M95512-W M95512-R

SO8 (MN)

150 mil width

TSSOP8 (DW)

169 mil width

WLCSP (CS)

UFDFPN8 (MC)

2 x 3 mm (MLP)

(preliminary data)

M95512-DR M95512-DF

512-Kbit serial SPI bus EEPROM

Datasheet − production data

Features

■ Compatible with the Serial Peripheral Interface

(SPI) bus

■ Memory array

– 512 Kb (64 Kbytes) of EEPROM

– Page size: 128 bytes

■ Write

– Byte Write within 5 ms

– Page Write within 5 ms

■ Additional Write lockable page (Identification

page)

■ Write Protect: quarter, half or whole memory

array

■ High-speed clock: 10 MHz

■ Single supply voltage:

– 2.5 V to 5.5 V for M95512-W

– 1.8 V to 5.5 V for M95512-R and M95512-

DR

– 1.7 V to 5.5 V for M95512-DF

■ Operating temperature range: from -40°C up to

+85°C

■ Enhanced ESD protection

■ More than 4 million Write cycles

■ More than 200-year data retention

■ Packages

– RoHS compliant and halogen-free

(ECOPACK

®

)

June 2012 Doc ID 11124 Rev 17 1/52

This is information on a product in full production.

www.st.com

1

Contents M95512-W M95512-R M95512-DR M95512-DF

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Serial Data Output (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Serial Data Input (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Chip Select (S

3.5 Hold (HOLD

3.6 Write Protect (W

3.7 V

3.8 V

supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CC

ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SS

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Connecting to the SPI bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 SPI modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Operating features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Supply voltage (VCC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.1 Operating supply voltage V

5.1.2 Device reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.3 Power-up conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.4 Power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Active Power and Standby Power modes . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Hold condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Data protection and protocol control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Write Enable (WREN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Write Disable (WRDI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Read Status Register (RDSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.1 WIP bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Contents

6.3.2 WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.3 BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3.4 SRWD bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 Write Status Register (WRSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 Read from Memory Array (READ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6 Write to Memory Array (WRITE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.6.1 Cycling with Error Correction Code (ECC) . . . . . . . . . . . . . . . . . . . . . . 25

6.7 Read Identification Page (available only in M95512-D devices) . . . . . . . . 26

6.8 Write Identification Page (available only in M95512-D devices) . . . . . . . . 27

6.9 Read Lock Status (available only in M95512-D devices) . . . . . . . . . . . . . 28

6.10 Lock ID (available only in M95512-D devices) . . . . . . . . . . . . . . . . . . . . . 29

7 Power-up and delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 Power-up state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2 Initial delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Doc ID 11124 Rev 17 3/52

List of tables M95512-W M95512-R M95512-DR M95512-DF

List of tables

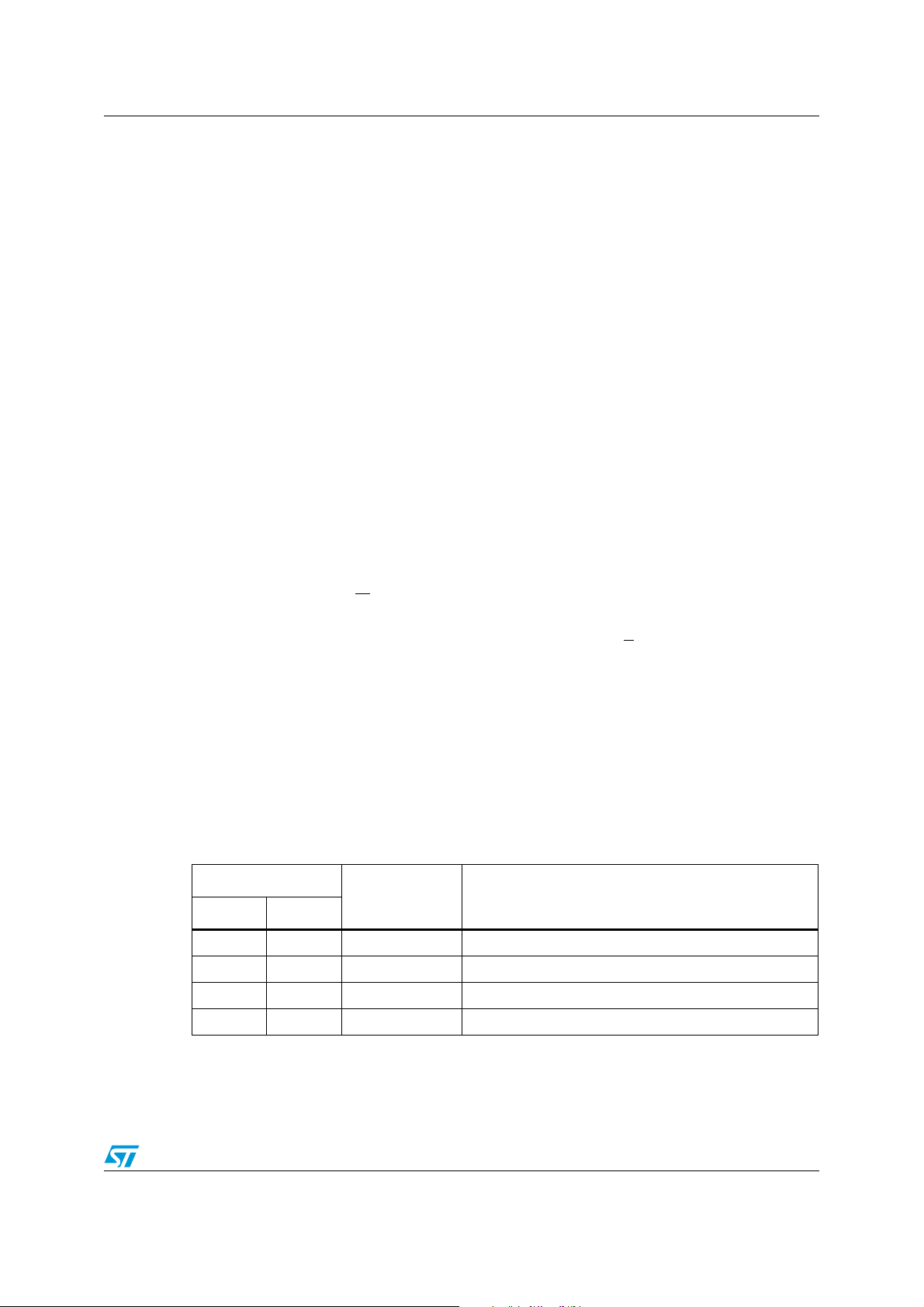

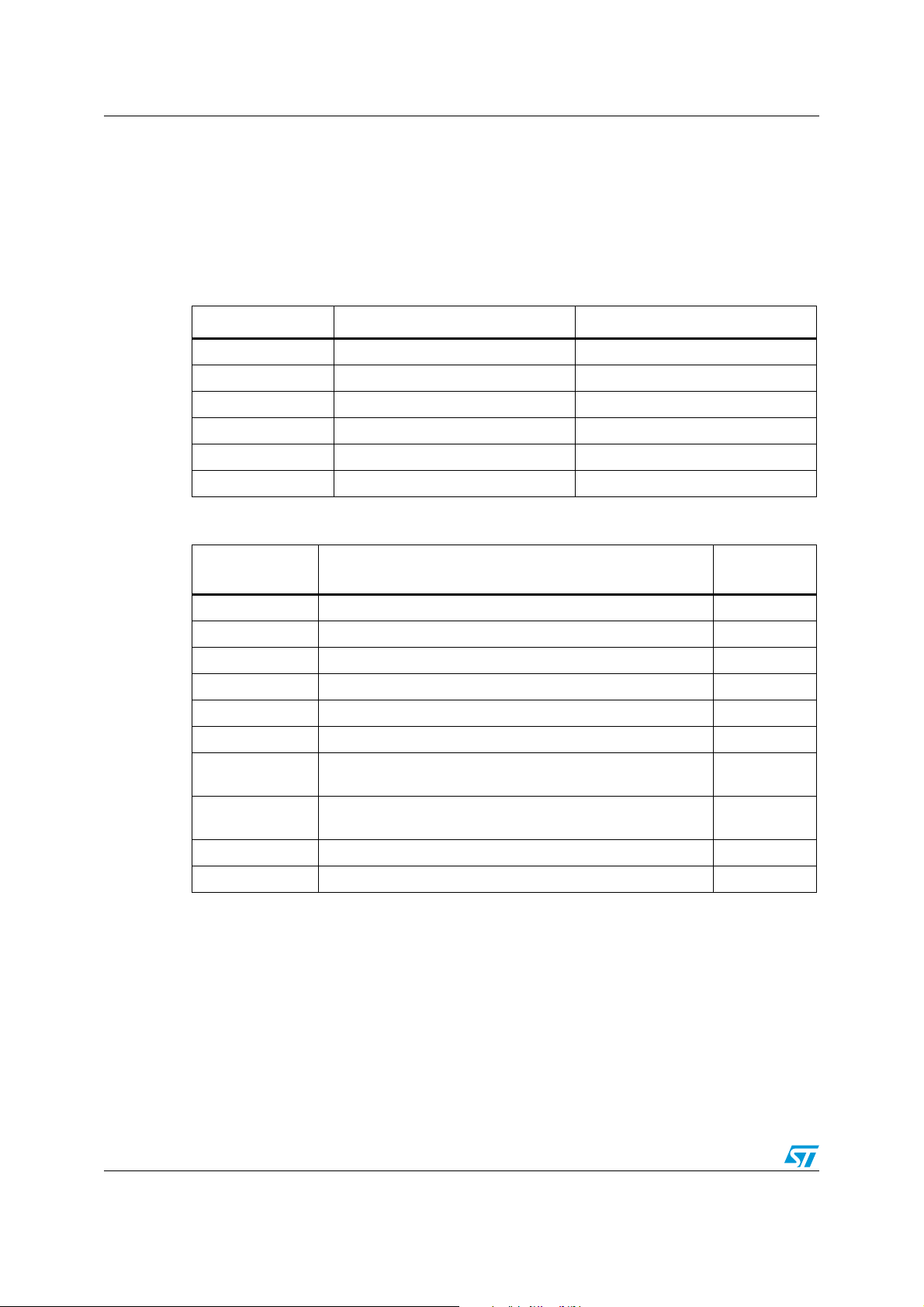

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Write-protected block size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 3. Instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4. M95512-D instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Status Register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. Protection modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 7. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 8. Operating conditions (M95512-W, device grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 9. Operating conditions (M95512-R and M95512-DR, device grade 6) . . . . . . . . . . . . . . . . . 32

Table 10. AC measurement conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 11. Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 12. Cycling performance by groups of four bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 13. Memory cell data retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 14. DC characteristics (previous M95512-W products, device grade 6). . . . . . . . . . . . . . . . . . 34

Table 15. DC characteristics (M95512-W products, device grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 16. DC characteristics (M95512-R and M95512-DR products, device grade 6). . . . . . . . . . . . 35

Table 17. DC characteristics (M95512-DF products, device grade 6) . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 18. AC characteristics (previous M95512-W products, device grade 6) . . . . . . . . . . . . . . . . . . 37

Table 19. AC characteristics (M95512-W products, device grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 20. AC characteristics (M95512-R and M95512-DF products, device grade 6) . . . . . . . . . . . . 39

Table 21. SO8N – 8-lead plastic small outline, 150 mils body width, mechanical data . . . . . . . . . . . 42

Table 22. UFDFPN8 (MLP8) – 8-lead ultra thin fine pitch dual flat package no lead

2 x 3 mm, data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 23. TSSOP8 – 8-lead thin shrink small outline, package mechanical data. . . . . . . . . . . . . . . . 44

Table 24. M95512-DFCS6TP/K, WLCSP 8-bump wafer-level chip scale package mechanical data. 46

Table 25. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 26. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF List of figures

List of figures

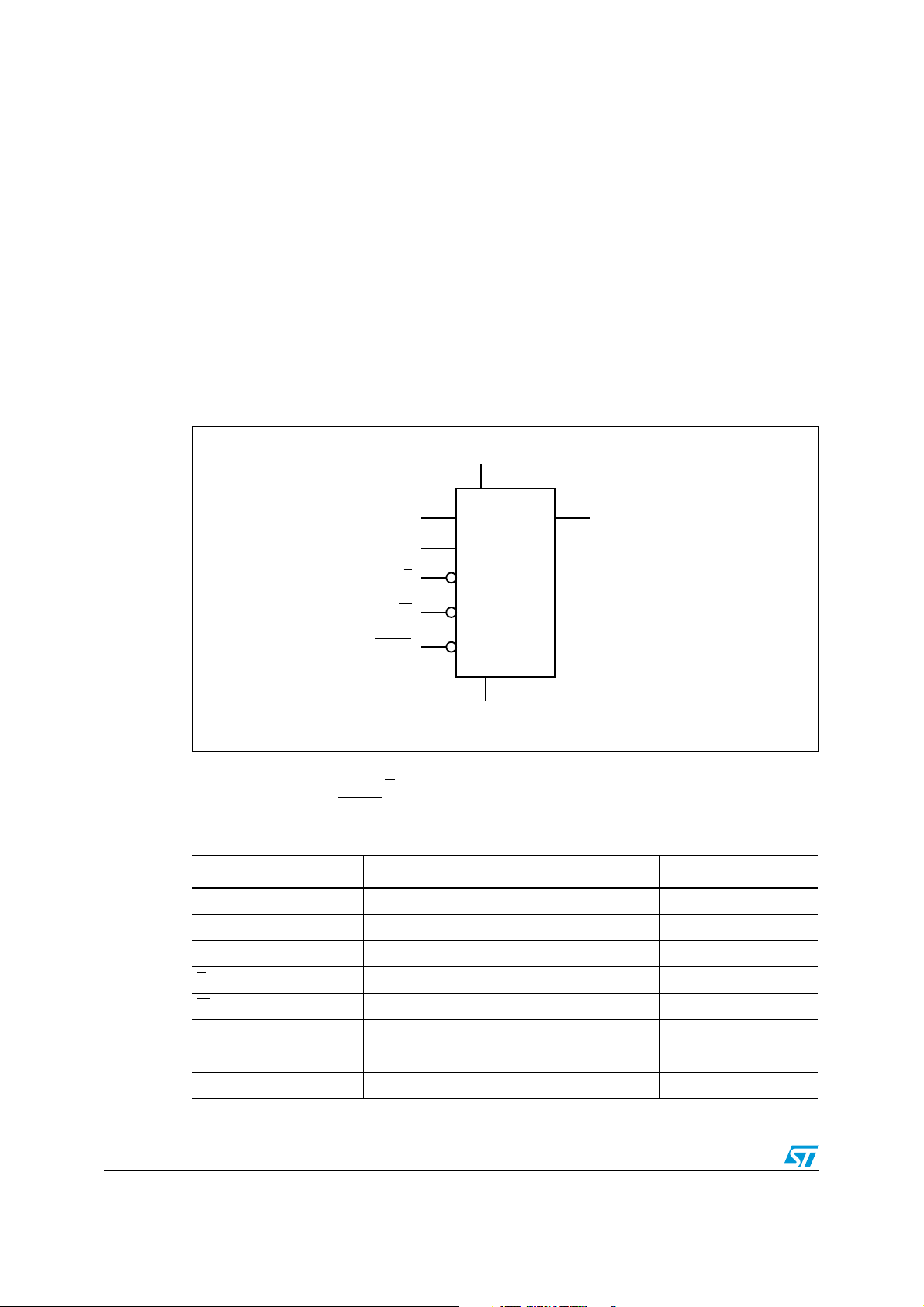

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. 8-pin package connections (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. WLCSP connections for the die identified by process letters “KB”

(top view, marking side, with balls on the underside) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

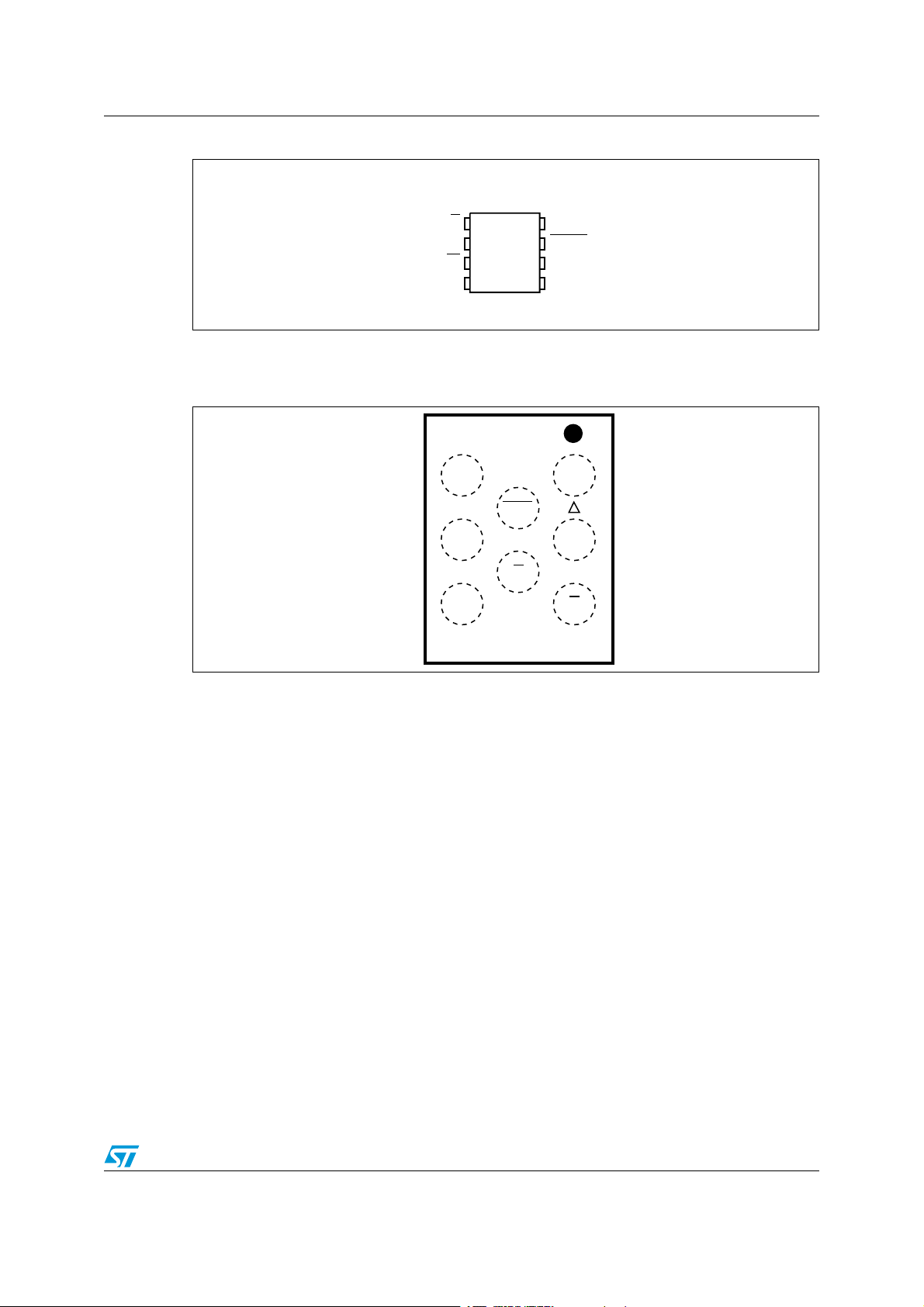

Figure 4. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

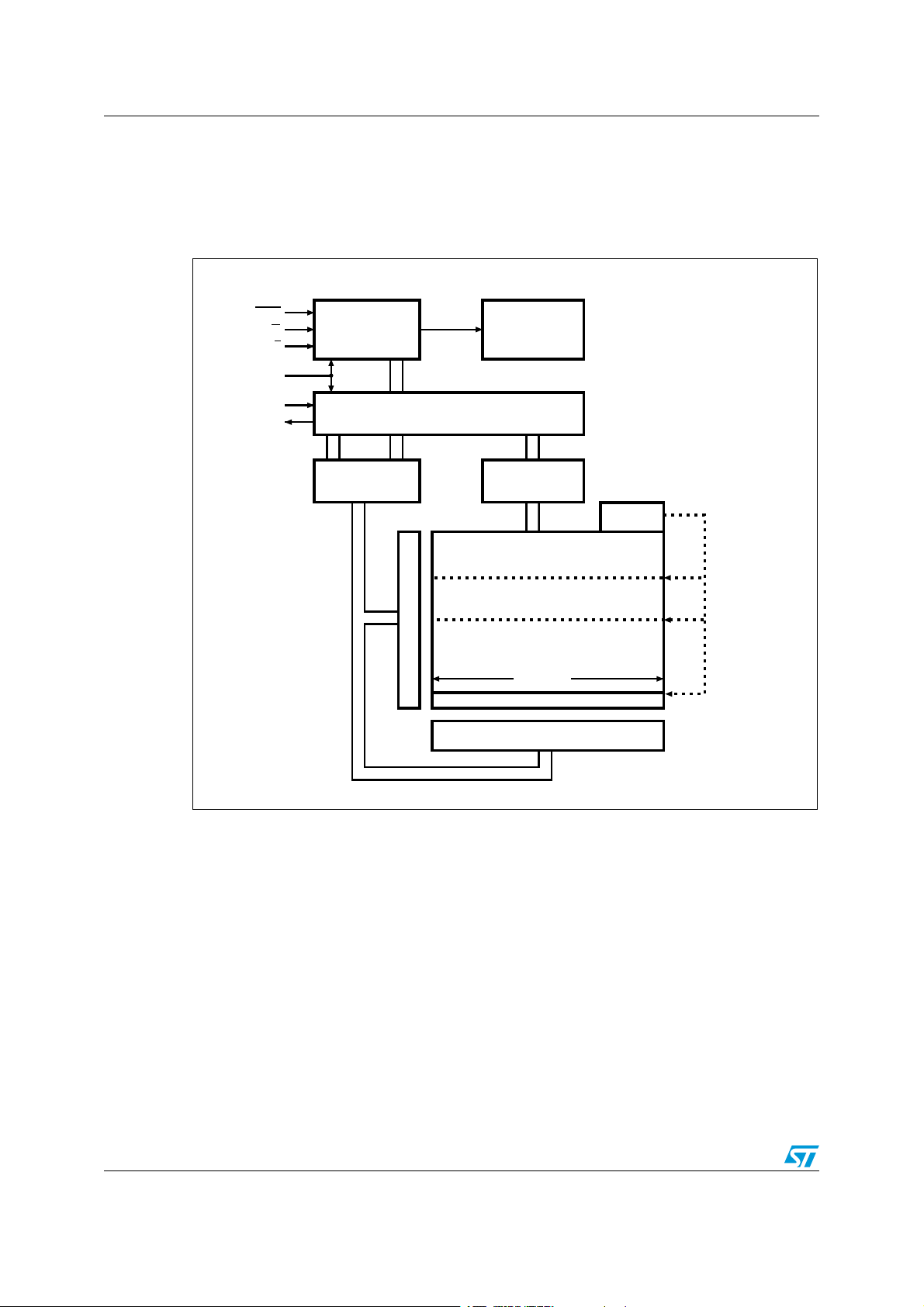

Figure 5. Bus master and memory devices on the SPI bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. SPI modes supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Hold condition activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Write Enable (WREN) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9. Write Disable (WRDI) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 10. Read Status Register (RDSR) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11. Write Status Register (WRSR) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12. Read from Memory Array (READ) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13. Byte Write (WRITE) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 14. Page Write (WRITE) sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. Read Identification Page sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16. Write identification page sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 17. Read Lock Status sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 18. Lock ID sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 19. AC measurement I/O waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 20. Serial input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 21. Hold timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 22. Serial output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 23. SO8N – 8-lead plastic small outline, 150 mils body width, package outline . . . . . . . . . . . . 42

Figure 24. UFDFPN8 (MLP8) – 8-lead ultra thin fine pitch dual flat no lead, package outline. . . . . . . 43

Figure 25. TSSOP8 – 8-lead thin shrink small outline, package outline . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 26. M95512-DFCS6TP/K, WLCSP 8-bump wafer-level chip scale package outline . . . . . . . . 45

Doc ID 11124 Rev 17 5/52

Description M95512-W M95512-R M95512-DR M95512-DF

AI01789C

S

V

CC

M95xxx

HOLD

V

SS

W

Q

C

D

1 Description

The M95512 devices are Electrically Erasable PROgrammable Memories (EEPROMs)

organized as 65536 x 8 bits, accessed through the SPI bus.

The M95512-W can operate with a supply voltage from 2.5 V to 5.5 V, the M95512-R and

M95512-DR can operate with a supply voltage from 1.8 V to 5.5 V, and the M95512-DF can

operate with a supply voltage from 1.7 V to 5.5 V, over an ambient temperature range of

-40 °C / +85 °C.

The M95512-D offers an additional page, named the Identification Page (128 bytes). The

Identification Page can be used to store sensitive application parameters which can be

(later) permanently locked in Read-only mode.

Figure 1. Logic diagram

The SPI bus signals are C, D and Q, as shown in Figure 1 and Tab l e 1 . The device is

selected when Chip Select (S

interrupted when the HOLD

Table 1. Signal names

Signal name Function Direction

C Serial Clock Input

D Serial Data Input Input

Q Serial Data Output Output

S

6/52 Doc ID 11124 Rev 17

W

Hold Input

HOLD

V

CC

V

SS

) is driven low. Communications with the device can be

is driven low.

Chip Select Input

Write Protect Input

Supply voltage

Ground

M95512-W M95512-R M95512-DR M95512-DF Description

DV

SS

C

HOLDQ

SV

CC

W

AI01790D

M95xxx

1

2

3

4

8

7

6

5

-36

6

##

$

6

33

3

#

(/,$

7

1

Figure 2. 8-pin package connections (top view)

1. See Section 10: Package mechanical data section for package dimensions, and how to identify pin 1.

Figure 3. WLCSP connections for the die identified by process letters “KB”

(top view, marking side, with balls on the underside)

Caution: As EEPROM cells lose their charge (and so their binary value) when exposed to ultra violet

(UV) light, EEPROM dice delivered in wafer form or in WLCSP package by

STMicroelectronics must never be exposed to UV light.

Doc ID 11124 Rev 17 7/52

Memory organization M95512-W M95512-R M95512-DR M95512-DF

-36

(/,$

3

7

#ONTROLLOGIC

(IGHVOLTAGE

GENERATOR

)/SHIFTREGISTER

!DDRESSREGISTER

ANDCOUNTER

$ATA

REGISTER

PAGE

8DECODER

9DECODER

#

$

1

3IZEOFTHE

2EADONLY

%%02/AREA

3TATUS

REGISTER

)DENTIFICATIONPAGE

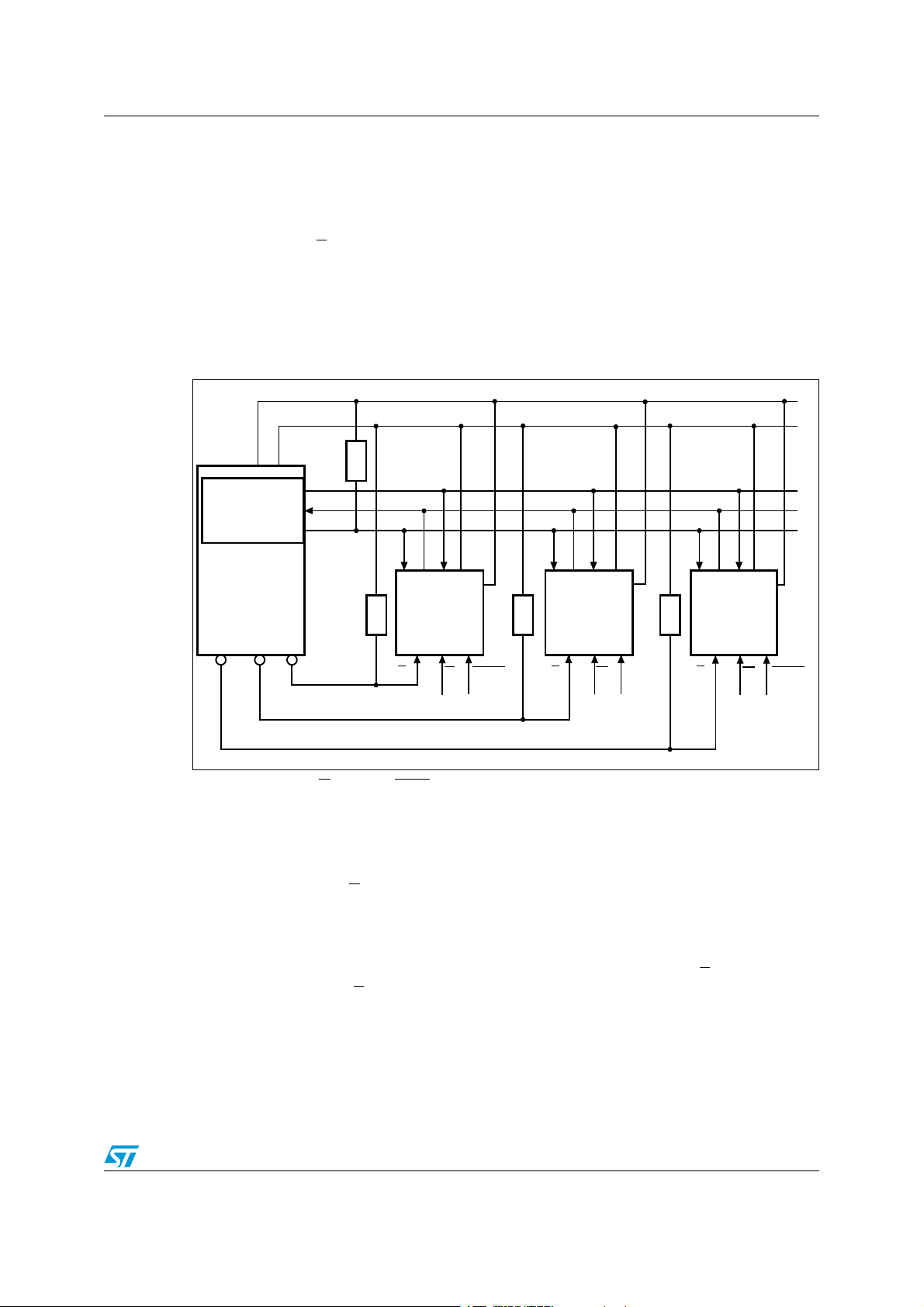

2 Memory organization

The memory is organized as shown in the following figure.

Figure 4. Block diagram

8/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Signal description

3 Signal description

During all operations, VCC must be held stable and within the specified valid range:

V

(min) to VCC(max).

CC

All of the input and output signals must be held high or low (according to voltages of V

V

, VIL or VOL, as specified in Section 9: DC and AC parameters). These signals are

OH

described next.

3.1 Serial Data Output (Q)

This output signal is used to transfer data serially out of the device. Data is shifted out on the

falling edge of Serial Clock (C).

3.2 Serial Data Input (D)

This input signal is used to transfer data serially into the device. It receives instructions,

addresses, and the data to be written. Values are latched on the rising edge of Serial Clock

(C).

,

IH

3.3 Serial Clock (C)

This input signal provides the timing of the serial interface. Instructions, addresses, or data

present at Serial Data Input (D) are latched on the rising edge of Serial Clock (C). Data on

Serial Data Output (Q) change from the falling edge of Serial Clock (C).

3.4 Chip Select (S)

When this input signal is high, the device is deselected and Serial Data Output (Q) is at high

impedance. The device is in the Standby Power mode, unless an internal Write cycle is in

progress. Driving Chip Select (S

After power-up, a falling edge on Chip Select (S

instruction.

3.5 Hold (HOLD)

The Hold (HOLD) signal is used to pause any serial communications with the device without

deselecting the device.

During the Hold condition, the Serial Data Output (Q) is high impedance, and Serial Data

Input (D) and Serial Clock (C) are Don’t Care.

To start the Hold condition, the device must be selected, with Chip Select (S

) low selects the device, placing it in the Active Power mode.

) is required prior to the start of any

) driven low.

Doc ID 11124 Rev 17 9/52

Signal description M95512-W M95512-R M95512-DR M95512-DF

3.6 Write Protect (W)

The main purpose of this input signal is to freeze the size of the area of memory that is

protected against Write instructions (as specified by the values in the BP1 and BP0 bits of

the Status Register).

This pin must be driven either high or low, and must be stable during all Write instructions.

3.7 V

supply voltage

CC

VCC is the supply voltage.

3.8 VSS ground

VSS is the reference for all signals, including the VCC supply voltage.

10/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Connecting to the SPI bus

AI12836b

SPI Bus Master

SPI Memory

Device

SDO

SDI

SCK

CQD

S

SPI Memory

Device

CQD

S

SPI Memory

Device

CQD

S

CS3 CS2 CS1

SPI Interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

W

HOLD

W

HOLD

W

HOLD

RR R

V

CC

V

CC

V

CC

V

CC

V

SS

V

SS

V

SS

V

SS

R

4 Connecting to the SPI bus

All instructions, addresses and input data bytes are shifted in to the device, most significant

bit first. The Serial Data Input (D) is sampled on the first rising edge of the Serial Clock (C)

after Chip Select (S

All output data bytes are shifted out of the device, most significant bit first. The Serial Data

Output (Q) is latched on the first falling edge of the Serial Clock (C) after the instruction

(such as the Read from Memory Array and Read Status Register instructions) have been

clocked into the device.

Figure 5. Bus master and memory devices on the SPI bus

) goes low.

1. The Write Protect (W) and Hold (HOLD) signals should be driven, high or low as appropriate.

Figure 5 shows an example of three memory devices connected to an SPI bus master. Only

one memory device is selected at a time, so only one memory device drives the Serial Data

Output (Q) line at a time. The other memory devices are high impedance.

The pull-up resistor R (represented in Figure 5) ensures that a device is not selected if the

Bus Master leaves the S

line in the high impedance state.

In applications where the Bus Master may leave all SPI bus lines in high impedance at the

same time (for example, if the Bus Master is reset during the transmission of an instruction),

the clock line (C) must be connected to an external pull-down resistor so that, if all

inputs/outputs become high impedance, the C line is pulled low (while the S

high): this ensures that S

t

requirement is met. The typical value of R is 100 kΩ..

SHCH

and C do not become high at the same time, and so, that the

Doc ID 11124 Rev 17 11/52

line is pulled

Connecting to the SPI bus M95512-W M95512-R M95512-DR M95512-DF

AI01438B

C

MSB

CPHA

D

0

1

CPOL

0

1

Q

C

MSB

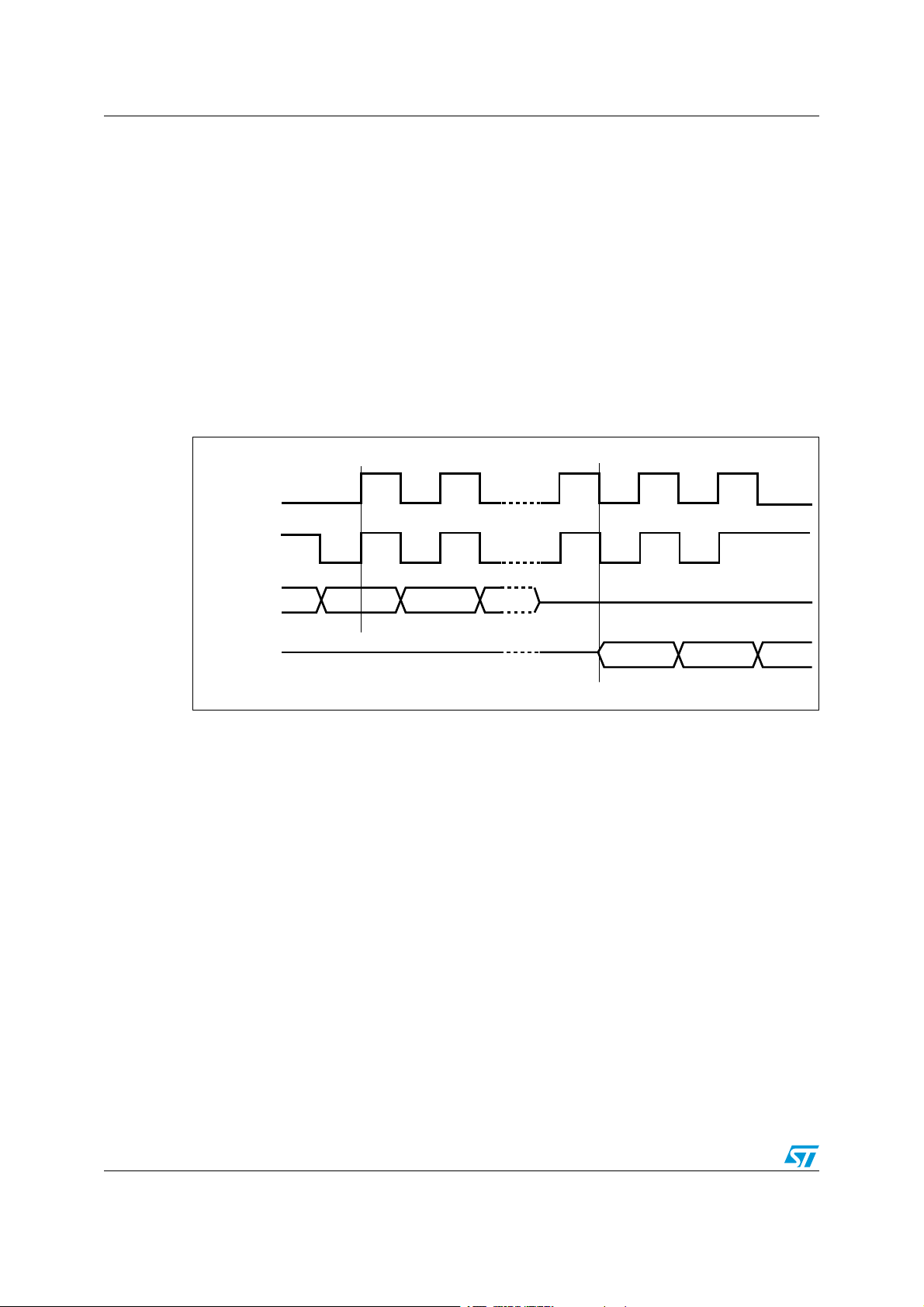

4.1 SPI modes

These devices can be driven by a microcontroller with its SPI peripheral running in either of

the following two modes:

● CPOL=0, CPHA=0

● CPOL=1, CPHA=1

For these two modes, input data is latched in on the rising edge of Serial Clock (C), and

output data is available from the falling edge of Serial Clock (C).

The difference between the two modes, as shown in Figure 6, is the clock polarity when the

bus master is in Stand-by mode and not transferring data:

● C remains at 0 for (CPOL=0, CPHA=0)

● C remains at 1 for (CPOL=1, CPHA=1)

Figure 6. SPI modes supported

12/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Operating features

5 Operating features

5.1 Supply voltage (VCC)

5.1.1 Operating supply voltage V

Prior to selecting the memory and issuing instructions to it, a valid and stable VCC voltage

within the specified [V

(min), VCC(max)] range must be applied (see Operating conditions

CC

in Section 9: DC and AC parameters). This voltage must remain stable and valid until the

end of the transmission of the instruction and, for a Write instruction, until the completion of

the internal write cycle (t

recommended to decouple the V

10 nF to 100 nF) close to the V

). In order to secure a stable DC supply voltage, it is

W

CC

CC/VSS

5.1.2 Device reset

In order to prevent erroneous instruction decoding and inadvertent Write operations during

power-up, a power-on-reset (POR) circuit is included. At power-up, the device does not

respond to any instruction until VCC reaches the POR threshold voltage. This threshold is

lower than the minimum V

and AC parameters).

At power-up, when V

CC

following state:

● in Standby Power mode,

● deselected,

● Status Register values:

– The Write Enable Latch (WEL) bit is reset to 0.

– The Write In Progress (WIP) bit is reset to 0.

– The SRWD, BP1 and BP0 bits remain unchanged (non-volatile bits).

operating voltage (see Operating conditions in Section 9: DC

CC

passes over the POR threshold, the device is reset and is in the

CC

line with a suitable capacitor (usually of the order of

device pins.

It is important to note that the device must not be accessed until V

stable level within the specified [V

conditions in Section 9: DC and AC parameters.

5.1.3 Power-up conditions

When the power supply is turned on, VCC rises continuously from VSS to VCC. During this

time, the Chip Select (S

therefore recommended to connect the S

Figure 5).

In addition, the Chip Select (S

sensitive as well as level-sensitive: after power-up, the device does not become selected

until a falling edge has first been detected on Chip Select (S

(S

) must have been high, prior to going low to start the first operation.

The V

voltage has to rise continuously from 0 V up to the minimum VCC operating voltage

CC

defined under Operating conditions in Section 9: DC and AC parameters, and the rise time

must not vary faster than 1 V/µs.

) line is not allowed to float but should follow the VCC voltage. It is

reaches a valid and

(min), VCC(max)] range, as defined under Operating

CC

CC

line to VCC via a suitable pull-up resistor (see

) input offers a built-in safety feature, as the S input is edge-

). This ensures that Chip Select

Doc ID 11124 Rev 17 13/52

Operating features M95512-W M95512-R M95512-DR M95512-DF

ai02029E

c

HOLD

Hold

condition

Hold

condition

5.1.4 Power-down

During power-down (continuous decrease of the VCC supply voltage below the minimum

V

operating voltage defined under Operating conditions in Section 9: DC and AC

CC

parameters), the device must be:

● deselected (Chip Select S should be allowed to follow the voltage applied on V

● in Standby Power mode (there should not be any internal write cycle in progress).

CC

),

5.2 Active Power and Standby Power modes

When Chip Select (S) is low, the device is selected, and in the Active Power mode. The

device consumes I

When Chip Select (S

.

CC

) is high, the device is deselected. If a Write cycle is not currently in

progress, the device then goes into the Standby Power mode, and the device consumption

drops to I

, as specified in DC characteristics (see Section 9: DC and AC parameters).

CC1

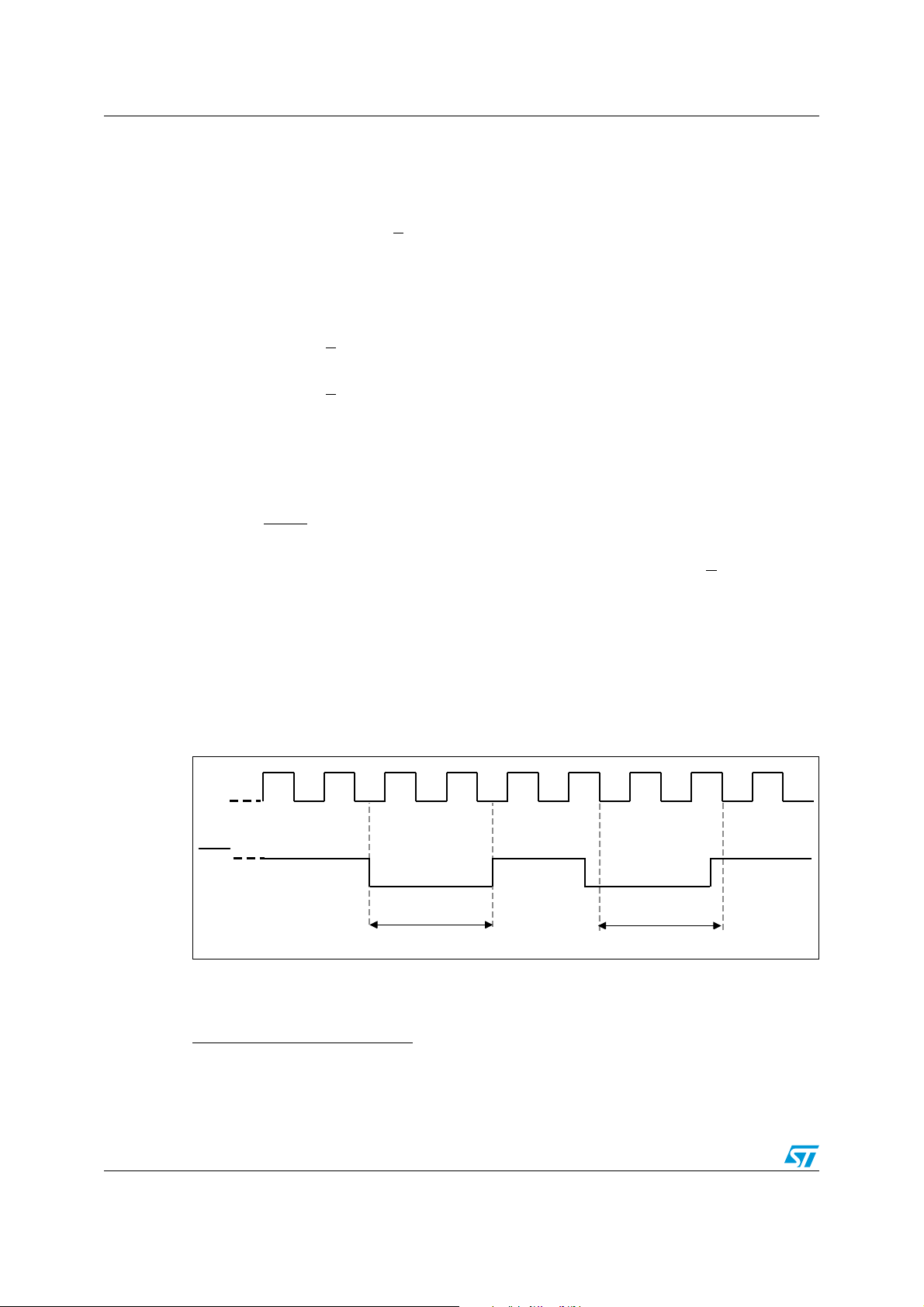

5.3 Hold condition

The Hold (HOLD) signal is used to pause any serial communications with the device without

resetting the clocking sequence.

To enter the Hold condition, the device must be selected, with Chip Select (S

) low.

During the Hold condition, the Serial Data Output (Q) is high impedance, and the Serial

Data Input (D) and the Serial Clock (C) are Don’t Care.

Normally, the device is kept selected for the whole duration of the Hold condition.

Deselecting the device while it is in the Hold condition has the effect of resetting the state of

the device, and this mechanism can be used if required to reset any processes that had

been in progress.

(a)(b)

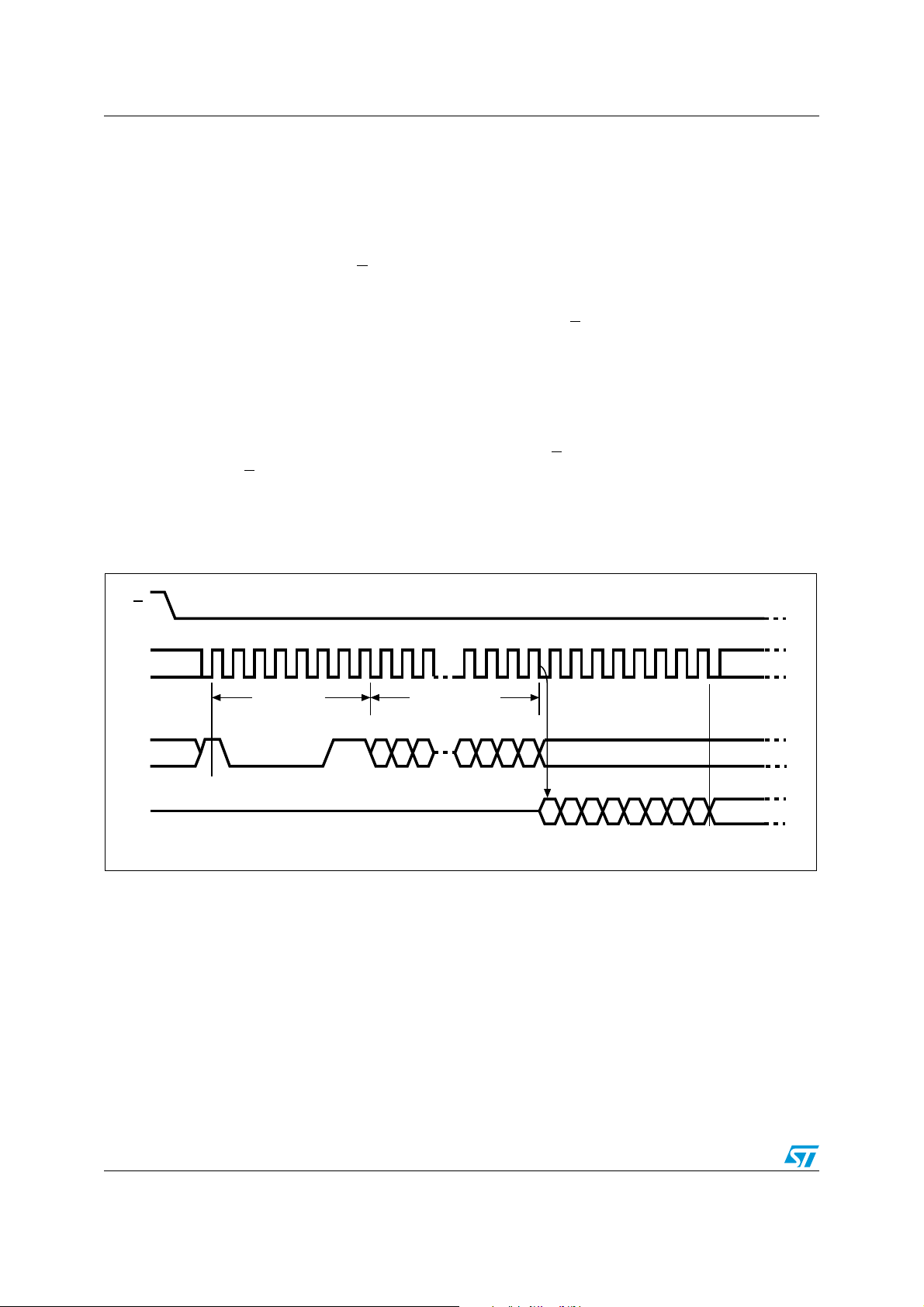

Figure 7. Hold condition activation

The Hold condition starts when the Hold (HOLD) signal is driven low when Serial Clock (C)

is already low (as shown in Figure 7).

a. This resets the internal logic, except the WEL and WIP bits of the Status Register.

b. In the specific case where the device has shifted in a Write command (Inst + Address + data bytes, each data

byte being exactly 8 bits), deselecting the device also triggers the Write cycle of this decoded command.

14/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Operating features

The Hold condition ends when the Hold (HOLD) signal is driven high when Serial Clock (C)

is already low.

Figure 7 also shows what happens if the rising and falling edges are not timed to coincide

with Serial Clock (C) being low.

5.4 Status Register

The Status Register contains a number of status and control bits that can be read or set (as

appropriate) by specific instructions. See Section 6.3: Read Status Register (RDSR) for a

detailed description of the Status Register bits.

5.5 Data protection and protocol control

The device features the following data protection mechanisms:

● Before accepting the execution of the Write and Write Status Register instructions, the

device checks whether the number of clock pulses comprised in the instructions is a

multiple of eight.

● All instructions that modify data must be preceded by a Write Enable (WREN)

instruction to set the Write Enable Latch (WEL) bit.

● The Block Protect (BP1, BP0) bits in the Status Register are used to configure part of

the memory as read-only.

● The Write Protect (W) signal is used to protect the Block Protect (BP1, BP0) bits in the

Status Register.

For any instruction to be accepted, and executed, Chip Select (S

) must be driven high after

the rising edge of Serial Clock (C) for the last bit of the instruction, and before the next rising

edge of Serial Clock (C).

Two points should be noted in the previous sentence:

● The “last bit of the instruction” can be the eighth bit of the instruction code, or the eighth

bit of a data byte, depending on the instruction (except for Read Status Register

(RDSR) and Read (READ) instructions).

● The “next rising edge of Serial Clock (C)” might (or might not) be the next bus

transaction for some other device on the SPI bus.

Table 2. Write-protected block size

Status Register bits

Protected block Protected array addresses

BP1 BP0

0 0 none none

0 1 Upper quarter C000h - FFFFh

1 0 Upper half 8000h - FFFFh

1 1 Whole memory 0000h - FFFFh

Doc ID 11124 Rev 17 15/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

6 Instructions

Each instruction starts with a single-byte code, as summarized in Ta b le 3 .

If an invalid instruction is sent (one not contained in Ta bl e 3 ), the device automatically

deselects itself.

Table 3. Instruction set

Instruction Description Instruction format

WREN Write Enable 0000 0110

WRDI Write Disable 0000 0100

RDSR Read Status Register 0000 0101

WRSR Write Status Register 0000 0001

READ Read from Memory Array 0000 0011

WRITE Write to Memory Array 0000 0010

Table 4. M95512-D instruction set

Instruction Description

Instruction

format

WREN Write Enable 0000 0110

WRDI Write Disable 0000 0100

RDSR Read Status Register 0000 0101

WRSR Write Status Register 0000 0001

READ Read from Memory Array 0000 0011

WRITE Write to Memory Array 0000 0010

Read Identification

Page

Write Identification

Page

Reads the page dedicated to identification. 1000 0011

Writes the page dedicated to identification. 1000 0010

Read Lock Status Reads the lock status of the Identification Page. 1000 0011

Lock ID Locks the Identification page in read-only mode. 1000 0010

1. Address bit A10 must be 0, all other address bits are Don't Care.

2. Address bit A10 must be 1, all other address bits are Don't Care.

(1)

(1)

(2)

(2)

16/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

C

D

AI02281E

S

Q

21 34567

High Impedance

0

Instruction

6.1 Write Enable (WREN)

The Write Enable Latch (WEL) bit must be set prior to each WRITE and WRSR instruction.

The only way to do this is to send a Write Enable instruction to the device.

As shown in Figure 8, to send this instruction to the device, Chip Select (S

) is driven low,

and the bits of the instruction byte are shifted in, on Serial Data Input (D). The device then

enters a wait state. It waits for the device to be deselected, by Chip Select (S

) being driven

high.

Figure 8. Write Enable (WREN) sequence

Doc ID 11124 Rev 17 17/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

C

D

AI03750D

S

Q

21 34567

High Impedance

0

Instruction

6.2 Write Disable (WRDI)

One way of resetting the Write Enable Latch (WEL) bit is to send a Write Disable instruction

to the device.

As shown in Figure 9, to send this instruction to the device, Chip Select (S

) is driven low,

and the bits of the instruction byte are shifted in, on Serial Data Input (D).

The device then enters a wait state. It waits for a the device to be deselected, by Chip Select

(S

) being driven high.

The Write Enable Latch (WEL) bit, in fact, becomes reset by any of the following events:

● Power-up

● WRDI instruction execution

● WRSR instruction completion

● WRITE instruction completion.

Figure 9. Write Disable (WRDI) sequence

18/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

C

D

S

21 3456789101112131415

Instruction

0

AI02031E

Q

7 6543210

Status Register Out

High Impedance

MSB

7 6543210

Status Register Out

MSB

7

6.3 Read Status Register (RDSR)

The Read Status Register (RDSR) instruction is used to read the Status Register. The

Status Register may be read at any time, even while a Write or Write Status Register cycle

is in progress. When one of these cycles is in progress, it is recommended to check the

Write In Progress (WIP) bit before sending a new instruction to the device. It is also possible

to read the Status Register continuously, as shown in Figure 10.

Figure 10. Read Status Register (RDSR) sequence

The status and control bits of the Status Register are as follows:

6.3.1 WIP bit

The Write In Progress (WIP) bit indicates whether the memory is busy with a Write or Write

Status Register cycle. When set to 1, such a cycle is in progress, when reset to 0, no such

cycle is in progress.

6.3.2 WEL bit

The Write Enable Latch (WEL) bit indicates the status of the internal Write Enable Latch.

When set to 1, the internal Write Enable Latch is set. When set to 0, the internal Write

Enable Latch is reset, and no Write or Write Status Register instruction is accepted.

The WEL bit is returned to its reset state by the following events:

● Power-up

● Write Disable (WRDI) instruction completion

● Write Status Register (WRSR) instruction completion

● Write (WRITE) instruction completion

6.3.3 BP1, BP0 bits

The Block Protect (BP1, BP0) bits are non volatile. They define the size of the area to be

software-protected against Write instructions. These bits are written with the Write Status

Register (WRSR) instruction. When one or both of the Block Protect (BP1, BP0) bits is set

to 1, the relevant memory area (as defined in Ta bl e 2 ) becomes protected against Write

(WRITE) instructions. The Block Protect (BP1, BP0) bits can be written provided that the

Hardware Protected mode has not been set.

Doc ID 11124 Rev 17 19/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

C

D

AI02282D

S

Q

21 3456789101112131415

High Impedance

Instruction Status

Register In

0

765432 0

1

MSB

6.3.4 SRWD bit

The Status Register Write Disable (SRWD) bit is operated in conjunction with the Write

Protect (W

signal enable the device to be put in the Hardware Protected mode (when the Status

Register Write Disable (SRWD) bit is set to 1, and Write Protect (W

mode, the non-volatile bits of the Status Register (SRWD, BP1, BP0) become read-only bits

and the Write Status Register (WRSR) instruction is no longer accepted for execution.

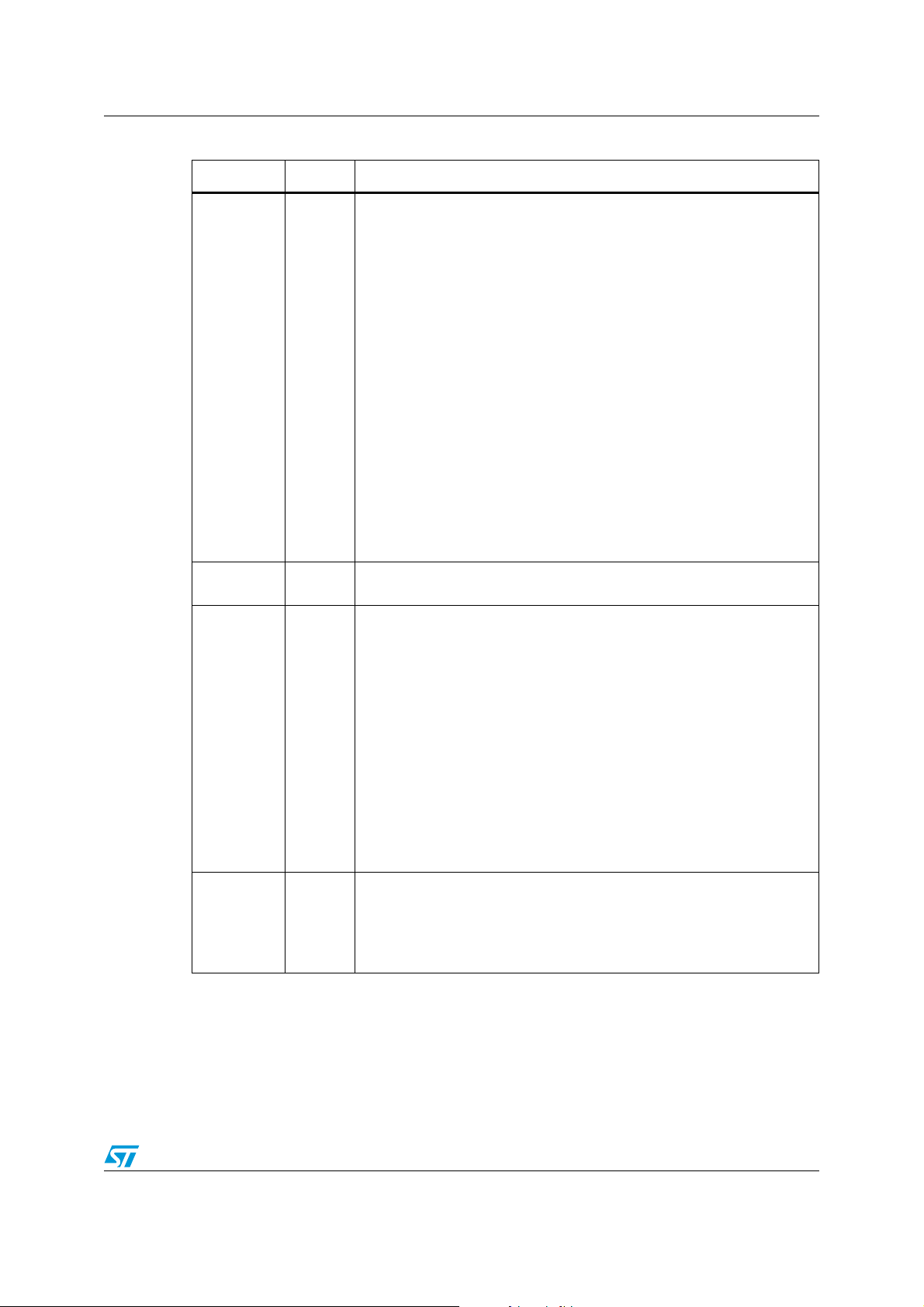

Table 5. Status Register format

Status Register Write Protect

) signal. The Status Register Write Disable (SRWD) bit and Write Protect (W)

) is driven low). In this

b7 b0

SRWD 0 0 0 BP1 BP0 WEL WIP

Block Protect bits

Write Enable Latch bit

Write In Progress bit

6.4 Write Status Register (WRSR)

The Write Status Register (WRSR) instruction is used to write new values to the Status

Register. Before it can be accepted, a Write Enable (WREN) instruction must have been

previously executed.

The Write Status Register (WRSR) instruction is entered by driving Chip Select (S

followed by the instruction code, the data byte on Serial Data input (D) and Chip Select (S

driven high. Chip Select (S

latches in the eighth bit of the data byte, and before the next rising edge of Serial Clock (C).

Otherwise, the Write Status Register (WRSR) instruction is not executed.

The instruction sequence is shown in Figure 11.

Figure 11. Write Status Register (WRSR) sequence

) must be driven high after the rising edge of Serial Clock (C) that

) low,

)

20/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

Driving the Chip Select (S) signal high at a byte boundary of the input data triggers the selftimed Write cycle that takes t

to complete (as specified in AC tables under Section 9: DC

W

and AC parameters).

While the Write Status Register cycle is in progress, the Status Register may still be read to

check the value of the Write in progress (WIP) bit: the WIP bit is 1 during the self-timed

Write cycle t

also reset at the end of the Write cycle t

, and 0 when the Write cycle is complete. The WEL bit (Write Enable Latch) is

W

.

W

The Write Status Register (WRSR) instruction enables the user to change the values of the

BP1, BP0 and SRWD bits:

● The Block Protect (BP1, BP0) bits define the size of the area that is to be treated as

read-only, as defined in Ta bl e 2 .

● The SRWD (Status Register Write Disable) bit, in accordance with the signal read on

the Write Protect pin (W

), enables the user to set or reset the Write protection mode of

the Status Register itself, as defined in Tab l e 6 . When in Write-protected mode, the

Write Status Register (WRSR) instruction is not executed.

The contents of the SRWD and BP1, BP0 bits are updated after the completion of the

WRSR instruction, including the t

Write cycle.

W

The Write Status Register (WRSR) instruction has no effect on the b6, b5, b4, b1, b0 bits in

the Status Register. Bits b6, b5, b4 are always read as 0.

Table 6. Protection modes

W

SRWD

signal

10

00

11

01

1. As defined by the values in the Block Protect (BP1, BP0) bits of the Status Register. See Table 2.

bit

Mode

Softwareprotected

(SPM)

Hardware-

protected

(HPM)

Write protection of the

Status Register

Status Register is

writable (if the WREN

instruction has set the

WEL bit).

The values in the BP1

and BP0 bits can be

changed.

Status Register is

Hardware writeprotected.

The values in the BP1

and BP0 bits cannot be

changed.

Protected area

Write-protected

Write-protected

Memory content

(1)

Unprotected area

Ready to accept

Write instructions

Ready to accept

Write instructions

The protection features of the device are summarized in Tab l e 6 .

When the Status Register Write Disable (SRWD) bit in the Status Register is 0 (its initial

delivery state), it is possible to write to the Status Register (provided that the WEL bit has

previously been set by a WREN instruction), regardless of the logic level applied on the

Write Protect (W

) input pin.

(1)

Doc ID 11124 Rev 17 21/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

C

D

AI01793D

S

Q

15

21 345678910 2021222324252627

1413 3210

28 29 30

76543 1 7

0

High Impedance

Data Out 1

Instruction 16-Bit Address

0

MSB

MSB

2

31

Data Out 2

When the Status Register Write Disable (SRWD) bit in the Status Register is set to 1, two

cases should be considered, depending on the state of the Write Protect (W

● If Write Protect (W) is driven high, it is possible to write to the Status Register (provided

) input pin:

that the WEL bit has previously been set by a WREN instruction).

● If Write Protect (W) is driven low, it is not possible to write to the Status Register even if

the WEL bit has previously been set by a WREN instruction. (Attempts to write to the

Status Register are rejected, and are not accepted for execution). As a consequence,

all the data bytes in the memory area, which are Software-protected (SPM) by the

Block Protect (BP1, BP0) bits in the Status Register, are also hardware-protected

against data modification.

Regardless of the order of the two events, the Hardware-protected mode (HPM) can be

entered by:

● either setting the SRWD bit after driving the Write Protect (W) input pin low,

● or driving the Write Protect (W) input pin low after setting the SRWD bit.

Once the Hardware-protected mode (HPM) has been entered, the only way of exiting it is to

pull high the Write Protect (W

) input pin.

If the Write Protect (W

) input pin is permanently tied high, the Hardware-protected mode

(HPM) can never be activated, and only the Software-protected mode (SPM), using the

Block Protect (BP1, BP0) bits in the Status Register, can be used.

6.5 Read from Memory Array (READ)

As shown in Figure 12, to send this instruction to the device, Chip Select (S) is first driven

low. The bits of the instruction byte and address bytes are then shifted in, on Serial Data

Input (D). The address is loaded into an internal address register, and the byte of data at

that address is shifted out, on Serial Data Output (Q).

Figure 12. Read from Memory Array (READ) sequence

If Chip Select (S) continues to be driven low, the internal address register is incremented

automatically, and the byte of data at the new address is shifted out.

22/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

C

D

AI01795D

S

Q

15

21 345678910 2021222324252627

1413 3210

28 29 30

High Impedance

Instruction 16-Bit Address

0

765432 0

1

Data Byte

31

When the highest address is reached, the address counter rolls over to zero, allowing the

Read cycle to be continued indefinitely. The whole memory can, therefore, be read with a

single READ instruction.

The Read cycle is terminated by driving Chip Select (S

Select (S

) signal can occur at any time during the cycle.

The instruction is not accepted, and is not executed, if a Write cycle is currently in progress.

6.6 Write to Memory Array (WRITE)

As shown in Figure 13, to send this instruction to the device, Chip Select (S) is first driven

low. The bits of the instruction byte, address byte, and at least one data byte are then shifted

in, on Serial Data Input (D).

The instruction is terminated by driving Chip Select (S

data. The self-timed Write cycle, triggered by the Chip Select (S

period t

end of which the Write in Progress (WIP) bit is reset to 0.

Figure 13. Byte Write (WRITE) sequence

(as specified in AC characteristics in Section 9: DC and AC parameters), at the

W

) high. The rising edge of the Chip

) high at a byte boundary of the input

) rising edge, continues for a

In the case of Figure 13, Chip Select (S) is driven high after the eighth bit of the data byte

has been latched in, indicating that the instruction is being used to write a single byte.

However, if Chip Select (S

) continues to be driven low, as shown in Figure 14, the next byte

of input data is shifted in, so that more than a single byte, starting from the given address

towards the end of the same page, can be written in a single internal Write cycle.

Each time a new data byte is shifted in, the least significant bits of the internal address

counter are incremented. If more bytes are sent than will fit up to the end of the page, a

condition known as “roll-over” occurs. In case of roll-over, the bytes exceeding the page size

are overwritten from location 0 of the same page.

Doc ID 11124 Rev 17 23/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

C

D

AI01796D

S

3433 35 36 37 38 39 40 41 42 44 45 46 4732

C

D

S

15

21 345678910 2021222324252627

1413 3210

28 29 30

Instruction 16-Bit Address

0

765432 0

1

Data Byte 1

31

43

765432 0

1

Data Byte 2

765432 0

1

Data Byte 3

65432 0

1

Data Byte N

The instruction is not accepted, and is not executed, under the following conditions:

● if the Write Enable Latch (WEL) bit has not been set to 1 (by executing a Write Enable

instruction just before),

● if a Write cycle is already in progress,

● if the device has not been deselected, by driving high Chip Select (S), at a byte

boundary (after the eighth bit, b0, of the last data byte that has been latched in),

● if the addressed page is in the region protected by the Block Protect (BP1 and BP0)

bits.

Note: The self-timed write cycle t

is internally executed as a sequence of two consecutive

W

events: [Erase addressed byte(s)], followed by [Program addressed byte(s)]. An erased bit is

read as “0” and a programmed bit is read as “1”.

Figure 14. Page Write (WRITE) sequence

24/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

6.6.1 Cycling with Error Correction Code (ECC)

M95512 and M95512-D devices offer an Error Correction Code (ECC) logic. The ECC is an

internal logic function which is transparent for the SPI communication protocol.

The ECC logic is implemented on each group of four EEPROM bytes

single bit out of the four bytes happens to be erroneous during a Read operation, the ECC

detects this bit and replaces it with the correct value. The read reliability is therefore much

improved.

Even if the ECC function is performed on groups of four bytes, a single byte can be

written/cycled independently. In this case, the ECC function also writes/cycles the three

other bytes located in the same group

(c)

. As a consequence, the maximum cycling budget is

defined at group level and the cycling can be distributed over the four bytes of the group: the

sum of the cycles seen by byte0, byte1, byte2 and byte3 of the same group must remain

below the maximum value defined in Tab le 1 2 .

(c)

. Inside a group, if a

c. A group of four bytes is located at addresses [4*N, 4*N+1, 4*N+2, 4*N+3], where N is an integer.

Doc ID 11124 Rev 17 25/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

#

$

!I

3

1

(IGHIMPEDANCE

$ATA/UT

)NSTRUCTION BITADDRESS

-3"

-3"

$ATA/UT

6.7 Read Identification Page (available only in M95512-D devices)

The Identification Page (128 bytes) is an additional page which can be written and (later)

permanently locked in Read-only mode.

Reading this page is achieved with the Read Identification Page instruction (see Ta bl e 4 ).

The Chip Select signal (S

bytes are then shifted in, on Serial Data Input (D). Address bit A10 must be 0, upper

address bits are Don't Care, and the data byte pointed to by the lower address bits [A6:A0]

is shifted out on Serial Data Output (Q). If Chip Select (S

internal address register is automatically incremented, and the byte of data at the new

address is shifted out.

The number of bytes to read in the ID page must not exceed the page boundary, otherwise

unexpected data is read (e.g.: when reading the ID page from location 90d, the number of

bytes should be less than or equal to 38d, as the ID page boundary is 128 bytes).

) is first driven low, the bits of the instruction byte and address

) continues to be driven low, the

The read cycle is terminated by driving Chip Select (S

Select (S

) signal can occur at any time during the cycle. The first byte addressed can be any

byte within any page.

The instruction is not accepted, and is not executed, if a write cycle is currently in progress.

Figure 15. Read Identification Page sequence

) high. The rising edge of the Chip

26/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

6.8 Write Identification Page (available only in M95512-D devices)

The Identification Page (128 bytes) is an additional page which can be written and (later)

permanently locked in Read-only mode.

Writing this page is achieved with the Write Identification Page instruction (see Ta b le 4 ). The

Chip Select signal (S

at least one data byte are then shifted in on Serial Data Input (D). Address bit A10 must be

0, upper address bits are Don't Care, the lower address bits [A6:A0] address bits define the

byte address inside the identification page. The instruction sequence is shown in Figure 16.

Figure 16. Write identification page sequence

3

) is first driven low. The bits of the instruction byte, address bytes, and

#

)NSTRUCTION BITADDRESS

$

(IGHIMPEDANCE

1

$ATABYTE

!I

Doc ID 11124 Rev 17 27/52

Instructions M95512-W M95512-R M95512-DR M95512-DF

#

$

!I

3

1

(IGHIMPEDANCE

$ATA/UT

)NSTRUCTION BITADDRESS

-3"

-3"

$ATA/UT

6.9 Read Lock Status (available only in M95512-D devices)

The Read Lock Status instruction (see Ta bl e 4 ) is used to check whether the Identification

Page is locked or not in Read-only mode. The Read Lock Status sequence is defined with

the Chip Select (S

then shifted in on Serial Data Input (D). Address bit A10 must be 1, all other address bits are

Don't Care. The Lock bit is the LSB (least significant bit) of the byte read on Serial Data

Output (Q). It is at “1” when the lock is active and at “0” when the lock is not active. If Chip

Select (S

) continues to be driven low, the same data byte is shifted out. The read cycle is

terminated by driving Chip Select (S

The instruction sequence is shown in Figure 17.

Figure 17. Read Lock Status sequence

) first driven low. The bits of the instruction byte and address bytes are

) high.

28/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Instructions

6.10 Lock ID (available only in M95512-D devices)

The Lock ID instruction permanently locks the Identification Page in read-only mode. Before

this instruction can be accepted, a Write Enable (WREN) instruction must have been

executed.

The Lock ID instruction is issued by driving Chip Select (S

code, the address and a data byte on Serial Data Input (D), and driving Chip Select (S

) low, sending the instruction

) high.

In the address sent, A10 must be equal to 1, all other address bits are Don't Care. The data

byte sent must be equal to the binary value xxxx xx1x, where x = Don't Care.

Chip Select (S

) must be driven high after the rising edge of Serial Clock (C) that latches in

the eighth bit of the data byte, and before the next rising edge of Serial Clock (C). Otherwise,

the Lock ID instruction is not executed.

Driving Chip Select (S

cycle whose duration is t

) high at a byte boundary of the input data triggers the self-timed write

(as specified in AC characteristics in Section 9: DC and AC

W

parameters). The instruction sequence is shown in Figure 18.

The instruction is discarded, and is not executed, under the following conditions:

● If a Write cycle is already in progress,

● If the Block Protect bits (BP1,BP0) = (1,1),

● If a rising edge on Chip Select (S) happens outside of a byte boundary.

Figure 18. Lock ID sequence

3

#

)NSTRUCTION BITADDRESS

$

(IGHIMPEDANCE

1

$ATABYTE

!I

Doc ID 11124 Rev 17 29/52

Power-up and delivery state M95512-W M95512-R M95512-DR M95512-DF

7 Power-up and delivery state

7.1 Power-up state

After power-up, the device is in the following state:

● Standby power mode,

● deselected (after power-up, a falling edge is required on Chip Select (S) before any

instructions can be started),

● not in the Hold condition,

● the Write Enable Latch (WEL) is reset to 0,

● Write In Progress (WIP) is reset to 0.

The SRWD, BP1 and BP0 bits of the Status Register are unchanged from the previous

power-down (they are non-volatile bits).

7.2 Initial delivery state

The device is delivered with the memory array set to all 1s (each byte = FFh). The Status

Register Write Disable (SRWD) and Block Protect (BP1 and BP0) bits are initialized to 0.

30/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Maximum rating

8 Maximum rating

Stressing the device outside the ratings listed in Ta bl e 7 may cause permanent damage to

the device. These are stress ratings only, and operation of the device at these, or any other

conditions outside those indicated in the operating sections of this specification, is not

implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Table 7. Absolute maximum ratings

Symbol Parameter Min. Max. Unit

Ambient operating temperature –40 130 °C

T

STG

T

LEAD

V

V

V

I

OL

I

OH

V

ESD

1. Compliant with JEDEC Std J-STD-020 (for small body, Sn-Pb or Pb assembly), with the ST ECOPACK®

7191395 specification, and with the European directive on Restrictions on Hazardous Substances (RoHS)

2002/95/EU.

2. Positive and negative pulses applied on different combinations of pin connections, according to AEC-

Q100-002 (compliant with JEDEC Std JESD22-A114, C1=100 pF, R1=1500 Ω, R2=500 Ω).

3. 3000 V for devices identified by process letters KA.

O

CC

Storage temperature –65 150 °C

Lead temperature during soldering See note

Output voltage –0.50 VCC+0.6 V

Input voltage –0.50 6.5 V

I

Supply voltage –0.50 6.5 V

DC output current (Q = 0) 5 mA

DC output current (Q = 1) 5 mA

Electrostatic discharge voltage (human body model)

(2)

4000

(1)

(3)

°C

V

Doc ID 11124 Rev 17 31/52

DC and AC parameters M95512-W M95512-R M95512-DR M95512-DF

!)#

6

##

6

##

6

##

6

##

)NPUTANDOUTPUT

TIMINGREFERENCELEVELS

)NPUTVOLTAGELEVELS

9 DC and AC parameters

This section summarizes the operating conditions and the DC/AC characteristics of the

device.

Table 8. Operating conditions (M95512-W, device grade 6)

Symbol Parameter Min. Max. Unit

V

T

Table 9. Operating conditions (M95512-R and M95512-DR, device grade 6)

Supply voltage 2.5 5.5 V

CC

Ambient operating temperature –40 85 °C

A

Symbol Parameter Min. Max. Unit

V

CC

T

A

Table 10. AC measurement conditions

Supply voltage 1.8 5.5 V

Ambient operating temperature –40 85 °C

Symbol Parameter Min. Max. Unit

C

Load capacitance 30 pF

L

Input rise and fall times ns

Input pulse voltages 0.2 VCC to 0.8 V

Input and output timing reference voltages 0.3 V

to 0.7 V

CC

CC

CC

Figure 19. AC measurement I/O waveform

V

V

32/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF DC and AC parameters

Table 11. Capacitance

Symbol Parameter Test conditions

(1)

Min. Max. Unit

C

OUT

Output capacitance (Q) V

= 0 V 8 pF

OUT

Input capacitance (D) VIN = 0 V 8 pF

C

IN

Input capacitance (other pins) V

1. Sampled only, not 100% tested, at TA = 25 °C and a frequency of 5 MHz.

Table 12. Cycling performance by groups of four bytes

Symbol Parameter

(1)

Test conditions Min. Max. Unit

TA ≤ 25 °C,

Ncycle Write cycle endurance

(2)

(min) < VCC < VCC(max)

V

CC

TA = 85 °C,

(min) < VCC < VCC(max)

V

CC

1. Cycling performance for products identified by process letters KB.

2. The Write cycle endurance is defined for groups of four data bytes located at addresses [4*N, 4*N+1,

4*N+2, 4*N+3] where N is an integer. The Write cycle endurance is defined by characterization and

qualification.

3. A Write cycle is executed when either a Page Write, a Byte Write, a WRSR, a WRID or an LID instruction is

decoded. When using the Byte Write, the Page Write or the WRID instruction, refer also to Section 6.6.1:

Cycling with Error Correction Code (ECC).

Table 13. Memory cell data retention

= 0 V 6 pF

IN

4,000,000

Write cycle

1,200,000

Parameter Test conditions Min. Unit

Data retention

1. For products identified by process letters KB. The data retention behavior is checked in production. The

200-year limit is defined from characterization and qualification results.

(1)

TA = 55 °C 200 Year

(3)

Doc ID 11124 Rev 17 33/52

DC and AC parameters M95512-W M95512-R M95512-DR M95512-DF

Table 14. DC characteristics (previous M95512-W products, device grade 6)

CC

< 5.5 V

(1)

Min. Max. Unit

± 2 µA

± 2 µA

3

5

6mA

5µA

CC

0.4 V

0.8 V

CC

mA

V

V

Symbol Parameter Test conditions

Input leakage

I

LI

current

LO

CC

Output leakage

current

Supply current

(Read)

I

I

= VSS or V

V

IN

= VCC, V

S

C=0.1V

CC

= VSS or V

OUT

/0.9 VCC at 5 MHz,

CC

VCC= 2.5 V, Q = open

C=0.1V

/0.9 VCC at 5 MHz,

CC

VCC= 5 V, Q = open

CC0

I

CC1

V

V

V

V

1. Not for new designs (previous products are identified by process letters AB).

2. Characterized only, not tested in production.

(Write)

Supply current

(Standby)

Input low voltage –0.45 0.3 V

IL

Input high voltage 0.7 VCCVCC+1 V

IH

Output low voltage

OL

Output high voltage

OH

Supply current

(2)

I

During tW, S = VCC,

2.5 V < V

S = VCC, 2.5 V <V

V

= VSS or V

IN

V

= 2.5 V and IOL = 1.5 mA or

CC

< 5.5 V

CC

CC

CC

VCC = 5 V and IOL = 2 mA

= 2.5 V and IOH = –0.4 mA or

V

CC

= 5 V and IOH = –2 mA

V

CC

34/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF DC and AC parameters

Table 15. DC characteristics (M95512-W products, device grade 6)

Symbol Parameter

I

LI

I

LO

Input leakage

current

Output leakage

current

Test conditions: V

= 2.5 to 5.5 V,

CC

TA = –40 to 85 °C

= VSS or V

V

IN

= VCC, voltage applied on Q = VSS or V

S

CC

CC

C = 0.1VCC/0.9VCC at 10 MHz, VCC=2.5V,

I

CC0

I

CC

I

CC1

V

V

V

V

Supply current

(Read)

Supply current

(1)

(Write)

Supply current

(Standby Power

mode)

Input low voltage –0.45 0.3 V

IL

Input high voltage 0.7 V

IH

Output low voltage

OL

Output high voltage

OH

Q = open

C = 0.1V

During t

= VCC, V

S

2.5 V < V

V

CC

/0.9VCC at 10 MHz, VCC= 5 V, Q = open 5 mA

CC

, S = VCC, 2.5 V < VCC < 5.5 V 2 mA

W

= VSS or VCC,

IN

< 5.5 V

CC

= 2.5 V and IOL = 1.5 mA or

VCC = 5 V and IOL = 2 mA

= 2.5 V and IOH = –0.4 mA or

V

CC

VCC = 5 V and IOH = –2 mA

Min. Max. Unit

± 2 µA

± 2 µA

4mA

5µA

CC

VCC+1 V

CC

0.4 V

0.8 V

CC

V

V

1. Characterized only, not tested in production.

Table 16. DC characteristics (M95512-R and M95512-DR products, device grade 6)

Symbol Parameter

I

LI

I

LO

I

CC

(3)

I

CC0

I

CC1

V

IL

V

IH

V

OL

V

OH

1. If the application uses the M95512-R with 2.5 V < VCC < 5.5 V and -40 °C < TA < +85 °C, please refer to Table 15 instead

of the above table.

2. Max clock frequency is 5 MHz (was 2 MHz for previous products identified with process letters AB).

3. Characterized only, not tested in production.

Test conditions:

VCC = 1.8 to 5.5 V, TA = –40 to 85 °C

Input leakage current V

= VSS or V

IN

CC

Output leakage current S = VCC, voltage applied on Q = VSS or V

Supply current (Read)

C = 0.1 V

frequency

V

CC

(2)

= 1.8 V, Q = open

CC

/0.9 V

,

at max clock

CC

(1)

CC

Min Max Unit

± 2 µA

± 2 µA

2.5 mA

Supply current (Write) During tW, S = VCC, 1.8 V < VCC < 2.5 V 1.5 mA

Supply current (Standby

Power mode)

Input low voltage –0.45 0.3 V

Input high voltage 0.7 V

S = VCC, V

1.8 V < V

= VSS or VCC,

IN

< 2.5 V

CC

CC

3µA

CC

VCC+1 V

Output low voltage IOL = 0.15 mA, VCC = 1.8 V 0.3 V

Output high voltage IOH = –0.1 mA, VCC = 1.8V 0.8V

CC

V

V

Doc ID 11124 Rev 17 35/52

DC and AC parameters M95512-W M95512-R M95512-DR M95512-DF

Table 17. DC characteristics (M95512-DF products, device grade 6)

Symbol Parameter

I

LI

I

LO

I

CC

(2)

I

CC0

I

CC1

V

IL

V

IH

V

OL

V

OH

1. If the application uses the M95512-DF with 2.5 V < VCC < 5.5 V and -40 °C < TA < +85 °C, please refer to Table 15 instead

of the above table.

2. Characterized only, not tested in production.

Test conditions:

VCC = 1.7 to 5.5 V, TA = –40 to 85 °C

Input leakage current V

= VSS or V

IN

CC

Output leakage current S = VCC, voltage applied on Q = VSS or V

Supply current (Read)

C=0.1V

Q = open

/0.9 VCC at 5 MHz, VCC=1.7V,

CC

(1)

CC

Min Max Unit

± 2 µA

± 2 µA

2.5 mA

Supply current (Write) During tW, S = VCC, 1.7 V < VCC < 2.5 V 1.5 mA

Supply current (Standby

Power mode)

Input low voltage –0.45 0.3 V

Input high voltage 0.7 V

S = VCC, V

1.7 V < V

= VSS or VCC,

IN

< 2.5 V

CC

CC

3µA

CC

VCC+1 V

Output low voltage IOL = 0.15 mA, VCC = 1.7 V 0.3 V

Output high voltage IOH = –0.1 mA, VCC = 1.7 V 0.8 V

CC

V

V

36/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF DC and AC parameters

Table 18. AC characteristics (previous M95512-W products, device grade 6)

Test conditions:

V

= 2.5 to 5.5 V at TA = –40 to 85 °C

CC

Symbol Alt. Parameter Min. Max. Unit

(1)

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

(2)

t

CH

(2)

t

CL

t

CLCH

t

CHCL

t

DVC H

t

CHDX

t

HHCH

t

HLCH

t

CLHL

t

CLHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

1. Not for new designs (previous products are identified by process letters AB).

2. tCH + tCL must never be less than the shortest possible clock period, 1 / fC(max).

3. Characterized only, not tested in production.

(3)

(3)

(3)

(3)

(3)

(3)

f

SCK

t

CSS1

t

CSS2

t

CS

t

CSH

t

CLH

t

CLL

t

RC

t

FC

t

DSU

t

DH

t

DIS

t

t

HO

t

RO

t

FO

t

LZ

t

HZ

t

WC

Clock frequency D.C. 5 MHz

S active setup time 90 ns

S not active setup time 90 ns

S deselect time 100 ns

S active hold time 90 ns

S not active hold time 90 ns

Clock high time 90 ns

Clock low time 90 ns

Clock rise time 1 µs

Clock fall time 1 µs

Data in setup time 20 ns

Data in hold time 30 ns

Clock low hold time after HOLD not active 70 ns

Clock low hold time after HOLD active 40 ns

Clock low setup time before HOLD active 0 ns

Clock low setup time before HOLD not active 0 ns

Output disable time 100 ns

Clock low to output valid 60 ns

V

Output hold time 0 ns

Output rise time 50 ns

Output fall time 50 ns

HOLD high to output valid 50 ns

HOLD low to output High-Z 100 ns

Write time 5 ms

Doc ID 11124 Rev 17 37/52

DC and AC parameters M95512-W M95512-R M95512-DR M95512-DF

Table 19. AC characteristics (M95512-W products, device grade 6)

Test conditions: VCC = 2.5 to 5.5 V, TA = –40 to 85 °C

Symbol Alt. Parameter Min. Max. Unit

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

(1)

t

CH

(1)

t

CL

(2)

t

CLCH

(2)

t

CHCL

t

DVC H

t

CHDX

t

HHCH

t

HLCH

t

CLHL

t

CLHH

(2)

t

SHQZ

t

CLQV

t

CLQX

(2)

t

QLQH

(2)

t

QHQL

t

HHQV

(2)

t

HLQZ

t

W

1. tCH + tCL must never be less than the shortest possible clock period, 1 / fC(max).

2. Characterized only, not tested in production.

f

SCK

t

CSS1

t

CSS2

t

CS

t

CSH

t

CLH

t

CLL

t

RC

t

FC

t

DSU

t

DH

t

DIS

t

t

HO

t

RO

t

FO

t

LZ

t

HZ

t

WC

Clock frequency D.C. 10 MHz

S active setup time 30 ns

S not active setup time 30 ns

S deselect time 40 ns

S active hold time 30 ns

S not active hold time 30 ns

Clock high time 45 ns

Clock low time 45 ns

Clock rise time 2 µs

Clock fall time 2 µs

Data in setup time 10 ns

Data in hold time 10 ns

Clock low hold time after HOLD not active 30 ns

Clock low hold time after HOLD active 30 ns

Clock low setup time before HOLD active 0 ns

Clock low setup time before HOLD not active 0 ns

Output disable time 40 ns

Clock low to output valid 40 ns

V

Output hold time 0 ns

Output rise time 40 ns

Output fall time 40 ns

HOLD high to output valid 40 ns

HOLD low to output High-Z 40 ns

Write time 5 ms

38/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF DC and AC parameters

Table 20. AC characteristics (M95512-R and M95512-DF products, device grade 6)

Test conditions: refer to Tab l e 9 and Table 10

(1)(2)

Min. Max. Min. Max.

Symbol Alt. Parameter

Previous

products

f

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

t

CH

t

CL

t

CLCH

t

CHCL

t

DVC H

t

CHDX

t

HHCH

t

HLCH

t

CLHL

t

CLHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

1. The test flow guarantees the AC parameter values defined in this table (when VCC = 1.8 V or VCC = 1.7 V) and the

parameter values defined in AC characteristics tables for M95512-W (when V

2. If the application uses the device at 2.5 V ≤ V

above table.

3. Not for new designs (previous products are identified by process letters AB)

4. t

CH

5. Characterized only, not tested in production.

t

t

(4)

(4)

(5)

(5)

(5)

(5)

(5)

(5)

+ tCL must never be less than the shortest possible clock period, 1 / fC(max)

Clock frequency D.C. 2 D.C. 5 MHz

SCK

S active setup time 200 60 ns

CSS1

S not active setup time 200 60 ns

CSS2

t

S deselect time 200 90 ns

CS

t

S active hold time 200 60 ns

CSH

S not active hold time 200 60 ns

t

Clock high time 200 80 ns

CLH

t

Clock low time 200 80 ns

CLL

t

Clock rise time 1 2 µs

RC

t

Clock fall time 1 2 µs

FC

t

Data in setup time 40 20 ns

DSU

t

Data in hold time 50 20 ns

DH

Clock low hold time after HOLD not active 140 60 ns

Clock low hold time after HOLD active 90 60 ns

Clock low setup time before HOLD active 0 0 ns

Clock low setup time before HOLD not active 0 0 ns

t

Output disable time 250 80 ns

DIS

t

Clock low to output valid 150 80 ns

V

t

Output hold time 0 0 ns

HO

t

Output rise time 100 80 ns

RO

t

Output fall time 100 80 ns

FO

t

HOLD high to output valid 100 80 ns

LZ

t

HOLD low to output High-Z 250 80 ns

HZ

t

Write time 5 5 ms

WC

> 2.5 V).

CC

≤ 5.5 V and –40 °C ≤ TA ≤ +85 °C, please refer to Table 19 instead of the

CC

(3)

Current products

Unit

Doc ID 11124 Rev 17 39/52

DC and AC parameters M95512-W M95512-R M95512-DR M95512-DF

C

Q

AI01448c

S

HOLD

tCLHL

tHLCH

tHHCH

tCLHH

tHHQVtHLQZ

Figure 20. Serial input timing

tSHSL

S

tSLCH

C

tDVCH

tCHCL

tCHDX

tCH

tCL

tCHSHtCHSL

tCLCH

tSHCH

D

Q

High impedance

Figure 21. Hold timing

MSB IN

LSB IN

AI01447d

40/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF DC and AC parameters

C

Q

AI01449f

S

D

ADDR

LSB IN

tSHQZ

tCH

tCL

tQLQH

tQHQL

tCHCL

tCLQX

tCLQV

tSHSL

tCLCH

Figure 22. Serial output timing

Doc ID 11124 Rev 17 41/52

Package mechanical data M95512-W M95512-R M95512-DR M95512-DF

SO-A

E1

8

ccc

b

e

A

D

c

1

E

h x 45˚

A2

k

0.25 mm

L

L1

A1

GAUGE PLANE

10 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Figure 23. SO8N – 8-lead plastic small outline, 150 mils body width, package outline

1. Drawing is not to scale.

Table 21. SO8N – 8-lead plastic small outline, 150 mils body width, mechanical data

millimeters inches

Symbol

Typ Min Max Typ Min Max

(1)

A 1.750 0.0689

A1 0.100 0.250 0.0039 0.0098

A2 1.250 0.0492

b 0.280 0.480 0.0110 0.0189

c 0.170 0.230 0.0067 0.0091

ccc 0.100 0.0039

D 4.900 4.800 5.000 0.1929 0.1890 0.1969

E 6.000 5.800 6.200 0.2362 0.2283 0.2441

E1 3.900 3.800 4.000 0.1535 0.1496 0.1575

e 1.270 - - 0.0500 - -

h 0.250 0.500 0.0098 0.0197

k 0°8° 0°8°

L 0.400 1.270 0.0157 0.0500

L1 1.040 0.0409

1. Values in inches are converted from mm and rounded to four decimal digits.

42/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Package mechanical data

$

%

:7?-%E6

!

!

EEE

,

E B

$

,

%

,

0IN

+

Figure 24. UFDFPN8 (MLP8) – 8-lead ultra thin fine pitch dual flat no lead, package

outline

1. Drawing is not to scale.

2. The central pad (area E2 by D2 in the above illustration) is internally pulled to V

connected to any other voltage or signal line on the PCB, for example during the soldering process.

Table 22. UFDFPN8 (MLP8) – 8-lead ultra thin fine pitch dual flat package no lead

. It must not be

SS

2 x 3 mm, data

millimeters inches

Symbol

Typ Min Max Typ Min Max

(1)

A 0.550 0.450 0.600 0.0217 0.0177 0.0236

A1 0.020 0.000 0.050 0.0008 0.0000 0.0020

b 0.250 0.200 0.300 0.0098 0.0079 0.0118

D 2.000 1.900 2.100 0.0787 0.0748 0.0827

D2 (rev MC) 1.200 1.600 0.0472 0.0630

E 3.000 2.900 3.100 0.1181 0.1142 0.1220

E2 (rev MC) 1.200 1.600 0.0472 0.0630

e 0.500 0.0197

K (rev MC) 0.300 0.0118

L 0.300 0.500 0.0118 0.0197

L1 0.150 0.0059

L3 0.300 0.0118

(2)

eee

1. Values in inches are converted from mm and rounded to four decimal digits.

2. Applied for exposed die paddle and terminals. Exclude embedding part of exposed die paddle from

measuring.

0.080 0.0031

Doc ID 11124 Rev 17 43/52

Package mechanical data M95512-W M95512-R M95512-DR M95512-DF

TSSOP8AM

1

8

CP

c

L

EE1

D

A2A

α

eb

4

5

A1

L1

Figure 25. TSSOP8 – 8-lead thin shrink small outline, package outline

1. Drawing is not to scale.

Table 23. TSSOP8 – 8-lead thin shrink small outline, package mechanical data

millimeters inches

Symbol

Typ Min Max Typ Min Max

(1)

A 1.200 0.0472

A1 0.050 0.150 0.0020 0.0059

A2 1.000 0.800 1.050 0.0394 0.0315 0.0413

b 0.190 0.300 0.0075 0.0118

c 0.090 0.200 0.0035 0.0079

CP 0.100 0.0039

D 3.000 2.900 3.100 0.1181 0.1142 0.1220

e 0.650 - - 0.0256 - -

E 6.400 6.200 6.600 0.2520 0.2441 0.2598

E1 4.400 4.300 4.500 0.1732 0.1693 0.1772

L 0.600 0.450 0.750 0.0236 0.0177 0.0295

L1 1.000 0.0394

α 0° 8° 0° 8°

N8 8

1. Values in inches are converted from mm and rounded to four decimal digits.

44/52 Doc ID 11124 Rev 17

M95512-W M95512-R M95512-DR M95512-DF Package mechanical data

8

AAA

7AFERBACKSIDE

$

%

3IDEVIEW

$ETAIL!

!

!

"UMPSSIDE

$ETAIL!

2OTATED

"UMP

EEE

!

3EATINGPLANE

#F?-%?6

B

BBB

:

:

8

CCC-

9

:

DDD-

8

9

:

:

2EFERENCE

E

E

'

&

E

E

2EFERENCE

Figure 26. M95512-DFCS6TP/K, WLCSP 8-bump wafer-level chip scale package

outline

1. Drawing is not to scale.

Doc ID 11124 Rev 17 45/52

Package mechanical data M95512-W M95512-R M95512-DR M95512-DF

Table 24. M95512-DFCS6TP/K, WLCSP 8-bump wafer-level chip scale package

mechanical data

Symbol millimeters inches

Typ Min Max Typ Min Max

A 0.540 0.500 0.580 0.0213 0.0197 0.0228

A1 0.190 0.0075

A2 0.350 0.0138

b 0.270 0.0106

D 1.271 1.291 0.0500 0.0508

E 1.937 1.957 0.0763 0.0770

e 1.000 0.0394

e1 0.866 0.0341

e2 0.500 0.0197

e3 0.433 0.0170

F 0.202 0.0080

G 0.469 0.0185

N 8.000 0.3150

aaa 0.110 0.0043

(1)

bbb 0.110 0.0043