Page 1

查询M50FW080供应商

FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

–V

■ TWO INTERFACES

– Firmware Hub (FWH) Interface for

– Address/Address Multiplexed (A/A Mux)

■ FIRMWARE HUB (FWH) HARDWARE

INTERFACE MODE

– 5 Signal Communication Interface

– Hardware Write Protect Pins for Block

– Register Based Read and Write

– 5 Additional General Purpose Inputs for

– Synchronized with 33MHz PCI clock

■ PROGRAMMING TIME

– 10µs typical

– Quadruple Byte Programming Option

■ 16 UNIFORM 64 KByte MEMORY BLOCKS

■ PROGRAM/ERASE CONTROLLER

– Embedded Byte Program and Block/Chip

– Status Register Bits

■ PROGRAM and ERASE SUSPEND

– Read other Blocks during Program/Erase

– Program other Blocks during Erase

■ FOR USE in PC BIOS APPLICATIONS

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: 2Dh

= 3V to 3.6V for Program, Erase and

CC

Read Operations

= 12V for Fast Program and Fast

PP

Erase (optional)

embedded operation with PC Chipsets

Interface for programming equipment

compatibility

supporting Read and Write Operations

Protection

Protection

platform design flexibility

Erase algorithms

Suspend

Suspend

M50FW080

8 Mbit (1M x8, Uniform Block)

3V Supply Firmware Hub Flash Memory

Figure 1. Packages

PLCC32 (K)

TSOP32 (NB)

8 x 14mm

TSOP40 (N)

10 x 20mm

1/47August 2004

Page 2

M50FW080

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

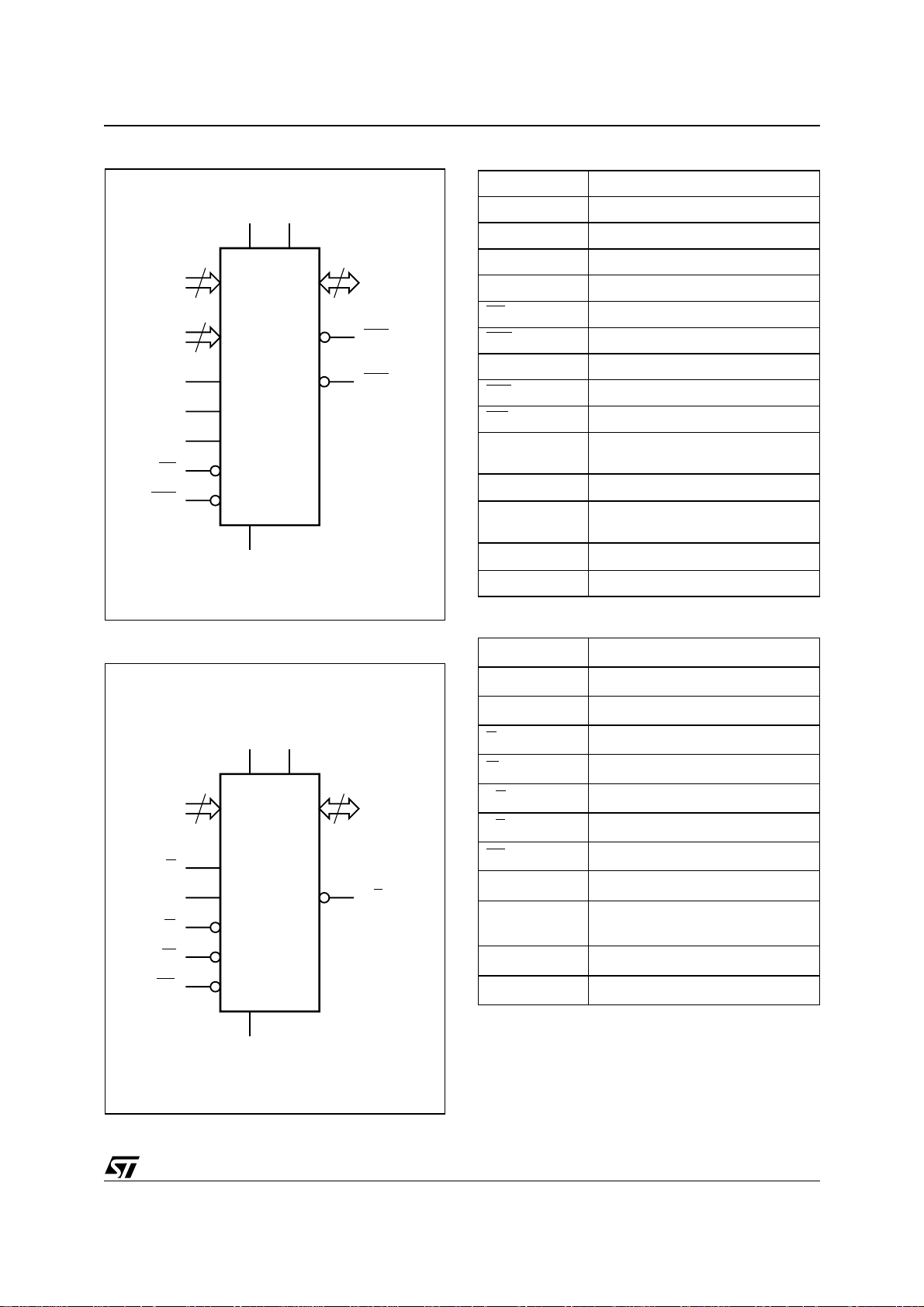

Figure 2. Logic Diagram (FWH Interface). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Logic Diagram (A/A Mux Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1. Signal Names (FWH Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Signal Names (A/A Mux Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

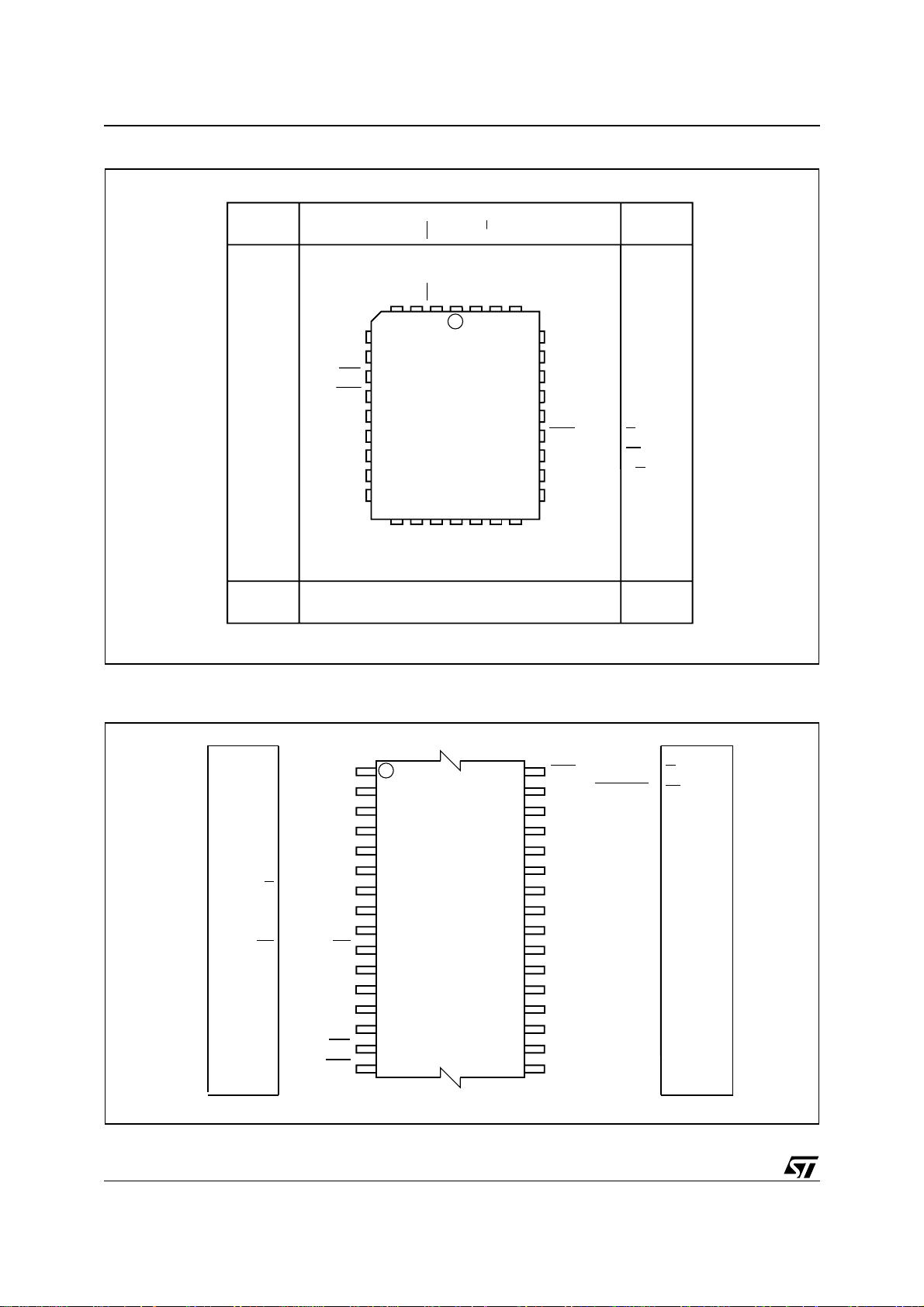

Figure 4. PLCC Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. TSOP32 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

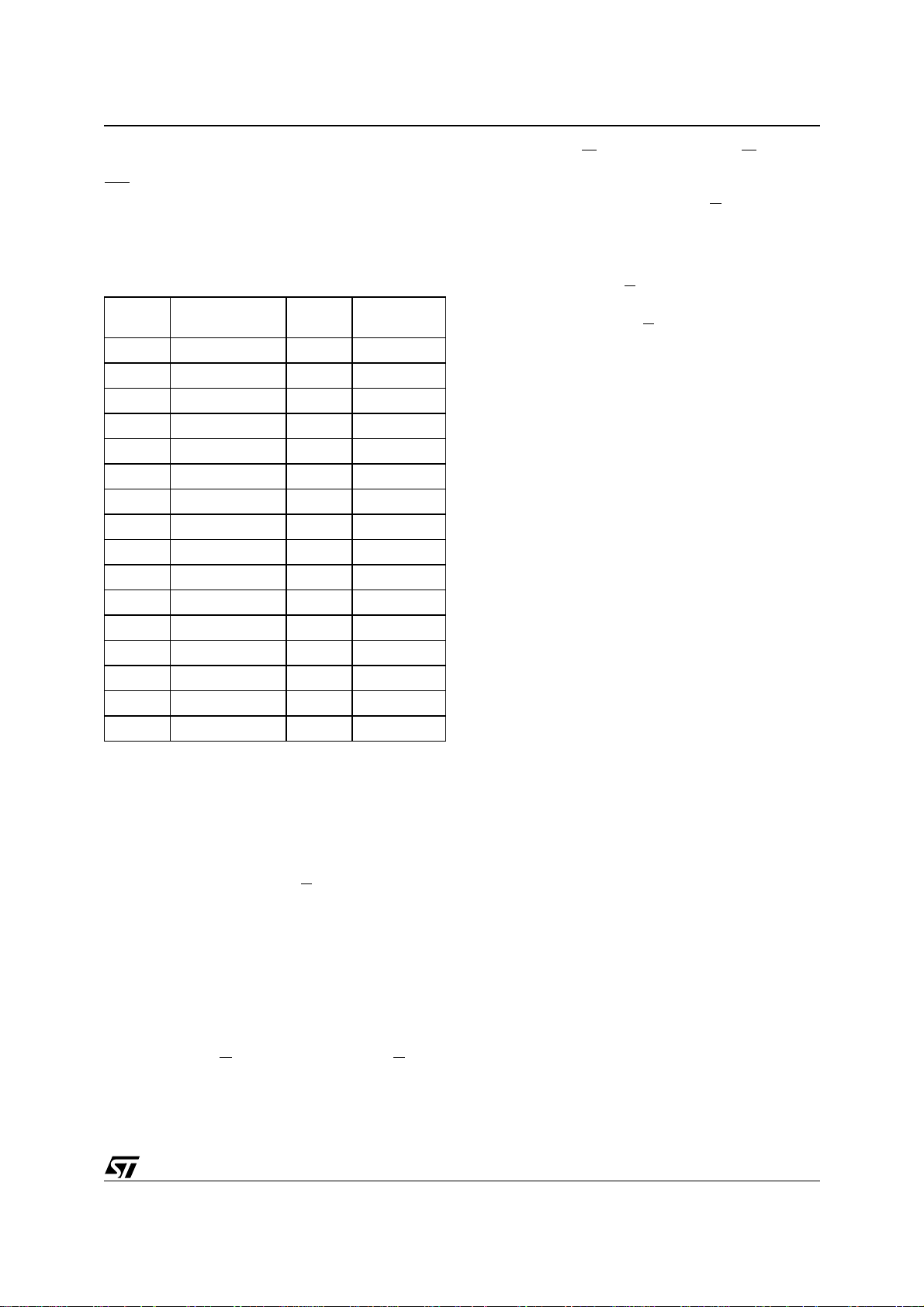

Figure 6. TSOP40 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Firmware Hub (FWH) Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input/Output Communications (FWH0-FWH3).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input Communication Frame (FWH4).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Identification Inputs (ID0-ID3).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Purpose Inputs (FGPI0-FGPI4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Interface Configuration (IC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Interface Reset (RP

CPU Reset (INIT

Clock (CLK). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Top Block Lock (TBL

Write Protect (WP

Reserved for Future Use (RFU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Block Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Address/Address Multiplexed (A/A Mux) Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 11

Address Inputs (A0-A10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output Enable (G

Write Enable (W

Row/Column Address Select (RC

Ready/Busy Output (RB

Supply Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

V

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CC

V

Optional Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PP

V

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SS

).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Firmware Hub (FWH) Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bus Abort. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2/47

Page 3

M50FW080

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Block Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Address/Address Multiplexed (A/A Mux) Bus Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4. FWH Bus Read Field Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

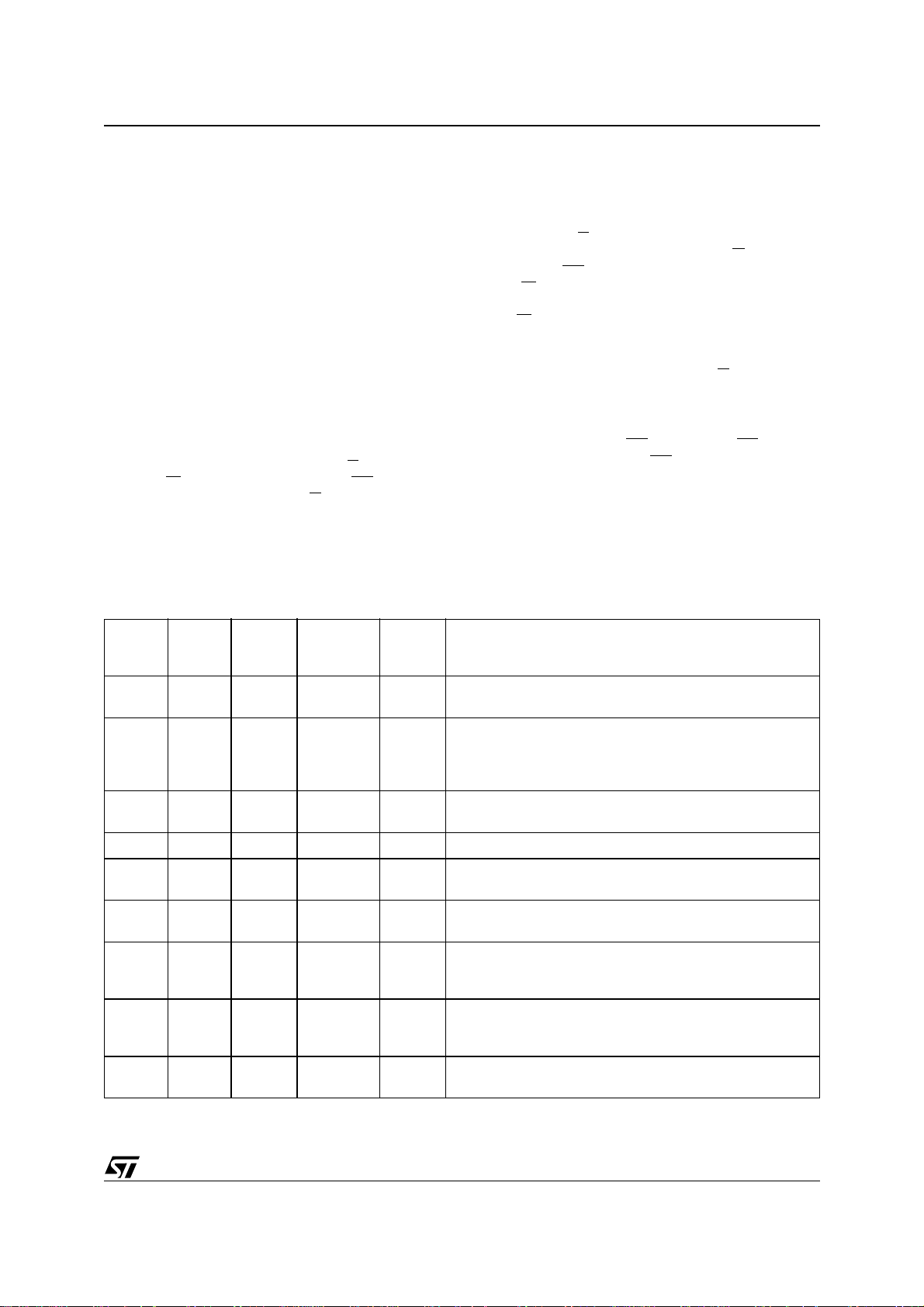

Figure 7. FWH Bus Read Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. FWH Bus Write Field Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

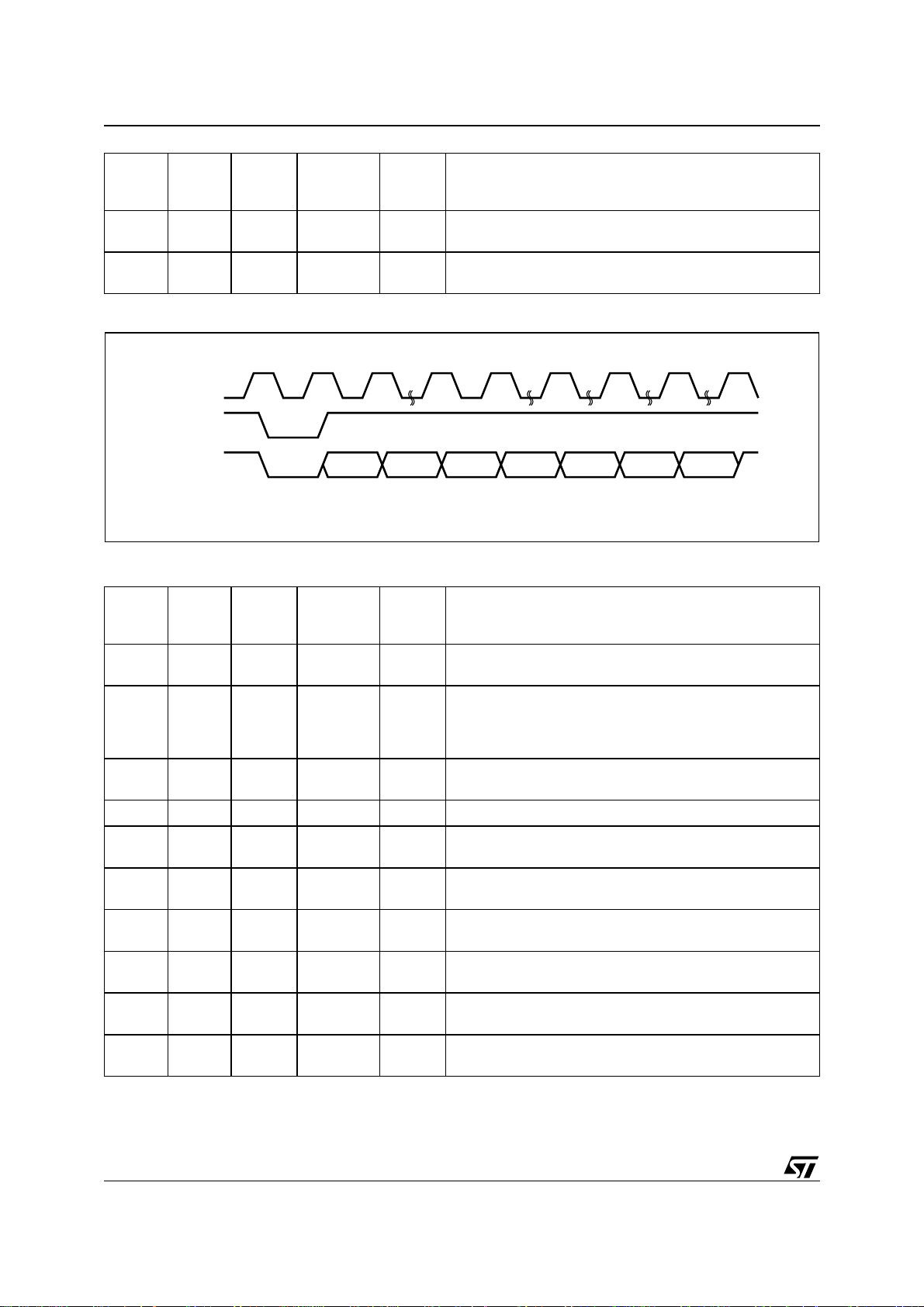

Figure 8. FWH Bus Write Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6. A/A Mux Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Manufacturer and Device Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Read Memory Array Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Read Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Read Electronic Signature Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Read Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Quadruple Byte Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Block Erase Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Clear Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Program/Erase Suspend Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Program/Erase Resume Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

STATUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program/Erase Controller Status (Bit 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Erase Suspend Status (Bit 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Erase Status (Bit 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program Status (Bit 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

V

Status (Bit 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PP

Program Suspend Status (Bit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Block Protection Status (Bit 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reserved (Bit 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 10. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FIRMWARE HUB (FWH) INTERFACE CONFIGURATION REGISTERS . . . . . . . . . . . . . . . . . . . . . . 21

Lock Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Write Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Read Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lock Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 11. Firmware Hub Register Configuration Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3/47

Page 4

M50FW080

Firmware Hub (FWH) General Purpose Input Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Manufacturer Code Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Device Code Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 12. Lock Register Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 13. General Purpose Input Register Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PROGRAM AND ERASE TIMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Table 14. Program and Erase Times. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 15. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 16. Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 17. FWH Interface AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 18. A/A Mux Interface AC Measurement Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 9. FWH Interface AC Testing Input Output Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 10.A/A Mux Interface AC Testing Input Output Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 19. Impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 20. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 11.FWH Interface Clock Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 21. FWH Interface Clock Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 12.FWH Interface AC Signal Timing Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 22. FWH Interface AC Signal Timing Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13.Reset AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 23. Reset AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 14.A/A Mux Interface Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 24. A/A Mux Interface Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 15.A/A Mux Interface Write AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 25. A/A Mux Interface Write AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 16.PLCC32 – 32 pin Rectangular Plastic Leaded Chip Carrier, Package Outline . . . . . . . . 35

Table 26. PLCC32 – 32 pin Rectangular Plastic Leaded Chip Carrier, Package Mechanical Data 36

Figure 17.TSOP32 – 32 lead Plastic Thin Small Outline, 8x14 mm, Package Outline . . . . . . . . . . 37

Table 27. TSOP32 – 32 lead Plastic Thin Small Outline, 8x14 mm, Package Mechanical Data. . . 37

Figure 18.TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Outline. . . . . . . . . 38

Table 28. TSOP40 – 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Mechanical Data . 38

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 29. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

APPENDIX A.FLOWCHARTS AND PSEUDO CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 19.Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 20.Quadruple Byte Program Flowchart and Pseudo Code (A/A Mux Interface Only) . . . . . 41

4/47

Page 5

M50FW080

Figure 21.Program Suspend and Resume Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . 42

Figure 22.Chip Erase Flowchart and Pseudo Code (A/A Mux Interface Only) . . . . . . . . . . . . . . . . 43

Figure 23.Block Erase Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 24.Erase Suspend and Resume Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . 45

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 30. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5/47

Page 6

M50FW080

SUMMARY DESCRIPTION

The M50FW080 is an 8 Mbit (1Mbit x8) non-volatile memory that can be read, erased and reprogrammed. These operations can be performed

using a single low voltage (3.0 to 3.6V) supply. For

fast programming and fast erasing in production

lines an optional 12V power supply can be used to

reduce the programming and the erasing times.

The memory is divided into blocks that can be

erased independently so it is possible to preserve

valid data while old data is erased. Blocks can be

protected individually to prevent accidental Program or Erase commands from modifying the

memory. Program and Erase commands are written to the Command Interface of the memory. An

on-chip Program/Erase Controller simplifies the

process of programming or erasing the memory by

taking care of all of the special operations that are

required to update the memory contents. The end

of a program or erase operation can be detected

and any error conditions identified. The command

set required to control the memory is consistent

with JEDEC standards.

Two different bus interfaces are supported by the

memory. The primary interface, the Firmware Hub

(or FWH) Interface, uses Intel’s proprietary FWH

protocol. This has been designed to remove the

need for the ISA bus in current PC Chipsets; the

M50FW080 acts as the PC BIOS on the Low Pin

Count bus for these PC Chipsets.

The secondary interface, the Address/Address

Multiplexed (or A/A Mux) Interface, is designed to

be compatible with current Flash Programmers for

production line programming prior to fitting to a PC

Motherboard.

6/47

Page 7

M50FW080

Figure 2. Logic Diagram (FWH Interface)

V

V

CC

PP

ID0-ID3

FGPI0-

FGPI4

FWH4

CLK

IC

RP

INIT

4

5

M50FW080

V

SS

4

FWH0FWH3

WP

TBL

AI03979

Table 1. Signal Names (FWH Interface)

FWH0-FWH3 Input/Output Communications

FWH4 Input Communication Frame

ID0-ID3 Identification Inputs

FGPI0-FGPI4 General Purpose Inputs

IC Interface Configuration

RP

INIT

CLK Clock

TBL

WP

RFU

V

CC

V

PP

V

SS

NC Not Connected Internally

Interface Reset

CPU Reset

Top Block Lock

Write Protect

Reserved for Future Use. Leave

disconnected

Supply Voltage

Optional Supply Voltage for Fast

Erase Operations

Ground

Figure 3. Logic Diagram (A/A Mux Interface)

V

V

CC

PP

A0-A10

RC

IC

W

RP

11

M50FW080

G

V

SS

8

DQ0-DQ7

RB

AI03981

Table 2. Signal Names (A/A Mux Interface)

IC Interface Configuration

A0-A10 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

G

W

RC

RB

RP

V

CC

V

PP

V

SS

NC Not Connected Internally

Output Enable

Write Enable

Row/Column Address Select

Ready/Busy Output

Interface Reset

Supply Voltage

Optional Supply Voltage for Fast

Program and Fast Erase Operations

Ground

7/47

Page 8

M50FW080

Figure 4. PLCC Connections

A/A Mux A/A Mux

A7

FGPI1

A6

FGPI0

A5

A4

A3

A2

A1

A0

DQ0

Note: Pins 27 and 28 are not internally connected.

WP

TBL

ID3

ID2

ID1

ID0

FWH0

9

RPA8V

A9

RP

FGPI2

FGPI3

M50FW080

V

FWH1

FWH2

V

DQ1

DQ2

1

17

SS

SS

CC

PP

V

CC

PP

V

V

32

RFU

FWH3

DQ3

DQ4

RC

CLK

RFU

DQ5

A10

FGPI4

25

RFU

DQ6

IC (VIL)

NC

NC

V

SS

V

CC

INIT

FWH4

RFU

RFU

IC (VIH)

NC

NC

V

SS

V

CC

G

W

RB

DQ7

A/A MuxA/A Mux

AI04897

Figure 5. TSOP32 Connections

NC

NC

NC

NC

IC (VIH)

A10

RC

V

CC

V

PP

A/A Mux

RP

A9

A8

A7

A6

A5

A4 A3

NC

NC

NC

V

SS

GPI4

CLK

V

CC

V

PP

RP

GPI3

IC

1

8

9

M50FW080

32

25

24

INIT

FWH4/LFRAME

NC

RFU

RFU

RFU

RFU

FWH3/LAD3

V

SS

FWH2/LAD2

FWH1/LAD1

GPI2 FWH0/LAD0

GPI1 ID0

GPI0

WP

TBL

16 17

ID1

ID2

ID3

G

W

NC

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A/A Mux

AI09757B

8/47

Page 9

Figure 6. TSOP40 Connections

M50FW080

NC

IC (VIH)

NC

NC

NC

NC

A10

NC

RC

V

CC

V

PP

A/A Mux

RP

NC

NC

A9

A8

A7

A6

A5

A4 A3

NC

IC (VIL)

NC

NC INIT

NC RFU

NC

FGPI4

NC

CLK

V

CC

V

PP

RP

NC

NC

FGPI3

FGPI2 FWH0

FGPI1 ID0

FGPI0

WP

TBL

1

10

M50FW080

11

20 21

40

31

30

V

V

FWH4

RFU

RFU

RFU

RFU

V

V

V

FWH3

FWH2

FWH1

ID1

ID2

ID3

SS

CC

CC

SS

SS

V

SS

V

CC

W

G

RB

DQ7

DQ6

DQ5

DQ4

V

CC

V

SS

V

SS

DQ3

DQ2

DQ1

DQ0

A0

A1

A2

A/A Mux

AI03980

9/47

Page 10

M50FW080

SIGNAL DESCRIPTIONS

There are two distinct bus interfaces available on

this device. The active interface is selected before

power-up, or during Reset, using the Interface

Configuration Pin, IC.

The signals for each interface are discussed in the

Firmware Hub (FWH) Signal Descriptions section

and the Address/Address Multiplexed (A/A Mux)

Signal Descriptions section, respectively, while

the supply signals are discussed in the Supply Sig-

nal Descriptions section.

Firmware Hub (FWH) Signal Descriptions

For the Firmware Hub (FWH) Interface see Figure

2. and Table 1..

Input/Output Communications (FWH0-FWH3).

All Input and Output Communication with the

memory take place on these pins. Addresses and

Data for Bus Read and Bus Write operations are

encoded on these pins.

Input Communication Frame (FWH4). The Input Communication Frame (FWH4) signals the

start of a bus operation. When Input Communication Frame is Low, V

Clock a new bus operation is initiated. If Input

Communication Frame is Low, V

operation then the operation is aborted. When Input Communication Frame is High, V

rent bus operation is proceeding or the bus is idle.

Identification Inputs (ID0-ID3). The Identification Inputs select the address that the memory responds to. Up to 16 memories can be addressed

on a bus. For an address bit to be ‘0’ the pin can

be left floating or driven Low, V

down resistor is included with a value of R

an address bit to be ‘1’ the pin must be driven

High, V

; there will be a leakage current of I

IH

through each pin when pulled to VIH; see Table

20..

By convention the boot memory must have address ‘0000’ and all additional memories take sequential addresses starting from ‘0001’.

General Purpose Inputs (FGPI0-FGPI4). The

General Purpose Inputs can be used as digital inputs for the CPU to read. The General Purpose Input Register holds the values on these pins. The

pins must have stable data from before the start of

the cycle that reads the General Purpose Input

Register until after the cycle is complete. These

pins must not be left to float, they should be driven

Low, V

or High, VIH.

IL,

Interface Configuration (IC). The Interface Configuration input selects whether the Firmware Hub

(FWH) or the Address/Address Multiplexed (A/A

Mux) Interface is used. The chosen interface must

be selected before power-up or during a Reset

and, thereafter, cannot be changed. The state of

, on the rising edge of the

IL

, during a bus

IL

, the cur-

IH

; an internal pull-

IL

IL

. For

LI2

the Interface Configuration, IC, should not be

changed during operation.

To select the Firmware Hub (FWH) Interface the

Interface Configuration pin should be left to float or

driven Low, V

; to select the Address/Address

IL

Multiplexed (A/A Mux) Interface the pin should be

driven High, V

included with a value of R

current of I

. An internal pull-down resistor is

IH

through each pin when pulled to VIH;

LI2

; there will be a leakage

IL

see Table 20..

Interface Reset (RP

). The Interface Reset (RP)

input is used to reset the memory. When Interface

Reset (RP

) is set Low, VIL, the memory is in Reset

mode: the outputs are put to high impedance and

the current consumption is minimized. When RP

set High, V

, the memory is in normal operation.

IH

is

After exiting Reset mode, the memory enters

Read mode.

CPU Reset (INIT

). The CPU Reset, INIT, pin is

used to Reset the memory when the CPU is reset.

It behaves identically to Interface Reset, RP

, and

the internal Reset line is the logical OR (electrical

AND) of RP

and INIT.

Clock (CLK). The Clock, CLK, input is used to

clock the signals in and out of the Input/Output

Communication Pins, FWH0-FWH3. The Clock

conforms to the PCI specification.

Top Block Lock (TBL

). The Top Block Lock in-

put is used to prevent the Top Block (Block 15)

from being changed. When Top Block Lock, TBL

is set Low, V

, Program and Block Erase opera-

IL

tions in the Top Block have no effect, regardless of

the state of the Lock Register. When Top Block

Lock, TBL

, is set High, VIH, the protection of the

Block is determined by the Lock Register. The

state of Top Block Lock, TBL

, does not affect the

protection of the Main Blocks (Blocks 0 to 14).

Top Block Lock, TBL

, must be set prior to a Program or Block Erase operation is initiated and

must not be changed until the operation completes

or unpredictable results may occur. Care should

be taken to avoid unpredictable behavior by

changing TBL

Write Protect (WP

during Program or Erase Suspend.

). The Write Protect input is

used to prevent the Main Blocks (Blocks 0 to 14)

from being changed. When Write Protect, WP

set Low, V

, Program and Block Erase operations

IL

, is

in the Main Blocks have no effect, regardless of

the state of the Lock Register. When Write Protect,

, is set High, VIH, the protection of the Block

WP

determined by the Lock Register. The state of

Write Protect, WP

, does not affect the protection of

the Top Block (Block 15).

Write Protect, WP

, must be set prior to a Program

or Block Erase operation is initiated and must not

be changed until the operation completes or un-

,

10/47

Page 11

M50FW080

predictable results may occur. Care should be taken to avoid unpredictable behavior by changing

during Program or Erase Suspend.

WP

Reserved for Future Use (RFU). These pins do

not have assigned functions in this revision of the

part. They must be left disconnected.

Table 3. Block Addresses

Size

(Kbytes)

64 F0000h-FFFFFh 15 Top Block

64 E0000h-EFFFFh 14 Main Block

64 D0000h-DFFFFh 13 Main Block

64 C0000h-CFFFFh 12 Main Block

64 B0000h-BFFFFh 11 Main Block

64 A0000h-AFFFFh 10 Main Block

64 90000h-9FFFFh 9 Main Block

64 80000h-8FFFFh 8 Main Block

64 70000h-7FFFFh 7 Main Block

64 60000h-6FFFFh 6 Main Block

64 50000h-5FFFFh 5 Main Block

64 40000h-4FFFFh 4 Main Block

64 30000h-3FFFFh 3 Main Block

64 20000h-2FFFFh 2 Main Block

64 10000h-1FFFFh 1 Main Block

64 00000h-0FFFFh 0 Main Block

Address Range

Block

Number

Block Type

Address/Address Multiplexed (A/A Mux)

Signal Descriptions

For the Address/Address Multiplexed (A/A Mux)

Interface see Figure 3. and Table 2..

Address Inputs (A0-A10). The Address Inputs

are used to set the Row Address bits (A0-A10) and

the Column Address bits (A11-A19). They are

latched during any bus operation by the Row/Column Address Select input, RC

.

Data Inputs/Outputs (DQ0-DQ7). The Data Inputs/Outputs hold the data that is written to or read

from the memory. They output the data stored at

the selected address during a Bus Read operation. During Bus Write operations they represent

the commands sent to the Command Interface of

the internal state machine. The Data Inputs/Outputs, DQ0-DQ7, are latched during a Bus Write

operation.

Output Enable (G

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interface.

Row/Column Address Select (RC

). The Row/

Column Address Select input selects whether the

Address Inputs should be latched into the Row Address bits (A0-A10) or the Column Address bits

(A11-A19). The Row Address bits are latched on

the falling edge of RC

whereas the Column Ad-

dress bits are latched on the rising edge.

Ready/Busy Output (RB

). The Ready/Busy pin

gives the status of the memory’s Program/Erase

Controller. When Ready/Busy is Low, V

OL

, the

memory is busy with a Program or Erase operation

and it will not accept any additional Program or

Erase command except the Program/Erase Suspend command. When Ready/Busy is High, V

OH

the memory is ready for any Read, Program or

Erase operation.

Supply Signal Descriptions

The Supply Signals are the same for both interfaces.

Supply Voltage. The VCC Supply Voltage

V

CC

supplies the power for all operations (Read, Program, Erase etc.).

The Command Interface is disabled when the V

CC

Supply Voltage is less than the Lockout Voltage,

. This prevents Bus Write operations from ac-

V

LKO

cidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid. After V

CC

becomes valid the Command Interface is reset to

Read mode.

A 0.1µF capacitor should be connected between

the V

Supply Voltage pins and the VSS Ground

CC

pin to decouple the current surges from the power

supply. Both V

Supply Voltage pins must be

CC

connected to the power supply. The PCB track

widths must be sufficient to carry the currents required during program and erase operations.

Optional Supply Voltage. The VPP Optional

V

PP

Supply Voltage pin is used to select the Fast Program (see the Quadruple Byte Program Command

description) and Fast Erase options of the memory

and to protect the memory. When V

PP

< V

PPLK

Program and Erase operations cannot be performed and an error is reported in the Status Register if an attempt to change the memory contents

is made. When V

erations take place as normal. When V

= VCC Program and Erase op-

PP

PP

= V

PPH

Fast Program (if A/A Mux interface is selected)

and Fast Erase operations are used. Any other

voltage input to V

will result in undefined behav-

PP

ior and should not be used.

,

11/47

Page 12

M50FW080

VPP should not be set to V

for more than 80

PPH

hours during the life of the memory.

BUS OPERATIONS

The two interfaces have similar bus operations but

the signals and timings are completely different.

The Firmware Hub (FWH) Interface is the usual interface and all of the functionality of the part is

available through this interface. Only a subset of

functions are available through the Address/Address Multiplexed (A/A Mux) Interface.

See the sections: The Firmware Hub (FWH) Bus

Operations and Address/Address Multiplexed (A/

A Mux) Bus Operations, for details of the bus op-

erations on each interface.

Firmware Hub (FWH) Bus Operations

The Firmware Hub (FWH) Interface consists of

four data signals (FWH0-FWH3), one control line

(FWH4) and a clock (CLK). In addition protection

against accidental or malicious data corruption

can be achieved using two further signals (TBL

and WP). Finally two reset signals (RP and INIT)

are available to put the memory into a known

state.

The data signals, control signal and clock are designed to be compatible with PCI electrical specifications. The interface operates with clock speeds

up to 33MHz.

The following operations can be performed using

the appropriate bus cycles: Bus Read, Bus Write,

Standby, Reset and Block Protection.

Bus Read. Bus Read operations read from the

memory cells, specific registers in the Command

Interface or Firmware Hub Registers. A valid Bus

Read operation starts when Input Communication

Frame, FWH4, is Low, V

correct Start cycle is on FWH0-FWH3. On the following clock cycles the Host will send the Memory

ID Select, Address and other control bits on

FWH0-FWH3. The memory responds by outputting Sync data until the wait-states have elapsed

followed by Data0-Data3 and Data4-Data7.

See Table 4. and Figure 7., for a description of the

Field definitions for each clock cycle of the transfer. See Table 22. and Figure 12., for details on the

timings of the signals.

Bus Write. Bus Write operations write to the

Command Interface or Firmware Hub Registers. A

valid Bus Write operation starts when Input Communication Frame, FWH4, is Low, V

rises and the correct Start cycle is on FWH0FWH3. On the following Clock cycles the Host will

send the Memory ID Select, Address, other control

bits, Data0-Data3 and Data4-Data7 on FWH0-

, as Clock rises and the

IL

, as Clock

IL

VSS Ground. VSS is the reference for all the volt-

age measurements.

FWH3. The memory outputs Sync data until the

wait-states have elapsed.

See Table 5. and Figure 8., for a description of the

Field definitions for each clock cycle of the transfer. See Table 22. and Figure 12., for details on the

timings of the signals.

Bus Abort. The Bus Abort operation can be used

to immediately abort the current bus operation. A

Bus Abort occurs when FWH4 is driven Low, V

IL

during the bus operation; the memory will tri-state

the Input/Output Communication pins, FWH0FWH3.

Note that, during a Bus Write operation, the Command Interface starts executing the command as

soon as the data is fully received; a Bus Abort during the final TAR cycles is not guaranteed to abort

the command; the bus, however, will be released

immediately.

Standby. When FWH4 is High, V

, the memory

IH

is put into Standby mode where FWH0-FWH3 are

put into a high-impedance state and the Supply

Current is reduced to the Standby level, I

CC1

.

Reset. During Reset mode all internal circuits are

switched off, the memory is deselected and the

outputs are put in high-impedance. The memory is

in Reset mode when Interface Reset, RP

Reset, INIT

Low, V

, is Low, VIL. RP or INIT must be held

, for t

IL

. The memory resets to Read

PLPH

, or CPU

mode upon return from Reset mode and the Lock

Registers return to their default states regardless

of their state before Reset, see Table 14.. If RP

goes Low, VIL, during a Program or Erase op-

INIT

or

eration, the operation is aborted and the memory

cells affected no longer contain valid data; the

memory can take up to t

to abort a Program

PLRH

or Erase operation.

Block Protection. Block Protection can be

forced using the signals Top Block Lock, TBL

Write Protect, WP

, regardless of the state of the

, and

Lock Registers.

Address/Address Multiplexed (A/A Mux) Bus

Operations

The Address/Address Multiplexed (A/A Mux) Interface has a more traditional style interface. The signals consist of a multiplexed address signals (A0A10), data signals, (DQ0-DQ7) and three control

signals (RC

, G, W). An additional signal, RP, can

be used to reset the memory.

The Address/Address Multiplexed (A/A Mux) Inter-

face is included for use by Flash Programming

,

12/47

Page 13

M50FW080

equipment for faster factory programming. Only a

subset of the features available to the Firmware

Hub (FWH) Interface are available; these include

all the Commands but exclude the Security features and other registers.

The following operations can be performed using

the appropriate bus cycles: Bus Read, Bus Write,

Output Disable and Reset.

When the Address/Address Multiplexed (A/A Mux)

Interface is selected all the blocks are unprotected. It is not possible to protect any blocks through

this interface.

Bus Read. Bus Read operations are used to output the contents of the Memory Array, the Electronic Signature and the Status Register. A valid

Bus Read operation begins by latching the Row

Address and Column Address signals into the

memory using the Address Inputs, A0-A10, and

the Row/Column Address Select RC

Enable (W

High, V

) and Interface Reset (RP) must be

, and Output Enable, G, Low, VIL, in order

IH

. Then Write

to perform a Bus Read operation. The Data Inputs/

Outputs will output the value, see Figure 14. and

Table 24., for details of when the output becomes

valid.

Table 4. FWH Bus Read Field Definitions

Clock

Cycle

Number

1 1 START 1101b I

2 1 IDSEL XXXX I

Clock

Cycle

Count

Field

FWH0-

FWH3

Memory

I/O

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by latching the Row Address and Column

Address signals into the memory using the Address Inputs, A0-A10, and the Row/Column Address Select RC

Data Inputs/Outputs; Output Enable, G

face Reset, RP

able, W

, must be Low, VIL. The Data Inputs/

. The data should be set up on the

, and Inter-

, must be High, VIH and Write En-

Outputs are latched on the rising edge of Write Enable, W

. See Figure 15. and Table 25., for details

of the timing requirements.

Output Disable. The data outputs are high-im-

pedance when the Output Enable, G

, is at VIH.

Reset. During Reset mode all internal circuits are

switched off, the memory is deselected and the

outputs are put in high-impedance. The memory is

in Reset mode when RP

held Low, V

IL

for t

PLPH

is Low, VIL. RP must be

. If RP is goes Low, VIL, during a Program or Erase operation, the operation is

aborted and the memory cells affected no longer

contain valid data; the memory can take up to t

to abort a Program or Erase operation.

RH

Description

On the rising edge of CLK with FWH4 Low, the contents of

FWH0-FWH3 indicate the start of a FWH Read cycle.

Indicates which FWH Flash Memory is selected. The value

on FWH0-FWH3 is compared to the IDSEL strapping on the

FWH Flash Memory pins to select which FWH Flash

Memory is being addressed.

PL-

3-9 7 ADDR XXXX I

10 1 MSIZE 0000b I Always 0000b (only single byte transfers are supported).

11 1 TAR 1111b I

12 1 TAR

13-14 2 WSYNC 0101b O

15 1 RSYNC 0000b O

16-17 2 DATA XXXX O

1111b

(float)

A 28-bit address phase is transferred starting with the most

significant nibble first.

The host drives FWH0-FWH3 to 1111b to indicate a

turnaround cycle.

The FWH Flash Memory takes control of FWH0-FWH3

O

during this cycle.

The FWH Flash Memory drives FWH0-FWH3 to 0101b

(short wait-sync) for two clock cycles, indicating that the data

is not yet available. Two wait-states are always included.

The FWH Flash Memory drives FWH0-FWH3 to 0000b,

indicating that data will be available during the next clock

cycle.

Data transfer is two CLK cycles, starting with the least

significant nibble.

13/47

Page 14

M50FW080

Clock

Cycle

Number

18 1 TAR 1111b O

19 1 TAR

Clock

Cycle

Count

Field

FWH0-

FWH3

1111b

(float)

Memory

I/O

N/A

Description

The FWH Flash Memory drives FWH0-FWH3 to 1111b to

indicate a turnaround cycle.

The FWH Flash Memory floats its outputs, the host takes

control of FWH0-FWH3.

Figure 7. FWH Bus Read Waveforms

CLK

FWH4

FWH0-FWH3

Number of

clock cycles

START IDSEL ADDR MSIZE TAR SYNC DATA TAR

11712322

Table 5. FWH Bus Write Field Definitions

Clock

Cycle

Number

1 1 START 1110b I

2 1 IDSEL XXXX I

3-9 7 ADDR XXXX I

10 1 MSIZE 0000b I Always 0000b (single byte transfer).

Clock

Cycle

Count

Field

FWH0-

FWH3

Memory

I/O

Description

On the rising edge of CLK with FWH4 Low, the contents of

FWH0-FWH3 indicate the start of a FWH Write Cycle.

Indicates which FWH Flash Memory is selected. The value

on FWH0-FWH3 is compared to the IDSEL strapping on the

FWH Flash Memory pins to select which FWH Flash

Memory is being addressed.

A 28-bit address phase is transferred starting with the most

significant nibble first.

AI03437

11-12 2 DATA XXXX I

13 1 TAR 1111b I

14 1 TAR

1111b

(float)

15 1 SYNC 0000b O

16 1 TAR 1111b O

17 1 TAR

1111b

(float)

14/47

O

N/A

Data transfer is two cycles, starting with the least significant

nibble.

The host drives FWH0-FWH3 to 1111b to indicate a

turnaround cycle.

The FWH Flash Memory takes control of FWH0-FWH3

during this cycle.

The FWH Flash Memory drives FWH0-FWH3 to 0000b,

indicating it has received data or a command.

The FWH Flash Memory drives FWH0-FWH3 to 1111b,

indicating a turnaround cycle.

The FWH Flash Memory floats its outputs and the host takes

control of FWH0-FWH3.

Page 15

Figure 8. FWH Bus Write Waveforms

CLK

FWH4

M50FW080

FWH0-FWH3

Number of

clock cycles

START IDSEL ADDR MSIZE DATA TAR SYNC TAR

11712212

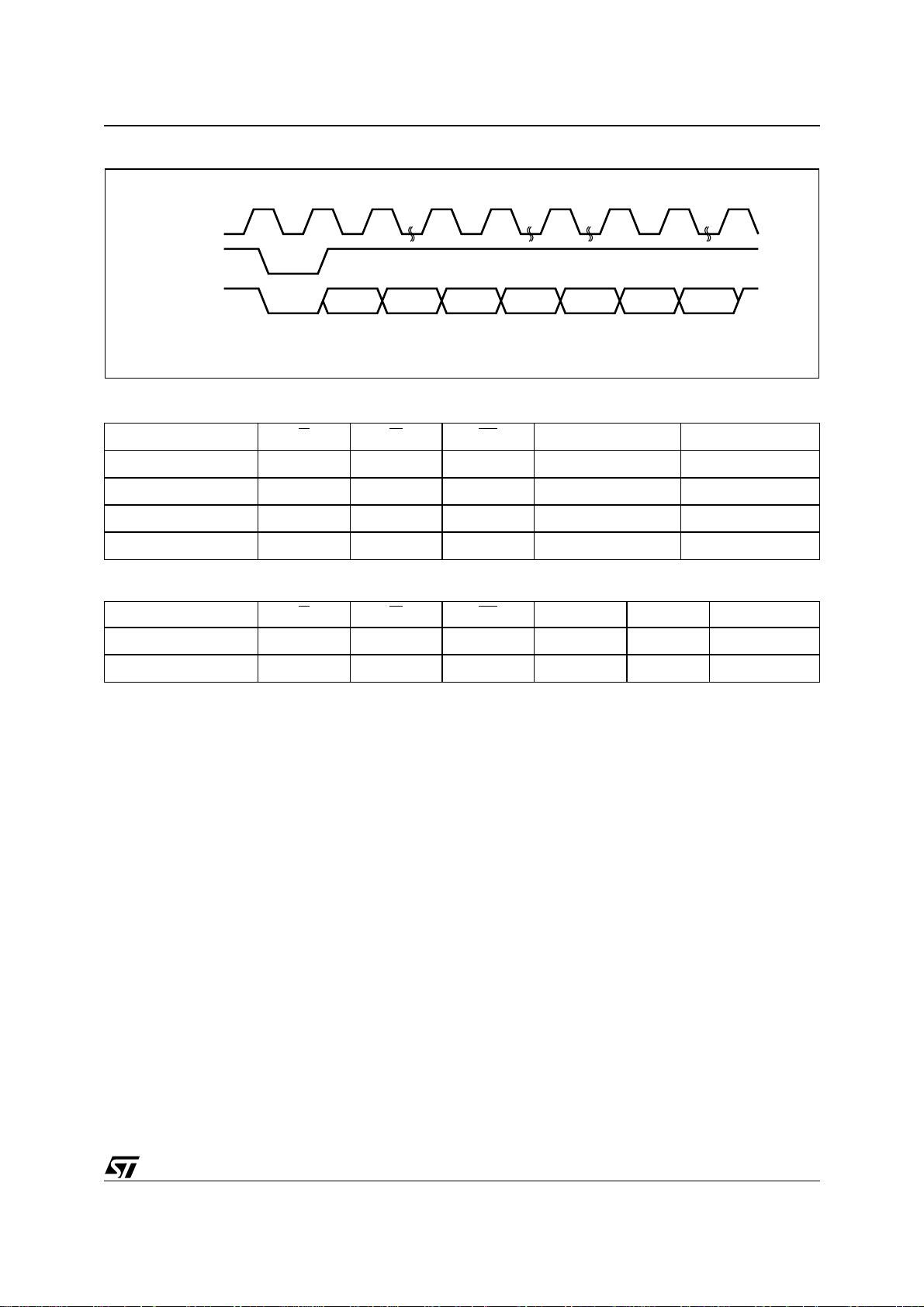

Table 6. A/A Mux Bus Operations

Operation G W RP

Bus Read

Bus Write

Output Disable

Reset

V

IL

V

IH

V

IH

V

or V

IL

IH

V

IH

V

IL

V

IH

VIL or V

Table 7. Manufacturer and Device Codes

Operation G

Manufacturer Code

Device Code

V

IL

V

IL

W RP A19-A1 A0 DQ7-DQ0

V

IH

V

IH

AI03441

V

PP

V

IH

V

IH

V

IH

IH

V

IL

V

IH

V

IH

Don’t Care Data Output

VCC or V

PPH

Don’t Care Hi-Z

Don’t Care Hi-Z

V

IL

V

IL

V

IL

V

IH

DQ7-DQ0

Data Input

20h

2Dh

15/47

Page 16

M50FW080

COMMAND INTERFACE

All Bus Write operations to the memory are interpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations.

After power-up or a Reset operation the memory

enters Read mode.

The commands are summarized in Table 9., Commands. The following text descriptions should be

read in conjunction with Table 9..

Read Memory Array Command. The Read

Memory Array command returns the memory to its

Read mode where it behaves like a ROM or

EPROM. One Bus Write cycle is required to issue

the Read Memory Array command and return the

memory to Read mode. Once the command is issued the memory remains in Read mode until another command is issued. From Read mode Bus

Read operations will access the memory array.

While the Program/Erase Controller is executing a

Program or Erase operation the memory will not

accept the Read Memory Array command until the

operation completes.

Read Status Register Command. The Read

Status Register command is used to read the Status Register. One Bus Write cycle is required to issue the Read Status Register command. Once the

command is issued subsequent Bus Read operations read the Status Register until another command is issued. See the section on the Status

Register for details on the definitions of the Status

Register bits.

Read Electronic Signature Command. The

Read Electronic Signature command is used to

read the Manufacturer Code and the Device Code.

One Bus Write cycle is required to issue the Read

Electronic Signature command. Once the command is issued subsequent Bus Read operations

read the Manufacturer Code or the Device Code

until another command is issued.

After the Read Electronic Signature Command is

issued the Manufacturer Code and Device Code

can be read using Bus Read operations using the

addresses in Table 8..

Table 8. Read Electronic Signature

Code Address Data

Manufacturer Code 00000h 20h

Device Code 00001h 2Dh

Program Command. The Program command

can be used to program a value to one address in

the memory array at a time. Two Bus Write operations are required to issue the command; the second Bus Write cycle latches the address and data

in the internal state machine and starts the Program/Erase Controller. Once the command is issued subsequent Bus Read operations read the

Status Register. See the section on the Status

Register for details on the definitions of the Status

Register bits.

If the address falls in a protected block then the

Program operation will abort, the data in the memory array will not be changed and the Status Register will output the error.

During the Program operation the memory will

only accept the Read Status Register command

and the Program/Erase Suspend command. All

other commands will be ignored. Typical Program

times are given in Table 14..

Note that the Program command cannot change a

bit set at ‘0’ back to ‘1’ and attempting to do so will

not cause any modification on its value. One of the

Erase commands must be used to set all of the

bits in the block to ‘1’.

See Figure 19., for a suggested flowchart on using

the Program command.

Quadruple Byte Program Command. The Quadruple Byte Program Command can be only used

in A/A Mux mode to program four adjacent bytes

in the memory array at a time. The four bytes must

differ only for the addresses A0 and A10. Programming should not be attempted when V

not at V

is below V

V

PP

. The operation can also be executed if

PPH

, but result could be uncertain.

PPH

PP

is

Five Bus Write operations are required to issue the

command. The second, the third and the fourth

Bus Write cycle latches respectively the address

and data of the first, the second and the third byte

in the internal state machine. The fifth Bus Write

cycle latches the address and data of the fourth

byte in the internal state machine and starts the

Program/Erase Controller. Once the command is

issued subsequent Bus Read operations read the

Status Register. See the section on the Status

Register for details on the definitions of the Status

Register bits.

During the Quadruple Byte Program operation the

memory will only accept the Read Status register

command and the Program/Erase Suspend command. All other commands will be ignored. Typical

Quadruple Byte Program times are given in Table

8..

Note that the Quadruple Byte Program command

cannot change a bit set to ‘0’ back to ‘1’ and attempting to do so will not cause any modification

on its value. One of the Erase commands must be

used to set all of the bits in the block to ‘1’.

See Figure 20., Quadruple Byte Program Flowchart and Pseudo Code, for a suggested flowchart

on using the Quadruple Byte Program command.

16/47

Page 17

M50FW080

Chip Erase Command. The Chip Erase Com-

mand can be only used in A/A Mux mode to erase

the entire chip at a time. Erasing should not be attempted when V

is not at V

PP

can also be executed if V

is below V

PP

. The operation

PPH

PPH

, but result could be uncertain. Two Bus Write operations

are required to issue the command and start the

Program/Erase Controller. Once the command is

issued subsequent Bus Read operations read the

Status Register. See the section on the Status

Register for details on the definitions of the Status

Register bits. During the Chip Erase operation the

memory will only accept the Read Status Register

command. All other commands will be ignored.

Typical Chip Erase times are given in Table 14..

The Chip Erase command sets all of the bits in the

memory to ‘1’. See Figure 22., for a suggested

flowchart on using the Chip Erase command.

Block Erase Command. The Block Erase command can be used to erase a block. Two Bus Write

operations are required to issue the command; the

second Bus Write cycle latches the block address

in the internal state machine and starts the Program/Erase Controller. Once the command is issued subsequent Bus Read operations read the

Status Register. See the section on the Status

Register for details on the definitions of the Status

Register bits.

If the block is protected then the Block Erase operation will abort, the data in the block will not be

changed and the Status Register will output the error.

During the Block Erase operation the memory will

only accept the Read Status Register command

and the Program/Erase Suspend command. All

other commands will be ignored. Typical Block

Erase times are given in Table 14..

The Block Erase command sets all of the bits in

the block to ‘1’. All previous data in the block is

lost.

See Figure 22., for a suggested flowchart on using

the Erase command.

Clear Status Register Command. The Clear

Status Register command can be used to reset

bits 1, 3, 4 and 5 in the Status Register to ‘0’. One

Bus Write is required to issue the Clear Status

Register command. Once the command is issued

the memory returns to its previous mode, subsequent Bus Read operations continue to output the

same data.

The bits in the Status Register are sticky and do

not automatically return to ‘0’ when a new Program

or Erase command is issued. If an error occurs

then it is essential to clear any error bits in the Status Register by issuing the Clear Status Register

command before attempting a new Program or

Erase command.

Program/Erase Suspend Command. The Program/Erase Suspend command can be used to

pause a Program or Block Erase operation. One

Bus Write cycle is required to issue the Program/

Erase Suspend command and pause the Program/Erase Controller. Once the command is issued it is necessary to poll the Program/Erase

Controller Status bit to find out when the Program/

Erase Controller has paused; no other commands

will be accepted until the Program/Erase Controller has paused. After the Program/Erase Controller has paused, the memory will continue to output

the Status Register until another command is issued.

During the polling period between issuing the Program/Erase Suspend command and the Program/

Erase Controller pausing it is possible for the operation to complete. Once Program/Erase Controller Status bit indicates that the Program/Erase

Controller is no longer active, the Program Suspend Status bit or the Erase Suspend Status bit

can be used to determine if the operation has completed or is suspended. For timing on the delay between issuing the Program/Erase Suspend

command and the Program/Erase Controller

pausing see Table 14..

During Program/Erase Suspend the Read Memory Array, Read Status Register, Read Electronic

Signature and Program/Erase Resume commands will be accepted by the Command Interface. Additionally, if the suspended operation was

Block Erase then the Program command will also

be accepted; only the blocks not being erased may

be read or programmed correctly.

See Figure 21., and Figure 24., for suggested

flowcharts on using the Program/Erase Suspend

command.

Program/Erase Resume Command. The Program/Erase Resume command can be used to restart the Program/Erase Controller after a

Program/Erase Suspend has paused it. One Bus

Write cycle is required to issue the Program/Erase

Resume command. Once the command is issued

subsequent Bus Read operations read the Status

Register.

17/47

Page 18

M50FW080

Table 9. Commands

Bus Write Operations

Command

Cycles

Read Memory Array 1 X FFh

Read Status Register 1 X 70h

Read Electronic Signature

1X 90h

1X 98h

2X 40hPAPD

Program

2X 10hPAPD

Quadruple Byte Program 5 X 30h

Chip Erase 2 X 80h X 10h

Block Erase 2 X 20h BA D0h

Clear Status Register 1 X 50h

Program/Erase Suspend 1 X B0h

Program/Erase Resume 1 X D0h

1X 00h

1X 01h

Invalid/Reserved

1X 60h

1X 2Fh

1XC0h

Note: X Don’t Care, PA Program Address, PD Program Data, A

Read Memory Array. After a Read Memory Array command, read the memory as normal until another command is issued.

Read Status Register. After a Read Status Register command, read the Status Register as normal until another command is issued.

Read Electronic Signature. After a Read Electronic Signature command, read Manufacturer Code, Device Code until another com-

mand is issued.

Block Erase, Program. After these commands read the Status Register until the command completes and another command is issued.

Quadruple Byte Program. This command is only valid in A/A Mux mode. Addresses A

differing only for address bit A0 and A10. After this command read the Status Register until the command completes and another command is issued.

Chip Erase. This command is only valid in A/A Mux mode. After this command read the Status Register until the command completes

and another command is issued.

Clear Status Register. After the Clear Status Register command bits 1, 3, 4 and 5 in the Status Register are reset to ‘0’.

Program/Erase Suspend. After the Program/Erase Suspend command has been accepted, issue Read Memory Array, Read Status

Register, Program (during Erase suspend) and Program/Erase resume commands.

Program/Erase Resume. After the Program/Erase Resume command the suspended Program/Erase operation resumes, read the

Status Register until the Program/Erase Controller completes and the memory returns to Read Mode.

Invalid/Reserved. Do not use Invalid or Reserved commands.

1st 2nd 3rd 4th 5th

Addr Data Addr Data Addr Data Addr Data Addr Data

A

PD

1

Consecutive Addresses, BA Any address in the Block.

1,2,3,4

A

PD

2

, A2, A3 and A4 must be conse cutive addresses

1

A

PD

3

A

PD

4

18/47

Page 19

STATUS REGISTER

The Status Register provides information on the

current or previous Program or Erase operation.

Different bits in the Status Register convey different information and errors on the operation.

To read the Status Register the Read Status Register command can be issued. The Status Register

is automatically read after Program, Erase and

Program/Erase Resume commands are issued.

The Status Register can be read from any address.

The Status Register bits are summarized in Table

10.. The following text descriptions should be read

in conjunction with Table 10..

Program/Erase Controller Status (Bit 7). The

Program/Erase Controller Status bit indicates

whether the Program/Erase Controller is active or

inactive. When the Program/Erase Controller Status bit is ‘0’, the Program/Erase Controller is active; when the bit is ‘1’, the Program/Erase

Controller is inactive.

The Program/Erase Controller Status is ‘0’ immediately after a Program/Erase Suspend command

is issued until the Program/Erase Controller pauses. After the Program/Erase Controller pauses the

bit is ‘1’.

During Program and Erase operation the Program/Erase Controller Status bit can be polled to

find the end of the operation. The other bits in the

Status Register should not be tested until the Program/Erase Controller completes the operation

and the bit is ‘1’.

After the Program/Erase Controller completes its

operation the Erase Status, Program Status, V

Status and Block Protection Status bits should be

tested for errors.

Erase Suspend Status (Bit 6). The Erase Suspend Status bit indicates that a Block Erase operation has been suspended and is waiting to be

resumed. The Erase Suspend Status should only

be considered valid when the Program/Erase

Controller Status bit is ‘1’ (Program/Erase Controller inactive); after a Program/Erase Suspend command is issued the memory may still complete the

operation rather than entering the Suspend mode.

When the Erase Suspend Status bit is ‘0’ the Program/Erase Controller is active or has completed

its operation; when the bit is ‘1’ a Program/Erase

Suspend command has been issued and the

memory is waiting for a Program/Erase Resume

command.

When a Program/Erase Resume command is issued the Erase Suspend Status bit returns to ‘0’.

Erase Status (Bit 5). The Erase Status bit can be

used to identify if the memory has applied the

maximum number of erase pulses to the block(s)

PP

M50FW080

and still failed to verify that the block(s) has erased

correctly. The Erase Status bit should be read

once the Program/Erase Controller Status bit is ‘1’

(Program/Erase Controller inactive).

When the Erase Status bit is ‘0’ the memory has

successfully verified that the block(s) has erased

correctly; when the Erase Status bit is ‘1’ the Program/Erase Controller has applied the maximum

number of pulses to the block(s) and still failed to

verify that the block(s) has erased correctly.

Once the Erase Status bit is set to ‘1’ it can only be

reset to ‘0’ by a Clear Status Register command or

a hardware reset. If it is set to ‘1’ it should be reset

before a new Program or Erase command is issued, otherwise the new command will appear to

fail.

Program Status (Bit 4). The Program Status bit

can be used to identify if the memory has applied

the maximum number of program pulses to the

byte and still failed to verify that the byte has programmed correctly. The Program Status bit should

be read once the Program/Erase Controller Status

bit is ‘1’ (Program/Erase Controller inactive).

When the Program Status bit is ‘0’ the memory has

successfully verified that the byte has programmed correctly; when the Program Status bit is

‘1’ the Program/Erase Controller has applied the

maximum number of pulses to the byte and still

failed to verify that the byte has programmed correctly.

Once the Program Status bit is set to ‘1’ it can only

be reset to ‘0’ by a Clear Status Register command or a hardware reset. If it is set to ‘1’ it should

be reset before a new Program or Erase command

is issued, otherwise the new command will appear

to fail.

Status (Bit 3). The VPP Status bit can be

V

PP

used to identify an invalid voltage on the V

during Program and Erase operations. The V

pin is only sampled at the beginning of a Program

or Erase operation. Indeterminate results can occur if V

becomes invalid during a Program or

PP

Erase operation.

When the V

pin was sampled at a valid voltage; when the

V

PP

Status bit is ‘1’ the VPP pin has a voltage that

V

PP

is below the V

Status bit is ‘0’ the voltage on the

PP

Lockout Voltage, V

PP

memory is protected; Program and Erase operation cannot be performed.

Once the V

Status bit set to ‘1’ it can only be re-

PP

set to ‘0’ by a Clear Status Register command or a

hardware reset. If it is set to ‘1’ it should be reset

before a new Program or Erase command is issued, otherwise the new command will appear to

fail.

PPLK

PP

, the

pin

PP

19/47

Page 20

M50FW080

Program Suspend Status (Bit 2). The Program

Suspend Status bit indicates that a Program operation has been suspended and is waiting to be resumed. The Program Suspend Status should only

be considered valid when the Program/Erase

Controller Status bit is ‘1’ (Program/Erase Controller inactive); after a Program/Erase Suspend command is issued the memory may still complete the

operation rather than entering the Suspend mode.

When the Program Suspend Status bit is ‘0’ the

Program/Erase Controller is active or has completed its operation; when the bit is ‘1’ a Program/

Erase Suspend command has been issued and

the memory is waiting for a Program/Erase Resume command.

When a Program/Erase Resume command is issued the Program Suspend Status bit returns to

‘0’.

Block Protection Status (Bit 1). The Block Pro-

gram or Block Erase operation has tried to modify

the contents of a protected block. When the Block

Protection Status bit is to ‘0’ no Program or Block

Erase operations have been attempted to protected blocks since the last Clear Status Register

command or hardware reset; when the Block Protection Status bit is ‘1’ a Program or Block Erase

operation has been attempted on a protected

block.

Once it is set to ‘1’ the Block Protection Status bit

can only be reset to ‘0’ by a Clear Status Register

command or a hardware reset. If it is set to ‘1’ it

should be reset before a new Program or Block

Erase command is issued, otherwise the new

command will appear to fail.

Using the A/A Mux Interface the Block Protection

Status bit is always ‘0’.

Reserved (Bit 0). Bit 0 of the Status Register is

reserved. Its value should be masked.

tection Status bit can be used to identify if the Pro-

Table 10. Status Register Bits

Operation Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

(1)

Program active ‘0’

Program suspended ‘1

Program completed successfully ‘1’

Program failure due to V

Program failure due to Block Protection (FWH Interface only) ‘1’

Program failure due to cell failure ‘1’

Erase active ‘0’‘0’‘0’‘0’‘0’‘0’‘0’

Block Erase suspended ‘1’‘1’‘0’‘0’‘0’‘0’‘0’

PP

Error

‘1’

X

X

X

X

X

X

‘0’‘0’‘0’‘0’‘0’

(1)

‘0’‘0’‘0’‘1’‘0’

(1)

‘0’‘0’‘0’‘0’‘0’

(1)

‘0’‘0’‘1’‘0’‘0’

(1)

‘0’‘0’‘0’‘0’‘1’

(1)

‘0’‘1’‘0’‘0’‘0’

Erase completed successfully ‘1’‘0’‘0’‘0’‘0’‘0’‘0’

Erase failure due to V

Block Erase failure due to Block Protection (FWH Interface

only)

Erase failure due to failed cell(s) ‘1’‘0’‘1’‘0’‘0’‘0’‘0’

Note: 1. For Program operations during Erase Suspend Bit 6 is ‘1’, otherwise Bit 6 is ‘0’.

20/47

PP

Error

‘1’‘0’‘0’‘0’‘1’‘0’‘0’

‘1’‘0’‘0’‘0’‘0’‘0’‘1’

Page 21

FIRMWARE HUB (FWH) INTERFACE CONFIGURATION REGISTERS

When the Firmware Hub Interface is selected several additional registers can be accessed. These

registers control the protection status of the

Blocks, read the General Purpose Input pins and

identify the memory using the Electronic Signature

codes. See Table 11. for the memory map of the

Configuration Registers.

Lock Registers

The Lock Registers control the protection status of

the Blocks. Each Block has its own Lock Register.

Three bits within each Lock Register control the

protection of each block, the Write Lock Bit, the

Read Lock Bit and the Lock Down Bit.

The Lock Registers can be read and written,

though care should be taken when writing as, once

the Lock Down Bit is set, ‘1’, further modifications

to the Lock Register cannot be made until cleared,

to ‘0’, by a reset or power-up.

See Table 12. for details on the bit definitions of

the Lock Registers.

Write Lock. The Write Lock Bit determines

whether the contents of the Block can be modified

(using the Program or Block Erase Command).

When the Write Lock Bit is set, ‘1’, the block is

write protected; any operations that attempt to

change the data in the block will fail and the Status

Register will report the error. When the Write Lock

Bit is reset, ‘0’, the block is not write protected

through the Lock Register and may be modified

unless write protected through some other means.

When V

tected and cannot be modified, regardless of the

state of the Write Lock Bit. If Top Block Lock, TBL

is Low, V

protected and cannot be modified. Similarly, if

Write Protect, WP

Blocks (Blocks 0 to 14) are write protected and

cannot be modified.

After power-up or reset the Write Lock Bit is always set to ‘1’ (write protected).

Read Lock. The Read Lock bit determines

whether the contents of the Block can be read

(from Read mode). When the Read Lock Bit is set,

‘1’, the block is read protected; any operation that

attempts to read the contents of the block will read

00h instead. When the Read Lock Bit is reset, ‘0’,

read operations in the Block return the data programmed into the block as expected.

After power-up or reset the Read Lock Bit is always reset to ‘0’ (not read protected).

Lock Down. The Lock Down Bit provides a

mechanism for protecting software data from simple hacking and malicious attack. When the Lock

Down Bit is set, ‘1’, further modification to the

Write Lock, Read Lock and Lock Down Bits cannot

be performed. A reset or power-up is required before changes to these bits can be made. When the

Lock Down Bit is reset, ‘0’, the Write Lock, Read

Lock and Lock Down Bits can be changed.

is less than V

PP

, then the Top Block (Block 15) is write

IL

all blocks are pro-

PPLK

, is Low, VIL, then the Main

M50FW080

,

21/47

Page 22

M50FW080

Table 11. Firmware Hub Register Configuration Map

Mnemonic Register Name

T_BLOCK_LK Top Block Lock Register (Block 15) FBF0002h 01h R/W

T_MINUS01_LK Top Block [-1] Lock Register (Block 14) FBE0002h 01h R/W

T_MINUS02_LK Top Block [-2] Lock Register (Block 13) FBD0002h 01h R/W

T_MINUS03_LK Top Block [-3] Lock Register (Block 12) FBC0002h 01h R/W

T_MINUS04_LK Top Block [-4] Lock Register (Block 11) FBB0002h 01h R/W

T_MINUS05_LK Top Block [-5] Lock Register (Block 10) FBA0002h 01h R/W

T_MINUS06_LK Top Block [-6] Lock Register (Block 9) FB90002h 01h R/W

T_MINUS07_LK Top Block [-7] Lock Register (Block 8) FB80002h 01h R/W

T_MINUS08_LK Top Block [-8] Lock Register (Block 7) FB70002h 01h R/W

T_MINUS09_LK Top Block [-9] Lock Register (Block 6) FB60002h 01h R/W

T_MINUS10_LK Top Block [-10] Lock Register (Block 5) FB50002h 01h R/W

T_MINUS11_LK Top Block [-11] Lock Register (Block 4) FB40002h 01h R/W

T_MINUS12_LK Top Block [-12] Lock Register (Block 3) FB30002h 01h R/W

T_MINUS13_LK Top Block [-13] Lock Register (Block 2) FB20002h 01h R/W

T_MINUS14_LK Top Block [-14] Lock Register (Block 1) FB10002h 01h R/W

T_MINUS15_LK Top Block [-15] Lock Register (Block 0) FB00002h 01h R/W

FGPI_REG Firmware Hub (FWH) General Purpose Input Register FBC0100h N/A R

MANUF_REG Manufacturer Code Register FBC0000h 20h R

DEV_REG Device Code Register FBC0001h 2Dh R

Memory

Address

Default

Value

Access

22/47

Page 23

M50FW080

Firmware Hub (FWH) General Purpose Input

Register

The Firmware Hub (FWH) General Purpose Input

Register holds the state of the Firmware Hub Interface General Purpose Input pins, FGPI0-FGPI4.

When this register is read, the state of these pins

is returned. This register is read-only and writing to

it has no effect.

The signals on the Firmware Hub Interface General Purpose Input pins should remain constant

throughout the whole Bus Read cycle in order to

guarantee that the correct data is read.

Manufacturer Code Register

Reading the Manufacturer Code Register returns

the manufacturer code for the memory. The manufacturer code for STMicroelectronics is 20h. This

register is read-only and writing to it has no effect.

Device Code Register

Reading the Device Code Register returns the device code for the memory, 2Dh. This register is

read-only and writing to it has no effect.

Table 12. Lock Register Bit Definitions

Bit Bit Name Value Function

7-3 Reserved

‘1’ Bus Read operations in this Block always return 00h.

2 Read-Lock

1 Lock-Down

0 Write-Lock

Note: Applies to Top Block Lock Register (T_BLOCK_LK) and Top Block [-1] Lock Register (T_MINUS01_LK) to Top Block [-15] Lock Reg-

ister (T_MINUS15_LK).

Bus read operations in this Block return the Memory Array contents. (Default

‘0’

value).

Changes to the Read-Lock bit and the Write-Lock bit cannot be performed. Once a

‘1’

‘1’ is written to the Lock-Down bit it cannot be cleared to ‘0’; the bit is always reset

to ‘0’ following a Reset (using RP

Read-Lock and Write-Lock can be changed by writing new values to them. (Default

‘0’

value).

Program and Block Erase operations in this Block will set an error in the Status

‘1’

Register. The memory contents will not be changed. (Default value).

Program and Block Erase operations in this Block are executed and will modify the

‘0’

Block contents.

or INIT) or after power-up.

Table 13. General Purpose Input Register Definition

Bit Bit Name Value Function

7-5 Reserved

Input Pin FGPI4 is at V

4FGPI4

3FGPI3

2FGPI2

1FGPI1

0FGPI0

Note: Applies to the General Purpose Input Register (FGPI_REG).

‘1’

Input Pin FGPI4 is at V

‘0’

Input Pin FGPI3 is at V

‘1’

Input Pin FGPI3 is at V

‘0’

Input Pin FGPI2 is at V

‘1’

Input Pin FGPI2 is at V

‘0’

Input Pin FGPI1 is at V

‘1’

Input Pin FGPI1 is at V

‘0’

Input Pin FGPI0 is at V

‘1’

Input Pin FGPI0 is at V

‘0’

IH

IL

IH

IL

IH

IL

IH

IL

IH

IL

23/47

Page 24

M50FW080

PROGRAM AND ERASE TIMES

The Program and Erase times are shown in Table

14..

Table 14. Program and Erase Times

Parameter Interface Test Condition Min

Byte Program 10 200

V

Quadruple Byte Program A/A Mux

Chip Erase A/A Mux

A/A Mux

Block Program

Block Erase

Program/Erase Suspend to Program pause

Program/Erase Suspend to Block Erase pause

Note: 1. TA = 25°C, VCC = 3.3V

2. This time is obtained executing the Quadruple Byte Program Command.

3. Sampled only, not 100% tested.

(3)

(3)

= 12V ± 5%

PP

= 12V ± 5%

V

PP

= 12V ± 5%

V

PP

V

PP

V

= 12V ± 5%

PP

V

PP

= V