6-row 32 mA LED driver with boost regulator

Features

■ Boost section

– 4.7 V to 28 V input voltage range

– Internal power MOSFET

– Internal +5 V LDO for device supply

– Up to 36 V output voltage

– Constant frequency peak current-mode

control

– 200 kHz to 1 MHz adjustable switching

frequency

– External synchronization for multi-device

application

– Pulse-skip power saving mode at light load

– Programmable soft-start

– Programmable OVP protection

– Stable with ceramic output capacitors

– Thermal shutdown

■ Backlight driver section

– Six rows with 32 mA maximum current

capability (adjustable)

– Up to 10 WLEDs per row

– Unused rows detection

– 500 ns minimum dimming time (1%

minimum dimming duty-cycle at 20 kHz)

– ± 2.1% current accuracy

– ± 2% current matching between rows

– LED failure (open and short circuit)

detection

PM6600

for LCD panel backlight

VFQFPN-24 4 mm x 4 mm

Description

The PM6600 consists of a high efficiency

monolithic boost converter and six controlled

current generators (ROWs), specifically designed

to supply LEDs arrays used in the backlight of

LCD panels. The device can manage a nominal

output voltage up to 36 V (i.e. 10 White-LEDs per

ROW). The generators can be externally

programmed to sink up to 32 mA and they can be

dimmed via a PWM signal (1% dimming dutycycle at 20 kHz can be managed). The device

allows to detect and manage the open and

shorted LED faults and to let unused ROWs

floating. Basic protections (output over-voltage,

internal MOSFET over-current and thermal

shutdown) are provided.

Applications

■ Notebook monitors backlight

■ UMPC backlight

Table 1. Device summary

February 2010 Doc ID 14248 Rev 7 1/60

Order codes Package Packaging

PM6600

PM6600TR Tape and reel

VFQFPN-24 4 mm x 4 mm

(exposed pad)

Tu b e

www.st.com

60

Contents PM6600

Contents

1 Typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

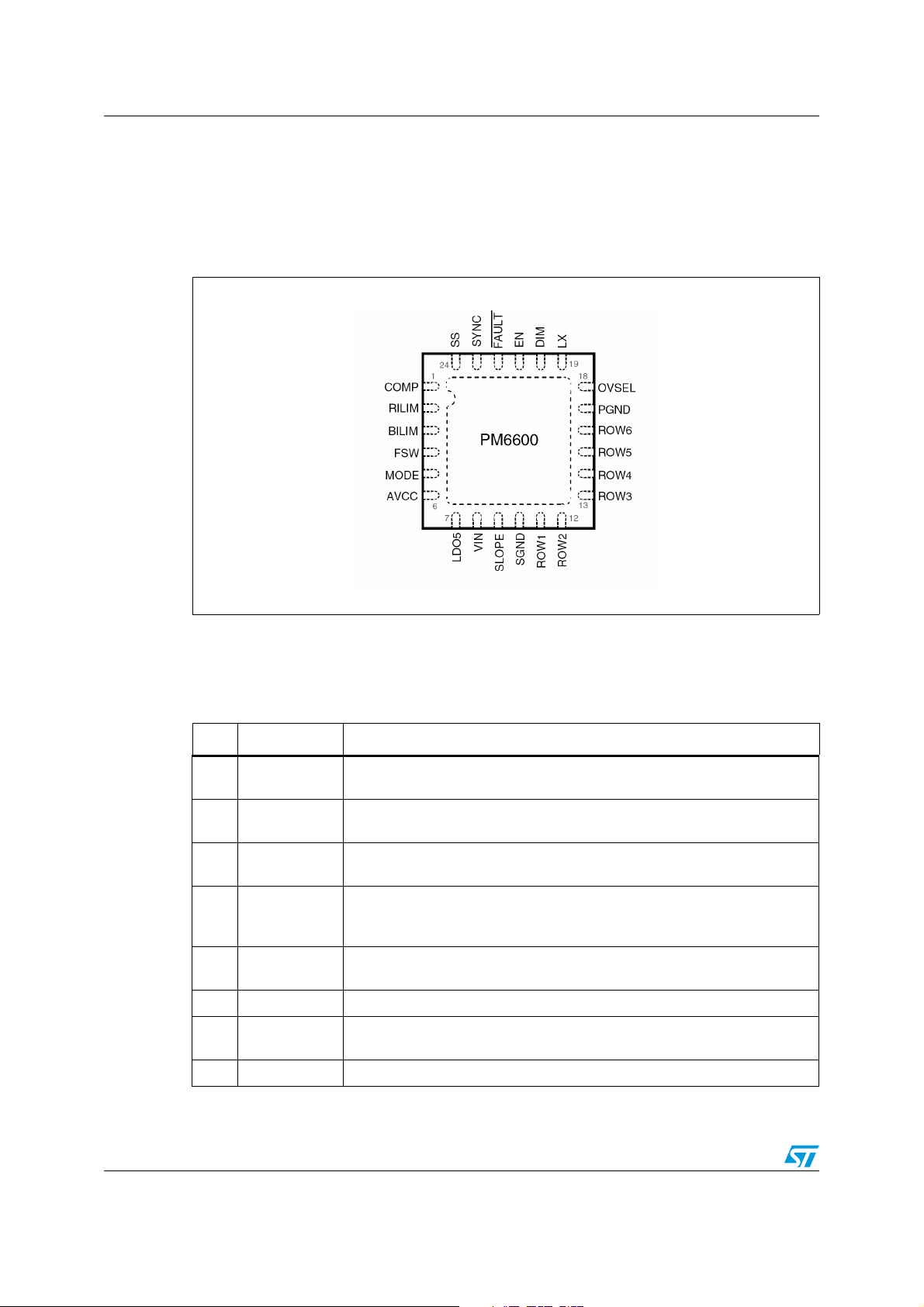

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Typical operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Operation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Boost section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Switching frequency selection and synchronization . . . . . . . . . . . . . . . . . 28

7.4 System stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4.1 Loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4.2 Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.5 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6 Boost current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.7 Enable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.8 Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8 Backlight driver section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1 Current generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.2 PWM dimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2/60 Doc ID 14248 Rev 7

PM6600 Contents

9 Fault management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 FAULT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.2 MODE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.3 Open LED fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.4 Shorted LED fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.5 Intermittent connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Appendix A Layout guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.1 Basic points: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.1.1 GNDs planes - 1 device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.1.2 GNDs planes - 3 devices (RGB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.2 Compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

A.3 LX area – vout power area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.4 Overvoltage divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.5 LDO5 – AVCC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

A.6 ROWs current generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

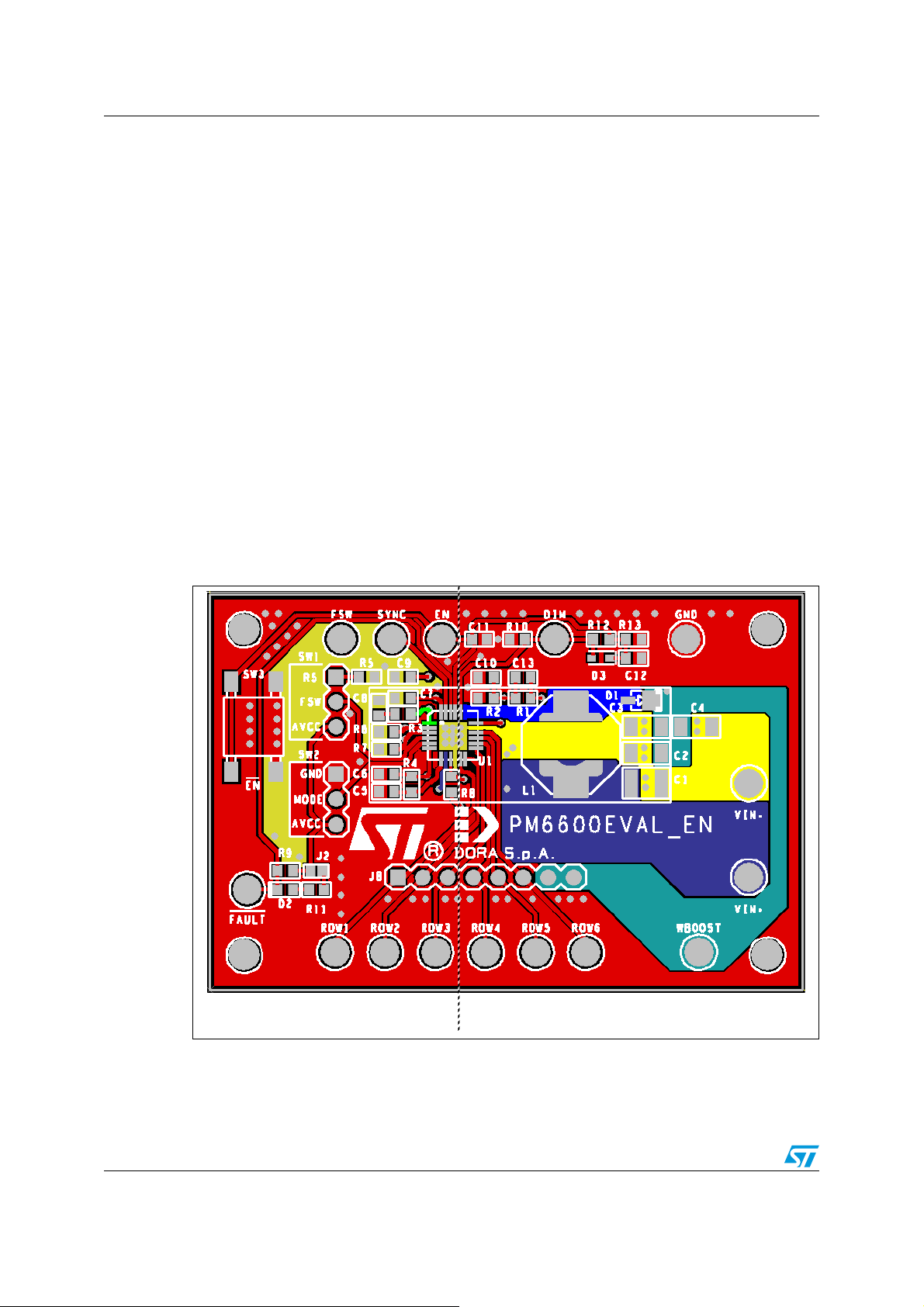

A.7 Top layer of the standard PM6600 demonstration board. . . . . . . . . . . . . . 46

Appendix B Application note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

B.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

B.2 Capacitors selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

B.3 Flywheel diode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

B.4 Design example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

B.4.1 Switching frequency setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

B.4.2 Row current setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

B.4.3 Inductor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

B.4.4 Output capacitor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

B.4.5 Input capacitor choice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

B.4.6 Overvoltage protection divider setting. . . . . . . . . . . . . . . . . . . . . . . . . . . 52

B.4.7 Compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.4.8 Boost current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.4.9 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Doc ID 14248 Rev 7 3/60

Contents PM6600

Appendix C Application suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

C.1 Full application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

C.2 EN, DIM path in production line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

C.3 ROW pins protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

C.4 Debug and measurements test points. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

C.5 Inductor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4/60 Doc ID 14248 Rev 7

PM6600 List of figures

List of figures

Figure 1. Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. Pin connection (through top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Efficiency vs DIM duty cycle @ fDIM = 200 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 4. Efficiency vs DIM duty cycle @ fDIM = 500 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5. Efficiency vs DIM duty cycle @ fDIM = 1 kHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Efficiency vs DIM duty cycle @ fDIM = 5 kHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Efficiency vs DIM duty cycle @ fDIM = 10 kHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8. Efficiency vs DIM duty cycle @ fDIM = 20 kHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Efficiency vs DIM duty cycle @ Vin = 8 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 10. Efficiency vs DIM duty cycle @ Vin = 12 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. Efficiency vs DIM duty cycle @ Vin = 18 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12. Efficiency vs DIM duty cycle @ Vin = 24 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 13. Efficiency vs Vin @ DIM duty cycles = 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14. Efficiency vs Vin @ DIM duty cycles = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 15. Efficiency vs Vin @ DIM duty cycles = 75% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 16. Efficiency vs Vin @ DIM duty cycles = 100% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 17. Working waveforms @ fDIM = 100 Hz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 18. Working waveforms @ fDIM = 100 Hz, D = 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 19. Working waveforms @ fDIM = 100 Hz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 20. Working waveforms @ fDIM = 100 Hz, D = 80% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 21. Working waveforms @ fDIM = 200 Hz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 22. Working waveforms @ fDIM = 200 Hz, D = 20% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 23. Working waveforms @ fDIM = 200 Hz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 24. Working waveforms @ fDIM = 200 Hz, D = 80% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 25. Working waveforms @ fDIM = 500 Hz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 26. Working waveforms @ fDIM = 500 Hz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 27. Working waveforms @ fDIM = 1 kHz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 28. Working waveforms @ fDIM = 1 kHz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 29. Working waveforms @ fDIM = 10 kHz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 30. Working waveforms @ fDIM = 10 kHz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 31. Working waveforms @ fDIM = 20 kHz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 32. Working waveforms @ fDIM = 20 Hz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 33. Output voltage ripple @ fDIM = 200 Hz, D = 1% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 34. Output voltage ripple @ fDIM = 200 Hz, D = 20% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 35. Output voltage ripple @ fDIM = 200 Hz, D = 50% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 36. Output voltage ripple @ fDIM = 200 Hz, D = 80% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 37. Shorted LED protection @ fDIM = 200 Hz all WLEDs connected . . . . . . . . . . . . . . . . . . . 23

Figure 38. Shorted LED protection @ fDIM = 200 Hz 1 WLED shorted . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 39. Shorted LED protection @ fDIM = 200 Hz 2 WLEDs shorted. . . . . . . . . . . . . . . . . . . . . . . 23

Figure 40. Shorted LED protection @ fDIM = 200 Hz 3 WLEDs shorted - ROW disabled . . . . . . . . . 23

Figure 41. Open ROW detection @ fDIM = 200 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 42. Simplified block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 43. AVCC filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 44. OVP threshold setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 45. Multiple device synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 46. External sync waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 47. Poor phase margin (a) and properly damped (b) load transient responses . . . . . . . . . . . . 31

Figure 48. Load transient response measurement set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Doc ID 14248 Rev 7 5/60

List of figures PM6600

Figure 49. Main loop and current loop diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 50. Effect of slope compensation on small inductor current perturbation (D > 0.5) . . . . . . . . . 33

Figure 51. Soft-start sequence waveforms in case of floating ROWs . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 52. fDIM enabling schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 53. VFQFPN-24 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 54. Top layer critical signals components assembly and layout . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 55. Top side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 56. Bottom side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 57. Inductor current in DCM operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 58. Full application schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 59. EN pin filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 60. DIM pin filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 61. ROW pins protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6/60 Doc ID 14248 Rev 7

PM6600 Typical application circuit

1 Typical application circuit

Figure 1. Application circuit

VBOOST

Cout

Rslope

C13

R1

D

C10

R2

9

18

16

17

25

LX

19

L

Cin

VIN+

OVSEL

VIN

8

SYNC

23

AVCC

6

AVCC

Cavcc

SLOPE

Rf ilt

FAULT

Cldo5

PGND

ROW111ROW212ROW313ROW414ROW515ROW6

PM6600

LDO5

7

DIM20EN21FAULT

22

EN

5

AVCC

DIM

SGND

THP D

COMP1MOD E

SW3

10

BILIM

3

RILIM

2

FSW

4

SS

24

Css

Rcomp

MOD E

Rbilim

Rrilim

SW2

FSW

AVCC

Rfsw

Ccomp

VIN-

Doc ID 14248 Rev 7 7/60

Pin settings PM6600

2 Pin settings

2.1 Connections

Figure 2. Pin connection (through top view)

2.2 Pin description

Table 2. Pin functions

N° Pin Function

1COMP

2 RILIM

3 BILIM

4FSW

5MODE

6 AVCC +5 V analog supply. Connect to LDO5 through a simple RC filter.

7LDO5

8 VIN Input voltage. Connect to the main supply rail.

Error amplifier output. A simple RC series between this pin and ground is

needed to compensate the loop of the boost regulator.

Output generators current limit setting. The output current of the ROWs can

be programmed connecting a resistor to SGND.

Boost converter current limit setting. The internal MOSFET current limit can

be programmed connecting a resistor to SGND.

Switching frequency selection and external sync input. A resistor to SGND

is used to set the desired switching frequency. The pin can also be used as

external synchronization input. See Section 7.3 on page 28 for details.

Current generators fault management selector. It allows to detect and

manage LEDs failures. See Section 9.2 on page 39 for details.

Internal +5 V LDO output and power section supply. Bypass to SGND with a

1 µF ceramic capacitor.

8/60 Doc ID 14248 Rev 7

PM6600 Pin settings

Table 2. Pin functions (continued)

N° Pin Function

Slope compensation setting. A resistor between the output of the boost

9SLOPE

converter and this pin is needed to avoid sub-harmonic instability.

Refer to section 1.4 for details.

10 SGND

Signal ground. Supply return for the analog circuitry and the current

generators.

11 ROW1 Row driver output #1.

12 ROW2 Row driver output #2.

13 ROW3 Row driver output #3.

14 ROW4 Row driver output #4.

15 ROW5 Row driver output #5.

16 ROW6 Row driver output #6.

17 PGND Power ground. Source of the internal power-MOSFET.

18 OVSEL

Over-voltage selection. Used to set the desired OV threshold by an external

divider. See Section 7.2 on page 27 for details.

19 LX Switching node. Drain of the internal power-MOSFET.

20 DIM

21 EN

22 FAULT

Dimming input. Used to externally set the brightness of the LEDs by using a

PWM signal.

Enable input. When low, the device is turned off. If tied high or left floating,

the device is turned on and a soft-start sequence takes place.

Fault signal output. Open drain output. The pin goes low when a fault

condition is detected (see Section 9.1 on page 39 for details).

23 SYNC Synchronization output. Used as external synchronization output.

24 SS

Soft-start. Connect a capacitor to SGND to set the desired soft-start

duration.

Doc ID 14248 Rev 7 9/60

Electrical data PM6600

3 Electrical data

3.1 Maximum rating

Table 3. Absolute maximum ratings

(1)

Symbol Parameter Value Unit

V

AVC C

V

LDO5

AVCC to SGND -0.3 to 6

LDO5 to SGND -0.3 to 6

PGND to SGND -0.3 to 0.3

V

IN

V

LX

VIN to PGND -0.3 to 40

LX to SGND -0.3 to 40

LX to PGND -0.3 to 40

RILIM, BILIM, SYNC, OVSEL, SS to SGND

V

AVC C

-0.3 to

+ 0.3

EN, DIM, FSW, MODE, FAULT to SGND -0.3 to 6

ROWx to PGND/ SGND -0.3 to 40

V

- 0.3 to

SLOPE to VIN

IN

V

+ 6

IN

SLOPE to SGND -0.3 to 40

Maximum LX RMS current 2.0 A

P

TOT

Power dissipation @ = 25 °C 2.3 W

Maximum withstanding voltage range test condition:

CDF-AEC-Q100-002- “human body model”

± 2000 V

acceptance criteria: “normal performance”

V

1. Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the

device. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

3.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

T

STG

T

T

10/60 Doc ID 14248 Rev 7

Thermal resistance junction to ambient 42 °C/W

Storage temperature range -50 to 150 °C

Junction operating temperature range -40 to 125 °C

J

Operating ambient temperature range -40 to 85 °C

A

PM6600 Electrical data

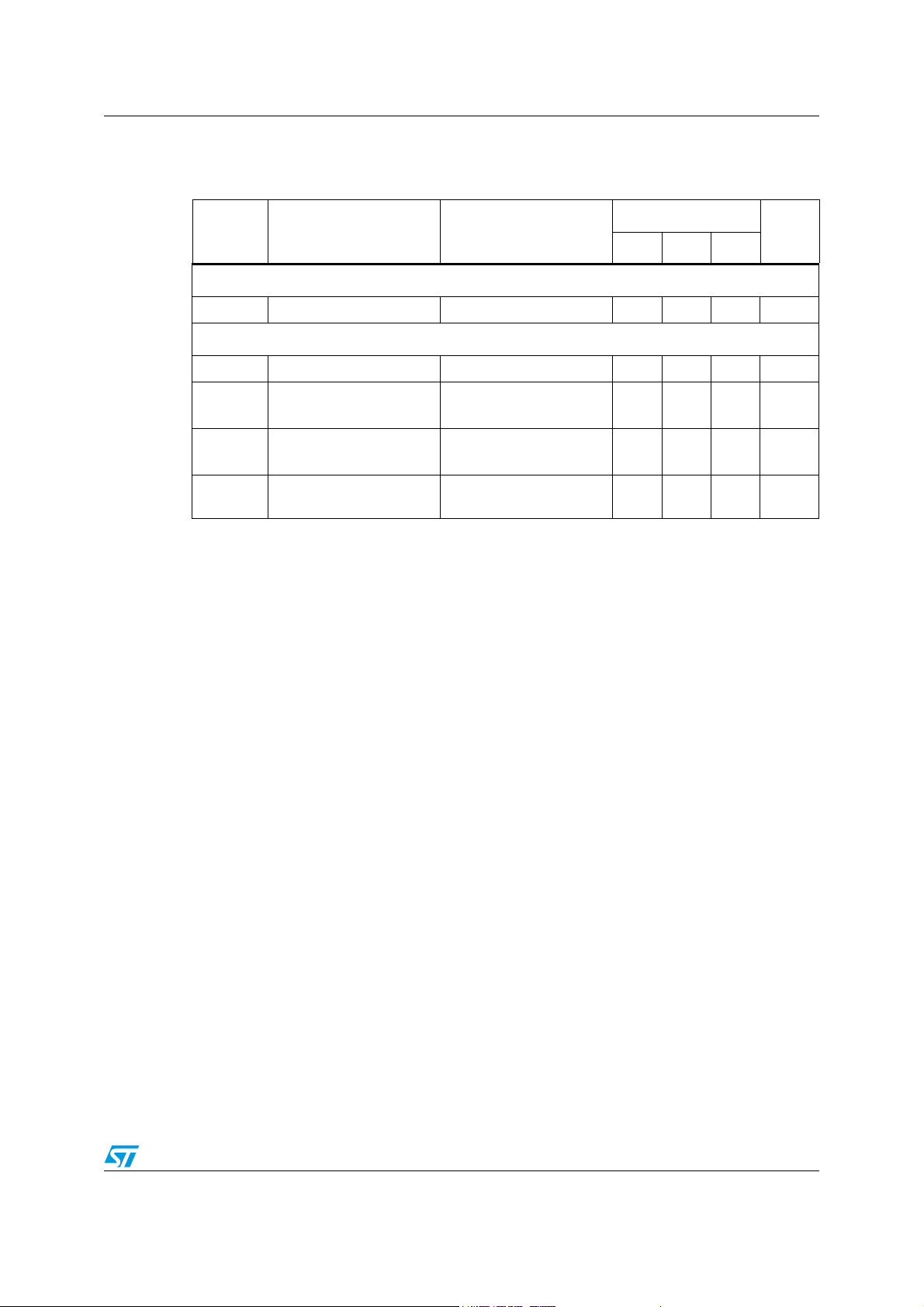

3.3 Recommended operating conditions

Table 5. Recommended operating conditions

Values

Symbol Parameter

Min Typ Max

Supply section

Unit

V

Input voltage range 4.7 - 28 V

IN

Boost section

V

BST

f

SW

Output voltage range - 36 V

Adjustable switching

frequency

FSW sync input

duty-cycle

I

rowx

ROWs output maximum

current

FSW connected

to R

FSW

200 - 1000 kHz

-40%

-32mA

Doc ID 14248 Rev 7 11/60

Electrical characteristics PM6600

4 Electrical characteristics

VIN = 12 V; TA = 0 °C to 85 °C and MODE connected to AVCC unless specified

Table 6. Electrical characteristics

Symbol Parameter Test condition

Supply section

V

LDO5, VAVC C

I

IN,Q

I

IN,SHDN

V

UVLO,ON

V

UVLO,OFF

LDO output and IC supply voltage

Operating quiescent current

Operating current in shutdown EN low 20 30 μA

LDO5 under voltage lockout upper

threshold

LDO5 under voltage lockout lower

threshold

LDO linear regulator

EN High,

= 0 mA

I

LDO5

R

= 51 kΩ,

RILIM

= 220 kΩ,

R

BILIM

R

SLOPE

= 680 kΩ

DIM tied to SGND.

(1)

.

Val ues

Unit

Min Typ Max

4.6 5 5.5 V

1mA

4.6 4.75

3.8 4.0

V

IN

= 30 mA

= 4.3 V,

= 10 mA

> V

< V

= 28 V,

UVLO,ON

UVLO,OFF

25 40 60

Line regulation

LDO dropout voltage

LDO maximum output current limit

1. TA = TJ. All parameters at operating temperature extremes are guaranteed by design and statistical analysis

(not production tested)

6 V = V

I

LDO5

V

IN

I

LDO5

V

LDO5

V

LDO5

25

mV

80 120

mA

30

12/60 Doc ID 14248 Rev 7

PM6600 Electrical characteristics

Table 6. Electrical characteristics (continued)

Val ues

Symbol Parameter Test condition

Min Typ Max

Boost section

Unit

t

on,min

Power switch

K

B

OV protections

Minimum switching

on time

200 ns

Default switching frequency FSW connected to AVCC 570 660 750

Minimum FSW

Sync frequency

FSW sync

Input low level threshold

FSW sync

Input hysteresis

FSW sync

Min ON time

SYNC output

duty-cycle

SYNC output

high level

SYNC output

low level

LX current coefficient R

Internal MOSFET R

DSon

240

FSW connected to AVCC

(Internal oscillator selected)

V

= 10 µA

I

SYNC

= -10 µA 20

I

SYNC

= 300 kΩ 5.7e5 6.7e5 7.7e5 V

BILIM

AVC C

-20

210

60

270 ns

34 40 %

280 500 mΩ

kHz

mV

mV

V

TH,OVP

V

TH,FRD

ΔV

OVP,FRD

Overvoltage protection reference

(OVSEL) threshold

Floating ROWs detection

(OVSEL) threshold

Voltage gap between the OVP

and FRD thresholds

1.190 1.235 1.280 V

1.100 1.145 1.190 V

90 mV

Doc ID 14248 Rev 7 13/60

Electrical characteristics PM6600

Table 6. Electrical characteristics (continued)

Val ues

Symbol Parameter Test condition

Min Typ Max

Soft-start and power management

EN, turn-on level threshold 1.6

Unit

EN, turn-off level threshold 0.8

DIM, high level threshold 1.3

DIM, low level threshold 0.8

EN, pull-up current 2.5

SS, charge current 4 5 6

SS, end-of-startup threshold 2 2.4 2.8

SS, reduced switching frequency

Release threshold

Current generators section

T

DIM-ON,min

K

R

ΔI

ROWx

V

IFB

V

TH,FAULT

V

FAU LT,L OW

Minimum dimming on-time R

ROWs current coefficient

accuracy

ROWs current mismatch

Feedback regulation voltage No LEDs mismatch 400 mV

Shorted LED fault detection

threshold

FAULT pin low-level voltage I

Thermal shutdown

(1)

0.8

= 51 kΩ 500 ns

RILIM

R

= 51 kΩ 998 ±21 V

RILIM

R

= 51 kΩ ±2 %

RILIM

8.2 V

FAULT,SINK

= 4 mA 350 mV

V

μA

V

T

SHDN

Thermal shutdown

Turn-off temperature

150 °C

Note: The current mismatch is the maximum current difference among the ROWs of one device.

14/60 Doc ID 14248 Rev 7

PM6600 Typical operating characteristics

5 Typical operating characteristics

All the measures are done with a standard PM6600EVAL demonstration board and a

standard WLED6021NB tamboured, with the components listed in the EVAL_KIT document.

The measures are done with this working conditions, unless specified:

● Vin = 12 V

● Vout = 6 rows x 10 WLEDs = 34 V (typ)

● Iout = 20 mA each row

● fsw = 660 kHz (nominal switching frequency, with FSW. AVCC)

● Vrow1 to Vrow6 = {0.697, 0.75, 0.818, 0.696, 0.822, 0.363} V

Figure 3. Efficiency vs

100

90

80

70

60

50

40

Effici ency [% ]

30

20

10

0

DIM duty cycle @ f

0 20406080100

DIM duty cycle [%]

= 200 Hz

DIM

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Figure 4. Efficiency vs

DIM duty cycle @ f

100

90

80

70

60

50

40

Effici ency [% ]

30

20

10

0

020406080100

DIM du ty cycle [%]

DIM

= 500 Hz

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Figure 5. Efficiency vs

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

DIM duty cycle @ f

0 2040 6080100

DIM du ty cycl e [%]

= 1 kHz

DIM

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Figure 6. Efficiency vs

DIM duty cycle @ f

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

0 20406080100

Doc ID 14248 Rev 7 15/60

DIM du ty cycle [%]

= 5 kHz

DIM

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Typical operating characteristics PM6600

Figure 7. Efficiency vs

100

90

80

70

60

50

40

Effic iency [%]

30

20

10

0

0 20406080100

DIM duty cycle @ f

DIM duty cyc le [%]

= 10 kHz

DIM

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Figure 9. Efficiency vs

100

90

80

70

60

50

40

Effici ency [% ]

30

20

10

0

DIM duty cycle @ Vin = 8 V

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10kHz

fDIM = 20kHz

0 20406080100

DIM du ty cycle [%]

Figure 8. Efficiency vs

DIM duty cycle @ f

100

90

80

70

60

50

40

Efficien cy [%]

30

20

10

0

0 20 40 60 80 100

DIM du ty cycle [%]

DIM

= 20 kHz

Vin = 6V

Vin = 12V

Vin = 18V

Vin = 24V

Figure 10. Efficiency vs

DIM duty cycle @ Vin = 12 V

100

90

80

70

60

50

40

Effici ency [% ]

30

20

10

0

020406080100

DIM duty cycle [%]

fDIM = 200 Hz

fDIM = 500 Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

Figure 11. Efficiency vs

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

16/60 Doc ID 14248 Rev 7

DIM duty cycle @ Vin = 18 V

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

020406080100

DIM d uty cycl e [%]

Figure 12. Efficiency vs

DIM duty cycle @ Vin = 24 V

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

0 20406080100

DIM duty cycle [%]

fDIM = 200 Hz

fDIM = 500 Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

PM6600 Typical operating characteristics

Figure 13. Efficiency

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

vs Vin @ DIM duty cycles = 10%

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

6121824

Vin [V]

Figure 14. Efficiency

vs Vin @ DIM duty cycles = 50%

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

6 121824

Vin [V]

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

Figure 15. Efficiency

96

94

92

90

88

Efficien cy [%]

86

84

82

6121824

vs Vin @ DIM duty cycles = 75%

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

Vin [V]

Figure 16. Efficiency

vs Vin @ DIM duty cycles = 100%

95

94

93

92

91

90

Efficiency [%]

89

88

87

6 121824

Vin [V]

fDIM = 200Hz

fDIM = 500Hz

fDIM = 1k Hz

fDIM = 5k Hz

fDIM = 10k Hz

fDIM = 20k Hz

Doc ID 14248 Rev 7 17/60

Typical operating characteristics PM6600

Figure 17. Working waveforms @

f

= 100 Hz, D = 1%

DIM

Figure 18. Working waveforms @

f

= 100 Hz, D = 10%

DIM

Figure 19. Working waveforms @

f

= 100 Hz, D = 50%

DIM

Figure 20. Working waveforms @

f

= 100 Hz, D = 80%

DIM

18/60 Doc ID 14248 Rev 7

PM6600 Typical operating characteristics

Figure 21. Working waveforms @

f

= 200 Hz, D = 1%

DIM

Figure 23. Working waveforms @

f

= 200 Hz, D = 50%

DIM

Figure 22. Working waveforms @

f

= 200 Hz, D = 20%

DIM

Figure 24. Working waveforms @

f

= 200 Hz, D = 80%

DIM

Doc ID 14248 Rev 7 19/60

Typical operating characteristics PM6600

Figure 25. Working waveforms @

f

= 500 Hz, D = 1%

DIM

Figure 27. Working waveforms @

f

= 1 kHz, D = 1%

DIM

Figure 26. Working waveforms @

f

= 500 Hz, D = 50%

DIM

Figure 28. Working waveforms @

f

= 1 kHz, D = 50%

DIM

20/60 Doc ID 14248 Rev 7

PM6600 Typical operating characteristics

Figure 29. Working waveforms @

f

= 10 kHz, D = 1%

DIM

Figure 31. Working waveforms @

f

= 20 kHz, D = 1%

DIM

Figure 30. Working waveforms @

f

= 10 kHz, D = 50%

DIM

Figure 32. Working waveforms @

f

= 20 Hz, D = 50%

DIM

Doc ID 14248 Rev 7 21/60

Typical operating characteristics PM6600

Figure 33. Output voltage ripple @

f

= 200 Hz, D = 1%

DIM

Figure 35. Output voltage ripple @

f

= 200 Hz, D = 50%

DIM

Figure 34. Output voltage ripple @

f

= 200 Hz, D = 20%

DIM

Figure 36. Output voltage ripple @

f

= 200 Hz, D = 80%

DIM

22/60 Doc ID 14248 Rev 7

PM6600 Typical operating characteristics

Figure 37. Shorted LED protection

@ f

= 200 Hz

DIM

all WLEDs connected

Figure 39. Shorted LED protection

@ f

= 200 Hz

DIM

2 WLEDs shorted

Figure 38. Shorted LED protection

@ f

= 200 Hz

DIM

1 WLED shorted

Figure 40. Shorted LED protection

@ f

= 200 Hz

DIM

3 WLEDs shorted - ROW disabled

Doc ID 14248 Rev 7 23/60

Typical operating characteristics PM6600

Figure 41. Open ROW detection @

f

= 200 Hz

DIM

24/60 Doc ID 14248 Rev 7

PM6600 Block diagram

_

CO

SYNC

U

G

6

O

SLO

CC

3

O

5

OVS

SG

O

g

O

6 Block diagram

Figure 42. Simplified block diagram

BILIM

FSW

AV

M

FA

MP

EN

DE

LT

VIN

+5V

LD

UVLO

Detector

UVLO

Current Limit

Soft Start

Prot_EN

Ext Sync

Detector

CONTROL

LOGIC

Thermal

PE

Current Sense

Ramp

Generator

+

+

÷2

OSC

Prot_EN

Boost_EN

UVLO

CTRL6

CTRL5

CTRL4

CTRL3

CTRL2

OVP

FRD

1.2V

+

m

_

Min Voltage

Selector

I to V

CTRL1

V

ROW1

ZCD

+

Boost

Control

_

Logic

0.4V

Boost_EN

FRD

OVP

VROW6

CTRL6

VROW5

CTRL5

VROW4

CTRL4

VROW3

CTRL3

VROW2

CTRL2

Generator 1

Current

LOGIC

Current

Generator 6

Current

Generator 5

Current

Generator 4

Current

Generator 3

Current

Generator 2

8.2V

I to V

+

_

_

+

+

VTH,FLT

1.143V

1.235V

LX

P

ND

EL

ROW

ROW

ROW4

ROW

R

W2

R

W1

RILIM

ND

Doc ID 14248 Rev 7 25/60

Operation description PM6600

7 Operation description

7.1 Boost section

7.1.1 Functional description

The PM6600 is a monolithic LEDs driver for the backlight of LCD panels and it consists of a

boost converter and six PWM-dimmable current generators.

The input voltage range is from 4.7 V up to 28 V.

The boost section is based on a constant switching frequency, Peak Current-Mode

architecture. The boost output voltage is controlled such that the lowest ROWs' voltage,

referred to SGND, is equal to an internal reference voltage (400 mV typ.).

In addition, the PM6600 has an internal LDO that supplies the internal circuitry of the device

and is capable to deliver up to 40 mA. The input of the LDO is the VIN pin. The LDO5 pin is

the LDO output and the supply for the power-MOSFET driver at the same time. The AVCC

pin is the supply for the analog circuitry and should be connected to the LDO output through

a simple RC filter, in order to improve the noise rejection.

Figure 43. AVCC filtering

VIN

Rfilt

4R7

Cavcc

100n

LDO5

AVCC

LDO

PM6600

SGND

Two loops are involved in regulating the current sunk by the generators.

The main loop is related to the boost regulator and uses a constant frequency peak currentmode architecture (see Figure 49), while an internal current loop regulates the same current

at each ROW according to the set value (RILIM pin).

A dedicated circuit automatically selects the lowest voltage drop among all the ROWs and

provides this voltage the main loop that, in turn, regulates the output voltage. In fact, once

the reference generator has been detected, the error amplifier compares its voltage drop to

the internal reference voltage and varies the COMP output. The voltage at the COMP pin

determines the inductor peak current at each switching cycle. The output voltage of the

boost regulator is thus determined by the total forward voltage of the LEDs strings:

Equation 1

OUT

N

ROWS

=

1i

m

LEDS

mV400)V(maxV

+=

j,F

Σ

=

1j

26/60 Doc ID 14248 Rev 7

PM6600 Operation description

++<<+

+⋅=

where the first term represents the highest total forward voltage drop over active ROWs and

the second is the voltage drop across the leading generator (400 mV typ.).

The device continues to monitor the voltage drop across all the rows and automatically

switches to the current generator having the lowest voltage drop.

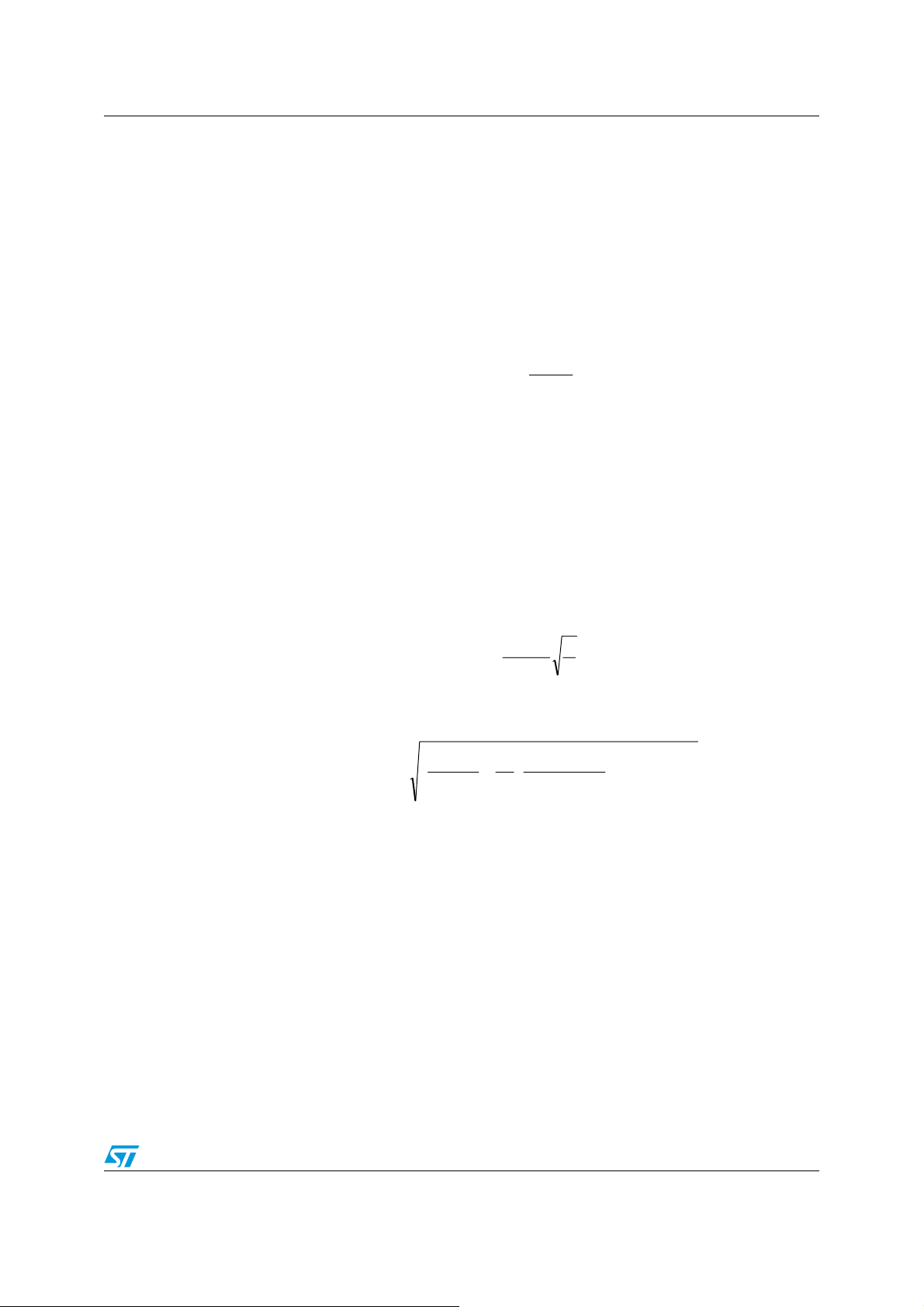

7.2 Overvoltage protection

An adjustable over-voltage protection is available. It can be set feeding the OVSEL pin with a

partition of the output voltage. The voltage of the central tap of the divider is thus compared

to a fixed 1.235 V threshold. When the voltage on the OVSEL pin exceeds the OV threshold,

the FAULT pin is tied low (see

condition is latched and the PM6600 is restarted by toggling the EN pin or by performing a

power-on reset (the POR occurs when the LDO output falls below the lower UVLO threshold

and subsequently crosses the upper UVLO threshold during the rising phase of the input

voltage). Normally, the value of the high-side resistors of the divider is in the order of 100k

to reduce the output capacitor discharge when the boost converter is off (during the off

phase of the dimming cycle).

The OVSEL divider should be a compensated one, with the capacitors C10 (typically in the

100 pF-330 pF range) that improves noise rejection at the OVSEL pin (see

C13 (typically 22 pF) that avoids OVP fault detection when a row is open.

Section 9 on page 39) and the device is turned off; this

Ω

Figure 44) and

The following formulas permit to properly select the OVP threshold, according to the VOUT

value and considering the worst case (maximum VF_WLED):

Equation 2

maxOUTOUTOVPmaxOUT

)V5.4VVVV3V

Equation 3

V4.0VnV

V

OUTmax

V

OVP

is the maximum output voltage considering the LED spread.

is the over-voltage protection threshold

maxWLED_Fseries_WLEDmaxOUT

The formula to choose the proper values for the resistors of the OVP divider is:

Equation 4

R1R

2

⎝⎠

1.235 1–

VOVP

⎛⎞

----------------------- -

=

Equation 5

R

2

C

1.5 C⋅

13

------ -

⋅=

10

R

1

Doc ID 14248 Rev 7 27/60

Operation description PM6600

Figure 44. OVP threshold setting

VIN

PM6600

LX

SGND

R1

OVSEL

R2

VOUT

C13

COUT

C10

7.3 Switching frequency selection and synchronization

The switching frequency of the boost converter can be set in the 200 kHz-1 MHz range by

connecting the FSW pin to ground through a resistor. Calculation of the setting resistor is

made using equation 3 and should not exceed the 80 kΩ-400 kΩ range.

Equation 6

f

SW

=

R

FSW

In addition, when the FSW pin is tied to AVCC, the PM6600 uses a default 660 kHz fixed

switching frequency, allowing to save a resistor in minimum components-count applications.

5.2

Figure 45. Multiple device synchronization

SLAVE

Sync Out

SYNC

PM6600

SGND

RFSW

MASTER

AVCC

FSW SYNC

SYNC

FSW

PM6600

SGND

The FSW pin can also be used as a synchronization input, allowing the PM6600 to operate

both as master or slave device. If a clock signal with a 210 kHz minimum frequency is

applied to this pin, the device locks synchronized (300 mV threshold). An Internal time-out

allows synchronization as long as the external clock frequency is greater than 210 kHz.

Keeping the FSW pin voltage lower than 300 mV for more than 1/210 kHz

≈ 5 μs results in

the device turn off. Normal operation is resumed as soon as FSW rises above the

mentioned threshold and the soft-start sequence is repeated.

28/60 Doc ID 14248 Rev 7

PM6600 Operation description

The SYNC pin is a synchronization output and provides a 34% (typ.) duty-cycle clock when

the PM6600 is used as master or a replica of the FSW pin when used as slave. It is used to

connect multiple devices in a daisy-chain configuration or to synchronize other switching

converters running in the system with the PM6600 (master operation).

When an external synchronization clock is applied to the FSW pin, the internal oscillator is

over-driven: each switching cycle begins at the rising edge of clock, while the slope

compensation ramp starts at the falling edge of the same signal. Thus, the external

synchronization clock is required to have a 40% maximum duty-cycle when the boost

converter is working in continuous-conduction mode (CCM). The minimum pulse width

which allows the synchronizing pulses to be detected is 270 ns.

Figure 46. External sync waveforms

FSW pin voltage (ext. sync)

Slave SYNC pin voltage

Slave LX pin voltage

270ns minimum

300mV threshold

Doc ID 14248 Rev 7 29/60

Operation description PM6600

⋅

≤

7.4 System stability

The boost section of the PM6600 is a fixed frequency, peak current-mode converter. During

normal operation, a minimum voltage selection circuit compares all the voltage drops across

the active current generators and provides the minimum one to the error amplifier. The

output voltage of the error amplifier determines the inductor peak current in order to keep its

inverting input equal to the reference voltage (400 mV typ). The compensation network

consists of a simple RC series (R

The calculation of R

COMP

dynamic performance of the boost converter and is strictly related to the operating

conditions.

7.4.1 Loop compensation

The compensation network can be quickly calculated using equations 4 through 9. Once

both R

order to get the optimal dynamic performance from the application.

The first parameter to be fixed is the switching frequency. Normally, a high switching

frequency allows reducing the size of the inductor but increases the switching losses and

negatively affects the dynamic response of the converter. For most of applications, the fixed

value (660 kHz) represents a good trade-off between power dissipation and dynamic

response, allowing to save an external resistor at the same time. In low-profile applications,

the inductor value is often kept low to reduce the number of turns; an inductor value in the

4.7 µH-15 µH range is a good starting choice.

COMP

and C

COMP

and C

have been determined, a fine-tuning phase may be required in

- C

COMP

is fundamental to achieve optimal loop stability and

COMP

) between the COMP pin and ground.

COMP

Even if the loop bandwidth of the boost converter should be chosen as large as possible, it

should be set to 20% of the switching frequency, taking care not to exceed the CCM-mode

right half-plane zero (RHPZ).

Equation 7

f2.0f

SWU

Equation 8

min,IN

OUT

2

⎞

⎟

⎟

⎠

⋅π

⎞

⎛

V

OUT

⎟

⎜

⎟

⎜

I

OUT

⎠

⎝

L2

is the overall output current,

V

OUT

I

OUT

V

⎛

⎜

2.0

R =

⎜

⎝

⋅=

OUT

V

2

RM

2.0f

U

Where V

Note that, the lower the inductor value (or the lower the switching frequency) the higher the

bandwidth can be achieved. The output capacitor is directly involved in the loop of the boost

is the minimum input voltage, I

IN,min

⋅≤

M =

L2

⋅π

V

min,IN

V

OUT

converter and must be large enough to avoid excessive output voltage drop in case of a

sudden line transition from the maximum to the minimum input voltages (ΔV

should not

OUT

exceed 50-100 mV):

30/60 Doc ID 14248 Rev 7

PM6600 Operation description

Equation 9

OUT

⎛

⎜

⎜

Cf2

⋅⋅π

U

⎝

V

OUT

I

=Δ

Once the output capacitor has been chosen, the R

Equation 10

R

COMP

=

Where GM = 2.7 S and gEA = 375 µS.

The C

capacitor is determined to place the frequency of the compensation zero 5

COMP

times lower than the loop bandwidth:

Equation 11

C

COMP

=

Where fZ = fU / 5.

The close loop gain function (G

) is thus given by equation 10:

LOOP

Equation 12

1

−

COMP

U

EAM

1

⋅⋅π

Rf2

V

V

⎞

MIN_IN

⎟

⎟

MAX_IN

⎠

can be calculated as:

Cf2

⋅⋅π

MgG

⋅⋅

COMPZ

−

⎛

⎜

RgGG

⎜

⎝

+⋅⋅=

COMPEAMLOOP

sC

1

COMP

⎞

⎟

⋅

⎟

⎠

RM

s1

+

A simple technique to optimize different applications is to replace R

trimmer and adjust its value to properly damp the output transient response. Insufficient

damping will result in excessive ringing at the output and poor phase margin. Figures 5a and

5b give an example of compensation adjustment for a typical application.

Figure 47. Poor phase margin (a) and properly damped (b) load transient responses

L

2

sRC1

COMP

RM

with a 20 kΩ

Doc ID 14248 Rev 7 31/60

Operation description PM6600

Figure 48. Load transient response measurement set-up

LDO5

BILIM

RILIM

SS

COMP

SGND

6.8μH

VIN= 6V

+5V

C

IN

7.4.2 Slope compensation

The constant frequency, peak current-mode topology has the advantage of very easy loop

compensation with output ceramic capacitors (reduced cost and size of the application) and

fast transient response. In addition, the intrinsic peak-current measurement simplifies the

current limit protection, avoiding undesired saturation of the inductor.

On the other side, this topology has a drawback: there is inherent open loop instability when

operating with a duty-ratio greater than 0.5. This phenomenon is known as “sub-harmonic

instability” and can be avoided by adding an external ramp to the one coming from the

sensed current. This compensating technique, based on the additional ramp, is called

“Slope Compensation”. In figure 11, where the switching duty-cycle is higher than 0.5, the

small perturbation ΔIL dies away in subsequent cycles thanks to the slope compensation

and the system reverts to a stable situation.

AVCC

DIM

LX

VIN

PM6600

FAULT

EN

VBST=30÷36V

4.7μF

MLCC

FSW

OVSEL

SLOPE

ROW1

ROW2

ROW3

ROW4

ROW5

ROW6

PGND

SYNC

MODE

Up to 10 WLEDs per row

R

=

L

500Hz

VBST

50mA

Figure 49. Main loop and current loop diagram

VIN

32/60 Doc ID 14248 Rev 7

COMP

PWM

g

m

LX

0.4V

Minimum voltage drop

selector

ROWx

SGND

RILIM

PM6600 Operation description

The SLOPE pin allows to properly set the amount of slope compensation connecting a

simple resistor R

between the SLOPE pin and the output. The compensation ramp

SLOPE

starts at 35% (typ.) of each switching period and its slope is given by the following equation:

Equation 13

⎞

VVV

−−

BEINOUT

⎟

⎟

⎠

Where K

⎛

KS

=

, VBE = 2 V (typ.) and SE is the slope ramp in [A/s].

SLOPE

⎜

SLOPEE

⎜

R

⎝

SLOPE

To avoid sub-harmonic instability, the compensating slope should be at least half the slope

of the inductor current during the off-phase for a duty-cycle greater than 50% (i.e. at the

lowest input voltage). The value of R

can be calculated according to equation 9.

SLOPE

Equation 14

)VVV(LK2

−−⋅⋅⋅

R

SLOPE

≤

)VV(

−

INOUT

BEINOUTSLOPE

Figure 50. Effect of slope compensation on small inductor current perturbation

(D > 0.5)

Inductor current (CCM)

0.35·T

SW

Programmed inductor peak current with

slope compensation (S

I

TRIP

E)

7.5 Soft-start

The soft-start function is required to perform a correct start-up of the system, controlling the

inrush current required to charge the output capacitor and to avoid output voltage overshoot.

The soft-start duration is set connecting an external capacitor between the SS pin and

ground. This capacitor is charged with a 5 μA constant current, forcing the voltage on the SS

pin to ramp up. When this voltage increases from zero to nearly 1.2 V, the current limit of the

power-MOSFET is proportionally released to its final value. In addition, during the initial part

of the Soft-Start, the switching frequency of the boost converter is reduced to half of the

ΔI

Inductor current

perturbation

L

T

SW

t

Doc ID 14248 Rev 7 33/60

Operation description PM6600

nominal value to permit to use inductors with lower saturation current value; the nominal

switching frequency is restored after the SS pin voltage has crossed 0.8 V. In this mode, the

current runaway is avoided.

Figure 51. Soft-start sequence waveforms in case of floating ROWs

OVP

Floating ROWs detection

Vth,FRD=

93% of OVP

Output voltage

AVCC

2.4V

1.2V

0.8V

SS pin voltage

Protections turn active

Nominal switching

frequency release

tss

100%

Current limit

EN pin voltage

t

During the soft-start phase it is also performed the floating ROWs detection. In presence of

one or more floating ROWs, the error amplifier is unbalanced and the output voltage

increases; when it reaches the floating ROW Detection (FRD) threshold (93% of the OVP

threshold), the floating ROWs are managed according to

39

). After the SS voltage reaches a 2.4 V threshold, the start-up finishes and all the

protections turn active. The soft-start duration can be calculated with the following formula:

Equation 15

Ta bl e 8 (see Section 9 on page

Where ISS = 5 µA.

Please refer to the application note section for the CSS value settings according to the

different working conditions.

34/60 Doc ID 14248 Rev 7

SS

C

SS

5.2t ≅

I

SS

PM6600 Operation description

7.6 Boost current limit

The design of the external components, especially the inductor and the flywheel diode, must

be optimized in terms of size relying on the programmable peak current limit. The PM6600

improves the reliability of the final application giving the way to limit the maximum current

flowing into the critical components. A simple resistor connected between the BILIM pin and

ground sets the desired value. The voltage at the BILIM pin is internally fixed to 1.2 V and

the current limit is proportional to the current flowing through the setting resistor, according

to the following equation:

Equation 16

K

I =

PEAK,BOOST

R

B

BILIM

where .

B

5

The maximum allowed current limit is 5 A, resulting in a minimum setting resistor

R

> 120 kΩ. The maximum guaranteed RMS current in the power switch is 2 Arms. The

BILIM

current limitation works by clamping the COMP pin voltage proportionally to R

inductor current is limited to the above threshold decreased by the slope compensation

contribution.

In a boost converter the r.m.s. current through the internal MOSFET depends on both the

input and output voltages, according to equations 15a (DCM) and 15b (CCM).

Equation 17 a

Equation 17 b

7.7 Enable function

%15V107.6K

±⋅=

. Peak

BILIM

DV

⋅

I

rms,MOS

⎛

D

=

⎜

II

OUTrms,MOS

⎜

()

−

D1

⎝

IN

=

SW

⎛

1

⎜

+

⎜

2

12

⎝

D

3

LF

⋅

V

OUT

SWOUT

2

⎞

⎟

()()

⎟

⋅⋅

LfI

⎠

⎞

3

⎟

−

D1D

⎟

⎠

The PM6600 is enabled by the EN pin. This pin is active high and, when forced to SGND,

the device is turned off. This pin is connected to a permanently active 2 μA current source;

when sudden device turn-on at power-up is required, this pin must be left floating or

connected to a delay capacitor. When turned off, the PM6600 quickly discharges the SoftStart capacitor and turns off the power-MOSFET, the current generators and the LDO. The

power consumption is thus reduced to 20 μA only.

The proper startup sequence is DIM ' VIN ' EN, or VIN ' DIM ' EN. If the dimming signal is

applied after the EN pin, the device will not perform the soft-start again, in fact it will start

switching with the maximum current limit in order to recover the output voltage.

In applications where the dimming signal is used to turn on and off the device, the EN pin

can be connected to the DIM pin as shown in

Doc ID 14248 Rev 7 35/60

Figure 52.

Operation description PM6600

Figure 52. f

enabling schematic

DIM

7.8 Thermal protection

In order to avoid damage due to high junction temperature, a thermal shutdown protection is

implemented. When the junction temperature rises above 150 °C (typ.), the device turns off

both the control logic and the boost converter and holds the FAULT pin low.

In order to turn on the device again, it is possible to perform a POR (power on reset) once

the junction temperature has been reduced by 30 °C.

220k

BAS69

100n

DIM

PM6600

EN

SGND

36/60 Doc ID 14248 Rev 7

PM6600 Backlight driver section

8 Backlight driver section

8.1 Current generators

The PM6600 is a LEDs driver with six channels (ROWs); each ROW is able to drive multiple

LEDs in series (max. 40 V) and to sink up to 32 mA maximum current, allowing to manage

different kinds of LEDs.

The LEDs current can be set by connecting an external resistor (R

) between the RILIM

RILIM

pin and ground. The voltage across the RILIM pin is internally set to 1.2 V and the ROWs

current is proportional to the RILIM current according to the following equation:

Equation 18

K

I =

ROWx

R

R

RILIM

Where KR = 998 ± 21 V (± 2.1%).

The current accuracy between the ROWs of more than one device is, consequently:

Equation 19

−

I

I

=Δ

MAX,ROW

=Δ

MIN,ROW

I

I

998K_ROW

=

R

−

II

998K_ROW

=

R

In the table below there are the maximum, typical and minimum I

R

:

RILIM

II

Table 7. I

R

RILIM

47.0 kΩ 20.79 mA 21.68 mA 21.68 mA

49.9 kΩ 19.58 mA 20.00 mA 20.42 mA

51.0 kΩ 19.16 mA 19.57 mA 19.98 mA

values versus R

ROW

RILIM

I

@ KR = 977 I

ROW

ROW

998K_ROW1019K_ROW

==

RR

==

RR

+≤

%1.2

998K_ROW977K_ROW

%1.2

−≥

values versus the

ROW

@ KR = 998 I

@ KR = 1019

ROW

The maximum current mismatch between the ROWs of one device is

± 2% @ I

= 20 mA, according to the formula:

ROWx

Doc ID 14248 Rev 7 37/60

Backlight driver section PM6600

⋅

=

Equation 20

II

I

I

I

=Δ

max,ROWx

=Δ

min,ROWx

6

I

∑

ROWi

1i

=

=

mean_ROW

6

−

I

II

−

I

mean_ROWmax_ROW

mean_ROW

mean_ROWmin_ROW

mean_ROW

%2

+≤

%2

−≥

Due to the spread of the LEDs' forward voltage, the total drop across the LED's strings will

be different. The device will manage the unconnected ROWs according to the MODE pin

setting (see

Ta bl e 8 ).

8.2 PWM dimming

The brightness control of the LEDs is performed by a pulse-width modulation of the ROWs

current. When a PWM signal is applied to the DIM pin, the current generators are turned on

and off mirroring the DIM pin behavior. Actually, the minimum dimming duty-cycle depends

on the dimming frequency. The real limit to the PWM dimming is the minimum on-time that

can be managed for the current generators; this minimum on-time is approximately 500 ns.

Thus, the minimum dimming duty-cycle depends on the dimming frequency according to the

following formula:

Equation 21

fns500D

DIMmin,DIM

For example, at a dimming frequency of 20 kHz, 1% of dimming duty-cycle can be

managed.

The device can manage the condition f

issue due to the human eye cutoff frequency, we recommend to use f

= 0 Hz. However, in order to avoid any flickering

DIM

> 100 Hz (condition

DIM

verified with discrete smd leds without any light guide).

The f

maximum value has to be 1/10 of the selected Fsw.

DIM

During the off-phase of the PWM signal the boost converter is paused, the current

generators are turned off and the output voltage is frozen across the output capacitor.

During the start-up sequence the dimming duty-cycle is forced to 100% to detect floating

ROWs regardless of the applied dimming signal.

38/60 Doc ID 14248 Rev 7

PM6600 Fault management

9 Fault management

The main loop keeps the ROW having the lowest voltage drop regulated to about 400 mV.

This value slightly depends on the voltage across the remaining active ROWs. After the softstart sequence, all protections turn active and the voltage across the active current

generators is monitored to detect shorted LEDs.

9.1 FAULT pin

The FAULT pin is an open-collector output, active low, which gives information regarding

faulty conditions eventually detected. This pin can be used either to drive a status LED (with

a series resistor to not exceed 4 mA current) or to warn the host system. The FAULT pin

status is strictly related to the MODE pin setting (see

9.2 MODE pin

The MODE pin is a digital input and can be connected to AVCC or SGND in order to choose

the desired fault detection and management. The PM6600 can manage a faulty condition in

two different ways, according to the application needs.

detects and handles the internal protections related to the boost section (over-current, overtemperature and over-voltage) and to the current generators section (open and shorted

LEDs).

Ta bl e 8 for details).

Ta bl e 8 summarizes how the device

Table 8. Faults management summary

FAULT MODE to GND MODE to VCC

Internal MOSFET over

current

Output over voltage

Thermal shutdown

Shorted LEDs on a single

row

FAULT pin HIGH

power-MOS turned OFF

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

faulty ROW DISABLED

VTH,FAULT = 8.2 V

FAULT pin LOW

Shorted LEDs on more rows

device latched OFF

VTH,FAULT = 8.2 V

Open row

More than one

open rows

Open rows plus shorted led

(different rows)

FAULT pin LOW

faulty ROW DISABLED

FAULT pin LOW

device latched OFF

FAULT pin LOW

device latched OFF

VTH,FAULT = 8.2 V

FAULT pin HIGH

power-MOS turned OFF

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

faulty ROW DISABLED

VTH,FAULT = 8.2 V

FAULT pin LOW

faulty ROWs DISABLED

VTH,FAULT = 8.2 V

FAULT pin HIGH

faulty ROW DISABLED

FAULT pin HIGH

faulty ROWs DISABLED

FAULT pin LOW

faulty ROWs DISABLED

VTH,FAULT = 8.2 V

Doc ID 14248 Rev 7 39/60

Fault management PM6600

9.3 Open LED fault

In case a ROW is not connected or a LED fails open, the device has two different behaviors

according to the MODE pin status.

If the MODE pin is high (connected to AVCC), the open ROW is excluded from the control

loop and the device continues to work properly with the remaining ROWs, without asserting

the FAULT pin.

Connecting the MODE pin to SGND, the PM6600 behaves in a different manner: as soon as

one open ROW is detected, the FAULT pin is tied low. In case a second open ROW is

detected, the device is turned off. The internal logic latches this status: to restore the normal

operation, the device must be restarted by toggling the EN pin or performing a power on

reset (POR occurs when the voltage at the LDO5 pin falls below the lower UVLO threshold

and subsequently rises above the upper one).

As a consequence, If less than six ROWs are used in the application, the MODE pin must be

set high.

9.4 Shorted LED fault

When a LED is shorted, the voltage across the related current generator increases of an

amount equal to the missing voltage drop of the faulty LED. Since the feedback voltage on

each active generator is constantly compared with a fixed fault threshold V

TH,FAULT

the device detects the faulty condition and acts according to the MODE pin status.

= 8.2 V,

In case the MODE pin is connected to AVCC, the PM6600 disconnects the ROWs whose

voltage is higher than the threshold and the FAULT pin is tied low. This option is also useful

to avoid undesired triggering of the shorted-LED protection simply due to the high voltage

drop spread across the LEDs.

If the MODE pin is low, when the voltage across one ROW is higher than V

threshold, the FAULT pin is set low and that ROW is disabled. If the voltage of a second

ROW becomes higher than V

latches this status until the EN pin is toggled or a POR is performed.

9.5 Intermittent connection

For intermittent connection it is intended the condition where the flat cable connector from

the leds backlight driver to the leds can have some issues on moving the panel of the

notebook. This kind of issue is represented as an intermittent connection, that means the

physical electrical connection between the ROWx pins of the PM6600 device and the White

LEDs can be open for a while.

The device will detect an open row fault.

There is one possible solution to determine whether the fault is due to the intermittent

connection or to a broken persistent electrical connection (open circuit). Since the device

disables the open rows during the intermittent connection, one possible solution is, on the

customer side, to toggle the EN pin and verify if the fault condition is still present.

In fact, once you disconnect one row, it will result as a off-row (Fault -> open row, latched).

When you connect it again, it is as a shorted led (Vrow higher than the threshold).

TH,FAULT

TH,FAULT

threshold, the device is turned off. The internal logic

This is because the short led detection is still active.

40/60 Doc ID 14248 Rev 7

PM6600 Fault management

If the fault disappears after toggling the EN pin, it means that the connection is again on and

the problem can be detected as a previous intermittent connection.

If the fault persists also after toggling the EN pin, it means that the problem is on the leds

(one or more open leds) or on the flat cable or the cable connector (broken wire).

The resultant Fault Management table will be:

Table 9. Intermittent connection faults management summary

FAULT MODE to GND MODE to VCC

Internal MOSFET over

current

Output over voltage

Thermal shutdown

Shorted LED on a single

row

Shorted LEDs on more row

Open row

More than one

open rows

Open row plus shorted LED

(different rows)

FAULT pin HIGH

power-MOS turned OFF

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

faulty ROW DISABLED

VTH,FAULT = 8.2 V

FAULT pin LOW

device latched OFF

VTH,FAULT = 8.2 V

FAULT pin LOW

faulty ROW DISABLED

FAULT pin LOW

device latched OFF

FAULT pin LOW

device latched OFF

VTH,FAULT = 8.2 V

FAULT pin HIGH

power-MOS turned OFF

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

device turned OFF latched

FAULT pin LOW

faulty ROW DISABLED

VTH,FAULT = 8.2 V

FAULT pin LOW

faulty ROWs DISABLED

VTH,FAULT = 8.2 V

FAULT pin LOW

faulty ROW DISABLED

FAULT pin LOW

faulty ROWs DISABLED

FAULT pin LOW

faulty ROWs DISABLED

VTH,FAULT = 8.2 V

Doc ID 14248 Rev 7 41/60

Package mechanical data PM6600

10 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Table 10. VFQFPN-24 mechanical data

Dim. Min Typ Max

A 0.80 0.90 1.00

A1 0.00 0.02 0.05

A3 0.20

b 0.18 0.25 0.30

D 3.85 4.00 4.15

D2 2.40 2.50 2.60

E 3.85 4.00 4.15

E2 2.40 2.50 2.60

e0.50

L 0.30 0.40 0.50

ddd 0.08

42/60 Doc ID 14248 Rev 7

PM6600 Package mechanical data

Figure 53. VFQFPN-24 mechanical data

Doc ID 14248 Rev 7 43/60

Layout guidelines PM6600

Appendix A Layout guidelines

A.1 Basic points:

● The device thermal pad is SGND.

● The device has 2 GND pins: SGND and PGND

A.1.1 GNDs planes - 1 device

If the pcb has 2 layers, the PGND area has to be in the top layer, together with the LX area

and the Vin and Vout area, in order to reduce the number of the vias.

The SGND plane is the bottom layer of the board and it is also present near the signal

components on the top layer.

The SGND and PGND connection can be made using the thermal pad of the device.

If the pcb has 4 layers, the PGND and SGND planes must be separated into 2 different

layers. Moreover, they must be connected together in only 1 point, near the PGND pin of the

device. It is recommended to duplicate the LX area into one inner layer, to reduce the

impedance and improve the noise rejection immunity of the device.

If the PM6600 device is mounted on a more complex demonstration board (ex. RGB, multidevice application, LCD driver + backlight driver board), the PGND and SGND connection

should be present only near the PGND pin of the device. This is relevant in complex

systems because of the possible cross-talking noise between each block of the system.

In order to connect together the PGND and SGND nets, it is not advisable to use a 0 Ω

resistor, because it can produce a voltage drop between the two GNDs planes and it may

damage the device.

It is preferable to connect together the PGND and SGND to the thermal pad of the device, or

with a short pcb trace near the PGND pin of the device.

A.1.2 GNDs planes - 3 devices (RGB)

The SGND plane is the same for all the PM6600 devices – bottom layer (or internal 2-3).

Each PM6600 device must have its own PGND area (top layer), connected to the main

SGND in one point, near the PGND pin of each device > totally 3 connections between the

SGND and PGND, 1 for each driver:

PGND_red - SGND; PGND_blue - SGND; PGND_green - SGND.

A.2 Compensation network

The components Rcomp – Ccomp of the compensation network should be as close as

possible to the COMP pin of the device. This permits to avoid any noise issue - instability of

the compensation.

This PCB trace should be designed in the opposite side of the device respect to the power

area (according to the pins position). This subdivision improves the noise rejection of the

system and permits to have a stable loop.

44/60 Doc ID 14248 Rev 7

PM6600 Layout guidelines

Take care not to design the LX switching copper area near the COMP network, in order to

avoid cross-talking between the power switching signal and the compensation one.

A very important thing is to keep the feedbacks (ROWs) and compensation traces as short

as possible to minimize noise pick up and to keep them away from noise or field sources

(the switch, diode, inductor). The feedbacks and compensation traces should never pass

under the inductor, switch or diode (even if on opposite sides of the PCB). They should not

run close to and parallel to a noisy (power critical) trace.

A.3 LX area – vout power area

The LX Switching node area should be properly dimensioned ‡ large and short enough to

assure a noise-free working. The power loop of LX, inductor, PGND must be as short as

possible, by mounting L, D, Cout as close as possible one each other. The power area

should be positioned away from the critical signals (mainly the compensation network).

The L, D, Cout components are in the power critical path.

The Cin position is less important than the L, D, Cout. However, it is preferable to have all

the power components in the same side of the device, to reduce the power path length and

to avoid noise coupling between power and signal traces.

A.4 Overvoltage divider

Since the PM6600 works with a compensated divider connected to the OVSEL pin to set the

Overvoltage threshold, the two capacitors should be mounted as close as possible to the

OVSEL pin of the device.

Then you can choose the resistors position near of them.

In the standard PM6600 demonstration board, the capacitors and resistors position is

swapped. This was done because of the need to test the application in different working

conditions.

The capacitors have the priority in the positioning because they clean the OVSEL signal of

the noise caused by the LX switching node.

A.5 LDO5 – AVCC filter

The 2 capacitors should be mounted as close as possible to the LDO5 and VCC pins of the

device. The resistor has to be mounted near of them or it can be omitted (short) where the

PCB dimensions are very small.

A.6 ROWs current generators

The ROWs current generators are referred to SGND. In order to assure the best

performances for current accuracy/mismatch the PCB traces lengths from the ROWs pins to

the LEDs should be the same for all the current generators.

Doc ID 14248 Rev 7 45/60

Layout guidelines PM6600

A.7 Top layer of the standard PM6600 demonstration board

While referring to the PM6600EVAL_EN demonstration board, the PGND and SGND

connections are more than one. In this case the PGND and SGND areas are separated in

the top layer (see Figure 1), while the bottom layer of the demonstration board is a unique

GND plane connected to SGND and PGND with the vias on the thermal pad and the vias

inside the test points.

Since the PM6600EVAL_EN demonstration board is an isolated system, there are no crosstalking issues between the GNDs areas.

When the device is mounted on a LCD board, together with other devices (digital, analog

and power ones), it is very important to properly follow the layout guidelines listed above, in

order to dedicate to each device the PGND and SGND portion of the entire board.

In the picture below:

● COMP > green

● Vin > dark blue

● LX > blue

● Vout > light blue

● PGND > light yellow

● SGND > dark yellow

Figure 54. Top layer critical signals components assembly and layout

Signal components Power components

46/60 Doc ID 14248 Rev 7

PM6600 Layout guidelines

The following pictures are the Gerber files of the PM6600EVAL_EN board.

Figure 55. Top side

1.1 cm

3 cm

Figure 56. Bottom side

Vias specs: diameter 0.8 mm, hole 0.3 mm

Doc ID 14248 Rev 7 47/60

Application note PM6600

Appendix B Application note

B.1 Inductor selection

Being the PM6600 mostly dedicated to notebook backlighting, real-estate applications

dictate severe constrain in selecting the optimal inductor. The inductor choice must take into

account different parameters like conduction losses (DCR), core losses (ferrite or ironpowder), saturation current and magnetic-flux shielding (core shape and technology).

The switching frequency of the PM6600 can be set in the 200 kHz-1 MHz range, allowing a

wide selecting room for the inductance value. Low switching frequencies takes to high

inductance value, resulting in significant DCR and size. On the other hand, high switching

frequencies result in significant core losses. The suggested range is 4.7-22 µH, even if the

best trade off between the different loss contributions varies from manufacturer to

manufacturer.

A 6.8 µH inductor has been experimentally found as the most suitable for applications

running at a 660 kHz switching frequency.

B.2 Capacitors selection