Pin description QST108

SNS_SCK1

32 31 30 29 28 27 26 25

24

23

22

21

20

19

18

17

9 101112131415

16

1

2

3

4

5

6

7

8

I2C_SCL/KOUT81) (HS)

RESET

NC

V

DD_1

GPO4/KOUT4/OPT4 (HS)

GPO5/KOUT5/OPT5 (HS)

IRQ/KOUT6/OPT6 (HS)

I2C_SDA/KOUT71) (HS)

V

SS_2VSS_3VSS_4

V

DD_2

SNSK_SCK1

SNS_SCK2

V

SS_1

SNS_SCK6

SNSK_SCK5

SNSK_SCK2

SNS_SCK3

SNS_SCK4

SNS_SCK5

SNSK_SCK4

SNSK_SCK3

SNS_SCK8

SNSK_SCK7

SNS_SCK7

SNSK_SCK6

GPO3/OPT3/KOUT3 (HS)

GPO2/OPT2/KOUT2 (HS)

GPO1/OPT1/KOUT1 (HS)

SNSK_SCK8

QST108KT6

(HS) 20 mA high sink capability (on N-buffer only)

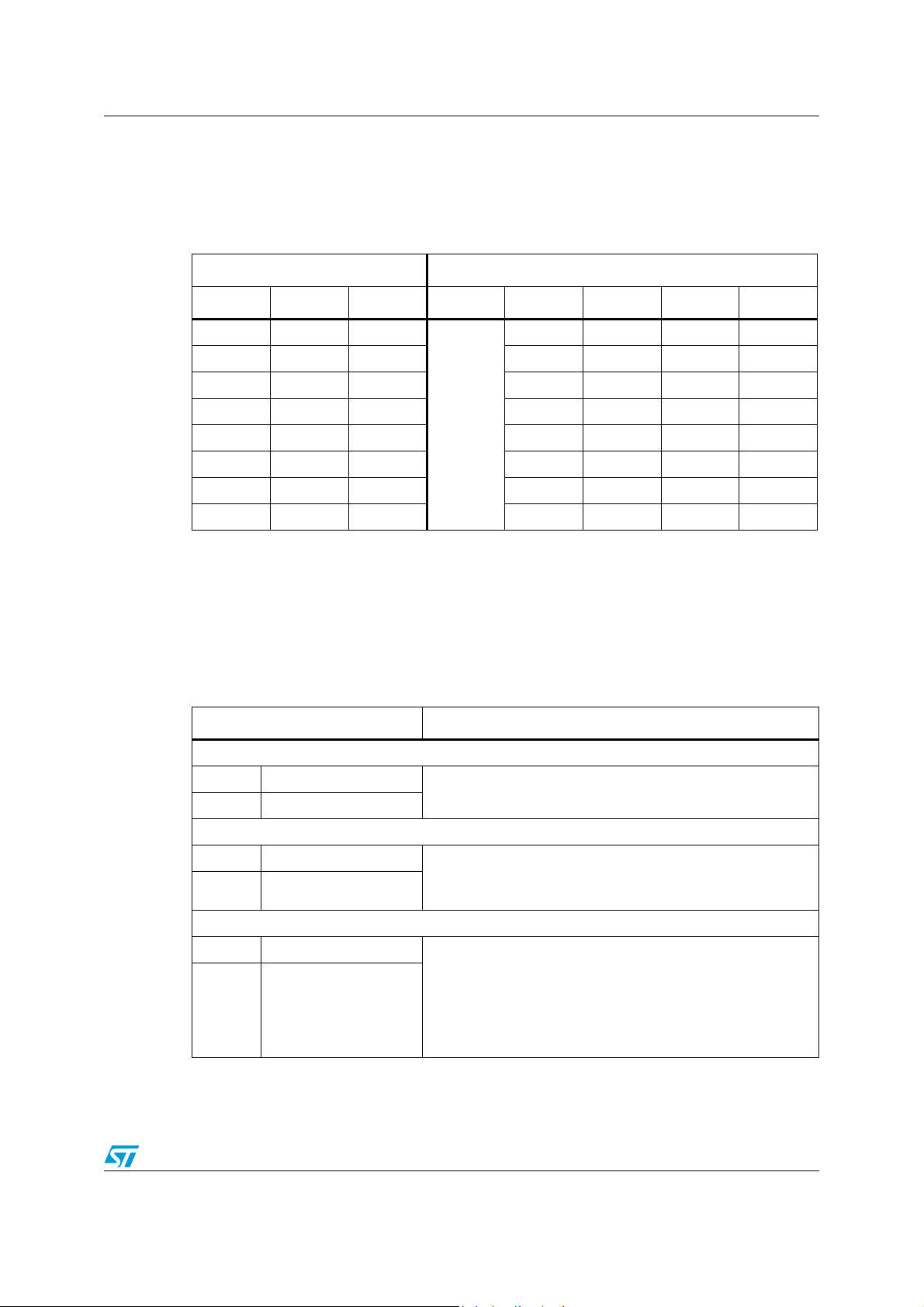

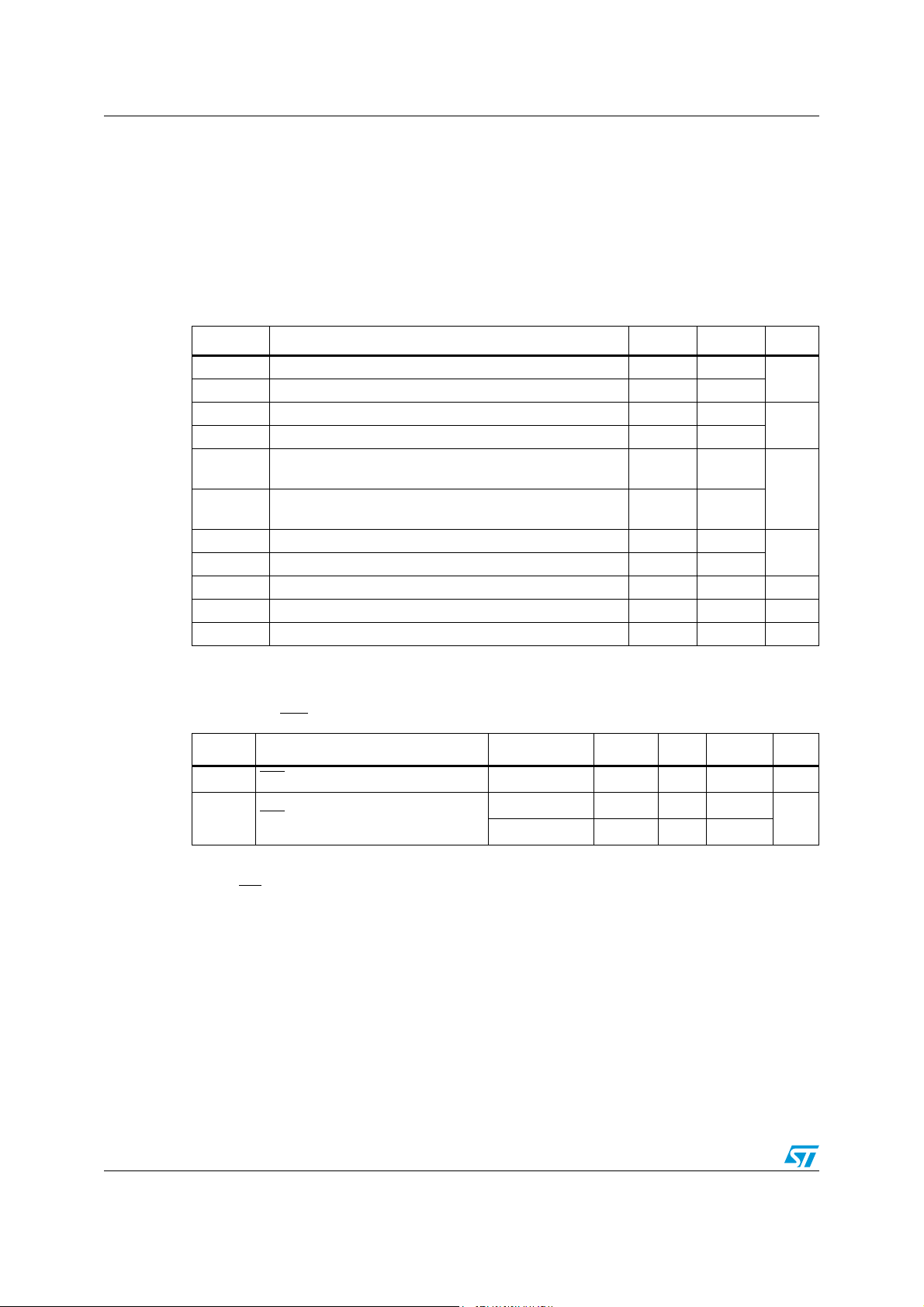

2 Pin description

Figure 1. 32-pin package pinout

Table 2. Device pin description

Pin Pin name Type

1 GPO4/OPT4/KOUT4

2 GPO5/OPT5/KOUT5

3 OPT6/KOUT6/IRQ

4 KOUT7/I2C_SDA

5 KOUT8/I2C_SCL

6/51

1. An external pull-up is required on these pins.

(1)

Stand-alone mode function I2C mode function If unused

(2)

PP (HS)

(2)

PP (HS)

(2)

(3)

(3)

PP/OD

(HS)

TOD

(HS)

TOD

(HS)

Key 4 output / BCD output 4

and MOD_0 option resistor

Key 5 output and

MOD_1 option resistor

Key 6 output and

OM_0 option resistor

Key 7 output I

Key 8 output I

General purpose output 4

and I²C address bit 2

option resistor

Option

resistor

Open or

General purpose output 5

option

resistor

Open or

Interrupt line (active low)

option

resistor

2

C serial data Open

2

C serial clock Open

Page 7

QST108 Pin description

Table 2. Device pin description (continued)

Pin Pin name Type

6 RESET

7 NC Not connected

(1)

Stand-alone mode function I2C mode function If unused

BD Reset (active low)

10nF

capacitor to

ground

8V

9V

10 V

11 V

12 V

13 V

DD_1

SS_1

SS_2

SS_3

SS_4

DD_2

S Supply voltage

S Ground voltage

S Ground voltage

S Ground voltage

S Ground voltage

S Supply voltage

14 SNS_SCK1 SNS Key 1 sense pin to Cs Open

15 SNSK_SCK1 SNS Key 1 sense pin to Cs/Rs Open

16 SNS_SCK2 SNS Key 2 sense pin to Cs Open

17 SNSK_SCK2 SNS Key 2 sense pin to Cs/Rs Open

18 SNS_SCK3 SNS Key 3 sense pin to Cs Open

19 SNSK_SCK3 SNS Key 3 sense pin to Cs/Rs Open

20 SNS_SCK4 SNS Key 4 sense pin to Cs Open

21 SNSK_SCK4 SNS Key 4 sense pin to Cs/Rs Open

22 SNS_SCK5 SNS Key 5 sense pin to Cs Open

23 SNSK_SCK5 SNS Key 5 sense pin to Cs/Rs Open

24 SNS_SCK6 SNS Key 6 sense pin to Cs Open

25 SNSK_SCK6 SNS Key 6 sense pin to Cs/Rs Open

26 SNS_SCK7 SNS Key 7 sense pin to Cs Open

27 SNSK_SCK7 SNS Key 7 sense pin to Cs/Rs Open

28 SNS_SCK8 SNS Key 8 sense pin to Cs Open

29 SNSK_SCK8 SNS Key 8 sense pin to Cs/Rs Open

(2)

(2)

(2)

PP (HS)

PP (HS)

PP (HS)

30 GPO1/OPT1/KOUT1

31 GPO2/OPT2/KOUT2

32 GPO3/OPT3/KOUT3

1. S: supply pin, BD: bidirectional pin, SNS: capacitive sensing pin, PP: Output push-pull, OD: Output open-drain,

TOD: Output true open-drain and HS: 20mA high sink capability (on N-buffer only)

2. During the reset phase, these pins are floating and their state depends on the option resistor.

3. An external pull-up is required on these pins.

Key 1 output / BCD output 1

and MODE option resistor

Key 2 output / BCD output 2

and AKS option resistor

Key 3 output / BCD output 3

and LP option resistor

General purpose output 1

and MODE option resistor

General purpose output 2

and I2C address bit 0

option resistor

General purpose output 3

and I2C address bit 1

option resistor

Option

resistor

Option

resistor

Option

resistor

7/51

Page 8

QST touch sensing technology QST108

Ai12569

SNS_SCKn

SNSK_SCKn

Sense capacitor

C

S

(a few nF)

Cx (~20 pF)

CT (~5 pF)

Earth

Serial resistor

R

S

(10 kΩ)

3 QST touch sensing technology

3.1 Functional description

QST devices employ bursts of charge-transfer cycles to acquire signals. Burst mode permits

low power operation, dramatically reduces RF emissions, lowers susceptibility to RF fields,

and yet permits excellent speed. Signals are processed using algorithms pioneered by

Quantum which are specifically designed to provide reliable, trouble-free operation over the

life of the product.

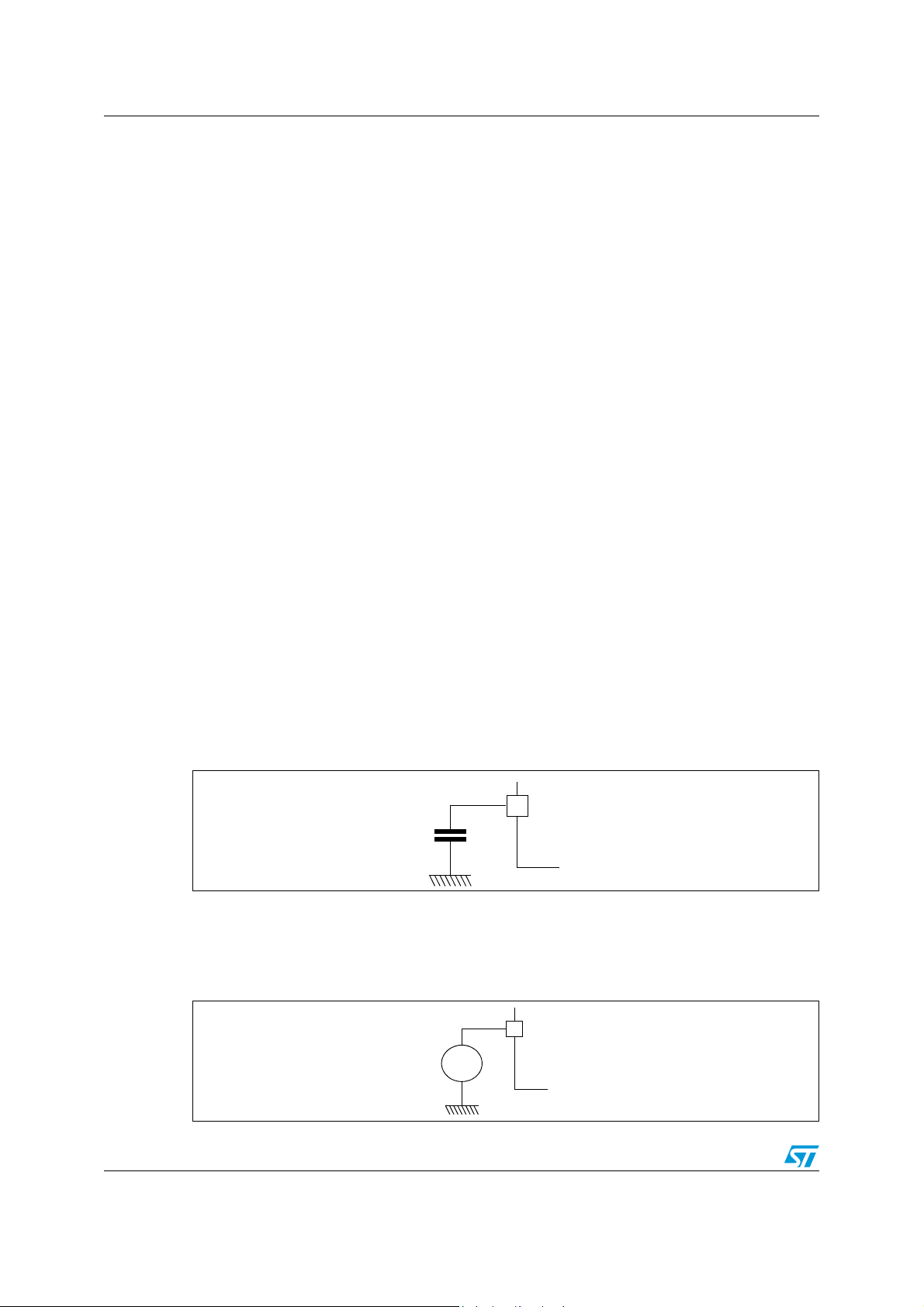

The QST switches and charge measurement hardware functions are all internal to the

device. An external C

then measured. Larger values of C

rapidly, reducing available resolution. As a minimum resolution is required for proper

operation, this can result in dramatically reduced gain. Larger values of C

of differential voltage across it, increasing available resolution by permitting longer QST

bursts. The value of C

The device is responsive to both C

changes in sensor gain.

Figure 2. QTouch™ measuring circuitry

capacitor accumulates the charge from sense-plate CX, which is

S

can thus be increased to allow larger values of CX to be tolerated.

S

cause the charge transferred into CS to rise more

X

reduce the rise

S

and CS, and changes in either can result in substantial

X

3.2 Spread-spectrum operation

The bursts operate over a spread of frequencies, so that external fields will have minimal

effect on key operation and emissions are very weak. Spread-spectrum operation works

with the Detection Integrator mechanism (DI) to dramatically reduce the probability of false

detection due to noise.

8/51

Page 9

QST108 QST touch sensing technology

3.3 Faulty and unused keys

Any sensing channel that does not have its sense capacitor (CS) fitted is assumed to be

either faulty or unused. This channel takes no further part in operation unless a Mastercommanded recalibration operation shows it to have an in-range burst count again. Faulty,

unused or disabled keys are still bursted but not processed to avoid modifying the sensitivity

of active keys.

This is important for sensing channels that have an open or short circuit fault across C

Such channels would otherwise cause very long acquire bursts, and in consequence would

slow the operation of the entire QST device.

To optimize touch response time and device power consumption, if some keys are not used,

we recommend to try suppressing the ones which belong to the same burst. Bursts which

do not have any keys implemented will then not be processed.

3.4 Detection threshold levels

The key capacitance change induced by the presence of a finger is sensed by the variation

in the number of charge transfer pulses to load the capacitor. The difference in the pulse

count number is compared to a threshold in order to detect the key as pressed or not.

Two different thresholds, one for detection and one for the end of detection, create an

hysteresis in order to prevent erratic behavior.

The default threshold levels and hysteresis values are described in Section 6.6: Capacitive

sensing characteristics on page 35.

3.5 Detection integrator filter

The Detection Integrator (DI) filter mechanism works together with spread spectrum

operation to dramatically reduce the effects of noise on key states. The DI mechanism

requires a specified number of measurements that qualify as detections (and these must

occur in a row) or the detection will not be reported.

.

S

In a similar manner, the end of a touch (loss of signal) also has to be confirmed over several

measurements. It is called the End of Detection Integrator (EDI).

This process acts as a type of “debounce” mechanism against noise.

The default DI and EDI values for confirming start of touch and end of touch are described in

Section 6.6: Capacitive sensing characteristics on page 35.

9/51

Page 10

QST touch sensing technology QST108

Burst count

Time

Reference count

Reference + EofDeTh

Reference + DeThHysteresis

Key Detection signal

= Sampling point

Figure 3 shows an example of detection with DI=2 and EDI=2 meaning 3 consecutive

samples are necessary to trigger the key detection or end of detection

Figure 3. Detection signals

3.6 Self-calibration

On power-up, all keys are self-calibrated to provide reliable operation under almost any

conditions. The calibration phase is used to compute a reference value per key which is then

used by the process determining if a key is touched or not. The reference is an average of 8

single acquisitions. As a result, the calibration time of the system can be simply calculated

using the following formula: t

= 8 * Burst_Period. The methodology used to measure the

CAL

burst period is described in application note AN2547. For a maximum calibration duration

(t

), please refer to Section 6.6: Capacitive sensing characteristics on page 35.

CAL

3.7 Fast positive recalibration

The device autorecalibrates a key when its signal reflects a decrease in capacitance higher

than a fixed threshold (PosRecalTh) for a defined number of acquisitions (PosRecalI).

3.8 Forced key recalibration

A recalibration of the device may be issued at any time by sending to the QST device the

appropriate I

It is possible to recalibrate independently any individual key using an I

2

C command or by tying the RESET pin to ground.

2

C command.

10/51

Page 11

QST108 QST touch sensing technology

3.9 Max On-Duration

The device can time out and automatically recalibrate each key independently after a fixed

duration of continuous touch detection. This prevents the keys from becoming ‘stuck on’ due

to foreign objects or other sudden influences. This is known as the Max On-Duration feature.

After recalibration, the key will continue to operate normally, even if partially or fully

obstructed. Max On-Duration works independently per channel: a timeout on one channel

has no effect on another channel.

Infinite timeout is useful in applications where a prolonged detection can occur and where

the output must reflect the detection no matter how long. In infinite timeout mode, the

designer should take care to ensure that drift in C

remain “stuck on” inadvertently even when the touching object is removed from the sense

field. Timeout durations are not accurate and can vary substantially depending on V

temperature values, and should not be relied upon for critical functions.

, CX, and VDD do not cause the device to

S

and

DD

3.10 Drift compensation

Signal drift can occur because of changes in CX, CS, and VDD over time. Depending on the

C

type and quality, the signal may vary substantially with temperature and veiling. If keys

S

are subject to extremes of temperature or humidity, the signal can also drift. It is crucial that

drift be compensated, otherwise false detections, non detections, and sensitivity shifts will

follow.

Drift compensation slowly corrects the reference level of each key while no detection is in

effect. The rate of reference adjustment must be performed slowly or else legitimate

detections can also be ignored. The device compensates drift on each channel

independently using a maximum compensation rate to the reference level.

Once a touch is sensed, the drift compensation mechanism ceases since the signal is

legitimately high, and therefore should not cause the reference level to change.

The signal drift compensation is “asymmetric”: the reference level compensates drift in one

direction faster than it does in the other. Specifically, it compensates faster for increasing

signals than for decreasing signals. Decreasing signals should not be compensated for

quickly, since an approaching finger could be compensated for partially or entirely while

approaching the sense electrode. However, an obstruction over the sense pad, for which the

sensor has already made full allowance, could suddenly be removed leaving the sensor with

an artificially elevated reference level and thus become insensitive to touch. In this latter

case, the sensor will compensate for the object's removal very quickly, usually in only a few

seconds.

Caution: When only one key is enabled or if keys are very close together, the common drift

compensation must be disabled or its rate must be reduced to ensure correct device

operation.

11/51

Page 12

QST touch sensing technology QST108

Burst count

Reference + DeTh

Reference Count

Reference Count + PosRelTh

Time

Drift Compensation

Temperature Change

Figure 4 illustrates an example of the drift compensation algorithm following a temperature

change.

Figure 4. Drift compensation example

3.11 Adjacent key suppression (AKS™)

Adjacent key suppression (AKS™) is a Quantum-patented feature which prevents multiple

keys from responding to a single touch. This can happen with closely spaced keys, or a

scroll wheel that has buttons very near it.

The QST108 supports two AKS modes:

● Locking AKS

Once a key is considered as “touched”, all other keys are locked in an untouched state.

To unlock these keys, the touched key must return to an untouched state. Then, the key

having the lowest key ID number is declared as the “touched” one.

● Unlocking AKS

On each acquisition, the signal strengths from each key are compared and the key with

the highest signal level is declared as the “touched” one.

2

In I

C mode, up to 8 AKS groups can be specified.

Note: All keys belonging to the same AKS group must have the same AKS mode.

12/51

Page 13

QST108 Device operating modes

4 Device operating modes

4.1 Reset and power-up

At power-up, the device configures itself according to the pull-up or pull-down option

resistors present on pins OPT1 to OPT6. The device start-up and configuration may take up

to t

When the power is established, it is possible to force a new device configuration by applying

a negative pulse on the RESET

Setup

.

pin.

The RESET

device resets itself (through an I²C command, for example).

A 10nF capacitor is recommended on the RESET

immunity.

pin is a bidirectional pin with an internal pull-up. The line is forced low when the

4.2 Burst operation

The device operates in “Burst” mode. Each key touch is acquired using a burst of chargetransfer sensing pulses whose count varies depending on the value of the sense capacitor

C

and the load capacitance CX. Key touches are acquired using two successive bursts of

S

pulses:

● Burst A: Keys 1, 2, 3, and 4

● Burst B: Keys 5, 6, 7, and 8

Bursts always operate in an A-B sequence. If Keys 5 to 8 are not implemented, the QST

device will not perform the Burst B to improve the response time and reduce the power

consumption when in Low Power (LP) mode.

In Low Power mode, the device sleeps in an ultra-low current state between bursts to

conserve power.

4.3 Low power mode

pin to ensure reliable start-up and noise

In order to reduce the device power consumption, the QST family include scalable low

power modes.

● Standard low power mode

When the device is in standard low power mode, a window with very low power

consumption is inserted between the acquisition of the last active key and the following

acquisition of the first active key.

This window duration is programmable as the 'sleep duration time'.

Note that the sleep window insertion is cancelled in the following conditions:

– If a change is detected on a key, in order to speed up the DI process, the sleep

window insertion is skipped until the end of the DI process.

–In I

– Inside an I

2

C mode, when a key change is actually detected and reported with a negative

pulse on the IRQ

command is received from the host.

2

period is skipped.

pin. In this case, the low power mode is disabled until a

C command, between the Write and the Read I2C frames, the sleep

13/51

Page 14

Device operating modes QST108

● Free run in detect

The behavior in this mode is the same as in the standard low power mode except that

the sleep window insertion is always skipped if any of the active keys is detected as

touched.

This is useful to improve the wheel response time.

● Deep Sleep mode

Caution: If an I

does not acknowledge the frame (even if it has an I

In Deep Sleep mode, the device enters a very low power mode indefinitely. The device

resumes its operations after receiving an I

2

C frame is received while in Sleep or Deep Sleep mode, the device wakes up but

2

C frame with any address or a reset.

2

C frame with the device address). The

host must therefore send again the frame until it is taken in account and acknowledged.

4.4 Mode selection

The device options are configured by connecting pull-up or pull-down resistors on OPTn

pins. The device operating mode is selected using option pin 1 (OPT1) while the device

settings are configured using option pins OPT2 to OPT6 (Tab le 3 ). Option pins are sampled

at power-up and after a reset.

To fit most applications, the QST108 device offers two different operating modes:

● Stand-alone mode

This mode allows the user to simply replace existing mechanical switches with a

capacitive sensing solution. It is designed for maximum flexibility and can

accommodate most popular sensing requirements via option resistors (AKS, Low

power, Max On-Duration and output modes).

In this mode, the 8 output pins reflect the status of the 8 sensing channels.

2

● I

C mode

In this mode, which is the most open one, the device is driven using the I

To avoid polling, the QST device features an output interrupt pin (IRQ

reports all key changes to the Master device. The QST (Slave) device can drive up to

five general-purpose outputs.

Table 3. Operating modes

2

C interface.

). The IRQ line

OPT1: Mode selection

Pin OPT1 is high at start-up Stand-alone mode AKS LP MOD_0 MOD_1 OM

Pin OPT1 is low at start-up I

14/51

2

C mode ADD0 ADD1 ADD2 Unused Unused

Option resistor function

OPT2 OPT3 OPT4 OPT5 OPT6

Page 15

QST108 Device operating modes

4.5 Stand-alone mode

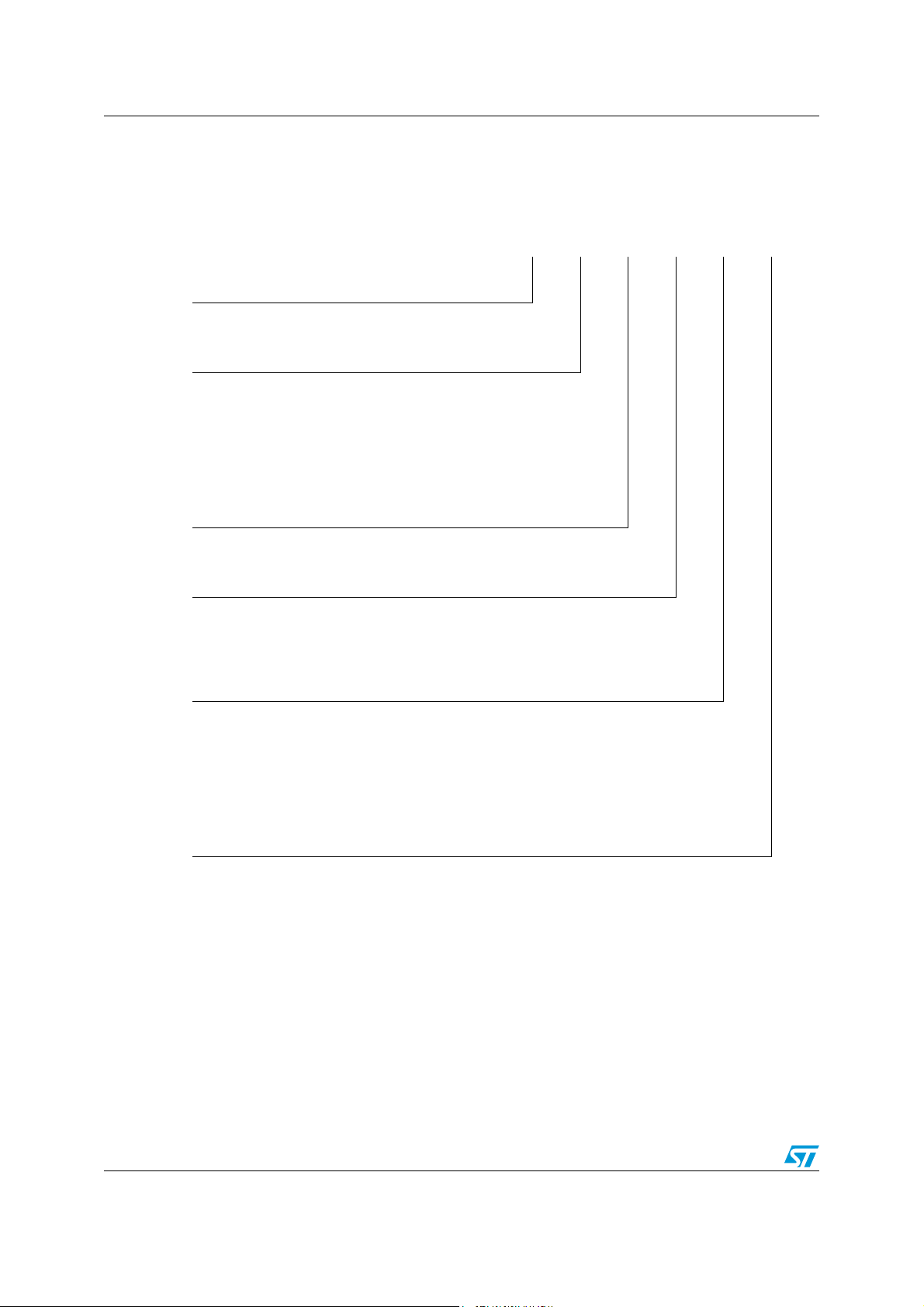

This mode allows the user to simply replace existing mechanical switch interface with a

capacitive sensing solution. It is designed for maximum flexibility and can accommodate

most popular sensing requirements via option resistors (see Figure 5).

4.5.1 Main features

● Pins KOUT1 to KOUT8 directly reflect the state of keys

● Selectable global adjacent key suppression (AKS™)

● Selectable sleep duration

● Selectable Max On-Duration values

● Selectable BCD mode

15/51

Page 16

Ai12560

MOD_1/KOUT5

MOD_0/KOUT4

LP/KOUT3

AKS/KOUT2

V

SS_1

V

SS_2

V

SS_3

V

SS_4

V

DD_1

V

DD_2

RESET

V

UNREG

4.7µF 4.7µF

2.4~5.5V

Volt. Reg.

OM/KOUT6

KOUT7

KOUT8

MODE/KOUT1

V

DD

Binarycoded

Output

Mode

10nF

V

DD

10kΩ 10kΩ

To Host

100nF 100nF

SNS_SCK1

SNSK_SCK1

Key1

R

S1

10kΩ

C

S1

Keep these parts close to IC

SNS_SCK2

SNSK_SCK2

Key2

R

S2

10kΩ

C

S2

SNS_SCK3

SNSK_SCK3

Key3

R

S3

10kΩ

C

S3

SNS_SCK4

SNSK_SCK4

Key4

R

S4

10kΩ

C

S4

SNS_SCK5

SNSK_SCK5

Key5

R

S5

10kΩ

C

S5

SNS_SCK6

SNSK_SCK6

Key6

R

S6

10kΩ

C

S6

SNS_SCK7

SNSK_SCK7

Key7

R

S7

10kΩ

C

S7

SNS_SCK8

SNSK_SCK8

Key8

R

S8

10kΩ

C

S8

1

2

3

4

5

6

8

9 101112

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1MΩ

V

DD

V

SS

KOUT6

1MΩ

V

DD

V

SS

KOUT5

1MΩ

V

DD

V

SS

KOUT4

1MΩ

V

DD

V

SS

KOUT3

1MΩ

V

DD

V

SS

KOUT2

1MΩ

V

DD

KOUT1

V

DD

KOUT8

KOUT7

Device operating modes QST108

Figure 5. Stand-alone mode typical schematic

4.5.2 KOUT outputs

16/51

KOUTn outputs directly reflect the state of keys. These pins are push-pull outputs except for

pins KOUT7 and KOUT8 which are true open-drain outputs. Under RESET, these pins are

floating and their state depends on the option resistors. Pins KOUTn are active high

meaning that when a key is “touched”, the corresponding KOUT pin outputs a ‘1’.

Page 17

QST108 Device operating modes

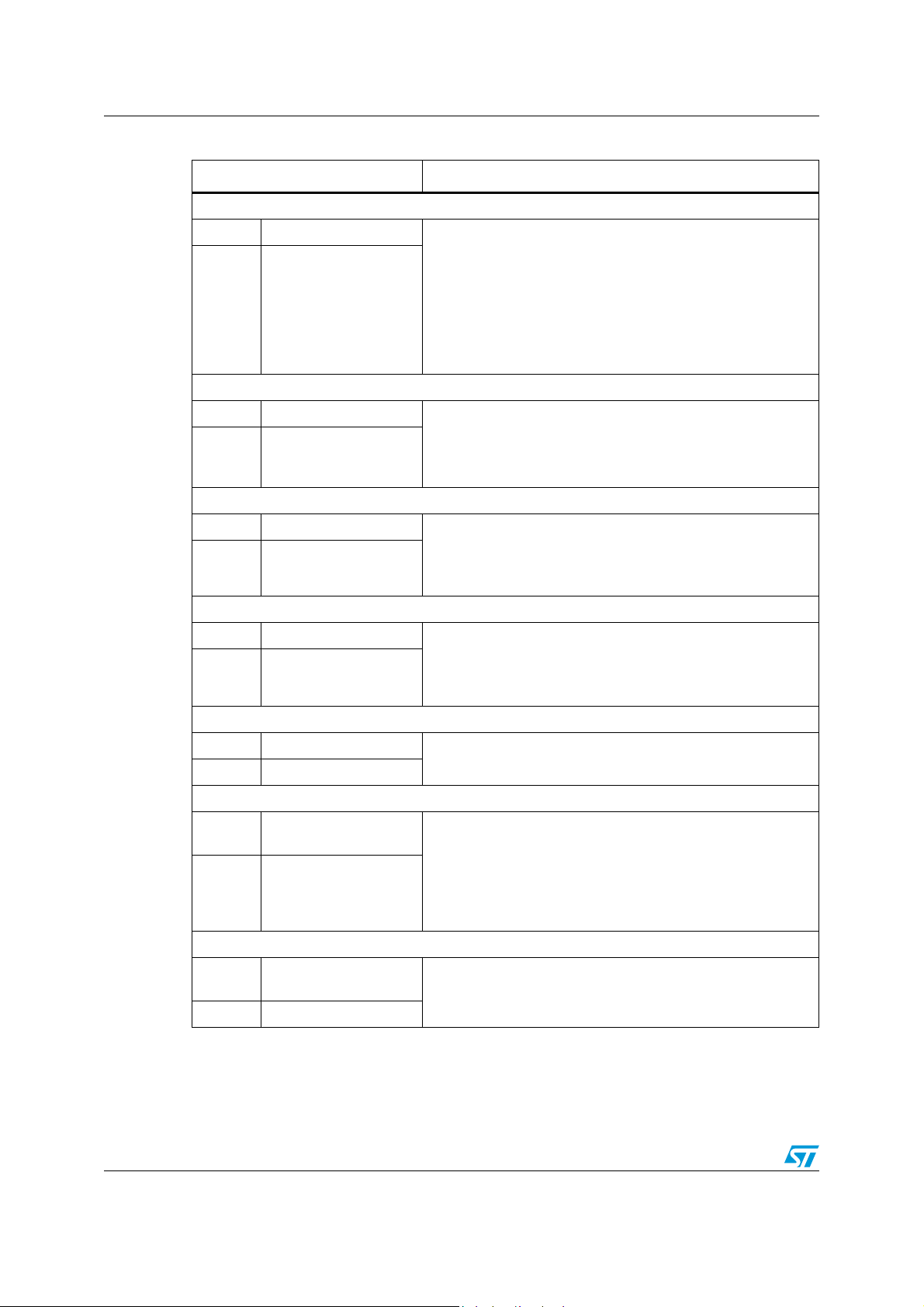

4.5.3 Option descriptions

Adjacent key suppression (AKS™)

The QST108 features an adjacent key suppression (AKS™) function.

This function is enabled using the AKS option resistor (OPT2) in standard output mode as

described in Ta bl e 4 . In BCD output mode, the AKS function is always enabled, regardless

of the option resistor configuration.

Table 4. AKS truth table

OPT2/AKS Description

V

SS

V

DD

Disabled

Global locking AKS on all available keys

Low Power mode option

This option resistor (OPT3) selects whether the device is always sensing the keys or if a low

power consumption phase is introduced between bursts as described in Tabl e 5 .

In Low Power mode, a very low consumption (sleep) phase of 100ms is inserted between

the Group B burst and the Group A burst. This significantly reduces the overall consumption

of the device. Sleep duration is not accurate and can vary substantially depending on V

and temperature values.

Note: In Low Power mode, the response time is increased.

Table 5. Low power (LP) mode truth table

OPT3/LP Description

V

SS

V

DD

Free running mode

100ms sleep duration

Max On-Duration

There are four recalibration timing options (“Max On-Duration”). The recalibration option

resistors (OPT4 and OPT5) control how long it takes for a continuous detection to trigger a

recalibration on a key as described in Tab le 6 . When such an event occurs, only the “stuck”

key is recalibrated.

Table 6. Max On-Duration (MOD) truth table

DD

OPT4/MOD_0 OPT5/MOD_1 Description

V

SS

V

SS

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

Infinite

60s

20s

10s

17/51

Page 18

Device operating modes QST108

Output mode option

The QST108 offers several outputs mode to fit any existing application.

Table 7. Output mode (OM) truth table

OPT6/OM Description

V

SS

V

DD

1. In BCD mode, the AKS function must be enabled.

Table 8. Binary code truth table

Individual key state output mode: One output per sensing channel

BCD output mode: Binary-coded touched key number (see Ta b le 8 )

KOUT4 KOUT3 KOUT2 KOUT1 Description

0 0 0 0 All released

0 0 0 1 Key 1 pressed

0 0 1 0 Key 2 pressed

0 0 1 1 Key 3 pressed

0 1 0 0 Key 4 pressed

0 1 0 1 Key 5 pressed

0 1 1 0 Key 6 pressed

0 1 1 1 Key 7 pressed

1 0 0 0 Key 8 pressed

Other Not used

(1)

18/51

Page 19

QST108 Device operating modes

Ai12559

I2C_SCL

I2C_SDA

GPO5

ADD2/GPO4

ADD1/GPO3

ADD0/GPO2

MODE/GPO1

V

SS_1VSS_2VSS_3VSS_4

SNS_SCK1

SNSK_SCK1

V

DD_1VDD_2

RESET

IRQ

Key1

SNS_SCK8

SNSK_SCK8

Key8

SNS_SCK7

SNSK_SCK7

Key7

V

DD

To

Host

MCU

R

S8

R

S7

R

S1

10kΩ

10kΩ

10kΩ

C

S8

C

S7

C

S1

SNS_SCK2

SNSK_SCK2

Key2

R

S2

10kΩ

C

S2

SNS_SCK3

SNSK_SCK3

Key3

R

S3

10kΩ

C

S3

SNS_SCK4

SNSK_SCK4

Key4

R

S4

10kΩ

C

S4

SNS_SCK5

SNSK_SCK5

Key5

R

S5

10kΩ

C

S5

SNS_SCK6

SNSK_SCK6

Key6

R

S6

10kΩ

C

S6

V

UNREG

4.7µF 4.7µF

2.4~5.5V

Volt. Reg.

2.7kΩ

2.7kΩ

4.7kΩ

100nF 100nF

To Host

10nF

Keep these parts close to IC

3

4

5

6

8

9101112

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1

2

30

31

32

GPO5

1MΩ

V

DD

V

SS

GPO4

1MΩ

V

DD

V

SS

GPO3

1MΩ

V

DD

V

SS

GPO2

1MΩ

V

SS

GPO1

V

DD

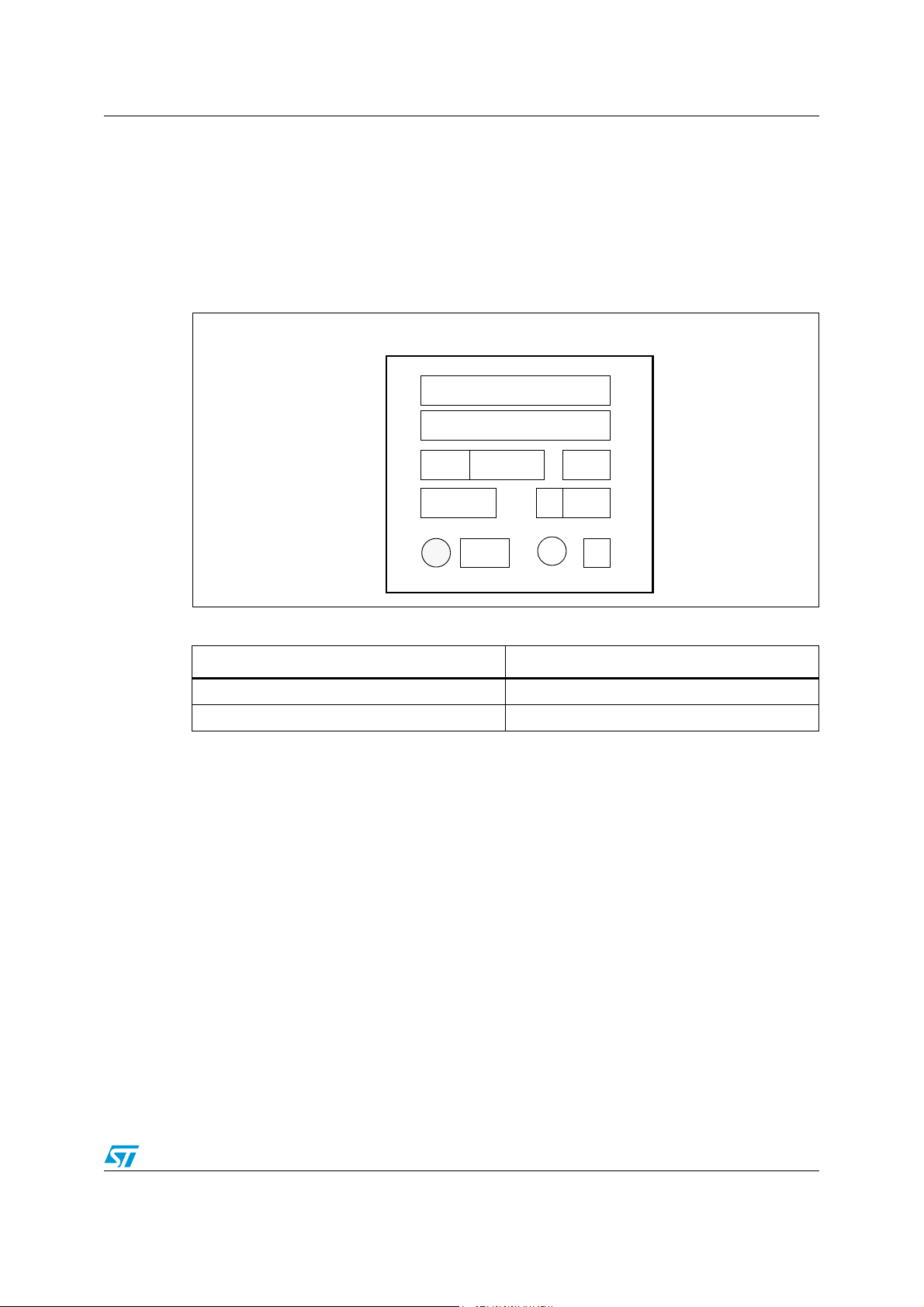

4.6 I2C mode

The I2C mode offers the largest configurability and functionality of the QST108.

4.6.1 Main features

● 5 general-purpose outputs

● Configuration of up to 8 AKS groups

● Additional low power modes

● Accessible internal capacitive sensing parameters

● Continuous range of Max On-Duration

Figure 6. I

2

C mode typical schematic

19/51

Page 20

Device operating modes QST108

Ai12570

GPOn

V

UNREG

R

C (10 nF)

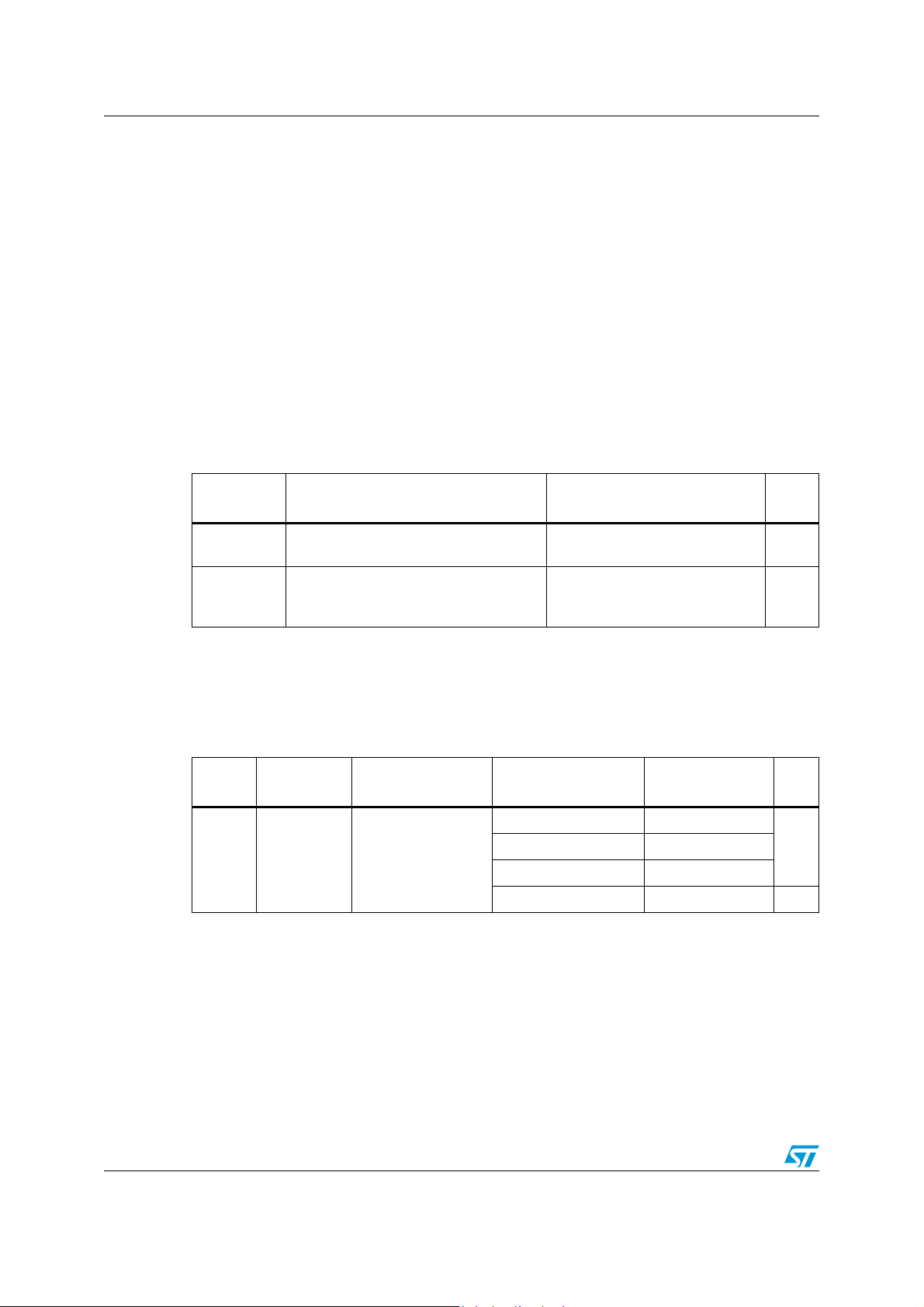

4.6.2 General-purpose outputs

I2C mode allows to drive up to 5 general-purpose outputs. These output pins are configured

in output push pull mode 0 by default. Their state can be changed using the

SET_GPIO_STATE I

Figure 7. Optional LED schematic

2

C command.

4.6.3 IRQ pin

The IRQ pin is an open drain output with an internal pull-up. It can be used to inform the

Master device about any change in the key status. The

state of any of the enabled keys changes. This includes any change in the touch state of the

key, a faulty key or a new calibration of one or more keys. The reported changes may then

be accessed by the Master device by using the GET_KEY_STATE command.

To improve communication response time, this signal suspends Low Power mode until the

Master device has issued a communication with the QST device.

4.6.4 Communication packet

The communication between the Master device and the QST108 (Slave) consists of two

standard I

The first frame is sent by the Master device using the QST108 device address with the write

bit set. The data bytes consist of the command byte which is eventually followed by the

parameters and a checksum byte.

The second one is sent by the Master device using the QST108 device address with the

write bit reset. The QST108 completes the frame with data according to the command

previously sent by the Master device. The device finishes the frame by sending a checksum

byte for communication integrity verification.

If the read frame is omitted, the command may not be taken into account.

To initiate the communicate with the QST108, the Master device must send the

GET_DEVICE_INFO command in order to unlock access to all the other commands.

2

C frames.

IRQ line is pulled low every time the

20/51

Page 21

QST108 Device operating modes

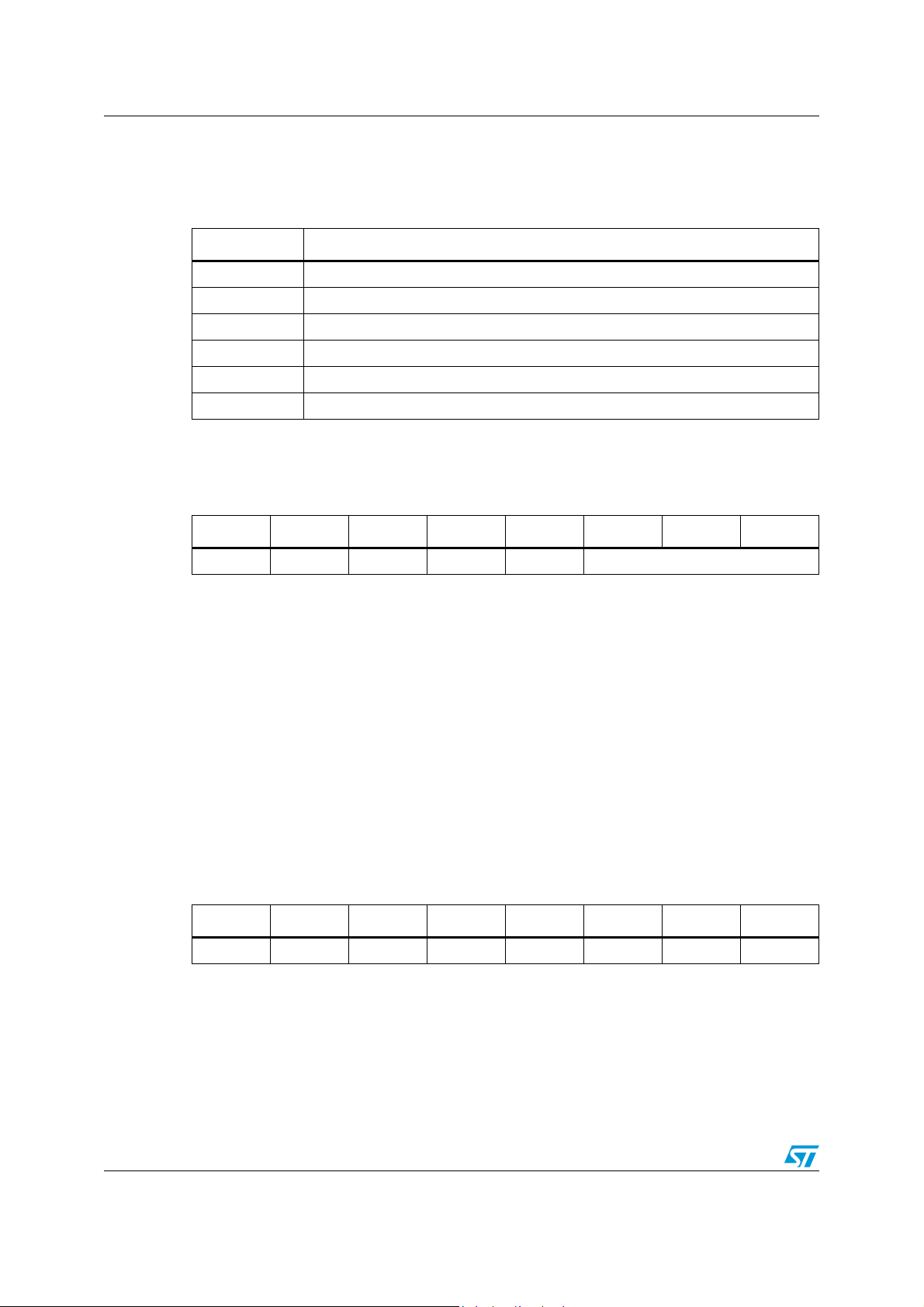

4.6.5 I2C address selection

The QST108 slave address is programmable using the option resistors mapped on pins

OPT2 to OPT4 (see Ta ble 9).

Table 9. I²C address versus option resistor

Option configuration I2C Address

OPT4 OPT3 OPT2 ADD[6:3] ADD2 ADD1 ADD0 Hex value

V

SS

V

SS

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

DD

V

DD

V

SS

V

SS

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

0101

0 0 0 0x28

0 0 1 0x29

0 1 0 0x2A

0 1 1 0x2B

1 0 0 0x2C

1 0 1 0x2D

1 1 0 0x2E

1 1 1 0x2F

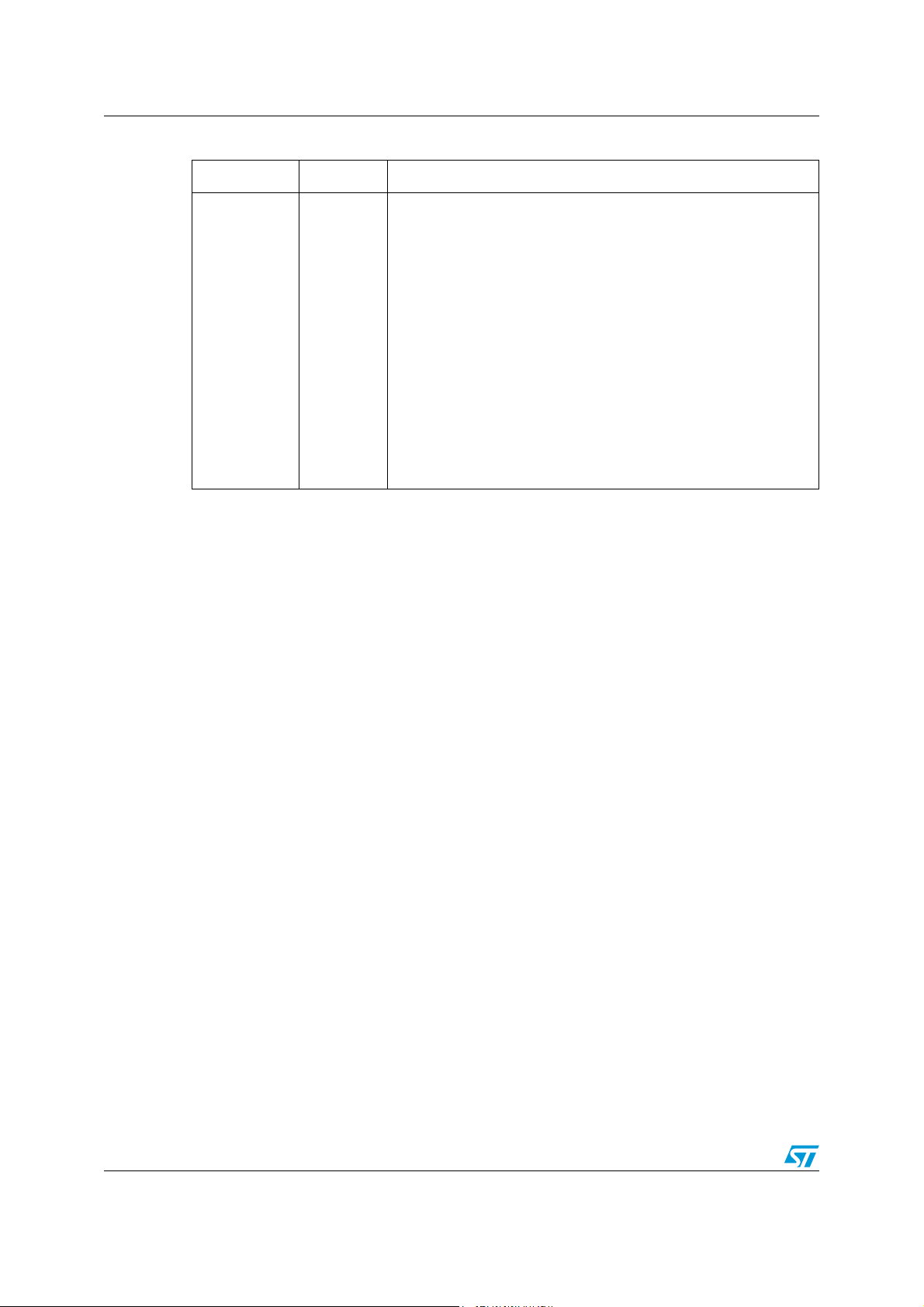

4.7 Supported commands

Table 10 lists the supported I²C commands and available arguments.

Note: For more information on the supported commands and I

standard communication protocol reference manual.

Table 10. Supported commands

I2C commands Description

CALIBRATE_KEY (All keys)

Write 0x98

Read ErrCode

Forces the recalibration of all keys.

ErrCode: Standard Error code (see Table 11)

2

C protocol, please refer to the QST

CALIBRATE_KEY (Single key)

Write 0x9B KeyID Checksum Forces the recalibration of a single key.

Read ErrCode

KeyId: Binary-coded key number (see Ta b le 1 4)

ErrCode: Standard Error code (see Table 11)

GET_DEBUG_INFO

Write 0xF7 KeyID Checksum Returns the debug info of the single KeyID channel.

KeyDbgState: Current Key Debug state (see Tab l e 1 9)

Read

0x0B KeyDbgState

RefMSB RefLSB

BCMSB BCLSB

Checksum

RefMSB: Reference Count MSB

RefLSB: Reference Count LSB

BCMSB: Burst Count MSB

BCLSB: Burst Count LSB

21/51

Page 22

Device operating modes QST108

Table 10. Supported commands (continued)

I2C commands Description

GET_DEVICE_INFO

Write 0x85 Returns the QST108 device version and ASCII-coded device

name. This command must be sent first to enable the

communication flow.

0x15 MainVers SubVers

Read

NbSCkey NbMCkey

‘Q’ ’S’ ‘T’ ‘1’ ‘0’ ‘8’

Checksum

GET_KEY_ERROR

Write 0xC4

0x10 KeyError1

Read

KeyError2 ... KeyError8

CheckSum

GET_KEY_STATE

Write 0xC1 Returns the state of all keys.

Read

0x04 AllKeyState

KeyError Checksum

GET_PROTOCOL_VERSION

Write 0x80 Returns the QST108 protocol version.

Read

0x07 MainVers SubVer

I2CSpeed Checksum

RESET_DEVICE

MainVers: Device main version

SubVer: Device sub-version

NbSCkey: 0x08 single-channel keys

NbMCkey: 0x00 multi-channel keys

Q S T 1 0 8: ASCII-coded device name

Returns the error information on each key.

KeyErrorN: KeyError byte description (see Table 12)

AllKeyState: Touched/untouched state for all 8 keys. Refer to

Table 13: AllKeyState.

KeyError: Refer to Table 12: KeyError byte description

MainVers: Protocol main version

SubVer: Protocol sub-version

I2CSpeed: 0x00 (100 kHz maximum)

Write 0xFD

Read ErrCode

Restarts the device (options Read and Calibration) after

reading the ErrCode (see Ta b le 1 1).

SET_DETECT_INTEGRATORS

Write

0x03 0x04 0x00 DI EDI

PosRecaII CheckSum

Sets the detection, End Of Detection and Positive Recalibration

Integrators for all keys.

DI: Detection Integrator

Read ErrCode

EDI: End of Detection Integrator

PosRecaII: Positive Recalibration Integrator

ErrCode: Standard Error code (see Table 11)

SET_GPIO_STATE

Write

0x08 0x01 GPOState

Checksum

Read ErrCode

Controls the state of the general-purpose outputs.

GPOState: State of general-purpose outputs (see Table 16)

ErrCode: Standard Error code (see Table 11)

22/51

1) 3)

1) 3)

1) 3)

Page 23

QST108 Device operating modes

Table 10. Supported commands (continued)

I2C commands Description

SET_KEY_ACTIVATION (see Note 4)

Write

Read ErrCode

SET_KEY_GROUP

Write

Read ErrCode

SET_LOW_POWER_MODE

Write

Read ErrCode

SET_MAX_ON_DURATION

Write

Read ErrCode

SET_SCKEY_PARAMETERS

Write

Read ErrCode

0x97 KeyActivation

Checksum

0x00 0x09

AKSGrpMode Key1Grp

Key2Grp ...Key8Grp

CheckSum

0x92 LowPowerMode

Checksum

0x8A MaxOnDuration

Checksum

0x01 0x04 0x00 DeTh

EofDeTh PosRecalTh

Checksum

Enables or disables a single key.

KeyActivation: Byte containing the key number selection and

requested state.

ErrCode: Standard Error code (see Table 11)

Defines the AKS groups for each key.

AKSGrpMode: AKS mode selection of each group (see

Tab l e 1 7 )

KeynGrp: AKS group selection for key n (see Table 18)

ErrCode: Standard Error code (see Table 11)

Selects standard or Low Power mode.

LowPowerMode: Configure Low Power mode (see Tab l e 1 5 )

ErrCode: Standard Error code (see Table 11)

Sets the maximum detected ON time before triggering an

automatic recalibration.

MaxOnDuration: Time, in second (0 for infinite)

ErrCode: Standard Error code (see Table 11)

Sets the Detection, End Of Detection and Positive

Recalibration Thresholds for a single key.

DeTh: Detection Threshold

EofDeTh: End of Detection Threshold

PosRecalTh: Positive Recalibration Threshold

ErrCode: Standard Error code (see Table 11)

1) 2)

1) 2)

1) 2)

Note: 1 See Section 6.6: Capacitive sensing characteristics on page 35 for default values.

2 The value is a signed character (0x80...0x7F <=> -128 ... +128).

3 The value is an unsigned number (0x01..0xFF <=> 1 ... 255).

4 Enabling or disabling keys triggers a new calibration of all enabled keys.

23/51

Page 24

Device operating modes QST108

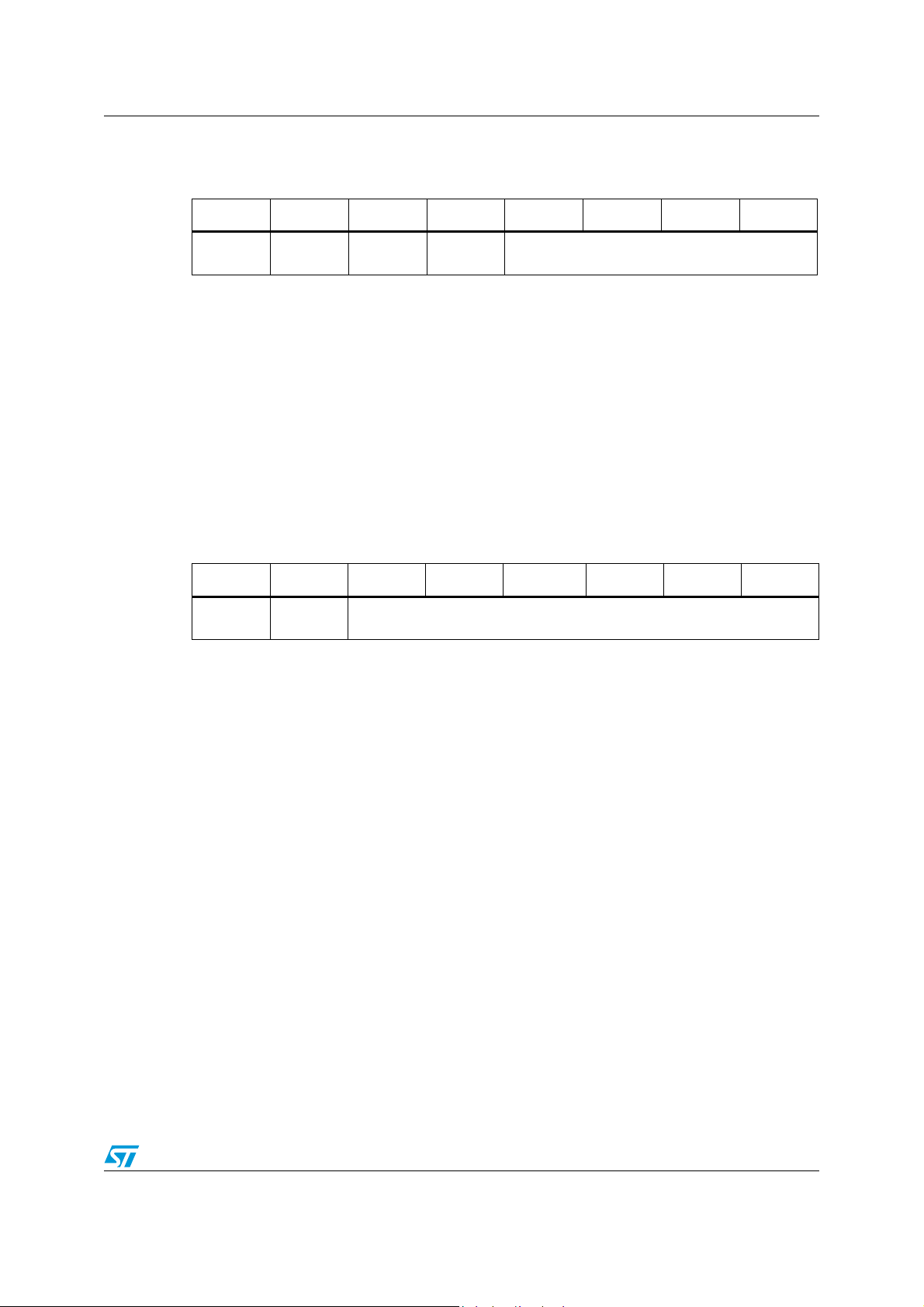

Error codes

Table 11 lists the I2C error codes.

Table 11. ErrCode

ErrCode Description

0x01 No Error

0x83 Command not supported

0x85 Parameter not supported

0xA1 Parity Error

0xA3 Checksum Error

0xE0 Initialization process (GET_FIRMWARE_INFO command not received)

KeyError byte description

Table 12. KeyError byte description

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Key State 0 0 0 0 Key error codes

Key state (Bit 7)

When set to ‘1’, the corresponding key is touched. This bit is always cleared for the

GET_KEY_STATE command.

Key error codes (Bits 2:0)

When answering the GET_KEY_STATE command, the key error code corresponds to

the error codes of all the keys ORed toghether. When answering the

GET_KEY_ERROR command, each key error code describes the errors of one defined

key.

Bit 0: When set to ‘1’, calibration in progress

Bit 1: When set to ‘1’, maximum count reached

Bit 2: When set to ‘1’, minimum count not reached

All key state description

Table 13. AllKeyState

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Key 8 State Key 7 State Key 6 State Key 5 State Key 4 State Key 3 State Key 2 State Key 1 State

Key n state

When set to ‘1’, the corresponding key is touched.

24/51

Page 25

QST108 Device operating modes

Key activation description

Table 14. KeyActivation

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Key

Activation

0 0 0 Key ID (binary coded)

Key activation (Bit 7)

0: Key disabled

1: Key enabled

Key identifier (Bits 3:0)

0000: All keys 0101: Key 5

0001: Key 1 0110: Key 6

0010: Key 2 0111: Key 7

0011: Key 3 1000: Key 8

0100: Key 4

Low power mode description

Table 15. SetLowPower

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0

Free Run in Detect (Bit 6)

Free Run

in Detect

Sleep Duration Factor

0: Low Power mode is always enabled, whatever the state of the keys.

1: Low Power mode is automatically suspended when any key is in Detect state.

Low Power mode is automatically resumed when no key is in Detect state.

Sleep Duration Factor (Bits 5 to 0)

0x00 or 0x1A to 0x3E: Low power mode is disabled.

0x01 to 0x19: Low Power mode. The sleep duration is ‘Sleep Duration Factor’ x 20

milliseconds (20 ms to 500 ms)

0x3F: Deep Sleep mode is entered immediately. A reset or any I2C

communication can be used to exit Deep Sleep mode.

Note: When the device is in Sleep or Deep Sleep, any I

2

The I

C QST device address is not acknowledged but forces the QST device to exit from

Low Power mode. The Master device will have to repeat the command to ensure that it is

taken in account.

25/51

2

C bus activity will wake-up the device.

Page 26

Device operating modes QST108

GPO state description

Table 16. GPOState

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

000

GPO 5

state

GPO 4

state

GPO 3

state

GPO 2

state

GPO 1

state

GPOState

Defines the state of the selected general-purpose output pin. For more information, see

Section 4.6.2: General-purpose outputs on page 20.

0: GPO state is ‘0’

1: GPO state is ‘1’

AKS group mode description

Table 17. AKSGrpnMode

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

AKSGrp8

Mode

AKSGrp7

Mode

AKSGrp6

Mode

AKSGrp5

Mode

AKSGrp4

Mode

AKSGrp3

Mode

AKSGrp2

Mode

AKSGrpnMode

Defines the type of AKS for the Group n:

0: Locking AKS: First key pressed within the group locks out all other keys.

1: Unlocking AKS: Most heavily pressed key (highest signal level) is selected over

all other keys in the group.

AKS group selection description

Table 18. KeynGrp

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Grp8 Grp7 Grp6 Grp5 Grp4 Grp3 Grp2 Grp1

Grpx

The selected key is a member of AKS Group x.

Key debug state description

Table 19. KeyDbgState

Value Description

0x01 On-going calibration

0x02 Key released

0x04 Key touched

0x08 Key in error

0x11 Key calibration filter triggered (PosRecalI)

0x14 Key detection filter triggered (DI)

0x24 Key end of detection filter triggered (EDI)

AKSGrp1

Mode

26/51

Page 27

QST108 Design guidelines

5 Design guidelines

5.1 CS sense capacitor

The CS sense capacitors accumulate the charge from the key electrodes and determine

sensitivity. Higher values of C

The values of C

can differ for each channel, permitting differences in sensitivity from key to

S

key or to balance unequal sensitivities. Unequal sensitivities can occur due to key size and

placement differences and stray wiring capacitances. More stray capacitance on a sense

trace will desensitize the corresponding key. Increasing the C

for the loss of sensitivity.

The C

The normal C

C

capacitors can be virtually any plastic film or low- to medium-K ceramic capacitor.

S

require better quality to ensure reliable sensing. In certain circumstances the normal CS

S

range is 1nF to 50nF depending on the sensitivity required: larger values of

S

range may be exceeded. Acceptable capacitor types for most uses include PPS film,

polypropylene film, and NP0 and X5R / X7R ceramics. Lower grades than X5R or X7R are

not recommended.

5.2 Sensitivity tuning

make the corresponding sensing channel more sensitive.

S

for that key will compensate

S

Sensitivity can be altered to suit various applications and situations on a channel-bychannel basis. The easiest and most direct way to impact sensitivity is to alter the value of

each C

: more CS yields higher sensitivity. Each channel has its own CS value and can

S

therefore be independently adjusted.

5.2.1 Increasing sensitivity

Sensitivity can also be increased by using larger electrode areas, reducing panel thickness,

or using a panel material with a higher dielectric constant.

5.2.2 Decreasing sensitivity

In some cases the circuit may be too sensitive. Gain can be lowered further by a number of

strategies:

● making the electrode smaller

● making the electrode into a sparse mesh using a high space-to-conductor ratio

● decreasing the C

capacitors

S

5.2.3 Key balance

A number of factors can cause sensitivity imbalances. Notably, SNS wiring to electrodes can

have differing stray amounts of capacitance to ground. Increasing load capacitance will

cause a decrease in gain. Key size differences, and proximity to other metal surfaces can

also impact gain.

The keys may thus require “balancing” to achieve similar sensitivity levels. This can be best

accomplished by trimming the values of the C

capacitors to achieve equilibrium. The RS

S

resistors have no effect on sensitivity and should not be altered. Load capacitances to

ground can also be added to overly sensitive channels to reduce their gain.

These should be in the order of a few picofarads.

27/51

Page 28

Design guidelines QST108

5.3 Power supply

If the power supply fluctuates slowly with temperature, the QST device compensates

automatically for these changes with only minor changes in sensitivity. However, if the

supply voltage drifts or shifts quickly, the drift compensation mechanism is not able to keep

up, causing sensitivity anomalies or false detections.

The power supply should be locally regulated, using a three-terminal regulator. If the supply

is shared with another electronic system, care should be taken to ensure that the supply is

free of digital spikes, sags and surges which can cause adverse effects. It is not

recommended to include a series inductor in the power supply to the QST device.

For proper operation, a 0.1 µF or greater bypass capacitor must be used between V

V

. The bypass capacitor should be routed with very short tracks to the device’s VDD and

SS

V

pins.

SS

The PCB should, if possible, include a copper pour under and around the device, but not

extensively under the SNS lines.

5.4 ESD protection

In normal environmental conditions, only one series resistor is required for ESD

suppression. A 10 kOhm R

resistor in series with the sense trace is sufficient in most

S

cases. The dielectric panel (glass or plastic) usually provides a high degree of isolation to

prevent ESD discharge from reaching the circuit. R

the C

load is high, RS can prevent total charge and transfer and as a result gain can

X

deteriorate. If a reduction in R

Conversely, increasing the R

increases gain noticeably, the lower value should be used.

S

can result in added ESD and EMC benefits, provided that the

S

increase does not decrease sensitivity.

5.5 Crosstalk precautions

Adjacent sense traces might require intervening ground traces in order to reduce capacitive

cross bleed if high sensitivity is required or high values of delta-C

example, from direct human touch to an electrode connection). In normal touch applications

behind plastic panels, this is rarely a problem regardless of how the electrodes are wired.

DD

should be placed close to the chip. If

S

are anticipated (for

X

and

Higher values of R

will make crosstalk problems worse; try to keep RS to 22 kOhm or less

S

if possible. In general try to keep the QST device close to the electrodes and reduce the

adjacency of the sense wiring to ground planes and other signal traces; this will reduce the

C

load, reduce interference effects, and increase signal gain. The one and only valid

x

reason to run ground near SNS traces is to provide crosstalk isolation between traces, and

then only on an as-needed basis.

5.6 PCB layout and construction

The PCB traces, wiring, and any components associated with or in contact with either SNS

pin will become touch sensitive and should be treated with caution to limit the touch area to

the desired location.

Multiple touch electrodes connected to any sensing channel can be used, for example, to

create control surfaces on both sides of an object.

28/51

Page 29

QST108 Design guidelines

It is important to limit the amount of stray capacitance on the SNS terminals, for example by

minimizing trace lengths and widths to allow for higher gain without requiring higher values

of C

. Under heavy delta-CX loading of one key, cross coupling to another key’s trace can

S

cause the other key to trigger. Therefore, electrode traces from adjacent keys should not be

run close to each other over long runs in order to minimize cross-coupling if large values of

delta-C

are expected, for example when an electrode is directly touched. This is not a

X

problem when the electrodes are working through a plastic panel with normal touch

sensitivity.

For additional information on PCB layout and construction, please contact your local ST

Sales Office for a list of available application notes.

29/51

Page 30

Electrical characteristics QST108

Output pin

V

IN

Input pin

6 Electrical characteristics

6.1 Parameter conditions

Unless otherwise specified, all voltages are referred to VSS.

6.1.1 Minimum and maximum values

Unless otherwise specified the minimum and maximum values are guaranteed in the worst

conditions of ambient temperature, supply voltage and frequencies by tests in production on

100% of the devices with an ambient temperature at T

the selected temperature range).

Data based on characterization results, design simulation and/or technology characteristics

are indicated in the table footnotes and are not tested in production. Based on

characterization, the minimum and maximum values refer to sample tests and represent the

mean value plus or minus three times the standard deviation (mean±3Σ).

6.1.2 Typical values

= 25°C and TA = TAmax (given by

A

Unless otherwise specified, typical data are based on TA = 25 °C, V

V

≤ 5.5 V voltage range) and VDD = 3.3 V (for the 3.0 V ≤ VDD ≤ 3.6 V voltage range).

DD

They are given only as design guidelines and are not tested.

6.1.3 Typical curves

Unless otherwise specified, all typical curves are given only as design guidelines and are

not tested.

6.1.4 Loading capacitor

The loading conditions used for pin parameter measurement are shown in Figure 8.

Figure 8. Pin loading conditions

6.1.5 Pin input voltage

The input voltage measurement on a pin of the device is described in Figure 9.

= 5 V (for the 4.5V ≤

DD

Figure 9. Pin input voltage

30/51

Page 31

QST108 Electrical characteristics

6.2 Absolute maximum ratings

Stresses above those listed as “absolute maximum ratings” may cause permanent damage

to the device. This is a stress rating only and functional operation of the device under these

conditions is not implied. Exposure to maximum rating conditions for extended periods may

affect device reliability.

Table 20. Thermal characteristics

Symbol Ratings Value Unit

T

STG

T

Table 21. Voltage characteristics

Storage temperature range −65 to +150

Maximum junction temperature

J

Symbol Ratings Maximum value Unit

− V

V

DD

V

IN

1. Directly connecting the RESET and I/O pins to VDD or V

internal reset is generated or an unexpected change of the I/O configuration occurs. To guarantee safe

operation, this connection has to be done through a pull-up or pull-down resistor (typical: 4.7kΩ for RESET

10kΩ for I/Os).

2. I

INJ(PIN)

cannot be respected, the injection current must be limited externally to the I

injection is induced by V

there is no positive injection current, and the corresponding V

Table 22. Current characteristics

Supply voltage 7.0

SS

Input voltage on any pin

must never be exceeded. This is implicitly insured if VIN maximum is respected. If VIN maximum

while a negative injection is induced by VIN<VSS. For true open-drain pads,

IN>VDD

(1)(2)

VSS−0.3 to VDD+0.3

could damage the device if an unintentional

SS

value. A positive

INJ(PIN)

maximum must always be respected.

IN

Symbol Ratings Maximum value Unit

I

VDD

I

VSS

Total current into VDD power lines (source)

Total current out of VSS ground lines (sink)

(1)

(1)

75

150

Output current sunk by RESET pin 20

I

IO

Output current sunk by output pin 40

Output current source by output pin − 25

°C

V

,

mA

Injected current on RESET pin ± 5

I

1. All power (VDD) and ground (VSS) lines must always be connected to the external supply.

2. I

3. When several inputs are submitted to a current injection, the maximum ΣI

(2)(3)

INJ(PIN)

ΣI

INJ(PIN)

INJ(PIN)

cannot be respected, the injection current must be limited externally to the I

injection is induced by V

there is no positive injection current, and the corresponding V

positive and negative injected currents (instantaneous values). These results are based on

characterisation with ΣI

Injected current output pin

Total injected current (sum of all I/O and control

(2)

must never be exceeded. This is implicitly ensured if VIN maximum is respected. If VIN maximum

pins)

while a negative injection is induced by VIN<VSS. For true open-drain pads,

IN>VDD

maximum current injection on four KOUT pins of the device.

INJ(PIN)

± 5

± 20

value. A positive

INJ(PIN)

maximum must always be respected.

IN

is the absolute sum of the

INJ(PIN)

31/51

Page 32

Electrical characteristics QST108

6.3 EMC characteristics

Susceptibility tests are performed on a sample basis during product characterization.

6.3.1 Functional EMS (electro magnetic susceptibility)

The product is stressed by two electro magnetic events until a failure occurs:

● ESD: Electro-Static Discharge (positive and negative) is applied on all pins of the

device until a functional disturbance occurs. This test conforms with the IEC 1000-4-2

standard.

● FTB: A Burst of Fast Transient voltage (positive and negative) is applied to V

V

through a 100pF capacitor, until a functional disturbance occurs. This test

SS

conforms with the IEC 1000-4-4 standard.

A device reset allows normal operations to be resumed. The test results are given in the

table below based on the EMS levels and classes defined in application note AN1709.

Table 23. Functional EMS

DD

and

Symbol Parameter Conditions

V

FESD

Voltage limits to be applied on any I/O

pin to induce a functional disturbance

Fast transient voltage burst limits to be

V

FFTB

applied through 100pF on V

DD

and V

pins to induce a functional disturbance

6.3.2 Electro magnetic interference (EMI)

The product is monitored in terms of emission. This emission test is in line with the norm

SAE J 1752/3 which specifies the board and the loading of each pin.

Table 24. EM emissions

Symbol Parameter Conditions

V

=5V, TA=+25°C,

S

1. Data based on characterization results, not tested in production.

EMI

Peak level

DD

complies with SAE J

1752/3

VDD=5V, TA=+25°C,

complies with IEC 1000-4-2

=5V, TA=+25°C

V

DD

DD

complies with IEC 1000-4-4

Monitored

Frequency Band

f

DEVICE

= 4 MHz

(1)

0.1 MHz to 30 MHz 20

130 MHz to 1 GHz 13

SAE EMI Level 2.5 -

Level/

Class

3B

4A

Unit

dBμV30 MHz to 130 MHz 20

32/51

Page 33

QST108 Electrical characteristics

6.3.3 Absolute maximum ratings (electrical sensitivity)

Based on three different tests (ESD, LU and DLU) using specific measurement methods, the

product is stressed in order to determine its performance in terms of electrical sensitivity.

For more details, refer to the application note AN1181.

Electro-static discharge (ESD)

Electro-Static Discharges (a positive then a negative pulse separated by 1 second) are

applied to the pins of each sample according to each pin combination. The sample size

depends on the number of supply pins in the device (3 parts*(n+1) supply pin). Two models

can be simulated: Human Body Model and Charge Device Model. These tests comply with

JESD22-A114A/A115A specifications.

Table 25. Absolute maximum ratings

Symbol Ratings Conditions Maximum value

(1)

Unit

V

ESD(HBM)

V

ESD(CDM)

1. Data based on characterization results, not tested in production.

Electro-static discharge voltage

(Human Body Model)

Electro-static discharge voltage

(Charge Device Model)

=+25°C 4000 V

T

A

=+25°C 500 V

T

A

Static and dynamic latch-up

● LU: 3 complementary static tests are required on 10 parts to assess the latch-up

performance. A supply overvoltage (applied to each power supply pin) and a current

injection (applied to each I/O pin) are performed on each sample. This test complies

with EIA/JESD 78 IC latch-up specifications.

● DLU: Electro-Static Discharges (one positive then one negative test) are applied to

each pin of 3 samples when the MCU is running to assess the latch-up performance in

Dynamic mode. Power supplies are set to the typical values and the component is put

in Reset mode. This test complies with IEC1000-4-2 and SAEJ1752/3 specifications.

For more details, refer to the application note AN1181.

Table 26. Electrical sensitivities

Symbol Parameter Conditions Class

LU Static latch-up class TA=+125°C A

DLU Dynamic latch-up class V

1. Class description: A Class is an STMicroelectronics internal specification. All its limits are higher than the

JEDEC specifications, that means when a device belongs to Class A it exceeds the JEDEC standard. B

Class strictly covers all the JEDEC criteria (international standard).

=5.5V, f

DD

= 4MHz, TA=+25°C A

DEVICE

(1)

33/51

Page 34

Electrical characteristics QST108

6.4 Operating conditions

Table 27. Operating conditions

Symbol Feature Value Unit

V

DD

T

Operating supply voltage 2.4 to 5.5 V

Operating temperature -40° to +85° C

A

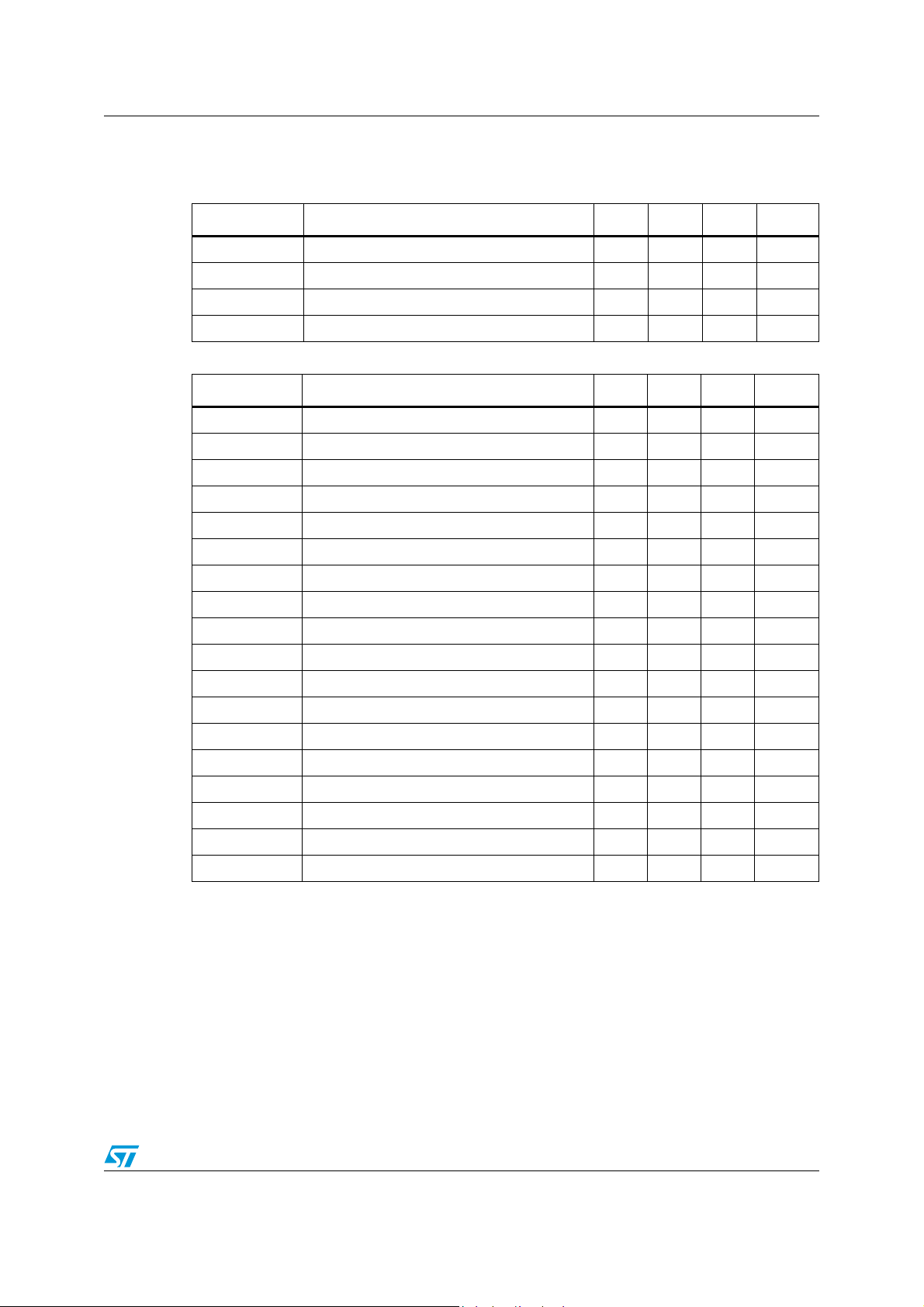

6.5 Supply current characteristics

Table 28. Supply current characteristics

Symbol Parameter Conditions Min. Typ.

V

= 2.4 V 1.71

IDD (FR)

I

(Sleep

100ms)

I

(Sleep

500ms)

I

Deep

Sleep

1. The results are based on CS = 2.7nF and CX = 12.5pF

Average suppy current

Free Run mode

DD

Average suppy current

100ms Sleep mode

DD

Average suppy current

500ms Sleep mode

DD

Average suppy current

Deep Sleep mode

DD

= 3.3 V 2.17

DD

V

= 5 V 3.35

DD

= 2.4 V 276

V

DD

= 3.3 V 389

DD

= 5 V 637

V

DD

= 2.4 V 108

V

DD

= 3.3 V 144

DD

= 5 V 246

V

DD

(1)

Max. Unit

5µA

mAV

µAV

µAV

Figure 10. IDD Sleep mode current characteristics

34/51

Page 35

QST108 Electrical characteristics

6.6 Capacitive sensing characteristics

Table 29. External sensing components

Symbol Parameter Min. Typ. Max. Unit

C

Sense capacitor 100 nF

S

Equivalent electrode capacitor 100 pF

C

X

C

T

Serial resistor 10 22 kOhm

R

S

Table 30. Capacitive sensing parameters

Symbol Parameter Min. Default Max. Unit

Calibration duration 2 s

t

CAL

t

Setup

DI Detection integrator

DeTh Detection threshold

EDI End of detection integrator

EofDeTh End of detection threshold

PosRecalI Positive recalibration integrator

PosRecalTh Positive recalibration threshold

MaxOnDuration Max on-duration delay

PosDiffDrift Positive differential drift compensation rate 0.1

NegDiffDrift Negative differential drift compensation rate 0.1

PosComDrift Positive common drift compensation rate 0.1

NegComDrift Negative common drift compensation rate 0.1

PosDriftI Positive drift integrator 0 10 255

NegDriftI Negative drift integrator 0 10 255

Equivalent touch capacitor 5 pF

Setup duration 100 ms

12255

-128 -10 -1

12 255

-128 -6 -1

12255

115127

1 Infinite 255

1

1

0.2

0.2

Samples

Counts

Samples

Counts

Samples

Counts

s

25.5 s/level

25.5 s/level

25.5 s/level

25.5 s/level

ComFact Common time step factor 0 2 255

DiffFact Differential time step factor 0 10 255

BurstCount Burst length 20 2000 Counts

35/51

Page 36

Electrical characteristics QST108

6.7 KOUTn/OPTn/GPOn pin characteristics

6.7.1 General characteristics

Subject to general operating conditions for VDD and TA unless otherwise specified.

Table 31. General characteristics

Symbol Parameter Conditions Min. Typ. Max. Unit

Input low level voltage

V

IL

Input high level voltage

V

IH

V

t

f(IO)out

t

r(IO)out

1. Not tested in production, guaranteed by characterization.

2. Data based on validation/design results.

Schmitt trigger voltage hysteresis

Hys

Input leakage current V

I

L

C

I/O pin capacitance 5 pF

IO

Output high to low level fall time

Output low to high level rise time

(1)

(1)

(2)

SS

CL = 50 pF

(2)

Between 10%

and 90%

(2)

≤ VIN ≤ V

VSS −0.3 0.3x V

0.7x V

DD

400 mV

DD

25

25

DD

VDD + 0.3

±1 μA

V

ns

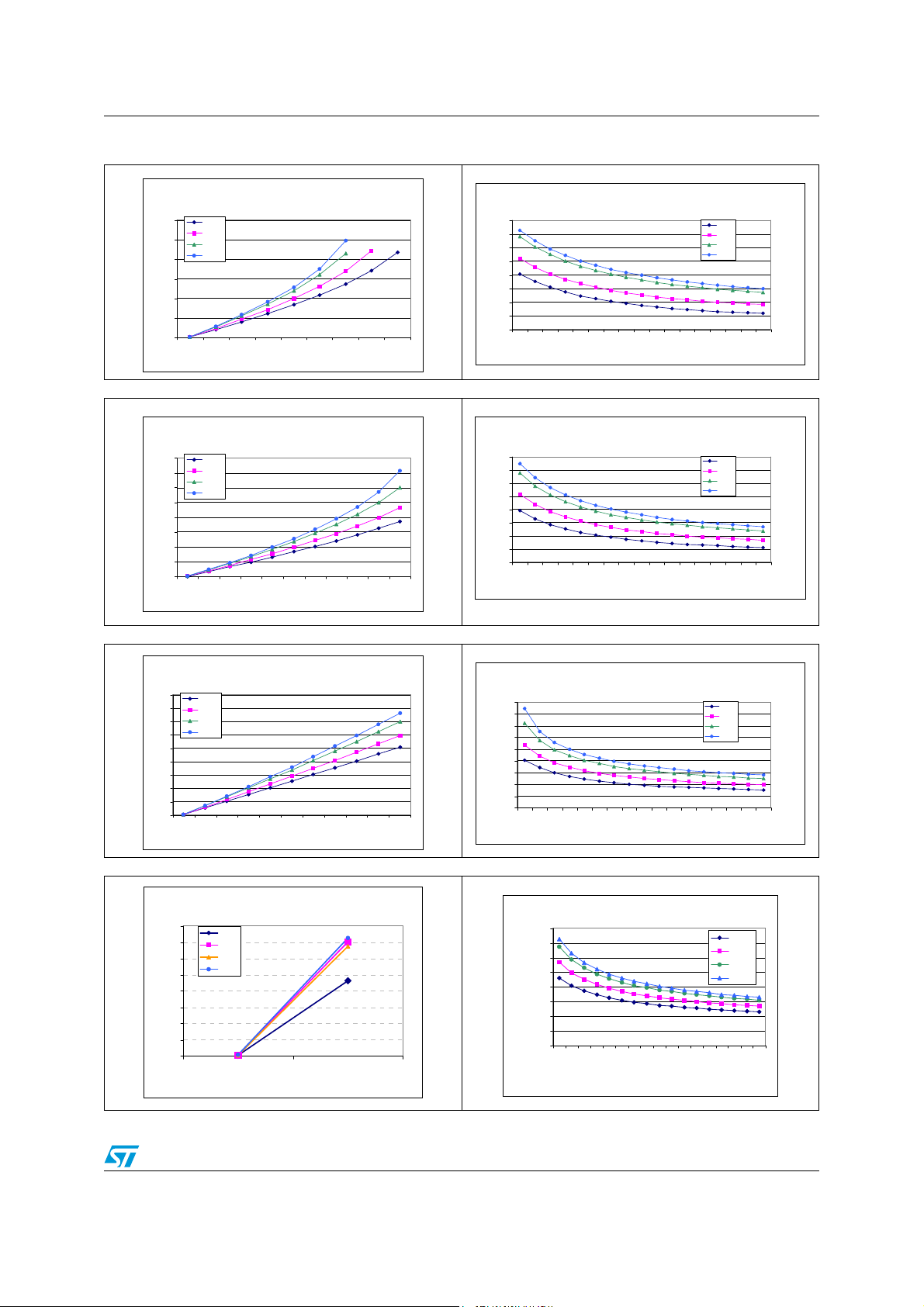

6.7.2 Output pin characteristics

Subject to general operating conditions for VDD, f

Table 32. Output pin current

Symbol Parameter Conditions Min. Max. Unit

Output low level voltage for a high sink I/O

(1)

V

OL

V

OH

V

OL

V

OH

V

OL

V

OH

1. The IIO current sunk must always respect the absolute maximum rating specified in Table 22 and the sum

2. The IIO current sourced must always respect the absolute maximum rating specified in Table 22 and the

3. Not tested in production, based on characterization results.

pin when 4 pins are sunk at same time

(Figure 16)

Output high level voltage for an I/O pin

(2)

when 4 pins are sourced at same time

(Figure 21)

Output low level voltage for a high sink I/O

(1)(3)

pin when 4 pins are sunk at same time

Output high level voltage for an I/O pin

(2)(3)

when 4 pins are sourced at same time

(Figure 19)

Output low level voltage for a high sink I/O

(1)(3)

pin when 4 pins are sunk at same time

Output high level voltage for an I/O pin

(2)(3)

when 4 pins are sourced at same time

of IIO (I/O ports and control pins) must not exceed I

sum of I

(output and RESET pins) must not exceed I

IO

VSS

, and TA unless otherwise specified.

CPU

I

= +20mA 1.3

IO

I

= +8mA 0.75

IO

= 5V

I

= -5mA VDD−1.5

IO

DD

V

I

= -2mA VDD−0.8

IO

I

= +8mA 0.5

IO

= 3.3V

I

= -2mA VDD−0.8

DD

IO

V

I

= +8mA 0.6

IO

= 2.4V

I

= -2mA VDD−0.9

DD

IO

V

.

..

VDD

V

36/51

Page 37

QST108 Electrical characteristics

VOL vs I

load

@ V

DD

= 2.4 V HS pins

0

200

400

600

800

1000

1200

0246810121416

I

load

[mA]

V

OL

[V]

-40°C

25°C

85°C

125°C

VOLvs VDD @I

load

=2 mA HS Pins

40

50

60

70

80

90

100

110

120

2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6 4.8 5 5.2 5.4 5.6

VDD [V]

V

OL

[mV]

-40°C

25°C

85°C

125°C

VOLvs I

load

@ V

DD

= 3 V HS pins

0

200

400

600

800

1000

1200

1400

1600

0 2 4 6 8 101214161820

I

load

[mA]

V

OL

[V]

-40°C

25°C

85°C

125°C

VOL vs VDD@I

load

= 8 mA HS Pins

140

190

240

290

340

390

440

490

540

2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6 4.8 5 5.2 5.4 5.6

VDD [V]

V

OL

[mV]

-40°C

25°C

85°C

125°C

VOL vs I

load

@ V

DD

= 5 V HS pins

0

100

200

300

400

500

600

700

800

900

02468101214161820

I

load

[mA]

V

OL

[V]

-40°C

25°C

85°C

125°C

VOL vs VDD @I

load

= 12 mA HS Pins

140

240

340

440

540

640

740

840

940

1040

2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6 4.8 5 5.2 5.4 5.6

VDD [V]

V

OL

[mV]

-40°C

25°C

85°C

125°C

VDD-VOH vs I

load

@ V

DD

= 2.4 V HS Pins

0

100

200

300

400

500

600

700

800

24

I

load

[mA]

V

DD

-V

OH

[mV]

-40°C

25°C

85°C

125°C

VDD-VOH vs VDD @I

load

= 2 mA HS Pin s

0

100

200

300

400

500

600

700

800

2.42.8

3.23.6

4

4.4

4.85.2

5.

6

VDD[V]

V

DD

-V

OH

[mV]

-40°C

25°C

85°C

125°C

Figure 11. Typical VOL at V

Figure 13. Typical VOL at V

= 2.4 V Figure 12. Typical VOL vs V

DD

= 3 V Figure 14. Typical VOL vs V

DD

DD

DD

at I

at I

load

load

= 2 mA

= 8 mA

Figure 15. Typical VOL at VDD = 5 V Figure 16. Typical VOL vs V

Figure 17. Typical VDD-VOH vs. I

load

at V

= 2.4 V Figure 18. Typical VDD-VOH vs. VDD at I

DD

DD

at I

= 12 mA

load

load

= 2 mA

37/51

Page 38

Electrical characteristics QST108

VDD-VOH vs I

load

@ V

DD