Page 1

查询NAND08GW3B2A供应商

Feature summary

■ High density NAND Flash Memory

– up to 8 Gbit memory array

– Up to 256 Mbit spare area

– Cost effective solution for mass storage

applications

■ NAND Interface

– x8 bus width

– Multiplexed Address/ Data

■ Supply voltage

– 3.0 V device : V

■ Page size

– (2048 + 64 spare) Bytes

■ Block size

– (128K + 4K spare) Bytes

■ Page Read/Program

– Random access: 25µs (max)

– Sequential access: 30ns (min)

– Page program time: 200µs (typ)

■ Copy Back Program mode

– Fast page copy without external buffering

■ Cache Program and Cache Read modes

– Internal Cache Register to improve the

program and read throughputs

■ Fast Block Erase

– Block erase time: 2ms (typ)

■ Status Register

■ Electronic Signature

■ Chip Enable ‘don’t care’

– for simple interface with microcontroller

■ Serial Number option

= 2.7 to 3.6V

DD

NAND04GW3B2B

NAND08GW3B2A

4 Gbit, 8 Gbit, 2112 Byte/1056 Word Page

3V, NAND Flash Memories

PRELIMINARY DATA

TSOP48 12 x 20mm

■ Data protection

– Hardware and Software Block Locking

– Hardware Program/Erase locked during

Power transitions

■ Data integrity

– 100,000 Program/Erase cycles

– 10 years Data Retention

■ ECOPACK

■ Development tools

– Error Correction Code software and

hardware models

– Bad Blocks Management and Wear

Leveling algorithms

– File System OS Native reference software

– Hardware simulation models

®

package

May 2006 Rev 2 1/58

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

1

Page 2

Contents NAND04GW3B2B, NAND08GW3B2A

Contents

1 Summary description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Memory array organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Bad Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Inputs/Outputs (I/O0-I/O7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Address Latch Enable (AL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Command Latch Enable (CL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Chip Enable (E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Read Enable (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Power-Up Read Enable, Loc k/Unlock Enab le (PRL) . . . . . . . . . . . . . . . . 13

3.7 Write Enable (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.8 Write Protect (WP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.9 Ready/Busy (RB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.10 V

3.11 V

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DD

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SS

4 Bus operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Command Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Address Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Command set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Device operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Read Memory Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.1 Random Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.2 Page Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/58

Page 3

NAND04GW3B2B, NAND08GW3B2A Contents

6.2 Cache Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Page Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.1 Sequential Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.2 Random Data Input in page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Copy Back Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.5 Cache Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.6 Block Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.7 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.8 Read Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.8.1 Write Protection Bit (SR7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.8.2 P/E/R Controller and Cache Ready/Busy Bit (SR6) . . . . . . . . . . . . . . . 28

6.8.3 P/E/R Controller Bit (SR5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.8.4 Cache Program Error Bit (SR1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.8.5 Error Bit (SR0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.8.6 SR4, SR3 and SR2 are Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.9 Read Electronic Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Data Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 Blocks Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 Blocks Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Blocks Lock-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.4 Block Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8 Software algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1 Bad Block Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2 Block Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 Garbage Collect ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.4 Wear-leveling Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.5 Error Correction Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.6 Hardware simulation models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.6.1 Behavioral simulation models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.6.2 IBIS simulations models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9 Program and Erase times and endurance cycles . . . . . . . . . . . . . . . . . 40

3/58

Page 4

Contents NAND04GW3B2B, NAND08GW3B2A

10 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.1 Ready/Busy Signal Electrical Charact e risti cs . . . . . . . . . . . . . . . . . . . . . 53

11.2 Data Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12 Package mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4/58

Page 5

NAND04GW3B2B, NAND08GW3B2A List of tables

List of tables

Table 1. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3. Valid Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Bus Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Address Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 6. Address Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 8. Copy Back Program addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 9. Status Register Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 10. Electronic Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 11. Electronic Signature Byte 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 12. Electronic Signature Byte 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 13. Block Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 14. Block Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 15. Program, Erase Times and Program Erase Endurance Cycles . . . . . . . . . . . . . . . . . . . . . 40

Table 16. Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 17. Operating and AC Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 18. Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 19. DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 20. AC Characteristics for Command, Address, Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 21. AC Characteristics for Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 22. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20 mm, Package Mechanical Data. . . 55

Table 23. Ordering Information Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 24. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5/58

Page 6

List of figures NAND04GW3B2B, NAND08GW3B2A

List of figures

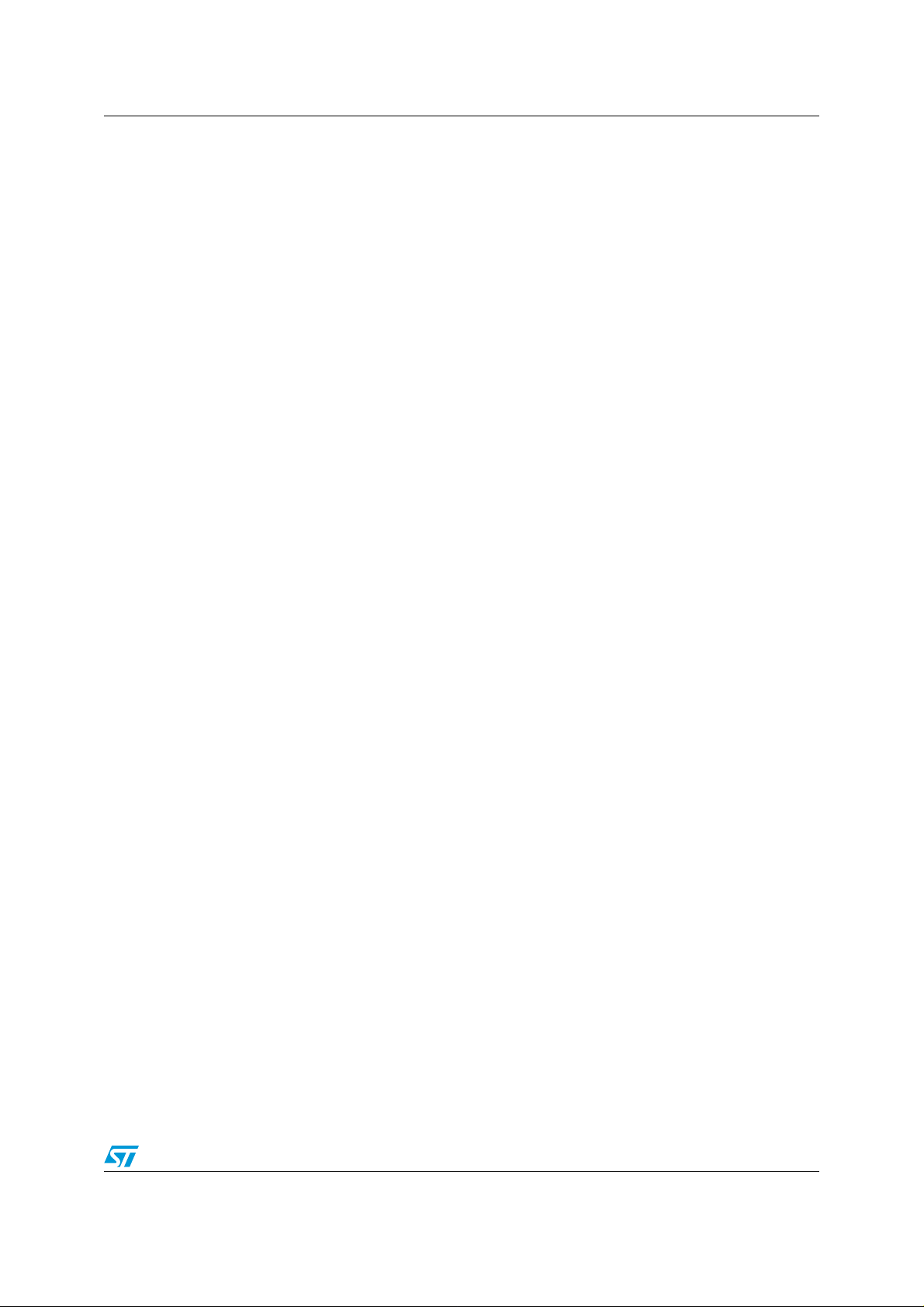

Figure 1. Logic Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

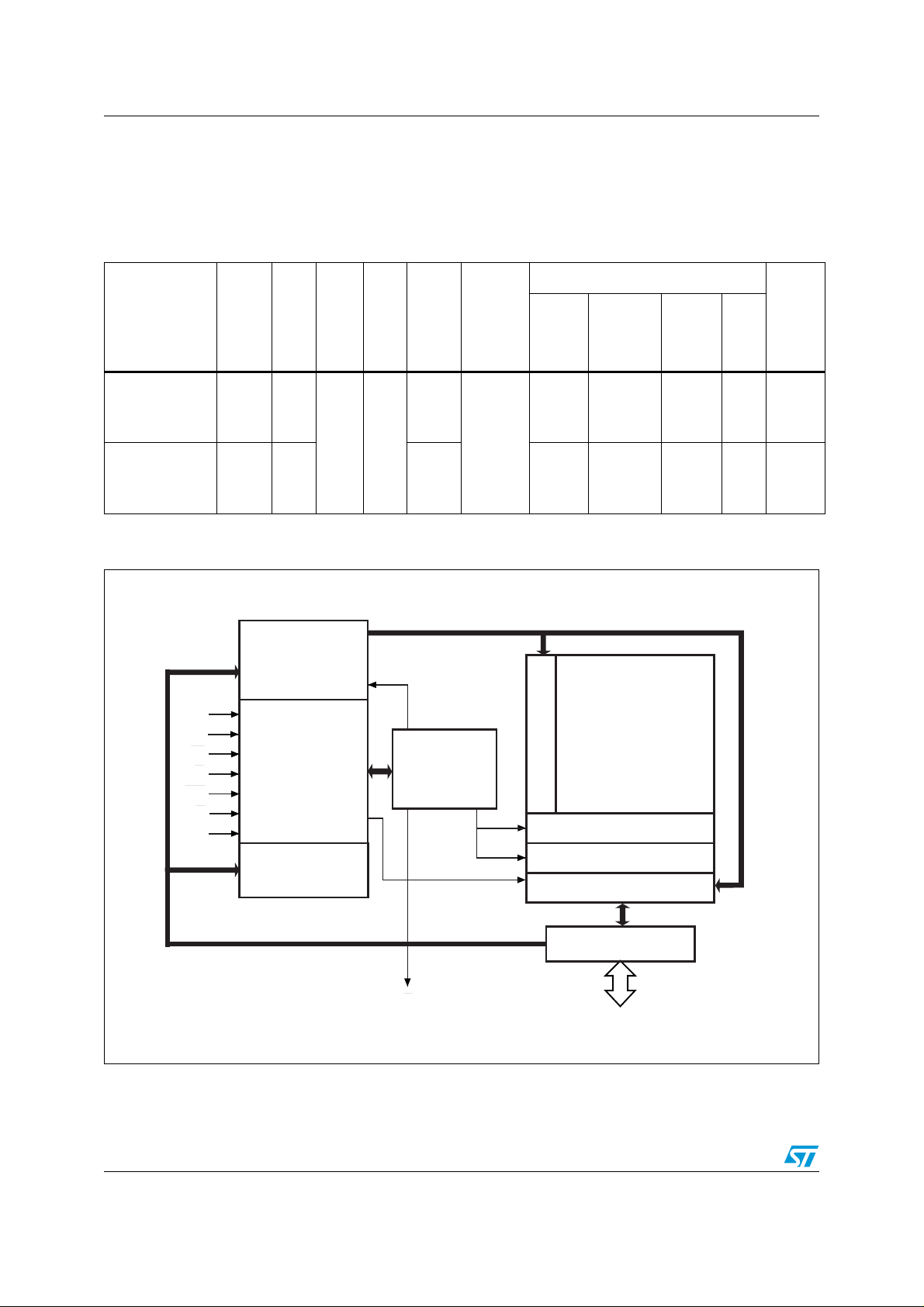

Figure 2. Logic Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

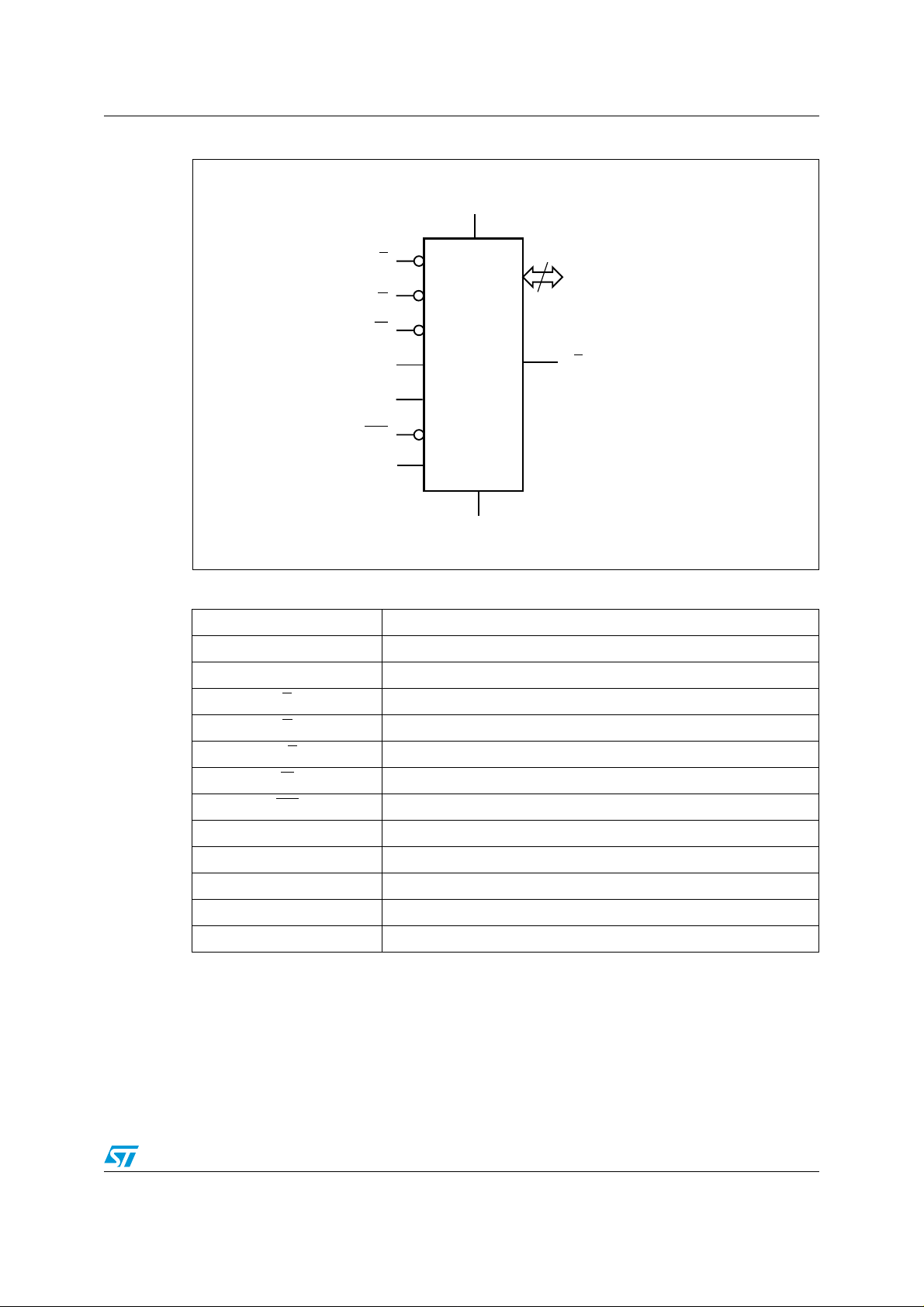

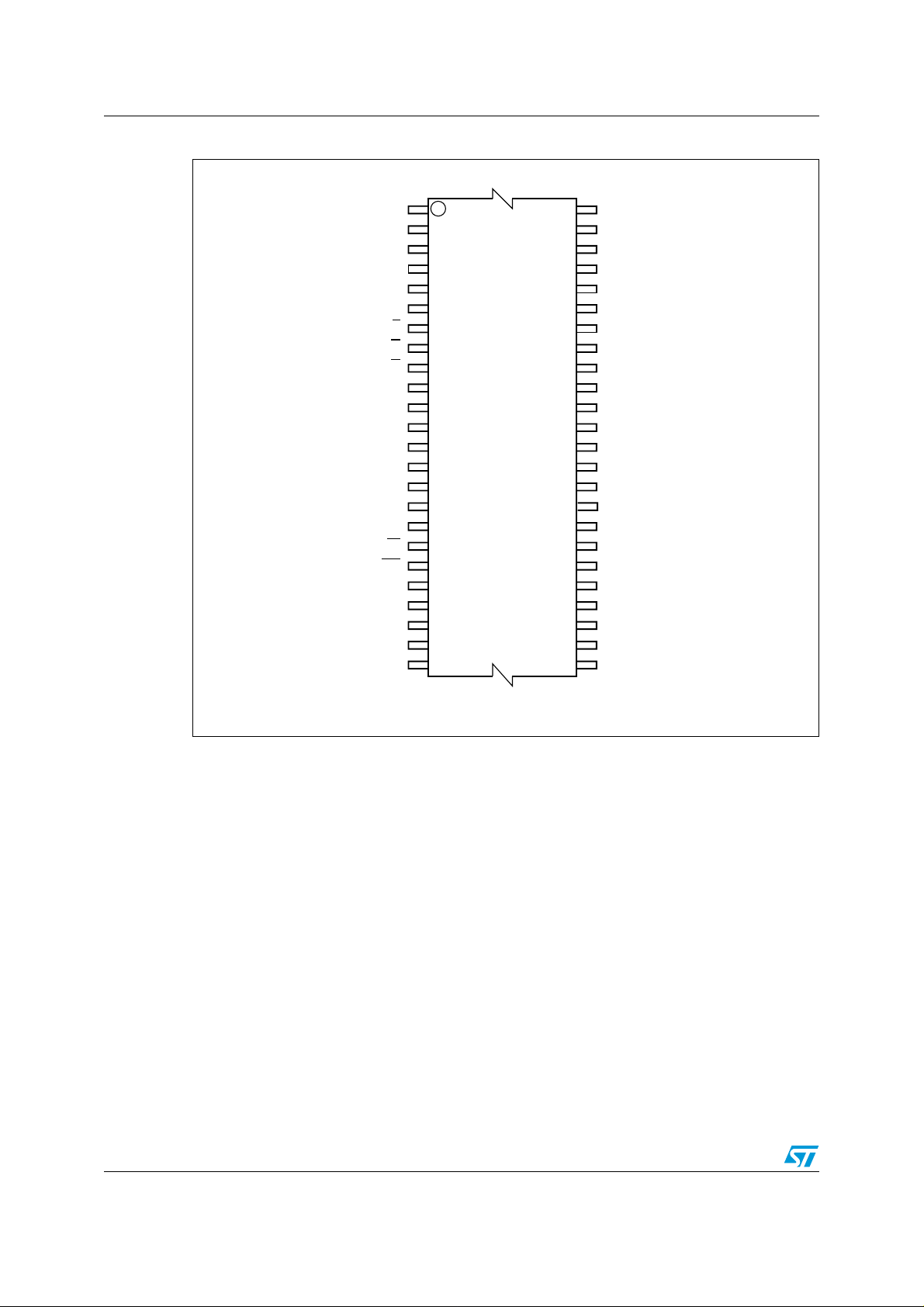

Figure 3. TSOP48 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Memory Array Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Read Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. Random Data Output During Sequential Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 7. Cache Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 8. Page Program Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. Random Data Input During Sequential Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. Copy Back Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 11. Page Copy Back Program with Random Data Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12. Cache Program Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13. Block Erase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 14. Blocks Unlock Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 15. Read Block Lock Status Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 16. Block Protection State Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 17. Bad Block Management Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 18. Garbage Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 19. Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 20. Equivalent Testing Circuit for AC Characteristics Measurement . . . . . . . . . . . . . . . . . . . . 43

Figure 21. Command Latch AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 22. Address Latch AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 23. Data Input Latch AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 24. Sequential Data Output after Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 25. Read Status Register AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 26. Read Electronic Signature AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 27. Page Read Operation AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 28. Page Program AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 29. Block Erase AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 30. Reset AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 31. Program/Erase Enable Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 32. Program/Erase Disable Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 33. Ready/Busy AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 34. Ready/Busy Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 35. Resistor Value Versus Waveform Timings For Ready/Busy Signal . . . . . . . . . . . . . . . . . . 54

Figure 36. Data Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 37. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20 mm, Package Outline . . . . . . . . . . 55

6/58

Page 7

NAND04GW3B2B, NAND08GW3B2A Summary description

1 Summary description

The NAND Flash 2112 Byte/ 1056 Word Page is a family of non-volatile Flash memories

that uses NAND cell technology. The NAND04GW3B2B and NAND08GW3B2A have a

density of 4 Gbits and 8 Gbits, respectively . The y operate from a 3V voltage supply. The size

of a Page is 2112 Bytes (2048 + 64 spare).

The address lines are multiplexed with the Data Input/Output signals on a multiplexed x8

Input/Output bus. This interface reduces the pin count and makes it possible to migrate to

other densities without changing the footprint.

Each block can be programmed and erased over 100,000 cycles. To extend the lifetime of

NAND Flash devices it is strongly recommended to implement an Error Correction Code

(ECC).

The device has hardware and software security features:

● A Write Protect pin is available to give a hardware protection against program and

erase operations.

● A Block Locking scheme is available to provide user code and/or data protection.

The device features an open-drain Ready/Busy output that can be used to identify if the

Program/Erase/Read (P/E/R) Controller is currently active. The use of an open-drain output

allows the Ready/Busy pins from several memories to be connected to a single pull-up

resistor.

A Copy Back Program command is available to optimize the management of defective

blocks. When a Page Program operation fails, the data can be programmed in another page

without having to resend the data to be programmed.

The NAND04GW3B2B and NAND08GW3B2A have Cache Program and Cache Read

features which improve the program and read throughputs for large files. During Cache

Programming, the device loads the data in a Cache Register while the previous data is

transferred to the Page Buffer and programmed into the memory array. During Cache

Reading, the device loads the data in a Cache Register while the previous data is

transferred to the I/O Buffers to be read.

The device has the Chip Enable Don’t Care feature, which allows code to be directly

downloaded by a microcontroller, as Chip Enable transitions during the latency time do not

stop the read operation.

The devices have the option of a Unique Identifier (serial number), which allows each device

to be uniquely identified.

The Unique Identifier options is subject to an NDA (Non Disclosure Agreement) and so not

described in the datasheet. For more details of this option contact your nearest ST Sales

office.

The device is available in a TSOP48 (12 x 20mm) package. In order to meet environmental

requirements, ST offers the NAND04GW3B2B and NAND08GW3B2A in ECOPACK

®

package. ECOPACK packages are Lead-free. The category of second Level Interconnect is

marked on the package and on the inner box label, in compliance with JEDEC Standard

JESD97. The maximum ratings related to soldering conditions are also marked on the inner

box label. ECOPACK is an ST trademark.

7/58

Page 8

Summary description NAND04GW3B2B, NAND08GW3B2A

For information on how to order these options refer to Table 23: Ordering Information

Scheme. Devices are shipped from the factory with Block 0 always valid and the memory

content bits, in valid blocks, erased to ’1’.

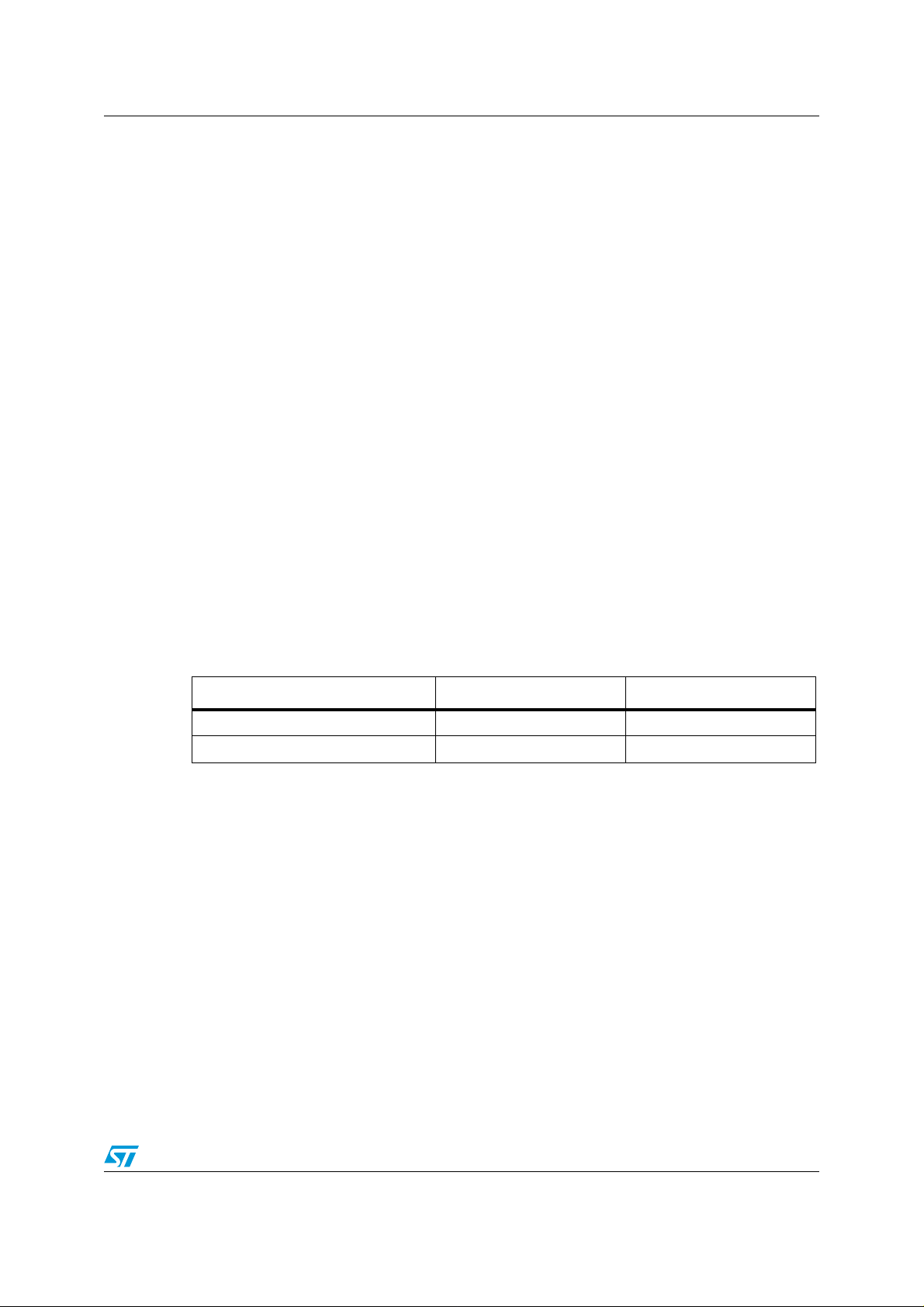

See Table 1: P ro duct Desc r ip tio n, for all the devices available in the family.

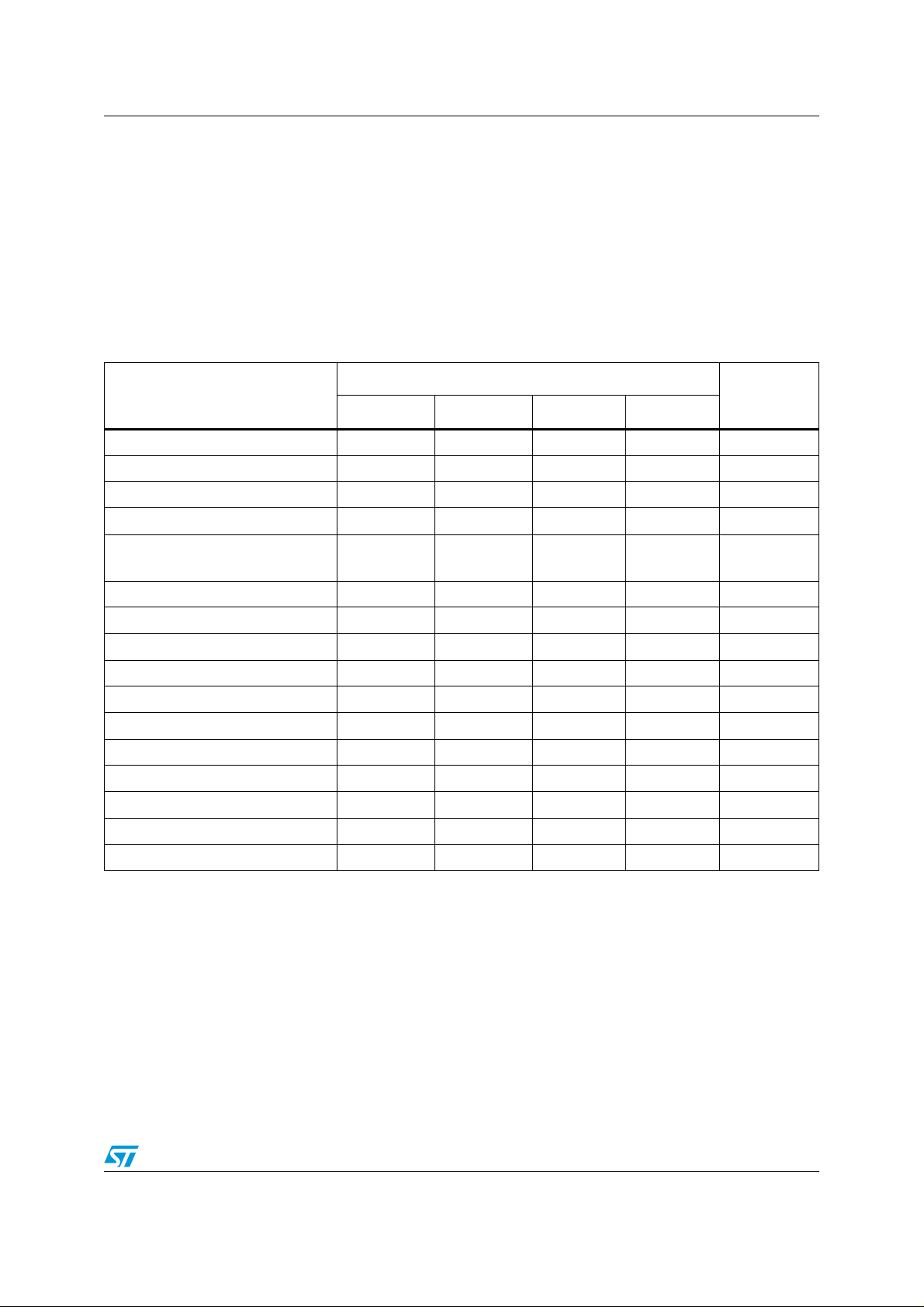

Table 1. Product Description

Part Number Density

NAND04GW3B2B 4 Gb x8

NAND08GW3B2A 8 Gb x8

1. The NAND08GW3B2A is composed of two 4 Gbit dice.

Timings

Bus

Page

Block

Width

Size

2048+

64

Bytes

Size

128K

+4K

Bytes

Memor

y Array

Pages x

Blocks

Pages x

Blocks

64

4096

64

8192

Operating

Voltage

2.7 to

3.6V

Random

access

time

(max)

25µs 30ns 200µs 2ms TSOP48

25µs 30ns 200µs 2ms

Sequential

access

time (min)

Page

Program

(typ)

Block

Erase

(typ)

Package

TSOP48

(1)

Figure 1. Logic Block Diagram

Address

Register/Counter

AL

CL

W

E

WP

R

PRL

Command

Interface

Logic

Command Register

P/E/R Controller,

High V oltage

Generator

RB

NAND Flash

Memory Array

X Decoder

Page Buffer

Cache Register

Y Decoder

I/O Buffers & Latches

I/O0-I/O7

8/58

AI12465

Page 9

NAND04GW3B2B, NAND08GW3B2A Summary description

Figure 2. Logic Diagram

V

DD

WP

PRL

Table 2. Signal Names

I/O0-7 Data Input/Outputs, Address Inputs, or Command Inputs

AL Address Latch Enable

CL Command Latch Enable

E

E

R

W

AL

CL

Chip Enable

NAND FLASH

V

SS

I/O0-I/O7

RB

AI12466b

R

Read Enable

RB Ready/Busy (open-drain output)

W

WP

Write Enable

Write Protect

PRL Power-Up Read Enable, Loc k /U nlock Enable

V

DD

V

SS

Supply Voltage

Ground

NC Not Connected Internally

DU Do Not Use

9/58

Page 10

Summary description NAND04GW3B2B, NAND08GW3B2A

Figure 3. TSOP48 Connections

V

V

NC

NC

NC

NC

NC

NC

RB

NC

NC

DD

SS

NC

NC

CL

AL

W

WP

NC

NC

NC

NC

NC

1

R

E

12

NAND FLASH

13

24 25

48

37

36

NC

NC

NC

NC

I/O7

I/O6

I/O5

I/O4

NC

NC

PRL

V

DD

V

SS

NC

NC

NC

I/O3

I/O2

I/O1

I/O0

NC

NC

NC

NC

10/58

AI12467b

Page 11

NAND04GW3B2B, NAND08GW3B2A Memory array organization

2 Memory array organization

The memory array is made up of NAND structures where 32 cells are connected in series.

The memory array is organized in blocks where each block contains 64 pages. The array is

split into two areas, the main area and the spare area. The main area of the array is used to

store data whereas the spare area is typically used to store Error correction Codes, software

flags or Bad Block identification.

The pages are split into a 2048 Byte main area and a spare area of 64 Bytes. Refer to

Figure 4: Memory Array Organization.

2.1 Bad Blocks

The NAND Flash 2112 Byte/ 1056 Word Page devices may contain Bad Blocks, that is

blocks that contain one or more invalid bits whose reliability is not guaranteed. Additional

Bad Blocks may develop during the lifetime of the device.

The Bad Block Information is written prior to shipping (refer to Section 8.1: Bad Block

Management for more details).

Table 3 shows the minimum number of valid blocks. The values shown include both the Bad

Blocks that are present when the device is shipped and the Bad Blocks that could develop

later on.

These blocks need to be managed using Bad Blocks Management, Block Replacement or

Error Correction Codes (refer to Section 8: Software algorithms).

Table 3. Valid Blocks

Density of Device Min Max

4 Gbits 4016 4096

(1)

8 Gbits

1. The NAND08GW3B2A is composed of two 4 Gbit dice.

8032 8192

11/58

Page 12

Memory array organization NAND04GW3B2B, NAND08GW3B2A

Figure 4. Memory Array Organization

x8 bus width

Block = 64 Pages

Page = 2112 Bytes (2,048 + 64)

Block

Page

Main Area

2048 Bytes

Page Buffer, 2112 Bytes

2,048 Bytes

Bytes

Bytes

64

64

Spare Area

8 bits

8 bits

AI12468

12/58

Page 13

NAND04GW3B2B, NAND08GW3B2A Signal descriptions

3 Signal descriptions

See Figure 2: Logic Diagram, and Table 2: Signal Names, for a brief overview of the signals

connected to this device.

3.1 Inputs/Outputs (I/O0-I/O7)

Input/Outputs 0 to 7 are used to input the selected address, output the data during a Read

operation or input a command or data during a Write operation. The inputs are latched on

the rising edge of Write Enable. I/O0-I/O7 are left floating when the device is deselected or

the outputs are disabled.

3.2 Address Latch Enable (AL)

The Address Latch Enable activates the latching of the Address inputs in the Command

Interface. When AL is high, the inputs are latched on the rising edge of Write Enable.

3.3 Command Latch Enable (CL)

The Command Latch Enable activates the latching of the Command inputs in the Command

Interface. When CL is high, the inputs are latched on the rising edge of Write Enable.

3.4 Chip Enable (E)

The Chip Enable input activates the memory control logic, input buffers, decoders and

sense amplifiers. When Chip Enable is low, V

high, v

mode.

, while the device is busy, the device remains selected and does not go into standby

IH

, the device is selected. If Chip Enable goes

IL

3.5 Read Enable (R)

The Read Enable pin, R, controls the sequential data output during Read operations. Data

is valid t

column address counter by one.

after the falling edge of R. The falling edge of R also increments the internal

RLQV

3.6 Power-Up Read Enable, Lock/Unlock Enable (PRL)

The Power-Up Read Enable, Lock/Unlock Enable input, PRL, is used to enable and disable

the lock mechanism. When PRL is High, V

If the Power-Up Read Enable, Lock/Unlock Enable input is not required, the PRL pin should

be left unconnected (Not Connected) or connected to V

, the device is in Block Lock mode.

IH

.

SS

13/58

Page 14

Signal descriptions NAND04GW3B2B, NAND08GW3B2A

3.7 Write Enable (W)

The Write Enable input, W, controls writing to the Command Interface, Input Address and

Data latches. Both addresses and data are latched on the rising edge of Write Enable.

During power-up and power-down a recovery time of 10µs (min) is required before the

Command Interface is ready to accept a command. It is recommended to keep Write Enable

high during the recovery time.

3.8 Write Protect (WP)

The Write Protect pin is an input that gives a hardware protection against unwanted program

or erase operations. When Write Protect is Low, V

program or erase operations.

, the device does not accept any

IL

It is recommended to keep the Write Protect pin Low, V

3.9 Ready/Busy (RB)

The Ready/Busy output, RB, is an open-drain output that can be used to identify if the P/E/R

Controller is currently active.

When Ready/Busy is Low, V

operation completes Ready/Busy goes High, V

The use of an open-drain output allows the Ready/Busy pins from several memories to be

connected to a single pull-up resistor. A Low will then indicate that one, or more, of the

memories is busy.

Refer to the Section 11.1: Ready/Busy Signal Electrical Characteristics for details on how to

calculate the value of the pull-up resistor.

3.10 V

Supply Voltage

DD

VDD provides the power supply to the internal core of the memory device. It is the main

power supply for all operations (read, program and erase).

An internal voltage detector disables all functions whenever V

Table 19) to protect the device from any involuntary program/erase during power-transitions.

, during po we r-u p an d po w er- do wn .

IL

, a read, program or erase operation is in progress. When the

OL

OH

.

is below V

DD

LKO

(see

Each devi ce in a sys tem sh oul d h a ve V

widths should be sufficient to carry the required program and erase currents

3.11 VSS Ground

Ground, V

ground.

14/58

is the reference for the power supply. It must be connected to the system

SS,

decoupled with a 0.1µF capacitor. The PCB track

DD

Page 15

NAND04GW3B2B, NAND08GW3B2A Bus operations

4 Bus operations

There are six standard bus operations that control the memory. Each of these is described

in this section, see Table 4: Bus Op eratio n s, for a summary.

Typically, glitches of less than 5 ns on Chip Enable, Write Enable and Read Enable are

ignored by the memory and do not affect bus operations.

4.1 Command Input

Command Input bus operations are used to give commands to the memory.

The Commands are input on I/O0-I/O7. Commands are accepted when Chip Enable is Low,

Command Latch Enable is High, Address Latch Enable is Low and Read Enable is High.

They are latched on the rising edge of the Write Enable signal.

See Figure 21 and Table 20 for details of the timings requirements.

4.2 Address Input

Address Input bus operations are used to input the memory addresses.

Addresses are input on I/O0-I/O7. Five bus cycles are required to input the addresses (refer

to Table 5: Address Insertion).

The addresses are accepted when Chip Enable is Low, Address Latch Enable is High,

Command Latch Enable is Low and Read Enable is High. They are latched on the rising

edge of the Write Enable signal.

See Figure 22 and Table 20 for details of the timings requirements.

4.3 Data Input

Data Input bus operations are used to input the data to be programmed.

Data is accepted only when Chip Enable is Low, Address Latch Enable is Low, Command

Latch Enable is Low and Read Enable is High. The data is latched on the rising edge of the

Write Enable signal. The data is input sequentially using the Write Enable signal.

See Figure 23 and Table 20 and Table 21 for details of the timings requirements.

4.4 Data Output

Data Output bus operations are used to read: the data in the memory array, the Status

Register, the lock status, the Electronic Signature and the Unique Identifier.

Data is output when Chip Enable is Low , Write Enable is High, Address Latch Enable is Low,

and Command Latch Enable is Low.

The data is output sequentially using the Read Enable signal.

See Figure 24 and Table 21 for details of the timings requirements.

15/58

Page 16

Bus operations NAND04GW3B2B, NAND08GW3B2A

4.5 Write Protect

Write Protect bus operations are used to protect the memory against program or erase

operations. When the Write Protect signal is Low the device will not accept program or erase

operations and so the contents of the memory array cannot be altered. The Write Protect

signal is not latched by Write Enable to ensure protection even during power-up.

4.6 Standby

When Chip Enable is High the memory enters Standby mode, the device is deselected,

outputs are disabled and power consumption is reduced.

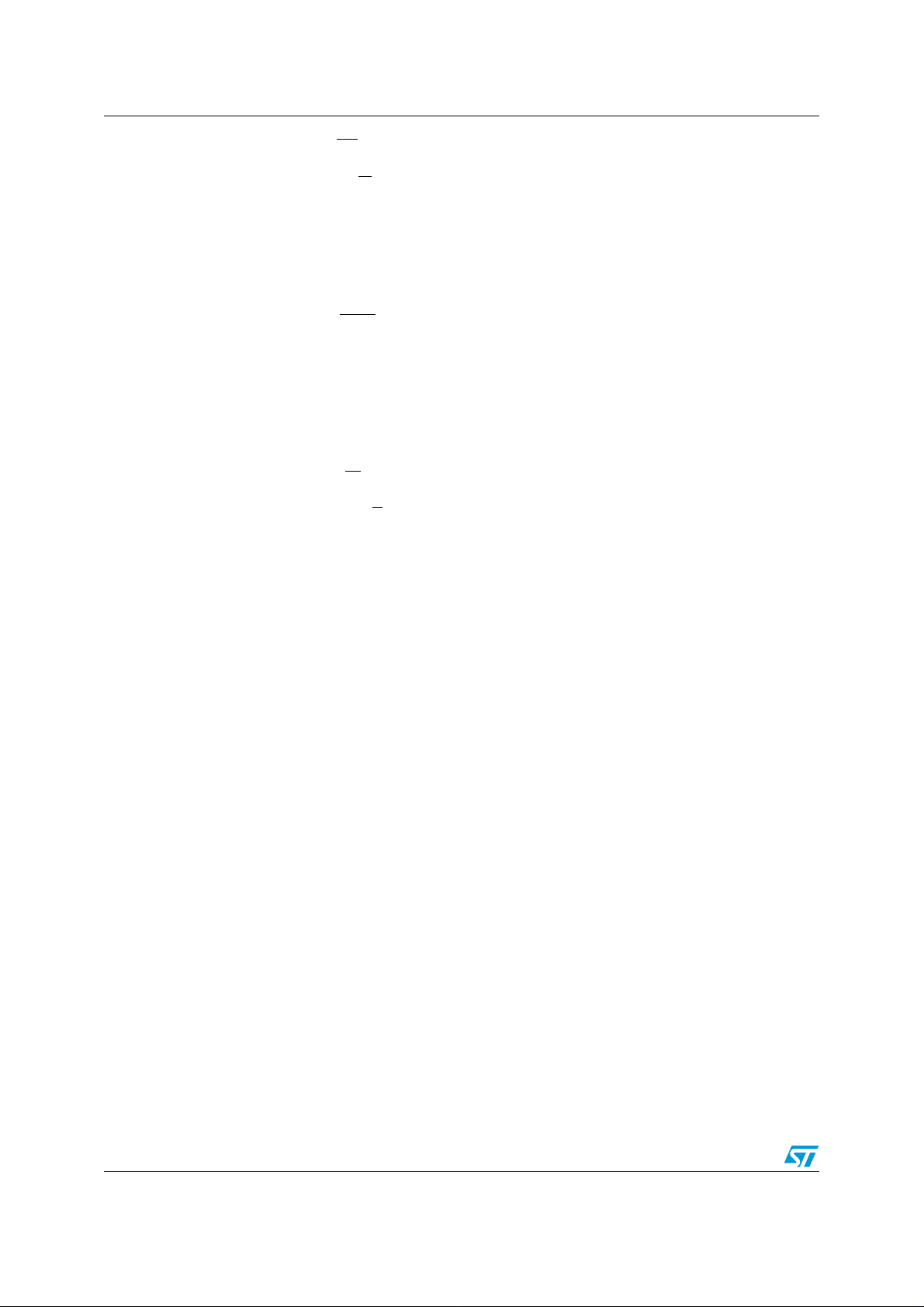

Table 4. Bus Operations

Bus Operation E AL CL R W WP I/O0 - I/O7

Command Input V

Address Input V

Data Input V

Data Output V

IL

IL

IL

IL

V

V

V

V

V

IL

IH

IL

IL

IH

V

IL

V

IL

V

IL

V

V

V

Rising X

IH

Rising X Address

IH

Rising V

IH

Falling V

Write Protect X X X X X V

Standby V

1. WP must be VIH when issuing a program or erase command.

Command set

Table 5. Address Insertion

IH

XXXXV

IH

(1)

IH

Command

Data Input

X Data Output

IL

IL/VDD

X

X

Bus

Cycle

st

1

nd

2

rd

3

th

4

th

5

1. Any additional address input cycles will be ignored.

2. A30 is only valid for the NAND08GW3B2A.

I/O7 I/O6 I/O5 I/O4 I/O3 I/O2 I/O1 I/O0

(1)

A7 A6 A5 A4 A3 A2 A1 A0

V

IL

V

IL

V

IL

A19 A18 A17 A16 A15 A14 A13 A12

A27 A26 A25 A24 A23 A22 A21 A20

V

IL

V

IL

V

IL

Table 6. Address Definition

Address Definition

A0 - A11 Column Address

A12 - A17 Page Address

A18 - A29 Block Address (NAND04GW3B2B)

A18 - A30 Block Address (NAND08GW3B2A)

V

IL

V

IL

A11 A10 A9 A8

V

IL

A30

(2)

A29 A28

16/58

Page 17

NAND04GW3B2B, NAND08GW3B2A Command set

5 Command set

All bus write operations to the device are interpreted by the Command Interface. The

Commands are input on I/O0-I/O7 and are latched on the rising edge of Write Enable when

the Command Latch Enable signal is high. Device operations are selected by writing

specific commands to the Command Register. The two-step command sequences for

program and erase operations are imposed to maximize data security.

The Commands are summarized in Table 7.

Table 7. Commands

Read 00h

Random Data Output 05h E0h – –

Cache Read 00h 31h – –

Exit Cache Read 34h – – – Yes

Page Program

(Sequential Input def a ult )

Random Data Input 85h – – –

Command

Bus Write Operations

(1)

1st cycle 2nd cycle 3rd cycle 4th cycle

(2)

30h – –

80h 10h – –

Commands

accepted

during busy

(3)

Copy Back Program 00h 35h 85h 10h

Cache Program 80h 15h – –

Block Erase 60h D0h – –

Reset FFh – – – Yes

Read Electronic Signature 90h – – –

Read Status Register 70h – – – Yes

Read Block Lock Status 7Ah – – –

Blocks Unlock 23h 24h – –

Blocks Lock 2Ah – – –

Blocks Lock-Down 2Ch – – –

1. The bus cycles are only shown for issuing the codes. The cycles required to input the addresses or input/output data are

not shown.

2. For consecutive Read operations the 00h command does not need to be repeated.

3. Only during Cache Read busy.

17/58

Page 18

Device operations NAND04GW3B2B, NAND08GW3B2A

6 Device operations

The following section gives the details of the device operations.

6.1 Read Memory Array

At Power-Up the device defaults to Read mode. T o enter Read mode from another mode the

Read command must be issued, see Table 7: Commands. Once a Read command is

issued, subsequent consecutive Read commands only require the confirm command code

(30h).

Once a Read command is issued two types of operations are available: Random Read and

Page Read.

6.1.1 Random Read

Each time the Read command is issued the first read is Random Read.

6.1.2 Page Read

After the first Random Read access, the page data (2112 Bytes) are transferred to the Page

Buffer in a time of t

Ready/Busy signal goes High. The data can then be read out sequentially (from selected

column address to last column address) by pulsing the Read Enable signal.

The device can output random data in a page, instead of the consecutive sequential data, by

issuing a Random Data Output command.

The Random Data Output command can be used to skip some data during a sequential

data output.

The sequential operation can be resumed by changing the column address of the next data

to be output, to the address which follows the Random Data Output command.

The Random Data Output command can be issued as many times as required within a

page.

The Random Data Output command is not accepted during Cache Read operations.

(refer to Table 21 for value). Once the transfer is complete the

WHBH

18/58

Page 19

NAND04GW3B2B, NAND08GW3B2A Device operations

Figure 5. Read Operations

CL

E

W

AL

R

tBLBH1

RB

I/O

00h

Command

Code

Address Input

30h

Command

Code

Data Output (sequentially)

Busy

ai12469

19/58

Page 20

Device operations NAND04GW3B2B, NAND08GW3B2A

Figure 6. Random Data Output During Sequential Data Output

tBLBH1

RB

R

(Read Busy time)

Busy

I/O

Row Add 1,2,3

00h

Cmd

Code

Address

Inputs

5 Add cycles

Col Add 1,2

30h

Cmd

Code

Main Area

Data Output

Spare

Area

05h

Cmd

Code

Address

Inputs

2Add cycles

Col Add 1,2

E0h

Cmd

Code

Main Area

Data Output

Spare

Area

ai08658

20/58

Page 21

NAND04GW3B2B, NAND08GW3B2A Device operations

6.2 Cache Read

The Cache Read operation is used to improve the read throughput by reading data using

the Cache Register. As soon as the user starts to read one page, the device automatically

loads the next page into the Cache Register.

An Cache Read operation consists of three steps (see Table 7: Commands):

1. One bus cycle is required to setup the Cache Read command (the same as the

standard Read command).

2. Five (refer to Table 5: Address Insertion) bus cycles are then required to input the Start

Address.

3. One bus cycle is required to issue the Cache Read confirm command to start the P/E/R

Controller.

The Start Address must be at the beginning of a page (Column Address = 00h, see Table 6:

Address Definition). This allows the data to be output uninterrupted after the latency time

(t

The Ready/Busy signal can be used to monitor the start of the operation. During the latency

period the Ready/Busy signal goes Low, after this the Ready/Busy signal goes High, even if

the device is internally downloading page n+1.

Once the Cache Read operation has started, the Status Register can be read using the

Read Status Register command.

), see Figure 7: Cache Read Operation.

BLBH1

During the operation, SR5 can be read, to find out whether the internal reading is ongoing

(SR5 = ‘0’), or has completed (SR5 = ‘1’), while SR6 indicates whether the Cache Register

is ready to download new data.

To exit the Cache Read operation an Exit Cache Read command must be issued (see

Table 7: Commands).

If the Exit Cache Read command is issued while the device is internally reading page n+1,

page n will still be output, but not page n+1.

Figure 7. Cache Read Operation

tBLBH1

(Read Busy time)

RB

R

I/O

00h

Read

Setup

Code

Address

Inputs

31h

Cache

Read

Confirm

Code

Busy

tRHRL2

1st page

2nd page

3rd page

Block N

tRHRL2

Data Output

last page

tBLBH4

34h

Exit

Cache

Read

Code

ai8661c

21/58

Page 22

Device operations NAND04GW3B2B, NAND08GW3B2A

6.3 Page Program

The Page Program operation is the standard operation to program data to the memory

array. Generally, the page is programmed sequentially, however the device does support

Random Input within a page.

It is recommended to address pages sequentially within a given block.

The memory array is programmed by page, however partial page programming is allowed

where any number of Bytes (1 to 2112) can be programmed.

The maximum number of consecutive partial page program operations allowed in the same

page is four. After exceeding this a Block Erase command must be issued before any further

program operations can take place in that page.

6.3.1 Sequential Input

To input data sequentially the addresses must be sequential and remain in one block.

For Sequential Input each Page Program operation consists of five steps (see Figure 8:

Page Program Operation):

1. One bus cycle is required to setup the Page Program (Sequential Input) command (see

Table 7: Commands).

2. Five bus cycles are then required to input the program address (refer to Table 5:

Address Insertion).

3. The data is then loaded into the Data Registers.

4. One bus cycle is required to issue the Page Program confirm command to start the

P/E/R Controller. The P/E/R will only start if the data has been loaded in step 3.

5. the P/E/R Controller then programs the data into the array.

6.3.2 Random Data Input in page

During a Sequential Input operation, the next sequential address to be programmed can be

replaced by a random address, by issuing a Random Data Input command. The following

two steps are required to issue the command:

1. One bus cycle is required to setup the Random Data Input command (see Table 7:

Commands)

2. Two bus cycles are then required to input the new column address (refer to Table 5:

Address Insertion)

Random Data Input can be repeated as often as required in any given page.

Once the program operation has started the Status Register can be read using the Read

Status Register command. During program operations the Status Register will only flag

errors for bits set to '1' that have not been successfully programmed to '0'.

During the program operation, only the Read Status Register and Reset commands will be

accepted, all other commands will be ignored.

Once the program operation has completed the P/E/R Controller bit SR6 is set to ‘1’ and the

Ready/Busy signal goes High.

The device remains in Read Status Register mode until another valid command is written to

the Command Interface.

22/58

Page 23

NAND04GW3B2B, NAND08GW3B2A Device operations

Figure 8. Page Program Operation

tBLBH2

RB

(Program Busy time)

Busy

I/O

80h

Page Program

Setup Code

Address Inputs

Data Input

Figure 9. Random Data Input During Sequential Data Input

RB

I/O

80h

Cmd

Code

Address

Inputs

5 Add cycles

Col Add 1,2Row Add 1,2,3

Data Intput

Main Area

Code

Spare

Area

85h

Cmd

Address

Inputs

2 Add cycles

Col Add 1,2

Data Input

10h

Confirm

Code

tBLBH2

(Program Busy time)

10h

Confirm

Code

Main Area

70h

Read Status Register

Busy

70h

Read Status Register

Spare

Area

SR0

ai08659

SR0

ai08664

23/58

Page 24

Device operations NAND04GW3B2B, NAND08GW3B2A

6.4 Copy Back Pr ogram

The Copy Back Program operation is used to copy the data stored in one page and

reprogram it in another page.

The Copy Back Program operation does not require external memory and so the operation

is faster and more efficient because the reading and loading cycles are not required. The

operation is particularly useful when a portion of a block is updated and the rest of the block

needs to be copied to the newly assigned block.

If the Copy Back Program operation fails an error is signalled in the Status Register.

However as the standard external ECC cannot be used with the Copy Back Program

operation bit error due to charge loss cannot be detected. For this reason it is recommended

to limit the number of Copy Back Program operations on the same data and or to improve

the performance of the ECC.

The Copy Back Program operation requires four steps:

1. The first step reads the source page. The operation copies all 2112 Bytes from the

page into the Data Buffer. It requires:

– One bus write cycle to setup the command

– 5 bus write cycles to input the source page address

– One bus write cycle to issue the confirm command code

2. When the device returns to the ready state (Ready/Busy High), the next bus write cycle

of the command is given with the 5 bus cycles to input the target page address. See

Table 8 for the addresses that must be the same for the source and target page.

3. Then the confirm command is issued to start the P/E/R Controller.

To see the Data Input cycle for modifying the source page and an example of the Copy Back

Program operation refer to Figure 10: Copy Back Program.

A data input cycle to modify a portion or a multiple distant portion of the source page, is

shown in Figure 11: Page Copy Back Program with Random Data Input.

Table 8. Copy Back Program addresses

Density Source and target page addresses

4 Gbits no constraint

8 Gbits same A30

Figure 10. Copy Back Program

I/O

00h

Read

Code

RB

1. Copy back program is only permitted between odd address pages or even address pages.

Source

Add Inputs

35h

tBLBH1

(Read Busy time)

Busy

85h

Copy Back

Code

Target

Add Inputs

(Program Busy time)

10h 70h SR0

Read Status Register

tBLBH2

Busy

ai09858b

24/58

Page 25

NAND04GW3B2B, NAND08GW3B2A Device operations

Figure 11. Page Copy Back Program with Random Data Input

RB

I/O

00h

Read

Code

Source

Add Inputs

(Read Busy time)

35h

tBLBH1

Copy Back

Busy

85h

Code

Target

Add Inputs

85h Data

Data

Unlimited number of repetitions

2 Cycle

Add Inputs

10h 70h

tBLBH2

(Program Busy time)

SR0

Busy

ai11001

25/58

Page 26

Device operations NAND04GW3B2B, NAND08GW3B2A

6.5 Cache Program

The Cache Program operation is used to improve the programming throughput by

programming data using the Cache Register. The Cache Program operation can only be

used within one block. The Cache Register allows new data to be input while the previous

data that was transferred to the Page Buffer is programmed into the memory array.

The following sequence is required to perform a Cache Program operation (refer to

Figure 12: Cache Program Operation):

1. First of all the program setup command is issued (one bus cycle to issue the program

setup command then five bus write cycles to input the address), the data is then input

(up to 2112 Bytes) and loaded into the Cache Register.

2. One bus cycle is required to issue the confirm command to start the P/E/R Controller.

3. The P/E/R Controller then transfers the data to the Page Buffer. During this the device

is busy for a time of t

4. Once the data is loaded into the Page Buffer the P/E/R Controller programs the data

into the memory array. As soon as the Cache Registers are empty (after t

Cache program command can be issued, while the internal programming is still

executing.

Once the program operation has started the Status Register can be read using the Read

Status Register command. During Cache Program operations SR5 can be read to find out

whether the internal programming is ongoing (SR5 = ‘0’) or has completed (SR5 = ‘1’) while

SR6 indicates whether the Cache Register is ready to accept new data. If any errors have

been detected on the previous page (Page N-1), the Cache Program Error Bit SR1 will be

set to ‘1', while if the error has been detected on Page N the Error Bit SR0 will be set to '1’.

WHBH2

.

) a new

WHBH2

When the next page (Page N) of data is input with the Cache Program command, t

affected by the pending internal programming. The data will only be transferred from the

Cache Register to the Page Buffer when the pending program cycle is finished and the Page

Buffer is available.

If the system monitors the progress of the operation using only the Ready/Busy signal, the

last page of data must be programmed with the Page Program confirm command (10h).

If the Cache Program confirm command (15h) is used instead, Status Register bit SR5 must

be polled to find out if the last programming is finished before starting any other operations.

Figure 12. Cache Program Operation

tBLBH5

(Cache Busy time)

RB

Busy

80h

Page

Program

Code

CACHEPG

Address

Inputs

is the program time for the last page + the program time for the (last − 1)th page − (Program command cycle time

I/O

1. Up to 64 pages can be programmed in one Cache Program operation.

2. t

+ Last page data loading time).

Data

Inputs

First Page

15h

Cache

Program

Code

Address

80h

Inputs

Page

Program

Code

Second Page

(can be repeated up to 63 times)

tBLBH5 tCACHEPG

Data

15h

Inputs

Cache Program

Confirm Code

Busy

Address

Inputs

Last Page

Data

Inputs

Page

Program

Confirm Code

Busy

WHBH2

SR070h80h 10h

Read Status

Register

ai08672

is

26/58

Page 27

NAND04GW3B2B, NAND08GW3B2A Device operations

6.6 Block Erase

Erase operations are done one block at a time. An erase operation sets all of the bits in the

addressed block to ‘1’. All previous data in the block is lost.

An erase operation consists of three steps (refer to Figure 13: Block Erase Operation):

1. One bus cycle is required to setup the Block Erase command. Only addresses A18A29 are used, the other address inputs are ignored.

2. Three bus cycles are then required to load the address of the block to be erased. Refer

to Table 6: Address Definition for the bloc k addresses of each device.

3. One bus cycle is required to issue the Block Erase confirm command to start the P/E/R

Controller.

The operation is initiated on the rising edge of write Enable, W

is issued. The P/E/R Controller handles Block Erase and implements the verify process.

During the Block Erase operation, only the Read Status Register and Reset commands will

be accepted, all other commands will be ignored.

Once the program operation has completed the P/E/R Controller bit SR6 is set to ‘1’ and the

Ready/Busy signal goes High. If the operation completed successfully, the Write Status Bit

SR0 is ‘0’, otherwise it is set to ‘1’.

Figure 13. Block Erase Operation

RB

I/O

60h

Block Erase

Setup Code

Block Address

Inputs

6.7 Reset

D0h

Confirm

Code

tBLBH3

(Erase Busy time)

Busy

, after the confirm command

70h

Read Status Register

SR0

ai07593

The Reset command is used to reset the Command Interface and Status Register. If the

Reset command is issued during any operation, the operation will be aborted. If it was a

program or erase operation that was aborted, the contents of the memory locations being

modified will no longer be valid as the data will be partially programmed or erased.

If the device has already been reset then the new Reset command will not be accepted.

The Ready/Busy signal goes Low for t

of t

depends on the operation that the device was performing when the command was

BLBH4

after the Reset command is issued. The value

BLBH4

issued, refer to Table 21 for the values.

27/58

Page 28

Device operations NAND04GW3B2B, NAND08GW3B2A

6.8 Read Status Register

The device contains a Status Register which provides information on the current or previous

Program or Erase operation. The various bits in the Status Register convey information and

errors on the operation.

The Status Register is read by issuing the Read Status Register command. The Status

Register information is present on the output data bus (I/O0-I/O7) on the falling edge of Chip

Enable or Read Enable, whichever occurs last. When several memories are connected in a

system, the use of Chip Enable and Read Enable signals allows the system to poll each

device separately , e ven when the Ready/Busy pins are common-wired. It is not necessary to

toggle the Chip Enable or Read Enable signals to update the contents of the Status

Register.

After the Read Status Register command has been issued, the device remains in Read

Status Register mode until another command is issued. Therefore if a Read Status Register

command is issued during a Random Read cycle a new Read command must be issued to

continue with a Page Read operation.

The Status Register bi ts are summarized in Table 9: Status Register Bits,. Refer to Table 9:

Status Register Bits in conjunction with the following text descriptions.

6.8.1 Write Protection Bit (SR7)

The Write Protection bit can be used to identify if the device is protected or not. If the Write

Protection bit is set to ‘1’ the device is not protected and program or erase operations are

allowed. If the Write Protection bit is set to ‘0’ the device is protected and program or erase

operations are not allowed.

6.8.2 P/E/R Controller and Cache Ready/Busy Bit (SR6)

Status Register bit SR6 has two different functions depending on the current operation.

During Cache operations SR6 acts as a Cache Ready/Busy bit, which indicates whether the

Cache Register is ready to accept new data. When SR6 is set to '0', the Cache Register is

busy and when SR6 is set to '1', the Cache Register is ready to accept new data.

During all other operations SR6 acts as a P/E/R Controller bit, which indicates whether the

P/E/R Controller is active or inactive. When the P/E/R Controller bit is set to ‘0’, the P/E/R

Controller is active (device is busy); when the bit is set to ‘1’, the P/E/R Controller is inactive

(device is ready).

6.8.3 P/E/R Controller Bit (SR5)

The Program/Erase/Read Controller bit indicates whether the P/E/R Controller is active or

inactive. When the P/E/R Controller bit is set to ‘0’, the P/E/R Controller is active (device is

busy); when the bit is set to ‘1’, the P/E/R Controller is inactive (device is ready).

6.8.4 Cache Program Error Bit (SR1)

The Cache Program Error bit can be used to identify if the previous page (page N-1) has

been successfully programmed or not in a Cache Program operation. SR1 is set to ’1’ when

28/58

Page 29

NAND04GW3B2B, NAND08GW3B2A Device operations

the Cache Program operation has failed to program the previous page (page N-1) correctly.

If SR1 is set to ‘0’ the operation has completed successfully.

The Cach e Program Error bit is only valid during Cache Program operations, during other

operations it is Don’t Care.

6.8.5 Error Bit (SR0)

The E r r o r bit is used to identify if any errors have been detected by the P/E/R Controller. The

Error Bit is set to ’1’ when a program or erase operation has failed to write the correct data to

the memory. If the Error Bit is set to ‘0’ the operation has completed successfully. The Error

Bit SR0, in a Cache Program operation, indicates a failure on Page N.

6.8.6 SR4, SR3 and SR2 are Reserved

Table 9. Status Register Bits

SR7 Write Protection

SR6

SR5

SR4, SR3, SR2 Reserved

SR1 Cache Program Error

SR0

Bit Name Logic Level Definition

'1' Not Protected

'0' Protected

Program/ Erase/ Read

Controller

Cache Ready/Busy

Program/ Erase/ Read

Controller

Generic Error

Cache Program Error

(1)

(2)

'1' P/E/R C inactive, device ready

'0' P/E/R C active, device busy

'1' Cache Register ready (Cache only)

'0' Cache Register busy (Cache only)

'1' P/E/R C inactive, device ready

'0' P/E/R C active, device busy

Don’t Care

'1' Page N-1 failed in Cache Program operation

'0' Page N-1 programmed successfully

‘1’ Error – operation failed

‘0’ No Error – operat ion successfu l

‘1’ Page N failed in Cache Program operation

‘0’ Page N programmed successfully

1. Only valid for Cache operations, for other operations it is same as SR6.

2. Only valid for Cache Program operations, for other operations it is Don’t Care.

29/58

Page 30

Device operations NAND04GW3B2B, NAND08GW3B2A

6.9 Read Electronic Signature

The d e vi ce c ont ai ns a Manuf acturer Code and Device Code. To read these codes three steps

are required:

1. One Bus Write cycle to issue the Read Electronic Signature command (90h)

2. One Bus Write cycle to input the address (00h)

3. Four Bus Read Cycles to sequentially output the data (as shown in Table 10: Electronic

Signature).

Table 10. Electronic Signature

Root Part

Number

Byte 1 Byte 2

Manufacturer Code Device code

Byte 3

(see Table 11)

Byte 4

(see Table 12)

NAND04GW3B2B 20h DCh 80h 95h

NAND08GW3B2A 20h D3h 81h 95h

Table 11. Electronic Signature Byte 3

I/O Definition Value Description

0 0

I/O1-I/O0 Internal Chip number

0 1

1 0

1 1

I/O3-I/O2 Cell Type

0 0

0 1

1 0

1 1

2-level cell

4-level cell

8-level cell

16-level cell

0 0

I/O5-I/O4

Number of simultaneously

programmed pages

0 1

1 0

1 1

I/O6

Interleaved Programming

between multiple devices

0

1

Not supported

Supported

1

2

4

8

1

2

4

8

I/O7 Cache Program

30/58

0

1

Not supported

Supported

Page 31

NAND04GW3B2B, NAND08GW3B2A Device operations

Table 12. Electronic Signature Byte 4

I/O Definition Value Description

I/O1-I/O0

I/O2

I/O7, I/O3

I/O5-I/O4

Page Siz e

(Without Spare Area)

Spare Area Size

(Byte / 512 Byte)

Minimum sequential

access time

Block Size

(without Spare Area)

I/O6 Organization

0 0

0 1

1 0

1 1

0

1

0 0

1 0

0 1

1 1

0 0

0 1

1 0

1 1

0

1

1 KBytes

2 KBytes

Reserved

Reserved

8

16

50ns

30ns

Reserved

Reserved

64 KBytes

128 KBytes

256 KBytes

Reserved

x8

x16

31/58

Page 32

Data Protection NAND04GW3B2B, NAND08GW3B2A

7 Data Protection

The device has both hardware and software features to protect against program and erase

operations.

It features a Write Protect, WP

and erase operations. It is recommended to keep WP

down.

In addition, to protect the memory from any involuntary program/erase operations during

power-transitions, the device has an internal voltage detector which disables all functions

whenever V

is below V

DD

The device features a Block Lock mode, which is enabled by setting the Power-Up Read

Enable, Lock/Unlock Enable, PRL, signal to High.

The Block Lock mode has two levels of software protection.

● Blocks Lock/Unlock

● Blocks Lock-down

Refer to Figure 16: Block Protection State Diagram for an overview of the protection

mechanism.

7.1 Blocks Lock

All the blocks are locked simultaneously by issuing a Blocks Lock command (see Table 7:

Commands).

All blocks are locked after power-up and when the Write Protect signal is Low .

Once all the blocks are locked, one sequence of consecutive blocks can be unlocked by

using the Blocks Unlock command.

, pin, which can be used to protect the device against program

at VIL during power-up and power-

(see Ta ble 19: DC Characteristics).

LKO

Refer to Figure 21: Command Latch AC Waveforms for details on how to issue the

command.

7.2 Blocks Unlock

A sequence of consecutive locked blocks can be unlocked, to allow program or erase

operations, by issuing an Blocks Unlock command (see Table 7: Commands).

The Blocks Unlock command consists of four steps:

● One bus cycle to setup the command.

● Three bus cycles to give the Start Block Address (refer to Table 6: Address Definition,

and Figure 14: Blocks Unlock Operation).

● One bus cycle to confirm the command.

● Three bus cycles to give the End Block Address (refer to Table 6: Address Definition,

and Figure 14: Blocks Unlock Operation).

The Start Block Address must be nearer the logical LSB (Least Significant Bit) than End

Block Ad dress.

32/58

Page 33

NAND04GW3B2B, NAND08GW3B2A Data Protection

If the Start Block Address is the same as the End Block Address, only one block is unlocked.

Only one consecutive area of blocks can be unlocked at any one time. It is not possible to

unlock multiple areas.

Figure 14. Blocks Unlock Operation

WP

I/O

23h

Blocks Unlock

Command

Add1

Start Block Address, 3 cycles

Add2

Add3

7.3 Blocks Lock-Down

The Lock-Down feature provides an additional level of protection. A Locked-down block

cannot be unlocked by a software command. Locked-Down blocks can only be unlocked by

setting the Write Protect signal to Low for a minimum of 100ns.

Only locked blocks can be locked-down. The command has no affect on unlocked blocks.

Refer to Figure 21: Command Latch AC Waveforms for details on how to issue the

command.

7.4 Block Lock Status

In Block Lock mode (PRL High) the Block Lock Status of each block can be checked by

issuing a Read Block Lock Status command (see Table 7: Commands).

The command consists of:

● One bus cycle to give the command code

● Three bus cycles to give the block address

24h

Add1

End Block Address, 3 cycles

Add2

Add3

ai08670

After this, a read cycle will then output the Block Lock Status on the I/O pins on the falling

edge of Chip Enable or Read Enable, whichever occurs last. Chip Enable or Read Enable

do not need to be toggled to update the status.

The Read Block Lock Status command will not be accepted while the device is busy (RB

Low).

The device will remain in Read Block Lock Status mode until another command is issued.

33/58

Page 34

Data Protection NAND04GW3B2B, NAND08GW3B2A

Figure 15. Read Block Lock Status Operation

W

tWHRL

R

I/O

Table 13. Block Lock Status

7Ah

Read Block Lock

Status Command

Add1

Block Address, 3 cycles

(1)

Add2

Add3

Dout

Block Lock Status

Status I/O7-I/O3 I/O2 I/O1 I/O0

Locked X 0 1 0

Unlocked X 1 1 0

Locked-Down X 0 0 1

Unlocked in Locked-

Down Area

1. X = Don’t Care.

X101

ai08669

34/58

Page 35

NAND04GW3B2B, NAND08GW3B2A Data Protection

Figure 16. Block Protection State Diagram

Power-Up

Block Unlock

(start + end block address)

Unlocked in

Locked Area

Blocks Lock-Down

Command

WP VIL >100ns

Command

Blocks Lock

Command

Locked

WP VIL >100ns

Unlocked in

Locked-Down

Area

1. PRL must be High for the software commands to be accepted.

Blocks Lock-Down

Command

WP VIL >100ns

Locked-Down

AI08663c

35/58

Page 36

Software algorithms NAND04GW3B2B, NAND08GW3B2A

8 Software algorithms

This section gives information on the software algorithms that ST recommends to implement

to manage the Bad Blocks and extend the lifetime of the NAND device.

NAND Flash memories are programmed and erased by Fowler-Nordheim tunnelling using a

high voltage. Exposing the device to a high voltage for extended periods can cause the

oxide layer to be damaged. For this reason, the number of program and erase cycles is

limited (see Table 15: Program, Erase Times and Program Erase Endurance Cycles for

value) and it is recommended to implement Garbage Collection, a Wear-Leveling Algorithm

and an Error Correction Code, to extend the number of program and erase cycles and

increase the data retention.

To help integrate a NAND memory into an application ST Microelectronics can provide a File

System OS Native reference software, which supports the basic commands of file

management.

Contact the nearest ST Microelectronics sales office for more details.

8.1 Bad Block Management

Devices with Bad Blocks have the same quality level and the same AC and DC

characteristics as devices where all the blocks are valid. A Bad Block does not affect the

performance of valid blocks because it is isolated from the bit line and common source line

by a select transistor.

The devices are supplied with all the locations inside valid blocks erased (FFh). The Bad

Block Information is written prior to shipping. Any block, where the 1st and 6th Bytes, or 1st

Word, in the spare area of the 1st page, does not contain FFh, is a Bad Block.

The Bad Block Information must be read before any erase is attempted as the Bad Block

Information may be erased. For the system to be able to recognize the Bad Blocks based on

the original information it is recommended to create a Bad Block table following the

flowchart shown in Figure 17: Bad Block Management Flowchart.

8.2 Block Replacement

Over the lifetime of the device additional Bad Blocks may develop. In this case the block has

to be replaced by copying the data to a valid block. These additional Bad Blocks can be

identified as attempts to program or erase them will give errors in the Status Register.

As the failure of a page program operation does not affect the data in other pages in the

same block, the block can be replaced by re-programming the current data and copying the

rest of the replaced block to an available valid block. The Copy Back Program command can

be used to copy the data to a valid block.

See Section 6.4: Copy Back Program for more details.

Refer to Table 14: Block Failure for the recommended procedure to follow if an error occurs

during an operation.

36/58

Page 37

NAND04GW3B2B, NAND08GW3B2A Software algorithms

Table 14. Block Failure

Operation Recommended Procedure

Erase Block Replacement

Program Block Replacement or ECC

Read ECC

Figure 17. Bad Block Management Flowchart

START

Block Address =

Block 0

Increment

Block Address

Figure 18. Garbage Collection

Old Area

Valid

Page

Invalid

Page

Data

= FFh?

YES

Last

block?

YES

END

NO

NO

Free

Page

(Erased)

Update

Bad Block table

AI07588C

New Area (After GC)

AI07599B

37/58

Page 38

Software algorithms NAND04GW3B2B, NAND08GW3B2A

8.3 Garbage Collection

When a data page needs to be modified, it is faster to write to the first available page, and

the previous page is marked as invalid. After several updates it is necessary to remove

invalid pages to free some memory space.

To free this memory space and allow further program operations it is recommended to

implement a Garbage Collection algorithm. In a Garbage Collection software the valid

pages are copied into a free area and the block containing the invalid pages is erased (see

Figure 18: Garbage Collection).

8.4 Wear-leveling Algorithm

For write-intensive applications, it is recommended to implement a Wear-leveling Algorithm

to monitor and spread the number of write cycles per block.

In memories that do not use a Wear-Leveling Algorithm not all blocks get used at the same

rate. Blocks with long-lived data do not endure as many write cycles as the blocks with

frequently-changed data.

The Wear-leveling Algorithm ensures that equal use is made of all the available write cycles

for each block. There are two wear-leveling levels:

● First Level Wear-le veling, new data is programmed to the free blocks that have had the

fewest write cycles.

● Second Level Wear-leveling, long-lived data is copied to another block so that the

original block can be used for more frequently-changed data.

The Second Level Wear-leveling is triggered when the difference between the maximum

and the minimum number of write cycles per block reaches a specific threshold.

8.5 Error Correction Code

An Error Correction Code (ECC) can be implemented in the NAND Flash memories to

identify and correct errors in the data.

For every 2048 bits in the device it is recommended to implement 22 bits of ECC (16 bits for

line parity plus 6 bits for column parity).

An ECC model is available in VHDL or Verilog. Contact the nearest ST Microelectronics

sales office for more details.

38/58

Page 39

NAND04GW3B2B, NAND08GW3B2A Software algorithms

Figure 19. Error Detection

New ECC generated

during read

XOR previous ECC

with new ECC

All results

= zero?

YES

22 bit data = 0

No Error

8.6 Hardware simulation models

8.6.1 Behavioral simulation models

Denali Software Corporation models are platform independent functional models designed

to assist customers in performing entire system simulations (typical VHDL/Verilog). These

models describe the logic behavior and timings of NAND Flash devices, and so allow

software to be developed before hardware.

8.6.2 IBIS simulations models

>1 bit

= zero?

YES

11 bit data = 1NO1 bit data = 1

Correctable

Error

NO

ECC Error

ai08332

IBIS (I/O Buffer Information Specification) models describe the behavior of the I/O buffers

and electrical characteristics of Flash devices.

These models provide information such as AC characteristics, rise/fall times and package

mechanical data, all of which are measured or simulated at voltage and temperature ranges

wider than those allowed by target specifications.

IBIS models are used to simulate PCB connections and can be used to resolve compatibility

issues when upgrading devices. They can be imported into SPICETOOLS.

39/58

Page 40

Program and Erase times and endurance cycles NAND04GW3B2B, NAND08GW3B2A

9 Program and Erase times and endurance cycles

The Program and Erase times and the number of Program/ Erase cycles pe r block are

shown in Table 15.

Table 15. Program, Erase Times and Program Erase Endurance Cycles

NAND Flash

Parameters

Min Typ Max

Page Program Time 200 700 µs

Unit

Block Erase Time

Program/Erase Cycles (per block) 100,000 cycles

Data Retention 10 years

2 3ms

40/58

Page 41

NAND04GW3B2B, NAND08GW3B2A Maximum rating

10 Maximum rating

Stressing the device above the ratings listed in Table 16: Absolute Maximum Ratings, may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the Operating sections of

this specification is not implied. Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality documents.

Table 16. Absolute Maximum Ratings

Value

Symbol Parameter

Min Max

Unit

T

BIAS

T

STG

(1)

V

IO

V

DD

1. Minimum Voltage may undershoot to –2V for less than 20ns during transitions on input and I/O pins.

Maximum voltage may overshoot to V

Temperature Under Bias – 50 125 °C

Storage Temperature – 65 150 °C

Input or Output Voltage – 0.6 4.6 V

Supply Voltage – 0.6 4.6 V

+ 2V for less than 20ns during transitions on I/O pins.

DD

41/58

Page 42

DC and AC parameters NAND04GW3B2B, NAND08GW3B2A

11 DC and AC parameters

This section summarizes the operating and measurement conditions, and the DC and AC

characteristics of the device. The parameters in the DC and AC characteristics Tables that

follow, are derived from tests performed under the Measurement Conditions summarized in

Table 17. Designers should check that the operating conditions in their circuit match the

measurement conditions when relying on the quoted parameters.

Table 17. Operating and AC Measurement Conditions

NAND Flash

Parameter

Min Max

Supply Voltage (VDD)2.7 3.6V

Units

Ambient Temperature (TA)

Grade 1 0 70 °C

Grade 6 – 40 85 °C

Load Capacitance (C

)

and C

L

Input Pulses Voltages 0 V

) (1 TTL GATE

L

50 pF

DD

Input and Output Timing Ref. Voltages VDD/2 V

Output Circuit Resistor R

8.35 kΩ

ref

Input Rise and Fall Times 5 ns

Table 18. Capacitance

(1)

Symbol Parameter Test Condition Typ Max Unit

C

C

I/O

1. T

= 25°C, f = 1MHz. CIN and C

A

2. Input/output capacitances double in stacked devices.

Input Capacitance VIN = 0V 10 pF

IN

Input/Output

Capacitance

(2)

are not 100% tested.

I/O

VIL = 0V 10 pF

V

42/58

Page 43

NAND04GW3B2B, NAND08GW3B2A DC and AC parameters

Figure 20. Equivalent Testing Circuit for AC Characteristics Measurement

V

DD

2R

ref

NAND Flash

C

L

2R

ref

Table 19. DC Characteristics

GND

GND

Ai11085

Symbol Parameter Test Conditions Min Typ Max Unit

t

I

DD1

I

DD2

I

DD3

I

DD4

I

DD5

I

V

V

V

V

I

LO

LI

IH

IL

OH

OL

Operating

Current

Standby current (TTL)

Standby Current (CMOS)

Input Leakage Current

Output Leakage Current

Input High Voltage - 0.8V

Input Low Voltage - -0.3 - 0.2V

Output High Voltage Level IOH = -400µA 2.4 - - V

Output Low Voltage Level IOL = 2.1mA - - 0.4 V

Sequential

Read

E=V

Program - - 15 30 mA

Erase - - 15 30 mA

(1)

(1)

(1)

(1)

V

IOL (RB) Output Low Current (RB) V

V

LKO

VDD Supply Voltage (Erase and

Prog ram lockout)

minimum

RLRL

= 0 mA

IL, IOUT

E=VIH, WP=0/V

E=VDD-0.2,

WP=0/V

DD

DD

-1530mA

1 mA

- 10 50 µA

VIN= 0 to VDDmax - - ±10 µA

= 0 to VDDmax - - ±10 µA

OUT

DD

= 0.4V 8 10 mA

OL

- VDD+0.3 V

DD

- - - 1.7 V