528 Byte/264 Word Page, 1.8 V/3V, NAND Flash Memories

FEATURES SUMMARY

NAND128-A, NAND256-A

NAND512-A, NAND01G-A

128 Mbit, 256 Mbit, 512 Mbit, 1 Gbit (x8/x16)

■ HIGH DENSITY NAND FLASH MEMORIES

– Up to 1 Gbit memory array

– Up to 32 Mbit spare area

– Cost effective solutions for mass storage

applications

■ NAND INTE RFACE

– x8 or x16 bus width

– Multiplexed Address/ Data

– Pinout compatibility for all densities

■ SUPPLY VOLTAGE

– 1.8V device: V

– 3.0V device: V

■ PAGE SIZE

= 1.7 to 1.95V

DD

= 2.7 to 3.6V

DD

– x8 device: (512 + 16 spare) Bytes

– x16 device: (256 + 8 spare) Words

■ BLOCK SIZE

– x8 device: (16K + 512 spare) Bytes

– x16 device: (8K + 256 spare) Words

■ PAGE READ / PROGRAM

– Random access: 12µs (max)

– Sequential access: 50ns (min)

– Page program time: 200µs (typ)

■ COPY BACK PROGRAM MODE

– Fast page copy without external buffering

■ FAST BLOCK ERASE

– Block erase time: 2ms (Typ)

■ STATUS REGISTER

■ ELECTRONIC SIGNATURE

■ CHIP ENABLE ‘DON’T CARE’ OPTION

– Simple interface wit h microcontroller

■ SERIAL NUMBER OPTION

■ HARDWARE DATA PROTECTION

– Program/Erase locked during Power

transitions

Figure 1. Packages

TSOP48 12 x 20mm

USOP48 12 x 17 x 0.65mm

FBGA

VFBGA55 8 x 10 x 1mm

TFBGA55 8 x 10 x 1.2mm

VFBGA63 9 x 11 x 1mm

TFBGA63 9 x 11 x 1.2mm

■ DATA INTEGRITY

– 100,000 Program/Erase cycles

– 10 years Data Retention

■ RoHS COMPLIANCE

– Lead-Free Components are Compliant

with the RoHS Directive

■ DEVELOPMENT TOOLS

– Error Correction Code software and

hardware models

– Bad Blocks Management and Wear

Leveling algorithms

– File System OS Native refer ence sof tware

– Hardware simulation models

1/57February 2005

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 1. P r o du c t List

Reference Part Number

NAND128R3A

NAND128-A

NAND256-A

NAND512-A

NAND01G-A

NAND128W3A

NAND128R4A

NAND128W4A

NAND256R3A

NAND256W3A

NAND256R4A

NAND256W4A

NAND512R3A

NAND512W3A

NAND512R4A

NAND512W4A

NAND01GR3A

NAND01GW3A

NAND01GR4A

NAND01GW4A

2/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Product List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Logic Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. TSOP48 and USOP48 Connections, x8 devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. TSOP48 and USOP48 Connections, x16 devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6. FBGA55 Connections, x8 devices (Top view through package) . . . . . . . . . . . . . . . . . . . 11

Figure 7. FBGA55 Connections, x16 devices (Top view through package). . . . . . . . . . . . . . . . . . 12

Figure 8. FBGA63 Connections, x8 devices (Top view through package) . . . . . . . . . . . . . . . . . . . 13

Figure 9. FBGA63 Connections, x16 devices (Top view through package). . . . . . . . . . . . . . . . . . 14

MEMORY ARRAY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Bad Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 4. Valid Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10.Memory Array Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inputs/Outputs (I/O0-I/O7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inputs/Outputs (I/O8-I/O15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Address Latch Enable (AL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Command Latch Enable (CL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chip Enable (E

Read Enable (R

Write Enable (W

Write Protect (WP

Ready/Busy (RB

V

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DD

V

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SS

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Command Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7

Address Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Data Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 5. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7

Table 6. Address Insertion, x8 Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 7. Address Insertion, x16 Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8. Address Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

COMMAND SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 9. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DEVICE OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pointer Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11.Pointer Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12.Pointer Operations for Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Read Memory Array. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Random Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Sequential Row Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13.Read (A,B,C) Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 14.Read Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 15.Sequential Row Read Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 16.Sequential Row Read Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5

Figure 17.Page Program Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Copy Back Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 10. Copy Back Program Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 18.Copy Back Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Block Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 19.Block Erase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Read Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Write Protection Bit (SR7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

P/E/R Controller Bit (SR6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Error Bit (SR0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SR5, SR4, SR3, SR2 and SR1 are Reserved. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 11. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Read Electronic Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 12. Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SOFTWARE ALGORITHMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Bad Block Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Block Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 13. Block Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 20.Bad Block Management Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 0

Figure 21.Garbage Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Garbage Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wear-leveling Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Error Correction Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 22.Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hardware Simulation Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Behavioral simulation models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

IBIS simulations models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PROGRAM AND ERASE TIMES AND ENDURANCE CYCLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 14. Program, Erase Times and Program Erase Endurance Cycles . . . . . . . . . . . . . . . . . . . 33

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 3

Table 15. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 16. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 4

Table 17. Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 18. DC Characteristics, 1.8V Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 19. DC Characteristics, 3V Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 20. AC Characteristics for Command, Address, Data Input . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 21. AC Characteristics for Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 23.Command Latch AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 24.Address Latch AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 25.Data Input Latch AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 26.Sequential Data Output after Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 27.Read Status Register AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 28.Read Electronic Signature AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 29.Page Read A/ Read B Operation AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 30.Read C Operation, One Page AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 31.Page Program AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 32.Block Erase AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 33.Reset AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Ready/Busy Signal Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 34.Ready/Busy AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 35.Ready/Busy Load Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 36.Resistor Value Versus Waveform Timings For Ready/Busy Signal . . . . . . . . . . . . . . . . 46

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 37.TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline . . . . . . . . . 47

Table 22. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data . 47

Figure 38.USOP48 – lead Plastic Ultra Thin Small Outline,12 x 17mm, Package Outline . . . . . . . 48

Table 23. USOP48 – lead Plastic Ultra Thin Small Outline, 12 x 17mm, Package Mechanical Data48

Figure 39.VFBGA55 8 x 10mm - 6x8 active ball array, 0.80mm pitch, Package Outline . . . . . . . . 49

Table 24. VFBGA55 8 x 10mm - 6x8 ball array, 0.80mm pitch, Package Mechanical Data . . . . . . 49

Figure 40.TFBGA55 8 x 10mm - 6x8 active ball array - 0.80mm pitch, Package Outline. . . . . . . . 50

Table 25. TFBGA55 8 x 10mm - 6x8 active ball array - 0.80mm pitch, Package Mechanical Data 50

Figure 41.VFBGA63 9x11mm - 6x8 active ball array, 0.80mm pitch, Package Outline . . . . . . . . . 51

Table 26. VFBGA63 9x11mm - 6x8 active ball array, 0.80mm pitch, Package Mechanical Data. . 51

Figure 42.TFBGA63 9x11mm - 6x8 active ball array, 0.80mm pitch, Package Outline. . . . . . . . . . 52

Table 27. TFBGA63 9x11mm - 6x8 active ball array, 0.80mm pitch, Package Mechanical Data . . 52

5/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 28. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

APPENDIX A.HARDWARE INTERFACE EXAMPLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 43.Connection to Microcontroller, Without Glue Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 44.Connection to Microcontroller, With Glue Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 45.Building Storage Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

RELATED DOCUMENTATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 29. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

6/57

SUMMARY DESCRIPTION

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

The NAND Flash 528 Byte/ 264 Word Page is a

family of non-volatile Flash memories that uses

the Single Level Cell (SLC) NAN D cell technology.

It is referred to as the Small Page family. The devices range from 128Mbits to 1Gbit and operate

with either a 1.8V or 3V voltage supply. The size of

a Page is either 528 Bytes (512 + 16 spare ) or 264

Words (256 + 8 spare) depending on whether the

device has a x8 or x16 bus width.

The address lines ar e multiplexed w ith the Data Input/Output signals on a multiplexed x8 or x16 Input/Output bus. This interface reduces the pin

count and makes it possible to migrate to other

densities without changing the footprint.

Each block can be programmed and erased over

100,000 cycles. To extend the lifetime of NAND

Flash devices it is strongly re commended to implement an Error Correction Code (ECC). A Write

Protect pin is available to give a hardware protection against program and erase operations.

The devices feature an open-drain Ready/Busy

output that can be used to identify if the Program/

Erase/Read (P/E/R) Controller is currently active.

The use of an open- drain output a llows the Ready/

Busy pins from several memo ries to be connect ed

to a single pull-up resistor.

A Copy Back command is availabl e to optimize the

management of defective blocks. When a Page

Program operation fails, the data can be programmed in another page without having to resend the data to be programmed.

The devices are available in the fol l owing pa ckages:

■ TSOP48 12 x 20mm for all products

■ USOP48 12 x 17 x 0.65mm for 128Mb, 256Mb

and 512Mb products

■ VFBGA55 (8 x 10 x 1mm, 6 x 8 ball array,

0.8mm pitch) for 128Mb and 256Mb products

■ TFBGA55 (8 x 10 x 1.2mm, 6 x 8 ball array,

0.8mm pitch) for 512Mb Dual Die product

■ VFBGA63 (9 x 11 x 1mm, 6 x 8 ball array,

0.8mm pitch) for the 512Mb product

■ TFBGA63 (9 x 11 x 1.2mm, 6 x 8 ball array,

0.8mm pitch) for the 1Gb Dual Die product

Two options are available for the NAND Flash

family:

Chip Enable Don’t Care, which allows code to be

directly downloaded by a microcontroller, as Chip

Enable transitions during the latency time do not

stop the read operation.

A Serial Number, which allows each device to be

uniquely identified. The Serial Number options is

subject to an NDA (Non Disclosure Agreement)

and so not described in the datasheet. For more

details of this option contact your near est ST Sales

office.

For information o n how to order thes e options refer

to Table 28., Ordering Information Scheme. De-

vices are shipped from the factory with Block 0 always valid and the memory content bits, in valid

blocks, erased to ’1’.

See Table 2., Product Description, for all the devices available in the family.

7/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 2. Product Description

Bus

Page

Reference Part Number Density

NAND128R3A

NAND128-A

NAND256-A

NAND512-A

NAND512-A

NAND01G-A

NAND128W3A 2.7 to 3.6V 12µs 50ns 200µs

NAND128R4A

NAND128W4A 2.7 to 3.6V 12µs 50ns 200µs

NAND256R3A

NAND256W3A 2.7 to 3.6V 12µs 50ns 200µs

NAND256R4A

NAND256W4A 2.7 to 3.6V 12µs 50ns 200µs

NAND512R3A

NAND512W3A 2.7 to 3.6V 12µs 50ns 200µs

(1)

NAND512R4A

NAND512W4A 2.7 to 3.6V 12µs 50ns 200µs

NAND512R3A

NAND512W3A 2.7 to 3.6V 12µs 50ns 200µs

NAND512R4A

NAND512W4A 2.7 to 3.6V 12µs 50ns 200µs

NAND01GR3A

NAND01GW3A 2.7 to 3.6V 12µs 50ns 200µs

NAND01GR4A

NAND01GW4A 2.7 to 3.6V 12µs 50ns 200µs

Note: 1. Dual Die device.

128Mbit

256Mbit

512Mbit

512Mbit

1Gbit

Width

x8

x16

x8

x16

x8

x16

x8

x16

x8

x16

Size

512+16

Bytes

256+8

Words

512+16

Bytes

256+8

Words

512+16

Bytes

256+8

Words

512+16

Bytes

256+8

Words

512+16

Bytes

256+8

Words

Block

16K+512

Bytes

8K+256

Words

16K+512

Bytes

8K+256

Words

16K+512

Bytes

8K+256

Words

16K+512

Bytes

8K+256

Words

16K+512

Bytes

8K+256

Words

Size

Memory

Array

32 Pages x

1024 Blocks

32 Pages x

2048 Blocks

32 Pages x

4096 Blocks

32 Pages x

4096 Blocks

32 Pages x

8192 Blocks

Operating

Voltage

1.7 to 1.95V 12µs 60ns 200µs

1.7 to 1.95V 12µs 60ns 200µs

1.7 to 1.95V 12µs 60ns 200µs

1.7to 1.95V 12µs 60ns 200µs

1.7to 1.95V 12µs 60ns 200µs

1.7 to 1.95V 12µs 60ns 200µs

1.7to 1.95V 15µs 60ns 200µs

1.7 to 1.95V 15µs 60ns 200µs

1.7 to 1.95V 15µs 60ns 200µs

1.7 to 1.95V 15µs 60ns 200µs

Random

Access

Max

Timings

Sequential

Access

Min

Page

Program

Typical

Block

Package

Erase

Typical

TSOP48

2ms

USOP48

VFBGA55

TSOP48

2ms

USOP48

VFBGA55

2ms TFBGA55

TSOP48

2ms

USOP48

VFBGA63

TSOP48

2ms

TFBGA63

Figure 2. Logic Diagram Table 3. Signal Names

I/O8-15 Data Input/Outputs for x16 devices

Data Input/Outputs, Address Inputs,

or Command Inputs for x8 and x16

devices

Chip Enable

Read Enable

Ready/Busy (open-drain output)

Write Enable

Write Protect

Supply Voltage

Ground

E

W

AL

CL

WP

V

DD

I/O8-I/O15, x16

I/O0-7

AL Address Latch Enable

CL Command Latch Enable

I/O0-I/O7, x8/x16

R

NAND Flash

RB

E

R

RB

W

WP

V

DD

V

SS

NC Not Connected Internally

DU Do Not Use

V

SS

AI07557C

8/57

Figure 3. Logic Block Diagram

Address

Register/Counter

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

AL

CL

W

E

WP

R

Command

Interface

Logic

Command Register

P/E/R Controller,

High V oltage

Generator

RB

NAND Flash

Memory Array

X Decoder

Page Buffer

Y Decoder

I/O Buffers & Latches

I/O0-I/O7, x8/x16

I/O8-I/O15, x16

AI07561c

9/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 4. TSOP48 and USO P 48 Connections, x8 devices

V

V

NC

NC

NC

NC

NC

NC

RB

NC

NC

DD

SS

NC

NC

CL

AL

W

WP

NC

NC

NC

NC

NC

1

R

E

NAND Flash

12

13

24 25

(x8)

48

37

36

NC

NC

NC

NC

I/O7

I/O6

I/O5

I/O4

NC

NC

NC

V

DD

V

SS

NC

NC

NC

I/O3

I/O2

I/O1

I/O0

NC

NC

NC

NC

Figure 5. TSOP48 and USOP4 8 Connections, x16 devices

V

V

NC

NC

NC

NC

NC

NC

RB

NC

NC

DD

SS

NC

NC

CL

AL

WP

NC

NC

NC

NC

NC

1

R

E

NAND Flash

12

13

W

24 25

(x16)

48

37

36

V

SS

I/O15

I/O7

I/O14

I/O6

I/O13

I/O5

I/O12

I/O4

NC

NC

V

DD

NC

NC

NC

I/O11

I/O3

I/O10

I/O2

I/O9

I/O1

I/O8

I/O0

V

SS

10/57

AI07585B

AI07559B

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 6. FBGA55 Connections, x8 devices (Top view through package)

87654321

A

B

C

D

E

F

G

H

DU

WP

NC

NC NC

NC

AL

NCNC

NC

I/O0

V

SS

R

CL

NC NC

NC

NCNC

NC

E

NC

W

NC

NC

NC

NCNC

NCNC

V

RB

NCNC

NC

NC

NC

DD

DU

DU

V

NC

SS

I/O1

I/O2

NC

DD

I/O4I/O3

I/O5V

I/O6

I/O7

V

SS

DUDU

DU

AI09366b

J

K

L

M

DU

11/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 7. FBGA55 Connections, x16 devices (Top view through package)

87654321

A

B

C

D

E

F

G

H

DU

WP

NC

NC NC

I/O8

I/O1

AL

R

NCNC

NC

V

SS

CL

NC NC

NC

NCNC

I/O10

E

NC

V

RB

NCNC

NC

NC

NC

DD

W

NC

NC

NC

I/O7I/O5

I/O14I/O12

DU

DU

12/57

J

K

L

M

DU

I/O0

V

SS

I/O9

I/O2

I/O3

DD

I/O4I/O11

I/O6V

I/O13

I/O15

V

SS

DUDU

DU

AI09365b

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 8. FBGA63 Connections, x8 devices (Top view through package)

87654321

A

B

C

D

E

F

G

DU DU

DU

WP

NC

NCNC

NC NC

NC

AL

DU

DU

V

SS

R

CL

NC

NC

NCNC

NC

NC

E

W

NC

NC

NC

NCNC

RB

NCNC

NC

NC

NC

109

DU

DU

H

J

K

L

M

DU DU

DU

DU

NC

NC

V

SS

I/O0

I/O1

I/O2

NC

NC

NCNC

DD

I/O4I/O3

I/O5V

I/O6

V

I/O7

V

DD

SS

DU DU

DU

DU

AI07586B

13/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 9. FBGA63 Connections, x16 devices (Top view through package)

87654321

A

B

C

D

E

F

G

DU DU

DU

WP

NC

NC NC

AL

NCNC

NC

DU

DU

V

SS

R

CL

NC

NC

NCNC

E

NC

NC

I/O7I/O5

W

NC

NC

NC

RB

NCNC

NC

NC

NC

109

DU

DU

H

J

K

L

M

DU DU

DU

DU

I/O8

I/O0

V

SS

I/O1

I/O9

I/O2

I/O10

I/O3

I/O14I/O12

V

DD

I/O4I/O11

I/O6

I/O13

V

DD

I/O15

V

SS

DU DU

DU

DU

AI07560B

14/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

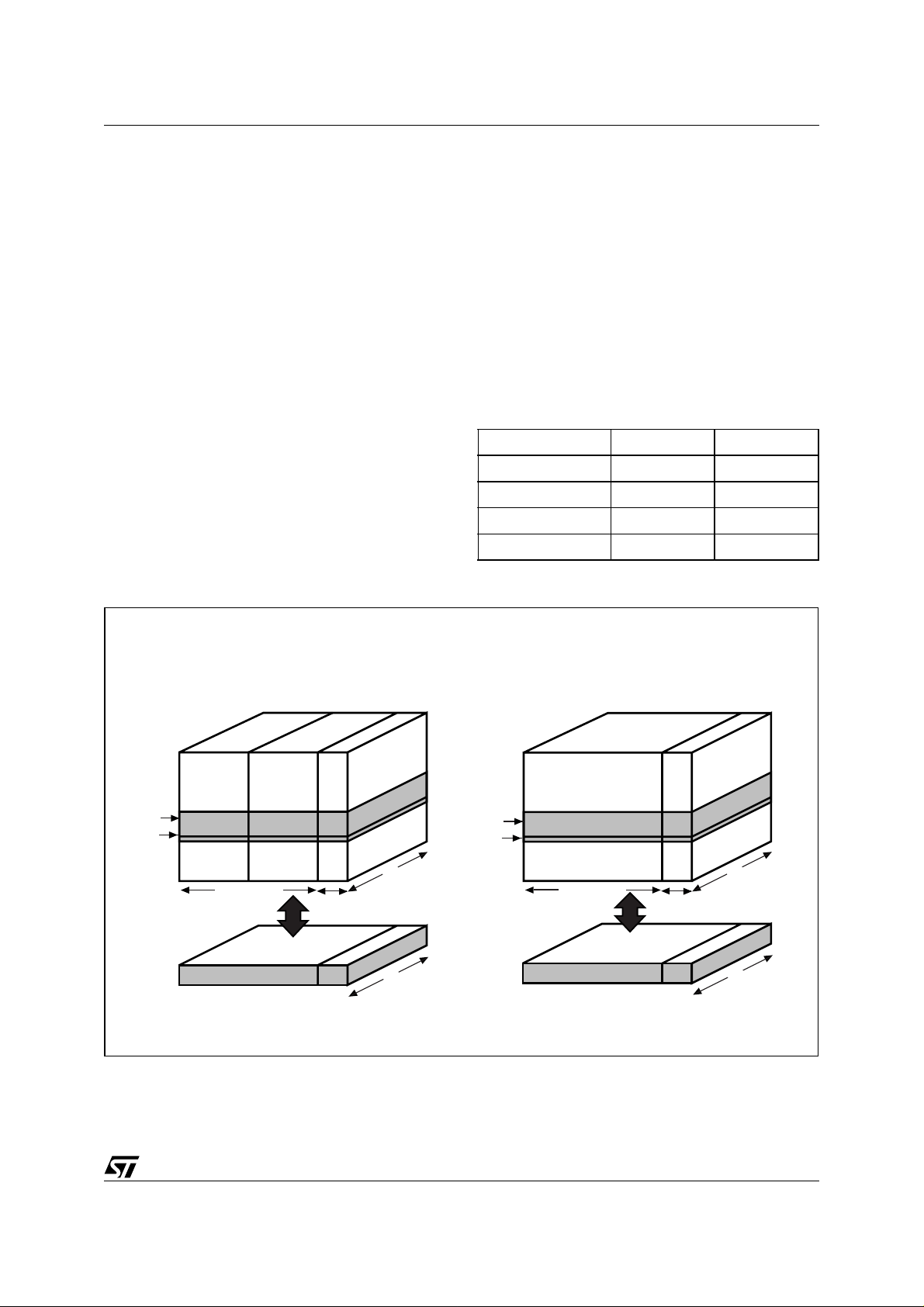

MEMORY ARRAY ORGANIZATION

The memory array is m ade up of N AND struc tures

where 16 cells are connected in series.

The memory array is organized in blocks where

each block contains 32 pages. The array is split

into two areas, the main area and the spare area.

The main area of the array is used to store data

whereas the spare area is typically used to store

Error correction Codes, software flags or Bad

Block identification.

In x8 devices the pages are split into a main area

with two half pages o f 256 Bytes each a nd a spare

area of 16 Bytes. In the x16 dev ices the p ages ar e

split into a 256 Word main area and an 8 Word

spare area. Refer t o Figure 10., Memory Arr ay Or-

ganization.

Bad Blocks

The NAND Flash 528 Byte/ 264 Wor d Page dev ices may contain Bad Blocks, that is blocks that contain one or more invalid bits wh ose reli ability i s not

guaranteed. Additional Bad Blocks may develop

during the lifetime of the device.

Figure 10. Memory Array Organization

The Bad Block Information is written prior to shipping (refer to Bad Block Management section for

more details).

Table 4. shows the minimum number of valid

blocks in each device. The values shown include

both the Bad Blocks that are pre sent when the device is shipped and the Bad Blocks that could develop later on.

These blocks need to be managed using Bad

Blocks Management, Block Replacement or Error

Correction Codes (refer to SOFTWARE ALGO-

RITHMS section).

Table 4. Valid Blocks

Density of Device Min Max

1Gbit 8032 8192

512Mbits 4016 4096

256Mbits 2008 2048

128Mbits 1004 1024

Block

Page

1st half Page

(256 bytes)

512 Bytes

Page Buffer, 512 Bytes

x8 DEVICES x16 DEVICES

Block = 32 Pages

Page = 528 Bytes (512+16)

16

Bytes

16

Bytes

Spare Area

2nd half Page

(256 bytes)

512 Bytes

Block

Page

8 bits

8 bits

Block = 32 Pages

Page = 264 Words (256+8)

Main Area

256 Words

Page Buffer, 264 Words

256 Words

8

Words

8

Words

Spare Area

16 bits

16 bits

AI07587

15/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

SIGNAL DESCRIPTIONS

See Figure 2., Logic Diagram, and Table

3., Signal Names, for a brief overview of the sig-

nals connected to this device. Inputs/Outputs (I/O0-I/O7). Input/Outputs 0 to 7

are used to input the selected address, output the

data during a Read operation or input a co mma nd

or data during a Write operation. The inputs are

latched on the rising edge of Write Enable. I/O0-I/

O7 are left floating when the device is deselected

or the outputs are disabled.

Inputs/Outputs (I/O8-I/O15). Input/Outputs 8 to 15 are only available in x16 devices. They are used to output the data duri ng a Read oper ation or input data during a Write operation. Comma nd and Address Inputs only require I/O0 to I/O7.

The inputs are latched on the rising edge of Write

Enable. I/O8-I/O15 are left floating when the device is deselected or the outputs are disabled.

Address Latch Enable (AL). The Address Latch

Enable activates the latching o f the Address inputs

in the Command Interface. When AL is high, the

inputs are latched on the rising edge of Write Enable.

Command Latch Enable (CL). The Command

Latch Enable activates the latching of the Command inputs in the Command Interface. When CL

is high, the inpu ts are l atched on the ri sing e dge of

Write Enable.

Chip Enable (E

). The Chip Enable input acti-

vates the memory control logic, input buffers, decoders and sense ampl ifiers. When Chip Enable is

low, V

, the device is selected.

IL

While the device is busy programming or erasing,

Chip Enable transitions to High, V

, are ignored

IH

and the device does not revert to the Standby

mode.

While the device is busy reading:

■ the Chip Enable input should be held Low

during the whole busy time (t

BLBH1

) for

devices that do not present the Chip Enable

Don’t Care option. Otherwise, the read

operation in progress is interrupted and the

device reverts to the Standby mode.

■ for devices that feature the Chip Enab le Don't

Care option, Chip Enable going High during

the busy time (t

) will not interrupt the

BLBH1

read operation and t he device will not revert to

the Standby mode.

Read Enable (R

). T he Read Enable, R, controls

the sequential data output during Read opera-

tions. Data is valid t

The falling edge of R

after the falling edge of R.

RLQV

also increments the internal

column address counter by one.

Write Enable (W

). The Write Enable input, W,

controls writing to the Command Interface, Input

Address and Data latches. Both addresses and

data are latched on the rising edge of Write Enable.

During power-up and power- down a rec overy time

of 1µs (min) is required before th e Command Interface is ready to accept a command. It is recommended to keep Write Enable high during the

recovery time.

Write Protect (WP

). The Write Protect pin is an

input that gives a hardware protection against unwanted program or erase operations. When Write

Protect is Low, V

, the device does not accept any

IL

program or erase operations.

It is recommended to keep the Write Protect pin

Low, V

Ready/Busy (RB

, during power-up and power-down.

IL

). The Ready/Busy output, RB,

is an open-drain output that can be used to identify

if the P/E/R Controller is currently active.

When Ready/Busy is Lo w, V

, a read, progra m or

OL

erase operation i s in progress . When the oper ation

completes Ready/Busy goes High, V

OH

.

The use of an open- drain output allows the Ready/

Busy pins from several mem ories to be c onnected

to a single pull-up resist or. A Low will then indicate

that one, or more, of the memories is busy.

Refer to the Ready/Busy Signal Electrical Charac-

teristics section for details on how to calculate the

value of the pull-up resistor.

V

Supply Voltage. VDD provides the power

DD

supply to the internal core of the memory device.

It is the main power suppl y for all ope rations (read,

program and erase).

An internal voltage detector disables all functions

whenever V

is below 2.5V (for 3V devices) or

DD

1.5V (for 1.8V devices) to protect the device from

any involuntary program/erase during power-transitions.

Each device in a system sh ould have V

DD

decoupled with a 0.1µF capaci tor . T he PCB tr ac k widths

should be sufficient to carry the required program

and erase currents

V

Ground. Ground, V

SS

is the reference for

SS,

the power supply. It must be connected to the system ground.

16/57

BUS OPERATIONS

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

There are six standard bus oper ati ons that contr ol

the memory. Each of these is described in this

section, see Table 5., Bus Operations, for a sum-

mary.

Command Input

Command Input bus operations are used to give

commands to the memory. Command are accepted when Chip Enable is Low, Command Latch Enable is High, Address Latch Enable is Low and

Read Enable is High. They are latched on the rising edge of the Write Enable signal.

Only I/O0 to I/O7 are used to input commands.

See Fi gure 23. an d Table 20. for d etails of the tim-

ings requirements.

Address Input

Address Input bus operations are used to input the

memory address. T hree bus cycles are r equired to

input the addresses for the 128Mb and 25 6Mb devices and four bus cycles are requi red to input t he

addresses for the 512Mb and 1Gb devices (refer

to Tables 6 and 7, Address Insertion).

The addresses are accepted when Chi p Enab le is

Low, Address Latch Enable is High, Command

Latch Enable is Low and Read Enable is High.

They are latched on the rising edge of the Write

Enable signal. Only I/O0 to I/O7 are used to input

addresses.

See Fi gure 24. an d Table 20. for d etails of the timings requirements.

Data Input

Data Input bus operations are used to input the

data to be programmed.

Data is accepted only when Chip Enable is Low,

Address Latch Enable is Low, Command Latch

Enable is Low and Read Enable is High. The data

is latched on the rising edge of the Write Enable

signal. The data is input sequentially using the

Write Enable signal.

See Fi gure 25. and Table 20. an d Tabl e 21. for details of the timings requirements.

Data Output

Data Output bus operations are used to read: the

data in the memory ar ra y, the Status Register, the

Electronic Signature and the Serial Number.

Data is output when Chip Enabl e is Low, Write Enable is High, Address Latch Enable is Low, and

Command Latch Enable is Low.

The data is output sequentially using the Read Enable signal.

See Fi gure 26. a nd Table 21. for detail s of the tim-

ings requirements.

Write Protect

Write Protect bus operations are used to protect

the memory against program or erase operations.

When the Write Protect signal is Low the device

will not accept program or erase operations and so

the contents of the memory array cannot be altered. The Write Protect signal is not latched by

Write Enable to ensure protection even during

power-up.

Standby

When Chip Enable is High the memory enters

Standby mode, the device is deselected, outputs

are disabled and power consumption is reduced.

Table 5. Bus Operations

Bus Operation E AL CL R W WP I/O0 - I/O7

Command Input

Address Input

Data Input

Data Ou tput

Write Protect X X X X X

Standby

Note: 1. Only for x16 devices.

WP must be VIH when issuing a program or erase command.

2.

V

IL

V

IL

V

IL

V

IL

V

IH

V

V

IH

V

V

XXXXX X X

V

IL

IL

IL

IH

V

IL

V

IL

V

Falling

IL

V

Rising

IH

V

Rising X Address X

IH

V

Rising X Data Input Data Input

IH

V

IH

(2)

X

X Data Output Data Output

V

IL

Command X

I/O8 - I/O15

XX

(1)

17/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 6. Address Insertion, x8 Devices

Bus Cycle I/O7 I/O6 I/O5 I/O4 I/O3 I/O2 I/O1 I/O0

st

1

nd

2

rd

3

th(4)

4

Note: 1. A8 is set Low or High by the 00h or 01h Command, see Pointer Operations section.

2. Any additional address input cycles will be ignored.

3. The 4th cycle is only required for 512Mb and 1Gb devices.

Table 7. Address Insertion, x16 Devices

Bus

Cycle

st

1

nd

2

rd

3

th(4)

4

Note: 1. A8 is Don’t Care in x16 devices.

2. Any additional address input cycles will be ignored.

3. The 01h Command is not used in x16 devices.

4. The 4th cycle is only required for 512Mb and 1Gb devices.

A7 A6 A5 A4 A3 A2 A1 A0

A16 A15 A14 A13 A12 A11 A10 A9

A24 A23 A22 A21 A20 A19 A18 A17

V

I/O8-

I/O15

IL

V

IL

V

IL

V

IL

V

IL

V

IL

A26 A25

I/O7 I/O6 I/O5 I/O4 I/O3 I/O2 I/O1 I/O0

X A7 A6 A5 A4 A3 A2 A1 A0

X A16 A15 A14 A13 A12 A11 A10 A9

X A24 A23 A22 A21 A20 A19 A18 A17

X

V

IL

V

IL

V

IL

V

IL

V

IL

V

IL

A26 A25

Table 8. Address Definitions

Address Definition

A0 - A7 Column Address

A9 - A26 Page Address

A9 - A13 Address in Block

A14 - A26 Block Ad dr ess

A8

A8 is set Low or High by the 00h or 01h Command, and is

Don’t Care in x16 devices

18/57

COMMAND SET

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

All bus write operations to the device are int erpreted by the Command Interface. The Commands

are input on I/O0-I/O7 and a re latched on the risi ng

edge of Write Enable when the Command Latch

Enable signal is high. Device operations are selected by writing specific commands to the Com-

mand Register. The two-step command

sequences for program and erase operations are

imposed to maximize data security.

The Commands are summarized in Table

9., Commands.

Table 9. Com m and s

Command

1st CYCLE 2nd CYCLE 3rd CYCLE

Read A 00h - Read B

Read C 50h - -

Read Electronic Si gnature 90h - Read Status Register 70h - - Yes

Page Program 80h 10h Copy Back Program 00h 8Ah 10h

Block Erase 60h D0h Reset FFh - - Yes

Note: 1. The bus cycles are only shown for issuing the codes. The cycles require d to input the addresses or input/out put data are not shown.

2. Any undefined command sequence will be ignored by the devic e.

01h

Bus Write Operations

(2)

- -

(1)

Command accepted

during busy

19/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

DEVICE OPERATIONS

Pointer Operations

As the NAND Flash memories contain two different areas for x16 devices and t hree differe nt areas

for x8 devices (see Figur e 11.) the read command

codes (00h, 01h, 50h) are used to act as pointers

to the different area s of the memory arr ay (they select the most significant column address).

The Read A and Read B commands act as pointers to the main memory area. Their use depends

on the bus width of the device.

■ In x16 devices the Read A command (00h)

sets the pointer to Area A (the whole of the

main area) that is Words 0 to 255.

■ In x8 devices the Read A com mand (00h) sets

the pointer to Area A (the first half of the main

area) that is Bytes 0 to 255, and the Read B

command (01h) sets the pointer to Ar ea B (the

Figure 11. Pointer Operations

x8 Devices x16 Devices

Area A

(00h)

Bytes 0- 255 Bytes 256-511

Area B

(01h)

Area C

(50h)

Bytes 512

-527

second half of the main area) th at is Bytes 256

to 511.

In both the x8 and x16 devices the Read C command (50h), acts as a poi nter to Area C (the spar e

memory area) that is Bytes 512 to 527 or Words

256 to 263.

Once the Read A and Read C commands have

been issued the pointer remains in the respective

areas until another pointer c ode is issued. H owever, the Read B command is effective for only one

operation, once an operation has been executed

in Area B the pointer retur ns au tomati cal ly to Ar ea

A.

The pointer operations can also be used before a

program operation, that is the appropriate code

(00h, 01h or 50h) can be issued before the program command 80h is issued (see Figure 12.).

Area A

(00h)

Words 0- 255

Area C

(50h)

Words 256

-263

A

Pointer

(00h,01h,50h)

CB

Page Buffer

A

Pointer

(00h,50h)

C

Page Buffer

AI07592

20/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 12. Pointer Operations for Programming

AREA A

80h

00h

I/O

Areas A, B, C can be programmed depending on how much data is input. Subsequent 00h commands can be omitted.

01h

50h

80h

80h

I/O

Areas B, C can be programmed depending on how much data is input. The 01h command must be re-issued before each program.

I/O

Address

Inputs

Address

Inputs

Address

Inputs

Only Areas C can be programmed. Subsequent 50h commands can be omitted.

Data Input

Data Input

Data Input

10h

AREA B

10h

AREA C

10h

00h

01h

50h

80h

80h

80h

Address

Inputs

Address

Inputs

Address

Inputs

Data Input

Data Input

Data Input

10h

10h

10h

ai07591

21/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Read Memory Array

Each operation to read the memory area starts

with a pointer operation as shown in the Pointer

Operations section. Once the area (main or spare)

has been selected using the Read A, Read B or

Read C commands four bus cycles (for 512Mb

and 1Gb devices) or three bus cycles (for 128Mb

and 256Mb devices) are required to input the address (refer to Table 6.) of the data to be read.

The device defaults to Read A mode after powerup or a Reset operation.

When reading the spare area addresses:

■ A0 to A3 (x8 devices)

■ A0 to A2 (x16 devices)

are used to set the start address of the spare area

while addresses:

■ A4 to A7 (x8 devices)

■ A3 to A7 (x16 devices)

are ignored.

Once the Read A or Read C commands have

been issued they do not need to be reissued for

subsequent read operations as the pointer remains in the respective area. However, the Read

B command is effective for only one operation,

once an operation has been executed in Area B

the pointer returns automatically to Area A and so

another Read B command is required to start another read operation in Area B.

Once a read command is issued th ree types of operations are available : Ran dom R ead, Pa ge Re ad

and Sequential Row Read.

Random Read. Each time the command is issued the first read is Random Read.

Page Read. After the Random Read access the

page data is transferred to the Page Buffer in a

time of

t

(refer to Table 21. for value). Once

WHBH

the transfer is complete the Ready/Busy signal

goes High. The data can then be read out sequentially ( from se lected column a ddress to last column

address) by pulsing the Read Enable signal.

Sequential Row Read. After the data in last column of the page is output, if the Read Enable signal is pulsed and Chip Enable remains Low then

the next page is automatically loaded into the

Page Buffer and the read operation continues. A

Sequential Row Read operation can only be used

to read within a block. If the block changes a new

read command must be issued.

Refer to Figure 15. and F igure 16. for details of Sequential Row Read operations.

To terminate a Seque ntial Row Read ope ration set

the Chip Enable sig nal to High for m ore than t

EHEL

Sequential Row Read is not available when the

Chip Enable Don't Care option is enabled.

.

22/57

Figure 13. Read (A,B,C) Operations

CL

E

W

AL

R

RB

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

tBLBH1

(read)

I/O

00h/

01h/ 50h

Command

Code

Address Input

Figure 14. Read Block Diagrams

Read A Command, X8 Devices

Area A

(1st half Page)

(1)

A9-A26

A0-A7

Read B Command, X8 Devices

Area A

(1st half Page)

(1)

A9-A26

A0-A7

Note: 1. Highest address depends on device density.

Area B

(2nd half Page)

Area B

(2nd half Page)

Area C

(Spare)

Area C

(Spare)

Busy

A9-A26

A0-A7

(1)

A9-A26

A0-A3 (x8)

A0-A2 (x16)

Data Output (sequentially)

Read A Command, X16 Devices

Area A

(main area)

(1)

Read C Command, X8/x16 Devices

Area A

A4-A7 (x8), A3-A7 (x16) are don't care

Area A/ B

ai07595

Area C

(Spare)

Area C

(Spare)

AI07596

23/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Figure 15. Sequential Row Read Operations

RB

I/O

00h/

01h/ 50h

Command

Code

tBLBH1

(Read Busy time)

Address Inputs

Busy

tBLBH1 tBLBH1

1st

Page Output

Figure 16. Sequential Row Read Block Diagrams

Read A Command, x8 Devices

Area A

(1st half Page)

Block

Read B Command, x8 Devices Read C Command, x8/x16 Devices

Area A

(1st half Page)

Block

Area B

(2nd half Page)

Area B

(2nd half Page)

Area C

(Spare)

Area C

(Spare)

1st page

2nd page

Nth page

1st page

2nd page

Nth page

2nd

Page Output

Read A Command, x16 Devices

Area A

(main area)

Block

Area A Area A/ B Area C

Block

BusyBusy

Nth

Page Output

Area C

(Spare)

1st page

2nd page

Nth page

(Spare)

1st page

2nd page

Nth page

ai07597

AI07598

24/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Page Program

The Page Program oper ation is the standard op eration to program data to the memory array.

The main area of the memory array is programmed by page, however pa rtial page progr amming is allowed where any number of bytes (1 to

528) or words (1 to 264) can be programmed.

The maximum number of cons ecut ive parti al pa ge

program operations allowed in the same page is

three. After exceeding this a Block Erase command must be issued before any further program

operations can take place in that page.

Before starting a Pag e Program operati on a Pointer operation can be perfo rme d to poi nt to the ar ea

to be programmed. Refer to the Pointer Opera-

tions section and Figure 12. for details.

Each Page Program operation consists of five

steps (see Figure 17.):

1. one bus cycle is required to setup the Page

Program command

2. four bus cycles are then required to input the

program address (refer to Table 6.)

Figure 17. Page Program Operation

3. the data is then input (up to 528 Bytes/ 264

Words) and loaded into the Page Buffer

4. one bus cycle is required to issue the confirm

command to start the P/E/R Controller.

5. T he P/E/R Controller then programs the data

into the array.

Once the program operation has started the Status Register can be read using the Read Status

Register command. During program operations

the Status Register will only flag errors for bits set

to '1' that have not been s uccessfull y progr ammed

to '0'.

During the program operation, only the Read Status Register and Reset commands will be accepted, all other commands will be ignored.

Once the program operatio n has completed the P/

E/R Controller bit SR6 is set to ‘1’ and the Ready/

Busy signal goes High.

The device remai ns in Read Status Register mode

until another valid com mand is w ritten to the C ommand Interface.

tBLBH2

RB

I/O

Note: Before starting a Page Program operation a Pointer operation can be performed. Refer to Pointer Operations section for details.

80h

Page Program

Setup Code

Address Inputs

Data Input

(Program Busy time)

10h

Confirm

Code

Busy

70h

Read Status Register

SR0

ai07566

25/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Copy Back Program

The Copy Back Program opera tion is used to copy

the data stored in one page an d reprogram it in another page.

The Copy Back Program operation does not require external memory and so the operation is

faster and more efficient because the reading and

loading cycles are not required. The operation is

particularly useful when a portion of a block is updated and the rest of t he bl oc k ne eds to be co pi ed

to the newly assigned block.

If the Copy Back Program operation fails an error

is signalled in the Status Register. However as the

standard external ECC cannot be used with the

Copy Back operation bit error due to charge loss

cannot be detected. For this reason it is recommended to limit the number of Copy Back operations on the same data and or to improve the

performance of the ECC.

The Copy Back Program operation requires three

steps:

1. The source page mu st be read using the Read

A command (one bus write cycle to setup the

command and then 4 bus write cycles to input

the source page address). This operation

copies all 264 Words/ 528 Bytes fr om the page

into the Page Buffer.

2. When the device returns to the ready state

(Ready/Busy High), the second bus write

cycle of the command is given with the 4 bus

cycles to input the target page addr ess. Refer

to Table 10. for th e addresses that mu st be the

same for the Source and Target pages.

3. T hen the confirm command is issued to start

the P/E/R Controller.

After a Copy Back Program operation, a partialpage program is not allowed in the target page until the block has been erased.

See Figure 18. for an example of the Copy Back

operation.

Table 10. Copy Back Program Addresses

Density

128 Mbit A23

256 Mbit A24

512 Mbit A25

512 Mbit DD

1 Gbit DD

Note: 1. DD = Dual Die.

(1)

Same Address for Source and

(1)

Target Pages

A24, A25

A25, A26

Figure 18. Copy Back Operation

tBLBH1

RB

I/O

Read

Code

(Read Busy time)

Source

Address Inputs

8Ah 70h00h

Copy Back

Code

(Program Busy time)

Target

Address Inputs

tBLBH2

10h

Busy

SR0

Read Status Register

ai07590b

26/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Block Erase

Erase operations are d one one blo ck at a time. An

erase operation sets all of the bits in the addressed block to ‘1’. All previous data in the block

is lost.

An erase operation consists of three steps (refer to

Figure 19.):

1. One bus cycle is required to setup the Block

Erase command.

2. Only three bus cycles for 512Mb and 1Gb

devices, or two for 128Mb and 256Mb devices

Figure 19. Block Erase Operation

RB

I/O

60h

Block Erase

Setup Code

Block Address

Inputs

are required to input the block address. The

first cycle (A0 to A7) is not required as only

addresses A14 to A26 (highest address

depends on device density) are valid, A9 to

A13 are ignored. In the last address cycle I/O2

to I/O7 must be set to V

.

IL

3. One bus cycle is required to issue th e confirm

command to start the P/E/R Controller.

Once the erase operation has completed the Status Register can be checked for errors.

tBLBH3

(Erase Busy time)

Busy

D0h

Confirm

Code

70h

Read Status Register

SR0

ai07593

Reset

The Reset command is used to reset the Command Interface and Status Register. If the Reset

command is issued during any operation, the operation will b e aborted. I f it was a program or eras e

operation that was aborted, the contents of the

memory locations bei ng modi fied w i ll no longer be

valid as the data will be partially programmed or

erased.

If the device has already been reset then the new

Reset command will not be accepted.

The Ready/Busy signal goes Low for t

the Reset command is i ssued. The val ue of t

BLBH4

after

BLBH4

depends on the operation that th e device wa s performing when the command was issued, refer to

Table 21. for the values.

27/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Read Status Register

The device contains a Status Register which provides information on the current or previous Program or Erase operation. The various bits in the

Status Register convey information and errors on

the operation.

The Status Register is read by issuing the Read

Status Register command. The Status Re gister information is present on the output data bus (I/O0I/O7) on the falling edge of Chip Enable or Read

Enable, whichever occurs last. When several

memories are connected in a system, the use of

Chip Enable and Read Enable signals allows the

system to poll each device separately, even when

the Ready/Busy pins are common-wired. It is not

necessary to toggle the Chip Enable or Read Enable signals to update the contents of the Status

Register.

After the Read Status Register command has

been issued, the device remains in Read Status

Register mode until another command is issued.

Therefore if a Read Status Register command is

issued during a Random Read cycle a new read

command must be issued to conti nue with a Page

Read or Sequential Row Read operation.

The Status Register bits are summarized in Table

11., Status Register Bits. Refer to Table 11. in

conjunction with the following text descriptions.

Write Protection Bit (SR7). The Write Protection

bit can be used to identify if the devi ce is protected

or not. If the W rite Pro tection b it is set to ‘1’ the device is not protected and program or erase operations are allowed. If the Write Protection bit is set

to ‘0’ the device is protected and pro gram or erase

operations are not allowed.

P/E/R Controller Bit (SR6). The Program/Erase/

Read Controller bit indicates whether the P/E/R

Controller is active or inactive. When the P/E/R

Controller bit is set to ‘0’, the P/E/R Controller is

active (device is busy ); when the bit is set to ‘1’, the

P/E/R Controller is inactive (device is ready).

Error Bit (SR0). The Error bit is used to identify if

any errors have been detected by the P/E/R Controller. The Error Bit is set to ’1’ w hen a program or

erase operation has faile d to write the correct d ata

to the memory. If the Error Bit is set to ‘0’ the operation has completed successfully.

SR5, SR4, SR3, SR2 and SR1 are Reserved.

28/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 11. Status Register Bits

Bit Name Logic Level Definition

SR7 Write Protection

SR6

SR5, SR4,

SR3, SR2, SR1

SR0 Generic Error

Program/ Erase/ Read

Controller

Reserved

'1' Not Protected

'0' Protected

'1' P/E/R C inactive, device ready

'0' P/E/R C active, device busy

Don’t Care

‘1’ Error – operation failed

‘0’ No Error – operation successful

Read Electronic Signature

The d ev i c e co n t ai n s a Manuf acture r Code and Device Code. To read these codes two steps are required:

1. first use one Bus Write cycle to issue the Read

Electronic Signature command (90h)

2. then perform two Bus Read operations – the

first will read the Manufacturer Code and the

second, the Device Code. Further Bus Read

operations will be ignored.

Refer to Table 12., Electronic Signature, for infor-

mation on the addresses.

Table 12. Electronic Si gnature

Part Number

NAND128R3A

NAND128W3A 73h

NAND128R4A

NAND128W4A 0053h

NAND256R3A

NAND256W3A 75h

NAND256R4A

NAND256W4A 0055h

NAND512R3A

NAND512W3A 76h

NAND512R4A

NAND512W4A 0056h

NAND01GR3A

NAND01GW3A 79h

NAND01GR4A

NAND01GW4A 0059h

Manufacturer

Code

20h

0020h

20h

0020h

20h

0020h

20h

0020h

Device code

33h

0043h

35h

0045h

36h

0046h

39h

0049h

29/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

SOFTWARE ALGORITHMS

This section gives information on the software algorithms that ST recommends to implement to

manage the Bad Blocks and extend the lifetime of

the NAND device.

NAND Flash memories are programmed and

erased by Fowler-N ordheim tunneling u sing a high

voltage. Exposing the device to a high voltage for

extended periods can cause the oxide layer to be

damaged. For this rea son , the num ber of pro gram

and erase cycles is limited (see Table 14. for value) and it is recommended to implement Garbage

Collection, a Wear-Leveling Algorithm and an Error Correction Code, to extend the number of program and erase cycles and increase the data

retention.

To help integrate a NAND memor y into an a pplication ST Microelectronics can provide:

■ File System OS Native reference software,

which supports the basic commands of file

management.

Contact the nearest ST Microelectronics sales office for more details.

Bad Block Manage ment

Devices with Bad Blocks have the same quality

level and the same AC and DC characteristics as

devices where all the blocks ar e valid. A Bad Block

does not affect the p erformanc e of valid blocks because it is isolated from the bit line and common

source line by a select transistor.

The devices are supplied with all the locations inside valid blocks erased (FFh). The Ba d Block Information is written prior to shipping. Any block

where the 6th Byte/ 1st Word in the spare area of

the 1st page does not contain FFh is a Bad Block.

The Bad Block Information must be read before

any erase is attempted as the Bad Block Information may be erased. For the system to be able to

recognize the Bad Blocks ba sed on th e origina l information it is recommended to create a Bad Block

table following the flowchart shown in Figure 20.

Block Replacement

Over the lifetime of the device additional Bad

Blocks may develop. In this case the block has to

be replaced by copying the data to a valid block.

These additional Bad Blocks can be identified as

attempts to program or erase them will give er r ors

in the Status Register.

As the failure of a page program operation does

not affect the data in other pages in the same

block, the block can be replaced by re-programming the current data and copying the rest of the

replaced block to an available valid block. The

Copy Back Program command can be used to

copy the data to a valid block.

See the “Copy Back Program” section for more details.

Refer to Table 13. for the recommended procedure to follow if an error occurs during an operation.

Table 13. Block Failure

Operation Recommended Procedure

Erase Block Replacement

Program Block Replacement or ECC

Read ECC

Figure 20. Bad Block Management Flowchart

START

Block Address =

Block 0

Data

= FFh?

YES

Last

block?

YES

END

NO

NO

Increment

Block Address

Update

Bad Block table

AI07588C

30/57

Figure 21. Garbage Collection

2

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Old Area

Valid

Page

Invalid

Page

Garbage Collection

When a data page needs to be modified, i t is faster

to write to the first available page, and the previous

page is marked as invalid. After sever al updates it

is necessary to remove invalid pa ges to free s ome

memory space.

To free this memory space and allow further program operations it is recommended to implement

a Garbage Collection algo rithm. In a Garba ge Collection software the valid pages are copied into a

free area and the bloc k c ontai ning the invalid pages is erased (see Figure 21.).

Wear-leveling Algorithm

For write-intensive applications, it is recommended to implement a Wear-leveling Algorithm to

monitor and spread the number of writ e cycles per

block.

In memories that do not use a Wear-L ev eling Algorithm not all blocks get used at the same rate.

Blocks with long- liv ed dat a do not endu re as man y

write cycles as the bloc ks with freque ntly-c hanged

data.

The Wear-leveling Algorithm ensures that equal

use is made of all the available write cycles for

each block. There are two wear-leveling levels:

■ First Level Wear-leveling, new data is

programmed to the free blocks that have had

the fewest write cycles

■ Second Level Wear-lev eling, long-lived da ta is

copied to another block so that the original

block can be used for more frequentlychanged data.

The Second Level Wear-l eveling is triggere d when

the difference be tween the maximu m and th e minimum number of write cycles per block reaches a

specific threshold.

New Area (After GC)

Free

Page

(Erased)

AI07599B

Error Correction Code

An Error Correction Code (ECC) can be implemented in the Nand Flash memories to identify

and correct errors in the data.

For every 2048 bits in the de vic e i t i s rec om mended to implement 22 bits of ECC (16 bits for line parity plus 6 bits for column parity).

An ECC model is available in VHDL or Verilog.

Contact the nearest ST Microelectronics sales office for more details.

Figure 22. Error Detection

New ECC generated

during read

XOR previous ECC

with new ECC

All results

= zero?

YES

22 bit data = 0

No Error

NO

YES

11 bit data = 1

Correctable

>1 bit

= zero?

Error

NO

1 bit data = 1

ECC Error

ai0833

31/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Hardware Simulation Models

Behavioral simulation models. Denali Software

Corporation models are platform independent

functional models designed to assist customers in

performing entire system simulations (typical

VHDL/Verilog). These models describe the logic

behavior and timings of NAND Flas h devi ce s, and

so allow software to be developed before hardware.

IBIS simulations models. IBIS (I/O Buffer Information Specification) models describe the behav-

ior of the I/O buffers and electrical characteristics

of Flash devices.

These models provide information such as AC

characteristics, rise/fall times and package mechanical data, all of which are measured or simulated at voltage and temperature ranges wider

than those allowed by target specifications.

IBIS models are used to simulate PCB connections and can be used to resolve compatibility issues when upgrading devices. They can be

imported into SPICETOOLS.

32/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

PROGRAM AND ERASE TIMES AND ENDURANCE CYCLES

The Program and Erase times and the number of

Program/ Erase cycles pe r block are shown in Ta-

ble 14.

Table 14. Program, Erase Times and Program Erase Endurance Cycles

Parameters

Min Typ Max

Page Program Time 200 500 µs

Block Erase Time

Program/Erase Cycles (per block) 100,000 cycles

Data Retention 10 years

NAND Flash

Unit

2 3ms

MAXIMUM RATING

Stressing the device above the ratings listed in Ta-

ble 15., Absolute Maximum Ratings, may cause

permanent damage to the device. These are

stress ratings only and operation of the device at

these or any other conditions abov e tho se ind icat-

not implied. Exposure to Absolute Maximum Rating conditions for ex tend ed p eri ods may affect device reliability. Refer also to the

STMicroelectronics SURE Program and other relevant quality documents.

ed in the Operating sections of this specif icatio n is

Table 15. Absolute Maximum Ratings

Symbol Parameter

T

BIAS

T

STG

(1)

VIO

V

DD

Note: 1. Minimum Voltage may undershoot to –2V for less than 20ns during transitions on input and I/O pins. Maximum voltage may over-

shoot to V

Temperature Under Bias – 50 125 °C

Storage Temperature – 65 150 °C

Input or Output Voltage

Supply Voltage

+ 2V for less than 20ns during transitions on I/O pins.

DD

1.8V devices – 0.6 2.7 V

3 V devices – 0.6 4.6 V

1.8V devices – 0.6 2.7 V

3 V devices – 0.6 4.6 V

Value

Unit

Min Max

33/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

DC AND AC PARAMETERS

This section summarizes the operating and measurement conditions, and the DC and AC characteristics of the device. The parameters in the DC

and AC characteristics Tables that follow, are derived from tests performed under the Measure-

ment Conditions summarized in Table

16., Operating and AC Measurement Conditions.

Designers should check that the operating conditions in their circuit match the measurem ent conditions when relying on the quoted parameters.

Table 16. Operating and AC Measurement Conditions

Parameter

Supply Voltage (V

Ambient Temperature (T

Load Capacitance (C

Input Pulses Voltage s

Input and Output Timing Ref. Voltages

Input Rise and Fall Times 5 ns

Output Circuit Resistors, R

)

DD

)

A

) (1 TTL GATE and CL)

L

ref

1.8V devices 1.7 1.95 V

3V devices 2.7 3.6 V

Grade 1 0 70 °C

Grade 6 –40 85 °C

1.8V devices 30 pF

3V devices (2.7 - 3.6V) 50 pF

3V devices (3.0 - 3.6V) 100 pF

1.8V devices 0

3V devices 0.4 2.4 V

1.8V devices 0.9 V

3V devices 1.5 V

NAND Flash

Min Max

V

DD

8.35 kΩ

Units

V

Table 17. Ca pacitance

Symbol Parameter Test Condition Typ Max Unit

C

IN

C

I/O

Note: TA = 25°C, f = 1 MHz. CIN and C

34/57

Input Capacitance

Input/Output Capacitance

are not 100% tested.

I/O

V

V

IN

IL

= 0V

= 0V

10 pF

10 pF

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 18. DC Characteristics, 1.8V Devices

Symbol Parameter Te st Cond itions Min Typ Max Unit

t

I

DD1

I

DD2

I

DD3

I

DD5

I

LI

I

LO

V

IH

V

IL

V

OH

V

OL

IOL (RB)

V

LKO

Sequential

Operating

Current

Read

Program - - 8 15 mA

E

Erase - - 8 15 mA

Stand-By Curre n t (CMOS)

128Mb, 256Mb, 512Mb devices

Stand-By Curre n t (CMOS)

512Mb and 1Gb Dua l Die devices

Input Leakage Current

Output Leakage Current

V

Input High Voltage Input Low Voltage - -0.3 - 0.4 V

Output High Voltage Level

Output Low Voltage Level

Output Low Current (RB)

VDD Supply Voltage (Erase and

Program lockout)

minimum

RLRL

=V

IL, IOUT

= 0 mA

E=VDD-0.2,

=0/V

WP

DD

VIN= 0 to VDDmax

= 0 to VDDmax

OUT

VDD-0.4

IOH = -100µA VDD-0.1

IOL = 100µA

V

= 0.2V

OL

- - - 1.5 V

- 8 15 mA

- 10 50 µA

- 20 100 µA

- - ±10 µA

- - ±10 µA

-

VDD+0.3

- - V

- - 0.1 V

3 4 mA

V

35/57

NAND128-A, NAND256-A, NAND512-A, NAND01G-A

Table 19. DC Characteristics, 3V Devices

Symbol Parameter Te st Cond itions Min Typ Max Unit

t

I

DD1

I

DD2

I

DD3

I

DD4

I

DD5

I

LI

I

LO

V

IH

V

IL

V

OH

V

OL

IOL (RB)

V

LKO

Sequential

Operating

Current

Read

Program - - 10 20 mA

E

Erase - - 10 20 mA

Stand-by Current (TT L) ,

128Mb, 256Mb, 512Mb devices

E=VIH, WP=0V/V

Stand-by Curre nt (TTL)

512Mb and 1Gb Dua l Die devices

Stand-By Curre n t (CMOS)

128Mb, 256Mb, 512Mb devices

Stand-By Curre n t (CMOS)

512Mb and 1Gb Dua l Die devices

Input Leakage Current

Output Leakage Current

V

Input High Voltage - 2.0 Input Low Voltage - −0.3 - 0.8 V

Output High Voltage Level

Output Low Voltage Level

Output Low Current (RB)

VDD Supply Voltage (Erase and

Program lockout)

minimum

RLRL

=V

IL, IOUT

= 0 mA

E=VDD-0.2,

WP

=0/V

DD

VIN= 0 to VDDmax

= 0 to VDDmax

OUT

IOH = −400µA

IOL = 2.1mA

V

= 0.4V

OL

- - - 2.5 V

- 10 20 mA

- - 1 mA

DD

- - 2 mA