Page 1

1

DIGITAL PANEL METER

N30H TYPE

USER’S MANUAL

Page 2

2

Page 3

3

Contents

1. APPLICATION AND METER DESIGN ........................................5

2. METER SET ..................................................................................6

3. BASIC REQUIREMENTS, OPERATIONAL SAFETY .................7

4. INSTALLATION ............................................................................ 8

5. SERVICE ....................................................................................11

6. RS-485 INTERFACE ..................................................................27

7. SOFTWARE UPDATE ................................................................ 27

8. ERROR CODES .........................................................................41

9. TECHNICAL DATA ....................................................................42

10. ORDER CODES .........................................................................44

11. MAINTENANCE AND GUARANTEE .........................................46

Page 4

4

Page 5

5

1. APPLICATION AND METER DESIGN

The N30H meter is a programmable digital panel meter destined for

the measurement of d.c. voltage or d.c. current. Additionally, the meter

enables the indication of the current time. The readout field is a LED

display, which allows the exposition of results in colours: red, green

and orange. The measured input signal can be arbitrary converted by

means of a 21-point individual characteristic.

Features of the N30H meter:

l display colour individually programmed in three intervals,

l programmable thresholds of displayed overflows,

l 2 NOC relay alarms operating in 6 modes,

l 2 switched relay alarms with a switching contact operating

in 6 modes (option),

l signaling of the measuring range overflow,

l automatic setting of the decimal point,

l programming of alarm and analog outputs with the reaction

on the chosen input quantity (main or auxiliary input),

l real-time clock with the function of the clock supply support

in case of the meter supply decay,

l programmed averaging time – function of walking window with the

averaging time up to 1 hour,

l monitoring of set parameter values,

l interlocking of introduced parameters by means of a password,

l recount of the measured quantity on the base of a 21-point

individual characteristic,

l service of the interface with MODBUS protocol in the

RTU mode (option),

l conversion of the measured value into a standard – programmable

current or voltage signal (option),

l highlight of any measuring unit acc. to the order.

Page 6

6

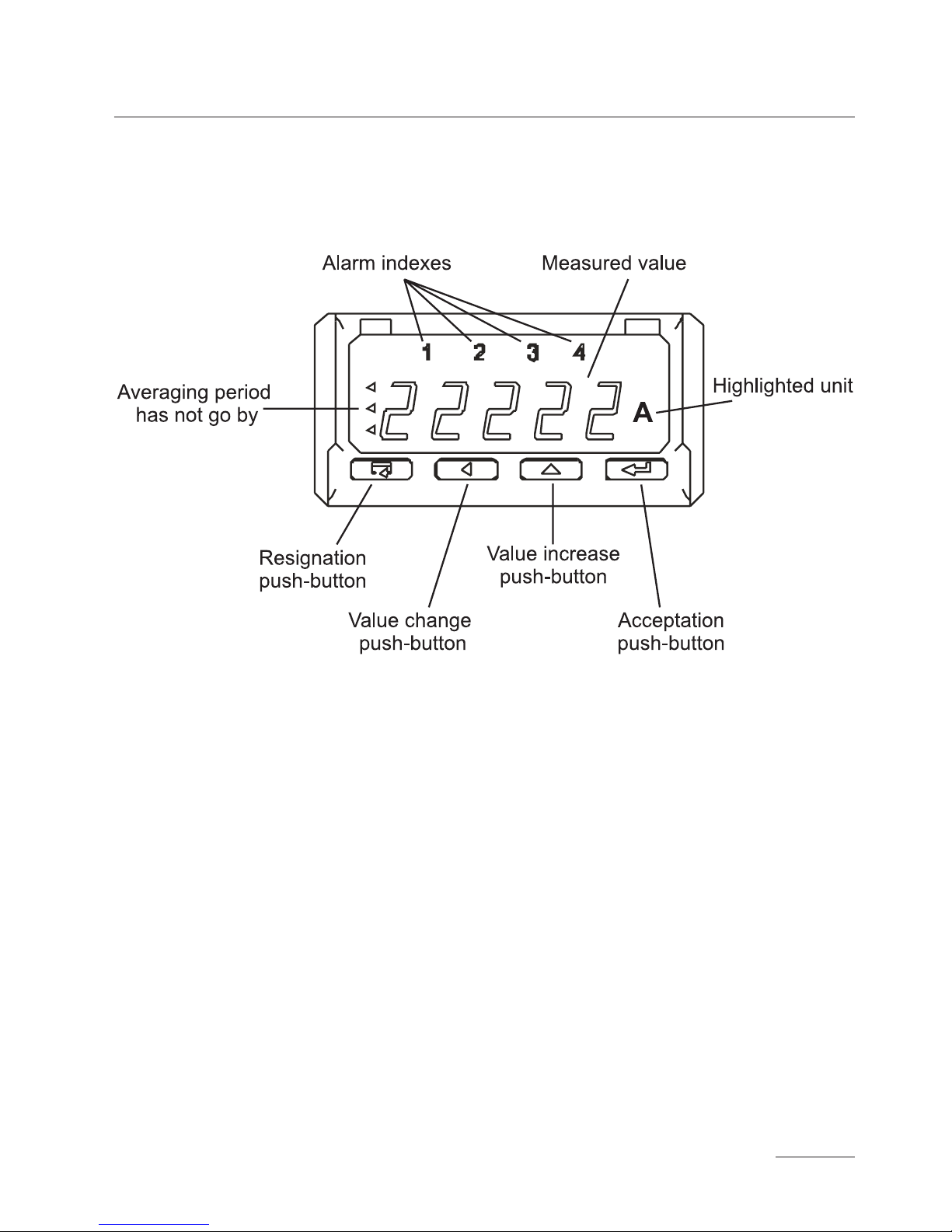

Fig. 1. View of the N30H meter

l signaling of alarm operation – switching the alarm on causes

the highlight of the output number,

l galvanic separation between connectors: alarm, supply, input,

analog output connections and RS-485 interface.

Protection degree from frontal side: IP65

Meter overall dimensions: 96 x 48 x 93 mm (with terminals).

The meter casing is made of plastics.

2. METER SET

The set is composed of:

- N30H meter .......................................................... 1 pc

- User’s manual ......................................................1 pc

- Guarantee card .................................................... 1 pc

- Clamps to fix in the panel ....................................4 pcs

- Seal ......................................................................1 pc

When unpacking the meter, please check whether the type and execution code on the data plate correspond to the order.

Page 7

7

3. BASIC REQUIREMENTS, OPERATIONAL

SAFETY

In the safety service scope, the N30H meter meets the requirements of

the EN 61010-1 standard.

Observations concerning the operational safety

l All operations concerning transport, installation, and commissioning

as well as maintenance, must be carried out by qualified, skilled personnel, and national regulations for the prevention of accidents must

be observed.

l The programming of N30H meter parameters must be carried out

after disconnecting measuring circuits

l Before switching the meter on, one must check the correctness of

connections.

l Do not connect the meter to the network through an autotransformer.

l Before removing the meter housing, one must switch the supply off

and disconnect measuring circuits.

l The meter is designed to be installed and exploited in electromag-

netic industrial environment conditions.

l Non-authorized removal of the housing, inappropriate use, incorrect

installation or operation, creates the risk of injury to personnel or meter

damage.

For more detailed information, please study the User’s Manual.

l When connecting the supply, one must remember that a switch or

a circuit-breaker should be installed in the building. This switch should

be located near the device, easy accessible by the operator, and

suitably marked as an element switching the meter off.

Page 8

8

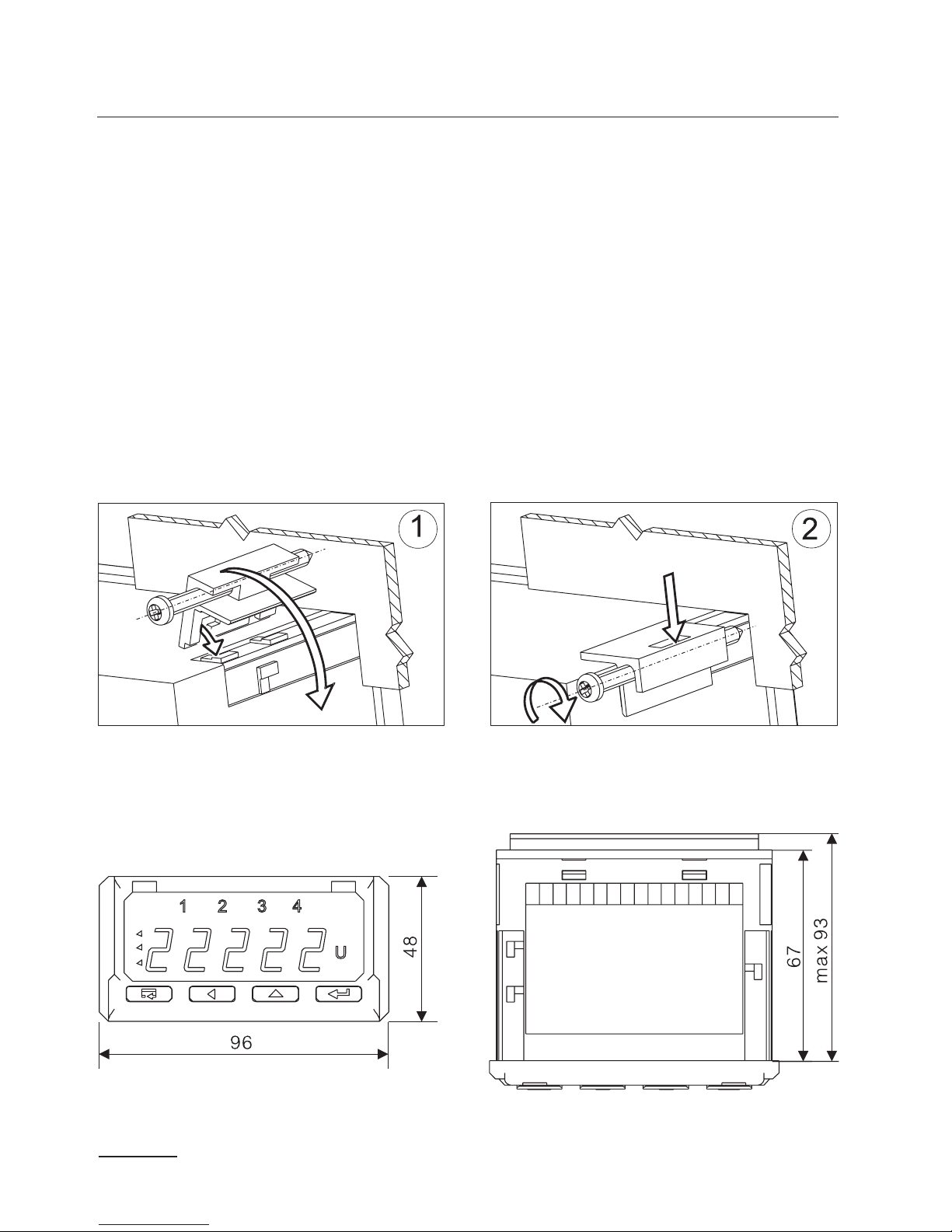

Fig. 3. Overall dimensions

Fig. 2. Meter fixing

4. INSTALLATION

The meter has separable strips with screw terminals, which enable the

connection of external wires of 2.5 mm2 cross-section. Strips of input

signals are protected against any accidental disconnection by means

of a screw joint.

One must prepare a hole of 92

+0,6

´ 45

+0,6

mm in the panel, which the

thickness should not exceed 6 mm.

The meter is adapted to be mounted in a panel. The meter must be

introduced from the panel front with disconnected supply voltage. Before the insertion into the panel, one must check the correct placement

of the seal. After the insertion into the hole, fix the meter by means of

clamps (fig.2).

Page 9

9

4.1. Signals Leads

Signals led out on the meter connectors are presented on the fig. 4.

All input signals are separated between them from remaining circuits.

Analog outputs are not separated between them. One don’t have to

take simultaneously advantage of voltage and current measurements, since measuring circuits of voltage and current are not galva-

nically isolated.

Fig. 4. Description of signals on connection strips

· 1 A, 5 A – terminals for the current measurement on the 1 A

or 5 A range.

· 100 V, 500 V – terminals for the voltage measurement on the 100 V

or 500 V range.

· OC –output of open collector type with an npn output transistor.

The output is turned on in case of a measuring range overflow.

Page 10

10

4.2. Examples of Connections

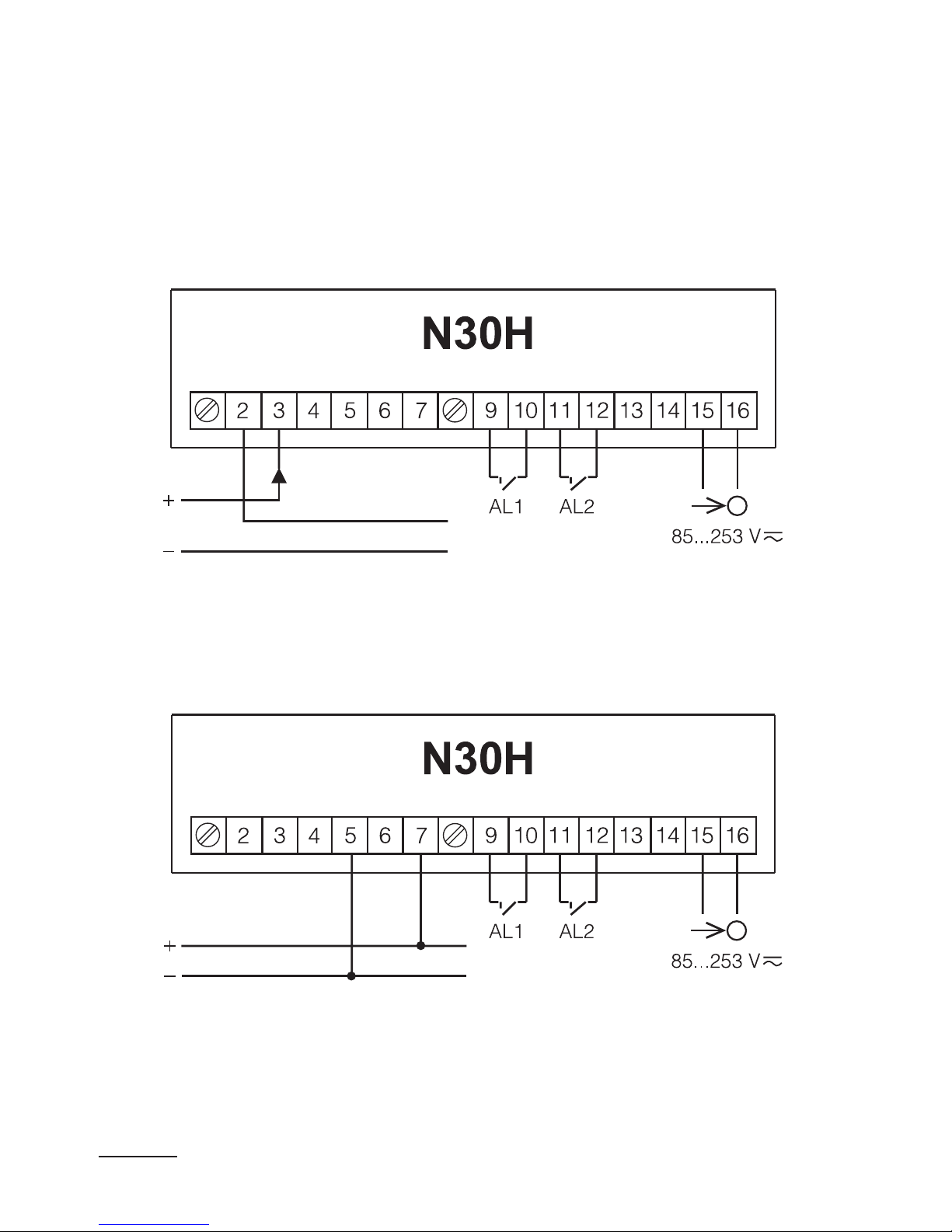

An example of the N30H meter connection for current measurement is

presented on the fig. 5.

However, an example of the meter connection in the configuration for

voltage measurement is presented on the fig. 6.

Fig. 5. Meter connection in the configuration for current measurement

Fig. 6. Meter connection in the configuration for voltage measurement

Page 11

11

5. SERVICE

5.1. Display Description

Fig. 7. Description of the meter frontal plate

5.2. Messages after Switching the Supply on

After switching the supply on, the meter displays the meter name

N30H, and next the program version in the form „r x.xx” – where

x.xx is the number of the current program version or the number of a

custom-made execution. Next, the meter carries out measurements

and displays the value of the input signal. The meter sets automatically the decimal point position, when displaying the value. The

format (number of places after the decimal point) can be limited by

the user.

Page 12

12

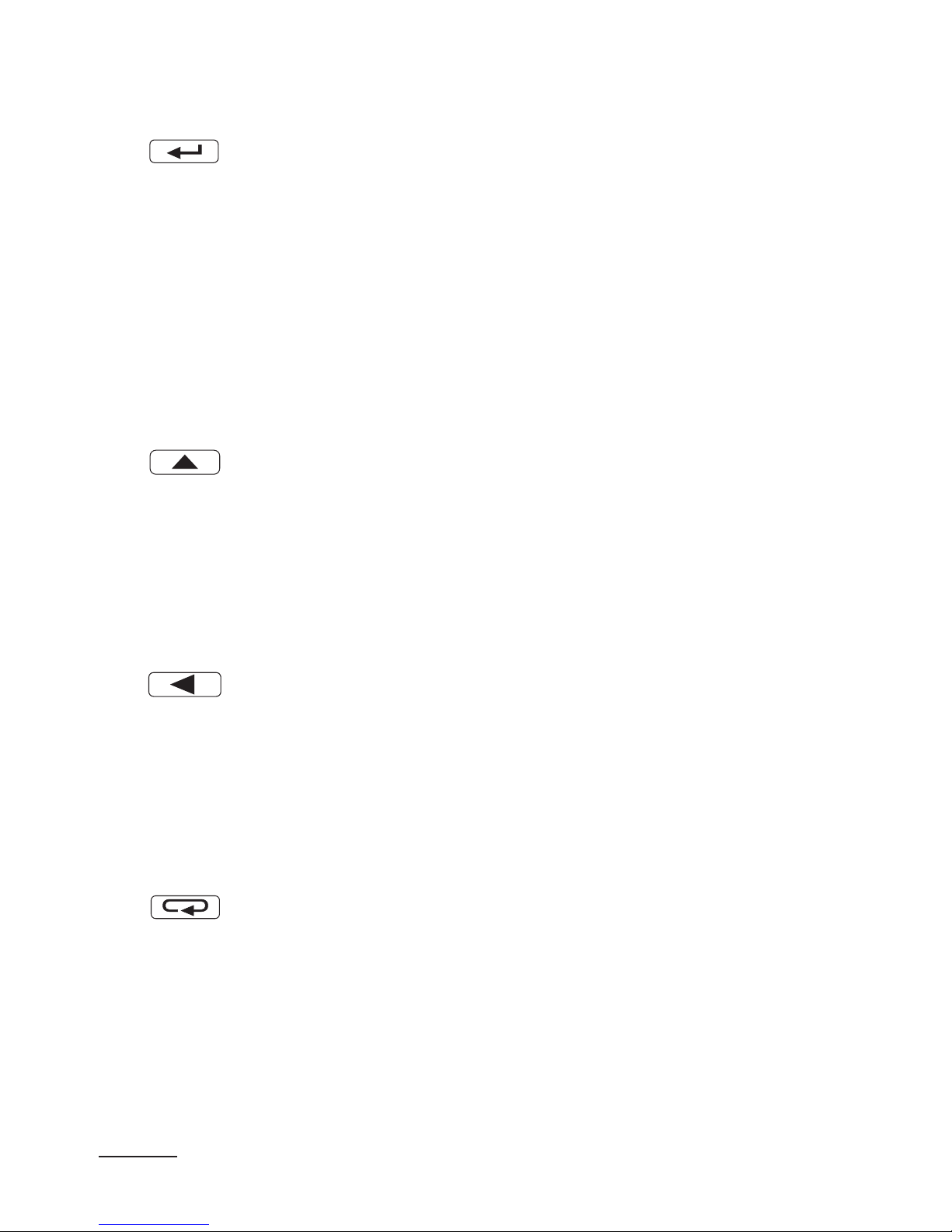

5.3. Functions of Push-buttons

- Acceptation push-button:

Þ entry in programming mode (press and hold ca 3 seconds)

Þ moving through the menu – level selection,

Þ entry in the mode changing the parameter value,

Þ acceptation of the changed parameter value.

Þ stop the measurement – when holding down the push, the result

is not updated. The measurement is still carried out.

Þ Turning on the power supply of the meter while holding the button

– entering the software-update mode through RS485 interface

- Push-button increasing the value:

Þ display of maximal value, The pressure of the push-button causes

the display of the maximal value during ca 3 seconds.

Þ entry in the level of the parameter group,

Þ moving on the chosen level,

Þ change of the chosen parameter value – increasing the value.

- Push-button to change the digit:

Þ display of minimal value, The pressure of the push-button causes

the display of the maximal value during ca 3 seconds.

Þ entry in the level of parameter group,

Þ moving through the chosen level,

Þ change of chosen parameter value – shift on the next digit,

- Resignation push-button:

Þ entry in the menu monitoring the meter parameters (press and

hold ca 3 seconds),

Þ exit from the menu monitoring meter parameters,

Þ resignation of the parameter change,

Þ strict exit from the programming mode (press and hold

ca 3 seconds).

Page 13

13

The pressure of the push-button combination and holding down them during ca 3 seconds causes the deletion of alarm signaling. This operation acts only when the support function is switched on.

The pressure of the push-button combination

causes

the erasing of the minimal value.

The pressure of the push-button combination

causes

the erasing of the maximal value.

The pressure and holding down the

push-button during ca 3

seconds causes the entry to the programming matrix. The programming matrix can be protected by a safety code.

The pressure and holding down the

push-button during ca 3

seconds causes the entry to the menu monitoring meter parameters.

One must move through the monitoring menu by means of

and

push-buttons. In this menu, all programmable meter parameters are available only for readout. In this mode, the menu Ser is not

available. The exit from the monitoring menu is carried out by means of

the

push-button. In the monitoring menu, parameter symbols

are displayed alternately with their values.

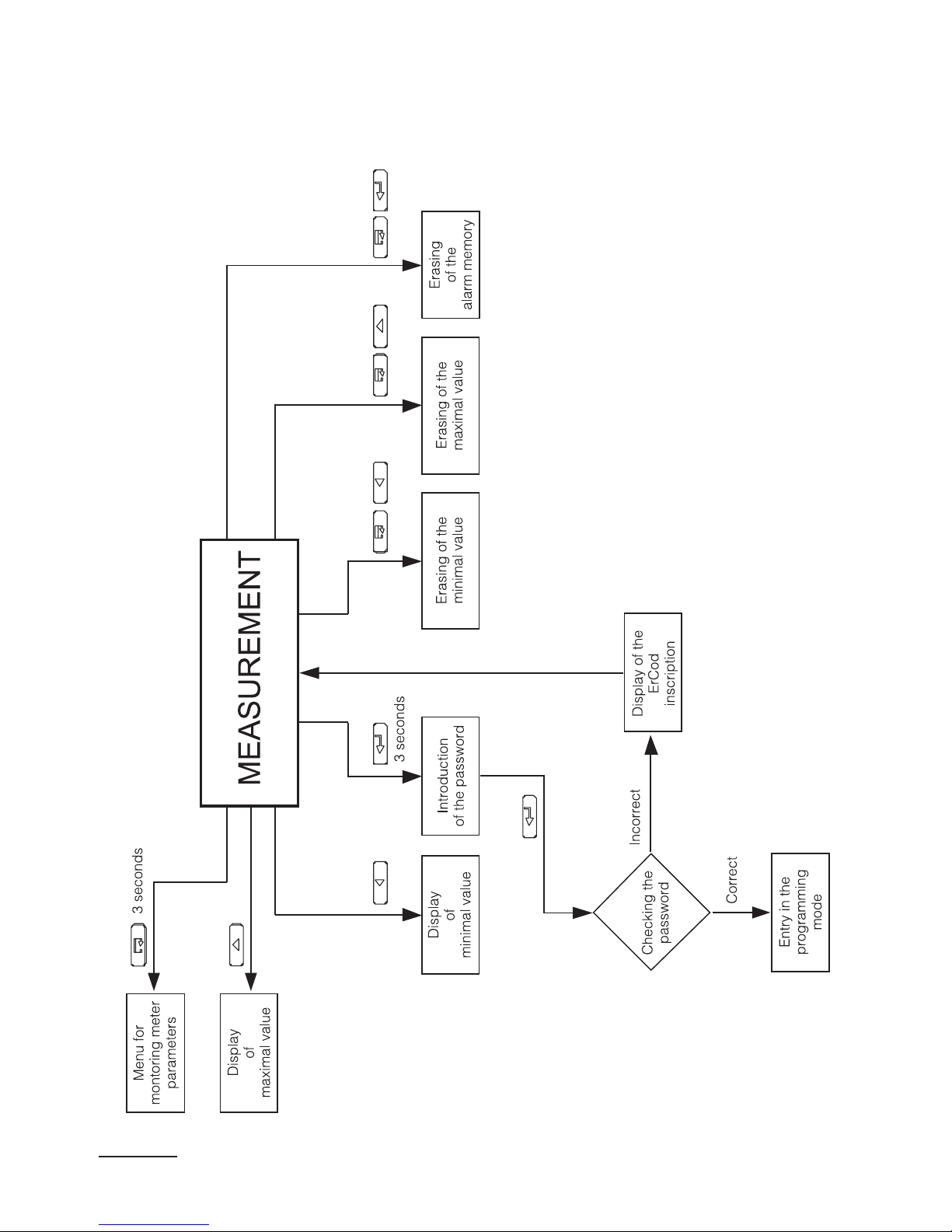

The service algorithm of the meter is presented on the fig. 8.

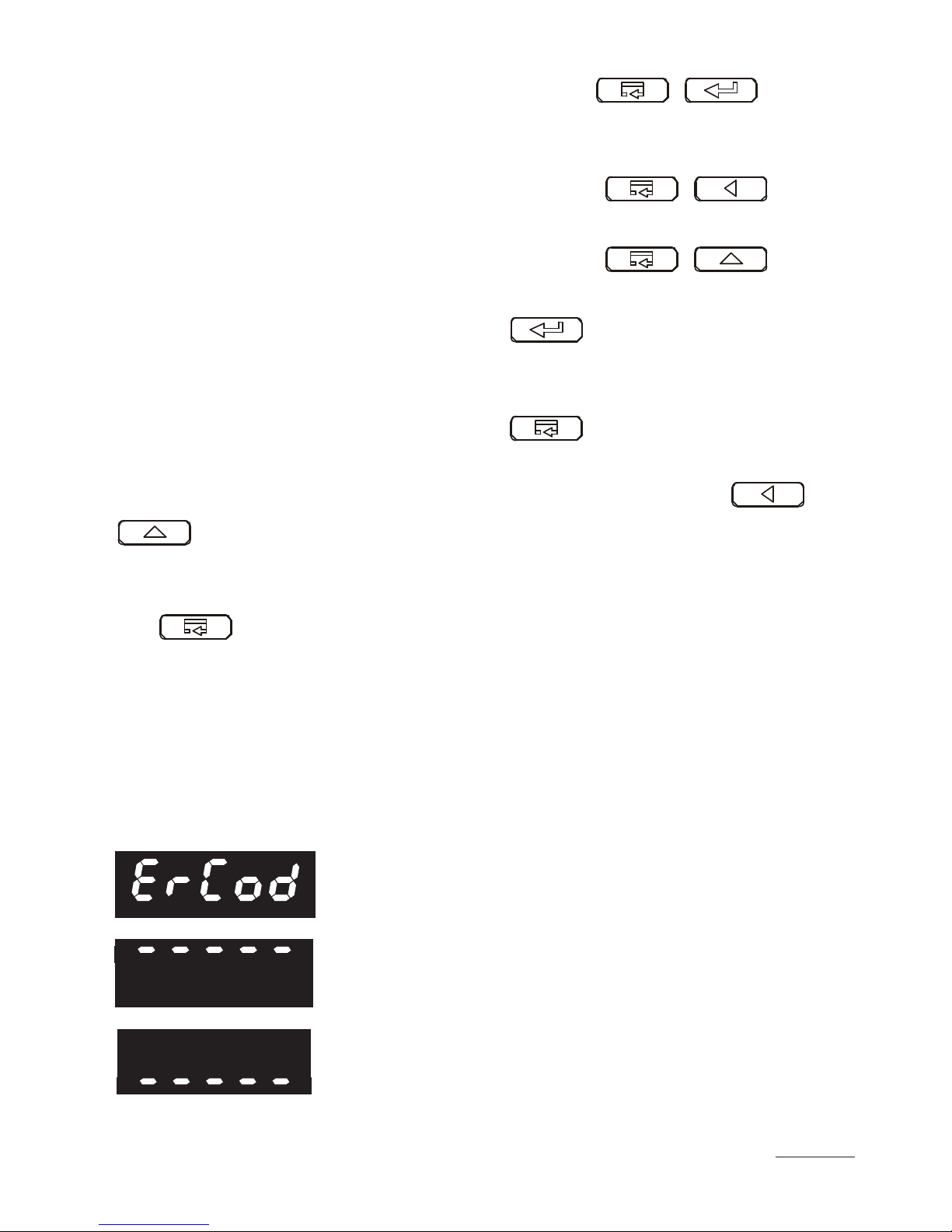

The appearance of the symbols mentioned below on the display

means:

- Incorrectly introduced safety code.

- Overflow of the upper measuring range.

- Overflow of the lower measuring range.

Page 14

14

Fig. 8. Service algorithm of the N30H meter

Page 15

15

5.4. Programming

The pressure of the push-button and holding it down through

ca 3 seconds causes the entry to the programming matrix. If the entry is

protected by a password, then the safety code symbol SEC is displayed alternately with the set value 0. The write of the correct code causes

the entry to the matrix, the write of an incorrect code causes the display

of the ErCod inscription. The matrix of transitions to the programming

mode is presented on the fig. 9. The choice of the level is made by

means of the

push-button, however the entry and moving

through the parameters of the chosen level is carried out by means of

the

and push-buttons. Parameter symbols are displayed alternately with their current values. In order to change the value

of the chosen parameter, one must use the

push-button. For

resignation from change, one must use the

push-button. In order to exit from the chosen level, one must chose the ----- symbol and

press the

push-button. To exit from the programming matrix,

one must press during ca 1 second the

push-button. Then, the

inscription End appears for ca 3 seconds and the meter transits to the

display of the measured value. In case of leaving the meter in the parameter programming mode, the automatic abandon of the programming

mode (the parameter and next the menu) follows after 30 seconds and

the meter transits to display the measured value.

5.4.1. Value Change Way of the Chosen Parameter

In order to increase the value of the chosen parameter, one must press

the

push-button. A single pressure of the push, causes the

increase of the value of 1. The increase of value when displaying the

digit 9, causes the set of 0 on this digit (or the minus mark in case of

the oldest display digit). The change of the cursor position after pressing the

push-button. In order to accept the set parameter,

Page 16

16

Fig. 9. Programming matrix

Page 17

17

InP 1

Parameter

symbol

Description Range of changes

tYP1

Kind of the connected input signal

500U – input 500 V.

100U – input 100 V

5A – input 5 A.

1A – input 1 A.

HoUr – current time.

Cnt1

The measurement time is expressed in

seconds. The result on the display presents the mean value counted in the Cnt1

period. This parameter is not taken into

consideration during the measurement

in the HoUr modes.

1...3600

Table 1

one must hold down the

push-button. Then, the write of the

parameter follows and the display of its symbol alternately with the new

value. The pressure of the

push-button during the change of

the parameter value will cause the resignation of the write.

5.4.2. Changing Floating-point Values

The change is carried out in two stages ( the transition to the next stage

follows after pressing the

push-button:

1) setting values from the range -19999M...99999, similarly as for

integral values;

2) setting decimal point positions (00000., 0000.0, 000.00, 00.000,

0.0000); the

push-button shifts the decimal point to the left,

however the

push shifts the decimal point to the right;

The pressure of the

push-button during the change of the pa-

rameter value will cause the resignation of the write.

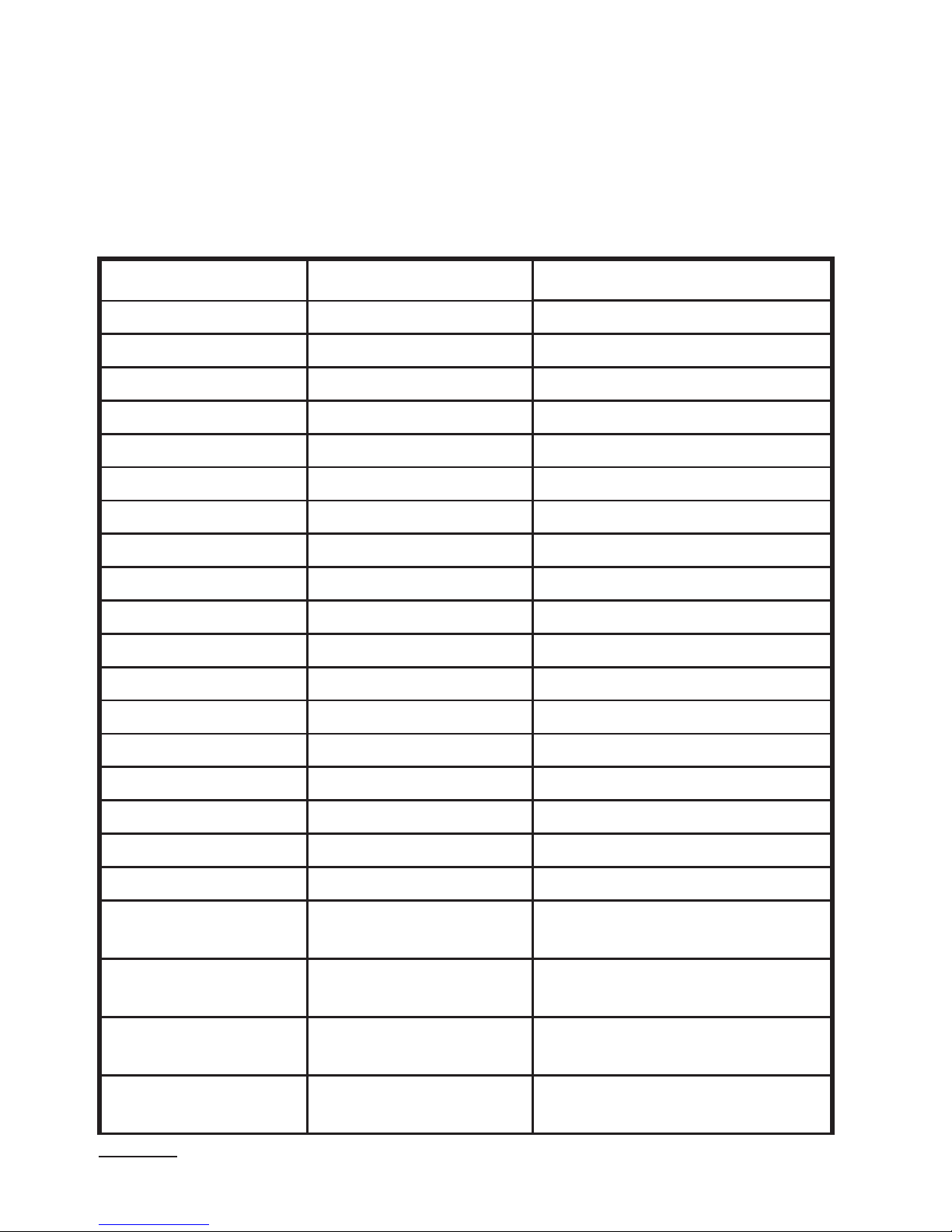

5.4.3. Characteristic of Programmed Parameters

Programmed parameters and the range of their quantity changes are

presented in the table below.

Page 18

18

Table 2

dISP

Parameter

symbol

Description Range of changes

d_P

Minimal position of the decimal point

when displaying the measured value

- display format. This parameter is not

taken into consideration during the

CoUntH and HoUr modes.

0.0000 – 0

00.000 – 1

000.00 – 2

0000.0 – 3

00000 – 4

CoLdo

Display colour, when the displayed

value is less than CoLLo.

rEd – red

grEEn – green

orAnG -orange

CoLbE

Display colour, when the displayed

value is higher than CoLLo and less

than CoLHi.

CoLuP

Display colour when the displayed value

is higher than CoLHi

CoLLo

Lower threshold of colour change

-19999..99999

CoLHi

Upper threshold of colour change

-19999..99999

ovrLo

Lower threshold of the display narrowing. Values below the declared

threshold are signaled on the display by

the symbol.

-----

.

-19999..99999

ovrHi

Upper threshold of display narrowing.

Values above the declared threshold are

signaled on the display by the symbol.

-----

.

-19999..99999

Table 3

Ind

Parameter

symbol

Description Range of changes

IndCp

Number of points of the individual characteristic. For a value less than 2, the

individual characteristic is switched off.

The number of segments is the number

of points decreased of one.

The individual characteristic is not taken

into consideration in the HoUr modes.

1...21

Xn

The point value for which we will expect

Yn (n-point number)

-19999...99999

Yn

Expected value for Xn.

-19999...99999

Page 19

19

Table 4

ALr1, ALr2, ALr3, ALr4

Parameter

symbol

Description Range of changes

P_A1

P_A2

P_A3

P_A4

Input quantity, steering the alarm.

InP1 – Main input (indicated

value).

HoUr – real time clock

tYP1

tYP2

tYP3

tYP4

Alarm type. Fig. 12 presents the

graphical imaging of alarm types.

n-on – normal (transition

from 0 to 1),

n-oFF – normal (transition

from 1 to 0),

on – switched on,

oFF – switched off,

H-on – manually switched

on; till the change time of

the alarm type, the alarm

output remains switched on

for good,

H-oFF – manually switched

off; till the change time of

the alarm type the output

alarm remains switched off

for good.

PrL1

PrL2

PrL3

PrL4

lower Alarm threshold.

-19999...99999

PrH1

PrH2

PrH3

PrH4

upper Alarm threshold.

-19999...99999

dLY1

dLY2

dLY3

dLY4

Delay of alarm switching.

0...900

Page 20

20

LEd1

LEd2

LEd3

LEd4

Support of alarm signalling. In

the situation when the support

function is switched on , after

the alarm state retreat, the

signalling diode is not blanked

. It signals the alarm state till its

blanking moment by means of

the

push-button combination. This function

concerns only and exclusively

the alarm signaling, thus relay

contacts will operate without

support according to the chosen

type of alarm.

oFF – function switched off

on – function switched on

out

Parameter

symbol

Description Range of changes

P_An

Input quantity, on which the

analog output has to react..

InP – main input (indicated

value).

HoUr – Real Time Clock

AnL

Lower threshold of the analog

output. One must give the value,

for which we want to obtain the

minimal value of signal on the

analog output.

-19999...99999

AnH

Upper threshold of the analog

output. One must give the value

on which we want to obtain the

maximal value of signal on the

analog output( 10 V or 20 mA).

-19999...99999

tYPA

Analog output type.

0_10U – napięciowe 0..10V

0_20A – prądowe 0..20mA

4_20A – prądowe 4..20mA

Table 5

Page 21

21

bAud

Baud rate of the RS485 interface

4.8 – 4800 bit/s

9.6 – 9600 bit/s

19.2 – 19200 bit/s

38.4 – 38400 bit/s

57.6 – 57600 bit/s

115.2 – 115200 bit/s

prot

Type of transmission frame of the

RS-485 interface.

r8n2

r8E1

r8o1

r8n1

Addr

Address in the MODBUS network.

The write of the value 0 switches

the interface off

.

0...247

Table 6

SEr

Parameter

symbol

Description Range of changes

SEt

Write of manufacturer’s settings.

The setting of the value YES

causes the write of standard

parameters into the meter.

The value of manufacturer’s

parameters is presented in the

table 7.

no – do nothing.

YeS – causes the write of

manufacturer’s settings.

SEC

Introduction of a new password.

The introduction of the value 0

switched the password off.

0...60000

HOUR

Setting of the current time. The

introduction of a wrong time cancels the introduction of time.

The introduced value will not be

collected.

0.00...23.59

unIt

Backlighting of the unit.

On – unit highlight switched

on.

Off – unit highlight switched

off.

tESt

Display test. The test consists of

a successive lighting up of digital

display segments. Alarm diodes

and unit highlighting diodes

should be lighted .

YeS – causes the test start.

The pressure of the

push-button ends the test.

no – do nothing.

Page 22

22

5.4.4 Individual Characteristic

N30H meters can recalculated the measured value into any value

thanks to the implemented individual characteristic function. The individual characteristic rescales the input signal measured according to the

set characteristic. The way of the individual characteristic interaction on

the meter operation has been presented on the fig.10.

Fig. 10. Action of the individual characteristic

The user can introduce maximally twenty linearizing functions by giving

points defining intervals of the given function operation and expected

values for successive points. On the base of given points and corresponding values to them, coefficients a and b of recalibrating straight

lines are calculated. The programming of the individual characteristic

consists on the definition of the number of points which the input function will be linearized by. On must remember that the number of linearizing functions is less of one than the number of points. Next, one must

program successive points by giving the measured value (Hn) and the

expected value corresponding to it, – value, which has to be displayed

(Yn). The graphic interpretation of the individual characteristic is presented on the fig. 11..

Page 23

23

Fig. 11. Individual characteristic

During the function approximation, one must remember that for the approximation of functions strongly differing from the linear characteristic

, the higher the number of linearizing segments, the smallest the error

related to the linearization.

If measured values are smallest from H1 then, recalculations will be

made on the base of the first straight line calculated on the base of

points (H1,Y1) an (H2,Y2). However, for values higher than Hn (where n

– the last declared measured value) the value to display will be calculated on the base of the last assigned linear function.

Note: All introduced points of the measured value (Hn) must be arranged in the increasing sequence, such to preserve the following dependence:

H1 < H2 < H3... < Hn

If the above is not fulfilled, the individual characteristic function will be

automatically switched off (will not be realized) and a diagnostic flag

will be set in the status register.

Page 24

24

a) n-on b) n-off

c) on d) off

Fig. 12. Alarm types: a) n-on, b) n-off c) on d) off.

5.4.5 Alarm Types

The N30U meter is equipped with 2 alarm outputs with NOC contact

(make contact) and two alarm outputs with NOC/NCC contact (make

and break contact) (option). Each of alarms can work in one of the six

modes . The work of alarms in modes is presented in the fig. 12. : n-on,

n-off, on, off. Two remaining modes : h-on and h-off mean respectively,

always switched on and always switched off. These modes are destined for the manual simulation of alarm states.

Page 25

25

Caution !

l In case of alarms of n-on, n-off, on, off types, the write of

PrL>PrH will cause the alarm switching off.

l In case of a measuring range overflow, the reaction of the relays

is compatible with written PrL, PrH, tYP parameters. In spite of the

displayed overflow, the meter still carries out the measurement.

l The meter controls currently the value of the introduced parame-

ter at the moment. In case when the introduced value overflows the

upper range given in the table 1, the meter will make automatically

the change into the maximal value. Similarly, in case when the

introduced value overflows the lower change range given in the

table 1, the meter will make automatically the change into the

minimal value.

5.4.6 Display Format

The N30H meter adapts automatically the display format (precision) to

the value of measured quantity. So that the function could be fully used,

one must choose the format 0.0000, then the meter will display the measured value with the possible highest accuracy. This function does not

operate for the time display, where the format is set automatically. The

current time (HOUr mode) is displayed in the 24 hours’ format, in the

form hh.mm, where hh – current time, and mm – current minute..

Page 26

26

Parameter symbol Level in the matrix

Standard value

tYP1 1

500U

Cnt1 1 1

indCP 2 no

H0 2 0

Y0 2 0

H1 2 100

Y1 2 100

... ... ...

Hn 2 (n-1)*100

Yn 2 (n-1)*100

d_P 3 0000.0

CoLdo 3 grEEn

CoLbE 3 orAng

CoLuP 3 rEd

CoLLo 3 50.00

CoLHi 3 80.00

ovrLo 3 -19999

ovrHi 3 99999

P_A1, P_A2,

P_A3, P_A4

4, 5, 6, 7 InP1

tYP1, tYP2,

tYP3, tYP4

4, 5, 6, 7 h-off

PrL1, PrL2,

PrL3, PrL4

4, 5, 6, 7 1000

PrH1, PrH2,

PrH3, PrH4

4, 5, 6, 7 2000

Table 7

5.5. Manufacturer’s Parameters

Standard settings of the N30U meter are presented in the table 8. These settings can be restored by means of the meter menu through the

choice of the option Set from the menu Ser.

Page 27

27

dLY1, dLY2,

dLY3, dLY4,

4, 5, 6, 7 0

LEd1, LEd2,

LEd3, LEd4

4, 5, 6, 7 oFF

P_An 8 InP1

tYPA 8 0_10U

AnL 8 0

AnH 8 99999

bAud 8 9.6

prot 8 r8n2

Addr 8 1

SEt 9 no

SEC 9 0

HOUR 9 not defined

unit 9 off

tESt 9 off

6. RS-485 INTERFACE

N30H programmable digital meters have a serial link in RS-485 standard for the communication in computer systems and with other devices fulfilling Master function. An asynchronous communication character protocol MODBUS has been implemented on the serial link. The

transmission protocol describes ways of information exchange between

devices through the serial link.

6.1. Connection Way of the Serial Interface

The RS-485 standard allows to a direct communication of 32 devices

on a single serial link of 1200 m long (at baud rate 9600 b/s). For the

connection of a higher quantity of devices, it is necessary to apply additional intermediate-separating systems ( e.g. PD51 converter).

Page 28

28

Fig. 13. Connection way of the RS-485 interface

The lead wire of the interface line is presented on the fig. 4. To obtain a

correct transmission, it is necessary to connect lines A and B in parallel

with their equivalents in other devices. The connection must be made

through a shielded wire. The wire shield must be connected to the protection terminal in the nearest possible neighbourhood of the meter

(connect the shield to a single point to the protection terminal).

The GND line serves to the additional protection of the interface line at

long connections. Then, one must connect GND signals of all devices

to the RS-485 bus.

To obtain the connection to the computer, a RS-485 interface card or

an appropriate converter is indispensable, e.g. PD51 or PD10.

The connection way of devices is shown on the fig. 13

The designation of transmission lines for the card in the PC computer

depends on the card producer.

Page 29

29

6.2. Description of the MODBUS Protocol

Implementation.

The implemented protocol is in accordance with the PI-MBUS-300 Rev

G of Modicon Company specification.

Set of the serial link parameters of N30U meters in MODBUS protocol:

l meter address: 1...247,

l baud rate: 4800, 9600, 19200, 38400,

57600, 115200 bit/s,

l work mode: RTU with a frame in formats: 8N2,

8E1, 8O1, 8N1,

l maximal time to start

the response : 100 ms.

The parameter configuration of the serial link consists on the settlement

of the baud rate (bAUd parameter), device address (Addr parameter),

and the format of the information unit (Prot parameter).

Notice:

Each meter connected to the communication network must have:

l unique address, different from addresses of other devices connec-

ted to the network,

l identical baud rate and type of information unit.

6.3 Description of Applied Functions

Following functions of the MODBUS protocol have been implemented

in the N30U meter:

l 03 – Readout of n-registers.

l 04 – Readout of input n-registers.

l 06 – Write of a single register.

l 16 – Write of n-registers.

l 17 – Identification of the slave device.

Page 30

30

6.4 Register Map

The register map of the N30H meter is presented below.

Notice:

All given addresses are physical addresses. In some computer programs logical addressing is applied, then addresses must be increased of 1.

Table 8

Range of addreses

Value type Description

4000-4049 integer (16 bits) Value placed in a 16-bit register.

7000-7025 float (32 bits)

Value placed in two successive 16bit registers. Registers include the

same data as 32-bit register from

the area 7500. Registers are only for

readout.

7200-7363 float (32 bits)

Value placed in two successive 16bit registers. Registers include the

same data as 32-bit register from

the area 7600. Registers can be

read out and written.

7500-7512 float (32 bits)

Value placed in a 32-bit register.

Registers are only for readout.

7600-7663 float (32 bits)

Value placed in a 32-bit register.

Registers can be read out and

written.

Page 31

31

6.5. Registers for Write and Readout

Table 9

The value is placed in

16-bit registers

write (w)/ readout (r)

Input type4000

tYP1

w/r 0...4

Range DescriptionSymbol

Value

0 0.0000

1 00.000

0 500U - voltage measurement in the 500 V range

1 100U - voltage measurement in the 100 V range

2 5A - voltage measurement in the 5 A range

3 1A - voltage measurement in the1 A range

4 HoUr -current time

Value

Reserved4001 w/r

Reserved4002 w/r

4003

Cnt

w/r 1...3600

Measurement time expressed in seconds. This time

defines the averaging time of the measured value.

The displayed value is the mean value calculated

from the Cnt1 period.

Reserved4004 w/r

Reserved4005 w/r

Reserved4006 w/r

Reserved4007 w/r

4008

IndCp

w/r 1...21

Number of points of the individual characteristic.

For the value 1, the individual characteristic is switched off. Segments of the individual characteristic

are defined by parameters Xn and Yn, where n

– point number..

Minimal position of the decimal point when displaying the measured value.

4009

d_P

w/r 0...4

Description

Page 32

32

Value

0 red

1 green

2 orange

2 000.00

3 0000.0

4 00000

Display colour when the displayed value is less

than coLLo

Description

4010

CoLdo

w/r 0...2

Value

0 red

1 green

2 orange

Display colour when the displayed value is higher

than coLLo and less than CoLHi

Description

4011

CoLbE

w/r 0...2

Value

0 red

1 green

2 orange

Display colour when the displayed value is higher

than coLHi

Description

4012

CoLUp

w/r 0...2

DescriptionValue

0 Main input

1 Clock

Input quantity controlling the alarm

4013

P_a1

w/r 0, 1

Value

0 n-on

1 n-off

2 on

3 off

4 h-on

5 h-off

Type of alarm 1 (description - fig. 6)

Description

4014

tyP1

w/r 0...5

Delay of alarm 1 (in seconds)

4015

dLY1

w/r 0...900

Page 33

33

Support of alarm 1 signalling

4016

LEd1

w/r 0...1

Value

0 Support switched off

1 Support switched on

Descritpion

DescriptionValue

0 Main input

1 Clock

Input quantity controlling the alarm

4017

P_a2

w/r 0, 1

Value

0 n-on

1 n-off

2 on

3 off

4 h-on

5 h-off

Type of alarm 2 (description - fig. 6)

Description

4018

tyP2

w/r 0...5

Delay of alarm 2 (in seconds)

4019

dLY2

w/r 0...900

Support of alarm 2 signalling

4020

LEd2

w/r 0...1

Value

0 Support switched off

1 Support switched on

Description

DescriptionValue

0 Main input

1 Clock

Input quantity controlling the alarm

4021

P_a3

w/r 0, 1

WartoϾ

0 n-on

1 n-off

2 on

3 off

4 h-on

5 h-off

Type of alarm 3 (description - fig. 6)

Opis

4022

tyP3

w/r 0...5

Delay of alarm 3 (in seconds)

4023

dLY3

w/r 0...900

Page 34

34

Support of alarm 3 signalling

4024

LEd3

w/r 0...1

Value

0 Support switched off

1 Support switched on

Description

DescriptionValue

0 Main input

1 Clock

Input quantity controlling the alarm

4025

P_a4

w/r 0, 1

Value

0 n-on

1 n-off

2 on

3 off

4 h-on

5 h-off

Type of alarm 4 (description - fig. 6)

Description

4026

tyP4

w/r 0...5

Delay of alarm 4 (in seconds)

4027

dLY4

w/r 0...900

Support of alarm 4 signalling

4028

LEd4

w/r 0...1

Value

0 Support switched off

1 Support switched on

Description

Input quantity, which the analog output has to

react on.

4029

P_an

w/r 0, 1

Value

0 Main input

1 Clock

Description

Type of analog output

4030

tYPa

w/r 0...2

Value

0 Voltage input 0...10 V

1 Current input 0...20 mA

2 Current input 4...20 mA

Description

Baud rate

4031

bAud

w/r 0...5

Value

0 4800 bit/s

1 9600 bit/s

2 19200 bit/s

Description

Page 35

35

Bit 15 Break of the supply

Bit 14 Re-set of the RTC clock.

3 38400 bit/s

4 57600 bit/s

5 115200 bit/s

Meter address. The write of the value 0 causes the

inerface switching off.

4033

Addr

z/o 0...247

Transmission mode4032

prot

z/o 0...3

Update transmission parameters. Causes the application of introduced RS-485 interface settings.

4034

sAvE

z/o 0...1

Value

0 RTU 8N2

1 RTU 8E1

2 RTU 8O1

3 RTU 8N1

Description

Write of standard parameters4035

SEt

z/o 0...1

Value

0 without changes

1 set standard parameters

Description

Password for parameters4036

SEc

z/o 0...6000

Value

0 without password

... Entry in parameters preceded by a

request about the password

Description

Current time4037

hour

z/o 0...2359

This parameter occurs in the ggmm format,where:

gg - means hours,

mm – means minutes.

The introduction of a wrong hour will cause the setting 23, however the introduction of wrong minutes

will generate the setting of the value 59.

Switch on/off the unit backlight4038

unit

z/o 0, 1

Value

0 Highlighting switched off

1 Highlighting switched on

Description

Reserved

...

...

... ...

Meter status. Describes the current state of the

meter. Successive bits present data of the event.

The bit set on 1 means, that the event took place.

Events can be only erased..

4048 Status1 z/o

0...65535

4039 z/o 0, 1

Extreme values’ deletion. Writing in “1” to the

register will cause the deletion of the minimum and

maximum values

Page 36

36

Bit 13 Not used

Bit 12

Lack of communication with data memory

Bit 11 Wrong settings

Bit 10 Manufacturer’s setting restored

Bit 9

Lack of measured values in data memory

Bit 8 Not used

Bit 7 Output plate was detected

Bit 6 Output plate - error or lack of calibration

Bit 5 Not used

Bit 4 Not used

Bit 3

Wrong configuration of the individual character.

Bit 2 Not used

Bit 1 Not used

Bit 0 Not used

Bit 15 Not used

Bit 14 Not used

Meter status. Describes the current state of the

meter. Successive bits present data of the event.

The bit set on 1 means, that the event took place.

Events can be only deleted.

Bit 13 Not used

Bit 12 Not used

Bit 11 Not used

Bit 10 Not used

Bit 9 Not used

Bit 8 Not used

Bit 7 LED4 - Signalling of alarm No.4

Bit 6 LED3 - Signalling of alarm No.3

Bit 5 LED2 - Signalling of alarm No.2

Bit 4 LED1 - Signalling of alarm No.1

Bit 3 Status of the alarm relay No.4

Bit 2 Status of the alarm relay No.3

Bit 1 Status of the alarm relay No.2

Bit 0 Status of the alarm relay No.1

4049 Status2 w/r

Page 37

37

The value is placed in two successive

16-bit registers. These registers include

the same data as 32-bit registers from

the area 7600.

The value is placed in 32-bit registers

Sym-

bol

write

(w)

/readout

(r)

Range Description

7200 7600

coLLo

w/r -19999...99999

Lower threshold of the display colour change

7202 7601

coLHI

w/r -19999...99999

Upper threshold of the display colour

change

7204 7602

ovrLo

w/r -19999...99999 Lower threshold of the display narrowing

7206 7603

ovrHI

w/r -19999...99999 Upper threshold of the display narrowing

7208 7604

PrL 1

w/r -19999...99999 Lower threshold of alarm 1

7210 7605

PrH 1

w/r -19999...99999 Upper threshold of alarm 1

7212 7606

PrL 2

w/r -19999...99999 Lower threshold of alarm 2

7214 7607

PrH 2

w/r -19999...99999 Upper threshold of alarm 2

7216 7608

PrL 3

w/r -19999...99999 Lower threshold of alarm 3

7218 7609

PrH 3

w/r -19999...99999 Upper threshold of alarm 3

7220 7610

PrL 4

w/r -19999...99999 Lower threshold of alarm 4

7222 7611

PrH 4

w/r -19999...99999 Upper threshold of alarm 4

7224 7612

AnL

w/r -19999...99999 Lower threshold of analog output

7226 7613

AnH

w/r -19999...99999 Upper threshold of analog output

7228 7614 w/r -19999...99999 Reserved

7230 7615 w/r -19999...99999 Reserved

7232 7616 w/r -19999...99999 Reserved

7234 7617 w/r -19999...99999 Reserved

7236 7618 w/r -19999...99999 Reserved

7238 7619 w/r -19999...99999 Reserved

Table 10

Page 38

38

7240 7620 w/r -19999...99999 Reserved

7242 7621 w/r -19999...99999 Reserved

7244 7622

H1

w/r -19999...99999

Point of the individual charachteristic

Point No.1.

7246 7623

Y1

w/r -19999...99999 Expected value for the point No. 1.

7248 7624

H2

w/r -19999...99999

Point of the individual charachteristic

Point No. 2.

7250 7625

Y2

w/r -19999...99999 Expected value for the point No. 2.

7252 7626

H3

w/r -19999...99999

Point of the individual charachteristic

Point No. 3.

7254 7627

Y3

w/r -19999...99999 Expected value for the point No. 3.

7256 7628

H4

w/r -19999...99999

Point of the individual charachteristic

Point No.4.

7258 7629

Y4

w/r -19999...99999 Expected value for the point No. 4.

7260 7630

H5

w/r -19999...99999

Point of the individual charachteristic

Point No. 5.

7262 7631

Y5

w/r -19999...99999 Expected value for the point No. 5.

7264 7632

H6

w/r -19999...99999

Point of the individual charachteristic

Point No. 6.

7266 7633

Y6

w/r -19999...99999 Expected value for the point No. 6.

7268 7634

H7

w/r -19999...99999

Point of the individual charachteristic

Point No. 7.

7270 7635

Y7

w/r -19999...99999 Expected value for the point No. 7.

7272 7636

H8

w/r -19999...99999

Point of the individual charachteristic

Point No. 8.

7274 7637

Y8

w/r -19999...99999 Expected value for the point No. 8.

7276 7638

H9

w/r -19999...99999

Point of the individual charachteristic

Point No. 9.

7278 7639

Y9

w/r -19999...99999 Expected value for the point No. 9.

7280 7640

H10

w/r -19999...99999

Point of the individual charachteristic

Point No.10.

7282 7641

Y10

w/r -19999...99999 Expected value for the point No. 10.

7284 7642

H11

w/r -19999...99999

Point of the individual charachteristic

Point No. 11.

7286 7643

Y11

w/r -19999...99999 Expected value for the point No. 11.

7288 7644

H12

w/r -19999...99999

Point of the individual charachteristic

Point No. 12.

Page 39

39

7290 7645

Y12

w/r -19999...99999 Expected value for the point No. 12.

7292 7646

H13

w/r -19999...99999

Point of the individual charachteristic

Point No. 13.

7294 7647

Y13

w/r -19999...99999 Expected value for the point No. 13.

7296 7648

H14

w/r -19999...99999

Point of the individual charachteristic

Point No. 14.

7298 7649

Y14

w/r -19999...99999 Expected value for the point No. 14.

7300 7650

H15

w/r -19999...99999

Point of the individual charachteristic

Point No. 15.

7302 7651

Y15

w/r -19999...99999 Expected value for the point No. 15.

7304 7652

H16

w/r -19999...99999

Point of the individual charachteristic

Point No. 16.

7306 7653

Y16

w/r -19999...99999 Expected value for the point No. 16.

7308 7654

H17

w/r -19999...99999

Point of the individual charachteristic

Point No. 17.

7310 7655

Y17

w/r -19999...99999 Expected value for the point No. 17.

7312 7656

H18

w/r -19999...99999

Point of the individual charachteristic

Point No. 18.

7314 7657

Y18

w/r -19999...99999 Expected value for the point No. 18.

7316 7658

H19

w/r -19999...99999

Point of the individual charachteristic

Point No. 19.

7318 7659

Y19

w/r -19999...99999 Expected value for the point No. 19.

7320 7660

H20

w/r -19999...99999

Point of the individual charachteristic

Point No. 20.

7322 7661

Y20

w/r -19999...99999 Expected value for the point No. 20.

7324 7662

H21

w/r -19999...99999

Point of the individual charachteristic

Point No. 21.

7326 7663

Y21

w/r -19999...99999 Expected value for the point No. 21.

Page 40

40

The value placed In two suc-

cessive 16-bit registers. These

registers include the same data as

32-bit registers from the area 7500

The value is placed in 32-bit

registers

Name

Write

(w)

/

rea-

dout

(r)

Unit Name of the quantity

7000 7500 Identifier O —

Constant identifying the device.

The value 187 means the N30H meter

7002 7501 Status O —

Status is register describing the current

state of the meter

7004 7502 Control O %

It is a register defining the control of the

analog outpu

7006 7503 Minimum O —

Minimal value of the currently displayed

value

7008 7504 Maximum O —

Maximal value of the currently displayed value

7010 7505

Displayed

value

O — Currently displayed value

7012 7506 O — Current time

7014 7507 O Reserved

7016 7508 O —

Password of analog-to-digital transducer

7018 7509 O Reserved

7020 7510 O

Measured value – not recalculated

In relation to the individual characteristic,

a.s.l

.

7022 7511 O Reserved

7024 7512 O Reserved

6.6. Registers only for Readout

Table 11

Page 41

41

7. SOFTWARE UPDATING

Note! After updating the software the manufacturer’s settings for the

transducer ought to be set, therefore it is advisable to store the meters

parameters before its updating using LPCon or eCon software.

After LPCon has been started, one ought to set serial port, baut rate,

mode and the transducer address in Options. Then choose the N30H

meter from the menu Devices and click the icon Read in order to read

all set parameters (necessary for their later restoration). After selecting

from the menu Updating the option Device software updating, the Lumel

Updater (LU) window opens – Fig. 13 b. Press Connect. The information

window Messages contains information on the updating process. At the

correctly opened port, the message Port opened displays.

Fig. 13. The view of program window: a) LPCon, b) Lumel Updater (LU)

a)

b)

The N30H meters (from the version 1.09) in version with RS-485 interface

come with the implemented function that allows for updating the software

from a PC with LPCon or eCon software. In order to update software the

RS-485 converter on USB, such as PD10 converter must be connected

to the computer.

Page 42

42

Entering the updating mode in the meter is carried out remotely

by LU program (based on the settings in LPCon - adres, mode,

baud rate, port Com) or by switching on the meter power supply with

pressed key . Pulsating of the meter state diode AL1 in green signals readiness for updating, whereas the LU program displays

the message Device found and the name and version of the program

of the conneted device. One should press the button ... and indicate

the meter updating file. At the correctly opened file, the information

File opened displays. One should press Send button. After updating being successfully completed the meter switches to normal work,

whereas the information window displays Done and the duration time

of the updating. After the LU window closure, one should go

to the parameters group Restoring manufacturer’s settings, mark the option and press Apply button. Then press the icon Save in order to save

readout initially set parameters. Current software version may also be

checked by reading the meter welcome messages after switching on

the power supply.

Note! Switching the supply off during the software updating process may result

in permenent damage of the meter!

Page 43

43

8. ERROR CODES

After switching the meter on to the network or during the work, messages about errors can appear.

Messages about errors and their reasons are presented below. .

Table 12

Error message Description

Overflow of the upper value of the measuring range value

or the programmed indication range.

Overflow of the lower value of the measuring range value

or the programmed indication range.

ErFrt

Communication error with the data memory. One must

contact the service workshop.

ErPar

Parameter error. Wrong configuration data. Manufacturer’s settings will be restored after pressing any push.

ErdEF

Default settings have been restored. One must press any

push to transit to a normal work.

ErFPL

Error of measured values stored by the meter (measured

value, maximal and minimal values). One must press any

push to transit to a normal work. After pressing the push

during 1 sec, the ErdEF message will be displayed.

ErCAo

Lack of calibration of analog outputs. One must press any

push to transit to the normal work. Analog outputs will not

be serviced. One must contact the service workshop.

ErCOd

Erroneous access code to meter parameters. The error

appears in the moment of giving a wrong access code to

meter parameters (only in case when meter parameters

are protected by a password).

Page 44

44

8. TECHNICAL DATA

Measuring ranges.

Table 13

Kind of input Indication of range class

500 V -600...600 V 0.1% of the range

100 V -130...130 V 0.1% of the range

5 A -6...6 A 0.1% of the range ± 5 mA

1 A -2...2 A 0.1% of the range ± 1 mA

Current time 00.00...23.59 0.5 seconds/24h

Relay outputs: - relays, NO voltageless contacts

load capacity 250 V~/0.5A~

- relays, switched voltageless contacts

load capacity 250 V~/0.5A~ (option)

Analog outputs (option): - programmable, current 0/4...20 mA

load resistance £ 500 W

- programmable, current 0..10 V

load resistance ³ 500 W

Alarm output OC

(option): output of OC type, passive npn,

30 V d.c./30 mA.

Serial interface: RS-485 (option)

Transmission protocol: MODBUS RTU

Error of analog output: 0.2% of the set range.

Protection grade ensured

by the casing:

frontal side IP65

terminal side IP10

Page 45

45

Weight: < 0.2 kg

Dimensions: 96 ´ 48 ´ 93 mm

Reference Conditions and Rated

Operating conditions:

- supply voltage 85..253 V d.c./a.c. 40..400Hz

or 20..40 V a.c. (40...400 Hz),

20...60 V d.c.

40..400Hz

- ambient temperature -25..23..+55

o

C

- storage temperature -33..+70

o

C

- reltive air humidity 25..95% (inadmissible vapour

condensation)

- work position any

Additional errors:

- from temperature changes: for analog inputs and outputs

50% of the class/10 K

Standards fulfilled by the meter:

Electromagnetic compatibility:

l Noise immunity acc. to EN 61000-6-2

l Noise emission acc. to EN 61000-6-4

Safety requirements:

Acc. to the EN61010-1 standard:

l isolation between circuits: basic,

l installation category: III,

l pollution level: 2,

l maximal phase-to-earth working voltage:

- 300 V for the supply circuit,

- for the measuring input 600 V for analog input signals

– cat. II (300 V – cat. III),

- 50 V for remaining circuits.

l altitiude above sea level < 2000 m.

Page 46

46

9. ORDER CODES

Table 14

*

- after agreeing with the Manufacturer

DIGITAL PANEL METER N30H - X X XX XX U X

Supply:

85... 253 V a.c. (40...400 Hz) or d.c. ........................ 1

20... 40 V a.c. (40...400 Hz), 20..60 V d.c. ............... 2

Additional outputs:

lack .................................................................................. 0

OC output, RS-485, analog outputs ................................ 1

OC output, RS-485, analog outputs,

switched-over relay outputs ............................................ 2

Unit:

unit code acc. to the table 15 ............................................... XX

Version:

standard ........................................................................................ 00

custom-made* .............................................................................. XX

Language:

English ................................................................................................... U

Acceptance tests:

without extra requirements ............................................................................ 0

with an extra quality inspection certificate .................................................... 1

Acc. to customer’s request* .......................................................................... X

Order example

The code N30H - 1 0 01 00 U 0 - means

N30H - programmable N30H panel digital meter

1 - supply: 85...253 V a.c./d.c

0 - lack of additional outputs

01 - unit „V” acc. to the table 2

00 - standard version

U - English language

0 - without extra requirements

Page 47

47

Code of the highlighted unit Table 15

Code Unit Code Unit

00 Lack of unit 29 %

01 V 30 %RH

02 A 31 pH

03 mV 32 kg

04 kV 33 bar

05 mA 34 m

06 kA 35 l

07 W 36 s

08 kW 37 h

09 MW 38 m

3

10 var 39 obr

11 kvar 40 szt

12 Mvar 41 imp

13 VA 42 rps

14 kVA 43 m/s

15 MVA 44 l/s

16 kWh 45 obr/min

17 MWh 46 rpm

18 kvarh 47 mm/min

19 Mvarh 48 m/min

20 kVAh 49 l/min

21 MVAh 50 m

3

/min

22 Hz 51 szt/h

23 kHz 52 m/h

24

W

53 km/h

25

kW

54 m

3

/h

26

o

C 55 kg/h

27

o

F 56 l/h

28 K XX On order

1)

1)

- after agreeing with the Manufacturer

Page 48

48

10. MAINTENANCE AND GUARANTEE

The N30H digital panel meter does not require any periodical

maintenance.

In case of some incorrect operations:

1. From the Shipping Date, During the Period Given in the

Annexed Guarantee Card:

One should take the meter down from the installation and

return it to the Manufacturer’s Quality Control Dept. If the

meter has been used in compliance with the instructions,

the Manufacturer warrants to repair it free of charge.

2. After the Guarantee Period:

One should turn over the meter to repair it in a certified

service workshop.The disassembling of the casing causes

the cancellation of the granted guarantee. Spare parts are

available for the period of five years from the date of

purchase.

Our policy is one of continuous improvement and we

reserve the right to make changes in design and specifications of any products as engineering advances or

necessity requires and revise the above specifications

without notice.

Page 49

49

Page 50

50

N30H-09A

Manufactured by:

Sifam Tinsley Instrumentation Inc

3105 Creekside Village Dr,

Unit 801, Kennesaw GA 30144

Distributed by:

Veracious Canada Inc

1101 Britannia Rd E,

Mississauga, ON L4W 3X1

E-mail: info@veraciousinc.ca

Contact: +1 416-640-5364

Fax:

+1 416-981-3933

www.veraciousinc.comWeb:

Loading...

Loading...