查询M45PE10供应商

1 Mbit, Low Voltage, Page-Erasable Serial Flash Memory

With Byte-Alterability and a 33 MHz SPI Bus Interface

FEATURES SUMMARY

■ 1Mbit of Page-Erasable Flash Memory

■ Page Write (up to 256 Bytes) in 11ms (typical)

■ Page Program (up to 256 Bytes) in 1.2ms

(typical)

■ Page Erase (256 Bytes) in 10ms (typical)

■ Sector Erase (512 Kbit)

■ 2.7 to 3.6V Single Supply Voltage

■ SPI Bus Compatible Serial Interface

■ 33MHz Clock Rate (maximum)

■ Deep Power-down Mode 1µA (typical)

■ Electronic Signature

– JEDEC Standard Two-Byte Signature

(4011h)

■ More than 100,000 Write Cycles

■ More than 20 Year Data Retention

■ Packages

– ECOPACK® (RoHS compliant)

M45PE10

Figure 1. Packages

8

1

SO8 (MN)

150 mil width

VDFPN8 (MP)

(MLP8)

1/34October 2005

M45PE10

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SIGNAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Data Output (Q). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Data Input (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chip Select (S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reset (Reset

Write Protect (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPI MODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATING FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sharing the Overhead of Modifying Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

An Easy Way to Modify Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A Fast Way to Modify Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Polling During a Write, Program or Erase Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Active Power, Standby Power and Deep Power-Down Modes . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WIP bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Protection Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MEMORY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Write Enable (WREN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Write Disable (WRDI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Read Identification (RDID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Read Status Register (RDSR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WIP bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Read Data Bytes (READ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Read Data Bytes at Higher Speed (FAST_READ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page Write (PW). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page Program (PP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page Erase (PE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sector Erase (SE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Deep Power-down (DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Release from Deep Power-down (RDP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/34

M45PE10

POWER-UP AND POWER-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

INITIAL DELIVERY STATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3/34

M45PE10

SUMMARY DESCRIPTION

The M45PE10 is a 1Mbit (128K x 8 bit) Serial

Paged Flash Memory accessed by a high speed

SPI-compatible bus.

The memory can be written or programmed 1 to

256 bytes at a time, using the Page Write or Page

Program instruction. The Page Write instruction

consists of an integrated Page Erase cycle followed by a Page Program cycle.

The memory is organized as 2 sectors, each containing 256 pages. Each page is 256 bytes wide.

Thus, the whole memory can be viewed as consisting of 512 pages, or 131,072 bytes.

The memory can be erased a page at a time, using

the Page Erase instruction, or a sect or at a time,

using the Sector Erase instruction.

In order to meet environmental requirements, ST

offers these devices in ECOPACK® packages.

ECOPACK® packages are Lead-free and RoHS

compliant.

ECOPACK is an ST trademark. ECOPACK specifications are available at: www.st.com.

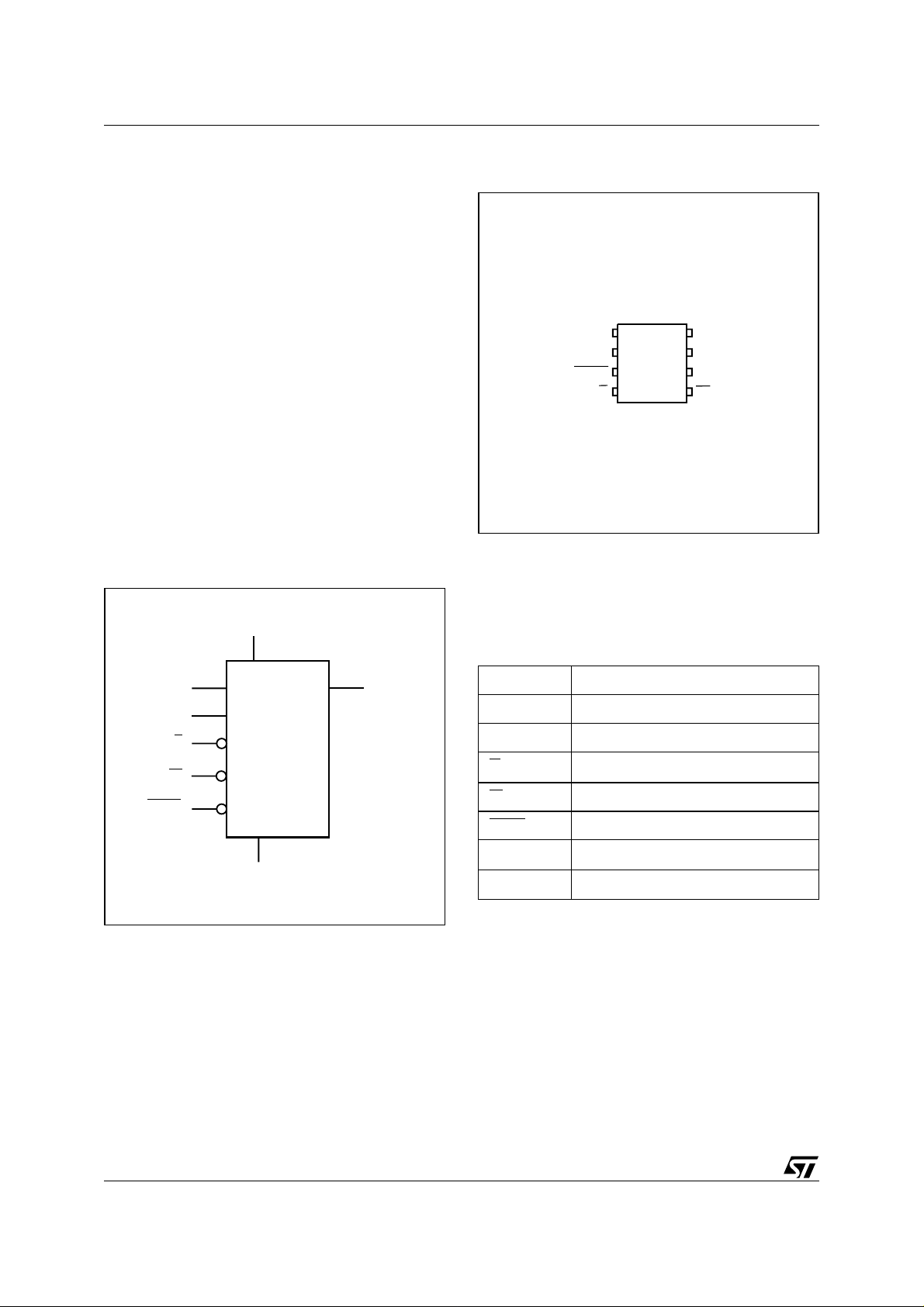

Figure 2. Logic Diagram

V

CC

Figure 3. SO and VDFPN Connections

M45PE10

DQ

1

C

2

Reset

Note: 1. The re is an exposed d ie paddle on th e underside of th e

MLP8 package. This is pulled, internally, to VSS, and

must not be allowed to be connecte d to any oth er voltage

or signal line on the PCB.

2. See PACKAGE MECHANICAL section for packag e dimensions, and how to identify pin-1.

3

4

8

7

6

5

AI07404

V

SS

V

CC

WS

W

Reset

Table 1. Signal Names

D

C

S

M45PE10

V

SS

Q

AI07403

C Serial Clock

D Serial Data Input

Q Serial Data Output

S

Write Protect

W

Reset

Reset

V

CC

V

SS

Chip Select

Supply Voltage

Ground

4/34

SIGNAL DESCRIPTION

Serial Data Output (Q). This output signal is

used to transfer data serially out of the device.

Data is shifted out on the falling edge of Serial

Clock (C).

Serial Data Input (D). This input signal is used to

transfer data serially into the device. It receives instructions, addresses, and the data to be programmed. Values are latched on the risin g edge of

Serial Clock (C).

Serial Clock (C). This input signal provides the

timing of the serial interface. Instructions, addresses, or data present at Serial Data Input (D) are

latched on the rising edge of Serial Clock (C). Data

on Serial Data Output (Q) changes after the falling

edge of Serial Clock (C).

Chip Select (S

the device is deselected and Serial Data Output

(Q) is at high impedance. Unless an interna l Read,

Program, Erase or Write cycle is in progress, the

device will be in the Standby Power mode (this is

not the Deep Power-down mode). Driving Chip

Select (S

Active Power mode.

). When this input signal is High,

) Low selects the device, placing it in the

M45PE10

After Power-up, a falling edge on Chip Select (S

is required prior to the start of any instruction.

Reset (Reset

a hardware reset for the memory. In this mode, the

outputs are high impedance.

When Reset (Reset

in the normal operating mode. When Reset (Reset) is driven Low, the memory will enter the Reset

mode, provided that no internal operation is currently in progress. Driving Reset (Reset

an internal operation is in progress has no effect

on that internal operation (a write cycle, program

cycle, or erase cycle).

Write Protect (W

vice in the Hardware Protected mode, when Write

Protect (W

256 pages of memory to become read-o nly by protecting them from write, program and erase operations. When Write Protect (W

, the first 256 pages of memory behave like

V

CC

the other pages of memory.

). Th e Reset (Reset) input provides

) is driven High, the memory is

) Low while

). This input signal puts the de-

) is connected to VSS, causing the first

) is connected to

)

5/34

M45PE10

SPI MODES

These devices can be driven by a microcon troller

with its SPI peripheral running in either of the two

following modes:

– CPOL=0, CPHA=0

– CPOL=1, CPHA=1

For these two modes, input data is latched in on

the rising edge of Serial Clock (C), and output data

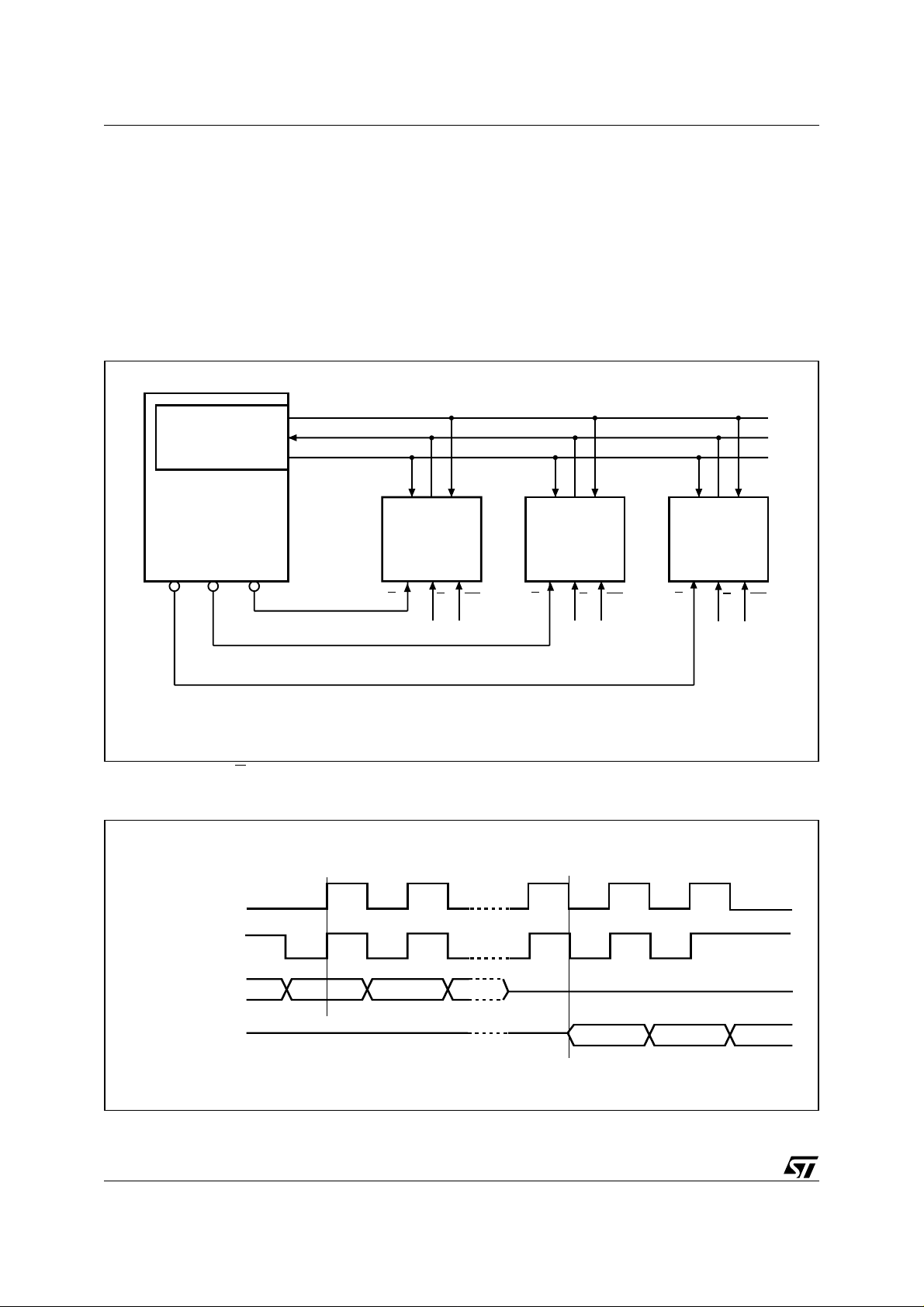

Figure 4. Bus Master and Memory Devices on the SPI Bus

is available from the falling edge of Serial Clock

(C).

The difference between the two modes, as shown

in Figure 5., is the clock polarity when the bus

master is in Stand-by mode and not transferring

data:

– C remains at 0 for (CPOL=0, CPHA=0)

– C remains at 1 for (CPOL=1, CPHA=1)

SPI Interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

Bus Master

(ST6, ST7, ST9,

ST10, Others)

CS3 CS2 CS1

Note: The Write Protect (W) signal should be driven, High or Low as appropriate.

SDO

SDI

SCK

CQD

SPI Memory

Device

S

RP

W

Figure 5. SPI Modes Supported

CQD

SPI Memory

Device

S

CQD

SPI Memory

Device

RP

W

S

W

AI04043B

RP

CPOL

6/34

CPHA

0

0

1

1

C

C

D

Q

MSB

MSB

AI01438B

OPERATING FEATURES

Sharing the Overhead of Modifying Data

To write or program one (or more) data bytes, two

instructions are required: Write Enable (WREN),

which is one byte, and a Page Write (PW) or Page

Program (PP) sequence, which consists of four

bytes plus data. This is followed by the internal cycle (of duration t

To share this overhead, the Page Write (PW) or

Page Program (PP) instruction allows up to 256

bytes to be programmed (changing bits from 1 to

0) or written (changing bits to 0 or 1) at a time, provided that they lie in consecutive addresses on the

same page of memory.

An Easy Way to Modify Data

The Page Write (PW) instruction provides a convenient way of modifying data (up to 256 contiguous bytes at a time), and simply requires the start

address, and the new data in the instruction sequence.

The Page Write (PW) instruction is entered by

driving Chip Select (S

the instruction byte, three address bytes (A23-A0)

and at least one data byte, and then driving Chip

Select (S

) High. While Chip Select (S) is being

held Low, the data bytes are written to the data

buffer, starting at the addr ess given in the third address byte (A7-A0). When Chip Select (S

High, the Write cycle starts. The remaining, unchanged, bytes of the data buffer are automatically

loaded with the values of the corresponding bytes

of the addressed memory page. The addressed

memory page then automatically put into an Erase

cycle. Finally, the addressed memory page is programmed with the contents of the data buffer.

All of this buffer management is handled internally,

and is transparent to the user. The user is given

the facility of being able to alter the contents of the

memory on a byte-by-byte basis.

For optimized timings, it is recommended to use

the Page Write (PW) instruction to write all consecutive targeted Bytes in a single sequence versus using several Page Write (PW) sequences

with each containing only a few Bytes (see Page

Write (PW) and AC Characteristics (33MHz operation)).

A Fast Way to Modify Data

The Page Program (PP) instruction provides a fast

way of modifying data (up to 256 contiguous byte s

at a time), provided that it only involves resetting

bits to 0 that had previously been set to 1.

This might be:

– when the designer is programming the device

for the first time

– when the designer knows that the page has

already been erased by an earlier Page Erase

or tPP).

PW

) Low, and then transmitting

) is driven

M45PE10

(PE) or Sector Erase (SE) instruction. This is

useful, for example, when storing a fast

stream of data, having first performed the

erase cycle when time was available

– when the designer knows that the only

changes involve resetting bits to 0 that are still

set to 1. When this method is possible, it has

the additional advantage of minimising the

number of unnecessary erase ope rations, and

the extra stress incurred by each page.

For optimized timings, it is recommended to use

the Page Program (PP) instruction to program all

consecutive targeted Bytes in a single sequence

versus using several Page Program (PP) sequences with each containing only a few Bytes

(see Page Program (PP) and AC Characteristics

(33MHz operation)).

Polling During a Write, Program or Eras e Cycle

A further improvement in the write, program or

erase time can be achieved by not waiting for the

worst case delay (t

In Progress (WIP) bit is provided in the Status

Register so that the application program can monitor its value, polling it to establish when the previous cycle is complete.

Reset

An internal Power On Reset circuit helps protect

against inadvertent data writes. Addition protection is provided by driving Reset (Reset

ing the Power-on process, and only driving it High

when V

V

CC

has reached the correct voltage level,

CC

(min).

Active Power, Standby Power and Deep

Power-Down Modes

When Chip Select (S

ed, and in the Active Power mode.

When Chip Select (S

lected, but could remain in the Active Power mode

until all internal cycles have completed (Program,

Erase, Write). The device then goes in to the

Standby Power mode. The device consumption

drops to I

CC1

.

The Deep Power-down mode is entered when the

specific instruction (the Deep Power-down (DP) instruction) is executed. The device consumption

drops further to I

mode until another specific instruction (the Release from Deep Power-down and Re ad Electro nic Signature (RES) instruction) is executed.

All other instructions are ignored while the device

is in the Deep Power-down mode. This can be

used as an extra software protection mechanism,

when the device is not in active use, to protect the

device from inadvertent Write, Program or Erase

instructions.

, tPP, tPE, or tSE). The Write

PW

) Low dur-

) is Low, the device is select-

) is High, the device is dese-

. The device remains in this

CC2

7/34

M45PE10

Status Register

The Status Register contains two status bits that

can be read by the Read Status Register (RDSR)

instruction.

WIP bit. The Write In Progress (WIP) bit indicates

whether the memory is busy with a Write, Progr am

or Erase cycle.

WEL bit. The Write Enable Latch (WEL) bit indicates the status of the internal Writ e Enable Latch.

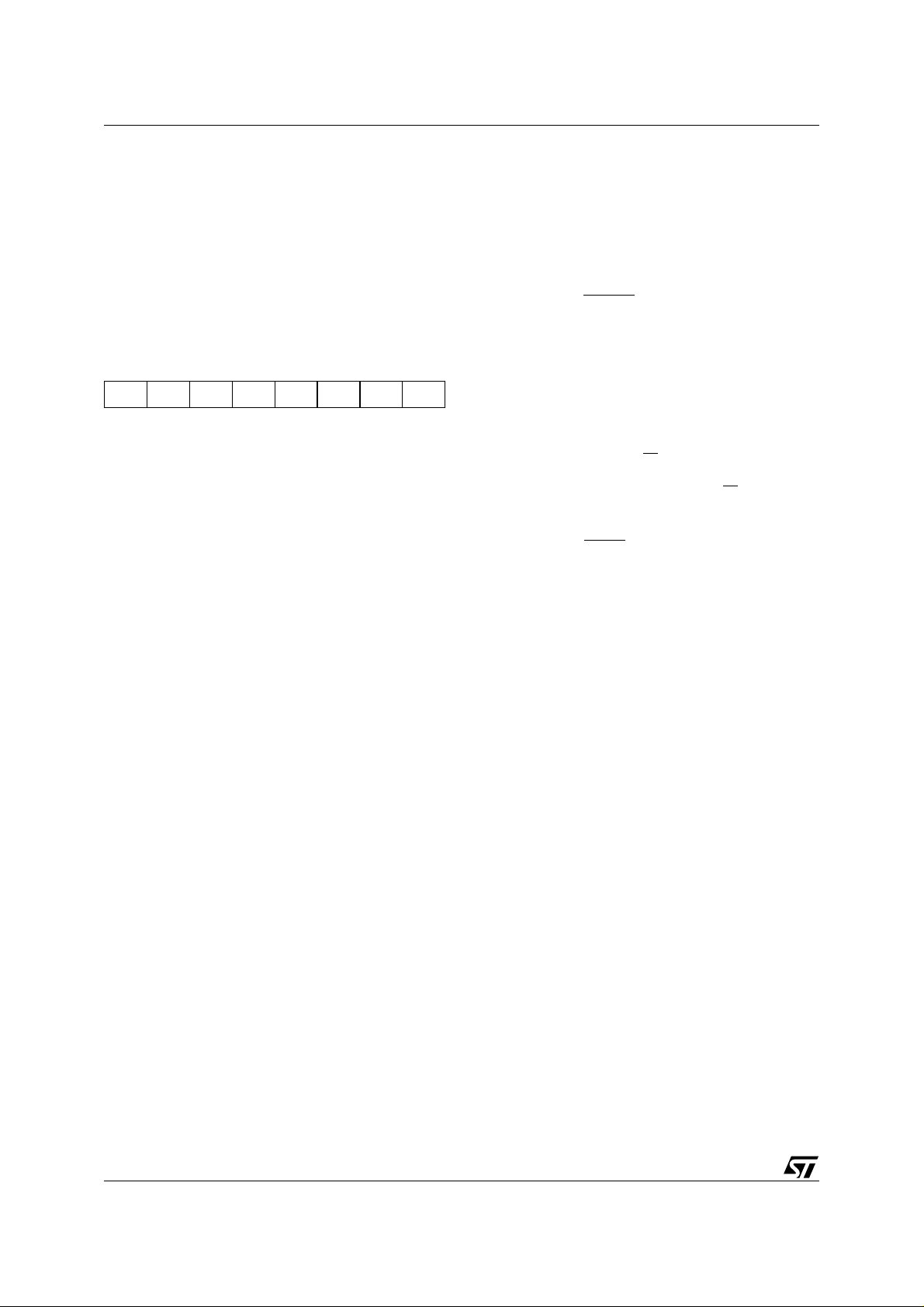

Table 2. Status Register Format

b7 b0

0 0 0 0 0 0 WEL WIP

Note: WEL and WIP are volatile read-only bits (WEL is set and re-

set by specific instructions; WIP is automatically set and reset by the internal logic of the device).

Protection Modes

The environments where non-volatile memor y devices are used can be very noisy. No SPI device

can operate correctly in the presence of excessive

noise. To help combat this, the M45PE10 features

the following data protection mechanisms:

■ Power On Reset and an internal timer (t

PUW

can provide protection against inadvertant

changes while the power supply is outside the

operating specification.

■ Program, Erase and Write instructions are

checked that they consist of a number of clock

pulses that is a multiple of eight, before they

are accepted for execution.

■ All instructions that modify data must be

preceded by a Write Enable (WREN)

instruction to set the Write Enable Latch

(WEL) bit. This bit is returned to its reset state

by the following events:

– Power-up

– Reset (RESET

) driven Low

– Write Disable (WRDI) instruction

completion

– Page Write (PW) instruction completion

– Page Program (PP) instruction completion

– Page Erase (PE) instruction completion

– Sector Erase (SE) instruction completion

■ The Hardware Protected mode is entere d

when Write Protect (W

) is driven Low, causing

the first 256 pages of memory to become

read-only. When Write Protect (W

High, the first 256 pages of memory behave

like the other pages of memory

■ The Reset (Reset) signal can be driven Low to

)

protect the contents of the memory during any

critical time, not just during Power-up and

Power-down.

■ In addition to the low power consumption

feature, the Deep Power-down mode offers

extra software protection from inadvertant

Write, Program and Erase instructions while

the device is not in active use.

) is driven

8/34

MEMORY ORGANIZATION

The memory is organized as:

■ 512 pages (256 bytes each).

■ 131,072 bytes (8 bits each)

■ 2 sectors (512 Kbits, 65536 bytes each)

Each page can be individually:

– programmed (bits are programmed from 1 to

0)

– erased (bits are erased from 0 to 1)

– written (bits are changed to either 0 or 1)

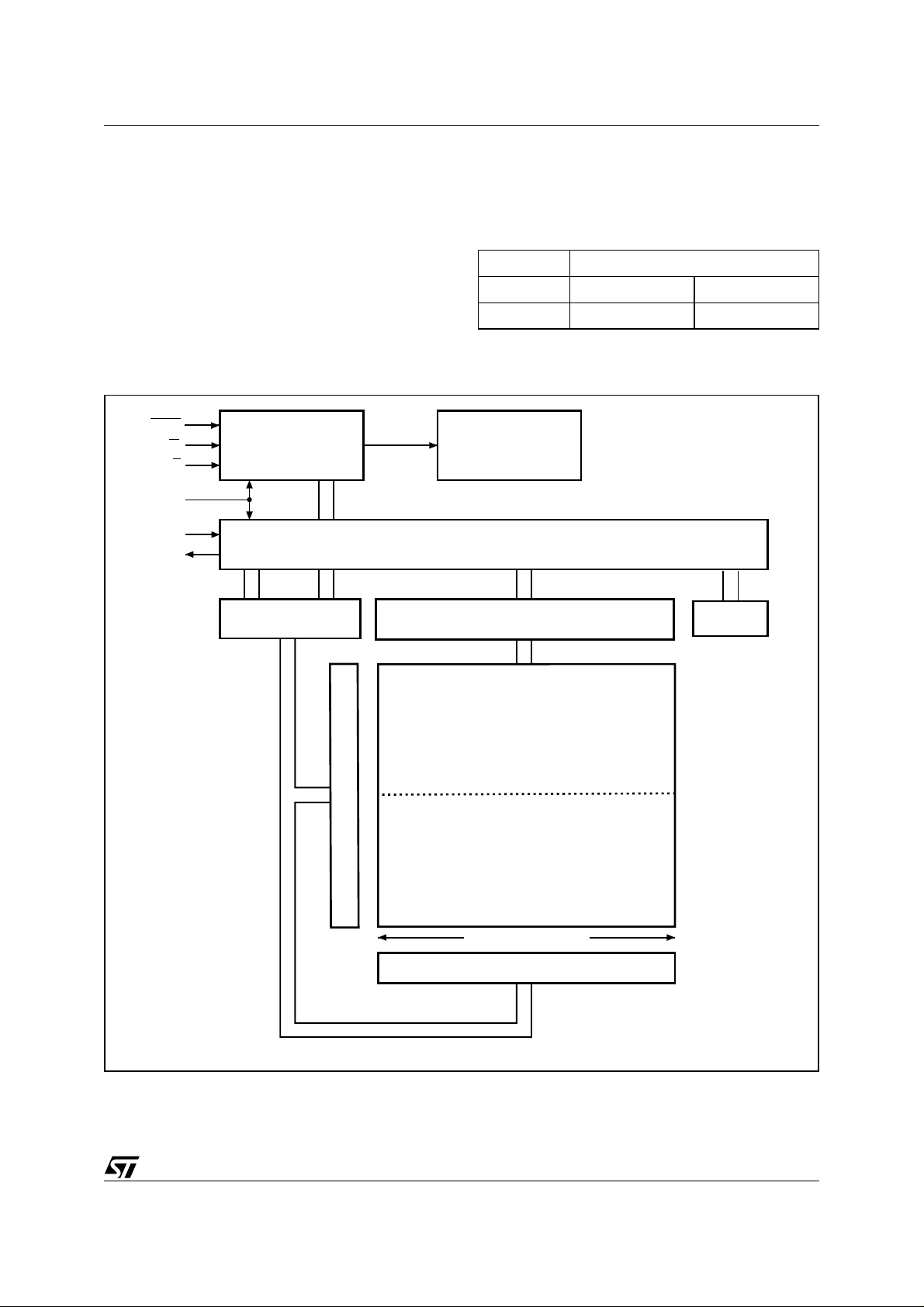

Figure 6. Block Diagram

M45PE10

The device is Page or Sector Erasable (bits ar e

erased from 0 to 1).

Table 3. Memory Organization

Sector Address Range

1 10000h 1FFFFh

0 00000h 0FFFFh

Reset

W

S

C

D

Q

Control Logic

Address Register

and Counter

10000h

Y Decoder

High Voltage

Generator

I/O Shift Register

256 Byte

Data Buffer

Status

Register

1FFFFh

First 256 Pages can

be made read-only

00000h

000FFh

256 Bytes (Page Size)

X Decoder

AI07405

9/34

M45PE10

INSTRUCTIONS

All instructions, addresses and data are shifted in

and out of the device, most significant bit firs t.

Serial Data Input (D) is sampled on the first rising

edge of Serial Clock (C) after Chip Select (S

) is

driven Low. Then, the one-byte instruction code

must be shifted in to the device, most significant bit

first, on Serial Data Input (D), each bit being

latched on the rising edges of Serial Clock (C).

The instruction set is listed in Table 4.

Every instruction sequence starts with a one-byte

instruction code. Depending on the instruction,

this might be followed by address bytes, or by data

bytes, or by both or none.

In the case of a Read Data Bytes (READ), Read

Data Bytes at Higher Speed (Fast_Read) or Read

Status Register (RDSR) instruction, the shifted-in

instruction sequence is followed by a data-out se-

quence. Chip Select (S

any bit of the data-out sequence is being shifted

out.

In the case of a Page Write (PW), Page Program

(PP), Page Erase (PE), Sector Erase (SE), Write

Enable (WREN), Write Disable (WRDI), Deep

Power-down (DP) or Release from Deep Pow erdown (RDP) instruction, Chip Select (S

driven High exactly at a byte boundary, otherwise

the instruction is rejected, and is not executed.

That is, Chip Select (S

number of clock pulses after Chip Select (S

driven Low is an exact multiple of eight.

All attempts to access the memory array during a

Write cycle, Program cycle or Erase cycle are ignored, and the internal Write cycle, Program cycle

or Erase cycle continues unaffected.

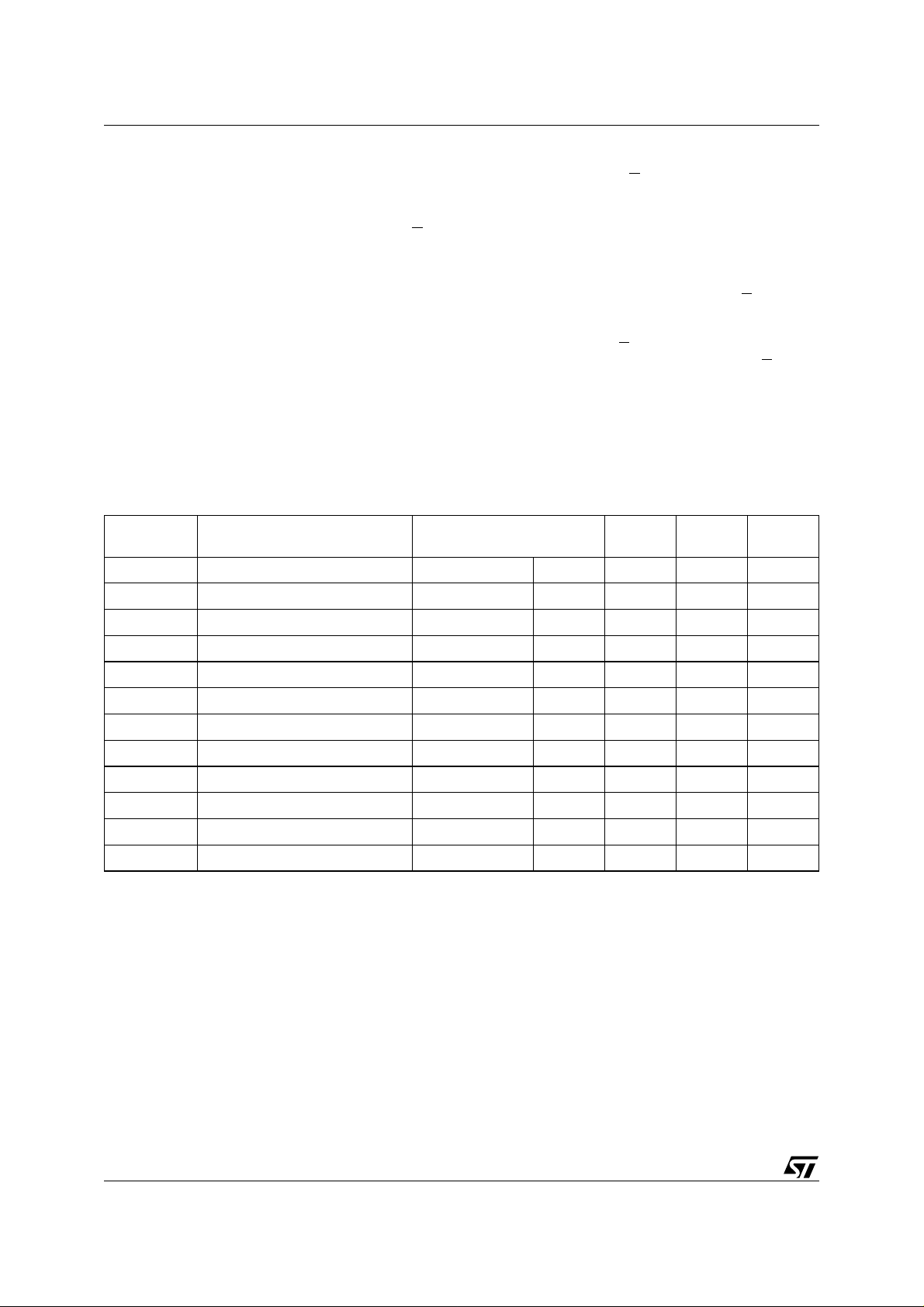

Table 4. Instruction Set

Instruction Description One-byte Instruction Code

WREN Write Enable 0000 0110 06h 0 0 0

WRDI Write Disable 0000 0100 04h 0 0 0

RDID Read Identification 1001 1111 9Fh 0 0 1 to 3

RDSR Read Status Register 0000 0101 05h 0 0 1 to ∞

READ Read Data Bytes 0000 0011 03h 3 0 1 to ∞

FAST_READ Read Data Bytes at Higher Speed 0000 1011 0Bh 3 1 1 to ∞

PW Page Write 0000 1010 0Ah 3 0 1 to 256

PP Page Program 0000 0010 02h 3 0 1 to 256

PE Page Erase 1101 1011 DBh 3 0 0

SE Sector Erase 1101 1000 D8h 3 0 0

DP Deep Power-down 1011 1001 B9h 0 0 0

RDP Release from Deep Power-down 1010 1011 ABh 0 0 0

) can be driven High after

) must be

) must driven High when the

) being

Address

Bytes

Dummy

Bytes

Data

Bytes

10/34

M45PE10

Write Enable (WREN)

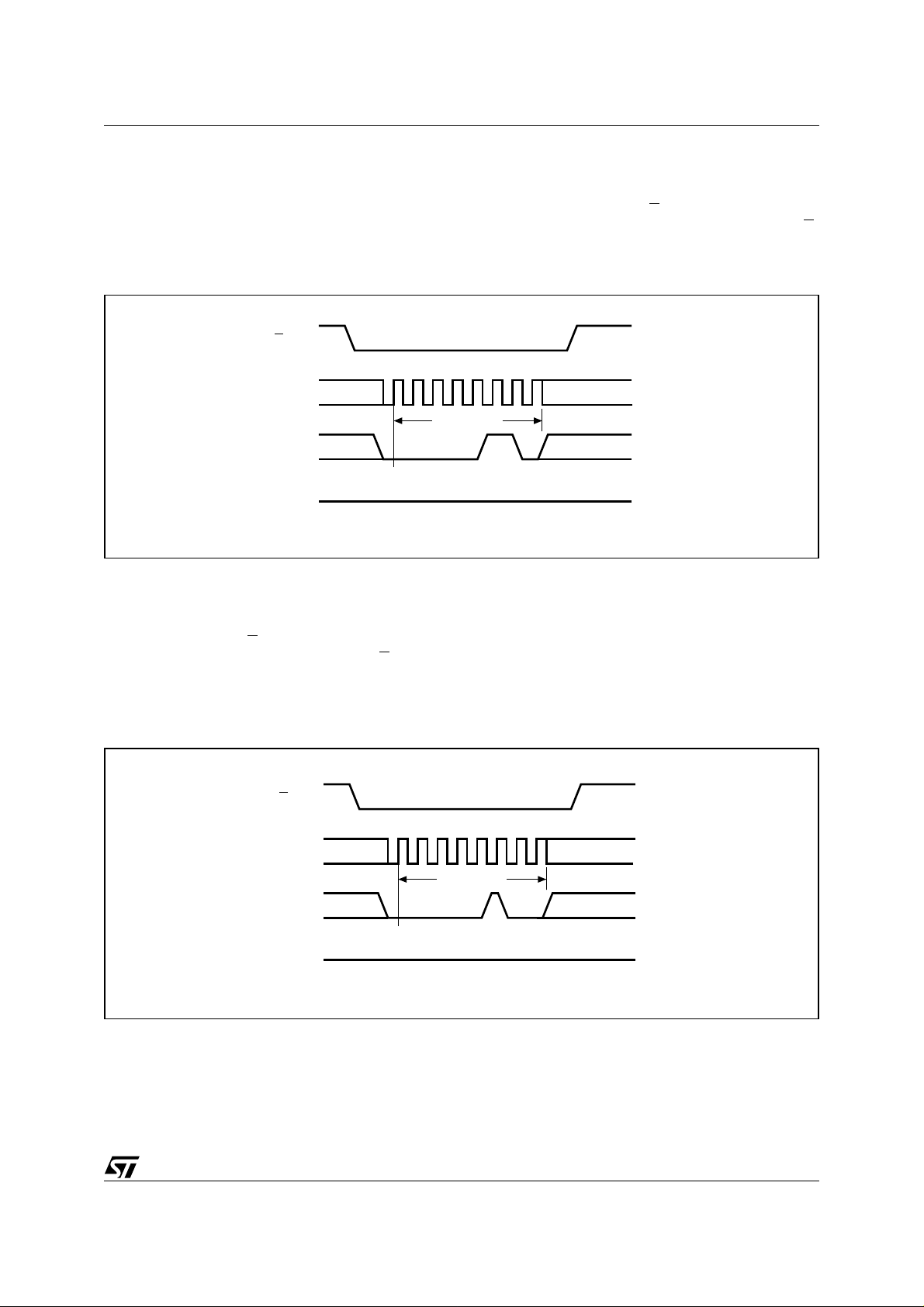

The Write Enable (WREN) instruction (Figure 7.)

sets the Write Enable Latch (WEL) bit.

The Write Enable Latch (WEL) bit must be set pr ior to every Page Write (PW), Page Progr am (PP),

Page Erase (PE), and Sector Erase (SE) instruction.

The Write Enable (WREN) instruction is entered

by driving Chip Select (S

struction code, and then driving Chip Select (S

High.

Figure 7. Write Enable (WREN) Instruction Sequence

S

0

21 34567

C

Instruction

D

High Impedance

Q

Write Disable (WRDI)

The Write Disable (WRDI) instruction (Figure 8.)

resets the Write Enable Latch (WEL) bit.

The Write Disable (WRDI) instruction is entered by

driving Chip Select (S

tion code, and then driving Chip Select (S

) Low, sending the instruc-

) High.

The Write Enable Latch (WEL) bit is r eset under

–Power-up

– Write Disable (WRDI) instruction completion

– Page Write (PW) instruction comple tio n

– Page Program (PP) instruction completion

– Page Erase (PE) instruction completion

– Sector Erase (SE) instruction completion

the following conditions:

) Low, sending the in-

)

AI02281E

Figure 8. Write Disable (WRDI) Instruction Sequence

S

0

21 34567

C

Instruction

D

High Impedance

Q

AI03750D

11/34

M45PE10

Read Identification (RDID)

The Read Identification (RDID) instruction allows

the 8-bit manufacturer identificat ion to be read, followed by two bytes of device identification. The

manufacturer identification is assigned by JEDEC,

and has the value 20h for STMicroelectronics. T he

device identification is assigned by the device

manufacturer, and indicates the memory type in

the first byte (40h), and the me mory capacity of the

device in the second byte (11h).

Any Read Identification (RDID) instruction while

an Erase or Program cycle is in progress, is not

decoded, and has no effect on the cycle that is in

progress.

struction is shifted in. This is followed by the 24-bit

device identification, stored in the memory, being

shifted out on Serial Data Output (Q), each bit being shifted out during the falling edge of Serial

Clock (C).

The instruction sequence is shown in Figure 9.

The Read Identification (RDID) instruction is termi-

nated by driving Chip Select (S

during data output.

When Chip Select (S

) is driven High, the device is

put in the Standby Power mode. Once in the

Standby Power mode, the device waits to be selected, so that it can receive, decode and execute

instructions.

The device is first selected by driving Chip Select

) Low. Then, the 8-bit instruct ion code f or the in-

(S

Table 5. Read Identification (RDID) Data- Out Sequence

Manufacturer Identification

Memory Type Memory Capacity

20h 40h 11h

Device Identification

Figure 9. Read Identification (RDID) Instruction Sequence and Data-Out Sequence

) High at any time

S

21 3456789101112131415

0

C

Instruction

D

Q

High Impedance

Manufacturer Identification

MSB

16 16 18 28 29 30 31

Device Identification

15 1413 3210

MSB

AI06809

12/34

M45PE10

Read Status Register (RDSR)

The Read Status Register (RDSR) instruction allows the Status Register to be read. The Status

Register may be read at any time, even while a

Program, Erase or Write cycle is in progress.

When one of these cycles is in progress, it is recommended to check the Write In Progress (WIP)

bit before sending a new instruction to the device.

It is also possible to read the Status Register continuously, as shown in Figure 10.

The status bits of the Status Register are as fol-

WIP bit. The Write In Progress (WIP) bit indicates

whether the memory is busy with a Write, Pr ogram

or Erase cycle. When set to 1, such a cycle is in

progress, when reset to 0 no such cycle is in

progress.

WEL bit. The Write Enable Latch (WEL) bit indicates the status of the internal Write Enable Lat ch.

When set to 1 the internal Write Enable Latch is

set, when set to 0 the internal Write Enable Latch

is reset and no Write, Program or Erase instruction

is accepted.

lows:

Figure 10. Read Status Register (RDSR) Instruction Sequence and Data-Out Sequence

S

21 3456789101112131415

0

C

Instruction

D

Q

High Impedance

Status Register Out

7 6543210

MSB

Status Register Out

7 6543210

MSB

7

AI02031E

13/34

M45PE10

Read Data Bytes (READ)

The device is first selected by driving Chip Select

) Low. The instruction code for the Read Data

(S

Bytes (READ) instruction is followed by a 3-byte

address (A23-A0), each bit being latched- in during

the rising edge of Serial Clock (C). Then the memory contents, at that address, is shifted out on Serial Data Output (Q), each bit being shifted out, at

a maximum frequency f

, during the falling edge of

R

Serial Clock (C).

The instruction sequence is shown in Figure 11.

The first byte addressed can be at any location.

The address is automatically incr emented to the

next higher address after each byte of data is sh ifted out. The whole memory can, ther efore, be read

with a single Read Data Bytes (READ) instruction.

When the highest address is reached, the a ddress

counter rolls over to 000000h, allowing the read

sequence to be continued indefinitely.

The Read Data Bytes (READ) instruction is terminated by driving Chip Select (S

) can be driven High at any time during data out-

(S

) High. Chip Select

put. Any Read Data Bytes (READ) instruction,

while an Erase, Program or Write cycle is in

progress, is rejected without having any effects on

the cycle that is in progress.

Figure 11. Read Data Bytes (READ) Instruction Sequence and Data-Out Sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-Bit Address

36 37 38

39

D

High Impedance

Q

Note: Address bits A23 to A17 are Don’t Care.

23

2221 3210

MSB

Data Out 1

76543 1 7

MSB

2

0

Data Out 2

AI03748D

14/34

M45PE10

Read Data Bytes at Higher Speed

(FAST_READ)

The device is first selected by driving Chip Select

) Low. The instruction code for the Read Data

(S

Bytes at Higher Speed (FAST_READ) instruction

is followed by a 3-byte address (A23-A0) and a

dummy byte, each bit being la tched-in during the

rising edge of Serial Clock (C). Then the memory

contents, at that address, is shifted out on Serial

Data Output (Q), each bit being shifted out, at a

maximum frequency f

, during the falling edge of

C

Serial Clock (C).

The instruction sequence is shown in Figure 12.

The first byte addressed can be at any location.

The address is automatically incr emented to the

next higher address after each byte of data is sh ifted out. The whole memory can, ther efore, be read

with a single Read Data Bytes at Higher Speed

(FAST_READ) instruction. When the highest address is reached, the address counter rolls over to

000000h, allowing the read sequence to be co ntinued indefinitely.

The Read Data Bytes at Higher Speed

(FAST_READ) instruction is terminated by driving

Chip Select (S

) High. Chip Select (S) can be driven High at any time during data output. Any Read

Data Bytes at Higher Speed (FAST_READ) instruction, while an Erase, Program or Write cycle

is in progress, is rejected without having any effects on the cycle that is in progress.

Figure 12. Read Data Bytes at Higher Speed (FAST_READ) Instruction Sequence and Data-Out

Sequence

S

21 345678910 28293031

0

C

Instruction 24 BIT ADDRESS

D

High Impedance

Q

S

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

D

Q

Note: Address bits A23 to A17 are Don’t Care.

765432 0

35

Dummy Byte

23

2221 3210

1

DATA OUT 1

765432 0

MSB

47

DATA OUT 2

7 6543210

1

MSB MSB

7

AI04006

15/34

M45PE10

Page Write (PW)

The Page Write (PW) instruction allows bytes to

be written in the memory. Before it can be accept ed, a Write Enable (WREN) instruction must previously have been executed. After the Write Enable

(WREN) instruction has been decoded, the device

sets the Write Enable Latch (WEL).

The Page Write (PW) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, three address bytes and at least

one data byte on Serial Data Input (D). The rest of

the page remains unchanged if no power failure

occurs during this write cycle.

The Page Write (PW) instruction performs a page

erase cycle even if only one byte is updated.

If the 8 least significant address bits (A7-A0) are

not all zero, all transmitted data exceeding the addressed page boundary wrap round, and are written from the start address of the same page (the

one whose 8 least significant address bits (A7- A0)

are all zero). Chip Select (S

) must be driven Low

for the entire duration of the sequence.

The instruction sequence is shown in Figure 13..

If more than 256 bytes are sent t o the device, pre-

viously latched data are discarded and the last 256

data bytes are guaranteed to be written correctly

within the same page. If less than 256 Data bytes

are sent to device, they are correctly writt en at t he

requested addresses without having any effects

on the other bytes of the same page.

For optimized timings, it is recommended to use

the Page Write (PW) instruction to write all consecutive targeted Bytes in a single sequence versus using several Page Write (PW) sequences

with each containing only a few Bytes (see AC

Characteristics (33MHz operation)).

Chip Select (S

) must be driven High after the

eighth bit of the last data byte has been latched in,

otherwise the Page Write (PW) instruction is not

executed.

As soon as Chip Select (S

timed Page Write cycle (whose duration is t

) is driven High, the self-

) is

PW

initiated. While the Page Write cycle is in progress,

the Status Register may be read to check the value of the Write In Progress (WIP) bit. The Wr ite In

Progress (WIP) bit is 1 during the self-timed Page

Write cycle, and is 0 when it is completed. At some

unspecified time before the cycle is co mplete, the

Write Enable Latch (WEL) bit is reset.

A Page Write (PW) instruction applied to a page

that is Hardware Protected is not executed.

Any Page Write (PW) instruction, while an Erase,

Program or Write cycle is in progress, is rejected

without having any effects on the cycle that is in

progress.

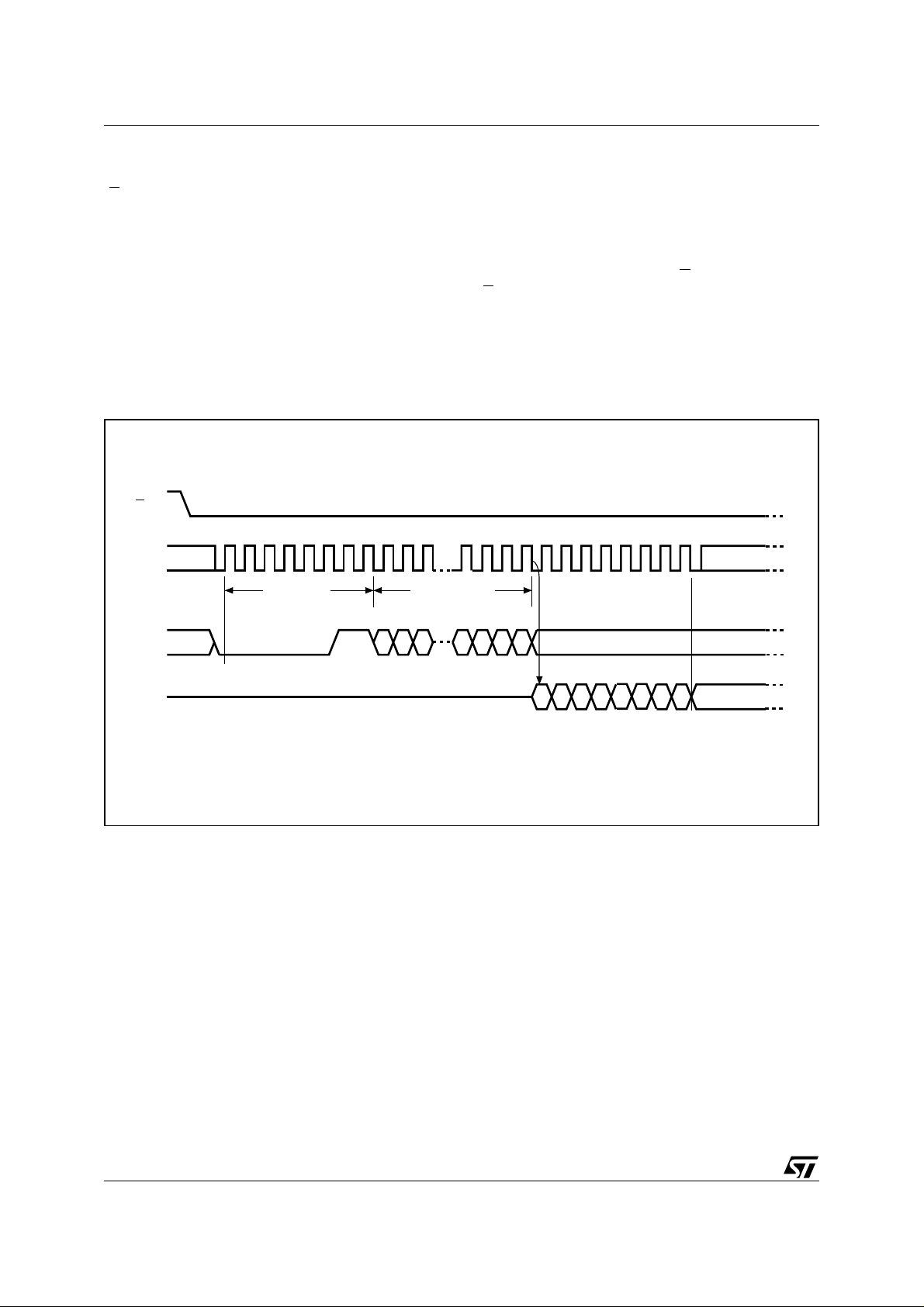

Figure 13. Page Write (PW) Instruction Sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-Bit Address

23

D

S

4241 43 44 45 46 47 48 49 50 52 53 54 5540

C

Data Byte 2

D

Note: 1. Address bits A23 to A17 are Don’t Care

2. 1 ≤ n ≤ 256

765432 0

MSB MSB MSB

1

2221 3210

MSB

Data Byte 3 Data Byte n

765432 0

36 37 38

Data Byte 1

765432 0

MSB

51

1

765432 0

39

1

1

AI04045

16/34

M45PE10

Page Program (PP)

The Page Program (PP) instruction allows bytes to

be programmed in the memory (changing bits from

1 to 0, only). Before it can be accepted , a Write Enable (WREN) instruction must previously have

been executed. After the Write Enable (WREN) instruction has been decoded, the device sets the

Write Enable Latch (WEL).

The Page Program (PP) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, three address bytes and at least

one data byte on Serial Data Input (D). If the 8

least significant address bits (A7-A0) are not all

zero, all transmitted data exceeding the addressed page boundary wrap round, and are programmed from the start address of the same page

(the one whose 8 least significant address bits

(A7-A0) are all zero). Chip Select (S

) must be driv-

en Low for the entire duration of the sequence.

The instruction sequence is shown in Figure 14..

If more than 256 bytes are sent t o the device, pre-

viously latched data are discarded and the last 256

data bytes are guaranteed to be programm ed correctly within the same page. If less than 256 Data

bytes are sent to device, they are correctly programmed at the requested addresses without having any effects on the other bytes of the same

page.

For optimized timings, it is recommended to use

the Page Program (PP) instruction to program all

consecutive targeted Bytes in a single sequence

versus using several Page Program (PP) sequences with each containing only a few Bytes

(see AC Characteristics (33MHz operation)).

Chip Select (S

) must be driven High after the

eighth bit of the last data byte has been latched in,

otherwise the Page Program (PP) instruction is not

executed.

As soon as Chip Select (S

timed Page Program cycle (whose duration is t

) is driven High, the self-

PP

is initiated. While the Page Program cycle is in

progress, the Status Register may be read to

check the value of the Write In Progress (WIP) bit .

The Write In Progress (WIP) bit is 1 duri ng the selftimed Page Program cycle, and is 0 when it is

completed. At some unspecified time before the

cycle is complete, the Write Enabl e Latch (WEL)

bit is reset.

A Page Program (PP) instruction applied to a page

that is Hardware Protected is not executed.

Any Page Program (PP) instruction, while an

Erase, Program or Write cycle is in progress, is rejected without having any effects on the cycle that

is in progress.

)

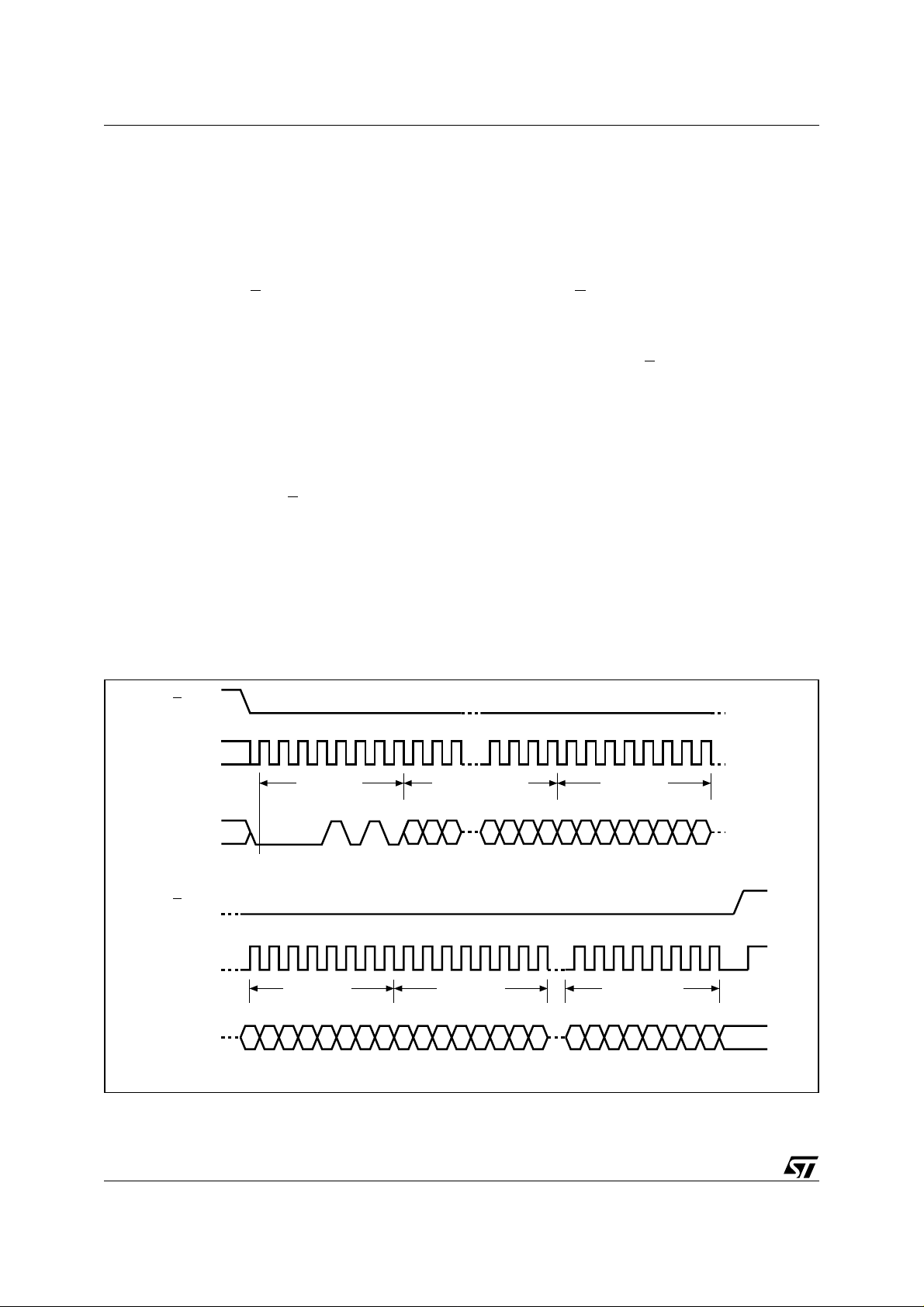

Figure 14. Page Program (PP) Instruction Sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-Bit Address

23

D

S

4241 43 44 45 46 47 48 49 50 52 53 54 5540

C

Data Byte 2

D

Note: 1. Address bits A23 to A17 are Don’t Care

2. 1 ≤ n ≤ 256

765432 0

MSB MSB MSB

1

2221 3210

MSB

51

Data Byte 3 Data Byte n

765432 0

36 37 38

Data Byte 1

765432 0

MSB

1

765432 0

39

1

1

AI04044

17/34

M45PE10

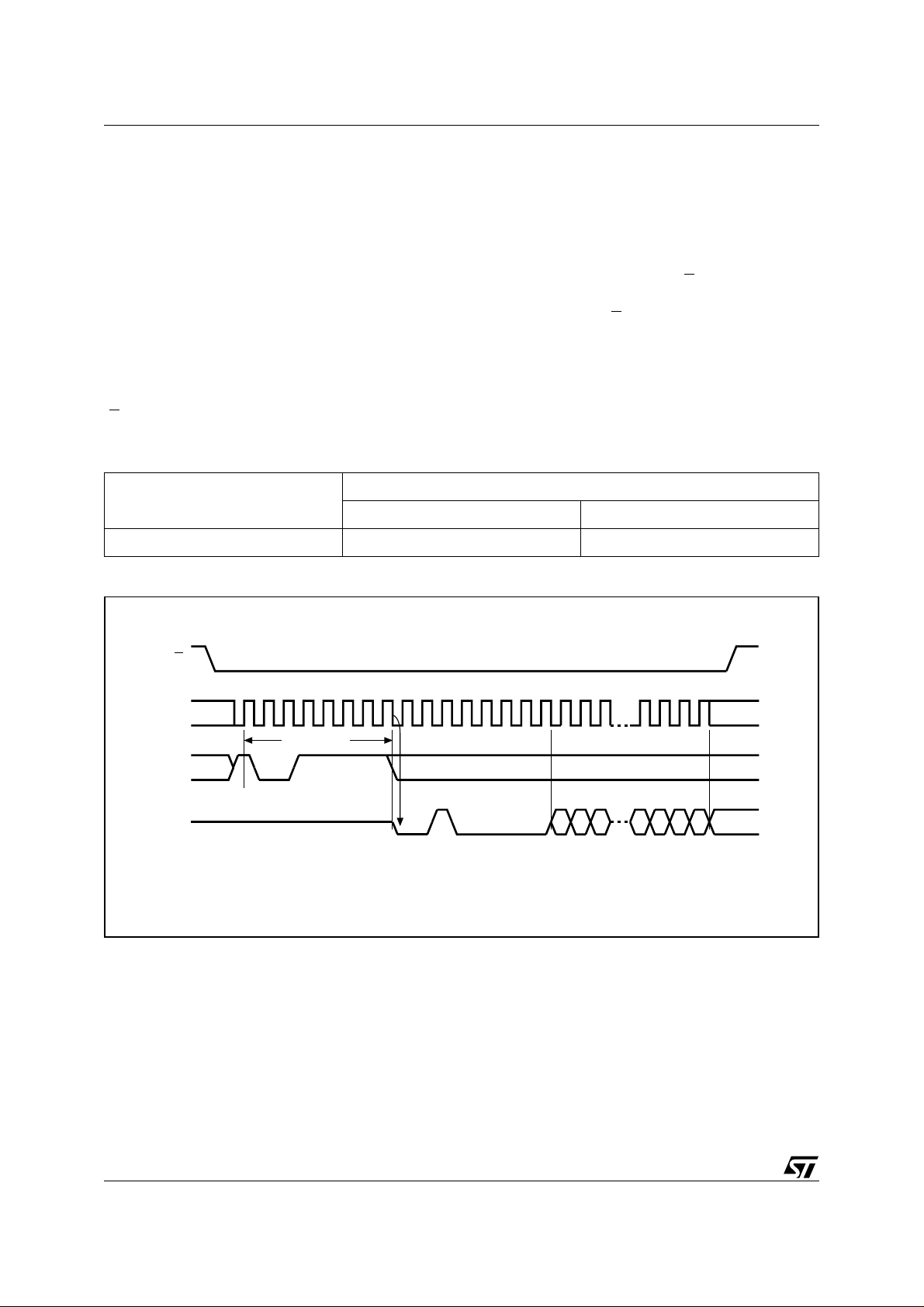

Page Erase (PE)

The Page Erase (PE) instruction sets to 1 (F Fh) all

bits inside the chosen page. Before it can be accepted, a Write Enable (WREN) instruction must

previously have been executed. After the Write

Enable (WREN) instruction has been decoded,

the device sets the Write Enable Latch (WEL).

The Page Erase (PE) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, and three address bytes on Serial

Data Input (D). Any address inside the Page is a

valid address for the Page Eras e (PE) in struc tion.

Chip Select (S

) must be driven Low for the entire

duration of the sequence.

The instruction sequence is shown in Figure 15..

Chip Select (S

) must be driven High after the

eighth bit of the last address byte has been latched

Figure 15. Page Erase (PE) Instruction Sequence

S

in, otherwise the Page Erase (PE) instruction is

not executed. As soon as Chip Select (S

) is driven

High, the self-timed Page Erase cycle (whose duration is t

) is initiated. While the Page Erase cy-

PE

cle is in progress, the Status Register may be r ead

to check the value of the Write In Progress (WIP)

bit. The Write In Progress (WIP) bit is 1 during the

self-timed Page Erase cycle, and is 0 when it is

completed. At some unspecified time before the

cycle is complete, the Write Enabl e Latch (WEL)

bit is reset.

A Page Erase (PE) instruction applied to a pag e

that is Hardware Protected is not executed.

Any Page Erase (PE) instruction, while an Erase,

Program or Write cycle is in progress, is rejected

without having any effects on the cycle that is in

progress.

0

C

D

Note: Address bits A23 to A17 are Don’t Care.

21 3456789 293031

Instruction

24 Bit Address

23 22 2 0

MSB

1

AI04046

18/34

M45PE10

Sector Erase (SE)

The Sector Erase (SE) instruction sets to 1 (FFh)

all bits inside the chosen sector. Before it can be

accepted, a Write Enable (WREN) instruction

must previously have been executed. After the

Write Enable (WREN) instruction has been decoded, the device sets the Write Enable Latch (WEL).

The Sector Erase (SE) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, and three address bytes on Serial

Data Input (D). Any address inside the Sector ( see

Table 3.) is a valid address for the Sector Erase

(SE) instruction. Chip Select (S

) must be driven

Low for the entire duration of the sequence.

The instruction sequence is shown in Figure 16..

Chip Select (S

) must be driven High after the

eighth bit of the last address byte has been latched

in, otherwise the Sector Erase (SE) instruction is

Figure 16. Sector Erase (SE) Instruction Sequence

not executed. As soon as Chip Select (S

) is driven

High, the self-timed Sector Erase cycle (whose duration is t

) is initiated. While the Sector Erase cy-

SE

cle is in progress, the Status Register may be r ead

to check the value of the Write In Progress (WIP)

bit. The Write In Progress (WIP) bit is 1 during the

self-timed Sector Erase cycle, and is 0 when it is

completed. At some unspecified time before the

cycle is complete, the Write Enabl e Latch (WEL)

bit is reset.

A Sector Erase (SE) instruction applied to a sector

that contains a page that is Hardware Protected is

not executed.

Any Sector Erase (SE) instruction, while an Erase,

Program or Write cycle is in progress, is rejected

without having any effects on the cycle that is in

progress.

S

0

C

D

Note: Address bits A23 to A17 are Don’t Care.

21 3456789 293031

Instruction

24 Bit Address

23 22 2 0

MSB

1

AI03751D

19/34

M45PE10

Deep Power-down (DP)

Executing the Deep Power-down (DP) instruction

is the only way to put the device in the lowest consumption mode (the Deep Power- down mode). It

can also be used as an extra software protection

mechanism, while the device is not in act ive use,

since in this mode, the device ignores all Write,

Program and Erase instructions.

Driving Chip Select (S

) High deselects the device,

and puts the device in the Standby Power mode (if

there is no internal cycle currently in progress). But

this mode is not the Deep Powe r-down mode. The

Deep Power-down mode can only be entered by

executing the Deep Power-down (DP) instruction,

to reduce the standby current (from I

CC1

to I

CC2

as specified in Table 11.).

Once the device has entered the Deep Power-

down mode, all instructions are ignored except the

Release from Deep Power-down (RDP) instruction. This releases the device from this mod e.

The Deep Power-down mode automatically stops

at Power-down, and the device always Powers-up

in the Standby Power mode.

The Deep Power-down (DP) instruction is entered

by driving Chip Select (S

struction code on Serial Data Input (D). Chip Select (S

of the sequence.

The instruction sequence is shown in Figure 17..

Chip Select (S

eighth bit of the instruction code has been latched

in, otherwise the Deep Power-down (DP) instruction is not executed. As soon as Chip Select (S

driven High, it requires a delay of t

,

supply current is reduced to I

Power-down mode is entered.

Any Deep Power-down (DP) instruction, while an

Erase, Program or Write cycle is in progress, is rejected without having any effects on the cycle that

is in progress.

Figure 17. Deep Power-down (DP) Instruction Sequence

) Low, followed by the in-

) must be driven Low for the entire duration

) must be driven High after the

) is

before the

DP

and the Deep

CC2

S

t

21 345670

C

Instruction

D

DP

Stand-by Mode

Deep Power-down Mode

AI03753D

20/34

M45PE10

Release from Deep Power-down (RDP)

Once the device has entered the Deep Powerdown mode, all instructions are ignored except the

Release from Deep Power-down (RDP) instruction. Executing this instruction takes the device out

of the Deep Power-down mode.

The Release from Deep Power-down (RDP) instruction is entered by driving Chip Select (S

) Low,

followed by the instruction code on Serial Data Input (D). Chip Select (S

) must be driven Low for the

entire duration of the sequence.

The instruction sequence is shown in Figure 18..

The Release from Deep Power-down (RDP) in-

struction is terminated by driving Chip Select (S

High. Sending additional clock cycles on Serial

Clock (C), while Chip Select (S

cause the instruction to be rejected, and not executed.

After Chip Select (S

lowed by a delay, t

Standby Power mode. Chip Select (S

main High at least until this period is over. The device waits to be selected, so that it can receive,

decode and execute instructions.

Any Release from Deep Power-down (RDP) instruction, while an Erase, Program or Write cycle

is in progress, is rejected without having any effects on the cycle that is in progress.

)

Figure 18. Release from Deep Power-down (RDP) Instruction Sequence

S

t

21 345670

C

Instruction

RDP

) is driven Low,

) has been driven High, fol-

, the device is put in the

RDP

) must re-

D

High Impedance

Q

Deep Power-down Mode

Stand-by Mode

AI06807

21/34

M45PE10

POWER-UP AND POWER-DOWN

At Power-up and Power-down, the device must

not be selected (that is Chip Select (S

the voltage applied on V

) until VCC reaches the

CC

correct value:

–V

(min) at Power-up, and then for a further

CC

delay of t

VSL

–VSS at Power-down

Usually a simple pull-up resistor on Chip Select (S

can be used to ensure safe and proper Power-up

and Power-down.

To avoid data corruption and inadvertent write operations during power up, a Power On Reset

(POR) circuit is included. The logic inside the device is held reset while V

is less than the Power

CC

On Reset (POR) threshold value, V

tions are disabled, and the device does not respond to any instruction.

Moreover, the device ignores all Write Enable

(WREN), Page Write (PW), Page Program (PP),

Page Erase (PE) and Sector Erase (SE) instructions until a time delay of t

the moment that V

CC

PUW

rises above the VWI threshold. However, the correct operation of the device

is not guaranteed if, by this time, V

(min). No Write, Program or Erase instruct ions

V

CC

should be sent until the later of:

–t

after VCC passed the VWI threshold

PUW

) must follow

– all opera-

WI

has elapsed after

is still below

CC

–t

after wrap roundVCC passed the

VSL

(min) level

V

CC

These values are specified in Table 6..

If the delay, t

above V

CC

READ instructions even if the t

, has elapsed, after VCC has risen

VSL

(min), the device can be selected for

delay is not yet

PUW

fully elapsed.

)

As an extra protection, the Reset (Reset

can be driven Low for the whole duration of the

Power-up and Power-down phases.

At Power-up, the device is in the following state:

– The device is in the Standby Power mode (not

the Deep Power-down mode).

– The Write Enable Latch (WEL) bit is reset.

Normal precautions must be taken for supply rail

decoupling, to stabilize the V

vice in a system should have the V

supply. Each de-

CC

CC

pled by a suitable capacitor close to the package

pins. (Generally, this capacitor is of the order of

0.1µF).

At Power-down, when V

drops from the operat-

CC

ing voltage, to below the Power On Reset (POR)

threshold value, V

, all operations are disabled

WI

and the device does not respond to any instruction. (The designer needs to be aware that if a

Power-down occurs while a Write, Program or

Erase cycle is in progress, some data corrup tion

can result.)

) signal

rail decou-

Figure 19. Power-up Timing

V

CC

VCC(max)

Program, Erase and Write Commands are Rejected by the Device

Chip Selection Not Allowed

VCC(min)

Reset State

of the

V

Device

WI

tVSL

tPUW

Read Access allowed Device fully

accessible

time

AI04009C

22/34

M45PE10

Table 6. Power-Up Timing and VWI Threshold

Symbol Parameter Min. Max. Unit

1

t

VSL

t

PUW

V

Note: 1. These parameters are characterized only, over the temperature range –40°C to +85°C.

VCC(min) to S low

1

Time delay before the first Write, Program or Erase instruction 1 10 ms

1

Write Inhibit Voltage 1.5 2.5 V

WI

30 µs

INITIAL DELIVERY STATE

The device is delivered with the memory array

erased: all bits are set to 1 (each byte contains

FFh). All usable Status Register bits are 0.

MAXIMUM RATING

Stressing the device outside the ratings listed in

Table 7. may cause permanent damage to the de-

vice. These are stress ratings only, and operation

of the device at these, or any other conditions outside those indicated in the Oper ating sections of

this specification, is not implied. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability. Refer also to

the STMicroelectronics SURE Program and other

relevant quality documents.

Table 7. Absolute Maximum Ratings

Symbol Parameter Min. Max. Unit

T

STG

T

LEAD

V

IO

V

CC

V

ESD

Note: 1. Compliant with JEDEC Std J-STD-020B (for small body, Sn-Pb or Pb assembly), the ST ECOPACK® 7191395 specification, an d

the European directive on Restrictions on Hazardous Substances (RoHS) 2002/95/EU

2. JEDEC Std JESD22-A114A (C1=100 pF, R1=1500 Ω, R2=500 Ω)

Storage Temperature –65 150 °C

Lead Temperature during Soldering

See note

1

°C

Input and Output Voltage (with respect to Ground) –0.6 4.0 V

Supply Voltage –0.6 4.0 V

Electrostatic Discharge Voltage (Human Body model)

2

–2000 2000 V

23/34

M45PE10

DC AND AC PARAMETERS

This section summarizes the operating an d measurement conditions, and the DC and AC characteristics of the device. The parameters in the DC

and AC Characteristic tables that follow are derived from tests performed under the Measure-

Table 8. Operating Conditions

Symbol Parameter Min. Max. Unit

ment Conditions summarized in the relevant

tables. Designers should check that the operating

conditions in their circuit match the measurement

conditions when relying on the quoted parameters.

V

CC

T

A

Supply Voltage 2.7 3.6 V

Ambient Operating Temperature –40 85 °C

Table 9. AC Measurement Conditions

Symbol Parameter Min. Max. Unit

C

L

Load Capacitance 30 pF

Input Rise and Fall Times 5 ns

to 0.8V

Input Pulse Voltages

Input and Output Timing Reference Voltages

Note: Output Hi-Z is defined as the point where data out is no longer driven .

0.2V

0.3V

CC

to 0.7V

CC

CC

CC

Figure 20. AC Measurement I/O Waveform

Input Levels

0.8V

CC

0.2V

CC

Input and Output

Timing Reference Levels

0.7V

CC

0.3V

CC

AI00825B

V

V

Table 10. Capacitance

Symbol Parameter Test Condition Min. Max. Unit

C

OUT

C

IN

Note: Sampled only, not 100% tested, at TA=25°C and a frequency of 20 MHz.

24/34

Output Capacitance (Q) V

= 0V 8 pF

OUT

Input Capacitance (other pins) VIN = 0V 6 pF

Table 11. DC Characteristics

Symbol Parameter

I

Input Leakage Current ± 2 µA

LI

I

I

I

I

I

V

V

V

I

CC1

CC2

CC3

CC4

CC5

V

Output Leakage Current ± 2 µA

LO

Standby Current

(Standby and Reset modes)

Deep Power-down Current

Operating Current

(FAST_READ)

Operating Current (PW)

Operating Current (SE)

Input Low Voltage – 0.5

IL

Input High Voltage

IH

Output Low Voltage

OL

Output High Volta ge

OH

Test Condition

(in addition to those in Table 8.)

S

C = 0.1V

C = 0.1V

= VCC, V

S

= VCC, V

/ 0.9.VCC at 25MHz, Q = open

CC

/ 0.9.VCC at 33MHz, Q = open

CC

= VSS or V

IN

= VSS or V

IN

S

= V

CC

S

= V

CC

I

= 1.6 mA

OL

I

= –100 µAV

OH

CC

CC

M45PE10

Min. Max. Unit

50 µA

10 µA

6

8

15 mA

15 mA

0.3V

CC

0.7V

CC

CCVCC

–0.2

+0.4

0.4 V

mA

V

V

V

25/34

M45PE10

Table 12. AC Characteristics (25MHz operation)

Test conditions specified in Table 8. and Table 9.

Symbol Alt. Parameter Min. Typ. Max. Unit

f

C

f

R

1

t

CH

1

t

CL

t

SLCH

t

CHSL

t

DVCH

t

CHDX

t

CHSH

t

SHCH

t

SHSL

2

t

SHQZ

t

CLQV

t

CLQX

2

t

RLRH

t

RHSL

t

SHRH

t

WHSL

t

SHWL

2

t

DP

2

t

RDP

(3)

t

PW

(3)

t

PP

t

PE

t

SE

Note: 1. tCH + tCL must be greater than or equal to 1/ fC(max)

2. Value guaranteed by characterization, not 100% tested in production.

3. When using PP and PW instructions to update consecutive Bytes, optimized timings are obtained with one sequence including all

the Bytes versus several sequ ences of only a few Bytes. (1 ≤ n ≤ 256)

f

t

CLH

t

CLL

t

CSS

t

DSU

t

DH

t

CSH

t

DIS

t

t

HO

t

RST

t

REC

C

V

Clock Frequency for the following

instructions: FAST_READ, PW, PP, PE,

D.C. 25 MHz

SE, DP, RDP, WREN, WRDI, RDSR

Clock Frequency for READ instructions D.C. 20 MHz

Clock High Time 18 ns

Clock Low Time 18 ns

Clock Slew Rate

2

(peak to peak)

0.03 V/ns

S Active Setup Time (relative to C) 10 ns

S Not Active Hold Time (relative to C) 10 ns

Data In Setup Time 5 ns

Data In Hold Time 5 ns

S Active Hold Time (relative to C) 10 ns

S Not Active Setup Time (relative to C) 10 ns

S Deselect Time 200 ns

Output Disable Time 15 ns

Clock Low to Output Valid 15 ns

Output Hold Time 0 ns

Reset Pulse Width 10 µs

Reset Recovery Time 3 µs

Chip should have been deselected

before Reset is de-asserted

10 ns

Write Protect Setup Time 50 ns

Write Protect Hold Time 100 ns

S to Deep Power-down 3 µs

S High to Standby Pow er mode 30 µs

Page Write Cycle Time (256 Bytes) 11

Page Write Cycle Time (n Bytes)

10.2+

n*0.8/256

25 ms

Page Program Cycle Time (256 Bytes) 1.2

Page Program Cycle Time (n Bytes)

0.4+

n*0.8/256

5ms

Page Erase Cycle Time 10 20 ms

Sector Erase Cycle Time 1 5 s

26/34

M45PE10

Table 13. AC Characteristics (33MHz operation)

33MHz only available for products marked since week 40 of 2005

Test conditions specified in Table 8. and Table 9.

Symbol Alt. Parameter Min. Typ. Max. Unit

Clock Frequency for the following

f

C

f

C

instructions: FAST_READ, PW, PP,

PE, SE, DP, RDP, WREN, WRDI,

D.C. 33 MHz

RDSR

Clock Frequency for READ

instructions

D.C. 20 MHz

Clock High Time 13 ns

Clock Low Time 13 ns

Clock Slew Rate

2

(peak to peak)

0.03 V/ns

S Active Setup Time (relative to C) 10 ns

S Not Active Hold Time (relative to C) 10 ns

Data In Setup Time 3 ns

Data In Hold Time 5 n s

S Active Hold Time (relative to C) 5 ns

S Not Active Setup Time (relative to C) 5 ns

S Deselect Time 200 ns

Output Disable Time 12 ns

Clock Low to Output Valid 12 ns

Output Hold Time 0 ns

Top Sector Lock Setup Time 50 ns

Top Sector Lock Hold Time 100 ns

S to Deep Power-down 3 µs

S High to Standby Pow er mode 30 µs

t

CH

t

CL

t

SLCH

t

CHSL

t

DVCH

t

CHDX

t

CHSH

t

SHCH

t

SHSL

t

SHQZ

t

CLQV

t

CLQX

t

THSL

t

SHTL

t

DP

t

RDP

f

R

(1)

(1)

(2)

(2)

(2)

t

CLH

t

CLL

t

CSS

t

DSU

t

DH

t

CSH

t

DIS

t

t

HO

V

Page Write Cycle Time (256 Bytes) 11

(3)

t

PW

Page Write Cycle Time (n Bytes)

10.2+

n*0.8/256

Page Program Cycle Time (256 Bytes) 1.2

(3)

t

PP

t

PE

t

SE

Note: 1. tCH + tCL must be greater than or equal to 1/ f

2. Value guaranteed by characterization, not 100% tested in production.

3. When using PP and PW instructions to update consecutive Bytes, optimized timings are obtained with one sequence including all

the Bytes versus several sequ ences of only a few Bytes. (1 ≤ n ≤ 256)

4. Details of how to find the date of marking are given in Application Note, AN1995.

Page Program Cycle Time (n Bytes)

Page Erase Cycle Time 10 20 ms

Sector Erase Cycle Time 1 5 s

C

0.4+

n*0.8/256

(4)

25 ms

5ms

27/34

M45PE10

Figure 21. Serial Input Timing

S

C

tDVCH

tSLCH

tSHSL

tCHSHtCHSL

tSHCH

tCHCL

tCHDX

D

Q

MSB IN

High Impedance

Figure 22. Write Protect Setup and Hold Timing

W

tWHSL

S

C

tCLCH

LSB IN

AI01447C

tSHWL

Q

28/34

D

High Impedance

AI07439

Figure 23. Output Timing

S

C

tCLQV

tCLQV

tCH

tCL

M45PE10

tSHQZ

tCLQX

Q

ADDR.LSB IN

D

tCLQX

Figure 24. Reset AC Waveforms

S

Reset

LSB OUT

tQLQH

tQHQL

AI01449D

tRHSLtSHRH

tRLRH

AI06808

29/34

M45PE10

PACKAGE MECHANICAL

Figure 25. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Outline

h x 45˚

Note: Drawing is not to scale.

B

SO-a

A

e

D

N

1

CP

E

H

C

LA1 α

Table 14. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Mechanical Data

Symb.

Typ. Min. Max. Typ. Min. Max.

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e1.27––0.050––

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α 0° 8° 0° 8°

N8 8

CP 0.10 0.004

mm inches

30/34

Figure 26. MLP8, 8-lead Very thin Dual Flat Package No lead, 6x5mm, Package Outline

D

D1

E

E1

eE2

b

M45PE10

A

Note: Drawing is not to scale.

A1

θ

A2

A3

D2

L

VDFPN-01

Table 15. MLP8, 8-lead Very thin Dual Flat Package No lead, 6x5mm, Package Mechanical Da ta

Symb.

Typ. Min. Max. Typ. Min. Max.

A 0.85 1.00 0.0335 0.0394

A1 0.00 0.05 0.0000 0.0020

A2 0.65 0.0256

A3 0.20 0.0079

b 0.40 0.35 0.48 0.0157 0.0138 0.0189

D 6.00 0.2362

D1 5.75 0.2264

D2 3.40 3.20 3.60 0.1339 0.1260 0.1417

E 5.00 0 .1969

E1 4.75 0.1870

E2 4.00 3.80 4.20 0.1575 0.1496 0.1654

e 1.27 0.0500

L 0.60 0.50 0.75 0.0236 0.0197 0.0295

θ 12° 12°

mm inches

31/34

M45PE10

PART NUMBERING

Table 16. Ordering Information Scheme

Example: M 45PE10 – V MP 6 T G

Device T ype

M45PE = Serial Flash Memory for Data Storage

Device Function

10 = 1Mbit (128K x 8)

Operating Voltage

V = V

Package

MN = SO8 (150 mil width)

MP = VDFPN8 6x5mm (MLP8)

Device Grade

6 = Industrial temperature range, –40 to 85 °C.

Device tested with standard test flow

= 2.7 to 3.6V

CC

Option

blank = Standard Packing

T = Tape and Reel Packing

Plating Technology

blank = Standard SnPb plating

P or G = ECOPACK® (RoHS compliant)

For a list of available options (speed, package,

etc.) or for further information on any aspect of this

device, please contact your nearest ST Sales Office.

The category of second Level Interconnect is

marked on the package and on the inner box label,

in compliance with JEDEC Standard JESD97. The

maximum ratings related to soldering conditions

are also marked on the inner box label.

32/34

REVISION HISTORY

Table 17. Document Revision History

Date Version Description of Revision

29-Apr-2003 1.0 Document written

04-Jun-2003 1.1

04-Dec-2003 1.2

25-Jun-2004 1.3

22-Sep-2004 2.0 Document promoted to Preliminary Data. Minor wording changes

08-Oct-2004 3.0 Document promoted to Mature Datasheet. No other changes

4-Oct-2005 4.0

Description corrected of entering Hardware Protected mode (W

cannot be left unconnected).

V

(min) extended to –0.6V, tPW(typ) and tPP(typ) improved. Table of contents, warning

IO

about exposed paddle on MLP8, and Pb-free options added. Change of naming for

VDFPN8 package.

Soldering temperature information clarified for RoHS compliant devices. De vice Grade

clarified.

Added AC Characteristics (33MHz operation). An Easy Way to Modify Data, A Fast

Way to Modify Data, Page Write (PW) and Page Program (PP) sections updated to

explain optimal use of Page Write and Page Program instructions. Updated I

values in Table 11., DC Characteristics. Updated Table 16., Ordering Information

Scheme. Added Ecopack® information.

M45PE10

must be driven, and

CC3

33/34

M45PE10

Information furnished is believe d to be accura te and re liable. Howev er, STMi croelec tronics assumes n o resp onsibil ity for t he consequences

of use of such information nor f or any infringement of pa tents or other rights of third parties which may re sult from its use. N o license is granted

by implication or otherwise und er an y pa ten t or patent rights of STMicroelectronics. Specifications mentioned in thi s p ub lic ation are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

34/34

Loading...

Loading...