查询M95010供应商

4Kbit, 2Kbit and 1Kbit Serial SPI Bus EEPROM

FEAT URES SUM MAR Y

■ Compatible with SPI Bus Serial Interface

(Positive Clock SPI Modes)

■ Single Supply Voltage:

– 4.5 to 5.5V for M950x0

– 2.5 to 5.5V for M950x0-W

– 1.8 to 5.5V for M950x0-R

■ High Speed

– 10MHz Clock Rate, 5ms Write Time

■ Status Register

■ BYTE and PAGE WRITE (up to 16 Bytes)

■ Self-Timed Programming Cycle

■ Adjustable Size Read-Only EEPROM Area

■ Enhanced ESD Protection

■ More than 1 Million Erase/Write Cycles

■ More than 40-Year Data Retention

M95040

M95020, M95010

With High Speed Clock

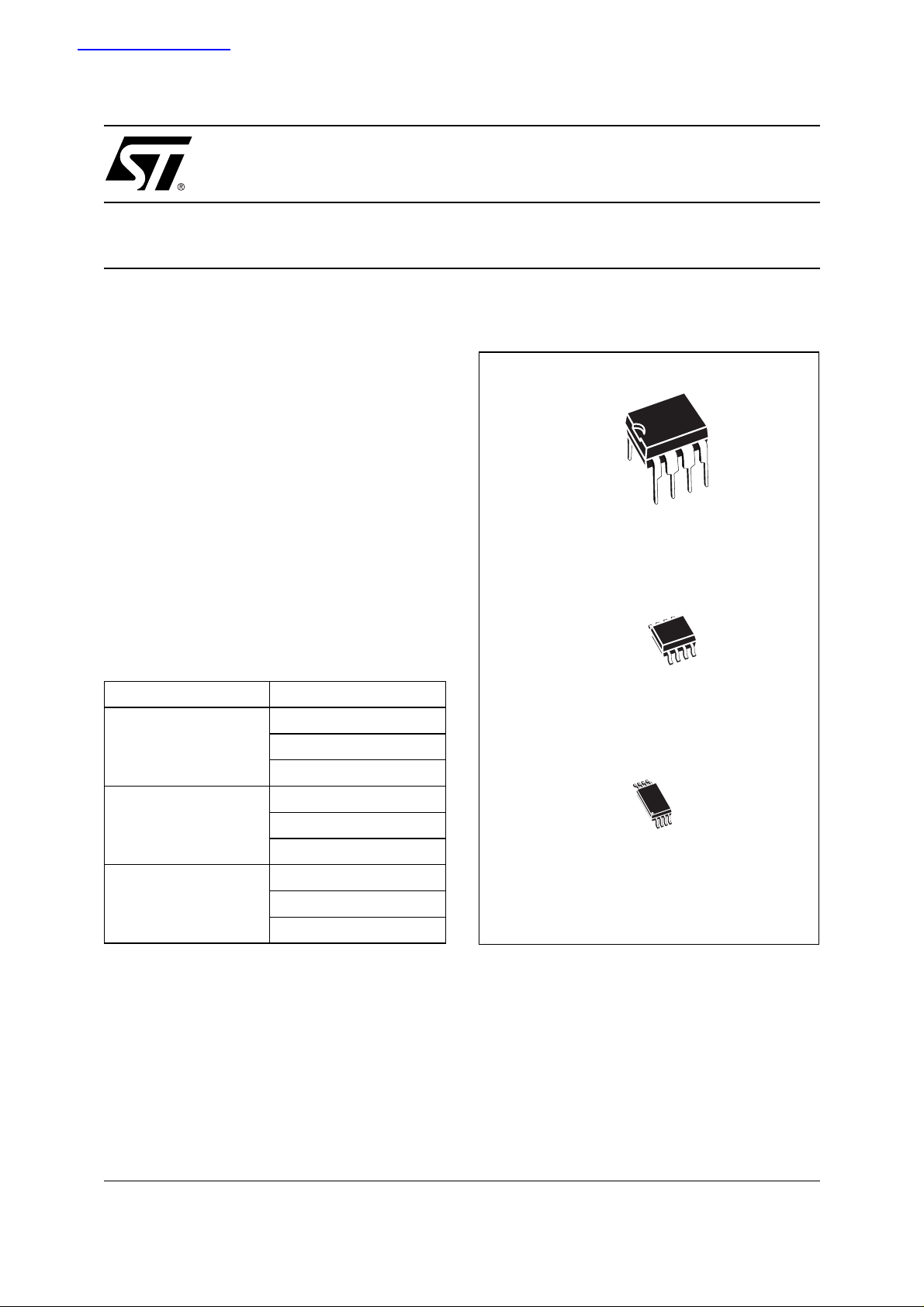

Figure 1. Packages

8

1

PDIP8 (BN)

8

Table 1. Product List

Reference Part Number

M95040

M95020

M95010

M95040

M95040-W

M95040-R

M95020

M95020-W

M95020-R

M95010

M95010-W

M95010-R

1

SO8 (MN)

150 mil width

TSSOP8 (DW)

169 mil width

1/37October 2004

M95040, M95020, M95010

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Product List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. DIP, SO and TSSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SIGNAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Data Output (Q). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Data Input (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chip Select (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hold (HOLD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Write Protect (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CONNECTING TO THE SPI BUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Bus Master and Memory Devices on the SPI Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPI Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. SPI Modes Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATING FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power-down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Active Power and Standby Power Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

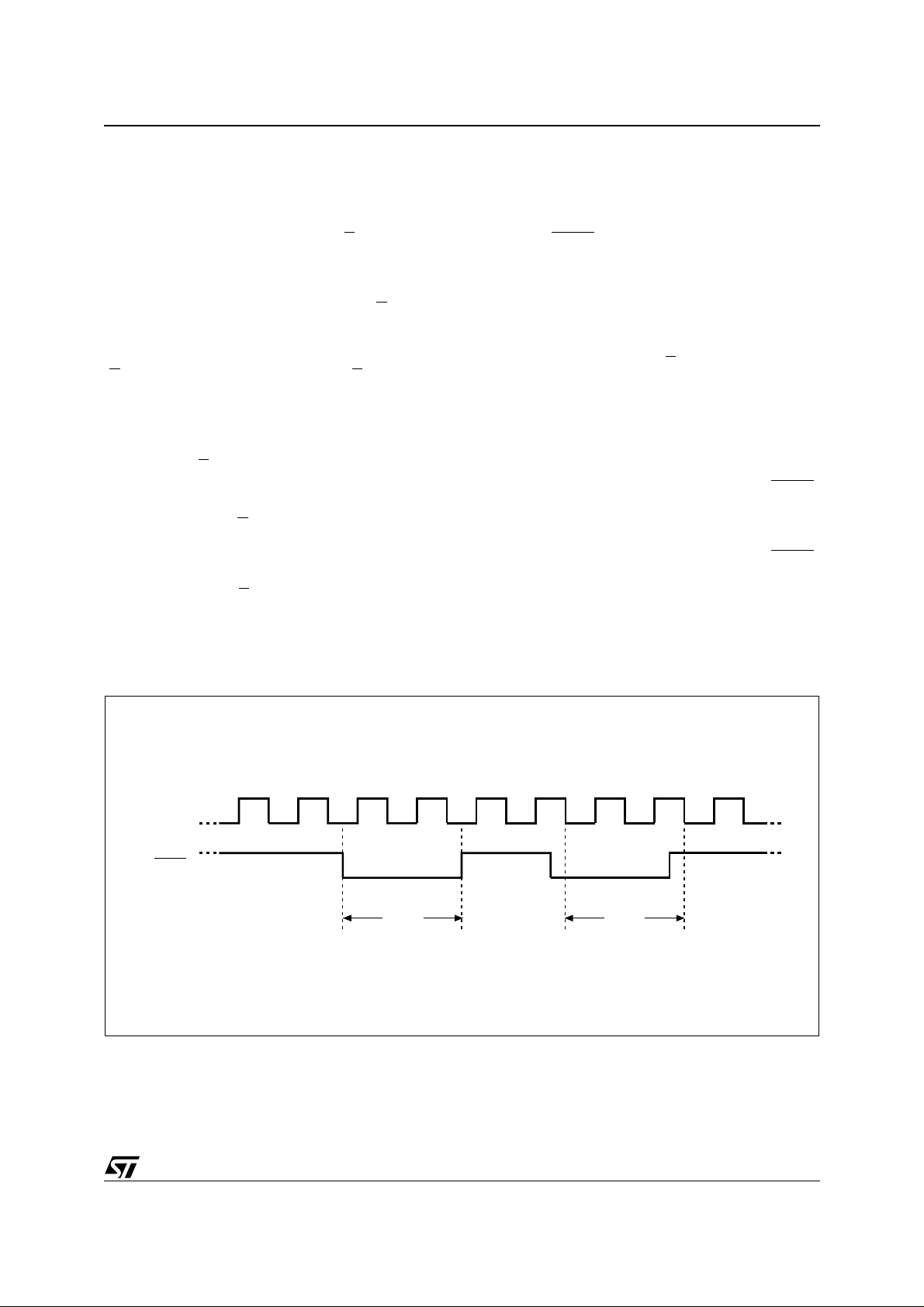

Hold Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Hold Condition Activation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WIP bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Status Register Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Data Protection and Protocol Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. Write-Protected Block Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

MEMORY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. Instruction Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Write Enable (WREN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8. Write Enable (WREN) Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/37

M95040, M95020, M95010

Write Disable (WRDI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. Write Disable (WRDI) Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Read Status Register (RDSR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

WIP bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10.Read Status Register (RDSR) Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Write Status Register (WRSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11.Write Status Register (WRSR) Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Read from Memory Array (READ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 6. Address Range Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12.Read from Memory Array (READ) Sequen ce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Write to Memory Array (WRITE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 13.Byte Write (WRITE) Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14.Page Write (WRITE) Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

POWER-UP AND DELIVERY STATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power-up State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Initial Delivery State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 7. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1

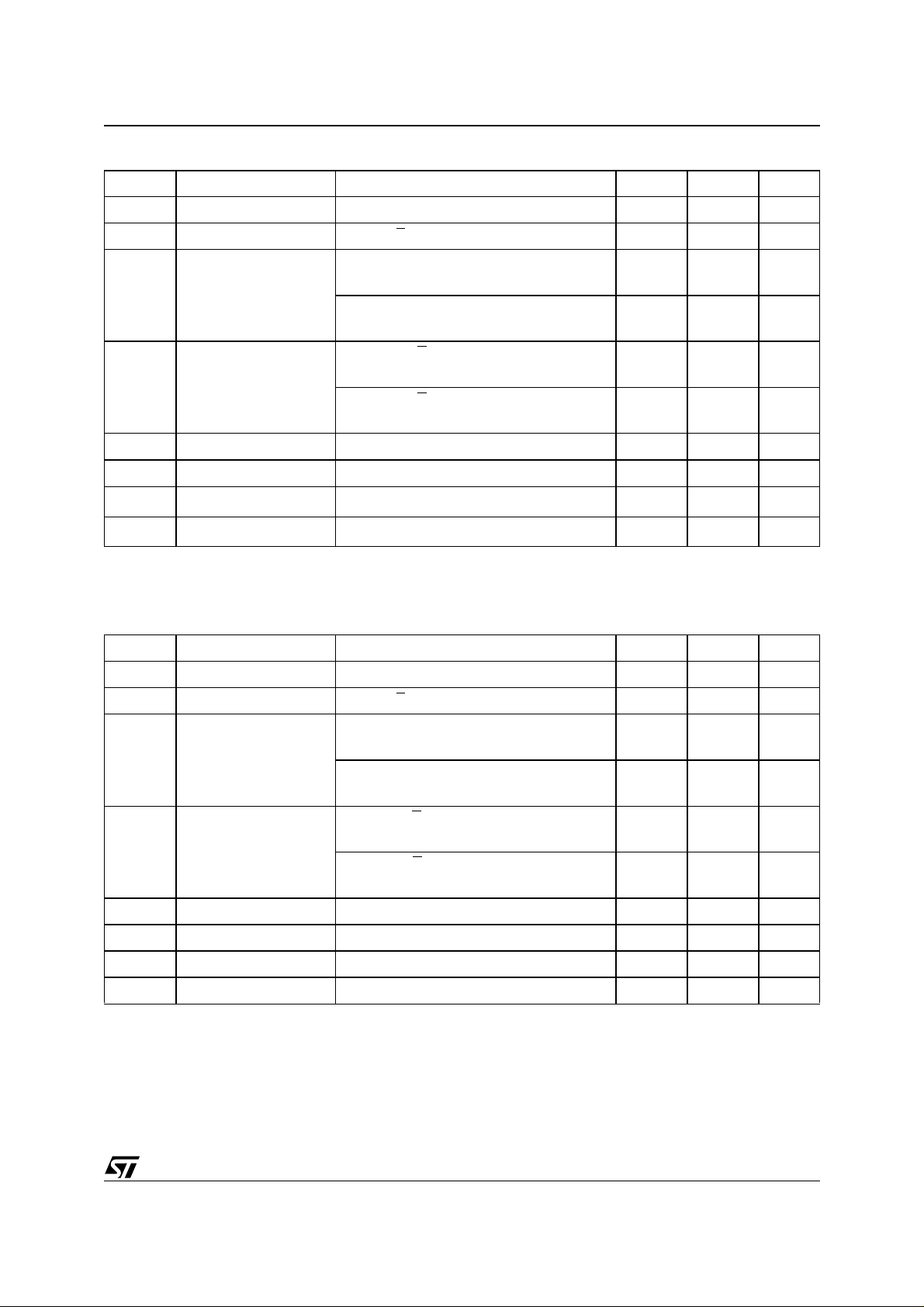

Table 8. Operating Conditions (M950x0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9. Operating Conditions (M950x0-W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Operating Conditions (M950x 0-R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 11. AC Measurement Condition s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 15.AC Measurement I/O Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 12.Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 13. DC Characteristics (M950x0, Device Grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 14. DC Characteristics (M950x0, Device Grade 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 15. DC Characteristics (M950x0-W, Device Grade 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 16. DC Characteristics (M950x0-W, Device Grade 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Table 17. DC Characteristics (M950x0-R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 18. AC Characteristics (M950x0, Device Grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 19. AC Characteristics (M950x0, Device Grade 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 20. AC Characteristics (M950x0-W, Device Grade 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 21. AC Characteristics (M950x0-W, Device Grade 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 22. AC Characteristics (M950x0-R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16.Serial Input Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17.Hold Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 18.Output Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 19.PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Outline . . . . . . . . . . . . . . . . . 32

3/37

M95040, M95020, M95010

Table 23. PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Mechanical Data . . . . . . . . . . 32

Figure 20.SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Outline . . . . 33

Table 24. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Mechanical Data

33

Figure 21.TSSOP8 – 8 lead Thin Shrink Small Outline, Package Outline . . . . . . . . . . . . . . . . . . . 34

Table 25. TSSOP8 – 8 lead Thin Shrink Sma ll Outline, Packag e Mechanica l Data . . . . . . . . . . . . 34

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 26.Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 27. How to Identify Present and Previous Pro ducts by the Process Identi fication Letter . . . 35

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 28. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4/37

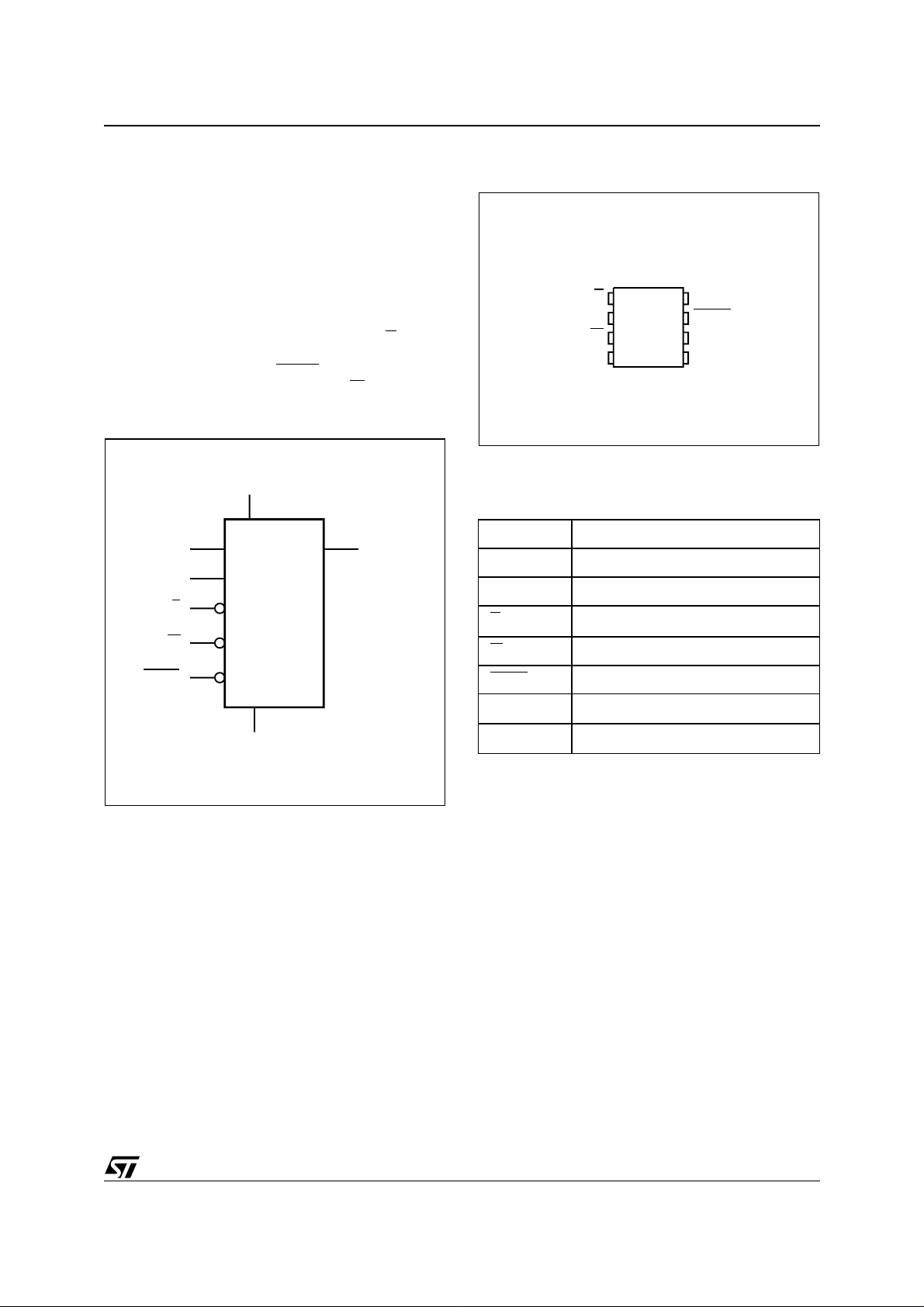

SUMMARY DESCRIPTION

The M95040 is a 4 Kbit (512 x 8) electrically erasable programmable memory (EEPROM), accessed by a high speed SPI-compatible bus. The other

members of the family (M95020 and M95010 ) are

identical, though proportionally smaller (2 and 1

Kbit, respe c ti v e ly).

Each device is accessed by a sim ple serial interface that is SPI-compatible. The bus signals are C,

D and Q, as shown in Table 2. and F igure 2..

The device is selected when Chip Select (S

en Low. Communications with the devi ce can be

interrupted using Hold (HOLD

). WRITE instruc-

tions are disabled by Write Protect (W

Figure 2. Logic Diagram

V

CC

D

C

S

W

M95xxx

) is tak-

).

Q

M95040, M95020, M95010

Figure 3. DIP, SO and TSSOP Connections

M95xxx

SV

1

2

W

3

4

SS

Note: See PACKAGE MECHANICAL section for package dimen-

sions, and how to ident i fy pi n-1.

Table 2. Signal Names

C Serial Clock

D Serial Data Input

Q Serial Data Output

S

Write Protect

W

Chip Select

8

7

6

5

AI01790D

CC

HOLDQ

C

DV

HOLD

HOLD

Hold

V

CC

V

V

SS

AI01789C

SS

Supply Voltage

Ground

5/37

M95040, M95020, M95010

SIGNAL DESCRIPTION

During all operations, VCC must be held stable and

within the specified valid range: V

(max).

V

CC

All of the input and output signals can be held High

or Low (according to voltage s of V

, as specified in Table 13. to Table 17.). These

V

OL

signals are described next.

Serial Data Output (Q). This output signal is

used to transfer data serially out of the device.

Data is shifted out on the falling edge of Serial

Clock (C).

Serial Data Input (D). This input signal is used to

transfer data serially into the device. It receives instructions, addresses, and the data to be written.

Values are latched on the rising edge of Serial

Clock (C).

Serial Clock (C). This input signal provides the

timing of the serial interface. Instructions, addresses, or data present at Serial Data Input (D) are

latched on the rising edge of Serial Clock (C). Data

on Serial Data Output (Q) changes after the falling

edge of Serial Clock (C).

(min) to

CC

, VOH, VIL or

IH

Chip Select (S

). When this input signal is High,

the device is des elected and Serial Data Ou tput

(Q) is at high impedance. Unless an internal Write

cycle is in progress, the device will be in the Standby Power mode. Drivi ng Chip Select ( S

) Low selects the device, placing it in the Active Power

mode.

After Power-up, a falling edge on Chip Select (S

is required prior to the start of any instruction.

Hold (HOLD

). The Hold (HOLD) signal is used to

pause any serial communications with the device

without deselecting the device.

During the Hold condition, the Serial Data Output

(Q) is high impedanc e, and Serial D ata Input (D)

and Serial Clock (C) are Don’t Care.

To start the Hold condition, the device must be selected, wit h Ch ip Select ( S

Write Protect (W

). This input signal is used to

) driven Low.

control whether the memory is write protected.

When Write Protect (W

) is held Low, writes to the

memory are disabled, but other operations remain

enabled. Write Protect (W

) must either be driven

High or Low, but must not be left floating.

)

6/37

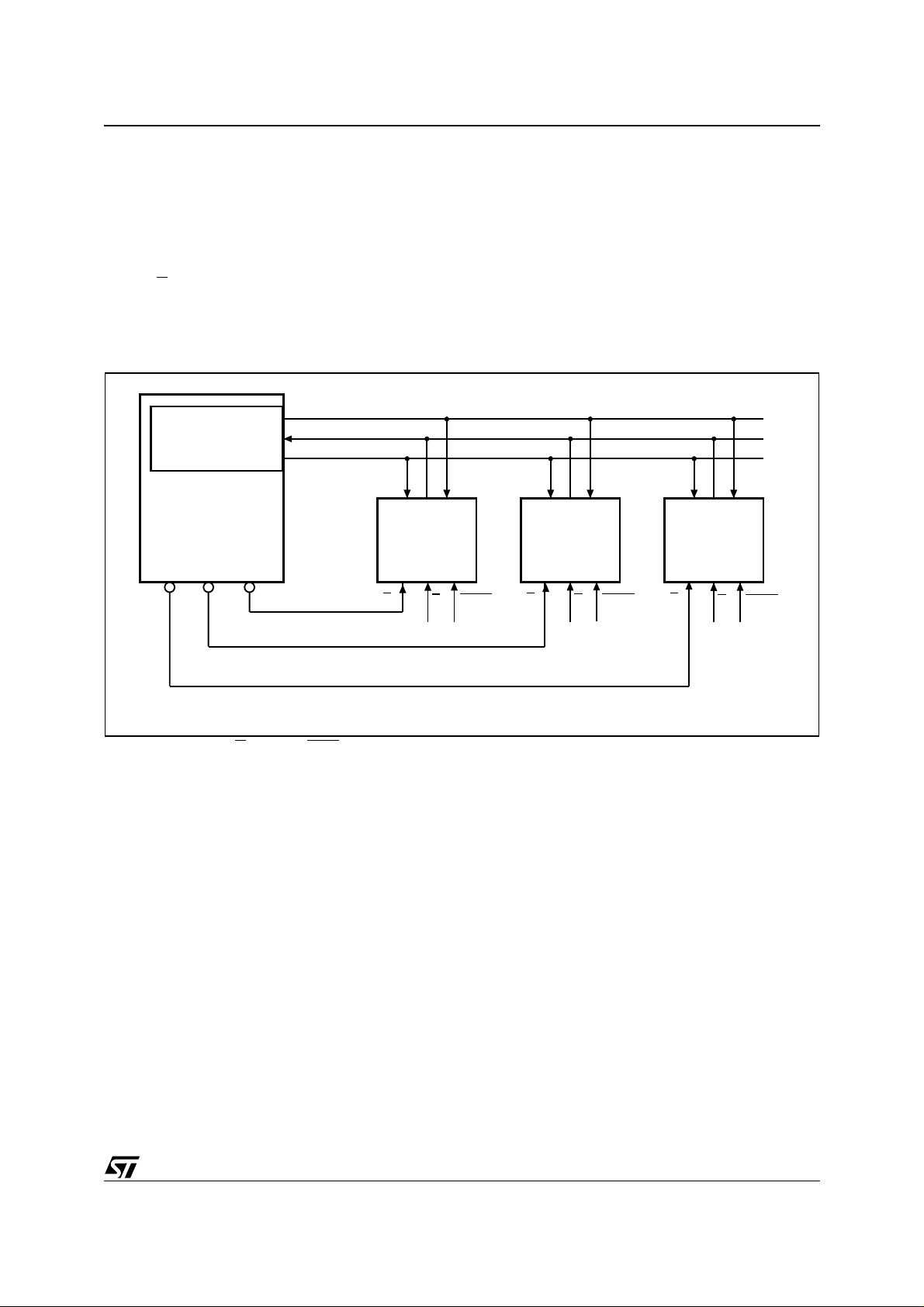

CONNECTI NG TO THE SPI BUS

These devices are fully compatible with the SPI

protocol.

All instructions, addresses and input data bytes

are shifted in to the device, most significant bit

first. The Serial Data Input (D) is sampled on the

first rising edge of the Serial Clock (C) after Chip

Selec t ( S

) goes Low.

All output data bytes are shifted out of the device,

most significant bit first. The Serial Data Output

Figure 4. Bus Master and Memory Devices on the SPI Bus

(Q) is latched on the first fa lling edge of the Serial

Clock (C) after the instruction (such as the Read

from Memory Array and Read Status Re gister instructions) have been clocked into the device.

Figure 4 . shows three devices, con nected to an

MCU, on a SPI bus. Only one device is selected at

a time, so only one de vice drives the Serial Data

Output (Q) line at a time, all the o thers be ing high

impedance.

M95040, M95020, M95010

SPI Interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

Bus Master

(ST6, ST7, ST9,

ST10, Others)

CS3 CS2 CS1

Note: The Write Protect (W) and Hold (HOLD) signals should be dri ven, High or Low as appropriat e.

SDO

SDI

SCK

CQD

SPI Memory

Device

S

CQD

SPI Memory

Device

HOLD

W

S

HOLD

W

CQD

SPI Memory

Device

S

W

AI03746D

HOLD

7/37

M95040, M95020, M95010

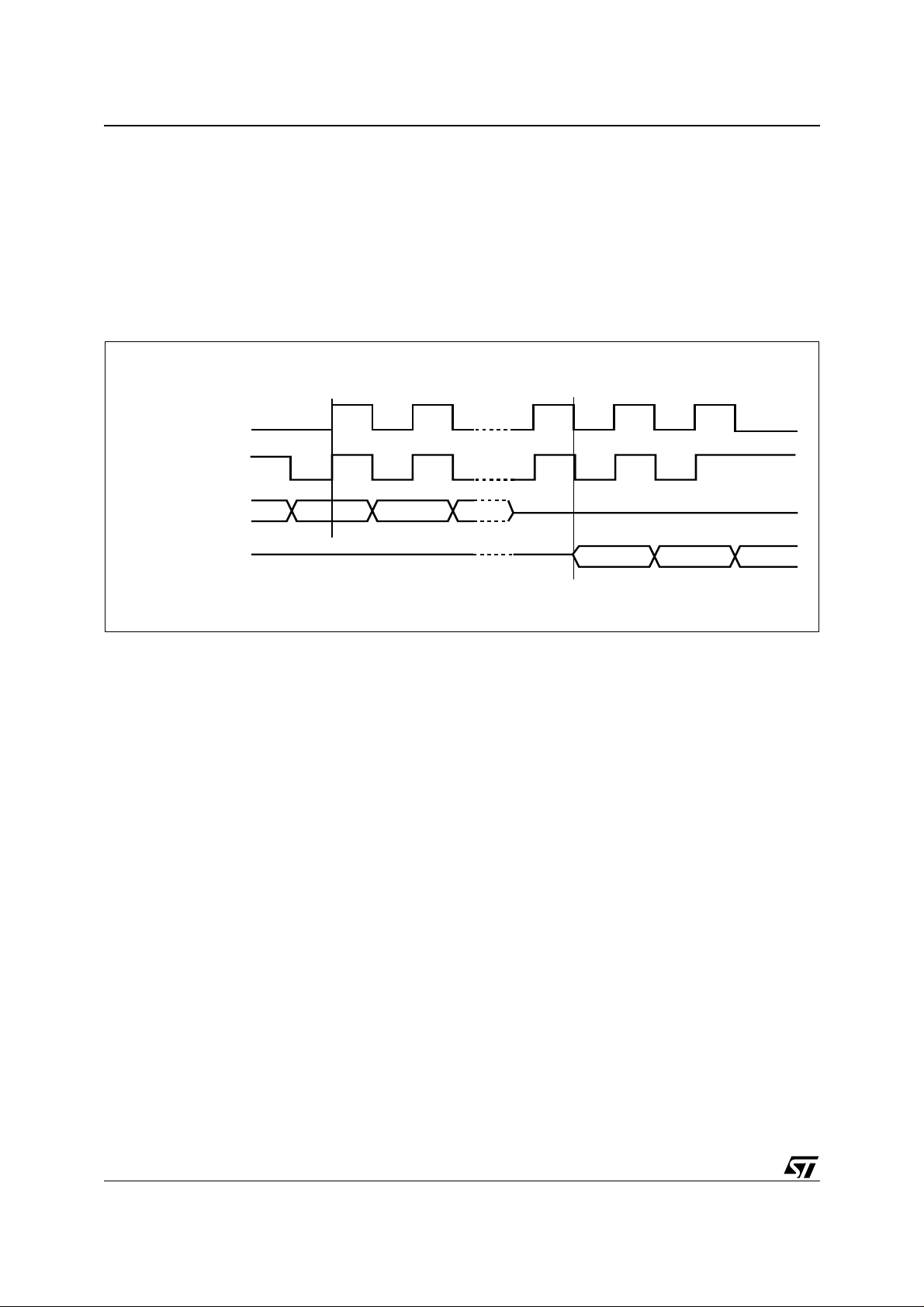

SPI Modes

These devices can be drive n by a microcont roller

with its SPI peripheral running in either of the two

following modes:

– CPOL=0, CPHA=0

– CPOL=1, CPHA=1

For these two modes, input data is latc hed in on

the rising edge of Serial Clock (C), and output data

Figure 5. SPI Mo de s S upported

CPHA

CPOL

0

0

1

1

C

C

D

Q

MSB

is avai lable from t he falling edge of S erial Clock

(C).

The difference between the two modes, as shown

in Figure 5., is the clock polarity when the bus

master is in Stand-by mode and not transferring

data:

– C remains at 0 for (CPOL=0, CPHA=0)

– C remains at 1 for (CPOL=1, CPHA=1)

MSB

AI01438B

8/37

OPERATING FEA T URES

Power-up

When the power supply is turned on, V

from V

During this time, the Chip Select (S

lowed to follow the V

to VCC.

SS

) must be al-

voltage. It must not be al-

CC

lowed to float, but should be connected to V

a suitable pull-up resistor.

As a built in safety feature, Chip Select (S

sensitive as well a s level sens itive. After P owerup, the device does not become s elected until a

falling edge has first been detected on Chip Select

). This ensures that Ch ip Select (S) must have

(S

been High, prior to going Low to start the first operation.

Power-down

At Power-down, the device must be deselected.

Chip Select (S

voltage applied on V

) should be allowed to follow the

.

CC

Active Power and Standb y Power M ode s

When Chip Select (S

) is Low, the device is selected, and in the Active Power mode. The device

consumes I

, as specified in Table 13. to Table

CC

17..

When Chip Select (S

) is High, the device is deselected. If an Erase/Write cycle is not currently in

progress, the device then goes in to the Standby

rises

CC

via

CC

) is edge

M95040, M95020, M95010

Power mode, and the device cons umption drops

CC1

.

) signal is used to pause any se-

) Low.

to I

Hold Condition

The Hold (HOLD

rial communications with the device without resetting the clocking sequence.

During the Hold condition, the Serial Data Output

(Q) is high impedanc e, and Serial D ata Input (D)

and Serial Clock (C) are Don’t Care.

To enter the Hold condition, the device must be

selecte d, with Chip Se lec t (S

Normally, the device is kept selected, for the whole

duration of the Hold condition. Deselecting the device while it is in the Hold condition, has the effect

of resetting the state of the device, and this mechanism can be used if it is required to reset any processes that had been in progress.

The Hold condition starts when the Hold (HOLD

signal is driven Low at the same time as Serial

Clock (C) already being Low (as shown in Figure

6.).

The Hold condition ends when the Hold (HOLD

signal is driven High at the same time as Serial

Clock (C) already being Low.

Figure 6 . also shows what happens if the rising

and falling edges are not timed to coincide with

Serial Clock (C) being Low.

)

)

Figure 6. Hold Condition Activation

C

HOLD

Hold

Condition

Hold

Condition

AI02029D

9/37

M95040, M95020, M95010

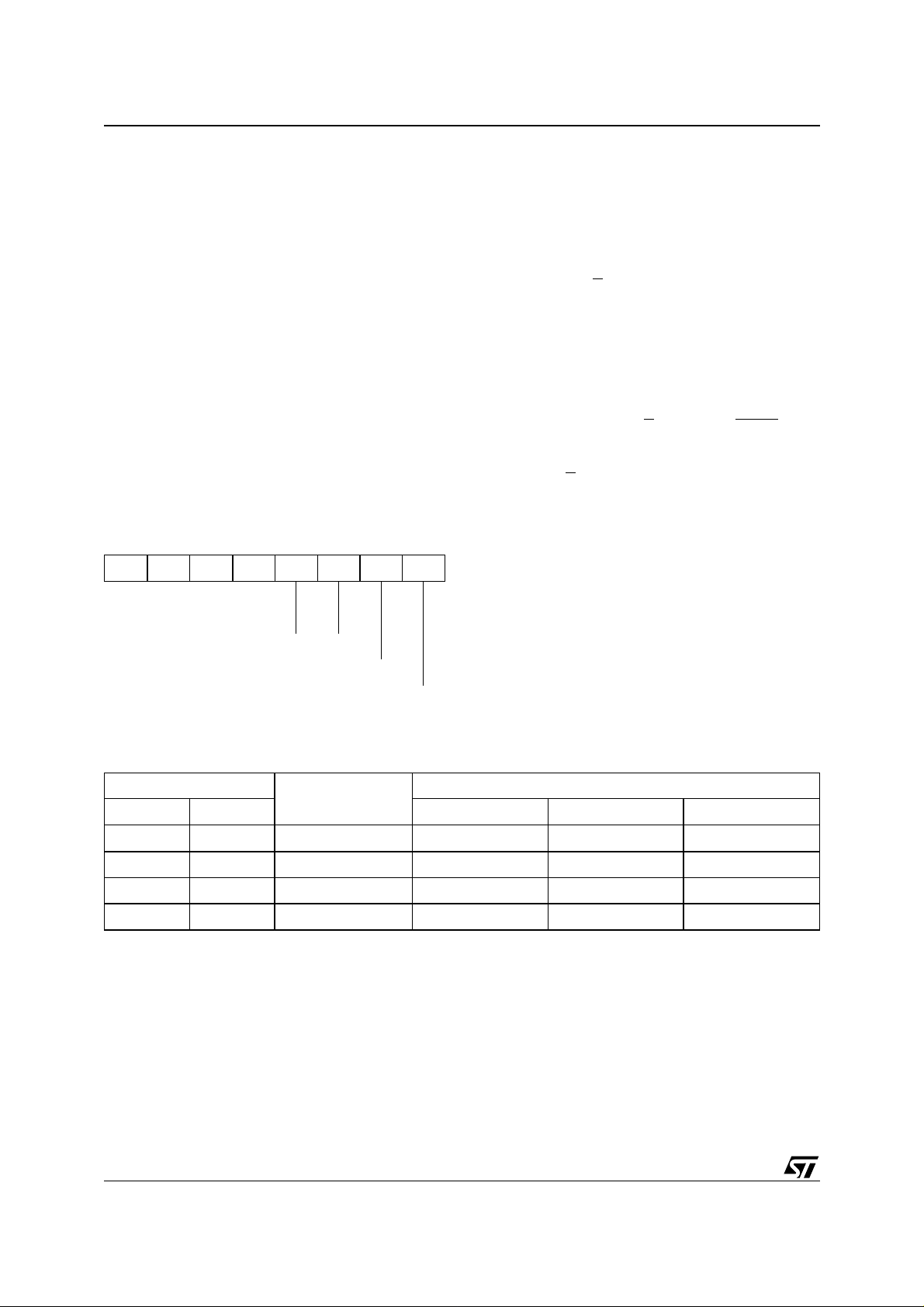

Status Register

Figure 7. shows the position of the Status Register

in the control logic of the device. This register contains a number of c ontrol bits and status bits, as

shown in Table 3..

Bits b7, b6, b5 and b4 are always read as 1.

WIP bit. The Write In Progress bit is a volatile

read-only bit that is automatically set and reset by

the internal logic of the device. When s et to a 1 , it

indicates that the memory is busy with a Write cycle.

WEL bit. The Write Enable Latch bit is a vol atile

read-only bit that is set and reset by specific instructions. When reset to 0, no WRITE or WRSR

instructions are accepted by the device.

BP1, BP0 bits. The Block Protect bits are nonvolatile read-write bits. These bits define the area

of memory that is protected against the execution

of Write cycles, as summarized in Table 4..

Table 3. Status Register Format

b7 b0

1 1 1 1 BP1 BP0 WEL WIP

Block Protect Bits

Write Enable Latch Bit

Write In Progress Bit

Data Protec ti on a n d Protocol Cont rol

To help protect t he d ev ice from data corruption in

noisy or poorly controlled environments, a number

of safety features have been built in to the device.

The main security measures can be summarized

as follows:

– The WEL bit is reset at power-up.

– Chip Select (S

) must rise after the eighth clock

count (or multiple thereof) in order to start a

non-volatile Write cycle (in the memory array

or in the Status Register).

– Accesses to the memory array are ignored

during the non-volatile programming cycle,

and the programming cycle continues

unaffected.

– Invalid Chip Select (S

) and Hold (HOLD)

transitions are ignored.

For any instruction to be accepted and executed,

Chip Select (S

) must be driven High after the rising

edge of Serial Clock (C) that latches the last bit of

the instruction, and before the next rising edge of

Serial Clock (C).

For this, “the last bit of the instruction” can be the

eighth bit of the instruction code, or the ei ghth bit

of a data byte, depending on the instruction (except in the case of RDSR and READ instructions).

Moreover, the "next rising edge of CLOCK" might

(or might not) be the next bus transaction for some

other device on the bus.

When a Write cycle is in progress, the device protects it against external interruption by ignoring

any subsequent READ, WRITE or WRSR instruction until the presen t cycl e is complete.

Table 4. Write-Protected Block Size

Status Register Bits

Protected Block

BP1 BP0 M95040 M95020 M95010

0 0 none none none none

0 1 Upper quarter 180h - 1FFh C0h - FFh 60h - 7Fh

1 0 Upper half 100h - 1FFh 80h - FFh 40h - 7Fh

1 1 Whole memory 000h - 1FFh 00h - FFh 00h - 7Fh

10/37

Array Addresses Protected

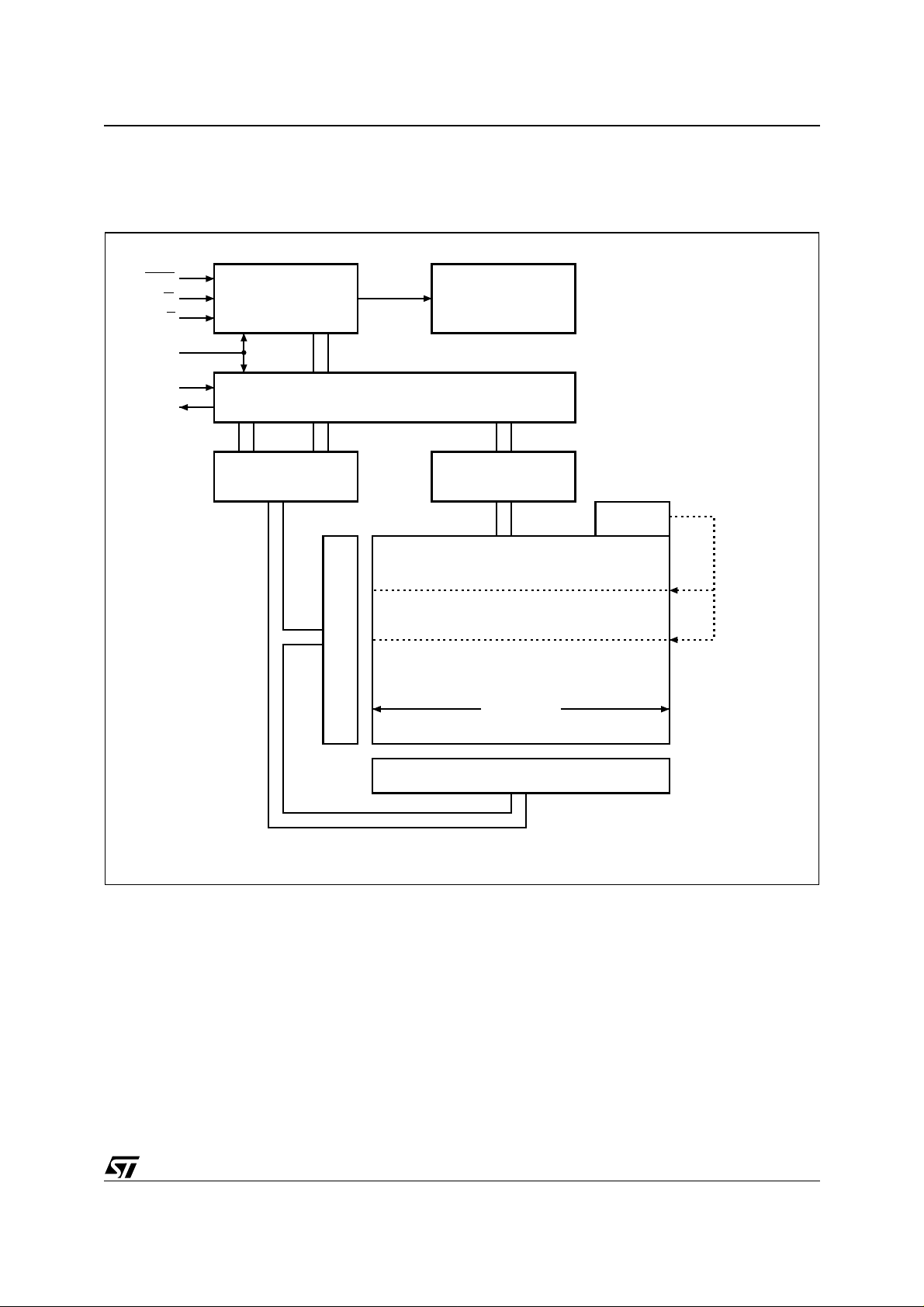

MEMOR Y ORGANIZATION

The memory is organized as shown in Figure 7..

Figure 7. Block Diagram

M95040, M95020, M95010

HOLD

W

S

C

D

Q

Control Logic

I/O Shift Register

Address Register

and Counter

Y Decoder

High Voltage

Generator

Data

Register

1 Page

Status

Register

Size of the

Read only

EEPROM

area

X Decoder

AI01272C

11/37

M95040, M95020, M95010

INSTRUCTIONS

Each instruction starts with a single-byte code, as

summarized in Table 5..

If an invalid instruction is s ent (one not con tained

in Table 5.), the device automatically deselects itself.

Table 5. Instruction Set

Instruc

tion

WREN Write Enable 0000 X110

WRDI Write Disable 0000 X100

RDSR Read Status Register 0000 X101

WRSR Write Status Register 0000 X001

READ Read from Memory Array

WRITE Write to Memory Array

Note: 1. A8 = 1 for the upper half of the memory array of the

M95040, and 0 for the lower half, and is Don’t Care fo r

other devices.

2. X = Don’ t Care.

Description

Instruction

Format

0000 A

0000 A

8

8

011

010

12/37

M95040, M95020, M95010

Write Enable (WREN)

The Write Enable Latch (WEL) bit must be set prior to each WRITE and WRSR instruction. The only

way to do this is to send a Write Enable instruction

to the device.

Figure 8. Write Enable (WREN) Sequence

S

0

C

D

High Impedance

Q

Write Disable (WRDI)

One way of resetting the Write Enable Latch

(WEL) bit is to send a Write Disable instruction to

the device.

As shown in Figure 9., to send this i nstruc tion t o

the devic e , C hip Selec t ( S

) is driven Low, and the

bits of the instruction byte are shifted in, on Serial

Data Input (D).

As shown in Figure 8., to send this instruction to

the devic e , C hip Selec t ( S

) is driven Low, and the

bits of the instruction byte are shifted in, on Serial

Data Input (D). The device then enters a wait

state. It waits for a the device to be deselected, by

Chip Selec t ( S

21 34567

Instruction

) being driven High.

AI01441D

The device then enters a wait state. It waits for a

the device to be deselected, by Chip Select (S

ing driven High.

The Write Enable Latch (WEL) bit, in fact, becomes reset by any of the following events:

–Power-up

– WRDI instruction execution

– WRSR instruction completion

– WRITE instruction completion

– Write Protect (W

) line being held Low.

) be-

Figure 9. Write Disable (WRDI) Sequence

S

C

D

Q

0

21 34567

Instruction

High Impedance

AI03790D

13/37

M95040, M95020, M95010

Read Status Register (RDSR)

One of the major uses of this inst ruction is to allow

the MCU to poll the state o f the Write I n Pr ogress

(WIP) bit. This is needed because the device wi ll

not accept further W RITE or WRSR i nstructions

when the previous Write cycle is not yet finished.

As shown in Figure 10., to send this instruction t o

the device, Chip Se l e ct (S

) is first driven Low. The

bits of the instruction byte are then shifted in, on

Serial Data Input (D). The current state of t he bi ts

in the Status Register is shifted out, on Serial Data

Out (Q). The Read Cycle is terminated by driving

Chip Selec t ( S

) High.

The Status Register may be read at any time, even

during a Write cycle (whether it be to the memory

area or to the Status Regist er). All bi ts of t he Status Register remain valid, and can be read using

the RDSR instruction. However, during the current

Write cycle, the values of the non-volatile bits

(BP0, BP1) become frozen at a constant value.

The updated value of these bits becomes available when a new RDSR instruction is executed, after completion of the Write cycle. On the other

hand, the two read-only bits (Write Enable Latch

(WEL), Write In Progress (WIP)) are dynamically

updated during the on-going Write cycle.

The status and control bits of t he Status Register

are as follows:

WIP bit. The Write In Progress (WIP) bit indicates

whether the memory is busy with a Write or Write

Status Register cycle. When set to 1, such a cycle

is in progress, when reset to 0 no such cycle is in

progress.

WEL bit. The Write Enable Latch (WEL) bit i ndicates the status of the internal Write Enable Latch.

When set to 1 the internal Write Enable Latch is

set, when set to 0 t he i nternal Write Enable La tch

is reset and no Write or Write Status Register instruction is accepted.

BP1, BP0 bits. The Block Protect (BP1, BP0) bits

are non-volatile. They define the size of the area to

be software protected against Write instructions.

These bits are written with the Write Status Register (WRSR) instruction. When one or bot h of the

Block Protect (BP1, BP0) bits is set to 1, the relevant memory area (as defined in Table 4.) be-

comes protected against Write (WRITE)

instructions. The Block Protect (BP1, BP0) bits

can be written provided that the Hardware Protected mode has not been set.

Figure 10. Read Status Register (RDSR) Sequence

S

21 3456789101112131415

0

C

Instruction

D

Q

High Impedance

Status Register Out

7 6543210

MSB

Status Register Out

7 6543210

MSB

7

AI01444D

14/37

M95040, M95020, M95010

Write Status Register (WRSR)

This instruction has no effect on bits b7, b6, b5, b4,

b1 and b0 of the Status Register.

As shown in Figure 11., to send this instruction t o

the device, Chip Se l e ct (S

) is first driven Low. The

bits of the instruction byte and d ata byte are then

shifted in on Serial Data Input (D).

The instruction is terminated by driving Chip Select (S

) High. Chip Select (S) must be driven High

after the rising edge of Serial Clock (C) that latches the eighth bit of the data byte, and before the

the next rising edge of Serial Clock (C). If this condition is not met, the Write Status Register

(WRSR) instruction is not executed. The selftimed Write Cycle starts, and continues for a peri-

Figure 11. Write Status Register (WRSR) Sequence

S

21 3456789101112131415

0

C

Instruction Status

(as specified in Table 18. to Table 22.), at

od t

W

the end of which the Write in Progress (WIP) bit is

rese t to 0.

The instruction is not accepted, and is not executed, under the following conditions:

– if the Write Enable Latch (WEL) bit has not

been set to 1 (by executing a Write Enable

instruction just before)

– if a Write Cycle is already in progress

– if the device has not been deselected, by Chip

Select (S

) being driven High, after the eighth

bit, b0, of the data byte has been latched in

– if Write Protect (W

Register In

) is Low.

D

High Impedance

Q

765432 0

MSB

1

AI01445B

15/37

M95040, M95020, M95010

Read from Memory Array (READ)

As shown in Figure 12., to send this instruction t o

the device, Chip Se l e ct (S

) is first driven Low. The

bits of the instruction byte and address byte are

then shifted in, on Serial Data Input (D). For the

M95040, the most significant address bit, A8, is incorporated as bit b3 of the instruction byte, as

shown in Table 5.. The address is loaded into an

internal address register, and the byte of data at

that address is shifted out, on Serial Data Output

(Q).

If Chip Select (S

) continues to be driven Low, an

internal bit-pointer is automatically incremented at

to be continued indefinitely. The whole memory

can, therefore, be read with a single READ instruction.

The Read cycle is terminated by driving C hip Select (S

(S

The first byte addressed can be a ny byte within

any page.

The instruction is not accepted, and is not executed, if a Write cycle is currently in progress.

Table 6. Address Range Bits

each clock cycle, and the corresponding data bit is

shifted out.

When the highest address is reached, the address

Address Bits A8-A0 A7-A0 A6-A0

counter rolls over to zero, allowing the Read cycle

Figure 12. Read from Memory Array (READ) Sequence

S

21 345678910111213141516171819

0

C

) High. The rising edge of the Chip Select

) signal can occur at any time during the cycle.

Device M95040 M95020 M95010

20 21 22

Instruction Byte Address

A7

D

High Impedance

Q

Note: Depending on the memory size, as shown in Table 6., the most significant addre ss bits are Do n’ t C a re.

A6 A5 A4 A3 A2 A1 A0A8

Data Out

76543

2

1

0

AI01440E

16/37

M95040, M95020, M95010

Write to Memory Array (WRITE)

As shown in Figure 13., to send this instruction t o

the device, Chip Se l e ct (S

) is first driven Low. The

bits of the instruction byte, address byte, and at

least one data byte are t hen shifted in, on Serial

Data Input (D).

The instruction is terminated by driving Chip Se-

) High after the rising edge of Serial Clock

lect (S

(C) that latches the last data bit, and before the

next rising edge of Serial Clock (C) occurs anywhere on the bus. In the case of Figure 13., this

occurs after the eighth bit of the data byte has

been latched in, indicating that the instruction is

being used to write a single byte. The self-timed

Write cycle starts, and continues for a period t

WC

(as specified in Table 18. to Table 22.), at the end

of which the Write in Progress (WIP) bit is reset to

0.

If, though, Chip Select (S

) continues to be driven

Low, as shown in Figure 14., the next byte of input

data is shifted in. In this way, all the bytes from the

Figure 13. Byte Write (WRITE) Sequence

given address to the end of the same page can be

programmed in a single instruction.

If Chip Sele ct ( S

) still continues to be driven Low,

the next byte of input data is shifted in, and is used

to overwrite the byte at the start of the current

page.

The instruction is not accepted, and is not executed, under the following conditions:

– if the Write Enable Latch (WEL) bit has not

been set to 1 (by executing a Write Enable

instruction just before)

– if a Write cycle is already in progress

– if the device has not been deselected, by Chip

Select (S

) being driven High, at a byte

boundary (after the rising edge of Serial Clock

(C) that latches the last data bit, and before

the next rising edge of Serial Clock (C) occurs

anywhere on the bus)

– if Write Protect (W

) is Low or if the addressed

page is in the region protected by the Block

Protect (BP1 and BP0) bits.

S

21 345678910111213141516171819

0

C

Instruction Byte Address

A7

D

High Impedance

Q

Note: Depending on the memory size, as shown in Table 6., the most significant addre ss bits are Do n’ t C a re.

A6 A5 A4 A3 A2 A1 A0A8

765432 0

20 21 22 23

Data Byte

1

AI01442D

17/37

M95040, M95020, M95010

Figure 14. P age Write (WRITE) Sequen ce

S

21 34567891011121314151617181920 21 22 23

0

C

Instruction Byte Address

D

S

2625 27 28 29 30 31

24

C

Data Byte 2

54

D

Note: Depending on the memory size, as shown in Table 6., the most significant addre ss bits are Do n’ t C a re.

76 3210

A7 A6 A5 A4 A3 A2 A1 A0A8 765432 0

8+8N

9+8N

10+8N

11+8N

12+8N

13+8N

14+8N

15+8N

136

Data Byte N

7 6543210765432 0

Data Byte 1

137

138

139

Data Byte 16

140

141

1

7

142

143

1

AI01443D

18/37

POWER-U P AND DELIVERY STAT E

Power-up S t a t e

After Power-up, the device is in the following state:

– low power Standby Power mode

– deselected (after Power-up, a falling edge is

required on Chip Select (S

instructions can be started).

– not in the Hold Condition

– the Write Enable Latch (WEL) is reset to 0

– Write In Progress (WIP) is reset to 0

The BP1 and BP0 bi ts of the Status Register are

unchanged from the previous power-down (they

are non-volatile bits).

) before any

M95040, M95020, M95010

Initi a l D e live ry St a te

The device is delivered with the memory array set

at all 1s (FFh). The Block Protect (BP1 and BP0)

bits are initialized to 0.

19/37

M95040, M95020, M95010

MAXIMUM RA T ING

Stressing the device outside the ratings listed in

Table 7. may cause permanent damage to the de-

vice. These are stress ratings only, and operation

of the device at these, or any other conditions outside those indicated in the Operating sections of

Table 7. Absolute Maximum Ratings

Symbol Parameter Min. Max. Unit

T

STG

T

LEAD Lead Temperature during Soldering

V

O

V

I

V

CC

V

ESD

Note: 1. Compliant w ith JE DEC Std J-S TD- 020B (for smal l bod y, Sn-P b or Pb assem bly ), the ST ECOPA CK® 71913 95 specif ication, and

the European direct i ve on Restri ct i ons on Hazar dous Substances (RoHS) 2002/95 /EU.

2. AEC -Q100-00 2 (compliant wi t h JE DEC Std JESD22-A11 4A , C1=100pF, R1=1500

Storage Temperature –65 150 °C

1

Output Voltage –0.50

Input Voltage –0.50 6.5 V

Supply Voltage –0.50 6.5 V

Electrostatic Discharge Voltage (Human Body model)

this specification, is not implied. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability. Refer also to

the STMicroelectronics SURE Program and other

relevant quality documents.

2

See note

V

–4000 4000 V

Ω, R2=500Ω)

CC

1

+0.6

°C

V

20/37

M95040, M95020, M95010

DC AND AC PARAMETERS

This section summarizes the operating and measurement conditions, and the DC and AC characteristics of the device. The parameters in the DC

and AC Characteristic tables that follow are derived from tests performed under the Measure-

Table 8. Operating Conditions (M950x0)

Symbol Parameter Min. Max. Unit

ment Conditions summarized in the relevant

tables. Designers should check that the operating

conditions in their circuit match t he measurem ent

conditions when relying on the quoted parameters.

V

CC

Supply Voltage 4.5 5.5 V

Ambient Operating Temperature (Device Grade 6) –40 85 °C

T

A

Ambient Operating Temperature (Device Grade 3) –40 125 °C

Table 9. Operating Conditions (M950x0-W)

Symbol Parameter Min. Max. Unit

V

CC

Supply Voltage 2.5 5.5 V

Ambient Operating Temperature (Device Grade 6) –40 85 °C

T

A

Ambient Operating Temperature (Device Grade 3) –40 125 °C

Table 10. Operating Conditions (M950x0-R)

Symbol Parameter Min. Max. Unit

V

CC

T

A

Supply Voltage 1.8 5.5 V

Ambient Operating Temperature –40 8 5 °C

Table 11. AC Measurement Conditions

Symbol Parameter Min. Max. Unit

C

L

Load Capacitance 100 pF

Input Rise and Fall Times 50 ns

Input Pulse Voltages

Input and Output Timing Reference Voltages

Note: Output Hi-Z is defined as the point where data out is n o l onger driven.

Figure 15. AC Measurem ent I/O W aveform

Input Levels

0.8V

CC

0.2V

CC

0.2V

0.3V

Input and Output

Timing Reference Levels

0.7V

CC

0.3V

CC

AI00825B

to 0.8V

CC

to 0.7V

CC

CC

CC

V

V

21/37

M95040, M95020, M95010

Table 12. Capacitance

Symbol Parameter Test Condition Min. Max. Unit

C

OUT

C

IN

Output Capacitance (Q) V

Input Capacitance (D) VIN = 0V 8 pF

Input Capacitance (other pins) V

Note: Sampled only, not 100% test ed, at TA=25°C an d a frequency of 5MHz.

Table 13. DC Characteristics (M950x0, Device Grade 6)

Symbol Parameter Test Condition Min. Max. Unit

= 0V 8 pF

OUT

= 0V 6 pF

IN

I

I

I

I

CC1

V

V

V

V

OH

Note: 1. For all 5V range devices, the device meets the output requireme nts for both T T L and CMOS sta ndards.

Input Leakage Current V

LI

Output Leakage Curren t S = VCC, V

LO

C=0.1V

VCC= 5 V, Q = open, Previous Product

Supply Current

CC

Supply Current

C = 0.1V

= 5 V, Q = open, Present Product

V

CC

V

= VSS or VCC, Previous Product

IN

(Standby Power mode)

= VSS or VCC, Present Product

V

IN

Input Low Voltage –0.45 0.3 V

IL

Input High Voltage 0.7 V

IH

1

Output Low Voltage IOL = 2 mA, VCC = 5 V 0.4 V

OL

1

Output High Voltage IOH = –2 mA, VCC = 5V 0.8V

2. Previous product: identified by Pr ocess Ident i fication lett er K.

3. Present product: identified by Process Identification letter W or G.

= VSS or V

IN

OUT

/0.9VCC at 5MHz,

CC

/0.9VCC at 10MHz,

CC

= V

= V

CC

CC

, V

, V

S

S

CC

= VSS or V

= 5 V,

CC

= 5 V,

CC

CC

2

3

2

3

CC

CC

± 2 µA

± 2 µA

5mA

5mA

10 µA

2µA

CC

V

VCC+1 V

V

22/37

M95040, M95020, M95010

Table 14. DC Characteristics (M950x0, Device Grade 3)

Symbol Parameter Test Condition Min. Max. Unit

V

I

I

Input Leakage Current

LI

Output Leakage Curren t

LO

S

C = 0.1V

V

= 5 V, Q = open, Previous Product

I

I

CC1

V

V

V

V

OH

Note: 1. For all 5V range devices, the device meets the output requireme nts for both T T L and CMOS sta ndards.

Supply Current

CC

Supply Current

(Standby Power mode)

Input Low Voltage –0.45

IL

Input High Voltage 0.7 V

IH

1

Output Low Voltage IOL = 2 mA, VCC = 5 V 0.4 V

OL

1

Output High Voltage IOH = –2 mA, VCC = 5V 0.8V

2. Previous product: identified by Pr ocess Ident i fication lett er K.

3. Present product: identified by Process Identification letter W or G.

CC

C = 0.1V

V

= 5 V, Q = open, Present Product

CC

V

= VSS or VCC, Previous Product

IN

V

= VSS or VCC, Present Product

IN

IN

= VCC, V

CC

CC

= V

S

S

= V

= VSS or V

OUT

CC

= VSS or V

/0.9VCC at 2 MHz,

/0.9VCC at 5 MHz,

, V

, V

CC

CC

= 5 V,

= 5 V,

CC

CC

CC

± 2 µA

± 2 µA

2

3

2

3

CC

CC

5mA

3mA

10 µA

5µA

0.3 V

CC

VCC+1 V

V

V

Table 15. DC Characteristics (M950x0-W, Device Grade 6)

Symbol Parameter Test Condition Min. Max. Unit

I

I

I

I

CC1

V

V

V

V

Note: 1. Previous product: id entified by Pr ocess Ident i fication lett er K.

Input Leakage Current V

LI

Output Leakage Curren t

LO

S

C = 0.1V

= 2.5 V, Q = open, Previous Product

V

CC

Supply Current

CC

C = 0.1V

VCC= 2.5 V, Q = open, Present Product

V

= VSS or VCC, Previous Product

Supply Current

IN

(Standby Power mode)

V

= VSS or VCC, Present Product

IN

Input Low Voltage –0.45 0.3 V

IL

Input High Voltage

IH

Output Low Voltage

OL

Output High Voltage IOH = –0.4 mA, VCC = 2.5 V 0.8 V

OH

2. Present product: identified by Process Identification letter W or G.

I

= VSS or V

IN

= VCC, V

S

OL

OUT

/0.9VCC at 2 MHz,

CC

/0.9VCC at 5 MHz,

CC

= V

, V

CC

S

= V

, V

CC

= 1.5 mA, VCC = 2.5 V

CC

= VSS or V

= 2.5 V,

CC

= 2.5V

CC

CC

1

2

1

2

0.7 V

CC

CC

± 2 µA

± 2 µA

2mA

2mA

2µA

1µA

CC

VCC+1

0.4 V

V

V

V

23/37

M95040, M95020, M95010

Table 16. DC Characteristics (M950x0-W, Device Grade 3)

Symbol Parameter Test Condition Min. Max. Unit

V

IN

= VCC, V

CC

CC

, V

= 2.5 V, V

CC

= VSS or V

OUT

CC

= VSS or V

/0.9VCC at 2 MHz,

/0.9VCC at 5 MHz,

= VSS or V

IN

CC

CC

± 2 µA

± 2 µA

1

2

2mA

2mA

2µA

I

I

I

CC1

I

Input Leakage Current

LI

Output Leakage Curren t

LO

S

C = 0.1V

V

= 2.5 V, Q = open, Previous Product

Supply Current

CC

Supply Current

(Standby Power mode)

CC

C = 0.1V

V

= 2.5 V, Q = open, Present Product

CC

S

= V

CC

V

V

V

V

Note: 1. Previous product: id entified by Pr ocess Ident i fication lett er K.

Input Low Voltage –0.45 0.3 V

IL

Input High Voltage 0.7 V

IH

Output Low Voltage IOL = 1.5 mA, VCC = 2.5 V 0.4 V

OL

Output High Voltage IOH = –0.4 mA, VCC = 2.5 V 0.8 V

OH

2. Present product: identified by Process Identification letter W or G.

CC

CC

Table 17. DC Characteristics (M950x0-R)

Symbol Parameter Test Condition

I

I

LO

I

CC

I

CC1

V

V

V

V

Note: 1. Preliminary data: Product under development. Please contact your nearest ST sales office for information .

Input Leakage Curren t V

LI

Output Leakage Current S = VCC, V

Supply Current

Supply Current

(Standby Power mode)

Input Low Voltage –0.45 0.25 V

IL

Input High Voltage 0.7 V

IH

Output Low Voltage

OL

Output High Voltage

OH

C=0.1V

S

= VCC, V

I

OL

I

OH

= VSS or V

IN

OUT

/0.9. VCC at 1 MHz,

CC

= 1.8 V, Q = open

V

CC

= VSS or V

IN

CC

= VSS or V

, V

CC

CC

= 1.8V

CC

= 0.15 mA, VCC = 1.8 V

= –0.1 mA, VCC = 1.8 V 0.8 V

Min.

1

CC

CC

CC

V

VCC+1 V

V

1

Max.

Unit

± 2 µA

± 2 µA

1mA

0.5 µA

CC

V

VCC+1 V

0.3 V

V

24/37

Table 18. AC Characteristics (M950x0, Device Grade 6)

Test conditions specified in Table 11. and Table 8.

Symbol Alt. Parameter

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

1

t

CH

1

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CHHL

t

CHHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

Note: 1. tCH + tCL must never be less than the shortest p ossible clock period, 1 / fC(max)

2. Val ue guaranteed by charact erization, not 100% tes ted in product i on.

3. Previous product: identified by Pr ocess Ident i fication lett er K.

4. Present product: identified by Process Identification letter W or G.

f

SCK

t

CSS1

t

CSS2

t

t

CSH

Clock Frequency D.C. 5 D.C. 10 MHz

S Active Setup Time 90 15 ns

S Not Active Setup Time 90 15 ns

S Deselect Time 100 40 ns

CS

S Active Hold Time 90 25 ns

S Not Active Hold Time 90 15 ns

t

CLH

t

CLL

2

t

2

t

t

DSU

t

Clock High Time 90 40 ns

Clock Low Time 90 40 ns

Clock Rise Time 1 1 µs

RC

Clock Fall Time 1 1 µs

FC

Data In Setup Time 20 15 ns

Data In Hold Time 30 15 ns

DH

Clock Low Hold Time after HOLD not Active 70 15 ns

Clock Low Hold Time after HOLD Active 40 20 ns

Clock High Set-up Time before HOLD Active

Clock High Set-up Time before HOLD not Active

2

t

DIS

t

2

t

2

t

t

2

t

t

WC

Output Disable Time 100 25 ns

t

Clock Low to Output Valid 60 35 ns

V

Output Hold Time 0 0 ns

HO

Output Rise Time 50 20 ns

RO

Output Fall Time 50 20 ns

FO

HOLD High to Output Valid 50 25 ns

LZ

HOLD Low to Output High-Z 100 35 ns

HZ

Write Time 10 5 ms

Min.

t

CH

t

CH

M95040, M95020, M95010

3

Max.3Min.4Max.

30 ns

30 ns

4

Unit

25/37

M95040, M95020, M95010

Table 19. AC Characteristics (M950x0, Device Grade 3)

Test conditions specified in Table 11. and Table 8.

Symbol Alt. Parameter

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

1

t

CH

1

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CHHL

t

CHHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

Note: 1. tCH + tCL must never be less than the shortest p ossible clock period, 1 / fC(max)

2. Val ue guaranteed by charact erization, not 100% tes ted in product i on.

3. Previous product: identified by Pr ocess Ident i fication lett er K.

4. Present product: identified by Process Identification letter W or G.

f

SCK

t

CSS1

t

CSS2

t

t

CSH

Clock Frequency D.C. 2 D.C. 5 MHz

S Active Setup Time 200 90 ns

S Not Active Setup Time 200 90 ns

S Deselect Time 200 100 ns

CS

S Active Hold Time 200 90 ns

S Not Active Hold Time 200 90 ns

t

CLH

t

CLL

2

t

2

t

t

DSU

t

Clock High Time 200 90 ns

Clock Low Time 200 90 ns

Clock Rise Time 1 1 µs

RC

Clock Fall Time 1 1 µs

FC

Data In Setup Time 40 20 ns

Data In Hold Time 50 30 ns

DH

Clock Low Hold Time after HOLD not Active 140 70 ns

Clock Low Hold Time after HOLD Active 90 40 ns

Clock High Set-up Time before HOLD Active

Clock High Set-up Time before HOLD not

Active

2

t

DIS

t

2

t

2

t

t

2

t

t

WC

Output Disable Time 250 100 ns

t

Clock Low to Output Valid 150 60 ns

V

Output Hold Time 0 0 ns

HO

Output Rise Time 100 50 ns

RO

Output Fall Time 100 50 ns

FO

HOLD High to Output Valid 100 50 ns

LZ

HOLD Low to Output High-Z 250 100 ns

HZ

Write Time 10 5 ms

Min.

t

t

CH

CH

3

Max.3Min.4Max.

60 ns

60 ns

4

Unit

26/37

Table 20. AC Characteristics (M950x0-W, Device Grade 6)

Test conditions specified in Table 11. and Table 9.

Symbol Alt. Parameter

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

1

t

CH

1

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CHHL

t

CHHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

Note: 1. tCH + tCL must never be less than the shortest p ossible clock period, 1 / fC(max)

2. Val ue guaranteed by charact erization, not 100% tes ted in product i on.

3. Previous product: identified by Pr ocess Ident i fication lett er K.

4. Present product: identified by Process Identification letter W or G.

f

SCK

t

CSS1

t

CSS2

t

t

CSH

Clock Frequency D.C. 2 D.C. 5 MHz

S Active Setup Time 200 90 ns

S Not Active Setup Time 200 90 ns

S Deselect Time 200 100 ns

CS

S Active Hold Time 200 90 ns

S Not Active Hold Time 200 90 ns

t

CLH

t

CLL

2

t

2

t

t

DSU

t

Clock High Time 200 90 ns

Clock Low Time 200 90 ns

Clock Rise Time 1 1 µs

RC

Clock Fall Time 1 1 µs

FC

Data In Setup Time 40 20 ns

Data In Hold Time 50 30 ns

DH

Clock Low Hold Time after HOLD not Active 140 70 ns

Clock Low Hold Time after HOLD Active 90 40 ns

Clock High Set-up Time before HOLD Active

Clock High Set-up Time before HOLD not Active

2

t

DIS

t

2

t

2

t

t

2

t

t

WC

Output Disable Time 250 100 ns

t

Clock Low to Output Valid 150 60 ns

V

Output Hold Time 0 0 ns

HO

Output Rise Time 100 50 ns

RO

Output Fall Time 100 50 ns

FO

HOLD High to Output Valid 100 50 ns

LZ

HOLD Low to Output High-Z 250 100 ns

HZ

Write Time 10 5 ms

Min.

t

CH

t

CH

M95040, M95020, M95010

3

Max.3Min.4Max.

60 ns

60 ns

4

Unit

27/37

M95040, M95020, M95010

Table 21. AC Characteristics (M950x0-W, Device Grade 3)

Test conditions specified in Table 11. and Table 9.

Symbol Alt. Parameter

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

1

t

CH

1

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CHHL

t

CHHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

Note: 1. tCH + tCL must never be less than the shortest p ossible clock period, 1 / fC(max)

2. Val ue guaranteed by charact erization, not 100% tes ted in product i on.

3. Previous product: identified by Pr ocess Ident i fication lett er K.

4. Present product: identified by Process Identification letter W or G.

f

SCK

t

CSS1

t

CSS2

t

t

CSH

Clock Frequency D.C. 2 D.C. 5 MHz

S Active Setup Time 200 90 ns

S Not Active Setup Time 200 90 ns

S Deselect Time 200 100 ns

CS

S Active Hold Time 200 90 ns

S Not Active Hold Time 200 90 ns

t

CLH

t

CLL

2

t

2

t

t

DSU

t

Clock High Time 200 90 ns

Clock Low Time 200 90 ns

Clock Rise Time 1 1 µs

RC

Clock Fall Time 1 1 µs

FC

Data In Setup Time 40 20 ns

Data In Hold Time 50 30 ns

DH

Clock Low Hold Time after HOLD not Active 140 70 ns

Clock Low Hold Time after HOLD Active 90 40 ns

Clock High Set-up Time before HOLD Active

Clock High Set-up Time before HOLD not

Active

2

t

DIS

t

2

t

2

t

t

2

t

t

WC

Output Disable Time 250 100 ns

t

Clock Low to Output Valid 150 60 ns

V

Output Hold Time 0 0 ns

HO

Output Rise Time 100 50 ns

RO

Output Fall Time 100 50 ns

FO

HOLD High to Output Valid 100 50 ns

LZ

HOLD Low to Output High-Z 250 100 ns

HZ

Write Time 10 5 ms

Min.

t

t

CH

CH

3

Max.3Min.4Max.

60 ns

60 ns

4

Unit

28/37

M95040, M95020, M95010

Table 22. AC Characteristics (M950x0-R)

Test conditions specified in Table 11. and Table 10.

Symbol Alt. Parameter Min. Max. Unit

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

1

t

CH

1

t

CL

2

t

CLCH

2

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CHHL

t

CHHH

2

t

SHQZ

t

CLQV

t

CLQX

2

t

QLQH

2

t

QHQL

t

HHQV

2

t

HLQZ

t

W

Note: 1. tCH + tCL must never be less than the shortest p ossible clock period, 1 / fC(max)

2. Val ue guaranteed by charact erization, not 100% tes ted in product i on.

3. Prel i m i nary data: Pr oduct under development. Please co ntact your nearest ST sales office for in f ormation .

f

SCK

t

CSS1

t

CSS2

t

CS

t

CSH

t

CLH

t

CLL

t

RC

t

FC

t

DSU

t

DH

t

DIS

t

t

HO

t

RO

t

FO

t

t

HZ

t

WC

LZ

Clock Frequency D.C. 2 MHz

S Active Setup Time 200 ns

S Not Active Setup Time 200 ns

S Deselect Time 200 ns

S Active Hold Time 200 ns

S Not Active Hold Time 200 ns

Clock High Time 200 ns

Clock Low Time 200 ns

Clock Rise Time 1 µs

Clock Fall Time 1 µs

Data In Setup Time 40 ns

Data In Hold Time 50 ns

Clock Low Hold Time after HOLD not Active 140 ns

Clock Low Hold Time after HOLD Active 90 ns

Clock High Set-up Time before HOLD Active 120 ns

Clock High Set-up Time before HOLD not Active 120 ns

Output Disable Time 250 ns

V

Clock Low to Output Valid 180 ns

Output Hold Time 0 ns

Output Rise Time 100 ns

Output Fall Time 100 ns

HOLD High to Output Valid 100 ns

HOLD Low to Output High-Z 250 ns

Write Time 10 ms

29/37

M95040, M95020, M95010

Figure 16. Se ri al Input Timing

S

C

tDVCH

tSLCH

tSHSL

tCHSHtCHSL

tSHCH

tCHCL

D

Q

Figure 17. Hol d T im i ng

S

C

Q

MSB IN

High Impedance

tCHDX

tCHHL

tCLCH

LSB IN

AI01447C

tHLCH

tHHCH

tCHHH

tHHQVtHLQZ

30/37

D

HOLD

AI02032B

Figure 18. Out put Timing

S

C

tCLQV

tCLQV

tCH

M95040, M95020, M95010

tCL

tSHQZ

tCLQX

Q

ADDR.LSB IN

D

tCLQX

LSB OUT

tQLQH

tQHQL

AI01449D

31/37

M95040, M95020, M95010

PACKAG E MECHANICAL

Figure 19. PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Outline

b2

A2

A1AL

be

D

8

E1

1

Note: Drawing is not to scale.

E

c

eA

eB

PDIP-B

Table 23. PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Mechanical Data

Symb.

Typ. Min. Max. Typ. Min. Max.

A 5.33 0.210

mm inches

32/37

A1 0.38 0.015

A2 3.30 2.92 4.95 0.130 0.115 0.195

b 0.46 0.36 0.56 0.018 0.014 0.022

b2 1.52 1.14 1.78 0.060 0.045 0.070

c 0.25 0.20 0.36 0.010 0.008 0.014

D 9.27 9.02 10.16 0.365 0.355 0.400

E 7.87 7.62 8.26 0.310 0.300 0.325

E1 6.35 6.10 7.11 0.250 0.240 0.280

e2.54––0.100––

eA 7.62 – – 0.300 – –

eB 10.92 0.430

L 3.30 2.92 3.81 0.130 0.115 0.150

M95040, M95020, M95010

Figure 20. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Outline

h x 45˚

Note: Drawing is not to scale.

B

SO-a

A

e

D

N

1

CP

E

H

C

LA1 α

Table 24. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Mechanical Data

Symb.

Typ. Min. Max. Typ. Min. Max.

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

mm inches

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e1.27––0.050––

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α 0° 8° 0° 8°

N8 8

CP 0.10 0.004

33/37

M95040, M95020, M95010

Figure 21. TSSOP8 – 8 lead Thin Shrink S mall Outlin e, Packa ge Ou tline

D

8

1

CP

Note: Drawing is not to scale.

5

EE1

4

α

A2A

A1

eb

L

L1

TSSOP8AM

Table 25. TSSOP8 – 8 lead Thin Shrink Small Outline, Package Mechanical Data

Symbol

Typ. Min. Max. Typ. Min. Max.

A 1.200 0.0472

A1 0.050 0.150 0.0020 0.0059

A2 1.000 0.800 1.050 0.0394 0.0315 0.0413

mm inches

c

34/37

b 0.190 0.300 0.0075 0.0118

c 0.090 0.200 0.0035 0.0079

CP 0.100 0.0039

D 3.000 2.900 3.100 0.1181 0.1142 0.1220

e 0.650 – – 0.0256 – –

E 6.400 6.200 6.600 0.2520 0.2441 0.2598

E1 4.400 4.300 4.500 0.1732 0.1693 0.1772

L 0.600 0.450 0.750 0.0236 0.0177 0.0295

L1 1.000 0.0394

α 0° 8° 0° 8°

M95040, M95020, M95010

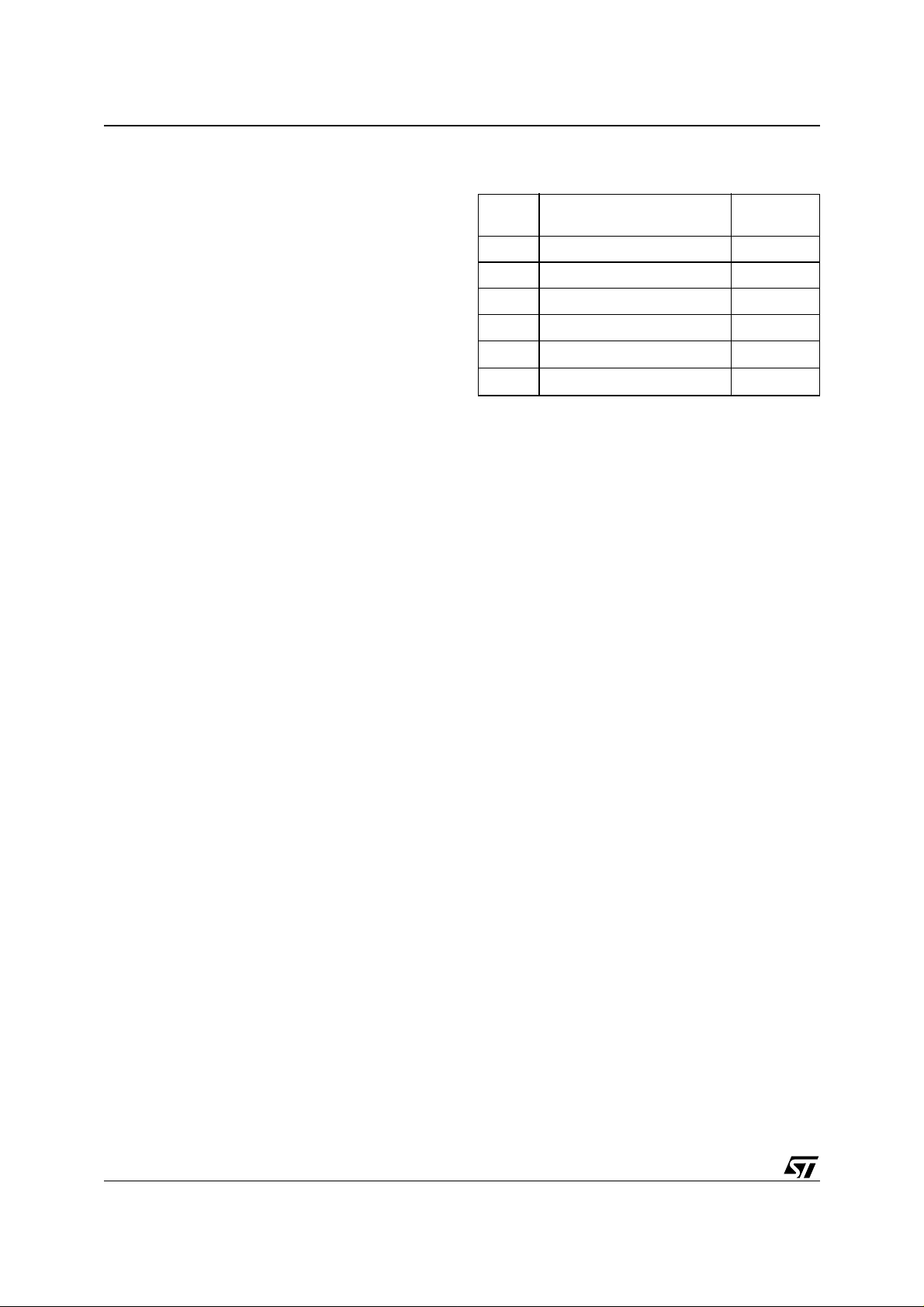

PART NUMBERING

Table 26. Ordering Information Scheme

Example: M95040 – W MN 6 T P /W

Device Type

M95 = SPI serial access EEPROM

Device Function

040 = 4 Kbit (512 x 8)

020 = 2 Kbit (256 x 8)

010 = 1 Kbit (128 x 8)

Operating Voltage

blank = V

W = V

R = V

Package

BN = PDIP8

MN = SO8 (150 mil width)

DW = TSSOP8 (169 mil width)

= 4.5 to 5.5V

CC

= 2.5 to 5.5V

CC

= 1.8 to 5.5V

CC

Device Grade

6 = Industrial temperature range, –40 to 85 °C.

Device tested with standard test flow

3 = Device tested with High Reliability Certified Flow

1

.

Automotive temperature range (–40 to 125 °C)

Option

blank = Standard Packing

T = Tape and Reel Packing

Plating Technology

blank = Standard SnPb plating

P = Lead-Free and RoHS compliant

G = Lead-Free, RoHS compliant, Sb

Process

2

-free and TBBA-free

2O3

blank = F6SP20%

/W = F6SP36%

Note: 1. ST strongly recommends the use of the Automotive Grade devices for use in an automotive environment. The High Reliability Cer-

For a list of available options (speed, package,

etc.) or for further information on any aspect of this

tified Flow (HRCF) is described in the quality not e QNEE9801. Please ask your neares t S T sales office for a copy.

2. Used only for Device Grade 3

device, please contact your nearest ST Sales Office.

Table 27. How to Identify Present and Previous Products by the Process Identification Letter

Markings on Present Products

95040W6

AYWWW (or AYWWG)

1

Markings on Previous Products

95040W6

AYWWK

1

35/37

M95040, M95020, M95010

REVISION HISTORY

Table 28. Document Revision History

Date Version Description of Revision

10-May-2000 2.2 s/issuing three bytes/issuing two bytes/ in the 2nd sentence of the Byte Write Operation

Human Body Model meets JEDEC std (Table 2). Minor adjustments to Figs 7,9,10,11 & Tab

16-Mar-2001 2.3

19-Jul-2001 2.4 Temperature range ‘3’ added to the -W supply voltage range in DC and AC characteristics

11-Oct-2001 3.0 Document reformatted using the new template

26-Feb-2002 3.1 Description of chip deselect after 8th clock pulse made more explicit

9. Wording changes, according to the standard glossary

Illustrations and Package Mechanical data updated

27-Sep-2002 3.2

Position of A8 in Read Instruction Sequence Figure corrected. Load Capacitance C

changed

24-Oct-2002 3.3 Minimum values for tCHHL and tCHHH changed.

24-Feb-2003 3.4 Description of Read from Memory Array (READ) instruction corrected, and clarified

28-May-2003 3.5 New products, identified by the process letter W, added

Correction to current products, identified by the process letter K not L.

25-Jun-2003 3.6

changed in DC characteristics, and t

CC

Voltage range -S upgraded by removing it, and adding the -R voltage range in its place

CHHL

, t

substituted in AC characteristics

CHHH

I

Temperature range 5 removed.

21-Nov-2003 4.0

02-Feb-2004 4.1

01-Mar-2004 5.0

Table of contents, and Pb-free options added. V

V

(max) and t

IL

Absolute Maximum Ratings for V

(max) changed

CLQV

(min) and VCC(min) improved. Soldering temperature

IO

information clarified for RoHS compliant devices. New 5V and 2.5V devices, with process

letter W, promoted from preliminary data to full data. Device Grade 3 clarified, with reference

(min) improved to -0.45V

IL

to HRCF and automotive environments

Product List summary table added. Process identification letter “G” information added. Order

05-Oct-2004 6.0

information for Tape and Reel changed to T. AEC-Q100-002 compliance. Device Grade

informaton clarified. tHHQX corrected to tHHQV. Signal Description updated.

10MHz, 5ms Write is now the present product. tCH+tCL<1/fC constraint clarified

L

36/37

M95040, M95020, M95010

Information furnished is believed to be accurate and reliable. However, STMicroelectronics a ssumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are sub j e c t

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authori zed for use as crit i cal compon ents in life support devic es or systems without express writt en approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroel ectronics.

All other nam es are the pro perty of their respectiv e owners

© 2004 STMi croelectro n ics - All righ ts reserved

Australi a - Belgium - B razil - Canada - China - Czech Republi c - Finland - F rance - Germ any - Hong Ko ng - I n dia - Israel - It al y - Japan -

Malaysia - M al ta - Morocco - Singapore - Spain - Sweden - Swit zerland - Un i ted Kingdom - United Sta tes of Americ a

STMicroelectron ics group of com panies

www.st.com

37/37

Loading...

Loading...